Page 1

Vehicle Care Handbook

Foreword

JAGUAR CARS LIMITED,

dedicated to the design and production of vehicles which meet

the expectations of the world's most discerning purchasers.

To complement the features, systems and technology of your

new vehicle we have produced this Vehicle Care Handbook. In

it we have undertaken to provide information on vehicle care

and maintenance to enable you to obtain lasting pleasure and

reliability from your vehicle.

The information contained herein applies to a range of vehicles

and not to a specific vehicle. For the specification of a particular

vehicle, owners should consult their Jaguar Dealer.

Published July 1999 by Parts and Service Communications Jaguar Cars Limited Publication Part No. JJM 18 16 12/00

as manufacturers, are

The Manufacturer reserves the right to vary its specifications

with or without notice, and at such times and in such manner as

it thinks fit. Major as well as minor changes may be involved in

accordance with the Manufacturer's policy of constant product

improvement.

All rights reserved. No part of this publication may be

reproduced, stored in a retrieval system or transmitted, in any

form, electronic, mechanical, photocopying, recording or other

means without prior written permission from the Service

Division of Jaguar Cars Limited.

Page 2

Contents

1. Introduction

General Information . . . . . . . . . . . . . . . . . . . . . . . .1-1

Safety Warning and Caution Labels . . . . . . . . . . . . .1 -5

General Precautions . . . . . . . . . . . . . . . . . . . . . . . .1 -6

Hood Release Control . . . . . . . . . . . . . . . . . . . . . . .1 - 8

2. Cleaning

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -1

Exterior Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -1

Interior Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3. Routine checks

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 -1

Regular Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Reservoir and Dipstick Locations . . . . . . . . . . . . . . .3 - 2

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Recommended Engine Oil . . . . . . . . . . . . . . . . . . . .3 -9

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 10

4. Roadside emergency service

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -1

Spare Wheel and Jacking Equipment . . . . . . . . . . . .4-1

Wheel Changing and Jacking . . . . . . . . . . . . . . . . . .4-2

Loosening the Wheel Nuts. . . . . . . . . . . . . . . . . . . . 4 -2

Emergency Starting . . . . . . . . . . . . . . . . . . . . . . . . .4- 8

Vehicle Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 10

Fuses and Fuse Boxes . . . . . . . . . . . . . . . . . . . . . . . 4 -12

Fuse Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 16

Control Modules – Identification and Location . . . .4-21

Relay Identification and Location. . . . . . . . . . . . . . .4-22

5. Vehicle maintenance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -1

Regular Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5- 6

Generator (GEN) . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 6

Bulb Renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -9

Bulb Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5- 18

Windscreen Wiper Blade . . . . . . . . . . . . . . . . . . . . .5-19

Windscreen Washers. . . . . . . . . . . . . . . . . . . . . . . .5-19

Page 3

6. Specifications

Weights (Average/Approximate) . . . . . . . . . . . . . . . 6- 2

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6- 5

Fuel Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

7. Accessories

Electrical Accessories . . . . . . . . . . . . . . . . . . . . . . . 7-1

Electrical Accessory Supply Sockets . . . . . . . . . . . . 7-1

Earth Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

A comprehensive index is located at the back of this book.

Contents

Page 4

Contents

Page 5

1 Introduction

Introduction 1-1

General Information

When left-hand or right-hand is used in

the text, this refers to the left-hand side

or right-hand side of the vehicle, viewed

from the rear.

Jaguar Dealers

Jaguar Dealers are chosen with care. Each

is dedicated to providing a Sales, Service

and Genuine Jaguar Parts facility of the

highest standard.

Jaguar Dealers provide full technical

back-up from the factory with

comprehensive training for all their

technicians. All Dealers’ workshops

operate to the highest standard and have

all the necessary approved tools and

equipment essential to maintain or repair

Jaguar vehicles.

The Jaguar Diagnostic System

Many of the vehicle systems are

controlled by complex electronic devices.

The equipment used to assist diagnosis of

faults in the electrical and electronic

systems of the vehicle is unique and is

only available to Jaguar Dealers. Use of

this equipment will enable the Dealer to

trace and rectify faults in the system and

ensure that only faulty components are

repaired or replaced.

Caution: Severe damage to the

electrical system and electronic

components can occur if any attempt

is made to diagnose faults in the

electrical system using conventional

diagnostic equipment (for example,

the use of test lamps, low impedance

voltmeters, etc.).

Regular Servicing

Each vehicle is given a full ‘Pre-Delivery

Inspection’ to ensure that all systems

function correctly and the vehicle meets

its specification.

Regular maintenance and servicing is the

responsibility of the owner. Jaguar

Dealers will be pleased to arrange

periodic servicing in accordance with the

USA/Mexico ‘

Booklet or Canadian ‘

Warranty and Benefits Information

Booklet.

USA and Mexico

arrange appointments on a mileage or

time interval basis to ensure that all

routine and corrective maintenance work

is undertaken and recorded in the

‘

Passport to Service

Canada

appointments on a distance or time

interval basis to ensure that all routine

and corrective maintenence work is

undertken and recorded in the ‘

Jaguar

Failure to implement maintenance at the

recommended intervals could result in

deterioration of vehicle performance and

possible infringement of regulations.

Passport to Service

Club Jaguar

: Jaguar Dealers will

’ Booklet.

: Jaguar Dealers will arrange

’ Warranty and Benefits Booklet.

’

’

Club

Page 6

1-2 Introduction

Maintenance Summary

It is the owner’s responsibility to ensure that the vehicle is

maintained in accordance with the Maintenance Schedules.

Repairs resulting from a failure to maintain are not covered by

the warranty.

The USA/Mexico ‘

‘

Club Jaguar

convenient document to record all maintenance services on the

vehicle.

All vehicle literature should be passed to any subsequent owner

at the time of resale.

USA and Mexico

available, a replacement may be obtained by writing to the

Consumer Relations Department, Jaguar Cars, 555 MacArthur

Boulevard, Mahwah, New Jersey 07430, quoting the vehicle

identification number from the plate located inside the

windscreen, plus the date of purchase and current mileage or

kilometres.

Canada

Information Booklet is not available, a replacement may be

obtained by writing to the consumer Relations Department,

Jaguar Canada, 8 Indel Lane, Bramalea, Ontario, L6T 4H3,

quoting the vehicle identification number from the plate located

inside the windscreen, plus the date of purchase and current

kilometres.

: If the ‘

Passport to Service

’ Warranty and Benefits information Booklet is a

: If the ‘

Club Jaguar

Passport to Service

’ Warranty and Benefits

’ Booklet or Canadian

’ Booklet is not

Scheduled Maintenance

The Maintenance Schedules list all the maintenance operations

and their intervals. Because of the need for the use of

specialized equipment and skills, it is strongly recommended

that all service work be entrusted to a Jaguar Dealer.

Should the vehicle cover a low annual mileage, have a high

proportion of short journeys or operate in severe conditions,

Jaguar Cars recommend that the lubrication service shown in

the maintenance schedule in the ‘

be performed at intervals not to exceed six months.

The Maintenance Schedules may be revised from time to time.

Jaguar Dealers will be notified of revisions by Service Policy

Letters or Technical Bulletins.

USA only

control devices and system may be performed by any

automotive repair establishment or individual using any

automotive part which has be certified by Jaguar Cars.

: Maintenance, replacement or repair of the emission

Passport to Service

’ Booklet

Page 7

Safety Precautions

Take particular note of

throughout this handbook.

!

WARNING:

Warnings are procedures which must be followed

precisely to help avoid the risk of personal injury.

Caution: Cautions are procedures which must be

followed precisely to reduce the possibility of damage to

the vehicle and resultant risk of personal injury or

inconvenience.

Warning symbols on the vehicle

On encountering the warning triangle and open book symbol on

the vehicle, it is important that you consult the relevant section

of this handbook before touching this part of the vehicle or

attempting adjustments of any kind.

WARNINGS

and

Cautions

given

Introduction 1-3

JLX-208

Page 8

1-4 Introduction

Safety Precautions

!

WARNING:

1. Many liquids and other substances used in vehicles are

poisonous and must never be consumed and should

be kept away from open wounds. These substances

include anti-freeze, brake fluid, fuel, windscreen

washer additives, lubricants and various adhesives.

2. The presence of any unusual fumes (e.g. petrol or

exhaust fumes) in the passenger compartment and/or

luggage compartment should be corrected

immediately by a Jaguar Dealer. If you must drive

under these conditions do so only with all windows

fully open.

3. Any modifications to the fuel system not specifically

designed for this Jaguar are prohibited. Such

modifications in some circumstances could result in a

fire. All service actions must be entrusted to a

Jaguar Dealer.

4. Alterations to the electrical system, including the

fitting of accessories not designed for this Jaguar may

cause damage to the electrical circuits and systems. In

some circumstances this could result in a fire. All

accessory work should be entrusted to a Jaguar Dealer.

5. No attempt should be made to repair a fuse that has

blown. Always install a fuse of the correct amperage

(see the fuse charts on pages 4-17 to 4-21). Failure to

comply with the above may cause a fire hazard or

serious damage elsewhere in the electrical circuit.

(continued)

6. Avoid contact with battery acid which is poisonous

and corrosive. Acid will cause burns to the skin as well

as to the eyes. In the event of skin or eye

contamination, wash the affected area with water

thoroughly. Seek immediate medical attention when

eye contact has occurred.

7. Never reverse the battery terminal connections.

Always disconnect both terminals before battery

charging.

8. When disconnecting the battery connections, always

disconnect the earth terminal first and reconnect last.

9. Batteries produce combustible gas (hydrogen) when

charging. Switch off the charger before connecting or

disconnecting terminal connections to avoid sparks

and short circuits.

10.Do not disconnect any pipes in the air conditioning

refrigeration system. A refrigerant is used which can

cause blindness if allowed to contact the eyes.

FIRST AID: If refrigerant should contact the eyes or

skin, wash the eyes or affected area with cold water for

several minutes. Do not rub. As soon as possible

thereafter, obtain treatment from a doctor or eye

specialist.

