Janome 1600P, 1600-DB, 1600-DBX Servicing Manual

Servicing Manual

1600P, 1600-DB &1600-DBX

Replacing the External Parts

Face plate .................................................................................................... 1

Top Cover .....................................................................................................1

Belt Cover ....................................................................................................1

Motor Cover .................................................................................................1

Base ............................................................................................................. 1

Mechanical Adjustment

Needle Bar Height ........................................................................................ 2

Presser Bar Height .......................................................................................2

Feed Dog Height ..........................................................................................3

Feed Dog Alignment .................................................................................... 3

Feed Cam Timing.........................................................................................4

Feed Lifting Cam Timing ..............................................................................5

Needle to Hook Timing................................................................................. 6

Clearance between Needle and Hook Point ................................................6

Hook Stopper Position ................................................................................. 7

Bobbin Winder Stopper ................................................................................8

Check Spring Stroke ....................................................................................9

Pretension Dial ............................................................................................. 9

Knee Lifter Lever ........................................................................................ 10

Needle Stop Position.................................................................................. 11

Needle Threader (1600P only) ................................................................... 12

Replacing the Electronic Components

Location of the Electronic Components .....................................................13

Location of the Connectors ........................................................................14

Internal Wiring ............................................................................................15

Circuit Board-A ........................................................................................... 16

Circuit Board-F and Slide Volume ..............................................................16

Driving Motor ........................................................................................ 17-18

Power Transformer ..................................................................................... 19

Machine Socket .......................................................................................... 19

Light Bulb ................................................................................................... 20

Adjustment of the Thread Cutter Mechanism

(1600P and 1600-DBX only)

Static Cutter Blade .....................................................................................21

Thread Cutter Blade................................................................................... 22

Thread Guide Plate .................................................................................... 23

Needle to Cutter Cam Timing..................................................................... 24

Thread Drawing Lever ................................................................................25

Auto Tension Release ................................................................................ 26

Thread Cutter Troubleshooting................................................................... 27

