Page 1

SeedStar

™

2 and SeedStar

™

Quick Reference Guide

XP Planter

A93891_19_17MAY12.indd 1 5/17/2012 8:19:41 AM

Page 2

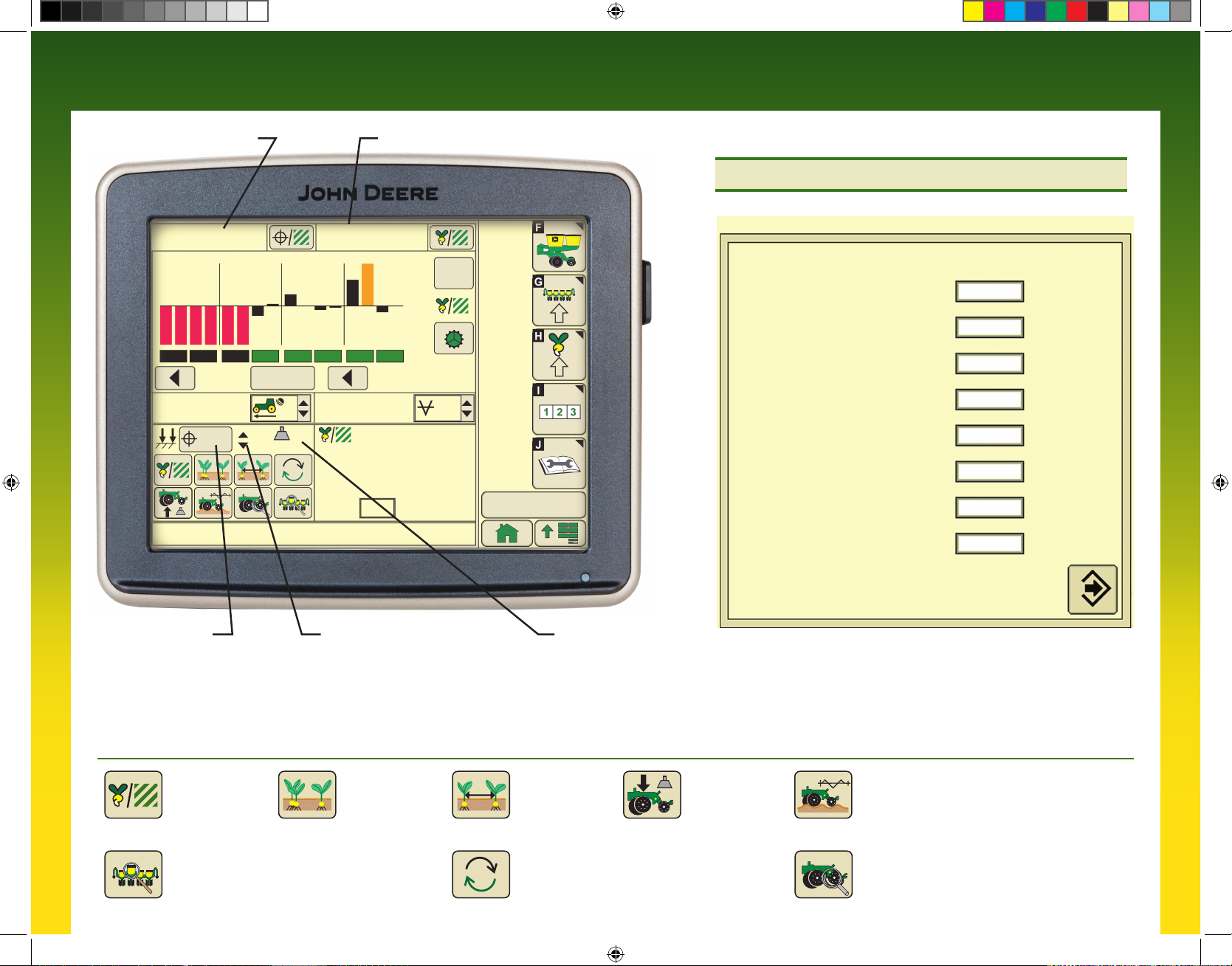

SeedStar TM2

SeedStar TM2

Planter Quick Reference Guide

Planter Quick Reference Guide

With Optional

RowCommand

Drive Status Bars

Green Bars: Section

active and ready to plant.