Page 9

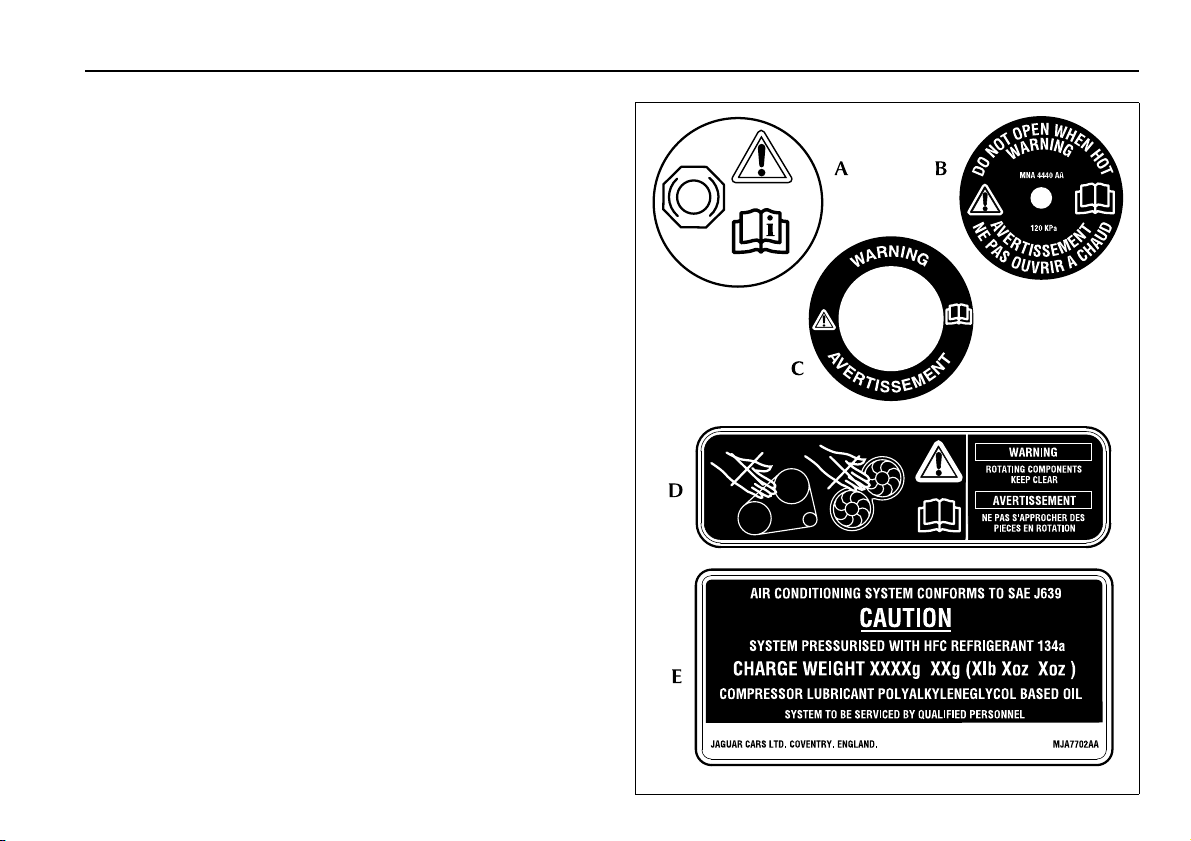

Safety Warning and Caution Labels

Do not remove any warning labels from the hood or

Note:

inside of the vehicle.

Braking System (A)

The brake fluid caution symbol is moulded into the master

cylinder filler cap.

Brake system warning information is moulded into the master

cylinder reservoir and states:

WARNING – CLEAN FILLER CAP BEFORE REMOVING. USE

ONLY SUPER DOT 4 BRAKE FLUID FROM A SEALED

CONTAINER.

Refer to SECTION 3 for topping up the power steering system.

Cooling System (B)

The header tank label is located on the filler cap and states:

WARNING – DO NOT OPEN WHEN HOT.

Power Steering System (C)

The label is located on the reservoir filler cap and states:

WARNING.

Rotating Components (D)

A label is located on the fan shroud and states:

WARNING – ROTATING COMPONENTS – KEEP CLEAR.

Climate Control System (E)

The label located under the hood on the left-hand side states:

CAUTION – System pressurised with HFC refrigerant 134a.

System to be serviced by qualified personnel.

Introduction 1-5

+

-

+

-

JLK-061

Page 10

1-6 Introduction

General Precautions

• Ensure that the vehicle is securely supported before working

underneath it.

handbrake.

• Whenever possible use a suitable wheel-free lift when

working beneath the vehicle.

If a jack is used to support the vehicle, use axle stands

carefully placed at the jacking points to provide a rigid

support.

Do not

member.

• Ensure that adequate ventilation is provided when volatile

degreasing agents are being used.

•

• Wear protective overalls, ensure loose clothing (ties, etc.) are

• Do not leave opened containers of oil, fuel, etc., about the

• Do not leave tools, equipment, spilt oil, etc., around or on

• Place a fire extinguisher close to the vehicle and disconnect

use volatile cleaning fluids under a vehicle standing

Never

over a pit. Many such fluids give off vapours which are

heavier than air and dangerous to inhale.

removed or covered when working adjacent to moving

components (fan belts, etc.).

work area. Always refit caps/seals to partially used

containers when storing them for later use.

the work area.

the negative battery terminal. Do not use a naked flame to

provide illumination, especially under the vehicle, or in the

engine and luggage compartments. Do not smoke while

working on the vehicle.

Chock a front wheel and apply the

use any jacking equipment under the front cross

• Do not apply heat in an attempt to free nuts or fittings. This

will damage protective coatings and there is a risk of damage

to electronic equipment and brake and fuel lines from

conducted heat.

• Inspect power leads of any mains electrical equipment for

damage, and check that it is properly earthed.

General Precautions Against Damage

• When working in the engine compartment protect the

exterior paintwork by using suitable covers over the wings

and scuttle.

• To prevent soiling the interior, carry out jobs requiring

access to the passenger or luggage compartments first. If a

job involves access to the interior in the course of other

work, prevent the transfer of oil and grease to the interior by

using seat and carpet covers and wearing clean overalls and

gloves.

• Always use a recommended service tool, where specified.

• Avoid spilling hydraulic fluid or battery acid on paintwork.

Wash off with water immediately if this occurs.

Page 11

Introduction 1-7

General Precautions

Used Engine Oil

!

WARNING:

Prolonged and repeated contact may cause serious skin

disorders, including dermatitis and cancer.

Always use a hand cream to protect the skin from oil

contamination. Avoid contact with the skin as far as possible

and wash thoroughly after any contact. Keep oils out of reach of

children.

PROTECT THE ENVIRONMENT:

water courses and soil. Use authorised waste collection

facilities, including civic amenity sites and garages providing

facilities for the disposal of used oil, oil filters and batteries. If in

doubt, contact your Local Authority for advice on disposal.

Engine and Throttle Settings

Do not attempt to make adjustments to the engine or throttle

settings. Many vehicle systems are controlled by complex

electronic devices and require specialist knowledge. Such work

should be entrusted to a Jaguar Dealer.

Battery/Ignition Isolator Switches

Non-approved battery isolator switches, which disconnect the

power supply to all electrical circuits, are

(continued)

It is illegal to pollute drains,

recommended.

not

Hydraulic Fluid

The Brake Hydraulic Fluid in the master cylinder and brake

operating system uses non-mineral polyglycol based brake fluid

with a minimum standard of JAGUAR SUPER DOT 4. ONLY

FLUID OF THIS TYPE AND STANDARD MAY BE USED.

!

WARNING:

Contamination of the brake system fluid by as little as

1 per cent will cause rapid deterioration of the system

seals. Ensure that the brake fluid reservoir cap is securely

fitted.

Electrical Accessories

The fitting of any electrical accessory

to a Jaguar Dealer. Refer to

SECTION 7. This information must be observed before fitting

any accessories.

Electrical Accessories

should only

be entrusted

in

Page 12

1-8 Introduction

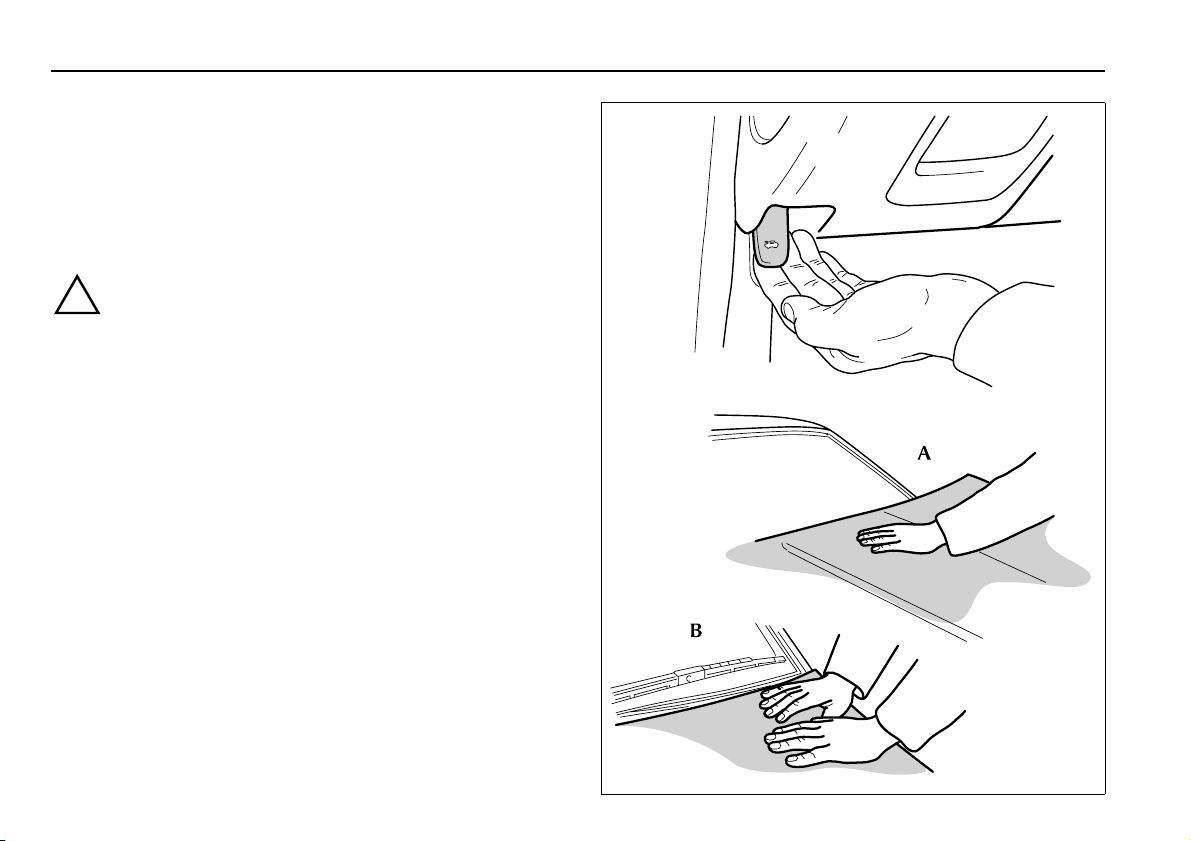

Hood Release Control

The hood lock release control is below the fascia on the driver’s

side of the vehicle.

To op en:

across to the centre of the hood and lift the rear edge. The gas

filled struts will assist raising the hood, and retain it in the fully

open position.

Before closing the hood ensure that no one is obstructing

the closing area and that hands and clothes are clear.

Remove tools, cleaning cloths, etc. from the engine

compartment.

Hood latching:

12 inches (250 to 300 mm) of the fully closed position. Place the

left hand on the hood as shown at (A). Then pressing

downwards slam the hood shut. This action should engage both

the right-hand and left-hand latches.

Should one latch fail to engage, place both hands, as shown

at (B), above the unlatched side and press down firmly on the

hood until it engages.

Release the hood lock by pulling the lever. Reach

!

WARNING:

Close the hood to within a distance of 10 to

JLX-149

Page 13

2Cleaning

Cleaning 2-1

Introduction

This section gives full details of the methods and cleaning agents

which should be used to achieve the best results and maintain

the finish of the vehicle, both internally and externally.

Read carefully the restrictions on the use of jet washes and

automatic car washes.

Exterior Care

Valet Kit

A valet kit containing a selection of Car Care products is

available from the Jaguar accessory range.

All the cleaning materials mentioned in this section are

Note:

available from the Jaguar Accessory Range.

Washing

For best results, do not wash the vehicle under strong sunlight.

Always allow the vehicle to cool down before washing.

Do not use a dry cloth to wipe dirty paintwork. Dust and gritty

substances are abrasive and will scratch the paintwork. Remove

dirt using a cellulose sponge and plenty of warm (never hot)

water. Rinse off with clean water and dry using a clean, damp

chamois leather.

Do not use household soaps or detergents. The use of Jaguar

Vehicle Shampoo is recommended.

Do not direct hoses at full force around door and luggage

compartment seals. Using high pressure water jets on the

paintwork is not recommended.

Do not allow bird droppings or tree sap to harden. Remove from

paintwork immediately with a lukewarm soap and water

solution.

In winter, when salt is used on the roads, wash the vehicle

frequently, and immediately after encountering such conditions.

