Page 1

SHD-R 3000

!

Betriebsanleitung

www.karcher.com

5.956-486 A2005937 (06/03)

Page 2

Operating Instructions

i

i

To be handed to the operator

Read these instructions carefully before starting up the unit

Retain for future reference

Notes about these operating

instructions

Before starting up the interior cleaner for the

first time, please carefully read through

these instructions. In particular, you should

note all the safety information. Store these

instructions in a safe place for future use.

For whom are these instructions

intended

All users

Users are persons who have received

instruction on how the system functions,

operators and trained specialists.

Trained specialists

Trained specialists are persons who are

professionally qualified to install and

commission this type of system.

Cleaning liquids

Please do not allow them to get into the

environment. Please protect the soil and

dispose of waste oil in an environmentally

friendly way.

Waste water containing mineral oil (i.e.

petrol, etc.)

Please do not allow this waste water to get

into the ground, bodies of water or the

sewers.

Mineral oil in the high-pressure pump

Mineral oil is used to lubricate the highpressure pump. The waste oil resulting from

an oil change, any oil and water mixture that

may occur, and rags that have been soaked

in oil should be delivered to a proper

collection point for disposal.

Important!

Envir onmental protection

Please dispose of the packaging in an

environmentally friendly way.

The packaging materials are recyclable.

Please do not throw the packaging into the

domestic waste but in the appropriate

recyclable waste collection containers

instead.

Please dispose of old units in an

environmentally friendly way

Old units contain valuable recyclable

materials, which should be reused. You

should never allow oil and similar materials

to get into the environment. Therefore,

please dispose of old units via suitable

collection systems.

Waste oil may only be disposed of by the

operators of special collection points.

Please deposit your waste oil at one of

these locations. Polluting the environment

with waste oil is a criminal offence.

Detergents

KÄRCHER detergents possess demulsifying

properties (ASF). This means that they do

not interfere with the function of an oil separator.

Important

These instructions contain descriptions of

different types of system, accessory kits

and other supplementary components.

There are significant differences between

the various parts so that you should not

encounter any problems with identifying all

the parts in your particular type of system.

Page 3

SHD-R 3000

Table of contents

English

A. For your safety

1. Safety information and instructions

2. Noise protection

3. Authorized operators

4. Personal protective equipment

5. Emergency drill

6. Safety devices

7. Applicable regulations

8. Using the system for its intended

purpose

9. Special conditions in hazardous area

10. Schematic diagram of area

classification

11. Area classification

B. Types of system, and operating

information

1. Types of system

2. System start-up

3. System shut-down

E. Care and maintenance

1. General information

2. Maintenance schedule

3. Maintenance tasks

F. Troubleshooting

1. Fault-finding

G. Mounting kits and accessories

1. Mounting kits (non-hazardous area)

2. Mounting kits (hazardous area)

3. Accessories

H. Warranty

I. System installation

J. Declaration of Conformity

K. Test record

C. System functions

D. Technical specifications

5.956-486 A2005937 (06/03)

1

Page 4

English

!

i

!

A. For your safety

SHD-R 3000

1. Safety information

and instructions

The following symbols are used throughout

these Operating Instructions:

Danger!

Denotes an immediate and present danger.

Failure to observe this notice could lead to

severe injury or death.

Caution!

Denotes a potentially hazardous situation.

Failure to observe this notice could lead to

minor injuries or damage to property.

Important!

Denotes operating hints and important

information.

Errors in operation or misuse can result in

danger to the operator or other persons

due to:

All persons charged with the installation,

commissioning, operation, maintenance or

service of the machine are required:

to be appropriately qualified,

to read and observe these operating

instructions,

to be aware of and observe associated

regulations.

2. Noise protection

The sound level generated by the system is

80 dB(A).

A noise hazard can occur if the water jet is

directed at resonating components (e.g.

large metal panels). In this case a hearing

protection device must be worn.

3. Authorized operators

The operation of the system is restricted to

persons over the age of 18 who have

received proper instruction as to how this

system is to be used (For exceptions for

trainees see BGV D15 Art. 6).

high water pressure,

hot liquids,

high voltages,

detergents and solvents,

Explosion hazard.

In order to avoid errors in operation or

potentially dangerous situations, read the

following before starting the system up for

the first time:

all safety information in the enclosed

brochure "Safety information for highpressure cleaning units" No. 5.951-949,

these operating instructions,

the legal requirements that are currently

applicable in your country.

4. Per sonal protective equipment

Danger!

Health hazard due to cleaning fluids.

Wear the prescribed protective equipment

for the cleaning liquid to be used, e.g.

protective clothing/overalls,

protective goggles or face mask,

watertight gloves,

watertight shoes.

A1

5.956-486 A2005937 (06/03)

Page 5

SHD-R 3000

!

i

A. For your safety

English

5. Emergency drill

Turn mains supply voltage off at system

master switch.

Turn off supply of cleaning liquid.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

6. Safety devices

Safety valve

Danger!

Injury hazard due to excessive pressure

within system. Do not adjust safety valve.

The safety valve has been preset and

sealed in the factory. Adjustments should

only be made by a Kärcher Customer

Service engineer.

If acids, alkaline solutions or solvents are to

be used:

Observe the legal requirements that are

currently applicable in your country. In

Germany the regulations of the industrial

employer's liability insurance

associations apply (BGI 504).

Observe instruction leaflets provided by

manufacturers of the detergent

concentrates that are to be used with this

system.

Important!

According to the UVV (accident prevention)

Guidelines (BGV D15, Art. 23), highpressure sprayers must be checked by an

expert with the initial startup and at least

every 12 months thereafter. Kärcher

Customer Service engineers are qualified to

carry out the prescribed tests on your

system.

7. Applicable regulations

Accident prevent regulations

Working with liquid sprayers BGV D15.

If water is used as the cleaning liquid:

Observe local regulations for disposal of

waste water.

Waste water should be directed into the

main drainage system in accordance with

local regulations.

If the water to be used is drawn from the

main supply network:

Install a mains disconnector to EN 1717

(e.g. float tank with float valve),

BetrSichV (industrial safety regulations).

The results of the test procedures must be

recorded in writing. A form into which the

test results can be entered is shown in

Chapter K: Test Record.

5.956-486 A2005937 (06/03)

A2

Page 6

English

A. For your safety

SHD-R 3000

8. Using the system for its

intended purpose

This system is used for pumping a cleaning

liquid at high-pressure, for the purpose of:

with the handgun attached – cleaning

containers, boxes, cases and equipment

parts, etc.

with the interior cleaner attached –

cleaning enclosed containers, drums,

barrels, etc.

Cleaning the following is considered to be

contrary to the intended purpose, and is

strictly forbidden:

Persons and animals

The high-pressure jet represents a serious

injury hazard.

Loose objects

Such items could be catapulted away by

the high-pressure jet, causing damage to

property or injury to persons.

6. The pump's flow rate must not exceed

50 l/min when used with solvents.

7. The operating temperature of the cleaning

liquid, made up of water with cleaning agent,

must not exceed 60 °C.

8. The operating temperature of the cleaning

liquids must not exceed 20 °C where

solvents, lyes (alkali solutions) and acids

are used.

9. The pump must be inspected after a

reasonable operating time to ensure it has a

faultless condition and function (among

other things, bearings for wear, pump for

leaks, tension in the V-belt). Repair if

necessary.

10. The pump may only be operated with

cleaning liquids against which the materials

from which the pump is made have

adequate resistance.

11. Cleaning liquids, which contain

combustible solvent fractions, must

correspond to the temperature classes IIA

and IIB. Solvents in the temperature class

IIC must not be sprayed.

If water is used as the cleaning liquid, the

system must be protected against freezing

temperatures. Damage could be caused if

water freezes inside the system.

9. Special Conditions in a

hazardous area

1. The pump may only be used in zones

which correspond to the type of explosion

protection given on the rating plate.

2. The cleaning liquid must not contain more

than 1% by weight of undissolved solids.

3. The interior cleaner must be

electrostatically grounded.

4. The cleaning liquid pump may only be run

if it is filled with liquid.

5. The nominal pressure of the pump must

not exceed 50 bar when used with solvents.

12. The pump may only be operated in Zone

1 during cleaning. Ensure compliance with

the conditions applicable within the scope of

the BetrSichV (industrial safety regulations)

and other national conditions.

13. Hoses must be electrostatically

conductive (resistance R < 1 MΩ).

14. Only use cleaning liquids with a

conductivity G > 1000 pS/m.

15. All parts in contact with the media are to

be connected to the earth connection

system.

16. The electric motor used must have a

prescribed type testing certificate to

94/9/EC.

