Kenwood DMS-500 Service manual

MINI DISC RECORDER

7 3

8

¡1

÷REC

REC

INPUT

REC

LEVEL

ON/STANDBY

MINI DISC RECORDER DM-S500

0

TIME

DISPLAY

¢4

L

R

L

R

REC

IN

DIGITAL IN

LINE

OPTICAL

1 2

PLAY

OUT

SYSTEM

CONTROL

DM-S500

SERVICE MANUAL

© 1997-11/B51-5398-00 (K/K) 2456

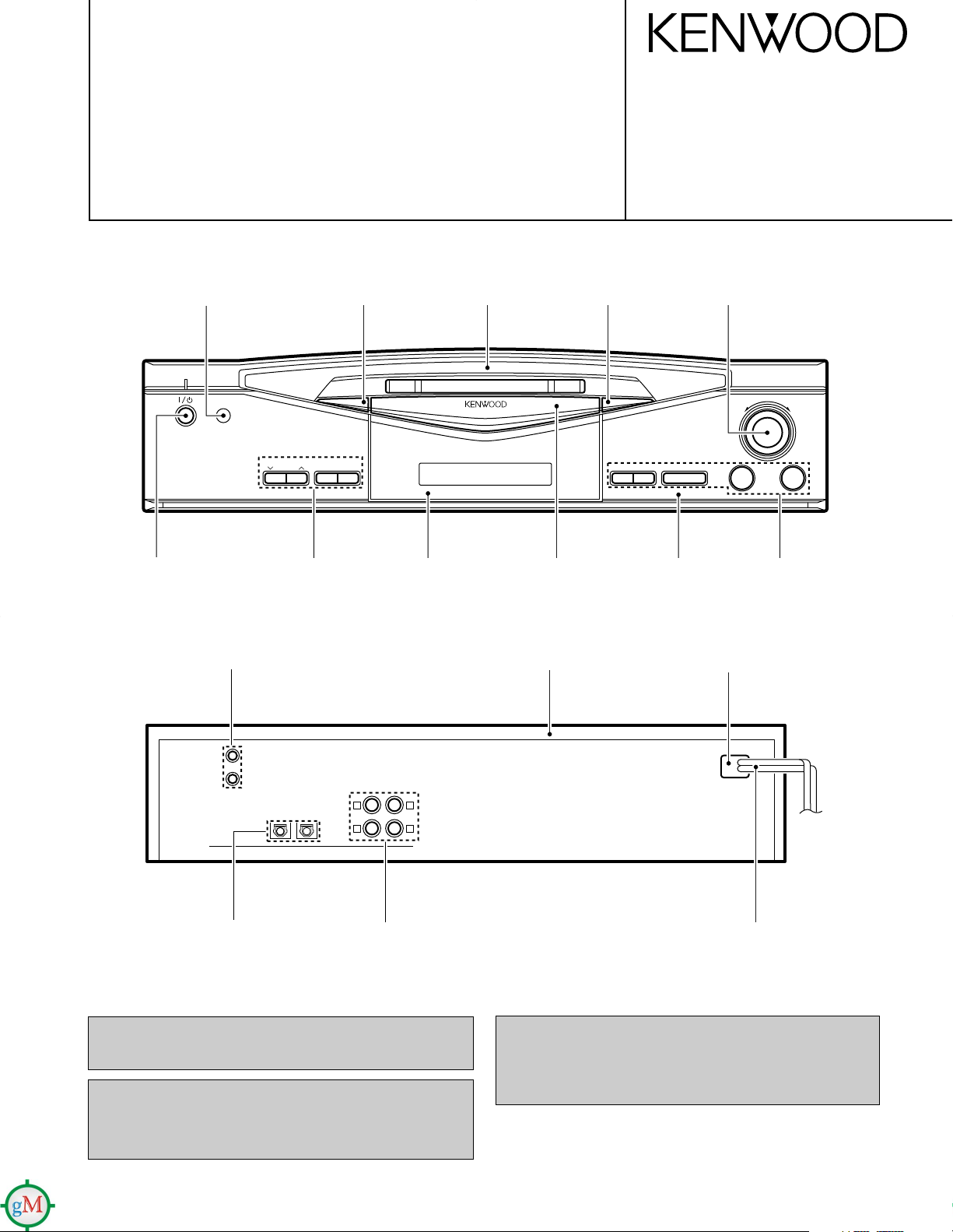

Indicator

(B12-0329-04)

Knob

(K29-6835-12)

Miniature phone jack

(E11-0188-05)

Dressing panel

(A21-3622-03)

Knob

(K29-6835-12)

Dressing panel

(A21-3620-02)

Front glass

(B10-2386-12)

Dressing panel

(A21-3623-03)

Dressing panel

(A21-3621-03)

Metallic cabinet

(A01-3444-01)

Knob

(K29-6945-04)

Panel *

(A60-)

Power cord bushing

(J42-0083-05)

Knob

(K29-6835-12)

Optic receiving module

(W02-1181-05)

In compliance with Federal Regulations, following are reproductions of labels on, or inside the product relating to laser product

safety.

KENWOOD-Crop. certifies this equipment conforms to DHHS

Regulations No. 21 DFR 1040. 10, Chapter 1, Subchapter J.

Phono jack

(E68-0120-05)

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM

AC power cord *

(E30-)

* Refer to parts list on page 25.

Refer to DM-SE7/SE9 (B51-5395-00) and

DM-5090/9090 (B51-5387-00) service manuals if require circuit description.

