Page 1

®

Telio

CAD A16

Instructions for Use

Page 2

Table of Contents

3 Telio System

4 Product Information

Description

Material

Uses

CAD/CAM partners

9 Fabricating a Telio CAD Hybrid Abutment Crown

Treatment / fabrication process

Shade – tooth shade and abutment shade

Preparation for the CAD/CAM process

Layer thicknesses

Block selection

Finishing

12 Completing the Telio CAD Structure

Polishing technique chairside

Polishing technique labside

13 Cementation of Ti Base / Telio CAD Structure

19 Seating and Aftercare

Intraoral preparation

Seating the hybrid abutment crown

Care notes – Implant Care

21 Designing the Emergence Profile

Chairside

Labside

25 General Information

Frequently Asked Questions

2

Page 3

®

Telio

Telio is a comprehensive system solution for temporary restorations which addresses dental technicians, CAD/CAM users

and dentists alike.

All products are suitable for the fabrication of conventional and implant-supported temporaries. Their materials are

compatible with each other and their shades are optimally coordinated.

System

Telio CS

Telio CAD

Laboratory Practice

Short treatment time Medium treatment time Long treatment time

Telio Lab

Telio CS

For dentists: Self-curing temporary crown and bridge material, supplemented by a desensitizer and cement

Telio CAD

For CAD/CAM users: Resin blocks and discs for the efficient fabrication of temporary crowns, hybrid abutment crowns and

bridges using the CAD/CAM technique

Telio Lab

For dental technicians: Temporary crown and bridge resin for the cold technique

3

Page 4

®

Telio

CAD Abutment Solutions

Product Information

Description

Telio® CAD A16 are CAD/CAM-fabricated implant-supported hybrid restorations for individual, temporary singletooth reconstructions. The material consists of a cross-linked polymer block (PMMA), enabling the fabrication of

individual, monolithic hybrid abutment crowns which are directly cemented to a Ti base. Shape, esthetics and

emergence profile can be easily designed and adjusted any time. Telio CAD A16 thus represents the basis for

the subsequent permanent restorations with IPS e.max® CAD Abutment Solutions and IPS e.max Press

Abutment Solutions.

Hybrid abutment crown

Hybrid abutment crowns are characterized by combining abutment

and monolithic crown in one piece. This is an efficient two-in-one

solution made of PMMA, which is directly cemented to a Ti base.

Shape, esthetics and emergence profile can be easily designed and

adjusted any time. For cases with immediate stress-bearing, a CAD/

CAM-milled instant temporary can be fabricated. For this purpose,

Telio CAD convinces users with its usual esthetic properties and

sufficient strength, durability and efficiency.

The monolithically milled hybrid abutment crown is extraorally

cemented to the Ti base by means of Multilink Hybrid Abutment HO 0.

Then, the restoration is screwed onto the implant – in one piece.

Finally, the screw channel is sealed with a composite (e.g. Tetric

EvoCeram

®

) or a light-curing temporary restorative material (e.g. Telio CS Inlay / Onlay).

Telio CAD

(PMMA)

Ti base

Telio CAD

Hybrid abutment

crown

Ideally coordinated – Multilink® Hybrid Abutment HO 0

The auto-curing Multilink Hybrid Abutment composite cement together with SR Connect and Monobond

the cementation of Telio CAD on adhesive bases made of titanium / titanium alloys.

This allows

– reliable adhesion due to high adhesion values;

– easy handling due to the convenient Automix syringe.

®

Plus are used for

4

Page 5

Material

Telio CAD

Telio CAD are cross-linked PMMA blocks for the fabrication of long-term temporaries by means of the

CAD/CAM technique. As a result of the industrial polymerization process, the blocks feature a high material

homogeneity. Polymerization shrinkage or inhibition layers no longer have to be taken into consideration.

Given the CAD/CAM fabrication, the temporary can be easily reproduced at any time. Stains and/or layering

materials can be used to apply final esthetic optimizations.

Physical properties

Test method Specifications Example values

Flexural strength MPa EN ISO 10477 ≥ 100 128

Flexural modulus MPa EN ISO 10477 ≥ 2800 3041

Water absorption µg/mm3EN ISO 10477 ≤ 40 22

Solubility µg/mm3EN ISO 10477 ≤ 7.5 0

Ball indentation hardness MPa Internal method

(358N, 30s)

Ti base

Ti bases are used for the fabrication of Telio CAD Abutment Solutions. The suitable Ti bases are selected in

accordance with the CAD/CAM system used. Please observe the instructions for use and processing of the

respective manufacturer.

– 176

Further information about the authorized CAD/CAM systems is available on the Internet from

www.ivoclarvivadent.com.

5

Page 6

Uses

Indications

Fabrication of temporary restorations by means of CAD/CAM technology

Contraindications

– Use for permanent restorations

– Bruxism

– Failure to observe the requirements stipulated by the implant manufacturer for using the selected

implant type (diameter and length of the implant must be approved for the respective position in the

jaw by the implant manufacturer)

– Failure to observe the permissible maximum and minimum Telio CAD layer thicknesses

– Use of a luting composite other than Multilink Hybrid Abutment HO 0 for the cementation of Telio

CAD to the Ti base

– Intraoral cementation of the Telio CAD structure to the Ti base

– All uses not stated as indications are contraindicated.

Important processing restrictions

– Processing of the blocks with non-authorized CAD/CAM systems

– Failure to observe the manufacturer's instructions regarding the processing of the Ti base

Side effects

If the patient is known to be allergic to any of the components, Telio CAD and the other materials

necessary for the fabrication should not be used.

Composition

– Telio CAD

Components: Poly(methyl methacrylate) (PMMA), pigments

– Multilink Hybrid Abutment HO 0

Components: Dimethacrylate, HEMA as well as fillers (barium glass, ytterbium trifluoride, spheroid

mixed oxide and titanium dioxide)

– SR Connect

Components: Methyl methacrylate, polymethyl methacrylate, dimethacrylates and initiators

Warnings

– Do not inhale grinding dust.

– SR Connect contains methyl methacrylate (MMA). MMA is highly flammable. Therefore, keep away

from sources of ignition and do not smoke. MMA is an irritant and is irritating to eyes, respiratory

organs and skin. Do not inhale vapours.

