Page 1

John Deere K Series

Air-Cooled

Engines

John Deere Horicon Works

CTM5 (20OCT92)

LITHO IN U.S.A.

ENGLISH

Page 2

FOREWORD

Introduction

This manual is written for an experienced technician.

Essential tools required in performing certain service

work are identified in this manual and are

recommended for use.

Live with safety: Read the safety messages in the

General Information Section of this manual and the

cautions presented throughout the text of the manual.

This is the safety-alert symbol. When you see

N

this symbol on the machine or in this manual,

be alert to the potential for personal injury.

Use this component technical manual in conjunction

with the machine technical manual. An application

listing in the beginning of each section identifies

product-model/component type-model relationship.

See the machine technical manual for information on

component removal and installation, and gaining

access to the components.

Information is organized in groups for the various

components requiring service instruction. At the

beginning of each group are summary listings of all

applicable essential tools, other materials needed to

do the job, and service parts kits.

Group 00, in the beginning of each section—Repair

Specifications, consist of all applicable specifications,

wear tolerances and specific torque values for various

components on each engine.

Binders, binder labels, and tab sets can be ordered

by John Deere dealers direct from the John Deere

Distribution Service Center.

This manual is part of a total product support

program.

FOS MANUALS—REFERENCE

TECHNICAL MANUALS—MACHINE SERVICE

COMPONENT MANUALS—COMPONENT SERVICE

Fundamentals of Service (FOS) Manuals cover basic

theory of operation, fundamentals of troubleshooting,

general maintenance, and basic type of failures and

their causes. FOS Manuals are for training new

personnel and for reference by experienced

technicians.

Technical Manuals are concise guides for specific

machines. Technical manuals are on-the-job guides

containing only the vital information needed for

diagnosis, analysis, testing, and repair.

Component Technical Manuals are concise service

guides for specific components. Component technical

manuals are written as stand-alone manuals covering

multiple machine applications.

MX,CTMIFC,A1 -19-21OCT92

CTM5 (20OCT92) K Series Air Cooled Engine

220596

PN=3

Page 3

Dealer Presentation Sheet

JOHN DEERE DEALERS

This is a complete revision to CTM5.

Discard your old CTM5, dated 26 JUN 91.

New information added to this manual includes:

1. The basic engine specifications have been updated to

include the new FC400V, 12.5 hp engine.

2. The engine applications charts have been updated to

include the new products introduced in 1992:

• 14ST and 14PT 21-Inch Walk-Behind Mowers

• 38-Inch Walk-Behind Commercial Mower

• GX95 Riding Mower

• 245 Lawn and Garden Tractor

• GT242 Lawn and Garden Tractor

• Gator 4 X 2

MX,CTM5,DPS -19-21OCT92

CTM5 (20OCT92) K Series Air Cooled Engine

220596

PN=4

Page 4

Dealer Presentation Sheet

CTM5 (20OCT92) K Series Air Cooled Engine

220596

PN=5

Page 5

Contents

SECTION 10—GENERAL INFORMATION

Group 05—Safety

Group 10—General Specifications

Group 15—Serial Number Locations

Group 20—Features

SECTION 20—FA130D and FA210D

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems—FA130D

Group 06—Fuel and Air Systems—FA210D

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems—FA130D

Group 31—Starting Systems—FA210D

SECTION 21—FA210V

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

SECTION 30—FC150V

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head and Valves

Group 20—Cylinder Block and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

SECTION 35—KF82D/FZ340D

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

SECTION 40—FC290V/FC400V/FC420V/FC540V

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head and Valves

Group 20—Cylinder Block and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

10

20

21

25

30

35

SECTION 45—FE290D and FE290R

SECTION 25—FG150G/FG150D

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

All information, illustrations and specifications in this manual are based on

the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

CTM5-19-20OCT92

CTM5 (20OCT92) i K Series Air Cooled Engine

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head and Valves

Group 20—Cylinder Block and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

Continued on next page

COPYRIGHT© 1992

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTION™ Manual

Copyright 1991, 1989, 1988, 1987 Deere & Company

All rights reserved

Previous Editions

220596

PN=506

40

45

50

100

Page 6

SECTION 50—FB460V

10

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

20

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

SECTION 100—COMPONENT ANALYSIS AND

21

Group 05—Valves

Group 10—Piston, Piston Rings, Crankshaft and

Group 15—Cylinder Block

GENERAL REPAIR

Connecting Rod

25

Index

Contents

30

35

40

45

50

100

CTM5 (20OCT92) ii K Series Air Cooled Engine

220596

PN=507

Page 7

Contents

SECTION 10—GENERAL INFORMATION

Group 05—Safety

Group 10—General Specifications

Group 15—Serial Number Locations

Group 20—Features

SECTION 20—FA130D and FA210D

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems—FA130D

Group 06—Fuel and Air Systems—FA210D

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems—FA130D

Group 31—Starting Systems—FA210D

SECTION 21—FA210V

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

SECTION 30—FC150V

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head and Valves

Group 20—Cylinder Block and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

SECTION 35—KF82D/FZ340D

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

SECTION 40—FC290V/FC400V/FC420V/FC540V

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head and Valves

Group 20—Cylinder Block and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

10

20

21

25

30

35

SECTION 45—FE290D and FE290R

SECTION 25—FG150G/FG150D

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

All information, illustrations and specifications in this manual are based on

the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

CTM5-19-20OCT92

CTM5 (20OCT92) i K Series Air Cooled Engine

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head and Valves

Group 20—Cylinder Block and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

Continued on next page

COPYRIGHT© 1992

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTION™ Manual

Copyright 1991, 1989, 1988, 1987 Deere & Company

All rights reserved

Previous Editions

220596

PN=506

40

45

50

100

Page 8

SECTION 50—FB460V

10

Group 00—Engine Application and Repair

Specifications

Group 05—Fuel and Air Systems

Group 10—Blower Housing and Flywheel

Group 15—Cylinder Head

20

Group 20—Cylinder Block, Valves and Internal

Components

Group 25—Ignition and Charging System

Group 30—Starting Systems

SECTION 100—COMPONENT ANALYSIS AND

21

Group 05—Valves

Group 10—Piston, Piston Rings, Crankshaft and

Group 15—Cylinder Block

GENERAL REPAIR

Connecting Rod

25

Index

Contents

30

35

40

45

50

100

CTM5 (20OCT92) ii K Series Air Cooled Engine

220596

PN=507

Page 9

Contents

INDX

CTM5 (20OCT92) iii K Series Air Cooled Engine

220596

PN=508

Page 10

Contents

INDX

CTM5 (20OCT92) iii K Series Air Cooled Engine

220596

PN=508

Page 11

INDX

Contents

CTM5 (20OCT92) iv K Series Air Cooled Engine

220596

PN=509

Page 12

GENERAL INFORMATION

Page

Group 05—Safety . . . . . . . . . . . . . . . . 10-05-1

Group 10—General Specifications

Basic Engine Specifications . . . . . . . . . . 10-10-1

Basic Engine Applications Chart . . . . . . . 10-10-2

Metric Bolt and Cap Screw Torque

Values . . . . . . . . . . . . . . . . . . . . . . 10-10-4

Group 15—Serial Number Locations

Serial Number Location

Engine . . . . . . . . . . . . . . . . . . . . . . 10-15-2

Carburetor . . . . . . . . . . . . . . . . . . . . 10-15-5

Group 20—Features

Engine Features

FA130D . . . . . . . . . . . . . . . . . . . . . . 10-20-1

FA210D . . . . . . . . . . . . . . . . . . . . . . 10-20-1

FA210V . . . . . . . . . . . . . . . . . . . . . . 10-20-2

FG150G/FG150D . . . . . . . . . . . . . . . 10-20-2

FC150V . . . . . . . . . . . . . . . . . . . . . . 10-20-3

KF82D/FZ340D . . . . . . . . . . . . . . . . . 10-20-3

FC290V . . . . . . . . . . . . . . . . . . . . . . 10-20-4

FC400V . . . . . . . . . . . . . . . . . . . . . . 10-20-4

FC420V . . . . . . . . . . . . . . . . . . . . . . 10-20-5

FC540V . . . . . . . . . . . . . . . . . . . . . . 10-20-5

FE290D/FE290R . . . . . . . . . . . . . . . . 10-20-6

FB460V . . . . . . . . . . . . . . . . . . . . . . 10-20-6

Section 10

10

Contents

CTM5 (20OCT92) 10-1 K Series Air Cooled Engine

220596

PN=486

Page 13

10

Contents

CTM5 (20OCT92) 10-2 K Series Air Cooled Engine

220596

PN=487

Page 14

RECOGNIZE SAFETY INFORMATION

Group 05

Safety

This is the safety-alert symbol. When you see this

symbol on your machine or in this manual, be alert to

the potential for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word—DANGER, WARNING, or CAUTION—is

used with the safety-alert symbol. DANGER identifies the

most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

10

05

1

T81389 -UN-07DEC88

DX,ALERT -19-04JUN90

TS187 -19-30SEP88

DX,SIGNAL -19-09JAN92

HANDLE FLUIDS SAFELY—AVOID FIRES

When you work around fuel, do not smoke or work near

heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not

incinerate or puncture pressurized containers.

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn

spontaneously.

TS227 -UN-23AUG88

DX,FLAME -19-04JUN90

CTM5 (20OCT92) 10-05-1 K Series Air Cooled Engine

220596

PN=6

Page 15

PREPARE FOR EMERGENCIES

10

Be prepared if a fire starts.

05

2

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance

service, hospital, and fire department near your

telephone.

AVOID HARMFUL ASBESTOS DUST

Avoid breathing dust that may be generated when

handling components containing asbestos fibers. Inhaled

asbestos fibers may cause lung cancer.

Components in products that may contain asbestos fibers

are brake pads, brake band and lining assemblies, clutch

plates, and some gaskets. The asbestos used in these

components is usually found in a resin or sealed in

some way. Normal handling is not hazardous as long as

airborne dust containing asbestos is not generated.

Safety

TS291 -UN-23AUG88

DX,FIRE2 -19-04JUN90

TS220 -UN-23AUG88

Avoid creating dust. Never use compressed air for

cleaning. Avoid brushing or grinding material containing

asbestos. When servicing, wear an approved respirator.

A special vacuum cleaner is recommended to clean

asbestos. If not available, apply a mist of oil or water on

the material containing asbestos.

Keep bystanders away from the area.

DX,DUST -19-15MAR91

CTM5 (20OCT92) 10-05-2 K Series Air Cooled Engine

220596

PN=7

Page 16

USE PROPER TOOLS

Safety

Use tools appropriate to the work. Makeshift tools and

procedures can create safety hazards.

Use power tools only to loosen threaded parts and

fasteners.

For loosening and tightening hardware, use the correct

size tools. DO NOT use U.S. measurement tools on

metric fasteners. Avoid bodily injury caused by slipping

wrenches.

Use only service parts meeting John Deere

specifications.

DISPOSE OF WASTE PROPERLY

Improperly disposing of waste can threaten the

environment and ecology. Potentially harmful waste used

with John Deere equipment include such items as oil,

fuel, coolant, brake fluid, filters, and batteries.

10

05

3

TS779 -UN-08NOV89

DX,REPAIR -19-04JUN90

Use leakproof containers when draining fluids. Do not

use food or beverage containers that may mislead

someone into drinking from them.

