Page 1

REEL MOWER GRINDER

RG5500

SPIN / RELIEF

This book consists of three manual s:

The OPERATO RS MANUAL in ENGLISH w hich contains all the information on operating and do ing routine

daily maintenance on this equipment.

The ASSEMBLY and SERVICE MANUAL which is used by the maintainence department to install the

equipment and to do all maintenance except routine daily maintenance.

The OPERA TORS MANUAL

(REV. 6/20/201 1)

in FRENCH

which is the same as the English version only translated into

1

French.

Page 2

DEALER PREPARATION/INSTALLATION CHECK LIST

Frontier RG5500 Spin/Relief Reel Mower Grinder

THIS CHECKLIST IS TO REMAIN IN OWNER’S MANUAL

It is the r esponsibility of the dealer to complete the procedures listed bel ow , then

review this checklist wi th the customer upon the delivery or the sale of this equipment.The ins tallation

trainin g goes over the basic op erational functi ons of the equipment. To ensure adequate train ing, we

require that the following i tems are r eviewed by your John D eere Dealer . Pleas e check off to ensure

that you under stand the follow ing items before the instal lation tr aining i s com plete:

1. Equipm ent i s c ompl etel y as sem bl ed

2. All s hields ar e in place and i n good condi tion.

3. All decals i n place and r eadable. ( See pages)

4. Overall c ondition good (i .e. paint, wel ds, electr ical)

5. V eri fy there is suffici ent electr ical power to oper ate

the machine.

6. Review Operators, Assembly & Ser v i ce Manuals,

and any addi tional tr aining m ateri al if availabl e.

Dealer 's Signature

Purchaser's Si gnature

Safety

IMPORT ANT SA FETY MESSA GE FOR OWNERS/OPERAT ORS OF REEL GRINDERS

Safety is a primary concern in the design, manufacture, sale,

and use of reel grinders. As manufacturer of reel grinders, we

want to confirm to you, our customers, our concern for safety. We

also want to remind you about the simple, basic, and common

sense rules of safety when using a reel grinder. Failure to follow

these rules can result in severe injury or d eath to operators or

bystanders.

It is essential that ever yone involved in the assembly, operation,

transport, maintenance, and storage of this equipment be

aware, concerned, prudent, and properly trained in safety.

Always use proper shielding as specified by the manufacturer.

Our current production machines include, as standard

equipment, guards or shields for the grinding wheel, safety

signs and an operators manual. Never bypass or operate the

machine with any of the guards or safety device removed.

Read and fully underst and all t he safety pr acti ces discussed

on pages 4 and 5 of this manual. All saf ety r ules must be

understood and foll owed by anyone who works wi th r eel

grinders.

7. Review proper posi tioni ng of reel

8. Explain use of reel grinder rel ief mechanis m

9. Review traverse proxi mity switch posi tioni ng

10. Ex plain use of reel grinder ali gnment gage

11. Explain reel gr inder s pin speed vs. quali ty

12. Di s cus s reel gr i nder s et- up char t in manual

13. Review Gener al Mai ntenance

Before operating a reel grinder, an operator must read and

und erstand all o f the info rmation in the ow ner’s man ual and in

the safety signs attached to the product. A person who has not

read or understood the owner’s manual and safety signs is not

qualified to operate the unit. Accidents occur often on machines

that are used by someone who has not read the owner’s

man ual a nd is no t f amiliar with the eq uipm ent . If yo u d o not have

an owner’s manual or current production safety signs, contact

the manufacturer or your dealer immediately.

Reel grinders are designed for one-man operation. Never

operate the grinder with anyone near, or in contact with, any part

of the grinder. Be sure no one else, includ ing bystanders, are

near you when you operate this product.

Follo wing th ese simple, b asic safety ru les, as well as o thers

identified in the owner’s manual and in product safety signs, will

help minimize the possibility of accidents and increase your

productivity in using this product. Be careful and make sure that

everyone who operates the grinder knows and understands that

this is a very powerfu l piece of m achinery, and if used

improperly, serious injury or death may result. The final

responsibility fo r sa fety r ests with the operator of this machin e.

2

Page 3

TO THE DEALER:

Assembly and pr oper inst allation of this pr oduct is the responsi bility of the John Deere dealer . R ead manual

instructi ons and s afety rules. M ake sur e all i tems on the Pr epar ation Chec k List in the Oper ator’s M anual are

complet ed before releasi ng equi pment to the owner.

TO THE OWNER:

Read this manual before operati ng your Fr ontier equipment. Keep this m anual handy for ready

reference. Requir e all operators to r ead this manual c arefully and become acquai nted with all

adjustments and operating pr ocedures before attem pting to operate the equipment. Replac ement

manuals can be obt ained from you sel ling dealer.

The equipmen t you h ave purc hased has been careful ly engi neered and manufacture d to provi de

dependable and satisfactory use. Like all mechani cal produc ts, it will requir e cleani ng and upkeep.

Lubricate the unit as specified. Pl ease observe al l safety information in this m anual and safety

decals on th e equipment.

For servi ce, your authorized John Deer e dealer has trained mechani cs, genuine Fronti er servic e

parts, and the necessary tools and equipment to handle all of your servic e needs.

Use only genuine Frontier servic e parts.

3

Page 4

SAFETY INSTRUCTIONS

Safety Awareness Symbols are inserted

into this manual to alert you to possible

Safety Hazards. Whenever you see these

symbols, follow their instructions.

!

The Warning Symbol identifies

special instructions or procedures

which, if not correctly followed,

could result in personal injury.

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE WRENCHES AND OTHER

TOOLS.

3. KEEP WORK AREA CLEAN.

4. DON'T USE IN DANGEROUS ENVIRONMENT.

Don't use Grinder in damp or wet locations.

Machine is for indoor use onl y. Keep work area

well lit.

5. KEEP A LL VISITORS AW AY . All visitors

should be kept a s afe distance from w or k ar ea.

6. MAKE WORK ARE A CHILD-PROOF with

padlocks or m as ter s wi t ches .

The Cauti on Sym bol identifies special

instructions or procedures which, if not

strictly observed, could result in damage

to or destruction of equipment.

12. DON'T OVERREACH. Keep proper footing and

balance at all times .

13.MAINTAIN GRINDER WITH CARE . Fo llow

instructi ons in Ser vic e M anual for lubr icati on and

preventiv e mai ntenance.

14.DISCONNECT PO WER BEFORE SERVICING,

or when changing the gr inding w heel.

15.REDUCE T HE RISK OF UNINTENTIONAL

STARTING. Make sure all switches are OFF

before plugging in the grinder.

16.USE RECOMMENDED ACCESSORIES. Consult

the manual for recom mended acces sories . Usi ng

improper access ories may cause ris k of personal

injury.

7. DON'T FORCE THE GRINDER. It will do the job

better and safer if used as specified in this

manual.

8. USE THE RIGHT TOOL. Don't force the grinder

or an attachm ent to do a j ob for which i t was not

designed.

9. WEA R PROPER A PPAREL. Wear no l oos e

clothing, gloves, neckti es, or j ewelr y which m ay

get caught in moving par ts . Nonslip footwear is

recommended. Wear protecti ve hair coveri ng to

contain long hai r.

10. ALW AYS USE SA FETY GLASSES.

11. SECURE Y OU R WORK. Make c ertain that the

cutting unit is securel y fastened with the clam ps

provided before ope rating.

17.CHECK DAMAGED PARTS. A guard or other

part that is damaged or will not perform its

intended function shoul d be properl y repai red or

replaced.

18.KNOW YOU R EQU I PMENT. Read this manual

carefully. Learn its applic ation and li mi tations as

well as specific potential hazards.

19.KEEP ALL SA FETY DECA LS CLEA N AND

LEGIBLE. If safety decals become damaged or

illegibl e for any reason, r eplace i mmedi ately.

Refer to replacement parts illustrations in Service

Manual for the proper l ocation and par t number s

of safety decals.

20.DO NOT OPERATE THE GRINDER WHEN

UNDER THE INFLUENCE OF DRUGS,

ALCOHOL, OR MEDICAT ION.

4

Page 5

SAFETY INSTRUCTIONS

IMPROPER USE OF GRINDING WHEEL MAY CAUSE

BREAKAGE AND SERIOUS INJURY.

!

Grindi ng is a safe operat ion if the few basi c rul es l isted bel ow ar e follow ed. Th ese ru les ar e based on mater ial

contained in the ANSI B7.1 Safety Code for "Use, Care and Protection of Abras ive Wheels". For your safety ,

we suggest you benefit from the experi ence of others and follow these r ules.

DO

1. DO always HANDLE AND STORE

wheels in a careful manner.

2. DO VISUALL Y INSPECT all w heel s before

mounting for poss ible dam age.

3. DO CHECK MACHINE SPEED against the

establis hed maxim um safe operating speed

marked on wheel .

4. DO CHECK MOUNTING FLANGES for equal

and correct di ameter.

5. DO USE MOUNTING BLOTTERS when supplied

with w heels.

6. DO be sure WORK REST is properly

adjusted.

7. DO always USE A SAFETY GUARD C OVER I NG

at least one-half of the grinding wheel.

DON'T

1. DON'T use a c racked wheel or one th at HAS BEEN

DROPPED or has become damaged.

2. DON'T FORCE a wheel onto the machine OR

ALTER the si ze of the m ounti ng hole- -if w heel w on't

fit the machine, get one that will.

3. DON'T ever EXCEED MAXIMUM OPERATING

SPEED establ ished for the wheel.

4. DON'T use mounting flanges on whic h the bear ing

surfaces ARE NOT CLEAN, FLAT AND FREE OF

BURRS.

5. DO N' T TI GH TE N t he m ounti ng nut EXCESSIVELY.

6. DON'T grind on the SIDE OF TH E WH EEL (see

Safety Code B7.2 for exception).

7. DON'T star t the machine until the WH EEL GU A RD

IS IN P LACE.

8. DO allow NEWLY MOUNTED WHEELS to run at

operating speed, with guard i n place, for at least

one minute before gr inding.

9. DO always WEAR SA FETY GLA SSES or som e

type of eye protection w hen grindi ng.

A VOID INHALATION OF DU ST gener ated by gri nding and cutting oper ations. Exp osure

to dust may cause respiratory ailments. Use approved NIOSH or MSHA respirators,

safety glasses or face shields, and protec ti ve c lothi ng. Pr ov ide adequate ventil ation to

eliminate dust, or to maintain dust level below the Threshold Limit Value for nuisance

dust as classi fied by OSHA.

