Page 1

BR 47/35 ESC

English 3

Français 19

Español 35

5.961-740.0 01/09

Page 2

2

Page 3

IMPORTANT SAFETY IN-

STRUCTIONS

READ ALL INSTRUCTIONS

BEFORE USING.

– Do not use to pick up flammable or

combustible liquids, such as gasoline, or

use in areas where they may be present.

– Connect to a properly grounded outlet

only. See Grounding Instruction.

SAVE THESE INSTRUCTIONS

WARNING

To reduce the risk of fire, electric shock, or

injury:

– Do not leave appliance when plugged in.

Unplug from outlet when not in use and

before servicing.

WARNING

– TO REDUCE THE RISK OF ELECTRIC

SHOCK-USE INDOORS ONLY

– Do not allow to be used as a toy. Close

attention is necessary when used by or

near children.

– Use only as discribed in this manual. Use

only manufacturer`s recommended

attachments.

– Do not use with damaged cord or plug. If

appliance is not working as it should, has

been dropped, damaged, left outdoors,

or dropprd into water, return it to a

service center.

– Do not pull or carry by cord, use cord as

a handle, close a door on cord, or pull

cord around sharp edges or corners. Do

not run appliance over cord. Keep cord

away from heated surfaces.

– Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

– Do not handle plug or appliance with wet

hands.

– Do not put any object into openings. Do

not use with any opening blocked; keep

free of dust, lint, hair, and anything that

may reduce air flow.

– Keep hair, loose clothing, fingers, and all

parts of body away from openings and

moving parts.

– Turn off all controls before unplugging.

– Use extra care when cleaning on stairs.

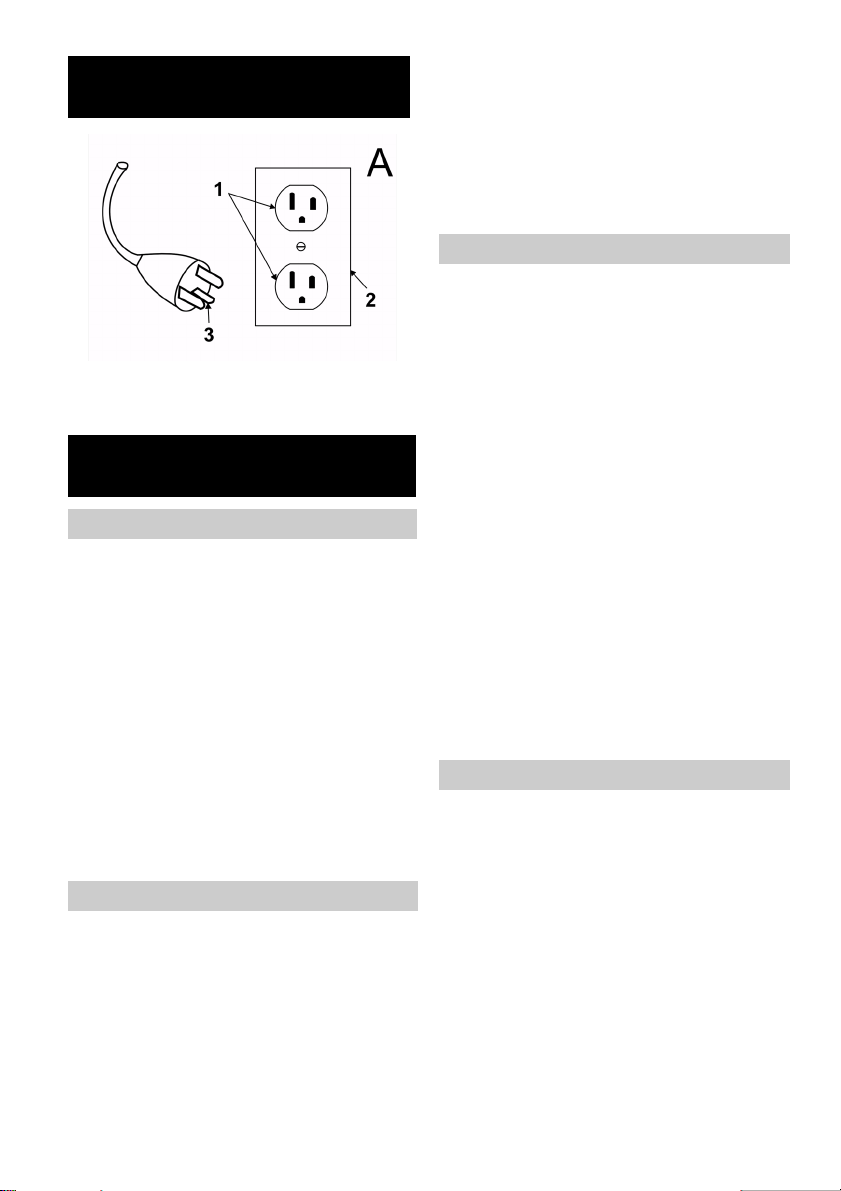

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it

should malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric

shock. This appliance is equipped with a

cord having an equipment-grounding conductor and a grounding plug. The plug must

be inserted into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

WARNING

Improper connection of the equipment

grounding conductor can result in a risk of

electric shock. Check with a qualified electrician or service person if you are in doubt as

to whether the outlet is properly grounded.

Do not modify the plug provided with the appliance-if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

This appliance is for use on a nominal 120volt circuit and has a grounding attachment

plug that looks like the plug illustrated in

sketchpicture A. Make sure that the

appliance is connected to an outlet having

the same configuration as the plug. No

adaptor should be used with this appliance.

English 3

Page 4

CONNECT TO A PROPERLY

GROUNDED OUTLET ONLY

1 Grounded outlet

2 Grounded outlet Box

3 Grounded Pin

OPERATING SAFETY RULES

AND PRACTICES

Operator Responsibility

Save operation is in the responsibility of the

operator.

The operator shall be familiar with the operation and function of all controls and instruments before undertaking to operate the

unit.

Before operating the unit, operators shall

have read and be familiar with the operator’s

manual for the particular unit being operated

and they shall also abide by the safety rules

and practices in the following paragraphs.

Before operating any unit, the operator shall

be familiar with unusual operating conditions

which may require additional safety precautions or special operating instructions.

General

Before starting to operate the unit be in operating position.

Do not start or operate the unit, any of its

functions or attachments, from any place

other than from the designated operators

position.

Before leaving the operator’s position:

A bring the unit to a complete stop;

B if the unit must be on an incline, block the

wheels.

Maintain a safe distance from the edge of

ramps, platforms, and other similar working

surfaces.

Do not add to, or modify the unit.

Do not block access to fire aisles, stairways

or fire equipment.

Travelling

Yield the right of way to pedestrians and

emergency vehicles such as ambulances

and fire trucks.

Cross railroad tracks at an angle wherever

possible. Do not park closer than 6 ft (1800

mm) to the nearest rail of a railroad track.

Keep a clear view of the path of travel and

observe for other traffic, personnel, and safe

clearances.

Under all travel conditions, operate the unit

at a speed that will pernit it to be brought to

a stop in a safe manner.

Do not indulge in stunt driving or horseplay.

Slow down for wet and slippery floors.

Before driving over a dockboard or bridge

plate, be sure that it is properly secured.

Drive carefully and slowly across the dockboard or bridge plate, and never exceed its

rated capacity.

When negotiating turns, reduce speed to a

safe level consistent with the operating environment. Make the turns smoothly.

Operator care of the unit

If the unit is found to be in need of repair or

in any way unsafe, or contributes to an unsafe condition, the matter shall be reported

immediately to the user’s designated authority, and the unit shall not be operated until it

has been restored to safe operating condition.

If during operation the unit becomes unsafe

in any way, the matter shall be reported immediately to the user’s designated authority,

and the unit shall not be operated until it has

been restored to safe operating condition.

Do not make repairs or adjustments unless

specifically authorized to do so.

4 English

Page 5

MAINTENANCE AND REBUILD

PRACTICES

Operation of the unit may be hazardous if

maintenance is neglected or repairs, rebuilds, or adjustments are not performed in

accordance with the manufacturer’s design

criteria. Therefore, maintenance facilities

(on or off premises), trained personnel, and

detailed procedures shall be provided.

Maintenance and inspection of the unit shall

be performed in conformance with the following practices:

A a schedules planned maintenance, lubri-

cation, and inspection system shall be

followed; consult the manufacturer’s recommendations.

B only tranined and authorized personnel

shall be permitted to maintain, repair, adjust, and inspect the unit, and in accord-

ance with manufacturer’s specifications.

Avoid fire hazards and have fire protection

equipment present in the work area. Do not

use open pans of fuel or flammable cleaning

fluids for cleaning parts.

FIRE SAFETY STANDARD

Any unit not in safe operating condition shall

be removed from service.

Repairs shall not be made in Class I, Class

II, and Class III locations.

Fire Prevention: The unit shall be kept in a

clean condition and reasonably free of lint,

excess oil, and grease. Noncombustible

agents are preferred for cleaning the unit.

Flammable liquids [those having flash points

at or above 100°F (37,8°C)] are not allowed.

Precautions regarding toxicity, ventilation,

and fire hazard shall be appropriate for the

agent or solvent used.

Nameplate Visibility: The unit type designations as shown on the nameplate and the

type markers shall not be covered over with

paint so that their identification information is

obscured.

The unit shall not be used in classified areas.

English 5

Page 6

Please read and comply with

these instructions prior to the

initial operation of your appliance. Retain

these operating instructions for future reference or for subsequent possessors.

Contents

Safety instructions 6

Function 6

Proper use 6

Environmental Protection, Disposal 7

Operating and Functional Elements 8

Before Startup 9

Start up 9

Operation 10

Shutting down 12

Maintenance and care 12

Transport 15

Troubleshooting 16

Specifications 16

Warranty 16

Accessories and Spare Parts 16

Safety instructions

For operator:

Please ensure that all users of the machine

have read and understood the contents of

this Operating Instructions Manual and are

familiar with the local regulations about work

safety. The users must have been technically trained to use this appliance.

For users:

Before using the appliance for the first time,

read and observe these operating instructions and the accompanying brochure: Safety information for brush cleaning units and

spray-extraction units, No. 5.956-251.

Safety Devices

Safety devices serve to protect the user and

must not be rendered inoperational or their

functions bypassed.

Foot pedal

The appliance can only be started when you

press the foot pedal fully downwards. The

machine stops when you release the foot

pedal.

Function

From he stationary escalator cleaner, detergent fluid (from the fresh water tank) is applied to the running travellator/ escalator.

The rolling brushes brush the detergent

againt the running direction into the ridges of

the travellator/ escalator. In the same working step, the dirty detergent is sucked into

the dirt water tank of the machine via the intake brushes.

Proper use

Use this appliance only as directed in these

operating instructions.

– The appliance may only be used to clean

the stepping areas of travellators/ escalators.

– The running or movement direction of

the unit to be cleaned must be adjusted

in such a way that the travellator/ escalator moves away from the machine.

– To clean the escalator, place the ma-

chine only at the lower end of the escalator.

– The appliance may only be equipped

with original accessories and spare

parts.

6 English

Page 7

Environmental protection

The packaging material can be

recycled. Please do not throw

the packaging material into

household waste; please send

it for recycling.

Old appliances contain valuable materials that can be recycled; these should be sent for

recycling. Batteries, oil, and

similar substances must not

enter the environment. Please

dispose of your old appliances

using appropriate collection

systems.

