Page 1

2260B Series

www.keithley.com

Verification

Procedure

A Tektronix

Company

A

G R E A T E R M E A S U R E O F C O N F I D E N C E

Multi-Range

Programming

DC Power

Supplies

077-1048

-01/ A

u

g

u

s

t

2015

Page 2

Series 2260B

Multi-Range Programmable DC Power Supplies

VERIFICATION PROCEDURE

ISO-9001 CERTIFIED MANUFACTURER

Page 3

This manual contains proprietary information, which is protected by copyright. All rights are reserved.

No part of this manual may be photocopied, reproduced or translated to another language without

prior written consent of Keithley company.

The information in this manual was correct at the time of printing. However, Keithley continues to

improve products and reserves the rights to change specification, equipment, and maintenance

procedures at any time without notice.

Page 4

Table of Contents

1

Table of Contents

Preparing for Verification ....................................................... 2

List of Equipment for Verification ............................................ 3

Constant Voltage Tests .......................................................... 4

Voltage Programming and Measurement Accuracy .............................................. 4

CV Load Regulation ............................................................................................. 5

CV Line Regulation .............................................................................................. 6

CV Ripple and Noise ............................................................................................ 7

Transient Recovery Time ..................................................................................... 8

Constant Current Tests ........................................................ 10

Current Programming and Measurement Accuracy ............................................ 10

CC Load Regulation ........................................................................................... 11

CC Line Regulation ............................................................................................ 12

Verification Test Record Form ............................................... 13

30V ................................................................................................................... 13

80V ................................................................................................................... 15

250V ................................................................................................................. 17

800V ................................................................................................................. 19

Page 5

2260B Verification Procedure

2

Preparing for Verification

Note

In order to ensure performance accuracy, we recommend

you to verify all items listed in this chapter at once.

When to verify the

specification

When using the power supply in a new environment

After replacing one of the major internal modules, such

as front panel or power supply PCB

When you need to make sure that the power supply is

malfunctioning or not

Verification

Environment

Location: Indoor, no direct sunlight, dust free

Relative Humidity: < 80%

Temperature: +18~+28°C

Warm-up time: ≥ 30 minutes

When the

verification fails…

Calibrate the instrument when a corresponding

calibration item exists.

For other items, send the power supply back to the

factory for repair.

Page 6

List of Equipment for Verification

3

List of Equipment for Verification

Here is the list of all equipment used in the service operations.

Type

Specifications

Recommended Model

Digital Voltmeter

Resolution: 1 uV @ 1V

Keithley Model

2000 or equivalent

Readout: 6 1/2 digits

Current Shunt

3A (0.1Ω) 0.02%, TC=10ppm/℃

30A (0.01Ω) 0.02%, TC=10ppm/℃

300A (0.001Ω) 0.02%,

TC=10ppm/℃

Oscilloscope

Sensitivity: 1 mV

Bandwidth Limit: 20 MHz

Probe: 1:1 with JEITA RC-9131B

Tektronix

DPO4014B or

equivalent

AC Power Source

Adjustable to highest rated input

voltage range.

Power: 3000 VA

Ametek 3001i or

equivalent

Electronic Load

60V, 240A minimum, with transient

capability and a slew rate of 1A/us

or better.

