Johnson Controls VG7000 Series Data Sheet

VG7000 Series Bronze Control Valves |

||

Product Bulletin |

Code No. LIT-977140 |

|

VG7000 Series |

||

Issued November 15, 2013 |

||

|

||

|

Supersedes March 29, 2013 |

|

|

Refer to the QuickLIT website for the most up-to-date version of this document. |

|

VG7000 Series Bronze Control Valves are designed primarily to regulate the flow of water and steam in response to the demand of a controller in Heating, Ventilating, and Air Conditioning (HVAC) systems. These valves are available in Normally Open (N.O.), Normally Closed (N.C.), and three-way mixing configurations. Both electric and pneumatic actuators are available for factory or field mounting.

|

Figure 1: VG7000 Series Bronze Control Valves |

Table 1: Features and Benefits |

|

|

|

Features |

Benefits |

Complete Family of 1/2 through |

Offers a broad selection to choose from, including electric spring return actuators, a |

2 in. Bronze Valves, Brass and |

true 1-1/4 in. valve body, a 3/4 in. valve with small oval top actuator, and Stainless |

Stainless Steel Trim, with Several |

Steel (SS) trim capable of 100 psig (690 kPa) saturated steam. |

Styles of Electric and Pneumatic |

|

Actuators |

|

|

|

Flexible Features and Options |

Suits your specific application via thousands of easy-to-select, factory-assembled |

Ordering Matrix |

combinations. |

Standard Johnson Controls® |

Provides industry-leading reliability and operating life. |

Ring Pack Packings |

|

|

|

Testing for Tight Shutoff of Every |

Provides energy conservation and ensures occupant comfort. |

Valve |

|

|

|

Standard Bonnet and Stem Design |

Allows easy field retrofit, easy field mounting, and interchangeability of actuators with |

|

the use of standardized mounting kits. |

|

|

VG7000 Series Bronze Control Valves Product Bulletin |

1 |

Ordering Data

Table 2: Ordering Data — VG7000 Series Bronze Control Valves1

V |

G |

|

|

|

|

|

|

|

|

|

|

|

|

|

Valve Global |

|

|

1 |

2 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

Product Family |

7 = Cast Bronze |

|

|

|

3 |

2 |

|

|

|

|

|

|

|

|

|

|

|

Body Type |

2 = Two-Way, Normally Open/Push-Down-to-Close |

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

= Two-Way, Normally Closed/Push-Down-to-Open |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

= Two-Way Angle, Normally Open/Push-Down-to-Close |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

= Three-Way Mixing |

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

End Connections |

4 = Threaded National Pipe Thread (NPT) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

= Union Globe/Union Angle (1/2 through 1-1/2 in. Body |

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sizes, PDTC Only, Brass Trim Valves Only)) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

= Union Sweat, 3/8 in. Tubing (1/2 in. Body Size Only, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brass Trim Valves Only)) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

= Union Sweat, Standard Tubing (Brass Trim Valves |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Only) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

= Union Sweat, 3/4 in. Tubing (1/2 in. Body Size Only, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brass Trim Valves Only)) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

Trim and Flow |

1 = Brass Equal Percentage (All Two-Way and 1/2 in. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Characteristics |

Three-Way) |

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

2 |

= Brass Linear (Three-Way Only) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

= Stainless Steel Equal Percentage (Two-Way Only) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

= Stainless Steel Linear (Three-Way Only) |

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

Size and Cv (Kv) |

C = 1/2 in., 0.73 Cv (0.63 Kv) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E = 1/2 in., 1.8 Cv (1.6 Kv) |

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G = 1/2 in., 4.6 Cv (4.0 Kv) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L = 3/4 in., 7.3 Cv (6.3 Kv) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N = 1 in., 11.6 Cv (10.0 Kv) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P = 1-1/4 in., 18.5 Cv (16.0 Kv) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R = 1-1/2 in., 28.9 Cv (25.0 Kv) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S = 2 in., 46.2 Cv (40.0 Kv) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

|

|

Stem Type |

T = Standard Threaded Stem (All Except V-3801, MP84, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VA-8x2x) |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

S = Slotted Stem and Small Bonnet (Factory-Mounted |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V-3801, VA-8x2x Only; Only Brass Trim Valves) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M = Large Threaded Stem (Factory-Mounted MP84 Only, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Only Stainless Steel Trim Valves) |

|

|

|

|

|

|

|

|

|

+ |

|

|

|

|

|

|

Actuator |

+ = Factory-Mounted Actuator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mounting |