English 7

Page 8

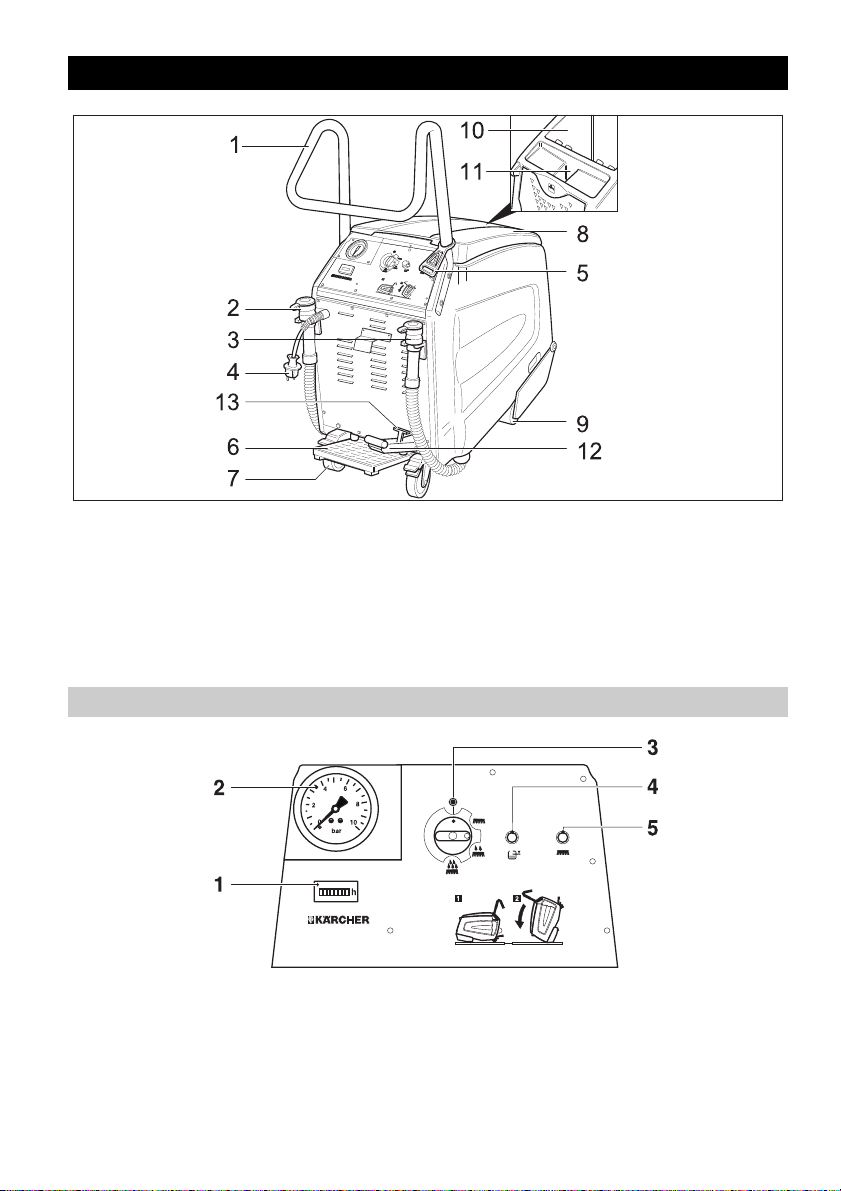

Operating and Functional Elements

1 Push handle

2 Drainage hose for fresh water

3 Dirt water discharge hose

4 Mains plug

5 Strain relief clamp

6 Foot pedal

7 Rear wheels with stopping lever

Operator console

1 Operating hour counter

2 Display pump pressure

3 Power switch

4 Indicator lamp "Dirt water tank full"

5 Indicator lamp "Brush motor overload"

8 Cover dirt water reservoir

9 Front wheels

10 Dirt water reservoir

11 Fresh water reservoir filler neck

12 Pedal for raising/ lowering the brush

head

13 Lever to lock the brush head

8 English

Page 9

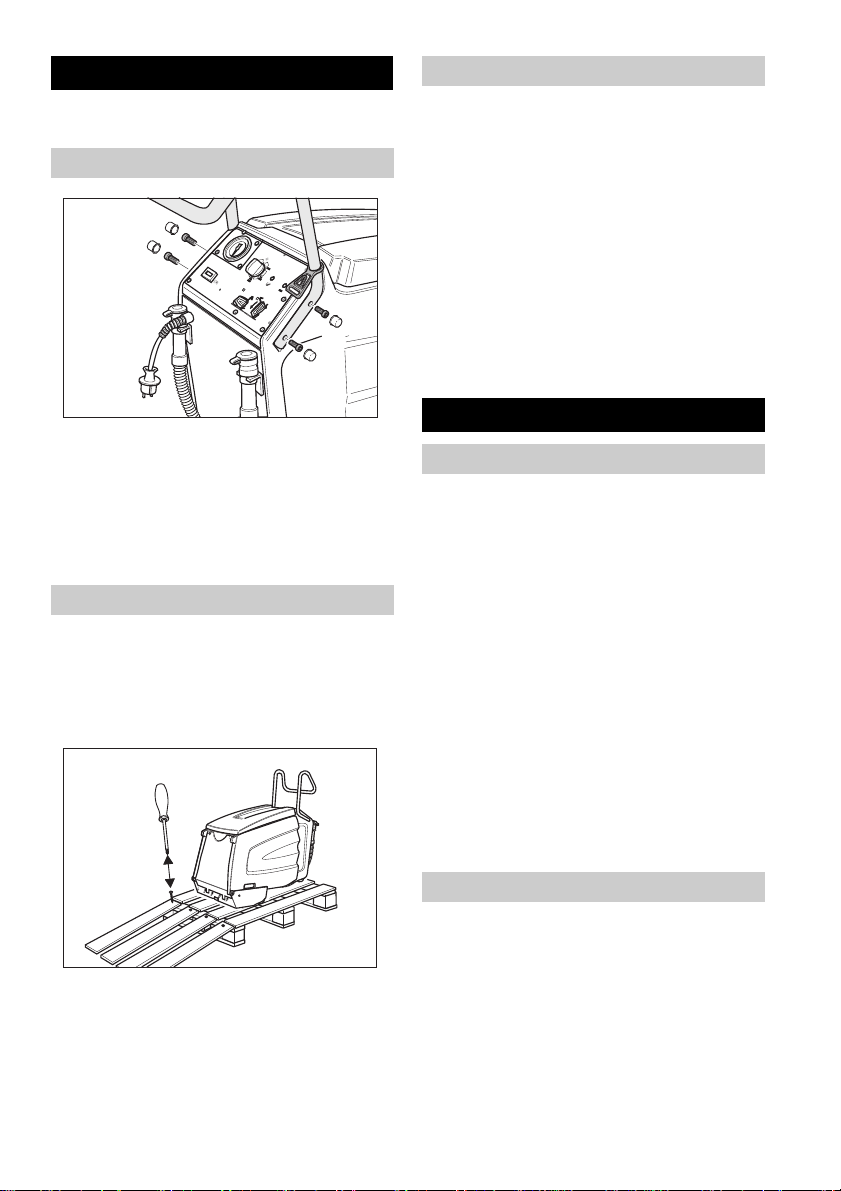

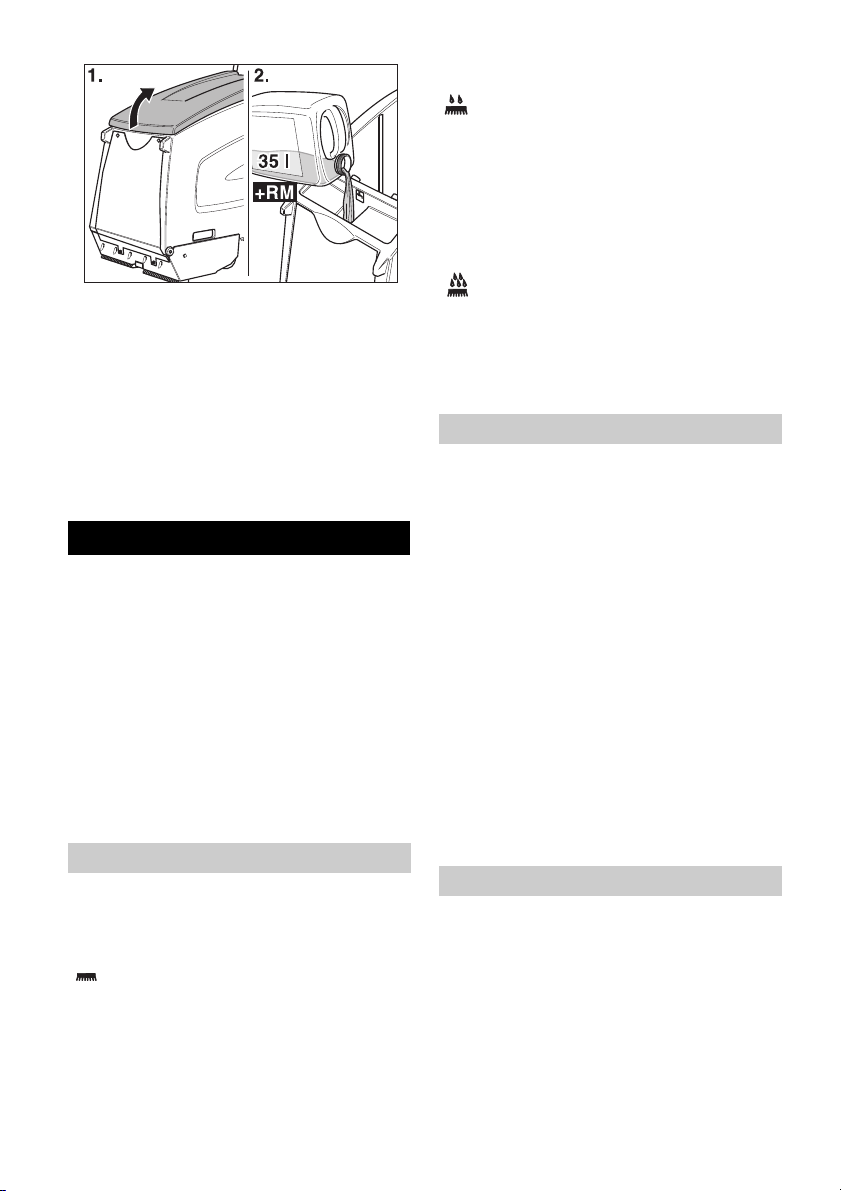

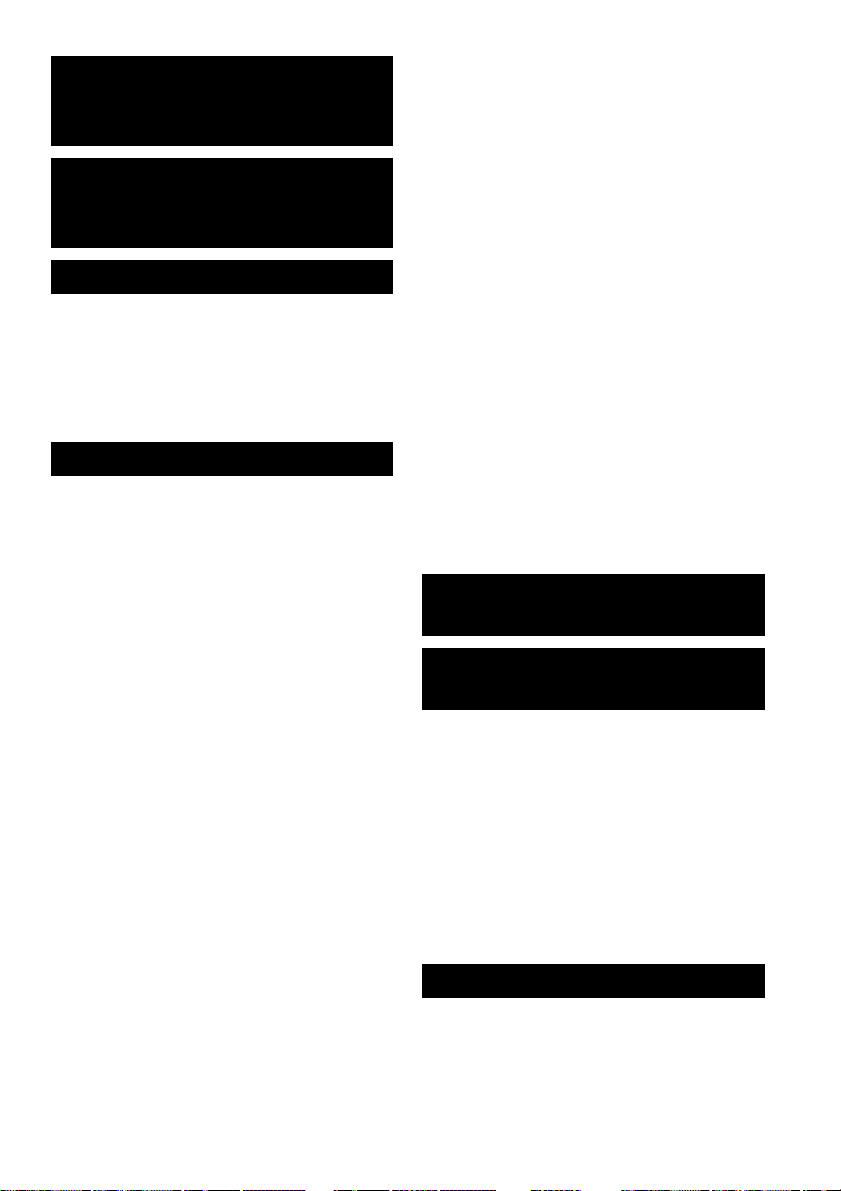

Before Startup

Î Remove all packaging material except

the wooden palette.

Installing the pushing handle

Removing anti-frost agents

Note

At the time of manufacturing the appliance,

it has already been flused using an anti-frost

agent. Before starting the machine for the

first time, you need to first remove the antifrost agent.

Î Fill in 10 litres of fresh water in the fresh

water reservoir.

Î Press the foot pedal.

Î Set the machine switch to basic clean-

ing.

Î Keep the machine running until the pres-

sure on the manometer falls.

Î Insert the pushing handle in the grooves

on the appliance.

Î Fasten the pushing handle with the 4

screws enclosed in the packet.

Î Fasten the covering flaps.

Î Hang in the strain relief clamp at the

pushing handle.

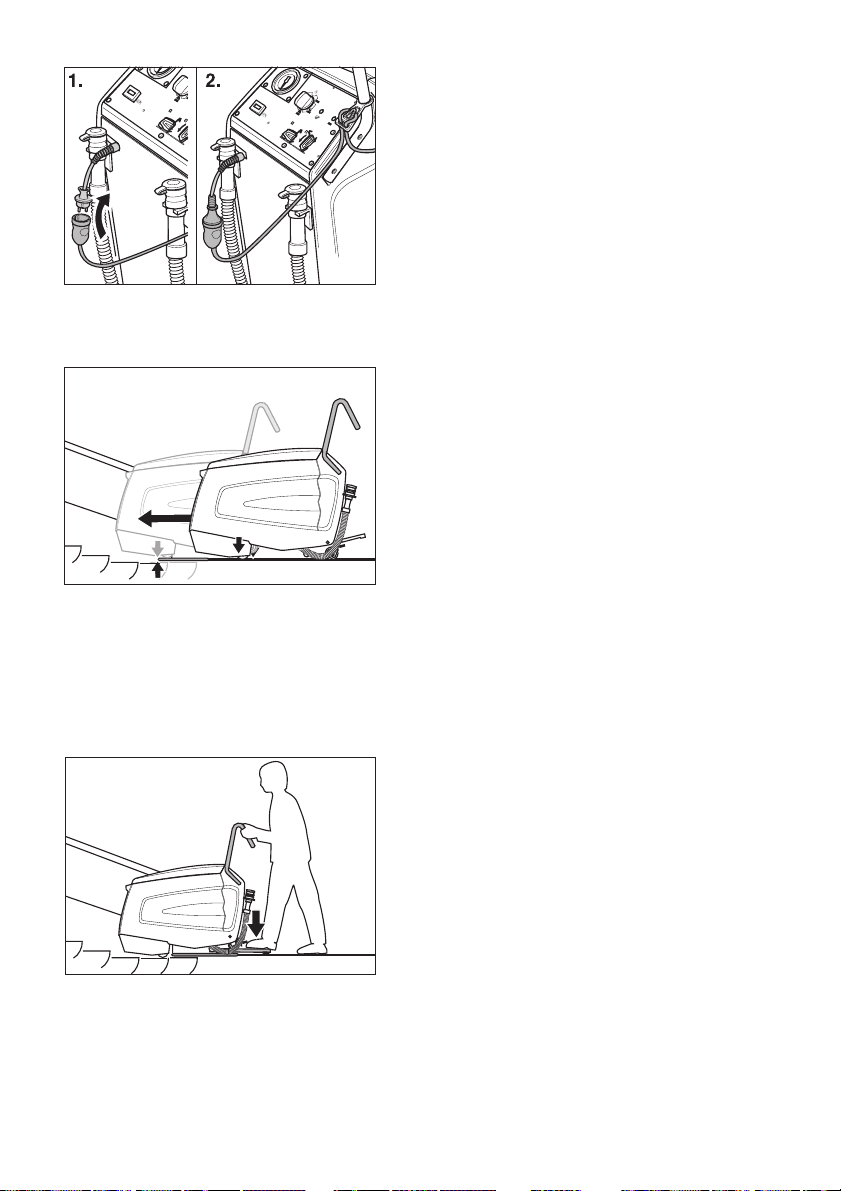

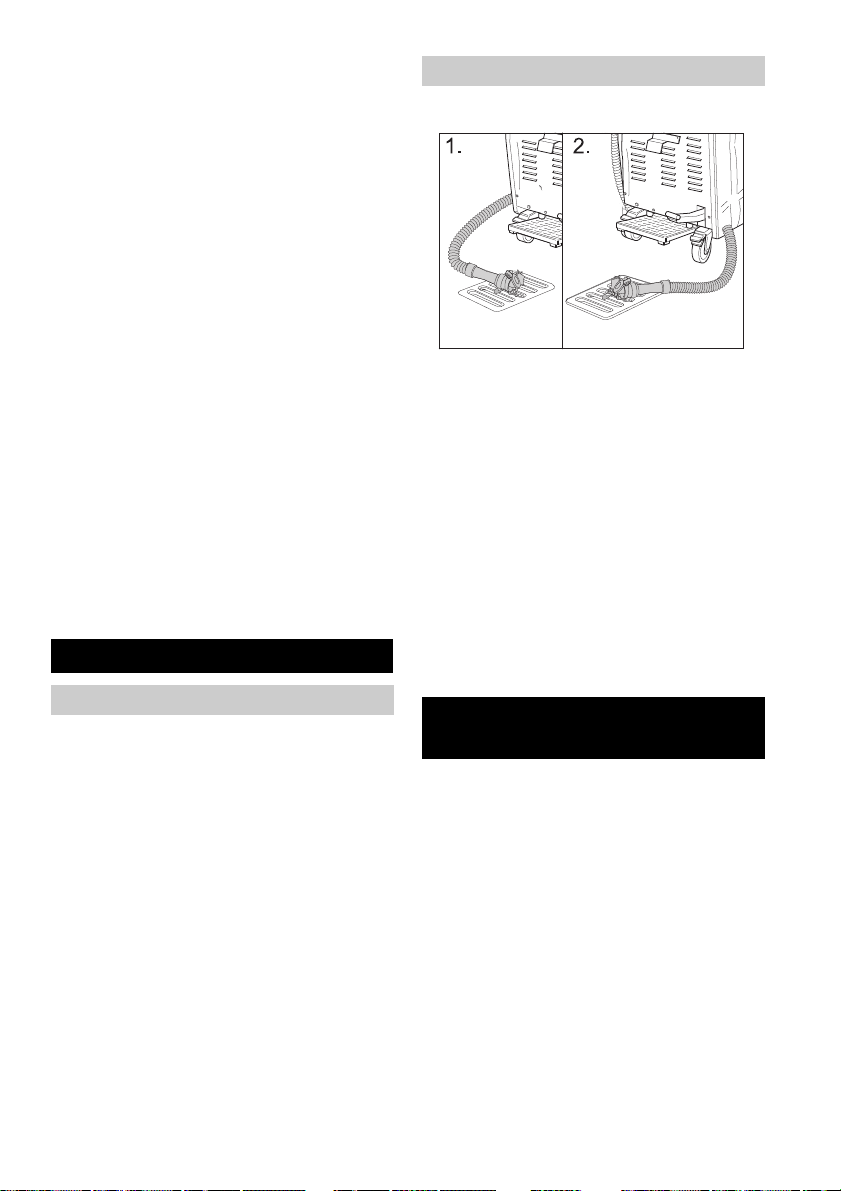

Unloading

Î Lock the rear wheels; remove the wood-

en blocks used for stopping the wheels.