Ametek SLH, SLM

or PLA series

electronic loads or

equivalent

500V, 60A minimum, with transient

capability and a slew rate of

0.4A/us or better

1000V, 12A minimum, with

transient capability and a slew rate

of 0.2A/us or better

Page 7

2260B Verification Procedure

4

Constant Voltage Tests

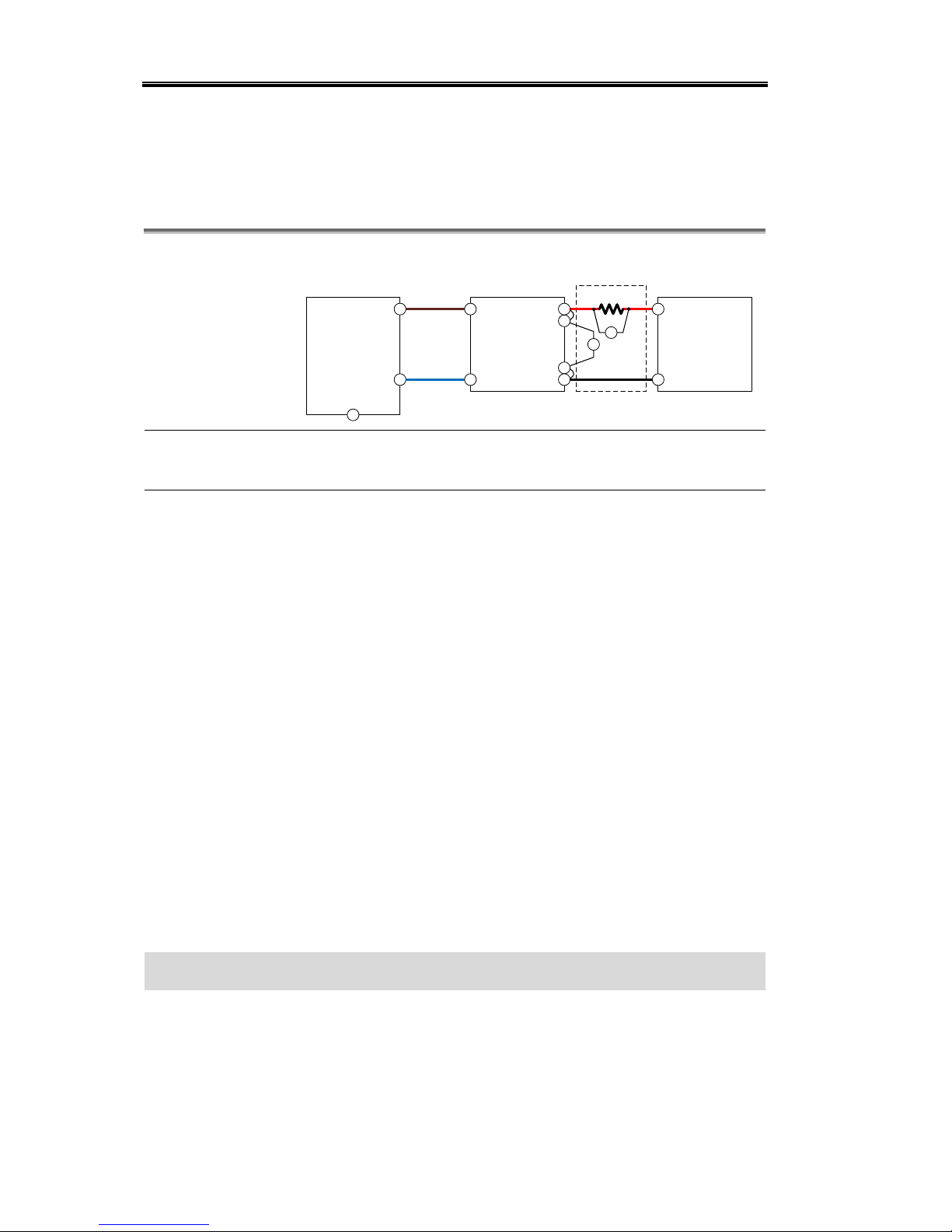

Voltage Programming and Measurement Accuracy

Connection

Fig. 1

L

N

G

AC Power Source

2260B

L

N

+

-

+

-

V

Precision

Current Shunt

A

+

-

+V

-V

+S

-S

Background

This test verifies that the voltage programming and

measurement functions are within specifications.

Procedure

1. Turn off the power supply and connect the DVM from

the PCS-1000 directly across the +S and -S terminals as

shown in the fig. 1 connection.