8. DON'T JAM wor k i nto the w heel .

9. DON'T STAND DIRECTLY IN FRONT of a

grinding wheel whenever a grinder is started.

10. DON'T FORCE GRINDING so that motor slows

noticeably or work get s hot.

5

Page 6

TABLE OF CONTENTS

This machine is intended for grinding the reel of reel type mower units ONLY.

Any use other than this may cause personal injury and void the warranty.

To assure the quality and safety of your ma chine and to maintain the warranty,

you MUST use original equipment manufactures replacement parts and have

any repair work done by a qualified professional.

ALL operators of this equi pment mus t be thoroughly trained BEFORE operating

the equipment.

Do not use compressed air to clean grinding dust from the machine. This dust

can cause personal injury as well as damage to the grinder. Machine is for

indoor use only. Do not use a power washer to clea n the mac hine.

Low V oltage Relay

The grinder is equi pped with a high-low volt age relay

which is factory pr eset at 100-140 V AC. I f the power

supply line does not del iver 100-140 VAC power under

load, the relay w i ll open and tr i p out the starter. I f this

occurs, your pow er suppl y l i ne is i nc or r ect and must be

correct before pr oceeding further with the gri nder.

!

TABLE OF CONTENTS

Safety Instructions ................................................................................................................. Page 4 - 7

Daily M aintenance ................................................................................................................. Page 6

Getting to Know Your Grinder ................................................................................................ Page 8 - 14

Operating Instructions............................................................................................................ Page 15 - 27

Reel Setup Chart ................................................................................................................... Page 28

DAILY MAINTENANCE BY THE OPERATOR

On a daily basis, clean the machine by wiping it off.

On a daily basis, remove all grinding grit from the grinding shaft, traverse shafts, and tooling

bar area.

On a daily basis, inspect the machine for loose fasteners or components.

Contact your company's Maintenance Department if damaged or defective parts are found.

DO NOT U SE C OMPRESSED A IR TO CLEAN

GRINDING DUST FROM GRINDER.

!

6

Page 7

SAFETY INSTRUCTIONS

PLEASE TAKE SPECIAL NOTE OF THE FOLLOWING WARNING DECALS LOCATED ON

THE GRINDER.

GRINDING WHEEL RPM

GENERAL INFORMATION

SHARP OBJECTS

ELECTRICIT Y

Label Sheet

(English and S panish)

Part Number 5NT155301

(English and French)

Part Number 5NT155302

7

Page 8

GETTING TO KNOW YOUR GRINDER

SPECIFICATIONS

Tr aversing Sw itches Solid st ate, non-contacting prox imity swi tches.

Overall Width 71" [181 cm]

Overall Height 69" [175 cm] w i th door cl os ed, 87" [221 c m] w i th door open

Overall Depth 42" [107 cm]without wor kst ation, 79" [201 cm] w ith optional wor kst ation

Weight 1450 lbs. [658 kg] 1650 lbs shipping weight [748 kg]

Base C onstru ction Precision heavy duty reinforced w elded steel bas e

Carriage R ails Precision Gr ound, Hardened S teel - 1.000 Di a. [25.4 mm]

Grind H ead M otor 1HP AC Motor, 3450 RPM

Spin M otor .20 HP Fan C ooled V ari able S peed D C M otor

Sound Lev el More than 75 Dba, Less than 95 Dba

Auto Tr averse Belt driven with easy to engage clamp system

Control System *Safety grind motor and spin dr ive door interrupt s witc hes

*Reversible S pin drive for variable speed Spin or variable torque relief functions

*V ariable s peed traverse contr ol.

Options: *Manual Winch and Boom Kit, Electr ic Winch and Boom Kit or Lift Platform.

8

Page 9

GETTING TO KNOW YOUR GRINDER (Continued)

CONTROL PANEL COMPONENT IDENTIFICATION

Review the following c ontrol panel component descr iptions before proc eeding wi th the i nstructi ons

SYSTEM START PUSHBUT TON

The green pushbutton is the system star t swi tch. Pushi ng

it will engage the magnetic star ter and power the control

panel. The magnetic s tarter will not engage unless the

emergency stop pushbutton i s pulled out and the gri nding

motor switc h and spi n m otor s wi tc h ar e tur ned off.

GRIND SELECTOR SWITCH

Variable speed spin

Switc h m ust be up to perform

s pin gr i ndi ng oper ati ons .

Variable Torq ue Relie f

Switc h m ust be down to perform

relief grinding operations .

SPIN DRIVE ROTATION SWITCH

Forward / Off / Reverse

This switch reverses the direction of the spin

drive motor.

IMPOR T ANT: Because the spin drive motor

c an be flippe d on the hor izontal adj ustm ent

arm, the direction m ay be opposite of what

is shown on the decal.

SPIN SPEED POTENT IOMETER DIAL RPM

Adjust s the s peed of reel r otation when you

have the grind selector switch set at variable

speed spin.

GUARD DOORS MUST BE S HUT FOR SPIN

DRIVE TO OPERATE.

9

Page 10

GETTING TO KNOW YOUR GRINDER (Continued)

PUSH-PULL EMERGENCY STOP BUTTON

Push in to cut all pow er to the control panel functions .

This removes power from all motors, including the

grinding motor, traverse motor, spin motor, etc. To

restore power, pull up on button and press the Start

button.

SPIN MOT OR SWITCH On / Off

Tur n the S pin M otor on and off.

GUARD DOORS MUST BE SHUT FOR GRIND

!

MOTOR TO OPER ATE.

RELIEF TORQUE DIAL

Adjust s the Spin Dri ve Motor tor que (the torque holding

the reel blade to the relief finger) when Gr ind Selector

Switch is set at var iable T orque R elief.

!

GRINDING WHEEL MOTOR SWITCH On / Off

T urn the Grindi ng Wheel Mo tor on a nd off.

GUARD DOORS MUST BE SHUT FOR GRIND

MOTOR TO OPER ATE.

TRAVERSE MOTOR SW ITCH

Tur ns the traver se dri ve motor ON /OFF.

TRAVERSE SPEED POTENTIOMETER

DIAL - FT / MIN

Adjust s the speed of the left & rig ht

movement of the Grindi ng wheel.

TRAVERSE REVERSE SWITCH

Reverses the di recti on of the grindi ng

head if pushed when the head is moving.

10

Page 11

GETTING TO KNOW YOUR GRINDER (Continued)

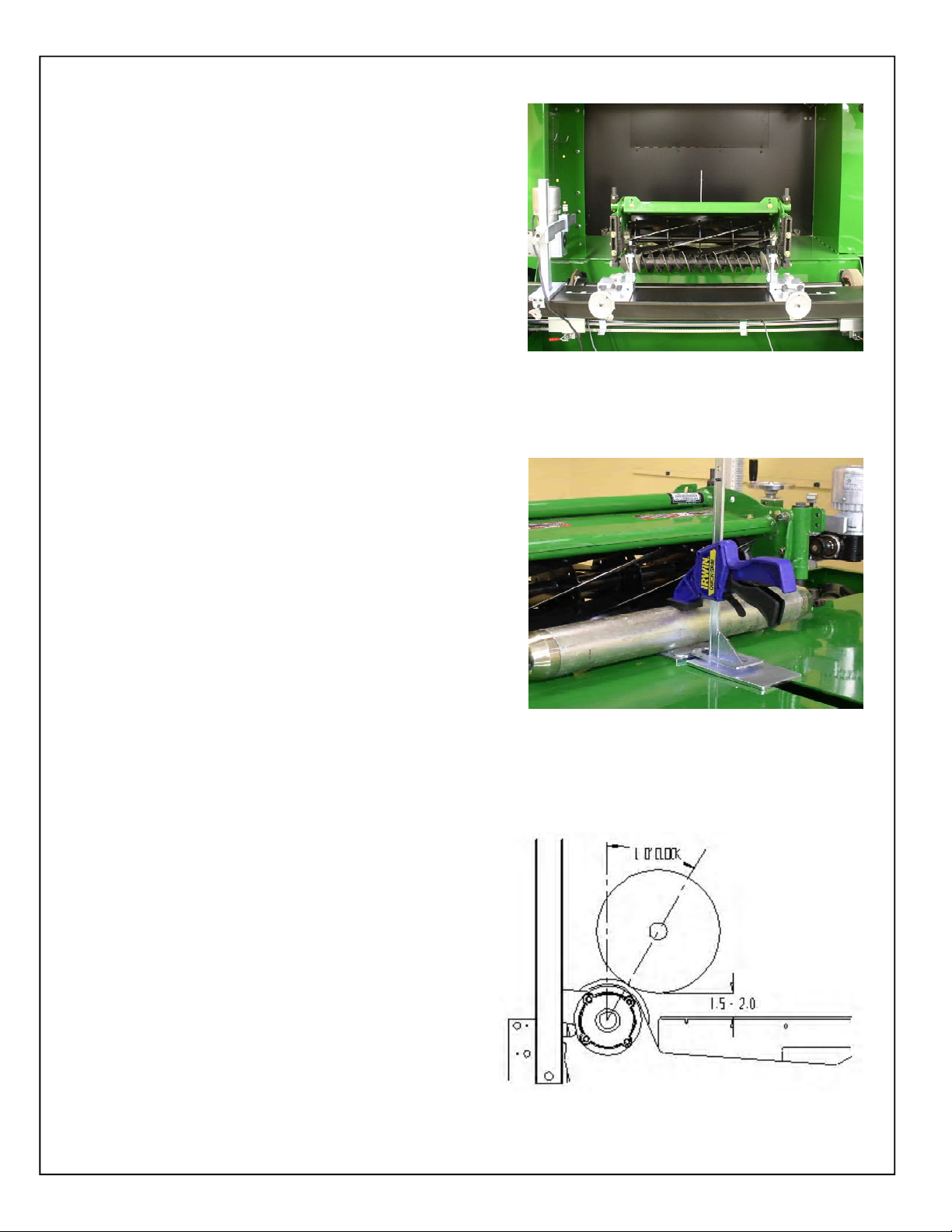

FRONT AND REAR MOWER MOUNTING

The mow ing uni t s hould b e placed in t he mac hine w ith

the rear roller on the table and front roller held in the

front tooling. The front tooling can be moved side to

side along t he too ling b ar s o they can b e posi tion ed as

far ap art as neces sar y to acco mmoda te al l reel wi dths.