Black Bars: Section

deactivated manually by

operator.

Outlined Bars:

Section deactivated by

SwathControlTM command

(when activated).

Bars Not Visible:

Section active, but cannot

be controlled manually or

with RowCommandTM.

RowCommandTM

Buttons: Select buttons

to turn sections on and off

manually.

Target Pneumatic

Down Force Level

Select button to view

Pneumatic Down Force

Control Panel

Pneumatic Down Force

System Indicator Arrows

Up arrow indicates system

is increasing down force

level.

Down arrow indicates

system is decreasing

down force level

TM

Planter At a Glance

Black bars indicate row is planting normally.

Orange bars indicate row is planting above or

below alarm setpoints.

Red bars indicate row is not planting.

32000

4 8 12 16 20

Enable All

Sections

5.4

(mph)

30

5.5

(mph)

40.0

(ac)

HI warn row #16

Speed Display Caution Message

Display

33 (lbs)

2

Population and Rates

Target Seeds per Area displays the desired seeding rate entered in Planter Rates Setup. On VRD machines,

(seeds/ac)

(seeds/ac)

select this button to toggle between programmed rates including prescriptions (Rate 6, VRD only).

Average Seeds per Area displays the actual average rate planted. Select button to toggle between whole

planter average and drive section average.

Other Useful

Buttons

Screens

Enter, Done,

Save, Finish

Drives Status ICON

Clutch Icon: Sections can only be controlled

manually by operator.

Section Icon: Sections are controlled by

John Deere Section ControlTM (when activated).

32300 32100

13.6

Row (seeds/ac)

Min: 11 27300

Max: 16 32900

Scan: 12 32200

4 0

User Defined

Totals

13.1

(In H2O)

Actual Pneumatic

Down Force Level

Toggle CancelToggle Home

Rotate Seed

Meters

QS

Reset

2:43 pm

Vacuum

Level Icon

QS

Reset

Quick Start

Reset

Getting Started

F

G

H

I

J

Planter – Main: Select for

planter main run screen.

Planter – Configuration:

Select to change planter frame,

drives, and sensor configuration.

Planter – Rates: Select to

change crop type, rates, and

meter configuration.

Totals: Select to view planted

area, hours, and calculators.

Diagnostics: Select to view

sensor readings and fault codes.

Pneumatic Down Force

Control Panel

147 (lbs)

145 (lbs)

Enter target down force in input box.

•

Select up or down arrow buttons to change

•

pneumatic down force by preset Step Value.

Enter low down force level alarm set point

•

and Step value in PDF Air Pressure Setup

Screen.

Select: Menu>>Planter>>Configuration

•

Softkey>>Sensor Tab>>Select PDF Air

Pressure from drop down menu.