Clean undersides and wheel arches using a high pressure jet.

Automatic Car Wash

Regular use of automatic car washes tends to dull the

Note:

lustre of the paintwork.

Before entering the car wash it is essential to:

Switch off the radio to retract the aerial,

Remove wing mounted telephone antennas,

Fold down screen mounted telephone antennas,

Fold in door mounted rear view mirrors.

If your vehicle is fitted with a Jaguar approved cellular

Note:

telephone, you are advised to switch the telephone and the

ignition OFF.

After leaving the car wash, switch on the windscreen wiper

immediately to remove water and prevent a build up of wax.

Jaguar Screen Clean Paste can be used to clean any residual wax

from the glass.

Removing Grease and Tar

Remove grease or tar with Jaguar Tar Remover or methylated

spirit (alcohol). White spirit is also effective, but must not be

applied to rubber, particularly the windscreen wiper blade.

Page 14

2-2 Cleaning

Exterior Care

Alloy Road Wheels

Alloy wheels have an anti-corrosion protective coating, which

should not be damaged.

Wash the wheels at two week intervals to avoid an accumulation

of particles which could become embedded in the wheel

surface.

An Alloy Wheel Clean Kit is included in the Jaguar accessory

range.

In salty conditions the wheels should be cleaned weekly.

Chromium-plated Alloy Road Wheels

It is recommended that chromium-plated alloy road wheels are

cleaned using Jaguar Vehicle Shampoo and Chrome Polish.

Caution: Do NOT use proprietary wheel cleaners.

Glass Surfaces

To avoid scratching glass surfaces,

paper or cloth. Use clean, warm water and a chamois

dry

leather which is reserved for glass only.

The following products will ensure glass surfaces and

windscreen wipers are kept in good condition:

Jaguar Screen Clean Paste

windscreen

windscreen wiper.

Jaguar Glass Cleaner

surfaces.

(continued)

do not

– Apply to the exterior of the

to ensure effective operation of the

only

– Interior and exterior of all other

clean dirty glass with

Jaguar Screen Wash

Jaguar Winter Care Kit comprising de-icer, ice scraper,

anti-mist wipe cloth and aerial cleaner

weather conditions.

Note:

Renew the wiper blade when worn to prevent scratching.

1.

Clean regularly with a mild detergent solution.

It is advisable to clean the windscreen with Jaguar Screen

2.

Clean Paste at regular intervals.

Polishing Paintwork and Chromium Plating

For maximum protection against road dust, salts, industrial

fallout etc., it is recommended that the vehicle is polished

regularly using Jaguar Polish, Chrome Polish and a Polishing

Cloth.

– Washer reservoir additive.

– for use in adverse

Page 15

Cleaning 2-3

Exterior Care

Underbonnet cleaning

Underbonnet cleaning using high pressure hoses or steam

cleaners should be done by a Jaguar Dealer. Indiscriminate use

of cleaning equipment could damage or contaminate the

electronic control modules and fuse boxes.

Aerial Care

Regular cleaning with a special aerial cleaner, will ensure

smooth and reliable operation of the aerial.

Always wipe the aerial in an upwards direction.

Lubricate using an aerial maintenance wipe cloth.

In freezing conditions check that no ice has formed over the top

of the aerial, which could prevent it being raised and cause

damage to the motor.

The Jaguar Aerial Cleaning Kit contains the necessary

maintenance items.

Paint Chips

Scratches and chips should be touched in before weathering

action begins. Inspect the paintwork immediately after the

vehicle has been washed.

(continued)

Interior Care

Brush and clean the interior regularly. Use a vacuum cleaner

where possible to remove all dust from the interior and trim.

Carpets

Marks or stains can be removed by gentle scrubbing with a weak

solution of soap and warm water.

For more stubborn stains a commercially available carpet

cleaner should be used. See your Jaguar Dealer for advice.

Headlining

Remove dust in the headlining with a vacuum cleaner. To

remove stains, rub briskly without pressing, using a lint-free

white cloth, moistened with methylated spirit.

Leather Upholstery

Dust and dirt can penetrate the pores and creases of leather,

causing surface wear and brittleness. Clean regularly to

maintain the leather in first class condition.

Wipe the surfaces using a cloth dampened with warm soapy

water; avoid flooding. Rinse with clean water. Allow to dry and

rub with a clean soft cloth. Use Jaguar Leather Cleaner for

heavily soiled areas.

Use only mild non-caustic soap. Do not use petrol, detergents or

household cleaners, as these could damage the leather.

The appearance and durability can be improved by using Jaguar

Hide Food and Jaguar Leather Conditioner.

Page 16

2-4 Cleaning

Page 17

3Routine checks

Routine checks 3-1

Introduction

The transmission, final drive unit and

supercharger (where fitted) are oil

filled-for-life units and do not require

checking by the driver. The few

maintenance tasks and checks required to

ensure reliable and safe day to day

running of the vehicle are detailed in this

section.

Only use lubricants and fluids which

meet the specifications recommended by

Jaguar Cars Limited.

Regular Checks

In the interests of safety and reliability, it

is advisable to carry out the following

checks at the recommended intervals,

and always before starting on a long

journey.

Daily

Check that there is sufficient fuel for the

journey intended, particularly at night

and before entering motorways.

Check that there is adequate windscreen

washer fluid for the intended journey.

Weekly

– Check the tyres, including the

Tyres

spare, for condition and pressure. See

SECTION 6 for the recommended tyre

pressures.

– Check that all exterior lights and

Lights

direction indicators function correctly

and that the lenses are clean.

If any of the high mounted stop lamp

bulbs have failed they must be replaced

to ensure that the correct lamp intensity

is maintained.

Engine Oil

on level ground, check the oil level and

top up if necessary with oil of the correct

grade, see pages 3-2, 3-3 and 3-9.

Engine Coolant

check the level of the coolant in the

engine header tank, see pages 3-2 and

3-7. Any loss of fluid must be checked by

a Jaguar Dealer.

Brake Fluid

in the brake fluid reservoir. Top up if

necessary with new, unused Jaguar

approved brake fluid, see pages 3-2 and

3-6.

The brake fluid reservoir is initially nearly

full, but the level will drop as the brake

pads wear. If the level appears unusually

low, location of the fluid leakage

checked by a Jaguar Dealer.

– With the vehicle standing

– With the engine cold,

– Check the level of the fluid

be

must

Power Steering Fluid

cold check the level of the fluid in the

power steering fluid reservoir,

see pages 3-2 and 3-4. Top up if

necessary with fluid of the correct

specification. Any loss of fluid should be

checked by a Jaguar Dealer.

The transmission and, where

Note:

fitted, the supercharger are sealed for life

units and do not require topping up.

Monthly

Windscreen Washer

recommended windscreen washer fluid

and clean soft water, see pages 3-2

and 3-5. Check the operation of the

washer. Use Jaguar Windscreen Washer

Fluid to keep the glass clean and also to

prevent the fluid from freezing during

cold weather.

Wiper Blade

wipe. If smearing or juddering is evident,

clean the windscreen as detailed in page

5-19 and renew the wiper blade.