Table of Contents

1

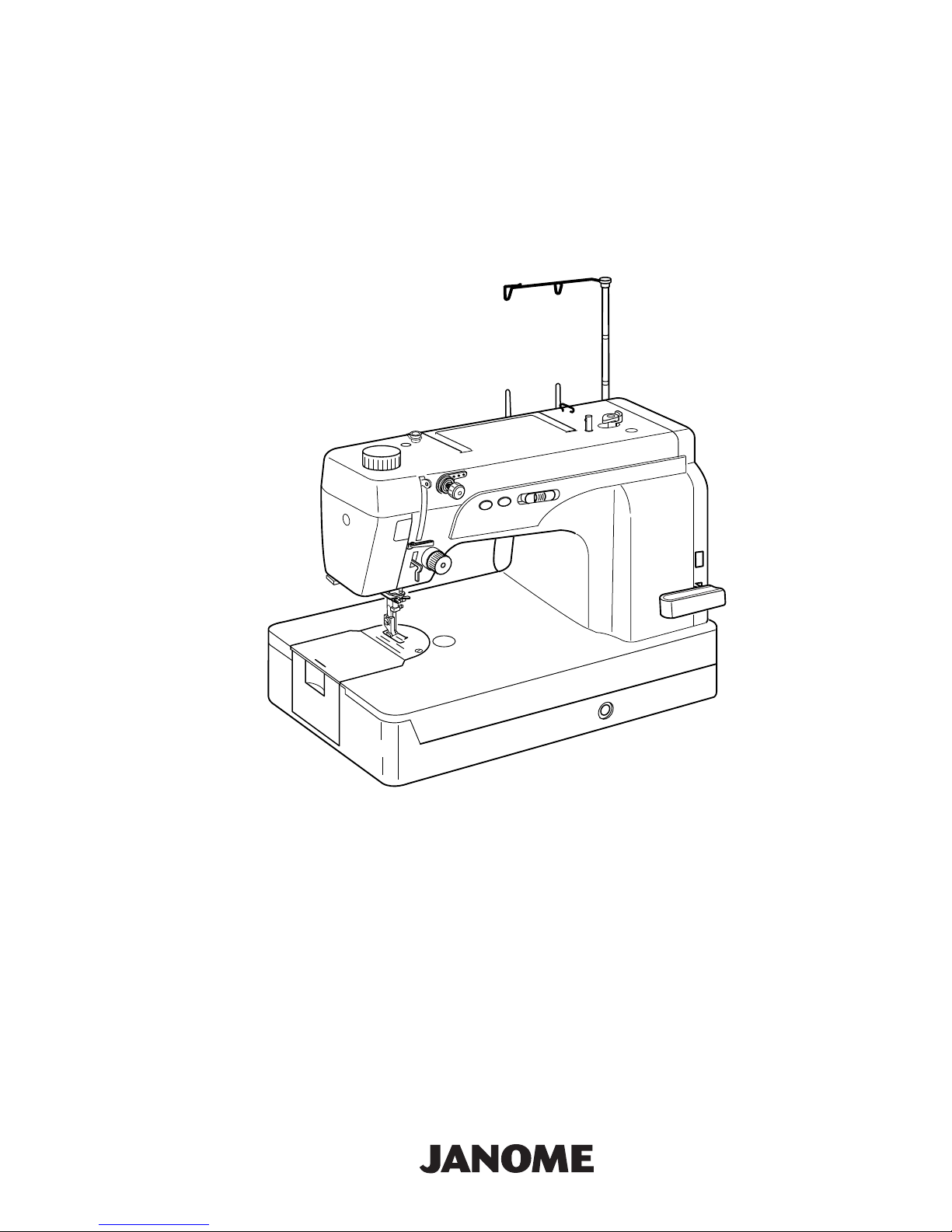

Replacing the External Parts

1. Face Plate

2. Top Cover

3. Belt Cover

4. Motor Cover

5. Base

Remove the setscrew (1) and washer (2). Remove the face plate (3).

Remove the 2 setscrews (4).

Lift the top cover (5) and pull out the motor

connector (6). Remove the top cover.

Remove the 3 setscrews (7) and remove the belt

cover (8).

NOTE:

When attaching the belt cover, engage the hooks

with the motor cover.

Remove the 3 setscrews (9) and remove the

motor cover (10).

Remove the 4 hinge screws (11), washers (12),

rubber feet (13) and base washers (14). Remove

the base (15).

(1)

(2)

(3)

(4)

(4)

(5)

(6)

(7)

(7)

(8)

(10)

(9)

(9)

(11)

(15)

(11)

(11)

(11)

(12)

(13)

Follow the above procedures in reverse.

To attach:

To remove:

(14)