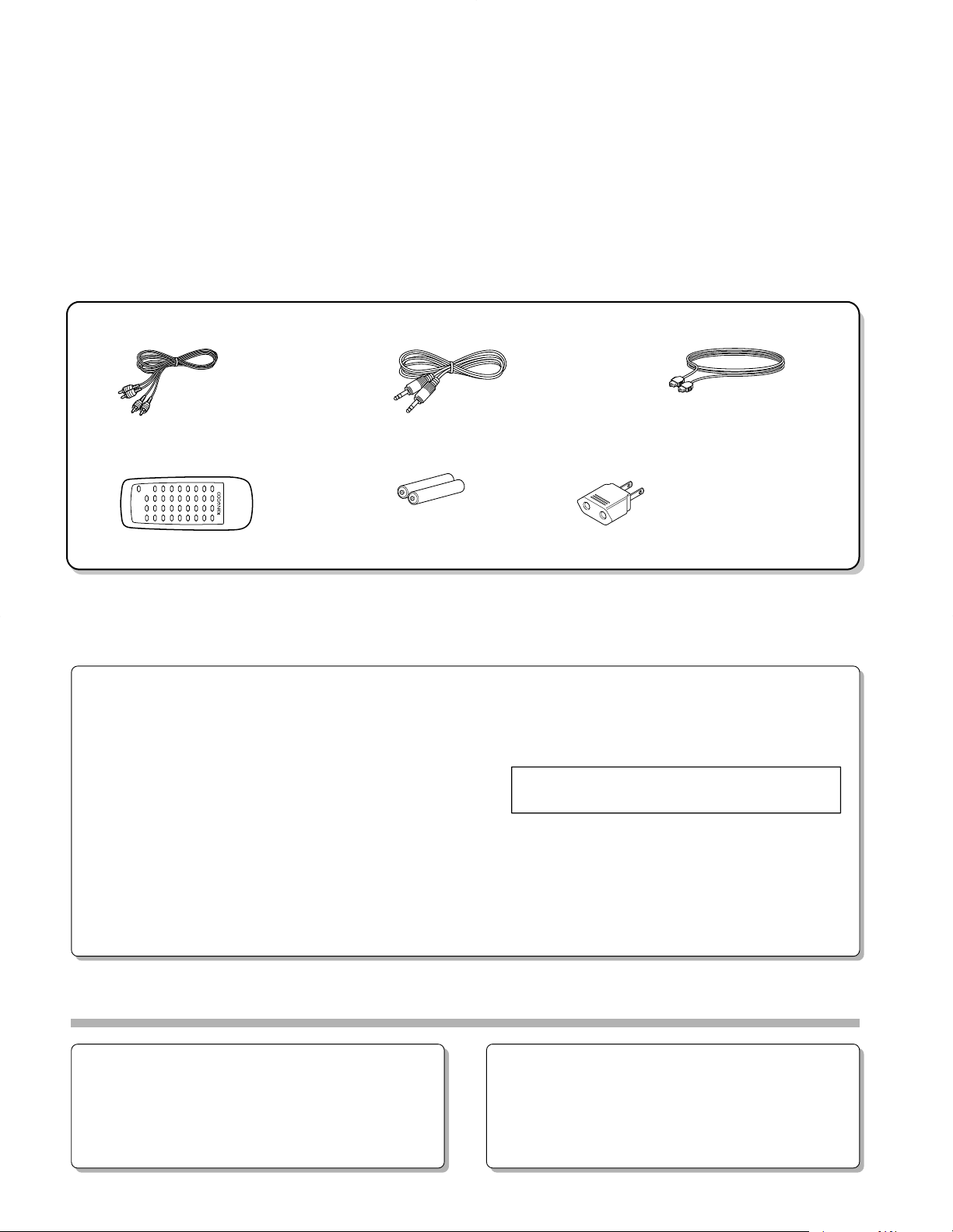

Audio cord (2)

System control cord (1)

Optical

(E30-0505-05)

(E30-2733-05)

(B19-1529-05)

fiber cable (1)

Remote control unit (1) Batteries (2)

AC

(A70-1187-05) (E03-0115-05)

plug adaptor (1)

Use to adapt the plug on

the power cord to the

shape of the wall outlet.

(Accessory only for regions

where use is necessary.)

Battery cover (A09-0356-08)

DM-S500

Note related to transportation and movement

Before transporting or moving this unit, carry out the

following operations.

1. With no disc loaded in the unit, press the ON/STANDBY

key to on.

÷ Check that no disc is present in the unit.

2. Wait a few seconds and verify that the display shown

appears.

3. Press the ON/STANDBY key to off (standby).

Cleaning

Unplug this appliance from the wall outlet before cleaning. Do not use

volatile solvents such as alcohol, paint thinner, gasoline, or benzine,

etc. to clean the cabinet. Use a clean dry cloth.

Caution against contact revitalizer

Do not use contact cleaners because it could cause a malfunction. Be

specially careful against contact cleaners containing oil, for they may

deform the plastic componente.

Maintenance

CONTENTS / ACCESSORIES / CAUTIONS

Contents

CONTENTS / ACCESSORIES / CAUTIONS...............2

CONTROLS.................................................................3

ADJUSTMENT............................................................ 5

PC BOARD ............................................................... 10

Accessories

SCHEMATIC DIAGRAM............................................13

EXPLODED VIEW .....................................................23

PARTS LIST...............................................................25

SPECIFICATIONS .......................................Back cover

Cautions

L

∞

N O IDISC

R

(−dB)

3

0130105

2

7 3

8

¡

1

÷REC

REC

INPUT

REC

LEVEL

ON/STANDBY

MINI DISC RECORDER DM-S500

0

TIME

DISPLAY

¢

4

SHUTTLE

REPEAT

(

-

dB)

MANUAL

REMAIN

TOTAL

SINGLE

TITLE

•

••••

•

•

•

••

R

L

••

3

0130105

SEARCH

PGM

DIGITAL 1 2

CD TEXT

MONITOR

ON/STANDBY

POWER

32 4 75 611

8 9 0 # $@!

