Page 1

Operation, Safety, Maintenance

and service Manual

Original Instructions - Keep this manual with the machine at all times.

Boom Lift Models

X14JH

X14JHR022

March, 2011

Page 2

JLG LIFT

FOREWORD

For:

• Accident Reporting

• Product Safety Publications

• Current Owner Updates

• Questions Regarding Product Safety

• Standards and Regulations Compliance Information

• Questions Regarding Special Product Applications

• Questions Regarding Product Modifications

Contact:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

or Your Local JLG Office

(See addresses on manual cover)

In USA:

Toll Free: 877‑JLG‑SAFE (877‑554‑7233)

Outside USA:

Phone: 240‑420‑2661

Fax: 301‑745‑3713

E‑mail: ProductSafety@JLG.com

X14JHR022

Page 3

X14JHR022

REVISION LOG

Rev. Manual code Date

Original Issue X14JHR002 January, 2011

01 X14JHR012 February, 2011

02 X14JHR022 March, 2011

JLG LIFT

FOREWORD

Page 4

BOOM LIFT MODELS X14JH

JLG

INDEX

CHAPTER 1 INTRODUCTION ..............................................................................................Page 07

CHAPTER 2 OPERATOR’S MANUAL .................................................................................Page 07

2.1 DESCRIPTION OF THE MACHINE ................................................................Page 07

2.1.1 MACHINE IDENTIFICATION PLATE............................................................Page 08

2.1.2 OVERALL DIMENSIONS OF THE MACHINE .............................................Page 09

2.1.2.1 DIMENSIONS......................................................................................................Page 09

2.1.3 TECHNICAL DATA............................................................................................Page 10

2.1.3.1 PLATFORM TECHNICAL DATA.....................................................................Page 10

2.1.3.2 PETROL ENGINE TECHNICAL DATA ..........................................................Page 11

2.1.3.3 DIESEL ENGINE TECHNICAL DATA ............................................................Page 11

2.1.3.4 HYDRAULIC SYSTEM TECHNICAL DATA..................................................Page 11

2.1.3.5 ELECTRIC SYSTEM TECHNICAL DATA.......................................................Page 12

2.1.4 TERMINOLOGY..................................................................................................Page 12

2.1.4.1 KEY.......................................................................................................................Page 13

2.2 GENERAL SAFETY RULES...............................................................................Page 14

2.3 SAFETY ADVICE ................................................................................................Page 16

2.3.1 GENERAL ADVICE............................................................................................Page 16

2.3.2 PICTOGRAMS SITUATED ON THE MACHINE ..........................................Page 17

2.3.3 NOISE AND VIBRATIONS................................................................................Page 25

2.4 INSTRUMENTS AND CONTROLS .................................................................Page 25

2.4.1 BASKET CONTROL DEVICE............................................................................Page 25

2.4.1.1 BASKET ELECTRIC PANEL..............................................................................Page 25

2.4.1.2 BASKET HYDRAULIC CONTROLS .................................................................Page 28

2.4.1.4 CRAWLER HYDRAULIC CONTROLS..............................................................Page 30

2.4.1.5 GROUND EMERGENCY CONTROLS SITUATED ON THE

REVOLVING TURRET .......................................................................................Page 33

2.5 SAFETY DEVICES...............................................................................................Page 35

2.5.1 BATTERY CUTOUT ............................................................................................Page 36

2.5.2 DISTRIBUTOR OVERPRESSURE VALVES .....................................................Page 36

2.5.3 CYLINDER STOP VALVES ................................................................................Page 37

2.5.4 PHOTOELECTRIC CELL AND SWITCH ALIGNMENT OVERHEAD

PART OF THE FRAME AND MACHINE BASE ...........................................Page 37

2.5.5 ENABLING DEVICE OF THE FRAME OVERHEAD PART........................Page 38

2.5.6 SENSOR OF CONTROL CAR LOAD...............................................................Page 38

2.5.7 CONTROL GUARDS..........................................................................................Page 39

2.5.8 THE WATER LEVEL..........................................................................................Page 39

2.5.9 LOCKING PIN SCREWS AND NUTS .............................................................Page 40

2.5.10 FOOTSWITCH.....................................................................................................Page 40

2.6 EMERGENCY DEVICES ....................................................................................Page 40

2.6.1 EMERGENCY STOP PUSHBUTTON...............................................................Page 41

2.6.2 SWITCH ENABLING EMERGENCY CONTROLS.......................................Page 41

2.6.3 HAND PUMP ......................................................................................................Page 42

2.6.4 SOLENOID VALVES FOR EMERGENCY DESCENT....................................Page 43

2.7 SAFETY REGULATIONS TO OBSERVE BEFORE USING THE PLATFORM......Page 44

2.7.1 DANGER OF ELECTRIC FULMINATION .....................................................Page 44

2.7.2 DANGER DUE TO BAD WEATHER CONDITIONS ....................................Page 45

2.7.3 DANGER DUE TO THE WORKING AREA ...................................................Page 45

2.8 PROCEDURES FOR A PROPER USE ...............................................................Page 46

2.8.1 OPERATOR’S RECAPITULATORY TABLE OF SAFETY REGULATIONS .....Page 46

2.8.2 WORKING AREA ...............................................................................................Page 47

2.9 USE OF THE OVERHEAD PLATFORM..........................................................Page 48

2.9.1 PRELIMINARY CHECKS BEFORE STARTING OPERATING....................Page 49

2.9.2 START OF THE PETROL/DIESEL (OPTIONAL) ENGINE ..........................Page 50

2.9.3 START OF THE ELECTRIC ENGINE ..............................................................Page 51

2.9.4 TRANSLATION ...................................................................................................Page 51

2.9.4.1 PARKING OF THE MACHINE ON A SOLPE OR DISCONNECTED

GROUND..............................................................................................................Page 53

2.9.5 STABILISING AND LEVELLING THE MACHINE.......................................Page 53

2.9.6 MOVING THE CONTROL CAR.......................................................................Page 54

2.9.7 MANUAL LEVELLING OF THE CONTROL CAR .......................................Page 56

2.9.8 MANOEUVRING THE BASKET EMERGENCY DESCENT........................Page 57

2.9.8.1 ACTIVATING THE BASKET EMERGENCY DESCENT...............................Page 57

1

X14JHR0220311

Page 5

2.9.8.2 ACTIVATING THE GROUND EMERGENCY DESCENT WITH

THE MACHINE IN PERFECT WORKING ORDER......................................Page 58

2.9.8.3 ACTIVATING THE GROUND EMERGENCY DESCENT WITH THE

HAND PUMP IN CASE OF ALL THE ENERGY SYSTEMS BREAKDOWN ....Page 58

2.9.9 MAIN USES PLANNED FOR THE PLATFORM ...........................................Page 60

2.9.9.1 SYSTEMS ..............................................................................................................Page 60

2.9.9.2 CLOSED PREMISES............................................................................................Page 60

