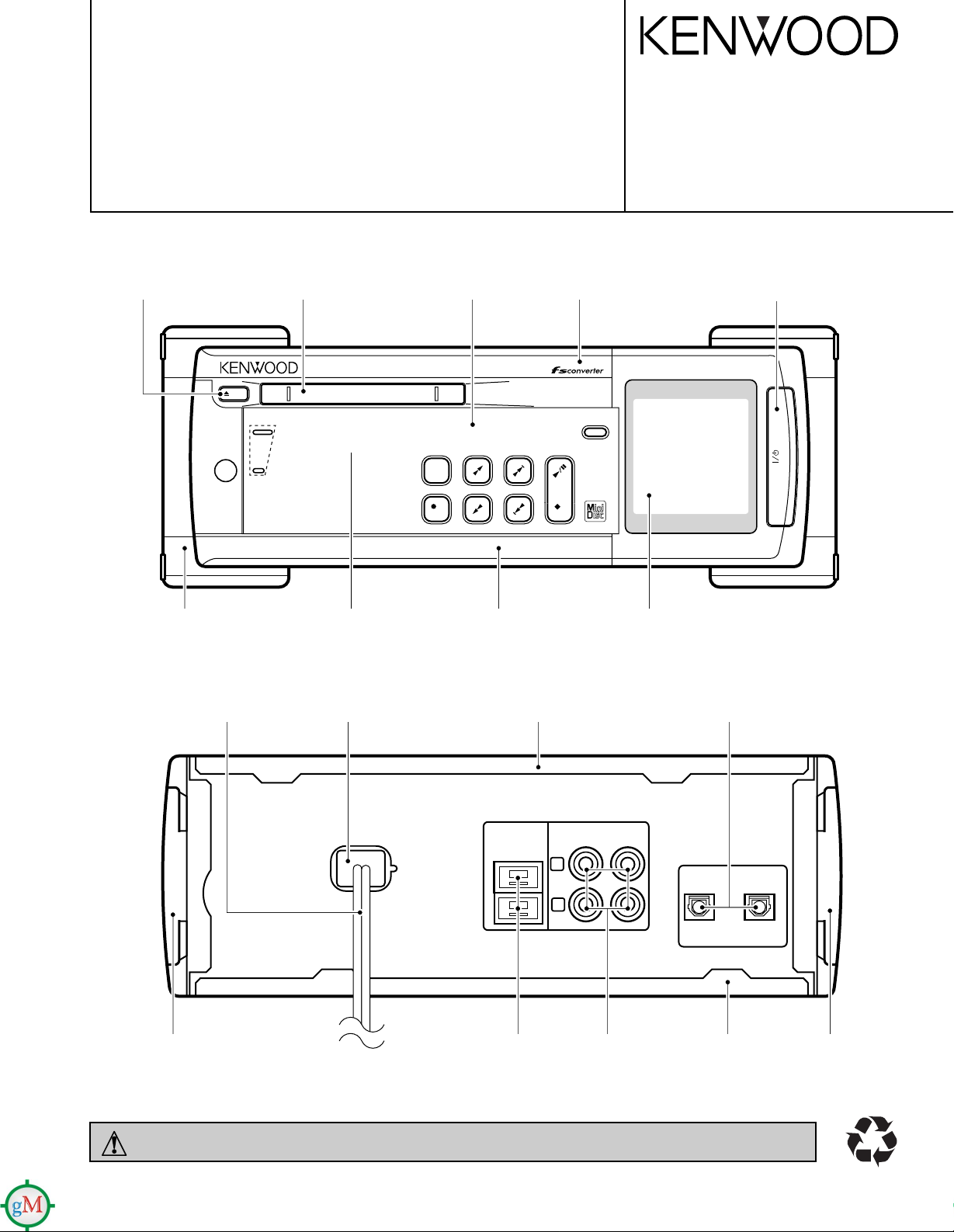

MINI DISC RECORDER

70%

646

609 608 606

617607619

660

rec level

recording

eject

standby

enter

stop

rec

o.t.e.

on/standby

mode

disc loading mechanism

minidisc recorder DM-VH7

20bit A/D&D/A converter

654 601 A1-A2

611

602J1J3

632

610

DIGITAL IN

OPTICAL

SYSTEM

CONTROL

L

R

RECINPLAY

OUT

12

DM-VH7

SERVICE MANUAL

© 1999-6/B51-5544-00 (K/K) 3632

Knob

(K29-7554-04)

Insulator assy

(J02-1444-14)

Panel

(A29-1051-14)

AC power cord *

(E30-)

Dressing panel

(A21-3762-13)

Indicator

(B12-0361-04)

AC power cord bushing

(J42-0083-05)

Dressing panel (TOP)

(A21-3757-12)

Dressing panel (BOTTOM)

(A21-3758-02)

Metallic cabinet (TOP)

(A01-3696-01)

Knob *

(K29-)

Front glass

(B10-3486-03)

Optic receiving module

(W02-1181-05)

Side plate R

(A50-1326-02)

Do not face the light of laser when a repair or action confirmation are done.

Refer to X-VH7 service manual (B51-5532-00), if need Disassembly for repair.

Rectangular receptacle

(E08-0312-05)

Phono jack

(E63-1065-05)

* Refer to parts list on page 27.

Metallic cabinet

(BOTTOM)

(A01-3698-01)

Side plate L

(A50-1327-02)

2ABC1 3DEF

5JKL 6MNO4GHI

8TUV 9WXY7PRS

EDIT

CANCEL

0QZ

,

,:? +10

&

(

)

-/

+100

RANDOM

REPEAT

CHECK

/SPACE

P.MODE

/CHARAC.