– Check the quality of the

– With the engine

– Top up with

Page 18

3-2 Routine checks

JLX-210

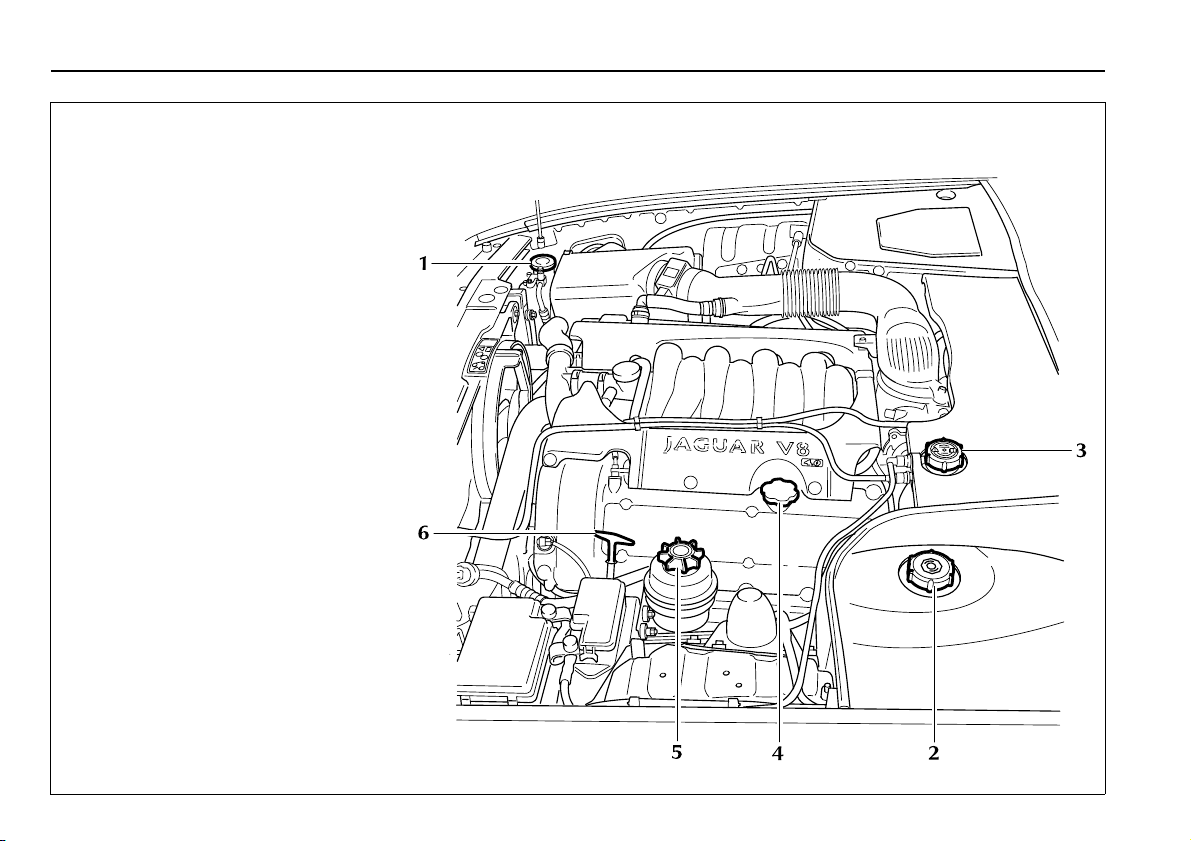

Reservoir and Dipstick Locations

1. Windscreen washer reservoir

2. Brake fluid reservoir

3. Coolant filler pressure cap

4. Engine oil filler

5. Power steering reservoir

6. Engine oil dipstick

Page 19

Routine checks 3-3

JLK-055

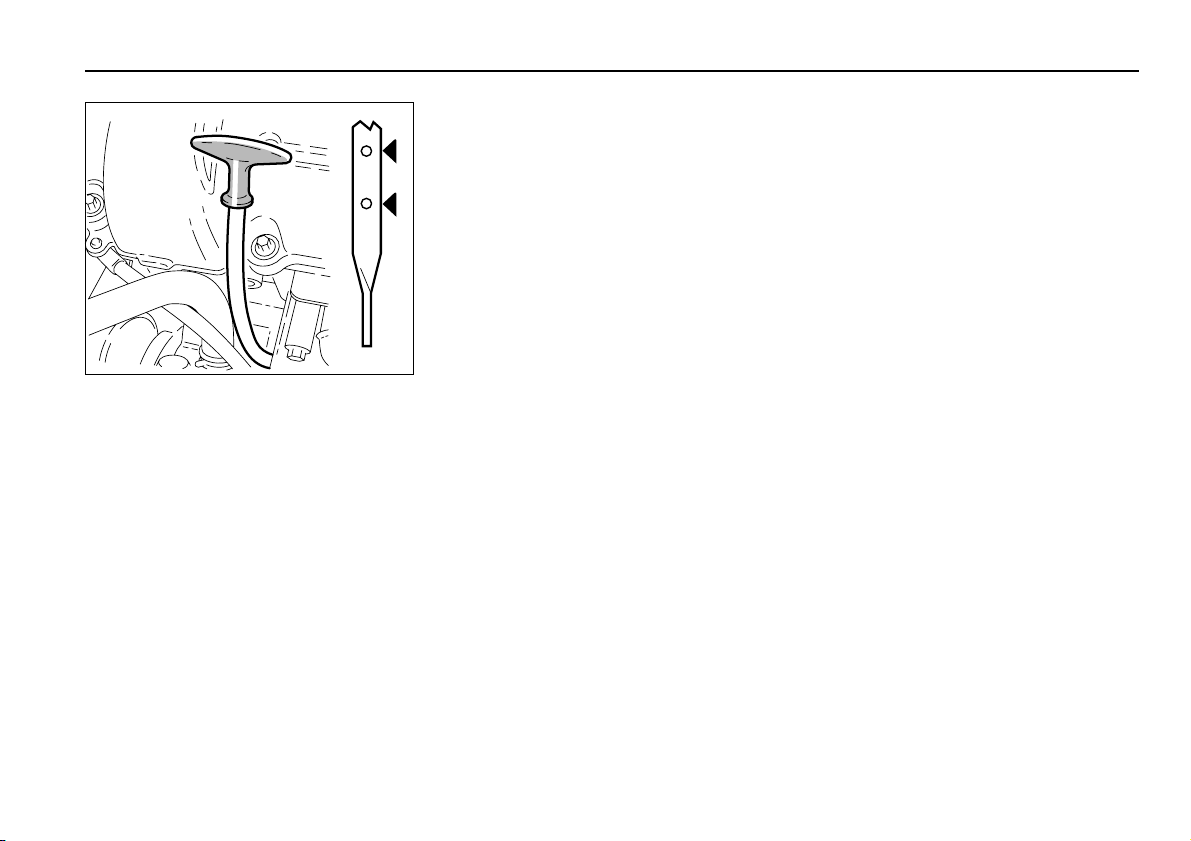

Checking and Replenishment

Check/Top Up Engine Oil Level

Check the oil level regularly with the

vehicle on flat, level ground.

Refer to page 3-2 for dipstick and oil filler

locations.

It is preferable to check the oil level after

the vehicle has been standing, that is,

with the engine completely cold.

If the engine has been started do not

check the oil level until the engine has

reached normal operating temperature.

Stop the engine and wait for a minimum

of 2 minutes to allow the oil to drain back

into the sump.

Remove the dipstick and wipe clean with

a non-fluffy cloth. Replace fully, then

withdraw the dipstick.

If the oil level is on or above the lower of

the two dots on the dipstick then no

additional oil is required.

If the oil level is below the lower of the

two dots, remove the oil filler cap and

add 1 quart (1 litre) of the correct

specification oil.

Lubricant and fluid specifications are

detailed on page 3-9.

Refit the filler cap and hand tighten

securely.

The supercharger (where fitted) is oil

filled-for-life and does not require any

checks to be made by the driver.

Page 20

3-4 Routine checks

JLX-174

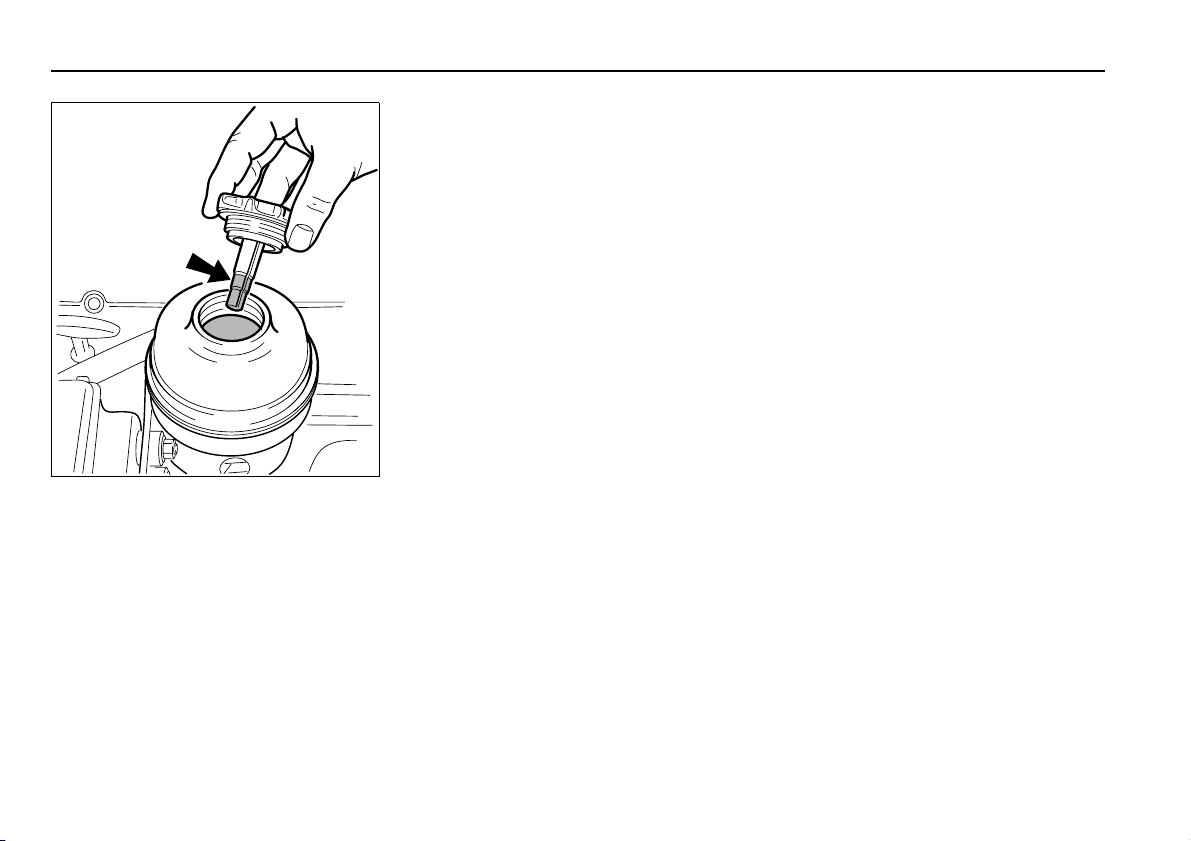

Checking and Replenishment

(continued)

Check/Top Up Power Steering Fluid

Reservoir

Caution: It is imperative that the

power steering system does not

become contaminated in any way.

Always dispense fluid from a fresh

sealed container and clean the area

around the reservoir neck both

before and after topping up. Never

return drained fluid to the system.

See page 3-2 for power steering fluid

reservoir location.

Check the fluid level when the engine is

‘COLD’ and the vehicle is on a flat, level

surface.

Wipe clean and remove the filler cap

from the reservoir; take great care to

prevent any foreign matter from entering.

Check that the fluid level is between the

marks on the dipstick.

If necessary, top up with DEXRON III

fluid, DO NOT OVERFILL.

Should the level be very low, report the

loss of fluid to the nearest Jaguar Dealer.

Page 21

Routine checks 3-5

JLX-173

Checking and Replenishment

(continued)

Check/Top Up Windscreen Washer/

Powerwash Reservoir

See page 3-2 for windscreen washer

reservoir location.

The washer reservoir contains the fluid

for the windscreen washers and the

headlamp powerwash system (where

fitted).

Fill to just below the neck with Jaguar

Windscreen Washer Fluid diluted with

clean, preferably soft water as specified in

the instructions on the bottle.

Do not over-fill.

Using a non-approved fluid may

Note:

adversely affect the wiper blade rubber,

resulting in ineffectual and noisy wiping.

Cold Weather Precautions

To prevent damage to the pump during

freezing conditions, use Jaguar

Windscreen Washer Fluid diluted with

water to the correct strength, as shown

on the bottle, for the anticipated ambient

temperature.

Caution:

1. Windscreen washer fluid is toxic

and in concentrated form is

flammable.

2. Under no circumstances must

cooling system anti-freeze be

used, since this will damage the

paintwork.

Page 22

3-6 Routine checks

JLK-091

Checking and Replenishment

(continued)

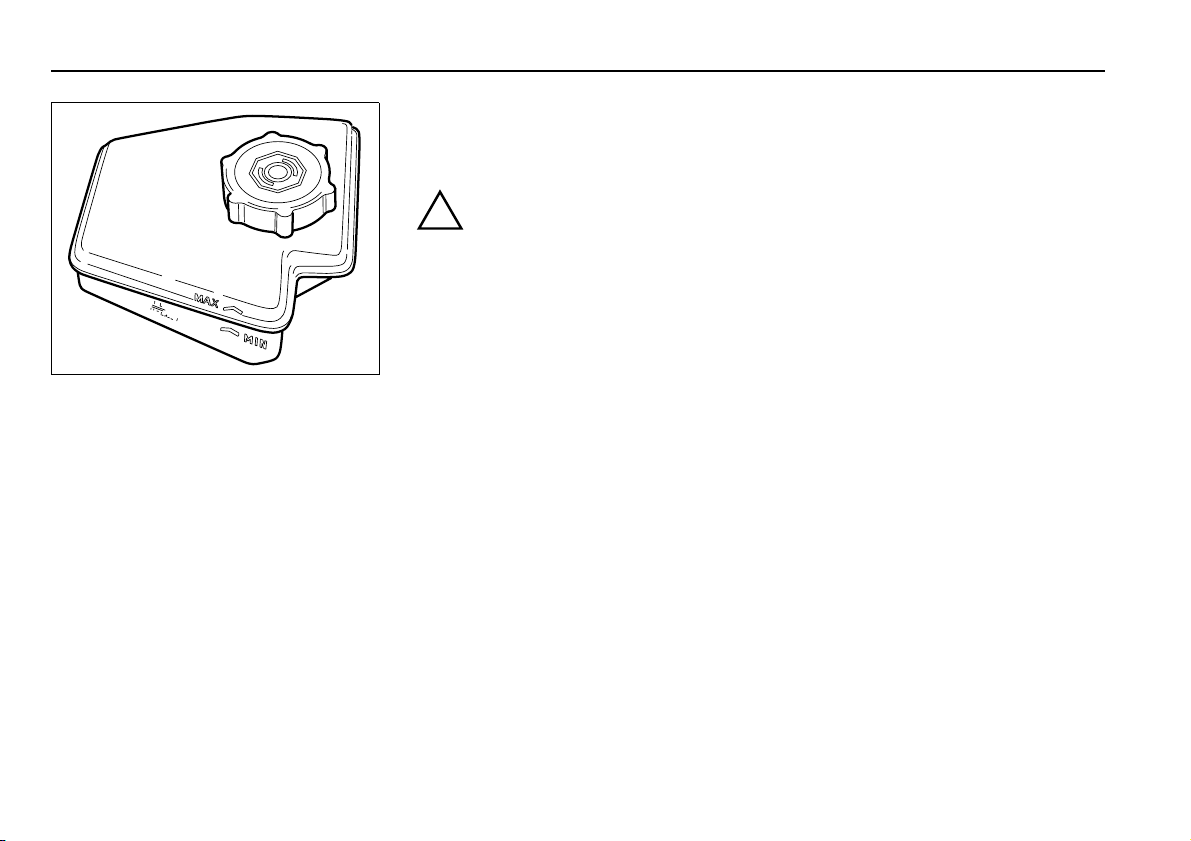

Check/Top Up Brake Fluid Reservoir

!

