Page 1

RX-8010RBK/ RX-8012RSL

SERVICE MANUAL

AUDIO/VIDEO CONTROL RECEIVER

RX-8010RBK

CATV/DBS VCR 1 TV AUDIO

DVD MUILTIDVD

CD

CDR

TV/DBS VIDEO PHONO

TAPE/MD

VCR 1 VCR 2

DSP

ANALOG/DIGITAL

SURROUND

MODE INPUTON/OFF

LINE DIF.ECT BOOST EFFECT

231

MENU

MIDNIGHT

TEST CTR TONE

MODE

564

ENTER

SUBWFR

L/R BAL*CENTER

SOUND

*

*

7/P

89

REAR L *REAR R

DIGITAL EQ

MUTING

*

*

0 +1010

RETURN FM MODE 100

CATV/DBS

CONTROL

CONTROL

BAL L

*

+-+-+

LEVEL TV VOL

CH/

*

TV/VIDEO

BAL R

*

PLAY

MENU

TEXT

/REW FF/

PAUSE

DISPLAY

SET

REC

PTY–PTY SEARCH–PTY

PAUSE

DISPLAY

MODE

STOP

A/V CONTROL RECEIVER

LIVENESS

VOLUME

CONTROL

RX-8012RSL

FM/AM

USB

SLEEP

ROOMBASS

SIZE

+

-

EXIT

SPEAKERS ON/OFF

SUBWOOFER OUT ON/OFF

PHONES

STANDBY

STANDBY/ON

1

2

FM/AM TUNING FM/AM PRESET FM MODE

DIGITAL

DIGITAL

SURROUND

SURROUND ON/OFF

USB AUDIO

S-VIDEO VIDEO

PUSH OPEN

MEMORY

INPUT

ANALOG/DIGITAL

INPUT ATT

VIDEO

MIDNIGHT MODEDSP MODE

L—AUDIO—R

AUDIO/VIDEO CONTROL RECEIVER

SOUCE NAME

TV SOUND/DBSVIDEOVCR 2VCR 1DVDDVD MULTI

SOUCE NAME

FM / AMUSB AUDIOTAPE / MDCDRCDPHONO

EON TA / NEWS / INFO DISPLAY MODE

DIGITAL

LEVEL

EQ

ADJUST

EFFECT SETTING

CONTROL

DOWN UP

PTY SEARCH

MASTER VOLUME

LINE DIRECT

BASS BOOST

Area Suffix

E

EN

Continental Europe

DIGITAL

Northern Europe

Contents

Safety precautions --------------------------------------------------------1-2

Disassembly method -----------------------------------------------------1-3

Adjustment method -------------------------------------------------------1-9

Self-diagnose function ----------------------------------------------------1-10

Description of major ICs -------------------------------------------------1-12~29

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No.20979

May. 2001

Page 2

http://getMANUAL.com

RX-8010RBK/ RX-8012RSL

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards .

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs m ust be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen pr inted side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

When replacing them, be sure to use the parts of the same type and rating as specified by the manufacturer.

(Except the JC version)

1-2

Page 3

RX-8010RBK/ RX-8012RSL

Disassembly method

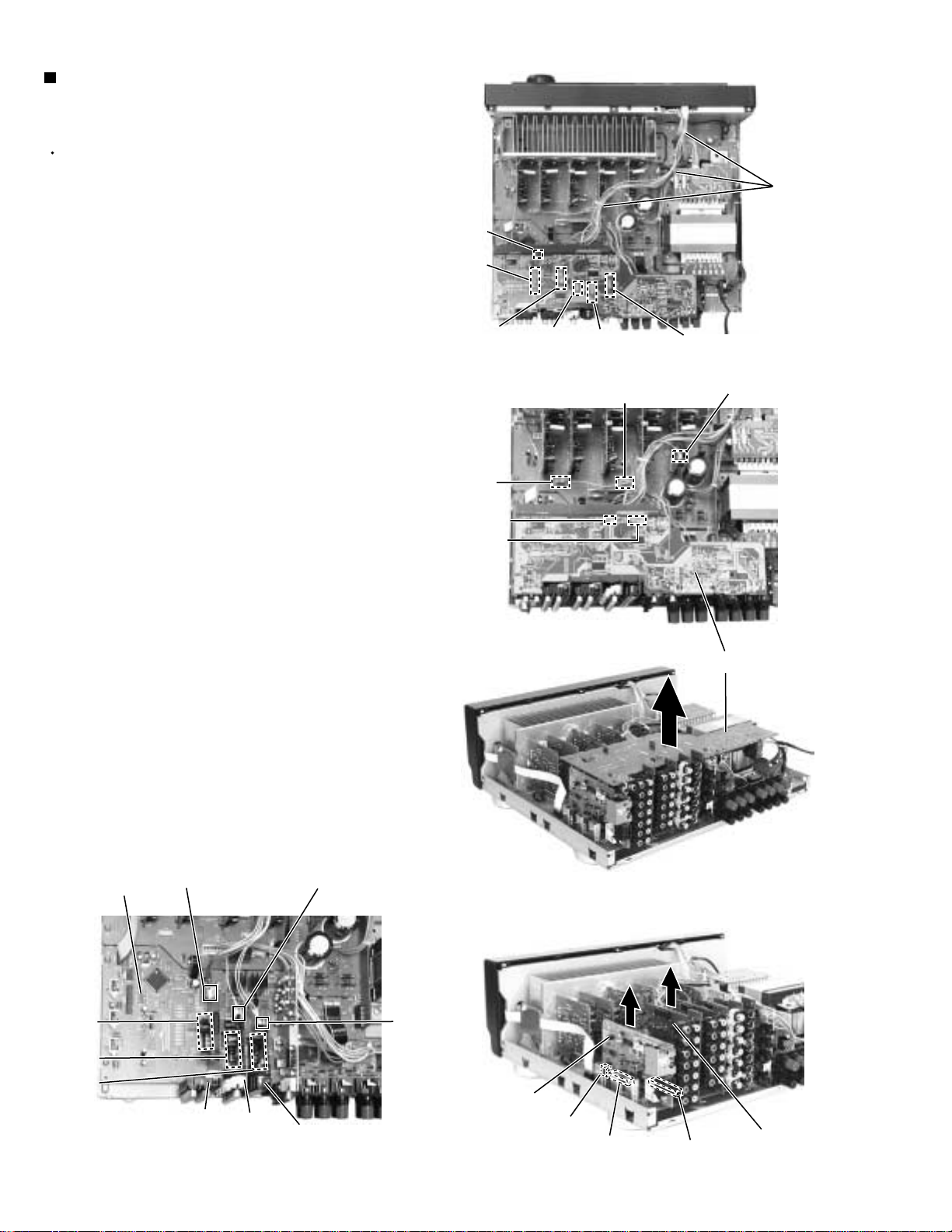

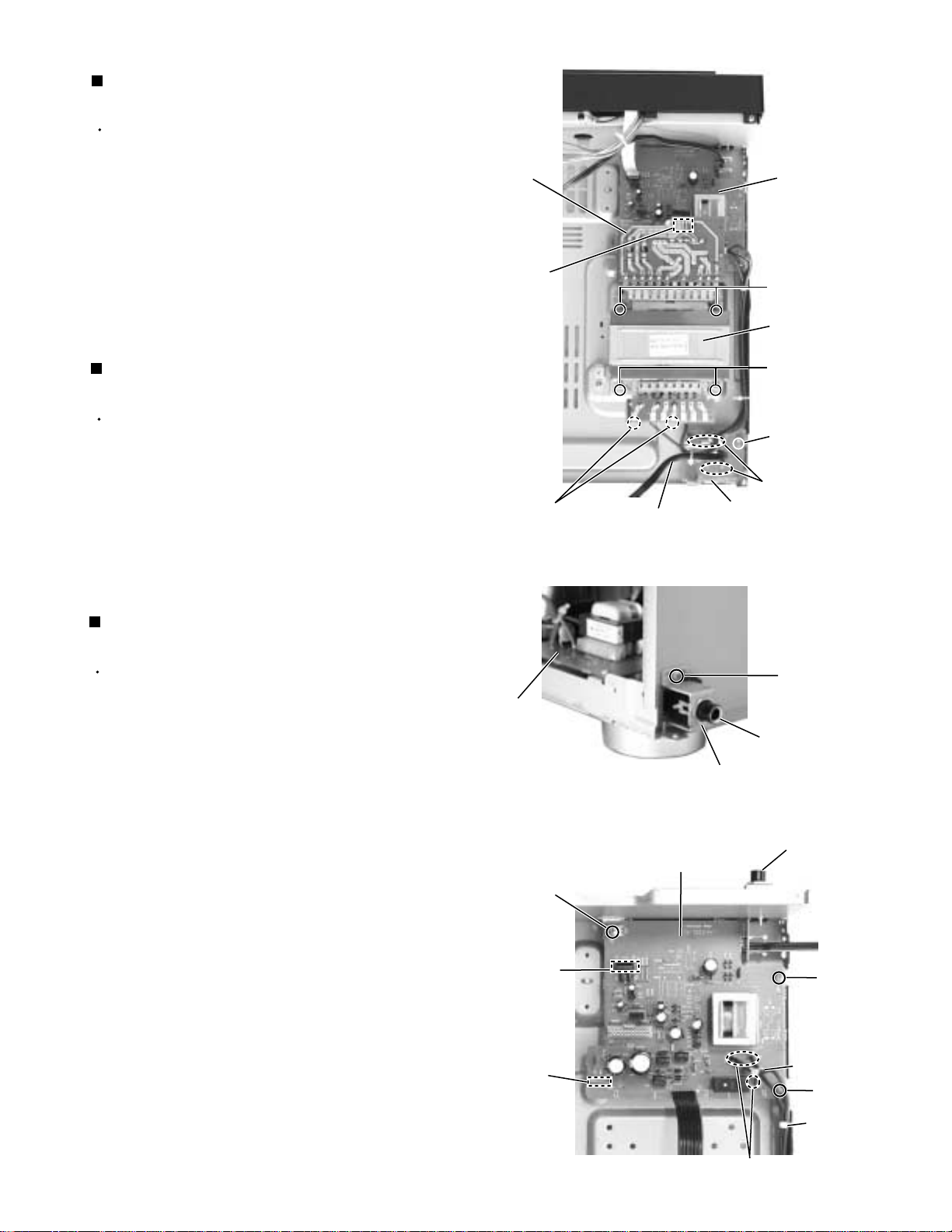

Removing the top cover (See Fig.1)

1.

Remove the four screws A attaching the top cover

on both sides of the body.

2.

Remove the three screws B on the back of the body.

3.

Remove the top cover from behind in the direction of

the arrow while pulling both sides outward.

Removing the front panel assembly

(See Fig.2 and 3)

Prior to performing the following procedure, remove

the top cover.

1.

Disconnect the card wire from connector CN400 on

the audio board and CN402 on the power supply

board in the front panel assembly.

2.

Cut off the tie band fixing the harness.

3.

Remove the three screws C attaching the front

panel assembly.

Top cover

A

Tie band

Main

board

CN400

Audio board

B

2

A

Fig.1

2

Front panel assembly

C

Fig.2

C

CN402

Power

supply

board

4.

Remove the four screws D attaching the front panel

assembly on the bottom of the body. Detach the front

panel assembly toward the front.

Removing the rear panel (See Fig.4)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the power cord stopper from the rear panel

by moving it in the direction of the arrow.

2.

Remove the thirty one screws E attaching the each

boards to the rear panel on the back of the body.

3.

Remove the three screws F attaching the rear panel

on the back of the body.

E

Front panel assembly

D

Fig.3

EE

E

D

Cord stopper

F

F

Rear panel

F

E

Fig.4

1-3

Page 4

RX-8010RBK/ RX-8012RSL

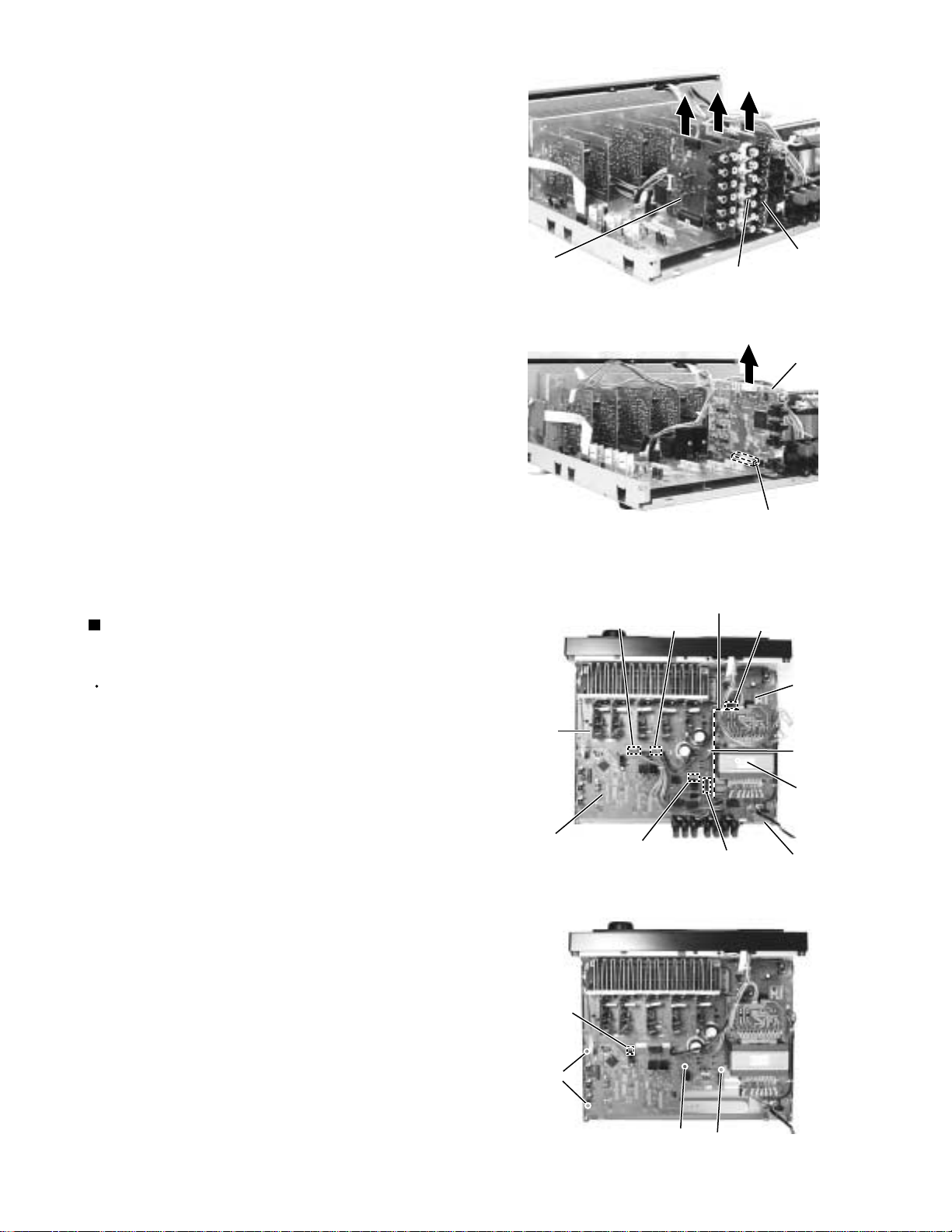

Removing each board connected to the

rear side of the audio board

(See Fig.5 to 11)

Prior to performing the following procedure, remove

the top cover and the rear panel.