CLEAR

DELETE

EDIT

SET ENTER

87

¡

14¢

REC MODE

TIME DISP.

TITLE

SEARCH

MONITOR

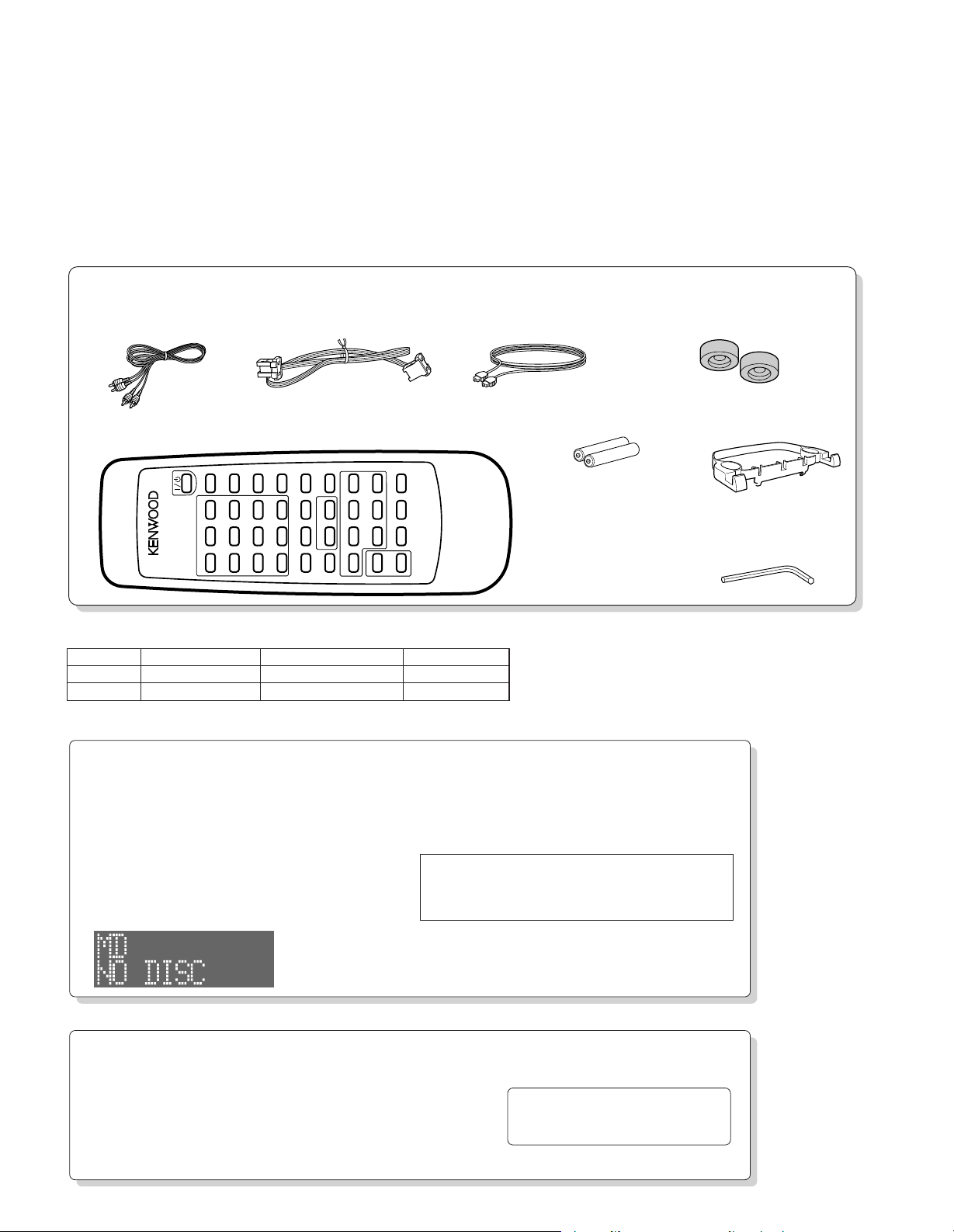

REMOTE CONTROL UNIT

RC-M0708

O.T.E.

÷

PLAY

£

TITLE

INPUT

REC INPUT

POWER

Audio cord (2)

(E30-0615-05)

(A70-1279-05)

(J02-0130-05)

(J19-5996-02)

Battery cover (A09-1106-08)

(E30-2628-05) (B19-1529-05)

(W01-0084-05)

System control cord (1) Optical fiber cable (1)

Remote control unit (1)

Batteries (R6/AA) (2)

Check that the following accessories are present.

Spacer (1)

Replacement front feet (2)

Allen wrench (1)

DM-VH7

Operation to reset

The microprocessor may fall into malfunction (impossibility

to operate erroneous display, etc.) when the power cord is

unplugged while power is ON or due to an external factor.

In this case, execute the following procedure to reset the

microprocessor and return it to normal condition.

Unplug the power cord from the power outlet then, while

holding the eject (0 eject) key depressed, plug the power

cord again.

¶ Please note that resetting the microprocessor clears

the contents stored in, it returns the microprocessor to

the condition when it left the factory.

Note related to transportation and

movement

Before transporting or moving this unit, carry

out the following operations.

1.With no disc loaded in the unit, press the “on/

standby” key to on.

¶ Check that no disc is present in the unit.