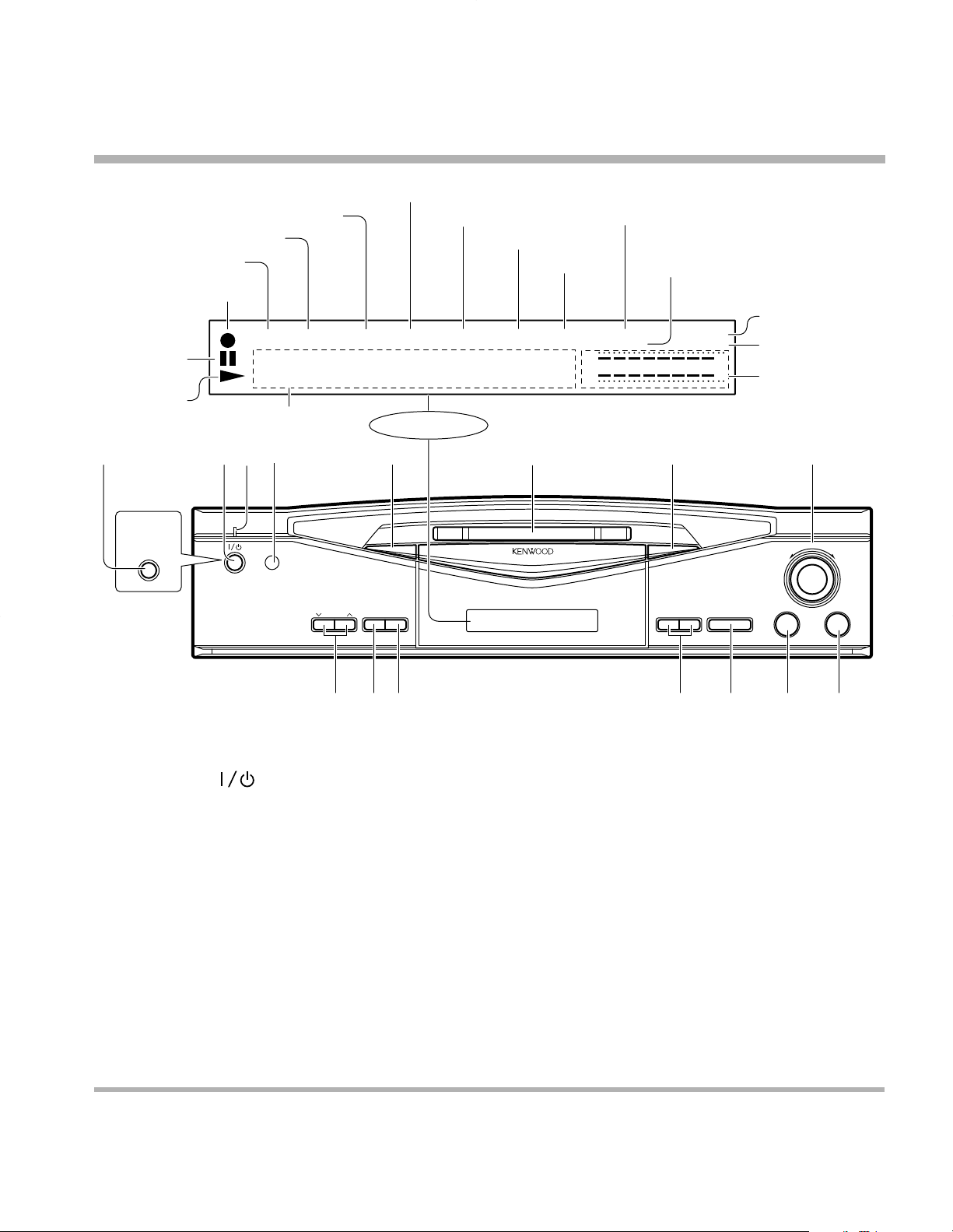

Play indicator

Character information display

Pause indicator

REC indicator

Peak level indicator

MANUAL indicator

Display / Main unit

REPEAT indicator

SINGLE indicator

PGM indicator

TOTAL indicator

REMAIN indicator

TITLE indicator

SEARCH

indicator

DIGITAL input indicator

Display

MONITOR indicator

For U.S.A.

and Canada

1 ON/STANDBY ( ) key

Press to turn the unit on or off (standby).

1 POWER key (For U.S.A. and Canada)

Press to turn the unit on or off.

2 Standby indicator

3 Remote control sensor

The key control signals from the remote control unit enter the

main

unit from here.

4 TIME DISPLAY key

5 Mini Disc insertion slot

Insert a minidisc.

6 Eject (0) key

Press to unload the Mini Disc.

7 SHUTTLE (4, ¢) knob

Use to skip disc tracks during playback.

During editing, this knob is used to select track numbers, title

and

characters.

8 REC LEVEL keys

This key is used to adjust the recording level.

9 REC INPUT key

This key is used to switch the recording input source.

0 REC (¶) key

Press when starting recording.

! Fast forward and fast backward (1, ¡)

During playback, this key is used to move the played position

forward

or backward.

At the time of editing, the cursor movement and the selected title

can

be confirmed.

@ Pause (8) key

Press to temporary stop the disc operation.

# Stop (7) key

Press to stop the disc operation.

$ Play (3) key

Press to start playback.

About the STANDBY mode

While the STANDBY indicator is lit on the display, a small amount of power is supplied to the system to back up the memory. This is called the

standby

mode. Under that condition, the system can be turned ON by the remote control unit.

CD TEXT indicator

CONTROLS

DM-S500

3

4

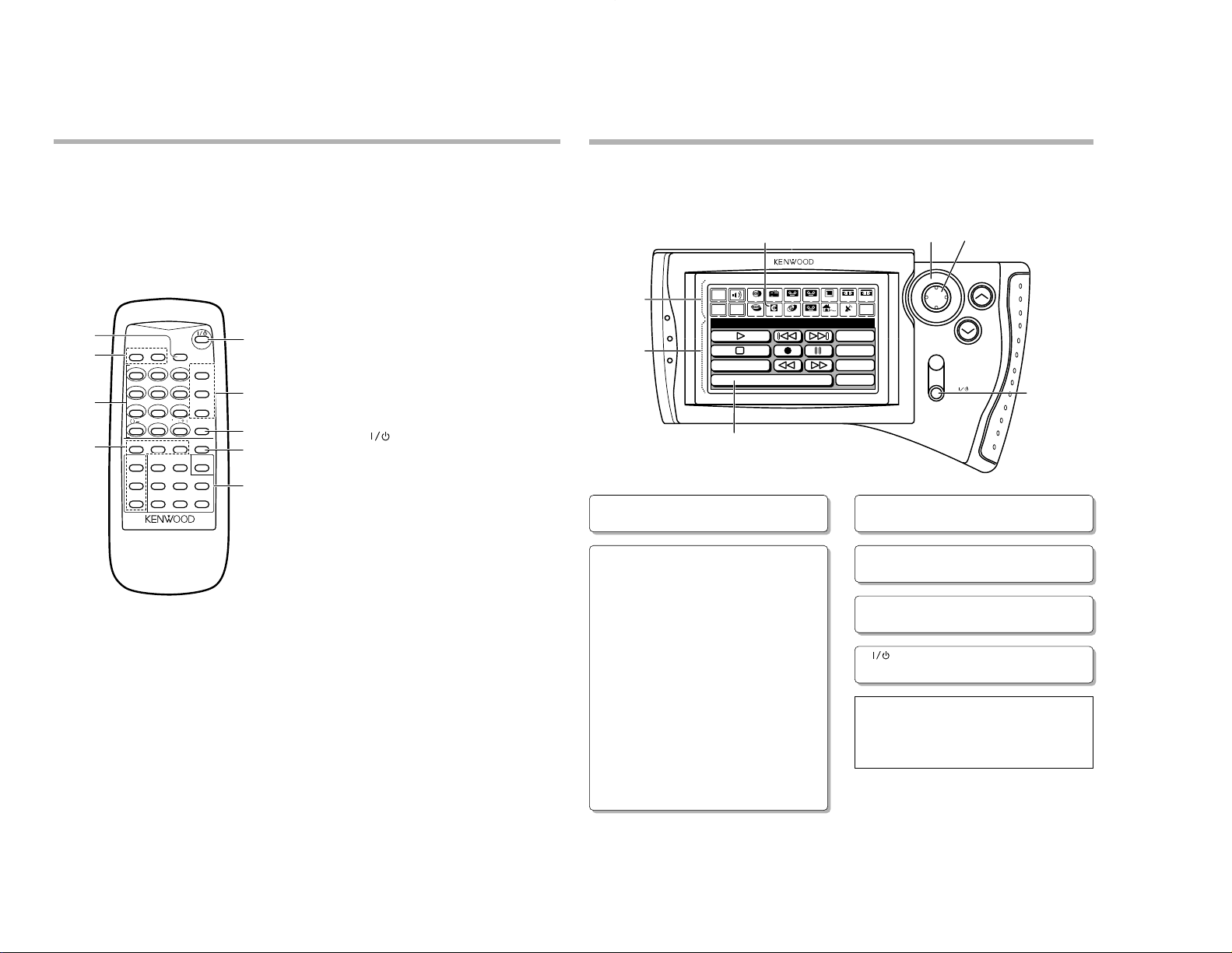

Remote control unit

1 TIME DISPLAY key

: Press to switch the time display mode.