Do not pour waste onto the ground, down a drain, or

into any water source.

Air conditioning refrigerants escaping into the air can

damage the Earth’s atmosphere. Government regulations

may require a certified air conditioning service center to

recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste

from your local environmental or recycling center, or from

your John Deere dealer.

TS1133 -UN-26NOV90

DX,DRAIN -19-09AUG91

CTM5 (20OCT92) 10-05-3 K Series Air Cooled Engine

220596

PN=8

Page 17

10

05

4

Safety

CTM5 (20OCT92) 10-05-4 K Series Air Cooled Engine

220596

PN=9

Page 18

BASIC ENGINE SPECIFICATIONS

Group 10

General Specifications

ENGINE FA130D FG150D/ FC150V FA210D FA210V KF82D/

FG150G FZ340D

CYLINDER 1 1 1 1 1 1

CYCLE 4 4 4 4 4 4

BORE 62 mm 64 mm 65 mm 72 mm 72 mm 80 mm

(2.44 in.) (2.51 in.) (2.56 in.) (2.83 in.) (2.83 in.) (3.15 in.)

STROKE 43 mm 47 mm 46 mm 51 mm 51 mm 68 mm

(1.69 in.) (1.85 in.) (1.81 in.) (2.01 in.) (2.01 in.) (2.68 in.)

DISPLACE- 129 cm

3

151 cm

3

153 cm

3

207 cm

3

207 cm

3

341 cm

3

MENT (7.92 cu. in.) (9.21 cu. in.) (9.30 cu. in.) (12.7 cu. in.) (12.7 cu. in.) (20.9 cu. in.)

HORSE- 2.3 kW 2.7 kW 3.4 kW 3.9 kW 4.5 kW 6.3 kW

POWER (3.1 HP) (3.6 HP) (4.5 HP) (5.2 HP) (6 HP) (8.5 HP)

ENGINE FC290V FE290D/ FB460V FC400V FC420V FC540V

FE290R

CYLINDER 1 1 1 1 1 1

10

10

1

CYCLE 4 4 4 4 4 4

BORE 78 mm 78 mm 89 mm 87 mm 89 mm 89 mm

(3.07 in.) (3.07 in.) (3.50 in.) (3.43 in.) (3.50 in.) (3.50 in.)

STROKE 60 mm 60 mm 74 mm 68 mm 68 mm 86 mm

(2.36 in.) (2.36 in.) (2.91 in.) (2.68 in.) (2.68 in.) (3.39 in.)

DISPLACE- 286 cm

3

286 cm

3

460 cm

3

400 cm

3

423 cm

3

535 cm

3

MENT (17.5 cu. in.) (17.5 cu. in.) (28.1 cu. in.) (24.4 cu. in.) (25.8 cu. in.) (32.6 cu. in.)

HORSE- 6.7 kW 7.5 kW 9.3 kW 9.3 kW 10.4 kW 12.7 kW

POWER (9 HP) (10 HP) (12.5 HP) (12.5 HP) (14 HP) (17 HP)

MX,1010A1,A1 -19-21OCT92

CTM5 (20OCT92) 10-10-1 K Series Air Cooled Engine

220596

PN=10

Page 19

General Specifications/Basic Engine Applications Chart

BASIC ENGINE APPLICATIONS CHART

10

Refer to the engine application chart to identify

10

product-model/engine type-model relationship.

2

WALK-BEHIND PRODUCTS

Machine Engine Model No.

20SR7 Reel Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA130D

3K Lawn Edger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA130D

E35 Lawn Edger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA130D

14PB 21-Inch Rear Discharge Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC150V

14SB 21-Inch Rear Discharge Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC150V

14SE 21-Inch Rear Discharge Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC150V

14SC 21-Inch Rear Discharge Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC150V

14ST 21-Inch Rear Discharge Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC150V

14PT 21-Inch Rear Discharge Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC150V

32/36/48/52-Inch Commercial Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FB460V

48/52-Inch Commercial Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC540V

48/54-Inch Commercial Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC420V or FC540V

38-Inch Commercial Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC400V

RIDING MOWERS

Machine Engine Model No.

RX63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA210V

RX73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC290V

RX75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC290V

RX95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FB460V

SX75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC290V

SX95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FB460V

GX70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC290V

GX75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC290V

SRX75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC290V

SRX95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FB460V

GX95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FB460V

LAWN TRACTORS

Machine Engine Model No.

112L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FB460V

130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC290V

160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FB460V

165 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FB460V

170 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC420V

175 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC420V

180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC540V

185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC540V

LX172 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC420V

LX176 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC420V

LX186 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC540V

MX,1010A1,A2 -19-21OCT92

CTM5 (20OCT92) 10-10-2 K Series Air Cooled Engine

220596

PN=11

Page 20

General Specifications/Basic Engine Applications Chart

BASIC ENGINE APPLICATIONS

CHART—CONTINUED

LAWN AND GARDEN TRACTORS

Machine Engine Model No.

240 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC420V

245 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC420V

260 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC540V

265 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC540V

GT262 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC540V

GT242 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC420V

FRONT MOWERS

Machine Engine Model No.

F710 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FC540V

GOLF AND TURF EQUIPMENT

10

10

3

Machine Engine Model No.

22 Greensmower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FG150G

22R Greensmower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FG150D

519 Walk-Behind Vertical Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA210D

529 Vacuum Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA210D

1200 Bunker and Field Rake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FE290R

MISCELLANEOUS

Machine Engine Model No.

1000 Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA130D

1400 Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA130D

Power Pak Material Collection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA210D

UTILITY VEHICLES

Machine Engine Model No.

AMT600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . KF82D/FZ340D

AMT622 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FE290D

AMT626 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FE290D

Gator 4x2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FE290D

MX,1010A1,A3 -19-21OCT92

CTM5 (20OCT92) 10-10-3 K Series Air Cooled Engine

220596

PN=12

Page 21

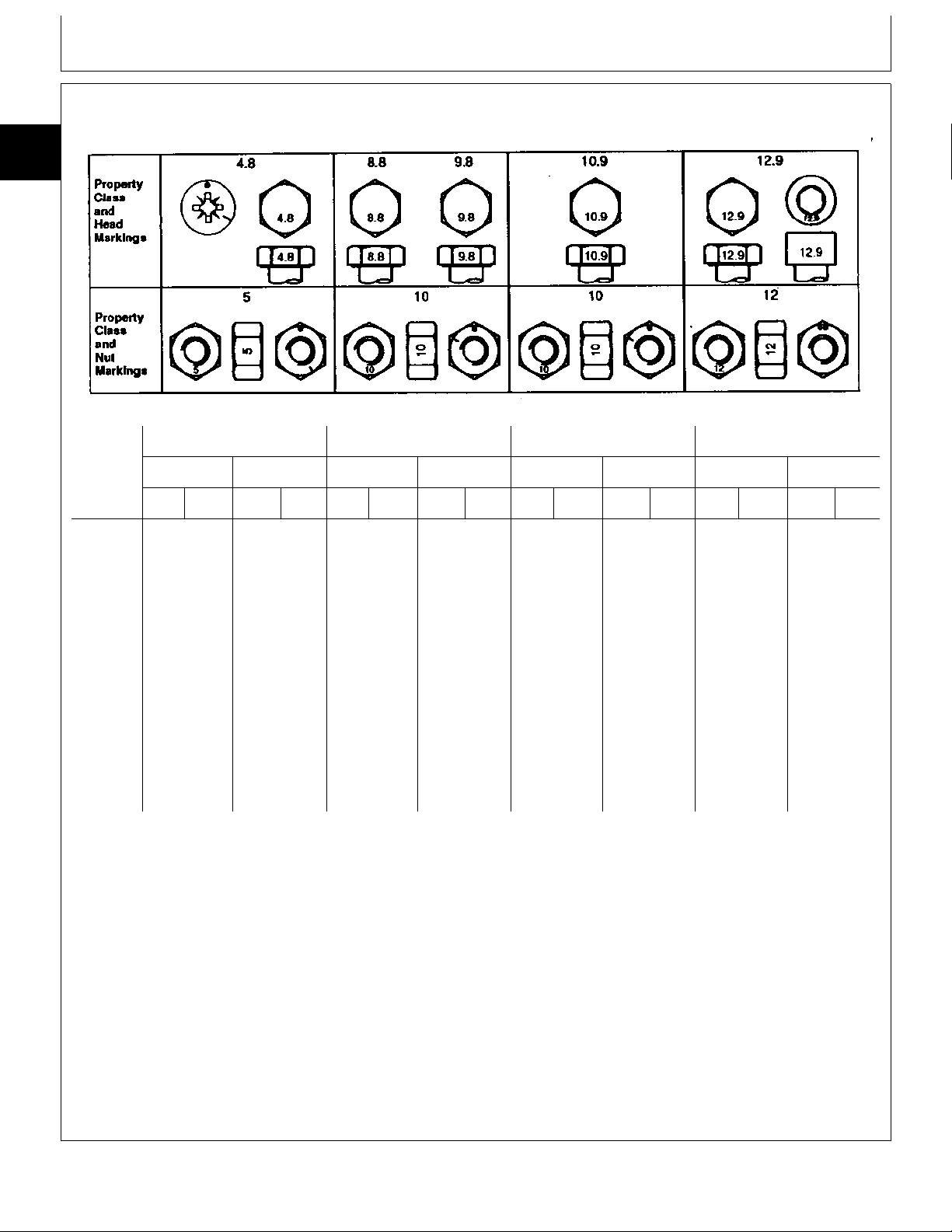

General Specifications/Metric Bolt and Cap Screw Torque Values

METRIC BOLT AND CAP SCREW TORQUE VALUES

10

10

4

Class 4.8 Class 8.8 or 9.8 Class 10.9 Class 12.9

TS1163 -19-04MAR91

Size Lubricated

N·m lb-ft N·m lb-ft N·m lb-ft N·m lb-ft N·m lb-ft N·m lb-ft N·m lb-ft N·m lb-ft

M6 4.8 3.5 6 4.5 9 6.5 11 8.5 13 9.5 17 12 15 11.5 19 14.5

M8 12 8.5 15 11 22 16 28 20 32 24 40 30 37 28 47 35

M10 23 17 29 21 43 32 55 40 63 47 80 60 75 55 95 70

M12 40 29 50 37 75 55 95 70 110 80 140 105 130 95 165 120

M14 63 47 80 60 120 88 150 110 175 130 225 165 205 150 260 190

M16 100 73 125 92 190 140 240 175 275 200 350 225 320 240 400 300

M18 135 100 175 125 260 195 330 250 375 275 475 350 440 325 560 410

M20 190 140 240 180 375 275 475 350 530 400 675 500 625 460 800 580

M22 260 190 330 250 510 375 650 475 725 540 925 675 850 625 1075 800

M24 330 250 425 310 650 475 825 600 925 675 1150 850 1075 800 1350 1000

M27 490 360 625 450 950 700 1200 875 1350 1000 1700 1250 1600 1150 2000 1500

M30 675 490 850 625 1300 950 1650 1200 1850 1350 2300 1700 2150 1600 2700 2000

M33 900 675 1150 850 1750 1300 2200 1650 2500 1850 3150 2350 2900 2150 3700 2750

M36 1150 850 1450 1075 2250 1650 2850 2100 3200 2350 4050 3000 3750 2750 4750 3500

a

DO NOT use these values if a different torque value

or tightening procedure is given for a specific

application. Torque values listed are for general use

Dry

a

Lubricated

a

Dry

a

Lubricated

a

Dry

a

Lubricated

a

Dry

a

Make sure fasteners threads are clean and that you

properly start thread engagement. This will prevent

them from failing when tightening.

only. Check tightness of fasteners periodically.