2. Turn on the power supply and program the output

voltage to zero and the output current to its maximum

programmable value (Imax) with the load off. The CV

indicator should be on and the output current reading

should be approximately zero.

3. Record the output voltage readings on the digital

voltmeter (DVM) and the voltage measured over the

interface. The readings should be within the limits

specified in the test record form for the appropriate

model under Voltage Programming and Measurement,

Minimum Voltage Vout.

4. Program the output voltage to its full-scale rating.

5. Record the output voltage readings on the DVM and

the voltage measured over the interface. The readings

should be within the limits specified in the test record

form for the appropriate model under Voltage

Programming and Measurement, Rated Voltage Vout.

Verifying Voltage Programming and Measurement Accuracy is complete

Page 8

Constant Voltage Tests

5

CV Load Regulation

Connection

Fig.2

L

N

G

AC Power Source

2260B

L

N

+

-

+

-

V

Electronic DC Load

Precision

Current Shunt

A

+

-

+V

-V

+S

-S

Background

This test measures the change in output voltage resulting

from a change in output current from full load to no load.

Procedure

1. Turn off the power supply and connect the DVM from

the PCS-1000 and an electronic load as shown in the fig.

2 connection.

2. Turn on the power supply and program the output

current to its maximum programmable value (Imax)

and the output voltage to its full scale value.

3. Set the electronic load for the output's full-scale

current. The CV indicator on the front panel must be

on. If it is not, adjust the load so that the output current

drops slightly.

4. Record the output voltage reading from the DVM.

5. Open the load and record the voltage reading from the

DVM again. The difference between the DVM readings

in steps 4 and 5 is the load effect, which should not

exceed the value listed in the test record form for the

appropriate model under CV Load Regulation.

Verifying CV Load Regulation is complete

Page 9

2260B Verification Procedure

6

CV Line Regulation

Connection

Fig. 3

L

N

G

AC Power Source

2260B

L

N

+

-

+

-

V

Electronic DC Load

Precision

Current Shunt

A

+

-

+V

-V

+S

-S

Background

This test measures the change in output voltage that

results from a change in AC line voltage from the

minimum to maximum value within the line voltage

specifications.

Procedure

1. Turn off the power supply and connect the ac power

source.

2. Connect the DVM from the PCS-1000 and an electronic

load as shown in the fig. 3 connection. Set the variable

ac voltage to nominal line voltage.

3. Turn on the power supply and program the output

current to its maximum programmable value (Imax)

and the output voltage to its full-scale value.

4. Set the electronic load for the output's full-scale

current. The CV indicator on the front panel must be

on. If it is not, adjust the load so that the output current

drops slightly.

5. Adjust the ac power source to the low-line voltage (85

VAC for 100/120 nominal line; 170 VAC for 200/240

nominal line).

6. Record the output voltage reading from the DVM.

7. Adjust the ac power source to the high-line voltage (132

VAC for 100/120 nominal line; 265 VAC for 200/240

nominal line).

8. Record the output voltage reading on the DVM. The

difference between the DVM reading in steps 5 and 7 is

the source effect, which should not exceed the value

listed in the test record form for the appropriate model

under CV Line Regulation.

Verifying CV Line Regulation is complete

Page 10

Constant Voltage Tests

7

CV Ripple and Noise

Connection

Fig. 4

L

N

G

AC Power Source

2260B

L

N

+

-

+

-

Electronic DC Load

+

-

50 Ohm

4700pF

Scope

BW: 20MHz

1:1 50 Ohm p robe

+V

-V

+S

-S

Connection

Fig. 5

L

N

G

AC Power Source

2260B

L

N

+

-

Electronic DC Load

Scope

BW: 10MHz

V

Low Pass Filter

BW: 1MHz

+

-

+

-

+V

-V

+S

-S

Background

Measure the DC output voltage with the (1:1) probe on.

Measurement frequency bandwidth is 10Hz to 20MHz for

peak to peak. Measurement frequency bandwidth is 5Hz

to 1MHz for rms.