2 Applied operation keys

RAMDOM key

: Used at the time of random playback.

REPEAT key

: Press to play tracks repeatedly.

3 Numeric keys

: Press to specify the desired track number.

: Used at the time of title input for selection of characters and

symbols.

4 Edit operation keys

EDIT key

: This key is used to switch the editing mode.

SET key

: Press to set the editing result or input title definitely in memory.

ENTER key

: Press to execute editing or title input operation.

TITLE INPUT key

: This key is used to switch the title input mode.

TITLE SEARCH key

: This key is used to switch the title search mode.

EDIT CANCEL key

: Used to cancel editing.

5 POWER ( ) key

: Press to turn the unit on or off (standby).

6 Program operation keys

P.MODE (Play mode)/CHARACTER key

: This key is used in program playback. During title input, it is used to

select the character group.

CHECK/SPACE key

: This key is used to check the program contents.

During title input, it is used to insert a blank space character.

CLEAR/DELETE key

: This key is used to clear the program. During title input, it is used to

delete a character.

7 REC INPUT (Recording input) key

: This key is used to switch the recording input source.

8 MONITOR key

: The sound of the unit connected to “DIGITAL 2” is heard.

9 Basic operation keys

1 ¡ : Fast forward and fast backward keys.

(Same function as the keys on the main unit.)

4 ¢ : Skip keys.

(Same function as the knob on the main unit.)

¶ : Record key 8 : Pause key

7 : Stop key 3 : Play key

AUTO/MANU. key

: This is used for selection of automatic (AUTO) or manual (MANU.)

track number assignment at the time of recording.

Model: RC-M0502

Infrared ray system

CURSOR/CHECK

1Segment screen

This screen is used for selecting the icons for the main equipment.

Graphical Remote Control Unit (GRC)

REMOTE CONTROL UNIT

ON /STANDBY

MUTE

VOLUME

ENTER

Return

VCR2VCR1

TV

Sat.Cable

TapeBTapeA

Confirm

Tape1

LDMDDVD

Tuner

CD

Set Up

Main

Menu

MD

Edit

Mode

PGM

10key

Power

Title Search

2

1

3

6

54

3

Model : GRC-151, GRC-102 or

GRC-101

Infrared ray system

A graphical remote control (GRC-151, GRC-102 or GRC-101) is sold separately.

To enable remote control operation, simply connect this unit, cassette deck (sold separately), and other accessories to the AV

CONTROL CENTER with the system control cords.

2Menu screen

This screen is used for selecting the icons for the operating modes.

MD recorder operation panel

Play icon (3)

Pause icon (8)

Stop icon (7)

Search icons (1, ¡)

These icons send the track forward or backward.

Mode icon

This icon is used to select the playback mode.

Skip icons (4, ¢)

When selected, the next track in the icon direction is played.

10key Pad icon

This icon switches to the Numeric Icon menu screen.

Power icon

This icon is used to turn the unit on or off. You can use this icon

only when you select “IR” in the setup menu.

Rec icon (¶)

This icon is used for recording.

PGM icon

This icon is used for program playback.

Edit icon

This icon is used to select the editing mode.

Title Search icon

This icon is used to switch the title search mode.

3Icons

Icons for the equipment used and operating mode are displayed.

4Joystick

The joystick is used when selecting the icons.

(Lightly press the edge of 5.)

5ENTER key

Press this button to input the selected icon (operation mode, and

so on).

6 (ON/STANDBY) key

This key turns ON/STANDBY this unit or the equipment connected with the system control cords.

If your GRC unit is the GRC-100 or GRC-150

If the GRC unit provided with your AV CONTROL CENTER

(optional) or receiver (optional) is the “GRC-100” or “GRC150”, the DM-S500 unit should be controlled using the

remote control unit provided with this unit.

DM-S500

RC-M0502

1

2

3

4

REPEAT

RANDOM

ABC DEF

1 2 3

GHI JKL MNO

4 5 6

PRS TUV WXY

7 8 9

/

QZ

&

+100 0 +10

EDIT

SET

TITLE

CURSOR/CHECK

INPUT

1 ¡

TITLE

4 ¢

SEARCH

EDIT

7

CANCEL

REMOTE CONTROL UNIT

TIME

DISPLAY

,

ENTER MONITOR

3

POWER

P.MODE

CHARACTER

CHECK

SPACE

CLEAR

DELETE

REC

INPUT

AUTO/

MANU.