Decals on the tooling bar make i t easy to position the

tooling based on the width of the reel. To move the

tooling, loosen the knob located at the front of the

tooling base and slide tooling along the tooling bar . The

tooling should be located as close to the frame as

possible leaving the maximum room to use the

position gauge (the gauge will be discussed in the

alignment section). The horizontal position is attained

by using the hand wheel located at the front of the

tooling. If yo u are gri nding a Quick Adjus t mow ing unit

(QA7 or QA5), use the decals loc ated on the tooling to

quickly position the reel. There are two positions for

each reel depending on how the front roller is mounted.

See FIG 2.

If you are using the all- pos it ion brac kets , the ver ti cal

and horizontal posi ti on c an be adj usted by l ooseni ng

the knobs located on the side of the tooling and

moving to a new set of pins.

Verify that the reel is positioned properly for the spin

wheel and relief wheel by checking the travel limits,

both wh ee ls will need to have clearance to come off

the reel on both sides. Checking during setup will

eliminate the need for major adjustments and

alignments when going from spin grinding to relief

grinding. W hen the mower is in place lock it into

posit ion by tigh tening all kno bs. L ift the rea r r oller onto

the angled bracket and clamp the roller firmly by

squeezing the clamp handl e.

REEL POSITION

The reel should b e positioned so that it i s at a o ne o’clock

or 30° angle position in reference to the grinding wheel.

See FIG 3. If the all - pos i ti on br ack ets ar e used tr y to

position the unit so that the bottom of the reel is

between 1.50-2.00" [38-51MM] off the table. W hen

using the roller mount styl e tooling try to maintain the

one o’clock positi on and check for clear ance between

the reel and grinding wheel. Verify that the proper relief

angle can be achieved with this setting and make

any adjustments i f necessary.

FIG . 1

QA5 AND QA7 REEL

LOCATION DECAL.

TOOLING POSITION

DECAL

FIG . 2

If you are grindi ng a QA7 or QA5 r eel usi ng the r ol l er

style mounts, use the decal s located on the tooli ng to

obtain the optimal posi tion to grin d the reel. See fIG 2

FIG . 3

11

Page 12

GETTING TO KNOW YOUR GRINDER (Continued)

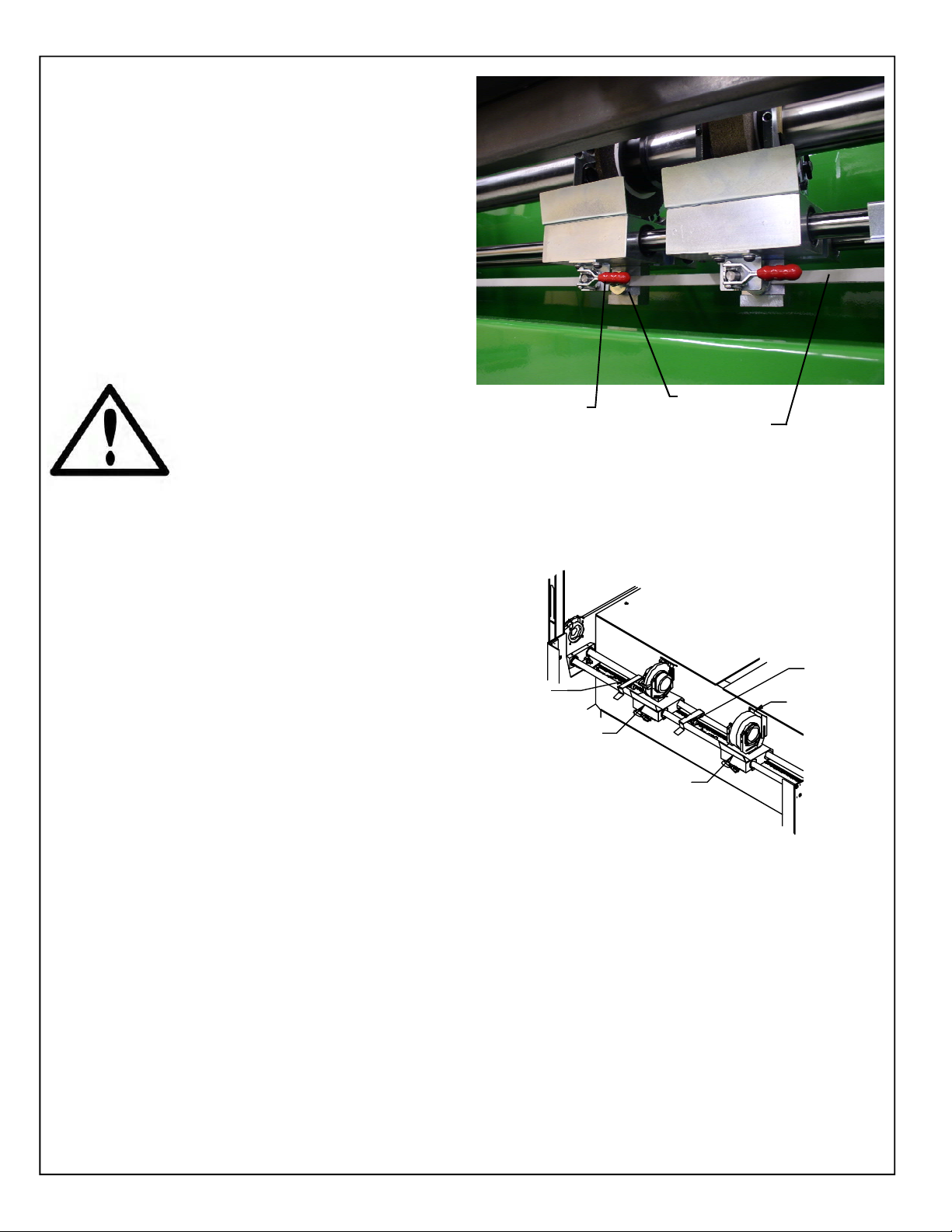

TRAVERSE ENGAGEMENT AND RELEASE

The belt that drives the relief and spin hubs left and

right can b e engaged and r eleased by flipping the c lamp

located on the bottom of the grinding head assemblies.

Moving the lever t o the left will engage the belt and

moving it to the right will disengage the belt. The tip

can be adjusted if necessary to i ncrease or decreas e

the tension on the belt. See adjustments in the

service m anual for m or e detai l s.

THE BELT CLAMP TIP IS

ADJUSTED AT THE FACTORY TO

ALLOW THE BEL T TO SLIP IF THE

HUB COMES IN CONTACT WITH

SOME THING. CAUTION SHO ULD

BE USED WHEN ADJUSTING THE

TIP. IF THE CLAMP IS OVERTIGHTENED, THE BELT WILL

NOT SLIP WHICH MAY CAUSE

DAMAGE TO THE MACHINE OR

REEL.

TRAVERSE BELT

ENGAGEMENT

LEVER

CLAMP TIP

TRAVERSE BELT

FIG .4

TRAVERSE PROXIMITY SWITCHES

T wo m ovabl e pr oxi mit y sw itches deter min e the lef t and

right lim it s of grinding head assembl y . An LED on the

switch li ghts when the grindi ng head gets close to the

head of t he pr oxim ity swi tch. The se nsor s ar e m ount ed

in the Proximity Brackets located on the traverse shafts.

The brackets can easil y be slid along the shafts for quick

and easy travel limit adjustments. When switching from

the spi n mode to the r elief mo de, the br acket s will need

to be lifted off the shafts and snapped back on the shafts

in the proper pos ition.

SPIN/RELIEF GRINDING HEAD

This gri nder is equi pped wi th separate spi n and rel ief

grinding wheel s. When the setup is done proper ly the

reel will be only need to be positioned and aligned once

for both cycles. The spin wheel i s located on the ri ght

side of the machine and is wider than the relief wheel.

Move the wheel that is not being used as far to that side

as possible to give the maximum amount of room to

setup and operate the machine. The proximity

sensors must be moved so that the wheel in use is

between the two sensors. Make sure that the wheel

that is not in use is not engaged to the drive belt.

TRAVERSE

LEFT LI MI T

PROXIMITY

SENSOR

RELIEF GRINDING

WHEEL & HUB

TRAVERSE

RIGHT LI MIT

PROXIMITY

SENSOR

DUST

DEFLECTOR

SPIN GRINDING

WHEEL & HUB

FIG . 5

12

Page 13

GETTING TO KNOW YOUR GRINDER (Continued)

RELIEF ANGLE A DJU STM EN T

Rotating the finger system around the grinding wheel wi ll

change the relief angle. By loosening the large ratchet

handle the finger system can be rotated to achieve the

factory angles, or whateve r angle you select. See FIG. 6.

By r otati ng th e finge r for war d the rel ief angle wi ll decr ease

and rotating it rearward the relief angle will increase.

Retighten the ratchet handle when adjustment i s correct .

RELIEF WHEEL DIAMETER ADJUSTMENT

As the wheel wears, the finger system will need to be

adjusted to maintain the correct gap between the f ixed

finger and wheel. To move the finger system loosen the

small ratchet handle. See FIG. 6. The gap between the

fixed finger and the grinding wheel should be between

.06" [1.5 m m] and .18" [4.6 mm] dependi ng on the amou nt

of existin g relief on the reel . Retighten the rat chet handle

after the adjustment i s made.

INDEX FINGER ADJUSTMENTS

The R elief Assemb ly incl udes tw o fing ers. S ee FIG. 6. The

Fixed Relief Finger hold the blade in position during the

relief grind process. The Movable Index S top Finger moves

from the Relief Finger Side (back side) of the reel blade

when traversing from right to left, to the grinding wheel

side (front s ide) of the reel blade when traver sing from left

to right. T he indexing finger all ows the gr inder to index to

the next blade automatically during the relief grind.

Improper adjustment of the relief f ingers assembly may

result in a bad grind or possibly damage to the reel or

machine.

INDEX FINGER

STOP POSITION

KNOB

W HEEL DIAMETER

ADJUSTMENT

HANDLE

RELIEF ANGLE

ADJUSTMENT

HANDLE

FIXED FINGER

INDEX STOP

PIN

MOVABLE

INDEXI NG

FINGER

FIG . 6

The Index Finger Stop Position Knob adjusts where the

Index finger stops when the reel blade indexes. See FIG . 6.

Proper positi on of this st op is cr itica l to allow the reel blade

to smoothly transition from the Index Finger to the Fixed

Finger.