A3

5.956-486 A2005937 (06/03)

Page 7

SHD-R 3000

A. For your safety

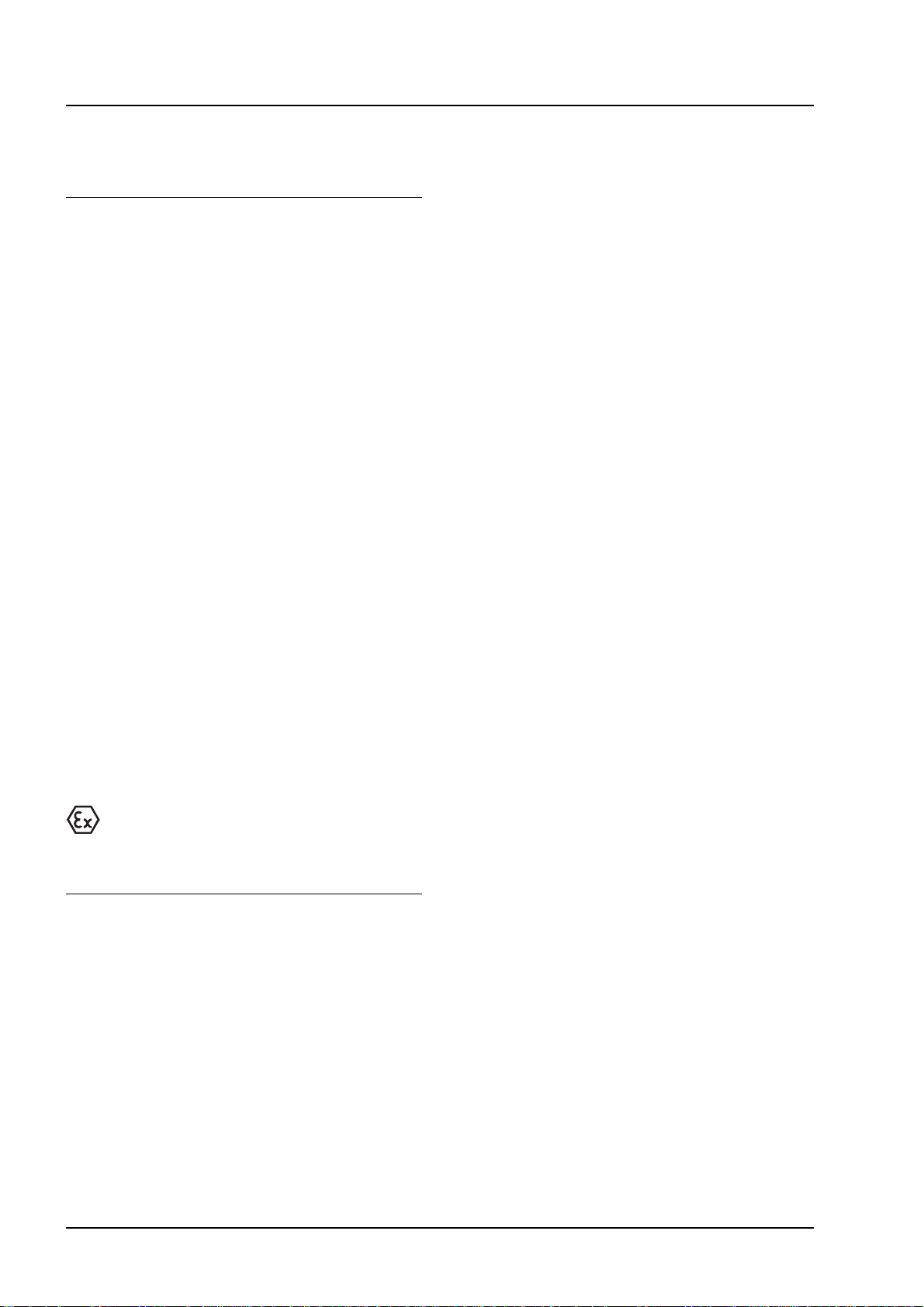

10 . Schematic diagram of area classification

English

5.956-486 A2005937 (06/03)

A4

Page 8

English

A. For your safety

11. Area Classification

In the BetrSichV and EN 1127-1, hazardous

(potentially explosive) areas are classified

into zones according to the frequency and

duration of the occurrence of hazardous,

potentially explosive atmospheres.

It is the responsibility of the owner/

operator to define these zones.

Notes on area classification are given in the

BetrSichV, EN 1127-1, BGR 104 - ExGuidelines of BG Chemie and in

DIN EN 60 079-10.

Zone 0

is an area in which hazardous, potentially

explosive atmospheres exists constantly,

for long periods of time or frequently as a

mixture of air and combustible gases,

vapours or mists.

SHD-R 3000

Zone 21

is an area in which hazardous, potentially

explosive atmospheres in the form of a

cloud of combustible dust contained in the

air can occasionally form during standard

operation.

Zone 22

is an area in which hazardous, potentially

explosive atmospheres in the form of a

cloud of combustible dust contained in the

air do not form during standard operation or

only for a short time.

Zone 1

is an area in which hazardous, potentially

explosive atmospheres consisting of a

mixture of air and combustible gases,

vapours or mists can occasionally form

during standard operation.

Zone 2

is an area in which hazardous, potentially

explosive atmospheres consisting of a

mixture of air and combustible gases,

vapours or mists do not normally occur

during standard operation or only for a short

time.

Zone 20

is an area in which hazardous, potentially

explosive atmospheres in the form of a

cloud of combustible dust contained in the

air exist constantly, frequently or for long

periods of time.

A5

5.956-486 A2005937 (06/03)

Page 9

SHD-R 3000

B. Types of system, and operating information

1. Types of system

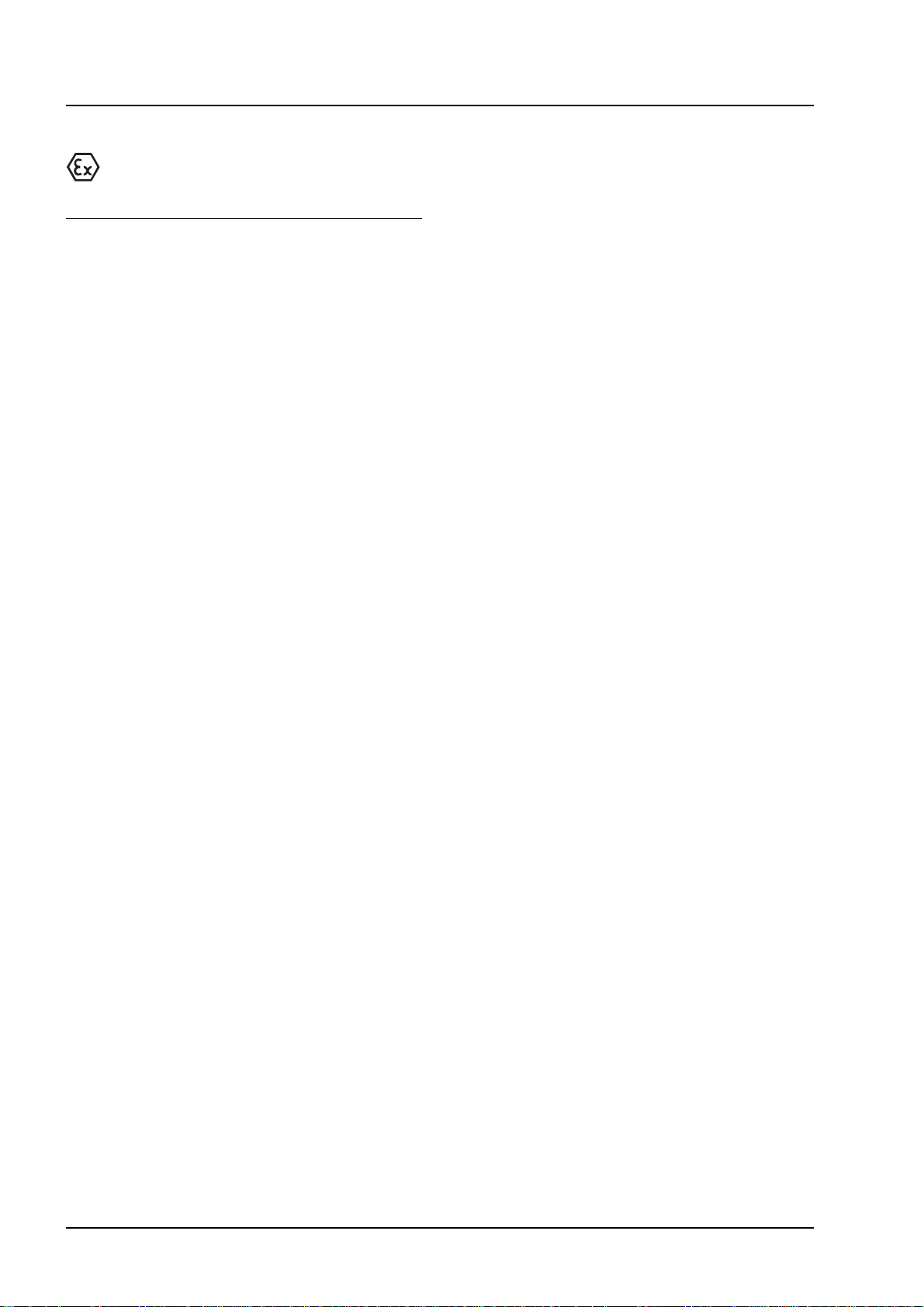

Static or mobile systems

The static system

is intended to be installed on a base,

has been mounted onto a rigid steel

frame,

is most suitable for use in conjunction

with fixed-installation high-pressure lines.

English

The mobile system

has been mounted onto a trolley,

can be used in different locations.

5.956-486 A2005937 (06/03)

B1

Page 10

English

Cleaning liquids

B. Types of system, and operating information

SHD-R 3000

Type of system

(see rating plate)

SHD-R 3000 (F)

SHD-R 3000 (F) S

SHD-R 3000 (F) SVA

Cleaning liquid Working

pressure/

Pressure

setting for

safety valve

[bar]

-

Water

- VE

-water

-

Water with

*

50/65 Standard version

Kärcher-RM

-

Water

- VE

-water

-

Water with

*

85/100 Standard version with

Kärcher-RM

-

Water

- VE

-water

-

Water with

*

85/100 Pump parts that come into

Kärcher-RM

Comments

increased working pressure

contact with the cleaning liquid

are made from stainless steel.

VE Fully demineralised water

* Conditionally resistant, use possible, however Cu and Zn ions in the medium

RM

(F) Mobile system

Other cleaning liquids may only be used after being released by Kärcher!

RM Alkali cleaning agent: e.g. RM31 (max. 0 - 2%)

Acidic cleaning agent: e.g. RM25 (max. 0 - 1%)

Max. temperature + 60˚C

(Higher temperatures available on request - precompression pump required!)