¶

8

5

6

7

8

9

CONTROLS

ADJUSTMENT

DM-S500

1. Test mode of the unit

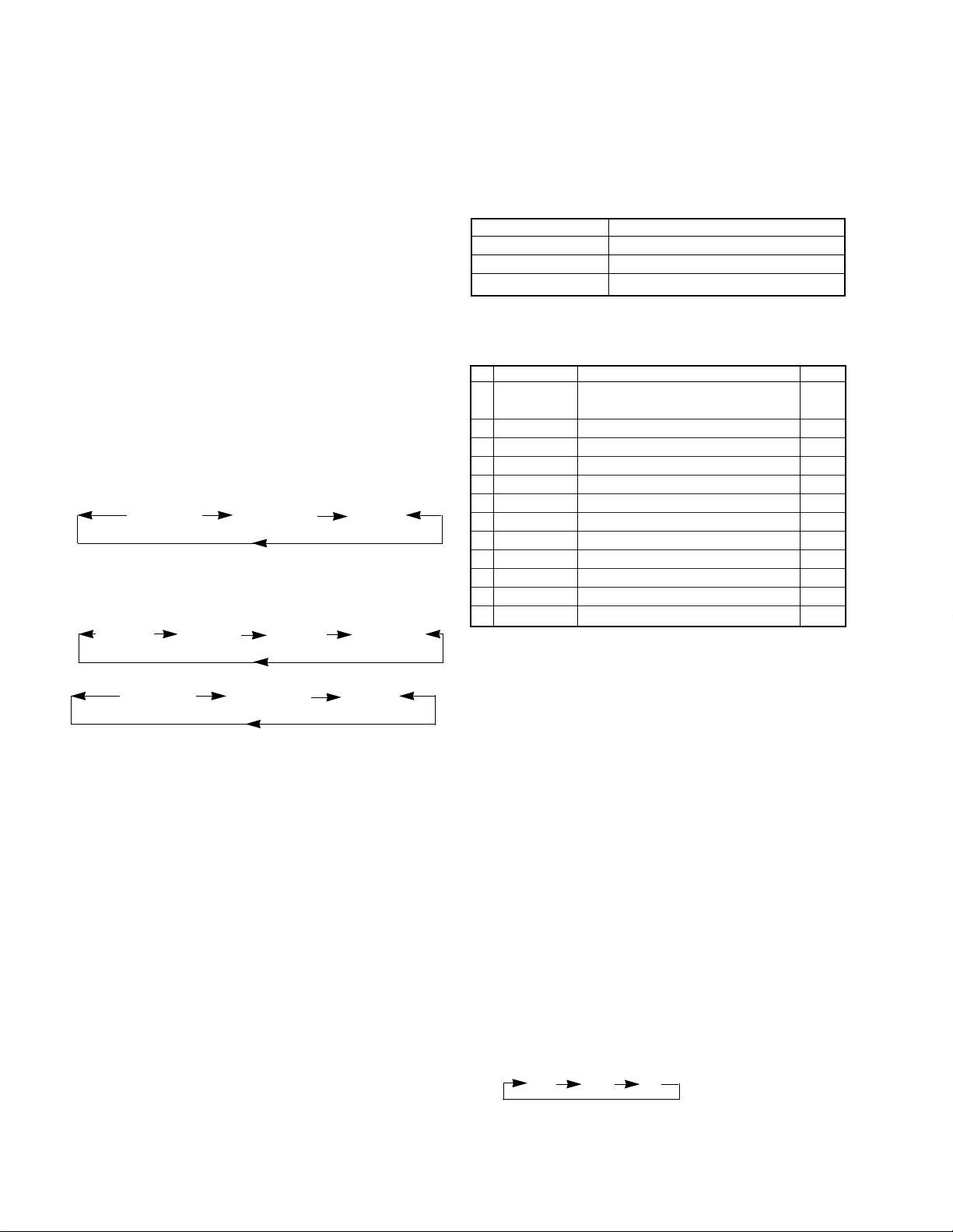

1-1 Setting of the test mode

While pressing the [STOP] key, plug the AC power cord

into the AC wall outlet.

1-2 Contents of the test mode

1 [DOT TEST]

2 [SEG TEST]

✣ 3 [KEY TEST]

✣ 4 [CYBER TEST] J type only

✣ Used for production line only

1-3 Function of the test mode

1 [DOT TEST]

The FL display starts the "NIAGARA MODE" by pressing

the [PLAY] key in the [DOT TEST] mode.

2 [SEG TEST]

Turn the FL indication ON by pressing the [PLAY] key in

the [SEG TEST] mode.

The FL indication changes cyclically as shown in the

below by turning the SHUTTLE (4¢).

FL LIGHT ON FL LIGHT OFF ENGLISH

1-4 Function of the key

1 SHUTTLE (¢) and down (4)keys

: Selects the test mode.

[DOT TEST] [SEG TEST] [KEY TEST] [CYBER TEST]

: Selects the FL indication

FL LIGHT ON FL LIGHT OFF ENGLISH

2 Play key

: Proceeds the test mode or return to test mode.

3 Stop key

: Cancel the test mode.

1-5 Microprocessor reset

The microprocessor can be initialized while pressing the

[EJECT] key, plug the AC power cord into the AC wall

outlet.

2. Mechanism test mode

2-1 Setting the test mode

While pressing the [PLAY] key, plug the AC power cord into

the AC wall outlet

2-2 Canceling the test mode

Unplug the AC power cord.

1. Test mode of the unit

2-3 Basic operation in test mode

All operations are performed using the SHUTTEL

(up/down), PLAY key and STOP key. The functions of each

key are shown in the table below.

Function Description

SHUTTEL (up/down) Changes the parameter and mode.

PLAY key Proceeds for definition.

STOP key Returns for interrupt.

2-4 Selection of test mode

12 test modes are selected by turning the SHUTTLE.

No. Display Description Section

1 TEMP ADJU The work of adjustment is unnecessary -

in this mode

2 LDPWR ADJU Laser power adjustment 3-5

3 LDPWR CHEC Laser power check 3-5

4 EFBAL ADJU Traverse adjustment 3-6

5 FBIAS ADJU Focus bias adjustment 3-7

6 CPLAY MODE Continuous playback mode 2-4-1

7 CREC MODE Continuous recording mode 2-4-2

8 STT-LIMIT Check the mechanism start limit SW position 9 JUMP MODE Track jump checking mode -

10 SRV DATA RE Servo data reading 11 EEP MODE E2PPROM data reading or rewrite 12 EEP INITIA E2PROM data initializing -

For more information on each adjustment mode, refer to

each section of 3, “Electrical adjustment”.

If other adjustment mode has been entered incorrectly,

press the STOP key to exit the mode.

* The number 8 - 12 are not used for service. If these

mode have been entered incorrectly, press the STOP

key immediately to exit the mode. Specially, do not use

EEP INITIAL. (E2PROM data has initialized if used it.)

2-4-1 Operation in continuous playback mode

1. Entering the continuous playback mode

(1) Insert a recordable disc or pre-mastered disc into the

unit.

(2) Turn the SHUTTLE to display “CPLAY MODE”.

(3) Press the PLAY key. The display then changes from

“CPLAY MODE” to “CPLAY MID”.

(4) After the access operation is completed, the display

changes from “CPLAY MID” to “C=#### a=##”.

Note: Numerals on the display appear the error rate and

ADIP error.

2. Change the playback point.

(1) Press the PLAY key during continuous playback. The

display then changes as follows.

MID OUT IN

(2) After the access operation is completed, the display

changes “C=####” a=##”.

5

DM-S500

Pick-up

Flexible board

Laser tap

ADJUSTMENT

Note: Numerals on the display appear the error rate and

ADIP error.

3. Terminating the continuous playback mode

(1) Press the STOP key. The display then changes to

“CPLAY MODE”.

(2) Press the EJECT key to take out the disc.

Note : The playback start addresses of IN, MID, and OUT

are described below.

IN 30H cluster

MID 300H cluster

OUT 700H cluster

2-4-2 Operation in continuous recording mode

1. Entering the continuous recording mode

(1) Insert a recordable disc into the unit.

(2) Turn the SHUTTLE to display “CREC MODE”.

(3) Press the PLAY key. The display then changes from

“CREC MODE” to “CREC MID”.

(4) Press the PLAY key again. The display changes from

“CREC MID” to “CREC (####)”, and the continuous

recording is started.

Note : Numerals on the display (####) appear the address

of recording point.

2. Change the recording point.

(1) Turn the SHUTTLE to clockwise while “CREC MID” is

displayed. The display changes as follows. (The recording point can be shifted.)

MID OUT IN

(2) Press the ENTER key. The display then changes to

“CREC(####)”, and the continuous recording is started.

Note : Numerals on the display (####) appear the address

of recording point.

3. Terminating the continuous recording mode

(1) Press the STOP key. The display then changes to

“CREC MODE” and the REC display goes off.

(2) Press the EJECT key to take out the disc.

Notes :

1. The recording start addresses of IN, MID, and OUT are

described below.

IN 30H cluster

MID 300H cluster

OUT 700H cluster

2. The STOP key can be pressed at any time to stop the

recording.