IMPORTANT! After adjusting the Index Finger Stop

Position Knob there should be 1/32" [0.8 mm] clearance

between the index finger and the reel blade when you push

on the index finger . This will allow the Fixed Relief Finger

to guide the reel blade during the relief grind cycle. The

Reel blade should never be riding on the Index Finger

when grinding.

The Index Stop Pin is height adjustable. It should be

adjusted to catch the reel blade and still leave enough

clearanc e to the reel spider after the r elief i s gr ound to the

depth required.

There is a forward position stop on the Finger system

located near the pivot poi nt of the I ndex Finger . T his w ill only

need to be adjusted if there is a clearance issue with the

finger when it travels forward. See FIG 7.

13

INDEX FINGER

FORWARD STOP

POSITION

SETSCREW

FIG . 7

Page 14

GETTING TO KNOW YOUR GRINDER (Continued)

ALIGNMENT GAUGE

A properly ground reel should be cylindrical. All taper

must be ground out of the reel. To ensure the reel will

be ground correct ly it MUST be aligned pr ecisely prior

to grinding. The digital alignment gauge is used for

accurate reel setup. The gauge is used for setting the

horizontal alignment and checking for taper within

thousands of an inch. The digi tal gauge al l ows y ou to

measure o ne end of the reel by extending the slide rai l

until you make c ontact w ith the cen ter shaft of the reel.

See FIG . 8. By measuring at the far left and the far right

on the center shaft you can adjust the horizontal

alignment using the front tooling adjustment knobs until

the alignment is w ithin .005 i nches [.13mm ].

When this is completed, you can then res et the gauge

to zero on the center shaft, retract the gauge slide

and measure the outer surface of a reel blade. By

comparing the readings on the left side of the reel to

the right side of the reel, you can determine exactly how

much taper you have in the reel. Compensating for

taper will be explained later in the grindin g proced ure.

INDICATOR SLIDE RAIL

IN / mm

REEL CENTER SHAFT

ZERO RESET

ON/OFF

FIG. 8

NOTE: The gauge can be set for both inch and metr ic

readout.

14

Page 15

OPERATING INSTRUCTIONS

PREPARE MOWING UNIT FOR SHARPENING

Always follow the procedures specified in the cutting

unit manual w hen pr epar i ng the uni t for shar peni ng. It

is recommended that the reel to be sharpened is

thoroughl y cl eaned . Remo ve the whee ls an d bed bar, if

possible, from the reel. The bedknives should be

sharpened when the reel is sharpened. Inspect,

adjust and/or r epl ac e any w or n or dam aged bear i ngs.

Mak e sure the ree l beari ngs are in go od wor king con dition and adjusted properly so the reel turns easily by

hand.

Becaus e thi s gri nder m ounts the r eel u sing the reel rear

roller and front roller if applicable, the bearings in the

rollers must be in good repair with no free play. The

front and rear rollers must be properly aligned

parallel to the reel prior to grinding.

REELS WITH EXCESS TENSION ON THE

BEARIN GS WILL BE EXTREMELY DIFFICULT

TO SPIN GRIND AND COULD CAUSE

DA MAGE TO THE REEL OR THE SPI N D RI VE

MECHANISM ON YOUR GRINDER. NO

MORE THAN 25. IN. LBS MAXIMUM TORQUE

!

LOAD TO ROTATE THE REEL IS ALLOWED

OR DAMAGE TO THE SP IN DRIVE COULD

OCCUR.

FIG. 9

LIFTING REEL INTO POSITION

The RG5500 grinder does not com e standar d wi th a l ift

device. If the facility does not have a lift, it is r ecommended

that the winch and b oom ki t or R ear Li ft Platform is us ed.

.

WINCH & BOOM KIT

The Winch & Boom kit mounts to the back right side of

the cabinet. When using the W inch & Boom, position

the cutting unit behind the machine and secure the

spreader bar to the cutti ng unit. Use the winc h to li ft the

unit and swing the reel into the working area of the

machine. (Refer to m anual in kit for further i nstructions.)

See FIG. 9 - Av ailable wi th a Manual or El ectric w inch.

REAR LIF T PLA TFOR M

The Rear Lift T able is a portable platform that can be used

to raise the r eel up l evel to the gr i nder. The r eel can be

rolled onto the platform with the front of the reel facing the

front of the grinder. With rear roll er cl am p r em oved the

reel can be roll ed fr om t he pla tform int o th e ma chin e from

the rear. The Workstation uses a 12V rechargeable

system to power the platform and can be moved around

the facility on the 4 caster wheels .

See FIG . 10

FIG. 10

15

Page 16

OPERATING INSTRUCTIONS (Continued)

INSTA LL REEL

Move the r eel to the appr oxim ate position having the r ear

roller on the tabletop, and front roller on the front roller

Mounts.

MAKE SURE THE GRINDING WHEEL IS LOW

ENOUGH TO CLEAR THE REEL. YOU CAN

LOWER THE GRINDING WHEEL BY

TURNING BOTH HANDWHEELS

!

Position front r eel in the center of the machine. Move the

roll er m ounts as far o ut as poss ible to the e nds of the fro nt

roller. (See FIG 11). Us e the dec al s on the tool i ng bar to

aid in the positioning of the front tooling. Check for

clearance to the tooling, front rol l er and fram e w i th both

the spin and relief wheels. This will ensure that yo u will

not have to move the reel between the spin and relief

grinding. NOTE: On large reels it may be necessary to

offset the r eel s light ly fro m cente r t o allow the s pin driv e to

be mounted on the app ropriate s ide of the cuttin g unit.

COUNTERCLOCKWISE.

FIG. 11

Place the rear roller onto the rear roller clamp.

(See FIG 12).

If using the all- position brac kets, set the vertical height of

the clamps so that the bottom of the reel i s 1.5-2. 0 inches

[38-51mm] above the table. It is also recommended to

mount the support ar m with as l ittle extensi on from the all

position bracket as possible leaving just enough clearance

for mounting the reel in the “V” of the support arm.

Position the reel in and out by adjusting the front

handwheels. The reel should be positioned so that the

reel shaft is located at a 1 o’clock or 30° position to the

grinding wheel. See figure 13. If there are clearance

issues the reel can be moved forward or backward to

resolve this is sue. If y ou are gr indi ng a QA5 or QA7 r eel

use the decals located on the tool ing to quic kly l ocate the

reel in the optimal position. See FIG 2. After the reel is

positioned corr ectly lock dow n the front roller and tighten

the rear clamp. Make sure all knobs are tight before

grinding.

FIG. 12

30° angle or

!

FIRMLY TIGHTEN ALL LOCKING KNOBS

BEFORE GRINDING. ANY LOO SE KNOBS,

CLAMPS OR BEARINGS WILL ADVERSELY

AFFECT THE GRIND QUALITY.

FIG. 13

16

Page 17

OPERATING INSTRUCTIONS (Continued)

AL I GN TH E REEL

IMPORTANT: When measuring to the reel center shaft

always mak e sur e you are contacti ng an area free of dirt

and grass.

The di gital gauge hor izonta l extens ion bra cket i s ver tical ly

adjustable to allow the digital gauge to be positioned to

avoi d any reel fr ame mem ber . In ad ditio n, the mo unting of

the vertical slide to the horizontal weldment has three

positions . Rem oved the kno b on the si de to adju st the til t

of the vertical slide if necessary to avoid a reel frame

member. Se e FI G . 14.

Before aligning the cutting unit, loosen the horizontal

locki ng knobs on the too ling, to all ow the cutti ng unit to be

adjusted i n the hor izont al pl ane. See F IG. 14.

T o alig n the cut ting unit, m ove the digi tal gauge as sembly

as far as possible to the left side of the reel. Extend the

digita l gauge maki ng sur e the t ip of t he gaug e is c enter ed

on the reel center shaft. See FIG 15. With the gauge

pressed against the reel center shaft, set the gauge to

zero. R etract the gauge and move to the r ight si de of the

reel and measure to the center of the reel shaft. Do not

rotate the reel shaft ex cept for a mini mum amoun t if ther e

are clearance issues to the reel blades. With the gauge

against the center s haft, adjust the horizon tal handw heel

until the gauge reads zero. Repeat adjustments going

from one side to the opposite side until the alignment is

within .005" [.13 mm ].

GAUGE ANGLE

ADJUSTMENT

T-KNOB

FORWARD AND

BACKWARD

MOUNTI NG HOL ES

TOOLING BA R

POSITION KNOB

HORIZONTAL

LOCKING T-KNOB

GAUGE VERTI CAL ADJUST MENT T-KNOB

HORIZONTAL

ADJUSTMENT

HANDWHEEL

GAUGE

BASE

FIG. 14

CHECKING FOR TAPER

First, m easure the left si de of the reel as far to the left as

possible wi th the di gital ali gnment gauge, make sur e the

tip of the gauge is centered on the reel center shaft. Set

the gauge to zero, then measure to the edge of one blade.

Remember or write thi s number down. Mov e to opposite

side and do the same thi ng. Compar e the tw o numbers ;

the difference is the amount of taper in the radius of the

wheel.

NOTE: TO OBT A IN A CORRECT TA PER REA DING TO

BE USED WITH THE TAPER CHART LATER, THE

READING MUST BE TAKEN AS CLOSE TO THE

ENDS OF THE REEL AS POSSIBLE GIVING THE

MAXIMUM DISTANCE BETWEEN READINGS.

T o r emove the taper in the reel , the side of the reel that i s

larger will need to be infed heavier to remove this extra

material.

Remove the gau ge and st ore the di gital gauge on the pin

located on the front r ight si de of the machine. The ga uge

base can be placed ins ide the mac hine out of the way.

FIG. 15

FIG. 16

17

Page 18

OPERATING INSTRUCTIONS (Continued)

ALIGNMENT OF GRINDING SHAFT T O REEL

T o ali gn the grin ding s haft t o the reel bri ng the sh aft up so th at

the spin wheel is about ¼ inch [6 mm] from the reel blades.

Move the spin wheel to one side of the reel and raise the

grinding shaft until the wheel just touches the blade. Move

the wheel to the other side of the reel and bring the shaft up

until the wheel jus t touches . Recheck from s i de to si de and

make minor adjustments until the wheel touches the same

on both ends of the reel. The grind shaft is now aligned

verti cal ly to the r eels ou ter diam eter. Ze ro the ga uges loc ated

on the vertical adjustm ent housing. Check for high spots in

the reel by moving the wheel the length of the reel while

spinning the reel. If there are high spots lower the shaft equally

on both ends and zero out the gauges again.