1.

Cut off the tie band fixing the harness.

2.

Extract the plastic rivet a, which prevents the PWB

from pulling out, from the audio input board.

3.

Disconnect the connect CN501, CN243, CN205,

CN381, CN361 on the DVD board.

4.

Disconnect the harness from connector CN721,

CN722 and CN723.

5.

Disconnect the tuner board and audio board from

connector CN101, CN102 and CN301 on the audio

board.

Plastic

rivet a

CN361

CN381

CN205

CN243

Fig.5

CN721

Tie band

CN501

CN722

6.

Pull out the video audio board, video board, S-video

board.

7.

Disconnect the DSP board from connector CN601 on

the audio board.

Audio

board

CN416

CN206

CN723

CN731

CN732

Fig.6

DVD board

Fig.7

1-4

CN303

CN201

CN241

Video audio

board

Video

board

Fig.9

S Video

board

CN244

Tuner

board

CN102

CN101

Fig.8

CN301

Audio input

board

Page 5

RX-8010RBK/ RX-8012RSL

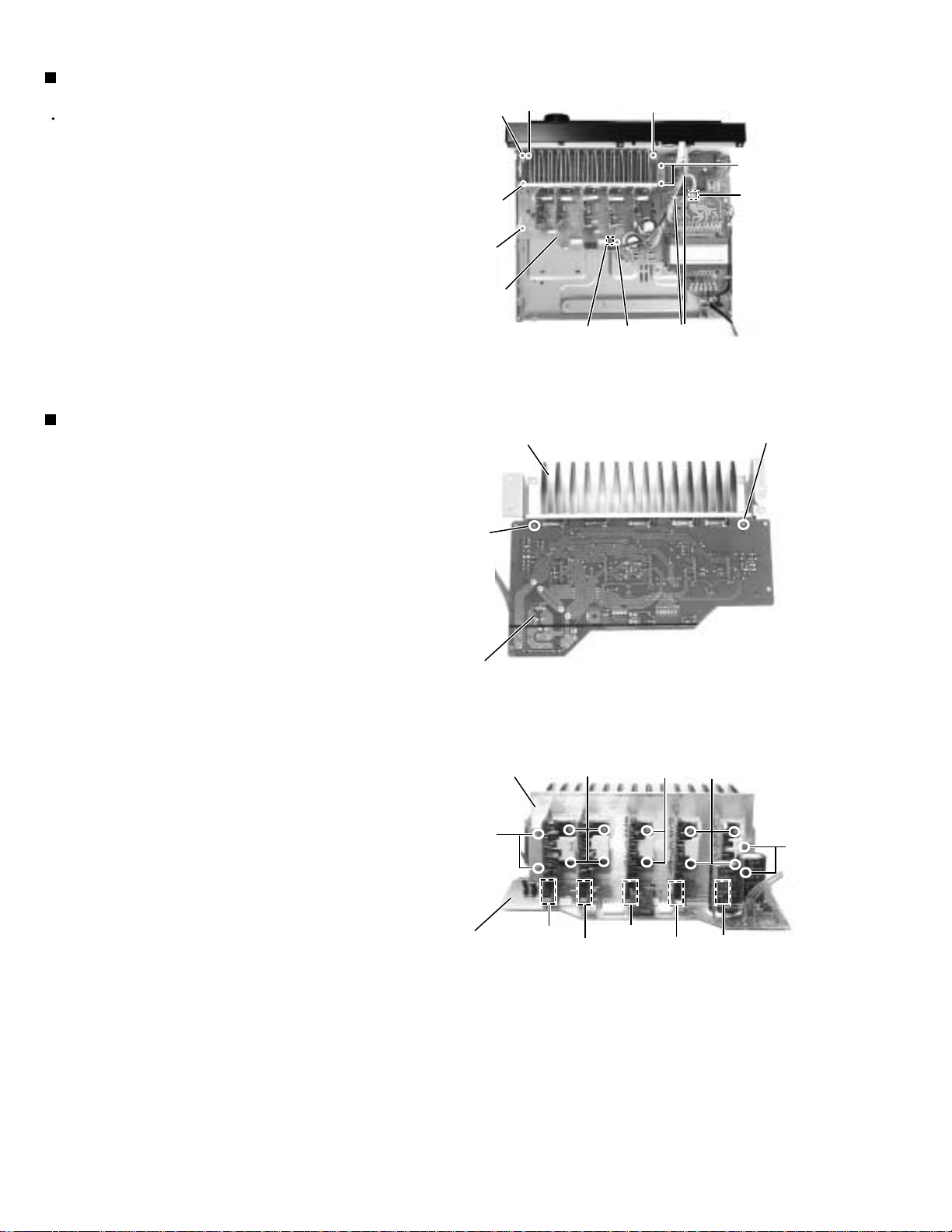

Removing the audio board

(See Fig.12 and 13)

Prior to performing the following procedure, remove

the top cover and the rear panel.

1.

Disconnect the harness from connector CN813 and

CN814 on the main board.

Video audio

board

Main

board

CN814

Fig.10

Fig.11

CN813

Video

board

CN601

Relay board

CN71

S Video

board

DSP board

power

supply

board

Tie band

2.

Disconnect the card wire from connector CN931 and

CN932 on the audio board.

3.

Cut off the tie band fixing the harness.

4.

Disconnect the relay board from the audio board and

the power supply board. (CN71,CN81)

5.

Disconnect the card wire from connector CN831 on

the main board.

6.

Remove the three screws G attaching the audio

board assembly.

7.

Remove the screw H attaching the audio board

assembly.

Audio board

CN831

G

CN931/ 932

Fig.12

Fig.13

G

CN81

H

Power

transformer

Power / Fuse

board

1-5

Page 6

RX-8010RBK/ RX-8012RSL

Removing the main board (See Fig.14)

Prior to performing the following procedure, remove

the top cover, the rear panel and audio board.

I

J

I

1.

Cut off the tie band fixing the harness.

2.

Disconnect the harness from connector CN811 on

the power supply board respectively.

3.

Disconnect the harness from connector CN881 on

the main board.

4.

Remove the four screws I and the two screws J

attaching the main board.

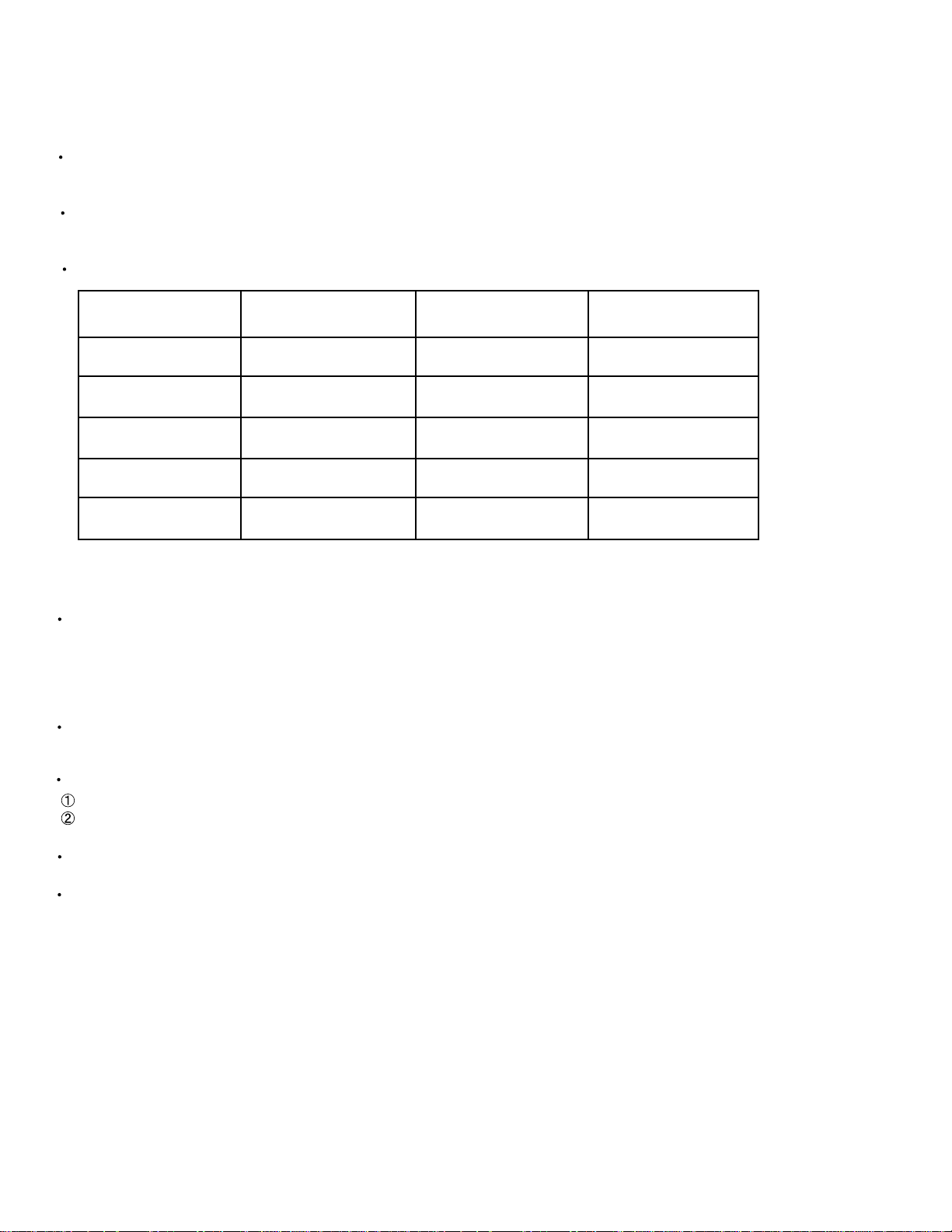

Removing the Heat sink

(See Fig.15 and 16)

1.

Remove the two screws L' attaching the heat sink

from the rear side of main board.

2.

Disconnect the connect CN701, CN702, CN703,

CN705 and CN706 on the main board.

3.

Remove the ten screws K and four screws L

attaching the heat sink.

J

I

Main

board

Heat sink

L'

CN881

I

Fig.14

J

CN811

Tie band

L'

Main board

rear side

Heat sink

L

Main board

CN706

K

CN705

Fig.15

CN702

Fig.16

K

CN701

K

L

CN703

1-6

Page 7

RX-8010RBK/ RX-8012RSL

Removing the power transformer

(See Fig.17)

Prior to performing the following procedures, remove

the top cover.

1.

Unsolder the two harnesses connected to the power

transformer.

2.

Disconnect the harness from connector CN55 and

CN56 on the power transformer board.

3.

Remove the four screws M attaching the power

transformer.

Power

transformer

board

CN55/

CN56

Power

supply

board

M

Power

transformer

Removing the power / fuse board

(See Fig.17)

Prior to performing the following procedure, remove

the top cover and the rear panel.

1.

Remove the screw N attaching the power / fuse

board.

2.

Unsolder the power cord and other harnesses

connected to the power / fuse board.

Removing the power supply board

(See Fig.18 and 19)

Prior to performing the following procedure, remove

the top cover and the front panel.

1.

Remove the screws b fixing a bonding ground.

2.

Remove the one nut attaching the headphone jack of

the power supply board on the front side of the body.

3.

Disconnect the card wire from connector CN402 on

the power supply board.

4.

Remove the three screws O attaching the power

supply board and pull out the power supply board

from the front bracket backward.

Power

supply

board

Solder

O

Power cord

Fig.17

Fig.18

Power supply

board

M

N

Solder

Power / fuse board

b

Headphone jack

Nut

Headphone jack

5.

Unsolder the three harnesses connected to the

power supply board.

CN402

Hook

Fig.19

O

Tie band

O

Tie band

Solder

1-7

Page 8

RX-8010RBK/ RX-8012RSL

Removing the system control board /

power switch board (See Fig.20 to 22)

Prior to performing the following procedure, remove

the top cover and the front panel assembly.

1.

Pull out the volume knob on the front side of the front

panel and remove the nut attaching the system

control board.

2.

Remove the two screws P attaching the power

switch board.

3.

Remove the two screws Q attaching the switch

board.

4.

Remove the cords from the three hooks a.

5.

Remove the eight screws R attaching the system

control board on the back of the front panel.

6.

On the back of the front panel, release the four joints

by pushing the joint tabs inward.

Remove the operation switch panel toward the front.

Operation switch panel

Switch

board

R

Q

Fig.20

Front panel assembly

Nut

Volume knob

Cords

R

Power switch

board

R

P

7.

Disconnect the harness from connector CN420 and

CN422 on the system control board.

8.

Release the two hooks b attaching the system

control board.

