Page 1

TM

TM

®

KBWM

VARI-DRIVE

NEMA-1

SCR Variable Speed DC Motor Control

For Per manent Magnet (PM),

Shunt Wound Motors and

Magnetic Particle Clutches

TWO MODELS COVER

1/100 - 1/3 Hp @ 90VDC

1/50 - 3/4 Hp @ 180 VDC

*

• Model KBWM-120 for 115 VAC line with 90 VDC motors (P/N 9380)

• Model KBWM-240 for 230 VAC line with 180VDC motors (P/N 9381)

DATA SHEET D-500

STANDARD FEATURES

®

• Plug-in Horsepower Resistor

▲

automatically calibrates

IR Comp.and Current Limit (CL).

▲

• AC line and ar mature

fusing.

• Rugged all-metal NEMA 1 enclosure.

• AC line ON/OFF switch with “power on” indicator lamp.

• Patented KBMM™ speed control module prevents

demagnetization of PM motors.

▲

Proper size Plug-in Horsepower Resistor®and armature fuse must be installed

for control to operate – distributor supplied.

ARMATURE FUSE SELECTION CHART

90 VDC Motor 180 VDC Motor

Horsepower

1/100 1/50 .1 2/10

1/50 1/25 .2 3/10

1/30 1/15 .3 1/2

1/20 1/10 .5 3/4

1/15 1/8 .7 1

1/10 1/5 1.0 1 1/2

1/8 1/4 1.3 2

1/6 1/3 1.7 3

1/4 1/2 2.5 4

1/3 3/4 3.3 5

Approx. DC Motor Fuse Rating

Current (amps) (AC amps)

SPECIFICATIONS

DESCRIPTION

The KBWM™ Vari-Drive™ adjustable speed SCR

control for DC motors offers proven reliability in a rugged

all-metal NEMA-1 enclosure.The V ari-Drives are equipped with

the ultimate KBMM™ speed control module.They are specifically

designed for fractional horsepower permanent magnet (PM)

DC motors. Two models are offered. The KBWM-120 is

designed for 115 VAC input and is rated 1/100 - 1/3Hp at 90

VDC. For motors rated 1/50 - 3/4 Hp at 180 VDC use Model

KBWM-240.

KB’s exclusive Plug-in Horsepower Resistor®*

automatically presets the drive’s IR Comp and CL circuits for

safe operation on various motors. Although factory

calibrated, internal trimpots for Min, Max, IR, CL, Accel and

Decel can be used to fine-tune the KBWM™ for specific

applications. Connections to the control are via a barrier

terminal block. By changing the orientation of the front cover,

the wiring can be brought in either from the bottom or the top

of the control.

Motor failure due to demagnetization is eliminated by the

patented ultra-fast Direct-Fed™ current limit circuit. The

controls contain AC line and armature* fusing, which provide

protection against catastrophic failure. Auto-Inhibit®, a KB

exclusive, allo ws the drive to be turned on and off rapidly using

the AC line without damage to the control and/or motor. The

internal CL LED is a diagnostic indicator that lights when the

motor is overloaded.

A conveniently located front panel lighted rocker switch

controls AC line input power to the drive.

*Plug-in Horsepower Resistor®and armature fuse supplied separately.

Speed Range (Ratio) ...................................................... 50:1

Load Regulation – Armature Feedback

(0 – Full Load, 50:1 Speed Range) (% Base Speed) ...... 1*

Line Voltage Regulation (at Full Load, ± 10% Line Variation)

(% Base Speed) ............................................................ 1/2*

Control Linearity (% Speed vs. Dial Rotation) ...................... 2

CL/Torque Range (% Full Load) ................................ 0 – 200

Accel Time Range (0 – Full Speed) (Secs.)................ .2 – 10

* CE Compliance Requires KBRF-200A RFI Filter

36

A Complete Line of Motor Drives

Decel Time Range (Full – 0 Speed)(Secs.) ................ .2 – 10

Min. Speed Tr impot Range (% Full Speed) ................ 0 – 30*

Max. Speed Tr impot Range (% Full Speed) ............ 50 – 120*

IR Comp.Trimpot Range (at Specified Full Load) (Volts).... 0 – 24

Max. Allowable Ambient Temperature at Full Rating

(°C/°F)........................................................................ 50/122

*Performance is for SCR rated PMmotors only.Lower performance can be

expected with other motor types.Factory setting is for 3% load regulation.

Rev.______(A_______)