(See Table 3 and Table 4.) |

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

(Leave Fields 9 through 15 blank for valve without |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

factory-mounted actuator. Valve without factory-mounted |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

actuator is available with standard threaded stem only.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 10 |

11 12 13 14 15 |

= Field |

|

|

|||||

V |

G |

7 |

2 |

4 |

1 |

L |

T |

+ |

|

|

|

|

|

|

Example: Cast bronze valve, two-way, normally open/push-down-to-close, |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

threaded (NPT) end connections, brass trim, equal percentage, |

||

|

|

|

Valve |

|

|

|

+ |

|

|

Actuator |

|||||||

|

|

|

|

|

|

|

|

3/4 in., 7.3 Cv, standard threaded stem. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.See Table 3 when adding a factory-mounted pneumatic actuator to a valve body. See Table 4 when adding a factory-mounted electric actuator to a valve body. For valid valve and actuator combinations, see Table 16 and Table 17.

2 VG7000 Series Bronze Control Valves Product Bulletin

Table 3: Ordering Data — Adding a Factory-Mounted Pneumatic Actuator1

V |

G |

7 |

2 |

4 |

3 |

L |

T |

+ |

3 |

0 |

0 |

8 |

|

|

V-3000/V-3801 |

3801 = V-3801-8001 Small Oval Top (Slotted Stem Only, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pneumatic |

Brass Trim Valves Only, Must be Factory Assembled) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Actuator2 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

|

|

3008 = V-3000-8012 Exposed |

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3003 = V-3000-8003 Enclosed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

Spring Range |

B = 3 to 6 psig (Suggested for N.O. Valves with Positioner) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(V-3000/V-3801) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

D = 4 to 8 psig (Suggested for Three-Way Valves with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Positioner) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E = 9 to 13 psig (Suggested for N.C. Valves with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Positioner) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

Accessories |

P = V-9502 Positioner (Not Available with V-3801-8001 or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(V-3000/V-3801) |

V-3000-8003) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

|

Blank = None |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

2 |

|

|

|

|

MP8000 Series |

82 = MP82, 25 sq in. Spring-Return-Up (SS or Brass Trim) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pneumatic |

|

|

|

|

|

|

|

|

|

|

10 |

11 |

|

|

|

|

Actuator2 |

84 = MP84, 50 sq in. Spring-Return-Up (SS Trim Only) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Only spring-return-up models of MP8000 Series |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pneumatic Actuators are available factory-mounted to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VG7000 Series Bronze Control Valves.) |

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

Stroke |

1 = 5/16 in. (1/2 or 3/4 in. Valves with MP82 Actuator Only) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(MP8000 |

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

2 = 1/2 in. (1 or 1-1/4 in. Valves with MP82 Actuator Only) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Series) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 = 3/4 in. (1-1/2 or 2 in. Valves with MP82 or MP84 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Actuator) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

Spring Range |

C = 3 to 7 psig (Suggested for N.O. Valves with Positioner) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(MP8000 |

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

|

Series) |

D = 4 to 8 psig (Suggested for Three-Way Valves with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Positioner) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E = 9 to 13 psig (Suggested for N.C. Valves with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Positioner) |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

Accessories |

00 = None |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(MP8000 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

15 |

01 = V-9502 Positioner |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Series) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

V |

G |

7 |

2 |

4 |

3 |

L |

T |

+ |

8 |

2 |

1 |

C |

0 |

1 |

|

|

|

Valve |

|

|

|

+ |

|

|

Actuator |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

= Field

Example: Cast bronze valve, two-way, normally open, threaded (NPT) end connections, stainless steel trim, equal percentage, 3/4 in., 7.3 Cv, standard threaded stem, MP82 Series Pneumatic Actuator, 5/16 in. stroke, 3 to 7 psig (21 to 48 kPa) spring range, with factory-mounted V-9502 Positioner.

1.See Table 2 when ordering a valve body only. See Table 4 when adding a factory-mounted electric actuator to a valve body. For valid valve and actuator combinations, see Table 16 and Table 17.

2.Refer to the actuator product bulletin or product/technical bulletin.