2

Mechanical Adjustment

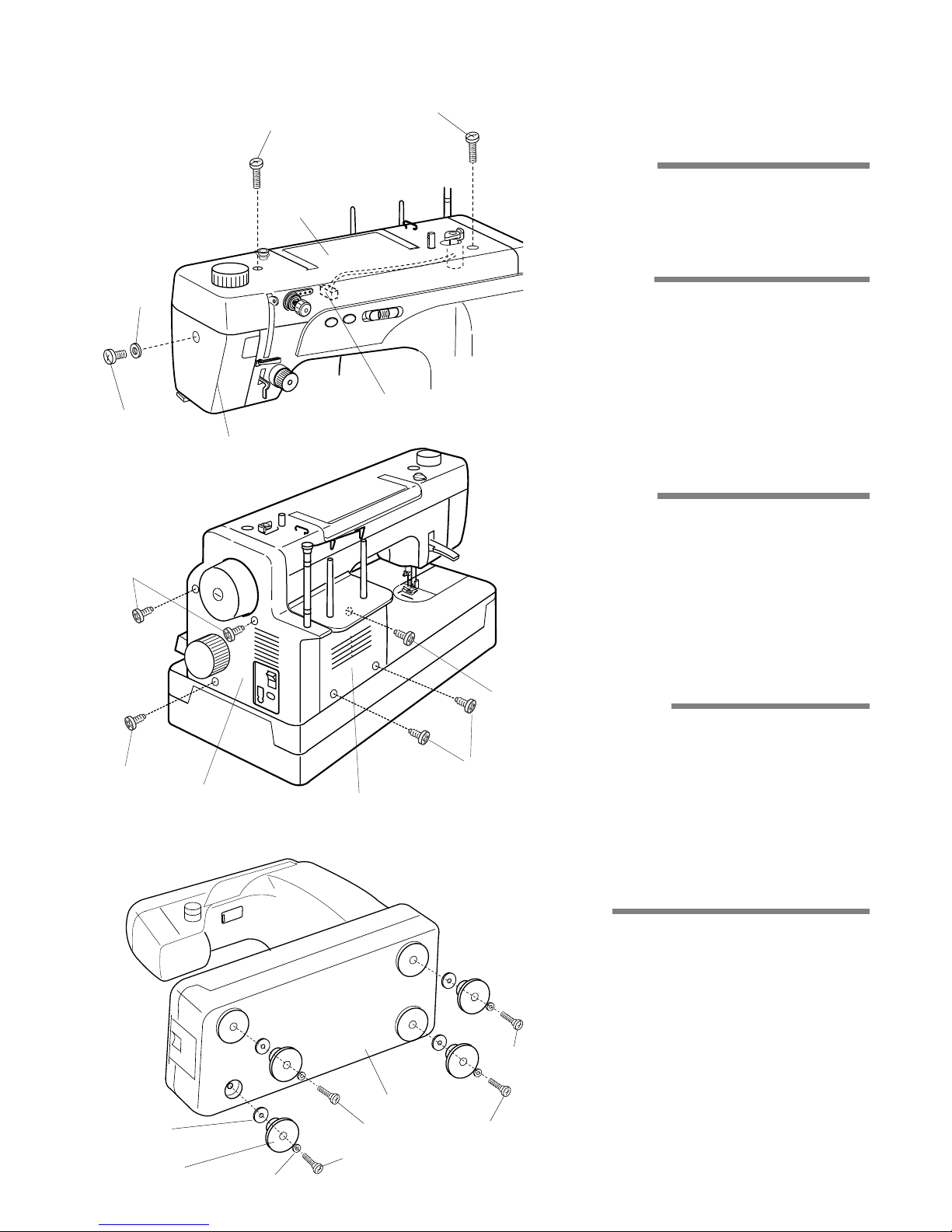

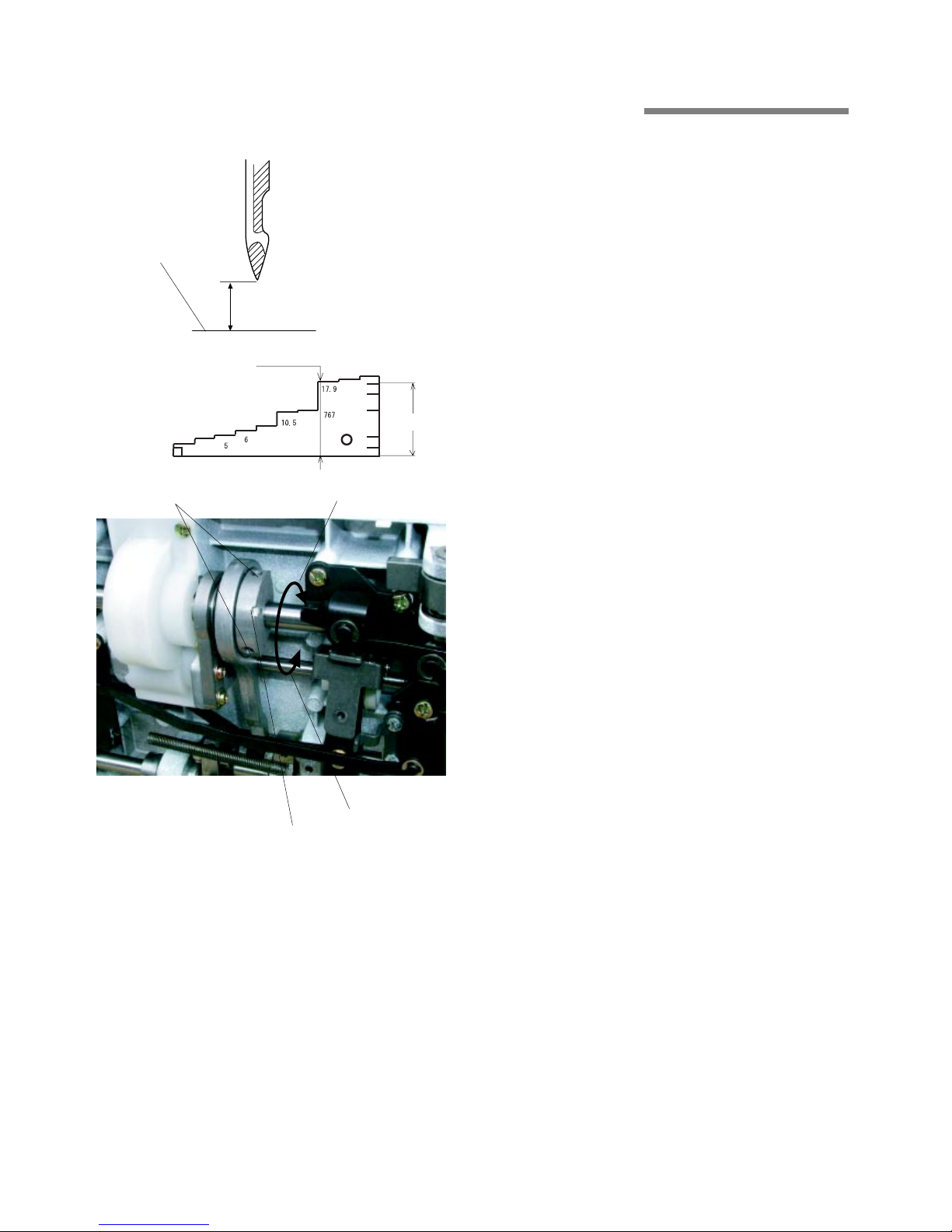

1. Needle Bar Height

2. Presser Bar Height

[1] Remove the face plate.

[2] Turn the handwheel to bring the needle bar (1) to the

lowest position.

[3] Loosen the setscrew (2). Move the needle bar (1) up

or down and match the upper hairline (3) with the

bottom edge of the needle bar bushing (4).

NOTE:

Be sure not to rotate the needle bar when adjusting the

needle bar height. The needle clamp screw should be

parallel to the upper shaft.

[4] Tighten the setscrew and attach the face plate.

(1)

(3)

(4)

(2)

The distance between the bottom of the presser foot in

up position and the needle plate should be 5.7 - 6.3 mm.

[1] Remove the face plate and needle.