Procedure

1. Turn off the power supply and connect the electronic

load (or load resistor), probe, and an oscilloscope (ac

coupled) to the output as shown in the fig. 4

connection.

2. Set the oscilloscope's bandwidth limit on 20 MHz, and

set the sampling mode.

3. Program the power supply to output current to its

maximum programmable value (Imax) and the output

voltage to its full-scale value and enable the output. Let

the oscilloscope run for a few seconds to generate

enough measurement points. The result should not

exceed the peak-to-peak limits the test record.

4. Use the oscilloscope to measure the RMS noise voltage

using the bandwidth shown in fig. 5. The result should

not exceed the rms limits in the test record form for the

appropriate model under CV Ripple and Noise - rms.

Page 11

2260B Verification Procedure

8

Verifying CV Ripple and Noise is complete

Transient Recovery Time

Background

This measures the time for the output voltage to recover to

within the specified value following a 50% to 100% change

in the load current.

Connection

Fig. 6

L

N

G

AC Power Source

2260B

L

N

+

-

+

-

Electronic DC Load

+

-

Scope

+V

-V

+S

-S

Procedure

1. Turn off the power supply and connect the output as in

the fig. 6 connection with the oscilloscope across the +S

and –S terminals.

2. Turn on the power supply and program the output

current to its maximum programmable value (Imax)

and the output voltage to its full-scale value.

3. Set the electronic load to operate in constant current

mode. Program its load current to 50% of the power

supply's full scale current value.

4. Set the electronic load's transient generator frequency

to 100 Hz and its duty cycle to 50%.

5. Program the load's transient current level to 100% of

the power supply's full-scale current value. Turn the

transient generator on.

6. Adjust the oscilloscope for a waveform similar to that

shown in the following fig. 7.

Fig. 7

t

v

v

t

50% to 100%

Load Transient

100% to 50%

Load Transient

Page 12

Constant Voltage Tests

9

7. The output voltage should return to within the

specified voltage in the specified time following the

50% to 100% load change. Check transients by

triggering on the positive and negative slope. Record

the voltage at time “t” in the performance test record

form under Transient Response.