Tighten plastic insert or crimped steel-type lock nuts

Shear bolts are designed to fail under predetermined

loads. Always replace shear bolts with identical

property class.

to approximately 50 percent of the dry torque shown

in the chart, applied to the nut, not to the bolt head.

Tighten toothed or serrated-type lock nuts to the full

torque value.

Fasteners should be replaced with the same or

higher property class. If higher property class

fasteners are used, these should only be tightened to

the strength of the original.

a

“Lubricated” means coated with a lubricant such as engine oil, or

fasteners with phosphate and oil coatings. “Dry” means plain or zinc

plated without any lubrication.

DX,TORQ2 -19-16APR92

CTM5 (20OCT92) 10-10-4 K Series Air Cooled Engine

220596

PN=13

Page 22

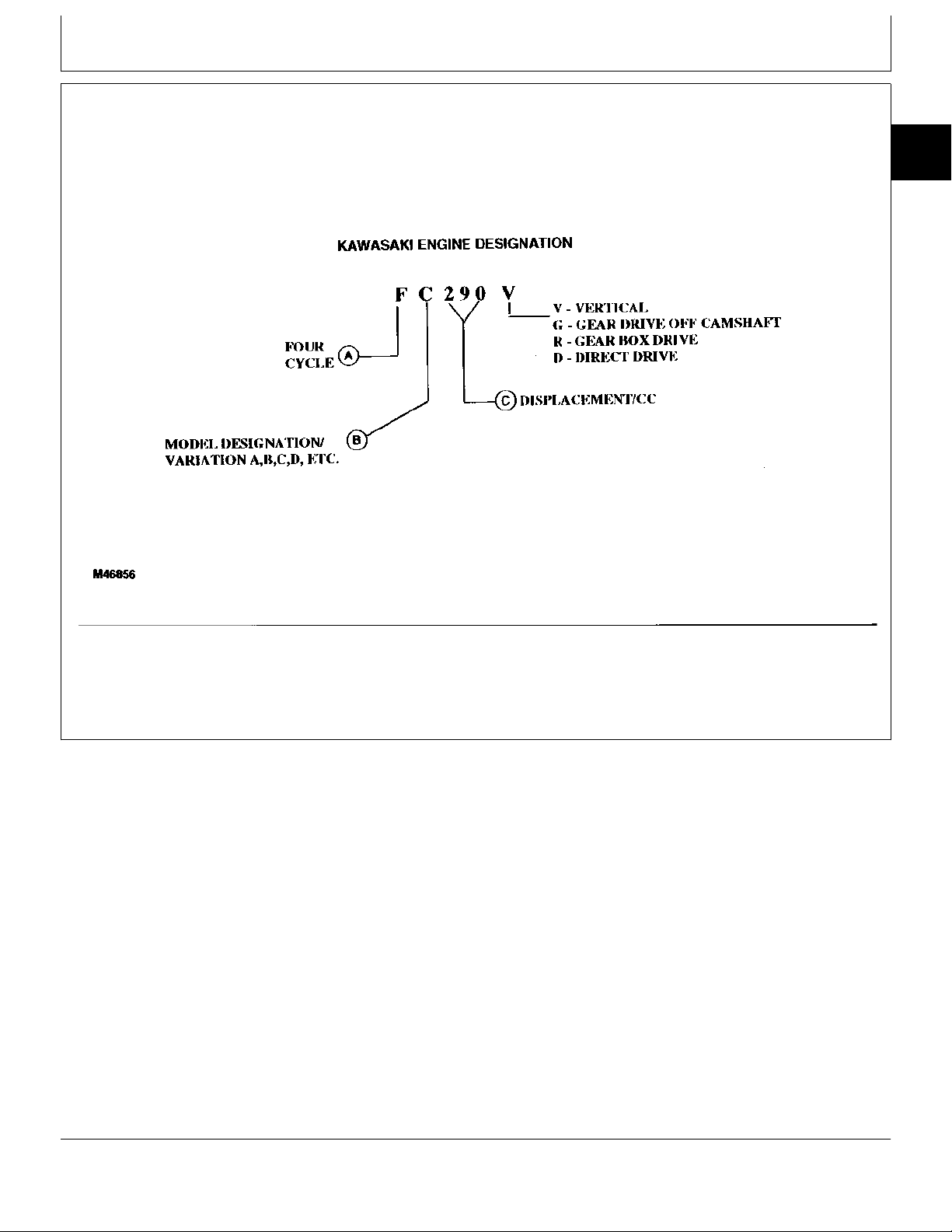

ENGINE DESIGNATION (KAWASAKI)

Group 15

Serial Number Locations

10

15

1

A—Four Cycle C—Displacement R—Gear Box Drive V—Vertical

B—Model Designation D—Direct Drive G—Gear Drive Off Camshaft

MX1020A1,A12 -19-21OCT92

M46856 -19-15OCT92

CTM5 (20OCT92) 10-15-1 K Series Air Cooled Engine

220596

PN=14

Page 23

Serial Number Locations/Serial Number Location

ENGINE SERIAL NUMBER LOCATION

10

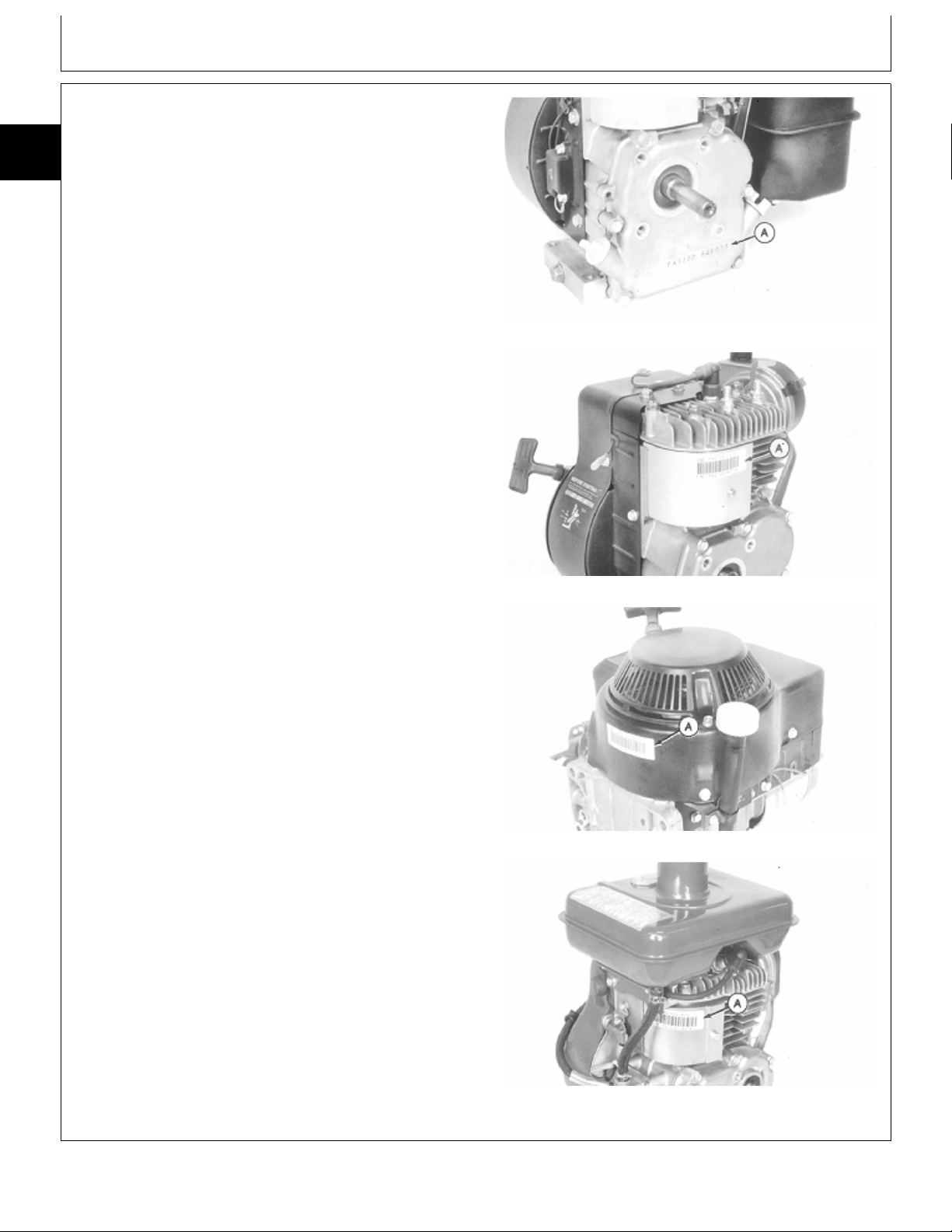

The complete serial number (A) is used to identify the

15

engine model, series, configuration, and serial number

2

range. Have this number available when referring to a

particular engine or requesting parts or service

information.