2.Wait a few seconds and verify that the display

shown appears.

3. Press the “on/standby” key to off (standby).

CAUTION :

Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

In compliance with Federal Regulations, following are reproductions of lables on, or inside the product relating to

laser product safety.

For the U.S.A.

- - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - -

KENWOOD CORPORATION

2967-3, ISHIKAWA-CHO,

HACHIOJI-SHI, TOKYO, JAPAN

KENWOOD CORP. CERTIFIES THIS

EQUIPMENT CONFORMS TO DHHS

REGULATIONS NO. 21 CFR 1040.10,

CHAPTER 1, SUBCHAPTER J.

- - - - - - - - - - -

Location: Back Panel

CONTENTS / ACCESSORIES / CAUTIONS

Contents

CONTENTS / ACCESSORIES / CAUTIONS............. 2

CIRCUIT DESCRIPTION............................................3

MECHANISM DESCRIPTION...................................11

PC BOARD .............................................................. 14

Accessories

SCHEMATIC DIAGRAM.......................................... 16

EXPLODED VIEW ....................................................25

PARTS LIST..............................................................27

SPECIFICATIONS ......................................Back cover

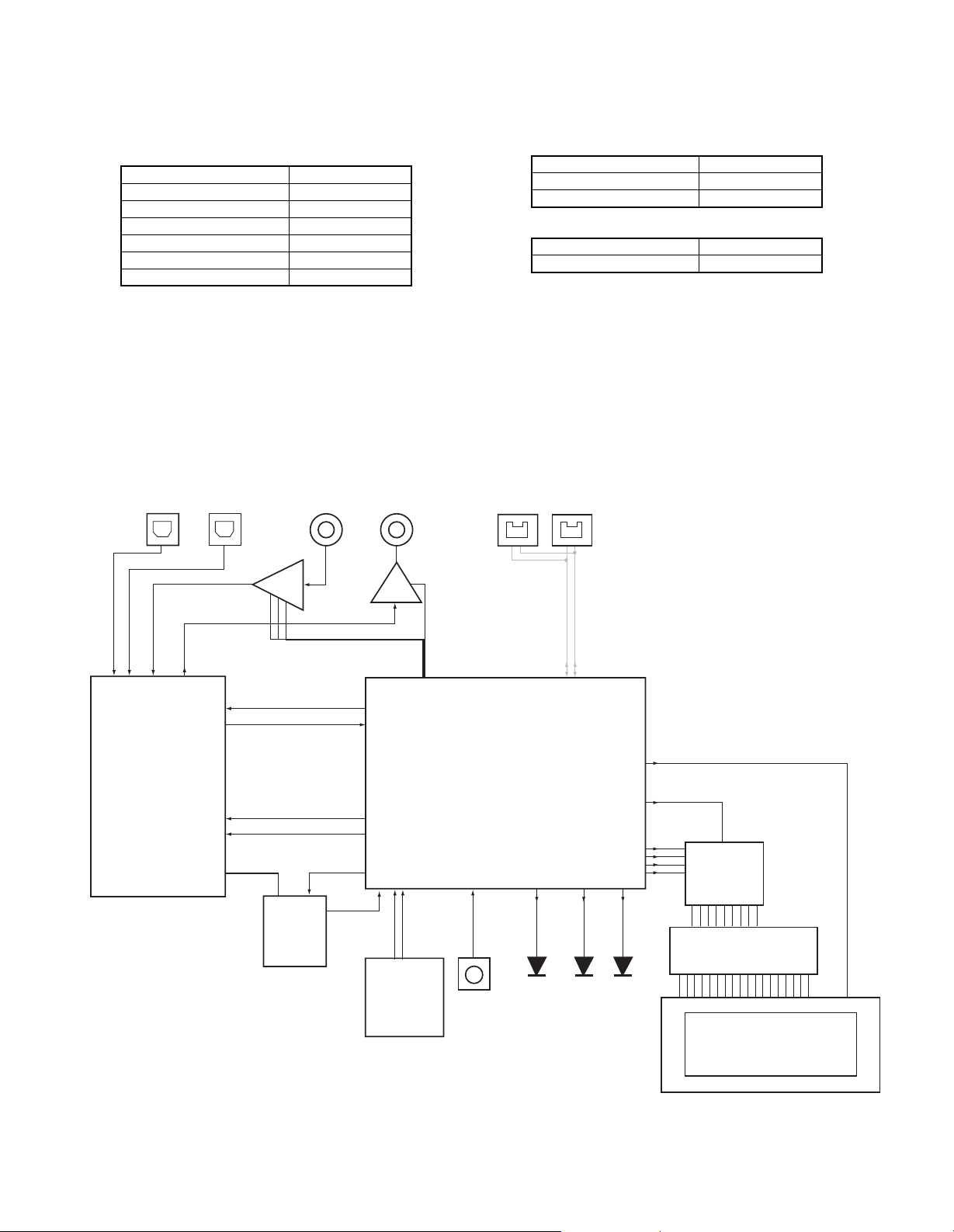

System configuration

CD RECEIVER CASSETTE DECK SPEAKERS

VH-600 RD-VH7 – LS-VH7

VH-700 RD-VH7 X-VH7 LS-VH7

Cautions

2

Backup item Initialization

• MONITOR OFF

• REC INPUT ANALOG

• REC INPUT/ LEVEL ANALOG=-12dB

• REC mode

TNO MARK AUTO

TNO MARK LEVEL 0(-55dB)

(MD ucom)

