Jvc KD-X220-UT, KD-X220-UR, KD-X220-U, KD-X220-J, KD-X220-EY Service Manual

...

SERVICE MANUAL

MA606<Rev.002>20154SERVICE MANUAL

KD-X120EE, KD-X120EU, KD-X120U,

KD-X120UT, KD-X125EE, KD-X220E,

KD-X220EN, KD-X220EY, KD-X220J,

KD-X220U, KD-X220UR, KD-X220UT

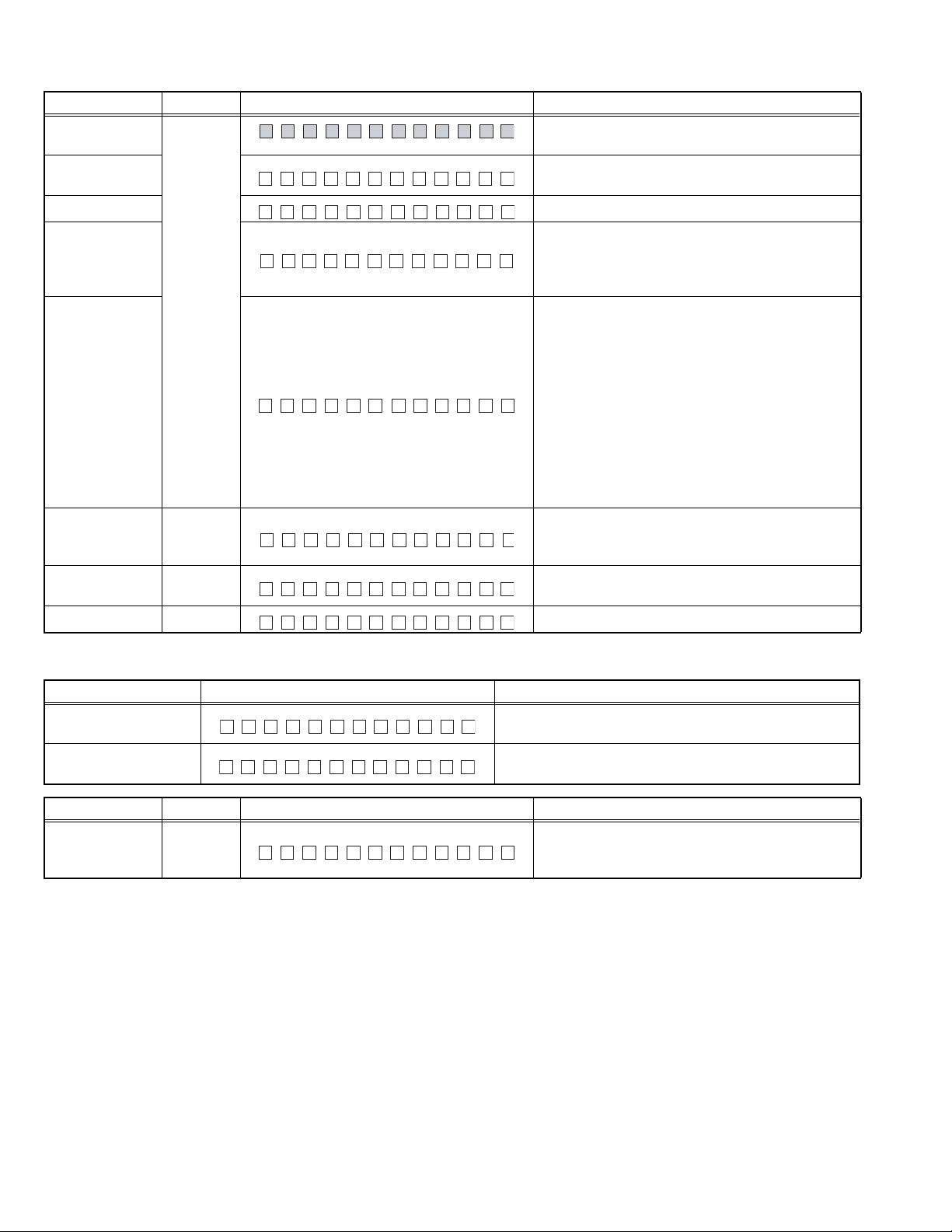

DIGITAL MEDIA RECEIVER

Mounting sleeve

(GE20342-001A)

Remote control unit

(RM-RK52M)

COPYRIGHT © 2015 JVC KENWOOD Corporation

DC cord

(QAM1329-001)

Carrying case

(GE40521-001A)

COPYRIGHT © 2015 JVC KENWOOD Corporation

DC cord

(QAM13xx-00x)

Hook

(GE40646-001A) x2

Lead free solder used in the board (material: Sn-Ag-Cu, melting point: 219 Centigrade)

Lead free solder used in the board (material: Sn-Cu, melting point: 230 Centigrade)

Trim Plate

(GE20363-001A)

DETACHABLE PANEL

Model Parts number

KD-X120EE

KD-X120EU

KD-X120U

KD-X120UT

KD-X125EE

KD-X220E

KD-X220EN

KD-X220EY

KD-X220J

KD-X220U

KD-X220UR

KD-X220UT

CP-X120EED

CP-X120EUD

CP-X120UD

CP-X120UD

CP-X125EED

CP-X220ED

CP-X220ED

CP-X220ED

CP-X220JD

CP-X220UD

CP-X220UD

No.MA606<Rev.002>

2015/4

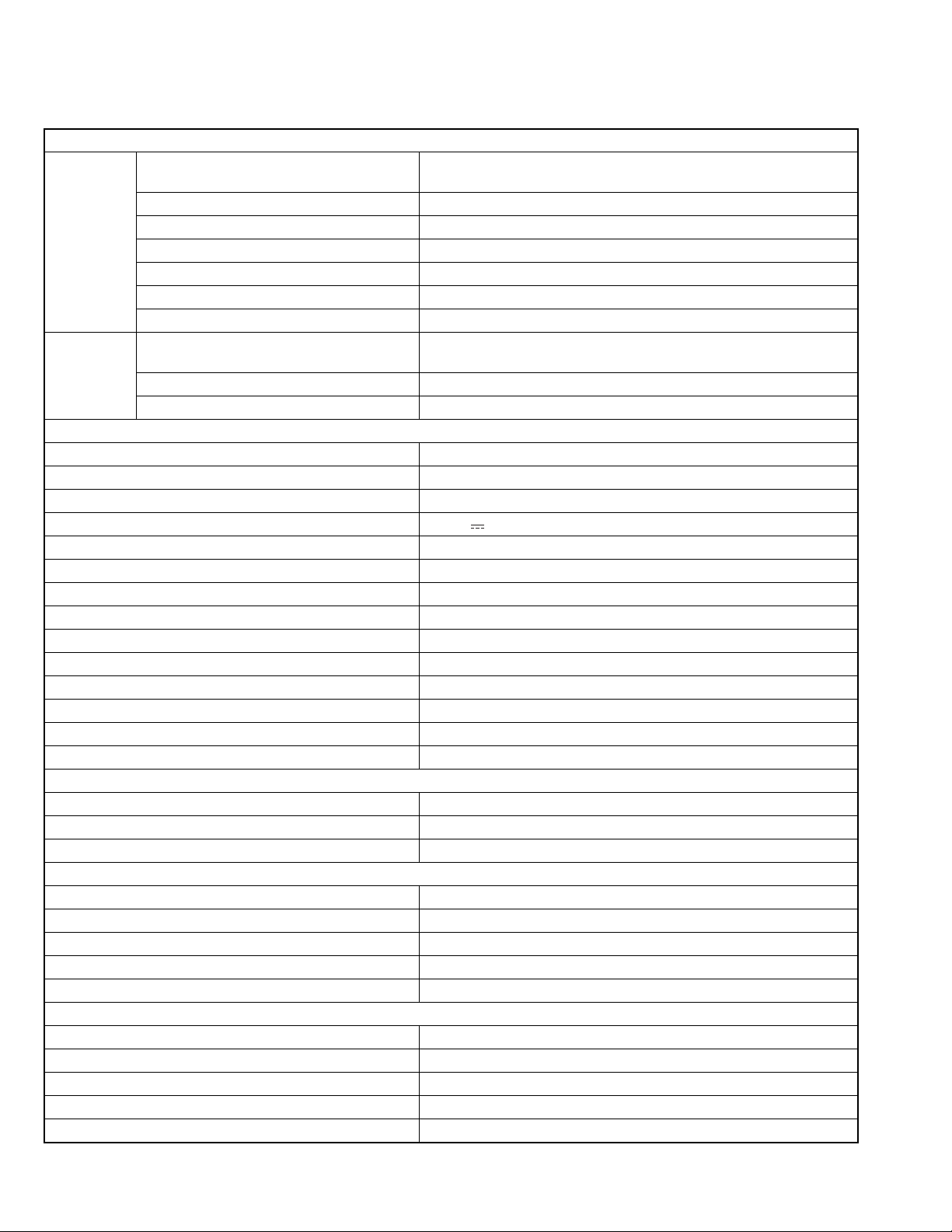

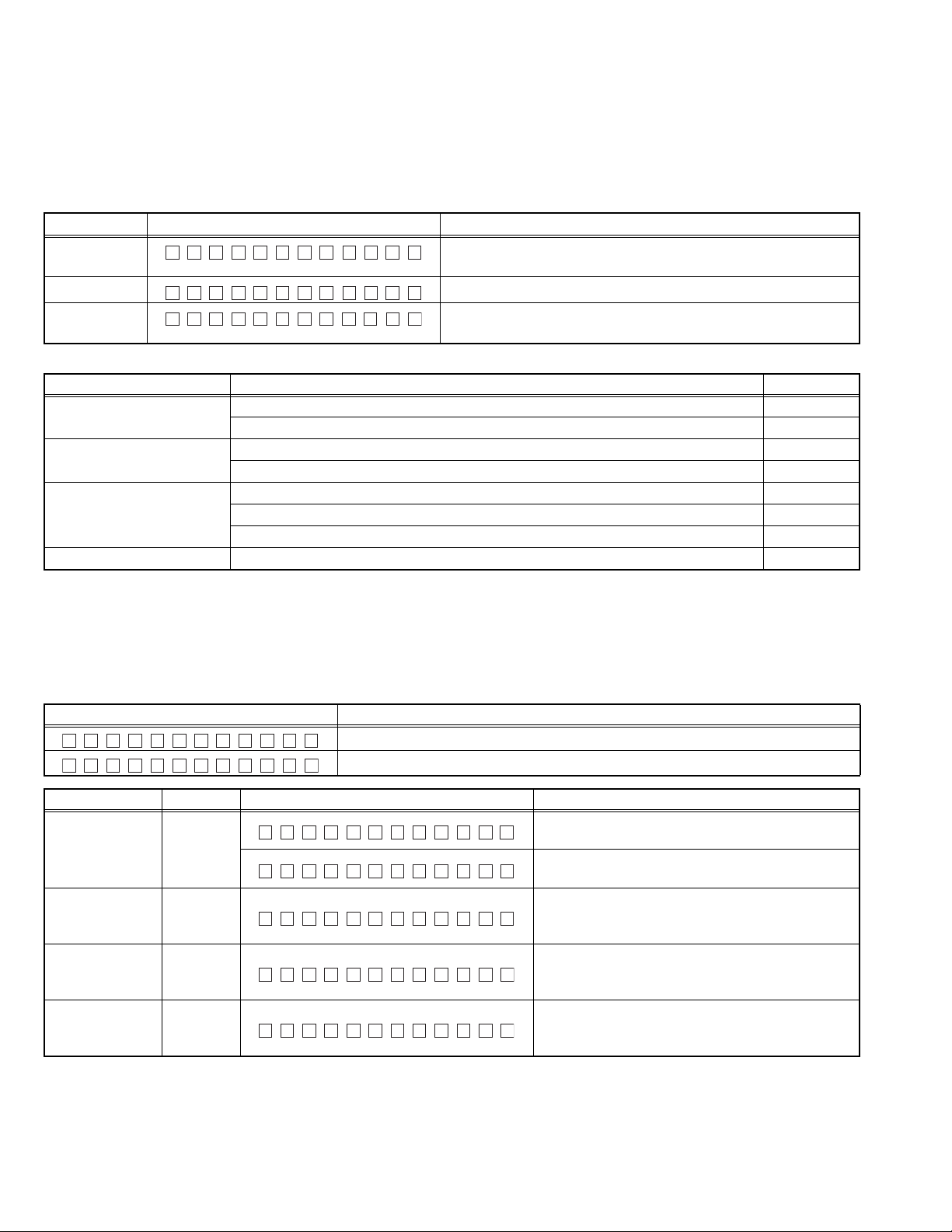

SPECIFICATION

For US

TUNER

FM Frequency Range 87.9 MHz - 107.9 MHz (200 kHz step)