VG7000 Series Bronze Control Valves Product Bulletin |

3 |

Table 4: Ordering Data — Adding a Factory-Mounted Electric Actuator1

V |

G |

7 |

2 |

4 |

1 |

L |

T |

+ |

7 |

1 |

5 |

0 |

|

|

|

VA-7150/ |

7150 = VA-7150-1001 On/Off (Floating) |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

|

|

|

VA-7200 |

7152 = VA-7152-1001 Proportional, 0-10 VDC |

|

|

|

Electric |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Actuator2, 3 |

7153 = VA-7153-1001 On/Off (Floating), Feedback |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7200 = VA-7200-1001 On/Off (Floating) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7202 = VA-7202-1001 Proportional, 0-10 VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7203 = VA-7203-1001 On/Off (Floating), Feedback |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

Voltage |

G = 24 VAC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(VA-7150/ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VA-7200) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Accessories |

Blank = None |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(VA-7150/ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VA-7200) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

2 |

3 |

|

|

|

|

VA-4233 |

Spring Return Up |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electric |

|

|

|

|

|

|

|

|

|

|

10 |

11 |

12 |

|

|

|

|

423 = VA-4233-xGx-2, 24 VAC/VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Actuator2 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

G |

A |

Features |

AGA = Floating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(VA-4233)4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

14 |

|

15 |

AGC = Floating, 2 Auxiliary Switches |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BGA = On/Off |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BGC = On/Off, 2 Auxiliary Switches |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GGA = Prop., 0-10 VDC, Feedback |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GGC = Prop., 0-10 VDC, Feedback, 2 Auxiliary Switches |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

2 |

N |

|

|

|

|

VA7810 |

Non-Spring Return |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VA7820/ |

|

|

|

|

|

|

|

|

|

|

10 |

11 |

12 |

|

|

|

|

71C = VA7810-xGx-2, 24 VAC/VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VA78305 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electric |

Spring Return |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Actuator2,6 |

72C = VA7820-HGx-2, Spring-Return Stem Up 24 VAC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

74C = VA7830-HGx-2, Spring-Return Stem Down 24 VAC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

G |

A |

Features |

AGA = On/Off (Floating) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(VA78x0)7 |

(Available only with VA7810 Actuator) |

|

|

|

|

|

|

|

|

|

|

|

|

13 |

14 |

|

15 |

|

AGC = On/Off (Floating), 2 Auxiliary Switches |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Available only with VA7810) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HGA = Proportional, 0-10 VDC, Feedback |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HGC = Proportional, 0-10 VDC, Feedback, 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

0 |

2 |

0 |

|

|

|

VA-8x2x |

8020 = VA-8020-1, On/Off (Floating) |

|

|

|

|

|

|

|

|

|

10 |

11 |

12 |

13 |

|

|

|

Electric |

8122 = VA-8122-1, Proportional |

|

|

|

|

|

|

|

|

|

|

|

|

Actuator2,3, 8 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

Voltage |

G = 24 VAC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(VA-8x2x) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Accessories |

Blank = None |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

(VA-8x2x) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

|

15 |

= Field |

|

V |

G |

7 |

2 |

4 |

1 |

L |

T |

+ |

8 |

0 |

2 |

0 |

G |

|

|

|

|

Valve |

|

+ |

|

|

Actuator |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Example: Cast bronze valve, two-way, push-down-to-close, threaded (NPT) end connections, brass trim, equal percentage, 3/4 in., 7.3 Cv, standard threaded stem, VA-8020-1 On/Off (Floating) Electric Actuator, 24 VAC supply.

1.See Table 2 when ordering a valve body only. See Table 3 when adding a factory-mounted pneumatic actuator to a valve body. For valid valve and actuator combinations, see Table 16 and Table 17.

2.Refer to the actuator product bulletin or product/technical bulletin.

3.Available only for PDTC Two-Way and Three-Way body styles.

4.Available only for NPT (threaded) and Union Sweat End Connections body style.

5.VA7830 actuator is available only on Three-Way Mixing body style.

6.Available only for NPT (threaded) body style.

7.VA7820 and VA7830 Proportional Control Actuators have selectable switches for field conversion to On/Off or Floating Control.

8.Available only for 1/2 and 3/4 in. valves.

4 VG7000 Series Bronze Control Valves Product Bulletin

Application Overview

IMPORTANT: The VG7000 Series Bronze Control Valves are intended to control saturated steam, hot water, and chilled water flow under normal equipment operating conditions. Where failure or malfunction of the VG7000 Series Valve could lead to personal injury or property damage to the controlled equipment or other property, additional precautions must be designed into the control system. Incorporate and maintain other devices, such as supervisory or alarm systems or safety or limit controls, intended to warn of or protect against failure or malfunction of the VG7000 Series Valve.