– The safety notes on the individual primary packaging and labels have to be observed.

CAD/CAM partners

Telio CAD has to be processed with an authorized CAD/CAM system. For questions regarding the

different CAD/CAM systems, please contact the respective cooperation partners.

Further information is available on the Internet from www.ivoclarvivadent.com.

6

Page 7

®

Telio

CAD Abutment Solutions

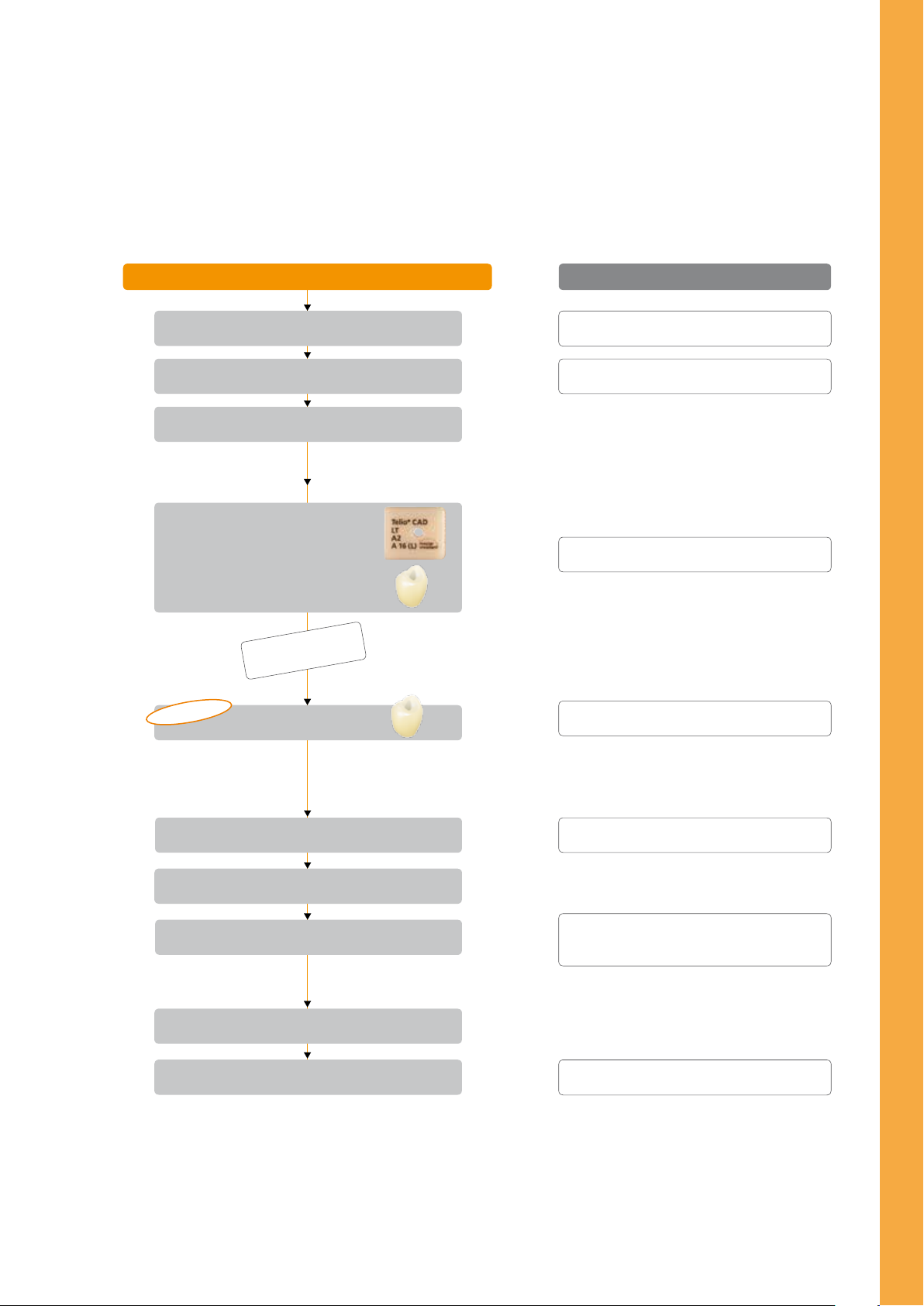

Fabricating a Telio CAD Hybrid Abutment Crown

Optional

Working Steps

Implantation,

healing phase

Shade determination,

impression-taking

CAD design

CAM

Hybrid abutment crown

Optional

Clinical try-in

Characterization,

adjustment

Ivoclar Vivadent Products

Cervitec® Plus, Cervitec® Liquid

®

OptraGate

Telio

SR Nexco

, Virtual®

®

CAD A16

®

, Telio® Lab LC

CAD Abutment Solutions – Fabricating a Telio CAD Hybrid Abutment Crown

®

Telio

Cementation of

Ti base / Telio CAD A16

Screwing in the

hybrid abutment crown

Sealing

the screw channel

Final check

Aftercare

Monobond

Multilink® Hybrid Abutment HO 0

Tetric EvoCeram®, Tetric EvoFlow®,

Telio® CS Inlay, Heliomolar®,

7

®

Plus, SR Connect,

Telio Add-On Flow

Implant Care

Page 8

Shade – tooth shade and abutment shade

For the Telio CAD hybrid abutment crown, the desired tooth shade results from the

– shade of the Telio CAD A16 block;

– the shade of Multilink Hybrid Abutment HO 0.

Preparation for the CAD/CAM process

Scanning

For the fabrication of Telio CAD Abutment Solutions, the clinical situation is digitalized either by a direct intraoral scan or

an indirect model scan, depending on the CAD/CAM system used. For notes regarding the scan, please observe the

manufacturer's instructions of the CAD/CAM system.

Selecting a Ti base

The required Ti base is selected depending on the inserted implant and the CAD/CAM system used.

