ISUZU 6SD1 Service Manual

-1

June, 2003

Diesel Injection Pump

Common Rail System for ISUZU

Operation

No. E-03-02

SERVICE MANUAL

6HK1/6SD1 Type Engine

00400018

For DENSO Authorized

ECD Service Dealer Only

0

GENERAL

The common rail system was designed for electronic control of injection quantity, injection tim-

ing and injection pressure to obtain optimal operational control.

Features

• Lower exhaust gas and higher output due to high pressure injection in all usage ranges.

• Reduction in noise and exhaust gas due to injection rate control.

• Improved performance due to increased flexibility in the injection timing setting.

• Independent control of injection pressure in response to engine speed and load.

Main Elements

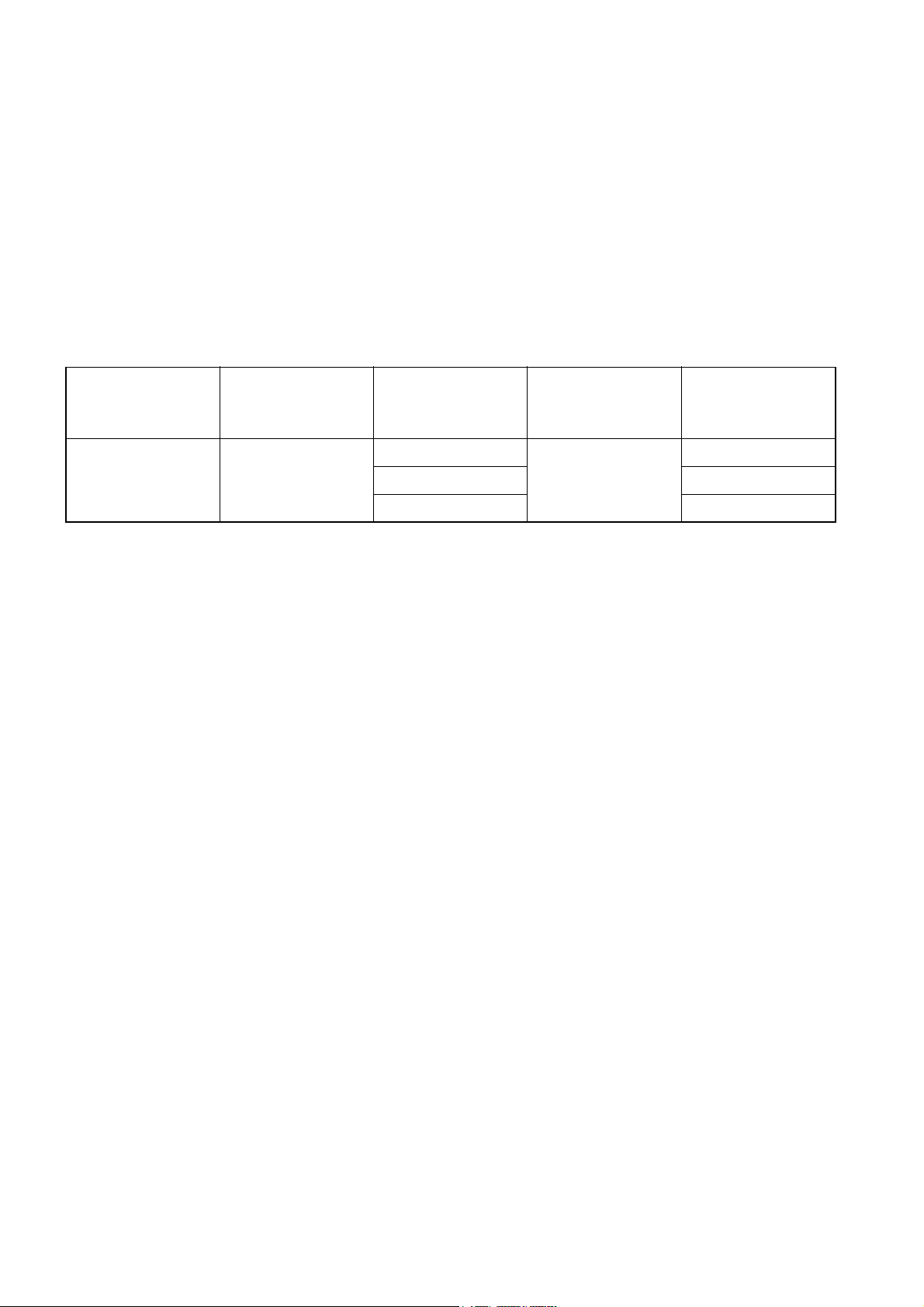

Manufacturer Vehicle Model Engine Model

Cylinder

Configuration

Total

Displacement

(cc)

ISUZU Forward

6HK1

Straight 6

7,800

6SD1 9,800

6WG1 15,600

1

1. Outline

1.1 System Outline

This system also provides the following functions:

• A self-diagnosis and alarm function using computer to diagnose the system’s major

components and alert the driver in the event of a problem.

• A fail-safe function to stop the engine, depending upon the location of the problem.

• A backup function to change the fuel regulation method, thus enabling the vehicle to

continue operation.

