Page 1

Model 224 Programmable Current Source

Instruction Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc.

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

KOREA: FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-130 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077 • Fax: 886-3-572-9031

28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

© Copyright 2001 Keithley Instruments, Inc.

Printed in the U.S.A.

11/01

Page 3

Model 224 Programmable Current Source

Instruction Manual

Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Fifth Printing, December 2001

Document Number: 224-901-01 Rev. E

Page 4

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

Page 6

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

11/01

Page 7

SPECIFICATIONS

ACCURACY

RANGE OUTPUT - 18z-280C SIZE ii=‘-18°C Et 28O-50°C

MAXIMUM +[%rdn + offset) STEP

IOOmA f101.00mA 0.1 % + 5OuA

1OmA I19.995mA 0.05% + l&A $A

ImA * 1.9995mA 0.05% + 1 pA 500nA 0.005% + 20nA

100 fi kl99.95 fi 0.05% + 100nA

IOfi kl9.995fi 0.05% + IOnA

OUTPUT RESISTANCE: Greater than lO’*g.

OUTPUT CAPACITANCE: Less than 2OpF.

LINE REGULATION: Less than 0.01% for AC power line changes within

specified limits.

VOLTAGE LIMIT: Bipolar, 1 to 105V in 1V programmable steps.

RESPONSE TIME: Less than 3ms to within 0.1% of programmed change.

TRANSIENT RECOVERY TIME: Less than 3ms to rated accuracy following

any change in compliance voltage.

NOISE

RANGE

IOOmA

IOfi to IOmA

GUARD OUTPUT: Maximum Load Capacitance: 10nF.

Maximum Load Current: Absolute total (Output + Guard) not to ex-

ceed 105mA.

Accuracy: * ImV (excluding output lead voltage drop).

INCREMENT/DECREMENT: Automatic, manual or trigger modes.

Range of Dwell Times: 50ms to 999.9s.

Accuracy of Dwell Times: f (0.05% + 20~s).

Step Size: Selected digit on a fixed range. Minimum step size 0.1% of

range.

Current Limit: Maximum is f (Full Scale) on range selected.

OUTPUT LOAD: Output load must be non-inductive

EXTERNAL TRIGGER: TTL-compatible EXTERNAL TRIGGER INPUT

and OUTPUT.

OUTPUT CONNECTIONS: Teflon@

Connector #30JRl21-I) for output; five way binding posts for GUARD

OUTPUT COMMON and CHASSIS; BNC (chassis isolated) connectors

for EXTERNAL TRIGGER INPUT and OUTPUT. All connections on

rear panel.

(1 YEAR)

5OU.A

50nA

NOISE

(p-p of range)

IOOppm

IOOppm

insulated triax connector (Specialty

TEMPERATURE

COEFFICIENT

f (%rda + offset)/OC

0.01 % + 2uA

0.005% + 20&A

0.005% + 2nA

5nA 0.005% + 20OpA

BANDWIDTH

0.1 Hz to 30kHz

O.lHz to 1OOHz

IEEE-488 BUS INTERFACE (ootion 22431

Multiline Commands: DCL, LLO, SDC, GET, GTL, UNT, UNL, SPE,

SPD.

Uniline Commands: IFC, REN, EOI, SRQ, ATN.

Interface Functions: SHl, AHI: T6, TEO, L4, LEO, SRl, RLI, PPO,

DCI, DTl, CO, El.

Output Connections: Amphenol or Cinch Series 87 IEEE and printed

circuit digital I/O port. All connections on rear panel.

Jnternal Programmable Parameters: Display Mode, Output,

(Prefix Data Format), EOI, SRQ (including mask for over V-limit),

Range, Terminator Character, Inputs (SOURCE, V-LIMIT, DWELL

TIME), Output Status.

Digital I/O Port: A separate I/O port consisting of four input and four

output lines as well as common (IEEE-4881 and +SVDC. Outputs will

drive one ‘ITL load. Inputs represent one TTL load. The 224 can be pro-

grammed to generate a “SRQ” upon any change in the four bit input

data. Mating connector supplied.

GENERAL

DISPLAY: 0.5” LED digits, 4%-digit signed mantissa, l-digit signed ex-

ponent.

OVER VOLTAGE LIMIT INDICATION: “V-LIMIT” LED will blink.

SELF TEST: Digital RAM,

upon power up.

WARMUP: 1 hour to rated accuracy.

POWER: 105125 or 210-250VAC (internal switch selected), 50 or 60H2,

60 watts maximum (80VA maximum). 90-105 or 180-210VAC operation

available.

COOLING: Internal fan for forced air cooling.

ENVIRONMENTAL LIMITS: Operating: O”-50°C; up to 35OC at 70%

non-condensing relative humidity. Storage: -25OC to 70°C.

DIMENSIONS, WEIGHT: 127mm high x 216mm wide x 359mm deep

(5-l/2” x &l/2” x 14-l/8”). Net weight 9 Ibs. 15 oz. (4.52kg).

MAXIMUM ALLOWABLE COMMON MODE VOLTAGE (OUTPUT

or OUTPUT COMMON to CHASSIS): 250V rms, DC to 60Hz.

ACCESSORIES SUPPLIED: Model 6011: Triaxial Test Lead (3 ft,)

ROM, and front panel LEDs

Specifications subject to change without notice.

Page 8

Page 9

TABLE OF CONTENTS

Para. Title Page

SECTION 1 — GENERAL INFORMATION

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 Manual Addenda . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.5 Safety Symbols and Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.6 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.7 Repacking for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.8 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.9 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

SECTION 2 — OPERATION

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.1 Correct Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.2 Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.3 Warm Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Operating lnstructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3.1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3.2 Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3.3 Rear Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3.4 Output Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.5 Inductive Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.6 Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.7 General Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.8 Front Panel Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.9 Examples of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.1 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.2 Resistivity Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.3 Diode Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.4.4 Low Resistance “Lindeck” Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.5 Detailed Front Panel Controls Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.6 Detailed Rear Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-l 5

SECTION 3 — PERFORMANCE VERIFICATION

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.4 Initial Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.5 Performance Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.5.1 100mA to 1mA Range Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.5.2 100µA and 10µA Range Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

SECTION 4 — THEORY OF OPERATION

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.4 Analog Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.5 Digital Board (Microcomputer). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

i

Page 10

TABLE OF CONTENTS CONT.

Para.

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.7.1

5.7.2

5.7.3

5.7.4

5.8

5.8.1

6.1

6.2

6.3

6.4

6.5

Title

SECTION 5-MAINTENANCE

Introduction

FuseReplacement

LineVoltageSelection

Disassembly......................................................~

FanFilterMaintenance

Special Handling of Static Sensitive Devices

Calibration ...................................................................................

RecommendedTestEquipment

Environmental Conditions.

Warmup.. ................................................................................

Calibration Adjustments

Troubleshooting ..............................................................................

DigitalSelfTest .............................................................................

..................................................................................

.............................................................................

.........................................................................

.........................................................................

.......................................................

................................................................

....................................................................

......................................................................

