Jenn-Air JGW8130DDB Installation Instruction

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

GAS

INSTALLATION MANUAL

30 BUILT-IN OVENS

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

THE MANUAL IS INTENDED TO ASSIST IN THE INITIAL INSTALLATION AND ADJUSTMENTS OF THE RANGE.

SPECIAL WARNING

Only qualified personnel should install or service this range.

Read “Safety Instructions” in the Use & Care book before using range.

Improper installation, adjustment, alteration, service, maintenance or use of oven can result in serious injury or property damage.

NOTE: Check the model number plate on your 30 gas wall oven, located on bottom of control panel lower trim, to see if it is approved for installation in Canada.

CAUTION: Some cabinets and building materials are not designed to withstand the heat produced by the normal safe operation of a listed appliance. Discoloration or damage, such as delamination, may occur.

YOUR RANGE MAY NOT BE EQUIPPED WITH SOME OF THE FEATURES REFERRED TO IN THIS MANUAL.

8101P530-60

(01-03-00)

30 BUILT-IN GAS OVEN

-2-

30 BUILT-IN GAS OVEN/MICROWAVE

COMBINATION

-3-

INSTALLATION

A WIRING DIAGRAM IS ENCLOSED IN THE ENVELOPE WITH THIS BOOKLET; ALSO THERE IS A DIAGRAM GLUED TO THE UNIT, BEHIND CONTROL PANEL.

Check the oven model number plate to see if the oven is approved for installation in mobile homes and/or recreational vehicles. If approved the following items are applicable. NOTE: Oven model number plate is located on bottom of control panel lower trim.

Mobile Homes

The installation of an oven designed for mobile home installation must conform with the Manufactured Home Construction and Safety Standard, Title 24 CFR, part 3280 (formerly The Federal Standard for Mobile Home Construction and Safety, Title 24, HUD part 280) or, when such standard is not applicable, the Standard for Manufactured Home Installation, ANSI A225.1/NFPA 501A, or with local codes.

In Canada the oven must be installed in accordance with the current CSA Standard C22.1 - Canadian Electrical Code Part 1 and Section Z240.4.1 - Installation Requirements for Gas Burning Appliances in Mobile Homes (CSA Standard CAN/CSA - Z240MH).

Recreational Vehicles

The installation of an oven designed for recreational vehicles must conform with state or other codes or, in the absence of such codes, with the Standard for Recreational Vehicles, ANSI A119.2-latest edition.

In Canada the oven must be installed in accordance with CAN/CSA - Z240.6.2 - Electrical Requirements for R.V.’s (CSA Standard CAN/CSA - Z240 RV Series) and Section Z240.4.2 - Installation Requirements for Propane Appliances and Equipment in R.V.’s (CSA Standard CAN/CSA - Z240 RV Series).