8

Page 9

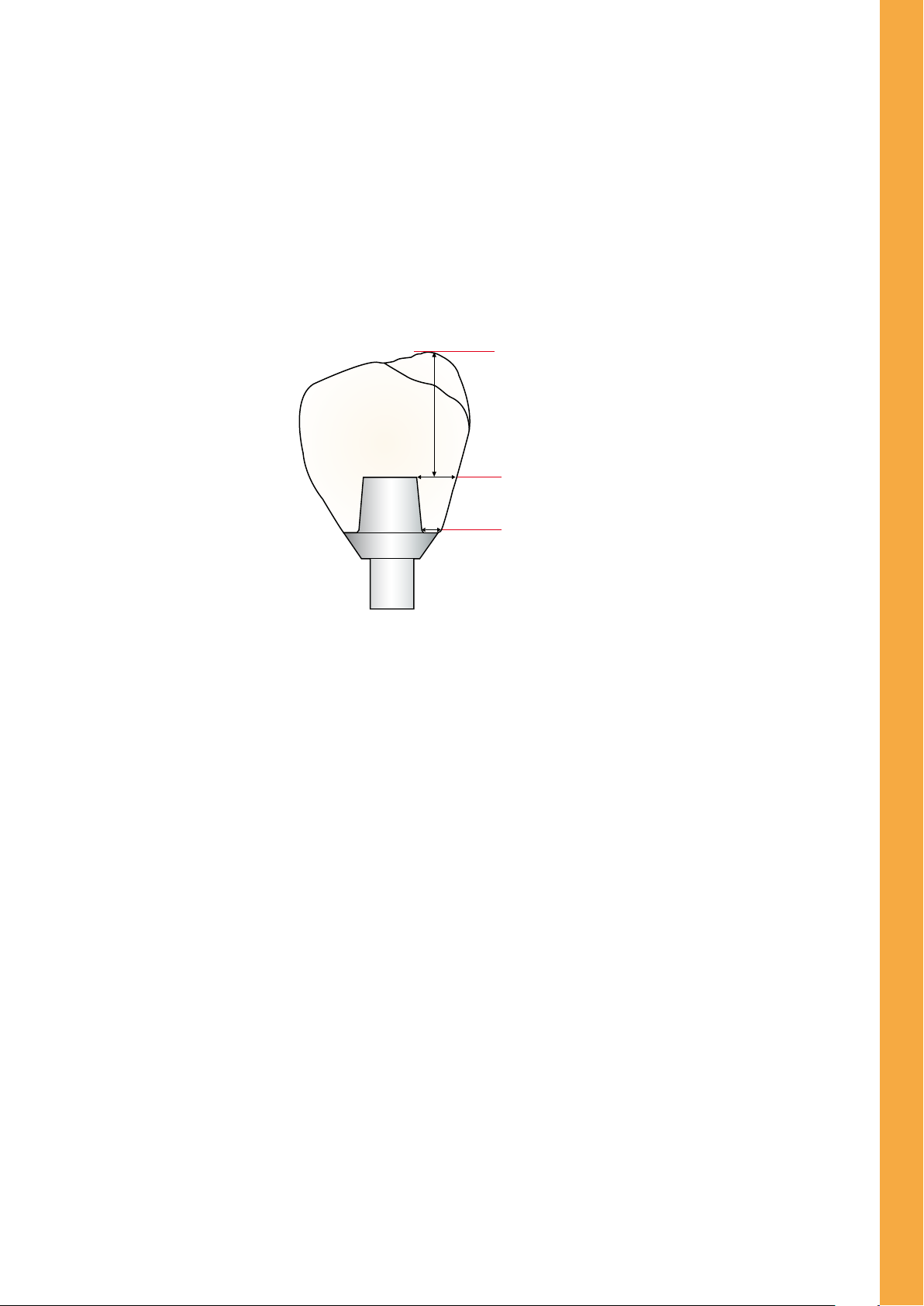

Layer thicknesses

Observing the geometry requirements of the Telio CAD structure is the key to success for a durable restoration. The more

attention is given to the design, the better the final results and the clinical success will turn out to be.

The following basic guidelines have to be observed:

Hybrid abutment crown

> 1.5 mm

> 0.8 mm

CAD Abutment Solutions – Fabricating a Telio CAD Hybrid Abutment Crown

®

> 0.5 mm

Minimum thicknesses

– occlusal: min. 1.5 mm

– circular: min. 0.8 mm

– Telio CAD A16 in the transition area to the Ti base rim: min. 0.5 mm

– The notes of the implant manufacturer regarding the maximum height of the hybrid abutment crown must be observed.

– In the transition area to the Ti base rim, the minimum thickness is 0.5 mm, which has to be continuously increased to

0.8 mm.

Block selection

When using a Ti base from Sirona, the dimensions of the interface to the Ti Base (S or L) have to be observed.