SECTION 6-REPLACEABLE PARTS

Introduction

PartsList

Orderinglnformation

FactoryService..

Schematic Diagrams and Component Location Drawings

..................................................................................

.....................................................................................

...........................................................................

.............................................................................

............................................

...........................

Page

5-l

5-l

5-1

5-2

5-2

52

5-4

5-4

5-4

5-4

5-4

5-5

5-5

6-l

6-l

6-l

6-l

6-1

ii

Page 11

LIST OF ILLUSTRATIONS

Figure Title Page

2-1 Model 224 Front and Rear Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-2 Output Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-3 Limiting Inductive Reaction Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-4 Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-5 External Input and Output Trigger Pulse Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-6 External Trigger Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-7 Unguarded Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-8 Guarded Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-9 Connections as a Current Sink with a Resistive Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2-10 Model 224 Recommended Operating Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2-11 Resistivity Measurement Using the Model 224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-12 Diode Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-13 Diode Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-14 Low Resistance Measurement Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

3-1 100mA to 1mA Range Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

4-1 Analog Circuitry Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2 Digital Circuitry Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-3 Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

5-1 Model 224 Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-2 Calibration Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-3 Memory Chip Number Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

6-1 Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Display Board, Component Location Drawing, Dwg. No. 220-110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6-3 Mother Board, Component Location Drawing, Dwg. No. 220-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-4 Analog Board, Component Location Drawing, Dwg. No. 224-120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6-5 Display Board, Schematic Diagram, Dwg. No. 220-116 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

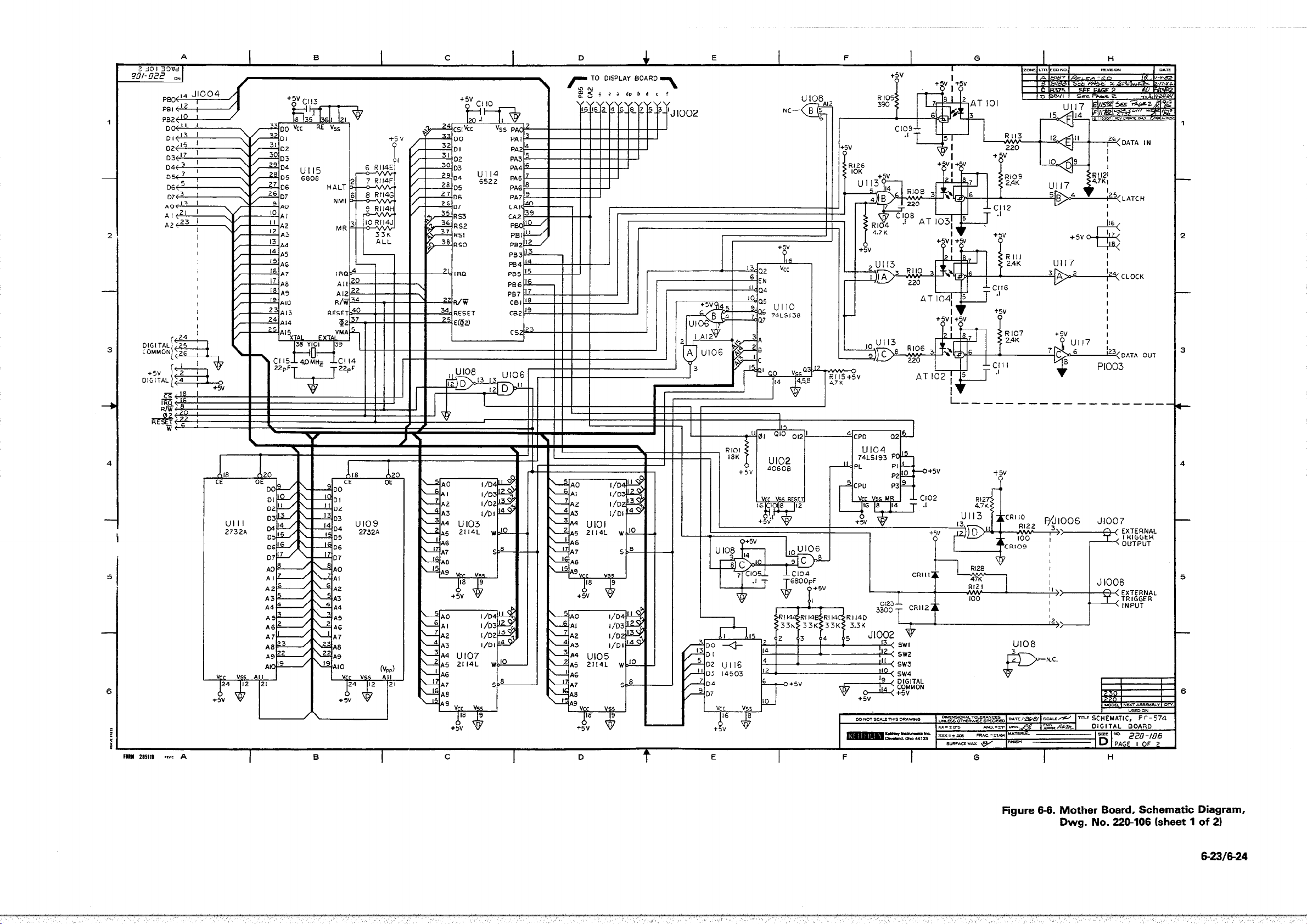

6-6 Mother Board, Schematic Diagram, Dwg. No. 220-106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6-7 Analog Board, Schematic Diagram, Dwg. No. 224-126 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

iii

Page 12

LIST OF TABLES

Table

2-l

2-2

2-3

$2

3-l

3-2

5-l

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

6-l

6-2

6-3

6-4

LineVoltageSetting ...........................................................................

Power Up Default Conditions.

Front PanelControls.. .........................................................................

RearPanel Description .........................................................................

Front PanelMessages ..........................................................................

RecommendedTestEquipment.....................................: ............................

100mAtolmAVerification .....................................................................

FuseReplacement,3AG Size ....................................................................

FuseReplacement,5mmSize ...................................................................

LineVoltageSelection .........................................................................

Model 224 Static Sensitive Devices

RecommendedTestEquipment ..................................................................

Model224Calibration ..........................................................................

PowerSupplyChecks ..........................................................................