[2] Lower the feed dog below the needle plate. Place a

block 6 mm thick under the presser foot and lower

thepresser foot lifter.

(Use the 4th step from the left of the Gauge 767G-

001).

[3] Loosen the setscrew (1). Raise the presser foot lifter

while holding presser bar. Tighten the setscrew (1)

firmly.

Attach the needle and face plate.

NOTE:

Make sure that the presser foot should be parallel to the

feed dog slots (2) in the needle plate and that the needle

does not touch the presser foot.

6 mm

(1)

(2)

Presser foot should be parallel

to the feed dog slots.

6mm

3

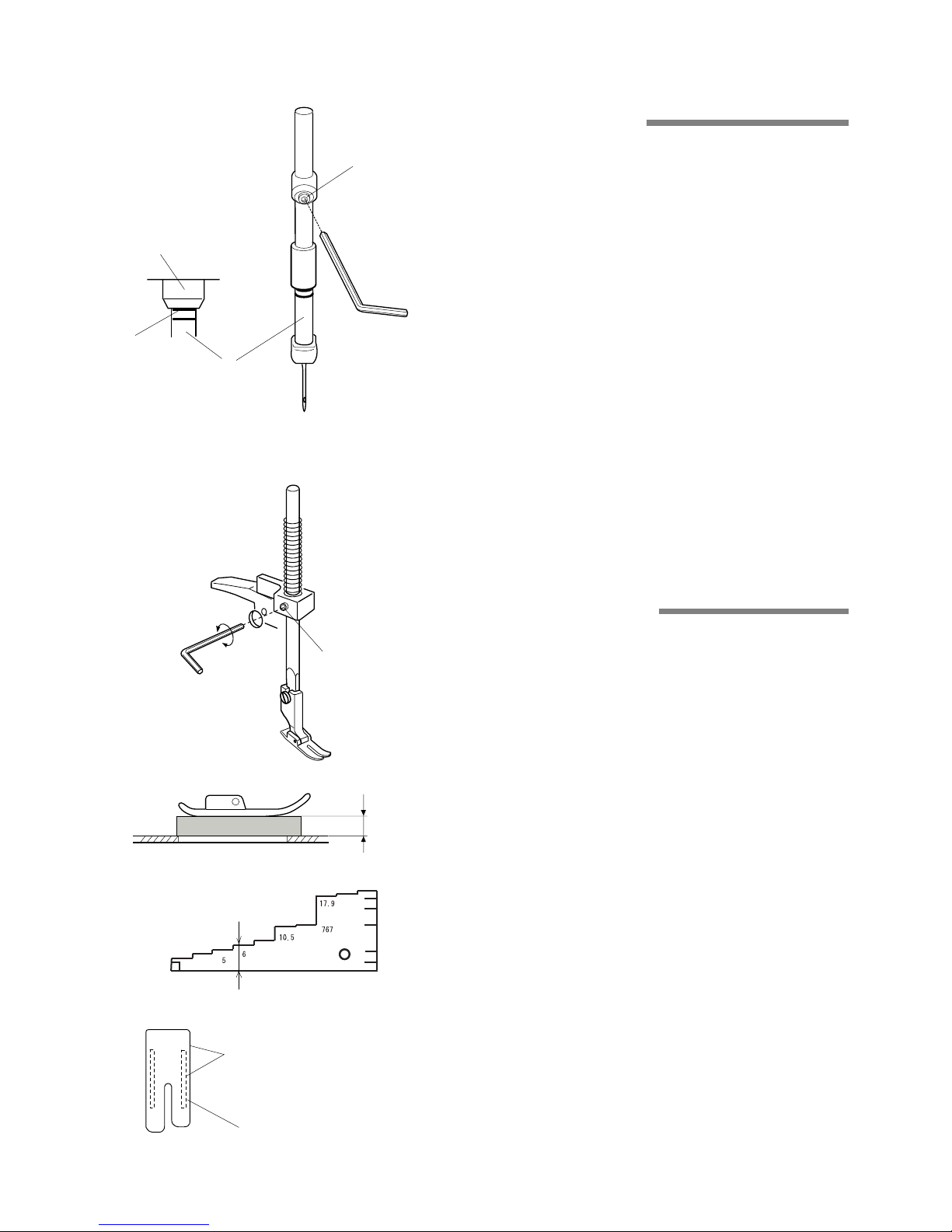

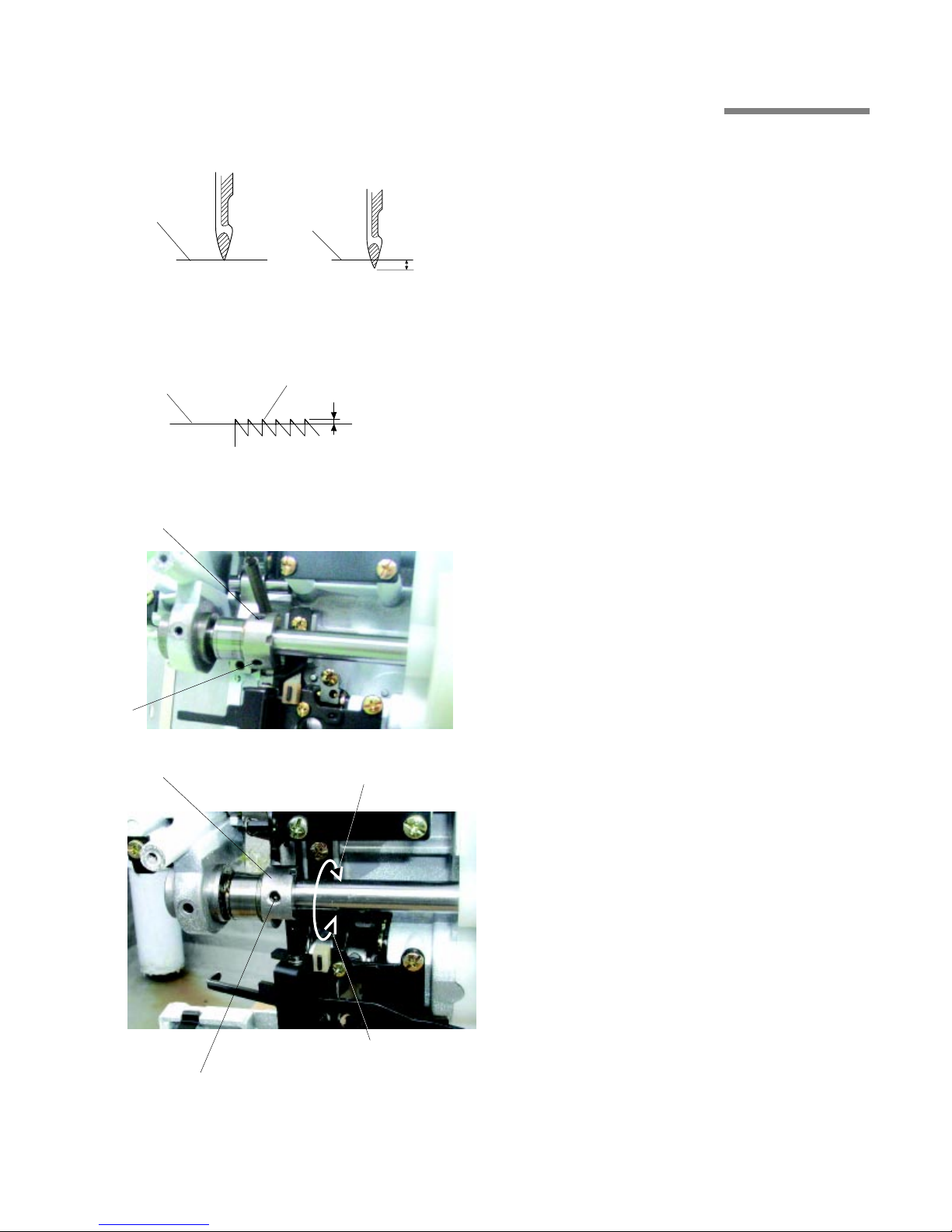

3. Feed Dog Height

When the feed dog is fully raised the height should be

0.8 - 1.0 mm above the needle plate.

[1] Set the stitch length dial at 6 (Maximum). Turn the

hand wheel to bring the feed dog to the highest

position.

[2] Loosen the setscrew (1).

[3] Turn the eccentric pin (2) to adjust the feed dog height

to 0.9 mm.

- If the feed dog is too low, turn the pin to the right (3).

- If the feed dog is too high, turn the pin to the left (4).

[4] Tighten the setscrew (1).

0.8 - 1.0

mm

(1)

(3)

(4)

(2)

4. Feed Dog Alignment

The lateral gaps between both sides of feed dogs and

needle plate slots should be even.

The clearance between the front end of the center feed

dog and center slot should be 4.2 - 4.8 mm when the

stitch length dial is set at 0.

[1] Remove the base and lay the machine on its back.

[2] Set the stitch length dial at 0.

[3] Loosen the setscrews (1). Move the feed base (2) up

or down to adjust the clearance (3) between the front

end of the center feed dog and center slot to 4.5 mm.

(Use the marking on the Gauge 767G-001). Adjust the

lateral position of the feed dogs by moving the feed

rock shaft (4) to the right or left if necessary.

[4] Tighten the setscrews (1). Set the stitch length dial

at 6 and turn the handwheel to check if the feed dogs

do not touch the needle plate.

[5] Attach the base.

(1)

(3)

(4)

(2)

Lateral gaps should be even.

