Page 1

SERVICE MANUAL

DVD/CD RECEIVER

MA437<Rev.003>200911SERVICE MANUAL

KD-ADV5580J, KD-DV5500J, KD-DV4504UI,

KD-DV4505U, KD-DV4505UN, KD-DV4505UT,

KD-DV4505A, KD-DV4506U, KD-DV4506UN,

KD-DV4506UT, KD-DV4506A, KD-DV4588UF,

KD-DV4505UH, KD-DV4506UH

KD-ADV5580/KD-DV5500

KD-DV4506

KD-DV4505

KD-DV4504

COPYRIGHT © 2009 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

COPYRIGHT © 2009 Victor Company of Japan, Limited

No.MA437<Rev.003>

2009/11

Page 2

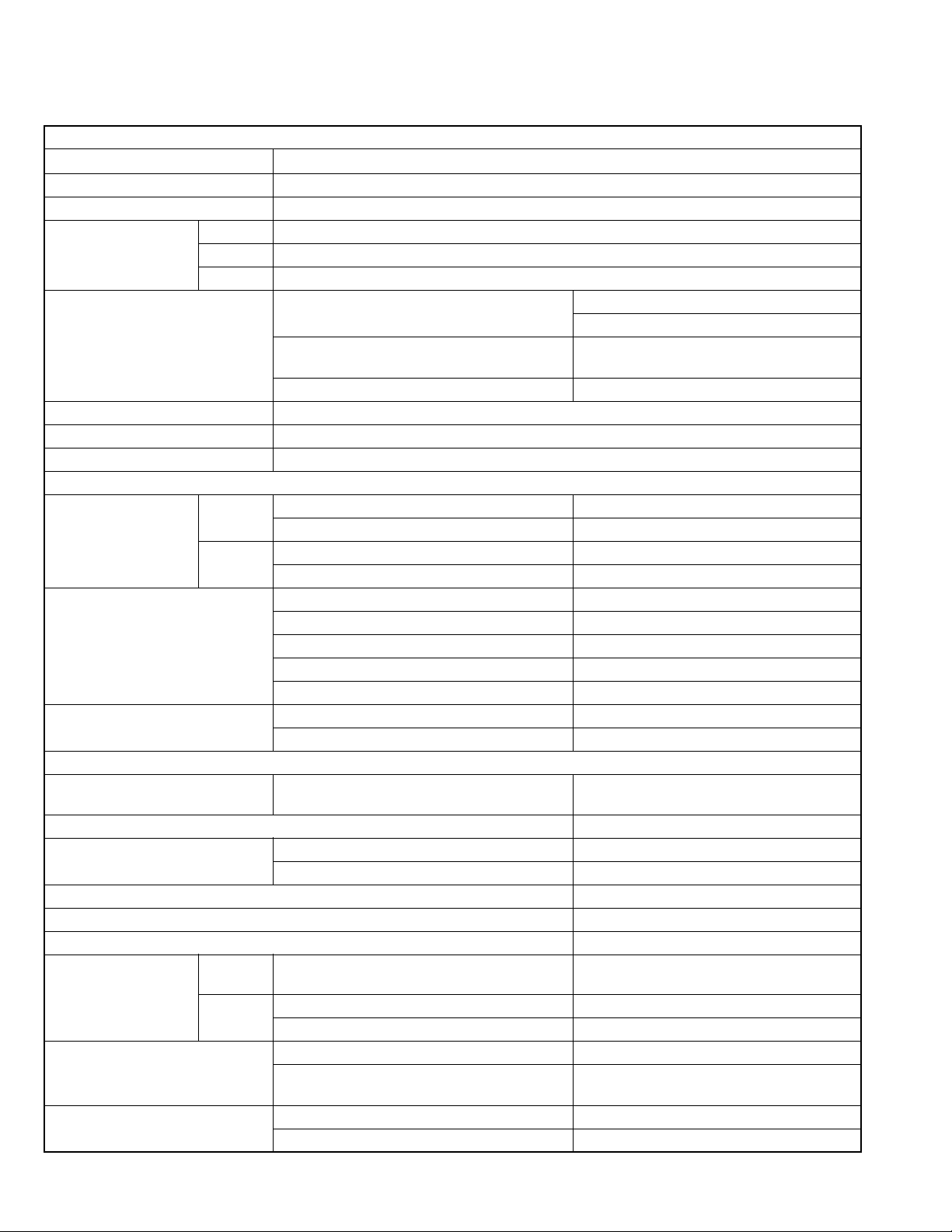

SPECIFICATION

KD-ADV5580/KD-DV5500

AUDIO AMPLIFIER SECTION

Power Output

Signal-to-Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz) Q0.5, Q1.0, Q1.5, Q2.0

Middle ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz) Q0.5, Q1.0, Q1.5, Q2.0

Treble ±12 dB (7.5 kHz, 10.0 kHz, 12.5 kHz, 15.0 kHz) Q0.75, Q1.25

Audio Output Level Digital (DIGITAL OUT: Optical) Signal wave length: 660 nm

Color System NTSC

Video Output (composite) 1 Vp-p/75 Ω

Other Terminal AUX (auxiliary) input jack, CD changer jack, Steering wheel remote input (for KD-ADV5580)

Frequency Range FM with channel interval set to 100 kHz or 200 kHz 87.5 MHz to 107.9 MHz

AM with channel interval set to 10 kHz 530 kHz to 1 710 kHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

AM Tuner Sensitivity 20 µV

Signal Detection System Non-contact optical pickup (semiconductor la-

Number of Channels 2 channels (stereo)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MPEG Video Video Max. Resolut ion 720 × 480 pixels (30 fps)

Audio Bit Rate 32 kbps - 320 kbps

MP3 Bit Rate 32 kbps - 320 kbps

WMA Bit Rate 32 kbps - 320 kbps

20 W RMS × 4 Channels at 4 Ω and < or = 1% THD+N

Output level: -21 dBm to -15 dBm

Line-Out Level/Impedance KD-ADV5580: 5.0 V/20 kΩ load (full scale)

KD-DV5500: 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

TUNER SECTION

with channel interval set to 50 kHz 87.5 MHz to 108.0 MHz

with channel interval set to 9 kHz 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

Sensitivity 40 dB

DVD/CD PLAYER SECTION

ser)

CD, fs=44.1 kHz 16 Hz to 20 000 Hz

720 × 576 pixels (25 fps)

Sampling Frequency 32 kHz, 44.1 kHz, 48 kHz

Sampling Frequency MPEG-1: 32 kHz, 44.1 kHz, 48 kHz

MPEG-2: 16 kHz, 22.05 kHz, 24 kHz

Sampling Frequency 22.05 kHz, 32 kHz, 44.1 kHz, 48 kHz

1-2 (No.MA437<Rev.003>)

Page 3

WAV Quantization Bit Rate 16 bit

Sampling Frequency 44.1 kHz

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 159 mm

(7-3/16” × 2-1/16” × 6-5/16”)

Panel Size (approx.) 188 mm × 58 mm × 6 mm

(7-7/16” × 2-5/16” × 1/4”)

Mass (approx.) 1.4 kg (3.1 lbs) (excluding accessories)

Design and specifications are subject to change without notice.

KD-DV4506

AUDIO AMPLIFIER SECTION

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8% total

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz) Q0.5, Q1.0, Q1.5, Q2.0

Middle ±12 dB (0.5 kHz, 1.0 kHz, 1.5 kHz, 2.5 kHz) Q0.75, Q1.0, Q1.25, Q1.5

Treble ±12 dB (7.5 kHz, 10.0 kHz, 12.5 kHz, 15.0 kHz) Q0.75, Q1.25

Signal-to-Noise Ratio 80 dB

Audio Output Level Digital (DIGITAL OUT: Optical) Signal wave length: 660 nm

Output level: -21 dBm to -15 dBm

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Color System PAL/NTSC

Video Output (composite) 1 Vp-p/75 Ω

Other Terminal AUX (auxiliary) input jack, CD changer jack

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

AM Tuner Sensitivity 20 µV

Selectivity 40 dB

DVD/CD PLAYER SECTION

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

CD, fs=44.1 kHz 16 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

(No.MA437<Rev.003>)1-3

Page 4

DivX/MPEG Video Video Max. Resolution: 720 × 480 pixels (30 fps)

720 × 576 pixels (25 fps)

Audio Bit Rate 32 kbps - 320 kbps

Sampling Frequency: DivX MPEG-1: 32 kHz, 44.1 kHz, 48 kHz

MPEG-2: 16 kHz, 22.05 kHz, 24 kHz

Sampling Frequency: MPEG Video 32 kHz, 44.1 kHz, 48 kHz

MP3 Bit Rate 32 kbps - 320 kbps

Sampling Frequency MPEG-1: 32 kHz, 44.1 kHz, 48 kHz

MPEG-2: 16 kHz, 22.05 kHz, 24 kHz

WMA Bit Rate 32 kbps - 320 kbps

Sampling Frequency 22.05 kHz, 32 kHz, 44.1 kHz, 48 kHz

WAV Quantization Bit Rate 16 bit

Sampling Frequency 44.1 kHz

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 159 mm

Panel Size (approx.) 188 mm × 58 mm × 6 mm

Mass (approx.) 1.4 kg (excluding accessories)

Design and specifications are subject to change without notice.

KD-DV4505/KD-DV4504/KD-DV4588

AUDIO AMPLIFIER SECTION

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) Front/Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz

at no more than 0.8% total

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz) Q0.5, Q1.0, Q1.5, Q2.0

Middle ±12 dB (0.5 kHz, 1.0 kHz, 1.5 kHz, 2.5 kHz) Q0.75, Q1.0, Q1.25, Q1.5

Treble ±12 dB (7.5 kHz, 10.0 kHz, 12.5 kHz, 15.0 kHz) Q0.75, Q1.25

Signal-to-Noise Ratio 80 dB

Audio Output Level Digital (DIGITAL OUT: Optical) Signal wave length: 660 nm

Output level: -21 dBm to -15 dBm

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Color System PAL/NTSC

Video Output (composite) 1 Vp-p/75 Ω

Other Terminal AUX (auxiliary) input jack, CD changer jack

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

1-4 (No.MA437<Rev.003>)

Page 5

AM Tuner Sensitivity 20 µV

Sensitivity 40 dB

DVD/CD PLAYER SECTION

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

CD, fs=44.1 kHz 16 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

DivX/MPEG Video Video Max. Resolution 720 × 480 pixels (30 fps)

720 × 576 pixels (25 fps)

Audio Bit Rate 32 kbps - 320 k bps

Sampling Frequency: DivX MPEG-1: 32 kHz, 44.1 kHz, 48 kHz

Sampling Frequency: MPEG Video 32 kHz, 44.1 kHz, 48 kHz

MP3 Bi t Rate 32 kbps - 320 kbps

Sampling Frequency MPEG-1: 32 kHz, 44.1 kHz, 48 kHz

MPEG-2: 16 kHz, 22.05 kHz, 24 kHz

WMA Bit Rate 32 kbps - 320 kbps

Sampling Frequency 22.05 kHz, 32 kHz, 44.1 kHz, 48 kHz

WAV Quantization Bit Rate 16 bit

Sampling Frequency 44.1 kHz

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 159 mm

Panel Size (approx.) 188 mm × 58 mm × 6 mm

Mass (approx.) 1.4 kg (excluding accessories)

Design and specifications are subject to change without notice.

(No.MA437<Rev.003>)1-5

Page 6

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-6 (No.MA437<Rev.003>)

Page 7

1.2 Preventing static electricity

Electrostatic discharge (ESD), w hi ch occ urs w hen sta tic ele ct ricit y sto r ed i n the bod y, fa bric , et c. is discharged, can de stro y th e laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the lase r diode in the optical pi ckup. The tester's i nternal powe r source ca n easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nip pers, etc. afte r replacing th e optical pi ckup. For spe cific deta ils, refer to the

replacement procedure in th e text. Remove the ant i-s tati c pin w he n re pla ci ng the trav ers e uni t. Be c arefu l not to take too long a

time when attaching it to the connector .

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed *Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land before the card wire is disconnected from the connector on the pickup unit.

(If the card wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the card wire.