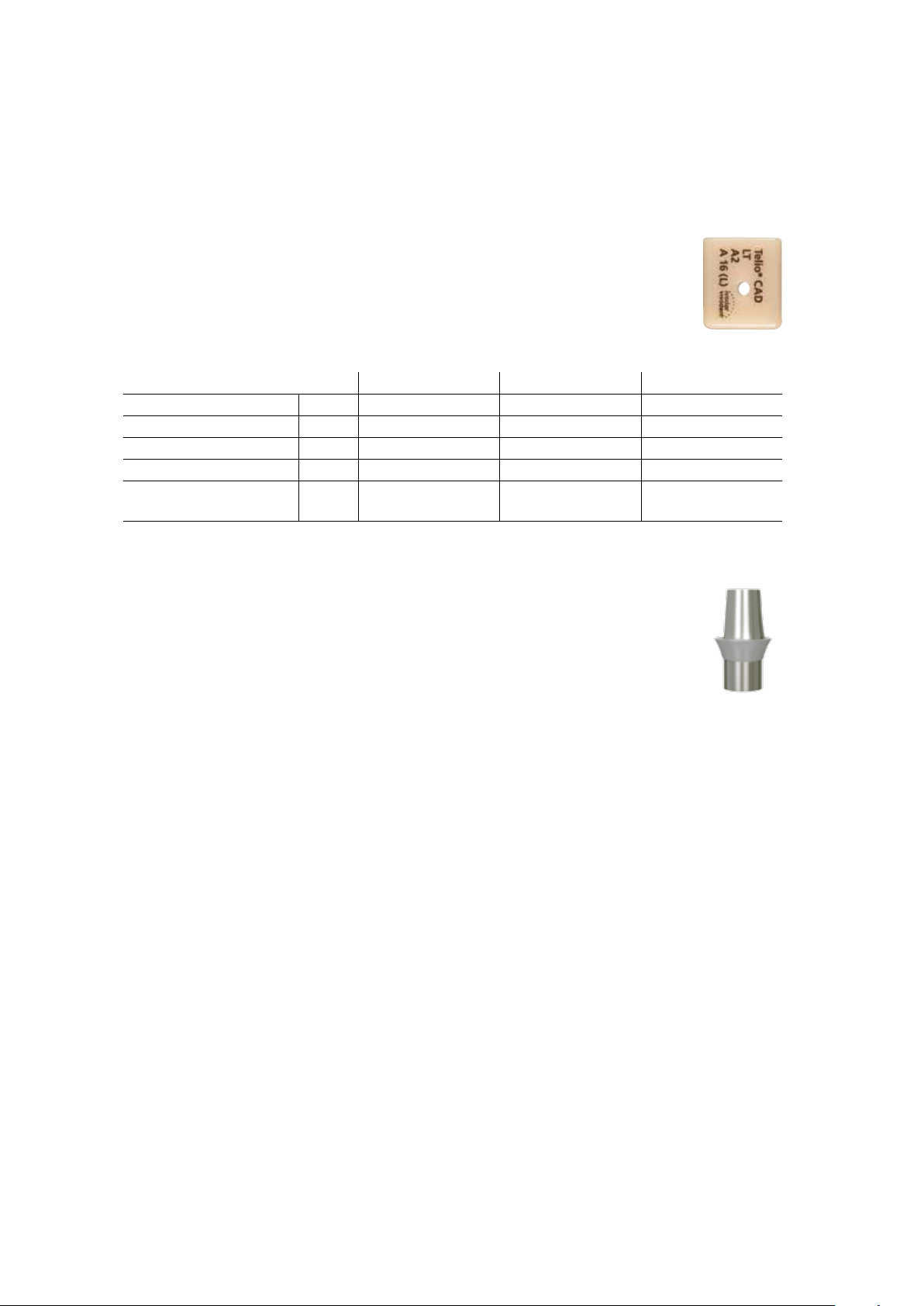

Available tooth shades Telio CAD A16 block with S or L interface:

LT A1, LT A2, LT A3, LT A3.5, LT B1, LT BL3

Telio

9

Page 10

Finishing

Conventional cross-cut tungsten carbide burs are suitable for finishing and adjusting the Telio CAD structure.

During finishing, make sure that the minimum layer thicknesses are observed. The milled Telio CAD structure is separated

from the block by means of a fine cross-cut bur or a diamond separating disc.

Checking the fit of the Telio CAD structures on the Ti base

Carefully place the CAD structures on the Ti base and check the fit. Observe the position of the rotation lock.

Separate the attachment point from the incisal using a fine, cross-cut bur or a

diamond separating disc.

Carefully place the Telio CAD structure on the Ti base and check the fit. Optimum fit of the Telio CAD structure on the Ti base

Finishing

Important!

– Do not finish the shoulder of the Telio CAD structure to prevent negatively affecting the Ti base.

– Finish the emergence profile if required taking the fit to the gingiva and the minimum thickness into account.

Finishing the outer surface of the Telio CAD structure (hybrid abutment crown)

– Smooth out the attachment point to the block with fine tungsten carbide burs taking the shape of the emergence profile

and the proximal contacts into account.

– Check the proximal, occlusal and basal contacts.

– Design surface textures.

Clean the Telio CAD structure in an ultrasounic bath or blast with the steam jet before further processing.

10

Page 11

Do not finish the shoulder to the Ti base. Be careful when finishing the emergence profile to prevent affecting the fit

to the gingiva.

CAD Abutment Solutions – Fabricating a Telio CAD Hybrid Abutment Crown

®

Telio

Smooth out the attachment point to the block taking the shape of the emergence

profile and the crown margin into account.

Adjust the surface texture where desired.

11

Page 12

®

Telio

CAD Abutment Solutions

Completing the Telio CAD Structure

Polishing technique chairside

Astropol

Step 1: Finishing with Astropol F (grey): With the Astropol F finisher, excess is removed and a smooth surface is achieved.

Step 2: Polishing with Astropol P (green): Polishing with Astropol P results in a smooth restoration surface.

Step 3: High-gloss polishing with Astropol HP (dusky pink): Do not apply pressure. The restoration surfaces are finished

Note:

Finishing and polishing is carried out using water spray for cooling and to remove the resulting polishing residue. If excess

has already been removed with a fine-grain diamond grinding instrument or if the surfaces of the restoration are rather

smooth, the first step (Astropol F) can be forgone.

Recommended speed: 7,500 – 10,000 rpm

OptraPol® NG

As an alternative, the OptraPol NG one-step polishing system can be used. The following instructions should be observed:

– Speed: 5,000 – 8,000 rpm

– Only use in conjunction with copious water spray.

The restoration is polished to a high gloss in only one polishing step and medium contact pressure.

®

and polished using medium contact pressure.

Polishing technique labside

Prepolishing is performed with rubber polishers and silicone wheels with various abrasive levels from rough to fine. A high

gloss is achieved with goat hair brush, cotton or leather buffing wheel as well as SR® Universal polishing paste.

12

Page 13

®

Telio

CAD Abutment Solutions

Cementation of Ti Base / Telio CAD Structure

Careful preparation of the bonding surfaces is a prerequisite for optimum adhesive cementation of the

Telio CAD structure to the Ti base. The following paragraphs outline the required procedures.

Required materials

– SR Connect

– Monobond® Plus

– Multilink® Hybrid Abutment HO 0

– Liquid Strip

Telio CAD A16 Ti base

Blasting – Observe manufacturer's instructions.

Apply SR Connect on the adhesive

surface to the Ti base, allow to react

Cementation preparation Telio CAD

Preparation for cementation –

for 30 s and polymerize for 40 s with

a polymerization device

(Bluephase

®

Style).