Î Four indicated floor boards of the pallet

are fastened with screws. Unscrew

these boards.

Î Place the boards on the edge of the pal-

let. Place the boards in such a way that

they lie in front of the four wheels of the

machine. Fasten the boards with screws.

Î Slowly push the machine down from the

ramp.

Start up

Preparing the travellator/ escalator

Danger

Risk of injury! The appliance can get stuck

and be dragged away by the travellator/ escalator. Before starting cleaning, check the

stepping areas and the ridge profile to see

that there are no deformations or any objects stuck therein. To be on the safer side,

make sure that you know where the emergency switch-off button of the travellator/ escalator is located.

Î Cordon off the travellator/ escalator as

long as cleaning operations are on and

the stepping areas are still wet.

Î Switch on the travellator/ escalator.

Î Ensure that the running direction of the

travellator/ escalator is away from the

machine.

Preparing the appliance

Î Check whether the combs and the guide

rails of the machine match the make of

the travellator/ escalator. Replace the

combs and the guide rails, if required.

English 9

Page 10

Regular cleaning

Cleaning slighly dirty travellators/ escalators

(normally, at short regular intervals). At this

setting, the appliance works with reduced

quantity of water. The water pump works

with regular strokes.

Basic cleaning

Î Open the cover of the fresh water reser-

voir.

Î Fill in fresh water.

Î Pour in detergent.

Use only those detergents approved by

the manufacturer of the appliance.

Î Close the cover of the fresh water reser-

voir.

Î Drive the machine in front of the travella-

tor/ escalator platform.

Operation

Danger

Risk of injury!

– Press the foot lever with only one foot.

The other foot must be placed firmly on

the ground.

– Hold the pushing handle firmly with at

least one hand.

– Loose fitting clothes and jewellery can

get entangled in the moving parts of the

travellator/ escalator. Hence, remove

jewellery and wear clothes fitting well on

the body and safety shoes.

Cleaning types

The cleaning time depends on the level of

dirt and is divided into three cleaning types.

Dry vacuum cleaning

Use dry vacuum clean on the travellators/

escalators that have already been cleaned.

Cleaning very dirty travellators/ escalators

(normally done when the escalator has not

been cleaned for a long time). Areas with

heavy dirt and stains should ideally be

cleaned manually.

Tips for cleaning

– First clear off loose, coarse dust manual-

ly.

– Remove hard objects (such as stones)

from the ridges of the steps.

– Clean the front side of the escalator

steps manually.

– Clean the stepping areas in overlapping

strips. To do that, first move the appliance from the working position and place

it on the side.

– Observe the steps while cleaning. They

should be moist but not wet. There

should not be any foam residue.

– First do moist cleaning (with detergent

liquid) and then dry (by setting the appliance to dry vacuum cleaning).

– Then clean using clear water so as to re-

move detergent residues.

Cleaning operations

Danger

Risk of injury and electrical shock! Always

lay the extension cable in such a way that it

does not get jammed or crushed and also

does not cause somebody to stumble over it.

Î Plug in the main plug.

10 English

Page 11

Î Insert the end of the extension cable as

a loop in the strain relief clamp.

Î Lock the rear wheels.

Î Place the machine on the platform in

such a way that the front wheels do not

touch the first step of the moving travellator/ escalator.

Î Press pedal for lowering the brush head.

The brush head will be lowered and the

lock lever will arrest in its position.

Î Press the foot pedal with one foot and

while doing so move the machine a little

back and forth towards the side. The machine will position itself centrally in the

grooves of the steps; you will then hear a

rustling sound.

Danger

Risk of injury! Do not push the appliance

onto the escalator any further than the indications given below. Otherwise, the machine will get dragged off by the escalator.

In case of danger, immediately press the

emergency stop switch of the escalator.

The cleaning head must lie flat on the escalator.

Î Set the appliance switch to regular or ba-

sic cleaning.

The machine is started.

Note

The machine switches off when the dirt water reservoir is full. To restart the machine,

empty the dirt water reservoir and briefly set

the appliance switch to "0".

Î Continue cleaning until the travellator/

escalator has completed 1 or 2 rounds.

Then move the machine towards the

side and start a new cleaning process.

Moving the appliance to the side

Î Set the appliance switch to 'dry vacuum

cleaning' position. Dry vacuum cleaning

is activated.

Î Let the pump pressure fall to 0 bar.

Î Set the appliance switch to "0".

Î Release the foot pedal.

Î Press pedal for raising the brush head.

Brush head is raised.

Î Move the appliance to the side.

Î Press pedal for lowering the brush head.

The brush head will be lowered and the

lock lever will arrest in its position.

Î Press the foot pedal and place the ma-

chine centrally in the ridges of the steps.

Î Set the appliance switch to regular or ba-

sic cleaning.

Î Then clean using clear water so as to re-

move detergent residues.

Danger

Risk of injury! To refill detergent, always

move out the machine first from the working

position.

English 11

Page 12

Shutting down

Maintenance and care

Complete cleaning

Î Set the appliance switch to 'dry vacuum

cleaning' position. Dry vacuum cleaning

is activated.

Î Let the pump pressure fall to 0 bar.

Î Set the appliance switch to "0".

Î Release the foot pedal.

Î Activate the lever to lock and the pedal to

raise the brush head. Brush head is

raised.

Î Release the rear wheels.

Î Drive out the machine from the working

position and the podium until it is on firm

ground.

Turn off device

Î Pull out the mains plug.

Î Drain off and disose the remaining deter-

gent fluid.

Î Drain out the dirt water and dispose it off.

Î Clean the inside and outside of the ma-

chine. Rinse the tanks with clear water.

Î Store the machine in a frost-free room on

an even and clean floor.

Î Lock the rear wheels.

Î Remove the cordon from the travellator/

escalator only when the entire working

area is dry again. There is risk of accident on account of slipping even if the

travellator/ escalator is slightly moist.

Danger

Risk of injury! Before doing any work on the

machine:

Î Set the appliance switch to "0".

Î Pull out the mains plug.

Î Lock the rear wheels.

Î Drain off and disose the remaining deter-

gent fluid.

Î Drain out the dirt water and dispose it off.

Cleaning the device

몇 Warning

Risk of damage! Do not wash down the appliance with water and do not use aggressive detergents.

Î Clean the outside of the appliance with a

damp cloth which has been soaked in

mild detergent.

Î Wipe the insides of the dirt water reser-

voir.

Î Clean the fluff filter.