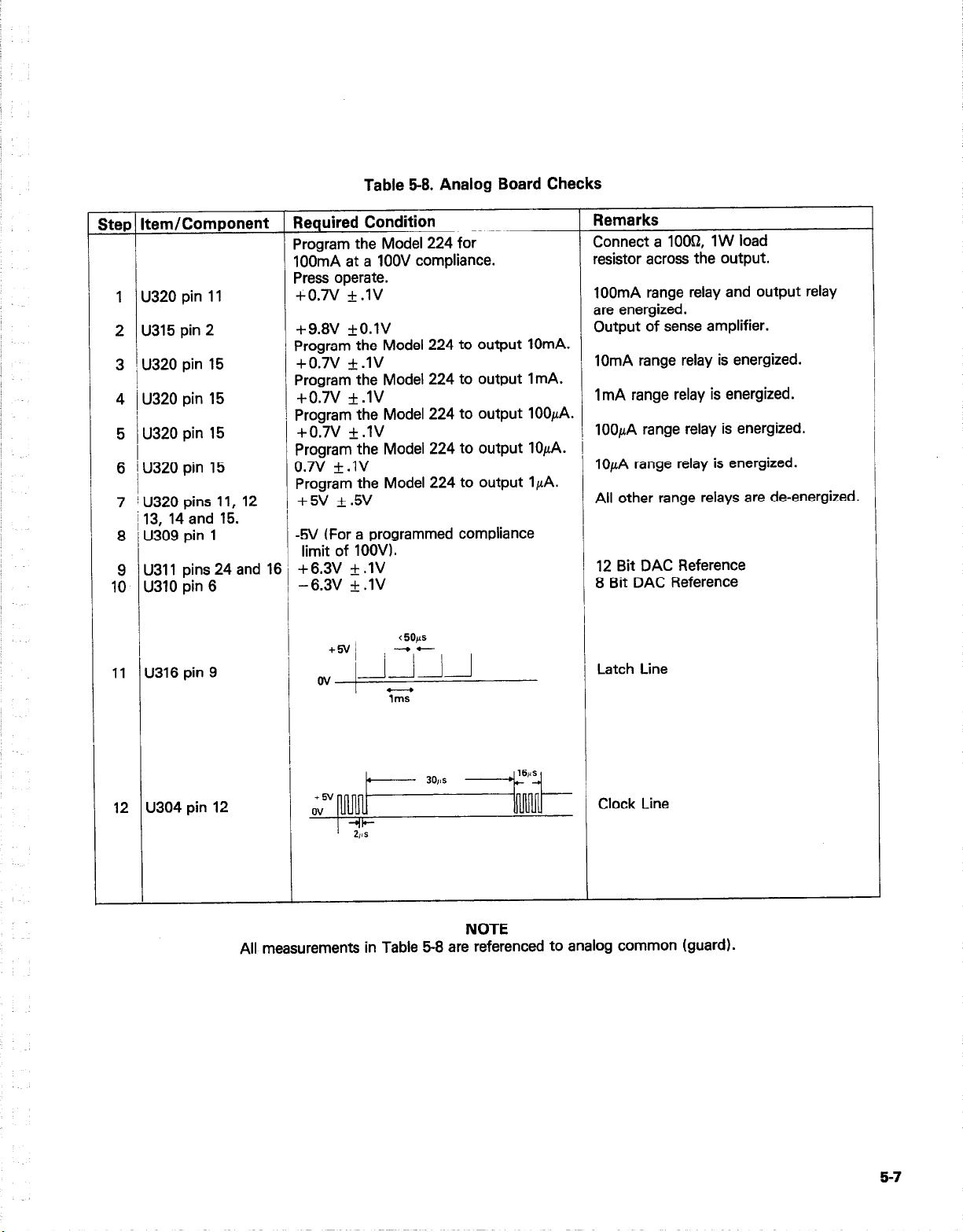

Analog BoardChecks.. ........................................................................

DigitalCircuitryChecks .........................................................................

Display Board Checks.. ........................................................................

Index of Model 224 Schematics and Component Layouts.

MotherBoard,PartsList ........................................................................

DisplayBoard,PartsList ........................................................................

AnalogBoard,PartsList ........................................................................

...................................................................

...............................................................

............................................

2-l

2-2

2-3

2-4

2-8

3-l

3-l

5-l

5-l

5-1

5-4

5-4

5-5

5-6

5-7

5-8

;:y

6-3

6-5

6-7

iv

Page 13

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION The Model 224 is a programmable current source with full

range current output of 20,uA to 101 mA. The smallest step of

output current is 5nA. The Model 224 has a selectable

voltage compliance of up to 105V in IV increments. The

value of output current can be modified in two ways: manually or automatically. The automatically modified current value

is incremented or decremented by the programmed rate. The

time button allows the modification of the programmed auto

increment/decrement rate. The control of the current value

modification can be activated by an external trigger pulse applied to the EXTERNAL TRIGGER INPUT. At the completion

of the current value modification (each digit) the Model 224

outputs a pulse that has the specifications shown in Figure

2-5. This pulse can be used to trigger another instrument

(printer, DMM, controller, etc.1 to start its programmed task.

With the Model 2243 IEEE-488 interface option installed, the

Model 224 can be used with any measurement system that

uses ?he IEEE-488 bus. For detailed operating instructions of

the Model 2243 IEEE-488 interface option, refer to the Model

2243 Instruction Manual

1.2 FEATURES

The Model 224 has several convenient and easy to use

features some of which are listed below.

@Selectable voltage compliance allows the user to select the

required voltage compliance.

04% digit display with appropriate exponent and decimal

point.

@The output current value can be modified either manually or

automatically.

*OPERATE button that places the display value of current at

the output connector on the rear panel. When not in operate

the Model 224’s output is set at O.OOO-6A while the display

remains the same.

@Data keys that allow the entry of numerical data onto the

display.

*External trigger input that when activated by the appropriate

signal instructs the Model 224 to increment or decrement

the displayed value of output current.

l

External trigger output places an output pulse at the external

trigger output connector upon completion of the increment

or decrement of the displayed current value.

@Guard terminal that allows guarded applications to be com-

pleted.

l

Selectable auto rate (TIME) of 50msec to 999.9sec.

aCANCEL button that momentarily blanks the display and

terminates the data modifying operation.

*I-LIMIT function that limits the output current between the

user programmed HI and LO current limits.

@IEEE-488 interface option allows the Model 224 to be incor-

porated into any system that uses programmed control

through the IEEE-488 bus.

1.3 WARRANTY INFORnhATlON

Warranty information is provided on the inside front cover of

this manual. If there is a need to exercise the warranty, contact the Keithley representative in your area to determine the

proper action to be taken, Keithley Instruments maintains

complete repair and calibration facilities in the United States,

United Kingdom and Europe. Information concerning the application, operation or service of your instrument should be

directed to the applications engineer in your area. Refer to the

inside front cover for address locations.

1.4 MANUAL ADDENDA

Improvements or changes to this manual will be explained on

an addendum sheet included with this manual.

1.5 SAFETY SYMBOLS AND TERMS

Safety symbols used throughout this manual are as follows:

The symbol ! A on the instrument denotes that the user

should refer to the operating instructions.

The symbol

voltage may be present on the output terminals.

The WARNING used in this manual explains dangers that

could result in personal injury or death.

The CAUTION used in this manual explains hazards that

could damage the instrument.

1.6 UNPACKING AND INSPECTION

The Model 224 is inspected both mechanically and electrically

before shipment. Upon receiving the Model 224 unpack all

items from the shipping container and check for any obvious

signs of damage that may have occurred during transit.

Report any damage to the shipping agent. Retain and use the

original packaging materials if reshipment is necessary. The

following items are shipped with all Model 224 orders:

Model 224 Programmable Current Source

Model 224 Instruction Manual

Model 6011 Triaxial Test Lead Set

Optional accessories as ordered.