B2

5.956-486 A2005937 (06/03)

Page 11

SHD-R 3000

)

Cleaning liquids

B. Types of system, and operating information

English

Type of system

(see rating plate)

SHD-R 3000 (F)

SSR

Cleaning liquid Working

-

Water

- VE

Water with

-

Kärcher-RM

- Acids

- Alkali

solutions

VE Fully demineralised water

RM

RM Alkali cleaning agent: e.g. RM31 (max. 0 - 2%)

Acidic cleaning agent: e.g. RM25 (max. 0 - 1%)

Max. temperature + 60 ˚C

(Higher temperatures available on request - precompression pump required!)

-water

1)

Comments

pressure/

Pressure

setting for

safety valve

[bar]

85/100 - The pistons are made

from ceramic materials,

other pump parts that

come into contact with

acids are made from

stainless steel.

2)

- Ex-versions possible.

1)

Caution!

Increased material removal in hydrochloric and sulphuric acid, therefore rinse/neutralise

immediately after use!

Reduced resistance against contaminated acids!

If necessary contact Kärcher!

Acids (max. temperature +

Nitric acid max. 10%

Acetic acid max. 10%

Formic acid max. 10%

Phosphoric acid max. 10%

Citric acid max. 10%

Sulphuric acid max. 0.5%

Hydrochloric acid max. 0.5%

2)

Sodium hydroxide solutions max. 10%, without hypochlorite fractions (max. temperature

+ 20 ˚C)

Potassium hydroxide max. 10%, without hypochlorite fractions (max. temperature + 20 ˚C

20 ˚C)

(F) Mobile system

Other cleaning liquids may only be used after being released by Kärcher!

5.956-486 A2005937 (06/03)

B3

Page 12

English

Cleaning liquids

B. Types of system, and operating information

SHD-R 3000

Type of system

(see rating plate)

SHD-R 3000 (F) SLA

SHD-R 3000 (F) LM

Cleaning liquid Working

pressure/

Pressure

setting for

safety valve

[bar]

–

Water

–

VE water*

85/100 –

– Water with

Kärcher-RM

– Alkali

solutions

–

Water

–

VE water*

2)

50/65 –

– Water with

Kärcher-RM

– Alkali

solutions

– Solvents

2)

3)

Comments

Version with increased

working pressure.

–

Leaked liquid is collected in

a pipe (leakage recycling).

–

Ex-versions possible.

Explosion-proof version.

–

Leaked liquid is collected in

a pipe (leakage recycling).

–

Additional pressure switch as

safety device (optional).

VE

*

RM

2)

3)

Fully demineralised water

Conditionally resistant, use possible, however Cu and Zn ions in the medium

Acidic cleaning agent: e.g. RM25 (max. 0 - 1%)

Max. temperature + 60

(Higher temperatures available on request - precompression pump required!)

Sodium hydroxide solutions max. 10%, without hypochlorite fractions

(max. temperature + 20 ˚C)

Potassium hydroxide max. 10%, without hypochlorite fractions (max. temperature + 20 ˚C)

Solvents (max. temperature + 20 ˚C)

1. Hydrocarbons, e.g.: petroleum

2. Aromatic compounds, e.g.: benzene, toluol

3. Ketones, e.g.: MEK (methyl ethyl ketones), acetone

4. Esters, e.g.: butyl acetate, methyl acetate

5. Glycols, e.g.: butyl glycol

6. Mixed solvents, e.g.: butyl acetate 85, isobutyl acetate 85

(85=85% butyl acetate + 15% n-butanol)

7. Regenerates, distillates made from various solvents which have already been used

f

or cleaning purposes or similar.

˚C

(F) Mobile system

Other cleaning liquids may only be used after being released by Kärcher!

B4

5.956-486 A2005937 (06/03)

Page 13

SHD-R 3000

i

i

!

B. Types of system, and operating information

English

2. System start-up

Emergency drill

Turn mains supply voltage of at system

master switch.

Turn off supply of cleaning liquid.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

Working with the handgun

!

Danger!

The high-pressure jet produces a recoil

effect.

Mobile and static system

Turn on cleaning liquid supply.

Switch system on at master switch.

Commence cleaning with high-pressure

jet.

Important !

In types LM, SLA and SSR the stuffing

boxes must be retightened after the initial

startup. The tension should be regulated

one, two, four and 10 hours after initial startup. (For the running-in phase of the seals,

see E.3 Maintenance work).

3. System shut-down

Important!

Before carrying out the shut-down

procedures, flush through without adding

cleaning agents. This prevents a crust

forming on the seals or that they become

stuck fast, either of which would lead to

premature wear.

You could lose your balance.

You could fall over.

Therefore:

Ensure that you have a firm footing.

Keep a tight grip on the handgun.

Do not wedge the handgun fast in the

open position.

If the lever is wedged fast, the recoil effect

causes the high-pressure hose to twist and

turn in various directions, which result in

damage to other equipment or persons.

Starting up the system

Mobile system

Place system on a horizontal, solid

surface.

Lock wheel brakes.

During the recirculation operation with

solvent, the system must be rinsed through

thoroughly using clean solvent before the

shut-down procedure takes place.

Switch system off at master switch.

Turn off cleaning liquid supply.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

5.956-486 A2005937 (06/03)

B5

Page 14

English

C. System functions

SHD-R 3000

1 Transmission casing

2 Crankshaft with drive

3 Seal (oil compartment)

4 Gland

5 Seal (grease compartment)

C1

6 Lubrication nipple or leakage pipe

7 Sealing pack (high-pressure)

8 Piston

9 Suction valve

10 Pressure valve

5.956-486 A2005937 (06/03)

Page 15

SHD-R 3000

!

C. System functions

English

Operational sequence of the highpressure pump

Cleaning liquid is taken in by the piston.

Suction valves (9) prevent cleaning liquid

from flowing backwards.

Action of piston pumps cleaning liquid

onwards.

Pressure valves (10) prevent cleaning

liquid from flowing backwards.

Action of piston takes in cleaning liquid

again.

Features of the high-pressure pump

Horizontal construction.

Drive runs in an oil bath.

Oil compartment for drive unit is separa-

ted from pressure chamber for cleaning

liquid.

Pump has three cylinders, each with a

pressure chamber, and one suction

chamber.

Safety valve

Danger!

Injury hazard due to excessive pressure

within system. Do not adjust safety valve.

the safety valve has been pre-set and

sealed in the factory. Adjustments should

only be made by a Kärcher Customer

Service engineer.

The safety valve opens if the pressure

exceeds the prescribed maximum level.

Cleaning liquid is allowed to escape,

thereby avoiding damage to the pump and

high-pressure hoses due to too much

pressure in the system.

Pulsation damper

The pulsation damper compensates for the

variations or peaks in pressure. This

reduces the wear on pump components.

Drive for the high-pressure pump

The high-pressure pump is driven by an

electric motor.

V-belts attached to the electric motor

provide the actual drive to the highpressure pump.

5.956-486 A2005937 (06/03)

C2

Page 16

English

D. T echnical specifications

SHD-R 3000

Unit SHD-R 3000 (F) SHD-R 3000 (F) S

SHD-R 3000 (F) SSR

SHD-R 3000 (F) SLA

SHD-R 3000 (F) LM

1)

1)

SHD-R 3000 (F) SVA

Electrical connection

Type of current

Frequency Hz

3~

50*

3~

50*

3~

50*

Voltage V 400** 400** 400**

Motor rating with

Class of protection IP55

Class of protection IP55 Ex

Mains fuse

kW

kW

5.5

–

11

13.5

–

6.8

A25 35 25

Direct starting

Mains fuse

A16 35 16

Star-delta starting

Performance data

Pump flow rate

L/h 3000 3000 3000

Working pressure bar 55 85 50

Pressure setting

bar 65 100 65

Safety valve

Max. inlet temperature for

˚C 60 60 60

water with detergents

Max. temperature for solvents,

˚C – 20 20

alkalis, acids

Noise pressure level

dB(A) 80 80 80

(EN 60704-1)

Dimensions and weight

Length approx. mm 1200 1200 1200

Width approx. mm 600 600 600

Height approx. mm 500 500 500

Weight approx. kg 125 165 135

Miscellaneous

Ambient conditions,

temperature

Type of protection –

˚C +2 ... +40 +2 ... +40 +2 ... +40

1)

possible

II 2 G ck T3 II 2 G ck T4

Oil capacity L 3 3 3

Type of oil Oil 40 Special Order no. 6.288-003 (3 x 1 litre pack)

* Available as special version with 60 Hz

** Versions for other voltages available

D1

5.956-486 A2005937 (06/03)

Page 17

SHD-R 3000

!

E. Care and maintenance

English

1. General information

It is a fundamental requirement for ensuring

that this system functions safely and reliably

that maintenance is carried out regularly in

accordance with the following schedule.

Use only original spare parts supplied by

the manufacturer or recommended alternatives, for example:

replacement and wearing parts

accessories

fuels, lubricants, etc.

detergents.

Danger!

Injury hazard while working on the system.

Before commencing any work:

Turn mains supply voltage off at system

master switch, and ensure that it cannot

be turned back on again unintentionally.

Who is permitted to carry out maintenance

tasks?

Operator

Tasks that are marked “Operator” may

only be carried out by persons who have

been instructed in the safe operation and

maintenance of high-pressure systems.

Customer service

Tasks that are marked “Customer service”

may only be carried out by Kärcher

Customer Service engineers.

Maintenance agreement

In order to ensure that the system functions

reliably, we recommend that you conclude

a service agreement. Please contact your

local authorized Kärcher Customer Service

agent.