FIG. 17

SETT ING T HE T RAVERSE L IMITS

Move the grinding wheel to the right until the wheel has

cleared the reel by approximately ¼ inch [6 mm] (if

clearance to the frame allows). Disengage both the relief

and Spin grinding assemblies from traverse belt. Turn the

Traverse speed potentiometer to zero and turn on the

Traverse Motor Switch. This will activate the proximity

sensors. Mov e the right T rav erse Tr avel Li mit s witch in until

the light on the proximity sensor illuminates. Move the wheel

to the opposite end, clearing the reel as mentioned above,

and set the left Traverse Travel Limit Switch. (Fig 17)

Engage the trave rse bel t and sl ow ly tu rn the Tr aver se S peed

up. Allow the wheel to traver se from end to end to verify the

switches stop and reverse the direction of the grinding wheel.

V erify t hat t he grindi ng wheel travel s fully of f the reel at each

end. Note: If the reel will hit the f rame , then adjust travel

sensors so the w heel does not contac t the fram e.

ATTACHING THE VARIABLE SPEED SPIN DRIVE

UNIT TO T HE REEL

IF THE REEL FRAME EXTENDS

BELOW THE REEL ITSELF, MAKE

SURE THE STOP IS SET SO THAT

THE GRINDING WHEEL DOES NOT

RUN INTO THE FRAME WHILE

!

GRINDING.

FIG. 18

The spin driv e unit attaches to the end of the reel shaft or a

drive system compo nent. Consult the cutti ng unit m anual for

proper spin drive placem ent and attachment. Determi ne which

side to mount the spin drive. This will generally be the same

drive system component used for backlapping. See FI G . 18.

IMPORTANT: When spin grinding, the reel should turn in

the same directi on as the grindi ng wheel. See FI G . 19.

Befo re po sitio n ing th e sp in u nit let us f a miliariz e o urs elve s

with the availabl e adj ustments and coupler /dri ve assembl ies.

See FI G . 20.

18

FIG.19

Page 19

OPERATING INSTRUCTIONS (Continued)

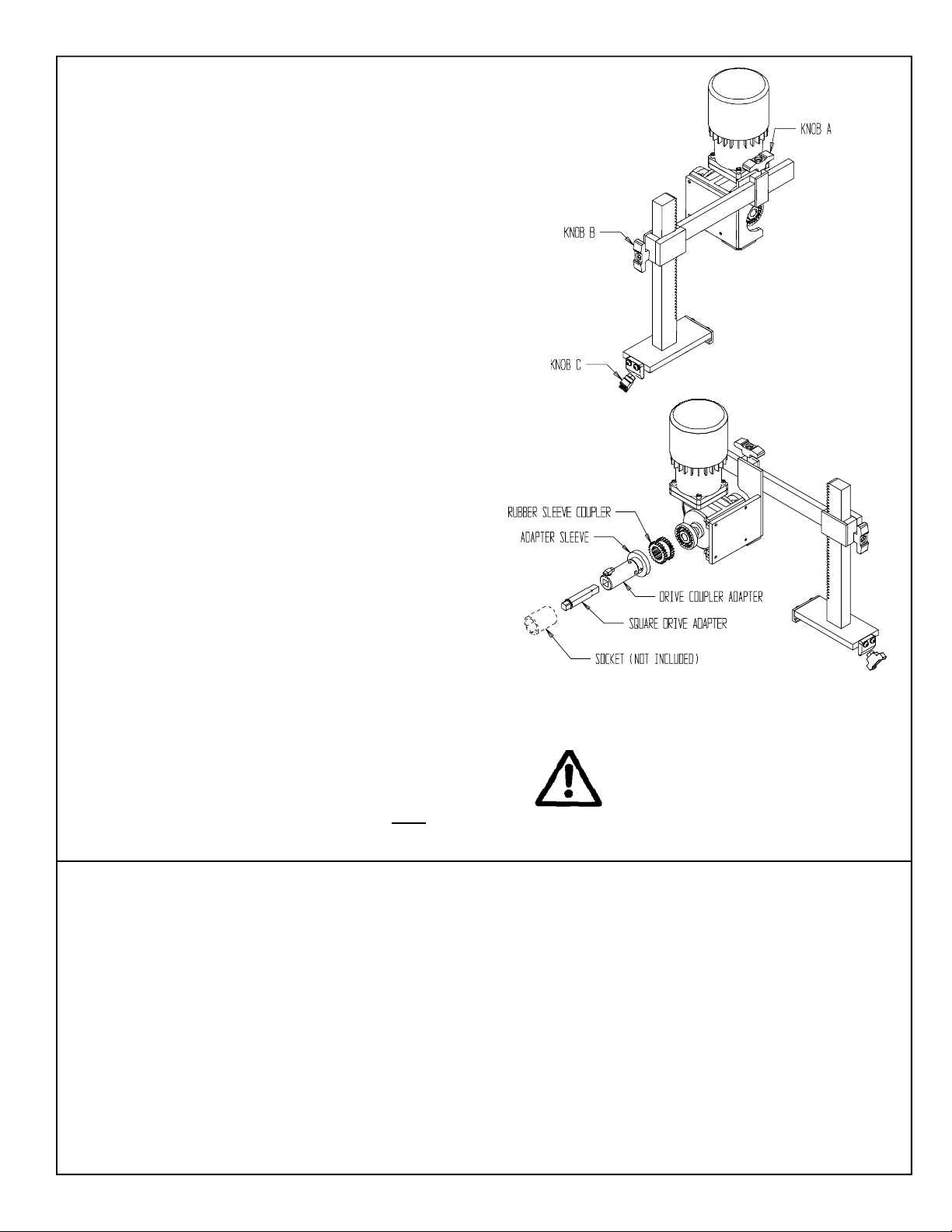

Knob A—

Allows the spi n unit to be loosened and moved in and out.

Knob B-

Allows the spi n unit to be loosened and moved up and down.

Knob C –

Allow s t he spi n ass embly t o be loosen ed from the to oling b ar and

moved sid e-to-si de.

When positioning the spin unit it may be necessar y to complete

several of the above adjustm ents to proper ly al ign the spi n unit to

the reel .

THE COUPLER ASSEMBLY INCLUDES:

RUBBER SLEEVE COU PLER: This is placed in the

corresponding flange c oupler already mounted in the s pin

drive shaft. See FIG. 21.

DRIVE COUPLER ADAPTER ASSEMBLY: This is

mounted to the rubber coupler .

Note: If the Drive Coupler Adapter is removed, there is a

short square drive shaft attached to the Adapter Sleeve.

This can be used with a socket if there is li mited space.

AD APTER SLEEVE: Connects the rubber coupler to the

square dri ve adapter .

SQUA RE DRIVE A DAPTER: This is inser ted into t he drive

coupler adapter. The square drive adapter has

approximately 2" [51 mm] of movement. It will be

necessary to move this when attaching reel to spin drive

unit. This adapter shaft has a groove machined into it on

the opposite end of the snap ring. This groove is there to

advise that you have reached the maximum extension of

the square drive shaft. If you cannot connect the reel

without extending past this groove, then the spin unit must

be repositioned on the tooling bar (Knob C). A 1/2"

[12.7 mm] sq uare driv e socket or reel drive a dapter is u sed

to connect the square dr ive adapter to the reel.

NOTE: The 1/2" [12.7 mm] square drive socket or adapter

that is plac ed on the reel w hen spin grindi ng is NOT

with the grinder. See next page for details

included

FIG.20

FIG. 21

DO NOT EXTEND SQUARE

SHAFT PAST GROOVE, INSTEAD

REPOSITION SPIN UNIT.

The followi ng procedur es will make setting up the spin drive unit easier .

1.

Move spin dri ve unit cl ose to the reel. Ali gn the shaft on the spin drive wi th the nut on reel by completing the

necessary adjus tm ents disc uss ed above.

2.

Now sl ide the spin drive uni t appr oxim ately 7 " [18 cm ] from the ree l dri ve co upling poi nt and secu rely fasten to

the tooling bar tighte ning the l ocking knob. (Kn ob C)

3.

Place the proper 1/2 " [12.7 mm ] square dr ive soc ket or adapt er on the reel driv e nut and then ins ert the squar e

drive shaft into the socket. Place the adapter sleeve over the drive shaft and insert the dri ve coupler adapter

assembly into it. Final ly pl ace the rubber coupler onto the drive coupl er adapter. See FIG. 21.

4.

By holding the square drive shaft firmly into position with your left hand you will be able to move the oth e r

components to the right and inser t the rub ber coupler i nto the flange on the spin driv e unit. When this is done

tighten the T - Knob on the adapter sleeve to hol d all part s in plac e.

Finally r eadjust the spin dr ive unit if it i s not in alignm ent.

5.

NOTE: It i s not necess ar y to have perfect alignment but it must be cl os e enough so that the coupler remains

engaged and that excess tor que is not appli ed to the reel.

19

Page 20

OPERATING INSTRUCTIONS (Continued)

REEL DRIVE ADAPTERS

T

his grinder is equipped wi th an adapter that transfers the rotation from the spi n drive gear box coupling to a

1/2" male square. To operate the grinder you need an adapter from this 1/2" male squar e to the reel shaft.

These adapters are NOT

Most cutti ng units In recent y ears have a mal e or female spl ine on the end of the reel shaft that c onnects to

a hydraulic or elec tric motor shaft.

If you have a reel shaft that has an internal threaded end whi ch you can access, instal l a hex head bolt or

socket head screw of that thread size w ith a jam nut ver y tight so i t does not loos en whil e spin gr inding and

then drive with a 1/2" driv e socket for that hex or hex key size.

JOHN DEERE REELS

COUPLERS- T he external spline shafts use a female splined coupler between the reel shaft and the male

splined hydraul ic m otor shaft. The spli ne is either an 8,9 or 11 toothed spline. Our r ecomm endation is to

purchase the female s plined coupler from John Deer e and w eld it to a shor t 1/2" square socket extens ion.

Note: The 8 tooth spline adapter can be used with a Square Socket Dri ve Adapter [3/8" s quare male to 1/2"

square female] without w elding.

included w ith this grinder.