If an additional instruction manual is required, order the

manual package (Keithley Part Number 224-901-00). The

manual package includes an instruction manual and all pertinent addenda.

on the instrument denotes that high

AM

l-l

Page 14

1.7 REPACKING FOR SHIPMENT

The Model 224 should be packed in its original carton. Before

packing, wrap the instrument in plastic. After it is placed in

the box, surround the instrument with Styrofoam packaging

material.

If the Model 224 is to be returned to Keithley Instruments for

calibration or repair include the following:

ATTENTION REPAIR DEPARTMENT on the address label.

Warranty status of the instrument.

Completed service form.

dard IEEE-488-1978 protocol. Additionally, the Model 2243

incorporates a separate digital I/O port that may be used to

interface the Model 224 to other digital instrumentation.

Model 6011 Triax Input Cable-The Model 6011 is a three

foot (1 meter) low noise triax cable terminated with alligator

clips at one end and a Teflon*

insulated triax connector at

the other end.

Model 6147 Triax to BlilC Adapter-The Model 6147 Triax to

BNC Adapter allows the Model 224 to be used with all

Keithley accessories and cables that require BNC connections.

1.6 SPECIFICATIONS For Model 224 specifications, refer to the specifications that

precede this section.

1.9 ACCESSORIES

The following accessories are available from Keithley In-

struments to enhance the capabilities of the Model 224 Programmable Current Source.

Model 1019A Universal Rack Mounting Kit-The Model

1019A Universal Rack Mounting Kit can accomodate one or

two Model 224’s. The dimensions are 133mm x 483mm

(5%in. x 19in.I.

Model 1019s is a slide type universal rack mounting kit. The

kit will accomodate up to two half rack size instruments (e.g.

Model 224) in a standard 5%” X 19” rack.

Model 2243 IEEE-488 Interface-The Model 2243 is an optional IEEE-488 interface for the Model 224 Programmable

Current Source. This interface adds extra versatility to the

Model 224 by allowing the transmission of data and commands over IEEE-488 bus. The interface provides all the logic

necessary to interface the Model 224 to the bus using stan-

Model 6167 Guarded Adapter-The Model 6167 Guarded

Adapter reduces effective cable capacity by driving the inner

shield of a triaxial cable at guard potential.

Model 7008-3 IEEE-488 Cable-The Model 7008-3 is a three

foot (1 meter) IEEE-488 cable. The cable has 24 stranded wire

conductors and is terminated with IEEE-488 standard connectors.

Model 7008-6 IEEE-488 Cable-The Model 7008-6 is a six

foot (2 meter) IEEE-488 cable. The cable has 24 stranded wire

conductors and is terminated with IEEE-488 standard connectors.

Model 7010 Cable Adapter-The Model 7010 is an IEEE-488

cable adapter. The adapter extends the IEEE-488 connector

by one connector width for easy access connections.

Model 7051-2-The Model 7051-2 is a BNC to BNC shielded

cable that is 2 feet long. This cable is especially useful when

utilizing the external input and output trigger connectors.

Model 7051-5-The Model 7051-5 is a BNC to BNC shielded

cable that is 5 feet long. This cable is especially useful when

utilizing the external input and output connectors.

1-2

Page 15

SECTION 2

OPERATION

2.1 INTRODUCTION This section contains operating instructions for the Model

224 Programmable Current Source. The operating instructions are divided into several categories including: prepara-

tion for use, operation, applications and detailed front and

rear panel descriptions.

For simple “getting started” information refer to paragraph

2.3.7 General Operating Procedure.

For front and rear panel illustrations of the Model 224 refer to

Figure 2-1.

2.2 PREPARATION FOR USE

2.2.1 Correct Line Voltage

Connect the Model 224 to a properly grounded power recep-

tacle. Refer to Table 2-l for the range of line voltage that the

Model 224 can operate on. For fuse replacement or line

voltage selection refer to Section 5 Maintenance.

WARNING

Ground the instrument through a properly earth

grounded receptacle before operation. Failure to

ground the instrument can result in severe personal injury or death in the event of a short circuit or malfunction.

Table 2-l. Line Voltage Setting

A. This is a display test. The operator can note inoperative

display segments by comparing the Model 224’s display

with the above figure.

B. In addition, the pushbutton and the TALK, LISTEN and

REMOTE indicators will light. All indicators will light

simultaneously if operating correctly.

2. After the display test is complete the Model 224 displays

the software revision level for approximately one second.

The following is an example of software revision level B

2.2.

Example:

3. If the Model 2243 IEEE interface is installed, the Model 224

displays the primary address for approximately one seccond. The primary address of the Model 2243 is factory

set at 19. If the Model 2243 is not installed in the Model

224, the power up sequence skips this step and goes on to

step 4.

4. At this point the Model 224 reverts to the default condi-

tions listed in Table 2-2.

2.2.3 Warm Up

To achieve rated accuracy the Model 224 requires one hour

for warm up.

2.3 OPERATING INSTRUCTIONS

2.3.1 Environmental Conditions

Operation of the Model 224 should be at an ambient

temperature within the range of O°C to 50°C, up to 35OC at

70% noncondensing relative humidity. Environmental condi-

tions for storage are from -25OC to 7OOC.

/---KF-j

For instruments equipped with low voltage

transformer TR-187.

2.2.2 Power Up

After the Model 224 is connected to a properly grounded

power source it can be powered up. When the instrument is

turned on it goes through a power up sequence that is outlined as follows:

1. Immediately after turning on the Model 224 via the power

switch, the display will indicate the following for several

seconds.

2.3.2 Front Panel Controls

Model 224 front panel controls are listed in Table 2-3. Their

operation and function are briefly described in the table. For

detailed information concerning the Model 224 front panel

refer to paragraph 2.5 and Figure 2-1.

2.3.3 Rear Panel Description

The rear panel of the Model 224 has several terminals and

connectors. These are listed and described in Table 2-4. For

detailed information concerning the rear panel refer to

paragraph 2.6 and Figure 2-1.

2-1

Page 16

Table 2-2. Power Up Default Conditions

Function

Power

output

Default Condition

On

Standby (OPERATE LED off). Programmed to

o.ooo-6A.

Auto

Trig

Source

V-limit

l-limit

Set to inactive (AUTO LED is off).

Set to inactive (TRIG LED is off).

Active (SOURCE LED is on).

Set to 3V.

HI Limit set to 0.000.

LO Limit set to 0.000.

Time Set to 50msec (50.00-3).

Digit

INCR

Set to inactive.

Set to inactive (INCR LED is off).

DECR Set to inactive (DECR LED is off).

Cancel

Enter

Exponent

Talk

Listen

Remote

Display

Set to inactive.

Not affected by power up.

Not affected by power up.

Talk function is disabled (TALK LED is off).

Listen function is disabled (LISTEN LED is off).

Remote function is disabled (REMOTE LED is off).