Solder short part

(No.MA437<Rev.003>)1-7

Page 8

1.5 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

1-8 (No.MA437<Rev.003>)

Page 9

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

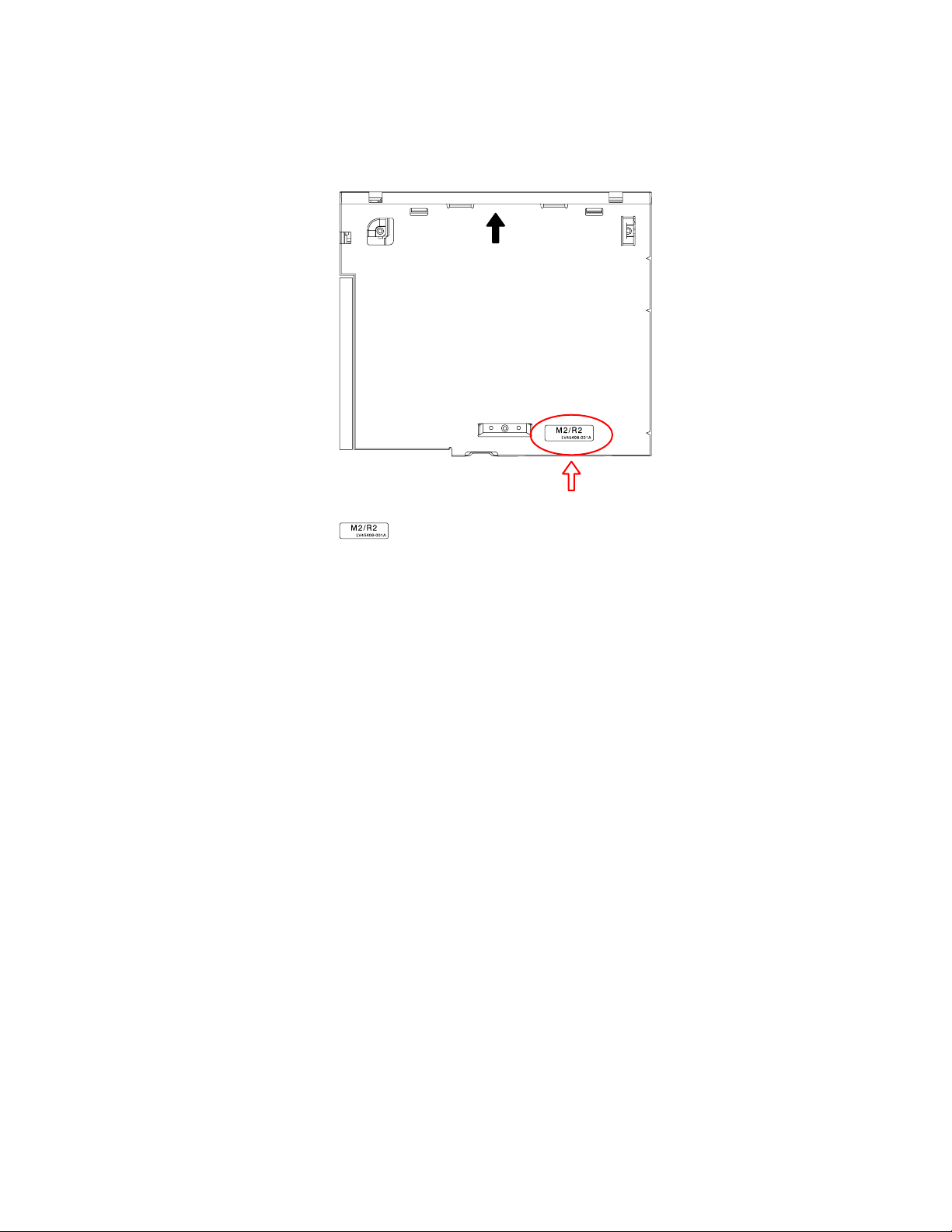

2.1 Identification method

Supported reduction in cost, and board contents and mechanism contents were changed.

A set put the following label on is an object.

Front side

Top view

Label position

Change pwb and mechanism parts

(No.MA437<Rev.003>)1-9

Page 10

SECTION 3

DISASSEMBLY

3.1 Main body (Used figure are KD-ADV5580J)

3.1.1 Removing the Bottom chassis (See Fig.1)

(1) Disengage six hooks a engaged Bottom chassis.

hook

a

Fig.1

3.1.2 Removing the Front chassis (See Fig.2)

(1) Disengage four hooks b both side of the Front chassis.

hook

a

3.1.4 Removing the Main board (See Fig.4 to 6)

(1) Remove the three screws D, two screws E, two screws F

and one screw G attaching the Rear bracket. (See Fig.4)

D

EFGF E

Fig.4

(2) Remove the three screws H attaching the Main board. (See

Fig.5)

H

H

hook

b

Fig.2

3.1.3 Removing the Heat sink (See Fig.3)

(1) Remove the two screws A, two screws B and one screw C

attaching the Heat sink.

A

BC

Fig.3

Fig.5

(3) Disconnect the card wire from Main board connected to

connector CN403

REFERENCE: Screw E, F and G are attaching and can take

off the main board.

of the Front end board. (See Fig.6)

CN403

Fig.6

1-10 (No.MA437<Rev.003>)

Page 11

3.1.5 Removing the DVD mechanism (See Fig.7)

(1) Remove the three screws J attachin g the DVD mechan ism.

J

Fig.7

3.1.6 Removing the Switch board (See Fig.8)

(1) Remove the Volume knob.

(2) Remove the four screws K attaching the Rear cover .

(3) Disengage eleven hooks c engaged Rear cover.

hook

c

K

JJ

hook

Fig.8

K

c

KK

(No.MA437<Rev.003>)1-11

Page 12

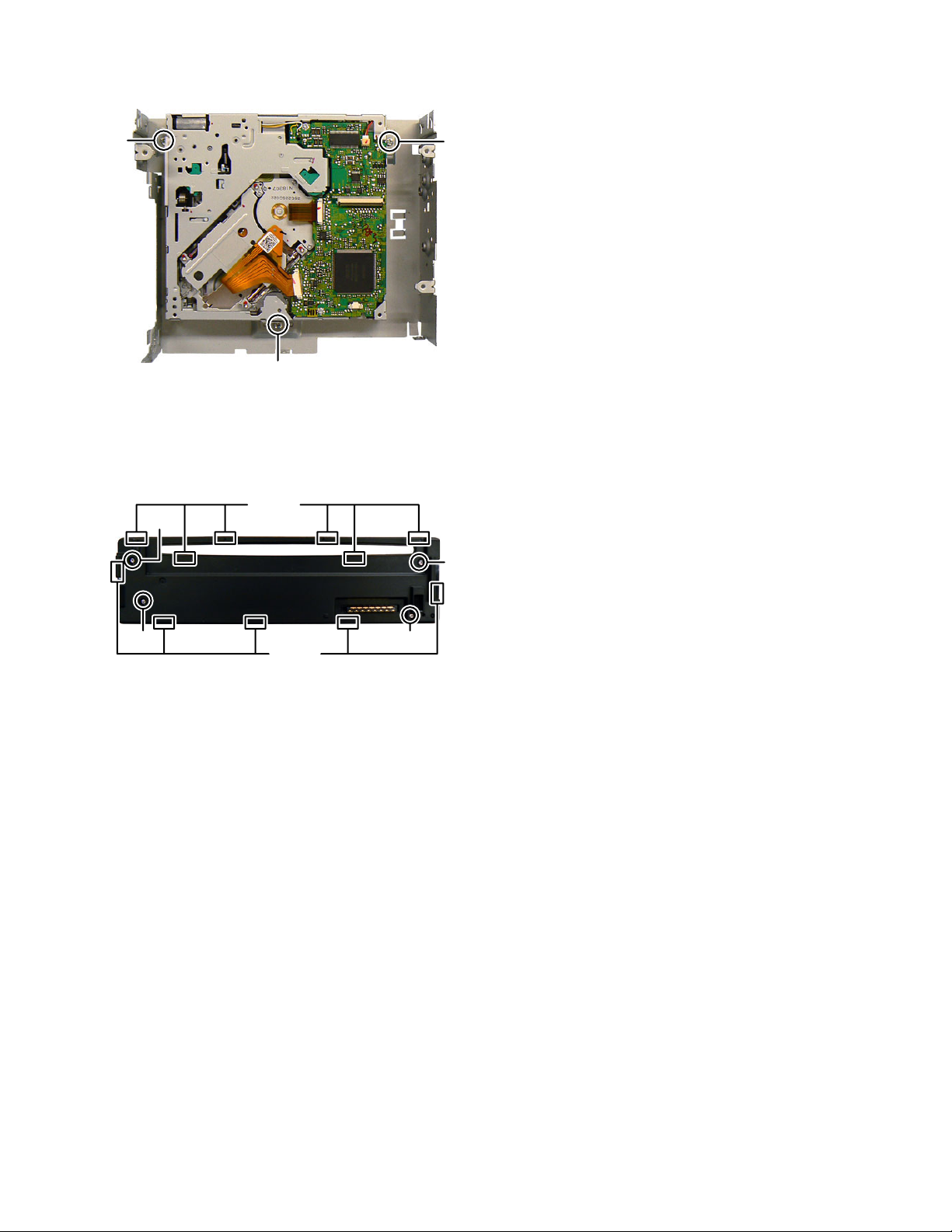

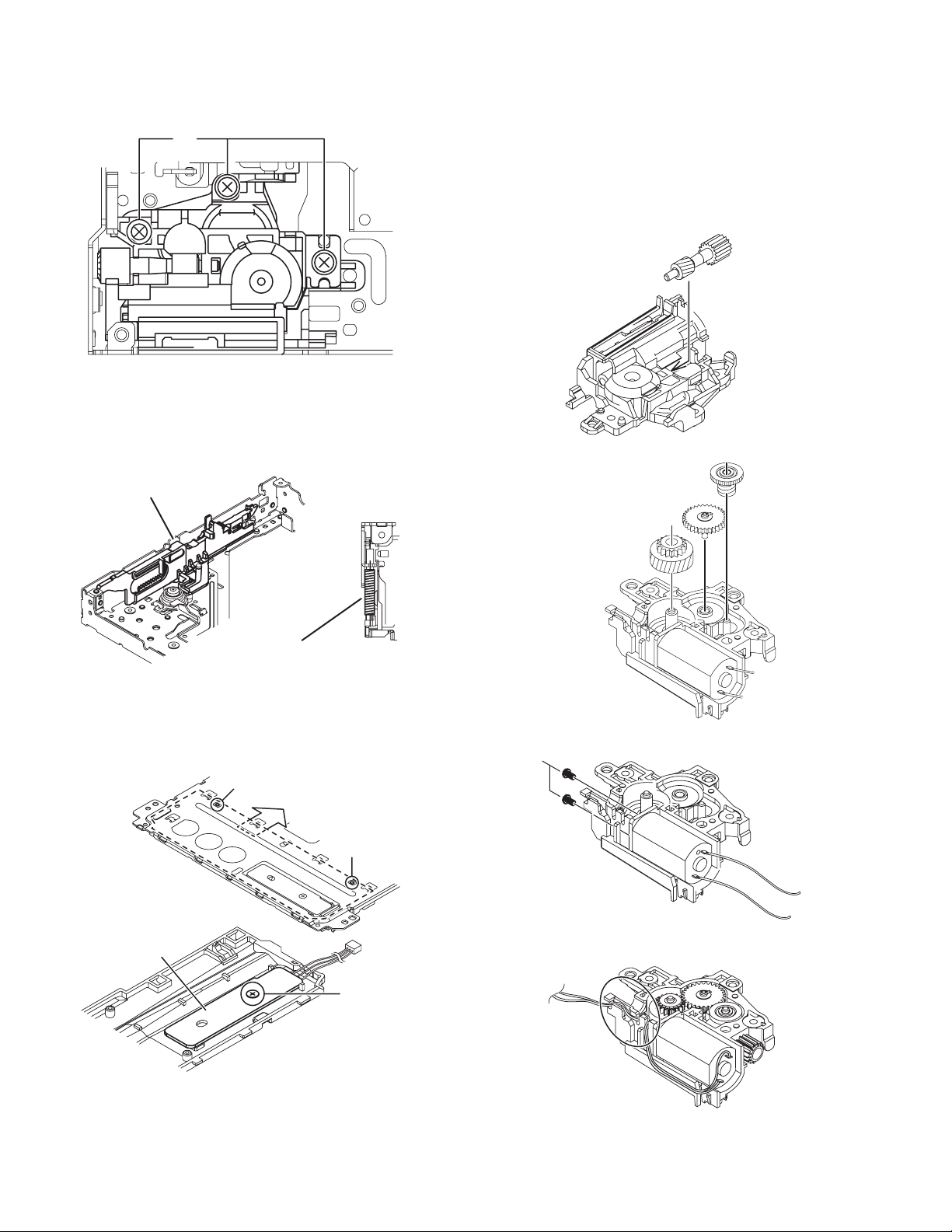

3.2 DVD mechanism assembly section

3.2.1 Removing the Traverse mechanism assembly (See

Fig.1 to 6)

(1) Solder the short land section on the flex ib le wire of pickup.