M80492 -UN-07JUN91M80493 -UN-07JUN91M80494 -UN-07JUN91M80495 -UN-07JUN91

FA130D

FA210D

FA210V

FG150D/FG150G

MX,1015A1,A1 -19-21OCT92

CTM5 (20OCT92) 10-15-2 K Series Air Cooled Engine

220596

PN=15

Page 24

Serial Number Locations/Serial Number Location

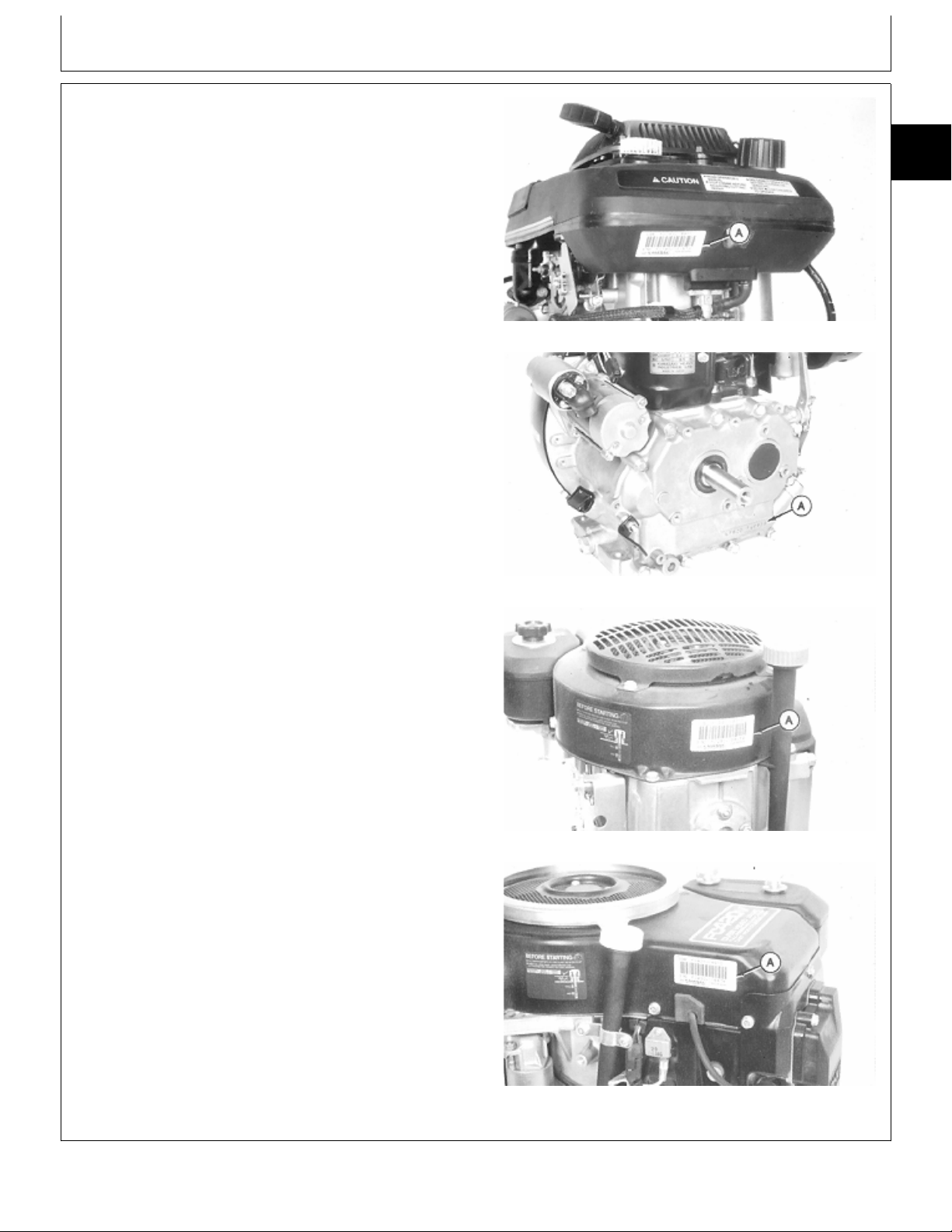

SERIAL NUMBER LOCATION—CONTINUED

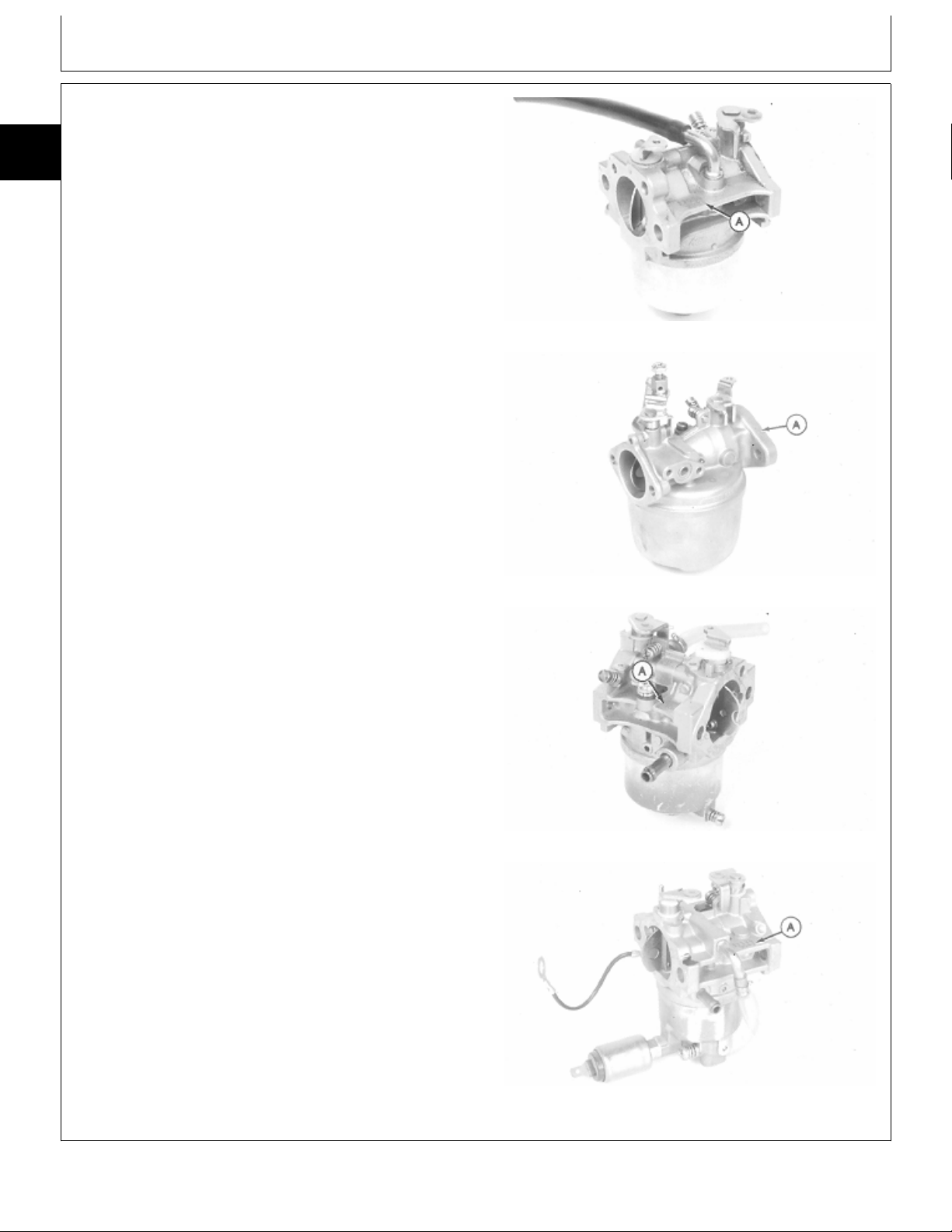

A—Serial Number Location

10

15

3

M80496 -UN-07JUN91M80497 -UN-07JUN91M80498 -UN-07JUN91M80499 -UN-07JUN91

FC150V

KF82D/FZ340D

FC290V

FC400V/FC420V

MX,1015A1,A2 -19-21OCT92

CTM5 (20OCT92) 10-15-3 K Series Air Cooled Engine

220596

PN=16

Page 25

Serial Number Locations/Serial Number Location

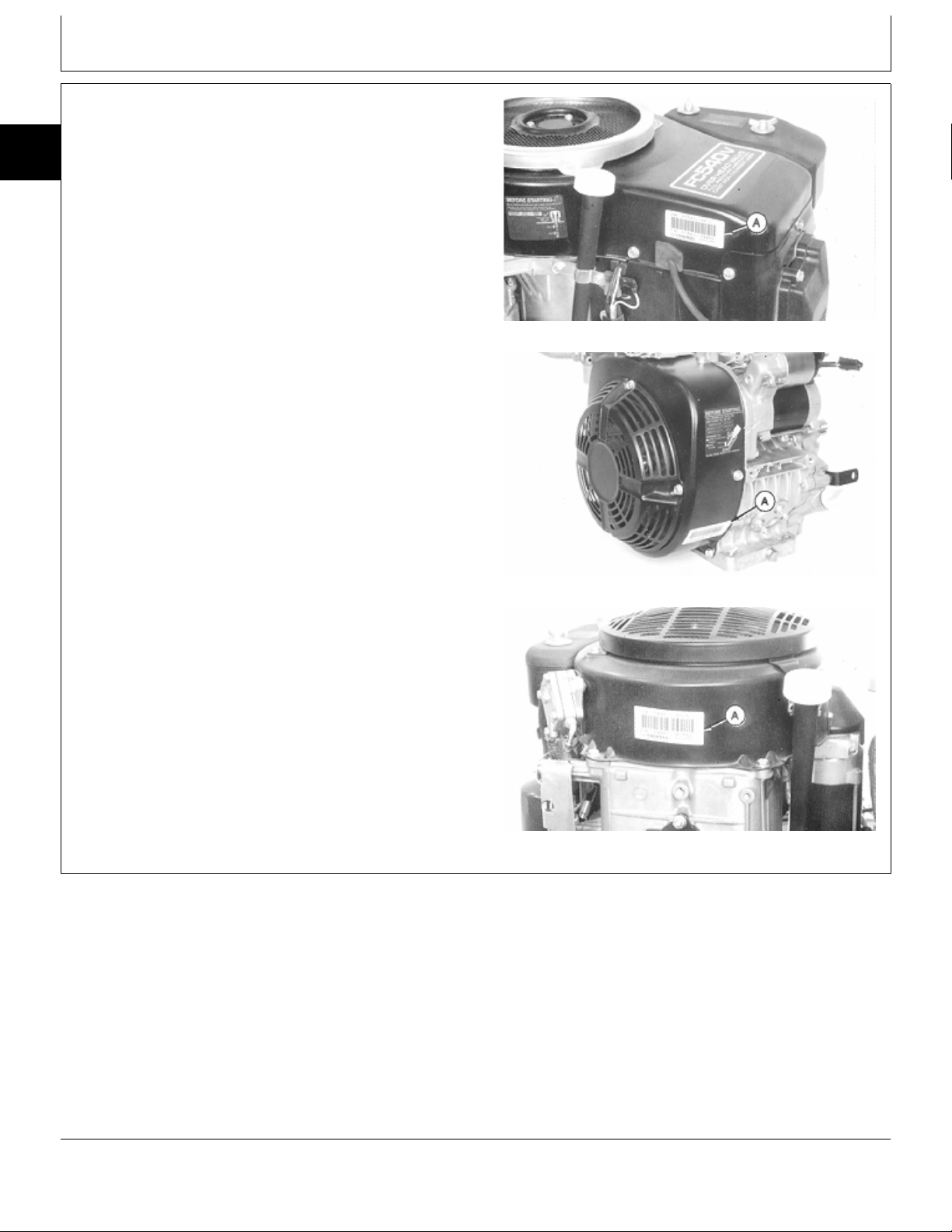

SERIAL NUMBER LOCATION—CONTINUED

10

15

4

A—Serial Number Location

M80500 -UN-07JUN91M80501 -UN-07JUN91M80502 -UN-07JUN91

FC540V

FE290D/FE290R

FB460V

MX,1015A1,A3 -19-21OCT92

CTM5 (20OCT92) 10-15-4 K Series Air Cooled Engine

220596

PN=17

Page 26

Serial Number Locations/Serial Number Location

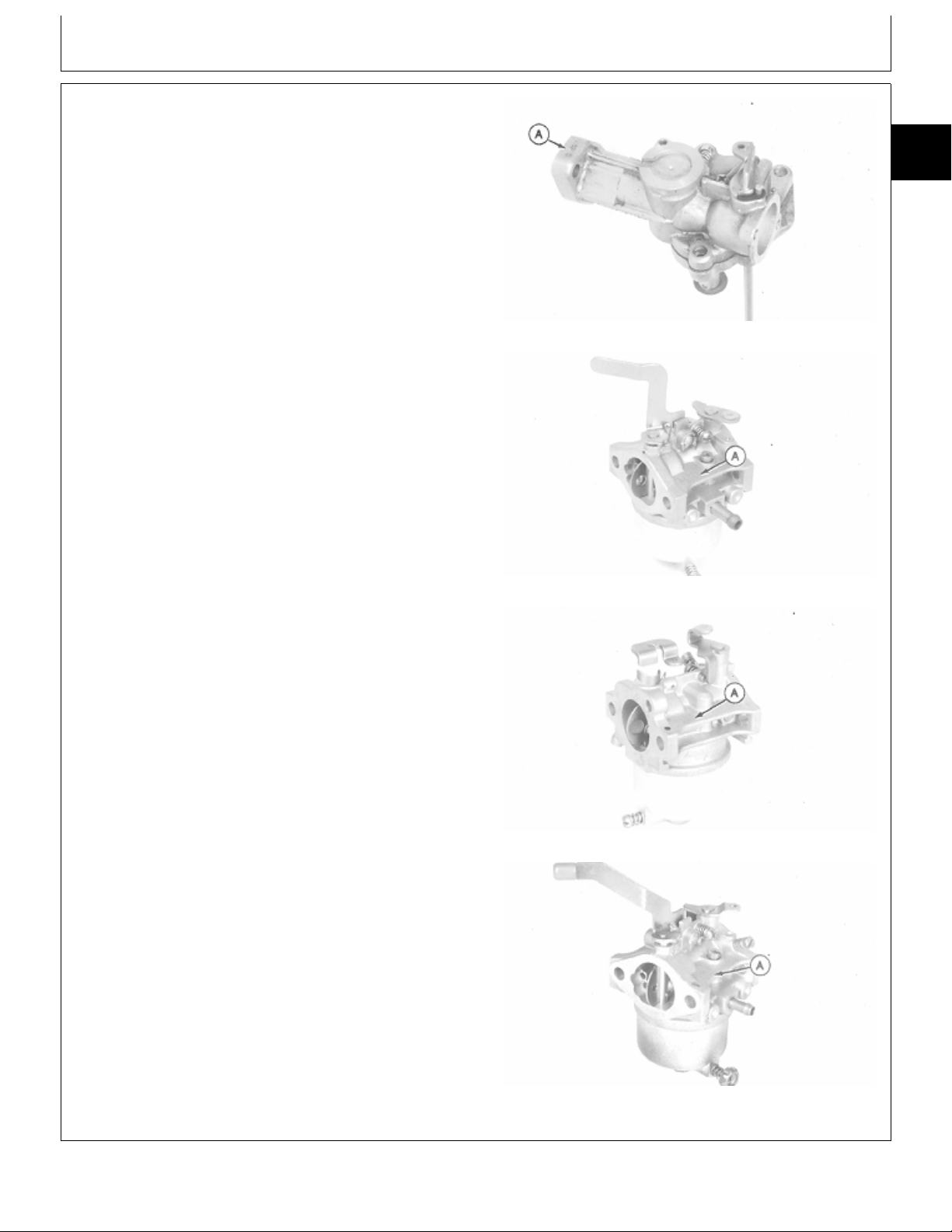

CARBURETOR SERIAL NUMBER LOCATION

NOTE: FA130D carburetor shown is used on

FA130D-AS16/AS19 and FA210D-AS20 engines.

FA130D-AN00 carburetor not shown.

FA210D carburetor shown is used on

FA210D-AS17/BS17/CS17 engines.

FA210D-AS19-01 carburetor not shown.

The serial number (A) is used to identify the carburetor.

Have this number available when requesting parts or

service information.

10

15

5

M80503 -UN-07JUN91M80504 -UN-07JUN91M80505 -UN-07JUN91M80506 -UN-07JUN91

FA130D

FA210D

FA210V

FG150G/FG150D

MX,1015A1,A4 -19-21OCT92

CTM5 (20OCT92) 10-15-5 K Series Air Cooled Engine

220596

PN=18

Page 27

CARBURETOR SERIAL NUMBER

LOCATION—CONTINUED

10

15

6

A—Serial Number Location

Serial Number Locations/Serial Number Location

M80507 -UN-07JUN91M80508 -UN-07JUN91M80509 -UN-07JUN91M80510 -UN-07JUN91

FC150V

KF82D/FZ340D

FC290V

FC400V/FC420V

MX,1015A1,A5 -19-21OCT92

CTM5 (20OCT92) 10-15-6 K Series Air Cooled Engine