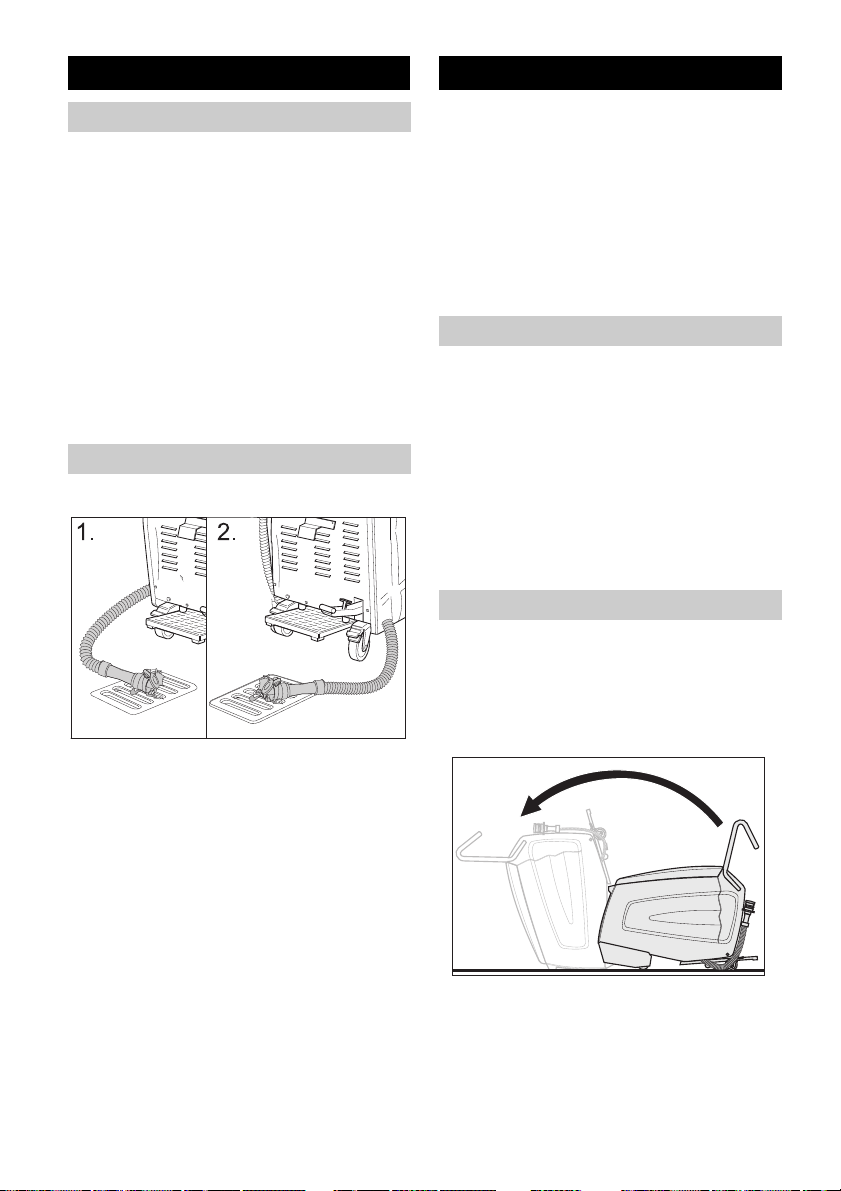

Maintenance intervals

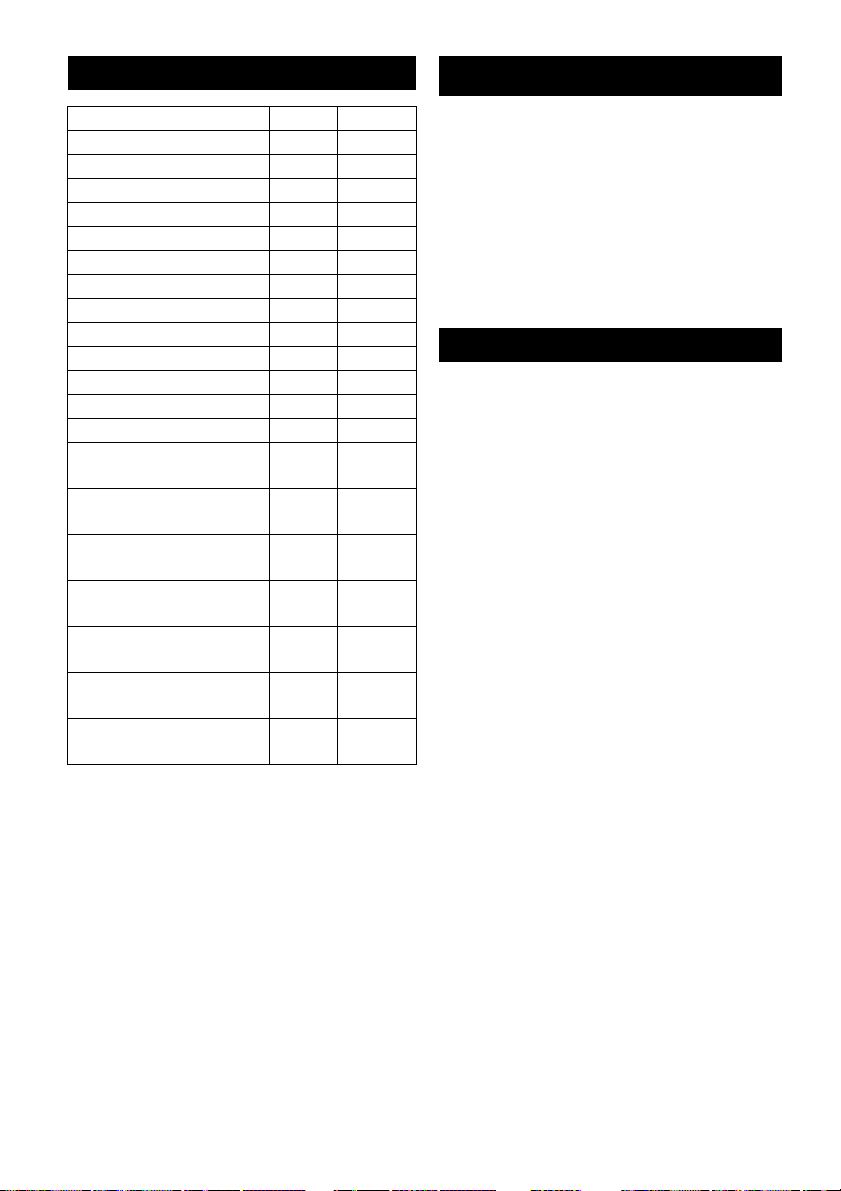

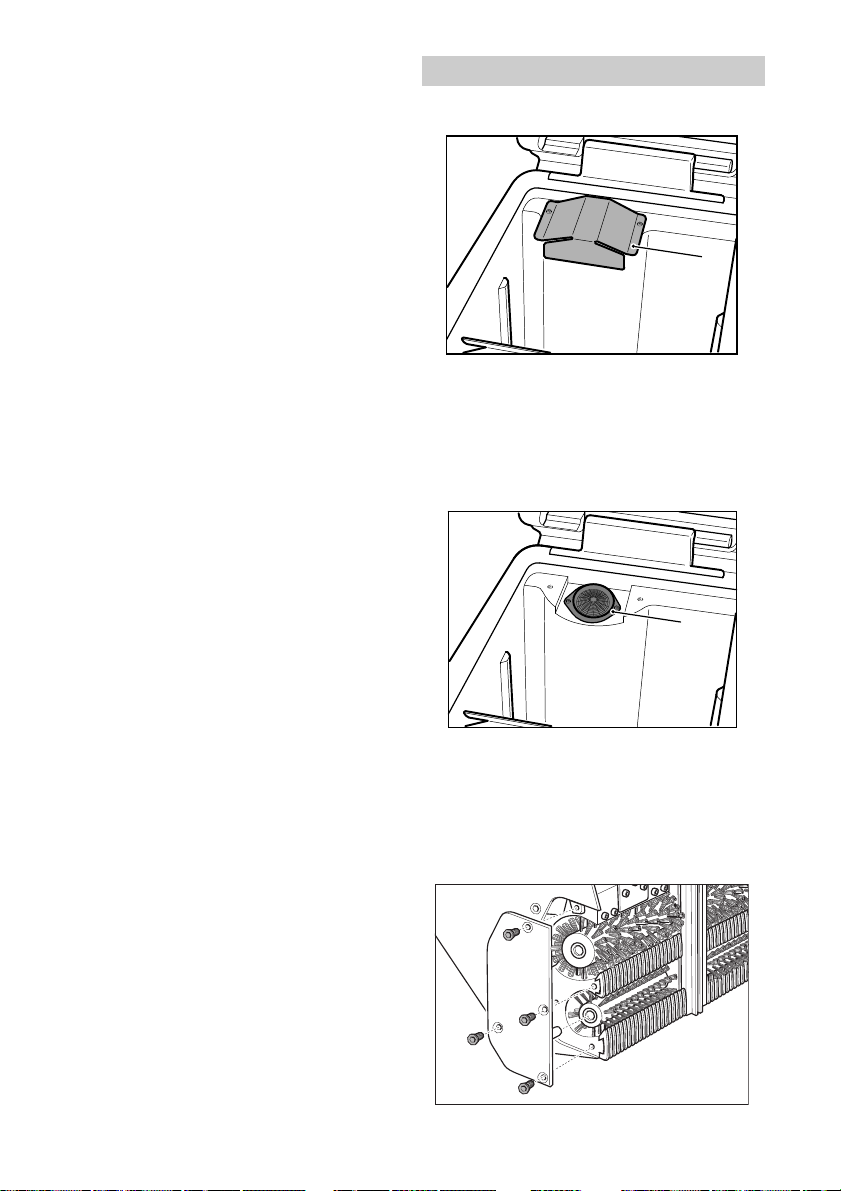

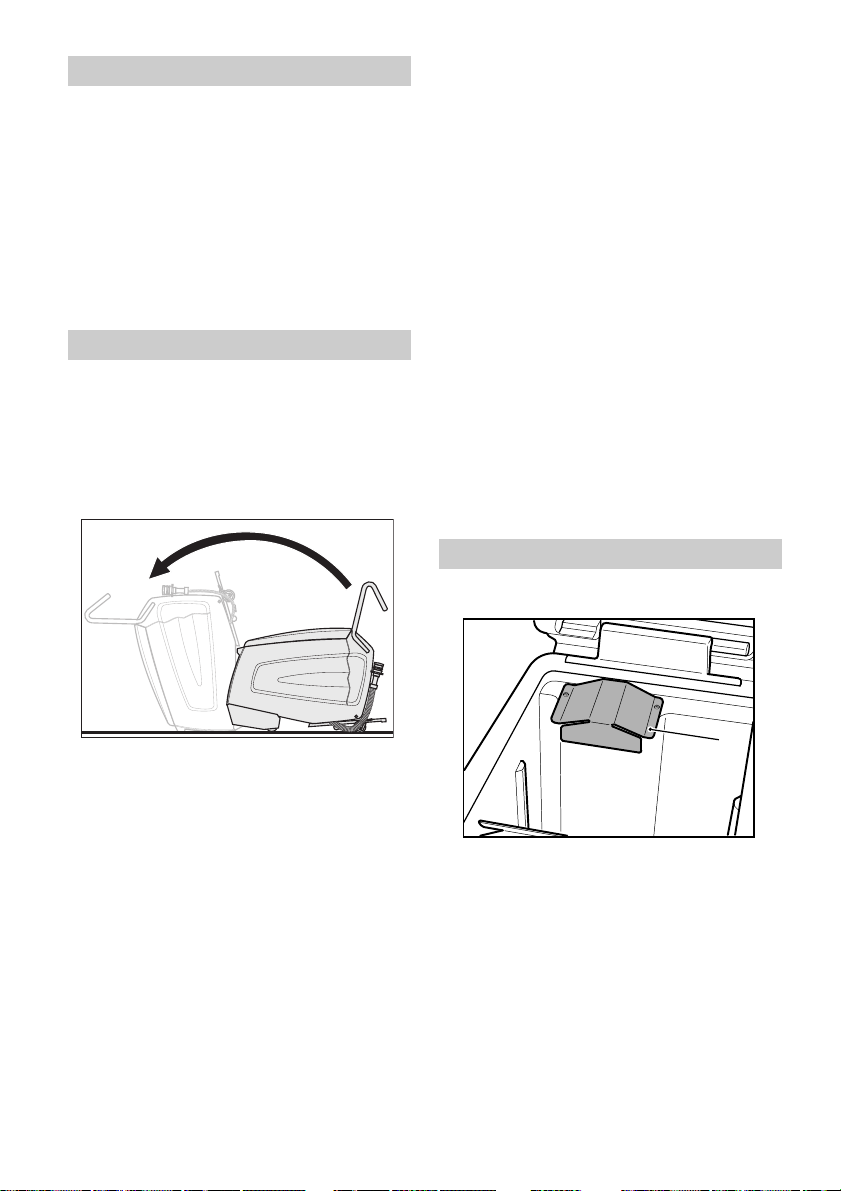

Tilt the machine in the maintenance position.

The escalator cleaner must be accessible

from the bottom side to perform any testing

or maintenance jobs on the machine.

Î Take the help of another person to tilt the

machine forward until it stands on the

front casing.

Daily before use

Î Check spray pattern of the nozzles.

Î Check if suction nozzles are dirty.

12 English

Page 13

Î Check emergency stop function of the

1

2

foot pedal.

Press the foot pedal, set the appliance

switch to 'dry vacuum cleaning', the ap-

pliance must run. Release the foot pedal; the appliance must stop.

Get the machine repaired only by authorised customer service agents.

Î Check the locking of the rear wheels.

Get the machine repaired only by authorised customer service agents.

Î Check for wear and tear:

Roller brushes, intake brushes, combs,

guide rails, hoses, stopper and front

wheels. Replace stopper and front

wheels, if required, only through authorised customer service agents.

Î Check mains cable and plug for damage

or breakage. Get them replaced only

through customer service agent or an

electrician.

After 100 operating hours

Î Check if all fasteners are fastened tight-

ly.

Î Check the drive belt for tension and wear

(Customer Service).

Maintenance Works

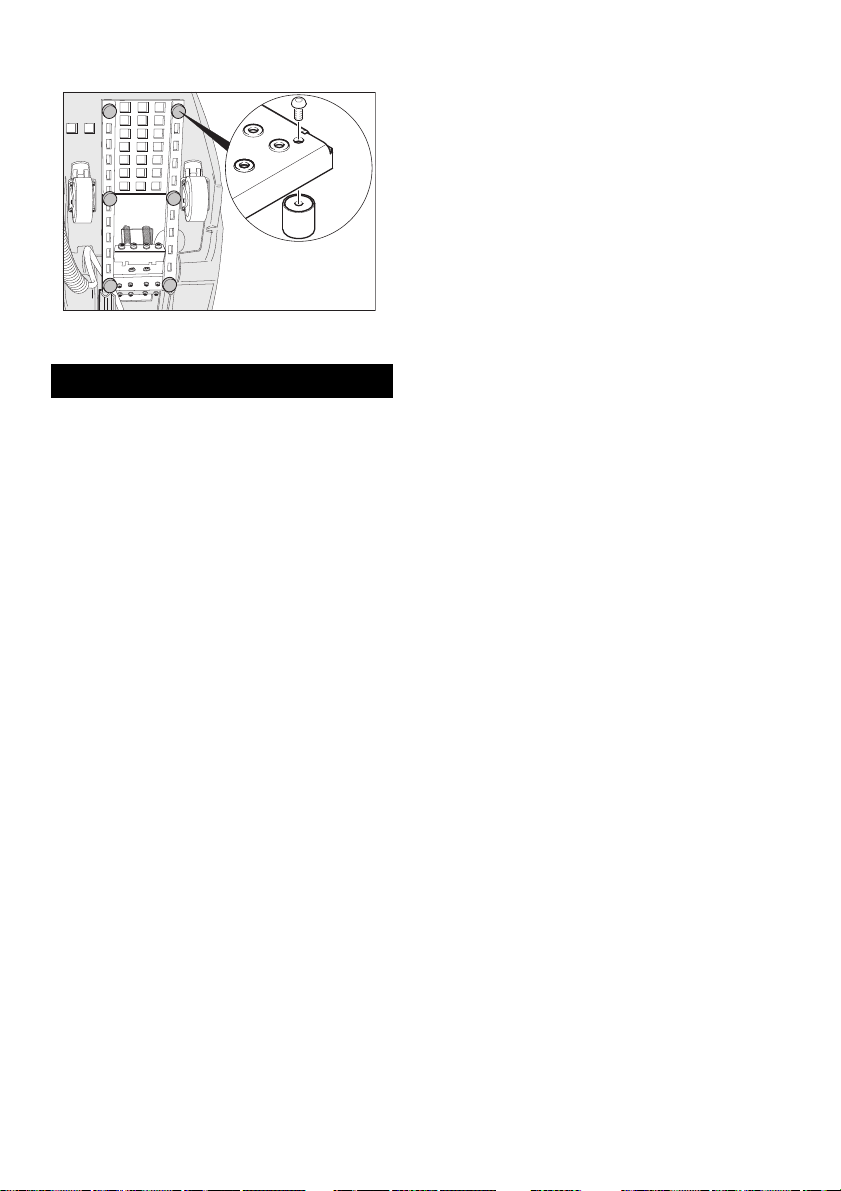

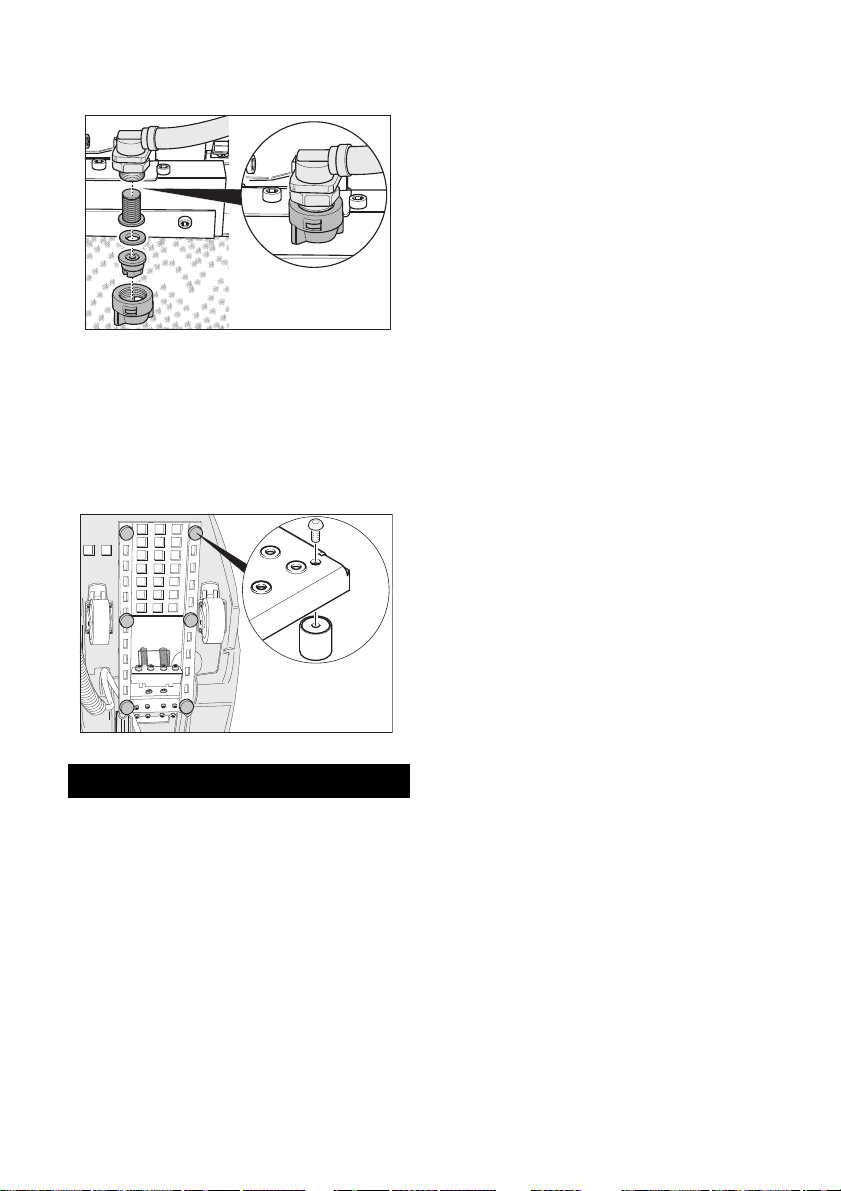

Clean the fluff filter

Î Clean the fluff filter.

Î Replace the tin plate.