(See Fig.1)

Caution:

* Solder the short land section on the flexible wire of pickup

before disconnecting the flexible wir e form the connector

on the Front end board.

CN101

If the flexible wire is disconnected without attaching the

solder, the pickup may be destroyed by static electricity.

* When attaching the Tr averse mechanism assembly, remove the solder from the short land section after connection

the flexible w ire to the connector CN101

on the Front end

board.

(2) Voltage supply to TP79

and TP81 approx DC 3.0V until

Clamper is shift to loading complete position. (See Fig.2)

(3) Disconnect the flexible wires from Traverse mechanism assembly

connected to connector CN101

and CN164 of the Front end

board. (See Fig.2)

(4) Remove the five screws A attaching the Top cover assembly.

(See Fig.3)

(5) From the bottom side, disconnect the connector wire from

Top cover assembly connected to connector CN2

of the

Front end board. (See Fig.4)

(6) From the bottom side, remove the spring from Traverse

mechanism assembly. (See Fig.5)

(7) From the top side, pull up the traverse mechanism and disenga ge

three dumper positions. (See Fig.6)

A

Fig.3

CN2

Fig.4

CN164

Fig.1

Fig.2

Solder short part

CN101

R312

R357

TP79

TP79 TP81

R317

TP67

R21

TP92

CENTER

WOOFER

DGND_7

TP81

D-

Voltage supply

position

Fig.5

Dumper

(same color spring)

Dumper

(Different color spring)

Fig.6

1-12 (No.MA437<Rev.003>)

Page 13

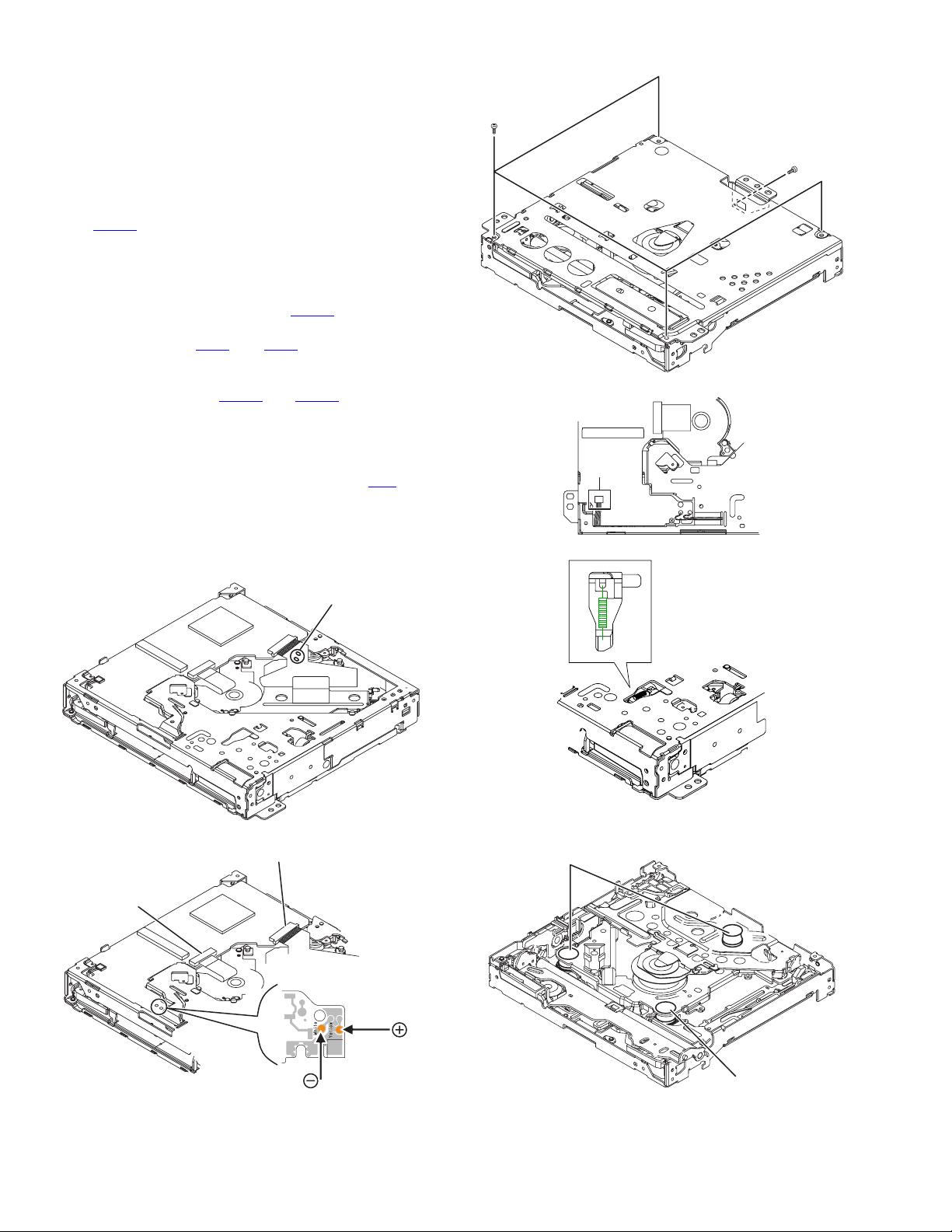

3.2.2 Removing the Front end board (See Fig.7)

(1) Remove the Motor wires from loading motor soldered to

and TP81 of the Front end board.

TP79

(2) Remove the two screws B attaching the Front end board.

TP81

TP79

B

B

Fig.7

3.2.3 Removing the Loading arm assembly (See Fig.8)

(1) Remove the Loading arm spring L from Loading arm assembly.

(2) Slide to left side and then disengage hook a then hook b.

hook b

Loading arm

assembly

Loading arm

spring L

Fig.9

C

hook

Loading arm spring L

Fig.8

3.2.4 Removing the Gear base assembly (See Fig.9, 10)

(1) Remove the Loading arm spring L. (See Fig.9)

(2) Remove the two screws C attaching the Gear base assembly.

(See Fig.10)

a

Fig.10

3.2.5 Removing the Loading arm holder. (See Fig.11)

(1) Remove the two screws D attaching the Loading arm holder.

(2) Remove the Loading arm spring R.

D

Loading arm

holder

Loading arm

spring R

Fig.11

(No.MA437<Rev.003>)1-13

Page 14

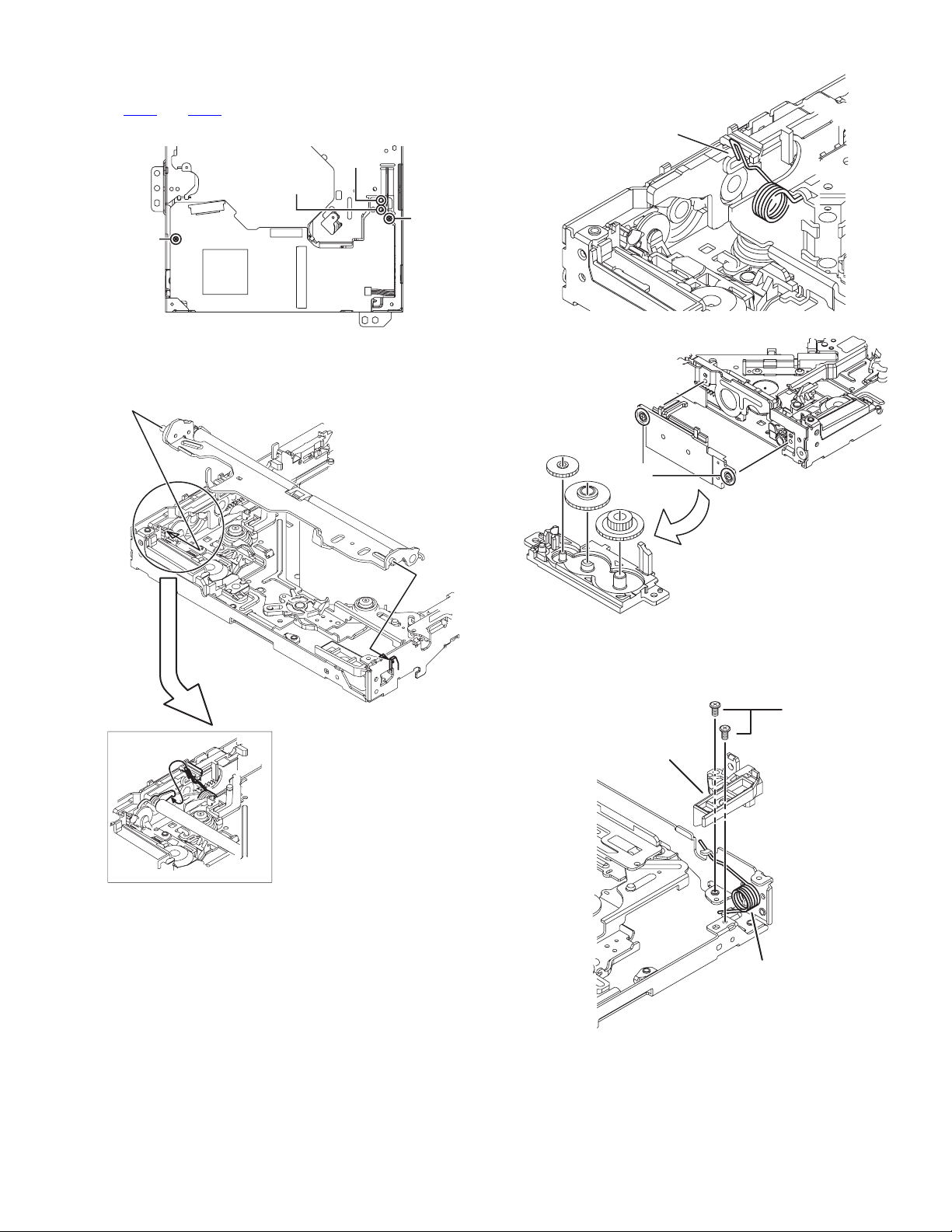

3.2.6 Removing the Loading moor assembly (See Fig.12)

r

(1) Remove the three screws E attaching the Loading motor

assembly.

E

Fig.12

3.2.7 Removing the Slide cam assembly (See Fig.13)

(1) Slide to backward the Slide c am as semb ly an d the r em ove

the Slide cam spring.

(2) Slide to frontward the slide cam assembly, and then take

out it.

Slide cam assembly

3.2.9 Removing the Loading motor (See Fig.15 to 18)

(1) Remove the A wheel gear. (See Fig.15)

(2) Remove the A worm gear, M connect gear and M wheel

gear by sequentially. (See Fig.16)

(3) Remove the two screws G attaching the Loading motor.

(Se Fig.17)

(4) When attaching the Loading motor, motor wire should arrange

to figure. (See Fig .18)

A Wheel gea

Fig.15

A worm gear

M connect gear

Slide cam spring

Fig.13

3.2.8 Removing the Photo board (See Fig.14)

(1) Pressing the hook c and then slide to backward (sl ide to the

arrow side) the Disc plate.