220596

PN=19

Page 28

Serial Number Locations/Serial Number Location

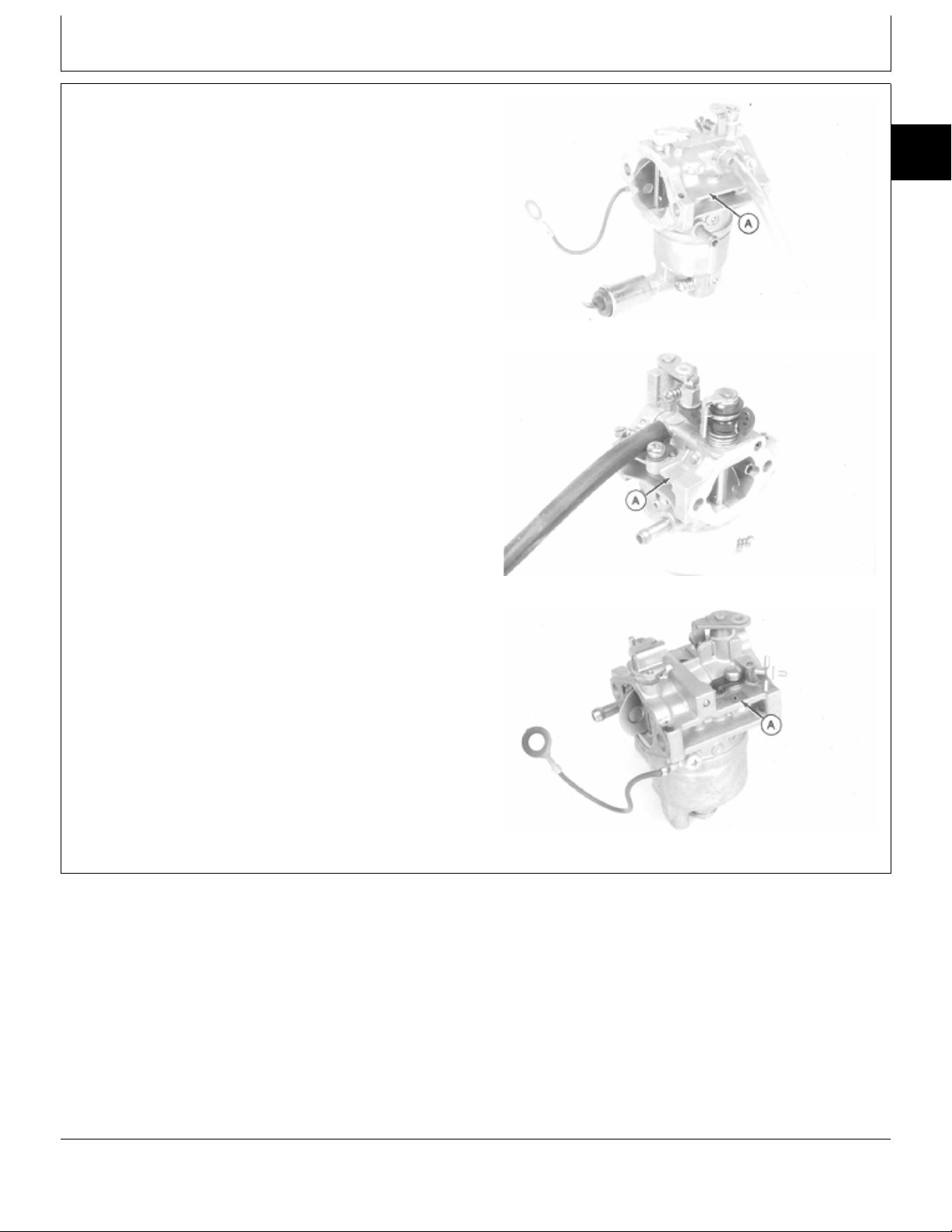

CARBURETOR SERIAL NUMBER

LOCATION—CONTINUED

A—Serial Number Location

10

15

7

M80511 -UN-07JUN91M80512 -UN-07JUN91M80513 -UN-07JUN91

FC540V

FE290D/FE290R

FB460V

MX,1015A1,A6 -19-21OCT92

CTM5 (20OCT92) 10-15-7 K Series Air Cooled Engine

220596

PN=20

Page 29

10

15

8

Serial Number Locations/Serial Number Location

CTM5 (20OCT92) 10-15-8 K Series Air Cooled Engine

220596

PN=21

Page 30

FA130D ENGINE FEATURES

Group 20

Features

•2.3 kW (3.1 hp)

•Pulse Pump carburetor (FA130D-AS16/AS19)

Float type carburetor (FA130D-AN00)

•Two stage air filter with dry paper filter

and foam precleaner (FA130D-AS16)

Single stage foam air filter (FA130D-AN00)

•Side valves

•Horizontal crankshaft

•Aluminum block

•Splash lubrication

•Low oil level sensor (FA130D-AN00)

•Electronic ignition

•Recoil starter

FA210D ENGINE FEATURES

•3.9 kW (5.2 hp)

•Fuel pump (FA210D-AS17/BS17/CS17)

•Pulse pump carburetor (FA210D-AS20)

Float type carburetor

(FA210D-AS17/BS17/CS17 & FA210D-AS19-01)

•Two stage air filter with dry paper

filter and foam precleaner

•Side valves

•Compression release mechanism

(FA210D-AS20)

•Horizontal crankshaft

•Aluminum block

•Splash lubrication

•Electronic ignition

•Recoil starter

10

20

1

M80514 -UN-07JUN91

MX,1020A1,A1 -19-21OCT92

M80515 -UN-07JUN91

MX,1020A1,A2 -19-21OCT92

CTM5 (20OCT92) 10-20-1 K Series Air Cooled Engine

220596

PN=22

Page 31

FA210V ENGINE FEATURES

10

•4.5 kW (6 hp)

20

•Float type carburetor

2

•Two stage air filter with dry paper

filter and foam precleaner

•Side valves

•Compression release mechanism

•Vertical crankshaft

•Aluminum block

•Splash lubrication

•Electronic ignition

•Recoil starter

Features/Engine Features

M80516 -UN-07JUN91

MX,1020A1,A3 -19-21OCT92

FG150G/FG150D ENGINE FEATURES

NOTE: Engines are the same except FG150G engine is

camshaft driven and FG150D engine is

crankshaft driven.