REEL DIA

REEL TYPE Recomendation

5 " G, M Has an 8-T, Extern a l shaft. U se co upler AET11038

7 " H Has an 11-T, External sha ft. Us e coupler TCA12581

(NOTE: THIS CAN ALSO BE DRIVEN WITH A 1.25 HEX SOCKET)

7 " 26H Has a 9-T, Extern al sh aft. U se co upler AET11310

(NOTE: THIS CAN ALSO BE DRIVEN WITH A 1.25 HEX SOCKET)

8 " ESP Has a M16 X 2, Externa l sha ft. Use nut A31869 and dr ive with

a 24mm Hex Socket.

5 " WB G M Use a 3/ 8"-24 UNF B olt, and d rive with a 9/ 16 Hex So cket

5" QA5 Has an 8-T, Internal Spline shaft. Use part AMT3022, to make

an adapter.

7" QA 7 Has an 11-T, Internal Spline shaft. Use a 1.25 Hex Socket or

make and a dapter from pa rt TCA18958.

TORO EQUIPMENT :

T oro uses a n 8 tooth female spline or a 9 tooth female spline on their reels. The 8 tooth female spline can be affectively

driven with a Square Socket Drive Adapter [3/8"square male to 1/2" square female]. The 9 tooth spline requires an

adapter . Our r ecommendation is to p urchas e ada pter Toro too l part nu mberTOR-4074 available from

K-Line Industries, Inc. 31 5 Garden Ave. Holland, MI 49424.

JACOBSEN EQUIPMENT :

Below is a list of drive systems based on the cutting units:

* 5" reel units can be driven from the non hydraulic motor end of the reel. Install a 3/8" bolt in the end of the reel shaft

with a jam nut very tight so it does not loosen while spinning. Use a 9/16" socket to drive. They can also be driven from

the hydraulic motor end by pressing a Square Socket Drive Adapter [3/8" square male to 1/2" square female] into the

splined reel coupling Jacobsen part number 337370 and use this pressed as sembly as the adapter.

* 7" reel units can be driven from either end. The reel unit has a coupler attached to the reel shaft a both ends. Purchase

Jacoben part number 4102440 Reel Motor Shaft and weld the hydraulic motor shaft form the kit to a 1/2" socket and use

this weldment as the adapter.

* Tri-King reel units can be driven on older pulley drive units with a 9/16" socket on the 3/8" bolt that holds the pulley. On

newer splined units, purchase the splined reel coupling Jacobsen part number 132002 and press a S quare Socket Drive

Adater [3/8" square male to 1/2"square female] into the splined reel coupling and use this assembly as the adapter.

20

Page 21

OPERATING INSTRUCTIONS (Continued)

RECOMEN DA TION FOR SPI N DRIVE RPM A ND

TRANSVERSE SPEED WHEN GRINDING

SPIN DRIVE RPM

SPIN DRIVE RPM IS VERY IMPORTANT IN

ACHIEVING A QUALITY GR IND. USE C ARE IN

ESTABLISHING THE SPIN DRIVE RPM, PER THE

INSTRUCTIONS BELO W.

Generally, the Spin Drive RPM will be be tween 180

RPM (45%) and 380 RPM (100%). The speed required

to spin a specific reel is dependant on reel diameter,

the number of reel blades, and reel hardness. For all

reels, there i s an opti m um Spin Speed where ther e i s

an AGGRESSIVE, yet smooth grind as you spin gri nd

the reel. Your objective is to spin grind the reel as

aggressi vely and as fast as pos sibl e w hile m aint aining

top quality .

It is r ecommen ded to star t grinding eac h reel at a S pin

Speed of 200 RPM (50%) and evaluate the RPM by

adjusting hi gher and lower to opt imiz e the S pin S peed

for that reel. If the Spin Speed is incorrectly set, you

can experience two problems, grinding wheel

dressing or grinding w heel resonance. Each of these

problems is explained below .

On some reels, especially small diameter high blade

count reels if the Spi n S peed RPM is s et too high, the

reel can act as a dr esser to the grinding w heel. T here

can develop what appears to be a very aggressive

grind (as if the infeed has self infed) and then a

sudden stop of grinding with no grinding wheel to reel

contact. If this occurs, your Spi n Speed was set too

high and you effectiv ely dressed y our g rinding w heel.

Some ree ls have a res onant R PM w here the reel goes

into harmonics with the grinding wheel and the

resonance vibrates the grinder and results in a very

bad grind. By changing the Spin S peed to a higher or

lower RPM you will move out of the resonant range.

After determini ng the best S pin S peed RPM for a reel,

note the RPM on the "Set-up Chart" in the "NOTES"

section. (Set-up chart is located at the back of th is

manu al) By no ting th e correct RPM, you will a void

evaluating the Spin S peed the next time y ou grind the

reel. Also note the spin drive position using the

position decals on the spin mounting and

documenting the position on the "Set-up Chart".

TRAVERSE DRIVE RPM

The T raver se Speed potentiom eter is adjust able from

approximately 5 feet per minute [1.5 meters per minute]

to 20 feet per minute (6 meters per minute). It is

recommended to grind between 15 and 20 feet per

minute (4 and 6 meters per mi nute).

Gri nding a t a slow er tr aver se spee d, 10 feet p er min ute

(3 meters per minute) as an example, will give a better

finish but will extend the gri nd cycle ti me. Grind finish

versus grind cycle time is controlled by the choice of

the operator .

COMPENSATING FOR TAPER.

To maintain the best quality of cut, the taper in a reel

must be removed returning the reel to a true cylinder.

T o re move the t aper that w as measur ed with the gauge

(as discussed previously in Checking For T aper Section)

first align the reel to the shaft by the touch m ethod (as

discussed previously). Then drop the side of the

grinding shaft that is hi gh (the sm all er side of the reel )

the amount suggested in the chart

[See char t on next page or Compensation for

Taper Chart located on the machine].

Example: For a r eel that is 22 i nches [56 c m ] long

with a measur ed t aper of .12" [3 m m ],

the adjuster on the smaller side of the reel

would be dropped to read-.546 [13.9 m m].

This will bring the grinding shaft parallel to the reel

center shaft. Z er o out the di gi tal g auges loc ated on the

vert ical adj ustme nt tower s and infeed both side equal ly

until the wheel just touches the large side of the reel.

Zero the gau ges again, you are now rea dy to grin d and

remove the taper. When grinding, the wheel will only

make contact with the larger side of the reel and will

gradually grind more as the larger areas are ground

away. The reverse button may be used to help speed

of this process . Gri nd until full c ontact is made acros s

the entire length of the reel, and the reel is sharp the

entire width of all blades .

AMOUNT OF

AMOUNT

OF TAPER

IN SHAFT

TAPE R IN REEL

21

Page 22

OPERATING INSTRUCTIONS (Continued)

TAPER A DJUSTMENT SETUP C HART

REEL WIDTH

16 18 20 22 24 26 28 30 32

0.005 0.033 0.029 0.025 0.023 0.021 0.019 0.017 0.016 0.015

0.010 0.066 0.058 0.051 0.045 0.041 0.038 0.035 0.032 0.030

0.015 0.100 0.086 0.076 0.068 0.062 0.056 0.052 0.048 0.045

0.020 0.133 0.115 0.102 0.091 0.082 0.075 0.069 0.064 0.060

0.025 0.166 0.144 0.127 0.114 0.103 0.094 0.086 0.080 0.075

0.030 0.199 0.173 0.153 0.136 0.123 0.113 0.104 0.096 0.089

0.035 0.233 0.202 0.178 0.159 0.144 0.132 0.121 0.112 0.104

0.040 0.266 0.231 0.203 0.182 0.165 0.150 0.138 0.128 0.119

0.045 0.299 0.259 0.229 0.205 0.185 0.169 0.156 0.144 0.134

0.050 0.332 0.288 0.254 0.227 0.206 0.188 0.173 0.160 0.149

0.060 0.399 0.346 0.305 0.273 0.247 0.225 0.207 0.192 0.179

MEASURED T APER

SPIN GRINDING

After the reel has been aligned and the taper has been

adjusted for , you ar e now ready to spin grind the r eel. Cl ose

the front and r ear guar d doors. (The g rinding w heel and spin

motors will not work unle ss th e doors are closed.) Position

the spin/relief selector switch to the spin position. Tu rn on

the Grinding M otor and the S pi n Dri ve M otor swi tch. Set the

spin speed at approximately 200 rpm (Refer to Spin Drive

RPM on per vious page) . M ake s ure spin r otation i s the same

as the grinding wheel – clockwise (CW) looking from right

end. See FI G 22.

0.070 0.465 0.403 0.356 0.318 0.288 0.263 0.242 0.224 0.209

0.080 0.532 0.461 0.407 0.364 0.329 0.301 0.277 0.256 0.238

0.090 0.598 0.519 0.458 0.409 0.370 0.338 0.311 0.288 0.268

0.100 0.665 0.576 0.508 0.455 0.412 0.376 0.346 0.320 0.298

0.120 0.798 0.692 0.610 0.546 0.494 0.451 0.415 0.384 0.358

Small side of reel downward adjustment.

IM PORTANT: When the reel turns i n the sam e rot ation as

the grinding wheel , the point of contact where they meet is

in opposit e direc tions.

Tur n on the tr averse dr ive m otor sw itch and turn the speed

dial up to approxi matel y 15- 20.

IM PORTANT: If the gri nd st arts get ting heav ier , adjust the

grindi ng head down u ntil yo u can tr avel th e full length of the

reel w ithout heav y grindin g.

When grinding, infeed the wheel approximately .005” [.13 mm]

at a time. Allow the grinding wheel to travel back and forth

across the reel 2 to 3 times before infeeding. The spin

grinding is completed when full contact is made across the

entire le ngth of the reel, the entire width of all bl ades and the

reel is s harp. The l ast pas ses shoul d be a norm al .005 [.13

mm] infeed gri nd at a slow trav erse speed (appr ox. 8 feet per

minute [2.5 meters per minute] or slo wer). Aft er the l ast pass

turn the grin der off.

(Note: Due to the positioning of the reel to the 1 o’ clock posi tion,

infeeding the wheel .015 inches [.38 mm] will remove .010

inches of material. )

22

FIG.22

Page 23

OPERATING INSTRUCTIONS (Continued)

RELIEF GRIND

T o change over to the relief grind, disengage the spin grinding wheel

hub assembly and par k i t as far to the ri ght as possibl e. Bring the

relief hub assembly over to the reel for relief grinding. This will

require repos itioning the tr avel pr oximity switch br ackets.