The 4% digit display is set to

2-2

Page 17

Table 2-3. Front Panel Controls

Control

POWER ON/OFF

OPERATE

SOURCE

V-LIMIT

I-LIMIT

TIME

DIGIT

INCR

DECR

CANCEL

ENTER

EXPONENT

DATA

AUTO

TRIG

Description

Turns the instrument on or off.

When activated (LED on), the Model 224 outputs the displayed value of current.

When deactivated (LED off), the Model 224 is set to standby (O.OOO-6A is present

at the output).

When activated (LED on), the source data function is selected and displayed.

When deactivated (LED off), the source data is not displayed.

When activated (LED on), the voltage compliance is displayed. When deactivated

(LED off), the voltage compliance is not displayed.

I-LIMIT button selects the window of output current limit. Default value is

+ .OOOO-OA. When activated (LED on), the current (I) limit is displayed. The HI limit

is displayed first. When the l-limit button is pressed a second time the LO limit is

displayed. When deactivated (LED off), the l-limit is not displayed. This function

is used only in the auto mode.

When activated (LED on), the time function for the auto INCRIDECR is

displayed for inspection or modification.

Pressing the DIGIT button selects a display digit (c segment is flashing) for

alteration. Pressing the button while in the digit function selects the next digit

on the right for alteration. The DIGIT button wraps the modify digit around to the

most significant digit on the display if the DIGIT button is pressed when the cursor is on the next to least significant digit.

In the manual mode, each time the button is pressed the selected digit is in-

cremented by one count. In the auto mode, the selected digit is incremented and

therefore, the source value, automatically at the programmed time rate, When the

programmed HI limit is reached the error message is displayed and the display remains at the HI limit. This function has the mathematical capability of carry. The

least significant digit does not increment.

In the manual mode, each time the button is pressed the selected digit is

decremented by one count. In the auto mode, the selected digit is decremented

and therefore the source value, automatically at the programmed time rate. When

the programmed Ld limit is reached the error message is displayed and the display

remains at the LO limit. This function has the mathematical capability.

of borrow. The least significant digit does not decrement.

When activated, the CANCEL button momentarily blanks the display and terminates the data modifying operation.

The ENTER button loads the displayed data into the Model 224.

The EXPONENT allows entry of exponent data onto the display.

The data group of buttons allows the entry of numerical data onto the display.

When activated (LED on), the AUTO button selects the auto function for

INCR/DECR of the source data.

When activated (LED on), an external trigger pulse via the rear panel triggers

the instrument to increment or decrement the display digit. When deactivated

(LED off), the trigger function is disabled.

2-3

Page 18

Table 2-4. Rear Panel Description

Connections

OUTPUT

GUARD

Description

The output connector is a Teflon@

insulated female triax connector.

The GUARD terminal provides a low impedance voltage source that is

equal to the output compliance voltage. The GUARD terminal is useful

in reducing leakage currents.

OUTPUT COMMON The OUTPUT COMMON connector provides easy access to the inner

shield of the OUTPUT connector.

CHASSIS GROUND

/ The chassis ground terminal provides easy access to chassis ground

I (earth ground).

EXTERNAL TRIGGER INPUT This input initiates the selected display digit to increment or decrement

(depending on which is enabled) upon receiving a TTL level negative

i transition with a minimum pulse width of lO@ec. Refer to Figure 2-5

for pulse specifications

EXTERNAL TRIGGER OUTPUT This output provides a negative going TTL level pulse of greater

! than lO@ec when the selected digit has been incremented or

decremented. Refer to Figure 2-5 for pulse specifications.

FUSE

This is the line power fuse and it is rated as listed in Table 5-l.

LINE RECEPTACLE This is the line power receptacle that mates with a three wire line cord.

Refer to Table 2-l for line power requirements.

“IEEE-488 INTERFACE This connector provides IEEE-488 bus connection to the Model 224.

The connector mates with the Model 7008-3 and 7008-6 IEEE cables.

*ADDRESS The address switches are used to set the primary address of the Model

2243 IEEE-488 interface. Factory set value is 19(10011 I.

*DIGITAL I/O The digital I/O port consists of four input and four output lines as well

as IEEE-488 common and +5VDC. The outputs will drive one TTL

load. The instrument can be programmed to generate an SRQ upon

any change in the four bit input data.

*These connectors are present only when the Model 2243 is installed in the Model 224.

For more information concerning these connectors refer to the Model 2243 Instruction Manual.

2-4

Page 19

KEITHLEY

OUTPUT

OPERATE

POWER

ON

OFF

224 PROGRAMMABLE CURRENT SOURCE

CONTROL

AUTO TRIG

SOURCE

AMPS VOLTS AMPS SECONDS

DISPLAY MODIFY

DIGIT

INCR

DECR

TALK

LISTEN

REMOTE

DISPLAY

V - LIMIT I - LIMIT TIME

DATA ENTRY

CANCEL ENTER EXPONENT

IEEE-488 INTERFACE

SH1

AH1TETEOL4LEO

SR1

RL1

PP0

DC1COE1

DATA

7

8

9

4

5

6

1

2

3

0

1

A1

A2

A3

A4

+ / -

0

EXTERNAL

TRIGGER

INPUT

OUTPUT

FUSE

SLOWBLOW

3/4A 90-125V

3/8A 180/250V

Figure 2-1. Model 224 Front and Rear Panels

DIGITAL I/O

LINE RATING

50-60 Hz AC, 80 VA MAX

LINE VOLTAGE SELECTED

90-110V

105-125V

KEITHLEY

180-220V

210-250V

MADE IN

U.S.A.

2-5

Page 20

(CENTER TRIAX CONDUCTOR)

OUTPUT HI

OUTPUT COMMON

(INNER TRIAX SHIELD)

CHASSIS COMMON

(OUTER TRIAX SHIELD)

Figure 2-2. Output Connector

250V

I

RMS MAX

f IOOV MAX

I

I

250V

RMS MAX

2.3.4 Output Connector

The output connector is a Teflon@

insulated triax connector

that is located on the rear panel. The maximum allowable

voltage potential between the HI and LO terminals is f 1OOV.

The maximum allowable common mode voltage between the

HI input terminal and the chassis common is 250Vrms DC to

60Hz. Refer to Figure 2-2.

2.3.5 Inductive Loads

In general, the output load connected to the Model 224

should be resistive. However, a small amount of inductance

can be tolerated if the inductive reaction voltage is limited to

less than 105V. Refer to Figure 2-3 for a suggested method

for limiting the inductive reaction voltage.

CAUTION

If the output load connected to the Model

224 is inductive, the inductive reaction

voltage MUST BE LIMITED to less than

105V. Otherwise instrument damage may

occur.

TWO BACK TO BACK

ZENER DIODES

~MOTOl?~CI~~~12OZ5lO~

LOAD

Figure 2-3. Limiting Inductive Reaction Voltage

2.3.6 Response Time

The response time is defined as the finite time difference be-

tween the actuation of the OUTPUT function and the output

reaching to within 0.1% of the programmed value. The actuation of the OUTPUT function could be from an external

trigger pulse or by pressing the OPERATE button on the front

panel. The actual time difference is small, but in some applications it may be helpful to know the response time. The

response time is depicted in Figure 2-4.