Turn off supply of cleaning liquid.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

5.956-486 A2005937 (06/03)

E1

Page 18

English

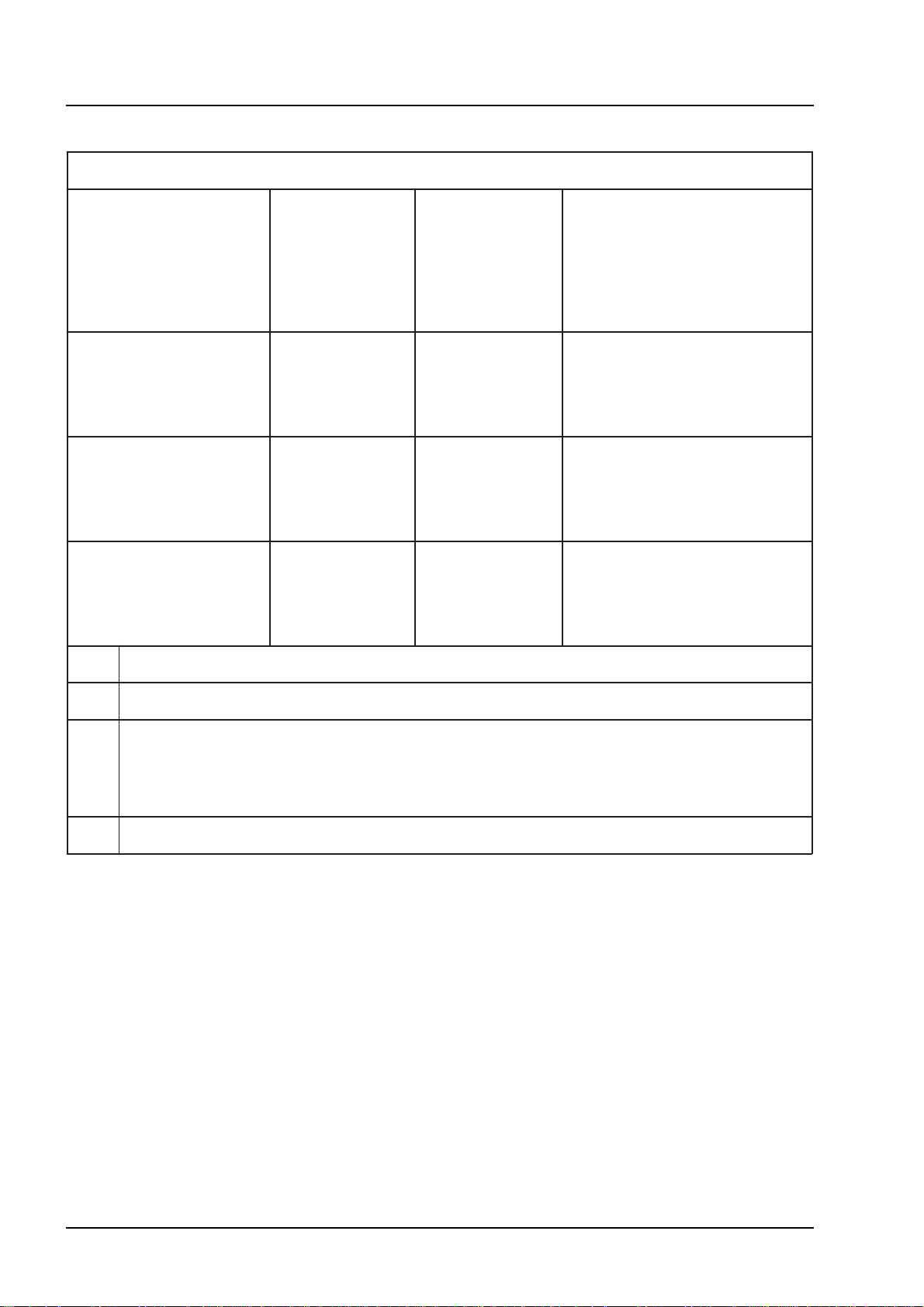

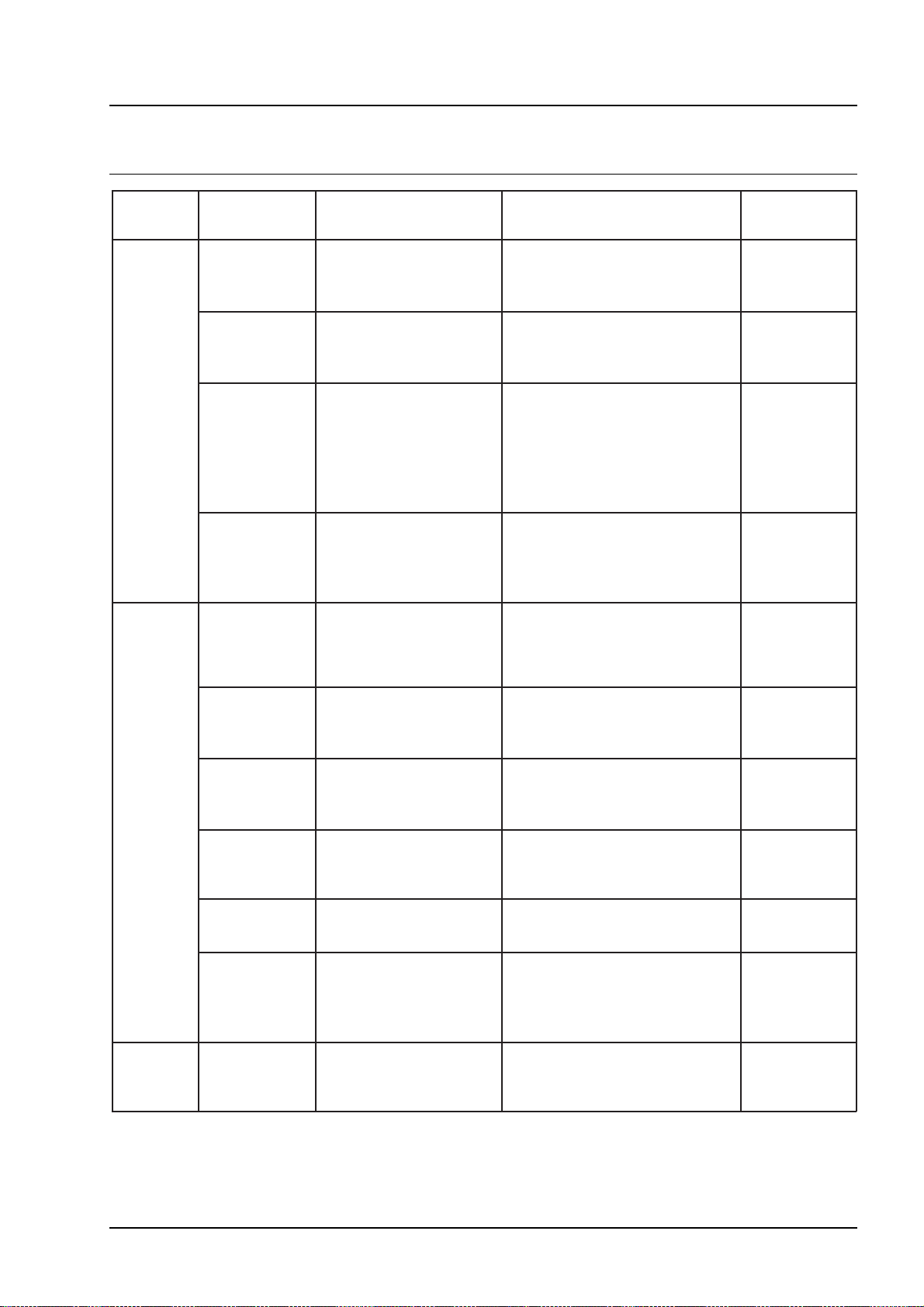

2. Maintenance schedule

E. Care and maintenance

SHD-R 3000

Frequency Type of pump

SHD-R 3000

(F)

1, 2, 4, 10

hours after

initial startup.

Once

only after

first 100

operating

hours

Weekly

or after

every 40

operating

hours

LM

SLA

SSR

all Check tension

all Oil change See Maintenance Tasks Operator

all Check oil level Oil level must be between MIN

Action Procedure By whom?

Regulate tension in

compression glands

of V-belt

See Maintenance Tasks Operator

See Maintenance Tasks Operator

Operator

and MAX marks. If level below

MIN, fill up with oil.

Standard

S / SVA

SLA

SSR

LM Check oil condition If oil has thinned out or is

all Check high-pressure

Check oil condition If oil is milky-white, change oil

and tighten piston seal (See

Maintenance Tasks)

discoloured, change oil and

tighten piston seal (See

Maintenance Tasks)

Visual check of high-pressure

hoses

hoses for signs of damage such

as

– wear due to abrasion

– inner fabric is visible

– creases due to bending

– porous and split rubber

Replace any damaged hoses

Operator

Operator

Operator

E2

5.956-486 A2005937 (06/03)