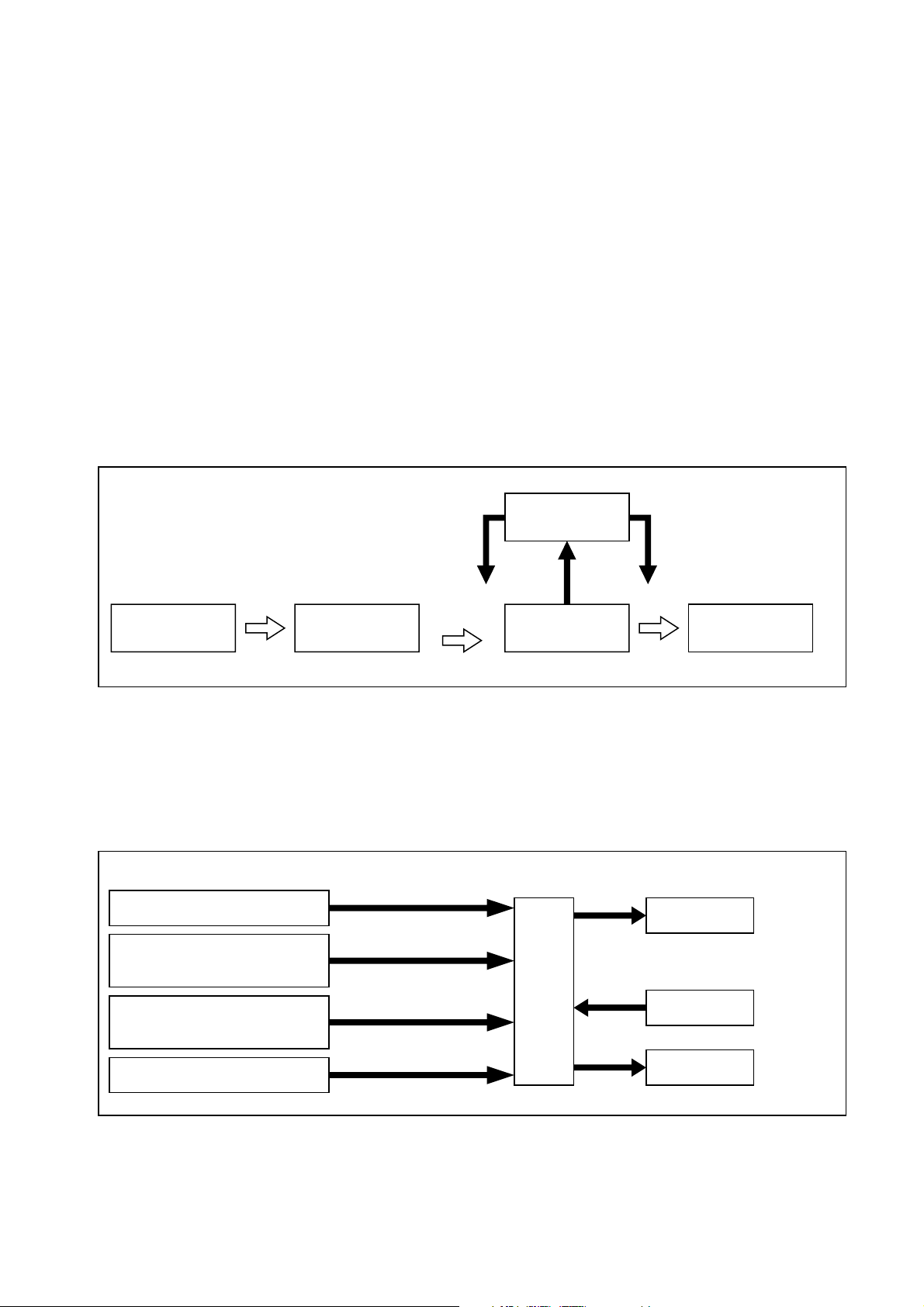

1.2 System Configuration

Divided by function, the system can be classified according to the fuel system and the control

system.

[1] Fuel System

High-pressure fuel that is generated by the supply pump is distributed to the cylinders using a

rail. Electromagnetic valves in the injectors then open and close the nozzle needle valve to con-

trol the start and end of fuel injection.

[2] Control System

Based on the signals received from various sensors mounted on the engine and the vehicle,

the ECU controls current timing and the duration in which the current is applied to the injectors,

thus ensuring an optimal amount of fuel is injected at an optimal time.

The control system can be broadly classified according to the following electronic components:

sensors, computers, and actuators.

Fuel tank Supply pump Rail

Electronic

control

Injector

Discharge

volume

Solenoid valve to control

the needle lift

Q000080E

Sensors Computers Actuators

Accelerator sensor

Injectors

Rail

Supply pump

Other sensors and switches

NE sensor

(Crankshaft position sensor)

TDC sensor

(Cylinder recognition sensor)

(Accelerator opening)

(Engine speed)

Cylinder

recognition signal

Fuel injection quantity

and injection timing control etc.

(Fuel pressure control)

ECU

( )

( )