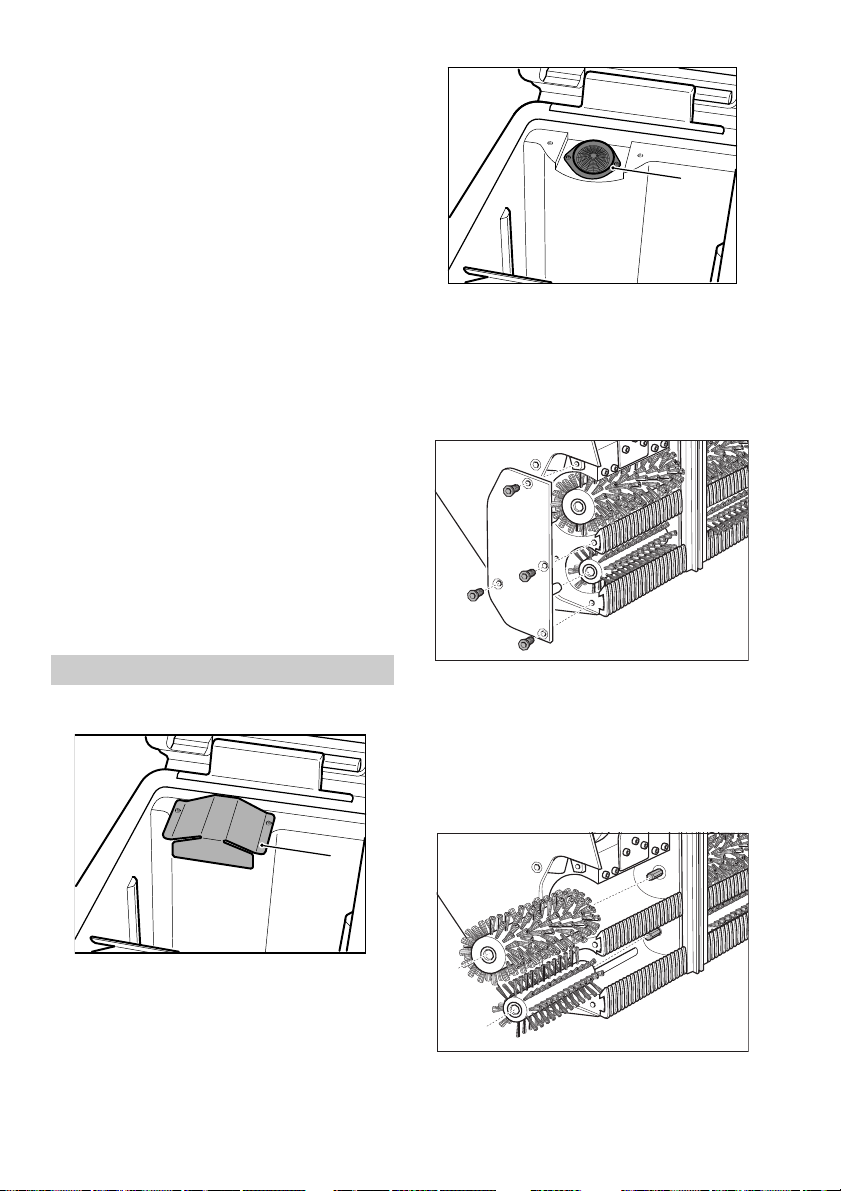

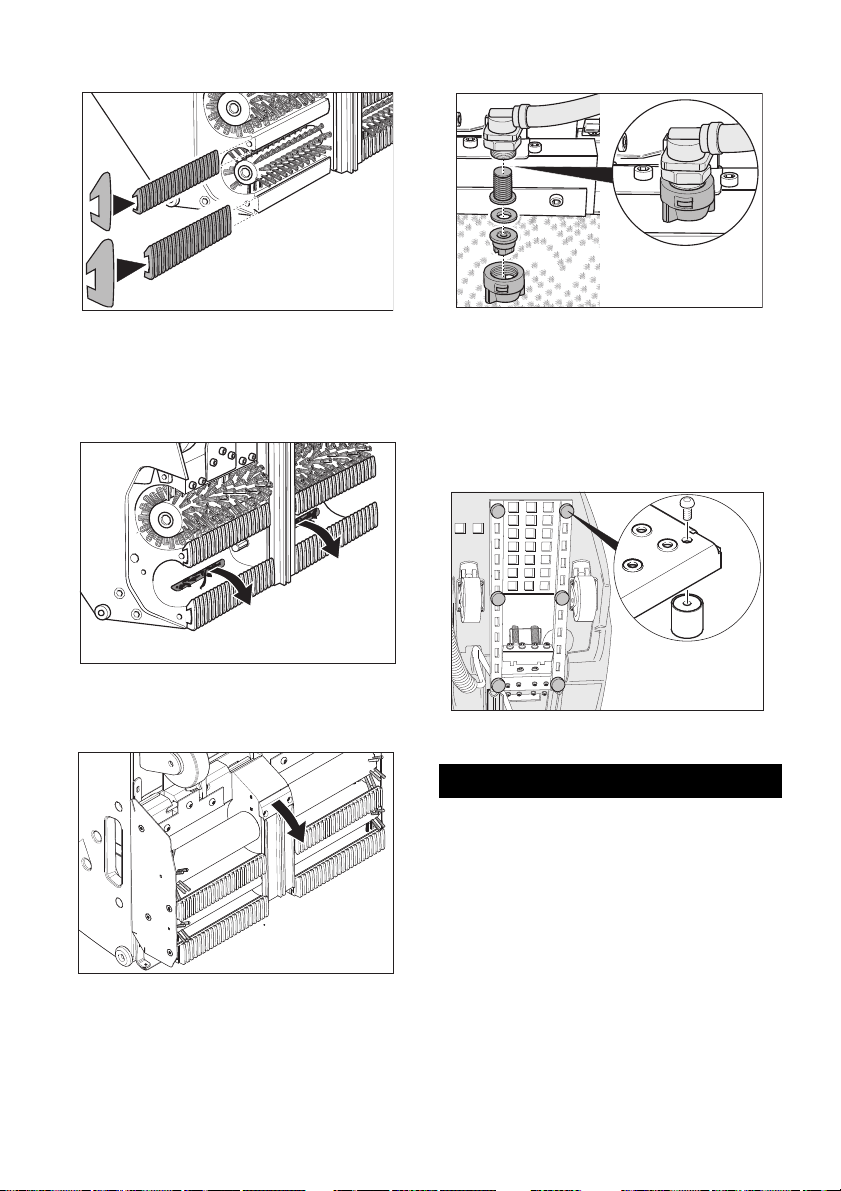

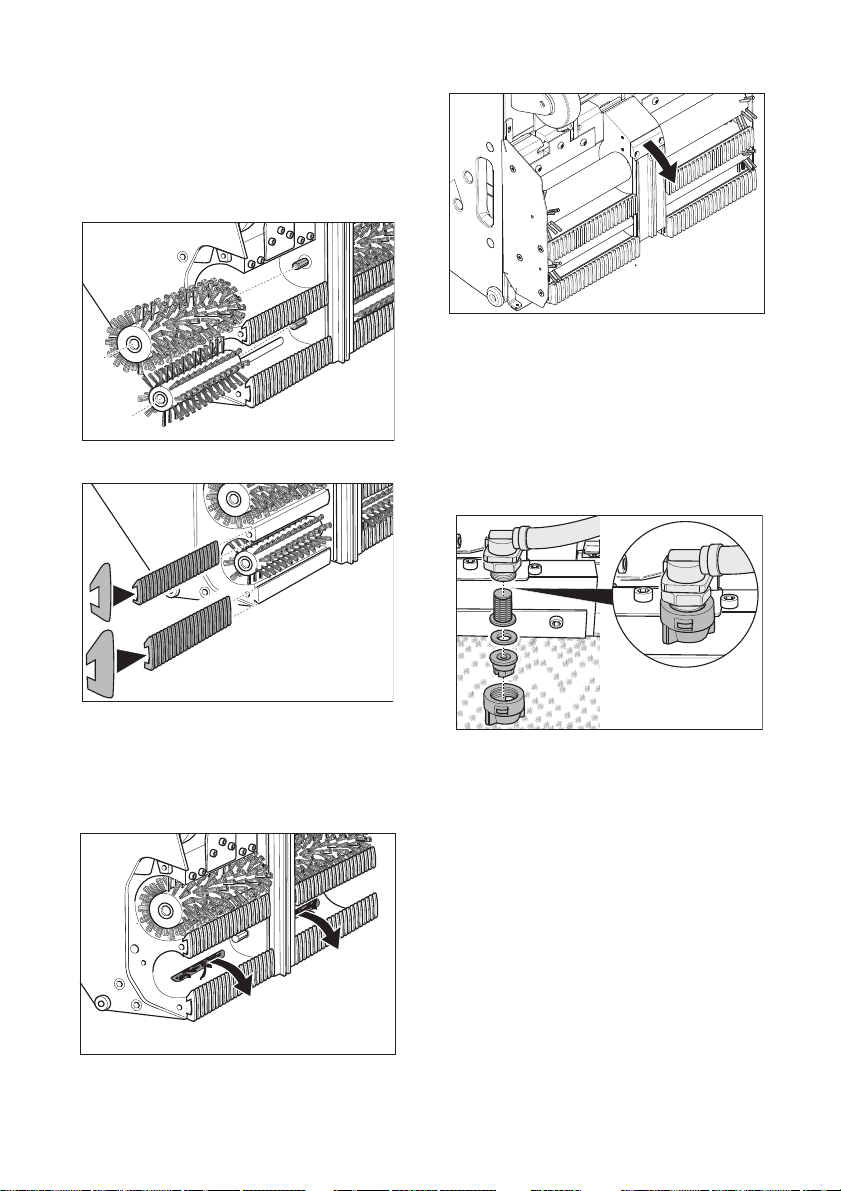

Replacing the roller brushes and the intake brushes

Î Loosen all the four screws and remove

the bearing lid.

Î Remove the roller brushes (large) and in-

take brushes (small) and replace them

(pay attention to the hexagonal intake of

the brushes!).

Also check simultaneously the combs

and the guide rails and replace or clean

them as required.

Î Unscrew the tin cover plate using a torx

spanner.

Note

You will find a torx spanner in the holder of

the drainage hose of the dirt water reservoir.

English 13

Page 14

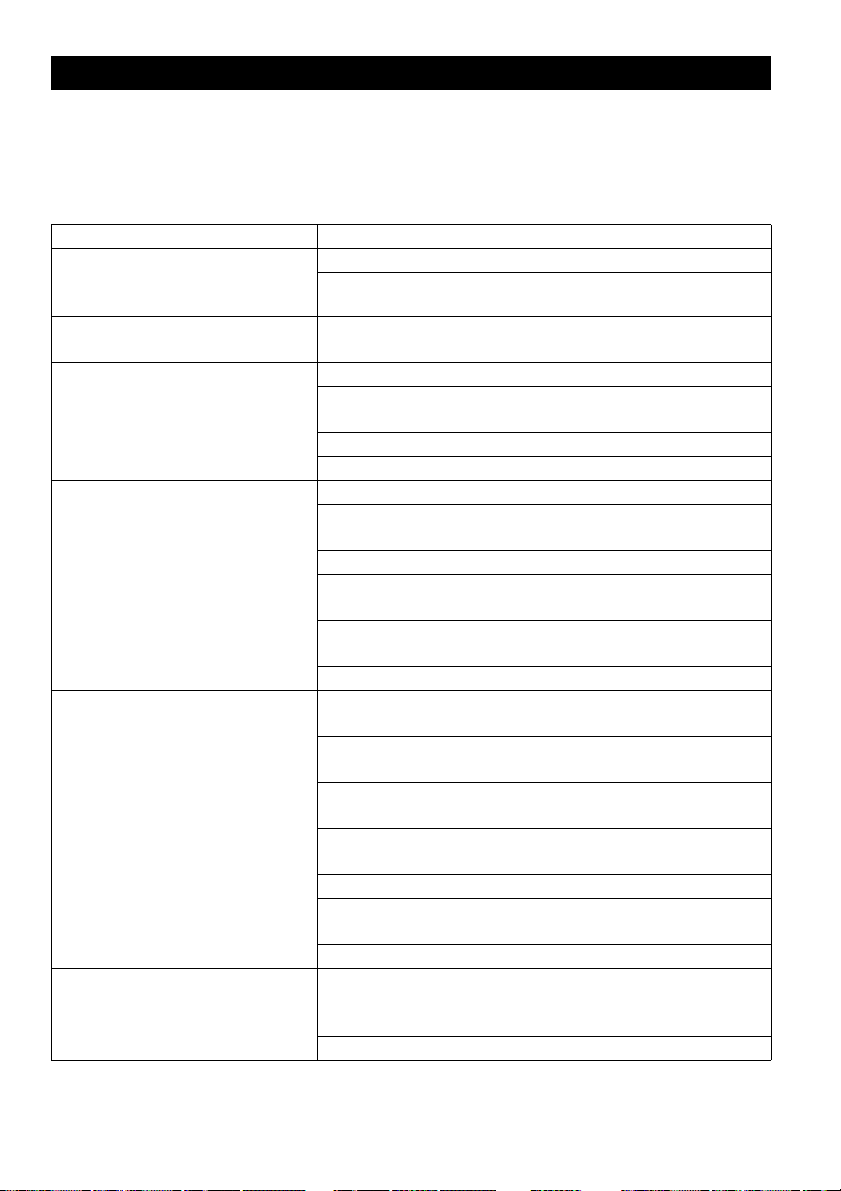

Replacing the combs

Check nozzles and filters for detergents

Î Remove the combs and replace them.

To do this, slide the inlet combs on the

narrow rails and the outlet combs on the

wider rails.

Cleaning the suction nozzles

Î Pull out all dirt particles from the suction

nozzles; do not push them in.

Replacing the guide rails

Î Loosen the fastening screws of the hold-

er for the guide rails.

Î Dismantle the guide rails.

Î Insert the guide rails in reverse se-

quence. Ensure that they sit properly.

Î Loosen the union joint. Remove nozzle,

washer and sieve.

Î Clean the nozzle or insert a new nozzle

in the union joint.

Î Insert washer and sieve and tighten the

union joint by hand.

Replacing the pad

Î Unscrew the pad with a screw-driver and

replace it.

Transport

Danger

Risk of injury! Do not drive over slopes greater than 5°. Never transport the machine over

the travellator/ escalator.

Î Lock the rear wheels.

Î Secure the machine with clamping belts

and ropes so that it doesn't slip off.

14 English

Page 15

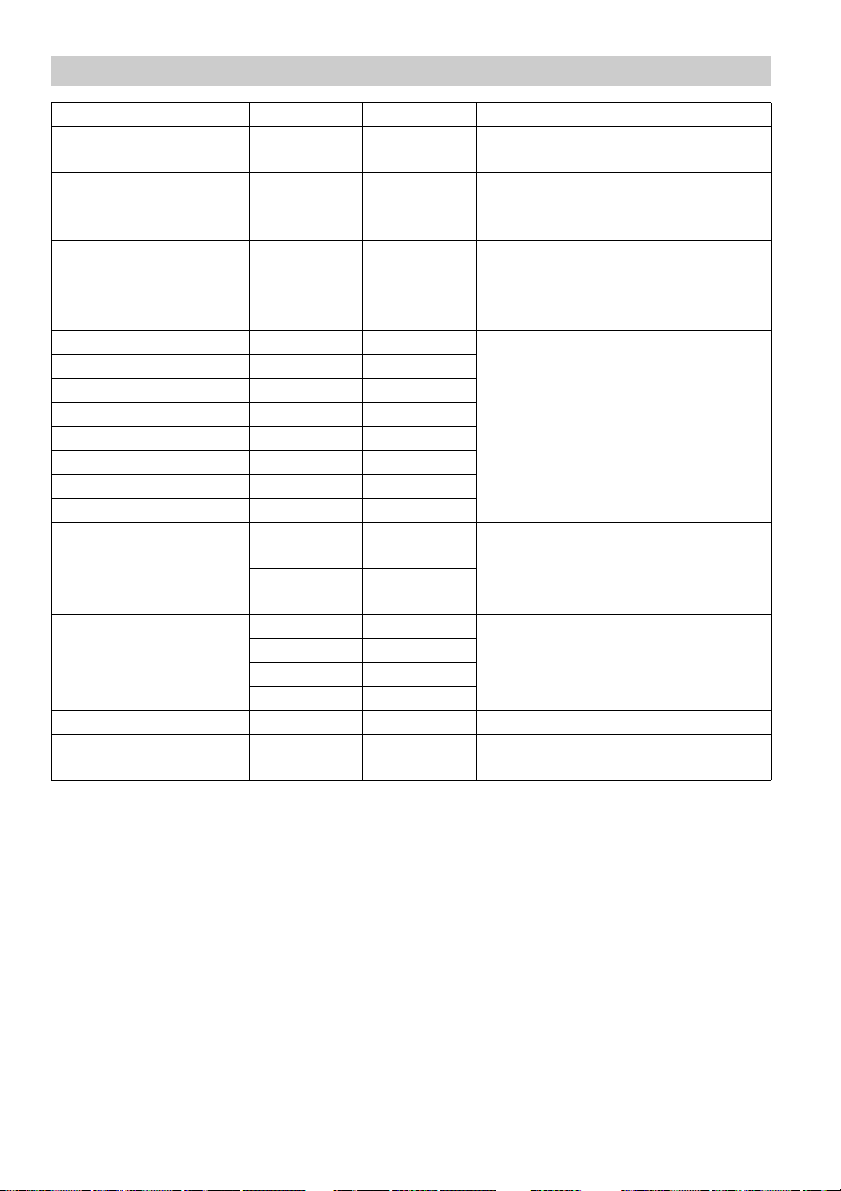

Troubleshooting

Danger

Risk of injury! Before doing any work on the

machine:

Î Set the appliance switch to "0".

Î Pull out the mains plug.

Fault Remedy

Motor/pump do not start or

switch off automatically when the

machine is on.

Indicator lamp "Dirt water tank

full" is glowing.

Working pressure of min. 3 bar is

not building up.

Cleaned steps are too wet. Check the combs for wear, replace if required.

Washed steps are not clean. Check detergent nozzles to see if they are blocked; clean

Indicator lamp "Brush motor

overload" is glowing.

Dirt water reservoir is full; empty it.

Press the foot pedal.

Dirt water reservoir is full; empty it.

If fresh water reservoir is empty, then fill it up (35 litres).

Check pipes to see if there are any leaks. If required, get

it sealed by customer service.

Check the nozzles.

Get customer service to clean the pump.

Check the condition of the seal of the dirt water reservoir

for damages, replace if required.

Check the intake brushes for wear, replace if required.

Check suction nozzles and hose for blockages; clean if

required.

Check whether the wastewater reservoir lid is completely

closed.

Check whether the correct combs have been installed.

or replace if required.

Check the condition of the seal of the dirt water reservoir

for damages, replace if required.

Check the brush rollers and intake brushes for wear, re-

place if required.

Check detergent. Check the concentration of the deter-

gent solution.

Check the intake brushes for wear, replace if required.

Check whether the wastewater reservoir lid is completely

closed.

Check whether the correct combs have been installed.

Set appliance switch to "0", then turn it back to the de-

sired operating position. If the fault recurs often, call customer service.

Remove belts or cords from brushes.

Î Lock the rear wheels.

Î Drain off and disose the remaining deter-

gent fluid.

Î Drain out the dirt water and dispose it off.

English 15

Page 16

Specifications

Warranty

1.310-105

Nominal voltage V 120

Frequency Hz 60

Control voltage V 12

Rated power (max.) W 1360

Suction engine output W 800

Brush engine output W 650

Pump pressure bar 3-4

Water Consumption l/h 25-50

Speed of roller brushes 1/min 870

Speed of intake brushes 1/min 1090

Working width mm 470

Width mm 480

Length mm 1150

Height with pushing

handle

Height without pushing

handle

Fresh/dirt water reser-

voir volume

Unladen weight kg approx.