Wet adhesive surface with

Monobond Plus for 60 s.

–

®

Cementation Multilink

Covering the cementation joint Liquid Strip

Curing Auto-polymerization: 7 min

Polishing the cementation joint Customary polishers for resin materials and polishing paste

Preparation of the Ti base

The following procedure should be observed when preparing the Ti base for the cementation with the Telio CAD structure:

– Prepare the Ti base according to the instructions of the manufacturer.

– Clean the Ti base in an ultrasonic bath or with the steam jet and then dry with blown air.

– Screw the Ti base onto a model analog.

– Place the Telio CAD structure on the Ti base and mark the relative position of the components with a waterproof pen.

This facilitates locating the correct position when the parts are assembled at a later stage.

– Do not blast or modify the emergence profile of the Ti base any way.

– If the manufacturer recommends that the bonding surface of the base be blasted, the following procedure

should be observed:

– Protect the emergence profile and the screw channel, e.g. by means of a silicone (Virtual® Extra Light Body Fast Set).

– Carefully blast the bonding area according to the instructions of the manufacturer.

– Remove silicone.

– Clean the Ti Base in an ultrasounic bath or with the steam jet.

– After the bonding surface has been cleaned, it must not be contaminated under any circumstances as this would

impair the bond.

– Note: Aggressive blasting negatively affects the anti-rotation lock. Blasting with max. 50 µm at 1–2 bar (15–29 psi) pres-

sure is recommended.

– Apply Monobond Plus on the cleaned bonding surface and allow to react for 60 s. After the reaction time, dry the

remaining residue with water- and oil-free air.

– Seal the screw channel with a foam pellet or wax. The bonding surface must not be contaminated in the process.

Hybrid Abutment HO 0

CAD Abutment Solutions – Completing the Telio CAD Structure | Cementation of Ti Base / Telio CAD Structure

®

Telio

13

Page 14

Screw the Ti base onto a model analog. Mark the relative position to the structure with

a waterproof pen.

Protect the emergence profile and the screw channel, e.g. by means of silicone

The instructions of the implant manufacturer must be observed.

(Virtual Extra Light Body Fast Set).

The instructions of the implant manufacturer must be observed. Carefully blast the

bonding surface with max. 50 µm and 1-2 bar (15-29 psi) pressure.

Apply Monobond Plus on the cleaned bonding surface and allow to react for 60 s.

After the reaction time, dry the remaining residue with water- and oil-free air.

Remove silicone and subsequently clean in an ultrasonic bath or with the steam jet.

Seal the screw channel with a foam pellet or wax.

14

Page 15

Preparing the Telio CAD structure

The following procedure must be observed when preparing the Telio CAD structure for cementation on the Ti base:

– Do not blast the Telio CAD structure in preparation for the cementation.

– Clean the Telio CAD structure in an ultrasonic bath or with the steam jet and subsequently blow dry.

– After cleaning, any contamination of the bonding surface must be prevented, since contaminations negatively influence

the bond.

– Thinly coat the bonding surface with SR Connect using a disposable brush and allow to react for 30 s. Subsequently,

polymerize with a polymerization light (e.g. Bluephase Style) for 40 s.

Device Bluephase® Style

(Polywave®, 1100 ± 10% mW/cm2)

Manufacturer Ivoclar Vivadent AG

SR Connect 40 s

Lumamat 100 Spectramat Labolight LV-III Solidilite V Visio Beta Vario HiLite Power

Ivoclar Vivadent Ivoclar Vivadent GC Shofu 3M Heraeus

P2: 11 min 2 min 3 min 3 min 4 x 20 s 90 s

Status 2014

Note:

The SR Connect reaction time of 30 s must be observed: If SR Connect is applied as a conditioner for Telio

CAD A16 for longer than that, the accuracy of fit may be compromised.

CAD Abutment Solutions – Cementation of Ti Base / Telio CAD Structure

®

Telio

Do not blast the Telio CAD structure. Thinly apply SR Connect with a disposable brush.

Do not disperse.

15

Light-cure for 40 s.

Page 16

Cementation with Multilink® Hybrid Abutment

The following instructions must be observed in the cementation procedure:

– Lay out the cleaned and conditioned components (Telio CAD structure, Ti base) for cementation.

– Carry out the subsequent cementation procedure quickly and without interruption. The working time of

Multilink Hybrid Abutment HO 0 is approximately 2 min at 23°C (± 1°C) or 73°F (± 1.8°F).

– As a general rule, attach a new mixing tip to the Multilink Hybrid Abutment HO 0 syringe prior to each use.

– Apply a thin layer of Multilink Hybrid Abutment HO 0 directly from the mixing tip to the bonding surface of the Ti base

and to the bonding surface of the Telio CAD structure.

– Leave the mixing tip on the Multilink Hybrid Abutment syringe until the next use. The remaining cement polymerizes in

the tip and functions as a seal.

– Place the Telio CAD structure on the Ti base in such a way that the position markings are aligned.

– Press the parts lightly and evenly together and check the correct relative position of the components (transition Ti base /

Telio CAD structure).

– Subsequently, tightly press the components together for 5 s.

– Carefully remove excess in the screw channel, e.g. with a microbrush or brush, using rotary movements.

Important:

– Do not remove circular excess cement before curing has started, i.e. 2-3 min after mixing. Use a suitable

dental lab instrument (e.g. Le Cron) for this purpose. Hold the components in place using light pressure.

– Apply glycerine gel (e.g. Liquid Strip) to the cementation joint to prevent the formation of an inhibition layer. Leave the

gel on the cementation joint until polymerization is complete.

– Next, the composite cement auto-polymerizes completely within 7 min.

– Important: Do not move the components until Multilink Hybrid Abutment HO 0 has completely cured. Hold

them in place using e.g. diamond-coated tweezers.

– After completed auto-polymerization, rinse off the glycerine gel with water.

– Cautiously polish the cementation joint with rubber polishers at a low speed (< 5,000 rpm) to avoid overheating.

Finally, polish the surface of the PMMA structure to a high gloss using polishing paste.

