Page 1

KBWS

Pulse Width Modulated (PWM)

Whisper-Drive™ DC Motor Speed Controls

with Built-in Input Signal Isolation

For Permanent Magnet DC Motors Rated:

1/50 – 1/2 HP (SCR), 3/4 HP (PWM) @ 115 Volts AC

1/25 – 1 HP (SCR), 11⁄2 HP (PWM) @ 208/230 Volts AC

TYPICAL APPLICATIONS

• Medical Equipment • Packaging Equipment

• Web Processing • Winding Machinery

• Conveyors • Machine Tools

DATA SHEET D-435

*

Model KBWS-15 Shown

BENEFITS

• Replaces costly choke and capacitor filtering.

• Provides quieter and cooler operation.

• Extended brush life on SCR rated motors.

STANDARD FEATURES

• Plug-in Horsepower Resistor®: Automatically calibrates IR

Compensation and Current Limit (supplied separately).

• Diagnostic LEDs: Power On (PWR ON) and Current Limit (CL).

• Short Circuit Protection: Protects the control from a short circuit

at the motor.

• Isolated Signal Input Circuit: Eliminates the need for an external signal

isolator (accepts 0 - 5 Volts DC input).

• Protection Features: Undervoltage protection. MOV input transient

protection. AC line inrush current limit protection.

• Inhibit Circuit: Provides electronic coast-to-stop.

• Auto AC Line Select: Control automatically adjusts for 115 or 208/230

Volt AC line input (dual voltage models).

• Motor Voltage Selection: Allows motor voltage to be set to 90/130

or 180 Volts DC (dual voltage models).

TRIMPOT ADJUSTMENTS

• Maximum Speed (MAX) • Minimum Speed (MIN)

• Current Limit (CL) • Deceleration (DEC)

• Acceleration (ACC) • IR Compensation (IR)

DESCRIPTION

The KBWS PWM (pulse width modulated) controls are designed to operate

PWM and SCR rated Permanent Magnet motors ranging from 1/50 HP to 1

They operate at a switching frequency greater than 16 kHz to provide high

motor efficiency and quiet operation. Another advantage of PWM is higher

output voltage (up to 130 Volts DC for 115 Volt AC line and 220 Volts DC for

208/230 Volt AC line) which provides increased motor speed.

The KBWS contains pulse-by-pulse current sensing, which provides short

circuit protection and prevents control damage due to commutator arcing.

Permanent magnet motor demagnetization is completely eliminated because

current peaks are reduced to safe levels. The controls contain an AC line inrush

current limiter (ICL) which reduces the AC line surge current during startup.

Standard features of the KBWS include diagnostic LEDs (Power On and

Current Limit) and adjustable trimpots (Maximum Speed, Minimum Speed,

Acceleration, Deceleration, Current Limit, IR Compensation). Also provided is a

connector for an Inhibit Switch and quick-connect terminals for AC line, motor

armature and Main Speed Potentiometer. The Plug-In Horsepower Resistor®

matches the motor characteristics to the control which eliminates the need to

recalibrate the Current Limit (CL) IR Compensation (IR) trimpots.

The KBWS contains built-in isolation for all inputs. This includes signal

voltage, Main Speed Potentiometer, Inhibit Circuit, and +5VDC Power Supply.

The dual voltage models contain a jumper to select motor voltage and special

circuitry which automatically accepts AC line input voltages of 115 or 208/230

Volts AC without having to make a jumper selection.

Optional accessories for the KBWS include a DIN Rail Mounting Kit, a

Product Safety Module (PSM), and an AC Line / Armature Fuse Kit.

1

⁄2 HP.

OPTIONAL ACCESSORIES

• DIN Rail Mounting Kit (Part No. 9995): Allows mounting of the control

to a DIN Rail.

• Product Safety Module (PSM) (Part No. 8611): Protects the machine

operator from injury due to a runaway or uncontrolled acceleration

condition.

• AC Line / Armature Fuse Kit (Part No. 9849)

*Requires CE RFI filter KBRF-300 (KB P/N 9484) or equivalent.

KB Electronics, Inc.

PWM SAFETY WARNING! This control does not contain protection circuitry

to prevent full speed runaway in the event of main power transistor failure.

However, an optional Product Safety Module (PSM) (Part No. 9995) can be installed

to prevent full speed runaway. If a PSM is not used, the installer of this product

should take proper precautions to include other means, such as mechanical

disconnects, warning notices, etc., to protect the operator of the machine involved.

Application Note: This control is not recommended for applications where the AC line is

to be rapidly cycled on and off.