Note: As the reel diameter get s sm aller and the num ber of blades

increases the relief grinding wheel diameter works better when

smaller. For exampl e a 5" [127 mm] diameter greensm ower r eels

with 1 1 bl ades ach ieve a greater rel ief angle wi th a sma ller gr inding

wheel.

REEL SPIRAL

Check to see if your mow ing unit is nor mal or reverse hel ix.

NOTE: As you look into the gui de finger on TH E NEXT PAGE, IT

SHOWS TH E NORM AL REEL HELIX. As you l ook into the guide

finger on the FOLLOW PAGE, IT SHOWS THE REVERSE

REEL HELIX. The high po int of the reli ef finger is on th e right h and

side of the grinding wheel .

Most m owing units ar e nor mal hel ix.

THE HIGH POINT OF THE RELIEF FINGER MUST

ALWAYS BE AT THE CORNER OF THE GRINDING WHEEL

THAT IS MAKING CONTACT WITH THE REEL. ON THIS

GRINDER THAT IS ALWAYS THE RIGHT HAND SIDE OF

!

WHEEL DRESSING

If the grinding wheel becomes loaded with material it may be

necessary to dress the wheel. The RG5500 is supplied with a

diamond dresser. To use, place the dresser on the spin drive

horizontal arm in the area where the wheel is to be dressed.

Adjust the dresser to the appropriate position and angle. Raise

the grinding wheel so it i s nearly touching the dress er .

For dressing the spin grinding wheel, put the dresser in the straight

position. Close the door s and infeed the spin grinding wheel into

the dresser and then move the gr inding wheel side to side agai nst

the dresser which will dress the full face of the wheel.

THE GRINDING WHEEL.

FIG.23

T ypic ally onl y infeed .002 " [.05 mm] per pas s. Infeeding too heavy

can dam age the dresse r or the w heel. Contin ue dres sing unti l the

wheel looks new or the proper shape is achieved.

For dressi ng the rel ief w heel, put the dr esser at the corr ect angle

for normal helix reel or reverse helix reel. Close the doors and

infeed the relief grinding wheel into the dresser. Do NOT move

the grinding wheel from s ide to side.

23

Page 24

OPERATING INSTRUCTIONS (Continued)

Matching Angle

Actual Grindi ng Wheel

Contac t Point

Prefered Dres sing

New S traight Wheel

Right Side of Wheel

Must Contact First

NORMAL HELIX

24

For a N ORMA L HELI X re el, the gr inding w heel

should wear to match the angle of the reel

blade.

NOTE: The square faced grinding wheel as

purchased from the factory can be used for

normal helix reels and will wear to match the

reel blade helix.

Normal helix reels are also refered to as Left

Hand Side Cutting First (Looking from front -

grass entry position.) or Right Throw reels

(Throws grass to the right of operator

position.)

Page 25

OPERATING INSTRUCTIONS (Continued)

Matching Angle

Actual Grinding Wheel

Contac t Point

Prefered Dressi ng

Right Sid e of Wheel

Must Contact First

For a REVERSE HELIX reel, the grinding wheel should

be dressed to match the angle of the reel blade. It is

recomm ended that a slightly larger angle is dressed on

the wheel so the right side of the wheel is contacting the

blade prior to the left side as shown. The grinding w heel

will then wear to a match.

REVERSE HELIX

25

If you do not dress the grinding wheel so the right side

contacts first you may not relief grind part of the last 3/8"

[10 mm] of the blade.

NOTE: A wheel that has been worn to match a norm al hel ix

can generally be rem oved and rev ersed to grinder rever se

helix. reels.

Reverse helix ree ls are also refered to as Right Side

Cutting First reels (Looking from the front - grass entry

side) or Left Throw reels (Throws grass to the left of the

operat or position .)

Page 26

OPERA TING INSTRUCTIONS (Continued)

RELIE F GRINDING CONTINUED

Reset the Traverse Limit Pr oxi m i ty Sw i tc h so the

grinding wheel clears the reel at both ends by

approximately 1/16" [1.5 mm].

Set Grind Selector s witch to variable tor que relief.

(IMPORTANT: The Spin Drive Rotation switch must be

in the OFF position when changing the Grind Selector

switch.) Set the Spin Drive Rotation switch to rotate the

reel into the stop finger, counterclockwise (CCW) when

look ing at the r ight s ide . NOTE: Relie f tor que r eel rotati on

is al ways opposi te spin r otati on. DO NOT T URN ON T HE

SPIN MOTOR SWITCH.

With the traverse in the home

position (right side traverse

proximity sensor lit), infeed the grinding relief wheel up

while manually rotating the reel until the index finger

touches t he blade.

Tur n the travers e speed potentiometer to zero, then turn

the traver se drive motor on. With the bel t drive dis engaged,

manually move the Relief Grinding Assembly to the left

until the r eel bl ade is on the fixed r elief finger.

INDEX FINGER

STOP POSITION

KNOB

WHEEL DIA METER

ADJUSTMENT

HANDLE

RELIEF ANGLE

ADJUSTMENT

HANDLE

FIXED FINGER

INDEX STOP

PIN

MOVABLE

INDEXI NG

FINGER

At this point, i f necessary , you can adj ust the rel ief angle

by adjusting the relief finger position. To make this

adjustment loosen the Relief Angle Adjustment handle.

See FIG 24. Rotating the finger system down will increase

the relief angle and rotating the finger system up will decrea se the reli ef angle. Adju sting the r elief angl e or index

finger stop position is easiest with the relief head at the

left side o f the reel.

Once you have the Grinding Head pos itioned with a reel

blade r esti ng on the F ixed R eli ef Fin ger high point , adju st

the indexing finger stop. There should be about 1/32"

[.8mm] to 1/16" [1.5m m ] free pl ay of the I ndex F i nger to

the back of the blade. The Inde x Finge r i s spri ng loaded

to the up posi tion or again st the back o f the r eel bl ade. To

check free play, push down on the Index Finger.

See FIG 24. If there is no free play of the Index Finger you

want to rotate the Adj ust able Index F inger S top Posi tion

Knob counter clockw i se. If there is m or e than 1/16" [1.5

mm] free play you want to rotate the Index Finger Stop

Position Knob clockwise.

IMPORTANT: The Index Finger position must be set to

stop the r eel blad e and al low tr aversi ng to the le ft witho ut

the blade hitti ng the side of the r elief finger . Thi s position

must also allow approxi mately 1/32" [.8 m m] free play of

the index finger when the blade is resting on the high point

of the relief finge r . See FIG . 24.

Infeed the grinding wheel up until there is minimal

clearance between the reel blade and the grinding wheel.

INDEX FINGER

FORWARD STOP

POSITION

SETSCREW

FIG 24.

FIG 25.

26

Page 27

OPERA TING INSTRUCTIONS (Continued)

RELIE F GRINDING CONTINUED

Close the front and rear doors.

Tur n the Spin Motor Switch on.

NOTE: The spin drive will apply torque load against

the finger s.

Set the Rel ief Torque Potentiom eter at appr oximate ly

15. IMPORTANT: Free turning reels may need a lower

value than 15 and sti ff reels or r eels with a drive tr ain

may need a higher torque than 15.

Engage the traverse belt and tr av er se al l the w ay to

the left watching for proper clearance between the

grinding wheel and the blade. Check for proper

clearance between the index finger (after releasing

from bl ade at far left posi tion) a nd the front side of the

blade on the return trip to the home

clearance to the reel blade support spiders. If

necessary the forward stop can be adjusted.

See FI G 25.

position. Also ver ify

Stop the traverse in home

proper blade index. The traverse drive control is

factory set with a two second dwell time before it

reverses the carri age tr avel . This i s to al l ow tim e for

the reel to rotate and the index finger to catch the next

blade. If necessary the dwell time can be adjusted

(refer to Control Board Potentiometer Adjustments

section in the Ass embly and Serv ice M anual).

Tur n on the Spin Drive Motor (should already be on)

and the Grinding Wheel Motor s witc h.

Turn the traverse speed potentiometer to proper

grind ing sp eed. Sl owly infe ed the grin ding w heel until

you are able to grind the full length of the reel evenly. A

typical infeed is b etween .010" to .020" [.25-.50 mm].

Be sure you have ground all the blades before

infeeding further.

NOT E : Traverse speed should be set to

approximately 15 fpm. If you are removing a small

amount of stock on initial infeeds, faster traverse

speeds are suggested. If you are removing a large

amount of stock on later infeeds, slower traverse

speed may be required.

position and check for a

After the relief grind is complete remove turn all

switches to off (it i s als o good practic e to push i n the

E-stop button) then remove cutting unit from the

machine. Use caution as the reel blades will be sharp.

27

Page 28

REEL SETUP CHART

NOTES

E

S

G

R

N

D

E

I

E

T

V

A

E

T

E

P

R

T

S

S

SPIN

TORQUE

SETTING

frame, reel dia., height of cut, roller position, etc.

Note: These dimensions will vary due to reel position in

SPIN

SPEED

SETTING

E

V

N

I

R

O

D

TI

I

N

S

I

P

Use these values as a guide only.

O

S

P

SPIN DRIVE

MOUNTING

SIDE R OR L

TOOLING

DISTANCE

APART

FRONT

TOOLING

MOUNT

POSITION

REEL SETUP CHART

FRONT

TOOLING

MOUNT

TYPE

REEL MAKE,

MODEL &

HEIG HT OF

CUT

28

Page 29

THIS PAGE LEFT INTEN TI ONALLY BLANK FOR NOTE TAKING PORPOSES.

29

Page 30

30

Page 31

ASSEMBLY

REEL MOWER GRINDER

RG5500

AND

SERVICE MANUAL

SPIN / RELIEF

(REV. 6/20/ 201 1)

1

Page 32

DEALER PREPARATION/INSTALLATION CHECK LIST

IS LOCATED IN THE OPERATOR'S MANUAL

SEE OPERA T OR'S M ANUAL F OR INSTALL TION CHEC KLIST

It is the r esponsibility of the dealer to com plete the procedures li sted in the Operators Manual then

review this checklist wi th the customer upon the delivery or the sale of this equipment.The ins tallation

trainin g goes over the basic op erational functi ons of the equipm ent. To ensure adequate train ing, we

require that the following i tems are r eviewed by your John D eere Dealer . Pleas e check off to ensure

that you under stand the follow ing items before the instal lation tr aining i s com plete:

Safety

IMPORT ANT SA FETY MESSA GE FOR OWNERS/OPERAT ORS OF REEL GRINDERS

Safety is a primary concern in the design,

manufacture, sale, and use of reel grinders. As

a manufa cturer of reel grinders, we w ant to confirm

to you, our customers, our concern for safety . We also

want to remind you about the simple, basic, and

common sen se rules of safety when using a reel

grinder. Failure to follow these rules can result in

severe injury or death to o perator s or bys tander s.