VG7000 Series Bronze Control Valves feature brass and stainless steel trim, and are available in two-way configurations with Push-Down-to-Close (PDTC)

(normally open if pneumatic or spring return) or Push-Down-to-Open (PDTO) (normally closed if pneumatic or spring return) with threaded (NPT), union sweat, union globe, and union angle end connections. The valve can be ordered with a variety of pneumatic actuators: V-3000-8012 (exposed, with or without a factory-mounted positioner), V-3000-8003 (enclosed), V-3801-8001 (oval top), and higher force MP8000 Series Actuators (with or without a factory-mounted pneumatic positioner).

VG7000 Series Valves can also be ordered with any of the following series electric actuators: VA-4233, VA-7150, VA-7200, VA-8x2x, VA7810, VA7820, or VA7830. All electric actuators are fully compatible with Johnson Controls® controllers, reducing installation costs. Valves without actuators can be ordered with the standard bonnet and threaded stem design, allowing easy interchangeability of actuators with the use of standardized mounting kits. See Table 2 through Table 4 for ordering data and additional details. For valid valve and actuator combinations, see Table 16 and Table 17.

The modulating valve plug of VG7000 Series Valves provides an equal percentage flow characteristic for two-way valves, and equal percentage or linear for three-way valves. Tight shutoff is ensured using a molded elastomeric disk in valves with brass trim, and a precisely machined metal-to-metal seat for valves with stainless steel trim. An arrow is cast on one side of the valve body indicating the direction of flow for proper piping.

Pneumatic Actuator Selection

See Table 7, Table 9, Table 11, and Table 16.

Do not confuse the V-3000-8012, V-3000-8003, and V-3801-8001 Pneumatic Actuators with the V-3000-1, V-3000-2, and V-3802-1 Pneumatic Actuators. Refer to the V-3000-8011 (Exposed) and V-3000-8003 (Enclosed) Pneumatic Valve Actuators Product/ Technical Bulletin (LIT-977252) for specifics regarding interchangeability. The V-3801-8001 is not a direct replacement for the V-3802-1 because V-3802-1 is not compatible with VG7000 Series Valves.

V-3801-8001 Pneumatic Actuator

The V-3801-8001 is a low force, oval top actuator designed specifically for 1/2 and 3/4 in. valves where mounting space is restricted. The V-3801-8001 has sufficient force to handle most seating pressures, and the molded diaphragm design provides a constant effective area (4 sq in.) throughout the valve stem stroke. Due to the simplicity of the design, it is more economical to replace the actuator than repair it. The actuator assembly can be removed or repositioned by loosening a single set screw without disturbing the rest of the valve assembly.

Because the V-3801-8001 uses a unique slotted valve stem for factory assembly (see the Stem Type section in Table 2), the spring kits available are for field mounting to standard threaded stem valves. See Table 7 for mounting kit code numbers.

V-3000-8012 Pneumatic Actuator

The V-3000-8012 is a versatile, medium-force pneumatic actuator that can be used in most HVAC applications, including sequential control of valves. See Table 9 and Table 11 for actuator sizing and selection.

The permanently captured, molded rolling diaphragm of the V-3000-8012 provides a constant effective area (8 sq in.) throughout the valve stem stroke. The actuator assembly can be removed or repositioned by loosening a single set screw without disturbing the rest of the valve assembly.

The V-9502 Pneumatic Positioner is also available for factory or field mounting to the V-3000-8012.

V-3000-8003 Pneumatic Actuator

The V-3000-8003, operationally similar to the V-3000-8012, is designed for enclosed installation in a location where the actuator might be subjected to tampering. The V-3000-8003 has a replaceable molded diaphragm design.

VG7000 Series Bronze Control Valves Product Bulletin |

5 |

MP8000 Series Pneumatic Actuators

The higher force MP82 (25 sq in. effective diaphragm area) and MP84 (50 sq in. effective diaphragm area) Pneumatic Actuators are used where higher maximum closeoff pressures are required, such as 1-1/2 and 2 in. brass trim valves and 1/2 through 2 in. stainless steel trim valves.

These actuators are equipped with a molded synthetic rubber diaphragm contained in a sturdy, carbon-steel housing that protects it against dirt and damage. The actuator can be easily removed to perform inline servicing to all parts of the valve. The MP8000 Actuators are available factory mounted or are easily field mounted to VG7000 Series Valves. See Table 7 for the appropriate mounting kit.

The MP8000 Actuators are designed to allow for reversing the action of the actuators in the field. If desired, the action of the MP8000 on Normally Open (N.O.) valves can be reversed from spring-return-up to spring-return-down or vice versa. To field reverse the actuator, refer to the MP8000 Pneumatic Valve Actuators Technical Bulletin (LIT-977258).