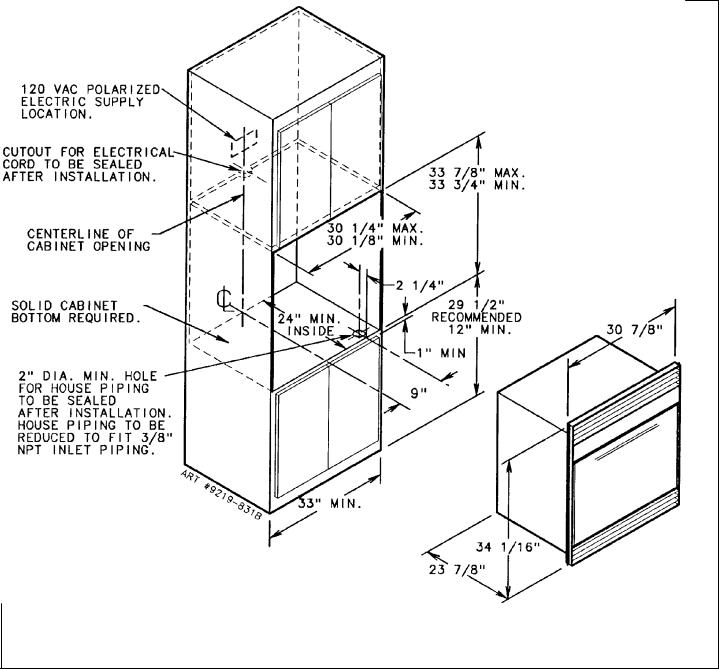

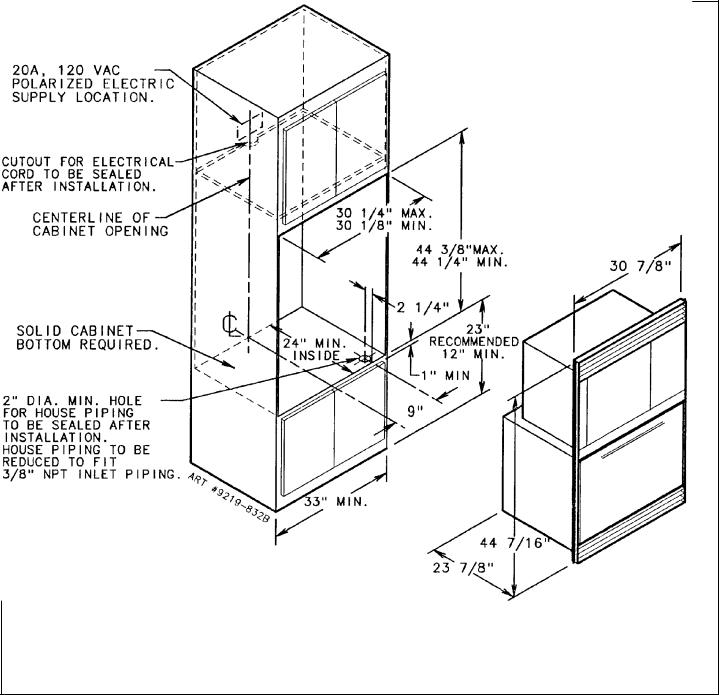

Clearance Dimensions

For complete information in regard to the installation of wall ovens and clearances see the installation drawings.

Locating The Unit

The installation drawing, gives the minimum dimensions of the cabinet cut-out for the oven and the location of the gas and electrical outlets. The dimensions given are for the oven bottom to be a minimum of 12 inches above the floor. The recess in which the oven is to be installed

should have a solid floor and be so constructed as to provide a complete enclosure around the recessed portion of the oven to prevent drafts which may result in inconsistent and unsatisfactory burner and baking performance, it should be perfectly level to provide a solid, level foundation for the oven unit. The openings in the enclosure for gas and electric service should be sealed before the oven is installed. Air for combustion enters at the extreme bottom of front panel. Do not block or obstruct this opening.

For SAFETY CONSIDERATIONS fasten the oven to the cabinet with the four (4) screws (shipped with the unit) through the holes in the trim behind the oven door. The unit should be leveled properly before being secured to the cabinet.

CONNECTING THE OVEN

Electric Supply

The appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

In Canada the oven must be installed in accordance with the current CSA Standard C22.1 - Canadian Electrical Code Part 1.

ELECTRICAL SUPPLY CONNECTION:

The oven requires 120 volts, 60 cycle alternating current from an outlet capable of supplying 15 amperes for non-combo units and 20 amperes for combo units (with microwave).

User may experience occasional circuit tripping if Ground Fault Circuit Interrupter (GFCI) outlet or breaker is in use.

WARNING

WARNING

Electrical Grounding Instructions

This appliance is equipped with a (three-prong) grounding plug for your protection against shock hazard and should be plugged directly into a properly grounded receptacle. Do not cut or remove the grounding prong from this plug.

WARNING

WARNING

DISCONNECT ELECTRICAL SUPPLY

BEFORE SERVICING THE APPLIANCE.

-4-

CONNECTING THE OVEN

Gas Supply

Installation of this oven must conform with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1-latest edition.

In Canada the oven must be installed in accordance with the current CGA Standard CAN/CGA-B149 - Installation Codes for Gas Burning Appliances and Equipment and/or local codes.

In The Commonwealth Of Massachusetts

This product must be installed by a licensed plumber or gas fitter when installed within the Commonwealth of Massachusetts.

A “T” handle type manual gas valve must be installed in the gas supply line to this appliance.

A flexible gas connector, when used, must not exceed a length of three (3) feet / 36 inches.

GAS SUPPLY CONNECTION:

A QUALIFIED SERVICEMAN OR GAS APPLIANCE INSTALLER MUST MAKE THE GAS SUPPLY CONNECTION. Leak testing of the appliance shall be conducted by the installer according to the instructions given in section h.

NATURAL GAS SUPPLY LINE MUST HAVE A NATURAL GAS SERVICE REGULATOR. INLET PRESSURE TO THIS APPLIANCE SHOULD BE REDUCED TO A MAXIMUM OF 14 INCHES WATER COLUMN (0.5 POUNDS PER SQUARE INCH (P.S.I.) LIQUEFIED PETROLEUM (L.P.)/PROPANE GAS SUPPLY LINE MUST HAVE A L.P. GAS PRESSURE REGULATOR. INLET PRESSURE TO THIS APPLIANCE SHOULD BE REDUCED TO A MAXIMUM OF 14 INCHES WATER COLUMN (0.5 P.S.I.). INLET PRESSURES IN EXCESS OF 0.5 P.S.I. CAN DAMAGE THE APPLIANCE PRESSURE REGULATOR AND OTHER GAS COMPONENTS IN THIS APPLIANCE AND CAN RESULT IN A GAS LEAK.