1. Backup and initialization

No backup item Initialization

PLAY mode TRACK MODE

REPEAT OFF

(MECHA ucom)

Backup item Initialization

DISC editing record UTOC information

DIN AIN AOUT

UART

A/D INT PWM

PWM

SIO

Mechanism unit

(X33)IC24

MECHA uCOM

HD6432227N01FA

Main uCOM

M30620MC-340FP

(X25)IC12

DISPLAY

LCD driver

(64 x 64 full_dot)

LCD module

HD6433297A17F

uCOM

standby eject rec

REM

Key matrix

(2 x 6)

Back up

circuit

Din1 Din2 REC PLAY SL16

vol

MUTE

(X25)IC11

DM-VH7

CIRCUIT DESCRIPTION

• The case of the system connection don't memorise

REC INPUT,REC LEVEL and stand up the same

initialization. System ON/OFF and POWER

ON/OFF are memorised the last selector position.

2. MD microprocessor M30620MC-340FP(X25: IC11)

2-1 Micoprocessor periphery block diagram

• The case of DISC exist editing record : the set dont

read TOC at AC power on

_ Setting of the initialization

While pressing the EJECT key, plug an AC power cord

into AC outlet.

3

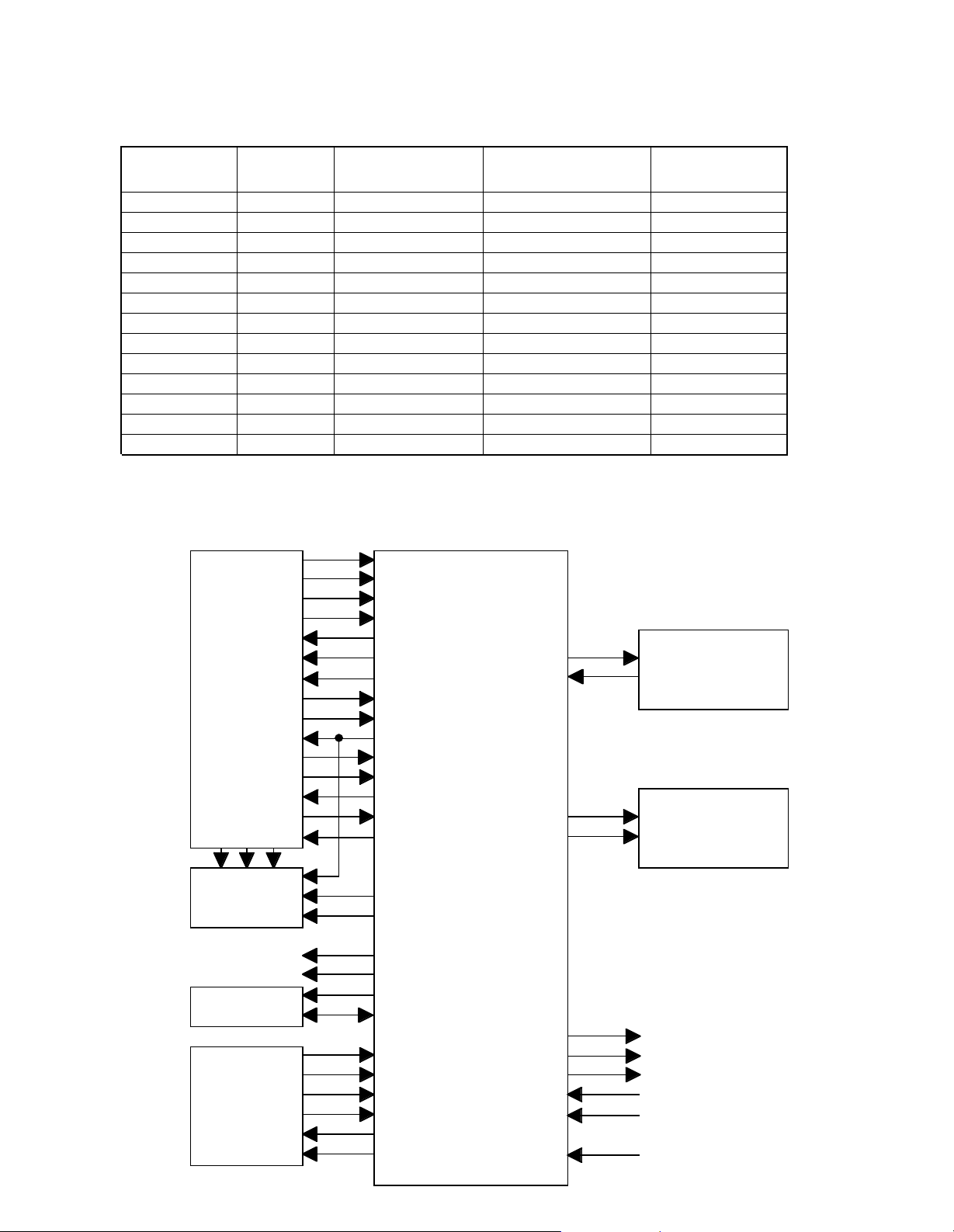

DM-VH7

CIRCUIT DESCRIPTION

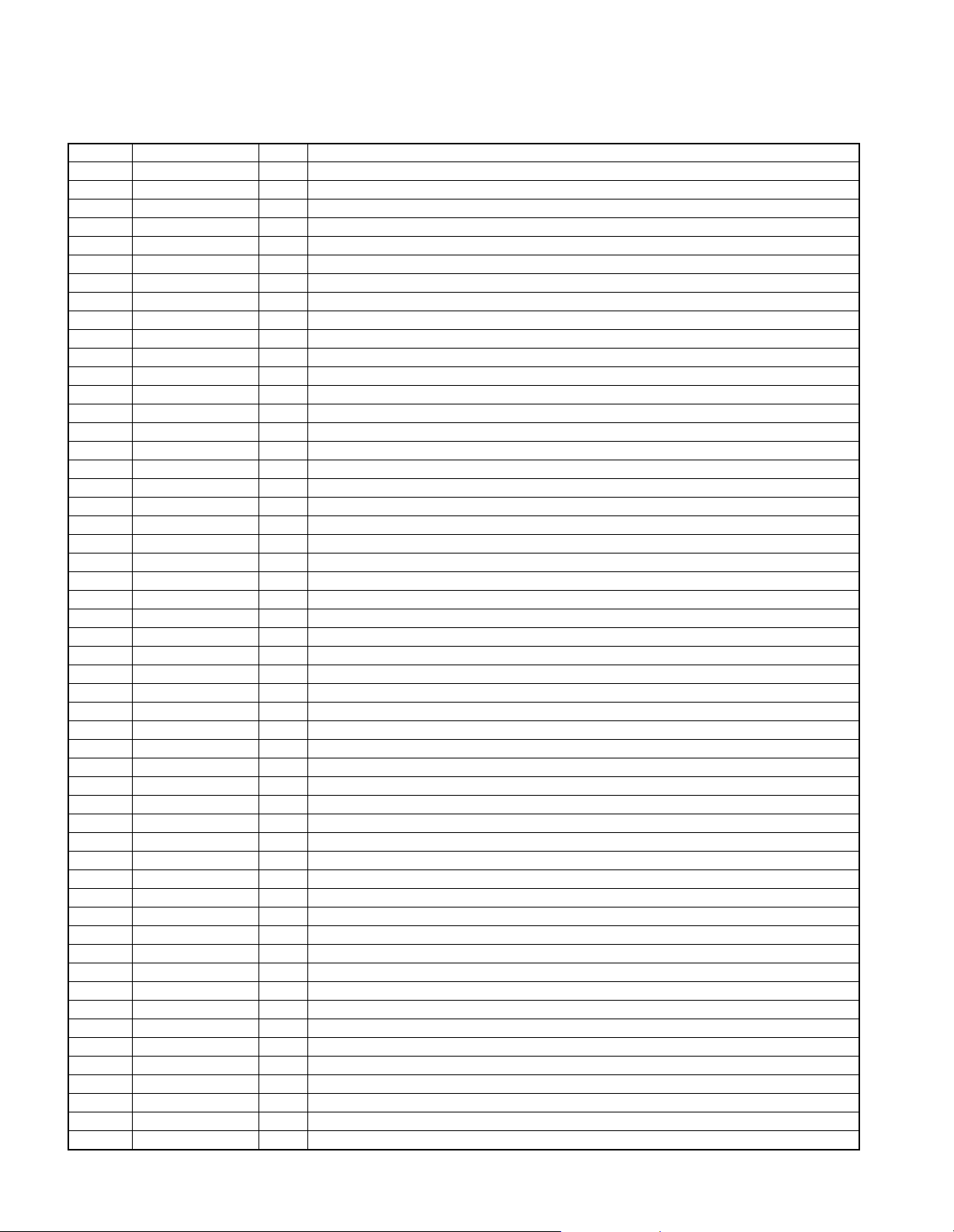

2-2 Pin description

Pin No. Name I/O Description

1 VOL_DT O Electric VOL IC • communication data

2 VOL_CK O Electric VOL IC • communication clock

3 - O Not used

4 DISP_CE O Display ucom • communication CE

5 DISP_OUT O Display ucom • communication data output

6 DISP_IN I Display ucom • communication data input

7 DISP_CLK O Display ucom • communication clock

8 BYTE - Ucom mode data bus setting

9 CNVss - Ucom mode • inner ROM

10,11 - - Not used