The V-9502 Pneumatic Positioner is also available for factory or field mounting to MP8000 Series Pneumatic Valve Actuators.

T-3000 Valve Top Thermostat Actuators

The T-3111 and T-3311 Series Valve Top Thermostat Actuators are available for field mounting to all VG7000 Series Valves (N.O., N.C., and three-way). The valve top thermostats are a combination of a pneumatic thermostat and a pneumatic valve actuator. The T-3111 and T-3311 are available in both direct and reverse acting models with various features and options. Refer to the T-3111 Integral Thermostat and Piston Top Valve Actuator Single Temperature, Single Pressure Product/ Technical Bulletin (LIT-7171137) and the T-3311 Integral Thermostat and Piston Top Valve Actuator Dual Temperature, Dual Pressure Product/Technical Bulletin (LIT-7171152) for specifications and ordering information.

Note: A mounting kit is required to field mount T-3111 or T-3311 Valve Top Thermostats to a valve. See Table 7 for the appropriate mounting kit code number.

Electric Actuator Selection

Factory-mounted electric actuators are available on two-way PDTC and three-way mixing valve configurations only. Actuators can be easily field reversed if required. The actuators can be field mounted on PDTO valves if desired. All proportional electric actuator assemblies are factory calibrated for nominal 0 to 10 VDC operation, to drive down with an increase in signal. The VA-4233 and VA78x0 are available on all valve styles: PDTO, PDTC, and threeway.

VA-4233 Series Electric Actuators

The VA-4233 Series Electric Actuators use a stepper motor to accurately position the valve. In the event of a power failure, a spring in the actuator automatically returns the valve to the full stem-up position. These direct-mount, spring return electric actuators provide a minimum 61 lb force output for floating, on/off, or proportional control, and can be factory mounted to 1/2 through 1-1/4 in. valve bodies with NPT (threaded) and union sweat end connections.

Integral auxiliary switches are available for indicating end stop position or to perform switching functions. On proportional models, position feedback is also available through a proportional DC voltage signal. All models feature a hand crank for manual positioning of the valve, independent of a power supply.

VA-7150 Series Electric Actuators

The VA-7150 Series Actuators use a reversible synchronous motor and magnetic clutch to accurately position the valve. This non-spring return actuator has a 90 lb force output. The magnetic clutch maintains a constant load at the end of travel, ensuring tight valve shutoff and automatically compensating for seat wear.

This actuator is available in three models: floating three-wire (VA-7150), floating with 0 to 2000 ohm feedback (VA-7153), or 0 to 10 VDC proportional control (VA-7152).

VA-7200 Series Electric Actuators

The VA-7200 Series Actuators use a reversible synchronous motor and a magnetic clutch to accurately position the valve. This non-spring return actuator has a 180 lb force output. The magnetic clutch maintains a constant load at the end of travel, which ensures tight shutoff and automatically compensates for seat wear. This actuator is available in three models: floating three-wire (VA-7200), floating with 0 to 2000 ohm feedback (VA-7203), or 0 to 10 VDC (0 to 20 mA) proportional control (VA-7202).

6 VG7000 Series Bronze Control Valves Product Bulletin

VA-8x2x Series Electric Actuators

The VA-8x2x Series Actuators are synchronous motor-driven, force sensor limited, non-spring return actuators that feature a 22 lb seating force in a compact design. The VA-8020 accepts floating control from a three-wire, 24 VAC control signal. The VA-8122 typically accepts proportional control from a 0 to

10 VDC control signal; however, it can be field adjusted to accept signals up to 20 VDC. In addition, the VA-8122 features an input signal reversing feature that allows it to be used in both heating and cooling applications.

Note: The VA-8x2x is only available factory mounted on 1/2 and 3/4 in. valves. Because the VA-8x2x requires a unique slotted valve stem for factory assembly, it is necessary to select the S option in the Stem Type section of Table 2.

VA7810 Series Electric Actuators

The VA7810 Series is a line of motor driven, direct mount, non-spring return actuators that operate on 24 VAC and are available for use with on/off (floating) or proportional controllers. The actuator is available factory mounted to 1/2 through 2 in. valve body styles with NPT (threaded) end connections. The actuator is available separately for field mounting to union sweat, union globe, and union angle VG7000 Series valves.

The actuator delivers a minimum stem force of 180 lb. Integral auxiliary switches are available for indicating end-stop position or to perform switching functions. For proportional models a 0 (2) to 10 VDC signal feedback is available.