2.9.9.3 USING FOR PRUNING......................................................................................Page 60

2.9.9.4 USE FOR REPAIRS AND MAINTENANCE OF ROOFS AND RAIN PIPES......Page 60

2.9.9.5 USE FOR PAINTING, SAND BLASTING AND PLASTERING...................Page 61

2.9.9.6 USE IN SALTY ENVIRONMENT....................................................................Page 61

2.10 REMOVAL OF THE BASKET............................................................................Page 61

2.11 TRANSPORT SAFETY REGULATIONS..........................................................Page 62

2.11.1 LOADING AND UNLOADING ON RAMPS.................................................Page 62

2.11.2 LIFTING THE MACHINE .................................................................................Page 63

2.11.2.1 HOW AND WHERE TO HOOK THE PLATFORM.......................................Page 64

2.11.2.2 WHAT TO USE FOR HOOKING THE PLATFORM......................................Page 64

2.11.3 TRANSPORT OF THE MACHINE...................................................................Page 65

CHAPTER 3 SPECIFICATIONS FOR GREASING AND LUBRICATING ...................Page 65

3.1 SAFETY RULES FOR GREASING AND LUBRICATING.............................Page 65

3.2 LUBRICATING POINTS ....................................................................................Page 66

3.3 GREASING POINTS ..........................................................................................Page 66

3.3.1 GREASING THE TELESCOPIC ARM..............................................................Page 67

CHAPTER 4 MAINTENANCE OF THE MACHINE ..........................................................Page 67

4.1 SAFETY REGULATIONS FOR MAINTENANCE OPERATIONS...............Page 67

4.2 PERIODIC GENERAL CONTROL ...................................................................Page 68

4.2.1 PERIODICAL MAINTENANCE TIMES..........................................................Page 69

4.3 RUBBER TRACK MAINTENANCE.................................................................Page 71

4.3.1 CHECKING TRACK TENSION........................................................................Page 71

4.3.2 OPERATIONS TO LOOSEN OR TIGHTEN TRACK.....................................Page 71

4.3.3 CHECKING RUBBER TRACKS ........................................................................Page 72

4.3.4 REPLACING RUBBER TRACKS.......................................................................Page 74

4.4 CHECKING BOLTS AND NUTS TIGHTNESS...............................................Page 75

4.5 CHECKING HYDRAULIC OIL LEVEL...........................................................Page 79

4.6 CHECKING LEAKS FROM THE HYDRAULIC SYSTEM............................Page 79

4.7 CHECKING FILTER CARTRIDGE...................................................................Page 79

4.8 CHECKING THE MACHINE PLATES INTEGRITY ...................................Page 80

4.9 CHECKING WORKING PRESSURES OF THE HYDRAULIC SYSTEM....Page 80

4.10 CHECKING THE TIGHTENING OF THE FIXING SCREWS OF

THE PIN STOPS AND THE RING NUTS ...........................................................Page 81

4.11 CHECKING WEAR AND TEAR OF THE TELESCOPIC ARM

SLIDING BLOCKS ..............................................................................................Page 81

4.12 CONTROL OF WEAR AND TEAR OF THE INTERIOR SLIDING

RING EXTENSION .............................................................................................Page 81

4.13 BATTERY: CHECKS AND MAINTENANCE.................................................Page 82

4.13.1 CHECKING ELECTROLYTE.............................................................................Page 82

4.13.2 RECHARCHING THE BATTERY .....................................................................Page 82

4.13.3 REPLACING THE BATTERY ............................................................................Page 83

4.13.4 DISCARDING THE BATTERY ..........................................................................Page 83

4.14 ENGINE MAINTENANCE................................................................................Page 83

CHAPTER 5 TROUBLESHOOTING .....................................................................................Page 84

CHAPTER 6 CHECKING THE MACHINE AFTER REPAIRS .........................................Page 85

6.1 CHECKING THE PROPER WORKING OF THE CONTROLS....................Page 85

6.2 CHECKING THE PROPER WORKING OF THE SAFETY DEVICES.........Page 85

CHAPTER 7 HYDRAULIC SYSTEM .....................................................................................Page 86

7.1 HYDRAULIC SYSTEM DIAGRAM..................................................................Page 86

7.2 KEY DIAGRAM HYDRAULIC SYSTEM........................................................Page 87

7.3 HYDRAULIC SYSTEM WITH 2

ND

SPEED .......................................................Page 88

7.4 KEY DIAGRAM HYDRAULIC SYSTEM WITH 2

ND

SPEED ................................Page 89

CHAPTER 8 ELECTRIC SYSTEM ..........................................................................................Page 90

2

X14JHR0220311

Page 6

3

FOREWORD

The aim of this manual is to provide the customer with all the necessary instructions and

operating procedures essential for the proper use of the machine in order to avoid serious

damages to the machine or others.

IMPORTANT

ALL THE INFORMATION IN THIS MANUAL IS MANDATORY AND MUST BE READ

CAREFULLY AND UNDERSTOOD BEFORE STARTING ANY OPERATION ON THE

MACHINE.

Being an important working tool, this manual must always be kept in a safe and easy to

reach place to be available at any time for further explanations.

Since it is not possible for the manufacturer to check the application of the machine and its

operation.

THE OPERATOR IS RESPONSIBLE to observe the safety instructions described in this

manual.

Before delivery, each machine is checked and tested carefully so that the operator does not

need to do any further adjustments.

IT IS ABSOLUTELY FORBIDDEN AND THE RESPONSIBILITY IS AT THE OPERATOR’S

OWN RISK to do any alterations and/or adjustments without any prior authorisation from

the Constructor.

IT IS THE EMPLOYER’S RESPONSIBILITY TO MAKE SURE THE OPERATOR HAS THE

NECESSARY SKILLS AND ABILITIES TO OPERATE PROPERLY THE MACHINE AND

THAT HE HAS READ AND UNDERSTOOD THE CONTENTS OF THIS INSTRUCTION

AND OPERATING MANUAL.

IT IS ALSO THE EMPLOYER’S RESPONSIBILITY TO TRAIN THE OPERATOR ACCOR‑

DING TO NATIONAL LAWS WHICH MIGHT BE SUPPLEMENTARY TO THE CONTENTS

OF THIS MANUAL.

If this manual gets damaged or lost, ask directly JLG for a replacement copy.

Note: all the pictures and drawings in the manual have been added to simplify the com‑

prehension of the texts. The machine in your possession may differ from the pictures and the

drawings in some details.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

Page 7

APPLIED STANDARDS

The machine has been designed, built and inspected according to that prescribed in the

EN280 prA2:2009 harmonised standard, which supplies the presumption of conformity with

the Essential Safety Requisites of the 2006/42/CE Machinery Directive even if a type C Volun‑

tary Technical Standard.

According to that stated in EN280 prA2, the platform is classified in GROUP B, as the verti‑

cal projection of the centre of gravity of the load can be outside of the tilting lines and in

TYPE 1 as traversing is only allowed with the platform at rest.

The stability tests of the machine have been made in accordance with what described in

paragraph 6.1.4.2 of the EN280 with load test calculated in conformity with 5.2.4 and have

been successful.

WARRANTY

When purchasing a platform you are given a warranty and test certificate where the war‑

ranty terms are clearly stated and where there must be specified any interventions on the

machine.

LIABILITY

The Constructor declines any responsibility or obligations for any damages caused to people

or things due to the following reasons:

• Not observing the instructions indicated in this INSTRUCTION AND OPERATING

MANUAL with regard to the operating, use and maintenance of the machine;

• Any sudden or violent actions or wrong manoeuvres in the use and maintenance of the

machine;

• Any alterations done to the structure and the components of the machine without any

prior authorisation from the Constructor and/or without using proper equipment;

• Any foreign events not related to the ordinary and proper use of the machine as descri‑

bed in this INSTRUCTION AND OPERATING MANUAL;

• Using non original and non authorised manufactured spare parts.

BOOM LIFT MODELS X14JH

JLG

4

X14JHR0220311

Page 8

5

DECLARATION OF CONFORMITY

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

EC DECLARATION OF

CONFORMITY

Manufacturer

Address

Technical File:

Authorised contact

Machine Type:

Model Type: ...

Serial Number:

Notified Body:

EC Number:

Address

JLG Industries Inc

1 JLG Drive

McConnellsburg

PA17233

USA

JLG Industries Inc

JLG Technology & Development Centre

Bruntingthorpe Aerodrome & Proving Ground

Lutterworth, Leicestershire

LE17 5QS

United Kingdom.

Alan S. McInt

Mobile Elevating Work Platform

...

ECO Certificazioni S.p.A

0714

Via Mengollna

33 - 48108

Faenza

Italy

yre

Position:

Manager, Engineering

Support - Europe

Certificate Number:

Reference Standards:

JLG Industries hereby declare that the above mentioned machine conforms

with the requirements of:

2006/42/EC Machiner

2004/108/EC EMC Directive

2000/14/EC Outdoor Noise

Signed:

Name: Alan S. McIntyre Position: Manager,Engineering Support-

Remark:

An

y modification to the above described machine violates the validity of this declaration.

This declaration conforms with the requirements of annex II-A of the council directive

2006/42/EC

Machine manufactured for JLG Industries Inc. by HINOWA S.p.a via Fontana 37054

NOGARA VR Ital

y

To Be Advised

EN12100-1 & 2:2003 + A1:2009

EN280:2001 + A2:2009

y

Date: ...

Europe

Place: Bruntingthorpe, UK

Page 9

BOOM LIFT MODELS X14JH

JLG

6

X14JHR0220311

y

y

EC DECLARATION OF

CONFORMITY

Manufacturer

Address

Machine Type:

Model Type:

Serial Number:

Document Control:

Measured

Lwa

Guaranteed

Lwa ...dB(A)

Engine Power:

...kW

Lwa = (Sound Power Level)

JLG Industries Inc

1 JLG Drive

McConnellsburg

PA17233

USA

Mobile Elevating Work Platform

...

...

HINOWA S.p.A

Via Fontana - 37054

Nogara

Italy

...dB(A)

Technical File:

JLG Industries Inc

JLG Technology &

Development Centre

Bruntingthorpe

Aerodrome & Proving

Ground

Lutterworth,

Leicestershire

LE17 5QS

United Kingdom.

Applicable Procedure:

Applicable Directive:

EN ISO 3744:1995

2000/14/EC Annex V Internal Control of Production.

We hereby declare that the above mentioned machine

conforms with the requirements of the "Noise Emission in

the Environment by Equipment for Use Outdoors"

Directive 2000/14/EC & 2005/88/EC

Remark:

This declaration conforms with the requirements of Annex II of the council directive

2000/14/EC

An

modification to the above described machine violates the validity of this declaration.

Machine manufactured for JLG Industries Inc. by HINOWA S.p.a via Fontana 37054

NOGARA VR Ital

Page 10

7

1. INTRODUCTION

In this manual, you can see safety‑warning signs used to bring the reader’s attention to some

warnings of particular importance.

The warning signs comes under two main types identified and described below.

DANGER

This sign accompanied by the word DANGER indicates that the situation descri‑

bed below, if not avoided, can cause serious injuries or even death to the people

concerned (operator, ground staff, people near the platform, people assigned to

maintenance etc.).

WARNING

This sign accompanied with the word WARNING indicates that the situation

described below indicates a potential risk to the structure of the machine. This

condition could cause dangerous conditions (even injuries and death) to the peo‑

ple concerned.

2. OPERATOR’S MANUAL

2.1. DESCRIPTION OF THE MACHINE

The machine is a self‑propelled hydraulic lifting device, equipped with a working control car

situated at the top of a rotating and extensible articulated structure. The lifting device is

meant for PLACING PEOPLE AND THEIR TOOLS AND MATERIALS IN PLACES HIGHER

THAN GROUND LEVEL.

The main control station of all the movements of the lifting device is situated on the control

car. Thanks to the main control station the operator can drive the machine, lift or lower the

extensible structure and rotate it towards the left or the right for an overall 300° angle.