Verifying Transient Recovery Time Regulation is complete

Page 13

2260B Verification Procedure

10

Constant Current Tests

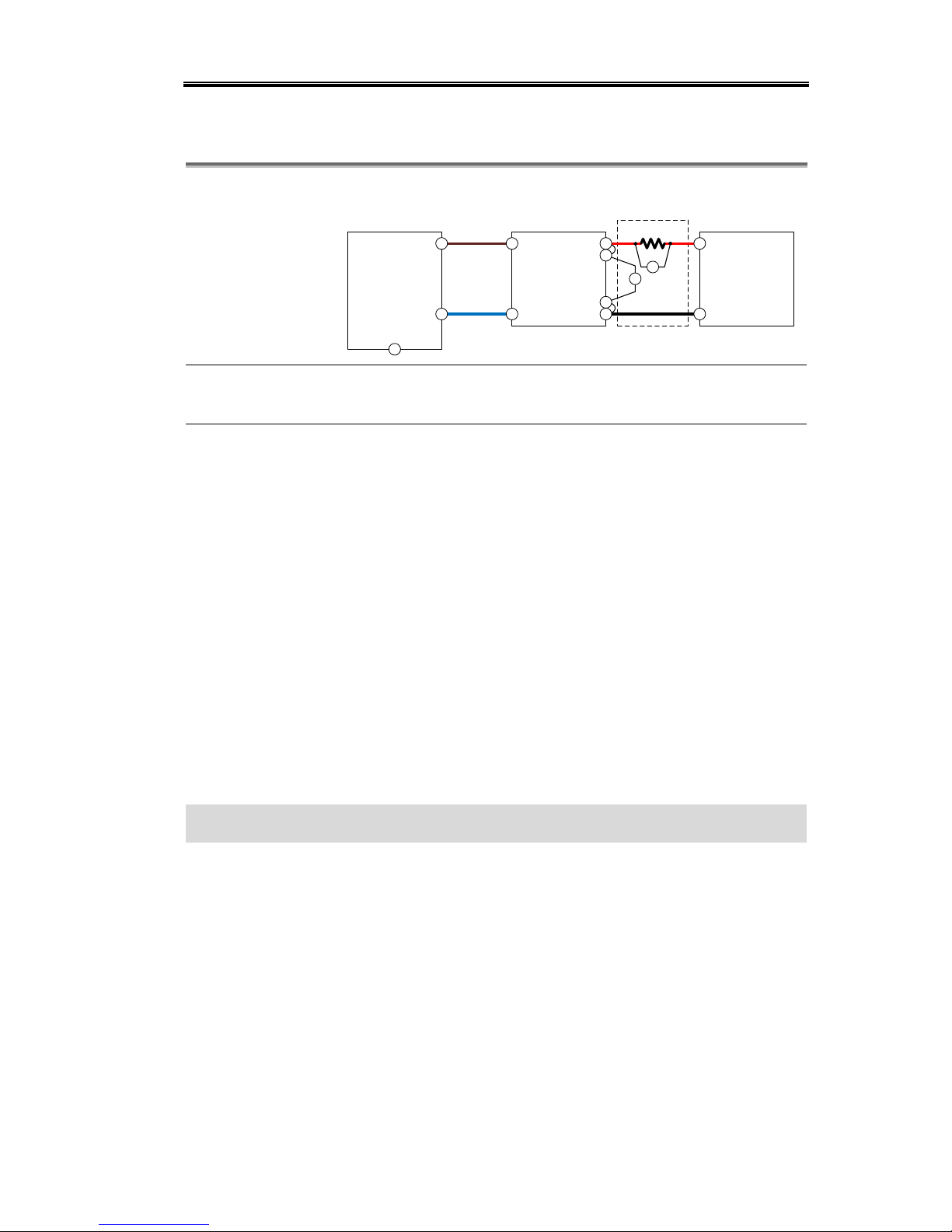

Current Programming and Measurement Accuracy

Connection

Fig. 8

L

N

G

AC Power Source

2260B

L

N

+

-

+

-

V

Precision

Current Shunt

A

+

-

+V

-V

+S

-S

Background

This test verifies that the current programming and

measurement functions are within specifications.

Procedure

1. Turn off the power supply and connect the current

shunt directly across the output as shown in the fig. 8

connection.

2. Turn on the power supply and program the output

voltage to its full-scale value and the output current to

zero. The CC indicator should be on and the output

voltage reading should be approximately zero.

3. Record the output current readings on the precision

current shunt (PCS-1000) and the current measured

over the interface. The readings should be within the

limits specified in the test record form for the

appropriate model under Current Programming and

Measurement, Minimum Current Iout.

4. Program the output current to its full-scale rating.

5. Record the output current readings on the precision

current shunt (PCS-1000) and the voltage measured

over the interface. The readings should be within the

limits specified in the test record form for the

appropriate model under Current Programming and

Measurement, Rated Current Iout.

Verifying Current Programming and Measurement Accuracy is complete

Page 14

Constant Current Tests

11

CC Load Regulation

Connection

Fig. 9

L

N

G

AC Power Source

2260B

L

N

+

-

+

-

V

Electronic DC Load

Precision

Current Shunt

A

+

-

+V

-V

+S

-S

Background

This test measures the change in output current resulting

from a change in output voltage from full scale to short

circuit.

Procedure

1. Turn off the power supply and connect the precision

current shunt and electronic load as shown in the fig. 9

connection.

2. Turn on the power supply and program the output

current to its maximum programmable value (Imax)

and the output voltage to its full-scale value.

3. With the electronic load in CV mode, set it for the

output’s full scale voltage. The CC indicator on the

front panel must be on. If it is not, adjust the load so

that the voltage drops slightly.