It is essential that everyone involved in the assembly ,

operation, transport, mainte nance, and storage of this

equipment be aware, concerned, prudent, and

properly trained in safety. Always use proper

shielding as specified by the manufacturer.

Our current production machines include, as

standard equipment, guards or shields for the

grinding wheel, safety signs and an operator's

manu al. Never by pass or opera te the m achine with

any of the guards or the saf ety devices rem oved.

Read and fully understand all the safety

practices discussed on pages 4 and 5 of this

manual. All safety rules must be understood

and followed by anyone who works with reel

grinders.

Before operating a reel grinder, an operator must

read and understand all of the information in the

operator’s m anual and in the saf ety signs atta ched

to the product. A person who has not read or

understood the ope rator’s man ual and safety s igns

is not qualified to operate the unit. Accidents occur

often on machines that are used by someone w ho

has not read the operator’s manual and is not

familiar with the equipment. If you do not have an

operator’s manual or the current production safety

signs, contact the manufacturer or your dealer

immediately.

Reel grinders are designed for one-m an operation.

Never operate the grinder with anyone near, or in

cont act wit h, any part of the grinder . B e sure no one

else, including bystanders, are near you w hen you

operat e this product.

Following these simple, basic safety rules, as well

as others identified in the owner’s manual and in the

product safety signs, will help minimize the

possibility of accidents and increase your

productivity in usi ng this product. Be careful and

make sure that everyone who operates the grinder

knows and understands that this is a very pow erful

piece of m achinery , and if used im properly, serious

injury or death may result. The final responsibility for

safety re sts with the operator of this mach ine.

2

Page 33

TO THE DEALER:

Assembly and pr oper inst allation of this pr oduct is the responsi bility of the John Deere dealer . R ead manual

instructi ons and s afety rules. M ake sur e all i tems on the Pr epar ation Chec k List in the Oper ator’s M anual are

complet ed before releasi ng equi pment to the owner.

TO THE OWNER:

Read the Oper ator's M anual before operati ng your Frontier equipment. Keep this and al l manuals handy for

ready reference. R equire all operator s to read the O perator's M anual carefull y and beco me acquainted with

all adjust ments and operating procedu res before at tempting to oper ate the equi pment. Repl acement

manuals can be obt ained from your selling deal er .

The equipmen t you h ave purc hased has been careful ly engineer ed and m anufacture d to provi de

dependable and satisfactor y use. Lik e all mechan ical pr oducts, it w ill require c leaning and upk eep. Lubricate

the unit as specified. Please obs erve all s afety information in the Oper ator's M anual and safety decals on

the equi pmen t.

For servi ce, your authorized John Deer e dealer has trained mechani cs, genuine Frontier servic e parts, and

the necessary tools and equipment to handle all of your ser vice needs.

Use only genuine Frontier servic e parts.

3

Page 34

SA FETY I NSTRUC TIONS

Safety Awareness Symbols are inserted

into this manual to alert you to possible

Safety Hazards. Whenever you see these

symbols, follow their instructions.

!

The Warning Symbol identifies

special instructions or procedures

which, if not correctly followed, could

result in personal injury .

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE WRENCHES AND OTHER

TOOLS.

3. KEEP WOR K AREA CLEAN.

4. DON'T USE IN DANGEROUS ENVIRONMENT.

Don't use Grinder in damp or wet locations.

Machine is for i ndoor use only . Keep work area

well lit.

5. KEEP A LL VISITORS AWAY . All visitors

should be kept a safe dis tance from wor k area.

6. MAKE WORK AREA CHILD-PROOF with

padlocks or master switches.

The Caution Sy mbol id entifi es spe cial

instructions or procedures which, if not

strictly observed, could result in damage to

or destruction of equipment.

12. DON'T OVERREACH. Keep proper footing and

balance at all times .

13.MAINTAIN GRINDER WITH CARE . Follow

instructi ons in Ser vice M anual for lubric ation and

prev entive m aintena nce.

14.DISCONNECT POWER BEFORE SERVICING,

or when changi ng the g rindi ng wheel.

15.REDUCE T HE RISK OF UNINTENTIONAL

STARTING. Make sure all switches are OFF

before plugg ing in the grinder .

16.USE RECOMMENDED ACCESSO RIES.

Consult the manual for recom mended

accessories. Using improper accessories may

cause risk of personal injury .

7. DON'T FORCE THE GRINDER. It will do the job

better and safer if used as speci fied in this

manual.

8. USE THE RIGHT TOOL. Don't force the gri nder

or an attachment to do a j ob for w hich it was not

designed.

9. WEA R PROPER APPA R EL. Wear no loose

clothing, gloves, neckti es, or j ewelr y which m ay

get caught in moving parts. Nons lip footwear is

recommended. Wear protective hair cover ing to

contai n long ha ir .

10. ALW AYS USE SAFETY GLASSES.

11. SECURE YOUR WORK. Make certain that the

cutting unit is securel y fastened with the clam ps

provided before operating.

17.CHECK DAMAGED PARTS. A guard or other

part that is damaged or will not perform its

intended function shou ld b e proper ly r epaired or

replaced.

18.KNOW YOUR EQUIPMENT. Read this manual

carefully . Lear n its applicati on and limit ations as

well as spec ific potenti al hazar ds.

19.KEEP ALL SAFETY DECALS CLEAN AND

LEGIBLE. If safety decals become damaged or

illegible for any reason, replace immediately .

Refer to replacement parts illustrations in Service

Manual for the proper location and part num bers

of safety decals.

20.DO NOT OPERATE THE GRINDER WHEN

UNDER THE INFLUENCE OF DRUGS,

ALCOHOL, OR MEDICAT ION.

4

Page 35

SA FETY I NSTRUC TIONS

IMPROPER USE OF GRINDING WHEEL MA Y CAUSE

BREAKAGE AN D SERIOUS INJURY .

!

Grindi ng is a safe opera tion i f the few bas ic r ules list ed below ar e follow ed. T hese rul es ar e based on mater ial

contained in the ANSI B7.1 Safety Code for "Use, Care and Protection of Abras ive Wheels". For your safety ,

we suggest you benefit from the experi ence of others and follow these rul es.

DO

1. DO always HANDLE AND STO RE

wheels in a careful manner.

2. DO VISUALLY INSPECT all wheels before

mounting for p ossible dam age.

3. DO CHECK MACHINE SPEED against the

established max imum safe operati ng speed

marked on w heel.

4. DO CHECK MOUNTING FLANGES for equal

and correct di ameter.

5. DO USE MOUNTING BLOTTERS when

supplied with wheels.

6. DO be sure WORK REST is properly

adjusted.

7. DO always USE A SAFETY GUARD C OVER I NG

at least one- half of the gr inding wh eel.

DON'T

1. DON'T use a whee that is cracked, HAS BEEN

DROPPED, or one that i s damaged.

2. DON'T FORCE a wheel onto the machine OR

ALTER the si ze of the m ounti ng hole- -if w heel w on't

fit the machine, get one that will.

3. DON'T ever EXCEED MAXIMUM OPERATING

SPEED established for the wheel.

4. DON'T use mounting flanges on whic h the bear ing

surfaces ARE NOT CLEAN, FLAT AND FREE OF

BURRS.

5. DO N' T TI GH TE N t he m ounti ng nut EXCESSIVELY.

6. DON'T grind on the SIDE OF THE WHEEL (see

Safety Code B7.2 for excepti on).

7. DON'T start the mac hine until the WH EEL GU A RD

IS IN P LACE.

8. DO allow NEWLY MOUNTED WHEELS to run at

operating speed, with guar d in pl ace, for at least

one mi nute be fore gri nding.

9. DO always WEAR SAFETY GLASSES or some

type of eye p rotec tion when g rindi ng.

A VOID INHALATION OF DU ST gener ated by gri nding and cutting oper ations. Exp osure

to dust may cause respiratory ailments. Use approved NIOSH or MSHA respirators, safety

glass es or face shiel ds, and pr otecti ve clo thing . Prov ide a dequate venti lat ion to eli mina te

dust, or to maintain dust level below the Threshold Limit Value for nuisance dust as

classified by OSHA.

8. DON'T JAM wor k into the wheel.

9. DON'T STAND DIRECTLY IN FRONT of a

grinding wheel whenever a grinder is started.

10. DON'T FORCE GRINDING so that motor slows

noticeably or w ork gets hot.

5

Page 36

TABLE OF CONTENTS

This machine is intended for grinding the reel of reel type mower units ONLY.

Any use other than this m ay cause personal injury and voi d the warranty.

To assure the quality and safety of your machine and to maintain the warranty,

you MUST use original equipment manufactur's replacement parts and have

any repair work done by a qualified professional.

ALL operators of this equi pment mus t be thoroughly trained BEFORE operating

the equipment.

Do not use compressed air to clean grinding dust from the machine. This dust

can cause personal injury as well as damage to the grinder. Machine is for

indoor use only. Do not use a power washer to clean the machine.

Low Voltage Relay

The gri nder is equipped wi th a high- low vol tage rel ay

which is factor y preset at 100-140 V AC. If the power

supply l ine d oes not deli ver 100- 140 V A C power under

load, the relay will open and trip out the star ter . If this

occurs, your pow er suppl y l i ne i s i nc or r ect and m us t be

correct ed before proceedi ng further with the gr inder .

TABLE OF CONTENTS

Safety Instructi ons ................................................................................................................. Page 2- 6

Dail y M aint enance.................................................................................................................. Page 6

Service Data.......................................................................................................................... Page 7

Assembly Instructions............................................................................................................ Page 8- 12

Maintenance............................................................ .............................................................. Page 13-19

Adjustments........................................................................................................................... Page 20 -25

Electri cal Troubleshooting...................................................................................................... Page 26-41

Mecha nical Tr oubleshooting .................................................................................................. Page 42-43

Exploded Views and parts Lis ts ............................................................................................. Page 44-71

Wiring Diagram & Schematic ................................................................................................ Page 72-74

DAILY MAINTENANCE BY THE OPERATOR