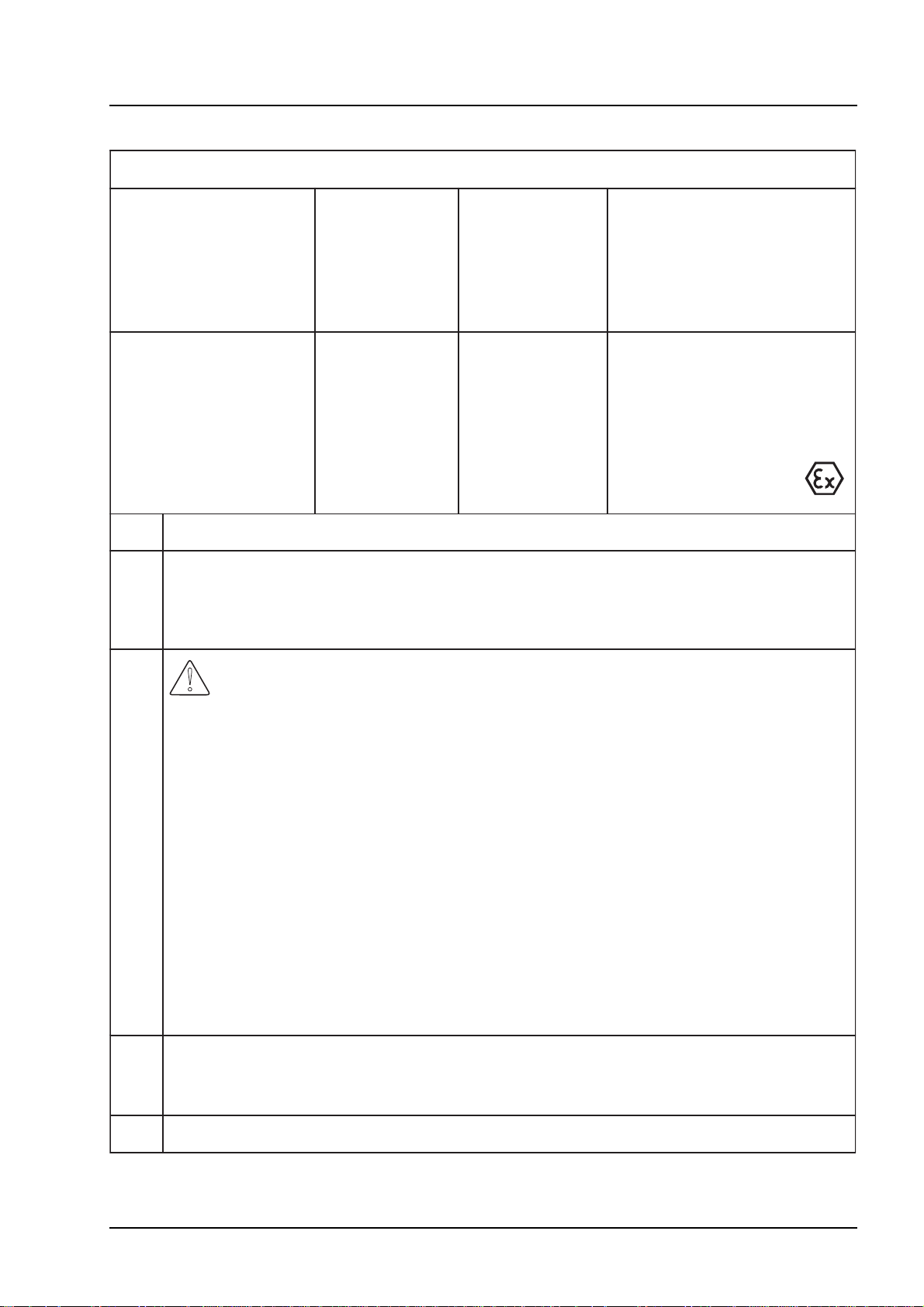

Page 19

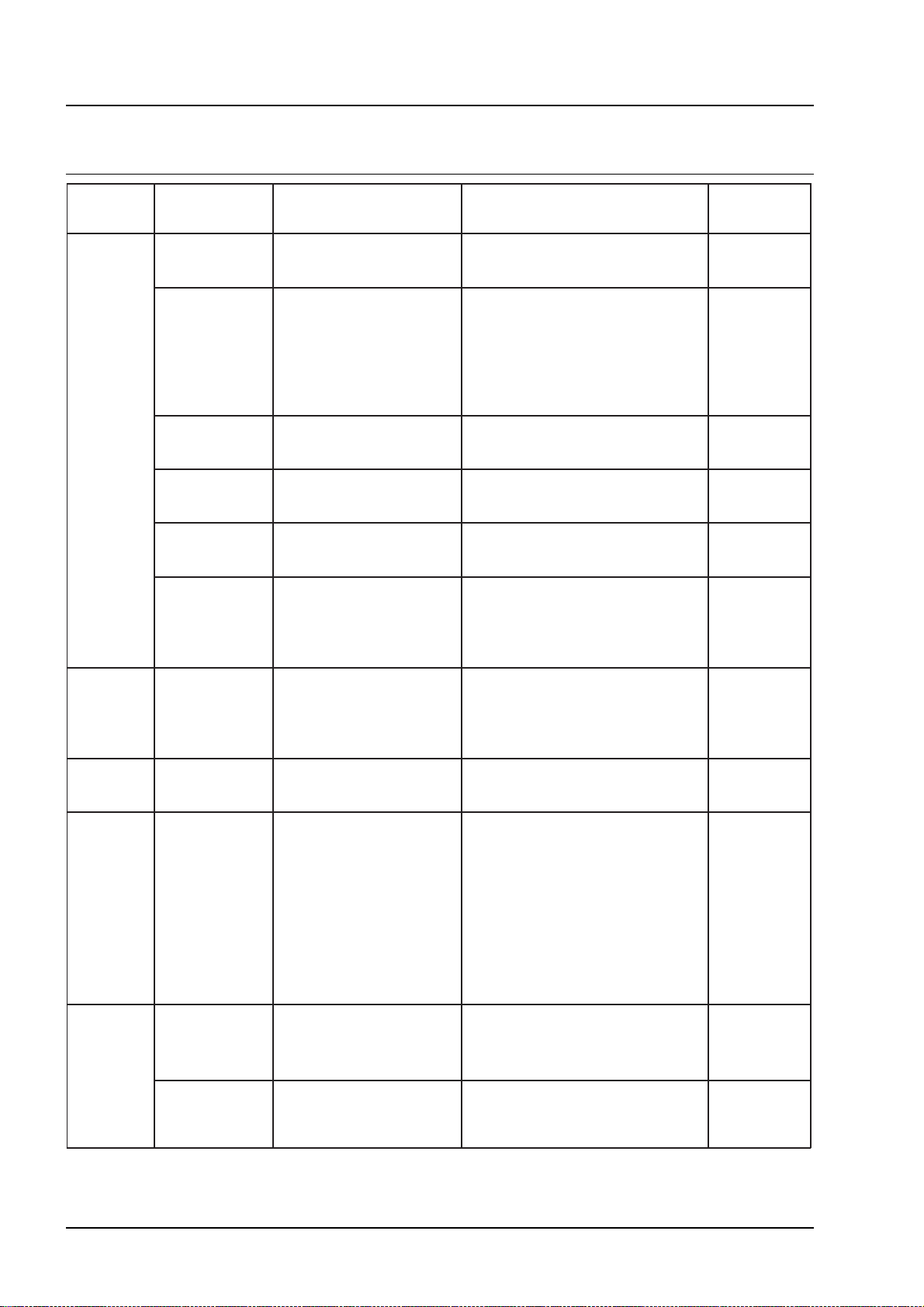

SHD-R 3000

2. Maintenance schedule

E. Care and maintenance

English

Frequency Type of pump

SHD-R 3000

(F)

Monthly

or after

every 160

operating

hours

After

every 200

operating

hours

Six-monthly

or after

every 500

operating

hours

Standard

S / SVA

Standard

S

LM Oil change See Maintenance Tasks Operator

Standard

S / SVA

SLA

SSR

Action Procedure By whom?

Check pump for leaks If during operation more than

5 droplets per minute leak from

the pump, tighten piston seal

Lubrication Lubricate with 2 pump strokes of

grease gun per nipple

Oil change See Maintenance Tasks Operator

Operator

Operator

After

every 1000

operating

hours

Annually all Check tension of V-belt See Maintenance Tasks Operator

all – Check and clean valves on pump

– Check piston

– Replace set of seals if required

– Oil change

– Check for correct functioning

all Formal test Inspection in accordance with

Directive on "Working With

Liquid-spraying Devices"

Customer

service

Specialist

5.956-486 A2005937 (06/03)

E3

Page 20

English

!

i

i

E. Care and maintenance

SHD-R 3000

3. Maintenance tasks

Changing the oil

Danger!

Burns hazard due to hot oil and hot system

components. Allow pump to cool down for

15 minutes before changing oil.

Important!

Waste oil may only be disposed of by the

operators of special collection points.

Please deposit your waste oil at one of

these locations. Polluting the environment

with waste oil is a criminal offence.

Oil type: Oil 40 special

Order no. 6.288-003 (3 x 1 litre pack)