– If there is any cement residue in the screw channel, remove it using suitable rotary instruments.

– Clean the restoration in an ultrasonic bath or with the steam jet.

Keep the cleaned and conditioned components that are to be cemented at hand. Attach a new mixing tip to the Multilink Hybrid Abutment syringe prior to each use.

16

Page 17

Apply a thin layer of Multilink Hybrid Abutment HO 0 directly from the mixing tip to

the bonding surface of the Ti base.

Apply a thin layer of Multilink Hybrid Abutment HO 0 directly from the mixing tip to

the bonding surface of the Telio CAD structure.

5 s

CAD Abutment Solutions – Cementation of Ti Base / Telio CAD Structure

®

Telio

Place the Telio CAD A16 structure on the Ti base in such a way that the position markings are aligned. Press the parts lightly and evenly together and check the correct relative position of the components (transition Ti base / Telio CAD structure).

Carefully remove excess in the screw channel, e.g. with a microbrush or brush, using

rotary movements.

Subsequently, tightly press the components together for 5 s.

2-3 min

Important: Do not remove circular excess cement before curing has started,

i.e. 2–3 minutes after mixing. Hold the components in place using light pressure.

7 min

Apply glycerine gel (e.g. Liquid Strip) to the cementation joint to prevent the

formation of an inhibition layer.

Important: Do not move the components until auto-polymerization is completed.

The composite cement auto-polymerizes within 7 min.

Hold them in place during this time.

17

Page 18

After completed auto-polymerization, rinse off the glycerine gel with water.

Cautiously polish the cementation joint with rubber polishers at low speed

(< 5,000 rpm) to avoid overheating. Finally, polish the surface of the PMMA structure

to a high gloss using polishing paste.

Remove any remaining cement residue in the screw channel with suitable rotating

instruments. Do not damage the Ti base.

Telio CAD hybrid abutment crown after polishing and cementation

18

Page 19

®

Telio

CAD Abutment Solutions

Seating and Aftercare

Hybrid abutment crowns must be disinfected before being incorporated in the oral cavity. The local statutory provisions and

hygiene standards that apply to dental practices have to be observed. For disinfection, the hybrid abutment crown can be

immersed in a disinfectant suitable for PMMA materials. Dürr MD 520 with a reaction time of 5 min is a suitable impression

disinfectant.

Intraoral preparation

Please observe the following procedure to prepare for the permanent cementation of the implant-supported restoration:

– Remove the gingiva former or healing cap.

– Clean the implant lumen.

– Check the periimplant tissue (emergence profile).

Seating the hybrid abutment crown

Seating the hybrid abutment crown

– Insert the hybrid abutment crown intraorally into the implant.

– Manually screw in the matching implant screw.

– Tighten the implant screw with a torque wrench (observe the instructions of the manufacturer).

– Check the screw channel for contamination / moisture and clean or dry with an air syringe, if necessary.

– Insert a sterile cotton or foam pellet or teflon tape into the screw channel.

– Seal the screw channel with a composite or a light-curing temporary restorative (e.g. Telio CS Inlay / Onlay) if the wear

period is intended to be shorter than 6 weeks. For a longer wear period, a composite (e.g. Telio Add-On Flow, Tetric

EvoCeram, Tetric EvoFlow, Heliomolar) has to be used, at best after conditioning of the surface with Monobond Plus and

Heliobond.

– Polymerize with a curing light (e.g. Bluephase Style).

– Check the occlusion / articulation after polymerization and correct possible interfering spots with suitable fine-grain

grinding instruments.

– Polish to a high gloss with silicone polishers (e.g. OptraPol / Astropol).

CAD Abutment Solutions – Seating and Aftercare

®

Telio

19

Page 20

Insert the hybrid abutment crown intraorally into the implant.

Manually screw in the matching implant screw.

Tighten the implant screw with a torque wrench (observe the instructions of the

manufacturer).

Polymerize with a curing light (e.g.Bluephase Style).

After insertion of e.g. a teflon tape, seal the screw channel with a composite

After polymerization, check the occlusion / articulation and correct possible rough spots

(e.g. Tetric EvoCeram) in the matching shade.

with suitable finishers or fine diamonds.

Polish to a high gloss using silicone polishers (e.g. Astropol P, Astropol HP or

Astrobrush).

Completed Telio CAD hybrid abutment crown

20

Page 21

®

Telio

CAD Abutment Solutions

Designing the emergence profile

Chairside

Blast the area to be supplemented (Al2O3, 100 µm grit, 1–2 bar / 15–29 psi) or roughen with a rough diamond bur and

then wet extraorally using Telio® Activator or SR Connect.

a) Use of Telio Activator

Wet the area to be supplemented extraorally with Telio Activator. To achieve even distribution, agitate the Activator over

the entire surface for 30 s using a brush. After that, allow to react for another 30 to 60 s (total reaction time: 1 to 2 min).

Now apply the Heliobond bonding agent, thinly disperse it with blown air and polymerize for ≥10 s (see Heliobond

Instructions for Use).

CAD Abutment Solutions – Designing the emergence profile

®

Telio

Roughen the area of the abutment crown which is to

be supplemented.

b) Use of SR Connect

Thinly apply SR Connect extraorally on the conditioned surface of the area to be supplemented using a disposable brush,

allow to react for 2–3 min and subsequently polymerize with light (see table on page 15).

Roughen the area of the abutment crown which is to be

supplemented.

Subsequently, apply Tetric EvoCeram in increments of max. 2 mm and adapt the material with a suitable instrument.

Polymerize each layer with light (e.g. Bluephase Style) according to the instructions for use of the respective material. As an

alternative, other light-curing Ivoclar Vivadent composites can be used.

Note: Do not apply any material on the Ti base as this may result in inaccuracies of fit.

Apply Telio Activator.

Apply SR Connect.

Polymerize with light after the application of Heliobond.

Light-cure with Bluephase Style.

Do not apply any material on the Ti base.

Apply Tetric EvoCeram with OptraSculpt Pad.

21

Polish with OptraPol.

Page 22

Labside

Labside adjustment of a temporary, chairside-modi-

Labside design of the emergence profile

fied emergence profile

– Screw the emergence profile modified by the operator

on a model analog.