87.5 MHz - 108.0 MHz (50 kHz step)

Channel Space Selection 50 kHz/200 kHz

Usable Sensitivity (S/N = 26 dB) 8.2 dBf (0.71 µV/75 Ω)

Quieting Sensitivity(DIN S/N = 46 dB) 17.2 dBf (2.0 µV/75 Ω)

Frequency Response (±3 dB) 30 Hz - 15 kHz

Signal-to-Noise Ratio (MONO) 64 dB

Stereo Separation (1 kHz) 40 dB

AM Frequency Range 530 kHz - 1 700 kHz (10 kHz step)

531 kHz - 1 611 kHz (9 kHz step)

Channel Space Selection 9 kHz/10 kHz

Usable Sensitivity (S/N = 20 dB) 29 dBµ (28.2 µV)

USB

USB Standard USB 1.1, USB 2.0 (Full speed)

Compatible Devices Mass storage class

File System FAT12/ 16/ 32

Maximum Supply Current DC 5 V 1 A

D/A Converter 24 Bit

Frequency Response (±1 dB) 20 Hz - 20 kHz

Signal-to-Noise Ratio (1 kHz) 105 dB

Dynamic Range 88 dB

Channel Separation 90 dB

MP3 Decode Compliant with MPEG-1/2 Audio Layer-3

WMA Decode Compliant with Windows Media Audio

AAC Decode AAC-LC ".m4a" files

WAV Decode RIFF waveform Audio Format (Linear PCM only)

FLAC Decode FLAC files

Auxiliary

Frequency Response (±3 dB) 20 Hz - 20 kHz

Input Maximum Voltage 1 000 mV

Input Impedance 30 kΩ

Audio

Maximum Output Power 50 W × 4 or 50 W × 2 + 50 W × 1 (Subwoofer = 4 Ω)

Full Bandwidth Power(at less than 1 % THD) 22 W × 4

Speaker Impedance 4 Ω - 8 Ω

Preout Level/Load (USB) 2 500 mV/10 kΩ

Preout Impedance ≤ 600 Ω

General

Operating Voltage (10.5 V - 16 V allowable) 14.4 V

Maximum Current Consumption 10A

Operating Temperature Range 0°C to + 40°C

Installation Size (W × H × D) 182 mm × 53 mm × 108 mm (7-3/16" × 2-1/8" × 4-5/16")

Weight 0.58 kg (1.3 lbs)

• Subject to change without notice.

(No.MA606<Rev.002>)2/20

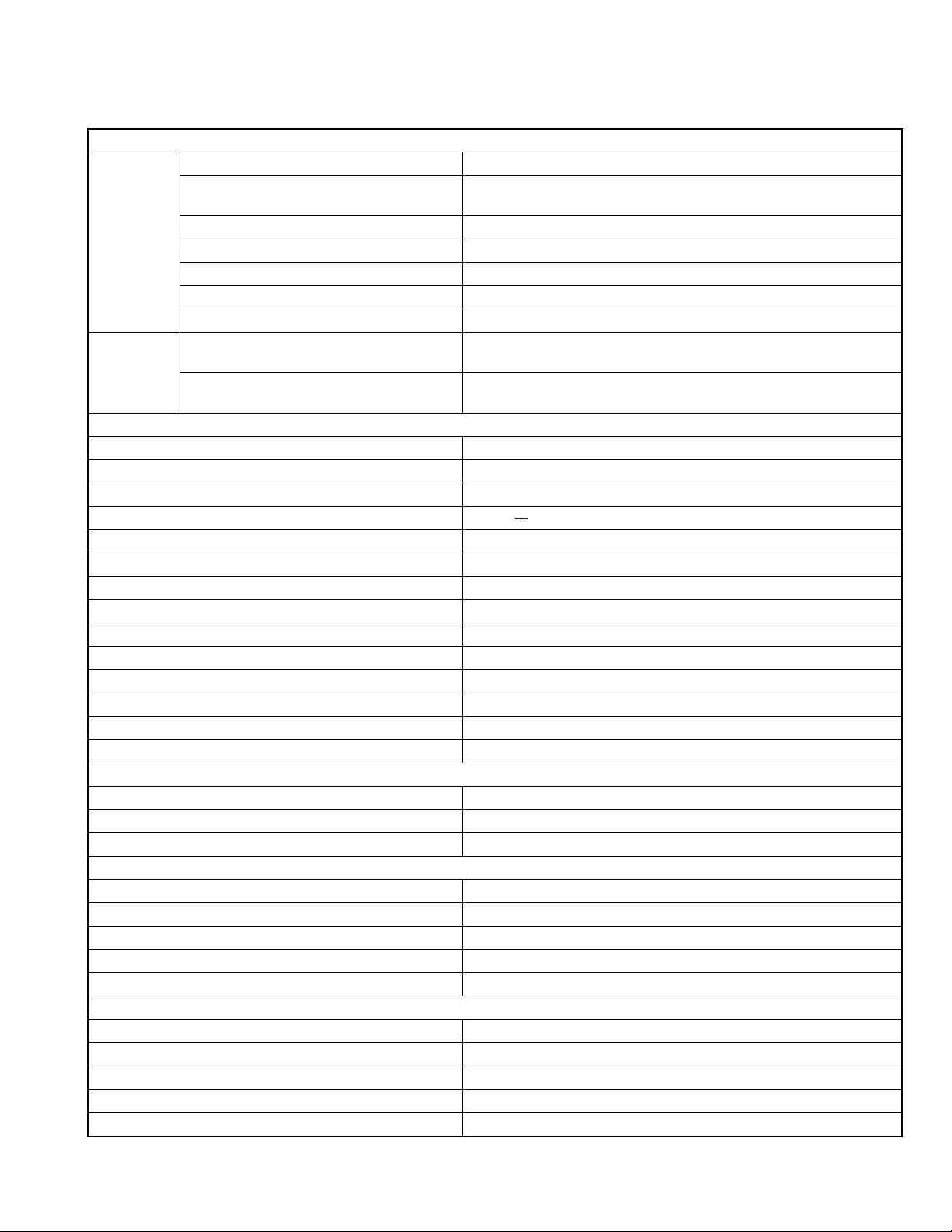

SPECIFICATION

For Europe

TUNER

FM Frequency Range (KD-X220) FM: 87.5 MHz - 108.0 MHz (50 kHz step)

Frequency Range (KD-X125/KD/X120) FM: 87.5 MHz - 108.0 MHz (50 kHz step)

FM-LO: 65.0 MHz - 74.0 MHz (30 kHz step)

Usable Sensitivity (S/N = 26 dB) 0.71 µV/75 Ω

Quieting Sensitivity(DIN S/N = 46 dB) 2.0 µV/75 Ω

Frequency Response (±3 dB) 30 Hz - 15 kHz

Signal-to-Noise Ratio (MONO) 64 dB

Stereo Separation (1 kHz) 40 dB

AM Frequency Range MW 531 kHz - 1 611 kHz (9 kHz step)

LW 153 kHz - 279 kHz (9 kHz step)

Usable Sensitivity (S/N = 20 dB) MW:28.2 µV

SW:50 µV

USB

USB Standard USB 1.1, USB 2.0 (Full speed)

Compatible Devices Mass storage class

File System FAT12/ 16/ 32

Maximum Supply Current DC 5 V 1 A

D/A Converter 24 Bit

Frequency Response (±1 dB) 20 Hz - 20 kHz

Signal-to-Noise Ratio (1 kHz) 105 dB

Dynamic Range 88 dB

Channel Separation 90 dB

MP3 Decode Compliant with MPEG-1/2 Audio Layer-3

WMA Decode Compliant with Windows Media Audio

AAC Decode AAC-LC ".m4a" files

WAV Decode RIFF waveform Audio Format (Linear PCM only)

FLAC Decode FLAC files

Auxiliary

Frequency Response (±3 dB) 20 Hz - 20 kHz

Input Maximum Voltage 1 000 mV

Input Impedance 30 kΩ

Audio

Maximum Output Power 50 W × 4 or 50 W × 2 + 50 W × 1 (Subwoofer = 4 Ω)

Full Bandwidth Power(at less than 1 % THD) 22 W × 4

Speaker Impedance 4 Ω - 8 Ω

Preout Level/Load (USB) 2 500 mV/10 kΩ

Preout Impedance ≤ 600 Ω

General

Operating Voltage (10.5 V - 16 V allowable) 14.4 V

Maximum Current Consumption 10A

Operating Temperature Range 0°C to + 40°C

Installation Size (W × H × D) 182 mm × 53 mm × 108 mm

Weight 0.58 kg

• Subject to change without notice.