WARNING:

The brake fluid level will drop as the

brake pads wear. If the level is very

low report the loss of fluid to the

nearest Jaguar Dealer. Do not drive

the vehicle until the cause is rectified.

Caution:

1. While handling brake fluid, take

extreme care; brake fluid must not

contact the vehicle paintwork.

2. Always use fresh, clean fluid from

a new container. Never introduce

used brake fluid into the system.

See page 3-2 for brake fluid reservoir

location.

After removal of the cover, the fluid is

visible through the translucent casing of

the reservoir and must be maintained at

the ‘MAX’ mark.

If necessary, top up as follows:

Before removing the cap, clean the

reservoir and cap thoroughly with a lint

free cloth to ensure that no foreign matter

enters the reservoir.

Unscrew the filler cap and top up to the

‘MAX’ level using new Jaguar brake fluid,

specification Jaguar ITT SUPER DOT 4.

This is a non-mineral polyglycol based

brake fluid.

Refit the filler cap securely.

To avoid contamination should any brake

fluid be spilt, replace the cap on the

reservoir before cleaning the spilt fluid

from the vehicle.

Page 23

Routine checks 3-7

JLX-154

Checking and Replenishment

(continued)

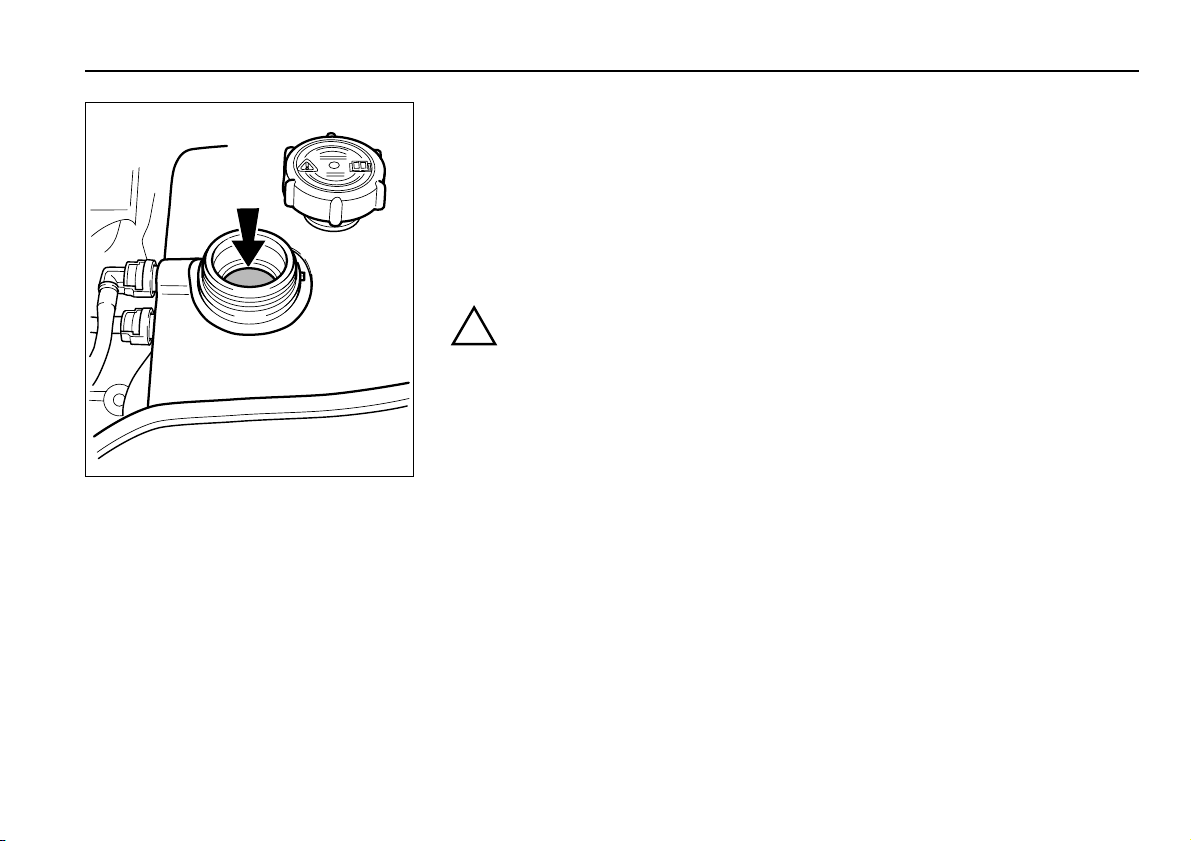

Checking Coolant Level

The coolant level must only be checked

when the engine is COLD.

See page 3-2 for coolant header tank

location and page 3-8 for the coolant

specification.

!

WARNING:

Do not remove the coolant expansion

tank filler/pressure cap while the

engine is hot. If the cap must be

removed, protect the hands against

escaping steam and slowly turn the

cap anti-clockwise until the excess

pressure can escape. Leave the cap in

this position until all the steam and

pressure have escaped, and then

remove the cap completely.

The coolant should be level with the

bottom of the filler neck of the header

tank. If persistent coolant loss is noticed

have a Jaguar Dealer investigate the cause

immediately.

Refit the filler cap and hand tighten

securely.

Topping up

Caution: Anti-freeze will damage

paintwork. Avoid spillage.

Top up until the coolant is level with the

bottom of the filler neck.

Use the correct concentration of Jaguar

Anti-freeze/Coolant/ Corrosion Inhibitor.

Page 24

3-8 Routine checks

Cooling System

The cooling system should be filled or

topped up with a mixture of 50 per cent

demineralised water and 50 per cent

Jaguar Anti-freeze, Coolant and Corrosion

Inhibitor conforming to specification

WSS M97B44-D, coloured orange,

Extended Life Coolant.

This anti-freeze mixture gives frost

protection for temperatures down to

-40°C (-40°F).

Caution: Do not mix with anti-freeze

of a different specification as this

would damage the cooling system.

Engine Anti-freeze

Anti-freeze, when used at the correct

concentration, not only protects the

engine from frost damage in winter, it

also provides all year round protection

against internal corrosion.

Use only anti-freeze to specification

WSS M97B44-D, coloured orange,

Extended Life Coolant. Inferior quality

anti-freeze may be ineffective in

maintaining adequate frost and corrosion

protection to the cooling system.

The coolant solution may remain in the

cooling system for five years or,

150 000 miles (240 000 kilometres) after

which the cooling system should be

drained, flushed and refilled.

!

WARNING:

Do not allow anti-freeze to make

contact with skin or eyes. If this

should happen, rinse the affected

area immediately with plenty of

water.

Engine Block Heater

If the vehicle is to be started at

temperatures of –30°C (–22°F) and lower,

it is recommended that an engine block

heater is fitted and used. Failure to do so

may result in damage to the drive belt.

For further information consult your

Jaguar Dealer.

Caution: The fitting of an engine

block heater does not eliminate

(lessen) the need for anti-freeze

under freezing conditions.

Page 25

Routine checks 3-9

Recommended Engine Oil

Oil Specification

API SJ / EC and ILSAC GF-2.

When topping up between oil changes, make sure that you use

oil that has the correct quality level (API service) and viscosity

grade. Your vehicle’s warranty may be invalidated if damage is

caused by use of improper engine oil.

When the oil level is at the lower dipstick mark, add one quart

(one litre) of engine oil.

Recommended SAE Viscosity Range / Ambient Temperature Scale

SAE Viscosity Rating

It is recommended that you use only approved engine oils to

meet the SAE Viscosity Range / Ambient Temperature Scale

shown below. For maximum fuel economy, 5W/30 oil is

recommended.

JOL.654

Page 26

3-10 Routine checks

Capacities

US Quarts Litres

Engine Oil – without oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.9 6,5

– with oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9 7,5

The rear axle (final drive unit), automatic transmission unit and

supercharger (where fitted) are oil filled-for-life and will not

normally require to be topped up.

Cooling system, including reservoir and climate control:

– Initial fill – 3.2 and 4.0 litre normally aspirated . . . . . . . . . . . . . . . . 10.6 10,0

– Initial fill – 4.0 litre supercharged . . . . . . . . . . . . . . . . . . . . . . . . . . 12.7 12,0

Windscreen Washer Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6 6,3

Fuel Tank

US Gallons Litres

Indicated refill capacity (E to F on fuel gauge) 19.8 75,0

Unindicated capacity (Below E on fuel gauge) 1.6 6,0

Total refill capacity 21.4 81,0

Page 27

4 Roadside emergency service

Introduction

In the event of a flat tyre, drivers should follow closely the

procedure for wheel changing and jacking given in this section.

The correct jacking points and how to locate them are shown. It

is important that only the correct jacking points are used.