(2) Remove the one screw F attaching the Photo board.

hook

c

hook

c

Photo board

F

M wheel gear

Fig.16

G

Fig.17

Wire arrangement

1-14 (No.MA437<Rev.003>)

Fig.14

Fig.18

Page 15

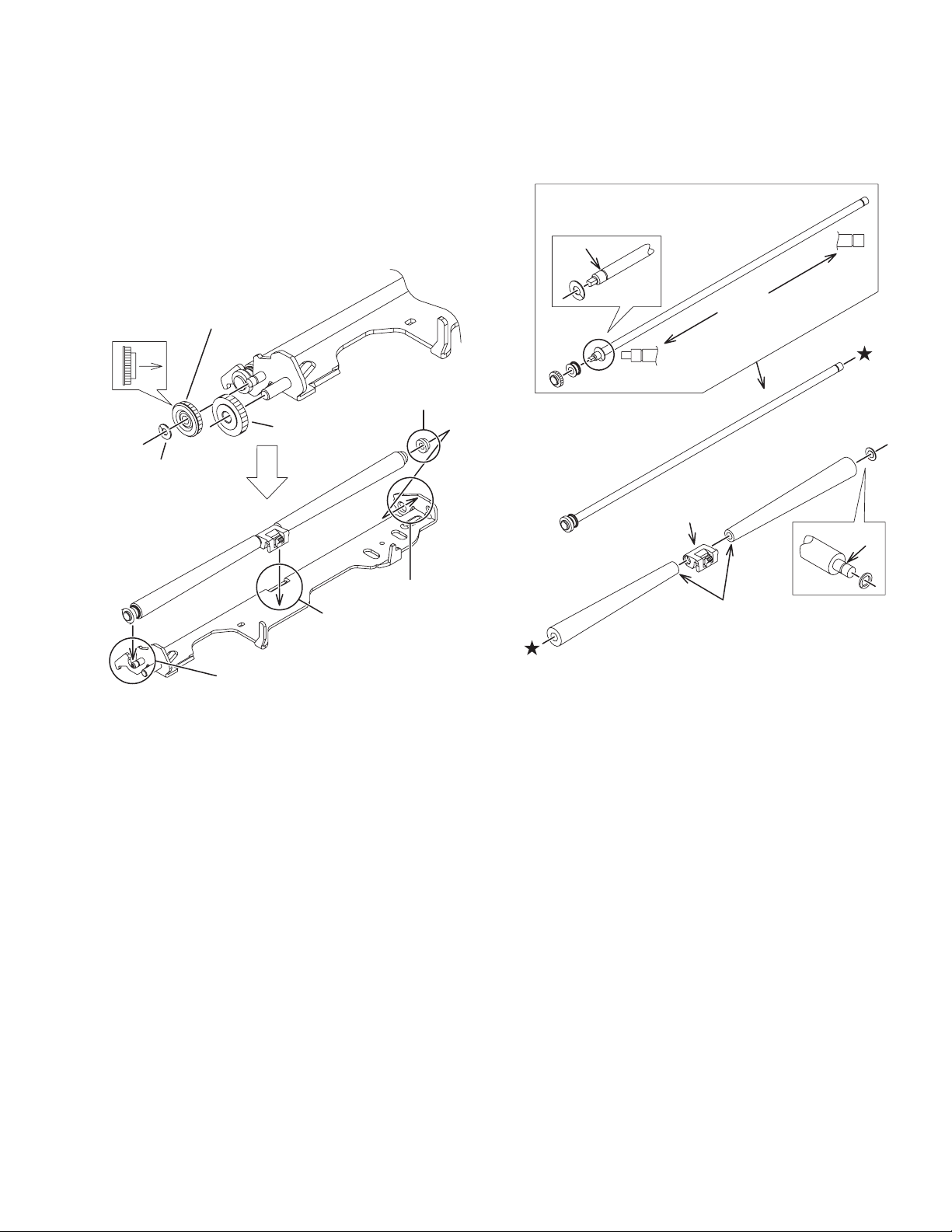

3.2.10 Removing the Roller assembly (See Fig.19)

(1) Remove the Slit washer.

(2) Remove the R middle gear.

(3) Remove the R connect gear.

(4) Snap off the part a of the Roller assembly.

(5) Lift up the part b of the Roller assembly, and then release

part c (When release part c, R co llar R is eas y to come off,

does not lose it).

CAUTION:

When reattach the Roller assembly, Middle gear should keep

direction and Slit washer should be change new part.

R middle gear

Direction

R collar R

R connect gear

Slit washer

3.2.11 Removing the Roller (See Fig.20)

(1) Remove the Slit washer.

(2) Pull out the Roller shaft.

CAUTION:

When reattach the Roller shaft, Slit washer should be change

new part.

slit

keep direction

keep direction

slit

part b

part c

small side

part a

Fig.20

Fig.19

(No.MA437<Rev.003>)1-15

Page 16

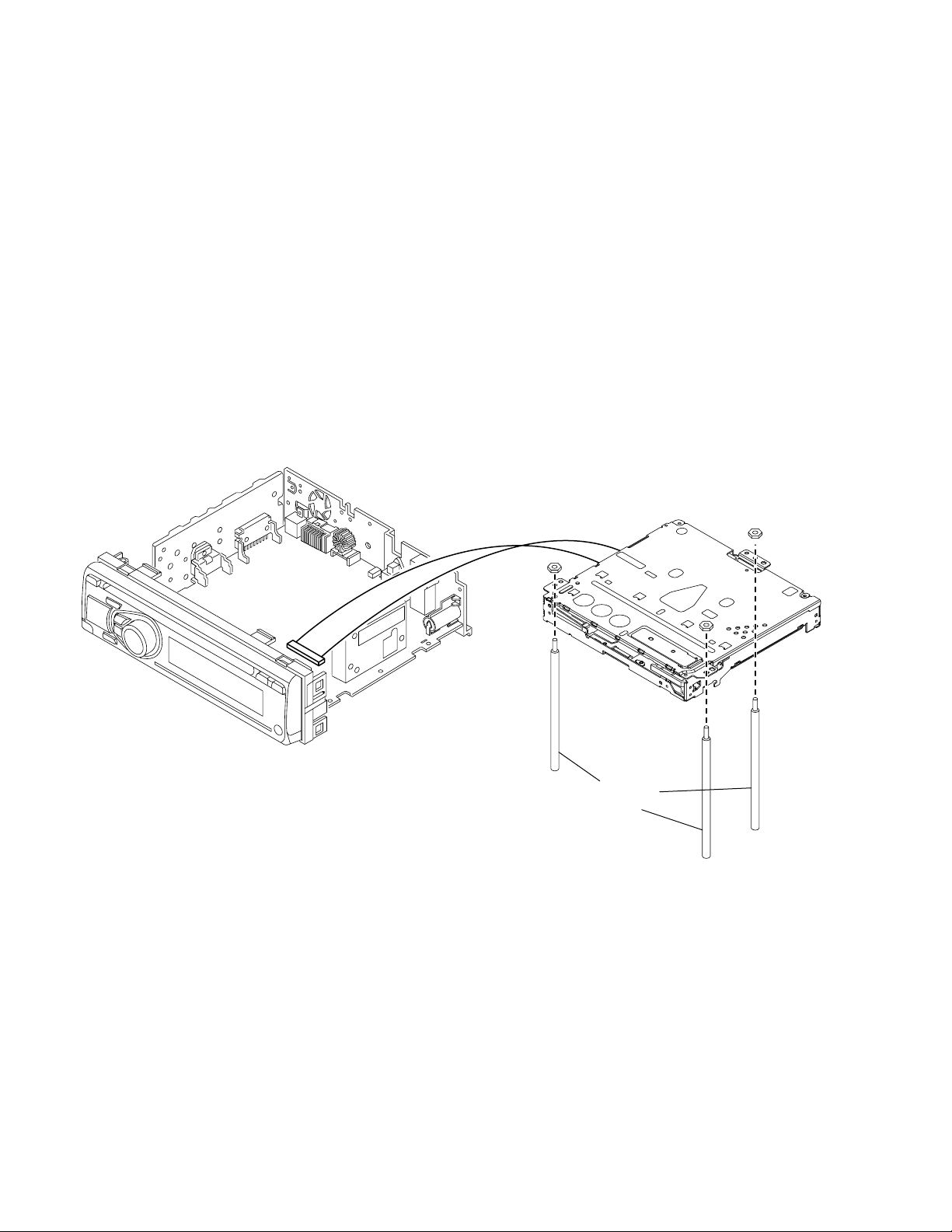

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Jitter meter

(3) Digital tester

(4) Electric voltmeter

(5) Tracking offset meter

(6) Test Disc : VT501 or VT502

(7) Extension studs : STDV001-3P

(8) Extension cable : EXTAV70X-50PF

4.3 Connection method

Connection procedure

Attach the front chassis assembly to the main board.

Connect the front panel assembly to the main board.

Attach the heat sink and rear bracket to the main board.

Attach the extension studs to the DVD mechanism assembly.

Connect the DVD mechanism assembly and the main board with a extension cable.

4.2 Standard measuring conditions

Power supply voltage DC14.4V(11V to 16V)

Load impedance 4 Ω(2 Speakers connection)

Line output 20kΩ

Caution:

Be sure to attach the heat sink and rear bracket onto th e power

amplifier IC and regulator IC respectively, before supply the

power.

If voltage is applied without attaching these parts, the power

amplifier IC and regulator IC will be destroyed by heat.

EXTAV70X-50PF

1-16 (No.MA437<Rev.003>)

STDV001-3P

Page 17

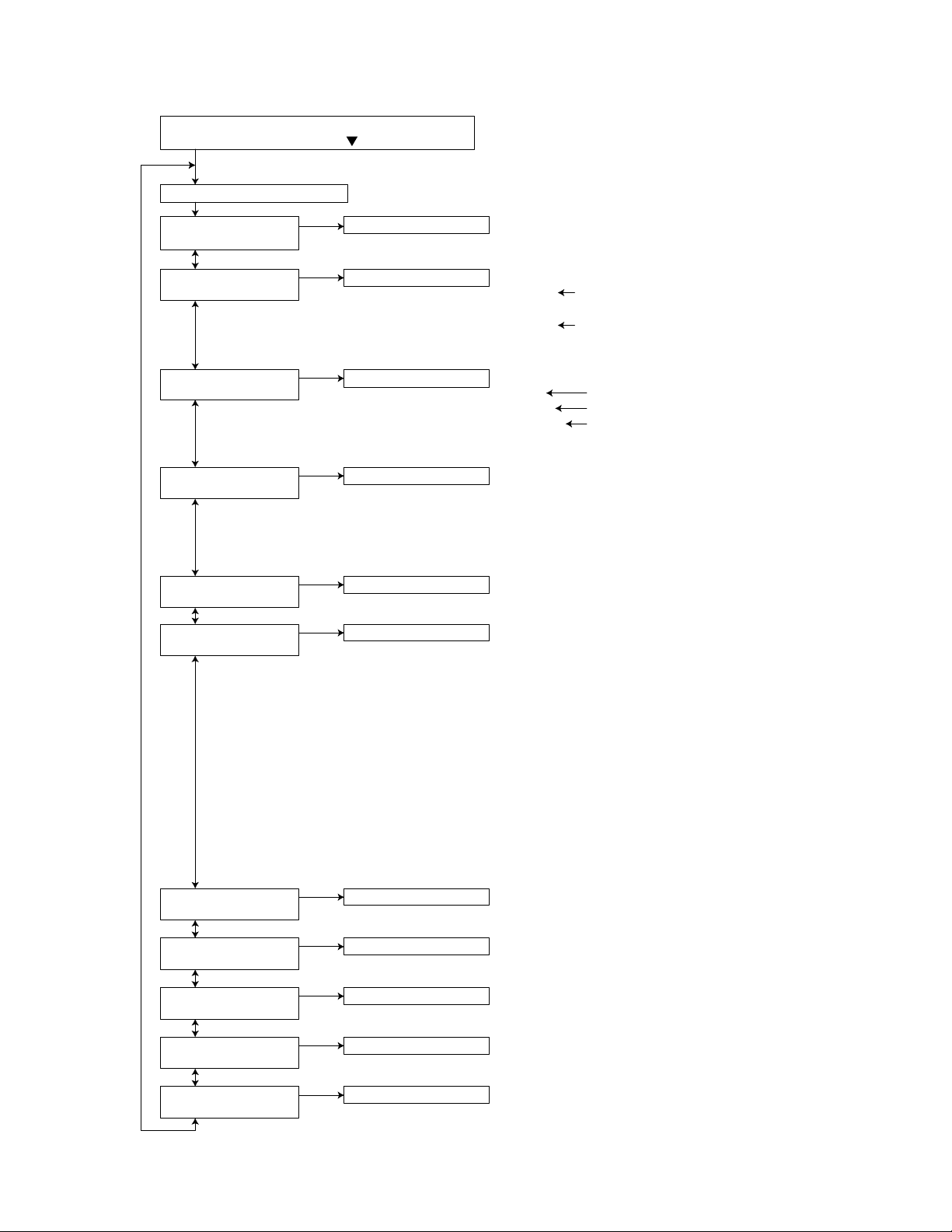

4.4 Service mode

Power ON.

Keep this state more than 3 seconds while continuing

pressing the [MENU] button and [ ] button sequentially.

The unit enters the service mode.

Exchanging it operate a menu of service mode with the [FF] button and [REW] button.

Operate choice of a menu with a [ENT] button.

"INIT" is

indicated on the LCD.

"VERSION" is

indicated on the LCD.

"AREA/RGN" is

indicated on the LCD.

"VIDEO" is

indicated on the LCD.

"CLR ERR" is

indicated on the LCD.

"CD ERROR" is

indicated on the LCD.

"DVD-TEMP" is

indicated on the LCD.

"SYS-TEMP" is

indicated on the LCD.

"CHK MODE" is

indicated on the LCD.

Press the [ENT] button Initialize user set data

Press the [ENT] button Micon version display

Press the [ENT] button Destination area/region display

Press the [ENT] button Setting of NTSC or PAL

Press the [ENT] button Clear loading/ejection error history

Press the [ENT] button Read loading and ejection error history

Press the [ENT] button Thermistor's temperature data readout

Press the [ENT] button Thermistor's temperature data readout

Press the [ENT] button DVD unit check mode

: The system control EEPROM is initialized except

for The loading/ejection error history.