Operating weight kg approx.

Sound pressure level

(EN 60704-1)

Vibration total value

(ISO 5349)

mm 1050

mm 760

l 35/35

90

125

dB(A) <75

2

m/s

0,43

The warranty terms published by the relevant sales company are applicable in each

country. We will repair potential failures of

your appliance within the warranty period

free of charge, provided that such failure is

caused by faulty material or defects in manufacturing. In the event of a warranty claim

please contact your dealer or the nearest

authorized Customer Service centre. Please

submit the proof of purchase.

Accessories and Spare Parts

Danger

Risk of injury and electrical shock! Repair

works may only be performed by the authorised customer service.

– Only use accessories and spare parts

which have been approved by the manufacturer. The exclusive use of original accessories and original spare parts

ensures that the appliance can be operated safely and troublefree.

– At the end of the operating instructions

you will find a selected list of spare parts

that are often required.

– For additional information about spare

parts, please go to the Service section at

www.kaercher.com.

16 English

Page 17

Accessories

Accessories Type Part no.: Description

Roller brushes, soft

(standard)

Roller brushes, hard 5.762-267 Roller brushes for regular cleaning,

Intake brushes 5.762-268 For transporting the dirt water trans-

Inlet combs, blue Kone 6.369-509 Combs for adjusting the appliance to

Outlet combs, blue Kone 6.369-519

Inlet combs, black OTIS 6.369-510

Outlet combs, black OTIS 6.369-520

Inlet combs, green Schindler 6.369-511

Outlet combs, green Schindler 6.369-521

Inlet combs, white CNIM 6.369-512

Outlet combs, white CNIM 6.369-522

Groove scraper Kone und

Schindler

OTIS und

Thyssen

Set Handpads Kone 6.369-513 For manually cleaning the front side

OTIS 6.369-514

Schindler 6.369-515

Thyssen 6.369-516

Detergent RM 758 For cleaning by machine.

Detergent RM 759 For basic cleaning (30 kg). For man-

5.762-266 Roller brushes for regular cleaning

(appliance needs 2 pieces).

for removing stubborn dirt (appliance needs 2 pieces).

port from the travellator/ escalator to

the suction nozzles (appliance requires 2 pieces).

the respective travellator/ escalator

brand (set with 2 pieces).

6.369-507 For manual pre-cleaning (removing

stones, chewing gum and other

6.369-508

sticky dirt).

of the steps (set with 5 green pads).

ually cleaning very dirty spots.

English 17

Page 18

Page 19

INSTRUCTIONS IMPORTANTES EN MATIÈRE DE SÉCU-

RITÉ

LIRE TOUTES LES INSTRUC-

TIONS AVANT DE FAIRE

FONKTIONNER

Attention

Pour réduire les risques d'incendie, de chok

électrique ou de blessure:

– Ne pas laisser l'appareil sans

surveillance lorsqu'il est branché.

Débrancher lorsque l'appareil n'est pas

utilisé et avant l'entretien.

Attention

– Pour réquire les risques de choc

électrique, utiliser à l'interieur seulement.

– Ne pas permettre aux enfants de jouer

avec l'appareil. Une attention particulière

est nécessaire lorsque l'appareil est

utilisé par des enfants ou à proximité de

ces derniers.

– N'utiliser que conformément à cette

notice avec les accessoires

recommandés par le fabricant.

– Ne pas utiliser si le cordon ou la fiche est

endommagé. Retourner l'appareil à un

atelier de réparation s'il ne fonctionne

pas bien, s'il est tombé ou s'il a été

endommagé, oublie à l'extérieur ou

immergé.

– Ne pas tirer soulever ni traîner l'appareil

par le cordon. Ne pas utiliser le cordon

comme une poignée, le coincer dans

l'embrasure d'une porte ou l'appuyer

contre des arêtes vives ou des coins. Ne

pas faire rouler l'appareil sur le cordon.

Garder le cordon à l'écart des surfaces

chaudes.

– Ne pas débrancher en tirant sur le

cordon. Tirer plutôt la fiche.

– Ne pas toucher la fiche ni l'appareil

lorsque vos mains sont humides.

– N'insérer aucun objet dans les

ouvertures. Ne pas utiliser l'appareil

lorsqu'une ouverture est bloquée.

S'assurer que de la poussière, de la

peluche, des cheveux ou d'autres

matières ne réduisent pas le debit d'air.

– Maintenir les cheveux, les vêtements

amples, les doigts et toutes les parties

du corps à l'écart des ouvertures et des

pièces mobiles.

– Mettre toutes les commandes à la

position ARRÊT avant de débrancher

l'appareil.

– User de prudence lors du nettoyage des

escaliers.

– Ne pas aspirer des liquides

inflammables ou combustibles, comme

de l'essence, et ne pas faire functionner

dans des endroits où peuvent se trouver

de tels liquides.

– Ne brancher qu'à une prise de courant

avec mise à la terre. Voir les instructions

la mise à la terre.

CONSERVER CES INSTRUC-

TIONS

INSTRUCTIONS VISANT LA

MISE À LA TERRE

Cet appareil doit être mis à la terre. En cas

de défaillance ou de panne, la mise à la terre

fournit au courant un chemin de moindre résistance qui réduit le risque de choc électrique. Cet appareil est pourvu d'un cordon

muni d'un conducteur de terre et d'une fiche

avec broche de terre. La fiche doit être

branchée dans une prise appropriée correctement installée et mise à la terre conformément aux règlements et ordonnances

municipaux.

Attention

Un conducteur de terre mal raccordé peut

entraîner un risque de choc électrique. Consulter un électricien ou un technicien d'entretien qualifié si vous n'êtes pas certain que la

prise est correctement mise à la terre. Ne

Français 19

Page 20

pas modifier la fiche fournie avec l'appareil si elle ne peut être insérée dans la prise, fair

installer une prise adéquate par un électricien qualifié.

Cet appareil est destiné à un circuit de 120

V et est muni d'une fiche de mise à la terre

semblable à celle illustrée par le croqui A.

S'assurer que l'appareil est branché à une

prise de courant ayant la même configuration que la fiche. Aucun adaptreur nr devrait

être utilisé avec cet appareil.

NE BRANCHER QU'À UNE

PRISE DE COURANT AVEC

MISE À LA TERRE

1 Sortie avec mise à la terre

2 Boîte avec mise à la terre

3 Fiche avec mise à la terre

REGLES ET PRATIQUES DE

SECURITE DE FONCTION-

NEMENT

Responsabilité de l'opérateur

Un fonctionnement sûr est la responsabilité

de l'opérateur.

L'opérateur doit être au courant du fonctionnement et des fonctions de toutes les commandes et de tous les instruments avant

d'entreprendre de faire fonctionner l'unité.

Avant de faire fonctionner l'unité, les opérateurs doivent avoir lu et bien connaître le

manuel d'utilisation pour l'unité particulière

en fonctionnement et ils doivent également

obéir aux règles et pratiques de sécurité

énoncées dans les paragraphes suivants.

Avant de faire fonctionner l'unité, l'opérateur

doit bien connaître les conditions de fonctionnement inhabituelles qui peuvent nécessiter des précautions de sécurité

supplémentaires ou des instructions de

fonctionnement spéciales.

Généralités

Avant de commencer à faire fonctionner

l'unité, soyez dans une position d'opération.

Ne démarrez pas ou n'opérez pas l'unité,

l'une quelconque de ses fonctions ou accessoires, depuis tout endroit autre que la position désignée pour les opérateurs.

Avant de quitter la position de l'opérateur :

A arrêtez complètement l'unité ;

B si l'unité doit se trouver sur un plan incli-

né, bloquez les roues.

Conservez une distance de sécurité depuis

le bord des rampes, plate-formes et autres

surfaces de travail similaires.

N'effectuez aucun ajout ou aucune modification à l'unité.

Ne bloquez pas l'accès aux couloirs à incendie, escaliers ou équipement de lutte contre

les incendies.

Déplacements

Donnez la priorité aux piétons et véhicules

d'urgence tels que les ambulances et les camions de pompiers.

Traversez les voies ferrées de manière angulaire si possible. Ne vous garez pas à

moins de 1800 mm du rail le plus proche

d'une voie ferrée.

Conservez une vision claire du chemin de

déplacement et prenez garde au reste de la

circulation, au personnel et aux dégagements sûrs.

Opérez l'unité à une vitesse qui lui permettra

d'être arrêtée de manière sûre dans toutes

les conditions de déplacement.

Ne vous adonnez pas aux cascades ou à la

brutalité.

Ralentissez en cas de sols mouillés et glissants.

Avant de passer sur un bord de quai ou sur

la chaussée d'un pont, assurez-vous qu'il/

20 Français

Page 21

elle est correctement fixé(e). Conduisez prudemment et lentement sur le bord de quai ou

la chaussée d'un pont et ne dépassez jamais sa capacité nominale.

Lors de la prise de virages, ralentissez à une

vitesse sûre en correspondance avec l'environnement de fonctionnement. Prenez les

virages en douceur.

Entretien de l'unité par l'opérateur

Si l'unité s'avère nécessiter des réparations

ou être dangereuse d'une manière quelconque ou contribue à une condition dangereuse, le problème doit être rapporté

immédiatement au supérieur désigné de

l'utilisateur et l'unité ne doit pas être opérée

jusqu'à ce qu'elle ait été remise en une condition de fonctionnement sûre.

Si l'unité devient dangereuse d'une manière

quelconque au cours du fonctionnement, le

problème doit être rapporté immédiatement

au supérieur désigné de l'utilisateur et l'unité

ne doit pas être opérée jusqu'à ce qu'elle ait

été remise en une condition de fonctionnement sûre.

N'effectuez pas de réparations ou de réglages à moins d'y être autorisé spécifiquement.

PRATIQUES D'ENTRETIEN

ET DE RECONSTRUCTION

Le fonctionnement de l'unité peut être dangereux si l'entretien est négligé ou si des réparations, reconstructions ou réglages ne sont pas

effectués conformément aux critères de conception du constructeur. Par conséquent, des

installations d'entretien (sur site ou au dehors),

du personnel qualifié et des procédures détaillées doivent être fournis.

L'entretien et l'inspection de l'unité doivent

être réalisés conformément aux pratiques

suivantes :

A un système d'entretien, de lubrification et

d'inspection planifié doit être suivi ; consultez les recommandations du constructeur.

B seul du personnel qualifié et autorisé doit

être autorisé à effectuer l'entretien, répa-

rer, régler et inspecter l'unité et ce conformément aux spécifications du

constructeur.

Evitez les risques d'incendie et disposez

d'un équipement de protection contre les incendies dans la zone de travail. N'utilisez

pas de récipients ouverts d'essence ou de

fluides de nettoyage inflammables pour le

nettoyage des pièces.

NORME DE SECURITE IN-

CENDIE

Toute unité ne se trouvant pas dans une

condition de fonctionnement sûre doit être

mise hors service.

Les réparations doivent être effectuées dans

les emplacements de Classe I, Classe II et

Classe III.

Prévention incendie : L'unité doit être conservée dans une condition propre et raisonnablement exempte de peluche, d'huile en

excès et de graisse. Des agents non combustibles sont préférés pour le nettoyage de

l'unité. Les liquides inflammables [ceux possédant des points d'inflammation à ou supérieurs à 100°F (37,8°C)] ne sont pas permis.

Les précautions concernant la toxicité, la

ventilation et les risques d'incendie doivent

être appropriées à l'agent ou au solvant utilisé.

Visibilité de la plaque signalétique : Les désignations du type d'unité telles qu'illustrées

sur la plaque signalétique et les marqueurs

de type ne doivent pas être recouverts par

de la peinture de sorte que les informations

concernant leur identification sont obscurcies.

L'unité ne doit pas être utilisée dans des zones classifiées.

Français 21

Page 22

Lisez attentivement ce mode

d’emploi avant la première utilisation de l’appareil et respectez les conseils

y figurant. Conservez ce mode d’emploi

pour une utilisation ultérieure ou un éventuel

repreneur de votre matériel.

Table des matières

Consignes de sécurité 22

Fonction 22

Utilisation conforme 22

Protection de l'environnement, élimination

23

Eléments de commande 24

Avant la mise en service 25

Mise en service 25

Fonctionnement 26

Mise hors service 28

Entretien et maintenance 28

Transport 31

Assistance en cas de panne 32

Données techniques 33

Garantie 33

Accessoires et pièces de rechange 33

Consignes de sécurité

Pour l'exploiteur:

S'assurez vous que tous les utilisateurs ont

lus ce manuel, ainsi qu'ils conaissent les reglèments nacionaux relatif à la sécurité du

travail. Les utilisateurs doivent être instruites

appropriement dans l'utilisation de l'apapreil.

Pour l'utilisateur:

Lire le présent mode d'emploi ainsi que la

brochure ci-jointe Consignes de sécurité

pour les aspirateurs eau/poussières n°

5.956251 avant d'utiliser l'appareil et respecter les instructions.

Dispositifs de sécurité

Les dispositifs de sécurité ont pour but de

protéger l'utilisateur et ils ne doivent donc jamais être désactivés ni évités.

Pédale à pied

Lorsque la pédale à pied est pressé totalement vers le bas, l'appareil peut être démarré. En lâchant la pédale, l'appareil s'arrête.

Fonction

Du nettoyeur fixe de l'escalier roulant est appliqué détergent (du réservoir d'eau propre)

sur le trottoir/l'escalier roulant en marche.

Les brosses rotatives balayent le détergent

dans le sens inverse de la direction de cours

dans les rainures du trottoir/l'escalier roulant. Au même process de travail, le détergent sale est aspiré par les brosses de

absorption dans le réservoir d'eau sale de

l'appareil.

Utilisation conforme

L'utilisation de l'appareil doit être faite en

conformité avec les consignes figurant dans

les instructions de service.

– L'appareil doit uniquement être utilisé

pour nettoyer les trottoir et les escaliers

roulantes.

– La sens de fabrication soir être réglée de

cette façon, que le trottoir/l'escalier roulante s'éloignent de l'appareil.

– Pour nettoyer les escaliers roulantes,

l'appareil peut être utilisée que au bout

inférieure de l'escalier roulante.

– L'appareil doit uniquement être équipé

d'accessoires et de pièces de rechange

d'origine.

22 Français

Page 23

Protection de l’environne-

ment

Les matériaux constitutifs de

l’emballage sont recyclables.

Ne pas jeter les emballages

dans les ordures ménagères,

mais les remettre à un système

de recyclage.

Les appareils usés contiennent

des matériaux précieux recyclables lesquels doivent être

apportés à un système de recyclage. Il est interdit de jeter

les batteries, l'huile et les substances similaires dans l'environnement. Pour cette raison,

utiliser des systèmes de collecte adéquats afin d'éliminer les

appareils hors d'usage.

Français 23

Page 24

Eléments de commande et de fonction

1 Guidon de poussée

2 Flexible de vidange d'eau propre

3 Flexible de vidange pour eau sale

4 Fiche secteur

5 Crochet de soulagement de traction

6 Pédale à pied

7 Les roues arrières avec un levier de blo-

cage

8 Couvercle du réservoir d'eau sale

Pupitre de commande

1 Compteur d'heures de service

2 Affichage de la pression de la pompe

3 Interrupteur principal

9 Roues d'avant

10 Réservoir d'eau sale

11 Orifice de remplissage pour réservoir

d'eau propre

12 Pédale pour abaisser/lever la tête des

brosses

13 Levier pour le blocage de la tête de bros-

se

4 Voyant de contrôle "réservoir de l'eau

sale plein"

5 Voyant de contrôle "Surcharge du mo-

teur des brosses"

24 Français

Page 25

Avant la mise en service

Î Eliminer completement l'emballage.

Monter le guidon de poussée

Enlever le produit antigel.

Remarque

A la fabrication, l'appareil était rincé avec

produit antigel. Avant la première mise en

service, le produit antigel doit être eliminé.