The machine is equipped with a ground control station that excludes the main control sta‑

tion by means of a switch. The ground controls check the movements of the extensible struc‑

ture and are used in case of emergency to bring the control car back to the ground when the

operator is not able to do it.

The ground emergency controls can be used when doing control checks before starting ope‑

rating.

The machine is a self‑propelled machine able to move easily on any type of ground, able to

overcome big slopes and, seen its contained dimensions, to enter into narrow places. The

control car is the only control location planned by the manufacturer that prevents the opera‑

tor from being injured during all the translation operations of the machine. In fact, the con‑

trols have been studied to be used from the said position to have a proper sight of the invol‑

ved area.

The travel function can be controlled from the ground position only when the machine has to

pass pass through reduced‑height or narrow spaces. In these cases, to allow the machine to

access these spaces, the two‑place cage must be removed. The machine must travel only

lengthwise and must be controlled by a specialist operator.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

I

Page 11

When controlling the translation of the machine from the control car, take the maximum care

of elements like cornices, terraces, lintels, branches etc. that could come into contact with the

operator.

If the machine translation is controlled from the ground (see the a.m. admitted cases),

remember that the machine must be orientated with the control car part towards the back so

that, in case of a wrong manoeuvre, the operator does not come into contact with the rubber

tracks.

Controlling the travel of the machine from the ground with the cage removed is conside‑

red an extraordinary procedure that should be adopted only when the work area cannot be

reached in any other way.

It is absolutely forbidden to do manoeuvres different from the above mentioned ones by con‑

trolling translation from the ground as a possible sharp movement of the machine could

crush the operator between itself and the elements present on the manoeuvring area or make

the operator come into contact with the rubber tracks or the platform stabilisers.

After reinstalling the cage, put back the iron caps immediately.

2.1.1 MACHINE IDENTIFICATION PLATE

The Manufacturer plate is situated on the right

side of the metallic frame sustaining the transla‑

tion/stabilising controls.

You can see the drawing below.

BOOM LIFT MODELS X14JH

JLG

8

X14JHR0220311

200

Manufactured by

HINOWA S.p.A.

Via Fontana

37054 NOGARA (VR)

ITALY

kg

2x80

kg

1°

kg

kg

40

N400

JLG Industries. Inc - McConnellsburg. PA - USA

Model

Serial number

Date of manufacture

G.V.W. (Dry)

MAXIMUM ALLOWABLE OPERATING INCLINATION

MAX

12.5

M/S

=+

MAX

12.5

M/S

120

1x80

kg

40

kg

200

kg

07041700

N

Page 12

9

2.1.2 OVERALL DIMENSIONS OF THE MACHINE

2.1.2.1 DIMENSIONS

Maximum length in running conditions........................3975 mm

Carriage width ..................................................................786‑1086 mm

Maximum height in running conditions........................1980 mm

Maximum ramp angle ......................................................18.5°

Maximum stabilising angle..............................................10°

Stabiliser base side ............................................................2700 mm

N.B. Standard version with two‑seater basket.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

Page 13

2.1.3 TECHNICAL DATA

2.1.3.1 PLATFORM TECHNICAL DATA

....................................................................................................LOAD 200 kg ....LOAD 120 kg

PLATFORM HEIGHT (tread level ) ......................................10,58 m ..........11,90 m

MAXIMUM WORKING HEIGHT ............................................12,68 m ..........14,00 m

STANDARD CONTROL CAR DIMENSIONS ..............................1330x694 H1100 mm

HORIZONTAL RANGE ..........................................................5,16 m ............6,50 m

MAXIMUM WORKING HORIZONTAL RANGE ..........................5,66 m ............7,00 m

ROTATION (non continuous) ....................................................300°................300°

PLATFORM CAPACITY ..........................................................200 kg, ............120 kg

MAX GROUND REACTION PER STABILISER ..............................................1330 daN

MAX GROUND PRESSURE PER STABILISER ..........................................1,9 daN/cm

2

OPERATORS N° ............................................................................2 ....................1

OPERATOR N° IN SINGLE- SEATER BASKET (OPTION) ..................1 ....................1

JIB-TYPE ARTICULATION ............................................................../ ......

80° (+0°/-80°)

MAX WORKING INCLINATION ..................................................................1°/1,75%

MAX STABILISING INCLINATION ......................................................................10°

OVERALL WEIGHT IN TRANSPORT POSITION..............................................1700 kg

THERMIC ENGINE....................................................HONDA GX270-9 CV-3000 rpm

............................................................HONDA GX390-13 CV-3000 rpm (Optional)

....................................................................................HATZ 1B30-7 CV-3000 rpm

ELECTRIC ENGINE......................................................2,2 kw/230V/50Hz 1500 rpm

..................................................................2,2 kw/110V/50Hz 1500 rpm (Optional)

ELECTRIC SYSTEM VOLTAGE............................................................................12 V

PUMPS ....................................................................................................2x3,15 cc

MAX TRANSLATION SPEED (thermic engine) ............................................1,4 km/h

MAX TRANSLATION SPEED (thermic engine) with 2

nd

speed (optional) ........1,4/2,8 km/h

STAB/TRANSLATION SYSTEM PRESSURE ....................................................175 bar

OVERHEAD PART PRESSURE ......................................................................180 bar

MAX UPPER SLANT IN RUNNING CONDITIONS (angle of attack) ........18,5°/33,5%

MAX WIND SPEED ....................................................................................12,5 m/s

MAX ADMITTED MANUAL FORCE ..................................................................40 kg

RUBBER CRAWLER WIDTH- OPEN/CLOSE ........................................786/1086 mm

NB: The side range is measured from the centre of the fifth wheel to the outer

side of the control car.

BOOM LIFT MODELS X14JH

JLG

10

X14JHR0220311

Page 14

11

It is absolutely forbidden to translate and/or manoeuvre on transversal slopes with the craw‑

ler not extended as the machine could turn over and cause serious damages to the operator.

2.1.3.2 PETROL ENGINE TECHNICAL DATA

Make/ModelHONDA GX270

Fuel/coolant ........................................................................PETROL/AIR

Power SAEJ1349 ................................................................6,6 kW (9 CV) / 3600 Giri/min

Max regulated rpm............................................................3000 giri/min

Maximum torque ..............................................................17,7 Nm/2500 Giri/min (80/1269/EC)

Cylinder n° ..........................................................................1

Cubic capacity....................................................................270 cm

3

Make/Model ......................................................................HONDA GX390

Fuel/coolant ........................................................................PETROL/AIR

Power SAEJ1349 ................................................................9,6 kW (13 CV) / 3600 Giri/min

Max regulated rpm............................................................3000 giri/min

Maximum torque ..............................................................25,1 Nm/2500 Giri/min (80/1269/EC)

Cylinder n° ..................................................................................1

Cubic capacity....................................................................389 cm

3

2.1.3.3 DIESEL ENGINE TECHNICAL DATA

Make/Model ......................................................................HATZ 1B30

Fuel/coolant ........................................................................DIESEL/AIR

Power SAEJ1349 ................................................................5,0 kW (6,8 CV) / 3600 Giri/min

Max regulated rpm............................................................3000 giri/min

Maximum torque ..............................................................18,2 Nm/2000 Giri/min (80/1269/EC)

Cylinder n° ........................................................................1

Cubic capacity....................................................................347 cm

3

2.1.3.4 HYDRAULIC SYSTEM TECHNICAL DATA

Hydraulic oil tank capacity..............................................25 litres

Pump ..................................................................................double 2x3,15cm

3

Hydraulic system max pressure......................................180 bar

For further information please consult the hydraulic diagram annexed to this manual or the

paragraph relative to the maintenance of the relative components.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

DANGER

PERICOLO

Page 15

2.1.3.5 ELECTRIC SYSTEM TECHNICAL DATA

Battery ................................................................................35 Ah ‑ 240 A ‑ 12V

Alternator: ‑ petrol engine..............................................10 A (3000rpm)

‑ diesel engine ..............................................14 A (3000rpm)

Electric engine: ‑ electrical connection..........................230 V

‑ frequency............................................50 Hz

‑ power ..................................................2,2 kW

For further information please consult the electric diagram annexed to this manual or the

paragraph relative to the maintenance of the relative components.