12 RESET I Ucom reset

13 Xout O Ucom oscillation 10MHz output

14 Vss - GND

15 Xin I Ucom oscillation 10MHz input

16 Vcc - Power supply

17 NMI - Ucom compulsion thrust

18 - O Not used

19 CE I Ucom CE

20 REM I Remote control input

21 DISP_RST O Display ucom reset

22 LCD_BL O LCD backlight (Dimmer)

23 POWER O Power supply circuit H: ON

24 LED_EJECT O LCD • EJECT(Dimmer)

25 BACK_V_CHK O Backup voltage check circuit H: ON

26 BACK_V_ON O Backup charge H: ON

27 MECHA_CE O MD mecha. ucom CE

28 MECHA_RST O MD mecha. reset L: RESET ON

29 MECHA_RXD I MD mecha. communication input

30 MECHA_TXD O MD mecha. communication output(N-ch)

31~34 - - Not used

35 TIRLER_TXD O Titular communication output

36 TIRLER_RXD I Titular communication input

37 SDATA I/O Serial data (SL16)

38 SBUSY I/O Serial busy (SL16)

39 RDY I Extension bus control

40 - - Not used

41 HOLD I Extension bus control

42~61 - - Not used

62 Vcc - Ucom power supply (5V)

63 - - Not used

64 Vss - Ucom power supply (GND)

65~74 - - Not used

75 AMUTE O Analog mute

76,77 - - Not used

78 LED_REC O LED REC

79 - - Not used

80 LED_STBY O LED STANDBY

81~88 - - Not used

89~91 KR0~2 I Key return

92 BACK_V I Backup voltage check

93 INISW I Destination switch H: except J type

94 XY_POSITION I X-Y position

95 I_PROTECTION I Current protection

96 AVss - A/D power supply (GND)

97 - - Not used

98 Vref - A/D reference voltage (5V)

99 AVcc - A/D power supply (GND)

100 VOL_LEN O Electric VOL IC • communication data latch

4

CIRCUIT DESCRIPTION

Voltage(V) KR0 (89) KR2 (91)KR1 (90)