Erase the area to be redesigned on the model with stone

or on the gingival mask.

– Take a silicone impression of the area of the emergence

profile to be adjusted.

– Remove the material applied by the operator.

With SR Nexco / Telio Lab LC (light-curing):

Blast the area to be supplemented (Al

, 100 µm, 1-2 bar / 15-29 psi). Then clean with steam and dry with oil-free

2O3

compressed air.

a) Use of Telio Activator or Telio Lab Cold Liquid

Condition with Telio Activator or Telio Lab Cold Liquid. For this purpose, distribute Telio Activator / Telio Lab Cold Liquid

evenly but generously on the conditioned surface and allow it to react for at least 2 min to a maximum of 4 min. Then,

apply SR Composiv according to the Instructions for Use, cure and subsequently layer the Telio Lab LC or SR Nexco

materials (see Telio CAD/Lab or SR Nexco Instructions for Use).

Roughening, Telio Activator and SR Composiv Apply SR Nexco.

22

Page 23

b) Use of SR Connect

Apply a thin layer of SR Connect on the conditioned surface of the area to be supplemented using a disposable brush,

allow to react for 2–3 min and subsequently polymerize. Then, layer Telio Lab LC or SR Nexco materials (see Telio CAD/Lab

or SR Nexco Instructions for Use).

CAD Abutment Solutions – Designing the emergence profile

®

Telio

Roughening, SR Connect

Apply SR Nexco.

With Telio Lab (cold-curing):

Blast the area to be supplemented (Al

, 100 µm, 1-2 bar / 15-29 psi). Then clean with steam and dry with oil-free com-

2O3

pressed air. Subsequently, condition with Telio Activator or Telio Lab Cold Liquid. For this purpose, distribute Telio Activator

evenly but generously on the conditioned surface and allow it to react for at least 2 min to a maximum of 4 min. Then

directly begin with the application of the Telio Lab material (see Telio CAD/Lab Instructions for Use).

After polymerization finish with cross-cut tungsten carbide burs and prepolish with rubber polishers and silicone wheels. A

high gloss is achieved with goat hair brush, cotton or leather buffing wheel as well as SR Universal polishing paste.

Condition the surface using e.g. Telio Activator.

Apply Telio Lab.

23

Page 24

Care notes – Implant Care

Implant Care comprises a coordinated product program for the professional care of patients during the different phases of

an implant treatment and the aftercare throughout the rest of their lives. Products for professional cleaning and bacteria

control contribute to ensure the long-term quality of the implant-supported restorations. Structural elements, periimplant

tissue, natural teeth, dentures, gingiva and mucous membrane obtain optimum treatment and care with regard to their

function and esthetic appearance.

24

Page 25

®

Telio

CAD Abutment Solutions

General Information

Frequently Asked Questions

Is it possible to fabricate an abutment crown

only with Telio CAD without the use of a

Ti base?

No! For this indication, Telio CAD needs the

support provided by the Ti base. In addition, the

Ti base allows an optimum (industrially fabricated)

fit to the implant.

Which Ti bases can be used for the fabrication

of Telio CAD Abutment Solutions?

Only Ti bases of authorized CAD/CAM systems

may be used. Further information about the

CAD/CAM cooperation systems is available on the

Internet from www.ivoclarvivadent.com.

Is it permissible to re-use the selected Ti base?

No. When using Telio CAD Abutment Solutions

and, when indicated, IPS e.max CAD Abutment

Solutions, the Ti base must not be re-used. The

instructions of the manufacturer regarding the

preparations for permanent cementation must be

observed.

Is it permissible to modify the selected

Ti base?

The Ti base must not be adjusted by grinding as

this would compromise the fit of the Telio CAD

structure. As far as the preparations for permanent

cementation are concerned, the instructions of the

manufacturer have to be observed.

Is a hybrid abutment crown indicated in the

anterior region?

This indication depends on the position and

inclination of the implant. If the screw channel

extends through the oral surface, a hybrid

abutment crown may also be fabricated in the

anterior region.

Can a clinical try-in be conducted with the

Telio CAD Abutment Solutions?

Yes. A clinical try-in may be performed. The

Ti base and Telio CAD structure are temporarily

joined in the laboratory by means of a silicone

material, e.g. Virtual Extra Light Body Fast Set. This

facilitates the intraoral handling during clinical tryin with the patient.

What material may be used for the cementation to the Ti base?

Exclusively Multilink Hybrid Abutment HO 0 may

be used for cementation. This ensures a highquality bond. Given the high opacity of the

composite cement, complete optical masking of

the Ti base is achieved and thus an excellent

esthetic appearance ensured.

How is the Ti base prepared for the cementation with Multilink Hybrid Abutment?

If approved by the manufacturer of the Ti base,

the adhesive surface is carefully blasted with Al

with low pressure until an even mat surface is

achieved. After cleaning, the area is conditioned

with Monobond Plus.

How is the screw channel of a hybrid abutment crown sealed after seating?

After the restoration has been intraorally screwed

down on the implant, the screw channel is

sealed with a temporary or permanent restorative

composite.

2O3

25

Page 26

26

Page 27

27

Page 28

Ivoclar Vivadent – worldwide

Ivoclar Vivadent AG

Bendererstrasse 2

9494 Schaan

Liechtenstein

Tel. +423 235 35 35

Fax +423 (235) 33 60

www.ivoclarvivadent.com

Ivoclar Vivadent Pty. Ltd.

1 – 5 Overseas Drive

P.O. Box 367

Noble Park, Vic. 3174

Australia

Tel. +61 3 9795 9599

Fax +61 (3) 9795 9645

www.ivoclarvivadent.com.au

Ivoclar Vivadent Ltda.

Alameda Caiapós, 723

Centro Empresarial Tamboré

CEP 06460-110 Barueri – SP

Brazil

Tel. +55 11 2424 7400

Fax +55 (11) 3466 0840

www.ivoclarvivadent.com.br

Ivoclar Vivadent Inc.