Matters that require attention during

replacement of IC400 (See Fig.24 and 25)

In case where there is a resistance array:

Both onetime IC and mask IC can be used

In case where there is no resistance array:

Only mask IC can be used

Joint

CN420

Joint

Fig.21

Hook b

Fig.22

System control board reverse side

Fig.24

Joint

System control board

Hook b

IC400

Joint

Hook a

CN422

1-8

Resistance array

System control board top view

Fig.25

Page 9

RX-8010RBK/ RX-8012RSL

Adjustment method

Tuner section

1.Tuner range

FM 87.5MHz~108.0MHz

AM(MW) 522kHz~1629kHz

(LW) 144kHz~288kHz

Power amplifier section

Adjustment of idling current

Measurement location B2204-B2205(Lch) , B2213-2214(Rch)

Adjustment part VR787(Lch) , VR788(Rch)

Attention

This adjustment does not obtain a correct adjustment value immediately after the amplifier is

used (state that an internal temperature has risen).

Please adjust immediately after using the amplifier after turning off the power supply of the

amplifier and falling an internal temperature.

<Adjustment method>

1.Set the volume control to minimum during this adjustment.(No signal & No load)

2.Set the surround mode OFF.

2.Turn VR787 and VR788 fully counterclockwise to warm up before adjustment.

If the heat sink is already warm from previous use the correct adjustment can not be made.

3.For L-ch,connect a DC voltmeter between B2204 and B2205 (Lch)

And,connect it between B2213 and B2214(Rch).

4.30 minutes later after power on, adjust VR787 for L-ch, or VR788 for R-ch so that the DC voltmeter

value has 1mV~10mV.

* It is not abnormal though the idling current might not become 0mA even if it is finished to turn variable

resistance (VR787,VR788) in the direction of counterclockwise.

Heat sink

B2213, B2214

VR788 (Rch)

VR787 (Lch)

B2204, B2205

1-9

Page 10

RX-8010RBK/ RX-8012RSL

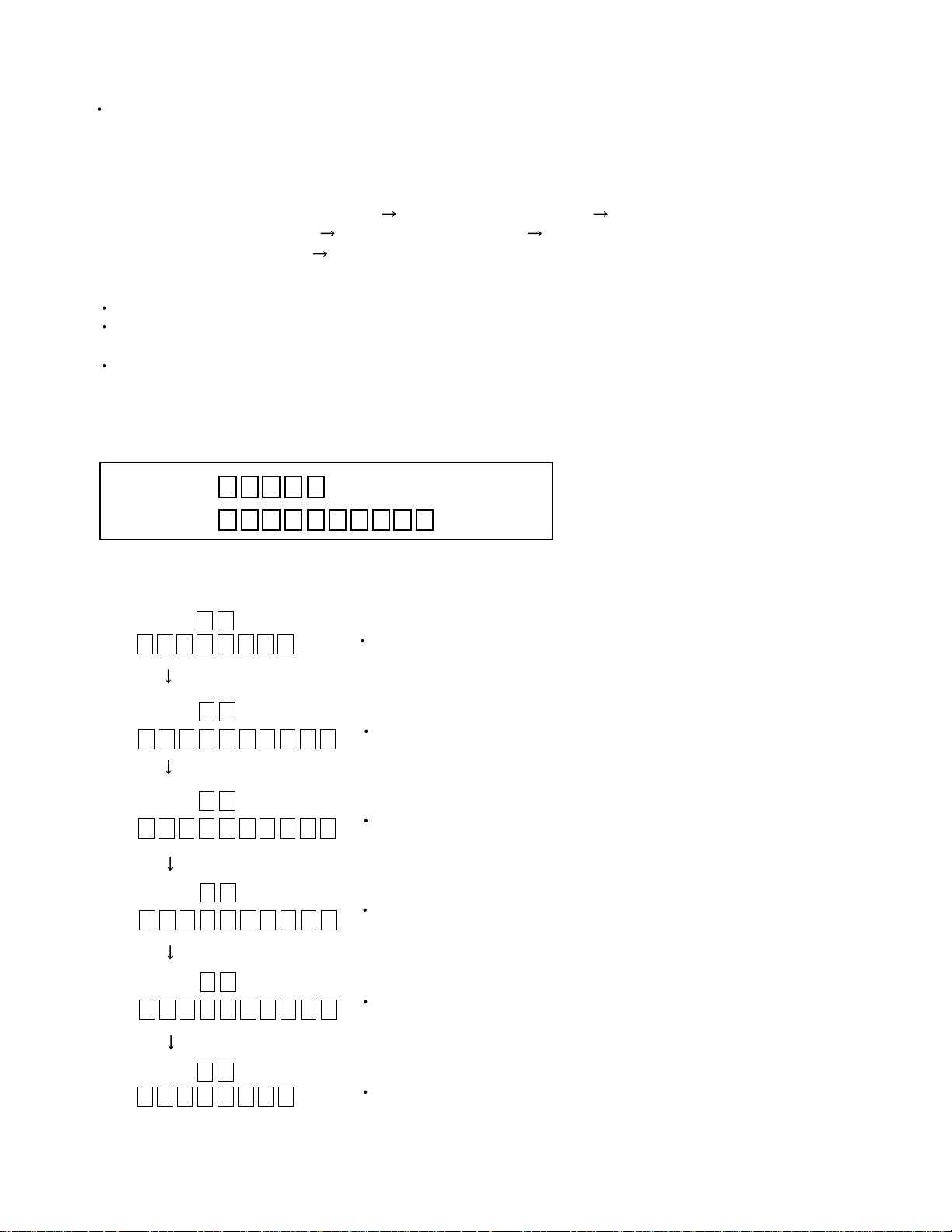

Self-diagnose function

1. Detection of abnormal power supply and voltage

When the power is turned ON, if an abnormality is detected during the signal input at the A/D port (IC901,

pin 2-5, 7) for one second continuously, the status will become STANDBY mode immediately.

When the power is turned ON again, detection of abnormal power supply and voltage will not be carried out

during the first 4 seconds.

Given below is a list of threshold values at the detection of abnormalities.

Pin 2

Micro-computer+5V

Pin 3

Digital+5V

Pin 4

Analog+5V

Pin 5

+12V

Pin 7

Tuner+9V

At abnormal state

(Low voltage)

Analog value

0 - 2.2V

Analog value

0 - 2.2V

Analog value

0 - 2.2V

Analog value

0 - 2.2V

Analog value

0 - 2.2V

At normal state

Analog value

2.2 - 2.8V

Analog value

2.2 - 2.8V

Analog value

2.2 - 2.8V

Analog value

2.2 - 2.8V

Analog value

2.2 - 2.8V

At abnormal state

(High voltage)

Analog value

2.8 - 5.0V

Analog value

2.8 - 5.0V

Analog value

2.8 - 5.0V

Analog value

2.8 - 5.0V

Analog value

2.8 - 5.0V

2. Initial setting on ship

To gain the initial setting on ship, put the power plug in the socket while pressing DOWN key and UP key

together simultaneously, then turn the power ON.

3. Test mode

To enter the test mode, put the power plug in the socket while pressing EFFECT key and UP key together

simultaneously, then turn the power ON.

Workings of test mode:

All FLs are turned ON for 3 seconds. (the FLs, which are divided in two groups, are turned ON alternatively)

Faster volume UP/DOWN operation can be achieved with the remote controller.

When the power is turned OFF, the test mode will be released.

The FL display returns to normal after the three seconds. Then the STANDBY LED is turned ON (flashing

ON and OFF for each one second) to show the present status being a test mode.

1-10

Page 11

RX-8010RBK/ RX-8012RSL

4. Self-diagnose

To enter the self-diagnose mode, put the power plug in the socket while pressing SETTING key and UP key

together simultaneously, then turn the power ON. With the UP/DOWN key operation, DSP microcomputer,

ROM No.of system microcomputer as well as working status of DSP can be displayed for five seconds.

While the working status is being displayed, the followings items can be switched with the UP/DOWN key

operation.

VERSION of system microcomputer Local microcomputer CH0

Local microcomputer CH01 Local microcomputer CH2

Local microcomputer CH3 Local microcomputer CH4

When the power is turned OFF, the self-diagnose mode will be released.

During the self-diagnose mode, the STANDBY LED is turned ON .

(flashing ON for one second then OFF for three seconds)

FL transient display will be carried out as follows. When the transient display is not carried out,

normal display/workings are carried out.

FL Display

S 0 0 1 1

2 0 0 0 1 2 0 9 0 0

D 0 0

D 0 1

D 0 2

Upper 1 2 3 4 5 digits

Lower 1 2 3 4 5 6 7 8 9 10 digits

Information on VERSION of system microcomputer (IC901)

Example : VER1.1 2000/12/9

Display of communication information on DSP microcomputer (IC581)

Display of communication information on DIR AK4112A (IC551)

Display of communication information on DSP XCA56367 (IC501)

D 0 3

D 0 4 1 1

2 0 0 0 1 2 0 9 0 0

Display of communication information on CODEC AK4527 (IC571)

Information on VERSION of DSP microcomputer (IC581)

Example :VER1.1 2000/12/9

1-11

Page 12

RX-8010RBK/ RX-8012RSL

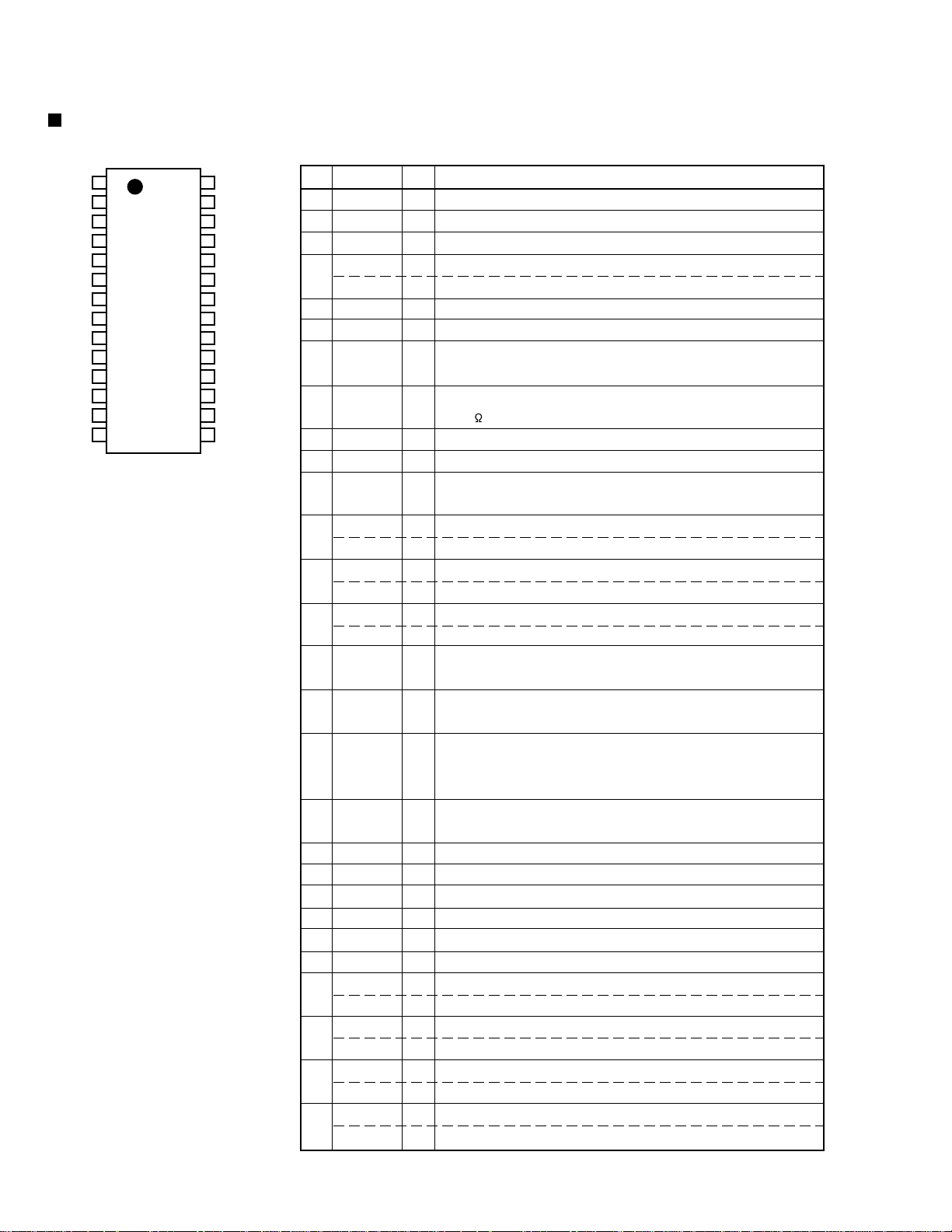

Description of major ICs

AK4112AVF (IC551) : Digital audio receiver

1.Pin layout

DVDD

DVSS

TVDD

V/ TX

XTI

XTO

PDN

R

AVDD

AVSS

RX1

RX2/ DIF0

RX3/ DIF1

RX4/ DIF2

2.Pin function

Function

Pin Name

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

CM0/ CDTO

CM1/ CDT1

OCKS1/ CCLK

OCKS0/ CSN

MCKO1

MCKO2

DAUX

BICK

SDTO

LRCK

ERF

FS96

P/ SN

AUTO

No.

1

2

3

4

5

6

7

8

9

10

11

12

DVDD

DVSS

TVDD

V

TX

XTI

XTO

PDN

R

AVDD

AVSS

RX1

DIF0

RX2

DIF1

13

RX3

DIF2

14

RX4

AUTO

15

P/S

16

FS96

17

ERF

18

LRCK

19

SDTO

20

BICK

21

DAUX

22

MCK02

23

MCK01

24

OCKS0

25

CSN

OCKS1

26

CCLK

CM1

27

CDTI

CM0

28

CDTO

I/O

Digital power supply pin, 3.3V

Digital ground pin

Input buffer power supply pin, 3.3V or 5V

Validity flag output pin in Parallel Mode

O

Transmit channel (through data) output pin in Serial Mode

O

X'tal input pin

I

X'tal output pin

O

Power-down mode pin

I

When "L", the AK4112A is powerd-down and reset.

External resistor pin

18k +/-1% resistor to AVSS externally.