4. Record the output current reading from the PCS-1000.

5. Short the electronic load. Record this value (Iout). The

difference in the current readings in steps 3 and 4 is the

load effect, which should not exceed the value listed in

the test record form for the appropriate model under

CC Load Regulation.

Verifying CC Load Regulation is complete

Page 15

2260B Verification Procedure

12

CC Line Regulation

Connection

Fig. 10

L

N

G

AC Power Source

2260B

L

N

+

-

+

-

V

Electronic DC Load

Precision

Current Shunt

A

+

-

+V

-V

+S

-S

Background

This test measures the change in output current that

results from a change in AC line voltage from the

minimum to maximum value within the line voltage

specifications.

Procedure

1. Turn off the power supply and connect the ac power

source..

2. Connect the current shunt and electronic load as shown

in the fig. 10 connection. Set the variable ac voltage to

nominal line voltage.

3. Turn on the power supply and program the output

current to its full-scale value and the output voltage to

its maximum programmable value (Vmax).

4. With the electronic load in CV mode, set it for the

output’s full scale voltage. The CC indicator on the

front panel must be on. If it is not, adjust the load so

that the voltage drops slightly.

5. Adjust the ac power source to the low-line voltage (85

VAC for 100/120 nominal line; 170 VAC for 200/240

nominal line).

6. Record the output current reading from the PCS-1000.

7. Adjust the ac power source to the high-line voltage (132

VAC for 100/120 nominal line; 265 VAC for 200/240

nominal line).

8. Record the output current reading on the PCS-1000.

The difference between the PCS-1000 reading in steps 5

and 7 is the source effect, which should not exceed the

value listed in the test record form for the appropriate

model under CC Line Regulation.

Verifying CC Line Regulation is complete

Page 16

Verification Test Record Form

13

Verification Test Record Form

Print out these pages and record the results. Keep it with the power supply.

30V

Model

2260B-30-36

2260B-30-72

2260B-30-108

Serial number

____________________

Date

Year___________

Month__________

Date___________

Verified by

Name____________________________

Company/Contact_________________________

Environment

Temperature______°C

Humidity______%

Constant Voltage Test

Model

Min. Specs.

Results

Max. Specs.

Voltage Programming and Measurement

Minimum Voltage V

out

All

- 10 mV

+ 10 mV

Measurement Accuracy

All

Vout - 10 mV

Vout + 10 mV

Rated Voltage Vout

All

29.960 V

30.040 V

Measurement Accuracy

All

Vout - 40 mV

Vout + 40 mV

CV Line Regulation

All

- 18 mV

+ 18 mV

CV Load Regulation

All

- 20 mV

+ 20 mV

CV Ripple and Noise

peak-to-peak

30-36

N/A

60 mV

30-72

N/A

80 mV

30-108

N/A

100 mV

rms

30-36

N/A

7 mV

30-72

N/A

11 mV

30-108

N/A

14 mV

Transient Response Time

Voltage @ 1ms

All

- 40 mV

+ 40 mV

Constant Current Test

Model

Min. Specs.

Results

Max. Specs.