a.A GAS CUTOFF VALVE SHOULD BE PUT IN AN ACCESSIBLE LOCATION IN THE SUPPLY LINE AHEAD OF THE UNIT, FOR TURNING ON AND TURNING OFF GAS SUPPLY. If the unit is to be connected to house piping with flexible or semi-rigid metal connectors for gas appliances, CONNECTOR

NUTS MUST NOT BE CONNECTED DIRECTLY TO PIPE THREADS. THE CONNECTOR MUST BE INSTALLED WITH ADAPTORS PROVIDED WITH THE CONNECTOR.

b.The house piping and/or oven connector used to connect the oven to the main gas supply must be clean, free of metal shavings, rust, dirt and liquids (oil or water). Dirt, etc. in the supply lines can cause failure of the gas valves or controls and clog burners.

CAUTION: DO NOT LIFT OR MOVE THE WALL OVEN BY THE DOOR HANDLES.

c.Turn off all pilots and main gas valve of other gas appliances.

d.Turn off main gas valve at meter.

e.Before connecting the unit, apply pipe thread compound approved for LPG to all threads.

f.Connect unit to gas supply.

g.Turn on main gas valve at meter, and relight pilots at other gas appliances.

h.Apply a non-corrosive leak detection fluid to all joints and fittings in the gas connection between the supply line shut-off valve and the range. Include gas fittings and joints in the range if connections were disturbed during installation. Check for leaks! bubbles appearing around fittings and connections will indicate a leak. If a leak appears, turn off supply line gas shut-off valve, tighten connections, turn on the supply line gas shut off valve, and retest for leaks. Never test for gas leaks with an open flame.

CAUTION: NEVER CHECK FOR LEAKS WITH A FLAME.

WHEN LEAK CHECK IS COMPLETE, WIPE OFF ALL RESIDUE.

i.Adjust burner air shutter to the widest opening that will not cause the flame to lift or blow off the burner when cold.

BEFORE LIGHTING ANY BURNER, SEE THAT ALL PACKING MATERIALS HAVE BEEN REMOVED FROM THE UNITS.

-5-

UNIT ADJUSTMENTS

Wall Oven Adjustment

ELECTRIC IGNITION - BAKE BURNER WITH ELECTRIC GLOW BAR

a.The bake burner is equipped with an electric control system as well as an electric oven burner ignitor. This control system requires NO adjustment. To operate, press Bake Temp or Broil button, turn set knob to desired temperature or Hi/Lo broil. Current will flow to the ignitor. It will “glow” similar to a light bulb. (This glow may be reflected into the oven through the openings in the oven bottom). When the ignitor has reached a temperature sufficient to ignite gas, the electrically controlled oven valve will open and flame will appear at the oven burner. There is a time lapse from 30 to 45 seconds after the unit is turned ON before flame appears at the oven burner. When the oven has reached the dial setting, the glowing ignitor will go OFF. The burner flame will go “out” in 20 to 30 seconds after the ignitor goes “OFF”. To maintain any given oven temperature this cycle will continue as long as the dial is at the given temperature.

b.In case servicing should become necessary, a manual gas valve to shut off the gas to the oven burner is supplied between the gas regulator and the gas inlet. It is located at the right front of the oven bottom. To access the shut off valve, remove the louvered bottom trim.

c.The oven CANNOT be used during periods of power outage. In case of power failure, turn the thermostat to the OFF position.

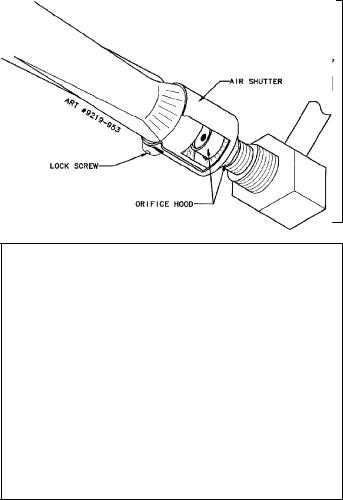

AIR SHUTTER - OVEN BURNER

a.The approximate length of the flame of oven burner is a 1/2 inch distinct blue flame, figure 1.

b.Oven burner flame can be checked as follows, without burner baffle in place:

1.Yellow flame on burner - open burner air shutter to the widest opening that will not cause the flame to lift or blow off the burner when cold. (See figure 2.)

2.Distinct blue flame but lifting - close burner air shutter to the point where it will not cause the flame to lift or blow off the burner when cold. (See figure 2.)