4.2 - 4.8

mm

4.5 mm

4

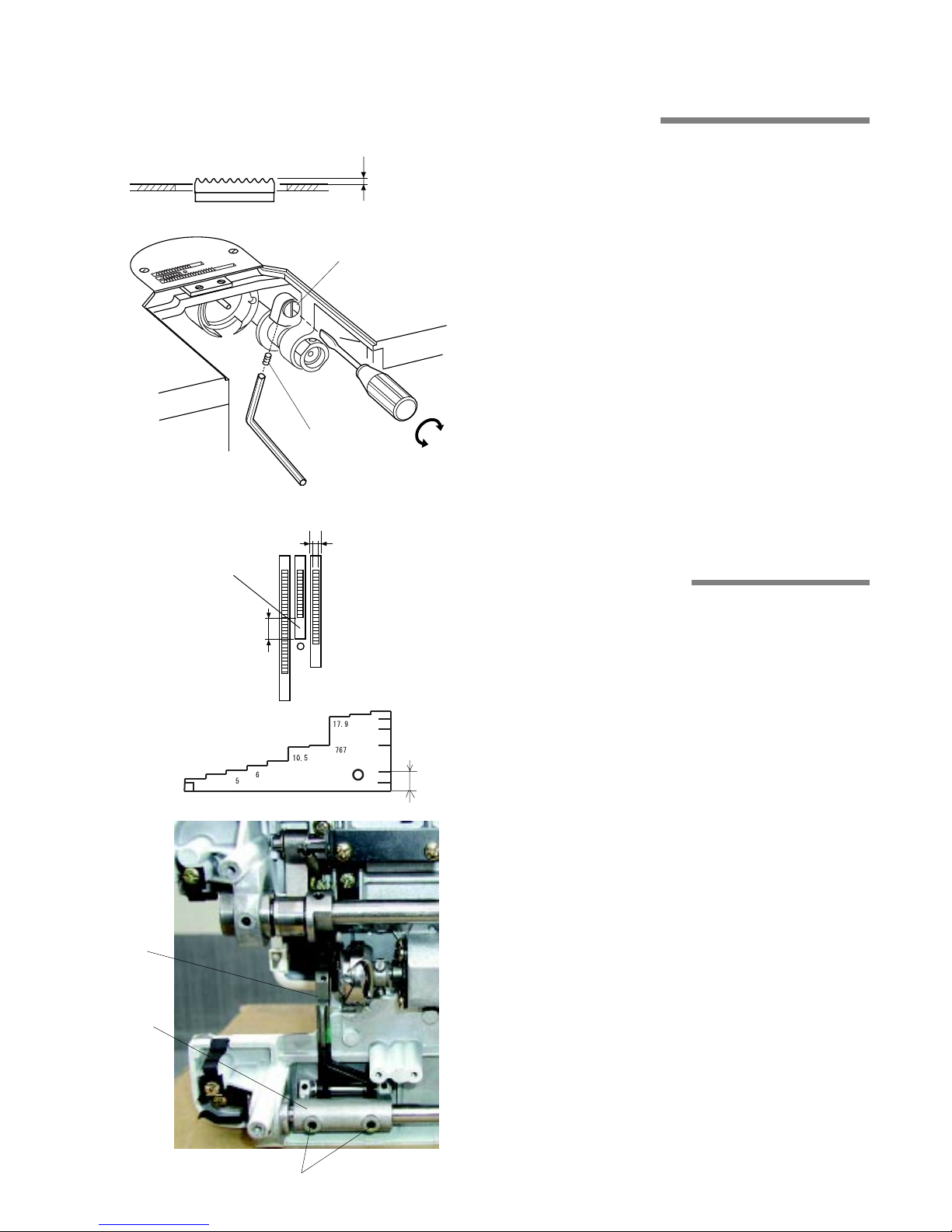

5. Feed Cam Timing

To Check:

[1] Lower the needle bar by turning the handwheel until

the point of the needle is 17.9 mm (for 1600P-DB/

DBX) or 17.5 mm (for 1600P) above the upper

surface of the needle plate (1).

[2] The feed dogs should not move when moving the

reverse stitch lever up and down.

If the feed dogs move, adjust the feed cam timing as

follows.

To Adjust:

[1] Remove the base and lay the machine on its back.

[2] Lower the needle bar until the needle point is 17.9

mm (for 1600P-DB/DBX) or 17.5 mm (for 1600P)

above the needle plate (1).

(Use the third step from the right for 17.9 mm or the

marking for 17.5 mm on the Gauge 767G-001).

[3] Loosen the setscrews (2).

While moving the reverse stitch lever, turn the feed

cam (3) in the direction either A or B until the feed

dogs stop moving.

[4] Tighten the setscrews (2) and attach the base.

(1)

(3)

(2)

A

B

17.9 mm (1600P-DB/DBX)

17.5 mm (1600P)

17.9 mm

17.5 mm

5

6. Feed Lifting Cam Timing

To check:

[1] Lower the needle bar until the point of needle is level

with the upper surface of the needle plate (1) (1600PDB/DBX) or 0.4 mm below the needle plate (1600P).

[2] The top of the feed dogs (2) should be 0 - 0.1 mm

above the needle plate.

To adjust:

[1] Remove the base and lay the machine on its back.