2.1.4 TERMINOLOGY

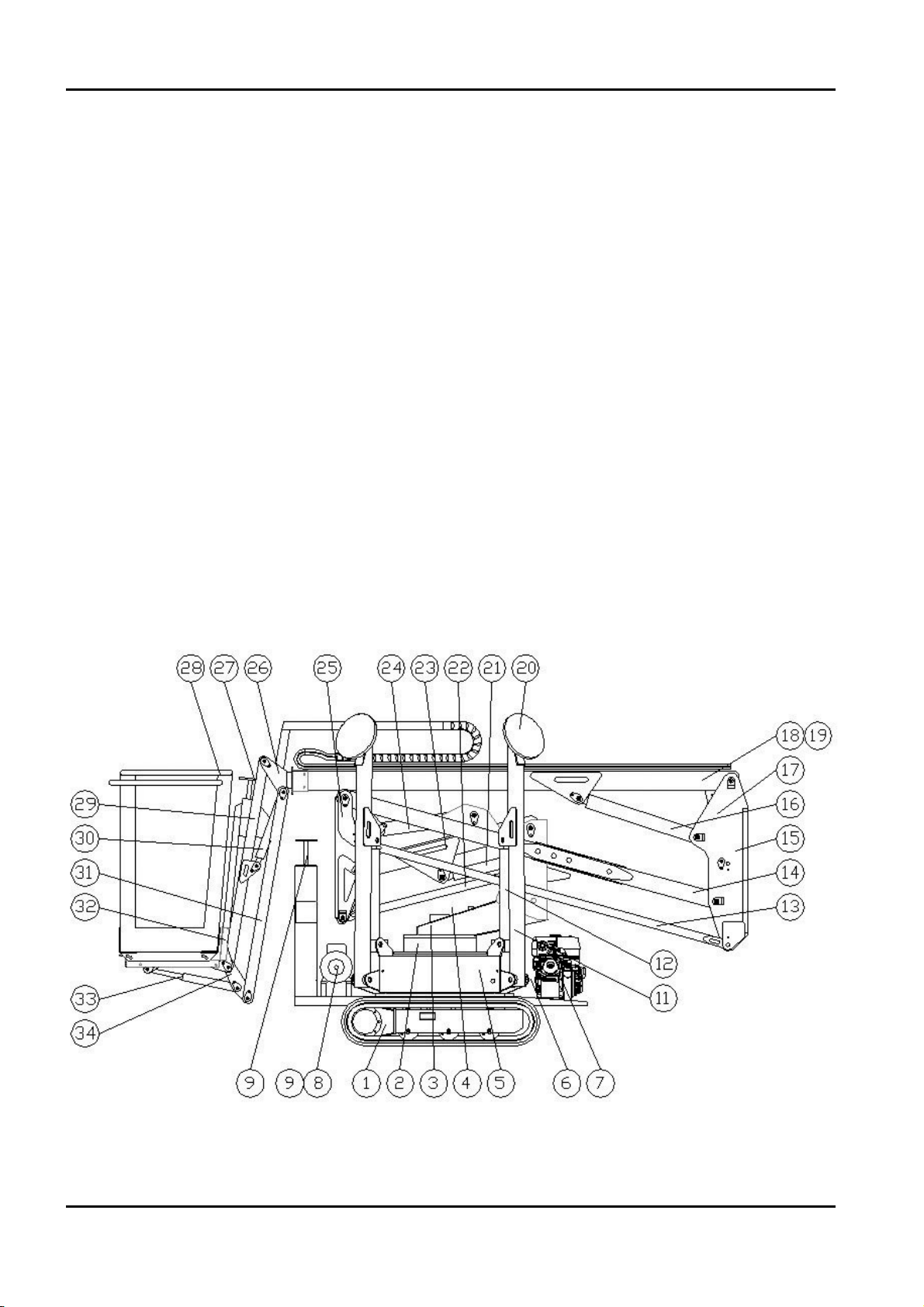

To make this manual easier to understand, there is a diagram that gives all the exact terms

identifying the different parts of the platform.

BOOM LIFT MODELS X14JH

JLG

12

X14JHR0220311

Page 16

13

2.1.4.1 KEY

1 Extensible rubber crawler

2 Fifth wheel + rotation engine

3 Revolving turret

4 Overhead part emergency controls

5 Base + electric components box + oil tank

6 Triple gear pump

7 Diesel/petrol engine

8 Electric engine

9 Triple gear pump

10 Translation and stabilisers controls

11 Stabilizer

12 Stabilizer cylinder

13 Second arm tie‑rod

14 Second arm

15 Second transmission

16 Third arm cylinder

17 Basket levelling cylinder on transmission

18 Third arm

19 Extraction cylinder

20 Stabilizer cap

21 First arm cylinder

22 First arm tie‑ rod

23 First arm

24 Second arm cylinder

25 First transmission

26 Extraction arm

27 Controls

28 Basket or control car

29 Jib arm

30 Jib cylinder

31 Jib tie‑rods

32 Basket support

33 Basket levelling cylinder on jib

34 Jib transmission

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

Page 17

2.2 GENERAL SAFETY RULES

NOT OBSERVING THE SAFETY PRECAUTIONS LISTED IN THIS SECTION AND

SHOWN ON THE MACHINE CAN CAUSE INJURIES OR DEATH TO THE STAFF AND

DAMAGES TO THE MACHINE AND IS A SERIOUS VIOLATION OF SAFETY RULES.

This section of this INSTRUCTION AND OPERATING MANUAL describes the dangerous

procedures or situations that could cause damages to things and/or people and what the

operator must do to avoid them.

• The operator must always work professionally, observing all the safety rules, taking care

not to underestimate their own responsibility towards themselves and all the things and

people around them.

• Before starting work it is essential that the operator makes sure the safety devices are in

perfect conditions, that they make the necessary checks on the machine and become fami‑

liar with the ground conditions where they must manoeuvre and stabilise.

• When working it is essential that one specialised person with knowledge of the use of the

machine and the contents of this INSTRUCTION AND OPERATING MANUAL stays on

the ground.

• It is absolutely forbidden to do any alterations to the machine without any prior written

authorisation from the Constructor as this could damage its functioning and its safety.

The Constructor declines any responsibility for injury or damage caused by such beha‑

viour.

Clothing and protective wear

Avoid wearing loose clothes, rings, watches or anything that

could get entangled inside the rotating parts.

When operating the machine or doing maintenance jobs,

wear a helmet, safety glasses and safety shoes, gloves and

noise protection earmuffs after checking their integrity.

Wear the homologated and certified safety belt

Before operating at height it is necessary to correctly wear the safety belts and to fasten them

to the anchorages of the basket.

The use of the safety belts is compulsory in connection with the local regulatins of every sin‑

gle State. In those States where the law does not require the use of holding systems, the choi‑

ce is of the employer or/and user.

BOOM LIFT MODELS X14JH

JLG

14

X14JHR0220311

ATTENZIONE

IMPORTANTE

IMPORTANT

WARNING

Page 18

15

Safety valves

Never alter and/or tamper with the safety valves and the controls in the main hydraulic

system. The Constructor declines any responsibility for damages to people, things or the

machine when the hydraulic valve standard gauging has been tampered with.

Fire prevention

Keep the engine compartment clean. Remove any pieces of

wood, paper and other flammable products; clean properly

any fuel leaks as they can be potential fire risks.

Petrol is extremely flammable and explosive under certain

conditions. Refuel in a well‑ventilated place and when the

engine is off.

Never smoke or cause sparks in the refuelling place or the fuel

storage place.

After refuelling, make sure that the cap is closed safely and

properly.

Take care not to touch the exhaust pipe when it is hot, as it remains hot during the working

of the machine and also after turning off the engine.

Preventing damages caused by washing the machine

When washing the machine do not direct high‑ pressure jets

onto the electric components. Do not use chemical or petrol

detergents that could cause serious damages to the plastic

components and the paint.

Preventing damages when the machine is at work.

When the machine has been stabilized and starts working, avoid entering in its working

range.

Manoeuvre systematically the controls slowly and regularly. Do not invert movements sharply.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

Page 19

2.3 SAFETY ADVICE

2.3.1 GENERAL ADVICE

To avoid accidents, before starting work and before doing any

operations of maintenance, read, understand and follow all

the warnings and instructions given in this manual. The

machine operator/user cannot be held responsible if they have

not read this manual and learnt how to manoeuvre the machi‑

ne under the supervision of a qualified operator.

Carefully read all the safety warnings in this manual and the

safety signs on your machine.

Keep the safety signs in proper order and replace them when

they are damaged.

Make sure that the new components on the machine have the proper safety signs.

BOOM LIFT MODELS X14JH

JLG

16

X14JHR0220311

Page 20

17

2.3.2 PICTOGRAMS SITUATED ON THE MACHINE

Here we report the positions of the various boards with pictograms on the machine.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