A93891_19_17MAY12.indd 2 5/17/2012 8:19:43 AM

Page 3

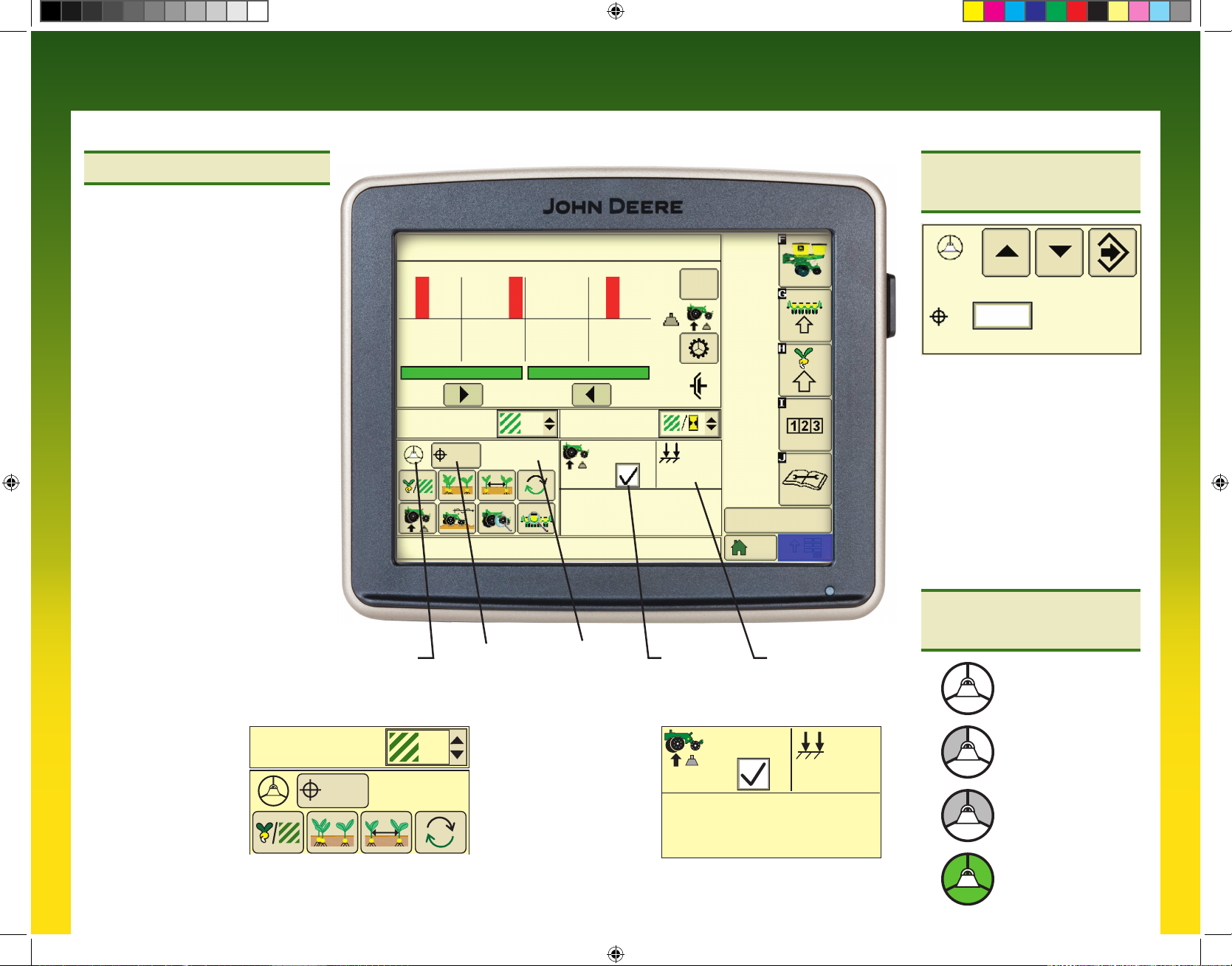

Crop Setup

– Ground Drive

Crop Setup – Variable Rate Drive

Select Rates Softkey (H).

Select Crop Name from drop down menu. Select desired crop from list. If desired crop

name is not listed, select a Custom crop name.

Select Target Rate input box and enter desire population.

High and low warning limits are automatically set to a percentage above and below

target rate. To change limits, select High and Low Warning input boxes and enter a

new value.

Refer to Rate Charts & Settings Manual or Seed Transmission Sprocket Calculator

(Menu>>Planter>>Totals>>Calculator>>Seed Transmission).

To access Seed Estimators and Vacuum Calculator select Totals softkey (I) >> Calc tab

>> and choose the desired calculator from the drop down menu.

Standard Run Screen

Planter At a Glance

Black bars indicate row is planting normally.

Orange bars indicate

row is planting above

or below alarm setpoints.

Red bars indicate row

is not planting.