Î Remplir 10 litres d'eau propre dans le ré-

servoir d'eau propre.

Î Actionner la pédale à pied.

Î Regler l'interrupteur d'appareil sur net-

toyage de base.

Î Laisser l'appareil en marche, jusqu"à la

pression abaisse sur le manomètre.

Mise en service

Î Poser le guidon de poussée dans les

ouvertures de l'appareil.

Î Fixer le guidon de poussée à l'aide des 4

vis.

Î Fixer l'évent.

Î Accrocher le crochet de soulagement de

traction au guidon de poussée.

Déchargement de la machine

Î Fixer les roues arrières, eliminer les

billots pour le blocage des roues.

Î Quatre planches de fond identifiées de la

palette sont vissées. Dévisser ces planches.

Î Poser les planches sur le bord de la pa-

lette. Orienter les planches de manière à

ce qu'elles reposent en amont des roues

de l'appareil. Fixer les planches à l'aide

des vis.

Î Pousser doucement l'appareil de la ram-

pe.

Préparation du trottoir roulant/de

l'escalier roulante

Danger

Risque de blessure ! L'appareil peut rester

accrochée et peut être emportée par le trottoir roulant/par l'escalier roulante. Contôler,

avant le nettoyage, les trottoirs roulants et le

profil des rainures, s'il y a des déformations

et eliminer des objets coincés. S'assurezvous pour le cas d'urgênce, où se trouve l'interrupteur d'arrêt d'urgênce du trottoir roulant/de l'escalier roulante.

Î Barrer le trottoir roulant/l'escalier roulant

dans un vaste périmètre, aussitôt que se

déroule le nettoyage et les trottoir roulants sont encore humides.

Î Mettre en marche le trottoir roulant/l'es-

calier roulant.

Î S'assurer que le sens de fabrication du

trottoir roulant/l'escalier roulant s'éloigne

de l'appareil.

Préparation de l'appareil

Î Contrôler si les brosses et les rails de

guidage de l'appareil s'ils sont accordés

au produit du trottoir roulant/l'escalier

roulant. En cas de besoin, échanger les

brosses et les rails de guidage.

Français 25

Page 26

Î Ouvrir le couvercle du réservoir d'eau

propre.

Î Remplir eau propre.

Î Remplir détergent.

Seul des détergents autorisés par le

constructeur de l'appareil peuvent être

utilisés.

Î Fermer le couvercle du réservoir d'eau

propre.

Î Placer l'appareil avant le l'estrade du

trottoir roulant/l'escalier roulant.

Fonctionnement

Danger

Risque de blessure !

– Actionner la pédale à pied seulement

avec un pied. L'autre pied doit rester fixe

au sol.

– Tenir le guidon de poussée au moins

avec une mains.

– Des pièces de vêtement ou des bijoux

qui sont amples peuvent être happés de

pièces mobiles du trottoir roulant/l'escalier roulant. Ce pour cela que vous devez retirez les bijoux et porter des

vétements collantes et des chaussures

de sécurité.

Modes de nettoyage

Le temps de nettoyage dépend du degré de

saleté et est divisé en trois modes de nettoyage.

Aspiration de poussières

Aspiration de poussières des trottoir roulants/ des escaliers roulants déjà nettoyés.

Nettoyge d'entretien

Nettoyage des trottoirs roulants/des escaliers roulants qui ne sont pas si sale (en règle géral en périodes courtes et régulières).

Dans cette position, l'appareil travaille avec

une quantité d'eau réduite. La pompe d'eau

travaille.

Nettoyage de base

Nettoyage des trottoirs roulants/des escaliers roulants qui sont très sale (en règle géral lorsque le nettoyage n'était pas effectué

pendant un période plus long). Des zones

trop sales doivent être nettoyées manuellement.

Consignes au nettoyage

– Balayer la saleté grossière manuelle-

ment.

– Eliminer des objets (p.ex. des pierres)

des rainures des trottoirs roulants.

– Nettoyer la face frontal des marches de

l'escalier roulante manuellement.

– Nettoyer les marches en voies chevau-

chentes. Pour cela, retirer l'appareil de

sa position de travail et déplacer à la côté.

– Observer les trottoirs roulants pendant le

nettoyage. Doivent être humides, mais

pas mouiller. Il ne doit pas resté de

mousse.

– Nettoyer avant humide (avec détergent),

ensuite sec (interrupteur de l'appareil sur

aspiration de poussière).

– A la fin rincer avec eau claire, pour elimi-

ner les restes du détergent.

Fonctionnement de nettoyage

Danger

Risque de blessure et de choc électrique!

Poser le cable prolongueur de cette façon

qu'il n'e peut être coincé ou écraissé et qu'il

ne provoque pas un risque de trébuche.

Î Brancher la fiche secteur.

26 Français

Page 27

Î Accrocher l'extrémité de la rallonge com-

me boucle dans le crochet de soulagement de traction.

Î Régler les roues arrières.

Î Poser l'appareil sur l'estrade de façon

que les roues d'avant ne touche pas la

première marche du trottoir roulant/de

l'escalier roulant en marche.

Î Activer la pédale pour abaisser la tête de

la brosse. La tête de la brosse est abaissée et le levier d'arrêt s'enclenche.

Î Actoinner la pédale à pied avec un pied

et bouger l'appareil un peu sur le côté.

L'appareil se centre dans les rainures de

la marche, ensuite un bruit est audible.

Danger

Risque de blessure ! Poser l'appareil seulement sur l'escalier roulant comme il est indiquer en bas. Sinon il y a un risque que

l'appareil est emporté de l'escalier roulant.

En cas de risque, appuyer immédiatement

sur la touche d'arrêt d’urgence de l'escalier

roulant.

La tête de nettoyage doit être poser superficiellement sur l'escalier roulant.

Î Positionner l'interrupteur de l'appareil

sur nettoyage d'entretien ou sur nettoyage de base.

Démarrer l'appareil.

Remarque

Lorsque le réservoir d'eau sale est plein,

l'appareil s'arrête. Pour une nouvelle mise

en marvhe, vider le réservoir d'eau sale et

positionner l'interrupteur de l'appareil brièvement sur "0".

Î Effectuer le nettoyage jusqu'à l'esclaier

roualnt/trottoir roulant en effectué 1 ou 2

rotations. Ensuite poser l'appareil sur la

côté et démarrer le nouveau processus

de nettoyage.

Poser l'appareil sur la côté

Î Mettre l'interrupteur de l'appareil sur "As-

piration de poussière". L'aspiration de

poussière est activée.

Î Laisser abaisser la pression de la pompe

sur 0 bar.

Î Mettre l'interrupteur principal sur "0".

Î Lâcher la pédale à pied.

Î Actionner la pédale pour léver la tête des

brosses La tête des brosses est relevée.

Î Poser l'appareil sur la côté.

Î Activer la pédale pour abaisser la tête de

la brosse. La tête de la brosse est abaissée et le levier d'arrêt s'enclenche.

Î Actionner la pédale à pied et centrer l'ap-

pareil dans les rainures de la marche.

Î Positionner l'interrupteur de l'appareil

sur nettoyage d'entretien ou sur nettoyage de base.

Î A la fin rincer avec eau claire, pour elimi-

ner les restes du détergent.

Français 27

Page 28

Danger

Risque de blessure ! Pour remplir détergent,

tirer l'appareil toujours de la position de travail.

Mise hors service

Terminer le nettoyage

Î Mettre l'interrupteur de l'appareil sur "As-

piration de poussière". L'aspiration de

poussière est activée.

Î Laisser abaisser la pression de la pompe

sur 0 bar.

Î Mettre l'interrupteur principal sur "0".

Î Lâcher la pédale à pied.

Î Activer le levier d'arrêt et la pédale pour

soulever la tête de la brosse La tête de la

brosse est soulevée.

Î Débloquer les roues arrières.

Î Retirer l'appareil de la position de travail

et de l'estrade.

Mettre l'appareil hors tension

Î Retirer le connecteur de la prise.

Entretien et maintenance

Danger

Risque de blessure ! Avant tous les travaux

à l'appareil.

Î Mettre l'interrupteur principal sur "0".

Î Retirer le connecteur de la prise.

Î Régler les roues arrières.

Î Vider et eliminer le reste du détergent.

Î Vider et eliminer l'eau sale.

Nettoyage de l’appareil

몇 Avertissement

Risque d'endommagement! Ne pas laver

l'appareil au jet d'eau et ne jamais utiliser de

détergents agressifs.

Î Nettoyer l'extérieur de l'appareil avec un

chiffon humide et imbibé de détergent

doux.

Î Essuier l'intérieur du réservoir d'eau sa-

le.

Î Nettoyer le tamis à peluches.

Fréquence de maintenance

Basculer l'appareil en position de maintenance.

Pour pouvoir effectuer quelques travaux de

réparation et de maintenance, le dessous

du nettoyer des escaliers roulant doit être

accessible.

Î Vider et eliminer le reste du détergent.

Î Vider et eliminer l'eau sale.

Nettoyer l'intérieur et l'extérieur de l'appa-

Î

reil. Rincer les réservoir avec eau claire.

Î Installer l'appareil uniquement dans des

espaces sans gelée et sur un sol plat et

propre.

Î Régler les roues arrières.

Î Eliminer le barrage du trottoir roulant/de

l'escalier roulant lorsque la zone complet

de travail est séche. Il ya un risque d'accident si le trottoir roulant.l'escalier roulant est mouillé.

28 Français

Î Basculer l'appareil avec une deusième

personne vers l'avant, jusqu'à l'appareil

est poder sur la face frontal du boîtier.

Page 29

Quotidiennement avant l'usage

1

2

Î Contôler le cône de vaporisation des bu-

ses.

Î Contrôler la buse d'aspiration s'il elle est

sale.

Î Contrôler la fonction d'arrêt d’urgence de

la pédale à pied.

Actionner la pédale à pied, positionner

l'interrupteur de l'appareil sur aspiration

de poussière, l'appareil doit être en marche. Lâcher la pédale à pied, l'appareil

doit s'arrête.

La réparation doit être effectuée que par

le service après-vente.

Î Contrôler le positionnement des roues

arrières.

La réparation doit être effectuée que par

le service après-vente.

Î Contrôler l'état d'usure:

Brosses rotatives, brosses d'absorption,

brosses, rails de guidage, flexibles,

stoppeur et roues avant. Faire échanger

le stoppeur et les roues avant en cas de

besoin par le service clientèle seulement.

Î Contrôler le cable d'alimentation et la fi-

che de secteur s'ils sont endommagés

ou cassés. L'échanger doit être effectuée que par le service après-vente ou

par une eléctricien.

Après 100 heures de service

Î Contrôler si les pièces de fixation sont

bien fixées.

Î Contrôler si la courroie de commande

est tendue ou usée (service après-vente).

Travaux de maintenance

Nettoyer le tamis à peluches

Î Dévisser le couvercle avec un tournevis

pour vis à tête six pans creux (Torx).

Remarque

Un tournevis pour vis à tête six pans creux

(Torx) se trouve dans le support du flexible

de vidange d'eau sale.

Î Nettoyer le tamis à peluches.

Î Fixer le couvercle.

Echanger les brosses rotatives et les

brosses d'absorption.

Î Dévisser toutes les 4 vis et retirer le cha-

peua de palier.

Français 29

Page 30

Î Retirer les brosses rotatives (grand) et

les brosses d'absorption (petit) et substituer (faire attention à l'absorption hexagonale!).

Contrôler aussi les buses d'aspiration et

en cas de besoin les échanger ou nettoyer.

Échanger les brosses

Echanger le rail de guidage

Î Dévisser les vis de fixation du support

pour les rails de guidage.

Î Démonter les rails de guidage.

Î Pour la montage des nouveaux rails de

guidage, procéder dans l'ordre inverse.

Faire attention s'ils sont biens fixés.

Contrôler les buses et le filtre pour le détergent.

Î Retirer les brosses et substituer. Pour

cela, poser les brosses d'entrée sur un

rail étroit et les brosses de sortie sur un

rail large.

Nettoyer les buses d'aspiration.

Î Eliminer des impuretés des buses d'as-

piration.

30 Français

Î Dévisser l'écrou raccord. Retirer la buse,

l'anneau de joint et le filtre.

Î Nettoyer la buse ou poser une nouvelle

buse dans l'écrou raccord.

Î Poser l'anneau de joint et le filtre et vis-

ser manuellement l'écrou raccord.

Page 31

Echanger le goëlette

Î Dévisser le goëlette avec un tournevis et

le substituer.

Transport

Danger

Risque de blessure ! Ne pas faire des pentes qui ont plus de 5°. Jamais transporter

l'appareil sur des escaliers roulants/des trottoirs roulants.

Î Régler les roues arrières.

Î Protéger la machine par des sangles ou

des cordes.

Français 31

Page 32

Assistance en cas de panne

Danger

Risque de blessure ! Avant tous les travaux

à l'appareil.

Î Mettre l'interrupteur principal sur "0".

Panne Remède

Le moteur/lapompe ne se

met pas en marche ou s'arrête toujours pendant le

service.

Voyant de contrôle "réservoir de l'eau sale plein"

s'allume.

La pression de travail de

au moins 3 bars n'est pas

attendue.

Les trottoirs roulants nettoyés sont trop mouillés.

Les trottoirs roulants nettoyés ne sont pas nettoyés.

Voyant de contrôle "Surcharge du moteur des

brosses" s'allume.

Vider le réservoir d'eau sale.

Actionner la pédale à pied.

Vider le réservoir d'eau sale.

Si le réservoir d'eau propre est vide, remplir completement (35

litres).

Examiner le système des conduites s'il est étanche. En cas de

besoins, laisser le boucher par le service après-vente.

Contrôler les buses.

Faire nettoyer la pompe par le service après-vente.

Contrôler le degré d'usure des brosses et le cas échéant, les

remplacer.

Contrôler les joints de la couvercle du réservoir d'eau sale, le

cas échéant, les remplacer.

Contrôler le degré d'usure des brosses et le cas échéant, les

remplacer.

Contrôler si les buses et les flexibles d'aspiration sont bouchés, en cas de besoin les nettoyer.

Contrôler si le couvercle du réservoir d'eau sale est bien fermé.

Contrôler, si les bonnes brosses sont montées.

Contrôler si les buses pour le détergent sont bouchés, en cas

de besoin les nettoyer.

Contrôler les joints de la couvercle du réservoir d'eau sale, le

cas échéant, les remplacer.

Contrôler le degré d'usure des brosses et le cas échéant, les

remplacer.

Contrôler le détergent. Contrôler la concentration du détergent.

Contrôler le degré d'usure des brosses et le cas échéant, les

remplacer.

Contrôler si le couvercle du réservoir d'eau sale est bien fermé.

Contrôler, si les bonnes brosses sont montées.

Positionner l'interrupteur de l'appareil sur "0" et ensuite encore

une fois sur la position de service souhaitée. Si le défaut apparaît plusieurs fois, contacter le service après-vente.

Ôter les fils et bandes des brosses.

Î Retirer le connecteur de la prise.

Î Régler les roues arrières.

Î Vider et eliminer le reste du détergent.

Î Vider et eliminer l'eau sale.

32 Français

Page 33

Données techniques

Garantie

1.310-105

Tension nominale V 120

Fréquence Hz 60

Tension de commande V 12

Puissance nominal

(max.)

Puissance du moteur

d'aspiration

Puissance de moteur de

brosses

Pression de la pompe bar 3-4

Consommation d'eau l/h 25-50

Vitesse de rotation des

brosses rotatives

Vitesse de rotation des

brosses d'absorption

Largeur de travail mm 470

Largeur mm 480

Longueur mm 1150

Hauteur avec guidon de

poussée

Hauteur sans guidon de

poussée

Volume du réservoir

d'eau propre/réservoir

d'eau sale

Poids à vide kg approx.

Poids de fonctionnement

Niveau de pression

acoustique (EN 60704-

1)

Valeur globale de vibra-

tions (ISO 5349)

W1360

W800

W650

1/min 870

1/min 1090

mm 1050

mm 760

l 35/35

90

kg approx.