•2.7 kW (3.6 hp)

•Float type carburetor

•Two stage air filter with dry paper

filter and foam precleaner

•Side valves

•Horizontal crankshaft

•Aluminum block

•Cast-iron cylinder liner

•Electronic ignition

•Recoil starter

FG150G Shown

M80517 -UN-07JUN91

MX,1020A1,A4 -19-21OCT92

CTM5 (20OCT92) 10-20-2 K Series Air Cooled Engine

220596

PN=23

Page 32

FC150V ENGINE FEATURES

Features/Engine Features

•3.4 kW (4.5 hp)

•3.7 kW (5.0 hp) (FS01 and ES06)

•Float type carburetor

•Two stage air filter with dry paper

filter and foam precleaner

•Flywheel brake (option)

•Overhead valves

•Compression release mechanism

•Vertical crankshaft

•Aluminum block

•Cast-iron cylinder liner

•Splash (AS00 and AS01)

•Full pressure lubrication

•Oil filter (optional)

•Electronic ignition

•Regulated charging system

•Recoil starter

•Electric starter (option)

10

20

3

M80518 -UN-07JUN91

KF82D/FZ340D ENGINE FEATURES

•6.3 kW (8.5 hp)

•Float type carburetor

•Two stage air filter with dry paper

filter and foam precleaner

•Side valves

•Horizontal crankshaft

•Dynamic balancer shaft

•Cast-iron cylinder block

•Aluminum crankcase

•Splash lubrication

•CDI ignition

•Regulated charging system

•Electric starter

MX,1020A1,A5 -19-21OCT92

M80519 -UN-07JUN91

MX,1020A1,A6 -19-21OCT92

CTM5 (20OCT92) 10-20-3 K Series Air Cooled Engine

220596

PN=24

Page 33

FC290V ENGINE FEATURES

10

•6.7 kW (9 hp)

20

•Float type carburetor

4

•Two stage air filter with dry paper

filter and foam precleaner

•Overhead valves

•Compression release mechanism

•Vertical crankshaft with reciprocating

balancer

•Aluminum block

•Cast-iron cylinder liner

•Splash lubrication

•Electronic ignition

•Regulated charging system

•Recoil starter

•Electric starter (optional)

Features/Engine Features

M80213 -UN-19JUN91

MX,1020A1,A7 -19-21OCT92

FC400V ENGINE FEATURES

•9.3 kW (12.5 hp)

•Float type carburetor

•Two stage air-filter with dry paper

filter and foam precleaner

•Overhead valves

•Compression release mechanism

•Vertical crankshaft with reciprocating

balancer

•Aluminum block

•Cast-iron cylinder liner

•Full pressure lubrication

•Oil filter

•Solid-state ignition

•Regulated charging system

•Recoil start

•Electric starter (optional)

M80214 -UN-19JUN91

MX,1020A1,A8 -19-21OCT92

CTM5 (20OCT92) 10-20-4 K Series Air Cooled Engine

220596

PN=25

Page 34

FC420V ENGINE FEATURES

Features/Engine Features

•10.4 kW (14 hp)

•Float type carburetor

•Two stage air-filter with dry paper

filter and foam precleaner

•Overhead valves

•Compression release mechanism

•Vertical crankshaft with reciprocating

balancer

•Aluminum block

•Cast-iron cylinder liner

•Full pressure lubrication

•Oil filter

•Solid-state ignition

•Regulated charging system

•Recoil start

•Electric starter (optional)

FC540V ENGINE FEATURES

•12.6 kW (17 hp)

•13 kW (17.5 hp) (Engine version AS12)

•Float type carburetor

•Two stage air filter with dry paper

filter and foam precleaner

•Overhead valves

•Compression release mechanism

•Vertical crankshaft with reciprocating balancer

•Aluminum block

•Cast-iron cylinder liner

•Full pressure lubrication

•Oil filter

•Solid-state ignition

•Regulated charging system

•Electric starter

10

20

5

M80214 -UN-19JUN91

MX,1020A1,A8A -19-21OCT92

M80215 -UN-19JUN91

MX,1020A1,A9 -19-21OCT92

CTM5 (20OCT92) 10-20-5 K Series Air Cooled Engine

220596

PN=26

Page 35

Features/Engine Features

FE290D/FE290R ENGINE FEATURES

10

NOTE: Engines are the same except, FE290R can be

20

6

•7.5 kW (10 hp)

•Float type carburetor

•Overhead valves

•Compression release mechanism

•Horizontal crankshaft with reciprocating

balancer

•Aluminum block

•Cast-iron cylinder liner

•Full pressure lubrication

•Oil filter (optional)

•Solid-state ignition

•Regulated charging system

•Recoil starter (optional)

•Electric starter

equipped with a reduction gearbox. Gearbox

attaches to crankcase cover.

M80216 -UN-19JUN91

FB460V ENGINE FEATURES

•9.3 kW (12.5 hp)

•Fuel pump

•Float type carburetor

•Two stage air filter with dry paper

filter and foam precleaner

•Side valves

•Compression release mechanism

•Vertical crankshaft with reciprocating

balancer

•Aluminum block

•Cast-iron cylinder liner

•Full pressure lubrication

•Oil filter (optional)

•Electronic ignition

•Regulated charging system

•Recoil starter

•Electric starter (optional)

MX,1020A1,A10 -19-21OCT92

MX,1020A1,A11 -19-21OCT92

CTM5 (20OCT92) 10-20-6 K Series Air Cooled Engine

220596

PN=27

Page 36

Page

Group 00—Engine Application and Repair

Specifications

Engine Application Chart . . . . . . . . . . . . 20-00-1

Repair Specifications

FA130D . . . . . . . . . . . . . . . . . . . . . . 20-00-2

FA210D . . . . . . . . . . . . . . . . . . . . . . 20-00-4

Group 05—Fuel and Air Systems—FA130D

Service Parts Kits . . . . . . . . . . . . . . . . 20-05-1

Remove, Inspect and Install Fuel

Tank—FA130D-AS16/AS19 . . . . . . . . . 20-05-1

Remove and Install Carburetor

FA130D-AS16/AS19 . . . . . . . . . . . . . 20-05-2

FA130D-AN00 . . . . . . . . . . . . . . . . . 20-05-2

Disassemble, Clean, Inspect and

Assemble Carburetor

FA130D-AS16/AS19 . . . . . . . . . . . . . 20-05-3

FA130D-AN00 . . . . . . . . . . . . . . . . . 20-05-4

Service Breather

FA130D-AS16/AS19 . . . . . . . . . . . . . 20-05-5

FA130D-AN00 . . . . . . . . . . . . . . . . . 20-05-6

Service Air Cleaner . . . . . . . . . . . . . . . 20-05-7

Group 06—Fuel and Air Systems—FA210D

Service Parts Kits . . . . . . . . . . . . . . . . 20-06-1

Remove, Inspect and Install Fuel

Tank—FA210D-AS20 . . . . . . . . . . . . . 20-06-1

Remove and Install Fuel

Pump—FA210D-AS17/BS17/CS17 . . . . 20-06-2

Remove and Install Carburetor

FA210D-AS20 . . . . . . . . . . . . . . . . . 20-06-2

FA210D-AS17/BS17/CS17 . . . . . . . . . 20-06-3

FA210D-AS19-01 . . . . . . . . . . . . . . . 20-06-4

Disassemble, Clean, Inspect and

Assemble Carburetor

FA210D-AS20 . . . . . . . . . . . . . . . . . 20-06-5

FA210D-AS19-01/AS17/BS17/CS17 . . . 20-06-6

R & I Intake Manifold -

A210D-AS19-01/AS17/BS17/CS17 . . . . 20-06-10

Service Breather

FA210D-AS20 . . . . . . . . . . . . . . . . . 20-06-10

FA210D-AS19-01 . . . . . . . . . . . . . . . 20-06-11

FA210D-AS17/BS17/CS17 . . . . . . . . . 20-06-11

Service Air Cleaner . . . . . . . . . . . . . . . 20-06-12

Section 20

FA130D and FA210D

Contents

Page

20

Group 10—Blower Housing and Flywheel

Remove and Install Blower Housing

FA130D and FA210D-AS20 . . . . . . . . 20-10-1

FA210D-AS19-01/AS17/BS17/CS17 . . . 20-10-2

Flywheel Screen Adjustment . . . . . . . . . 20-10-2

Remove and Install Flywheel

FA130D and FA210D-AS20 . . . . . . . . 20-10-3

FA210D-AS19-01/AS17/BS17/CS17 . . . 20-10-3

Group 15—Cylinder Head

Other Material . . . . . . . . . . . . . . . . . . . 20-15-1

Remove and Install Cylinder Head . . . . . 20-15-2

Inspect Cylinder Head . . . . . . . . . . . . . . 20-15-3

Group 20—Cylinder Block, Valves and Internal

Components

Other Materials . . . . . . . . . . . . . . . . . . 20-20-1

Service Parts Kits . . . . . . . . . . . . . . . . 20-20-1

Remove and Install Valves and Springs . . 20-20-2

Inspect Valve Springs . . . . . . . . . . . . . . 20-20-3

Inspect Valve Guides . . . . . . . . . . . . . . 20-20-3

Recondition Valve Seats . . . . . . . . . . . . 20-20-4

Check Valve-To-Tappet Clearance . . . . . 20-20-5

Remove and Install Crankcase Cover . . . 20-20-6

Camshaft

Remove and Install . . . . . . . . . . . . . . 20-20-6

Inspect . . . . . . . . . . . . . . . . . . . . . . 20-20-7

Inspect Plain Bearings . . . . . . . . . . . . 20-20-7

Inspect Automatic Compression Release . 20-20-8

Remove, Inspect and Install Tappets . . . . 20-20-8

Piston and Connecting Rod

Remove and Install . . . . . . . . . . . . . . 20-20-9

Disassemble, Inspect and Assemble . . . 20-20-10

Inspect Piston . . . . . . . . . . . . . . . . . . . 20-20-11

Inspect Connecting Rod . . . . . . . . . . . . 20-20-13

Piston Rings

Remove and Install . . . . . . . . . . . . . . 20-20-14

Check End Gap . . . . . . . . . . . . . . . . 20-20-14

Crankshaft

Remove, Inspect and Install . . . . . . . . 20-20-15

Inspect Plain Bearings . . . . . . . . . . . . 20-20-16

Continued on next page

CTM5 (20OCT92) 20-1 K Series Air Cooled Engine

220596

PN=488

Page 37

Crankshaft—Continued

Replace Bearing Shell . . . . . . . . . . . . 20-20-16

Inspect Ball Bearing . . . . . . . . . . . . . 20-20-17

Check Alignment (TIR) . . . . . . . . . . . . 20-20-17

20

Measure End Play . . . . . . . . . . . . . . . 20-20-17

Inspect

Oil Seals . . . . . . . . . . . . . . . . . . . . . 20-20-18

Cylinder Block . . . . . . . . . . . . . . . . . 20-20-18

Rebore Cylinder Block . . . . . . . . . . . . . 20-20-19

Inspect and Replace Oil Splasher . . . . . . 20-20-20

Check Low Oil Level Sensor . . . . . . . . . 20-20-20

Inspect and Replace Governor . . . . . . . . 20-20-21

Inspect and Replace Governor Shaft . . . . 20-20-22

Governor Adjustment

FA130D-AS16/AS19 & FA210D-AS20 . . 20-20-22

FA210D-AS19-01/AS17/BS17/CS17 . . . 20-20-23

Group 25—Ignition and Charging System

Remove and Install Armature with Coil . . 20-25-1

Adjust Armature Air Gap . . . . . . . . . . . . 20-25-1

Replace Ignitor—FA130D and

FA210D-AS20 . . . . . . . . . . . . . . . . . 20-25-2

Contents

Page

Group 30—Starting Systems—FA130D

Recoil Starter—FA130D-AS16/AS19

Disassemble . . . . . . . . . . . . . . . . . . 20-30-1

Inspect . . . . . . . . . . . . . . . . . . . . . . 20-30-2

Replace Spring . . . . . . . . . . . . . . . . . 20-30-3

Assemble . . . . . . . . . . . . . . . . . . . . 20-30-3

Recoil Starter—FA130D-AN00

Disassemble . . . . . . . . . . . . . . . . . . 20-30-4

Inspect . . . . . . . . . . . . . . . . . . . . . . 20-30-6

Replace Spring . . . . . . . . . . . . . . . . . 20-30-7

Assemble . . . . . . . . . . . . . . . . . . . . 20-30-7

Group 31—Starting Systems—FA210D

Recoil Starter

Disassemble . . . . . . . . . . . . . . . . . . 20-31-1

Inspect . . . . . . . . . . . . . . . . . . . . . . 20-31-2

Replace Spring . . . . . . . . . . . . . . . . . 20-31-4

Assemble . . . . . . . . . . . . . . . . . . . . 20-31-4

CTM5 (20OCT92) 20-2 K Series Air Cooled Engine

220596

PN=489

Page 38

Group 00

Engine Application and Repair Specifications

ENGINE APPLICATIONS CHART

Refer to the engine application chart to identify

product-model/engine type-model relationship.