Drives Status Bar

Green bar indicates that

clutch or motor is engaged

and drives are active.

Gray bar indicates that clutch or motor is disengaged and drives are inactive.

Transport Mode:

To disable seed sensor warnings while in transport, navigate to: Planter >> Planter

Configuration >> depress “Transport Mode” key. To disable “Transport Mode” to

resume planting, depress key on screen.

Headland Warning Suppression:

Check box (Planter Configuration >> Sensor >> Seed) to disable seed sensor warnings

when the planter is raised in field position (requires a height sensor and height sensor

must be calibrated).

32000 32000

4 8 12

(seeds/ac)

Select Rates Softkey (H).

Select Use 1 Rate for All Motors check box. A check indicates one rate for all motors.

An empty box indicates different rates for each motor.

Rate 6 is used for map based prescription. To enable controller to use a prescription,

select the On drop down box under rate 6. From RUN screen select the Rx rate. Once rate

is selected, the run page has a small Rx indicator near the Target Seeds per Area icon.

Select Crop Name from drop down menu. Select desired crop from list. If desired crop

name is not listed, select a Custom crop name.

Select Disk Type drop down menu. If planter has mechanical meters, mechanical meter

selections appear. If planter has vacuum meters, vacuum disk selections appear.

Select meter or crop from list.

Select Seed Disk drop down menu and select the vacuum disk used. Verify this disk

is in meter.

Select Show Rates button, then select Change Rates button.

If using different rates for each motor, select Motor drop down menu to assign rates

to each motor.

Select Rate drop down menu and choose a rate from the list to assign a population

to that rate.

Select Target input box and enter the target population for the selected rate.

High and low warning limits are automatically set to a percentage above and below

target rate. To change limits, select High and Low Warning input boxes and enter a

new value.

To see a rate on the RUN page as a choice, select On and Off drop down box and

choose ON.

Select Enter button.

VRD Status

1.

No Activity Wheel Motion, Sensor Active

3.

Planter Lowered Drives Engaged

2.

4.

A93891_19_17MAY12.indd 3 5/17/2012 8:19:44 AM

Page 4

SeedStar TMXP

SeedStar TMXP

Target Seeds per Area Average Seeds per Area

Planter Quick Reference Guide

Planter Quick Reference Guide

Alarms and Limits Setup

32000

4 8 12

Enable All

Sections

5.4

(mph)

30

HI warn row #14

Target Pneumatic

Down Force Level

Select button to view Pneumatic

Down Force Control Panel

33 (lbs)

31600 32900

QS

Reset

+

%

-

13.6

Row (seeds/ac)

Min: 7 30900

Max: 14 36900

Scan: 14 36900

4 0

Pneumatic Down Force System

Indicator Arrows

Up arrow indicates system is

increasing down force level

Down arrow indicates system

is decreasing down force level

13.1

(In H2O)

2:43 pm

Actual Pneumatic

Down Force Level

Alarms and Limits Setup

Singulation Alarm 92 %

Seed Spacing CV Alarm 0.35

Ride Quality Alarm 90 %

Step Value 5 (lb)

Active PDF Pause Timer 5 sec

High Margin Alarm 131 (lb) + 75%

Target Margin 75 (lb)

Low Margin Alarm 37 (lb) - 50%

Alarms and Limits Setup Page:

Select and hold any SeedStar XP monitor navigation button for 4 seconds

to change alarm setpoints for that function. Enter “0” to disable alarm for

monitor function.

SeedStar XP Navigation Buttons

Seed Population

Select to view all SeedStar

XP monitor information on

one sceen.

Planter Details

A93891_19_17MAY12.indd 4 5/17/2012 8:19:45 AM

Seed Singulation Down Force

Seed Spacing

Scan

Select to scan SeedStar XP

run screens. Select and hold

to change scan settings.

Ride Dynamics

Select to view all monitored

information for a specific row.