TIME -

TRIGGER

p=

OUTPUT

:-i-i 0.1% of final value

4

A :B!

,

Trigger Mode

“X’

EXTERNAL TRIGGER

INPUT

“A”

5.0mS

l.OmS

“B”

1 .OmS

1 .OmS

TOTAL

6.0mS

2.0mS

Figure 2-4. Response Time

2.3.7 General Operating Procedure

The Model 224 has several different operating parameters.

These parameters W-LIMIT, I-LIMIT, source value, time, etc)

are to be programmed into the Model 224 before actual

operation. The general procedure is designed to get the un-

familiar user familiar with the basic operation of the Model

224. Several programming examples follow the general procedure. These programming examples show several various

ways to operate the Model 224.

1. Turn on the Model 224. Allow one hour warm up to

achieve rated accuracy.

2. Select the desired l-limits. HI and LO l-limits must be set

on the same range. (HI and LO are .0000-O at power up.)

A. Press I-LIMIT.

B. Press the numbers that correspond to the desired HI

limit. Maximum is lOl.OO-3A.

C. Press ENTER.

D. Press I-LIMIT.

E. Press the numbers that correspond to the desired LO

limit. Minimum is -101 .OO-3A.

F. Press ENTER.

I 3. Select the desired V-limit.

A. Press V-LIMIT.

-

2-6

Page 21

B. Press the numbers that correspond to the desired

V-limit (Default is 3V.I

C. Press ENTER.

4. Select the desired source value. (Default is O.OOO-6A.)

There are two ways to select the source value: auto and

manual.

Manual Selection:

A. Press SOURCE.

B. Press the numbers (DATA keys) that correspond to the

desired source value. The source value ranges are from

-101 .OO-3A to O.OOO-6A to + 101.003A.

C. Press ENTER.

Auto Selection:

A. Press TIME. (Selects the output range mode. Default is

5Omsec. 1

B. Press the numbers that correspond to the desired in-

crement/decrement rate. The rate ranges from

50.00~3sec to 999.9sec.

C. Press ENTER.

D. Press SOURCE.

E. Press DIGIT the desired amount of times to select the

digit that is to be modified. The DIGIT button reverts

the modify digit to the most significant digit if the DIGIT

button is pressed when the cursor is presently on the

digit just before the least significant digit. The least

significant digit does not increment or decrement.

F. Press AUTO.

G. Press the INCR button to increment the displayed

value. Press DECR button to decrement the displayed

value.

NOTE

The INCR function has the mathematical carry

capability. The DECR function has the

mathematical borrow capability. The least

significant digit and the exponent digit do not increment or decrement. Use manual selection to

modify these digits.

H. Press AUTO to stop the display at the desired value.

5. Connect the appropriate load.

6. Press OPERATE to output the displayed value. The output

is programmed to O.OOO-6A when not in the operate mode

and the display remains the same.

NOTE

The output load must be noninductive. A small

amount of inductance in the load can be

tolerated if the inductive reaction voltage

(L $ 1 is limited to less than 105V. Refer to

paragraph 2.3.5.

2.3.8 Front Panel Messages

The Model 224 has several front panel messages. These

messages appear throughout the operation of the Model 224

and are listed in Table 2-5.

2.3.9 Examples of Operation

The following examples present several operating methods

and variations.

Example 1 Output 10mA: In this example the Model 224

will be programmed to output a source value of 10mA with a

compliance voltage of IOV.

Required Output: 10mA with 1OV compliance.

Use the following procedure to program the Model 224 to

output the preceding parameters.

1. Turn on the Model 224. Allow one hour for warm up.

2. Press SOURCE,l,O,EXPONENT,3,ENTER. (Programs a

source value of lOmA.

3. Press V-LIMIT,l,O,ENTER. (Programs V-LIMIT of 1OV).

4. Connect load.

5. Press OPERATE.

If the ENTER button is not pressed in the sequence indicated

the operation will not take place as intended. Upon the actuation of step 5 the Model 224 outputs 1OmA with a 1OV compliance limit. Press the SOURCE button to verify that the

1OmA was actually programmed into the Model 224. Press

the V-LIMIT button to verify that the 1OV limit was actually

programmed into the Model 224.

Example 2 Output POnA: In this example the Model 224 will

be programmed to output a source value of 20nA with a

compliance of 26V.

Required Output: 20nA with a 26V compliance limit.

Use the following procedure to program the Model 224 to

output the preceding parameters.

1. Turn on the Model 224 and allow one hour for warm up.

2. Press SOURCE,2,0,EXPONENT,S,ENTER. (Programs a

source value of 20nA.I

3. Press WLIMIT,2,6,ENTER. (Programs a 26V compliance

limit.)

4. Connect load.

5. Press OPERATE.

Example 3 Output 20nA: In this example the Model 224 will

be programmed to output a source value of 20nA with a

compliance voltage of 26V. This example is the same as Example 2 except for the method used to program the source

value.

Required Output: 20nA with a 26V compliance limit.

Use the following procedure to program the Model 224 to

output the preceding parameters.

1. Turn on the Model 224 and allow one hour for warm up.

2. Press SOURCE,O,.,0,2,EXPONENT,G,ENTER. (Programs

a source value of 20nA.I

2-7

Page 22

3. Press VLIMIT,2,6,ENTER. (Programs a compliance

voltage of 26V.I

4. Connect load.

5. Press OPERATE.

Upon actuation of step 5 the Model 224 outputs 20nA with a

26V compliance limit. The end result of this example is the

same as the end result of Example 2. The only difference is

the method used to program the source value. Press the

SOURCE button to verify that 20nA was actually programmed into the Model 224. Once the SOURCE button has

been activated the source value is displayed on the front

panel. Press the V-LIMIT button to verify that a 26V compliance limit was actually programmed into the Model 224.

Once the V-LIMIT button has been activated the V-limit is

displayed on the front panel.

Message

+H30fMd3 p

T-TITJ

m

p7c-j

b--

-7c-T-y

Err]

Example of the software revision level.

Factory set value of the IEEE-488 interface.

Error, one of the following conditions exists.

Selecting source value that is out of the range of the Model 224.

(Greater than 101 .OO-3A or less than -101 .OO-3A).

Selecting auto time of less than 50.00~3sec or greater than 999.9sec.

Selecting l-limit that is less than -101 .OO-3A or greater than 101 .OO-3A.

Table 2-5. Front Panel Messages

Description

ower up display segment test.

HI limit of the l-limit.

LO limit of the l-limit.

’

Selecting V-limit that is less than 1V or greater than 105V.

Selecting source value that is less than or greater than the programmed

limits. (Auto mode only)

Selected LO limit is higher than selected HI limit after auto is pressed.

When l-limit or full scale is reached in auto mode.

Example 4 Manual INCWDECR Operation: The value of

current can be modified either manually or automatically.

This example shows how to modify the current value manual-

IY.