Page 2

MOTOR

(OPEN TO RUN)

INHIBIT* SWITCH OR RELAY

AC LINE

KBWS

J1

180V

90V

A+A-

L1

L2

PWR ON

P2P3 P1

CL

CON1

(SUPPLIED SEPARATELY)

*FOR ENABLE (OPEN TO STOP,

CLOSE TO RUN), WIRE A CONTACT

IN SERIES WITH THE HIGH SIDE

(P3) OF THE MAIN SPEED

POTENTIOMETER

MAIN SPEED

RESISTOR®

HORSEPOWER

PLUG-IN

(FRONT VIEW)

POTENTIOMETER*

LOW (WHITE)

HIGH (VIOLET)

WIPER (ORANGE)

–

+

CLDECMIN ACC IR

MAX

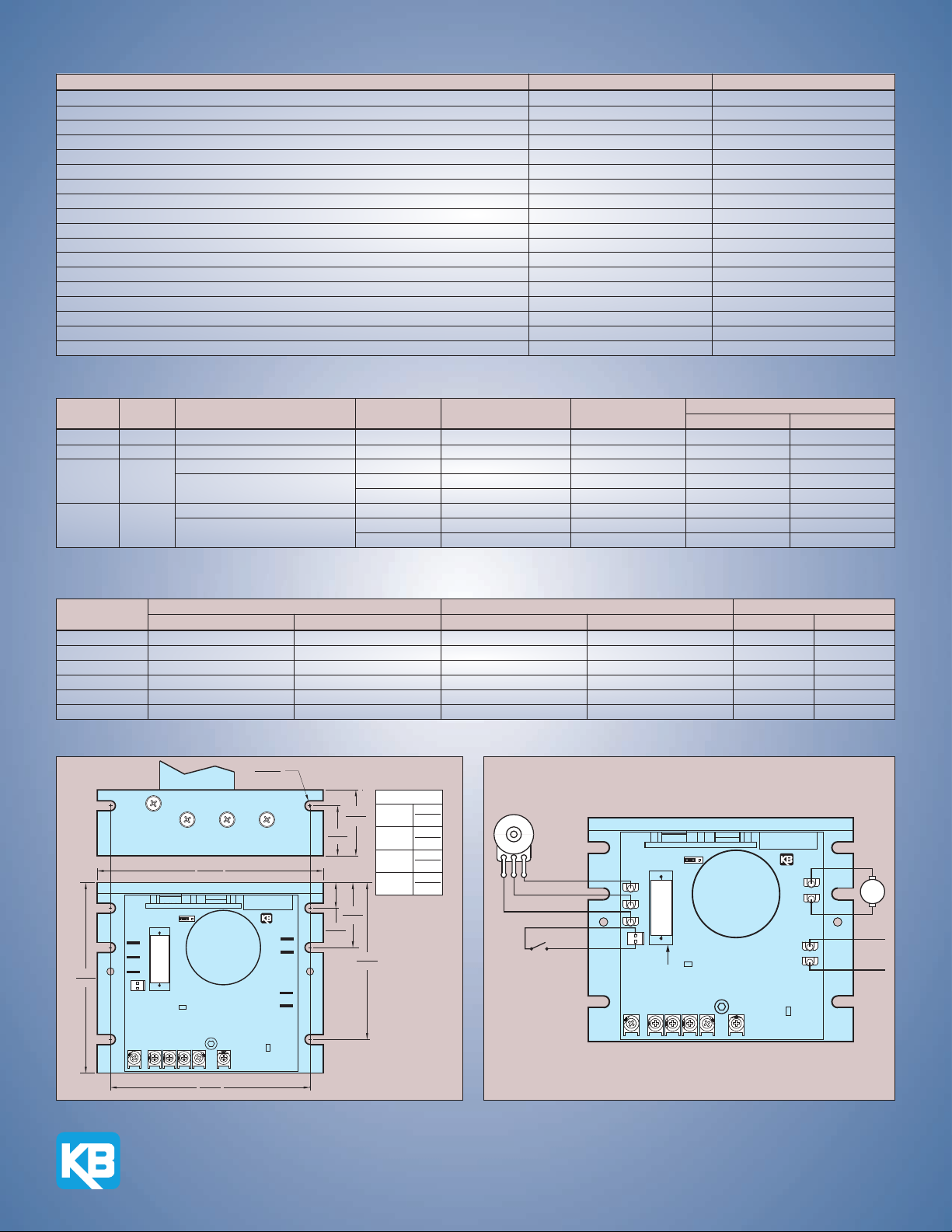

TABLE 1 – GENERAL PERFORMANCE SPECIFICATIONS

KBWS

180V 90V

A+A-

L1

L2

CL

PWR ON

J1

P3 P2 P1

CON1

IRCLDECMIN ACC

2.98

[75.8]

1.23

[31.4]

0.48

[12.3]

4.30

[109.2]

3.62

[92.1]

3.80

[96.5]

8 PLACES

Ø0.19

[Ø4.83]

1.25

[31.8]

0.95

[24.1]

MAX

Maximum Height

2.19

[55.5]

KBWS-12

[50.5]

1.99

KBWS-15

[55.5]

2.19

KBWS-22D

3.17

[80.5]

KBWS-25D

DATA SHEET D-435

Description Specification Factory Setting

AC Line Voltage Regulation (% Base Speed) 0.5 —

Armature Voltage Range at 115 Volt AC Line Input (Volts DC) 0 – 130 90

Armature Voltage Range at 208/230 Volt AC Line Input (Volts DC) 0 – 130, 0 – 220 180