FIGURE 1

FIGURE 2

-6-

GAS CONVERSION

General

All ovens are equipped with double coaxial (universal) orifices and with a convertible appliance pressure regulator. The oven model number plate states which gas it was adjusted for at the factory. NOTE: Oven model number plate is located on bottom of control panel lower trim. To convert the unit to either Natural gas or LP gas will require adjustment of the orifice hood and air shutter on the burner and adjustment of the appliance pressure regulator converter cap.

Inlet pressure to the appliance pressure regulator should be as follows for both operation and checking of appliance pressure regulator setting:

INLET PRESSURE IN |

NATURAL |

LP |

INCHES OF WATER COLUMN |

GAS |

GAS |

Minimum |

5 |

11 |

Maximum |

14 |

14 |

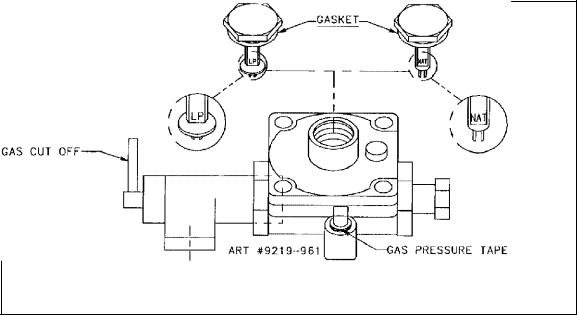

Appliance Pressure Regulator Conversion

The ovens appliance pressure regulator must be set to match the type of gas supply used. If converting from natural gas to LP gas, the appliance pressure regulator must be converted to regulate LP gas. If converting from LP gas to natural gas, the appliance pressure regulator must be converted to regulate natural gas. The type of gas for which the regulator is set for will be visible on the plastic plunger which is snapped on to the bottom of the brass hex nut (either Nat. or LP).

TO CONVERT THE APPLIANCE PRESSURE REGULATOR FROM ONE GAS TO ANOTHER, DO THE FOLLOWING:

1. Remove the brass hex nut from the regulator.

2.Unsnap the plastic plunger from the bottom of the brass hex nut, and turn the plunger over. The gas type you are converting to MUST be visible on lower side of plunger.

3.Snap plunger back in to bottom of the brass hex nut, and install brass hex nut back into regulator. (See figure 3).

Checking Manifold Gas Pressure

BUILT-IN OVENS:

On built-in ovens, remove 1/8 inch pipe plug from side of gas pressure regulator, install 1/8 “B” valve, 1/8 inch piece of pipe, connect manometer, make sure main burner is on to obtain accurate pressure check.

Be sure the gas supply (house piping) pressure is at least one inch (1 ) above specified range manifold pressure. The gas supply pressure should never be over fourteen inches (14 ) water column.

Checking Pressure Of House Piping

System

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2 lbs./sq. in. (14 in. W.C.).

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 lbs./sq. in. (14 in. W.C.).

(SHOWN IN OFF POSITION) TURN COUNTERCLOCKWISE TO “ON” POSITION.

WHEN THE INSTALLER HAS COMPLETED INSTALLATION OF APPLIANCE, LEAVE THE APPLIANCE PRESSURE REGULATOR SHUT-OFF VALVE IN THE “ON” POSITION.

-7-

ORIFICE CONVERSION

1.FROM NATURAL GAS TO LP/PROPANE GAS:

a.Change the appliance pressure regulator from natural to LP setting. (See figure 3).

b.Screw the burner orifice hoods down tight against the pins. (See figure 4B). Use care to not over tighten. Over tightening can damage the coaxial pin inside the orifice hood.

c.Adjust burner air shutter to the widest opening that will not cause the flame to lift or blow off the burner when cold.

NOTE: Correctly adjusted sealed burners, can have flames that will lift or blow without a pot over the burner. These should be adjusted with a pot in place.

FIGURE 4A |

FIGURE 4B |

NATURAL GAS |

LP GAS |

SETTING |

SETTING |

|

|

2.FROM LP/PROPANE GAS TO NATURAL GAS:

a.Change the appliance pressure regulator from LP to natural setting. (See figure 3).

b.Screw the burner orifice hoods away from the pins. (See figure 4A). Approximately 1 1/2 to 2 turns.

c.Adjust burner air shutter to the widest opening that will not cause the flame to lift or blow off the burner when cold.

NOTE: Correctly adjusted sealed burners, the flame will lift or blow without a pot over the burner. These should be adjusted with a pot in place.

SERVICE - PARTS INFORMATION

WHEN YOUR RANGE REQUIRES SERVICE OR REPLACEMENT PARTS, CONTACT YOUR DEALER OR AUTHORIZED SERVICE AGENCY. PLEASE GIVE THE COMPLETE MODEL AND SERIAL NUMBERS OF THE RANGE WHICH IS LOCATED ON THE RANGE MODEL NUMBER PLATE.

-8-

Loading...

Loading...