* You may set the stitch length dial at any position.

[2] Loosen the setscrew (3).

Lower the needle bar until the needle point is level

with the needle plate (1)(1600P-DB/DBX) or 0.4 mm

below the needle plate (1600P).

[3] Loosen the setscrew (4).

[4] If the feed dogs are higher, turn the feed lifting cam

(5) in the direction A.

If the feed dogs are lower, turn the feed lifting cam (5)

in the direction B.

[5] Tighten the setscrew (3) and attach the base.

(1)

(4)

(2)

(1)

(1)

(5)

A

B

0.4 mm

0 - 0.1 mm

1600P-DB/DBX

1600P

(3)

(4)

6

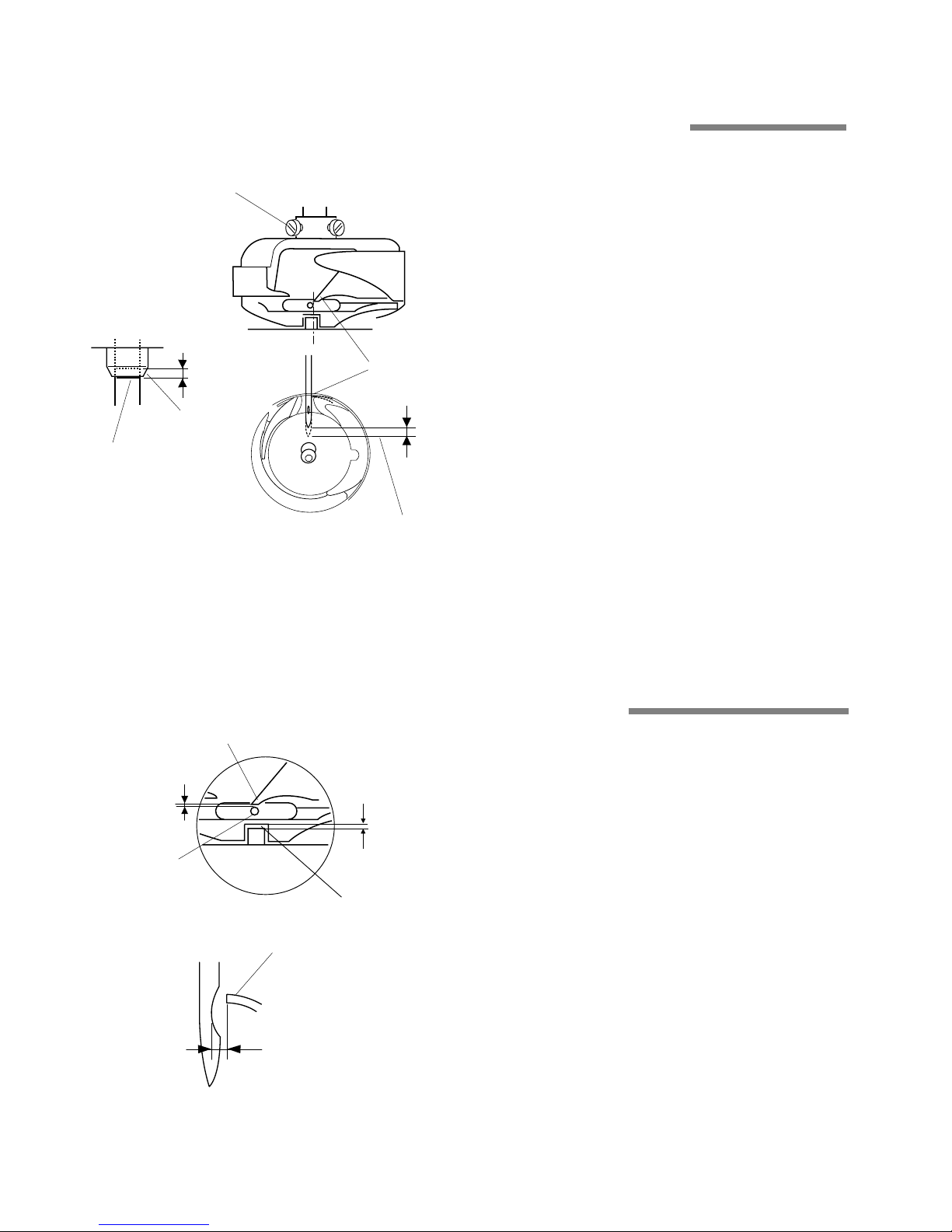

7. Needle to Hook Timing

8. Clearance between Needle

and Hook Point

[1] Remove the needle plate.

[2] Loosen the 3 setscrews (1). Pull out the hook race

very slightly (less than 0.5 mm).

[3] Raise the needle bar from the lowest position until the

lower hairline (2) of the needle bar matches the edge

of the needle bar bushing (3).

NOTE:

The needle bar rises 2 mm from the lowest position.

[4] Rotate the hook to match the hook point (4) with the

right side of the needle.

[5] Tighten the setscrews (1) slightly and proceed with

the adjustment of the clearance between the needle

and hook point.