Maximum Load Capacity (% for 2 Minutes) 150 —

Switching Frequency at Motor (kHz) >16 —

Signal Following Input Voltage Range (Volts DC) 0 – 5 —

Maximum Speed Trimpot (MAX) Range (% Base Speed) 70 – 100 100

Minimum Speed Trimpot (MIN) Range (% Base Speed) 0 – 30 0

Acceleration Trimpot (ACC) Range (Seconds) 0.2 – 10 1

Deceleration Trimpot (DEC) Range (Seconds) 0.2 – 10 1

Current Limit Trimpot (CL) Range (% Full Load) 0 – 200 150

IR Compensation Trimpot (IR) Range at 90/130 Volts DC Output (Volts DC) 0 – 10 5

IR Compensation Trimpot (IR) Range at 180/220 Volts DC Output (Volts DC) 0 – 20 10

Speed Regulation (50:1 Speed Range) (% Base Speed) 1—

Speed Range (Ratio) 50:1 —

Operating Temperature Range (ºC / ºF) 0 – 40* / 32 – 104 —

Operating Humidity Range (% Relative, Non Condensing) 0 – 95 —

Storage Temperature Range (ºC / ºF) -25 – +85 / -13 – +185 —

* All models are rated at 40 ºC, maximum ambient temperature, at the Rated Load Current..

TABLE 2 – ELECTRICAL RATINGS

1

Model Part No.

2

KBWS-12

2

KBWS-15

AC Line Input Voltage (±10%,50/60Hz)

(Single Phase Volts AC)

9490 115 0 - 90, 130 4.0 2.5 1/4, (0.18) 1/3, (0.25)

9491 115 0 - 90, 130 8.0 5.0 1/2, (0.37) 3/4, (0.5)

Motor Voltage

(Volts DC)

115 0 - 90, 130 4.0 2.5 1/4, (0.18) 1/3, (0.25)

KBWS-22D 9492

208/230

0 - 180, 220 4.0 2.5 1/2, (0.37) 3/4, (0.5)

0 - 90, 130 4.0 2.5 1/4, (0.18) 1/3, (0.25)

115 0 - 90, 130 8.0 5.0 1/2, (0.37) 3/4, (0.5)

KBWS-25D 9493

208/230

Notes: 1. For ambient temperatures above 40 ºC, all drives are derated 2.5% per ºC. 2. Minimum Order, 100 Pieces.

0 - 180, 220 8.0 5.0 1, (0.75) 1

0 - 90, 130 8.0 5.0 1/2, (0.37) 3/4, (0.5)

Maximum AC Line Current

(Amps AC)

Maximum Load Current

(Amps DC)

Maximum Horsepower Rating HP, (kW)

SCR Rated Motors PWM Rated Motors

1

⁄2, (1)

Motor Current

TABLE 3 – PLUG-IN HORSEPOWER RESISTOR® SELECTION CHART

(Amps DC)

3.3 – 5.0 1/3, (0.25) – 1/2, (0.37) 3/4, (0.5) – 1, (0.75) 1/2, (0.37) – 3/4, (0.5) 1, (0.75) – 1

2.5 1/4, (0.18) 1/2, (0.37) 1/3, (0.25) 3/4, (0.5) 0.18 9837

1.3 – 2.0 1/8, (0.09) – 1/6, (0.1) 1/4, (0.18) – 1/3, (0.25) 1/6, (0.1) – 1/4, (0.18) 1/3, (0.25) – 1/2, (0.37) 0.25 9836

0.7 – 1.0 1/15, (0.05) – 1/10, (0.08) 1/6, (0.1) – 1/5, (0.15) 1/12, (0.06) – 1/8, (0.09) 1/6, (0.1) – 1/4, (0.18) 0.51 9834

0.4 – 0.6 1/30, (0.02) – 1/20, (0.04) 1/15, (0.05) – 1/10, (0.08) 1/20, (0.04) – 1/15, (0.05) 1/8, (0.09) – 1/6, (0.1) 1.0 9833

0.1 – 0.3 1/100, (0.007) – 1/50, (0.01) 1/50, (0.01) – 1/25, (0.03) 1/50, (0.01) – 1/30, (0.02) 1/25, (0.03) – 1/20, (0.04) 2.0 9949

FIGURE 1 – MECHANICAL SPECIFICATIONS (Inches/mm)

KB ELECTRONICS, INC.

12095 NW 39th Street, Coral Springs, FL 33065-2516 • (954) 346-4900 • FAX (954) 346-3377

Outside Florida Call Toll Free (800) 221-6570 • info@kbelectronics.com

www.kbelectronics.com

SCR Rated Motor Horsepower Ranges [HP, (kW)] PWM Rated Motor Horsepower Ranges [HP, (kW)] Plug-in Horsepower Resistor®

90 Volt DC 180 Volt DC 130 Volt DC 200 Volt DC Ω Part No.

1

⁄2, (1) 0.1 9838

FIGURE 3 – CONTROL LAYOUT & CONNECTION DIAGRAM

COPYRIGHT © 2010 KB Electronics, Inc.

(A42105) – Rev. B – 04/2010

PC – 6K – 07/2010

Loading...

Loading...