(No.MA606<Rev.002>)3/20

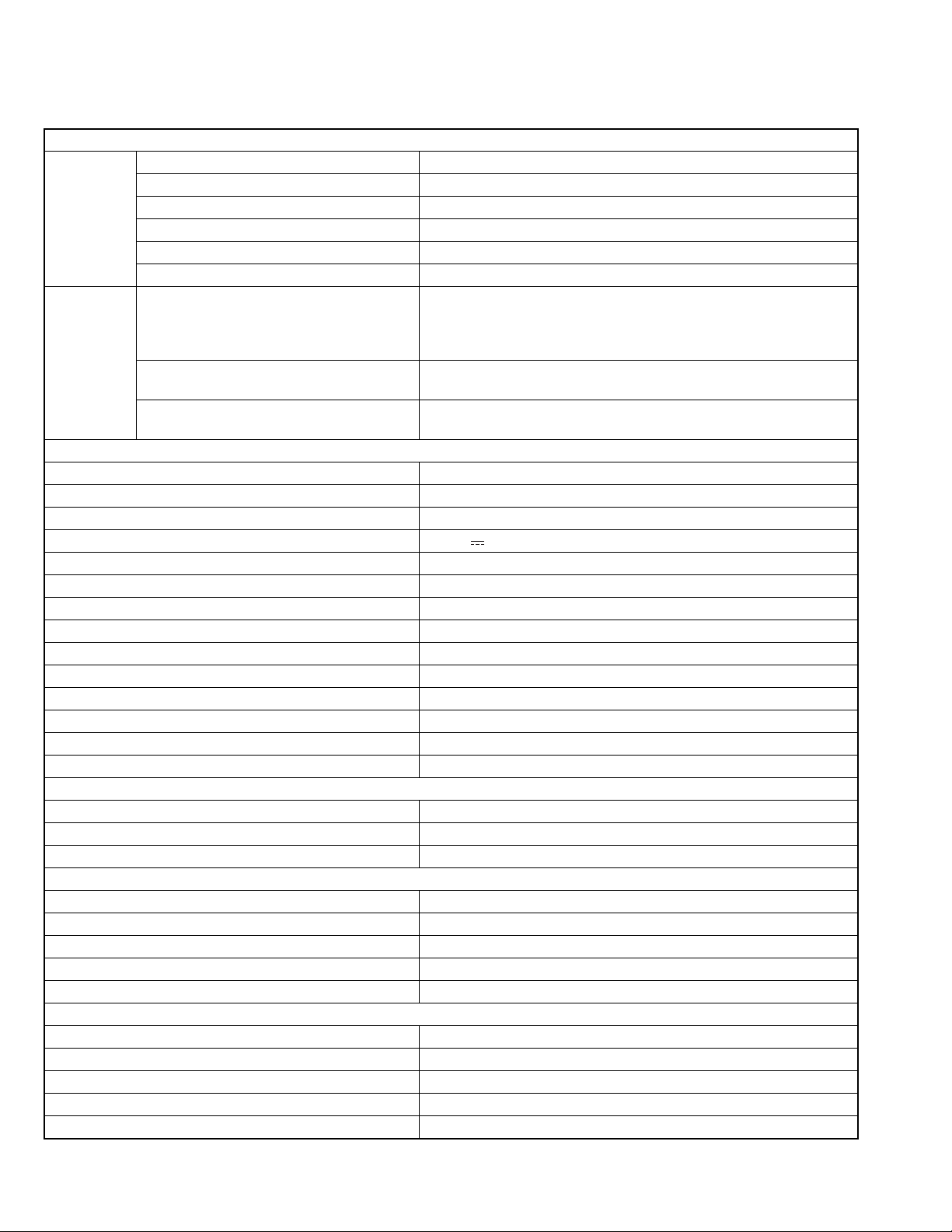

SPECIFICATION

For ASIA

TUNER

FM Frequency Range 87.5 MHz - 108.0 MHz (50 kHz step)

Usable Sensitivity (S/N = 26 dB) 8.2 dBf (0.71 µV/75 Ω)

Quieting Sensitivity(DIN S/N = 46 dB) 17.2 dBf (2.0 µV/75 Ω)

Frequency Response (±3 dB) 30 Hz - 15 kHz

Signal-to-Noise Ratio (MONO) 64 dB

Stereo Separation (1 kHz) 40 dB

AM Frequency Range Band 1 (MW): 531 kHz - 1 611 kHz (9 kHz step)

Band 2 (SW1): 2 940 kHz - 7 735 kHz (5 kHz step)

Band 3 (SW2): 9 500 kHz - 10 135 kHz /11 580 kHz - 18 135 kHz (5 kHz

step)

Channel Space Selection Band 1: 9 kHz

Band 2/3: 5 kHz

Usable Sensitivity (S/N = 20 dB) MW: 29 dBµ (28.2 µV)

SW: 30 dBµ (32 µV)

USB

USB Standard USB 1.1, USB 2.0 (Full speed)

Compatible Devices Mass storage class

File System FAT12/ 16/ 32

Maximum Supply Current DC 5 V 1 A

D/A Converter 24 Bit

Frequency Response (±1 dB) 20 Hz - 20 kHz

Signal-to-Noise Ratio (1 kHz) 105 dB

Dynamic Range 88 dB

Channel Separation 90 dB

MP3 Decode Compliant with MPEG-1/2 Audio Layer-3

WMA Decode Compliant with Windows Media Audio

AAC Decode AAC-LC ".m4a" files

WAV Decode RIFF waveform Audio Format (Linear PCM only)

FLAC Decode FLAC files

Auxiliary

Frequency Response (±3 dB) 20 Hz - 20 kHz

Input Maximum Voltage 1 000 mV

Input Impedance 30 kΩ

Audio

Maximum Output Power 50 W × 4 or 50 W × 2 + 50 W × 1 (Subwoofer = 4 Ω)

Full Bandwidth Power(at less than 1 % THD) 22 W × 4

Speaker Impedance 4 Ω - 8 Ω

Preout Level/Load (USB) 2 500 mV/10 kΩ

Preout Impedance ≤ 600 Ω

General

Operating Voltage (10.5 V - 16 V allowable) 14.4 V

Maximum Current Consumption 10A

Operating Temperature Range 0°C to + 40°C

Installation Size (W × H × D) 182 mm × 53 mm × 108 mm

Weight 0.58 kg

• Subject to change without notice.

(No.MA606<Rev.002>)4/20

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

1.5 Remote control

The Lithium battery is in danger of explosion if replaced incorrectly. Replace it only with the same or equivalent type.

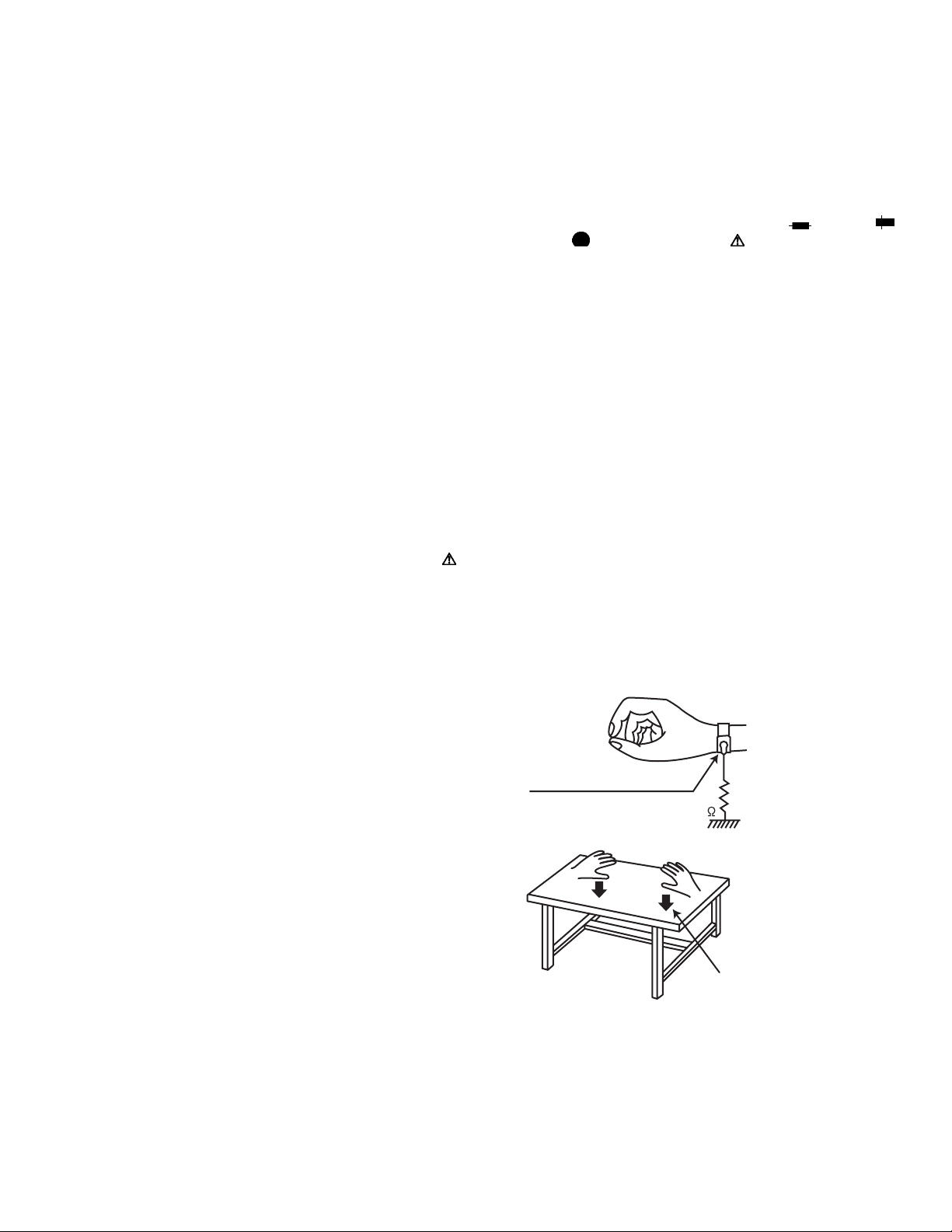

1.6 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the

semi conductors. Take care to prevent this when performing repairs.

1.6.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the semi conductors.

Be careful to use proper grounding in the area where repairs are

being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such

as a conductive sheet) or an iron plate over it before placing the unit on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity

built up in your body.