62

34

56X56 MM56X56 MM56X56 MM56X56 MM

3637

57

65x41 MM

58

30

65x41 MM

40 40

64

32

53

3

15

19

28

Ed. 03-05-2011

Tav. 01

cod.17065000

46

2929

26

50 51

180X93MM

1717

1212

35

4

1

21

18

57

10

27

ADHESIEKIT - X14J-H

KIT ADHESIVOS - X14J-H

9

54

14

19

SET OF DECALS - X14J-H

KIT COLLANTS - X14J-H

KIT ADESIVI - X14J-HAUFKLEBERSATZ - X14J-H

66

3

19

15

28

38

47

16

48

Page 21

BOOM LIFT MODELS X14JH

JLG

18

X14JHR0220311

5

6

63

65

30

60

11

56

Ed. 03-05-2011

2

66

50

51

65x41 MM

25

13

55

56X56 MM56X56 MM56X56 MM56X56 MM

Tav. 0 2

cod.17065000

65x41 MM

31

3

60

19

65

15

28

ADHESIEKIT - X14J-H

KIT ADHESIVOS - X14J-H

17

43

1212

23

21

26

37

2929

180X93MM

1

4

8

33

45

25

45

KIT ADESIVI - X14J-HAUFKLEBERSATZ - X14J-H

KIT COLLANTS - X14J-H

SET OF DECALS - X14J-H

17

19

30

60

28

38

48

47

3

15

14

19

16

Page 22

19

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

Pos. Code Q.ty

01 07060500 02

02 06924300 01

03 1603940004 04

04 1603940005 02

05 07059200 01

06 06555300 01

07

08 1603940015 01

09 1603940016 01

10 1603940017 01

11 06039500 01

12 06039600 08

13 06039700 01

14 06086700 02

15 06039900 04

16 06040000 02

17 06040100 08

18 06040200 01

19 06040300 06

20

21 06040500 02

22

23 1702155 01

24

25 06040900 02

26 1703814 02

27 1701504 01

28 06041200 04

29 06041300 04

30 06561200 03

31 06041500 01

32 1701505 01

32 1701542 01

33 06041800 01

33 07034200 01

34 06041900 01

35 06042000 01

36 06042100 01

37 07060600 02

38 1704277 02

39

Pos. Code Q.ty

40 06044000 04

41

42

43 06056300 01

44

45 07056600 02

46 07064500 01

47 06448200 02

48 06448100 02

49

50 07056700 02

51 1701499 02

52

53 06232100 01

54 06165000 01

55 1603940025 01

56 1603940013 01

57 1706898 02

58 06068600 01

59

60 1001125483 03

61

62 1706493 01

63 1705828 01

64 1706098 01

65 07050700 02

66 07060900 02

Page 23

LANGUAGE STICKERS

BOOM LIFT MODELS X14JH

JLG

20

X14JHR0220311

Pos. Code Q.ty

170650IT

06 06555300 01

30 06561200 04

45 07056600 02

46 07064500 01

47 06448200 02

48 06448100 02

55 1603940025 01

170650GB

06 06562600 01

30 06561200 04

30 06042400 04

30 not install 04

47 06462700 02

48 06462100 02

55 1603940026 01

170650FR

06 06562700 01

30 06561200 04

47 06462800 02

48 06462200 02

55 1603940019 01

170650DE

06 06562800 01

30 06561200 04

47 06462900 02

48 06462300 02

55 1603940024 01

170650ES

06 06562900 01

30 06561200 04

47 06463000 02

48 06462400 02

55 1603940027 01

Pos. Code Q.ty

170650NL

06 06563000 01

30 06561200 04

47 06463100 02

48 06462500 02

55 1603940014 01

170650PT

06 06563100 01

30 06561200 04

47 06463200 02

48 06462600 02

55 1603940028 01

Page 24

21

BOOM LIFT MODELS X14JH

JLG

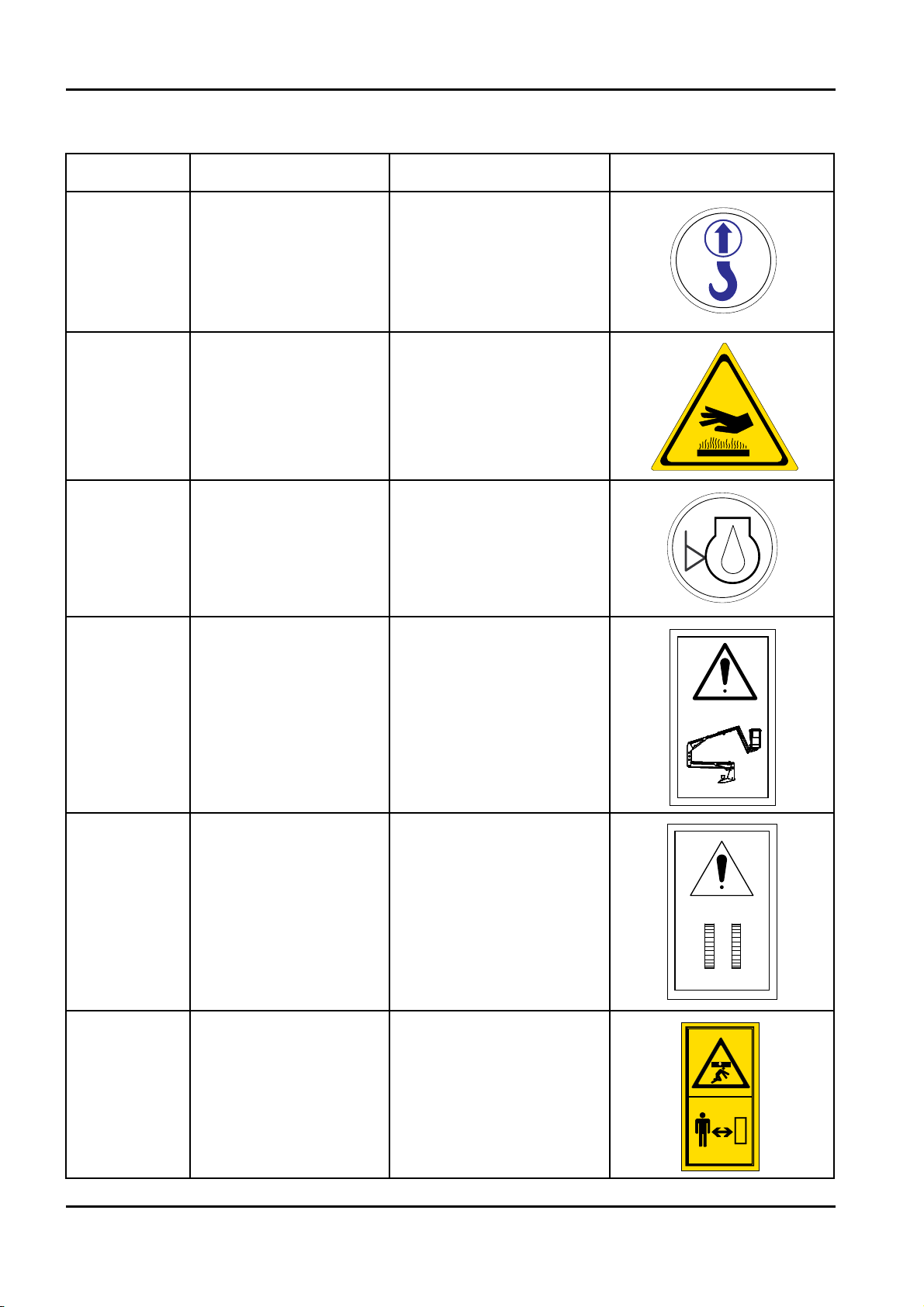

X14JHR0220311

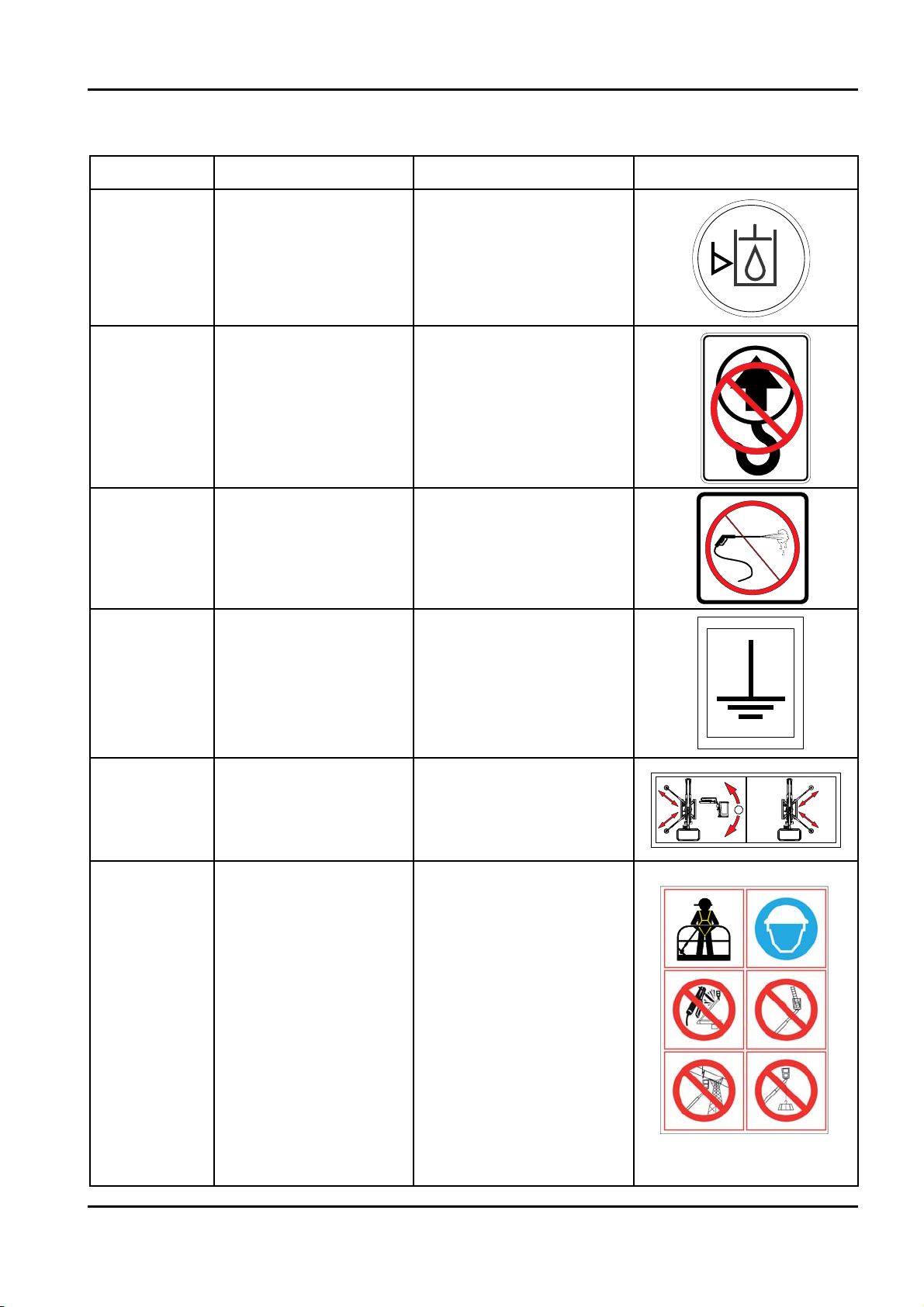

Code Name Description Identikit

06040300

WARNING KEEP SAFE

DISTANCE

06040500

SENSE OF MOVING

UNDERCARRIAGE

DEFINED AS THE

DIRECTION FORWARD

06040800

CRUSHING HAZARD

PERSON

06040900

OBLIGATION TO

READ THE MANUAL

BEFORE USE OF

MACHINE

1703814

FIXING POINT FOR

TRANSPORT

INDICATES CORRECT

FIXING POINT FOR

TRANSPORT OF THE

MACHINE

06041200

CRUSHING HAZARD

FEET

INDICATES AREAS

WHERE THERE IS A

DANGER OF CRUSHING

LOWER LIMBS FOR THE

OPERATOR

06041300

CRUSHING HAZARD

PERSON

INDICATES AREAS

WHERE THERE IS A

DANGER OF CRUSHING

UPPER LIMBS FOR THE

OPERATOR

06040300

06040500

06040800

06040900

1703814A

06041200

06041300

Page 25

BOOM LIFT MODELS X14JH

JLG

22

X14JHR0220311

Code Name Description Identikit

06044000 LIFTING POINT

INDICATES CORRECT

LIFTING POINTS FOR

LIFT THE MACHINE

06056300

DANGER HIGHT

TEMPERATURE

06060000 ENGINE OIL LEVEL

06085900

EMERGENCY DEVICE

FOR AERIAL PART

DEVICE THAT ALLOWS

TO EXCLUDE THE

SAFETY OF THE

AEREAL PART IN CASE

OF EMERGENCY OPE‑

RATIONS

06086000

EMERGENCY DEVICE

FOR UNDERCARRIA‑

GE

DEVICE THAT ALLOWS

TO EXCLUDE THE

SAFETY OF THE

UNDERCARRIAGE IN

CASE OF EMERGENCY

OPERATIONS

06086600

WARNING KEEP SAFE

DISTANCE AND CRU‑

SHING HAZARD PER‑

SON

0

6

0

4

4

0

0

0

06056300

0

0

0

0

6

0

6

0

06085900

06086000

06086600

Page 26

23

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

Code Name Description Identikit

06165000

HYDRAULIC OIL

LEVEL

1701499

FORBIDDEN LIFTING

POINT

1001125483

DO NOT WASH WITH

WATER

06560500 GROUNDING

06040200

HAND PUMP

LEGEND

QUICK INSTRUCTIONS

FOR USING THE EMER‑

GENCY HAND PUMP

06924300

BE CAREFULL AT

WORK

USING SAFETY HAR‑

NESSES, USE PROTECTI‑

VE EQUIPMENT (HEL‑

MET), PROHIBITION OF

WELD ON THE MACHI‑

NE, PROHIBITION OF

USE SYSTEMS TO

INCREASE THE AREA

OF WORK INSIDE THE

BASKET , PROHIBITION

OF WORKING IN THE

VICINITY OF VOLTAGE

ELECTRIC, PROHIBI‑

TION OF USE OF THE

PLATFORM FOR RAI‑

SING LOADS

1701499

1001125483

0

0

0

5

6

1

6

0

06560500

06040200

0692430006924300

Page 27

REPLACE ALL STICKERS AND PLATES AS SOON AS THEY GET WORN.

NOT OBSERVING INSTRUCTIONS REGARDING WEAR AND TEAR, LOST OR NOT

CONSULTING A SAFETY STICKER CAN CAUSE SERIOUS ACCIDENTS.

BOOM LIFT MODELS X14JH

JLG

24

X14JHR0220311

Page 28

25

2.3.3 NOISE AND VIBRATIONS

JLG platforms with thermic engine have been field‑tested according to the parameters of the

European Regulations 2000/14 CE and have registered a guaranteed 97dB (A) acoustic pres‑

sure level.

During overhead operations, this figure decreases as the control car moves away from the

main source of noise.

The vibrations figures transmitted to the operator both through the controls and directly