VA7820/VA7830 Series Electric Actuators

The VA7820/VA7830 Series is a line of motor driven, direct mount, spring return actuators that operate on 24 VAC. The actuators ship already set for 0 to 10 VDC Proportional control. With a simple change of DIP switch settings, the actuator can be reconfigured in the field for On/Off (Floating) Control. Position feedback is available via switches or a 0 (2) to 10 VDC signal. The actuator delivers a minimum stem force of 180 lb. If the power fails, the automatic spring returns the valve stem up for the VA7820 actuator or the valve stem down for the VA7830 actuator. A manual override allows manual positioning of the valve when power is not available. The actuator is available factory mounted to 1/2 through 2 in. valves body styles with NPT (threaded) end connections. The actuator is available separately for field mounting to union sweat, union globe, and union angle VG7000 Series valves.

VG7000 Series Bronze Control Valves Product Bulletin |

7 |

Shipping Weights

Table 5: Shipping Weights for Brass Trim Valves1 |

|

|

|

|

|||

Actuator |

|

|

|

Valve Weight, lb |

|

|

|

|

|

|

|

|

|

|

|

|

1/2 |

3/4 |

|

1 |

1-1/4 |

1-1/2 |

2 |

|

|

|

|

|

|

|

|

V-3801-8001 |

2.5 |

3.1 |

|

--- |

--- |

--- |

--- |

|

|

|

|

|

|

|

|

V-3000-8012 |

3.4 |

4.5 |

|

6.5 |

6.5 |

12.1 |

17.2 |

|

|

|

|

|

|

|

|

V-3000-8003 |

3.2 |

4.3 |

|

6.3 |

6.2 |

11.9 |

17.0 |

|

|

|

|

|

|

|

|

MP82 |

--- |

--- |

|

14.0 |

16.0 |

19.0 |

24.0 |

|

|

|

|

|

|

|

|

MP84 |

--- |

--- |

|

--- |

--- |

--- |

--- |

|

|

|

|

|

|

|

|

VA-4233 |

5.3 |

6.4 |

|

8.4 |

8.3 |

--- |

--- |

|

|

|

|

|

|

|

|

VA-7150 |

3.9 |

5.0 |

|

7.0 |

6.9 |

12.6 |

17.7 |

|

|

|

|

|

|

|

|

VA-7200 |

--- |

--- |

|

7.5 |

7.4 |

13.1 |

18.2 |

|

|

|

|

|

|

|

|

VA-8x2x |

4.6 |

5.9 |

|

--- |

--- |

--- |

--- |

|

|

|

|

|

|

|

|

VA7810 |

--- |

--- |

|

6.2 |

6.2 |

11.8 |

16.9 |

|

|

|

|

|

|

|

|

VA7820/ |

--- |

--- |

|

7.9 |

7.9 |

13.5 |

18.6 |

VA7830 |

|

|

|

|

|

|

|

1.Weights are approximate and based on the heaviest valve. Add 2 lb (0.9 kg) for pneumatic assemblies with a positioner.

Table 6: Shipping Weights for Stainless Steel Trim Valves1 |

|

|

|

|||

Actuator |

|

|

Valve Weight, lb |

|

|

|

|

1/2 |

3/4 |

1 |

1-1/4 |

1-1/2 |

2 |

|

|

|

|

|

|

|

V-3000-8012 |

3.7 |

4.5 |

6.9 |

8.9 |

--- |

--- |

|

|

|

|

|

|

|

V-3000-8003 |

3.5 |

4.2 |

6.7 |

8.7 |

--- |

--- |

|

|

|

|

|

|

|

MP82 |

11.0 |

12.0 |

14.0 |

16.0 |

19.0 |

24.0 |

|

|

|

|

|

|

|

MP84 |

--- |

--- |

--- |

--- |

32.0 |

37.0 |

|

|

|

|

|

|

|

VA-4233 |

5.3 |

5.6 |

8.0 |

10.0 |

--- |

--- |

|

|

|

|

|

|

|

VA-7150 |

3.9 |

4.2 |

6.6 |

8.6 |

12.6 |

17.7 |

|

|

|

|

|

|

|

VA-7200 |

4.7 |

5.5 |

7.9 |

9.9 |

13.1 |

18.2 |

|

|

|

|

|

|

|

VA7810 |

3.1 |

4.2 |

6.6 |

8.6 |

11.8 |

16.9 |

|

|

|

|

|

|

|

VA7820/ |

4.8 |

5.9 |

8.3 |

10.3 |

13.5 |

18.6 |

VA7830 |

|

|

|

|

|

|

1.Weights are approximate and based on the heaviest valve. Add 2 lb (0.9 kg) for pneumatic assemblies with a positioner.