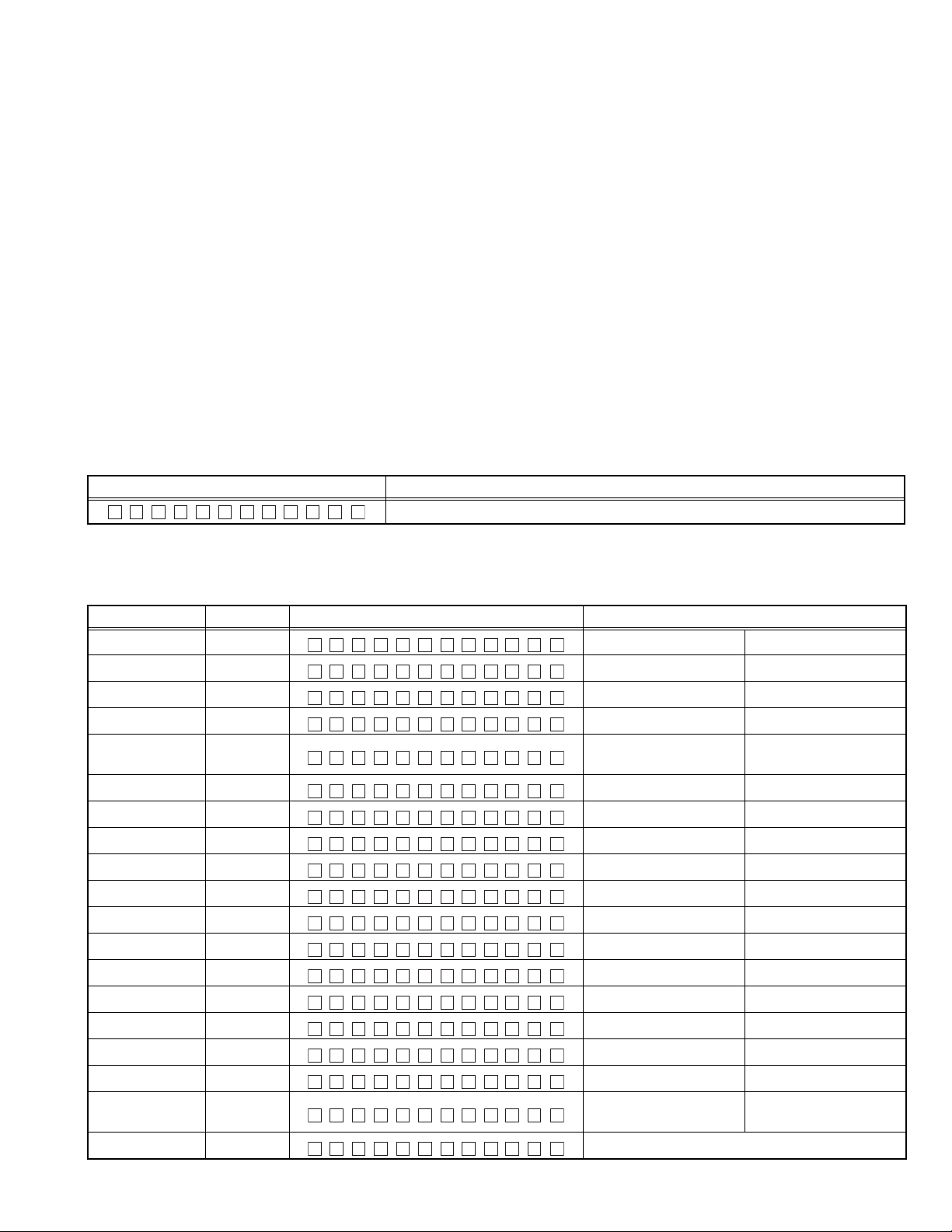

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

(No.MA606<Rev.002>)5/20

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

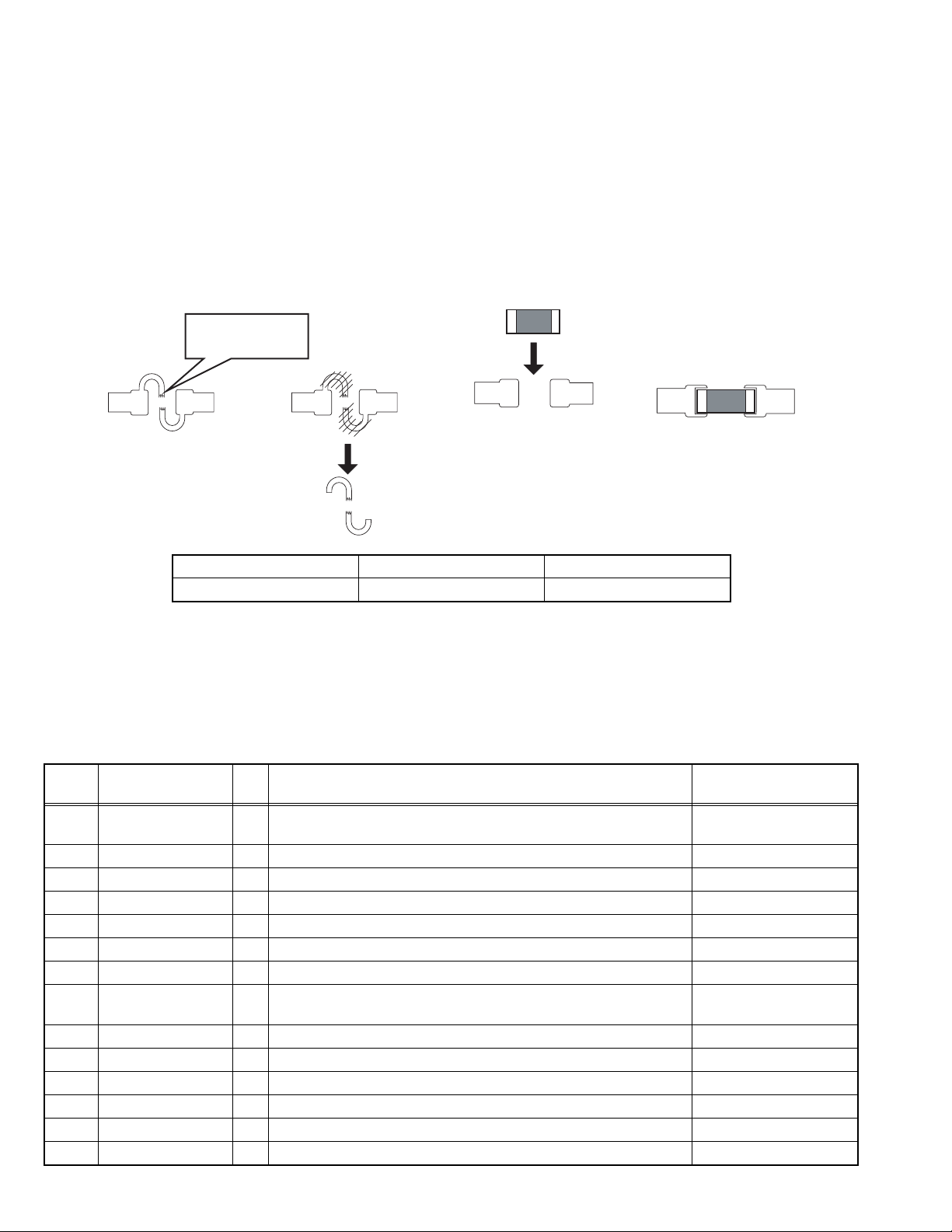

2.1 How to repair a fuse pattern

2.1.1 Purpose of fuse pattern

In order to prevent serious damage on the circuit, fuse pattern is prepared on the GND line of RCA Terminal. This damage may

take due to improper part replacement with a external equipment via RCA line.

2.1.2 Repair Procedure

(1) Check the shorted circuit at the meltdown point.

Need to clean up if the shorted circuit or carbonization happen at the fuse pattern.

(2) Add following part on the fuse pattern.

(3) Check output level.

Meltdown point

Part Number Part Name SPEC

F53-0513-08 PATTERN FUSE 4A

2.1.3 After finished repair

Due to improper part replacement, this meltdown occurs.

Thus please notice following information when the unit is returned to your customer.

Things to be checked before installing the unit.

(1) Check the GND line of external amplifier or other equipment which must connect properly.

(2) Check whether the GND line is not short-circuited with the battery terminal. (do not short-circuit these lines)