Manual INCR/DECR Notes:

1. The DIGIT button must be pressed the desired number of

times to select the digit that is to be modified.

2. The term increment means that the increasing direction is

toward the positive current limit. The term decrement

‘means that the decreasing direction is toward the negative

current limit.

2-8

3. The displayed value is also the output value.

4. In this mode, the AUTO, INCR and DECR LED’s are

turned off.

5. The INCR function has the mathematical carry capability.

6. The DECR function has the mathematical borrow capability.

7. The least significant digit does not increment or decrement.

8. The exponent digit does not increment or decrement.

9. Only the source can be modified by INCR or DECR.

Page 23

In this example we will choose the following parameters:

1. Output is 5pA.

2. Voltage compliance is 50V.

Use the following procedure to program the Model 224 to

output 5pA with a voltage compliance of 50V.

1. Turn on the Model 224 and allow one hour for warm up.

2. Press V-LIMIT,5,0,ENTER. (Programs a compliance limit

of 5OV.I

3. Press SOURCE. (Activates the source function.1

4. Press DIGIT,DIGIT. (Selects the digit that is to be

modified. Notice the C segment cursor is flashing.)

5. Press INCR,INCR,INCR,INCR,INCR,ENTER. (Modifies

the selected digit to numeral 5.1

6. Connect the load.

7. Press OUTPUT. (Outputs the displayed value of current to

the rear panel output connector.)

In this procedure it is easy to see how simple it is to program

the Model 224 to the exact value of current desired. The ex-

ample could also be used to decrement the value of current.

To do this change step 5 of the procedure to:

5. Press DECR,DECR,DECR,DECR,DECR,ENTER.

This causes the display to decrement the display to 0.000-6 if

it is done after the procedure was completed with the 5,uA

output. If this change is done before increment then the

display would go in the negative direction to -5.000-6A.

8. Decrementing a value lower or higher than the present

current range causes the ERR (error) message to be

displayed. The Model 224 will remain at the highest or

lowest value for that range.

9. Pressing the CANCEL button while in the auto mode will

abort the operation.

10. The least significant digit, or the exponent digit, does not

increment or decrement.

11. To auto step the source value from the HI l-limit to LO

l-limit without causing the error message to be displayed

and the auto step action to be stopped the l-limits (HI and

LO) must be set on the same range.

For example:

HI l-limit = + lOOE-3A on the lOOE-3A range

LO l-limit = - IOOE - 3A on the 100E - 3A range

These values are valid and allow the scan from HI to LO

or LO to HI to be completed.

Example of inappropriate values for the auto scan:

HI l-limit = + lOOE-3A on the IOOE-3A range

LO l-limit = + lOE-6A on the lOE-6A range

With these limits set, attempting to auto scan from the HI

to the LO limit causes the error message to be displayed,

scan operation to stop and the source value remains at

OO.OOE-3A. The same is true for scanning from the LO

limit to the HI limit. When the source value reaches

+ 19.00E-6A the error message is displayed, the scan

operation is stopped and the source value remains at

+ 19.00E - 6A.

Required Output: 33mA with a 1OOV compliance limit.

Example 5 Using the Auto Mode: In this example the

Model 224 will be programmed to output 33mA with a compliance limit of 1OOV using the auto mode. The auto mode

allows adjustment of the source value to be automatically incremented or decremented at a predetermined rate.

Auto Mode Notes:

1. The time (auto increment/decrement rate) must be programmed to the desired value before using the auto

mode. Power up value of time is 50.00~3sec.

2. The SOURCE button must be activated before using the

auto mode.

3. The digit button cursor must be placed at the appropriate

digit on the display before the auto mode is activated.

4. The furthest digit on the left of the display is either a

blank or a “1”.

5. Incrementing a value higher than the HI limit causes the

Model 224 to display ERR, deactivate the auto mode and

remain at the HI l-limit.

6. Decrementing a value lower than the LO limit causes the

Model 224 to display ERR, deactivate the auto mode and

remain at the LO l-limit.

7. Pressing the AUTO button while the Model 224 is auto

incrementing/decrementing stops the auto increment/

decrement action. Pressing AUTO again resumes the

operation.

The auto rate will be programmed to one second. Use the

following procedure to program the Model 224 for the

preceding parameters.

1. Turn on the Model 224 and allow one hour for warm up.

2. Press I-LIMIT,l,O,O,EXPONENT,3,ENTER. (Programs HI

l-limit to lOOmA.

3. Press I-LIMIT, + /-,l,O,O,EXPONENT,B,ENTER. (Programs the LO l-limit to -1OOmA.I

4. Press V-LIMIT,l,O,O,ENTER. (Programs a voltage compliance of 1OOV.I

5. Press TIME,l,U(PONENT,O,ENTER. (Programs the auto

rate to one second.)

6. Press SOURCE. (Selects the source function.1

7. Press DIGIT,DIGIT,DIGIT,AUTO,INCR. (Selects the

third digit on the left of the display, the auto function and

starts the automatic increment. When the display

reaches 3.3, press AUTO to stop the auto increment

function.)

8. Press CANCEL. (Deactivates the auto mode.1

9. Press EXPONENT,2,ENTER. (Programs the Model 224

for the 33mA value.)

10. Connect the Load.

11. Press OPERATE. (Outputs 33mA at the rear panel output

connector.)

2-9

Page 24

The auto rate may be varied from 50msec to 999.9sec. The

power up default value of the auto rate is 50msec. The one

second rate used in this example is used just for learning

purposes. In another situation, the rate could be programmed

much faster or slower. Once the desired value is reached,

deactivating the AUTO button stops the auto increment/

decrement action.

The auto mode is a convenient function that allows for precise

currents to be stepped. This could be used to test

semiconductors at several different current values, The only

difference between this example and the example of stepping

the current is the actual value of current; and the OUTPUT

button is activated.

The auto mode could also be used to decrement the current

value. After step 11, press DIGIT,DIGIT,DIGIT,AUTO,DECR.

Then observe the display decrease the value of current by

1mA every second. Stop the decrement at the 1mA level,

otherwise the Model 224 will display the ERR (error) message

and remain at the value of 00.00-3A. The error message is

displayed because the instrument was on the 100mA range

and then it was instructed to auto increment outside of that

range. Refer to the Auto Mode Notes in this example.

Example 6 Triggering: The Model 224 may be triggered to

increment or decrement the selected digit in two ways:

1. With the front panel TRIG button activated, apply a trigger

pulse (TTL level-negative going) to the rear panel

EXTERNAL TRIGGER INPUT. Refer to Figure 2-5 for

pulse specifications.

2. With commands given over the IEEE bus. This action

requires that the Model 2243 IEEE-488 interface option

be installed.

7. While the auto or trig modes are activated, the four buttons in the DISPLAY group (SOURCE, V-LIMIT, I-LIMIT

and TIME) are locked out.

This example covers the front panel TRIG button, the external

trigger input and output connectors. The external trigger operates in conjunction with the front panel TRIG button. That is,

the front panel TRIG button must be activated before the

Model 224 will accept an external trigger stimulus.