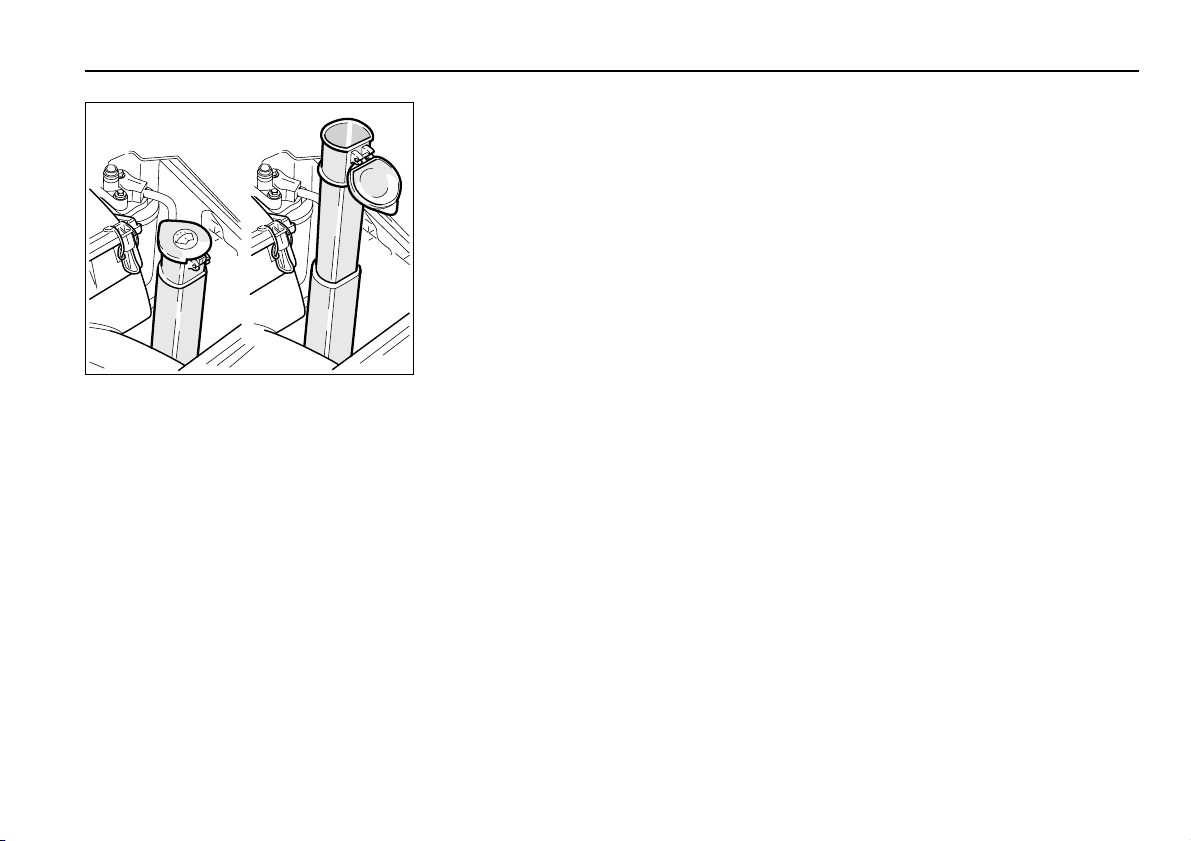

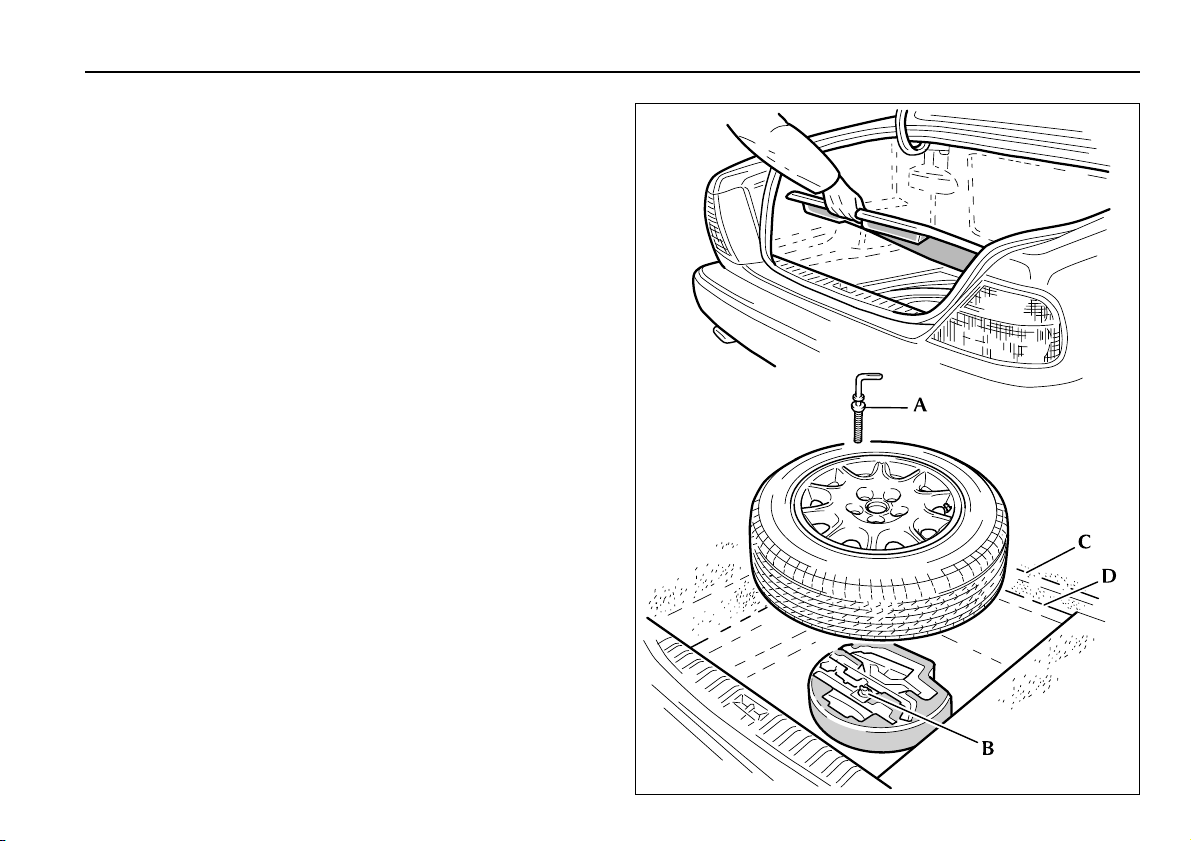

Spare Wheel and Jacking Equipment

The spare wheel, jacking equipment and wheel chock are stored

under the luggage compartment floor panel.

To remove the spare wheel, remove the luggage compartment

floor panel and unscrew the retaining screw (A).

The tray containing the jacking equipment kit can be removed

from the luggage compartment by unscrewing the yellow

securing bolt (B).

The kit comprises: the jack; jack ratchet handle with socket

extension; wheel nut wrench with telescopic extension and a

wheel chock. For vehicles fitted with locking wheel nuts, a

wheel locking nut extractor tube and key socket are included in

the tray.

Note: Examine the jack occasionally, clean and grease the

threads to ensure it is always ready for an emergency.

Stow the replaced road wheel in the luggage compartment so

that it fits over the jacking equipment tray. Reposition the

luggage compartment floor panel in the upper location slots (C).

(D) is the panel location slots for vehicles with a space saver

wheel.

Roadside emergency service 4-1

JLX-186

Page 28

4-2 Roadside emergency service

Wheel Changing and Jacking

Be prepared for a flat tyre. Know where equipment is stowed

and read the wheel changing and jacking instructions carefully.

Stopping the Vehicle

Pull off the road completely, clear of all traffic and park on as

level, solid ground as possible. Switch on hazard warning lights

and, where legally required, display the warning triangle.

!

WARNING:

It can be dangerous to change a wheel when the vehicle

is on a slope or soft, uneven ground.

Remove the spare wheel (see page 4-1) to obtain the jack and

wheel changing tools.

To Gain Access to the Wheel Nuts:

Alloy Wheels with Plain Wheel Nut Covers

Carefully remove the wheel nut cover using the flattened end of

the spare wheel retaining screw.

Loosening the Wheel Nuts

Always slightly loosen the wheel nuts before raising the vehicle.

A label showing correct use of the wheel nut wrench is printed

on its shaft, as shown opposite and states:

WHEEL NUT REMOVAL WHEEL NUT TIGHTEN

JLX.213

JLK 053

Page 29

Wheel Changing and Jacking (continued)

Removing Locking Wheel Nuts (where fitted)

Some vehicles are fitted with one locking wheel nut on each

wheel. These can only be removed using the extractor tube and

key socket from the jacking equipment tray.

The locking wheel nut is provided with a cover which makes it

visually similar to standard wheel nuts. The top of the cover has

an indentation (A) to aid identification.

Push the extractor tube firmly over the locking wheel nut cover,

as shown at (B), until it is fully located.

Withdraw the extractor tube to remove the cover.

Fit the key socket over the locking wheel nut as shown at (C).

Fit the wheel nut wrench over the key socket and loosen the

locking wheel nut.

Locking Wheel Nut Security Coding

Locking wheel nuts have a letter stamped on their upper

surface. The key socket is stamped with a corresponding

number. Only key sockets with the correct matching number

will fit the locking wheel nut.

Should a new key socket be required, note the letter on the

locking wheel nut and contact your Jaguar Dealer. Proof of

vehicle ownership will be required.

Roadside emergency service 4-3

JLX-156

Page 30

4-4 Roadside emergency service

Wheel Changing and Jacking (continued)

Before Lifting the Vehicle

!

WARNING:

Before attempting to lift the vehicle with the jack, chock

one of the front wheels

when jacked up.

A folding wheel chock is supplied with the jacking equipment.

The chock must be unfolded into a triangular form before use.

Chock the front wheel on the opposite side of the vehicle to the

side being jacked up, as detailed below:

VEHICLE FACING DOWN A SLOPE VEHICLE FACING UP A SLOPE VEHICLE HORIZONTAL

Chock the front of the front wheel Chock the rear of the front wheel Front wheel change: Chock at A

to prevent the vehicle from rolling

Note:

1. Ensure that all passengers are in a safe place, clear of the

vehicle.

2. Firmly apply the handbrake and select gear

position ‘P’ (Park).

3. Ensure that the jack is on firm and level ground.

Using the wheel nut wrench with the handle extended, slacken,

but do not remove, the wheel nuts.

Rear wheel change: Chock at B

JLX-155

Page 31

Wheel Changing and Jacking (continued)

Jacking

!

WARNING:

Never work under the vehicle using only the jack as a

support, always use axle stands or suitable supports

under the jacking points.

Observe the instructions printed on the jack.

Use the jack only for lifting the vehicle during wheel changing,

and only use the jack which is stored in the vehicle.

Do not start or run the engine while the vehicle is only

supported by a jack.

Note: When one rear wheel is lifted off the ground the

automatic transmission ‘P’ (Park) position will not prevent the

vehicle from moving and possibly slipping off the jack.

There are four jacking points, two each side. These provide

positive location for the jack and are on the underside of the

floor near each wheel. Remove the rubber cover from the end of

the jacking point adjacent to the road wheel to be changed.

Caution: Never use bumpers or any other part of the body

to lift the vehicle.

Roadside emergency service 4-5

JLX-143

!

WARNING:

Do not attempt to lift the vehicle unless the jack arm is

fully engaged in the jacking point square socket.

Place the jack squarely beneath the appropriate jacking point

and insert the jack arm in the jacking point square socket.

Page 32

4-6 Roadside emergency service

JLX-179

Wheel Changing and Jacking

(continued)

Ensure that the jack arm is fully engaged.

Carefully raise the vehicle by turning the

ratchet handle. Stop jacking the

vehicle when the tyre just clears the

ground. Minimum tyre lift gives

maximum vehicle stability. Remove

the wheel nuts and the wheel.

Fitting the Spare Wheel

!

WARNING:

When using the wheel nut wrench,

use the extension handle only for

removing wheel nuts, NOT for

tightening.

Fit the spare wheel and secure with the

wheel nuts.

Using the wheel nut wrench, lightly

tighten the wheel nuts alternately using

the sequence shown in the illustration.

Ensure that the taper on the wheel nuts is

seated fully onto the taper faces of the

wheel disc.

Lower the jack and, with the wrench

handle not extended, tighten the wheel

nuts alternately. At the earliest

opportunity have the wheel nuts

tightened with a torque wrench to

50–60lbf.ft (68–82Nm) for steel

wheels, and 65 – 75 lbf.ft (88 – 102 Nm)

for alloy wheels. This torque must not be

exceeded.

Remove the jack from the vehicle and

replace the jacking point rubber cover.

Page 33

Wheel Changing and Jacking (continued)

Re-fit the Centre Badge or Wheel Nut Cover

Alloy Wheels with Centre Badge

Carefully remove the centre badge to allow the wheel to be

stowed. Transfer the badge to the replacement wheel . Press fit

the centre badge into position on the wheel.

Alloy Wheels with Plain Wheel Nut Covers

Push the wheel nut cover firmly into position on the wheel.

Stowing the Equipment

Remove the chock and fold flat.

Stow the jack, wheel chock and tools in the jacking equipment

tray. If removed, refit the equipment tray in the luggage

compartment and secure with the yellow securing bolt.

Place the road wheel over the equipment tray and refit the

luggage compartment floor panel.

Roadside emergency service 4-7

JLX-212

Page 34

4-8 Roadside emergency service

Emergency Starting

Rolling Start

A start by pushing or towing cannot be achieved on a

vehicle with automatic transmission.

Emergency Starting using Jump Leads

Both the booster and discharged battery should be treated with

great care when using jump leads. Always use high quality leads

capable of carrying the starter current of the vehicle to be

started.

Before commencing, the following precautions must be taken:

1. When the battery of another vehicle is being used, ensure

that the vehicles do not touch. Alternatively, remove the

charged battery and place near to, not on, the vehicle with

the discharged battery.

2. Ensure that both vehicles have all electrical services OFF, the

handbrake is ON and the transmission is in Park.

3. Where the jump leads are of a different colour, e.g. red and

black, use red for positive (+). This aids identification and

helps to avoid crossing positive (+) to negative (–). Take extra

care to avoid crossing the polarity when using cables of the

same colour.

Caution:

1. If using a jump start vehicle, under no circumstances

should the vehicles come into contact with each other.