1-6600 Dixie Road

Mississauga, Ontario

L5T 2Y2

Canada

Tel. +1 905 670 8499

Fax +1 (905) 670 3102

www.ivoclarvivadent.us

Ivoclar Vivadent Shanghai

Trading Co., Ltd.

2/F Building 1, 881 Wuding Road,

Jing An District

200040 Shanghai

China

Tel. +86 21 6032 1657

Fax +86 (21) 6176 0968

www.ivoclarvivadent.com

Ivoclar Vivadent Marketing Ltd.

Calle 134 No. 7-B-83, Of. 520

Bogotá

Colombia

Tel. +57 1 627 3399

Fax +57 (1) 633 1663

www.ivoclarvivadent.co

Ivoclar Vivadent SAS

B.P. 118

F-74410 Saint-Jorioz

France

Tel. +33 4 50 88 64 00

Fax +33 (4) 50 68 91 52

www.ivoclarvivadent.fr

Ivoclar Vivadent GmbH

Dr. Adolf-Schneider-Str. 2

73479 Ellwangen, Jagst

Germany

Tel. +49 7961 889 0

Fax +49 7961 6326

www.ivoclarvivadent.de

Wieland Dental + Technik

GmbH & Co. KG

Schwenninger Strasse 13

D-75179 Pforzheim

Germany

Tel. +49 7231 3705 0

Fax +49 (7231) 3579 59

www.wieland-dental.com

Ivoclar Vivadent Marketing (India)

Pvt. Ltd.

503/504 Raheja Plaza

15 B Shah Industrial Estate

Veera Desai Road, Andheri (West)

Mumbai, 400 053

India

Tel. +91 22 2673 0302

Fax +91 (22) 2673 0301

www.ivoclarvivadent.in

Ivoclar Vivadent s.r.l.

Via Isonzo 67/69

40033 Casalecchio di Reno (BO)

Italy

Tel. +39 051 6113555

Fax +39 051 6113565

www.ivoclarvivadent.it

Ivoclar Vivadent K.K.

1-28-24-4F Hongo

Bunkyo-ku

Tokyo 113-0033

Japan

Tel. +81 3 6903 3535

Fax +81 (3) 5844 3657

www.ivoclarvivadent.jp

Ivoclar Vivadent Ltd.

12F W-Tower, 1303-37

Seocho-dong, Seocho-gu,

Seoul 137-855

Republic of Korea

Tel. +82 2 536 0714

Fax +82 (2) 596 0155

www.ivoclarvivadent.co.kr

Ivoclar Vivadent S.A. de C.V.

Av. Insurgentes Sur No. 863.

Piso 14, Col. Napoles

03810 México, D.F.

México

Tel. +52 55 5062 1000

Fax +52 (55) 5062 1029

www.ivoclarvivadent.com.mx

Ivoclar Vivadent BV

De Fruittuinen 32

2132 NZ Hoofddorp

Netherlands

Tel. +31 23 529 3791

Fax +31 (23) 555 4504

www.ivoclarvivadent.com

Ivoclar Vivadent Ltd.

12 Omega St, Rosedale

PO Box 303011 North Harbour

Auckland 0751

New Zealand

Tel. +64 9 914 9999

Fax +64 (9) 914 9990

www.ivoclarvivadent.co.nz

Ivoclar Vivadent Polska Sp. z o.o.

Al. Jana Pawla II 78

00-175 Warszawa

Poland

Tel. +48 22 635 5496

Fax +48 (22) 635 5469

www.ivoclarvivadent.pl

Ivoclar Vivadent Marketing Ltd.

Prospekt Andropova 18 korp. 6/

office 10-06

115432 Moscow

Russia

Tel. +7 499 418 0300

Fax +7 (499) 418 0310

www.ivoclarvivadent.ru

Ivoclar Vivadent Marketing Ltd.

Qlaya Main St.

Siricon Building No.14, 2

Office No. 204

nd

Floor

P.O. Box 300146

Riyadh 11372

Saudi Arabia

Tel. +966 11 293 8345

Fax +966 (11) 293 8344

www.ivoclarvivadent.com

Ivoclar Vivadent S.L.U.

C/ Ribera del Loira nº 46, 5ª planta

28042 Madrid

Spain

Tel. + 34 913 757 820

Fax + 34 913 757 838

www.ivoclarvivadent.es

Ivoclar Vivadent AB

Dalvägen 14

S-169 56 Solna

Sweden

Tel. +46 8 514 939 30

Fax +46 8 514 939 40

www.ivoclarvivadent.se

Ivoclar Vivadent Liaison Office

: Tesvikiye Mahallesi

Sakayik Sokak

Nisantas’ Plaza No:38/2

Kat:5 Daire:24

34021 Sisli – Istanbul

Turkey

Tel. +90 212 343 0802

Fax +90 (212) 343 0842

www.ivoclarvivadent.com

Ivoclar Vivadent Limited

Ground Floor Compass Building

Feldspar Close

Warrens Business Park

Enderby

Leicester LE19 4SE

United Kingdom

Tel. +44 116 284 7880

Fax +44 (116) 284 7881

www.ivoclarvivadent.co.uk

Ivoclar Vivadent, Inc.

175 Pineview Drive

Amherst, N.Y. 14228

USA, if necessary.

Tel. +1 800 533 6825

Fax +1 (716) 691 2285

www.ivoclarvivadent.us

Manufacturer:

Ivoclar Vivadent AG, 9494 Schaan, Liechtenstein

www.ivoclarvivadent.com

Date information prepared: 2014-06-24/Rev. 1

Some products and/or indications may not be regulatory cleared/released in all markets. Please contact the local

Ivoclar Vivadent sales office for the current national status.

These materials have been developed solely for use in dentistry. Processing should be carried out strictly

according to the Instructions for Use. Liability cannot be accepted for damages resulting from failure to

observe the Instructions or the stipulated area of application. The user is responsible for testing the products

for their suitability and use for any purpose not explicitly stated in the Instructions. Descriptions and data constitute no warranty of attributes and are not binding. These regulations also apply if the materials are used in

conjunction with products of other manufacturers.

Printed in Liechtenstein

© Ivoclar Vivadent AG, Schaan / Liechtenstein

666040/en

Loading...

Loading...