(4)

(1)

(2)

(3)

Lowest position

2 mm

2 mm

The clearance between the needle and hook point

should be 0 - 0.1 mm.

[1] Turn the handwheel to bring the hook point (1) behind

the needle (2).

[2] Knock on the hook race rim lightly to make a slight

clearance between the needle and hook point.

NOTE:

Do not knock on the hook body.

[3] Tighten the setscrews firmly and check the needle to

hook timing and the thread path (3) (0.4 - 0.8 mm). If

not, replace the hook race stopper with new one.

(There is no way to adjust.)

[4] Attach the needle plate.

(1)

(2)

(1)

0 - 0.1

mm

0 - 0.1

mm

0.4 - 0.8 mm

(3)

7

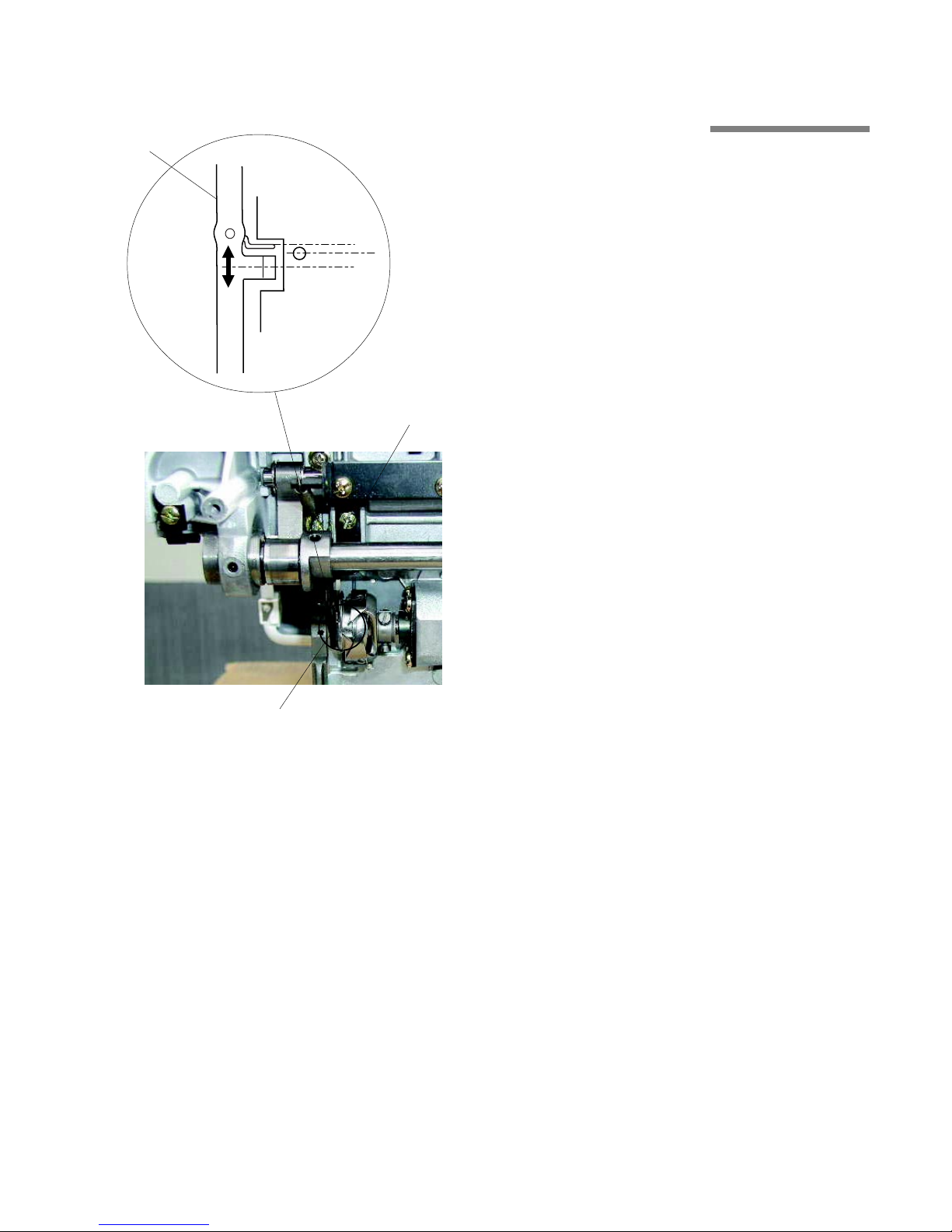

9. Hook Stopper Position

[1] Remove the base, needle plate and feed dog.

[2] Loosen the setscrew (1) and move the hook stopper

(2) so that the center of the needle (3) is located

between the center of the hook stopper (4) and outer

side of the hook stopper spring (5).

[3] Tighten the setscrew (1) and attach the feed dog,

needle plate and base.

(1)

(2)

(3)

(5)

(4)

(2)

Loading...

Loading...