Analog power supply pin

Analog ground pin

Receiver channel 1

I

This channel is selected in Parallel Mode or default of Serial Mode.

Audio data interface format 0 pin in Parallel Mode

I

Receiver channel 2 in Serial Mode

I

Audio data interface format 1 pin in Parallel Mode

I

Receiver channel 3 in Serial Mode

I

Audio data interface format 2 pin in Parallel Mode

I

Receiver channel 4 in Serial Mode

I

Non-PCM detect pin

O

"L" : No detect, "H" : Detect

Parallel/ Serial select pin

I

"L" : Serial Mode, "H" ; Parallel Mode

96kHz sampling detect pin

O

(RX Mode) "H" : fs=88.2kHz or more, "L" fs=54kHz or less.

(X'tal Mode) "H" : XFS96=1, "L" : XFS96=0.

Unlock & parity error output pin

O

"L" : No error, "H" : Error

Output channel clock pin

I/O

Audio serial data output pin

O

Audio serial data clock pin

I/O

Auxiliary audio data input pin

I

Master clock #2 output pin

O

Master clock #1 output pin

O

Output clock select 0 pin in Parallel Mode

I

Chip select pin in Serial Mode

I

Output clock select 1 pin in Parallel Mode

I

Control data clock pin in Serial Mode

I

Master clock operation Mode pin0 in Parallel Mode

I

Control data input pin in Serial Mode

I

Master clock operation Mode pin1 in Parallel Mode

I

Control data output pin in Serial Mode

O

1-12

Note 1 : All input pins except internal pull-down pins should not be left floating.

Page 13

RX-8010RBK/ RX-8012RSL

AK4527 (IC571) : A/D,D/A Converter

1.Pin layout

CDTO

CDTI

CCLKCSPIS

XTO

XTI

AVSS

AVDD

VREFH

VCOM

2.Block diagram

LIN+

LIN-

SDOS

OCKS

MIS

BCLK

LRCK

SDTI1

SDTI2

SDTI3

SDTO

DAUX

DFS

4443424140393837363534

1

2

3

4

5

6

7

8

9

10

11

1213141516171819202122

DEM1

DEM0

MCKO

DVDD

ADC

DVSSPDICkS2

HPF

ICKS1

ICKS0

CAD1

Audio

I/F

33

32

31

30

29

28

27

26

25

24

23

CAD0

VREFL

RIN+

RINLIN+

LINROUT1

LOUT1

ROUT2

LOUT2

ROUT3

LOUT3

RIN+

RIN-

LOUT1

ROUT1

LOUT2

ROUT2

LOUT3

ROUT3

HPF

DA TT

DA TT

DA TT

DA TT

DA TT

DA TT

LRCK

BICK

MCLK

SDOUT

SDIN1

SDIN2

SDIN3

LPF

LPF

LPF

LPF

LPF

LPF

ADC

DAC

DAC

DAC

DAC

DAC

DAC

Block Diagram (DIR and AC-3) DSP are external parts)

DAUX

Format

Converter

SDOS

SDTO

SDTI1

SDTI2

SDTI3

1-13

Page 14

RX-8010RBK/ RX-8012RSL

3. Pin function

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Pin name

SDOS

OCKS

MIS

BICK

LRCK

SDTI1

SDTI2

SDTI3

SDTO

DAUX

DFS

DEM1

DEM0

MCKO

DVDD

DVSS

PD

ICKS2

ICKS1

ICKS0

CAD1

CAD0

LOUT3

ROUT3

LOUT2

ROUT2

LOUT1

ROUT1

LINLIN+

RINRIN+

I/O

SDTO Source select pin

I

Function

"L" : Internal ADC output, "H" : DAUX input

ORed with serial control register if P/S="L".

MCKO Clock frequency select pin

I

"L" : MCLK, "H" : MCLK/2. ORed with serial control register if P/S= "L".

Connect to GND

I

Audio serial data clock pin

I

Input/Output channel clock pin

I/O

DAC1 Audio serial data input pin

I

DAC2 Audio serial data input pin

I

DAC3 Audio serial data input pin

I

Audio serial data output pin

O

AUX Audio serial data input pin

I

Double speed sampling mode pin

I

"L" : Normal speed, "H" : Double speed, the ADC is powered down.

ORed with serial control register if P/S="L".

De-emphasis pin

I

ORed with serial control register if P/S="L"

De-emphasis Pin

I

ORed with serial control register if P/S="L"

Master clock output pin

O

Digital power supply pin

Digital ground pin

Power-down & Reset pin

I

When "L", the AK4527 is powered-down and the control registers are reset

to default state. If the state of CAD0-1 changes, then the AK4527

must be reset by PDN.

Input clock select 1 pin

I

Input clock select 1 pin

I

Input clock select 0 pin

I

Chip address pin

I

Used during the serial control mode.

Chip address pin

I

Used during the serial control mode.

Lch #3 analog output pin

O

Rch #3 analog output pin

O

Lch #2 analog output pin

O

Rch #2 analog output pin

O

Lch #2 analog output pin

O

Rch #1 analog output pin

O

Lch analog negative Input Pin

I

Lch analog positive Input Pin

I

Rch analog negative Input Pin

I

Rch analog positive Input Pin

I

AK4527(1/2)

1-14

Page 15

RX-8010RBK/ RX-8012RSL

3.Pin function

No.

33

34

35

36

37

38

39

Pin Name

VREFL

VCOM

VREFH

AVDD

AVSS

XTI

XTO

MCKI

40

41

P/S

DIF0

CS

42

DIF1

CCLK

43

LOOP0

CDTI

44

LOOP1

CDTO

I/O

I

O

I

-

I

O

I

I

I

I

I

I

I

I

I

O

AK4527(2/2)

Function

Negative voltage reference Input pin, AVSS

Common voltage output pin,AVDD/2

Large external capacitor around 2.2uF is used to reduce power-supply noise

Positive voltage reference input pin,AVDD

Analog power supply pin

Analog ground pin

X'tal input pin

X'tal output pin if XTS="H"

External master clock input pin if XTS="L"

Parallel/Serial select pin

"L" : Serial control mode, "H" : Parallel control mode

Audio data interface format pin in parallel mode

Chip select pin in serial mode

Audio data interface format pin in parallel mode

Control data clock pin in serial mode

Loop back mode pin in parallel mode

Enables digital loop-back from ADC to 3 DACs.

Control data input pin in serial mode

Loop back mode pin in parallel mode

Enable all 3 DAC channels to be input from SDTII.

Control data output pin in serial mode

1-15

Page 16

RX-8010RBK/ RX-8012RSL

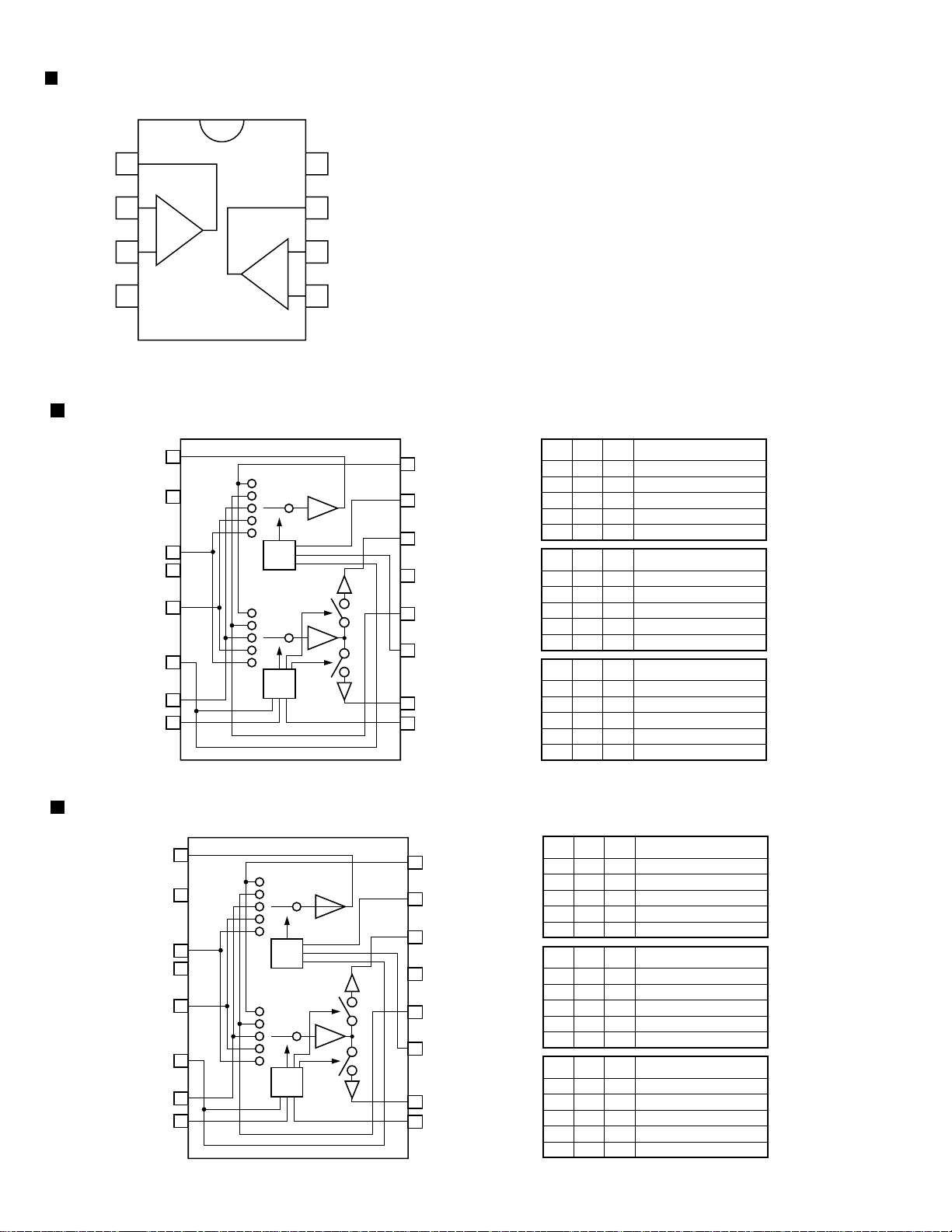

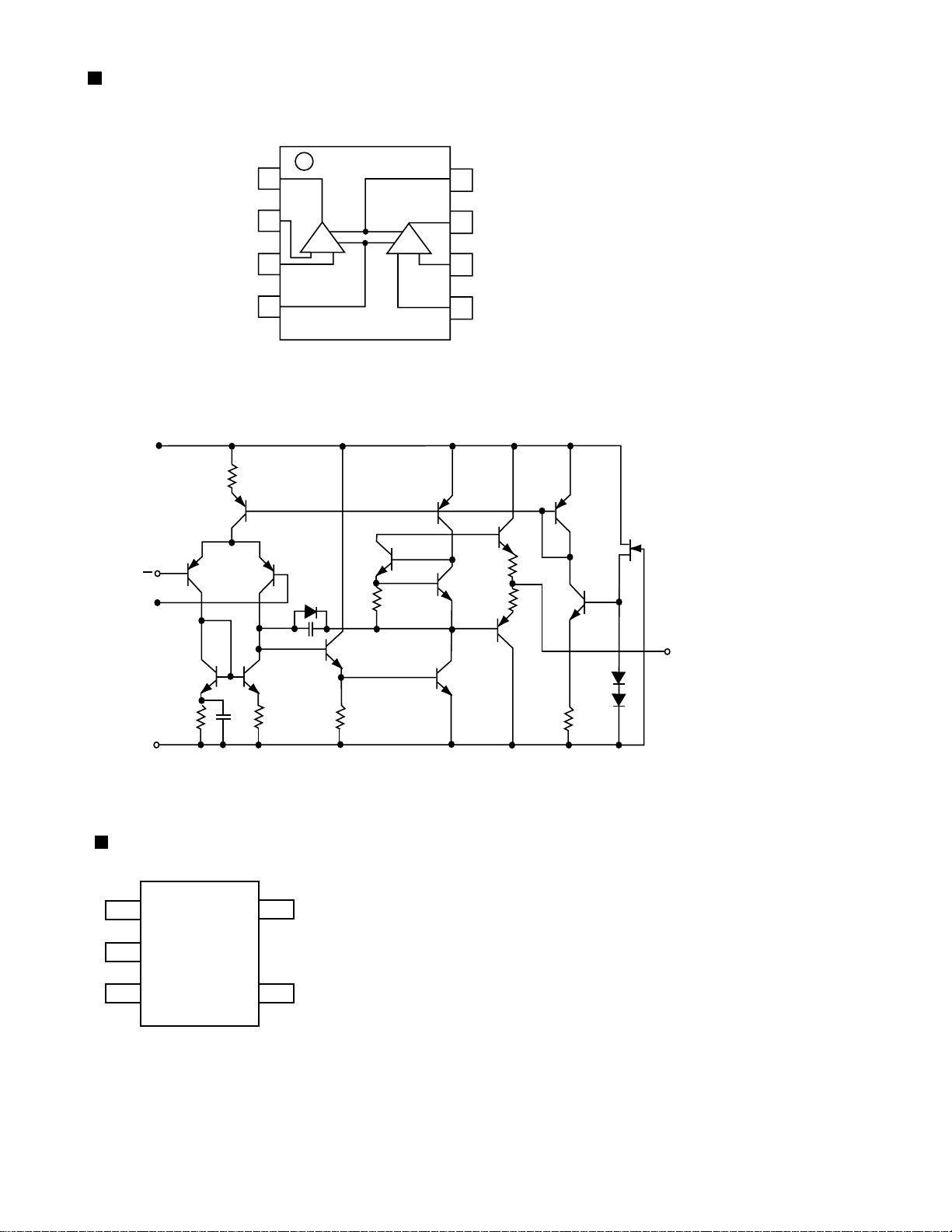

BA15218F (IC303, IC304, IC372, IC385, IC386, IC521, IC522, IC523, IC524, IC525, IC526,

IC527, IC528, IC529) : Op amp.