S-XXX-YY

DVD-XXX

*Exchanging it operate each indication with the

[FF] button and [REW] button.

SYS-XX

DVD-AXX

DVDRGN X

*Exchanging it operate each indication with the

[FF] button and [REW] button.

"NTSC" or "PAL" are indicated on the LCD.

*Exchanging it operate each indication with the

[FF] button and [REW] button.

Note:

There is the model that is not equipped with

this mode by a version.

:The error history stored in the EEPROM is cleared.

:The error history saved in the system control

is read and displayed.

TOT-XXXX : Total error count.

Enyyzzzz : Latest three error history

0nyyzzz : First five error history

: Data in the temperature sensor in the DVD unit

is read every 5 seconds and displayed in hex numbers.

: Data in the temperature sensor in the system control

is read every 5 seconds and displayed in hex numbers.

(See section "DVD check mode" for details.)

System control CPU version/

ROM correction version

DVD version

System control destination

DVD unit destination

DVD unit region

(A figure between 0 and 9999 is displayed.

10000 or more is also displayed as 9999.)

n: Counter

yy: Error code

zzzz: Detailed error code

n: Counter

yy: Error code

zzzz: Detailed error code

*Exchanging it operate each indication with the

[FF] button and [REW] button.

(See section "Error code tables" for details.)

"RUNNING" is

indicated on the LCD.

"MEMCHECK" is

indicated on the LCD.

Press the [ENT] button Running mode : For use in running tests.

Press the [ENT] button Memory check

: The remaining data capacity of the disc is displayed on the LCD.

(No.MA437<Rev.003>)1-17

Page 18

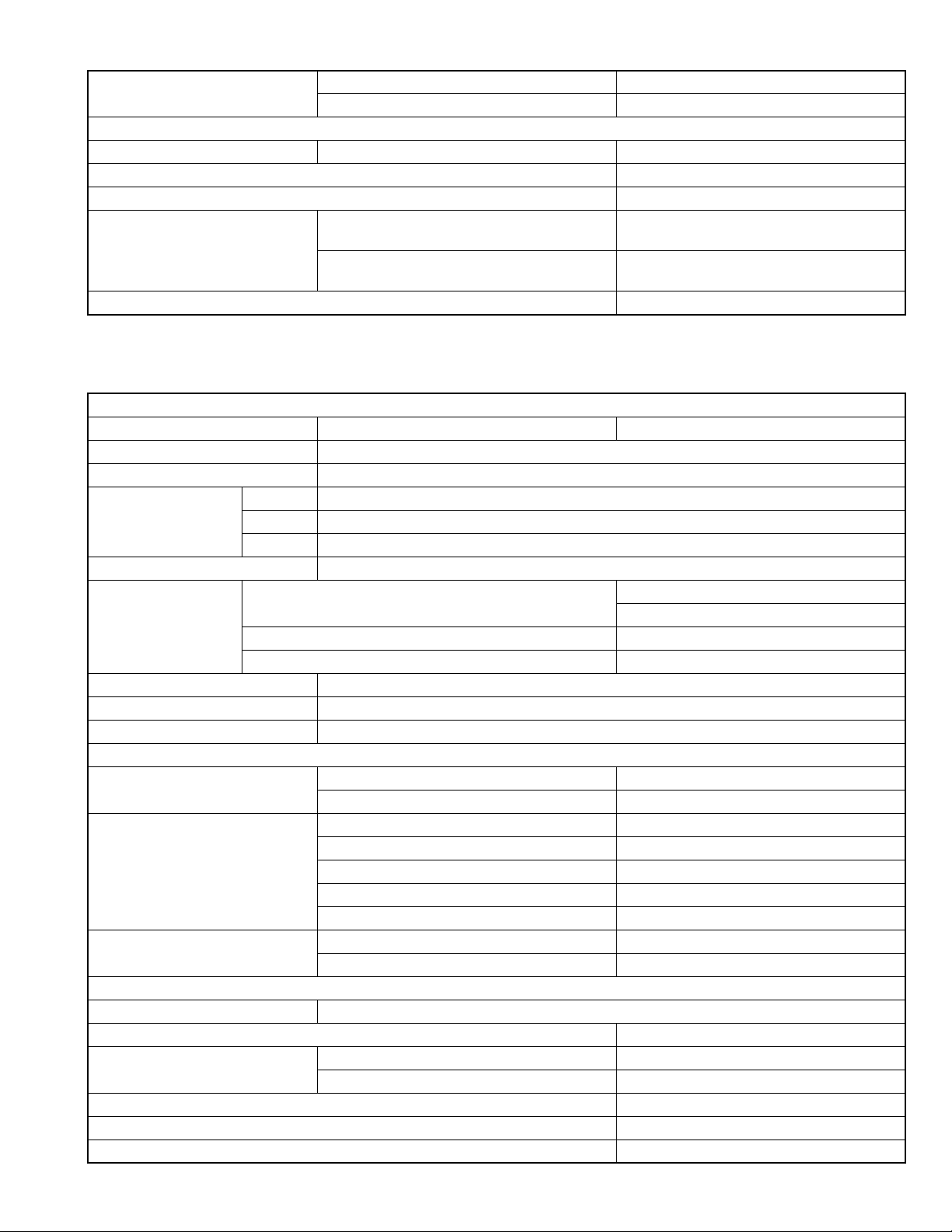

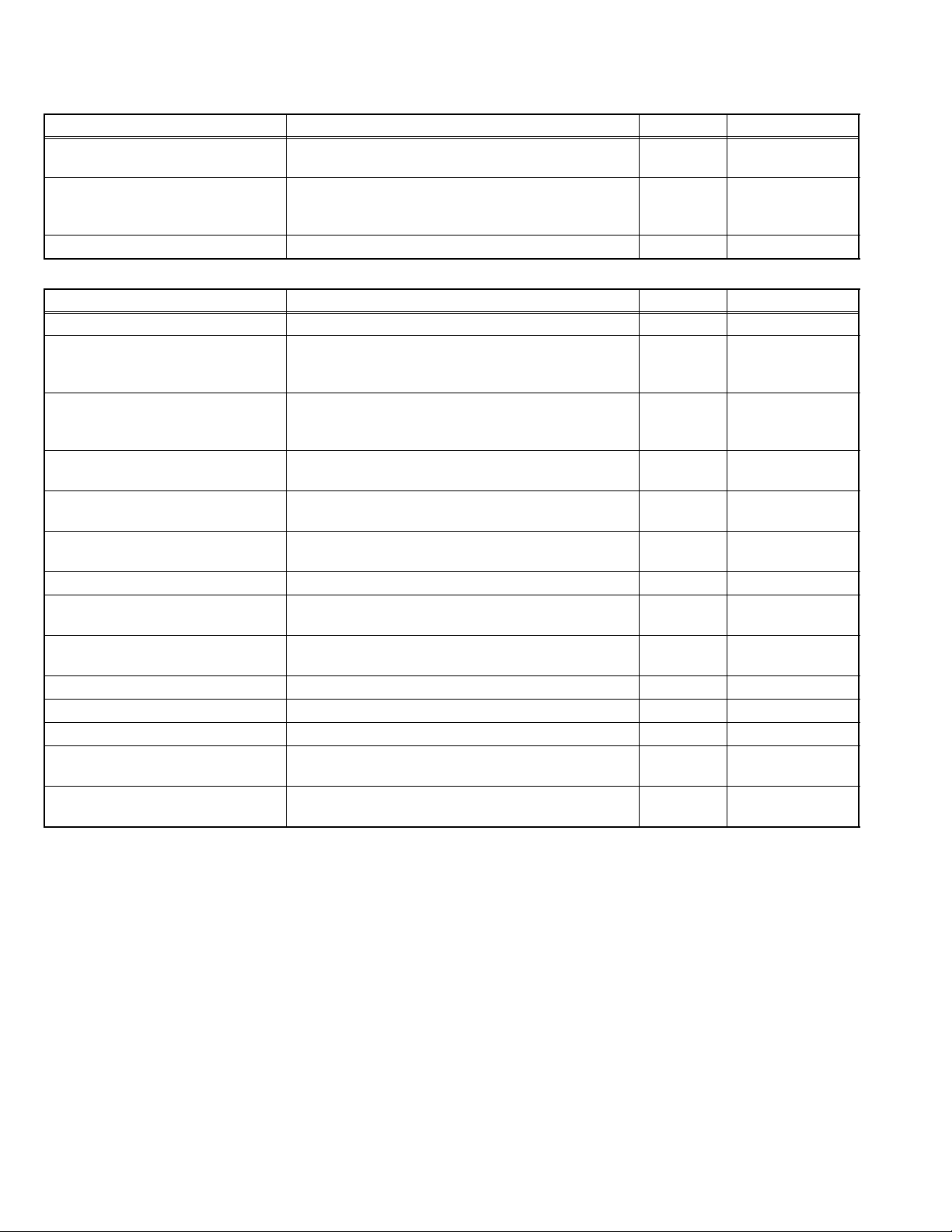

4.5 Error code tables

4.5.1 Mechanism error code

Error contents Details Error code Detailed error code

Disc loading error

(1)D1 time out 09 0013

Eject error

(1)B1 time out

(2)C1 time out

Error in loading wait Loading of a running mo de Disc was pulled out in a w ait. 09 0031

4.5.2 Disc error code

Error contents Details Error code Detailed error code

TOC read error TOC read movement of a CD is not completed. 84 0059

First track access error Even if TOC reading passes after the end with CD run-

ning mode for 30 s econds, the first track access is not finished.

Last track access error Even if first track passes after the end with CD running

mode for 30 seconds, the last track access is not finished.

T1 access error Eve n if T1 access passes in a DVD running mode for 30

seconds, it is not finished.

T12 access error Even if T12 ac cess passes in a DVD ru nning mode for 30

seconds, it is not finished.

T24 access error Even if T24 access passes in a DVD running mode for

30 seconds, it is not finished.

Read-in area read error Read-in area read operation of DVD is not completed. 84 0072

DVD L1 layer adjustment error Adjustment of L1 layer of DVD is not finished normally.

(including focus jump failure)

DVD L0 layer adjustment error Adjustment of L0 layer of DVD is not finished normally.

(including focus jump failure)

NO DISC judgment Judgment without disc. 80 0090

It is NO DISC by start failure Start is impossible 80 0091

It is stopped by playback inability Stop in running mode playback 80 0093

Logic format NG Logic format analysis inability or non-correspondence

logic format

Seek access error It cannot arrive a t an ai m add ress eve n if i t pass es fo r 15

seconds.

01

01

80 0060

80 0061

80 0069

80 0070

80 0071

80 0074

80 0075

80 0094

80 0095

0023

0024

1-18 (No.MA437<Rev.003>)