Oil capacity per pump: 3 L

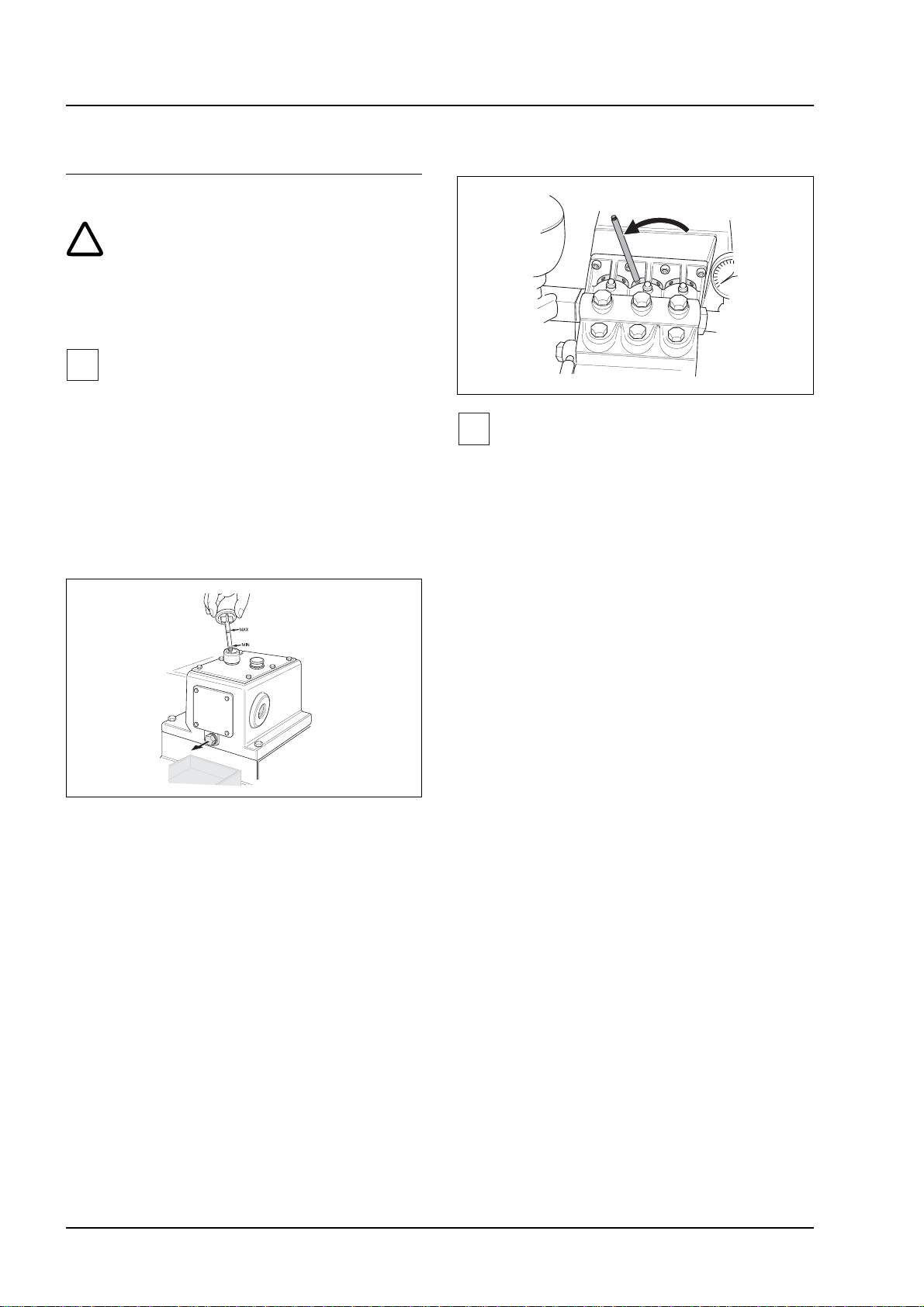

Tightening the piston seals

Important!

If the piston seal is held too tight by the

gland, it will be subjected to increased wear.

Insert rod into gland and turn in direction

indicated by arrow. This increases the

tension on the piston seal.

Tighten all three piston seals uniformly,

by turning the glands until they are handtight.

Oil change procedure:

place drip pan under pump to collect

waste oil

remove oil drain plug, and collect waste

oil in drip pan

wash out pump casing with diesel

allow diesel to drain thoroughly

fit new sealing ring (A18 x 22), and refit

oil drain plug

slowly fill up with fresh oil as far as MAX

mark

Relieving tension on piston seal:

Insert rod into gland and turn in opposite

direction to that indicated by arrow.

This relieves the tension on the piston

seal.

Relieve the tension on all three piston

seals uniformly.

deliver waste oil to an appropriate

collection point.

E4

5.956-486 A2005937 (06/03)

Page 21

SHD-R 3000

E. Care and maintenance

English

V-belt

Test tension of V-belt and adjust as follows:

Switch off system, and ensure that it

cannot be switched back on again

unintentionally.

Remove guard over V-belt.

Test belt tension.

Press down on belt which should not

move by more than 1 cm. If necessary,

adjust as follows:

Replacing the V-belt:

Switch off system, and ensure that it

cannot be switched back on again unintentionally.

Remove guard over V-belt.

Slacken off mounting bolts (1).

Unscrew bolts (2) fully, and push motor

towards pump.

Replace V-belt.

Tension belt by adjusting bolts (2).

Ensure that V-belt runs in a straight line.

Tighten mounting bolts (1).

Refit belt guard.

Slacken off mounting bolts (1).

Tension V-belt by adjusting bolts (2).

Ensure that V-belt runs in a straight line.

Tighten mounting bolts (1).

Refit belt guard.

5.956-486 A2005937 (06/03)

E5

Page 22

English

!

Danger!

Injury hazard while working on the system.

Before commencing any work:

Turn mains supply voltage off at system

master switch, and ensure that it cannot

be turned back on again unintentionally.

Turn off supply of cleaning liquid.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

F . T roubleshooting

SHD-R 3000

Who is permitted to repair faults on the

system?

Operator

Tasks that are marked “Operator” may

only be carried out by persons who have

been instructed in the safe operation and

maintenance of high-pressure systems.

Qualified electrician

Persons who have a professional qualification in an electrical engineering

discipline.

Customer Service

Tasks that are marked “Customer Service”

should only be carried out by a Kärcher

Customer Service engineer.

F1

5.956-486 A2005937 (06/03)

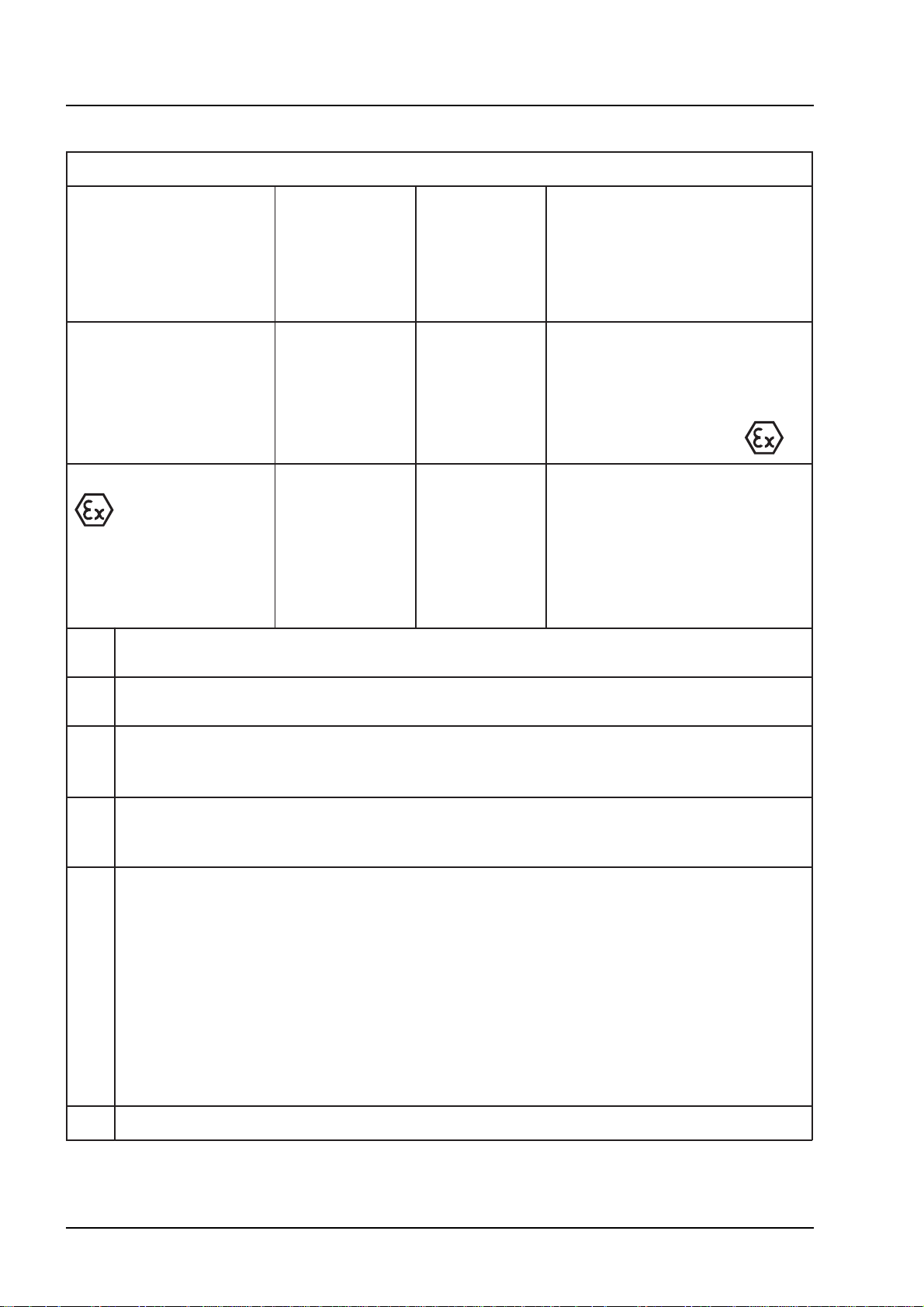

Page 23

SHD-R 3000

F . T roubleshooting

English

1. Fault-finding

Problem Component Possible cause Remedy By whom?

System

does not

start up

System

does not

build up

pressure

Control

circuitry

Control

circuitry

Control

circuitry

Pressure

switch

(Accessory

kit)

V-belt No tension in V-belt Tighten V-belt (see Maintenance

Filter or

strainer

(Accessories)

No voltage supply to

system or control

circuitry

Fault on

– motor contactor

– fuses

Bimetal relay has

switched off

Defective or wrongly

adjusted pressure switch

Blocked filter or strainer

in supply line

Check mains voltage Electrician

Check Electrician

Wait for motor to cool down, and

then re-set relay.

Measure motor current. If

current consumption is too high,

relieve tension on piston seal

(see Maintenance Tasks).

Release pressure from system,

and check pressure valve.

Tasks)

Remove and clean filter or

strainer.

Electrician

Customer

service

Operator

Operator

Screech-

ing noise

Inlet hose Supply volume too small Test whether the correct amount

of cleaning liquid is being

supplied to system.

High-pressure

pump

High-pressure

pump

Detergent

reservoir

(Accessory

kit)

V-belt Incorrect V-belt tension Tighten V-belt (see Maintenance

Worn out valves or

broken valve spring

Defective piston, seal or

valve

Pump taking in air due

to empty detergent

container

Replace defective part. Operator

Replace defective part. Customer

Fill detergent reservoir. Operator

Tasks).

Operator

service

Operator

5.956-486 A2005937 (06/03)

F2

Page 24

English

F . T roubleshooting

SHD-R 3000

1. Fault-finding

Problem Component Possible cause Remedy By whom?