1OUT1

2-IN1

-

8

7

V

CC

OUT2

1

3+IN1

+

-

-IN2

6

2

EE

4

+

5V

+IN2

BA7625 (IC201, IC242) : Video selector

MONITOR OUT

GND

IN5

GND

IN4

CTL E

IN3

CTL D

1

2

3

4

5

6

7

8

logic

logic

16

15

14

13

12

11

10

11

IN1

CTL A

VOUT 1

CC

V

IN2

CTL B

VOUT 2

CTL C

A B E MONITOR OUT

LL

HL

LH

H H L IN4

H H H IN5

*

*

*

IN1

IN2

IN3

C D E VOUT1

LL

HL

LH

H H L IN4

H H H IN5

*

*

*

-IN2

IN3

C D E VOUT2

LL

HL

LH

H H L IN4

H H H IN5

*

*

*

IN1

--

IN3

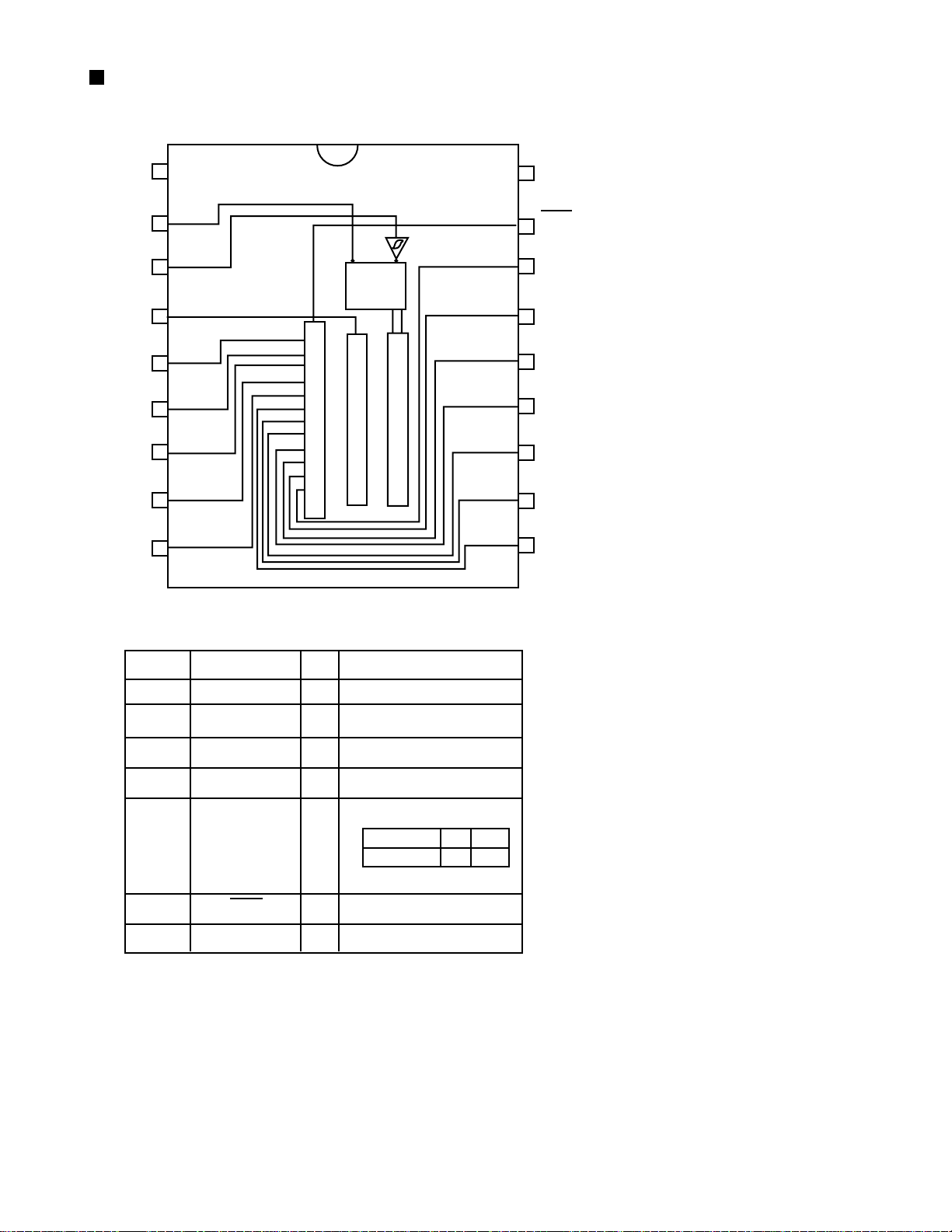

BA7626 (IC241) : Video selector

MONITOR OUT

1-16

GND

IN5

GND

IN4

CTL E

IN3

CTL D

1

2

3

4

5

6

7

8

logic

logic

16

15

14

13

12

11

10

11

IN1

CTL A

VOUT 1

V

CC

IN2

CTL B

VOUT 2

CTL C

A B E MONITOR OUT

LL

HL

LH

H H L IN4

H H H IN5

*

*

*

IN1

IN2

IN3

C D E VOUT1

LL

HL

LH

H H L IN4

H H H IN5

*

*

*

-IN2

IN3

C D E VOUT2

LL

HL

LH

H H L IN4

H H H IN5

*

*

*

IN1

--

IN3

Page 17

RX-8010RBK/ RX-8012RSL

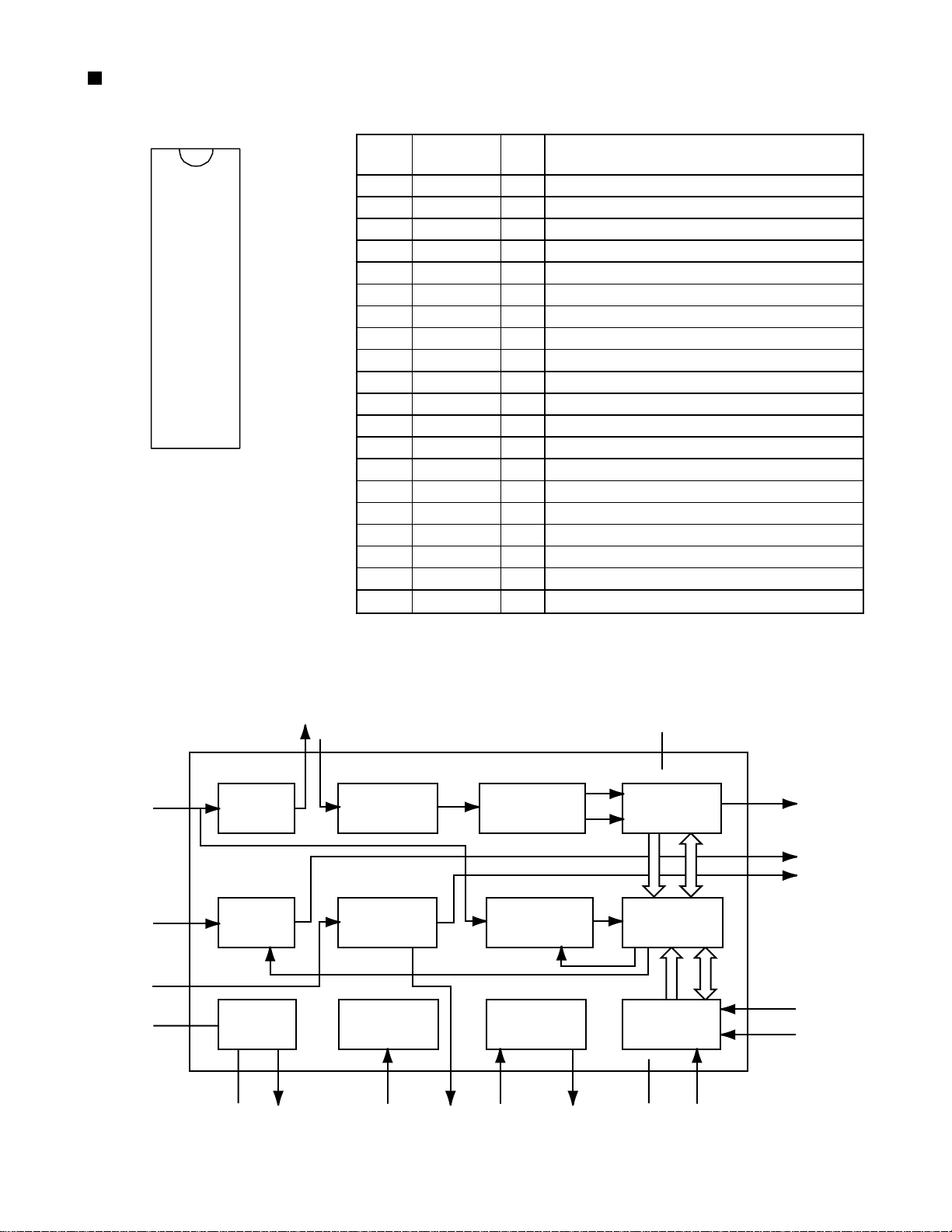

BU2092(IC402) : Port expander

1.Terminal Layout

Vss

DATA

CLOCK

LCK

Q0

Q1

Q2

Q3

Q4

1

2

3

4

5

6

7

8

9

CONTROL

CIRCUIT

12BIT SHIFT RESISTER

12BIT STRAGE RESISTER

OUTPUT BUFFER(OPEN DRAIN)

17

16

15

14

13

12

11

10

18

Vdd

OE

Q11

Q10

Q9

Q8

Q7

Q6

Q5

2.Pin Function

Pin No.

1

2

3

4

5~16

17

18

Symbol

Vss

DATA

CLOCK

LCK

Q0~Q11

OE

Vdd

I/O

I

I

I

O

I

-

Function

Connect to GND

Serial Data input

Shift Clock of Data

Latch Clock of Data

Parallel Data Output

Latch Data L H

OUTPUT ON OFF

Output Enable

Power Supply

1-17

Page 18

RX-8010RBK/ RX-8012RSL

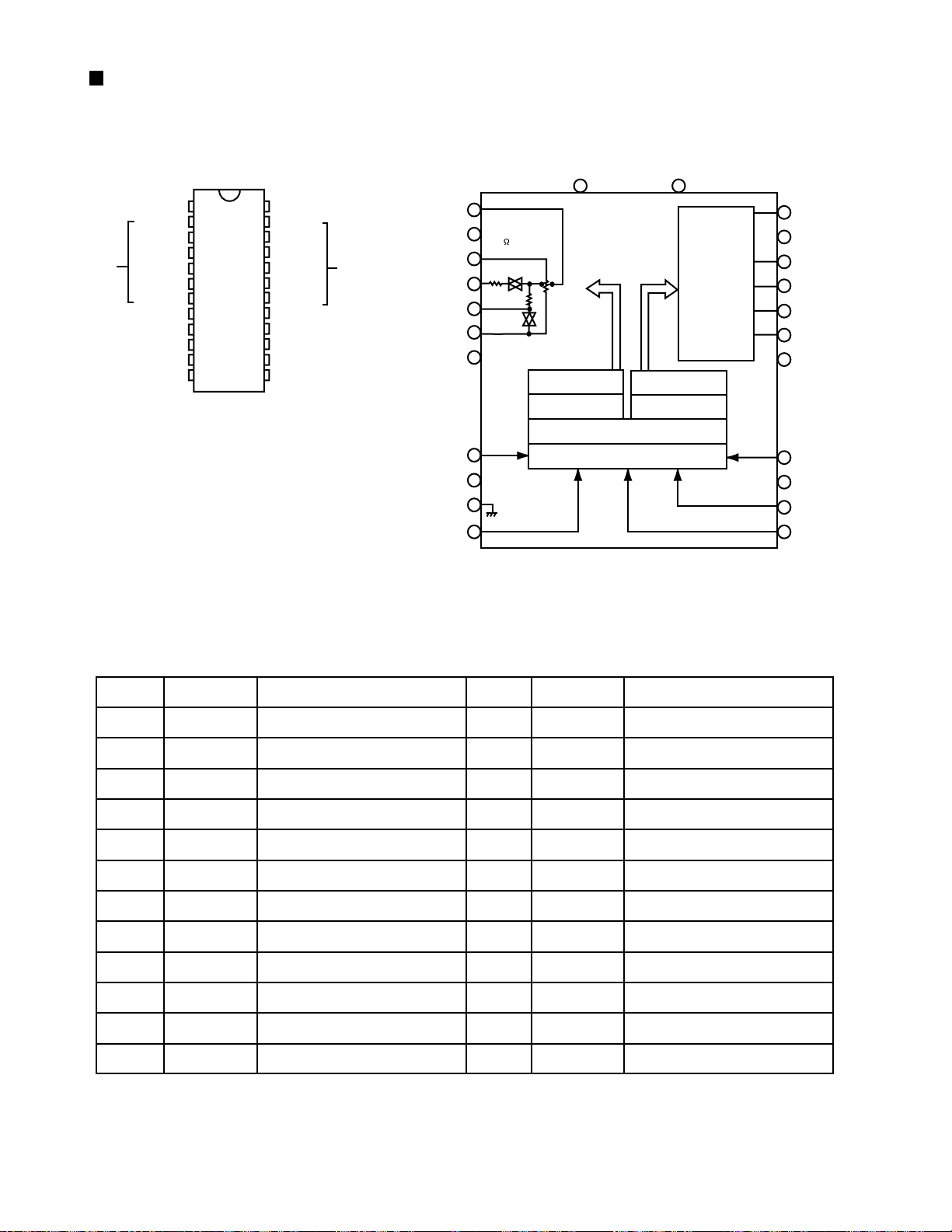

LA1838(IC102) : FM AM IF AMP&detector, FM MPX decoder

1. Block Diagram

30

ALC

BUFF

FM

S-METER

FM IF

1

2. Pin Function

Pin

Symbol

No.

FM IN

1

AM MIX

2

3

FM IF

AM IF

4

GND

5

6

TUNED

STEREO

7

8

VCC

9

FM DET

10

AM SD

FM VSM

11

AM VSM

12

13

MUTE

14

FM/AM

MONO/ST O

15

29

28

AM

OSC

SD

COMP

S-CLRVE

PM

DET

2

I/O

I

This is an input terminal of FM IF

REG

AM

MIX

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

GND

Function

DET

TUNING

DRIVE

5

signal.

This is an out put terminal for AM

O

mixer.