Row Details

Page 5

Seed Population

Center line is target population. Bars above line

indicate rows planting above target. Bars below line

indicate rows planting below target. Bars turn orange

when above or below alarm setpoint. Bars turn red

when row is not planting (less than 2 seeds/second).

Select Menu>>Planter>>Rates Softkey to change

alarm setpoints.

Seed Population

4

8

12

%

QS

Reset

+

Row (seeds/ac)

Min: 7 31200

Max: 14 33500

-

Scan: 10 32100

4 0

Seed Singulation

Center line is perfect singulation (100%). Bars above

line indicate increasing percentage of multiples.

Bars below line indicate increasing percentage of

skips. Bars turn orange when nearing alarm setpoint.

Bars turn red when multiples or skip percentage

is above alarm setpoint. Change Singulation alarm

setpoint on Alarms and Limits Setup Page.

Seed Spacing Coefficient of Variation (CV)

Bottom of graph is perfect seed spacing (CV = 0).

Bars increase in height as seed spacing becomes

more variable. Bars turn orange when nearing alarm

setpoint. Bars turn red when seed spacing CV is

above alarm setpoint. Change Seed Spacing CV alarm

setpoint on Alarms and Limits Setup Page.

Down Force Margin

Center line is target down force margin. Bars above

line indicate rows with gauge wheel loads above

target margin. Bars below line indicate rows with

gauge wheel loads below target margin. Bars turn

orange when nearing alarm setpoint. Bars turn red

when down force margin is above alarm setpoint.

Change Down Force Margin target and alarm setpoint

on Alarms and Limits Setup Page.

Ride Dynamics

Top of graph is optimum ride quality (100%). Bottom of

graph is poorest ride quality (0%). Bars decrease in

height as row unit ride quality decreases. Bars turn

orange when nearing alarm setpoint. Bars turn red

when ride quality is below alarm setpoint. Change

Ride Quality alarm setpoint on Alarms and Limits

Setup Page.

4

Seed Singulation

4

Seed Spacing Coefficient of Variation (CV)

4

Down Force Margin

4

Ride Dynamics

8

8

8

8

12

12

12

12

QS

Reset

Singulation

Avg. 95 %

Skips High: 9

1 % 5 %

Multiples High: 14

3 % 21 %

QS

Reset

C

V

Seed Spacing CV

Avg. 0.18

Skips High: 4

1 % 5 %

Multiples High: 9

3 % 10 %

QS

Reset

(lbs)

+

-

Margin Low: 4 High: 9

65 35 102

Row %

Min: 4 85

Max: 9 100

Scan: 14 93

%

O

K

QS

Reset

Good Ride: 93

A93891_19_17MAY12.indd 5 5/17/2012 8:19:47 AM

Page 6

SeedStar TM

SeedStar TM

Pneumatic Down Force Quick Reference Guide

Pneumatic Down Force Quick Reference Guide

Active Down Force Pneumatic Down Force

This system automatically makes down

force adjustments based on target down

force margin and feedback from the gauge

wheel sensors. Data from the row unit gauge

wheel sensors is displayed as margin on the

monitor.

The operator selects a desired target margin

(the amount of extra down force applied to

the row unit, over and above what is required

for the opener disks to penetrate the soil and

achieve full planting depth). Active Down

Force automatically monitors the readings

from the gauge wheel down force sensors

and make pressure changes to the air spring

system to ensure the actual margin is equal

to the target margin. As field conditions

change the system automatically makes the

necessary pressure adjustments to maintain

target margin.

Target Margin:

The center line of the Down Force at

a Glance chart is the target margin.

Down Force at a Glance bars above the

center line indicate down force levels are

higher than desired. Bars below the center

line indicate down force levels are less

than desired.

ALL SEED RATES OFF

4 8 12

0.0

(ac)

70

The Height Sensor is not calibrated.

Active PDF

status

Target margin Actual margin

1

– – (lbs)

(lbs)

Margin Low High

– –,R – – –,R – –

(ac/h)

Active

PDF

+

-

0.0

Active system

on/off check box

QS

Reset

(lbs)

0

4:50 am

Actual down force in

air spring circuit

Margin Control Panel

75 0 (lbs)

Enter target margin in input box.