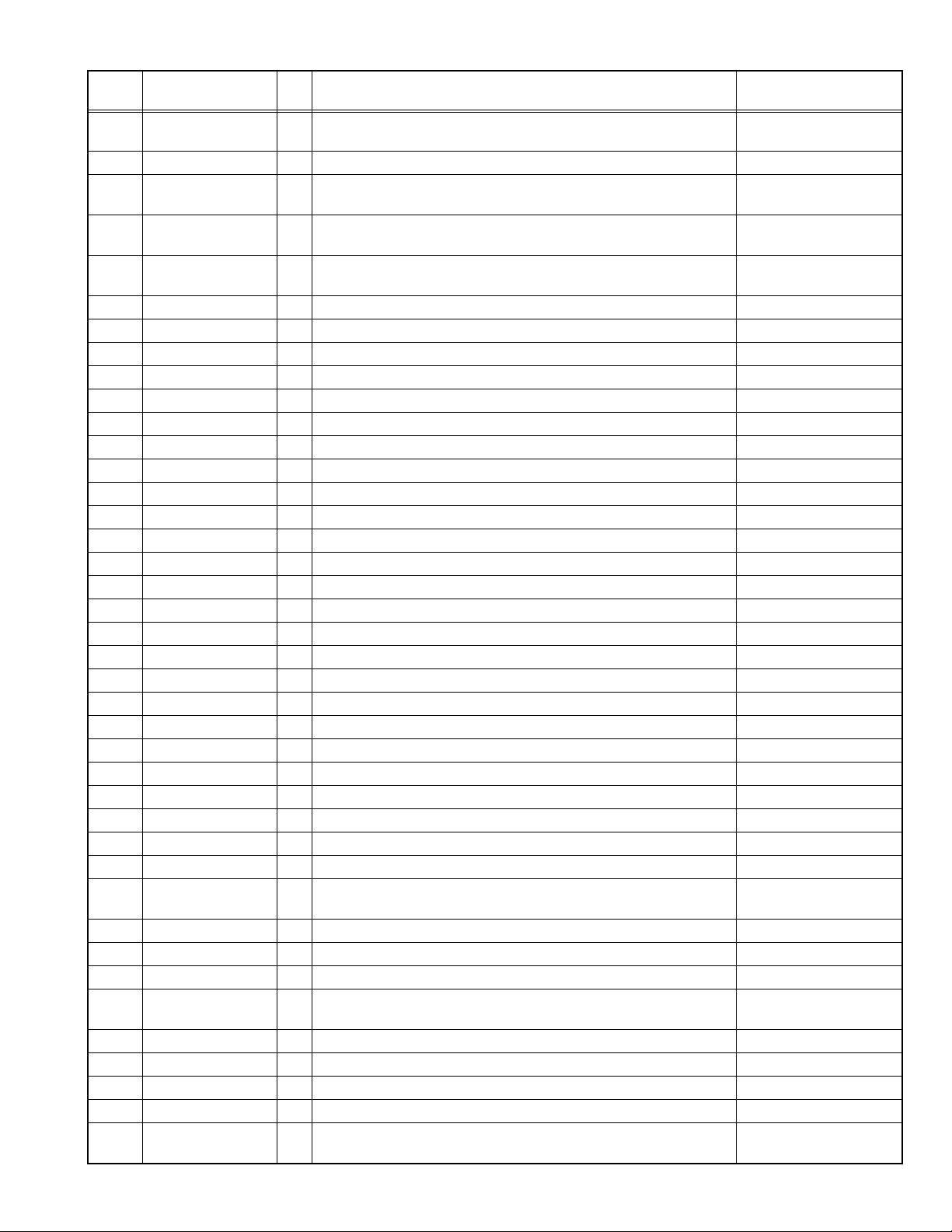

2.2 MICROCOMPUTER’S TERMINAL DESCRIPTION

IC701 (R5S726A0D216FP) on MAIN PWB ASSY

Pin No. Pin Name I/O Application

1 LCD_INH O Display On/Off Control L: Display OFF/

2 DAB_COM_ON O Enable DAB micon (For DAB model) H: ON/L: OFF

2 NC O No Use (for non DAB model)

3 PVcc - Power supply for I/O circuits

4 DZF I Zero Input Detect L: Mute OFF/H: Mute ON

5Vss -GND

6 PANEL_PON O Supply Control to Panel L: ON/H: OFF

7 DC_ERR2 I Detect DC Clip (for ST Power Amp IC) L: DC Error ON/

8 PWIC_MUTE O Muting Output for Power Amp IC L: Mute ON/H: Mute OFF

9 LCD_CE O LCD Driver IC Chip Enable Output (for LCD Model)

10 Vss - GND

11 LCD_CLK O LCD CLK Output

12 Vcc - Power supply

13 RGB_CLK O I2C Clock Output for RGB Driver (For RGB Model)

Processing/Operation/

Description

H: Display ON

H: DC Error OFF

(No.MA606<Rev.002>)6/20

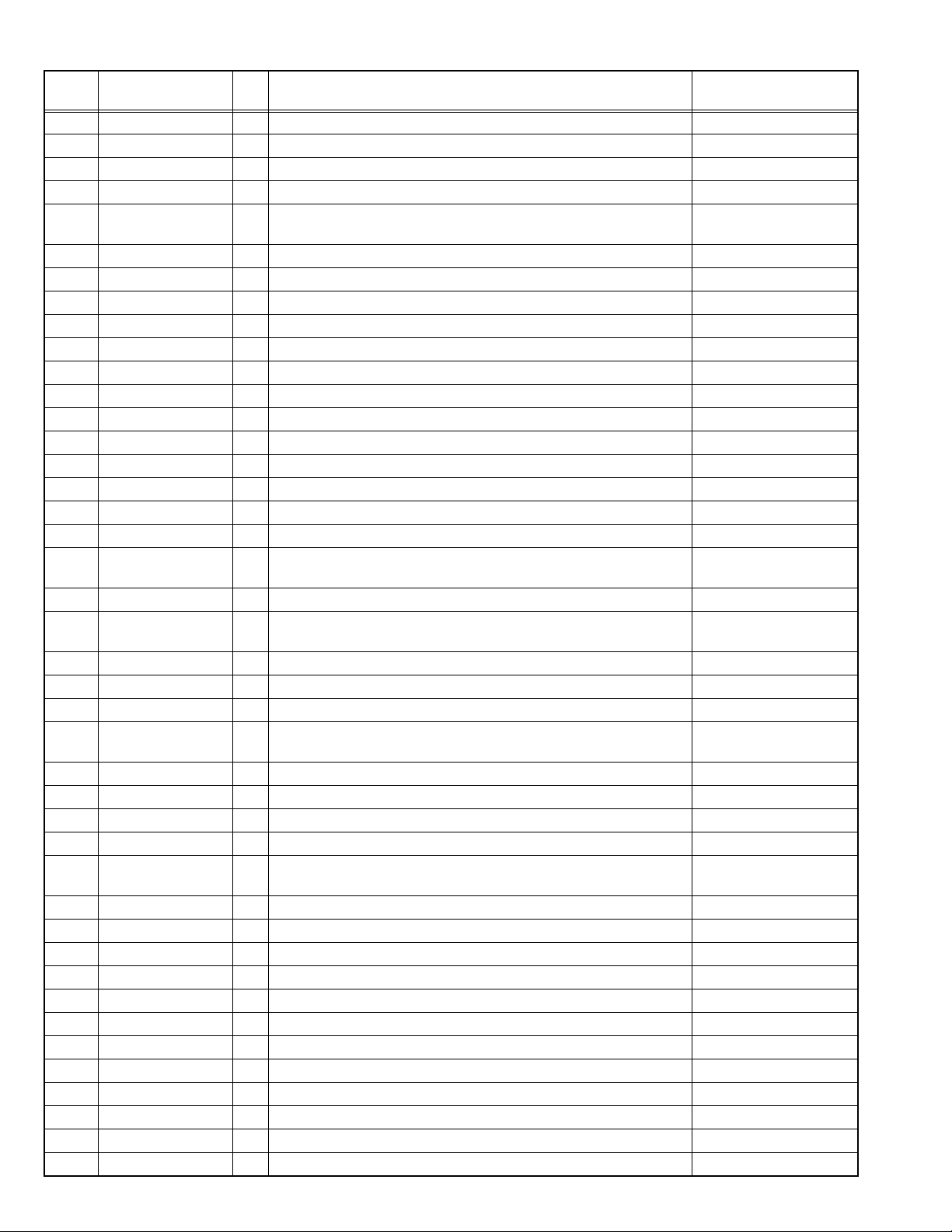

Pin No. Pin Name I/O Application

13 PCB_TEST_MODE

_RX

14 LCD_DATA_SYS O LCD DATA Output (for LCD Model)

14 LCD/

RGB_DATA_SYS

14 PCB_TEST_MODE

_TX

15 USB_PON O Enable Output for High Side Switch L: HisideSW OFF/

16 PVcc - Power supply for I/O circuits

17 BT_DATA_BT I BT Data Input (For BT model only)

17 NC O No Use (for non BT model)

18 Vss - GND

19 BT_DATA_SYS O BT Data Output (For BT model only)

19 NC O No Use (for non BT model)

20 Vcc - Power supply

21 PWIC_STBY O Output to Power On Power Amp IC L: Standby/H: Play

22 SXM_DATA_SXM I SXM Data Input (For SXM model only)

22 NC O No Use (for non SXM model)

23 SXM_DATA_SYS O SXM Data Output (For SXM model only)

23 NC O No Use (for non SXM model)

24 DEBUG_1A O For Debug

24 DAB_COM_CLK O Clock to DAB (for DAB model only)

24 HD_SPICLK O Clock to HD Decoder (for HD model only)

25 DEBUG_1B O For Debug

25 DAB_REQ_SYS O Command Request from main micon to DAB micon (for DAB model)

25 HD_REQ_SYS O Command Request from SYS-com to HD (for HD model)

26 DEBUG_1C O For Debug

26 DAB_DATA__SYS O DAB Data Output (for DAB model only)

26 HD_DATA_SYS O HD Data Output (for DAB model only)

27 DAB_DATA_DAB I DAB Data Input (for DAB model only)

27 HD_DATA_HD I HD Data Input (for HD model only)

27 NC O No Use (for non DAB / HD model)

28 PVcc - Power supply for I/O circuits

29 FREQ_SEL O Frequency Select Pulse: Power On/

30 Vss - GND

31 ENC2 I Volume Encoder Pulse Input 2

32 ENC1 I Volume Encoder Pulse Input 1

33 REMO I Remocon Input L (Pulse): Remote control

34 LCD_DATA_LCD I LCD DATA Intput (for LCD Model)

35 MRC_DATA_MRC I Marine REMO Data Input UART 57.6kHz (For MARINE model)

35 DEBUG_2A O For Debug

36 PVcc - Power supply for I/O circuits

37 NC O System Clock Output to External Devices (for LCD Model)

I PCB Test Mode RX

O LCD and RGB DATA Output (for RGB Model)

O PCB Test Mode TX

No Use

Processing/Operation/

Description

H: HisideSW ON

L: Power Off

data/H: Standby

(No.MA606<Rev.002>)7/20

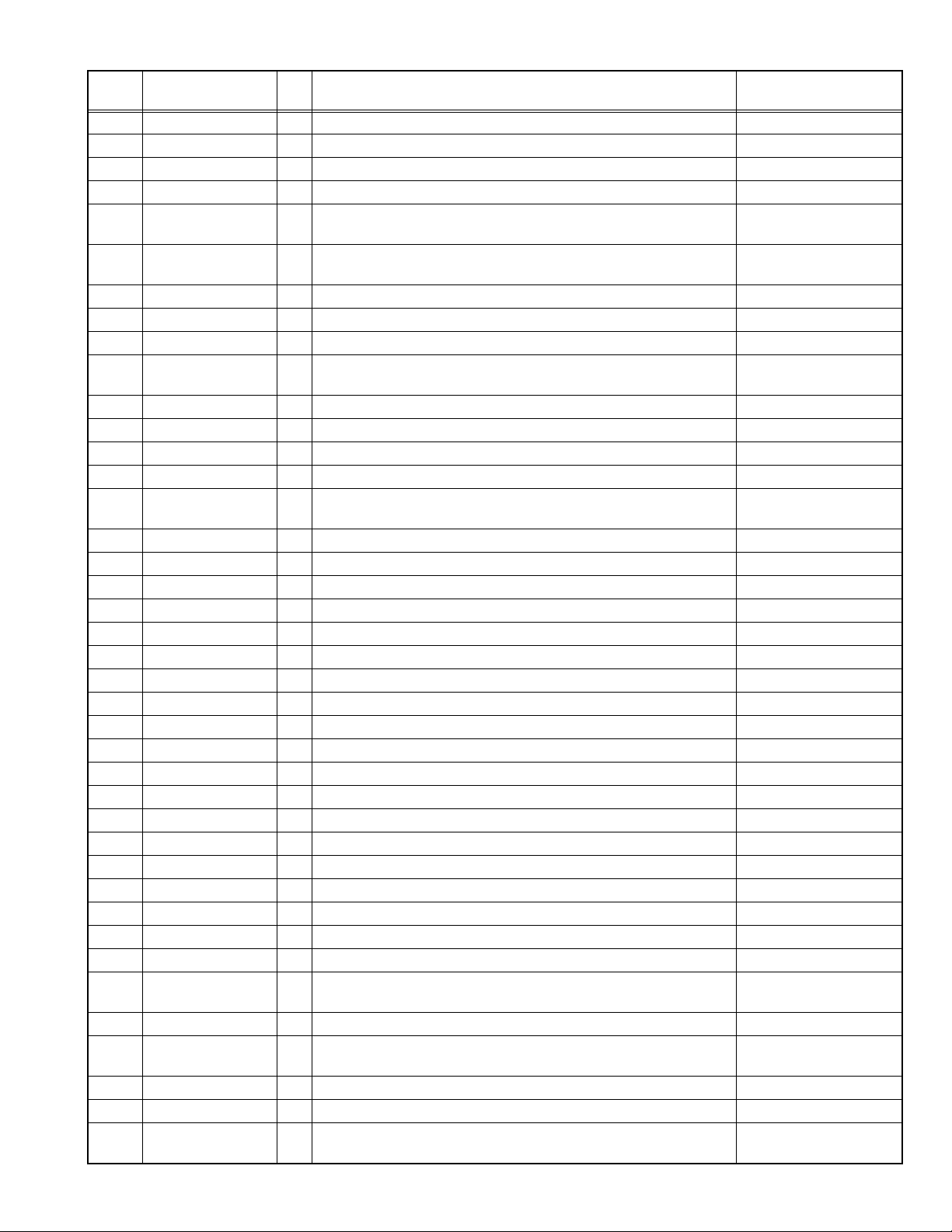

Pin No. Pin Name I/O Application

38 Vss - GND

39 RESET I Reset Input

40 Vss - GND

41 PLLVcc - Power supply for PLL

42 PAN_DET I Panel Detection input L: Panel Attached/

43 Vcc - Power supply

44 EXTAL I High Speed Clock 12MHz

45 XTAL O High Speed Clock 12MHz

46 Vss - GND

47 Vss - GND

48 PVcc - Power supply for I/O circuits

49 D-0 I/O USB Data- 0

50 D+0 I/O USB Data+ 0

51 ASEMD I ASE Mode Select Pin

52 NC I No Use

53 BT_MUTE I BT Mute L: Mute OFF/H: Mute ON

53 NC I No Use (for non BT model)

54 STAGE2 I Model Selecting Input 2

54 STEERING_REMO2I OE Remote In 2 (for DOP models)

Processing/Operation/

Description

H: Panel Detached

55 STAGE1 I Model Selecting Input 1

55 STEERING_REMO1I OE Remote In 1 (for DOP models)

56 TEL_MUTE I Tel Mute Detection Input (for JVC Model)

56 LINE_MUTE I Line Mute Detection Input (For KWD Model)

56 No Use I No Use (for non support Tel mute model)

57 DC_ERR1 I Detect DC Offset Error from EVOL IC L: DC Error ON/

H: DC Error OFF

58 Avss - GND

59 Avcc - Power Supply

60 Avref - Reference Power Supply

61 TRST I Debugging Interface. Reset Input.

62 ASEBRKAK/ASE-

BRK

63 TDO O Debugging Interface. Serial Output for Instructions and Data

64 TDI I Debugging Interface. Serial Input for Instructions and Data

65 TMS I Debugging Interface. Test Mode Select Signal Input.

66 TCK I Debugging Interface. Test Clock Input.

67 AUDIO_X2 O Audio Clock 16.9MHz (for External DAC)

68 AUDIO_X1 I Audio Clock 16.9MHz (for External DAC)

69 PVcc - Power supply for I/O circuits

70 SPBCLK O FLASH SPI Multi I/O Bus Clock output

71 Vss - GND

72 SPBSSL O FLASH SPI Multi I/O Bus Slave Select Output

73 SPBIO0 I/O FLASH SPI Multi I/O Bus I/O Data 0

74 SPBIO1 I/O FLASH SPI Multi I/O Bus I/O Data 1

I/O Emulator Break Mode Acknoledge/Break Input

(No.MA606<Rev.002>)8/20

Pin No. Pin Name I/O Application

75 SPBIO2 I/O FLASH SPI Multi I/O Bus I/O Data 2

76 Vss - GND

77 SPBIO3 I/O FLASH SPI Multi I/O Bus I/O Data 3

78 Vcc - Power supply

79 MD_CLK I Clock Mode Set (Power ON Reset)

EXTAL Pin Input Clock Ranges from 10 to 12 MHz

80 MD_BOOT I BOOT Mode Set L: Boot mode 0/

81 AUDIO_XOUT O DAC Audio Clock Output 16.9MHz

82 PVcc - Power supply for I/O circuits

83 DAB_PON O Control 3..3V power for DAB Module (for DAB model only) H: ON/L: OFF

83 HD_PON O Control 3.3V power for HD module (for HD model only) HD source= H: ON/

83 NC O No Use (for non DAB/non HD model)

84 Vss - GND

85 MUTE O Muting Output for Evol & Line Out L: Mute ON/H: Mute OFF

86 Vcc - Power supply

87 BT_RST O BT Reset Output (For BT model) L: Reset ON/

87 NC O No Use (for non BT model)

88 DCDC6V_PON O Enable Output for DC-DC Regulator

89 SXM_PWR O Power Supply for SXM (For SXM model only) L: PWR Off/H: PWR On

89 NC O No Use (for non SXM model)

90 DAB_REQ_DAB I Command Request from DAB micon to main micon

90 NC O No Use (for non DAB model)

91 EVOL_SCL I/O I2C Clock 391kHz for E-Vol

91 EP_SCL I/O I2C Clock 391kHz for E2PROM

91 TU_SCL I/O I2C Clock 391kHz for Tuner

92 EVOL_SDA I/O I2C Data for E-Vol

92 EP_SDA I/O I2C Data for E2PROM

92 TU_SDA I/O I2C Data for Tuner

93 IPOD_SCL O iPod Authentication IC I2C Clock Clock speed 23kHz

93 NC O No Use (For non-iPod Model)

94 IPOD_SDA O iPod Authentication IC I2C Data

94 NC O No Use (For non-iPod Model)

95 REG_SCL O I2C Clock for Regulator IC

96 REG_SDA O I2C Data for Regulator IC

97 NC O No Use

98 DIM_IN I Dimmer Control Input (for JVC Model) L: Dimmer Detect ON/

98 NC O No Use (For KWD Model) keep L output setting

99 REG_FLG I Power Detection L: Detect OFF/

100 Vss - GND

101 PVcc - Power supply for I/O circuits

102 MRC_REQ_MRC I Command Request from Marine REMO to SYS-com

(For MARINE model)