Threshold

voltage(V)

5.00 (no key on) (no key on) (no key on)

4.59

4.17 ----- eject -----

3.75

3.33 power/standby o.t.e. -----

2.92

2.50 stop ff/level_up -----

2.09

1.67 down up -----

1.25

0.88 fb/level_down play/pause -----

0.42

0.00 rec mode -----

(X33)CI2 (X33)IC24

MNT0

ATRAC

MD ucom

AD/DA

MNT1

CXD2654R MNT2

MNT3

(X25)IC11

SWDT

SCLK CTXD

XLAT CRXD

SRDT

SENS

XRST

SQSY

DQSY

(X33)IC12

RECP

XINT ADDARST

TX EMPHA

LDON

CXA2523AR RMS

HMUTE

(X33)IC6 SRVMOD

E2PROM

MECHA

RF amp

SCL

SDA

POWER

IDSW MUTE

HEADPOS MUTE_BAR

MDM-06 DISCIN RESET

STTLMT CE

LOADIN

LOADOUT BITRATE

2-3 Key matrix

3. MD mechanism microprocessor HD6432227N01FA(X33: IC24)

DM-VH7

3-1 Microprocessor periphery block diagram

5

DM-VH7

CIRCUIT DESCRIPTION

3-2 Pin description

Pin No. Name I/O Description

1 SCL O E2PROM clock

2 SDA I/O E2PROM data

3~11 - O Not used

12 VCC - VDD/power supply

13 - - Not used

14 VSS - GND

15~30 - - Not used

31 SRVMOD O X-Y position output

32~34 - - Not used

35 MUTE_BAR O Mute L:MUTE ON

36 POWER O Power ON/OFF (Periphery circuit power supply )

37 MUTE O Mute

38 ADDARST O AD / DA converter reset

39 EMPHA O Emphasis

40 LOADIN O Mecha. loading motor IN direction moving

41 LOADOUT O Mecha. loading motor OUT direction moving

42 AVSS - A/D GND

43 STTLMT I Pickup position switch

44 DISCIN I DISC insert detection

45 - - Not used

46 BITRATE I MD ucom communication speed changeover

47 HEADPOS I Head position (PLAY/REC) switch (AD)

48 IDSW I Mecha. DISC protection/high reflection/low reflection switch (AD)

49~52 - - Not used

53 Vref - A/D reference voltage

54 AVCC - A/D power supply

55,56 MODE0,1 I VDD/mode (MD0,MD1,MD2)=(1,1,1)