8 VG7000 Series Bronze Control Valves Product Bulletin

Field Mounting

A standard bonnet/stem design allows for easy field mounting of actuators. See Table 2 to order valves without actuators; Table 7, and Table 8 to order the appropriate mounting kits; and Table 16 and Table 17 to identify compatible actuators. Refer to the appropriate actuator product bulletin for specific actuator code number information.

Table 7: Field Mounting Kits for Pneumatic Actuators1 |

|

|

|

Actuator Style |

Valve Size, in. (DN)2 |

Spring Range psig (kPa) |

Mounting Kit |

|

|

|

Code Number |

T-3x11 |

1/2 or 3/4 (DN15 or DN20) |

3 to 6 (21 to 41) |

VG7000-10013 |

V-3000-8012 |

5/16 in. (8 mm) Stroke |

|

|

4 to 8 (28 to 55) |

VG7000-10023 |

||

V-3000-8003 |

|

|

|

|

|

9 to 13 (62 to 90) |

VG7000-10033 |

T-3x11 |

1 or 1-1/4 (DN25 or DN32) |

3 to 6 (21 to 41) |

VG7000-10043 |

V-3000-8012 |

1/2 in. (13 mm) Stroke |

|

|

4 to 8 (28 to 55) |

VG7000-10053 |

||

V-3000-8003 |

|

|

|

|

|

9 to 13 (62 to 90) |

VG7000-10063 |

T-3x11 |

1-1/2 or 2 (DN40 or DN50) |

3 to 6 (21 to 41) |

VG7000-10073 |

V-3000-8012 |

3/4 in. (19 mm) Stroke |

|

|

4 to 8 (28 to 55) |

VG7000-10083 |

||

V-3000-8003 |

|

|

|

|

|

9 to 13 (62 to 90) |

VG7000-10093 |

V-3801-8001 |

1/2 or 3/4 (DN15 or DN20) |

3 to 6 (21 to 41) |

VG7000-10103 |

|

5/16 in. (8 mm) Stroke |

|

|

|

4 to 8 (28 to 55) |

VG7000-10113 |

|

|

|

9 to 13 (62 to 90) |

VG7000-10123 |

V-3801-8001 |

1/2 or 3/4 (DN15 or DN20) |

Kit with Three Springs: |

VG7000-10153 |

|

5/16 in. (8 mm) Stroke |

3 to 6, 4 to 8, and 9 to 13 (Includes |

|

|

|

hardware to adapt one valve only.) |

|

|

|

|

|

MP82/MP83 |

1/2 or 3/4 (DN15 or DN20) with Stainless |

Not Applicable |

MP8000-67014 |

|

Steel Trim |

|

|

|

|

|

|

MP82/MP83 |

1 through 2 (DN25 through DN50) with 1/4 in. |

Not Applicable |

MP8000-67024 |

|

Stem and Stainless Steel or Brass Trim |

|

|

|

|

|

|

MP84/MP85 |

1-1/2 through 2 (DN40 through DN50) with |

Not Applicable |

MP8000-67035 |

|

3/8 in. Stem and Stainless Steel Trim |

|

|

|

|

|

|

1.Use all mounting kits with valves with standard threaded stem design only.

2.DN is the European designation for body size in metric units (mm).

3.The mounting kits include: upper spring seat, spring, stem extension, stem locking screw (or set screw), and a bonnet adaptor for the V-3801-8001. Use this only on valves with threaded stems.

4.The mounting kits include: stem nut (1), stem extender nuts (2), stem extender (1), and yoke nut (1).

5.The mounting kit includes: stem nuts (2) and yoke nut (1).

Table 8: Field Mounting Kits for Electric Actuators1 |

|

|

Actuator Style |

Valve Size, in. (DN) |

Mounting Kit Code Number |

VA-4233 |

1/2 through 1-1/4 (DN15 through DN32) |

None Required |

|

|

|

VA-715x |

1/2 through 2 (DN15 through DN50) |

None Required |

|

|

|

VA-720x |

1 through 2 (DN25 through DN50) |

None Required |

|

|

|

VA-8x2x |

1/2 and 3/4 in. (DN15 and DN??) |

VA-8020-100 (Refit only) |

|

|

|

VA78x0 |

1/2 through 2 (DN15 through DN50) |

None Required |

|

|

|

1.Use all mounting kits with valves with standard threaded stem design only.

VG7000 Series Bronze Control Valves Product Bulletin |

9 |

C |

C |

|

N.C. |

||

|

||

|

(PDTO) |

N.O.