This could establish an earth connection, which may

cause sparks and damage.

2. Do not run the jump start vehicle’s engine when boost

starting a Jaguar Vehicle. If the jump start vehicle’s

engine is running and the jump leads are

disconnected, damage to the Jaguar vehicle’s electrical

system will result.

3. The booster battery voltage must not exceed 12 volts.

Continued

Page 35

Emergency Starting (continued)

The following procedure must be followed exactly, being careful

not to cause sparks.

1. Apply the handbrake, select Park and turn off all the vehicles

electrical services.

2. Remove the luggage compartment floor panels.

3. Unclip the battery positive (+) terminal cover.

4. Attach one end of the red jump lead to the positive (+)

terminal of the booster battery and the other end to the

positive (+) terminal of the discharged battery. Make sure

that a good connection is made.

Caution: Do not connect the negative jump lead directly

to the negative (–) terminal of the discharged vehicle.

5. Attach one end of the black jump lead to the negative (–)

terminal of the booster battery and the other end to an earth

point on the vehicle being started. (See illustration). The earth

point must be at least 12 inches (305 mm) from the

discharged battery. Make sure that a good connection is

made.

6. When started, allow the engine to idle for 5 minutes before

disconnecting the cables.

7. Disconnect the black jump lead from the earth point and the

booster battery negative (–) terminal.

8. Disconnect the red jump lead from the positive (+) terminals

of both batteries.

9. Refit the positive (+) terminal cover.

10. Refit the luggage compartment floor panels.

Roadside emergency service 4-9

JLX-180

Page 36

4-10 Roadside emergency service

Vehicle Recovery

The preferred vehicle recovery method is by using a flat bed

transporter or rear suspended tow. The front and rear towing

loops are primarily for emergency use when towing for SHORT

DISTANCES, e.g. removing the vehicle if it is causing an

obstruction or for winching the vehicle onto a recovery

transporter.

Transporting

If the vehicle is being transported on a trailer or vehicle flat bed

transporter, the handbrake must be applied, the wheels chocked

and the gear selector lever moved to position ‘N’ or ‘D’ but

NEVER to ‘P’.

The vehicle must be securely tied down to the transporter or

trailer. There are four transporter tie-down brackets on the

vehicle underbody. Do not attach tie-down hooks to the towing

loops.

Suspended Towing

Ensure that the recovery team follow these instructions:

Do not tow with sling-type equipment since damage to the

bodywork may result.

Caution: Do not tow vehicle by suspending the front end.

1. Remove the key from the ignition switch.

2. Raise the rear of the vehicle using a ‘spectacle frame’ type

lifting device where a cradle is positioned under each rear

wheel, as indicated.

Vehicles with Defective Automatic Transmission

The vehicle must be towed with the rear wheels clear of the

ground.

JLX-147

Page 37

Towing Loops

Caution: The towing loops are not suitable for ‘solid bar

towing’.

Care must be taken to avoid damaging the bumpers and

front apron.

The front loop is welded to the right-hand bumper mounting

bracket.

Turn the three fasteners (A) anti-clockwise and remove the grille

vane (B) before using the front towing loop.

The rear eye is welded to the right-hand side of the luggage

compartment underfloor panel.

Always obey towing regulations: In certain countries the

registration number of the towing vehicle and an ‘ON TOW’

sign or warning triangle must be displayed in a prominent

position at the rear of the vehicle being towed.

When being towed, the vehicle’s gear selector lever must be in

neutral (position ‘N’) with the ignition key turned to position ‘II’

to release the steering lock and render the indicators, horn and

brake lights operational.

Vehicles may be towed for SHORT DISTANCES (maximum

0.5 mile/0.8 kilometre) with the gear selector lever in

position ‘N’ provided a speed of 30 mph (48 km/h) is not

exceeded.

Roadside emergency service 4-11

JLX-176

!

WARNING:

When the engine is not running the steering and brakes

will no longer be power-assisted. Therefore, be prepared

for relatively heavy steering and the need for greatly

increased brake pedal pressure.

Page 38

4-12 Roadside emergency service

Fuses and Fuse Boxes

Fuse failure is identified by an inoperative circuit.

Do not fit a new fuse if the wiring is damaged; contact a

Jaguar Dealer. After renewing a fuse have the circuit checked by

a Jaguar Dealer.

A special tool for removing and replacing the fuses is supplied

underneath the electrical carrier lid in the luggage

compartment, together with spare fuses.

Use only the spare fuses supplied. Replace the spare with a

Jaguar approved fuse of the same amperage rating.

Checking and Renewing a Blown Fuse

Make sure the new fuse is the correct rating (amperage). Fuses

are colour coded according to the amperage and the rating is

also marked on each fuse. The colour code is as follows:

TAN 5 amp CLEAR 25 amp

RED 10 amp LIGHT GREEN 30 amp

LIGHT BLUE 15 amp BRIGHT ORANGE 40 amp

YELLOW 20 amp

JLX-145

Push the tool on to the suspect fuse and withdraw it.

If the wire in the fuse is broken, the fuse has blown.

A – Fuse in good condition. B – Blown fuse.

Fit a new fuse using the tool.

Page 39

Fuse Box Locations

There are five separate fuse boxes fitted to the vehicle, each one

containing fuses protecting a different group of circuits.

There are two types of fuse box:

Type A – 18 fuse positions with one relay

Type B – 22 fuse positions with seven relays.

The locations are as follows:

Type A Fuse boxes

B Engine management fuse box

C Rear compartment fuse box

D Rear compartment fuse box

Type B Fuse boxes

A Engine compartment fuse box

E Luggage compartment fuse box

Note: Relays are detailed on page 4-22.

Roadside emergency service 4-13

!

WARNING:

1. Do not fit a fuse of a different amperage from that

specified on the Master Label. The electrical circuits

may become overloaded with the subsequent

possibility of a fire.

2. No attempt should be made to repair a fuse that has

blown. This may cause a fire hazard or serious damage

elsewhere in the electrical circuit.

JLX-144

Page 40

4-14 Roadside emergency service

Engine Compartment Fuse Boxes

There are two fuse boxes in the main engine compartment,

located on the left-hand side. The larger of the fuse boxes, the

engine compartment fuse box, contains 22 fuse positions. The

smaller fuse box, the engine management fuse box, has 18 fuse

positions.

Caution: When a fuse box lid is removed, take care to

protect the box from moisture, and refit the lid at the

earliest opportunity.

Remove the larger fuse box lid by pressing the retaining lugs and

lifting.

When refitting, press the fuse box lid in the area of the retaining

lugs until the lid engages.

The circuits protected are listed on page 4-16.

Remove the smaller fuse box lid by compressing and lifting the

‘U’-shaped latching mechanism (A).

To refit the fuse box lid, position into the slots and push down

until the latching mechanism is engaged.

The circuits protected are listed on page 4-17.

JLK-022

JLK-023

Page 41

JLX-142

Rear Passenger Compartment Fuse

Boxes

Two fuse boxes are located behind the

right-hand and left-hand side heelboard

trim panels below the rear seat.

To detach the heelboard trim panel, turn

the fastener 90 degrees and pull the

heelboard panel forwards. Long

wheelbase vehicles with electrically

operated rear seats have a captive

heelboard which hinges upwards, after

loosening the fastener, for access to the

fuses.

Roadside emergency service 4-15

JLX-141

To refit the heelboard trim panel, first

insert the top of the panel under the seat

pan and push the bottom of the panel

until it is correctly located. Fit the

securing fastener.

The circuits protected are listed on pages

4-18 and page 4-19.

Luggage Compartment Fuse Box

A fuse box is located in the luggage

compartment electrical carrier which is

situated to the rear of the battery.

A list of protected circuits and fuse ratings

is given on the fuse allocation chart

(Master Label) which is attached to the lid

of the electrical carrier.

Caution: When the carrier lid is

removed, take care to protect the box

from moisture ingress, and refit the

lid at the earliest opportunity.

Remove the luggage compartment floor

panels.

Remove the electrical carrier lid by

pulling the retaining clips and pulling the

lid upwards.

Spare fuses and a special tool for

removing the fuses are supplied

underneath the electrical carrier lid in the

luggage compartment.

Reposition the lid and press down until

the retaining clips engage.

The circuits protected are listed on

page 4-20.

Page 42

4-16 Roadside emergency service

Fuse Ratings

Engine Compartment Fuse box – Left-hand Side

Fuse NoRatings

(amps)

1 10 Transmission control module.

2 5 Screen heaters relay, alternator regulator.

3 10 Security sounder, headlamp levelling,

ignition coils +Ve, fog lamp switches.

4 5 ABS control module.

5 10 Adaptive damping, starter relay coil, engine

management control module and relays.

6 10 Right-hand dipped beam headlamp.

7 30 Powerwash pump.

8 10 Left-hand dipped beam headlamp.

9 10 Security sounder.

10 5 Rain Sensing.

11 10 Right-hand horn.

A on location illustration, page 4-13.

Circuit

Fuse NoRatings

(amps)

12 30 Radiator cooling fans series/right-hand fast.

13 10 Left-hand horn.

14 30 Cooling fans left-hand fast.

15 10 Air conditioning coolant pump.

16 30 ABS pump control.

17 15 Front fog lamps.

18 30 ABS pump motor.

19 10 Right-hand main beam headlamp.

20 – Not used.

21 10 Left-hand main beam headlamp.

22 30 Wiper motor.

Circuit

Page 43

Fuse Ratings and Circuits

Engine Compartment – Engine Management Fuse box

Roadside emergency service 4-17

Fuse NoRating

(amps)

1 20 Adaptive damping.

2 15 Intercooler water pump (Supercharger).

3 25 Starter solenoid.

4 5 Engine control module.

5 10 Fuel injectors.

6 5 Transmission control module.

7–Not used.

8 10 Air conditioning compressor clutch.

9 30 Throttle motor.

10 5 Engine control module, Park/Neutral switch,

cruise control VSV 1 and 2 (where fitted),

EGR valves.

B on location illustration, page 4-13.

Circuit

Fuse NoRating

(amps)

11 30 HO2 sensor heaters.

12 10 Air flowmeter, VVT solenoids.

13 – Not used.

14 10 HO2 sensor heaters relay (where fitted),

EVAP valve, ignition coils relay, throttle

motor relay, AC compressor clutch relay,

radiator fans control module, CCV.

15 30 Windscreen left-hand heater.

16 5 Control module compartment cooling fan.

17 30 Windscreen right-hand heater.

18 10 Ignition coils, ignition amplifier.

Circuit

Page 44

4-18 Roadside emergency service

Rear Compartment Fuse box – Right-hand Heelboard

Fuse NoRating

(amps)

1 20 Left-hand seat control module.

2 15 Door lock relay, door locking actuators.

3 15 Body processor module.

4 10 Door mirror heaters, mirror foldback.

5 5 Passenger seat switchpack.

6 10 Air conditioning.

7 20 Body processor module (column motor

power).

8 5 Rear window switchpack, passenger door

switchpack.

9 20 Rear seat heaters.

10 5 Jaguar Diagnostic System.

C on location illustration, page 4-13.

Circuit

Fuse NoRating

(amps)

11 20 Air conditioning right-hand blower relay.

12 5 Right-hand / left-hand rear seat timer.

13 25 Right-hand rear door control module.

14 - Not used.

15 25 Right-hand door control module.

16 - Not used.

17 15 Sunroof.

18 25 Right-hand and left-hand seat heaters.

Circuit

Page 45

Rear Compartment Fuse box – Left-hand Heelboard

Roadside emergency service 4-19

Fuse NoRating

(amps)

1 20 Right-hand seat control module.