Page 2

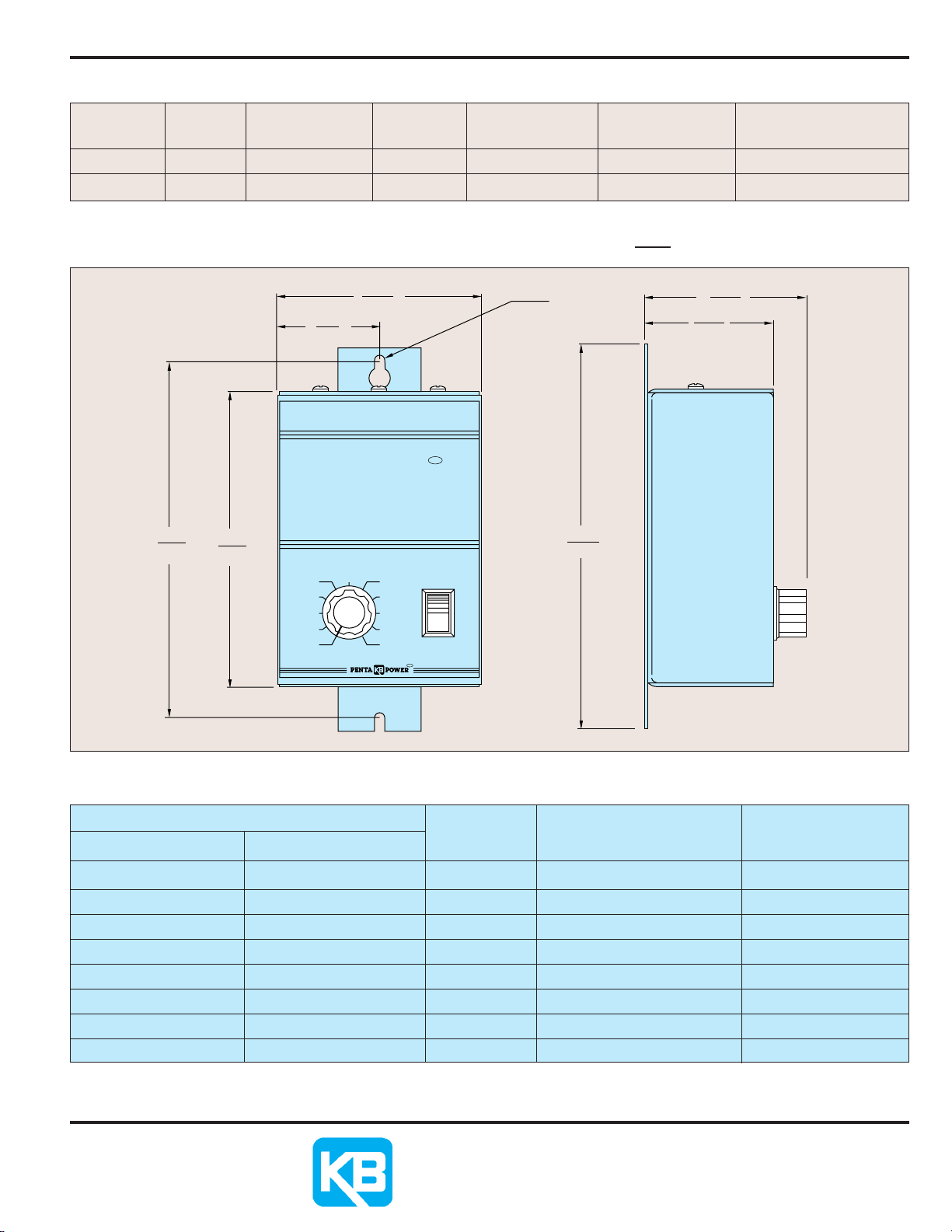

ELECTRICAL RATINGS

Model KB Part Input Line Voltage Armature Maximum AC Load Maximum DC Load Maximum Power (Hp) [KW]

Number No. (VAC - 50/60 Hz) Voltage (VDC) Current (RMS AMPS) Current (DC Amps)

KBWM-120 9380 115 0 - 90 5.0 3.5 1/3 [.25]

KBWM-240 9381 230 0 - 180 5.0 3.5 3/4 [.50]

6.36

[161.50]

5.28

[134.00]

MECHANICAL SPECIFICATIONS

3.69

[93.60]

1.84

[46.80]

VARI-

DRIVE

DC MOTOR

SPEED CONTROL

50

40

30

20

10

0

(%) SPEED

60

70

80

90

100

INCHES

[mm]

0.09

[R2.30]

TM

6.81

[173.00]

ON

OFF

TM

[73.60]

2.31

[58.60]

2.90

PLUG-IN HORSEPOWER RESISTOR®CHART

Motor Horsepower

Armature Voltage 90VDC Armature Voltage 180VDC

(2)

Motor Current Plug-in Horsepower Resistor

(DC Amps) Value (ohms) Horsepower Resistor

(1)

®

1/100 1/50 .1 1.0 9833

1/50 1/25 .2 .51 9834

1/30, 1/25 1/15 .35 .35 9835

1/20 1/10 .5 .25 9836

1/15, 1/12 1/6 .8 .18 9837

1/10, 1/8, 1/6 1/4 1.3 .1 9838

1/4 1/2 2.5 .05 9839

1/3 3/4 3.3 .035 9840

Notes: (1) Motor horsepower and armature current must be specified in order to select correct Plug-in Horsepower Resistor®.

(2) For motor horsepower not indicated use lower ohm value Plug-in Horsepower Resistor®.

KB ELECTRONICS, INC.

12095 NW 39th Street, Coral Springs, FL 33065-2516

(954) 346-4900 • FAX (954) 346-3377

Outside Florida Call TOLLFREE (800) 221-6570

www.kbelectronics.com

Individual Plug-in

®

Part No.

© 1998 KB Electronics, Inc.

Rev.______(A_______)

37

Loading...

Loading...