Page 19

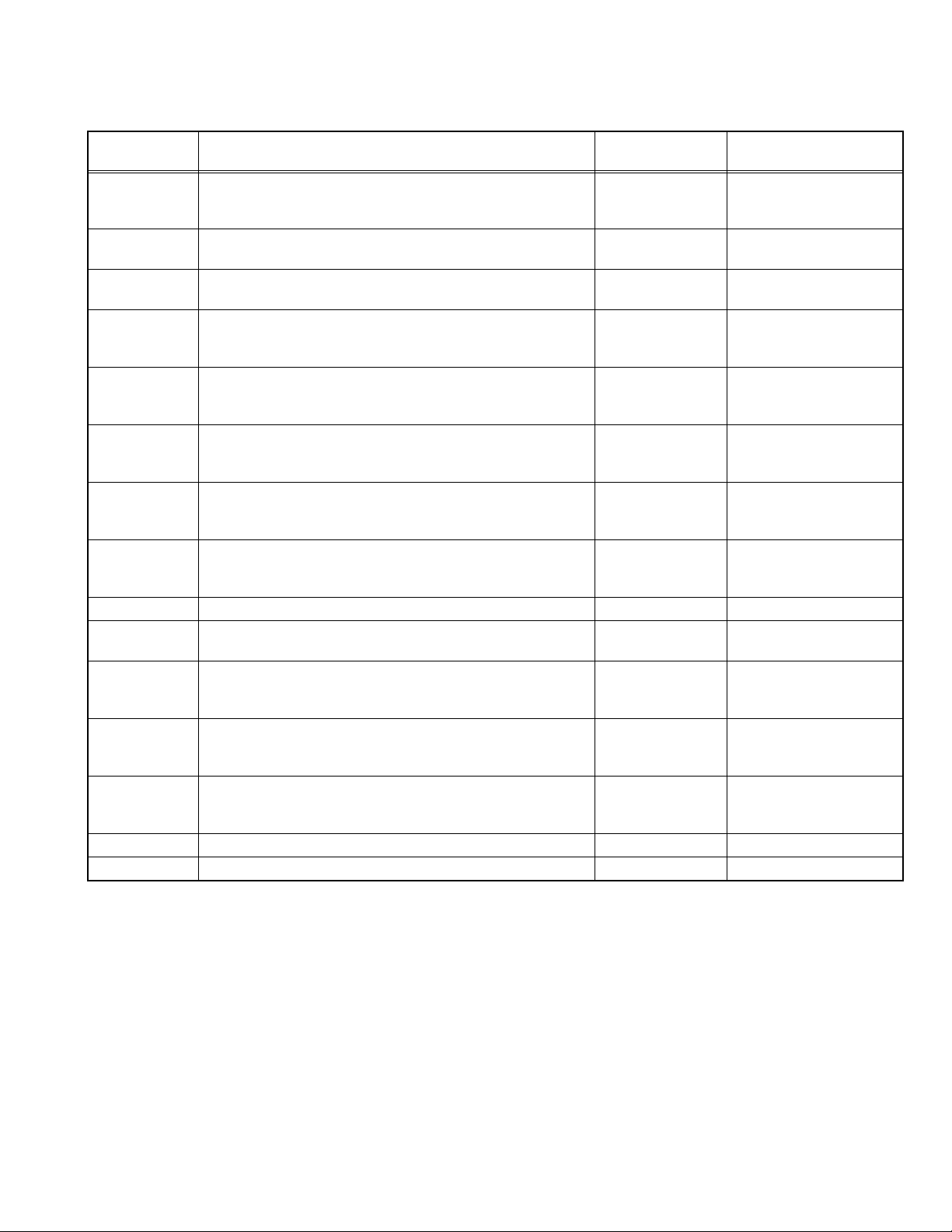

4.6 DVD check mode

Change LCD indication with a [FF] button and a [REW] button.

Operate choice of a menu with a [ENT] button.

LCD indication DVD unit operation

TEST-1 Start at normal speed

(After start, it is measured JITTER on the internal position)

TEST-2 Tracking off on The outermost position of CD EF-BAL

TEST-3 Tracking off on The innermost position of CD EF-BAL

TEST-4 CD_LD lights and laser current is displayed CDLD ON

TEST-5 DVD_LD lights and laser current is displayed DVDLD ON

TEST-6 DVD ×1 jitter measuring mode

(for use in mechanism measurement)

TEST-7 Indication of EEPROM contents ROM DATA

TEST-8 Indication of EEPROM contents ROM DATA

TEST-9 Initialization of EEPROM contents ROMCLEAR

TEST-10 Indicati on of temperature TEMP

TEST-11 Search & jitter measurement to an appointed position of DVD DVD JIT

TEST-12 Setting of MONITOR terminal MONITOR

TEST-13 DVD ×1 double speed start

(After start, it is measured JITTER on the internal position)

[DISC DW ] Disc stopped & LD-OFF STOP

[EJECT] EJECT OPEN

NORMPLAY

CUR ****

JIT ****

OUTROFF For EF phase error

INNTROFF For EF phase error

CUR ****

JIT ****

CUR ****

JIT ****

DVD×1JIT

CUR ****

JIT ****

ADDR ****

DATA ****

ADDR ****

DATA ****

TEMP **** Temperature

PLC ****

JIT ****

M1 ****

M2 ****

×1PLAY

CUR ****

JIT ****

Example of LCD

indication

Indication contents

Laser current value

Jitter value

Laser current value

Jitter value

Laser current value

Jitter value

Laser current value

Jitter value

EEPROM address

EEPROM contents

EEPROM address

EEPROM contents

(Position measured with

VT-501 jitter value)

Laser current value

Jitter value

(No.MA437<Rev.003>)1-19

Page 20

SECTION 5

TROUBLESHOOTING

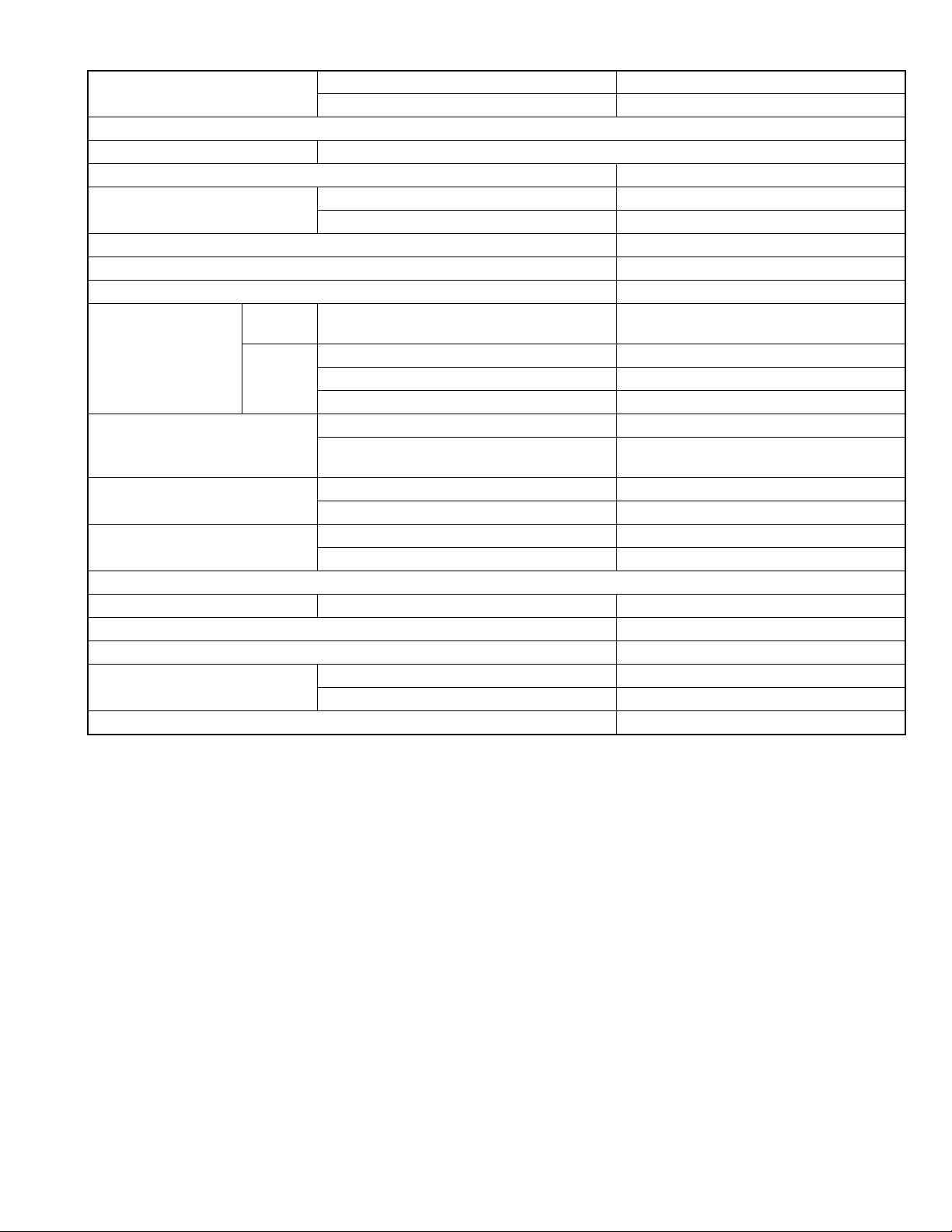

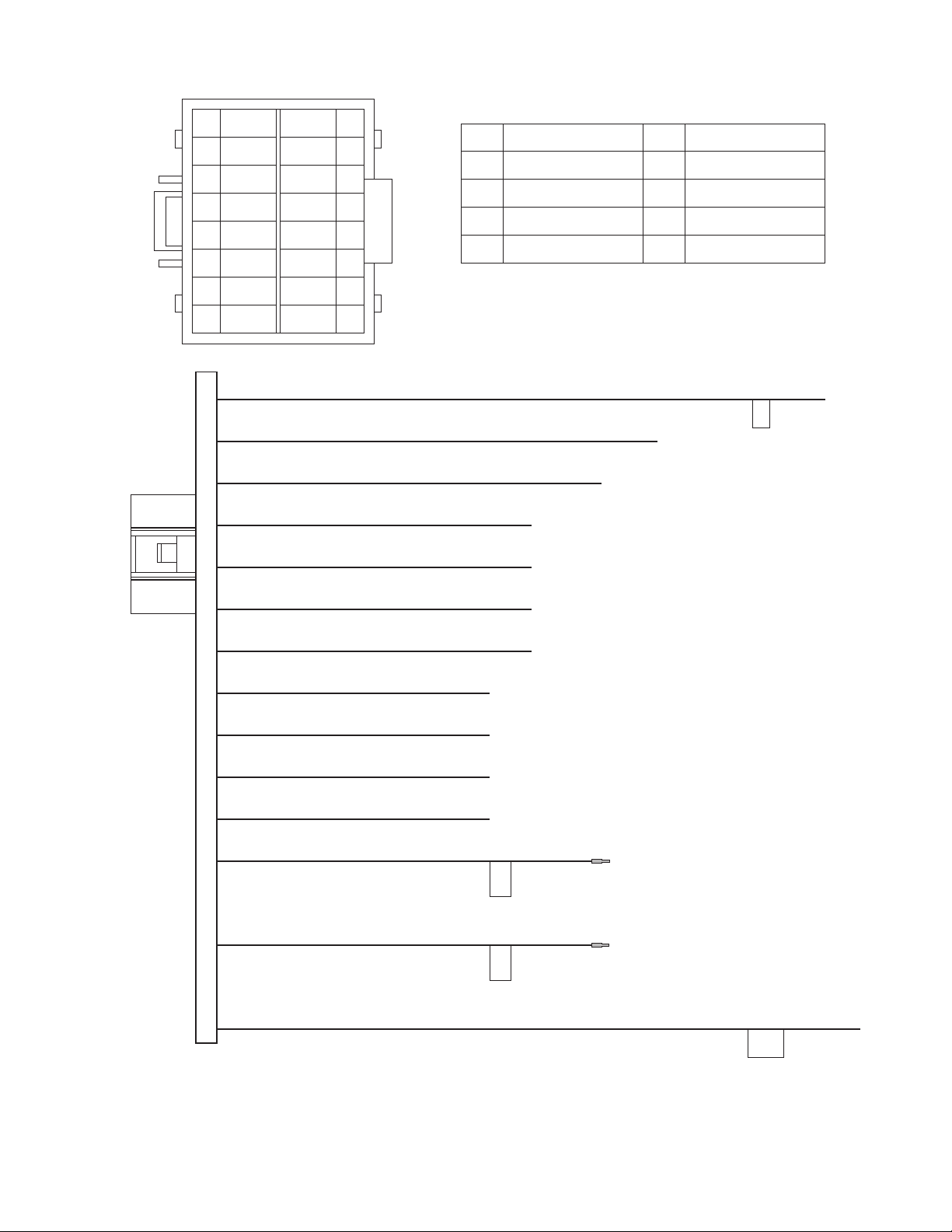

5.1 16 PIN CORD DIAGRAM (for KD-ADV5580, KD-DV5500)

1

16

2

8

8

7

6

5

4

3

2

1

GN

GN/BK

VI/BK

VI

NC

BL/WH

RD

BK

BK

YL

RD

GN

WH

WH/BK

GY/BK

GY

NC

YG

NC

YL

9

10

11

12

13

14

15

16

BK

RD

BL

WH

VI

Black

Red

Blue

White

Violet

GN

GY

YG

YL

Green

Gray

Yellow Green

Yellow

7

5

6

9

10

12

11

3

14

GN/BK

VI

VI/BK

WH

WH/BK

GY

GY/BK

BL/WH

YG

1-20 (No.MA437<Rev.003>)

Page 21

5.2 16 PIN CORD DIAGRAM (for KD-DV4504, KD-DV4505, KD-DV4506, KD-DV4588)

8

7

6

5

4

3

2

1

1

16

2

8

7

GN/BK

VI/BK

VI

BL

BL/WH

RD

BK

BK

YL

RD

GN

GN/BK

WHGN

WH/BK

GY/BK

GY

NC

YG

NC

YL

9

10

11

12

13

14

15

16

BK

RD

BL

WH

VI

Black

Red

Blue

White

Violet

GN

GY

YG

YL

Green

Gray

Yellow Green

Yellow

5

6

9

10

12

11

3

4

14

VI

VI/BK

WH

WH/BK

GY

GY/BK

BL/WH

BL

YG

(No.MA437<Rev.003>)1-21

Page 22

Victor Company of Japan, Limited

Mobile Entertainment Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA437<Rev.003>)