Current Programming and Measurement

Minimum Current Iout

30-36

- 30 mA

+ 30 mA

30-72

- 60 mA

+ 60 mA

30-108

- 100 mA

+ 100 mA

Measurement Accuracy

30-36

Iout - 30 mA

Iout + 30 mA

30-72

Iout - 60 mA

Iout + 60 mA

Page 17

2260B Verification Procedure

14

30-108

Iout - 100 mA

Iout + 100 mA

Rated Current Iout

30-36

35.934 A

36.066 A

30-72

71.898 A

72.102 A

30-108

107.862 A

108.138 A

Measurement Accuracy

30-36

Iout - 66 mA

Iout + 66 mA

30-72

Iout - 102 mA

Iout + 102 mA

30-108

Iout - 138 mA

Iout + 138 mA

CC Line Regulation

30-36

- 41 mA

+ 41 mA

30-72

- 77 mA

+ 77 mA

30-108

- 108 mA

+ 108 mA

CC Load Regulation

30-36

- 41 mA

+ 41 mA

30-72

- 77 mA

+ 77 mA

30-108

- 108 mA

+ 108 mA

Page 18

Verification Test Record Form

15

80V

Model

2260B-80-13

2260B-80-27

2260B-80-40

Serial number

____________________

Date

Year___________

Month__________

Date___________

Verified by

Name____________________________

Company/Contact_________________________

Environment

Temperature______°C

Humidity______%

Constant Voltage Test

Model

Min. Specs.

Results

Max. Specs.

Voltage Programming and Measurement

Minimum Voltage V

out

All

- 10 mV

+ 10 mV

Measurement Accuracy

All

Vout - 10 mV

Vout + 10 mV

Rated Voltage Vout

All

79.910 V

80.090 V

Measurement Accuracy

All

Vout - 90 mV

Vout + 90 mV

CV Line Regulation

All

- 43 mV

+ 43 mV

CV Load Regulation

All

- 45 mV

+ 45 mV

CV Ripple and Noise

peak-to-peak

80-13

N/A

60 mV

80-27

N/A

80 mV

80-40

N/A

100 mV

rms

80-13

N/A

7 mV

80-27

N/A

11 mV

80-40

N/A

14 mV

Transient Response Time

Voltage @ 1ms

All

- 90 mV

+ 90 mV

Constant Current Test

Model

Min. Specs.

Results

Max. Specs.

Current Programming and Measurement

Minimum Current Iout

80-13

- 10 mA

+ 10 mA

80-27

- 30 mA

+ 30 mA

80-40

- 40 mA

+ 40 mA

Measurement Accuracy

80-13

Iout - 10 mA

Iout + 10 mA

80-27

Iout - 30 mA

Iout + 30 mA

80-40

Iout - 40 mA

Iout + 40 mA

Rated Current Iout

80-13

13.476 A

13.524 A

80-27

26.943 A

27.057 A

80-40

40.419 A

40.581 A

Page 19

2260B Verification Procedure

16

Measurement Accuracy

80-13

Iout - 24 mA

Iout + 24 mA

80-27

Iout - 57 mA

Iout + 57 mA

80-40

Iout - 81 mA

Iout + 81 mA

CC Line Regulation

80-13

- 18.5 mA

+ 18.5 mA

80-27

- 32 mA

+ 32 mA

80-40

- 45.5 mA

+ 45.5 mA

CC Load Regulation

80-13

- 18.5 mA

+ 18.5 mA

80-27

- 32 mA

+ 32 mA

80-40

- 45.5 mA

+ 45.5 mA

Page 20

Verification Test Record Form

17

250V

Model

2260B-250-4

2260B-250-9

2260B-250-13

Serial number

____________________

Date

Year___________

Month__________

Date___________

Verified by

Name____________________________

Company/Contact_________________________

Environment

Temperature______°C

Humidity______%

Constant Voltage Test

Model

Min. Specs.

Results

Max. Specs.

Voltage Programming and Measurement

Minimum Voltage V

out

All

- 200 mV

+ 200 mV

Measurement Accuracy

All

Vout - 200 mV

Vout + 200 mV

Rated Voltage Vout

All

249.55 V

250.45 V

Measurement Accuracy

All

Vout - 450 mV

Vout + 450 mV

CV Line Regulation

All

- 128 mV

+ 128 mV

CV Load Regulation

All

- 130 mV

+ 130 mV

CV Ripple and Noise

peak-to-peak

250-4

N/A

80 mV

250-9

N/A

100 mV

250-13

N/A

120 mV

rms

250-4

N/A

15 mV

250-9

N/A

15 mV

250-13

N/A

15 mV

Transient Response Time

Voltage @ 1ms

All

- 260 mV

+ 260 mV

Constant Current Test

Model

Min. Specs.

Results

Max. Specs.