Knocking

noise

Leaking

pressure

switch

V-belt V-belt has snapped Replace V-belt (see Maintenance

Tasks)

Detergent

metering on

suction side of

pump

(Accessory

kit)

Cleaning

liquid

High-pressure

pump

High-pressure

pump

Pulsation

damper

(Accessory

kit)

Pressure

switch

(Accessory

kit)

Pump is taking in air ––Fill up with cleaning liquid.

Check hoses to establish

whether they are taking in air

Cleaning liquid is too

warm

Broken valve spring Replace valve springs Operator

Flange has come loose Tighten flange (see Maintenance

Defective pulsation

damper

Defective seal Replace seal. Customer

Check supply temperature of

cleaning liquid

Tasks)

Replace pulsation damper. Customer

Operator

Operator

Operator

Operator

service

service

Leaking

pump

System

does not

switch off

although

handgun

is closed

Float tank

overflows

High-pressure

switch

Pressure

switch/Volume

control valve

(Accessory

kit)

Float tank

(Accessory

kit)

Float tank

(Accessory

kit)

Too much free play in

piston seal

Wrongly adjusted

pressure switch or

volume control valve

Wrongly adjusted

closing force or

maximum filling level

Defective seal on float

valve

Tighten piston seal (see

Maintenance Tasks)

Re-adjust pressure switch and

volume control valve.

Re-adjust closing force and filling

level, see Chapter G1: Float

tank.

Replace seal. Operator

Operator

Customer

service

Operator

F3

5.956-486 A2005937 (06/03)

Page 25

SHD-R 3000

!

!

i

Hazard!

The following mounting and accessory kits

must not be used for operation with solvents

or in a hazardous (potentially explosive

atmosphere) area.

G. Mounting kits and accessories

1. Mounting kits

(non-hazardous area)

English

V olume control v alve

Function

If only a part of the pump delivery volume is

required, the remainder is fed back to the

suction side of the pump via the volume

control valve.

This item is required when the system is

used with handguns.

Float tank with float valve

Function

The float valve fitted inside the float tank

controls the level of liquid.

The float tank serves as a service

reservoir for the cleaning liquid.

If water is used as the cleaning agent,

the float tank corresponds to mains

disconnection according to EN 1717.

In the case of the mobile systems, the

float tank is fitted to the trolley.

Pressure switch

Danger!

Danger due to high voltage. The pressure

switch has been pre-set in the factory,

adjustments should only be made by a

Kärcher Customer Service engineer.

Function

The pressure switch

switches the system off if the working

pressure is exceeded.

switches the system back on when the

pressure drops again.

Pulsation damper

Caution!

Settings

Closing force

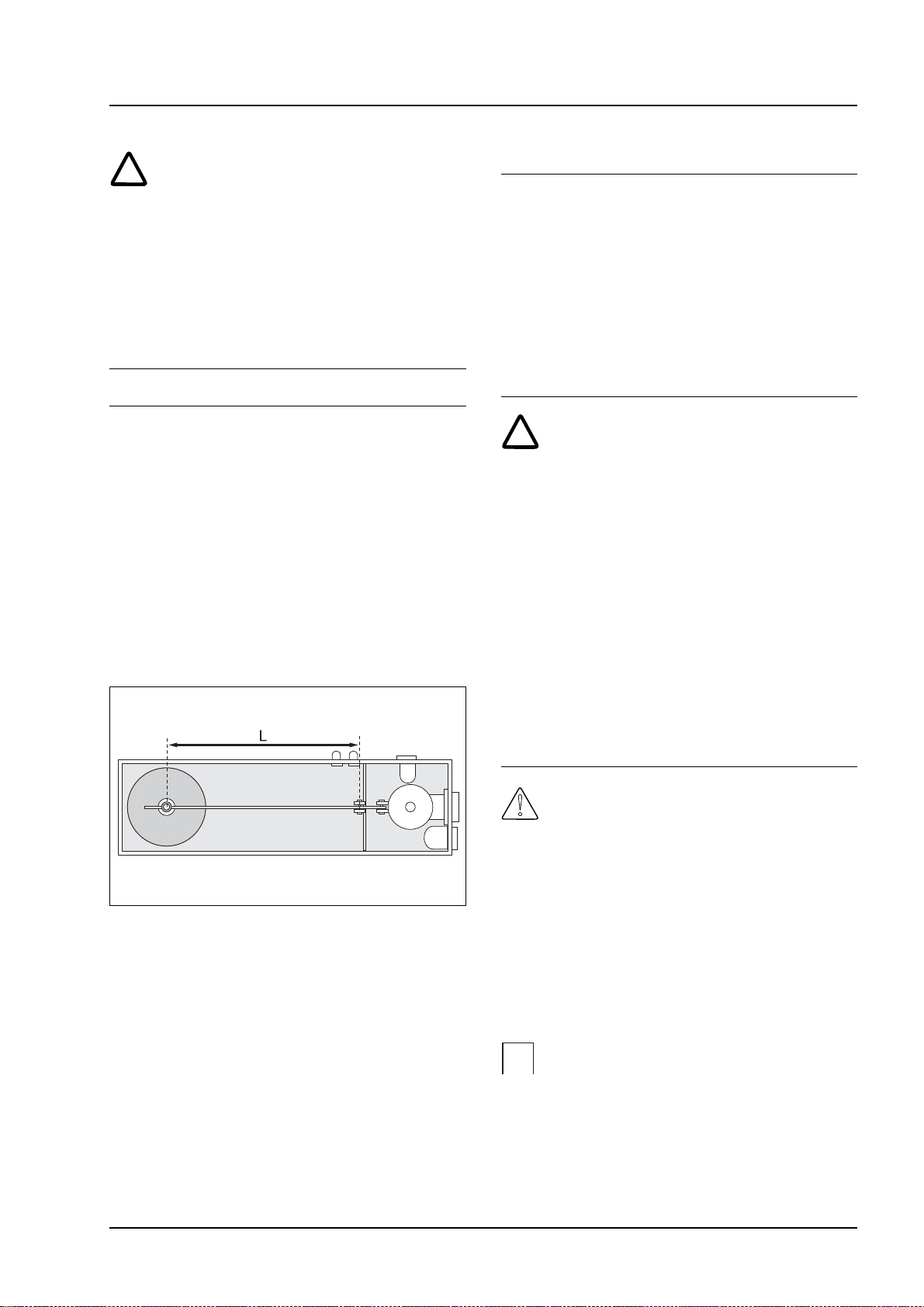

Extending the length of L increases the

amount of closing force, i.e. even when the

cleaning liquid is fed in at quite high pressure

the float valve is able to shut off the supply.

Technical specification

Capacity up to overflow: 30 litres.

5.956-486 A2005937 (06/03)

As the membrane in the pulsation damper is

not suitable for solvents, do not use the

pulsation damper for operation with

solvents.

Function

The pulsation damper evens out variations

or peaks in pressure while the system is in

operation.

Important!

Volume control valve, pressure switch and

pulsation damper are usually employed

together as an automatic volume control

system.

G1

Page 26

English

G. Mounting kits and accessories

SHD-R 3000

Pressure-relief valve

Function

The pressure-relief valve is an integrated

solenoid valve.

The pressure-relief valve is only active

during the start-up phase when the

system is configured for star-delta

starting.

When the pressure-relief valve is opened,

the liquid delivered by the pump flows

back to the suction side. As a result, no

pressure is built up, and the load on the

motor is reduced during the start-up

phase.

Detergent metering at the suction

side of the pump

Danger!

If the detergent reservoir is empty and the

metering valve is open, the pump takes in

air. This can lead to damage to the pump,

therefore:

check detergent reservoir regularly,

do not open metering valve until actual

work commences,

close metering valve as soon as work

has ended.

Function

A diaphragm has been inserted into the

pump intake connection,

detergent is taken in from an external

reservoir,

the amount taken in is determined by a

metering valve,

metering is switched on or off by a solenoid

valve.

Detergent metering at the pressure

side of the pump

Function

Detergents are taken in from an external

reservoir and fed to the output from the

pump,

an injector mixes the detergent with the

high-pressure jet (double spray lance

required for detergent metering),

detergents can also be metered by

means of a high-pressure metering pump.

2. Mounting kits

(hazardous area)

Please contact Kärcher about mounting kits

for hazardous (potentially explosive

atmosphere) areas.

For representations, please refer to figures

A 170/1, A 172, A 173, A 161 and A 154.

3. Accessories

Lubricants:

Oil for pump: Oil 40 special

Order no. 6.288-003 (1 litre pack)

Lubricating grease for:SHD-R 3000 (F)

SHD-R 3000 (F) S/

SHD-R 3000 (F) SVA

(6.288-034)

For normal use:

Order no. 6.288-015 (Tin with 1 kg)

The following grease is prescribed for foodprocessing operations:

Order no. 6.288-034 (Tin with 1 kg)

High-pressure hoses, nozzles,

detergents

Ask your dealer for further details about

these or any other accessories, or contact

Kärcher Plant Engineering.

G2

5.956-486 A2005937 (06/03)

Page 27

SHD-R 3000

Figure A 170/1

G. Mounting kits and accessories

English

5.956-486 A2005937 (06/03)

G3

Page 28

English

Figure A 172

G. Mounting kits and accessories

SHD-R 3000

G4

5.956-486 A2005937 (06/03)

Page 29

SHD-R 3000

Figure A 173

G. Mounting kits and accessories

English

5.956-486 A2005937 (06/03)

G5

Page 30

English

Figure A 161

G. Mounting kits and accessories

SHD-R 3000

G6

5.956-486 A2005937 (06/03)

Page 31

SHD-R 3000

Figure A 154

G. Mounting kits and accessories

English

5.956-486 A2005937 (06/03)

G7

Page 32

English

The applicable warranty conditions in

different countries are issued by the

respective national distributor of KÄRCHER

products.