I

Bypass of FM IF

Input of AM IF Signal.

I

I

This is the device ground terminal.

When the set is tuning, this terminal

O

becomes "L".

O

Stereo indicator output. Stereo "L",

Mono: "H"

III

This is the power supply terminal.

I

FM detect transformer.

I

This is a terminal of AM ceramic filter.

O

Adjust FM SD sensitivity.

O

Adjust AM SD sensitivity.

I/O

When the signal of IF REQ of IC121(

LC72131) appear, the signal of FM/AM

IF output. //Muting control input.

Change over the FM/AM input.

I

"H" :FM, "L" : AM

Stereo : "H", Mono: "L"

25

21

DECODER

ANIT-BIRDIE

10

I/O

O

O

20

STEREO

5N

SW

FF

38k

11

Left channel signal output.

Right channel signal output.

Input terminal of the left channel post

I

24

STEREO

DRIVE

6

7

22

23

P-DET

VCC

89

Pin

Symbol

No.

16

L OUT

17

R OUT

18

L IN

VCO

384KHz

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

/

LS

Function

17 16

PILOT

DET

15

14

AMP.

Input terminal of the right channel

19

R IN

I

post AMP.

Mpx Right channel signal output.

20

21

22

23

24

25

RO

LO

IF IN

FM OUT

AM DET

AM AGC

O

O

Mpx Left channel signal output.

I

Mpx input terminal

FM detection output.

O

AM detection output.

O

This is an AGC voltage input terminal

I

for AM

I

26

AFC

This is an output terminal of voltage

for FM-AFC.

27

28

AM RF

REG

AM RF signal input.

I

Register value between pin 26 and pin28

O

desides the frequency width of the

input signal.

29

AM OSC

I

This is a terminal of AM Local

oscillation circuit.

30

OSC BUFFER

AM Local oscillation Signal output.

O

1-18

Page 19

RX-8010RBK/ RX-8012RSL

MB90088 (IC203) : On screen display controller

1.Terminal Layout

YIN

VIN

CIN

AVcc

IOUT

VOC

Vcc

EXS

XS

HSYNC

VSYNC

EXHSYN

EXVSYN

Vss

2.Block Diagram

SIN

SCLK

CS

EXHSYN

EXVSYN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

AVss

27

YOUT

26

VOUT

25

COUT

24

CS

23

SIN

22

SCLK

21

TEST

20

BOUT

19

ROUT

18

GOUT

17

VOB

16

XD

15

EXD

Serial Input

Control

H/V Separate

Each Control, Data

VIN

YIN

CIN

HSYNC

VSYNC

XS

EXS

XD

EXD

NTSC/PAL

Signal OSC

Display Memory

Control

VRAM

4FSC CLK

OSC

Dot CLK

OSC

Each Block

Each Block

Analog SW

Video Signal

OSC

Output

Control

CGROM

VOUT

YOUT

COUT

BOUT

ROUT

GOUT

IOUT

VOC

VOB

1-19

Page 20

RX-8010RBK/ RX-8012RSL

3.Functions

pin

Symbol I/O Function

no

YIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

VIN

CIN

AVcc

IOUT

VOC

Vcc

EXS

XS

HSYNC

VSYNC

EXHSYN

EXVSYN

Vss

EXD

XD

VOB

GOUT

ROUT

BOUT

TEST

SCLK

SIN

CS

COUT

VOUT

YOUT

AVss

I

Lux signal Input terminal for Superinpause indication

I

Composite video signal input terminal for Superinpause indication

Contrast signal input terminal for Superinpause indication

I

-

Analog power supply terminal

O

Color (Lux) signal output terminal

Character output terminal

O

Power supply terminal

Clock generater outside circuit terminal for color burst

I

O

O

Horizontal signal output terminal

O

Vertical signal output terminal

EXT horizontal signal input terminal

I

EXT vertical signal input terminal

I

GND

Dot clock generater outside circuit signal terminal for indication

I

O

Character & background signal output terminal

O

Color signal (Green, Red, Blue)

O

I

Test signal input terminal

Shift clock input terminal for serial transmission

I

Serial data input terminal

I

Chip select terminal

I

Contrast signal output terminal

O

Composite video signal output terminal

O

Lux signal output terminal

O

Analog GND terminal

-

NJM2285V-W(IC202) : 2-Input 3channel VIDEO switch

+

H

CLAMP TYPE

1-20

IN1A GND1 IN2B V CTL2 IN2A GND3 IN3B

16 15 14 13 12 11 10 9

BIAS TYPE

L

H

1 2 3 4 5 6 7 8

IN1B CTL1 OUT1 GND2 OUT2 OUT3 CTL3 IN3A

L

H

CLAMP TYPE

L

Page 21

RX-8010RBK/ RX-8012RSL

NJM4580DD (IC301) : LPF, Mic and H.phone Amp.

1.Terminal layout

2.Block diagram

+

V

INPUT

+

A OUT

A -IN

A +IN

V

1

2

A

3

-

4

(TOP VIEW)

B

8

7

6

5

+

V

B OUT

B -IN

B +IN

-

V

NJU7241F33(IC411) : Voltage regulator

PIN FUNCTION

1

5

2

3

4

1. GND

2. VIN

3. VOUT

4. +NC

5. STB

OUTPUT

1-21

Page 22

RX-8010RBK/ RX-8012RSL

PCM2702E-X (IC410) : Digtal / Analog converter

1.Pin layout

XTI

1

DD

C

V

2

DGNDC

3

DD

V

4

DGND

5

D+

6

D-

7

BUS

V

8

DGND

9

PLYBCK

10

SSPND

11

ZERO

12

TEST3

13

TEST2

14

3.Pin function

XTO

VccP

AGNDP

VccL

AGNDL

OUT

V

Vcc

COM

V

AGND

OUT

V

AGNDR

VccR

TEST0

TEST1

2. Block diagram

PLYBCK

28

27

26

25

24

L

23

22

21

20

R

19

18

17

16

15

D+

D-

VBUS

DGNDU

VDDC

DGNDC

SSPDN

USB I/F

MCLK

USB clock

generator

Crystal OSC

XTI

XTO

USB packet

data

WRCLK

FIFO

SPACT

audio

data

RDCLK

ZERO

8x

Oversampling

Digital Filter

System Clock

Audio clock

generator

DGNDP

VDDP

Multi-level

Delta-Sigma

Modulator

VccL

AGNDL

VccR

AGNDR

DAC

DAC

Power supply

VCC AGND VDD DGND

Low-pass

Filter

Low-pass

Filter

VOUTL

VCOM

VOUTR

PIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Symbol

XTI

DD

C

V

DGNDC

DD

V

DGND

D+

D-

BUS

V

DGNDU

PLYBCK

SSPND

ZERO

TEST3

TEST2

TEST1

TEST0

VccR

AGNDR

OUT

R

V

AGND

COM

V

Vcc

OUT

L

V

AGNDL

VccL

AGNDP

VccP

XTO

I/O

IN

-

-

-

I/O

I/O

IN

-

OUT

OUT

OUT

IN

IN

IN

IN

-

-

OUT

-

-

-

OUT

-

-

-

-

OUT

Function

Crystal Oscillator Input.

Digital Power Supply for Clock Generator, +3.3V.

Digital Ground for Clock Generator.

Digital Power Supply, +3.3V.

Digital Ground.

USB Differential Input/Output Plus.

USB Differential Input/Output Minus.

USB Bus Power (This pin NEVER consumes the USB bus power).

Digital Ground for USB Transceiver.

Playback flag, active LOW. (LOW: playback, HIGH: idle).

Suspend flag, active LOW. (LOW: suspend, HIGH: operational).

Zero flag, (LOW: Normal, HIGH: ZERO).

Test pin 3. Connect to digital ground.

Test pin 2. Connect to digital ground.

Test pin 1. Connect to digital ground.

Test pin 0. Connect to digital ground.

Analog Supply for R-channel, +5V.

Analog Ground for R-channel.

Analog Output for R-channel.

Analog Ground.

Common for DAC.

Analog Supply, +5V.

Analog output for L-channel.

Analog Ground for L-channel.

Analog Supply for L-channel, +5V.

Analog Ground for PLL.

Analog Supply for PLL, +5V.

Crystal Oscillator Output.

(1)

(2)

(2)

(2)

(2)

(2)

1-22

Note:

(1) 3.3V tolerant.

(2) Schmitt trigger input with internal pull-down, 5V tolerant.

Page 23

RX-8010RBK/ RX-8012RSL

SAA6588 (IC191) : RDS detector

1.Terminal Layout

MRO

MPTH

TCON

OSCO

OSCI

VSSD

VDDD

DAVN

SDA

SCL

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

LVIN

CIN

SCOUT

Vref

MPX

VSSA

VDDA

AFW

MAD

PSWN

2.Pin Function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

MRO

MPTH

TCON

OSCO

OSCI

VSSD

VDDD

DAVN

SDA

SCL

PSWN

MAD

AFW

VDDA

VSSA

MPX

Vref

SCOUT

CIN

LVIN

FunctionI/OSymbol

Multi-path rectifier output

O

Multi-path detector output

Test control input pin

I

Oscillator output

O

Oscillator input

I

Digital ground (0V)

Digital power supply (5V)

Data available output (active LOW)

O

IC-bus serial data I/O

I/O

IC-bus serial clock input

I

Pause switch output (active LOW)

Slave addrese (LSB) input

Audio signal input

Analog power supply (5V)

Connect to ground

Multiplex input signal

I

Reference voltage output

O

Band-pass filter output

O

Comparator output

O

Level input

I

3.Block Diagram

16

MPX

AFIN

LVIN

VDDA

14

8th ORDER

BAND-PASS

13

DETECTOR

20

AND RESET

VSSA

SCOUT

57 kHz

PAUSE

POWER

SUPPLY

15

18

17

Vref

19

CLOCK

COMPARATOR

MULTI-PATH

DETECTOR

TEST

CONTROL

3

TCON

RDS/RDBS

DEMODULATOR

SIGNAL QUALITY

DETECTOR

OSCILLATOR

AND CLOCK

1

MRO

OSCI OSCO

VDDDCIN

7

DAVN

12

MAD

11

10

8

2

9

PSWN

MPTH

SDA

SCL

RDS/RDBS

DECODER

INTERFACE

REGISTER

IC-BUS SLAVE

TRANSCEIVER

5

4

6

VSSD

1-23

Page 24

RX-8010RBK/ RX-8012RSL

TC9162AN (IC380) : Analog switch

VSS

L-S1

L-S2

L-COM1

L-S3

L-S4

L-COM2

L-S5

L-S6

L-COM3

L-S7

L-COM4

ST

GND

L-S1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

2

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VDD

R-S1

R-S2

R-COM1

R-S3

R-S4

R-COM2

R-S5

R-S6

R-COM3

R-S7

R-COM4

DATA

CK

VSS

GND VDD

1

14

28

27

R-S1

L-S2

L-COM1

L-S3

L-S4

L-COM2

L-S5

L-S6

L-COM3

L-S7

L-COM4

ST

3

4

5

6

7

8

9

10

11

12

13

LEVEL SHIFTER

LATCH CIRCUIT

LATCH CIRCUIT

LEVEL SHIFTER

26

25

24

23

22

21

20

19

18

17

16

R-S2

R-COM1

R-S3

R-S4

R-COM2

R-S5

R-S6

R-COM3

R-S7

R-COM4

DATA

1-24

SHIFT REGISTER

15

CK

Page 25

RX-8010RBK/ RX-8012RSL

TC9163AF-X (IC371) : Analog switch

VSS

L-S1

L-S2

L-S3

L-COM1

L-S4

L-S5

L-S6

L-COM2

L-S7

L-S8

L-COM3

ST

GND

L-S1

L-S2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

2

3

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VDD

R-S1

R-S2

R-S3

R-COM1

R-S4

R-S5

R-S6

R-COM2

R-S7

R-S8

R-COM3

DATA

CK

VSS

GND VDD

1

14

28

27

26

R-S1

R-S2

L-S3

L-COM1

L-S4

L-S5

L-S6

L-COM2

L-S7

L-S8

L-COM3

ST

10

11

12

13

4

5

6

7

8

9

LEVEL SHIFTER

LATCH CIRCUIT

LATCH CIRCUIT

LEVEL SHIFTER

SHIFT REGISTER

25

24

23

22

21

20

19

18

17

16

15

R-S3

R-COM1

R-S4

R-S5

R-S6

R-COM2

R-S7

R-S8

R-COM3

DATA

CK

1-25

Page 26

RX-8010RBK/ RX-8012RSL

TC9164AF-X (IC302) : Analog switch

VSS

L-S1

L-S2

L-S3

L-S4

L-COM1

L-S5

L-S6

L-COM2

L-S7

L-S8

L-COM3

ST

GND

L-S1

L-S2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

2

3

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VDD

R-S1

R-S2

R-S3

R-S4

R-COM1

R-S5

R-S6

R-COM2

R-S7

R-S8

R-COM3

DATA

CK

VSS

GND VDD

1

14

28

27

26

R-S1

R-S2

L-S3

L-S4

L-COM1

L-S5

L-S6

L-COM2

L-S7

L-S8

L-COM3

ST

10

11

12

13

25

24

23

22

21

20

19

18

17

16

15

R-S3

R-S4

R-COM1

R-S5

R-S6

R-COM2

R-S7

R-S8

R-COM3

DATA

CK

4

5

6

7

8

LEVEL SHIFTER

9

LATCH CIRCUIT

LATCH CIRCUIT

LEVEL SHIFTER

SHIFT REGISTER

1-26

Page 27

RX-8010RBK/ RX-8012RSL

TC9459F (IC381, IC382, IC383) : Electronic volume control

1.Terminal layout

VSS

L-OUT

NC

L-ch

L-IN

L-LD1

L-LD2

L-A-GND

NC

CS1

NC

GND

CK

2. Block diagram

VSS

1

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

VDD

R-OUT

NC

R-IN

R-LD1

R-LD2

R-A-GND

NC

CS2

NC

STB

DATA

R-ch

L-OUT

NC

L-1N

L-LD1

L-LD2

L-A-GND

NC

CS1

NC

GND

CK

9

10

11

12

2

3

4

5

6

7

8

50k /

915TEP

VR

L-ch 7 to 91

decoder

L-ch data

latch circuit

Shift register (24BIT)

Level shift circuit

VDD

24

R-ch 7 to 91

decoder

R-ch data

latch circuit

Same as L-ch

Circuit

23

22

21

20

19

18

17

16

15

14

13

R-OUT

NC

R-IN

R-LD1

R-LD2

R-A-GND

NC

CS2

NC

STB

DATA

3.Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

Symbol

VSS

L-OUT

NC

NC

L-LD1

L-LD2

L-A-GND

NC

CS1

NC

GND

CK

Function

Negative power supply pin

Volume output pin

No connection

No connection

Loudness tap output pin

Loudness tap output pin

Analog GND pin

No connection

Chip select input pin

No connection

Digital GND pin

Clock input pin

Pin No.