Processing/Operation/

Description

H: Boot mode 1

Other source= L: OFF

H: Reset OFF

H: Dimmer Detect OFF

H: Detect ON

(No.MA606<Rev.002>)9/20

Pin No. Pin Name I/O Application

102 NC O No Use (for non Marine model)

103 SSISCK O DAC Audio Serial Data Clock 44.1kHz

104 SSIWS1 O DAC L/R Clock 44.1kHz

105 MRC_PON O Enable Marine REMO Power Supply (For MARINE model)

105 DEBUG 2C O For Debug H: Power On / L: Power Off

106 SSITx O Servo DSP Data Output

107 Vss - GND

108 DAC_CCLK O DAC Control Data Clock

109 Vcc - Power supply

110 DAC_CDTI O DAC control Data Input

111 TU_RST O HELIO/CAYMAN (HD) Reset L: Reset ON/

111 NC O No Use (For non DAB/HD model)

112 PVcc - Power supply for I/O circuits

113 MRC_DATA_SYS O Marine REMO Data Output UART 57.6kHz (For MARINE model)

113 NC O No Use (for non Marine model)

114 Vss - GND

115 DAC_CS O DAC Chip Select

116 BEEP O Output for Beep Tone Generator H (Pulse): BEEP/L: OFF

117 MRC_REQ_SYS O Command Request from SYS-com to Marine REMO

(For MARINE model)

117 NC O No Use (for non Marine model)

118 PCB_TEST_MODE I PCB Test Mode Switch L: Normal Mode/H: Check

118 WDT O Watch Dog Timer output L: Normal Mode /

119 MRC_EN O Marine REMO Data Select (For MARINE model)

119 DEBUG_2B O For Debug

119 Field Test 2 O RDS data log output (standby for field test)

120 Field Test 1 O RDS data log output (standby for field test)

120 FDAC_RST O DAC reset L: DAC reset/

Processing/Operation/

Description

H: Reset OFF

Mode (After Reset software need to check the

pin input. If detect high it

should enter Serial Number mode)

H: Reset by WDT

H: DAC reset off

(No.MA606<Rev.002>)10/20

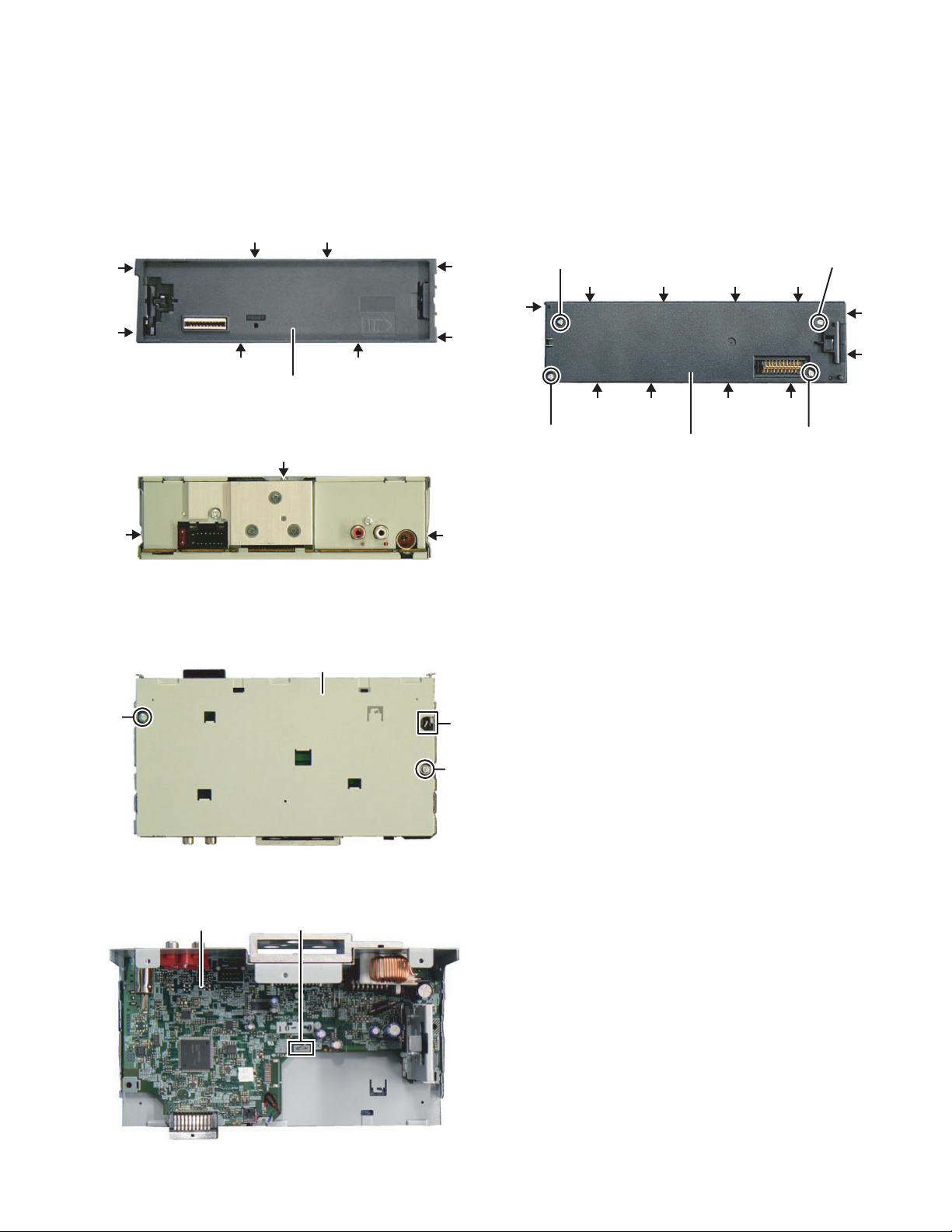

SECTION 3

DISASSEMBLY

3.1 Main body

3.1.1 Removing the MAIN PWB (See Fig.1 to 4)

(1) Disengage the 8 hooks a, and remove the FRONT CHAS-

SIS ASSY.

(See Fig.

1)

aa

a

a

aa

FRONT CHASSIS ASSY

Fig.1

(2)

Remove the 3 screws A . (See Fig.

2)

A

A

Fig.2

(3) Remove the 2 screws B. (See Fig.3)

(4) Disengage the 1 hook b, and remove the BOTTOM

COVER with MAIN PWB.

(See Fig.3)

BOTTOM COVER

A

3.1.2 Removing the SWITCH PWB (See Fig.5)

(1) Remove the VOLUME KNOB.

(2) Remove the 4 screws D.

(3) Disengage the 11 hooks d, and remove the REAR

COVER.

(4) Remove the SWITCH PWB.

a

D

d d d d

d

D

d

a

d

d ddd

D

REAR COVER

Fig.5

D

B

Fig.3

(5) Disengage the 1 hook c, and remove the MAIN PWB.

(See Fig.4)

MAIN PWB

c

Fig.4

b

B

(No.MA606<Rev.002>)11/20

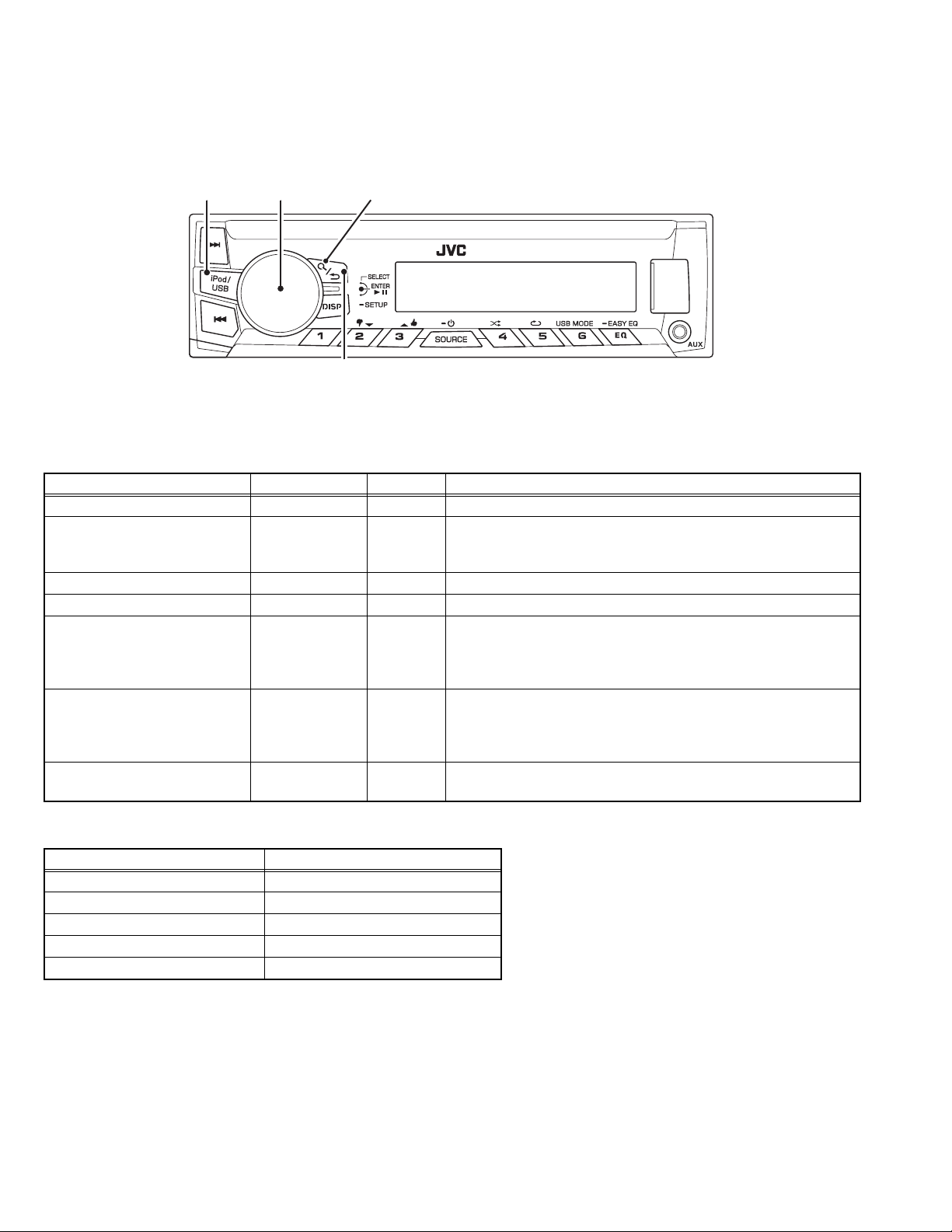

SECTION 4

ADJUSTMENT

4.1 Outline

4.1.1 Panel

ACCENT SEARCHVOL

RETURN

A symbol "" in the key column indicates that the key should be pressed and held for 1 second or longer.