Current Programming and Measurement

Minimum Current Iout

250-4

- 5 mA

+ 5 mA

250-9

- 10 mA

+ 10 mA

250-13

- 15 mA

+ 15 mA

Measurement Accuracy

250-4

Iout - 5 mA

Iout + 5 mA

250-9

Iout - 10 mA

Iout + 10 mA

250-13

Iout - 15 mA

Iout + 15 mA

Rated Current Iout

250-4

4.4905 A

4.5095 A

250-9

8.9810 A

9.0190 A

250-13

13.471 A

13.529 A

Page 21

2260B Verification Procedure

18

Measurement Accuracy

250-4

Iout - 9.5 mA

Iout + 9.5 mA

250-9

Iout - 19 mA

Iout + 19 mA

250-13

Iout - 29 mA

Iout + 29 mA

CC Line Regulation

250-4

- 9.5 mA

+ 9.5 mA

250-9

- 14 mA

+ 14 mA

250-13

- 18.5 mA

+ 18.5 mA

CC Load Regulation

250-4

- 9.5 mA

+ 9.5 mA

250-9

- 14 mA

+ 14 mA

250-13

- 18.5 mA

+ 18.5 mA

Page 22

Verification Test Record Form

19

800V

Model

2260B-800-1

2260B-800-2

2260B-800-4

Serial number

____________________

Date

Year___________

Month__________

Date___________

Verified by

Name____________________________

Company/Contact_________________________

Environment

Temperature______°C

Humidity______%

Constant Voltage Test

Model

Min. Specs.

Results

Max. Specs.

Voltage Programming and Measurement

Minimum Voltage V

out

All

- 400 mV

+ 400 mV

Measurement Accuracy

All

Vout - 400 mV

Vout + 400 mV

Rated Voltage Vout

All

798.8 V

201.2 V

Measurement Accuracy

All

Vout - 1.2 V

Vout + 1.2 V

CV Line Regulation

All

- 403 mV

+ 403 mV

CV Load Regulation

All

- 405 mV

+ 405 mV

CV Ripple and Noise

peak-to-peak

800-1

N/A

150 mV

800-2

N/A

200 mV

800-4

N/A

200 mV

rms

800-1

N/A

30 mV

800-2

N/A

30 mV

800-4

N/A

30 mV

Transient Response Time

Voltage @ 1ms

All

- 260 mV

+ 260 mV

Constant Current Test

Model

Min. Specs.

Results

Max. Specs.

Current Programming and Measurement

Minimum Current Iout

800-1

- 2 mA

+ 2 mA

800-2

- 4 mA

+ 4 mA

800-4

- 6 mA

+ 6 mA

Measurement Accuracy

800-1

Iout - 2 mA

Iout + 2 mA

800-2

Iout - 4 mA

Iout + 4 mA

800-4

Iout - 6 mA

Iout + 6 mA

Rated Current Iout

800-1

1.4365 A

1.4435 A

800-2

2.8731 A

2.8869 A

800-4

4.3096 A

4.3304 A

Page 23

2260B Verification Procedure

20

Measurement Accuracy

800-1

Iout - 3.5 mA

Iout + 3.5 mA

800-2

Iout - 6.9 mA

Iout + 6.9 mA

800-4

Iout - 10.4 mA

Iout + 10.4 mA

CC Line Regulation

800-1

- 6.44 mA

+ 6.44 mA

800-2

- 7.88 mA

+ 7.88 mA

800-4

- 9.32 mA

+ 9.32 mA

CC Load Regulation

800-1

- 6.44 mA

+ 6.44 mA

800-2

- 7.88 mA

+ 7.88 mA

800-4

- 9.32 mA

+ 9.32 mA

Page 24

Specifications are subject to change without notice.

All Keithley trademarks and trade names are the property of Keithley Instruments, Inc.

All other trademarks and trade names are the property of their respective companies.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY • www.keithley.com

A Tektronix Company

Loading...

Loading...