13

14

15

16

17

18

19

20

21

22

23

24

Symbol

DATA

STB

NC

CS2

NC

R-A-GND

R-LD2

R-LD1

R-IN

NC

R-OUT

VDD

Function

Data input pin

Strobe input pin

No connection

Chip select input pin

No connection

Analog GND pin

Loudness tap output pin

Loudness tap output pin

Volume input pin

No connection

Volume output pin

Positive power supply pin

1-27

Page 28

RX-8010RBK/ RX-8012RSL

TC7S04FU (IC502, IC503) :CMOS Inverter

NC

IN A

GND

1

2

3

5

4

VDD

OUT Y

TC7SET32FU (IC582) : Z-Input or gate

IN B

1

2

IN A

GND

3

54VCC

OUT Y

W24L010AJ-12 (IC511) : CMOS static RAM

1. Pin layout

V

DD

32

A15

31

CS2

30

WE

29

A13

28

A8

27

A9

26

A11

25

OE

24

A10

23

CS1

22

I/O8

21

I/O7

20

I/O6

19

I/O5

18

I/O4

17

32

OE

31

A10

30

CS1

29

I/O8

28

I/O7

27

I/O6

26

I/O5

25

I/O4

24

Vss

23

DO3

22

DO2

21

DO1

19

A0

18

A1

17

A2

16

A3

VDD

1

NC

2

A16

3

A14

4

A12

5

A7

6

A6

7

A5

8

A4

9

A3

10

A2

11

A1

12

A0

13

I/O1

14

I/O2

15

I/O3

16

Vss

1

A11

2

A9

3

A8

4

A13

5

WE

6

CS2

7

A15

8

9

NC

10

A16

11

A14

12

A12

13

A7

14

A6

15

A5

16

A4

32-pin

TSOP

2. Block diaglam

DD

V

Vss

A0

DECODER

A16

CS2

CS1

CONTROL

OE

WE

3. Pin function

SYMBOL

A0 - A16

I/O1 - I/O8

CS1, CS2

WE

OE

DD

V

Vss

NC

CORE

ARRAY

DATA I/O

I/O1

I/O8

DESCRIPTION

Address Input

Data Input/Output

Chip Select Inputs

Write Enable Input

Output Enable Input

Power Supply

Ground

No Connection

1-28

Page 29

RX-8010RBK/ RX-8012RSL

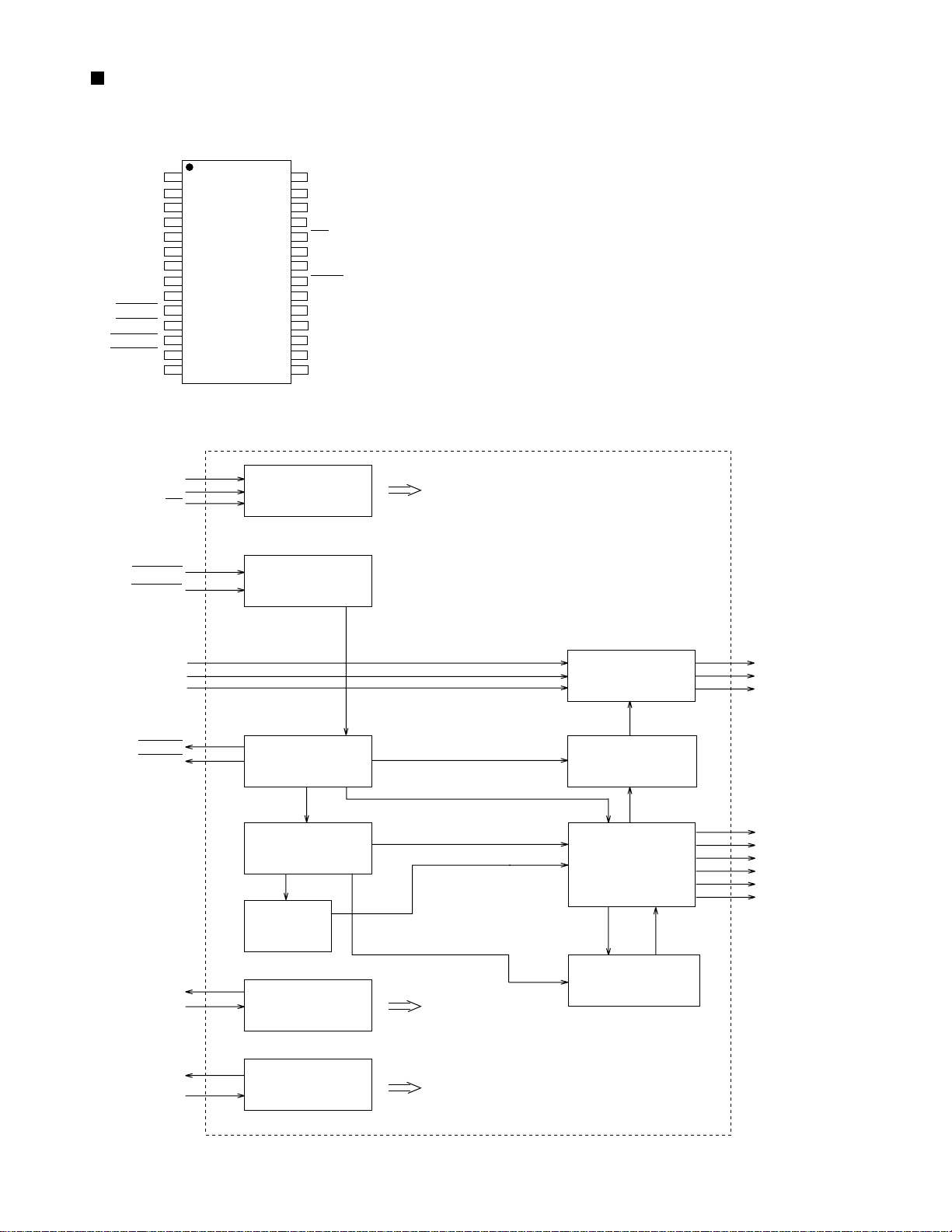

UPD784215AGC132(IC581) : Unit CPU

1.Pin layout

75 ~ 51

76

~

50

~

100

1 ~ 25

26

2.Pin function

Pin No. Symbol I/O Function

1~8

9

10

11

12

13

14

15

16

17

18

19~22

23

24

25~32

33

34,35

36

37,38

39

40

41

42

43

44

45,46

47

48

49

50,51

52

53

54

55

56

57~63

64,65

66

67

68~70

71

72

73~75

76

77

78

79,80

81

82,83

84

85

86

87

88

89~93

94

95~100

VDD

X2

X1

VSS

XT2

XT1

RESET

AUTO

ERR

Fz96k

P03~P06

AVDD

AV REF0

P10~P17

AVSS

P130, P131

AV REF1

RX, TX

DSPCOM

DSPSTS

DSPCLK

DSPRDY

MIDIO_IN/OUT

MICK

HREQ

SS

DSP_RST

D_CS

PD/ DIR

CDTI/CDTO

CCLK

CS

PD

GND

EQ

CTR TONE

3D

VDD

ANA_TT

LEF_MIX

LEF_OUT

MIX_OUT

S_MUTE

TEST

Non connect

Power supply terminal

Connecting the crystal oscillator for system main clock

Connecting the crystal oscillator for system main clock

I

Connect to GND

Connecting the crystal oscillator for system sub clock

Connect VSS

I

System reset signal input

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Power supply terminal

Connect to GND

Connect to GND

Connect to GND

Non connect

O

Power supply terminal

Not use

O

Non connect

O

Communication port from IC901

I

Status communication port to IC901

O

Clock input from IC901

I

Ready signal input from IC901

I

Non connect

O

Interface I/O terminal with microcomputer

I/O

Interface I/O terminal with microcomputer of clock signal

O

HREQ

I

System slave select

O

Non connect

Reset signal output of DSP

O

Non connect

Chip setselct output

O

Non connect

Reset signal output

O

Non connect

Interface I/O terminal with microcomputer

O/I

Interface I/O terminal with microcomputer of clock signal

O

CS

O

Non connect

Reset signal output

O

Connect to GND

Non connect

EQ

O

CENTER TONE

O

3D-Phonic

O

Non connect

Power supply

Non connect

Analog./T.TONE

O

Select 1

O

Select 2

O

Select 3

O

S.MUTE

O

Non connect

Test terminal

Non connect

-

1-29

Page 30

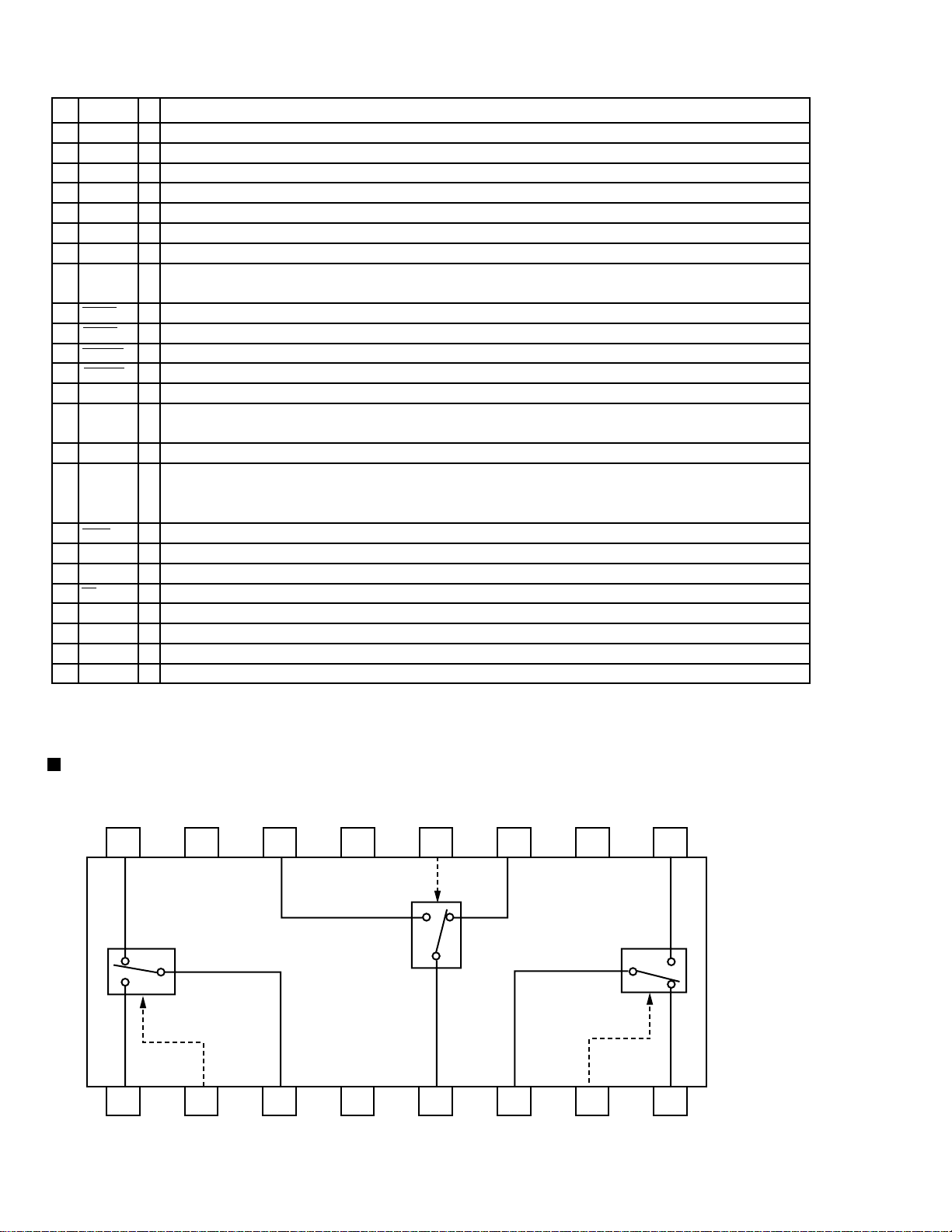

Block diagrams

Signal I/O block section

5

CN244 CN242

CN406

SYSTEM CONTROL

& FL

CN243

COMP LINK

TEXT LINK

CN731 CN732

L/R

CEN

SL/SR

Main section

LVA10220-1

L ch

Q761

Q763

CN711

CN701

LVA10221-1

RX-8010RBK/ RX-8012RSL

LVA10221-2

RY831

L

SPK1

R

CN240

LVA10222-1

S Video

LVA10219-5

MON

MON

IC381

IC382

IC383

R ch

Q762

Q764

CN712

CN702

CN813

CN823

RY832

L

SPK2

R

4

L/R

CN200 CN204 CN206

Video

LVA10219-4

DATA

CEN

L/R

CN587 CN581

SL/SR

CN501 CN205

IC380

DSP

3

CPU

IC901

2

DATA

CN313 CN371 CN416

V Audio input

CN311 CN351

LVA10223

LVA10219-3

CN381

V SIG

CN361

AUDIO

DVD REAR

CEN

SW

DVD

SUB WOOFER

DVD CENTER

IC386

SL/SR

DVD

SUB WOOFER

DVD

CENTER

LVA10220-2

LVA10220-3

CEN

CN722

Q1751

Q1752

LVA10220-4

CN713

R

CN721

L

CEN

CN703

SL

SR

CN723

CN814CN881

CN824

RY851

RY852

CENTER

REAR L

REAR R

Audio input

LVA10219-2

CN101CN102 CN301 CN303 CN601 CN201 CN241

CN111

LVA10219-1

RL ch

Q1851

Q1853

CN715

CN705

FW881

& FL

CN112

1

CN400

LVA10009

Tuner

CN406

SYSTEM CONTROL

RR ch

Q1852

Q1854

CN716

LVA10222-7

CN706

LVA10220-5

CN410

SYSTEM

CONTROL

& FL

ABCD E F G

2-1

Page 31

RX-8010RBK/ RX-8012RSL

Video section

DVD

TV/DBS

5

R

VCR1

P

R

VCR2

P

SW

IC 201

4

MON

Y/C SEP

IC 202

V SIG

FRONT VIDEO

IN (RCA)