4.1.2 Test Modes

These test modes are available in normal production ROM.

Transition to Test Mode shall be available during DC Error detection.

Test Mode Mode Source Operation

Production Test Mode - All Press and hold [DISP] key and [SOURCE] key and reset.

Service Test Mode Normal Mode /

Production Mode

Service Information Clear Mode - All Press and hold [RETURN] key and [SOURCE] key and reset.

DC Error Information Mode - All Press and hold [DISP] key and [] key and reset.

DOP Test Mode Normal Mode All Pressing and holding [SELECT] key, press [DISP] key for 7 sec-

Bluetooth Device Name Select

Mode

Tunisia Area /

Tuner Span Change Mode

4.1.3 Release from Test Mode

These actions will release the Test Mode and transit back to Normal Mode

Method Remarks

Reset All Modes

Momentarily voltage drop All Modes

ACC OFF All Modes

POWER OFF All Modes

Panel Detach All Modes

Normal Mode BT Audio Pressing and holding [ACCENT] key, press [DISP] key for 3 sec-

Normal Mode All Pressing and holding [VOL] key, press [RETURN] key for 3 sec-

All Pressing and holding [DISP] key, press [] key for 7 seconds.

(Starting to press [DISP] key and [] key at the same time can not

be entered into the mode)

onds.

(Starting to press [SELECT] key and [DISP] key at the same time

can not be entered into the mode)

onds.

(Starting to press [ACCENT] key and [DISP] key at the same time

can not be entered into the mode)

onds.

(No.MA606<Rev.002>)12/20

4.2 Production Test Mode

Press and hold [1] key and [3] key and reset.

4.2.1 Test Mode Defaults

During Production Test Mode, the following settings defer from the Normal Mode.

The settings will change immediately after mode activation.

Difference in action Setting value

Period to prohibit TEL/LINE MUTE function (Normal Mode: 10 secs) 1 second

Writing-in to E2PROM when DC error is detected Prohibited

"DEMO" item in Setup Menu OFF

Power supply during ACC OFF (Back Up On) MUTE terminal turns OFF after 2 seconds

"BEEP" item in Setup Menu ON

Volume range 0 to 44

Source change interval timer 0 seconds

When detected the 0 bit mute Mute off

Various setting item Setting value

Default Volume 15

"BASS BOOST" OFF

"LOUDNESS" OFF

"TEL MUTING" ON

Initial Source FM (Mechaless Models) /

CD (Non-Mechaless Models)

Language English

EQ FLAT

Fader / Balance Center

Digital Track Expander / Sound Reconstruction Set OFF

"VOL ADJUST" / "VOLUME OFFSET" 0

DEMO Mode Setting OFF

4.2.2 Mode structure

The following table shows the test modes that can be accessed from the different sources in Production Test Mode.

Source Test mode

Tuner TUNER Test Mode

USB USB Test Mode

4.2.3 Mode content

Syscon shall display the following information after entering Production Test Mode.

Display content Details

All lights on (BOTH LCD & LED including dual color switchable)

Set should not be able to power on if sub clock is not functioning.

The display is released when another operation is executed.

4.2.4 Special Operation by Key Input

Behaviour Details

Volume Adjustment to 44

Only during Normal display

(Invalid during Menu)

4.2.5 How to transit to Version Display Mode

Item Operation Display content Details

Transit to Display

Mode

RETURN

Pressing and holding [DISP] key, press [] key for 0.5 seconds.

(Starting to press [DISP] key and [] key at the same time can not be entered into

the mode)

Transit to Version Display Mode

(Default status: All Lights ON)

(No.MA606<Rev.002>)13/20

4.2.6 Version Display Mode

Item Operation Display content Details

All Lights ON/

All lights ON

TEST

Syscom version

display

Stage Setting ##: Stage Setting for current hardware

Y–SS##@@@

TSAGE :21 ##

## = File Number

@@@ = Syscon Version Number

Serial No. Display (8 digits)

Serial No. display

SN 00000000

Display to support ASCII characters

********: Blank

@@@@@@@@: EEPROM Read Error

DISP

(Toggle)

## = Blank: Verifying

OK: IC mounted

NG: IC not mounted

iPod IC Mount

Verification Status

Display

(USB models

only)

iPod ##

**: Non iPod support model

In addition, upon entering this mode, P-CON is

turned ON.

When a result is OK, P-CON is turned off.

Upon exit, P-CON remains OFF.

When a result is NG, P-CON is kept ON condition.

Upon exit, P-CON remains ON.

Pre-out Switch

(1 Pre-out / 2 Pre-

EQ

L/O SU B.W

Switch Pre-out with toggle

out model only)

Mode release

SOURCE

Transition

Mode release RETURN

Return to Normal mode

Return to Normal mode

4.2.7 Tuner Test Mode Specification

The following display shall be indicated according to the TUNER status.

Status Display content Details

TUNER IC

Communication Error

RDS/RBDS Specified

data reception

TUN CON NG

DRS STTE

Communication to TUNER IC not available

(indicated unless the mode is in Clock Display Mode).

Turn OFF P-CON forcibly if PS=RDS TEST is received.

P-CON recovers with Power OFF/ON.

Item Operation Display content Details

Display TUNER IC version

TUNER IC display EQ

TA2********

'AT2 ********' is eg "AtomIC2 57V1B101" indicating

"AtomIC2 TEF6657V1B 1.01"

*Not applicable and no function for HD and DAB models

(No.MA606<Rev.002>)14/20

4.2.8 USB Test Mode Specification

Applicable for iPod model only.

Status Display content Details

## = Blank: Verifying

NG: IC not mounted

**: Non iPod support model

Upon source change to USB source or USB

device plug in:

Verifying: Show "iPod: ##"

NG: Always show "iPod: NG" even during "NO

DEVICE" or playback.

**: Always show "iPod: **" even during "NO

iPod IC Mount Verification Status

Display

iPod ##

DEVICE"

OK: Change back to nomal display ("NO DE-

VICE / normal playback display).

In addition, upon enter to this mode, P-CON is

turned ON.

When a judgment result is OK, P-CON is

turned off.

Upon exit, P-CON still remain OFF.

When a judgment result is NG, P-CON is kept

ON condition.

Upon exit, P-CON still remain ON.

4.3 Service Test Mode

In the STANDBY source, while pressing and holding [2] key, press [6] key for 7 seconds.

(Starting to press [2] key and [6] key at the same time can not be entered into the mode)

4.3.1 Default status immediately after the mode activation

It shall be same as the normal activation.

4.3.2 Mode content

Syscon shall display the following information after entering this mode.

Display content Details

RSVT TES

Display is released when an operation is executed.

4.3.3 Common operation mode for only STANDBY sources

Item Operation Display content Details

Syscom version

display

6

Y–SS##@@@

## = File Number

@@@ = Syscon Version Number

00 to 50 are displayed in "XX".

Power ON

duration display

OPNTM HX0X

2

OPNTM XXXXX

For less than 1 hour, the display is indicated per 10

minutes.

00001 to 10922 are displayed in "XXXXX".

MAX 10922 (hours)

(No.MA606<Rev.002>)15/20

4.4 Service Information Clear Mode

Press and hold [2] key and [5] key and reset.

4.4.1 Default status immediately after the mode activation

It shall be same as normal activation.

4.4.2 Mode content

After entering this mode, Syscon shall clear the information stored for service and output the result to the display.

Cleared information changes will take place only after reset.

Display Display content Details

Data Clear in

IIINTALIZE

Data Clearing in Progress.

Progress

Data Clear OK Data cleared successfully.

Data Clear NG Data cleared with error, clear the data.

TDA A CLR OK

TDA A CLR NG

Display Blinks (250ms interval)

The following table shows the data that is cleared.

Information to Clear Details Storage area

Service information

DC error information

CD EJECT number of times display E2PROM

Forced Power OFF information display E2PROM

DC error 1 display (wrong connection & other detection information in detecting duration) E2PROM

DC error 2 display (capacitor leakage detection number information) E2PROM

Tuner Area Setting E2PROM

Tuner information

Preset Frequency E2PROM

Preset PI code E2PROM

Tagging information Token data memory index E2PROM

4.5 DC Error Information Mode

Press and hold [3] key and [6] key and reset.

4.5.1 Default status immediately after the mode activation

It shall be same as normal activation.

4.5.2 Mode content

Syscon shall display the following information after entering this mode.

Display content Details

DC ERR

DC OK

When DC error is detected

When DC error is not detected

Item Operation Display content Details

DC 1 ER R

DC ERR1display

DC1 OK

When wrong connection & DC error in other detection duration is detected.

When wrong connection & DC error in other detection duration is not detected.

Clear detection information when wrong connection

DC ERR1 clear

DC1 OK

& DC error in other detection duration is displayed.

(Clear data flash)

Display detecting number of times in capacitor leak-

DC ERR2 display

DC2 4

age detection duration.

#: 0 to 4

Clear number of times for detection information in

DC ERR2 clear

DC 2 0

capacitor leakage detection duration. (Clear data

flash)

(No.MA606<Rev.002>)16/20

4.6 DOP Test Mode

Pressing and holding [SELECT] key, press [DISP] key for 7 seconds.

4.6.1 DOP Mode Common Setting

Common settings for all car makers are as follows:

Demo: No demo animation

Remove all DEMO related items

Power on animation: Show carmaker's name

Only opening animation will show "Car maker's name"

Setup menu: Delete Demo

Color setting for RGB model: Refer to manufacturer preference below:

4.6.2 EEPROM DOP Read Error Display

In the case of an EEPROM read error or EEPROM DOP read error, the unit will behave accordingly.

(1) No Power on animation

(2) No Demo animation

(3) Demo removed in setup menu

(4) Color settings set to default

(5) Serial number display replaced by "SN @@@@@@@@"

4.6.3 Mode content

1) Enter DOP Mode. Pressing and holding [SELECT] key, press [DISP] key for 7 seconds.

Display content Details

PMODEDO

2) Select manufacturer setting.

Note: RGB color save as USER color. DEFAULT color set to USER.

The order is priority. Lower Priority brand need to press and hold(2 secs)

: press and hold (2 second) on button mentioned as follow

Display content Operation Display content Color

No Demo 1

Toyota 2

Honda 3

Ford 4

Suzuki 5

Hyundai 6

Mitsubishi

FIAT

Iveco DISP

Alfa Romeo 1

KIA 2

Volkswagen 3

Chevrolet 4

Peugeot 5

Nissan 6

Isuzu

Skoda

Daihatsu DISP

Default RETURN

JVC

TOYOTA

HONDA

FORD

SUZUKI

HYUNDA I

MI TSUBISHI

FIAT

IVECO

ALFA ROMEO

KIA

VOL KSWAGEN

CHE VRO L E T

PEUGEOT

NISSAN

ISUZU

SKODA

DAIHATSU

DEFAUL T

(same as Daihatsu)

Blue

Lime

Blue

Greenish Blue

Yellow Amber

Blue

Apple

White

White

Red

Blue

White

Red

Green

Orange

Red

Yellowish Green

Yellow Amber

(Same as Suzuki)

Return to default JVC normal setting.