To illustrate the front panel TRIG button and the external trigger input use the following procedure:

1. Connect the external trigger source to the rear panel BNC

EXTERNAL TRIGGER INPUT connector.

2. Press the SOURCE button to activate the source function.

3. Press the DIGIT button to select the desired digit that is to

be modified.

4. Press the front panel TRIG button to activate the trigger

mode.

5. Press INCREMENT or DECREMENT.

6. To trigger the instrument, apply a pulse to the EXTERNAL

TRIGGER INPUT. The pulse must conform to the specifications shown in Figure 2-5.

7. With just one pulse applied the Model 224 modifies the

selected digit by one count.

8. Press OPERATE to output the current.

TRIGGER ON

NEGATIVE

TTL

HIGH

GOING

PULSE

External T rigger Notes:

1. The front panel TRIG button is used to control the rear

panel EXTERNAL TRIGGER INPUT connector. Pressing

this button once enables the external trigger and turns on

the TRIG LED. Pressing the button again disables the

external trigger operation and turns off the TRIG LED.

2. The TRIG and the AUT O functions are mutually exclusive.

3. The DIGIT button must be activated before the TRIG button is activated.

4. INCR or DECR must be selected after TRIG is activated.

5. While in the TRIG mode, pressing the TRIG button stops

the operation. Pressing TRIG once more resumes the

operation from where it was stopped.

6. The external trigger output is controlled by the TRIG button. When the selected digit is incremented or decremented a pulse (TTL level-negative going) appears at the

EXTERNAL TRIGGER OUTPUT connector. The specifications of the pulse are shown in Figure 2-5.

2-10

TTL

LOW

10µSEC

MINIMUM

CAUTION: DO NOT EXCEED NORMAL TTL LEVELS

Figure 2-5. External Input and Output Trigger Pulse

Specifications

Page 25

For an example using external input and output triggering,

I

assume the Model 224 is to be used with the Keithley Model

195A System DMM. Like the Model 224, the Model 195A

has external input and output triggering. The triggering sequence would occur as follows:

The Model 195A outputs a pulse to the Model 224. This pulse

triggers the Model 224 to increment or decrement the

selected digit by one count. After the selected digit is

modified, the Model 224 outputs a pulse to the Model 195A.

With this pulse the Model 195A takes a reading. When the

reading is complete the Model 195A outputs a pulse to the

Model 224. Then the cycle repeats itself until it is programmed to stop or it is interrupted.

To use the Model 224 with the Model 195A perform the

following steps:

1. Connect the Model 224’s EXTERNAL TRIGGER INPUT

connector to the Model 195A’s VOLTMETER COMPLETE

(trigger out) connector. Connect the Model 224’s EXTERNAL TRIGGER OUTPUT to the Model 195A’s EXTERNAL

TRIGGER INPUT. Refer to Figure 2-6 for a block diagram.

2. Place the Model 195A in the external trigger mode.

3. Set the Model 224 l-limits.

4. Press the SOURCE button on the Model 224 to activate

the source function and press OPERATE.

5. Press the DIGIT button on the Model 224 to select the ap-

propriate digit to be modified.

6. Press the front panel TRIG button to activate the trigger

mode and INCR or DECR.

7. Press RESOLN. To start the trigger action press the PRGM

and TRIG button on the Model 195A in sequence to activate the one shot trigger mode of the Model 195A.

8. Observe the Model 224’s display and notice that the

selected digit is being modified by the Model 195A.

NOTE

The initial condition of the Model 195A may

prove that it is in the one shot mode. If this is the

case then pressing the PRGM and TRIG in sequence would toggle the Model 195A into an

alternate trigger mode. Consult the Model 195A

Instruction Manual for complete details concern-

ing the trigger mode.

Example 7 Using Guard: Leakage resistance between low

current conductors and nearby voltage sources can cause

significant error currents, For example, if a printed circuit ele-

ment has a leakage path with a resistance of 16% to a nearby

15V supply terminal, a current of 15nA will be generated. This

is illustrated in Figure 2-7. In order to keep this current low

(less than 1 pA) the leakage resistance would have to be

above 1.5 x 10%. The high resistance is difficult to maintain

in many situations. In order to eliminate such stringent insulation resistance requirements, guarding techniques may beused as shown in Figure 2-8.

+15v

PICOAMMETER

IL = 15v = E = ,5”A

RL l@

Figure 2-7. Unguarded Circuit

Guarding is defined as surrounding the sensitive input with a

conductor (the guard) connected to a low impedance point

which is at (virtually) the same potential. The GUARD tir-

minal located on the rear panel provides an easy connection

to a low impedance voltage source which is equivalent to the

output compliance voltage.

The maximum load capacitance for the guard output is

O.OlhF. The maximum load current which includes guard and

output is not to exceed 105mA. The accuracy of the guard

+ 1 mV. That is excluding the I*R drop of

+15V

IS

the

output lead.

EXTERNAL

TRIGGER

INPUT

MODEL 224

EXTERNAL

TRIGGER

OUTPUT

Figure 2-6. External Trigger Connections

MODEL 195A DMM

‘VOLTMETER

COMPLETE

EXTERNAL

TRIGGER INPUT

I

/)I

Figure 2-8. Guarded Circuit

Example 8 Operation as an ACTIVE LOAd (Current

Sink): The Model 224 can be used as an active current sink.

Refer to Figure 2-9 for an illustration of this concept. The

put voltage V, is a function of E, I and R, where:

V, = E + IR,

E = Extended Voltage Source

I = Programmed Current on the Model 224

R, = Load Resistance

PICOAMMETER

out-

2-I 1

Page 26

CAUTION

When the Model 224 is connected so as to

sink current (that is, power is delivered to

the Model 224 by an external supply). care

should be taken to limit the power

delivered to the Model 224. Figure 2-10

shows the specifications of the power

limits to the Model 224.

For resistive loads the Model 224 will deliver the programmed current up to the compliance voltage (V, = Vc).

The power limits must be observed, otherwise damage to the

instrument may occur.

MODEL 224

probes of a hard metal such as tungsten are used. Because

contact resistance is so high, a four point probe is used. The

outer contacts supply a constant current, the inner two contacts measure the voltage drop across a portion of the sample. With the geometry of the probe and wafer known,

resistivity can then be calculated.

The current source must be stable and accurate. The Model

224 is suitable for this application. The accurate and stable

current output required can be programmed before making

the measurement.

4

r-

r

Figure 2-9. Connections as a Current Sink with a

2.4 APPLICATIONS The Model 224’s wide range of current values allows it to be

used in a variety of applications. Some of these applications

include: calibration,

characterization and low resistance measurements, etc. The

following discussions explain the preceding applications.

2.4.1 Calibration

The Model 224’s high accuracy and programmability allows it

to be used as an automatic calibration source for current. In

many calibration situations a source of accurate and stable

current is required at a controller’s (computer) programmed

request. With the IEEE-488 bus option the Model 224 is ideal

for this type of application.

The controller may be programmed to instruct the Model 224