from the control car floor were assessed as lower than the maximum authorised limits.

2.4 INSTRUMENTS AND CONTROLS

You will find below the indication for all the control functions and the indicators on the

platform. Each device has a sticker nearby which describes briefly its applied function, but

there are very often symbols used for encouraging a quick and safe use. Before operating the

platform, read the description below to understand further the functions of each device and

possibly learn the manufacturer’s advice.

Before starting operating the platform the operator must read and understand perfectly the

instructions given in this manual.

2.4.1 BASKET CONTROL DEVICE

2.4.1.1 B

ASKET ELECTRIC PANEL

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

Page 29

BOOM LIFT MODELS X14JH

JLG

26

X14JHR0220311

REF. DESCRIPTIONS PICTOGRAMS NEAR THE

CONTROL

1 Starter pushbutton

2

Engine starting pushbutton

It allows a selected start of the engine by means

of selector 4 directly from the control place on the

control car.

3

Work selector

For the machine, you can select two working methods by

using the jib or not.

Without the jib method the maximum admitted

load on the control car is 200 kg (2 x 80 kg people + 40kg

equipment) in std two‑seater basket.

Using the jib method the maximum admitted load on

the control car is 120 kg (1 x 80kg person + 80kg equip‑

ment).

4

Engine type and emergency descent selector

This selector allows to choose either electric or

petrol/diesel engine or, in case of emergency to excite, for

emergency descent, the solenoid valves situated on the

cylinders on the first, second and third arm descending

the frame overhead part through gravity. The particular

construction of this selector forces the operator, in case of

emergency descent, to keep it continuously rotating,

otherwise the selector would go back automatically to

the pre‑selected position.

5

Emergency stop pushbutton

It allows stopping all the machine functions.

Turn the pushbutton to make the machine operative.

6

PLC feeding pilot light

This green light indicates voltage in the electric system of

the machine and therefore in the PLC which controls all

its functions.

THERMIC ENGINE

ELECTRIC ENGINE

EMERGENCY DESCENT

Page 30

27

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

REF. DESCRIPTIONS PICTOGRAMS NEAR THE

CONTROL

7

Load cell pilot light.

This red light indicates that the maximum admitted load

on the platform control car has been exceeded.

On the machine the light comes on when:

‑ you exceed 120 kg on the control car and the jib method

has been selected with selector 4.

‑ you exceed 200 kg on the control car and no jib method

has been selected with selector 4.

When the light comes on, it is accompanied by an inter‑

mittent alarm.

8

Machine closed pilot light

This red light indicates that the overhead part of the

machine frame has been completely lowered and aligned

with the base and that the withdrawing has completely

happened. When this light comes on, the stabiliser

controls and the crawler movements have been enabled.

Two golden arrows, situated near the hydraulic controls

on the crawler, visually signal the machine alignment.

9

Stabilised machine pilot light

This green light indicates that the stabiliser cylinders are

completely opened and therefore all the stabilisers are

resting on the ground.

Once the machine is stabilised the controls for moving

the overhead part of the frame and rotating the fifth

wheel are enabled.

The operator must make sure that the machine is

stabilised without the 1° maximum limit admitted by

the manufacturer.

10

Second speed button (optional)

If pressed and kept in position during the machine’s

translation it controls the switching of the second speed.

Page 31

2.4.1.2 BASKET HYDRAULIC CONTROLS

BOOM LIFT MODELS X14JH

JLG

28

X14JHR0220311

REF. DESCRIPTION OPERATION/

MOVEMENT

PICTOGRAM NEAR THE

CONTROL

1 Basket levelling control

This lever allows acting on the levelling

cylinder of the control car to adjust any

misalignments due to possible anomalies

in the system.

Being an emergency device and a dange‑

rous manoeuvre, the operator must use a

tool (e.g. screwdriver) to activate the

distributor.

Lever forward:

basket rotating

toward the machine

Lever backward:

basket rotating away

from the machine

2 Lever controlling movement of third arm

This lever allows the operator to raise or

lower the platform third arm.

Lever forward:

raising third arm

Lever backward:

lowering third arm

3 Lever controlling first and second arm

This lever allows the operator to raise and

lower the first and second arm of the

platform. The synchronisation of the

movement between the first and the

second arm allows to always have the

maximum range when working and can

be obtained thanks the particular configu‑

ration of the system and does not depend

on the operator.

lever forward:

synchronised raising

of the first and

second arm

lever backward:

synchronised lowe‑

ring of the first and

second arm

4 Jib control lever

This lever allows the operator to raise and

lower the jib.

lever forward:

raising jib arm

lever backward:

lowering jib arm

Page 32

29

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

REF. DESCRIPTION OPERATION/

MOVEMENT

PICTOGRAM NEAR THE

CONTROL

5 Withdrawal control lever

This lever allows the operator to extract

and insert back the arm.

lever forward:

re‑entry withdrawal

toward the machine.

lever backward:

withdrawal towards

the outside

6 Rotation lever

This lever allows the operator to rotate

the overhead part of the platform frame

around the fifth wheel axis.