7

25

5

3

16

7

14

User

User

13

7

User

13

24

16

13

User (R=22, G=31, B=0)

15

(No.MA606<Rev.002>)17/20

4.7 Tuner Span Change Mode

Pressing and holding [VOL] key, press [RETURN] key for 3 seconds.

4.7.1 Default status immediately after the mode activation

It shall be same as normal activation.

After selection of the setting item, the receiver should exit this mode and return to the display before entering this mode.

This setting will be stored in EEPROM.

4.7.2 Mode content

Syscon shall display the following information after entering this mode.

Item Operation Display content Details

Tuner Span

Change Mode

VOL +/-

(*1)

Tuner Span

Change Mode

VOL +/-

(*2)

Release Mode VOL

ARE A AS I A

AREA TUNISIA

AREA EUROPE

AREA TUNISIA

Default setting for Asia models.

Change to 'Asia' area type.

Change to 'Tunisia' area type.

Default setting for Europe models.

Change to 'Europe' area type.

Change to 'Tunisia' area type.

Depending on display pattern in normal mode.

*1: Only applicable for Asia ('U') models

*2: Only applicable for Europe ('E') models

(No.MA606<Rev.002>)18/20

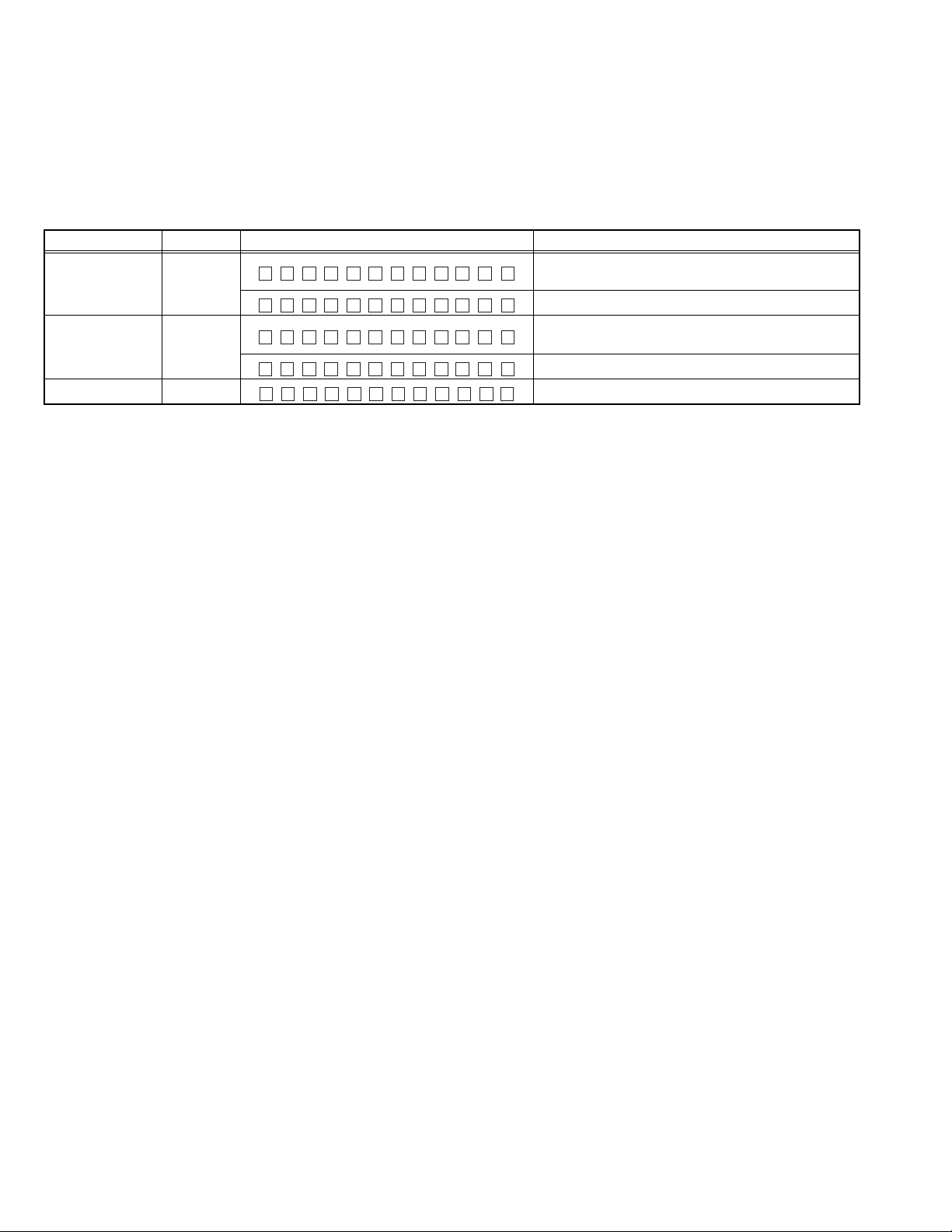

4.8 DC Offset error description

A

4.8.1 DC Offset detection circuit design

• Purpose:

To prevent breakdown, when occur DC offset between speaker output "+" and "-".

• Target:

Detect DC offset, then stop the Power Amp operation and shift

to specified condition.

4.8.2 Possible causes of DC offset at speaker output lines

(1) Mis-connection for Speaker output for example touch to car

body or battery line.

(2) Current leak of coupling capacitor for Power IC input.

(3) Current leak of AC-GND capacitor for Power IC AC-GND.

(4) Capacitor shorted of above parts due to foreign object.

C-tc

E-Vol

Win_TC

Win_In

DC Error

C-in

C-in

R3

C-in

C-in

C-ac2C-ac1

Sw5V

R2

R1

C3

R4

Audio Pwr Amp

In 1

In 2

In 3

In 4

AcGnd

Offset Detect

Out

Micon

ADC In

4.8.5 Manipulate after detect DC Offset

• If detected error 10 consecutive times, and 10th error occurred

in "Mis-connect detection period", judge as "Mis-connect".

• If detected error 10 consecutive times, and 10th error occurred

in "Capacitor leak detection period", judge as "Capacitor leak ".

• If detected error 10 consecutive times, and 10th error occurred

in "Other detection period" and detected another 10 errors consecutively, then judge as "Other".

• If judge as "Mis-connect".

- turn off speaker output.

- display "MISWIRING", check wiring connection then reset.

- key access disable except button of Eject, Reset and service

mode

- record error in EEPROM "DC1 ERR"

- the product is able to be recovered by Reset button.

• If judge as "Capacitor leak ".

- turn off speaker output.

- display "WIRING", check wiring connection then reset.

- key access disable except button of Eject, Reset and service

mode

- record error in EEPROM "DC2 #" (# means counter number)

- the product can be recovered by pressing the Reset button

before the capacitor leak error counter reach "DC2 4".

After that, only clear the counter back to "0" can recover the

product.

• If judge as "Other" (manipulation same as mis-connect)

SECTION 5

TROUBLESHOOTING

4.8.3 Type of checking

4.8.3.1 To detect DC Offset Error

• Mis-connection

- Short any one speaker out line to GND or Vcc

• Capacitor leak

- Parallel 330kΩ to either any one of coupling cap or AC-GND

capacitor (to simulate current leakage of capacitor)

- Shorted either any one of coupling capacitor or AC-GND capacitor.

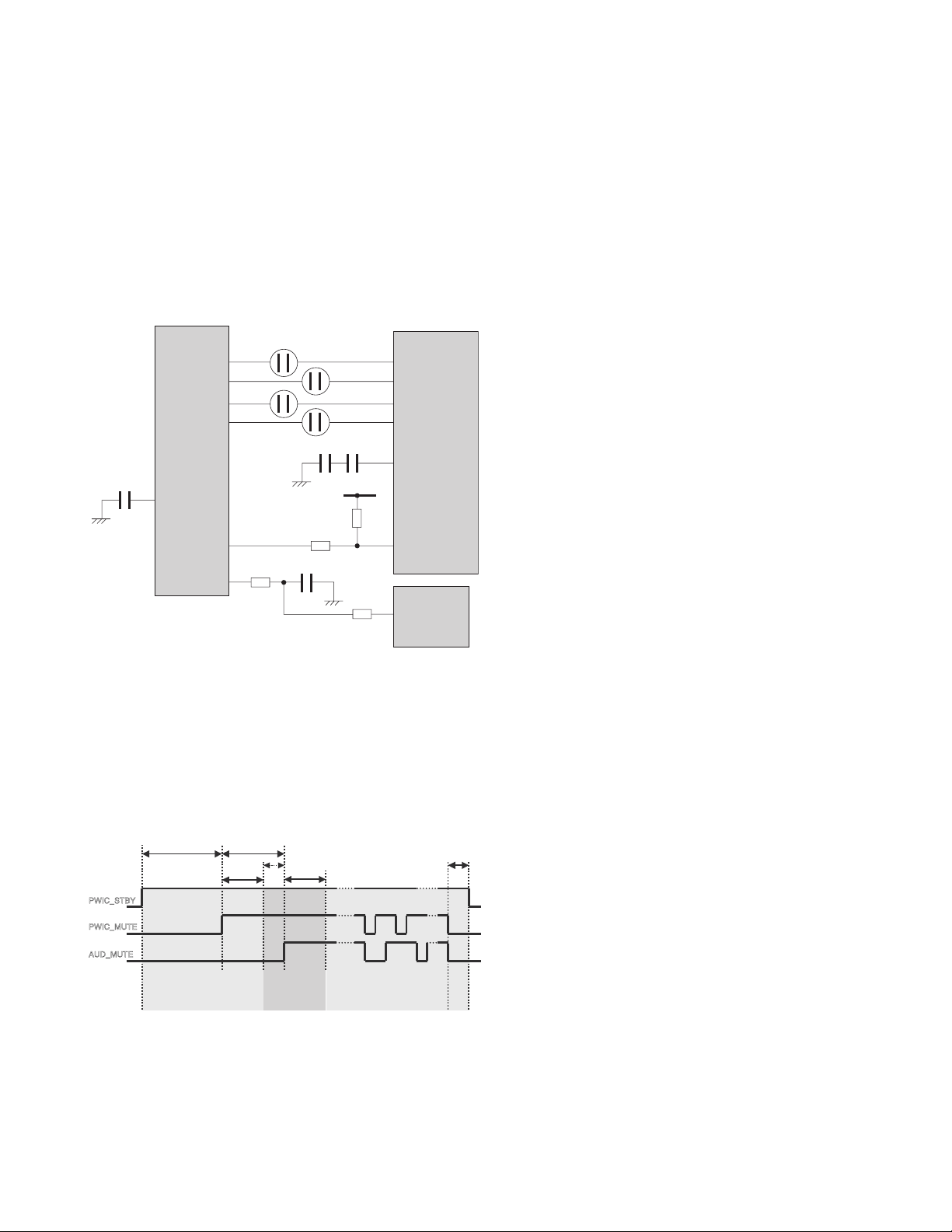

4.8.4 Detection Timing chart

PWIC_STBY

PWIC_MUTE

UD_MUTE

2.0sec or more

Missconnect

detection period

1.5sec or more

0.8sec

0.7sec or more

1.0sec

Capacitor leak

detection period

Other (miss detection etc.)

detection period

50ms

or more

5.1 How to cancel DC offset error

Check to be sure the terminals of the speaker leads are covered

with insulating tape properly, then reset the product.

If an error message does not disappear even after a reset, there

is a need for internal repair.

5.2 How to clear DC offset error recorded in EEPROM

Refer to “4.5 DC Error Information Mode”.

(No.MA606<Rev.002>)19/20

Loading...

Loading...