3. An erasure prevention control is not detected in the test

mode. Be careful not to enter the continuous recording

mode using a disc containing the data that should not be

erased.

4. Do not record continuously for more than five minutes.

5. Take care that no vibration is applied during continuous

recording.

2-5 Other key function

Function Description

3 Plays back continuously when this key is pressed during

stop. Turn on and off the tracking servo when it is

pressed during continuous playback.

7 Stops the continuous playback and recording.

1 The thread moves to the inner circumference while this key

is pressed.

¡ The thread moves to the outer circumference while this

key is pressed.

Note : An erasure prevention control is not detected in the

test mode. Notice that recording is performed irrespective

of the erasure prevention control position when the REC key

is pressed.

2-6 Precaution on use of test mode

✣ An erasure prevention control is not detected in the test

mode. Therefore, when the recording laser power mode

such as continuous recording mode and traverse adjustment mode is entered, the contents of the existing

recording are erased irrespective of the control position.

Be careful not to enter the continuous recording mode

and traverse adjustment mode when using a disc, containing the data that should not be erased, in the test

mode.

3. Electrical adjustment

3-1 Precaution during confirmation of Laser Diode

emission

During adjustment, do not view the emission of a laser diode

from just above for confirmation. This may damage your

eyes.

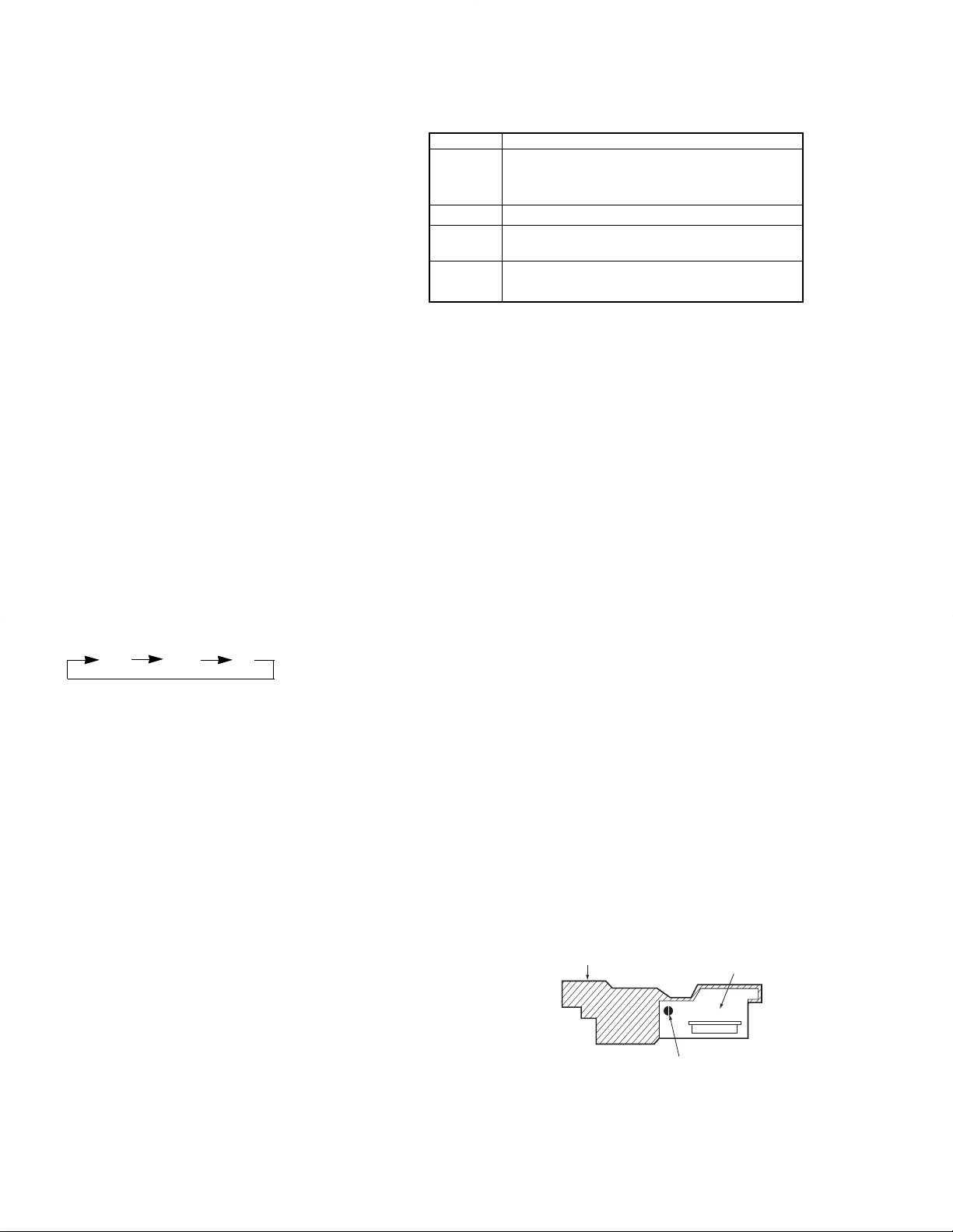

3-2 Precaution on handling of Optical pick-up

(KMS-260A)

The laser diode in an optical pick-up is easy to be subject to

electrostatic destruction. Therefore, solder-bridge the laser

tap on the flexible board when handling the optical pick-up.

When removing the flexible board from the connector, make

a solder bridge in advance, then remove the board. Be

careful not to remove the solder bridge before inserting the

connector. Moreover, take careful measures against electrostatic destruction. The flexible board is cut easily. Handle the flexible board with care.

3-3 Precaution during adjustment

1) Perform the adjustment and confirmation marked with

“O” in the order shown in the table when the parts below

are replaced.

6

+

-

Laser

power meter

Digital

voltmeter

Objective lens of

optical pick up

TP2

TP1

X33

ADJUSTMENT

ADJUSTMENT

DM-S500

2) In the test mode, perform the adjustment. After adjustment is completed, cancel the test mode.

Optical BD board

1.Temperature compensation offset adjustment

2.Laser power adjustment O O X O

3.Traverse adjustment O O X O

4.Focus bias adjustment O O X O

5.Error rate confirmation O O X O

pick-up IC6 D101 IC1,IC2,IC10

X O O O

3) Perform the adjustment in the order described.

4) Use the following tools and measurement equipment.

• CD test disc TGYS-1

• Laser power meter

• Oscilloscope (with bandwidth of more than 40 MΩ)

(Calibrate the probe before measurement.)

• Digital voltmeter

• Thermometer

5) Take care that VC and GND (ground) are not connected

on the oscilloscope when two or more signals are monitored on the oscilloscope. (VC and GND are short-circuited in this case.)

Note : The "#" display on the screen indicates an arbitrary

figure.

3-4 Creating the recordable continuous recording

disc

This disc is used for focus bias adjustment and error rate

confirmation. How to create the recordable continuous

recording disc is described below.