Printed in Japan

VSE

Page 23

REVISION INFORMATION

DVD/CD RECEIVER

KD-ADV5580J, KD-DV5500J, KD-DV4504UI,

KD-DV4505U, KD-DV4505UN, KD-DV4505UT,

KD-DV4505A, KD-DV4506U, KD-DV4506UN,

KD-DV4506UT, KD-DV4506A, KD-DV4588UF,

KD-DV4505UH, KD-DV4506UH

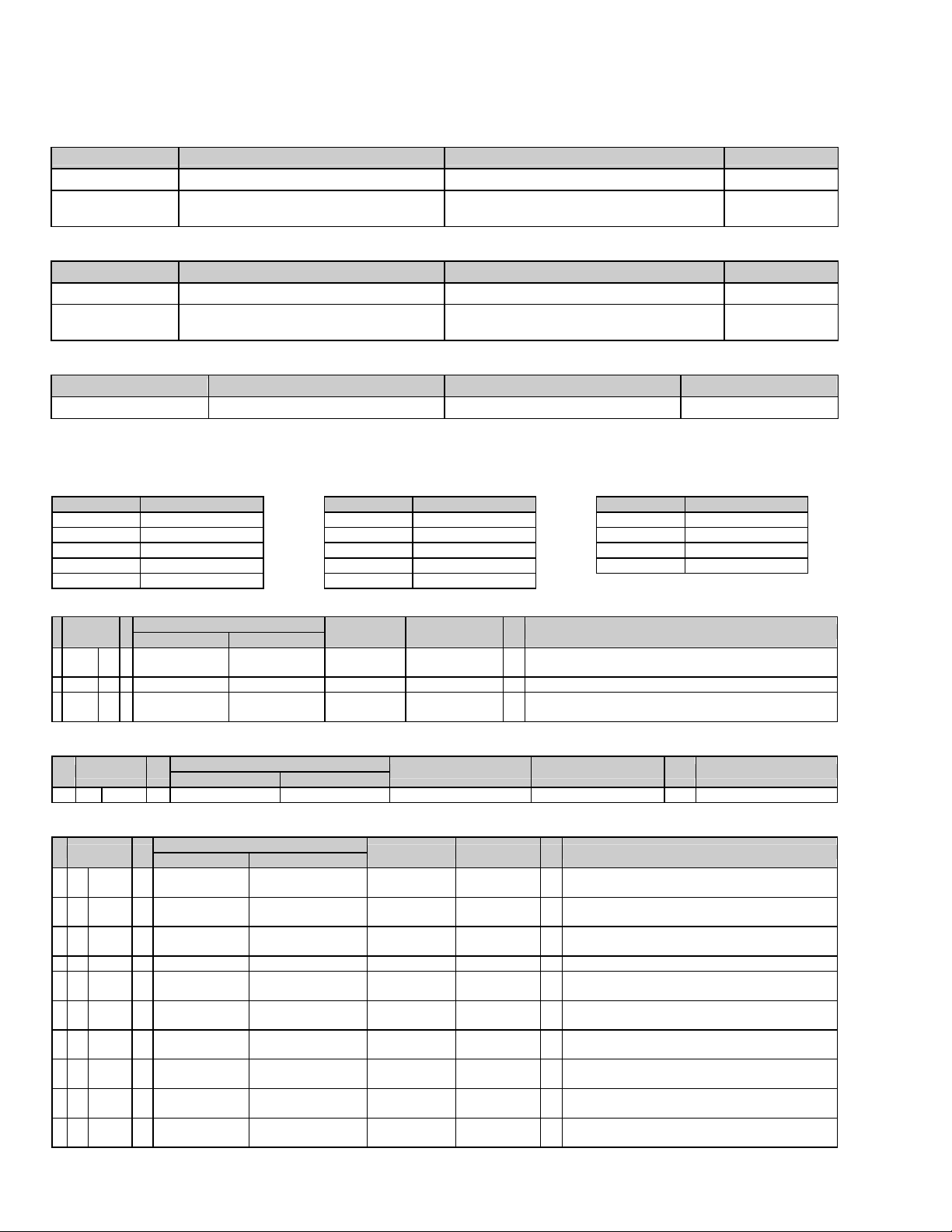

■ OVERVIEW

Add KD-DV4505UH and KD-DV4506UH.

■ DETAILS

COVER SECTION

Title Line No.MA437<Rev.001> No.MA437<Rev.002> Description

Revision Rev.001 Rev.002

Issue Date 2009/01 2009/08

Model No. KD-ADV5580J, KD-DV4504UI, KD-DV4505A,

KD-DV4505U, KD-DV4505UN, KD-DV4505UT,

KD-DV4506A, KD-DV4506U, KD-DV4506UN,

KD-DV4506UT, KD-DV4588UF, KD-DV5500J

KD-ADV5580J, KD-DV4504UI, KD-DV4505A,

KD-DV4505U, KD-DV4505UH, KD-DV4505UN,

KD-DV4505UT, KD-DV4506A, KD-DV4506U,

KD-DV4506UH, KD-DV4506UN, KD-DV4506UT,

KD-DV4588UF, KD-DV5500J

SECTION 2 SPECIFIC SERVICE INSTRUCTIONS

Title Line No.MA437<Rev.001> No.MA437<Rev.002> Description

2 SPECIFIC SERVICE

INSTRUCTIONS

2.1 Identification method T - 2.1 Identification method

1 - Supported reduction in cost, and board

2 - ILLUSTRATION(ma437_2001.png)

1 This servi ce manual does not describe

SPECIFIC SERVIC E INSTRUCTIONS.

-

contents was changed.A set put the following

label on is an object.

COPYRIGHT © 2009 Victor Company of Japan, Limited

MA437-R002

2009/08

Page 24

STANDARD SCHEMATIC DIAGRAMS

r

Schematic Diagram

Diagram Name No.MA437<Rev.001> No.MA437<Rev.002> Description

Menu Main section Old Main section (Except DV4505/4506UH)

Menu - Main section (Common)

ma437_s005.svgz

Printed Circuit Board

Diagram Name No.MA437<Rev.001> No.MA437<Rev.002> Description

Menu Main Board Old Main Board (Except DV4505/4506UH)

Menu - Main Board (Common)

ma437_p005.svgz

Description of Major ICs

Diagram Name No.MA437<Rev.001> No.MA437<Rev.002> Description

Menu IC1: TEF6606T/V3-X IC1: TEF6606T/V5-X

PARTS LIST

MODEL No. LIST

Model No. No.MA437<Rev.002>

KD-ADV5580J 01

KD-DV4504UI 03

KD-DV4505A 07

KD-DV4505U 04

KD-DV4505UH 0D

General assembly [M1MM]

Symbol o

!

M1MM 11 ------------ GE10242-005A FRONT

M1MM 38 ------------ GE32926-002A INSULATOR (Addition) 1 0D,0E

M1MM 56 ------------ LV45386-001A R2

<Rev.001> <Rev.002>

Part No.

Model No. No.MA437<Rev.002>

KD-DV4505UN 05

KD-DV4505UT 06

KD-DV4506A 0B

KD-DV4506U 08

KD-DV4506UH 0E

Part Name Description Qty Models

(Addition) 1 0D,0E

CHASSIS

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,0D,0E

INDICATION

Model No. No.MA437<Rev.002>

KD-DV4506UN 09

KD-DV4506UT 0A

KD-DV4588UF 0C

KD-DV5500J 02

Switch board [02]

Symbol or

!

02 R654 ------------ NRSA63J-511X MG RESISTOR (Addition) 1 0D,0E

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

Main board common [04]

Symbol or

!

! 04 IC1 ------------ TEF6606T/V5-X IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 IC161 ------------ BD3700FV-X IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

! 04 IC301 ------------ TB2926CHQ IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 IC361 ------------ NJM2160BV-X IC (Addition) 1 01

04 IC402 ------------ TOTX177L OPT

04 IC411 ------------ MM1510XN-X IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 IC471 ------------ NJM4565E-X IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

! 04 IC721 ------------ JES1552 IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 IC801 ------------ SN74AHCT126PW-X IC(DIGITAL) (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

! 04 IC911 ------------ R2S25400DS-E IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

2 (MA437-R002)

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

TRANSMITTER

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

Page 25

Symbol or

!

! 04 IC922 ------------ LV5749V-X IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 IC952 ------------ NJM2878F4-33-X IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q301 ------------ 2SC1623A/5-6/-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q301 or ------------ 2SC3928A/QR/-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q321 ------------ IMX9-W PAIR

04 Q701 ------------ RT1N141C-X DIGI

04 Q701 or ------------ UN2211-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q702 ------------ RT1P141C-X DIGI

04 Q702 or ------------ UN2111-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q703 ------------ RT1N141C-X DIGI

04 Q703 or ------------ UN2211-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q704 ------------ RT1P141C-X DIGI

04 Q704 or ------------ UN2111-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q851 ------------ 2SB1132/QR/-W TRANSISTOR (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 Q852 ------------ RT1N141C-X DIGI

04 Q852 or ------------ UN2211-X TRANSISTOR (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 Q861 ------------ RT1P141C-X DIGI

04 Q861 or ------------ UN2111-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q862 ------------ RT1P141C-X DIGI

04 Q862 or ------------ UN2111-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q885 ------------ RT1N141C-X DIGI

04 Q885 or ------------ UN2211-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

! 04 Q921 ------------ MCH6406-W MOS

! 04 Q922 ------------ MCH6406-W MOS

04 Q951 ------------ RT1P441C-X DIGI

04 Q951 or ------------ UN2113-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q952 ------------ RT1N441C-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q952 or ------------ UN2213-X DIGI

04 Q976 ------------ RT1N441C-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q976 or ------------ UN2213-X DIGI

04 Q977 ------------ 2SA812A/5-6/-X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 Q977 or ------------ ISA1530AC1/QR/X TRANSISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D302 ------------ 1SS355W-X DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D302 or ------------ MA111-X SI DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D322 ------------ MC2836-X DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D322 or ------------ MA152WA-X DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

TRANSISTOR

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

(MA437-R002) 3

Page 26

Symbol or

!

04 D701 ------------ UDZW6.2B-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D701 or ------------ MA8062/M/-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D702 ------------ UDZW6.2B-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D702 or ------------ MA8062/M/-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D703 ------------ UDZW6.2B-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D703 or ------------ MA8062/M/-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D704 ------------ UDZW6.2B-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D704 or ------------ MA8062/M/-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D711 ------------ UDZW6.2B-X Z DIODE (Addition) 1 01

04 D711 or ------------ MA8062/M/-X Z DIODE (Addition) 1 01

04 D851 ------------ MA22D23-X SB DIODE (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 D851 or ------------ RB160M-30-X SB DIODE (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 D852 ------------ MA22D39-X SB DIODE (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 D861 ------------ 1SS355W-X DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D861 or ------------ MA111-X SI DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D862 ------------ 1SS355W-X DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D862 or ------------ MA111-X SI DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D863 ------------ UDZW11B-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D863 or ------------ MA8110/M/-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D885 ------------ 1SS355W-X DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D885 or ------------ MA111-X SI DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D901 ------------ 1N5401-F64 SI DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D901 or ------------ 1N5401-TU-15 SI DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D911 ------------ 1SS355W-X DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D911 or ------------ MA111-X SI DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D922 ------------ MA22D23-X SB DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D922 or ------------ RB160M-30-X SB DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D974 ------------ UDZW5.1B-X SB DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D974 or ------------ MA8051/M/-X Z DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D981 ------------ MA22D23-X SB DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D981 or ------------ RB160M-30-X SB DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 D982 ------------ MA22D39-X SB DIODE (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C1 ------------ NCB31HK-102X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C2 ------------ NDC31HJ-7R0X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C3 ------------ NCB31HK-102X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C4 ------------ NCB31CK-224X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C5 ------------ NDC31HJ-150X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C7 ------------ NDC31HJ-220X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

4 (MA437-R002)

Page 27

Symbol or

!