The machine alignment is indicated in

paragraph 2.4.1.1

lever forward:

anticlockwise rota‑

tion of the overhead

part

lever backward:

clockwise rotation of

the overhead part

Page 33

2.4.1.4 CRAWLER HYDRAULIC CONTROLS

The controls for translating and stabilising the machine have been designed to be operated

from the basket. This way the operator is protected from any risks caused by contact with the

rubber tracks and the stabilisers and they are able to see clearly the levelling indicator for

stabilising the control car.

When controlling the translation of the machine from the control car, take the maximum care

to elements like cornices, terraces, lintels, branches etc. that could come into contact with the

operator.

If the machine translation is controlled from the ground (see par.2.1), remember that the

machine must be orientated with the part of the control car toward the back so that, in case

of a wrong manoeuvre, the operator does not come into contact with the rubber tracks.

It is absolutely forbidden to do manoeuvres different from those mentioned above, by con‑

trolling translation from the ground as a possible sharp movement of the machine could

crush the operator between itself and the elements present on the manoeuvring area or could

make the operator come into contact with the platform rubber tracks.

BOOM LIFT MODELS X14JH

JLG

30

X14JHR0220311

WARNING

WARNING

WARNING

ATTENZIONE

ATTENZIONE

ATTENZIONE

Page 34

31

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

REF. DESCRIPTION OPERATION/

MOVEMENT

PICTOGRAM NEAR THE

CONTROL

1 Track widening lever

This lever allows the operator to

increase the width of the rubber

crawler to increase the stability of

the machine in particular on une

ven and soft ground.

By putting the width back into

shape you can obtain a narrower

machine able to enter narrow places.

lever forward:

track widening

lever backward:

track narrowing

2 Lever controlling left rear stabiliser

This lever allows the operator to raise

and lower the left rear stabiliser.

lever forward:

raising left rear stabi‑

liser

lever backward:

lowering left rear sta‑

biliser

3 Lever controlling left front stabiliser

This lever allows the operator to raise and

lower the left front stabiliser

lever forward:

raising left front sta‑

biliser

lever backward:

lowering left front

stabiliser

4 Lever controlling left track movement

This lever allows the operator to move the

track back and forward

lever forward:

moving forward left

track

lever backward:

moving backward

left track

Page 35

ATTENTION!

Only use the acceleration lever located on the hydraulic control panel on the undercarriage,

and not the lever located on the engine as indicated in the picture.

BOOM LIFT MODELS X14JH

JLG

32

X14JHR0220311

REF. DESCRIPTION OPERATION/

MOVEMENT

PICTOGRAM NEAR THE

CONTROL

5 Lever controlling right track movement

This lever allows the operator to move the

right track forward or backward.

lever forward:

moving right track

forward

lever backward:

moving right track

backward

6 Lever controlling the right front stabiliser

This lever allows the operator to raise or

lower the right front stabiliser.

lever forward:

raising right front

stabiliser

lever backward:

lowering right front

stabiliser

7 Lever controlling right rear stabiliser

This lever allows the operator to raise or

lower the right front stabiliser

lever forward:

raising right rear sta‑

biliser

lever backward:

lowering right rear

stabiliser

8 Accelerator lever

This lever allows the operator to accelera‑

te the diesel/petrol engine

lever forward:

accelerating

lever backward:

decelerating

YES

NO

Page 36

33

2.4.1.5 GROUND EMERGENCY CONTROLS SITUATED ON THE REVOLVING TURRET

These controls have been designed to manoeuvre the overhead part of the control car from

the ground only in case of emergency after putting on the proper switch.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

REF. DESCRIPTION OPERATION/

/

MOVEMENT

PICTOGRAM NEAR THE

CONTROL

1 Rotation lever

This lever allows the operator to rotate

the overhead part of the platform structu‑

re around the axis of the fifth wheel

The machine alignment is indicated in

paragraph 2.4.1.1

lever forward:

rotating anticlockwi‑

se the overhead part

lever forward:

rotating clockwise

the overhead part

2 Lever controlling first and second arm

This lever allows the operator to raise and

lower the first and second arm of the

platform. The synchronisation of the

movement between the first and second

arm allows having the maximum working

range and this is obtained thanks to the

particular configuration of the system and

does not depend on the operator.

lever forward:

synchronised raising

first and second arm

lever backward:

synchronised lowe‑

ring of the first and

second arm

Page 37

BOOM LIFT MODELS X14JH

JLG

34

X14JHR0220311

REF. DESCRIPTION OPERATION/

/

MOVEMENT

PICTOGRAM NEAR THE

CONTROL

3 Lever controlling third arm movement

This lever allows the operator to raise or

lower the platform third arm.

lever forward:

raising third arm

lever backward:

lowering third arm

4 Withdrawing lever control

This lever allows the operator to pull out

and reenter the withdrawing arm

lever forward:

pulling out toward

the outside

lever backward:

re‑entering toward

the machine

Page 38

35

2.5 SAFETY DEVICES

The instructions reported below regarding the safety devices are given to the user in order to

understand the machine behaviour and the possible working sequences; it will also be possi‑

ble to identify possible breakdowns and to be able to give more detailed information to the

customer service and thus obtaining quicker and cheaper interventions.

The machine is equipped with safety devices able to prevent dangerous situations for the

operator. Before starting any operation, the operator should check the perfect working of

these devices.

If a safety device does not work, either due to a breakdown or tampering, this could cause

serious damage to the machine and could jeopardise the operator’s life. The Constructor has

designed the machine and the safety devices to guarantee the maximum to its customers.

Anyhow the devices must be checked periodically according what described in this manual

and must never be tampered with.

Never intervene, on one’s initiative, on the safety devices. In case of tampering, the manufac‑

turer declines any responsibly regarding possible accidents resulting from such interven‑

tions.

It is absolutely forbidden to tamper with the lead seal or the calibration of the maximum val‑

ves. In case of tampering, the manufacturer declines any responsibility for any possible acci‑

dents resulting from such interventions.

The Constructor declines any responsibility for any damages caused by the machine to

things and/or people if the above mentioned has not been observed.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

IMPORTANTE

DANGER

DANGER

DANGER

IMPORTANT

IMPORTANT

PERICOLO

PERICOLO

PERICOLO

IMPORTANTE

Page 39

2.5.1 BATTERY CUTOUT

This device situated on the right side of the electric components box cuts the electric circuit of the

machine locking all its movements. It can be seen easily and is of easy access without any tools. It

must be put on every time you leave the machine at the end of a work shift or for longer periods.

By turning the key clockwise you cut the electric circuit of the machine. By turning the key anti‑

clockwise you cut the electric circuit of the machine and you can remove the key.

2.5.2 DISTRIBUTOR OVERPRESSURE VALVES

All the distributors on the platform are equipped with an overpressure valve that limits the

pressure reached inside the system to the calibration pressure of the valve itself. These valves

are calibrated by qualified people, when testing the platform and they must never be tampe‑

red with.

BOOM LIFT MODELS X14JH

JLG

36

X14JHR0220311

Page 40

37

2.5.3 CYLINDER STOP VALVES

The stabiliser cylinders are equipped with a double stop valve that, in case of breakdown of

the system or breaking of the tubes, stop the cylinder avoiding dangerous situations of

platform instability.

All the cylinders that move the overhead part of the platform structure are equipped with

stop valves that, in case of breakdown of the system or breakage of the tubes, stop the cylin‑

der avoiding that the control car drops through gravity.

Qualified people calibrate these valves when testing the platform and they must never be

tampered with.

2.5.4 PHOTOCELLS AND SWITCH ALIGNMENT OVERHEAD PART OF THE STRUC‑

TURE AND MACHINE BASE

The machine is provided with a double safety photocell which controls that the aerial part of

the structure of the machine is completely lowered and aligned with the base and that the

telescopic arm is completely retracted.

If one of these conditions does not occur, a signal is given to a switch that deactivates the

translation and the stabiliser movement and feeds the overhead part of the structure.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

Page 41

2.5.5 ENABLING DEVICE OF THE STRUCTURE OVERHEAD PART

When all the stabilisers are properly placed on the ground, the stabiliser cylinder goes

towards the end of course releasing the micro‑switches situated at the end of the rods. The

micro‑switches send a signal to a solenoid valve that sends oil coming from the carry‑over

device to the controls for the movement of the overhead part of the structure. If for any rea‑

son a micro‑switch should reactivate during the movement of the basket (for example the

raising of a stabiliser or the sinking of the ground) all the movements of the overhead part of

the machine would be inhibited.

2.5.6 SENSOR OF CONTROL CAR LOAD

The load sensor present on the basket made up of a two‑shaft basket support that allows

exclusively vertical movement of the basket. Basket support is supplied by the load cell itself.

Two extensometers are positioned inside the sensor positioned under the basket, which swit‑

ch the relative weight inside the basket to an electric signal. The electric signal is sent to a

card (see photo) that elaborates it and identifies any dangerous conditions.

The maximum load depends on the work modality selected (par. 2.4.1.1 point 3). If the work

mode with jib has been selected, the load equals 120 kg. For the work mode with jib closed

jib the max. accepted load is 200 kg.

When the max. accepted load is reached, a flashing red light appears on the electric control

board as well as an acoustic signal and all platform movement is obstructed.

To restore platform functioning it is necessary to remove excess weight so as to fall within

the max. accepted weight.

BOOM LIFT MODELS X14JH

JLG

38

X14JHR0220311

Page 42

39

• Another alarm is triggered off, obstucting any aerial movement, in case, for any reason, the

basket is lifted by the loading sensor.