1. Insert a commercial recordable disc (blank disc).

2. Turn the SHUTTLE to display “CREC MODE.”

3. Press the PLAY key to display “CREC MID”.

4. After pressed the PLAY key, a display indicates

“CREC(0300)” and the recording begins.

5. Terminate the recording within five minutes.

6. Press the STOP key to stop the recording.

7. Press the EJECT key to take out the recordable disc.

As a result, a continuously recorded disc can be created for

focus bias adjustment and error rate confirmation.

Note : Take care that no vibration is applied during continuous recording.

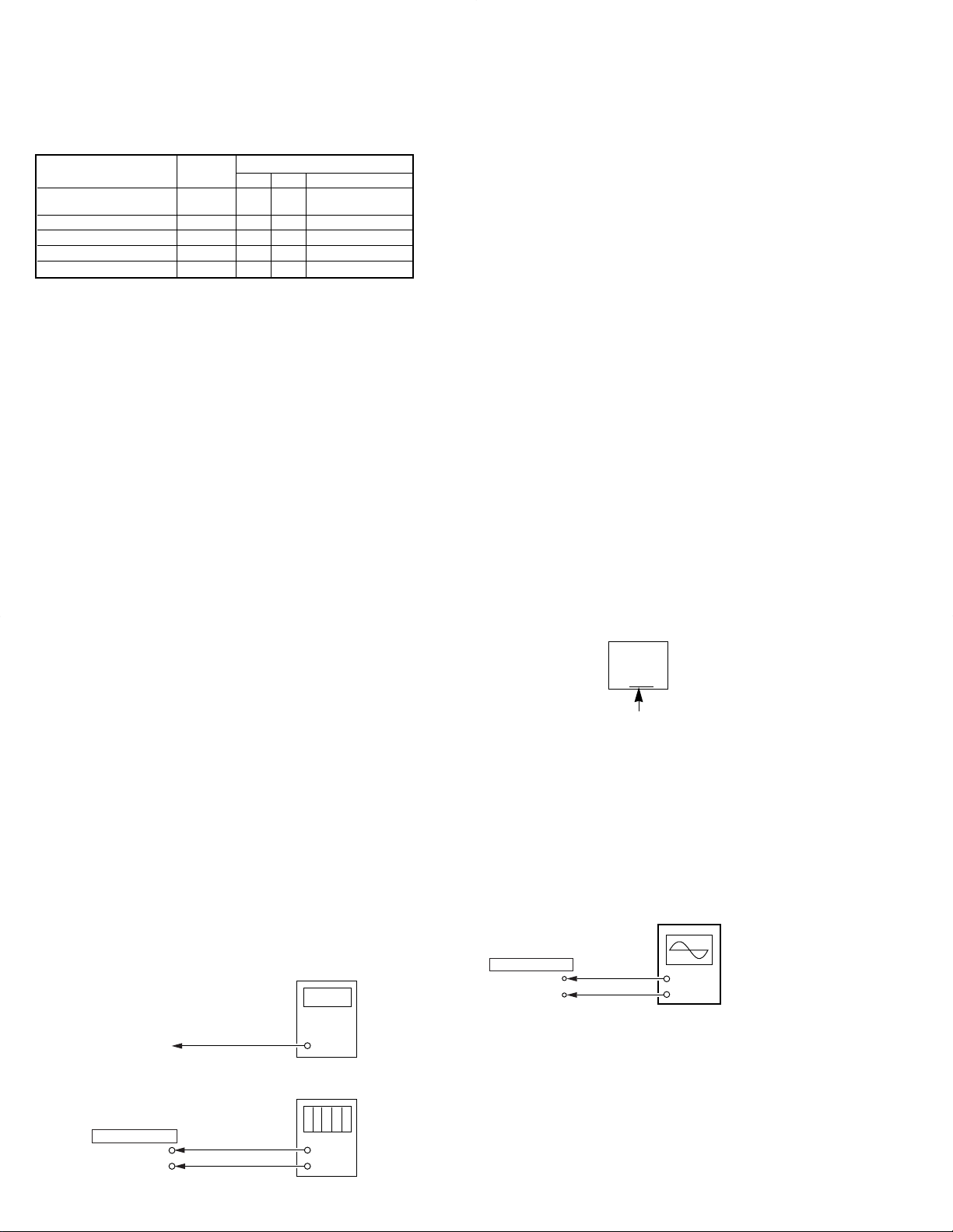

3-5 Laser power adjustment

Connection :

Adjustment :

1. Put the laser power meter on the objective lens of the

optical pick-up. Connect the digital voltmeter to TP1 and

TP2.

2. Turn the SHUTTLE to display “LDPWR ADJU”.

(Laser power : For adjustment use)

3. Press the PLAY key to display “(0.9mW)$##”.

4. Adjust to turn SHUTTLE so that the laser power meter

reads 0.86 - 0.94mW.

Set range 10mW of the laser power meter,then save to

press PLAY key.

5. “(7.0mW)$##” is displayed.

6. Adjust to turn the SHUTTLE so that laser power meter

reads 6.9-7.1mW, then save to press PLAY key.

("LDPWR<$##" is displayed momentarily.)

✣ Don't output the laser power of 7.0mW more than 15sec.

7. Next turn the SHUTTLE to display "LDPWR CHEC".

8. Press PLAY key to display "(0.9mW)$##". Check the

laser power meter reads 0.85-0.95mW.

9. Next set range 10mW of the laser power meter, then

press PLAY key to display "(7.0mW)$##". Confirm that

the laser power meter and digital voltmeterat that time

read the specified value.

Specification :

Reading of laser power meter : 7.0 ±0.1 mW

Reading of digital voltmeter : Optical pick-up indication

value ±10%

(Optical pick-up label)

In this case, lop = 82.5 mA

lop(mA) = Reading of digital voltmeter (mV)/1(Ω)

KMS

27x40

B0825

260A

10.Press the PLAY key to display “LDPWR CHEC” and

stop the laser emission. (The STOP key can be pressed

at any time to stop the laser emission.)

Note : The "#" display on the screen indicates an arbitrary

figure.