2 5 Rear window switchpack, driver door key

barrel, driver door switchpack and memory.

3 5 Dimmer module.

4 5 Diagnostic connector.

5 15 Body processor module.

6 5 Centre console switchpack (includes clock),

reader exciter ECM.

7 15 Body processor module (battery supply for

solenoids, lamps and motors).

8 5 Steering column adjust switch, driver seat

switchpack.

9 10 Radio/cassette head unit.

10 5 Airbag/SRS.

11 20 Air conditioning left-hand blower motor.

D on location illustration, page 4-13.

Circuit

Fuse NoRating

(amps)

12 10 Door mirror heaters relay, air conditioning,

blower motor relays, power steering control

module.

13 25 Left-hand rear window.

14 10 Cruise control switch, instrument cluster,

catalytic converter over temperature

warning.

15 25 Left-hand door control module.

16 5 Electrochromic interior mirror (where fitted),

centre console switchpack, gear selector,

traction control switch illumination, J-gate

mode switch illumination. Pin A9 luggage

compartment fuse box, heated rear window

relay, fuel pump relay, secondary fuel pump

relay (supercharged). Pin A5: feed to fuses 10

& 12 in right-hand heelboard.

17 10 Accessory supply.

18 5 Instrument cluster.

Circuit

Page 46

4-20 Roadside emergency service

Luggage Compartment Fuse box – Electrical Carrier

Fuse NoRating

(amps)

1 10 Security and locking control module

(Reversing lamps, rear fog lamps, stop lamps,

electrochromic mirror).

2 5 Fuel filler flap.

3 5 Audio system.

4 5 Radio telephone, ‘E’ post lamps, navigation.

5 25 Cigar lighters.

6 - Not used.

7 20 Fuel pump.

8 10 High mounted stop lamp, caravan/trailer

stop lamps.

9 10 Antenna motor.

10 10 Security and locking control module (luggage

compartment release, caravan/trailer

direction indicators, fuel filler flap relay).

E on location illustration, page 4-13.

Circuit

Fuse NoRating

(amps)

11 10 Accessory sockets.

12 30 Audio system power amplifier.

13 - Not used.

14 5 Navigation.

15 20 Fuel pump (supercharger, where fitted).

16 20 Caravan/trailer connector.

17 25 Heated rear screen.

18 20 Rear seat movement.

19 5 Right-hand side lamps, left-hand and

right-hand number plate lights, caravan/

trailer.

20 20 Rear seat movement.

21 5 Left-hand side lamps, left-hand and

right-hand sidemarker lights, caravan/trailer.

22 5 Audio / telephone.

Circuit

Page 47

Control Modules – Identification and Location

Roadside emergency service 4-21

Control Module Location

Adaptive Damping

(where fitted)

Airbag (Supplementary

Restraint System)

Anti-lock Braking

System and Traction

Control

Body Processor Fascia, mounted on passenger airbag

Climate Control Right-hand side of the climate control

Under the fascia, on the bulkhead,

passenger side.

On the tunnel forward of the J-gate.

Engine compartment, left-hand side.

Mounted below the ABS hydraulic

control unit.

bracket.

unit.

Control Module Location

Door (four-one in each

door)

Engine Management Engine compartment, passenger side,

Front Seat Seat cushion frame.

Rear Seat (where fitted) Rear of the centre armrest.

Security and Locking Luggage compartment electrical

Transmission Engine compartment, passenger side,

Door interior, between the inner and

outer panels.

within bulkhead extension.

carrier to the rear of the battery.

within bulkhead extension.

Page 48

4-22 Roadside emergency service

Relay Identification and Location

The following chart identifies and gives locations for the relays

which control the vehicle’s electrical services. The relays have

coloured harness connectors and cases for identification. Where

the connector colour differs from the case, both colours will be

listed.

Location Functions Case Colour

Engine compartment fuse box, left-hand side,

to the rear of the brake control modulator.

Luggage compartment fuse box, to the rear of

the battery, under the electrical carrier lid.

Layout as diagram:

R1 Air conditioning water pump.

R2 Front fog lamps.

R3 Main beam headlamps.

R4 Power wash pump (where fitted).

R5 Dipped beam headlamps.

R6 Horns.

R7 Ignition +.

Layout as diagram:

R1 Fuel pump s/c only.

R2 Heated rear window.

R3 Tail and number plate lamps.

R4 Fuel pump.

R5 Stop lamps.

R6 Accessory socket (where fitted).

R7 Auxiliary +.

Relays, where not mounted in a fuse box, are arranged in groups

of three. Each group has a black plastic cover, which slots into

the harness connector and can be easily removed for access.

When left-hand or right-hand is used in the text, this refers to

the left-hand side or right-hand side of the vehicle, viewed from

the rear.

ÿþ

ÿ

ÿ

Brown

Brown

Brown

Brown

ÿ

ÿÿÿ

Brown

Brown

Brown

Brown

ÿþÿÿÿÿÿÿ

Brown

Brown

Brown

Brown

Brown

Brown

Page 49

Relay Identification and Location (continued)

Location Functions Case Colour

Roadside emergency service 4-23

Engine compartment, engine and

transmission control modules compartment,

passenger side.

Engine compartment, left-hand side, engine

management fuse box

Engine compartment, left-hand side behind

the radiator.

Engine compartment, centrally at bulkhead. Front screen heater – right-hand side (where fitted).

Engine compartment, left-hand side, below

the brake modulator under spoiler.

Layout as diagram:

R1 Intercooler water pump

(where fitted), (micro-relay).

R2 Air conditioning compressor clutch.

R3 Ignition coil.

R4 Throttle motor.

R5 Starter solenoid.

R6 HO2 sensor heaters.

R7 Fuel injection (micro-relay).

Engine management system control. Brown

Wiper on/off

Wiper fast/slow.

Front screen heater – left-hand side (where fitted).

Radiator fan control module. Black

ÿÿÿÿÿ ÿ

Black

Brown

Brown

Brown

Brown

Brown

Black

Black

Black

Black

Black

Page 50

4-24 Roadside emergency service

Relay Identification and Location (continued)

Location Functions Case Colour

In the passenger compartment below the

driver seat.

In the passenger compartment below the

front passenger seat.

In the passenger compartment behind the

right-hand side rear seat heelboard.

In the passenger compartment behind the

left-hand side rear seat heelboard.

In the passenger compartment in the

left-hand side rear seat fuse box.

In the luggage compartment fuse box. Fuel flap lock: micro-relay.

Seat heater – driver (where fitted). Brown

Seat heater – front passenger (where fitted). Brown

Right-hand blower – air conditioning: micro-relay.

Left-hand blower – air conditioning: micro-relay.

Door mirror heater: micro-relay.

Left-hand lumbar deflate, rear seat: micro-relay (where fitted).

Door lock: micro-relay.

Air conditioning isolate: micro-relay

Door mirror fold flat: micro-relay (where fitted).

Door mirror fold out: micro-relay (where fitted).

Ignition + Brown

Fuel flap unlock: micro-relay.

Black

Black

Black

Black

Black

Black

Black

Black

Black

Black

Page 51

5 Vehicle maintenance

Vehicle maintenance 5-1

Introduction

Owners are responsible for ensuring that

the vehicle is regularly maintained and

serviced at the correct mileage/time

intervals as specified in the ‘Maintenance

Schedules’. The first part of this section

deals with regular servicing.

The condition of the tyres is of the utmost

importance. Advice about tyre wear and

correct usage is given in this section. If in

any doubt about the condition of your

tyres, contact a Jaguar Dealer.

Regular Servicing

Regular maintenance and servicing is the

responsibility of the owner.

Jaguar Dealers will be pleased to arrange

periodic servicing in accordance with the

USA and Mexico

Booklet or Canadian

Warranty and Benefits Information

Booklet.

Failure to implement maintenance at the

recommended intervals could result in

deterioration of vehicle performance and

possible infringement of regulations.

‘Passport to Service’

‘Club Jaguar’

Tool Kit

A tool kit is provided for some vehicles/

markets and is located under the bonnet,

on the passenger side, in a tray on the

bulhead extension cover.

Tyres

Tyres of the correct type and dimensions,

with correct cold inflation pressures are

an integral part of every vehicle’s design.

Regular maintenance of tyres contributes

not only to safety, but to the designed

function of the vehicle. Road-holding,

steering and braking are especially

vulnerable to incorrectly pressurised,

badly fitted or worn tyres.

Tyres of the correct size and type but of

different make have widely varying

characteristics. It is therefore

recommended that Jaguar approved tyres

(see SECTION 6:

fitted to all wheels.

Wheel/Tyre Data

) are

Do not interchange tyres from side to

side, front to rear or vice versa as tyre

wear produces characteristic patterns

depending upon their position and, if the

position is changed after wear has

occurred, the performance of the tyre will

be adversely affected.

Tyre Repair

It is recommended that damaged tyres

are discarded and new tyres fitted. They

must not be repaired in view of the high

performance capability of the vehicle.

Page 52

5-2 Vehicle maintenance

Tyre Use after Vehicle Storage

After a long period of a vehicle standing,

tyres may become locally distorted with a

flat area. This will cause an uneven ride

for a few miles until the tyres have

warmed up and the ‘flat’ rounds off.

However, to reduce the effects of

flat-spotting, the tyres of a stored vehicle

may be inflated to pressures not

2

exceeding 50 lbf/in

Refer to SECTION 6,

Tyre Pressures

(343 kPa, 3,4 bar).

Recommended

for normal operating

pressures.

Tyre Size, Type, Pressures

The tyre pressures recommended (see

SECTION 6:

Wheel/Tyre Data

) provide

optimum ride and handling

characteristics for all normal operating

conditions. The pressures should be

checked, and correctly set, if necessary,

once per week. This should be done with

the tyres cold. Tyre temperatures and

pressures increase when running.

Deflating a warm tyre to the

recommended pressure will result in

under-inflation which may be dangerous.

A slight natural pressure loss occurs with

2

time. If this exceeds 2 lbf/in

(0,14 kg/cm

2

, 0,14 bar) per week, the

(14 kPa,

cause should be investigated and

rectified.

It is an offence in many States and certain

other countries to drive a vehicle with

tyres that are not inflated in accordance

with the vehicle’s proper use.

A vehicle fitted with winter tread tyres

must only be driven at speeds below the

speed rating moulded into the tyre’s

side-wall.

Tyre Renewal

When renewal of tyres is necessary it is

preferable to fit a complete vehicle set.

Should either front or rear tyres only

show need for renewal, new tyres must

be fitted, as axle sets, to replace worn

ones.

After new tyres have been fitted

Note:

the wheels need to be dynamically

balanced.

The radial ply tyres specified are designed

to meet the high-speed performance

capability of this vehicle.

Only tyres of identical specification as

shown in SECTION 6:

Wheel/Tyre Data

must be fitted. Do not fit tyres with a

different tread pattern, size or speed

rating.

Damage

Excessive local distortion can cause the

casing of a tyre to fracture and may lead

to premature failure. Tyres should be

examined especially for cracked walls,

exposed cords, etc. Flints and other sharp

objects must be removed from the tyre

tread; if left in they may work through the

cover. Clean off any oil or grease

contamination by using a suitable

cleaner.

Caution: Do not use paraffin

(kerosene), because this has a

detrimental effect on rubber.

Page 53

Wear

All tyres fitted as original equipment include tread wear

indicators (TWI) in their tread pattern. When the tread has worn

to a remaining depth of 0.063 inch (1,6 mm) the indicators

appear at the surface as bars which connect the tread pattern

across the full width of the tyre.

It is illegal in many States and certain other countries to

continue to use tyres after the tread has worn to less than

0.063 inch (1,6 mm) over three quarters of the width and the

entire circumference of the tyre.