(PDTC)

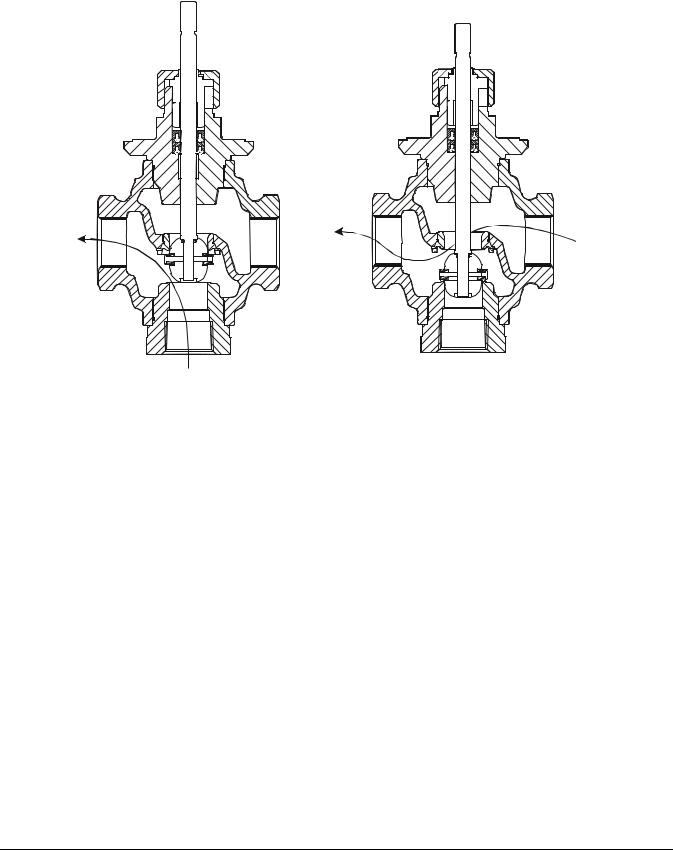

Stem Up Position

With the stem in the up position, the lower port (N.O.) is open to the Common port (C).

N.O.

(PDTC)

Stem Down Position

With the stem in the down position, the inline port (N.C.) is open

to the Common port (C).

N.C.

(PDTO)

<![if ! IE]><![endif]>FIG:VG7FG02P

Figure 2: Three-Way Mixing Valves Fluid Flow Direction and Port Designation

Table 9: Brass Trim – Maximum Closeoff Pressures, psig (kPa) for Pneumatically Actuated Valves (Part 1 of 2)

Actuator |

Valve Size, |

Maximum |

Two-Way Normally Open or |

Two-Way Normally Closed or |

||||

Style |

in. (DN) |

Cv (Kv) |

Three-Way N.O. Port |

Three-Way N.C. Port |

||||

|

Brass Trim |

Factor |

(with 20 psig Supply) |

(with 0 psig Supply) |

||||

|

|

|

Spring Range (psig)1 |

Spring Range (psig)1 |

||||

|

|

|

3 to 62 |

4 to 8 |

9 to 13 |

3 to 62 |

4 to 8 |

9 to 13 |

|

|

|

(21 to 41) |

(28 to 55) |

(62 to 90) |

(21 to 41) |

(28 to 55) |

(62 to 90) |

|

|

|

|

|

|

|

|

|

V-3801-8001 |

1/2 |

0.73 |

186 |

157 |

84 |

37 |

57 |

158 |

(248°F |

(DN15) |

(0.63) |

(1,282) |

(1,082) |

(579) |

(255) |

(393) |

(1,089) |

[120°C]) |

|

|

|

|

|

|

|

|

|

1.8 |

186 |

157 |

84 |

37 |

57 |

158 |

|

|

|

|||||||

|

|

(1.6) |

(1,282) |

(1,082) |

(579) |

(255) |

(393) |

(1,089) |

|

|

|

|

|

|

|

|

|

|

|

4.6 |

105 |

89 |

48 |

18 |

28 |

76 |

|

|

(4.0) |

(723) |

(613) |

(331) |

(124) |

(193) |

(524) |

|

|

|

|

|

|

|

|

|

|

3/4 |

7.3 |

67 |

56 |

30 |

11 |

16 |

45 |

|

(DN20) |

(6.3) |

(462) |

(386) |

(207) |

(76) |

(110) |

(310) |

|

|

|

|

|

|

|

|

|

10 VG7000 Series Bronze Control Valves Product Bulletin

Loading...

Loading...