In the event of a warranty claim, please

contact your original dealer or the nearest

authorized customer service centre.

H. W arranty

SHD-R 3000

H1

5.956-486 A2005937 (06/03)

Page 33

SHD-R 3000

!

I. System installation

English

This system should only be installed by

Kärcher Customer Service engineers,

persons who have been specially

authorized by Kärcher.

Unpacking the system

Unpack the system and deliver the packaging materials to an appropriate collection

point for recycling.

For static systems

Preparing the installation site

A horizontal, flat area or base of 1400 x

750 mm is required for installing the

system.

Place the system on the designated area

or base and align it exactly.

Check the oil level

The level of oil in the reservoir on the highpressure pump should be between the MIN

and MAX marks. Fill up with oil if the level

is below the MIN mark.

Electrical connections

Danger!

Dangerous voltage. The electrical installation

should only be carried out by a qualified

electrician in accordance with current local

regulations.

Connect the electric motor into the

terminal strip.

Switch on motor briefly, and check

direction of rotation.

Install the unit in such a way as to ensure

that it can be easily accessed for

maintenance work.

Secure in position with suitable materials.

For static and mobile systems

Connecting hoses for supply

of cleaning liquid

Caution!

Vibrations generated by the system during

operation could cause damage to the main

water supply network, therefore connect the

system by means of flexible hoses.

Connect the supply hose for cleaning

liquid to the system (Thread R 1 1/4").

Connect the high-pressure hose for the

cleaning liquid output to the system

(Thread M22 x 1.5).

Start up the system

Switching off in an emergency

(see Chapter B)

5.956-486 A2005937 (06/03)

I1

Page 34

English

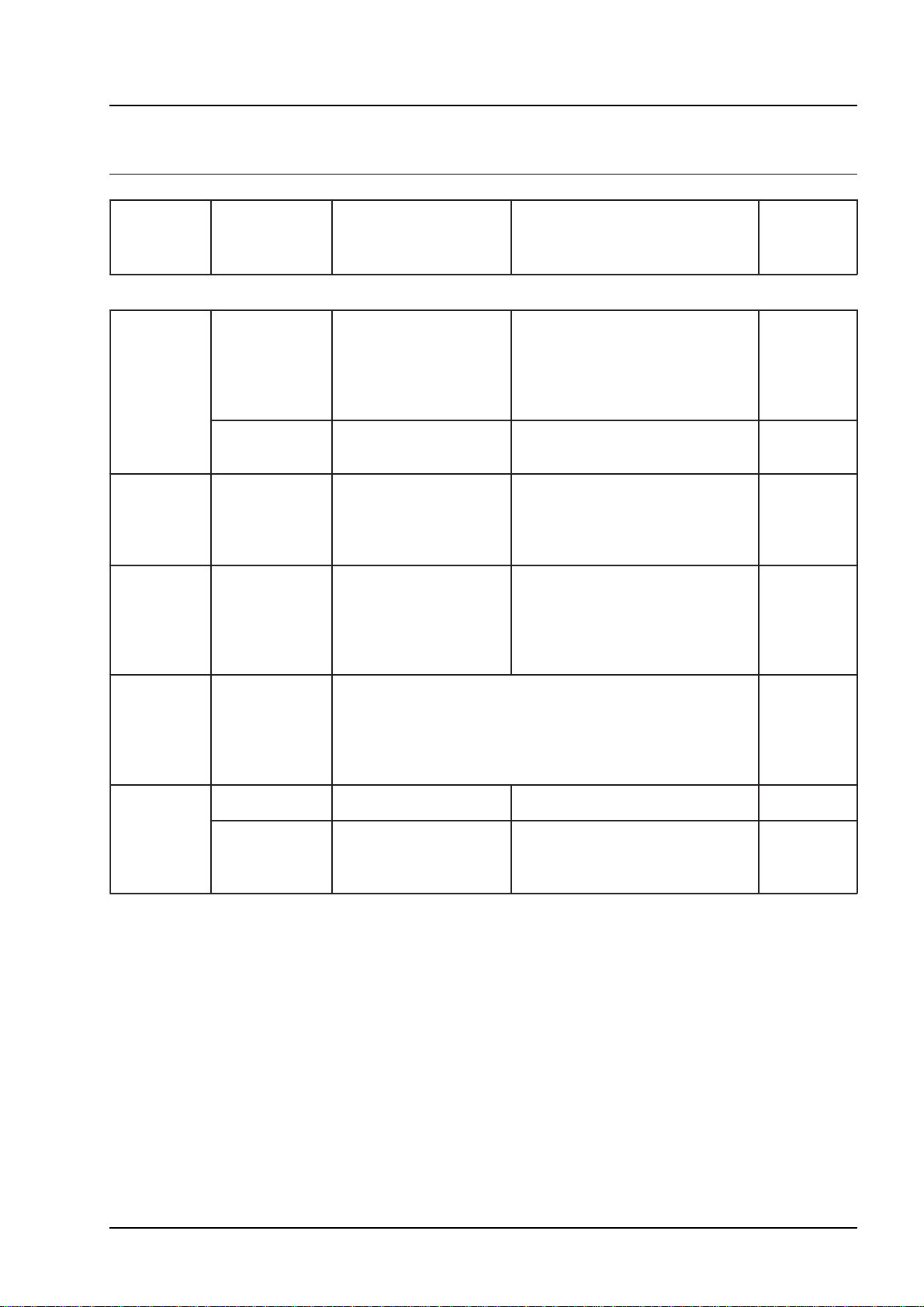

Dimensional diagram:

Static system

Mobile system

I. System installation

SHD-R 3000

approx. 1100

I2

5.956-486 A2005937 (06/03)

Page 35

SHD-R 3000

J. Declaration of Conformity

EC Declaration of Conformity

English

We herewith declare that the design and

type of machine named in the following as

well as the model marketed by us complies

with the relevant fundamental health and

safety requirements of the EC Directives.

This declaration becomes invalid if

modifications are made to the machine

which have not been previously agreed with

us.

Product: High-pressure cleaner

Type: SHD-R 3000 (F), S, SVA

Relevant EC Directives:

EC Machinery Directive (98/37/EC)

EC Low Voltage Directive (73/23/EEC),

amended by 93/68/EEC

EC Electromagnetic Compatibility

Directive (89/336/EEC), amended by

91/263/EEC, 92/31/EEC, 93/68/EEC

Alfred Kärcher GmbH & Co. KG

Cleaning Systems

Alfred-Kärcher-Str. 28-40

P.O. Box 160

D-71349 Winnenden

Tel.: ++ 49 71 95 14-0

Fax: ++ 49 71 95 14-22 12

5.957-383 (01/02)

Alfred Kärcher Kommanditgesellschaft.

Registered offices: Winnenden.

Register court: Waiblingen, HRA 169.

Personally liable shareholder: Kärcher

Reinigungstechnik GmbH.

Registered office: Winnenden, 2404

Waiblingen register court, HRB

Managing Directors: Dr. Bernhard Graf,

Hartmut Jenner, Georg Metz

Harmonised standards used:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 79

DIN EN 55 014 - 1:2000 + A1 : 2001

DIN EN 55 014 - 2 : 1997

DIN EN 61 000 - 3 - 2 : 2000

DIN EN 61 000 - 3 - 3 : 1995 + A1 : 2001

National standards used: –

Internal measures ensure that serial

production units always comply with the

requirements of the current EC Directives

and the standards used.

The undersigned act on behalf of and with

power of attorney issued by the

Management.

S. Reiser H. Jenner

5.956-486 A2005937 (06/03)

J1

Page 36

English

J. Declaration of Conformity

EC Declaration of Conformity

SHD-R 3000

We herewith declare that the design and

type of machine named in the following as

well as the model marketed by us complies

with the relevant fundamental health and

safety requirements of the EC Directives.

This declaration becomes invalid if

modifications are made to the machine

which have not been previously agreed with

us.

Product: High-pressure cleaner

Type: SHD-R 3000 (F), LM, SSR, SLA

Relevant EC Directives:

EC Machinery Directive (98/37/EC)

EC ATEX Directive (94/9/EC)

Harmonised standards used:

DIN EN 60 335 - 1

DIN EN 60 335 - 79

Alfred Kärcher GmbH & Co. KG

Cleaning Systems

Alfred-Kärcher-Str. 28-40

P.O. Box 160

D-71349 Winnenden

Tel.: ++ 49 71 95 14-0

Fax: ++ 49 71 95 14-22 12

5.957-384 (06/03)

Alfred Kärcher Kommanditgesellschaft.

Registered office: Winnenden.

Register court: Waiblingen, HRA 169.

Personally liable shareholder:

Kärcher Reinigungstechnik GmbH.

Registered office: Winnenden, 2404

Waiblingen register court, HRB

Managing Directors: Dr. Bernhard Graf,

Hartmut Jenner, Georg Metz

DIN EN 13463 - 1 : 2002

prEN 13463 - 5 : 2002

EN 1127 - 1 : 1997

National standards used: –

No. of nominated test institute: 0123

Test report No. 070039582

Type LM designation: Ex II 2 G ck T4

Type SSR, SLA designation: Ex II 2 G ck T3

Internal measures ensure that serial

production units always comply with the

requirements of the current EC Directives

and the standards used.

The undersigned act on behalf of and with

power of attorney issued by the

Management.

S. Reiser H. Jenner

J2

5.956-486 A2005937 (06/03)

Page 37

SHD-R 3000

Type no.: Factory no.: Commissioned on:

Tests carr ied out on:

..............................................................................................................

Results

Tests carr ied out on:

..............................................................................................................

Results

K. T est record

.......................................

Signature

English

Tests carr ied out on:

..............................................................................................................

Results

Tests carr ied out on:

..............................................................................................................

Results

.......................................

Signature

.......................................

Signature

5.956-486 A2005937 (06/03)

.......................................

Signature

K1

Loading...

Loading...