57,58 - - Not used

59 RESET I Reset input

60 NMI I VDD/non mask able thrust

61 STBY I VDD/hardware standby input

62 VCC - VDD/power supply

63 XTAL I Clock inverse input

64 VSS - GND

65 EXTAL - Clock input

66 FWE I GND(Flash ROM writing permission)

67 MODE2 I VDD/mode (MD0,MD1,MD2)=(1,1,1)

68~74 - - Not used

75 CE I Ucom CE

76 CTXD O MD ucom transmit data

77 CRXD I MD ucom receive data

78 DQSY I DIN sub-Q thrust

79,80 - - Not used

81 SQSY I EFM/ADIP SYNC thrust

82 XLAT O ACRIC/ATRAC en/decoder IC latch

83 SWDT O ACRIC/ATRAC en/decoder IC output data

84 SRDT I ACRIC/ATRAC en/decoder IC input data

85 SCLK O ACRIC/ATRAC en/decoder IC clock

86 HMUTE O Pull up/over writing head mute output (TX inverse)

87 SENS I ACRIC/ATRAC en/decoder IC SENS (inner status)

88 MNT3 I ACRIC/ATRAC en/decoder IC spindle rock

89 MNT2 I ACRIC/ATRAC en/decoder IC busy

90 MNT0 I ACRIC/ATRAC en/decoder IC FOK

6

CIRCUIT DESCRIPTION

Pin No. Name I/O Description

91 MNT1 I ACRIC/ATRAC en/decoder IC shock (track jump) detection

92 XINT I ATRAC thrust

93~95 - - Not used

96 TX O ACRIC/ATRAC en/decoder IC TX (Recording data output enable)

97 RECP O ACRIC/ATRAC en/decoder IC RECP (Laser power changeover)

98 XRST O ACRIC/ATRAC en/decoder IC reset

99 LDON O Laser ON

100 RMS O Pickup frequency changeover

DM-VH7

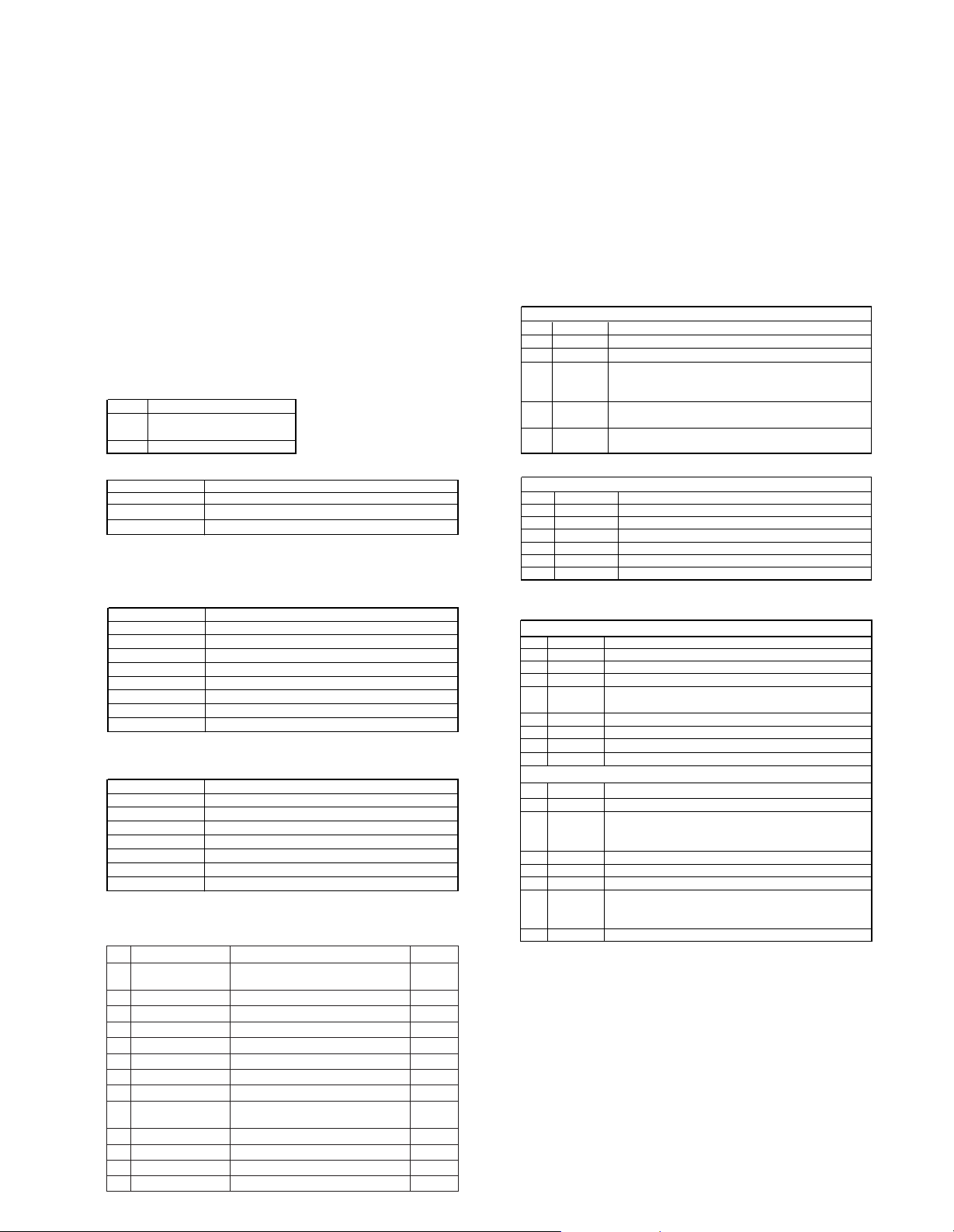

3-3 Port control

EBITRATE (46 pin): UART communication speed

changeover

Input voltage Bit rate

Vref × 1.0 9600bps

~

Vref × 0.8 14400bps

~

Vref × 0.6 28800bps

~

Vref × 0.4 33600bps

~

Vref × 0.2 38400bps

~

Vref × 0.0 19200bps

EHEADPOS(47pin): Head position detection

Input voltage Head position

Vref × 1.0 OFF

~

Vref × 0.62 PLAY position

~

Vref × 0.45 REC position

EIDSW(48 pin): DISC type detection

Input voltage DISC type

Vref × 1.0 LOW REFLECTION DISC

(PROTECT ON)

~

Vref × 0.69 LOW REFLECTION DISC

(PROTECT OFF)

~

Vref × 0.32 HIGH REFLECTION DISC

4. LCD display microprocessor

HD6433297A17F(X25:IC12)

4-1 Description

Pin No. Name I/O Description

1 DO O Communication data output

2 DI I Communication data input

3 CLK I Communication clock input

4 RESET I Ucom reset

5 NMI I (Non mask able thrust)

6 Vcc - Ucom power supply

7 STBY I Ucom standby

8 Vss - Ucom power supply)GND)

9 XTAL - ucom OSC(16MHz)

10 EXTAL I ucom OSC(16MHz)

11 MD1 I Ucom mode MD0/MD1

12 MD0 I Ucom mode inner ROM

extension mode :

13 AVss - Ucom A/D power supply(GND)

14~21 - - Not used

22 AVcc - Ucom A/D power supply

23~30 - - Not used

31 Vcc - Ucom power supply

32~39 - - Not used

40 Vss - Ucom power supply (GND)

41~47 - - Not used

48 A0 O LCD drive control

49~56 D0~D7 I/O LCD drive control

57 - - Not used

58 LAT I Communication latch /thrust

59 - I Not used

60 RD O LCD drive control

61 WR O LCD drive control

62 CS1 O LCD drive control

63 - - Not used

64 - - Not used(Pull up)

7

DM-VH7

Key Description

O.T.E. [LCD (LED)]

[all on (blink)] or [off (off)]

STOP Cancel of mode

Key Operation

UP/DOWN Select parameter and mode.