Machine Engine Model No.

3K Lawn Edger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA130D-AS16

E35 Lawn Edger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA130D-AS19

1000/1400 Generators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA130D-AN00

20SR7 Reel Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA130D-AS16

519 Walk-Behind Vertical Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA210D-AS20

529 Vacuum Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA210D-AS19-01

Power Pak Material Collection System

(Engine S.N. —254693) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA210D-AS17

(Engine S.N. 254694—289197) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA210D-BS17

(Engine S.N. 289198— ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FA210D-CS17

MX,2000A1,A1 -19-21OCT92

20

00

1

CTM5 (20OCT92) 20-00-1 K Series Air Cooled Engine

220596

PN=28

Page 39

Engine Application and Repair Specifications/Repair Specifications

FA130D REPAIR SPECIFICATIONS

GROUP 10—BLOWER HOUSING AND FLYWHEEL

Item Specification

Flywheel Nut Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 N·m (44 lb-ft)

20

GROUP 15—CYLINDER HEAD

00

2

Cylinder Head

Maximum Cylinder Head Warp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm (0.010 in.)

Cap Screw Torque In Sequence

Initial Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 N·m (89 lb-in.)

Final Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 N·m (186 lb-in.)

Spark Plug Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 N·m (156 lb-in.)

GROUP 20—CYLINDER BLOCK, VALVES AND INTERNAL COMPONENTS

Valve Clearance (cold)

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.12—0.18 mm (0.005—0.007 in.)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10—0.34 mm (0.004—0.013 in.)

Valves and Springs

Minimum Spring Free Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.50 mm (0.930 in.)

Maximum Valve Guide I.D.

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.10 mm (0.2401 in.)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.09 mm (0.2397 in.)

Minimum Valve Stem Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.95 mm (0.234 in.)

Valve Clearance (cold)

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.12—0.18 mm (0.005—0.007 in.)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10—0.34 mm (0.004—0.013 in.)

Valves and Springs

Minimum Spring Free Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.50 mm (0.930 in.)

Maximum Valve Guide I.D.

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.10 mm (0.2401 in.)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.09 mm (0.2397 in.)

Minimum Valve Stem Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.95 mm (0.234 in.)

Maximum Valve Stem Bend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03 mm (0.001 in.)

Valve Seating Surface Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45˚

Valve Seating Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.00—1.60 mm (0.039—0.063 in.)

Valve Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.60 mm (0.020 in.)

Valve Narrowing Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30˚

Continued on next page

MX,2000A1,A2 -19-21OCT92

CTM5 (20OCT92) 20-00-2 K Series Air Cooled Engine

220596

PN=29

Page 40

Engine Application and Repair Specifications/Repair Specifications

GROUP 20—CYLINDER BLOCK, VALVES AND INTERNAL COMPONENTS—CONTINUED

Item Specification

Crankcase Cover

Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 L (1.06 pt)

Cap Screw Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 N·m (53 lb-in.)

Drain Plug Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 N·m (121 lb-in.)

Camshaft

Minimum End Journals O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.94 mm (0.469 in.)

Minimum Lobe Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.25 mm (0.915 in.)

Maximum Cover and Crankcase Bearing I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.04 mm (0.474 in.)

Piston

Maximum Ring Groove Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15 mm (0.006 in.)

Minimum Ring End Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.18 mm (0.007 in.)

Maximum Ring End Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.00 mm (0.039 in.)

Minimum Pin O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.98 mm (0.511 in.)

Maximum Pin Bore I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.04 mm (0.513 in.)

Maximum Piston-to-Piston Pin Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm (0.002 in.)

Minimum Piston O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61.86—61.89 mm (2.435—2.437 in.)

Piston-to-Cylinder Bore Clearance

Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm (0.0098 in.)

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.087—0.137 mm (0.0034—0.0054 in.)

Connecting Rod

Maximum Crankshaft Bearing I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.05 mm (0.947 in.)

Maximum Piston Pin Bearing I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.04 mm (0.513 in.)

Maximum Connecting Rod-to-Piston Pin Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm (0.002 in.)

Maximum Connecting Rod-to-Crankpin Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10 mm (0.004 in.)

End-Cap Screw Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 N·m (106 lb-in.)

20

00

3

Crankshaft

Minimum Flywheel Side Journal O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.97 mm (0.865 in.)

Minimum Connecting Rod Journal O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.95 mm (0.943 in.)

Maximum Crankcase Plain Bearing I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.10 mm (0.869 in.)

Maximum T.I.R. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm (0.002 in.)

End Play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0—0.30 mm (0—0.012 in.)

PTO Side Oil Seal Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 mm (0.158 in.)

Cylinder Bore

Standard Cylinder Bore I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61.90—62.00 mm (2.439—2.443 in.)

Maximum Cylinder Bore I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62.07 mm (2.446 in.)

Low Oil Level Sensor Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.50—15.50 mm (0.374—0.610 in.)

GROUP 25—IGNITION AND CHARGING SYSTEM

Ignition Coil Air Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.50 mm (0.019 in.)

See Ignition Tests in this Group.

MX,2000A1,A3 -19-21OCT92

CTM5 (20OCT92) 20-00-3 K Series Air Cooled Engine

220596

PN=30

Page 41

Engine Application and Repair Specifications/Repair Specifications

FA210D REPAIR SPECIFICATIONS

GROUP 10—BLOWER HOUSING AND FLYWHEEL

Item Specification

Flywheel Nut Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 N·m (44 lb-ft)

20

Flywheel Screen Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1—3 mm (0.039—0.118 in.)

00

4

GROUP 15—CYLINDER HEAD

Cylinder Head

Maximum Cylinder Head Warp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 mm (0.015 in.)

Cap Screw Torque In Sequence

Initial Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 N·m (89 lb-ft)

Final Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 N·m (186 lb-in)

Spark Plug Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 N·m (212 lb-in.)

GROUP 20—CYLINDER BLOCK, VALVES AND INTERNAL COMPONENTS

Valve Clearance (cold)

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.12—0.18 mm (0.005—0.007 in.)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.12—0.34 mm (0.005—0.013 in.)

Valves and Springs

Minimum Spring Free Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.50 mm (0.930 in.)

Maximum Valve Guide I.D.

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.10 mm (0.240 in.)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.13 mm (0.242 in.)

Maximum Valve Stem Bend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03 mm (0.001 in.)

Valve Seat and Face Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45˚

Valve Seating Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.30 mm (0.050 in.)

Valve Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.60 mm (0.020 in.)

Valve Narrowing Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30˚

Continued on next page

MX,2000A1,A4 -19-21OCT92

CTM5 (20OCT92) 20-00-4 K Series Air Cooled Engine

220596

PN=31

Page 42

Engine Application and Repair Specifications/Repair Specifications

GROUP 20—CYLINDER BLOCK, VALVES AND INTERNAL COMPONENTS—CONTINUED

Item Specification

Crankcase Cover

Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.6 L (1.27 pt)

Cap Screw Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 N·m (186 lb-in.)

Camshaft

Minimum End Journals O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.94 mm (0.509 in.)

Minimum Lobe Height

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26.45 mm (1.041 in.)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26.35 mm (1.037 in.)

Maximum Bearing I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.05 mm (0.514 in.)

Piston

Maximum Ring Groove Clearance

Top Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15 mm (0.006 in.)

Second Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.13 mm (0.005 in.)

Oil Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.12 mm (0.004 in.)

Minimum Ring End Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.18 mm (0.007 in.)

Maximum Ring End Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.00 mm (0.039 in.)

Minimum Pin O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.98 mm (0.590 in.)

Maximum Pin Bore I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15.04 mm (0.593 in.)

Maximum Piston-to-Piston Pin Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.06 mm (0.003 in.)

Piston O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71.86—71.89 mm (2.829—2.830 in.)

Piston-to-Cylinder Bore Clearance

Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.163 mm (0.0064 in.)

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.087—0.137 mm (0.0034—0.0054 in.)

20

00

5

Connecting Rod

Maximum Crankshaft Bearing I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.06 mm (1.065 in.)

Maximum Piston Pin Bearing I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15.04 mm (0.592 in.)

Maximum Connecting Rod-to-Piston Pin Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . 0.06 mm (0.002 in.)

Maximum Connecting Rod-to-Crankpin Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.12 mm (0.005 in.)

End-Cap Screw Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 N·m (168 lb-in.)

Crankshaft

Minimum PTO Side Journal O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.96 mm (0.983 in.)

Minimum Flywheel Side Journal O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.96 mm (0.983 in.)

Minimum Connecting Rod Journal O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26.95 mm (1.061 in.)

Maximum T.I.R. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm (0.002 in.)

End Play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0—0.30 mm (0—0.012 in.)

PTO Side Oil Seal Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 mm (0.158 in.)

Crankcase Plain Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.10 mm (0.988 in.)

MX,2000A1,A5 -19-21OCT92

CTM5 (20OCT92) 20-00-5 K Series Air Cooled Engine

220596

PN=32

Page 43

Engine Application and Repair Specifications/Repair Specifications

GROUP 20—CYLINDER BLOCK, VALVES AND INTERNAL COMPONENTS—CONTINUED

Item Specification

Cylinder Bore

Standard Cylinder Bore I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71.98—72.00 mm (2.834—2.835 in.)

Maximum Cylinder Bore I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72.06 mm (2.837 in.)

20

GROUP 25—IGNITION AND CHARGING SYSTEM

00

6

Ignition Coil Air Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 mm (0.012 in.)

See Ignition Tests in this Group.

MX,2000A1,A6 -19-21OCT92

CTM5 (20OCT92) 20-00-6 K Series Air Cooled Engine

220596

PN=33

Page 44

SERVICE PARTS KITS

The following kits are available through your parts

catalog:

Carburetor Gasket Kit—Engine Number FA130D-AS16

Group 05

Fuel and Air Systems—FA130D

Complete Carburetor

REMOVE, INSPECT AND INSTALL FUEL

TANK—FA130D-AS16/AS19

CAUTION: Gasoline vapor is explosive. Do not

N

expose to spark or flame. Serious personal

injury can result.

1. Remove air cleaner assembly or intake manifold and

gasket (A).

2. Remove choke lever and linkage (C).

3. Remove screws (B) and cap screw and washer (D).

Remove fuel tank and gasket.

4. Inspect fuel tank for cracks or damage. Repair or

replace as necessary.