MON Y/C OUT

MON Y/C IN

LVA10219-4

IC 203

DATA

CN200CN204CN206

Video input section

DVD F

TV/DBS

VCR1 REC

VCR1 P.B

VCR2 REC

VCR2 P.B

LVA10219-3

DATA/CLK

CN313

SOUTCE

SELECTOR

IC 371

V SIG

CN371

IC372

USB

CN416

FRONT AUDIO

DSP section

S Video section

LVA10223

3

LVA10219-5

DIGITAL

DATA

CN240

C

C

FRONT Y/C

Y

MON Y/C

MON Y/C

CN244

CN242

IC 241

SW

DVD

2

TV/DBS

R

VCR1

P

R

VCR2

P

MON

(C)

IC 242

SW

(Y)

Y

1

IN1

DIGITAL

IN2

DIGITAL

IN3

DIGITAL

IN4

DIGITAL

OUT

SELECTOR

IC 551

DSP

CONTROLLER

IC 581

DSP

IC 501

DATA

AD/DA

CONVERTER

IC 571

SD RAM

IC 511

CN587

R/L

C

SR/SL

CN581

2-2

HABC DEFG

Page 32

RX-8010RBK/ RX-8012RSL

Tuner section

LVA10009

RDS

IC 191

5

FM

TUNER

RF 101

AM/FM DET

IC102

TUNER

System control & FL section

LVA10218-1

FL DISPLAY D400

CN412

SYSTEM CONTROLLER

AM

MW RF & OSC

T111

4

Audio input section

PLL

IC102

DATA

CN111 CN112

KEY

Y/C

VIDEO

IC 400

CN410

AUDIO

CN406

PHONO

L/R

EQ

IC 301

LVA10219-2

USB

3

CD

L/R

TAPE

P.B

DATA/CLK

TUNER

CN311

SOURCE

2

TAPE

REC

CDR

P.B

SELECTOR

IC 302

V SIG

AUDIO

CN351

IC 303

CDR

REC

1

DVD

REAR

IC 304

ABCD E F G

DVD REAR

2-3

Page 33

Standard schematic diagrams

Power supply section

5

RX-8010RBK/ RX-8012RSL

PW60

T2

QQT0281-002

D52

1SR35-400A

1SR35-400A

D57

1SS133

R53

PW10

PW11

PW12

PW13

PW14

PW15

PW16

6.8

C1

0.0047

RY1

QSK0098-001

R54

PW28

PW29

PW40

PW70

Q53

KRC105M

Q52

KTD863/Y/

C55

C54

470/16

0.0047

D56

MTZ6.2JB

C81

0.1

820

131

132

C62C61

0.1MY0.1MY

1SR35-400A

TH71

QAD0095-4R7

113

112

111

123

122

121

134

133

D51

1SR35-400A

D53

1SR35-400A

C51

0.0047/100

F2

C52

1000/25

D54

CN811

4

CN55

sheet 10/11

3

CN72

2

sheet 5/11

CN82

CN402

CN71

C69

0.047MY

C68

0.047MY

100K

R74

C74

1/50

D75

MTZ8.2JC

Q74

KTC3200/GL/

KTA1046/Y/

C73

R73 D74 C72

22K

CN56

FW51

Q71

22/50

MTZ33JC

F61

F62

R61

D61

10E2-FD

D63

10E2-FD

C65 C66

3300/35 1000/35

D73

1SR35-400A

3.3k

R72

C71

100/63

22/50

8.2

1SR35-400A

D62

C63

0.1MY

C70

220/50

D71

1SR35-400A

D72

1SR35-400A

D64

PW20

PW17

PW26

PW18

PW19

PW30

F1

TA1

TA2

EP51

SHEET

NUMBER

1/11

POWER SUPPLY

2/11

MAIN

3/11

1

AUDIO

4/11

AUDIO SIGNAL INPUT

5/11

VIDEO SIGNAL INPUT

6/11

DVD

7/11

AUDIO AMP (FRONT CHANNEL)

8/11

AUDIO AMP (CENTER, REAR CHANNEL)

9/11

DSP

10/11

SYSTEM CONTROL

11/11

TUNER

CIRCUIT DESCRIPTION

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

SHEET 1/11

2-4

HABC DEFG

Page 34

RX-8010RBK/ RX-8012RSL

Main & Speaker terminal section

C845

C833

220p

sheet 8/11sheet 8/11sheet 8/11 sheet 7/11 sheet 7/11sheet 6/11 sheet 6/11

5

CN703

4

C801

D801

30DF2-FC

D803

C807C808

100K100K

R801R802

6800/716800/71

C802

D802

D804

CN801

sheet 1/11

30DF2-FC

C805

30DF2-FC

30DF2-FC

3

CN701

C816

47/25

D816

MTZ18JC

R816

3.3k

12

R815

R811

C811

CN721

Q811

2SD2395/EF/

3.3K

R812

0.0047

D811

R814

KTC3200/GL/

Q812

10k

47k

R813

CN702

2

FRONT Signal

CENTER Signal

CN705

Parts are safety assurance parts.

CN723

10/25

10K

R825

C824

Q824

KTC3200/GL/

R823

10K

R826

100K

47/16

Q825

KTA1268/GL/

Q823

130K

R824

KTC3199/GL/

C823

sheet 3/11

CN706

CN823

CN813

0.45

L844

B124

0.45

L845

B125

0.45

L843

R841

100K

R842

82K

R843

100K

R844

100K

R845

82K

12

R871

1SS133

D825

CN831

D871

1SS133

RY871

QSK0109-001

CN881

FW881

R91

R92

470

470

CN824

B123

CN814

C91

C92

470P470P

R831

12

RY831

RY832

RY833

RY851

RY852

J91

D831

1SS133

R832

12

D832

1SS133

R835

12

D835

R851

12

1SS133

D851

R852

12

1SS133

D852

FW931

C835

0.022

1SS133

R885

C885

0.1

R888

C888

0.1

C887

0.1

R887

When replacing those parts make

REAR Signal

sure to use the specified one.

0.022

R833

10

C834

0.022

220P 220P

C836

0.022

10

C842 C841

R834

C846

220P

C847

220P

1010

R837R838

C837

0.022

C839

C838

0.022 0.022

220P

C848

C891

220P

10

220P

C886

220P

10

C890

C892

220P

220P

10

C889

C893

220P

C850

4.7/50

D841

MTZ5.1JC

3.9K

R855

D845

1SS133

D846

1SS133

R867

10K

ST831

220P220P

C843C844

C840

0.022

C881

220p

ST851

C884

220p

C883

220p

S831

22K

22K

22K

R862

D843

R859

R856

1SS133

D844

1SS133

D842

1SS133

R857

6.8K

6.8K

6.8K

R860

R863

KRC109M

R864

4.7K

Q831

KRC109M

R861

R858

4.7K

4.7K

Q832

KRC109M

KRC109M

C852

C851

C853

4.7/504.7/504.7/50

R866

4.7K

Q836

Q834

KRC109M

KRC109M

Q835

Q830

KRC109M

R865

4.7K

Q833

1

SHEET 2/11

ABCD E F G

2-5

Page 35

Audio section

RX-8010RBK/ RX-8012RSL

R915

R916

8.2

8.2

5

R971

0.0047

C972

R973

12

3.3K

Q951

2SD2395/EF/

C951

100/25

D951 D961

MTZ13JC

2SD2395/EF/

C971

100/25

Q971

D971

MTZ10JC

C952

0.0047

R951

R953

2.2K

12

C961

100/25

Q961

KTA1046/Y/

MTZ13JC

4

CN301

220

R955

R956

R944

R945

R946

R947

R948

R949

R954

220

220

220

220

220

220

220

220

R940

4.7

sheet 4/11

CN303

MAIN_STB

MAIN_CLK

MAIN_DAT

SUB_STB

SUB_CLK

SUB_DAT

-15V

+15V

VOL_STB

VOL_CLK

VOL_DAT

3

sheet 4/11

2

sheet 11/11

sheet 11/11

SUBV_STB

SUB_PRE

SUB_MUTE

S_MUTE

SW_MUTE

CN101

TUNER_DATA

TUNER_CE

TUNER_CK

TUNER_MUTE

TUNED

STEREO

CN102

RDS_ST

RDS_DATA

RDS_CLK

R936

R935

R934

R937

R938

R939

R999

22

R975

C975

470/6.3

FL991

220

220

220

10K

220

220

220

QQR0590-001

0.0056

FL992

QQR0590-001

C991

0.0056

C992

R991

R992

4.7K

4.7K

R908

DVD_S/C

DBS_S/C

VCR1_S/C

VCR2_S/C

CN201

VIDEO1

VIDEO2

VIDEO3

VIDEO4

OSD_CS

OSD_DAT

OSD_CLK

VIDEO5

VIDEO6

CN241

C985

0.01

Q901

KRC107M

22K

0.0047

C962

D904

1SS133

R910

R961

12

R963

2.2K

IC903

IC-PST9139

R911

4.7K

C904

2.2/50

22k

220

220

220

220

R927

R928

R925

R926

DSPCLK

DSPREADY

DSPSTATUS

DSPCOMMAND

CN601

220

R929

DSPRESET

MTZ5.6JC

R903

C903

2SD2395/EF/

C941

100/25

D941

330

2200/6.3

C905

0.022

C994

270P

Q941

R976

R978

R993

R995

R997

100/6.3

C901

4.7K

6.2K

13K

15K

0.0047

4.7K

1.5

C902

C942

X901

D975

4.7K

R977

D976

1SS133

8MHz

R943

2.7K

4.7K

5.1K

R994

R979

D977

OSD_DAT

OSD_CS

OSD_CLK

M_COMMAND

M_STATUS

R941

R942

3.3K

R996

D978

M_CLK

33

33

5.6K

R998

D979

M_RESET

M_CS

C921

100/25

TUNED

M_BUSY

STEREO

RDS_ST

2SD2395/EF/

D921

MTZ5.6JC

PROTECT

Q921

C922

0.0047

IC901

MN101C49GHM

TUNER_CK

4/8_IN

TUNER_MUTE

TUNER_DATA

C993

100P

TUNER_CE

RDS_DATA

RDS_CLK

D993

1SS133

R921

R923

2.7K

R922

33

33

4/8_OUT

D903

1SR35-400A

STANDBY_LED

DSPRESET

100/25

D902

1SR35-400A

10K

10K

10K

R967

R965

R966

VCR2_S/C

VCR1_S/C

DVD_S/C

DSPSTATUS

DSPCLK

DSPCOMMAND

C931

D901

10K

10K

R969

R968

VIDEO_S/C

DBS_S/C

DSPREADY

SW_MUTE

2SD2395/EF/

D931

MTZ6.2JC

D900

1SR35-400A

VIDEO6

S_MUTE

Q931

1SR35-400A

R924

C932

0.0047

10K

SUBV_STB

SUB_DAT

SUB_CLK

SUB_STB

MAIN_DAT

MAIN_CLK

MAIN_STB

VOL_DAT

VOL_CLK

VOL_STB

VIDEO4

VIDEO3

VIDEO2

VIDEO1

Q908

KRC105M

HP_RELAY

VIDEO5

SUB_MUTE

SUB_PRE

SUB_RELAY

SUR_RELAY

C_RELAY

F2_RELAY

F1_RELAY

HP_RELAY

SUB_RELAY

SUR_RELAY

PROTECT

4/8_OUT

F1_RELAY

F2_RELAY

C_RELAY

4/8_IN

R933

2.7K

R931

R932

R917

10

CN81

FW831

sheet 2/11

CN400

R980

R930

R981

R982

R983

R984

R985

R986

R987

10K

Q907

220

220

220

220

220

220

220

220

Q906

KRC105M

330P

C981

Q905

KRC105M

330P

C983

C982

KRC105M

330P

Q904

KRC105M

M_CLK

M_COMMAND

M_STATUS

M_CS

M_BUSY

M_RESET

STANDBY_LED

VCR_S/C

330P

C984

Q903

KRC105M

CN931

CN932

sheet 10/11

EP901

sheet 2/11

1

sheet 6/11sheet 5/11sheet 5/11

TUNER Signal

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

SHEET 3/11

2-6

HABC DEFG

Page 36

Audio / V Audio signal input section

RX-8010RBK/ RX-8012RSL

C301

R301

2.2k

4.7/50

5

C333

R333

470 470

R323

470

R325

470

R327

470

R329

470

CDR.REC-L

4

CDR.PLAY-L

R331

470

C361

4.7/50

100k100k

R361R362

R363R364

C362

4.7/50

390p

C321 C322

220p

C323 C324

220p

C325 C326

220p

C327 C328

220p

C329 C330

220p

C331 C332

220p

100k100k

BA15218F

IC304

BA15218F

IC304

C334

R334

390p

220p

R324

470

220p

R326

470

220p

R328

470

220p

R330

470

220p

R332

470

220p

C363

4.7/50

R365R366

C364

4.7/50

CDR.PLAY-R

100k100k

REC-RREC-L

PLAY-RPLAY-L

CDR.REC-R

C302

R302

2.2k

4.7/50

J301

CD-RCD-L

J302

J303

100p100p

C303

C304

DVD-LS

DVD-RS

R305

C309C310

47k47k

R303R304

100p100p

620

NJM4580DD

100/10

C314 C313

100/10

R306

620

R335

68

C335

22/25

IC302

TC9164AF-X

C336

22/25

R336

68

IC301

IC301