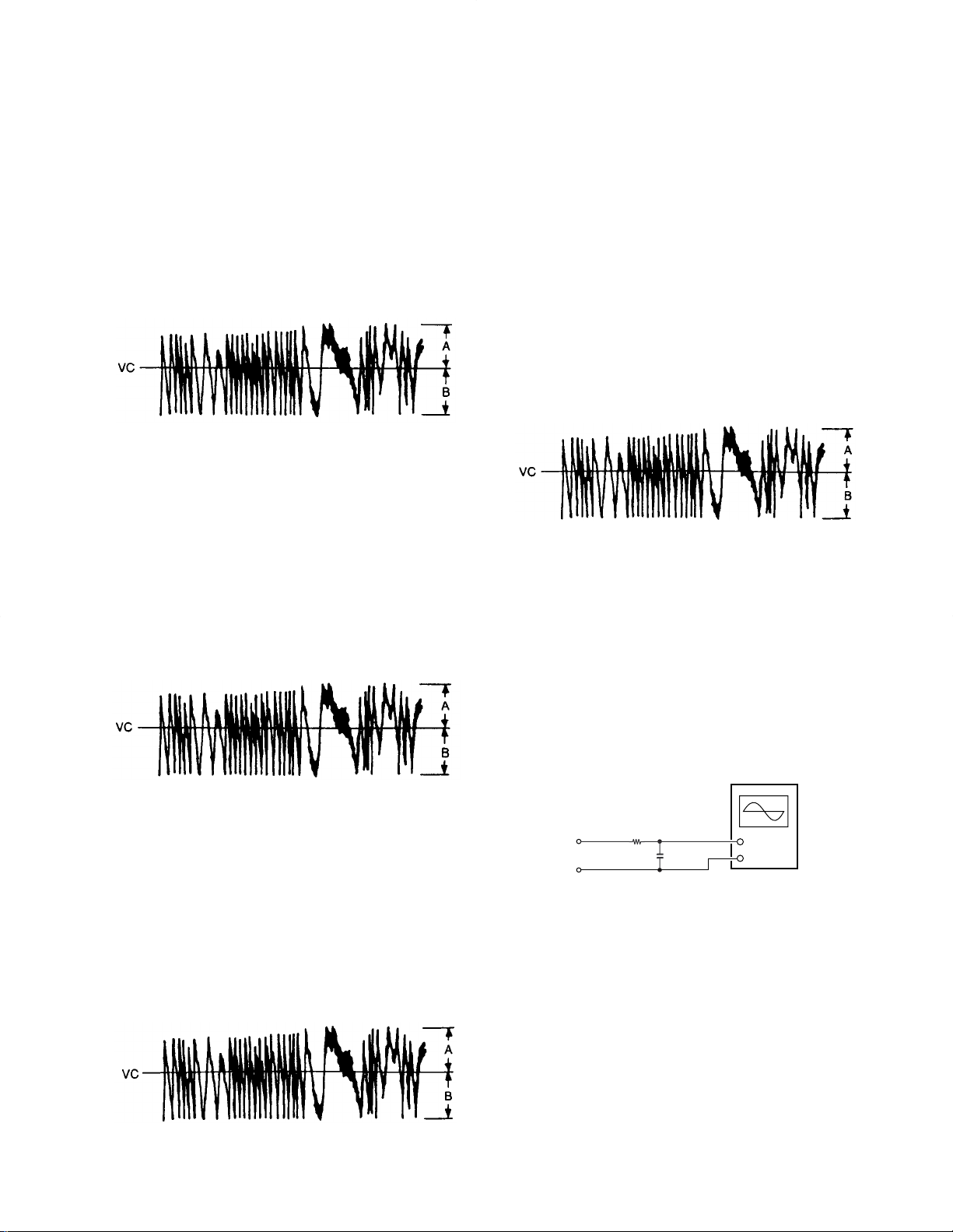

3-6 Traverse Adjustment

Connection :

Oscilloscope

X33

ADJUSTMENT

TE2

VC

+

-

V: 0.5V/div H: 10ms/div

INPUT: DC mode

7

Adjustment :

1. Connect the oscilloscope to (TE2) and (VC) on the X33

board.

2. Insert a commercial recordable disc.

3. Turn the SHUTTLE to display “EFBAL ADJU”.

(TE2)

330kΩ

10pF

(VC)

Oscilloscope

+

-

DM-S500

ADJUSTMENT

4. Press the PLAY key to display “EFBAL MO-W” and after

that press the PLAY key again to display

"EF=$##MOW".

5. Turn the SHUTTLE so that the waveform on the

oscilloscope satisfies the specified value. (When the

SHUTTLE is turned, the #-marked figure in "EF=$##"

changes and the waveform also changes.)During this

adjustment, the oscilloscope changes in units of about

3%. Adjust so that the waveform comes nearest to the

specified value. (MO groove read power traverse

adjustment)

(Traverse waveform)

Specification : A = B

6. Press the PLAY key to display "EFB=##XSA"

momentarily. After that, "EF=$##MOR" is displayed.

(Laser power READ power, forcus servo ON, tracking

servo OFF, and spindle(S) servo ON.)

7. Turn the SHUTTLE so that the waveform on the

oscilloscope satisfies the specified value. (When the

SHUTTLE is turned, the #-marked figure in "EF-##"

changes and the waveform also changes.) During this

adjustment, the oscilloscope changes in units of about

2%. Adjust so that the waveform comes nearest to the

specified value. (MO groove read power traverse

adjustment)

(Traverse waveform)

11.Press the PLAY key to display “EFB=##XSA”

momentarily and save the adjustment result in

nonvolatile memory. After that, “EFBAL CHAN” is

displayed. The disc rotation stops automatically.

Note : The "#" display on the screen indicates an arbitrary

figure.

12.Press the EJECT key to take out a recordable disc.

13.Insert test disc TGYS-1.

14.Press the PLAY key to display “EF=$##CD”. A servo is

established automatically.

15.Turn the SHUTTLE so that the waveform on the

oscilloscope comes near to the specified value. During

this adjustment, the waveform changes in units of about

2%. Adjust so that the waveform comes nearest to the

specified value.

(Traverse waveform)

Specification : A = B

16.Press the PLAY key to display “EFB=##XSA”

momentarily and save the adjustment result in

nonvolatile memory. After that, “EFBAL ADJU” is

displayed.

17.Press the EJECT key to take out test disc TGYS-1.

Notes :

1. Data is erased during MO write when a recorded disc is

used for this adjustment.

2. If the traverse waveform is difficult to be monitored,

connect an oscilloscope as shown in the figure below.

Specification : A = B

8. Press the PLAY key to display “EFB=##XSA”

momentarily and save the adjustment result in

nonvolatile memory After that, "EFBAL MO-P" is

displayed.

9. Press PLAY key to display "EF=$##MOP".(A pick-up

moves automatically to pit block area.)

10.Turn the SHUTTLE so that the waveform on the

oscilloscope comes near to the specified value. During

this adjustment, the waveform changes in units of about

2%. Adjust so that the waveform comes nearest to the

specified value.

(Traverse waveform)

Specification : A = B

8

3-7 Focus bias adjustment

Connection :

1. Insert a continuously recorded disc (refer to 3-4,

“Creating the recordable continuous recording disc”).

2. Turn the SHUTTLE to display “CPLAY MODE”.

3. Press the PLAY key to display “CPLAY MID”.

4. Press the STOP key when "C=✽✽✽✽ a=✽✽" is

displayed.

5. Turn the SHUTTLE to display “FBIAS ADJU”.

6. Press the PLAY key to display “a=## ####/”. The fourdigit figure indicates the C1 error rate, and the two-digit

figure after “a=” indicates the focus bias value.

Loading...

Loading...