125

dB(A) <75

2

m/s

0,43

Dans chaque pays, les conditions de garantie en vigueur sont celles publiées par notre

société de distribution responsable. Les

éventuelles pannes sur l’appareil sont réparées gratuitement dans le délai de validité de

la garantie, dans la mesure où celles-ci relèvent d'un défaut matériel ou d'un vice de fabrication. En cas de recours en garantie,

adressez-vous à votre revendeur ou au service après-vente agréé le plus proche munis

de votre preuve d'achat.

Accessoires et pièces de re-

change

Danger

Risque de blessure et de choc électrique!

Seul le service après-vente agréé est autorisé à effectuer des travaux de réparation sur

l'appareil.

– Utiliser uniquement des accessoires et

des pièces de rechange autorisés par le

fabricant. Des accessoires et des pièces

de rechange d’origine garantissent un

fonctionnement sûr et parfait de l’appareil.

– Une sélection des pièces de rechange

utilisées le plus se trouve à la fin du

mode d'emploi.

– Plus information sur les pièces de re-

change vous les trouverez sous

www.kaercher.com sous le menu Service.

Français 33

Page 34

Accessoires

Accessoires Type Référence Description

Brosses rotatives, doux

(standard)

Brosses rotatives,dur 5.762-267 Brosses rotatives pour le nettoyage

Brosses d'absorption 5.762-268 Pour soutenir le trasnport d'eau sale

Brosses d'entrée,

bleues

Broses de sortie, bleues Kone 6.369-519

Brosses d'entrée, noires

Brosses de sortie, noi-

res

Brosses d'entrée, ver-

tes

Brosses de sortie, vertes

Brosses d'entrée, blan-

ches

Brosses de sortie, blan-

ches

Grattoir pour les rainures

Set Handpads Kone 6.369-513 Pour un nettoyage manuel des faces

Produit détergent RM 758 Pour le nettoyage manuel.

Produit détergent RM 759 Pour le nettoyage de base (30 kg).

Kone 6.369-509 Brosses pour l'adaptation de l'appa-

OTIS 6.369-510

OTIS 6.369-520

Schindler 6.369-511

Schindler 6.369-521

CNIM 6.369-512

CNIM 6.369-522

Kone und

Schindler

OTIS und

Thyssen

OTIS 6.369-514

Schindler 6.369-515

Thyssen 6.369-516

5.762-266 Brosses rotatives pour le nettoyage

d'entretien (l'appareil besoin 2).

de base, pour des saletés dures

(l'appareil besoin 2).

du trottoir roulant/de l'escalier roulant aux buses d'aspiration (l'appareil besoin de 2).

reil au produit de trottoir roulant/l'escalier roulant (kit avec 2).

6.369-507 Pour un prénettoyage manuel (elimination des pierres, de chewing-gum

6.369-508

et d'autres impuretés).

frontales des marches (kit avec 5

pads verts).

Pour le nettoyage manuel des endroits très sales.

34 Français

Page 35

INSTRUCCIONES IMPOR-

TANTES DE SEGURIDAD

LEA TODAS LAS INSTRUC-

CIONES ANTES DE USAR LA

MÁQUINA

ADVERTENCIA

Para evitar el peligro de incendio, descarga

eléctrica o heridas:

– No se aleje de la máquina mientras esté

enchufada. Saque el enchufe de la base

cuando no la esté usando, y antes del

mantenimiento.

ADVERTENCIA

– PARA EVITAR PELIGRO DE

DESCARGAS ELÈCTRICAS, LA

MÀQUINA SÒLO DEBE EMPLEARSE

EN INTERIORES

– La máquina no es un juguete. Llevar

mucho cuidado si va a utilizarse donde

hay niños.

– La máquina sólo debe emplearse tal

como se describe en este manual. Sólo

deben usarse los accesorios

recomendados por el fabricante.

– No emplearla si el cable o el enchufe

están dañados. Si la máquina no

funciona correctamente, si se ha caído,

si está averiada, si ha permanecido al

exterior o si ha caído al agua, devolverla

al servicio posventa.

– No tirar de la máquina ni alzarla con el

cable, no emplear el cable como manija,

no aprisionarlo con una puerta ni pasarlo

sobre esquinas o bordes agudos. No

pasar la máquina sobre el cable.

Mantener el cable alejado de fuentes de

calor.

– Al desenchufar, no tirar del cable. Para

desenchufar, tomar el enchufe y no el

cable.

– No tocar el enchufe ni la máquina con las

manos mojadas.

– No colocar objetos en las aberturas. No

usar la máquina con las aberturas

obstruidas; éstas deben estar libres de

polvo, pelusa, pelos y cualquier otro

objeto que pueda impedir el paso de

aire.

– Mantener el cabello, la ropa, los dedos y

todas las partes del cuerpo alejadas de

las aberturas y las piezas móviles.

– Apagar la máquina antes de

desenchufarla.

– Llevar mucho cuidado al trabajar en

escaleras.

– No emplearla para recoger líquidos

inflamables o combustibles, p.ej.

gasolina, ni en zonas donde pueda

haber dichos líquidos.

– Es imprescindible que la toma eléctrica

esté debidamente puesta a tierra.

Véanse las Instrucciones de Puesta a

Tierra.

GUARDE ESTAS INSTRUC-

CIONES

INSTRUCCIONES DE PUES-

TA A TIERRA

La máquina debe ser puesta a tierra. Si no

funciona bien, o si se estropea, la puesta a

tierra constituye una vía de menor resistencia para la corriente eléctrica, para disminuir

el peligro de descarga eléctrica. La máquina

está provista de cable con conductor de

puesta a tierra, y enchufe con puesta a tierra. El enchufe debe insertarse en una base

de enchufe adecuada, debidamente instalada y puesta a tierra, conforme a la legislación y las normas válidas en el lugar de

utilización.

ADVERTENCIA

Si el conductor de puesta a tierra de la

máquina está mal conectado, puede haber

peligro de descarga eléctrica. Consulte a un

electricista experto o a un técnico de mantenimiento, si Ud. no sabe con certeza si la

base de enchufe está correctamente puesta

Español 35

Page 36

a tierra. No cambie el enchufe suministrado

con la máquina - no encajará en la base de

enchufe; acuda a un electricista experto.

La máquina está diseñada para emplearla

en un circuito de

120 voltios; tiene un enchufe de puesta a

tierra cuyo aspecto es como se ilustra en la

Figura A. Cerciórese de conectar la máquina a una base de enchufe de la misma configuración que el conector. Con esta

máquina no deben emplearse adaptadores.

CONECTAR SÓLO A UNA

BASE DE ENCHUFE CO-

RRECTAMENTE PUESTA A

TIERRA

1 Enchufe puesto a tierra

2 Caja de enchufe puesta a tierra

3 Pin puesto a tierra

NORMAS Y PROCEDIMIEN-

TOS DE SEGURIDAD DU-

RANTE EL

FUNCIONAMIENTO

Responsabilidad del operario

El operario será responsable de garantizar

un funcionamiento seguro.

El operario deberá estar familiarizado con el

manejo y las funciones de todos los elementos de mando y todos los instrumentos antes

de proceder al manejo de la unidad.

Antes de poner en funcionamiento la unidad, los operarios deberán haber leído el

manual de instrucciones de la unidad parti-

cular de que se trate y estar familiarizados

con él; además, deberán respetar las normas y procedimientos de seguridad que se

describen a continuación.

Antes de poner en funcionamiento una unidad cualquiera, el operario deberá conocer

bien las posibles condiciones inusuales de

funcionamiento que requieren la adopción

de determinadas precauciones especiales o

para las que existen unas instrucciones de

manejo especiales.

Generalidades

Antes de poner en funcionamiento la unidad, ésta deberá encontrarse en la posición

de servicio.

No ponga en marcha ni utilice la unidad ni

ninguna de sus funciones o sus aditamentos

desde un lugar que no sea el concebido

para el operario.

Antes de abandonar la posición del operario:

A pare la unidad por completo;

B si es necesario dejar la unidad en una

pendiente, bloquee las ruedas.

Guarde una distancia segura respecto a los

bordes de las rampas y las plataformas, y

respecto a los de otras superficies de trabajo similares.

No efectúe ampliaciones ni modificaciones

en la unidad.

No bloquee el acceso a las salidas previstas

en caso de incendio, las escaleras o los extintores.

Durante la circulación

Ceda el paso a los peatones y a los vehículos de emergencia, como son las ambulancias y los camiones de bomberos.

Siempre que sea posible, cruce las vías férreas formando un ángulo con ellas. No estacione a menos de 6 ft (1800 mm) de

distancia respecto a los raíles o las vías férreas más cercanos.

Asegúrese de mantener una vista libre de

obstáculos del trayecto a recorrer, respete

las normas de tráfico, tenga cuidado con las

36 Español

Page 37

personas y guarde las distancias de seguridad.

Sean cuales sean las condiciones de circulación, conduzca la unidad siempre a una

velocidad tal que le permita detenerse por

completo de modo seguro.

Durante la conducción, no acceda jamás a

realizar acrobacias o competiciones.

Cuando circule por pisos húmedos o resbaladizos, reduzca la velocidad.

Antes de circular por un muelle o por el tablero de un puente, asegúrese de que dichos elementos estén correctamente

sujetos. Conduzca con precaución y despacio por el muelle y el puente, y no sobrepase

nunca la capacidad nominal de los mismos.

Cuando tenga que efectuar giros, reduzca la

velocidad hasta que sea seguro efectuarlos

conforme al entorno en que esté maniobrando. Realice los giros con suavidad.

Cuidado de la unidad por parte del

operario

Si se descubre la necesidad de reparar la

unidad o se detecta que ésta resulta insegura de alguna manera o que contribuye a

crear condiciones de inseguridad, se debe

informar de inmediato a la autoridad designada por el usuario. Además, la unidad no

deberá volver a utilizarse hasta que se la

haya devuelto a un estado operativo seguro.

Si, durante el funcionamiento, la unidad se

vuelve insegura de alguna manera, se debe

informar de inmediato a la autoridad designada por el usuario. Además, la unidad no

deberá volver a utilizarse hasta que se la

haya devuelto a un estado operativo seguro.

No lleve a cabo reparaciones ni practique

ajuste alguno a no ser que haya sido expresamente autorizado para ello.

TAREAS DE MANTENIMIEN-

TO Y ACONDICIONAMIENTO

Si se descuida el mantenimiento o se practican en la unidad reparaciones, tareas de

acondicionamiento o ajustes en los que no

se respeten los criterios de diseño del fabricante, su manejo puede resultar peligroso.

Por ello, se debe disponer de servicios de

mantenimiento (dentro o fuera de las instalaciones), contar con personal cualificado y

establecer unos modos de proceder detallados.

El mantenimiento y la inspección de la unidad deberán llevarse a cabo respetando las

tareas que se indican a continuación:

A se deben seguir unos esquemas de

mantenimiento, lubricación e inspección

conforme a su planificación; consulte las

recomendaciones del fabricante.

B el mantenimiento, las reparaciones, los

ajustes y las inspecciones de la unidad

sólo podrán ser llevados a cabo por personal cualificado y autorizado; además,

dichas tareas se realizarán siempre de

conformidad con las especificaciones

del fabricante.

Evite las posibles fuentes de peligro de incendio y disponga siempre de extintores en

la zona de trabajo. En la limpieza de las piezas, no use recipientes de combustible

abiertos ni líquidos limpiadores inflamables.

Español 37

Page 38

NORMAS DE SEGURIDAD

CONTRA INCENDIOS

Cuando las condiciones operativas de una

unidad no sean seguras, ésta deberá ponerse fuera de servicio.

En los emplazamientos de la clase I, la clase

II y la clase III está prohibido efectuar reparaciones.

Prevención contra incendios: la unidad se

debe mantener limpia y debe estar razonablemente libre de pelusas, restos de aceite

y grasa. Para limpiar la unidad, se recomienda usar preferiblemente agentes incombustibles. No está permitido emplear líquidos

inflamables [aquellos cuyo punto de inflamación esté en 100°F (37,8°C) o por encima].

Se deben adoptar precauciones adecuadas

al tipo de agente o disolvente empleado en

lo que a la toxicidad, la ventilación y el peligro de incendios respecta.

Visibilidad de la placa de características: las

denominaciones de tipo y las marcas de tipo

de la unidad indicadas en la placa de características no deben cubrirse con pintura que

oscurezca la información identificativa allí

contenida.

No se debe utilizar la unidad en zonas clasificadas.

38 Español

Page 39

Antes de poner en marcha por

primera vez el aparato, lea el

presente manual de instrucciones y siga las

instrucciones que figuran en el mismo. Conserve estas instrucciones para su uso posterior o para propietarios ulteriores.

Índice de contenidos

Instrucciones de seguridad 39

Función 39

Uso previsto 39

Protección del medio ambiente, eliminación

40

Elementos de operación y funcionamiento

41

Antes de la puesta en marcha 42

Puesta en marcha 42

Funcionamiento 43

Puesta fuera de servicio 45

Conservación y mantenimiento 45

Transporte 48

Ayuda en caso de avería 49

Datos técnicos 50

Garantía 50

Accesorios y piezas de repuesto 50

Instrucciones de seguridad

Para el propietario:

Asegúrese, de que todos los usuarios del

aparato estén familiarizados con instrucciones de uso y con las normativas nacionales

sobre seguridad en el trabajo. Los usuarios

tienen que estar formados técnicamente en

el manejo del aparato.

Para usuarios:

Antes de utilizar por primera vez el aparato,

lea y tenga en cuenta el presente manual de

instrucciones y el folleto adjunto relativo a

las indicaciones de seguridad para aparatos

de limpieza con cepillos y aparatos pulverizadores, 5.956-251.

Dispositivos de seguridad

La función de los dispositivos de seguridad

es proteger al usuario y está prohibido ponerlos fuera de servicio y modificar o ignorar

su funcionamiento.

Pedal

Ahora, el aparato sólo se puede arrancar si

se pisa totalmente el pedal. Después de soltar el pedal se para la máquina.

Función

Desde el limpiador de escaleras mecánicas

se aplica detergente líquido (del depósito de

agua limpia) sobre el andén/ escalera mecánica en movimiento. Al hacerlo, los cepillos

de rodillo cepillan en la dirección contraria a

la marcha de las ranuras del andén rodante/

la escalera mecánica. El detergente líquido

sucio se aspira a la vez por los cepillos de

entrada y pasa al depósito de agua sucia del

aparato.

Uso previsto

Utilice el aparato únicamente de conformidad con las indicaciones del presente manual de instrucciones.

– El aparato sólo se puede utilizar para

limpiar andenes rodantes y escaleras

mecánicas.

– Se debe ajustar la dirección de marcha

de la instalación a limpiar de forma que

se mueva en la dirección contraria del

andén rodantes/escalera mecánica.

– Sólo se puede utili8zar el aparato para

limpiar la parte inferior de la escalera

mecánica.

– Sólo está permitido dotar al aparato de

accesorios y piezas de repuesto originales.

– Sólo pueden utilizar el aparato personas

que tengan un peso corporal de al menos 65 kg.

Español 39

Page 40

Protección del medio ambien-

te, eliminación

Los materiales de embalaje son

reciclables. Por favor, no tire el

embalaje al cubo de basura; llé-

velo a un lugar de reciclaje.

Los aparatos viejos contienen

materiales valiosos reciclables

que debieran aprovecharse.

Evite el contacto de baterías,

aceites y materias semejantes

con el medioambiente. Deshá-

gase de los aparatos viejos re-

curriendo a sistemas de

recogida apropiados.

40 Español

Page 41

Elementos de operación y funcionamiento

1 estribo de empuje

2 Manguera de salida de agua limpia

3 Manguera de salida de agua sucia

4 Clavija de red

5 Gancho de relajación de esfuerzos me-

cánicos

6 Pedal