04 C8 ------------ NCBA1CK-103W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C9 ------------ NCB31CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C10 ------------ NCB31CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C11 ------------ NCBA1CK-103W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C12 ------------ NCBA1CK-103W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C14 ------------ NCB31CK-224X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C15 ------------ NCBA1AK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C16 ------------ NCBA1CK-103W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C17 ------------ NCBA1AK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C18 ------------ NCBA1CK-103W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C19 ------------ NCBA1AK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C20 ------------ NCBA1CK-103W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C21 ------------ NCBA1AK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C22 ------------ NDC31HJ-150X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C25 ------------ NCJ21CK-106X-R C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C162 ------------ QTE1H64-225Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C167 ------------ NCB21CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C168 ------------ NCB21CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C172 ------------ QTE1H64-225Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C176 ------------ NCB21CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C177 ------------ NCB21CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C178 ------------ NCB21CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C181 ------------ QEKJ1CM-476Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C182 ------------ QEKJ1CM-107Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C183 ------------ NCBA1CK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C301 ------------ QFV91HJ-474Z MF

04 C302 ------------ QFV91HJ-474Z MF

04 C303 ------------ NDCA1HJ-101W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C304 ------------ NDCA1HJ-101W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C309 ------------ NCB31CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C310 ------------ NCB31CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C311 ------------ QFV91HJ-474Z MF

04 C312 ------------ QFV91HJ-474Z MF

04 C313 ------------ NDCA1HJ-101W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C314 ------------ NDCA1HJ-101W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

CAPACITOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

CAPACITOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

CAPACITOR

(Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

CAPACITOR

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

(MA437-R002) 5

Page 28

Symbol or

!

04 C315 ------------ NCB31EK-223X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C316 ------------ QTE1C57-476Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C317 ------------ NCB21AK-225X-A C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C318 ------------ QEKJ1CM-226Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C319 ------------ NCB31EK-223X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C321 ------------ NCBA1CK-223W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C322 ------------ NCBA1CK-223W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C323 ------------ NDCA1HJ-101W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C324 ------------ QEKJ1HM-475Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C333 ------------ NDCA1HJ-101W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C334 ------------ QEKJ1HM-475Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C383 ------------ QEKJ1HM-475Z E CAPACITOR (Addition) 1 01

04 C384 ------------ QEKJ1HM-475Z E CAPACITOR (Addition) 1 01

04 C385 ------------ NCBA1CK-104W C CAPACITOR (Addition) 1 01

04 C386 ------------ NCBA1CK-104W C CAPACITOR (Addition) 1 01

04 C387 ------------ NCB31HK-152X C CAPACITOR (Addition) 1 01

04 C388 ------------ NCB31HK-152X C CAPACITOR (Addition) 1 01

04 C389 ------------ QEKJ1CM-107Z E CAPACITOR (Addition) 1 01

04 C390 ------------ QEKJ1CM-107Z E CAPACITOR (Addition) 1 01

04 C392 ------------ QEKJ0JM-476Z E CAPACITOR (Addition) 1 01

04 C405 ------------ NDC31HJ-220X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C406 ------------ NCBA1CK-103W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C411 ------------ QEKJ1AM-227Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C412 ------------ NCBA1AK-473W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C413 ------------ QCZ0202-155Z C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C414 ------------ QEKJ0JM-337Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C471 ------------ QTE1H57-225Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C472 ------------ QTE0J57-476Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C473 ------------ NDC31HJ-680X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C474 ------------ NDC31HJ-560X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C475 ------------ NCBA1CK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C476 ------------ QEKJ1CM-107Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C481 ------------ QTE1H57-225Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C482 ------------ QTE0J57-476Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C483 ------------ NDC31HJ-680X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C484 ------------ NDC31HJ-560X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C701 ------------ NCBA1AK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C702 ------------ NCBA1CK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C703 ------------ NCBA1AK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C711 ------------ NDCA1HJ-101W C CAPACITOR (Addition) 1 01

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

6 (MA437-R002)

Page 29

Symbol or

!

04 C731 ------------ NCB31HK-102X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C741 ------------ NDC31HJ-270X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C742 ------------ NDC31HJ-220X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C743 ------------ NCB31CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C744 ------------ NDC31HJ-120X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C745 ------------ NDC31HJ-120X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C746 ------------ QEKJ0JM-337Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C747 ------------ QEKJ0JM-337Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C749 ------------ NCBA1AK-473W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C801 ------------ NDC31HJ-220X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C802 ------------ NCBA1AK-473W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C803 ------------ QEKJ1HM-225Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C804 ------------ QEKJ1HM-225Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C851 ------------ QEKJ1EM-106Z E CAPACITOR (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 C852 ------------ NCB31CK-224X C CAPACITOR (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 C861 ------------ QEKJ0JM-476Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C862 ------------ QEKJ1CM-107Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C885 ------------ NCB31CK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

! 04 C901 ------------ QEZ0869-278 E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C902 ------------ NCB31EK-104X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C903 ------------ QEKJ1HM-225Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C910 ------------ NCBA1CK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C911 ------------ QEKJ1EM-106Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C912 ------------ QEKJ0JM-337Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C913 ------------ QEKJ1CM-476Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C914 ------------ NCBA1CK-103W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C915 ------------ QEKJ1EM-106Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C916 ------------ QEKJ1EM-106Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C917 ------------ NCBA1CK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C919 ------------ QEKJ1CM-226Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C920 ------------ NCBA1CK-473W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C925 ------------ NCBA1AK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C926 ------------ NCB31AK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C927 ------------ NCBA1AK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C928 ------------ NCBA1HK-102W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C929 ------------ NDC31HJ-681X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

(MA437-R002) 7

Page 30

Symbol or

!

04 C930 ------------ NCB31AK-105X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C931 ------------ NCJ11EK-106X-A C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C932 ------------ NCJ11EK-106X-A C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C933 ------------ NCB10JK-106X-A C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C934 ------------ NCB10JK-106X-A C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C935 ------------ QEZ0595-477Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C953 ------------ NCBA1AK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C955 ------------ NDC31HJ-120X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C962 ------------ NCBA1AK-473W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C964 ------------ NCBA1AK-473W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C966 ------------ NCBA1CK-103W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C967 ------------ NCBA1AK-473W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C974 ------------ NCB31HK-102X C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C975 ------------ QEKJ1AM-227Z E CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 C981 ------------ NCBA1CK-104W C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R1 ------------ NRSA63J-474X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R2 ------------ NRSA63J-474X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R3 ------------ NRSA63J-101X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R4 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R5 ------------ NRS181J-220X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R6 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R7 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R12 ------------ NRS181J-4R7X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R161 ------------ NRSA6AJ-224W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R162 ------------ NRSA6AJ-393W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R163 ------------ NRSA6AJ-393W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R303 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R304 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R305 ------------ NRSA63J-103X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R307 ------------ NRSA63J-473X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R308 ------------ NRSA63J-103X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R309 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R310 ------------ NRS181J-100X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R313 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R314 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

8 (MA437-R002)

Page 31

Symbol or

!

04 R321 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R322 ------------ NRSA6AJ-102W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R323 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R324 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R331 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R332 ------------ NRSA6AJ-102W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R333 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R334 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R361 ------------ NRSA6AJ-102W MG RESISTOR (Addition) 1 01

04 R362 ------------ NRSA6AJ-102W MG RESISTOR (Addition) 1 01

04 R363 ------------ NRSA6AJ-104W MG RESISTOR (Addition) 1 01

04 R364 ------------ NRSA6AJ-104W MG RESISTOR (Addition) 1 01

04 R365 ------------ NRSA6AJ-223W MG RESISTOR (Addition) 1 01

04 R366 ------------ NRSA6AJ-223W MG RESISTOR (Addition) 1 01

04 R367 ------------ NRSA6AJ-333W MG RESISTOR (Addition) 1 01

04 R368 ------------ NRSA6AJ-333W MG RESISTOR (Addition) 1 01

04 R371 ------------ NRSA6AJ-0R0W MG RESISTOR (Addition) 1 02,03,04,05,06,07,08,09,0A,0B,0C,0D,

04 R372 ------------ NRSA6AJ-0R0W MG RESISTOR (Addition) 1 02,03,04,05,06,07,08,09,0A,0B,0C,0D,

04 R403 ------------ NRSA6AJ-471W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R404 ------------ NRSA6AJ-1R0W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R405 ------------ NRSA6AJ-0R0W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R412 ------------ NRSA6AD-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R413 ------------ NRSA6AD-181W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R414 ------------ NRSA6AJ-102W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R415 ------------ NRSA6AJ-750W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R417 ------------ NRSA6AJ-100W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R471 ------------ NRSA6AJ-224W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R472 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R473 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R474 ------------ NRSA6AJ-203W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R475 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R476 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R477 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R481 ------------ NRSA6AJ-224W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R482 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R483 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R484 ------------ NRSA6AJ-203W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R485 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R486 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0E

0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

(MA437-R002) 9

Page 32

Symbol or

!

04 R487 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R701 ------------ NRSA63J-471X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R702 ------------ NRSA6AJ-392W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R703 ------------ NRSA6AJ-562W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R704 ------------ NRSA6AJ-271W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R705 ------------ NRSA6AJ-271W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R711 ------------ NRSA6AJ-271W MG RESISTOR (Addition) 1 01

04 R731 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R732 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R733 ------------ NRSA6AJ-152W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R734 ------------ NRSA6AJ-152W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R735 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R736 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R737 ------------ NRSA6AJ-104W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R738 ------------ NRSA6AJ-104W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R739 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R740 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R741 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R743 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R744 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R745 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02

04 R746 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 02,03,04,05,06,07,08,09,0A,0B,0C,0D,

04 R747 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R748 ------------ NRSA6AJ-331W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R749 ------------ NRSA6AJ-331W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R750 ------------ NRSA6AJ-152W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R751 ------------ NRSA6AJ-432W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R752 ------------ NRSA6AJ-0R0W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R754 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R755 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R756 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R757 ------------ NRSA6AJ-224W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R758 ------------ NRSA6AJ-224W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R760 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01

04 R761 ------------ NRSA6AJ-223W MG RESISTOR (Addition) 1 01

04 R762 ------------ NRSA6AJ-333W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R763 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

10 (MA437-R002)

Page 33

Symbol or

!

04 R764 ------------ NRSA6AJ-183W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R765 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R766 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R767 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R768 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R769 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R770 ------------ NRSA6AJ-0R0W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R771 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R780 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R782 ------------ NRSA6AJ-682W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R783 ------------ NRSA6AJ-562W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R784 ------------ NRSA6AJ-393W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R785 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R786 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R787 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R789 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R790 ------------ NRSA6AJ-393W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R791 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R793 ------------ NRSA6AJ-222W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R795 ------------ NRSA6AJ-0R0W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R796 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R797 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R798 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R799 ------------ NRSA6AJ-102W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R801 ------------ NRSA6AJ-0R0W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R802 ------------ NRSA6AJ-104W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R803 ------------ NRSA6AJ-682W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R804 ------------ NRSA6AJ-392W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R805 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R806 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R807 ------------ NRSA6AJ-104W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R808 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R809 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R810 ------------ NRSA6AJ-392W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R811 ------------ NRSA6AJ-682W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

(MA437-R002) 11

Page 34

Symbol or

!

04 R812 ------------ NRSA6AJ-104W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R813 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R814 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R851 ------------ NRSA6AJ-472W MG RESISTOR (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 R852 ------------ NRSA6AJ-473W MG RESISTOR (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 R853 ------------ NRS181J-102X MG RESISTOR (Addition) 1 03,04,05,06,07,08,09,0A,0B,0C,0D,0E

04 R861 ------------ NRSA6AJ-471W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R885 ------------ NRSA6AJ-223W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R886 ------------ NRSA6AJ-153W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R887 ------------ NRSA6AJ-103W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R901 ------------ QRE142J-102X C RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R902 ------------ NRS181J-912X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R903 ------------ NRSA63J-472X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R912 ------------ NRSA6AJ-0R0W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R921 ------------ NRSA63D-152X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R922 ------------ NRSA63D-103X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R923 ------------ NRSA63J-244X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R924 ------------ NRSA63J-202X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R925 ------------ NRSA63J-102X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R926 ------------ NRSA63J-682X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R927 ------------ NRSA63J-474X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R928 ------------ NRS181J-100X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R929 ------------ NRS181J-100X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R961 ------------ NRSA6AJ-101W MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R972 ------------ NRS181J-221X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R976 ------------ NRSA63J-563X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R977 ------------ NRSA63J-183X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 R981 ------------ NRS181J-332X MG RESISTOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 L1 ------------ NQL093K-R47X COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 L2 ------------ NQL093K-1R8X COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 L3 ------------ QQL213M-R22Z COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 L4 ------------ QQR1813-001 COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 L5 ------------ NQL114K-561X P COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 L6 ------------ NQL114K-561X P COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 L8 ------------ QQL244J-4R7Z P COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

! 04 L901 ------------ QQR0703-001 CHOKE COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

! 04 L901 or ------------ QQR1852-001 CHOKE COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

0D,0E

12 (MA437-R002)

Page 35

Symbol or

r

!

04 L922 ------------ QQL92AK-330Z COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,

04 L923 ------------ NQLB7GM-100X COIL (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,0C,