The Constructor recommends the maximum care in the proper keep of the entire safety com‑

ponents and in particular the system of the load sensor on the control car. Always check its

proper working if the basket should hit objects when doing jobs as this could cause problems

to the system (e.g. pruning, painting etc.).

2.5.7 CONTROL GUARDS

The control levers of all the distributors are protected against the

accidental falls of objects from the top and from involuntary acti‑

vating from the operator of special welded protection structures

and plate protections.

2.5.8 THE WATER LEVEL

The water level is situated near the control levers in a well visi‑

ble place from the basket. This is the manufacturer’s established

place to carry out all the translating, stabilising and raising ope‑

rations. The water level must be used to check that when the

platform is working, it is levelled at the maximum 1° admitted

inclination. To reach this, the water level must never be out of

the white zone.

An approximate levelling outside the limits imposed by the manufacturer can be seriously

dangerous and can jeopardise the stability of the platform causing risks, even mortal, to the

operator and the other people operating nearby and on the machine.

Never alter the regulations on the water level; this device has been calibrated by the Con‑

structor during the test prior to the sale. Only technicians having the proper tools and autho‑

rised by the Constructor can intervene on the water level.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

IMPORTANTE

DANGER

DANGER

IMPORTANT

PERICOLO

PERICOLO

Page 43

2.5.9 LOCKING PIN SCREWS AND NUTS

All the pins used in the platform have been treated against wear and are provided with wel‑

ded flanges (1) to prevent them from rotating inside their seat.

Some pins are provided with rotation locking screws (2) while others are provided with a

retaining block that is welded on the machine body (3).

The pins located in the most delicate positions have threaded ends and are provided with

self‑locking nuts (4) or self‑locking threaded ring nuts (4) to prevent the structure from colla‑

psing.

The correct tightening of all the pin locking devices must be checked carefully and regularly,

according to the intervals indicated by the machine manufacturer.

Never loosen the pin blocks and check regularly their proper tightening. Even If a pin comes

partially out of its seat, this could cause sudden and uncontrollable movements and also the

lost of stability of the machine and/or the falling of the control car.

2.5.10 FOOTSWITCH

To allow the aerial, undercarriage and stabilization movement

of the machine the footswitch device inside the basket must be

pushed.

2.6 EMERGENCY DEVICES

The emergency instructions reported below regarding the emergency devices are supplied to

the user so that they can understand the behaviour of the machine and the possible working

sequences; it will also be easier to identify them clearer and thus act quickly in case of emer‑

gency.

Before starting any operations, it is important that the operator checks the perfect working

order of the emergency devices.

BOOM LIFT MODELS X14JH

JLG

40

X14JHR0220311

4

1

1

2

3

DANGER

IMPORTANT

PERICOLO

IMPORTANTE

Page 44

41

2.6.1 EMERGENCY STOP PUSHBUTTON

It allows the complete stop of any function of the machine in case of emergency.

There are two devices on the machine for emergency stop. The first one is situated on the

platform crawler near the controls just above the fifth wheel (1), the second one is situated on

the basket and is directly fixed on the electric control panel of the control car (2). When the

device is on, turn the pushbutton to make the machine operative.

It is strongly recommended to follow the rule that forbids operating the platform without

anyone on the ground. In fact, an incidental operation (e.g. the falling of a branch) or volun‑

tary from strangers of the emergency stop pushbutton on the revolving turret would put the

occupants of the basket in the difficult situation of not been able to operate any movements,

except the descent with the emergency descent devices (par.2.4.1.5.).

2.6.2 SWITCH ENABLING EMERGENCY CONTROLS

These devices (1‑3) is a tap that allows the operator on the ground to switch the controls

from the control car to the emergency position situated on the revolving turret (2).

It is strongly recommended to follow the rule that forbids operating the platform without anyone

on the ground. In fact, activating the switch by unqualified people could put the occupants of the

basket in a difficult situation of not been able to operate any movements and to be dependable on

the operating movements from the ground. If this was to happen, activate the emergency push‑

button and ask for help, or use the emergency descent devices (par. 2.9.8).

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

2

1

IMPORTANTE

2

1

IMPORTANTE

IMPORTANT

IMPORTANT

3

Page 45

To avoid this danger there is a lever locking system by means of a padlock. You are remin‑

ded that the ground staff must always have a padlock key to intervene when needed.

2.6.3 HAND PUMP

The hand pump (2) serves to send the oil under pressure to do the manoeuvres in case of

emergency due to breakdowns of the main hydraulic system.

The hand pump is equipped with a manual switch (1) which allows to select the control of

the two right stabilisers (position 1) or the control of the two left stabilisers and the overhead

part of the structure (position 2).

The stabiliser control is only allowed if there are no anomalies in the electric system and

when the ignition key is ON.

In case of breakdown of the electric system, the overhead ‑

undercarriage change over switch must be manually applied

by using the mechanical switch inside the electrical compo‑

nents opening (see photo).

Always remember to remove the mechanical switch and restore the standard configuration

of the switch as soon as you finish the emergency operations. If there is the mechanical swit‑

ch when doing ordinary working operations this will compromise the safety of the machine,

causing possible dangerous situations.

Manoeuvring the stabilisers in case of emergency is only allowed in case of breakdown

of the machine and requires the closing the stabilisers for road transport.

BOOM LIFT MODELS X14JH

JLG

42

X14JHR0220311

1

2

DANGER

IMPORTANT

IMPORTANTE

PERICOLO

Page 46

43

To control the overhead part of the structure without electric current, always remove the nip‑

ple (3) of the electric valve (4 ) (the outer lead seal automatically breaks by unscrewing and

taking off the cap) and arm it manually pushing and turning the knob (5) underneath, il the

inner lead‑covered cable automatically breaks by reinforcing the electrovalve.

The manoeuvre of the stabilisers can be done through the hand pump by only turning the

ignition key ON and making sure that there is no failure of the electric system.

Remember to put back the solenoid valve knob (5) in the originary position paying attention

to reassemble the protective cap and to restore the double lead seal.

When manoeuvring the platform with the emergency controls you are without any safety

devices. It is therefore necessary and mandatory to act on the controls only to bring back the

basket to the ground and making sure to do these manoeuvres without causing the instabi‑

lity of the working platform.

2.6.4 SOLENOID VALVES FOR EMERGENCY DESCENT

The cylinders of the first, second and third arm are equip‑

ped with solenoid valves for emergency descent (1). Acting

on the emergency descent selector on the electric panel con‑

trols situated on the control car excites this solenoid valves

allowing the descent of the overhead part of the structure

through gravity.

The use of this emergency device is bound to the presence of

voltage in the platform electric system.

Follow the same precautions as reported at point 2.6.3

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

3

4

5

IMPORTANTE

1

DANGER

IMPORTANT

PERICOLO

Page 47

2.7 SAFETY REGULATIONS TO OBSERVE BEFORE USING THE PLATFORM

2.7.1 DANGER OF ELECTRIC FULMINATION

If the operator uses the machine near electrical lines, they must keep a clear distance. In the

chart below are the relative values for keeping a minimum distance from the electrical lines

according to their voltage.

Keep a safety distance from the distribution lines and electrical installations bearing in mind

the possible arc movements and oscillations of your working platform. Also bear in mind the

electric lines own oscillations.

Before starting operating, inspect the working area, taking note of the overhead electric lines,

of moving machinery like for example bridge cranes or road, railway or building equipment.

BOOM LIFT MODELS X14JH

JLG

44

X14JHR0220311

SAFETY DISTANCE NEAR ELECTRIC LINES

TYPE OF VOLTAGE SAFETY DISTANCE

FROM TO (METRES)

0 V 300 V 5

300 V 50 KV 5

50 KV 200 KV 5

200 KV 350 KV 6,1

350 KV 500 KV 7,6

500 KV 750 KV 10,7

750 KV 1000 KV 13,7

ATTENZIONE

ATTENZIONE

WARNING

WARNING

Page 48

45

2.7.2 DANGER DUE TO BAD WEATHER CONDITIONS

NEVER OPERATE IN BAD WEATHER

Never operate when there are storms, snow, fog and wind exceeding 12m/s. Never start the

machine when the ambient temperature is below –20°C and over +40°C.

In case of unexpected rain, always check that the machine is properly stabilised and that the

ground has a proper consistency before starting work again.

2.7.3 DANGER DUE TO THE WORKING AREA

THE MACHINE CAN EXCLUSIVELY WORK ON COMPACT AND LEVELLED GROUND.

Always check that the ground slope where the platform is positioned does not exceed 10°.

When stabilising, check with the water level near the main controls that the maximum incli‑

nation of the fifth wheel plane with respect to the horizontal line does not exceed 1°.

In running conditions, check if there are no people, holes, juttings, obstacles, rubble or things

that might cover holes.

Before entering high risk areas (petrol refineries, supply‑stations etc…), check its feasibility

with the plant safety staff.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

ATTENZIONE

IMPORTANTE

IMPORTANT

WARNING

Page 49

2.8 PROCEDURES FOR A PROPER USE

You will find below the using procedures of JLG platforms. Any use different from what is

specified here, unless previously authorised the Constructor, is absolutely forbidden.

2.8.1 OPERATOR’S RECAPITULATORY TABLE OF SAFETY REGULATIONS

You will find below the recapitulatory table with the general safety regulations that the ope‑

rator must follow carefully before starting operating the platform.