PLAY Fix items. Change of display in every check.

STOP Cancel or back of test mode.

Key Operation

DOWN(SHIFT+) Select servo of PIT or GROOVE

PLAY(SHIFT+) Servo on

REC Pickup stops to move. Skip modes.

STOP(SHIFT+) Servo off

MODE Display change.

UP(SHIFT+) Servo on/off

F F Pickup moves outwards when press FF key

F B Pickup moves inwards when press FB key

(SHIFT+): Show the "SHIFT" on the display by pressing the O.T.E. key

1. Setting of Continuous Playback Mode

No. Key

1 UP/DOWN Select [CPLAY MODE]

2 Load disc

3 PLAY [CPLAY MID]

[c=xxxx a=yy] error

(xxxx=C1 error, yy=ADIP error)

4 MODE [CPLAY(zzzz)] CPLAY address

(MID=0300h, OUT=0700h, IN=0030h cluster)

5 MODE [h✽✽✽✽d@@@@] address

(✽✽✽✽=current head address, @@@@=ADIP address)

In No.5, Display shows [-] if can't read disc.

2. Change of Playback Points(in continuous playback mode)

No. Key

Display/Function

Display/Function

1 PLAY [CPLAY OUT]

2 Carry out No.4 and 5 in the above table.

3 PLAY [CPLAY IN]

4 Carry out No.4 and 5 in the above table.

5 STOP [CPLAY MODE]

6 EJECT Disc out

1. Continuous Recording Setting

No. Key Display/Function

1 UP/DOWN Select [CREC MODE]

2 Load the recordable disc

3 PLAY [CREC MID]

4 PLAY [CREC (zzzz)] CREC address

(0300h cluster=recording start point)

5 MODE [h✽✽✽✽d@@@@] address

6 MODE [c=xxxx a=yy] error

7 MODE [CREC (zzzz)]

8 STOP [c=xxxx a=yy]

2. Change and End of Recording Points

1 Carry out No.1 to 3 in the above table Select[CREC MID]

2 UP [CREC OUT]

3 PLAY [CREC (zzzz)] CREC address

(0700h cluster=recording start point)

Carry out No.5 to 8 in the above table

4 Carry out No.1 to 3 in the above table

5 PLAY Select [CREC MID]

6 UP(twice) Select [CREC IN]

7 PLAY [CREC (zzzz)] CREC address

(0300h cluster=recording start point)

Carry out No.5 to 8 in the above table

8 EJECT Disc out

Starting address is the followings.

IN=30h cluster, MID=300h cluster, OUT=700h cluster

LCD Display Descriptions

PLAY(logo) Servo on

PAUSE(logo) Tracking servo on

REC(logo) Record (laser write power)

GRV Servo groove mode

CLV-S Rough servo clock

CLV-A Spindle lock

RECORD Recordable disc or no disc

No. Display Description Section

1 TEMP ADJUST

The work of adjustment is

6-5

unnecessary in this mode

2 LDPWR ADJUST Laser power adjustment 6-6

3 LDPWR CHECK Laser power check 6-6

4 EFBAL ADJUST Traverse adjustment 6-7

6 FBIAS ADJUST Focus bias adjustment 6-8

5 TE B. ADJUST Automatic EF balance adjustment.

7 CPLAY MODE Continuous playback mode 5-5

8 CREC MODE Continuous recording mode 5-6

9 STT-LIMIT SW

Check the mechanism start

–

limit SW position

10 JUMP MODE Track jump checking mode –

11 SRV DAT READ Servo data reading –

12 EEP MODE E2PPROM data reading or rewrite –

13 EEP INITIAL E2PROM data initializing –

CIRCUIT DESCRIPTION

5. TEST MODE

5-1 How to Setting and Cancel Test Mode

Setting: While pressing the ON/STANDBY and MODE

keys, insert the power cord to the wall outlet.

Cancel: Pull out the power cord.

Mechanism Initialization

Setting: While pressing the EJECT key, insert the power

cord to the wall outlet.

Display shows [INITIALIZE]. Mechanism is in normal

mode after unload the disc if it loaded

Display

Setting: While pressing the MODE key, insert the power

cord to the wall outlet.

Cancel: Pull out the power cord.

Key Operation for Ajustment

5-2 Remaind Keys Operation

Caution: Data of E2PROM will be erased if pressed

O.T.E. key for more 3seconds.

For more information on each adjustment mode, refer to

each section of 6, "Electrical adjustment".

If other adjustment mode has been entered incorrectly,

press the STOP key to exit the mode.

* The number 9 - 13 are not used for service. If these

mode have been entered incorrectly, press the STOP

key immediately to exit the mode. Specially, do not use

EEP INITIAL. (E2PROM data has initialized if used it.)

5-5 Continuous Playback Mode

5-6 Continuous Recording Mode

5-3 Display of Mechanism operation in Test Mode

5-4 Selection of test mode

13 test modes are selected by pressing UP/DOWN keys.

8

1. The recording start addresses of IN, MID, and OUT

are described below.

IN 30H cluster

MID 300H cluster

OUT 700H cluster

2. An erasure prevention control is not detected in the

test mode. Be careful not to enter the continuous

recording mode using a disc containing the data that

should not be erased.

3. Do not record continuously for more than five

minutes.

4. Take care that no vibration is applied during

continuous recording.

Loading...

Loading...