•

Select up or down arrow buttons

•

to change margin target by preset

Step Value.

Use default high and low margin

•

alarm values or enter custom values

as desired in Alarms and Limits

setup page.

Select:

•

From main run screen select

and hold any SeedStar XP monitor

navigation button for 4 seconds.

Active Down

Force Status

1. No Activity

Active Downforce input

screen. When the Active

Down Force Status icon

is shown, the system is

in active mode and margin

is displayed.

A93891_19_17MAY12.indd 6 5/17/2012 8:19:48 AM

70

0.0

(ac)

1

– – (lbs)

The Active Down Force

Margin run screen contains

the active on/off check box,

actual system down force,

the row with the lowest

margin, and the row with

the highest margin.

Active

PDF

(lbs)

Margin Low High

– –,R – – –,R – –

(lbs)

0

2. Sensor Diagnostic

Check OK

3. Wheel Motion

Sensor Active

4. Planter Lowered

(System Active

Page 7

Set-Point Down Force

Pneumatic Down Force

This system allows the operator to make

manual down force adjustments on the

display. Data from the air pressure sensor

located in the air tank valve block is

displayed as down force on the monitor.

The operator selects a desired target margin

(the amount of extra down force applied to

the row unit, over and above what is required

for the opener disks to penetrate the soil and

achieve full planting depth). The operator

then monitors the readings from the gauge

wheel down force sensors to determine

if down force changes are necessary to

ensure the actual margin is equal to the

target margin. As field conditions change,

margin should be monitored to determine if

down force adjustments should be made to

maintain target margin.

Target Margin:

The center line of the Down Force at

a Glance chart is the target margin.

Down Force at a Glance bars above the

center line indicate down force levels are

higher than desired. Bars below the center

line indicate down force levels are less

than desired.

The set-point Down Force

input screen displays target

down force and actual

down force in the air spring

circuit. Pressure changes

are made when the target

is changed by the operator

and on a timed interval

to ensure that target and

actual down force is equal.

ALL SEED RATES OFF

4 8 12

QS

Reset

+

-

0.0

(ac)

0

The Height Sensor is not calibrated.

Target down force Actual down force Margin run page

1

0 (lbs)

(lbs)

Margin Low High Avg.

– –,R – – –,R – –

0.0

(ac/h)

(lbs)

The set-point Down Force

0.0

(ac)

1

0 (lbs)0

Margin run screen displays

average margin, the row

with the lowest margin, and

the row with the highest

margin.

(lbs)

Margin Low High Avg.

– –,R – – –,R – – – –

7:18 am

Control Panel

Enter target down force in input box.

•

Select up or down arrow buttons to

•

change pneumatic down force by

preset Step Value.

Enter low down force level alarm set

•

point and Step value in Alarms and

Limits setup page.

Select:

•

From main run screen select and

hold any SeedStar XP monitor

navigation button for 4 seconds.

Down Force Margin

Enter target down

•

force margin based on

field conditions.

Use default high and low margin

•

alarm values or enter custom values

as desired in Alarms and Limits

setup page.

Select:

•

From main run screen select and

hold any SeedStar XP monitor

navigation button for 4 seconds.

A93891_19_17MAY12.indd 7 5/17/2012 8:19:49 AM

Page 8

Copyright © 2012 Deere & Company. All Rights Reserved. THIS MATERIAL IS THE PROPERTY OF DEERE & COMPANY. ALL USE AND/OR REPRODUCTION NOT SPECIFICALLY AUTHORIZED BY DEERE & COMPANY IS PROHIBITED.

All information, illustrations and specifications in this manual are based on the latest information available at the time of publication. The right is reserved to make changes at any time without notice.

A93891 (17MAY12)

A93891_19_17MAY12.indd 8 5/17/2012 8:19:49 AM

Loading...

Loading...