5. Install fuel tank and gasket.

20

05

1

MX,2005A1,A1 -19-21OCT92

M80231 -UN-11MAR91

A—Intake Manifold and Gasket

B—Screw (3 used)

C—Choke Lever and Linkage

D—Cap Screw and Washer

6. Install choke lever and linkage.

7. Install intake manifold and gasket or air cleaner

assembly.

MX,2005A1,A2 -19-21OCT92

CTM5 (20OCT92) 20-05-1 K Series Air Cooled Engine

220596

PN=34

Page 45

Fuel and Air Systems—FA130D/Remove and Install Carburetor

REMOVE AND INSTALL

CARBURETOR—FA130D-AS16/AS19

1. Remove fuel tank. (See this group.)

2. Remove two nuts and washers (C).

3. Separate carburetor from spacer (A). Remove

20

05

carburetor.

2

4. Disconnect throttle control linkage (B).

5. Remove spacer (A) and gaskets.

6. Make repairs as necessary. (See this group.)

7. Install gaskets and spacer.

8. Connect linkage and install carburetor.

9. Install washers and nuts.

M80232 -UN-11MAR91M80233 -UN-11MAR91

10. Install fuel tank.

REMOVE AND INSTALL

CARBURETOR—FA130D-AN00

1. Remove air cleaner assembly and gasket.

2. Remove nuts and washers (A).

3. Separate carburetor from spacer (D). Remove

carburetor (B).

4. Disconnect throttle control linkage.

5. Remove spacer(D) and gaskets (C and E).

6. Make repairs as necessary. (See this group.)

7. Install gaskets and spacer.

8. Connect linkage and install carburetor.

MX,2005A1,A3 -19-21OCT92

TY15011 -UN-06DEC89

A—Mounting Nuts and Washers

B—Carburetor

C—Small Gasket

D—Spacer

E—Large Gasket

9. Install washers and nuts.

10. Install air cleaner assembly and gasket.

MX,2005A1,A4 -19-21OCT92

CTM5 (20OCT92) 20-05-2 K Series Air Cooled Engine

220596

PN=35

Page 46

Fuel and Air Systems—FA130D/Disassemble, Clean, Inspect and Assemble Carburetor

DISASSEMBLE, CLEAN, INSPECT AND

ASSEMBLE

CARBURETOR—FA130D-AS16/AS19

IMPORTANT: Do not clean holes or passages with

small drill bits or wire.

1. Soak carburetor body and all parts, except gaskets

and plastic rings, in carburetor cleaning solvent for 1/2

hour maximum.

2. Spray all passages with a carburetor cleaning spray to

verify that all internal passages are open.

IMPORTANT: Rinse carburetor body in warm water to

neutralize corrosive action of cleaner

on aluminum.

3. Rinse carburetor with warm water and dry with

compressed air. Do not use rags or paper to dry parts:

lint may plug holes or passages.

4. Inspect all parts for wear or damage, replace as

necessary.

A—Throttle Shaft

B—Choke Shaft

C—Pilot Screw

D—Spring

E—Bushing

F—Spring

G—Idle Screw

H—Screw

I—Gasket

J—Choke Valve

K—Spring

L—Spring Cap

M—Gasket

N—Diaphragm

O—Lower Housing

P—Main Jet

Q—Bushing

R—Strainer

S—Upper Housing

20

05

3

M51767 -UN-07SEP88

MX,2005A1,A5 -19-21OCT92

CTM5 (20OCT92) 20-05-3 K Series Air Cooled Engine

220596

PN=36

Page 47

Fuel and Air Systems—FA130D/Disassemble, Clean, Inspect and Assemble Carburetor

DISASSEMBLE, CLEAN, INSPECT AND

ASSEMBLE CARBURETOR—FA130D-AN00

IMPORTANT: To remove float, use a long nosed

pliers on end of pin (M). Do not strike

opposite end of pin. Damage to pin

holder may result.

20

05

4

1. Soak carburetor body and all parts, except gaskets

and plastic rings, in carburetor cleaning solvent for 1/2

hour maximum.

2. Spray all passages with a carburetor cleaning spray to

verify that all internal passages are open.

IMPORTANT: Rinse carburetor body in warm water to

Do not clean holes or passages with

small drill bits or wire.

neutralize corrosive action of cleaner

on aluminum.

3. Rinse carburetor with warm water and dry with

compressed air. Do not use rags or paper to dry parts:

lint may plug holes or passages.

4. Inspect all parts for wear or damage, replace as

necessary.

A—Throttle Plate N—Washer

B—Throttle Shaft O—Plug

C—Pilot Jet P—Drain Screw

D—Choke Shaft Q—Spring

E—Pilot Screw R—Float Chamber

F—Idle Screw S—Float

G—Spring (2 used) T—Bleed Pipe

H—Carburetor Body U—Main Nozzle

I—Spring V—Washer

J—Ball W—Main Jet

K—Choke Plate X—Needle Valve

L—Gasket Y—Washer

M—Float Pin

M80236 -UN-19MAR91

MX,2005A1,A6 -19-21OCT92

CTM5 (20OCT92) 20-05-4 K Series Air Cooled Engine

220596

PN=37

Page 48

Fuel and Air Systems—FA130D/Service Breather

IMPORTANT: Do not push on float or inlet needle

valve when adjusting float level.

5. Adjust float level. With carburetor upside down, float

surface must be parallel (A) to carburetor body. Bend

tang (B) to adjust float surface angle.

SERVICE BREATHER—FA130D-AS16/AS19

NOTE: The tappet chamber cover is an oil breather.

1. Remove fuel tank. (See this group.)

2. Remove throttle lever assembly (B).

20

05

5

TY15085 -UN-02SEP88

MX,2005A1,A7 -19-21OCT92

3. Remove tappet chamber cover/breather and gasket

(A).

4. Clean cover/breather and tube. Inspect for cracks or

damage. Replace if necessary.

5. Install new gasket and cover/breather.

6. Install throttle lever assembly.

7. Install fuel tank.

M80238 -UN-11MAR91

MX,2005A1,A8 -19-21OCT92

CTM5 (20OCT92) 20-05-5 K Series Air Cooled Engine

220596

PN=38

Page 49

Fuel and Air Systems—FA130D/Service Breather

SERVICE BREATHER—FA130D-AN00

NOTE: The tappet chamber cover is an oil breather.

1. Remove carburetor. (See this group.)

2. Remove tappet chamber cover/breather and gasket

(A).

20

05

6

3. Clean cover/breather and tube. Inspect for cracks or

damage. Replace if necessary.

4. Install new gasket and cover/breather.

5. Install carburetor.

TY15018 -UN-02SEP88

MX,2005A1,A9 -19-21OCT92

CTM5 (20OCT92) 20-05-6 K Series Air Cooled Engine

220596

PN=39

Page 50

Fuel and Air Systems—FA130D/Service Air Cleaner

SERVICE AIR CLEANER

NOTE: Replace elements yearly or every 25 hours as

required.

1. Remove and disassemble air cleaner.

IMPORTANT: Do not clean elements with solvent or

compressed air.

2. Wash foam element (A) in detergent and water. Dry

element.

3. Put 12—15 drops of engine oil on foam element (A).

Squeeze out excess oil.

4. Gently tap paper element (B) to remove dust:

—Element is still usable if you can see light through

element and paper appears clean.

—Install new element if element is oily, dirty, bent, torn,

crushed, or obstructed in any way.

5. Inspect cover (C), body (E), and base (D) for damage.

Replace if necessary.

IMPORTANT: Any time air cleaner base is removed,

check for free choke operation during

reassembly.

6. Assemble and install air cleaner.

20

05

7

M80240 -UN-11MAR91M80241 -UN-06APR91

FA130D-AS16

FA130D-AN00

A—Foam Element

B—Paper Element

C—Cover

D—Base

E—Body

MX,2005A1,A10 -19-21OCT92

CTM5 (20OCT92) 20-05-7 K Series Air Cooled Engine

220596

PN=40

Page 51

20

05

8

Fuel and Air Systems—FA130D/Service Air Cleaner

CTM5 (20OCT92) 20-05-8 K Series Air Cooled Engine

220596

PN=41

Page 52

SERVICE PARTS KITS

The following kits are available through your parts

catalog:

Carburetor Gasket Kit:

Group 06

Fuel and Air Systems—FA210D

Engine Number

FA210D-AS19-01

FA210D-AS17

FA210D-BS17

FA210D-CS17

Main Jet High Altitude Kit:

Engine Number

FA210D-AS17

FA210D-BS17

FA210D-CS17

Complete Carburetor

Complete Fuel Pump:

FA210D-AS17

FA210D-BS17

FA210D-CS17

REMOVE, INSPECT AND INSTALL FUEL

TANK—FA210D-AS20

20

06

1

MX,2006A1,A1 -19-21OCT92

CAUTION: Gasoline vapor is explosive. Do not

N

expose to spark or flame. Serious personal

injury can result.

1. Remove air cleaner assembly.

2. Remove choke lever and linkage (B).

3. Remove two screws (A) and cap screw and washer

(C). Remove fuel tank and gasket.

4. Inspect fuel tank for cracks or damage. Repair or

replace as necessary.

5. Install fuel tank and gasket.

6. Install choke lever and linkage.

7. Install air cleaner assembly.

MX,2006A1,A2 -19-21OCT92

CTM5 (20OCT92) 20-06-1 K Series Air Cooled Engine

220596

PN=42

M80289 -UN-11MAR91

Page 53

Fuel and Air Systems—FA210D/Remove and Install Carburetor

REMOVE AND INSTALL FUEL

PUMP—FA210D-AS17/BS17/CS17

1. Disconnect fuel hose (A) and vacuum hose (C). Close

all openings using caps and plugs.

2. Remove fuel pump (B).

20

06

3. Inspect pump for cracks or damage. Replace if

2

necessary.

4. Install fuel pump.

5. Connect hoses.

REMOVE AND INSTALL

CARBURETOR—FA210D-AS20

1. Remove fuel tank. (See this group.)

2. Remove two nuts and washers (C).

M80277 -UN-19MAR91M80278 -UN-19MAR91

FA210D-AS17

FA210D-BS17/CS17

MX,2006A1,A3 -19-21OCT92

3. Separate carburetor from spacer (A). Remove

carburetor.

4. Disconnect throttle control linkage (B).

5. Remove spacer (A) and gaskets.

6. Make repairs as necessary. (See this group.)

7. Install gaskets and spacer.

8. Connect linkage and install carburetor.

9. Install washers and nuts.

10. Install fuel tank.

MX,2006A1,A4 -19-21OCT92

CTM5 (20OCT92) 20-06-2 K Series Air Cooled Engine

220596

PN=43

M80232 -UN-11MAR91M80233 -UN-11MAR91

Page 54

Fuel and Air Systems—FA210D/Remove and Install Carburetor

REMOVE AND INSTALL

CARBURETOR—FA210D-AS17/BS17/CS17

1. Remove air cleaner elements.

2. Disconnect hose (B). Close all openings using caps

and plugs.

3. Remove cap screws and washers (C), air cleaner

base (D) and gasket.

20

06

3

4. Disconnect linkage (A).

5. Remove carburetor and gasket.

6. Make repairs as necessary. (See this group.)

7. Install carburetor and new gasket.

8. Connect throttle linkage.

9. Install new gasket, air cleaner base and cap screws

and washers.

10. Connect fuel hose.

11. Install air cleaner elements.