Q000081E

2

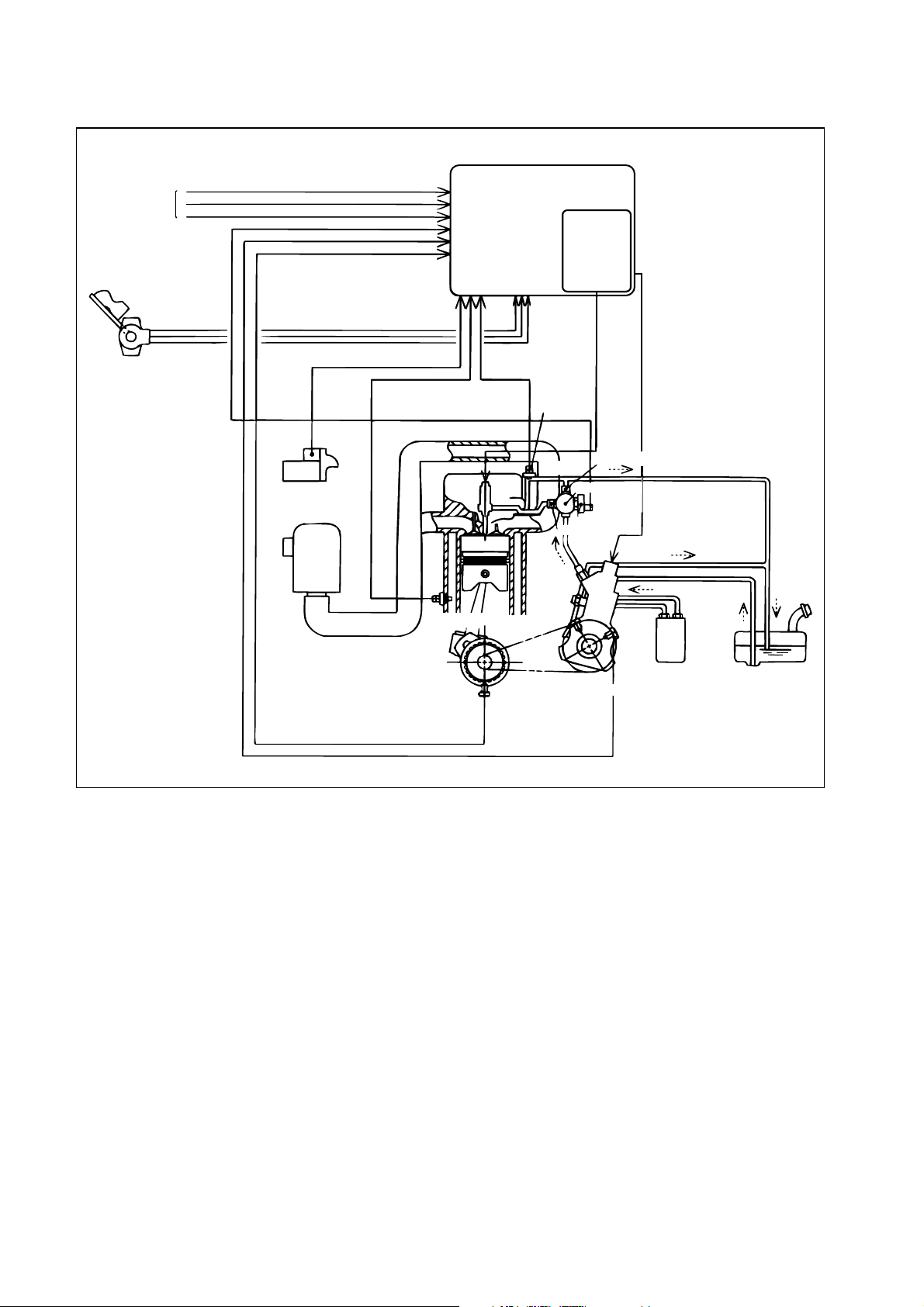

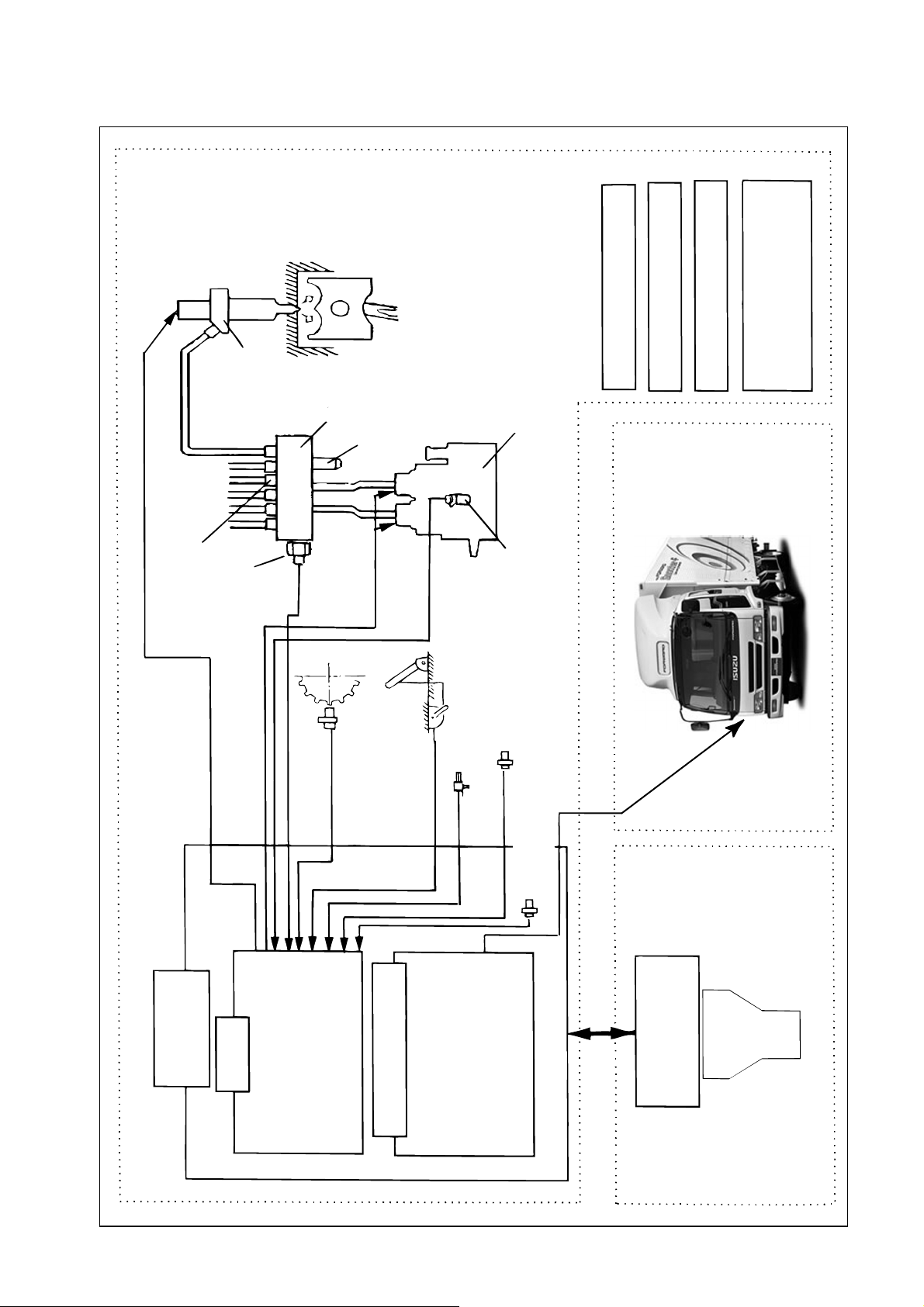

[3] System Configuration (1)

Q000082E

Signals from

switches

ACCP

Accelerator position

sensor

ECU

Charge-up

circuit

Starter signal

Air cleaner

Water temp. sensor

THW

THL

STA

Fuel temp.

sensor

Leak pipe

Flow damper

NE sensor

TDC sensor

Fuel filiter

Fuel tank

Supply

pump

Pressure limiter

Rail

3

[4] System Configuration (2)

Q000083E

Fuel

Injection

·Injection Quantity Control

·Injection Timimg Control

·Injection Pressure Control

Engine

Vehicle

·A/T Control

·Exhaust Break Control

·Engine Shut-down control

·TECHΤ COMMUNICATION

Communication

Service Tool

(Scan Tool)

(Dealer)

Rail Pressure sensor

Flow Damper

Injector

(inside Head Cover)

Rail

Pressure Limiter

Crank Position

Sensor (NE Sensor)

Boost Pressure Sensor

Accelerator Position

Sensor

(inside ECU)

·

Coolant Temperature Sensor

·Fuel Temperature Sensor

·

Atmospheric Air Temperature Sensor

Cylinder Recognition

Sensor (TDC Sensor)

Supply Pump

Injection Rate Control

Injection Quantity Control

Injection Timing Control

Injection Pressure Control

(Pressure Control in Rail)

TECHΤ

ECU

Atmospheric Air

Pressure Sensor

4

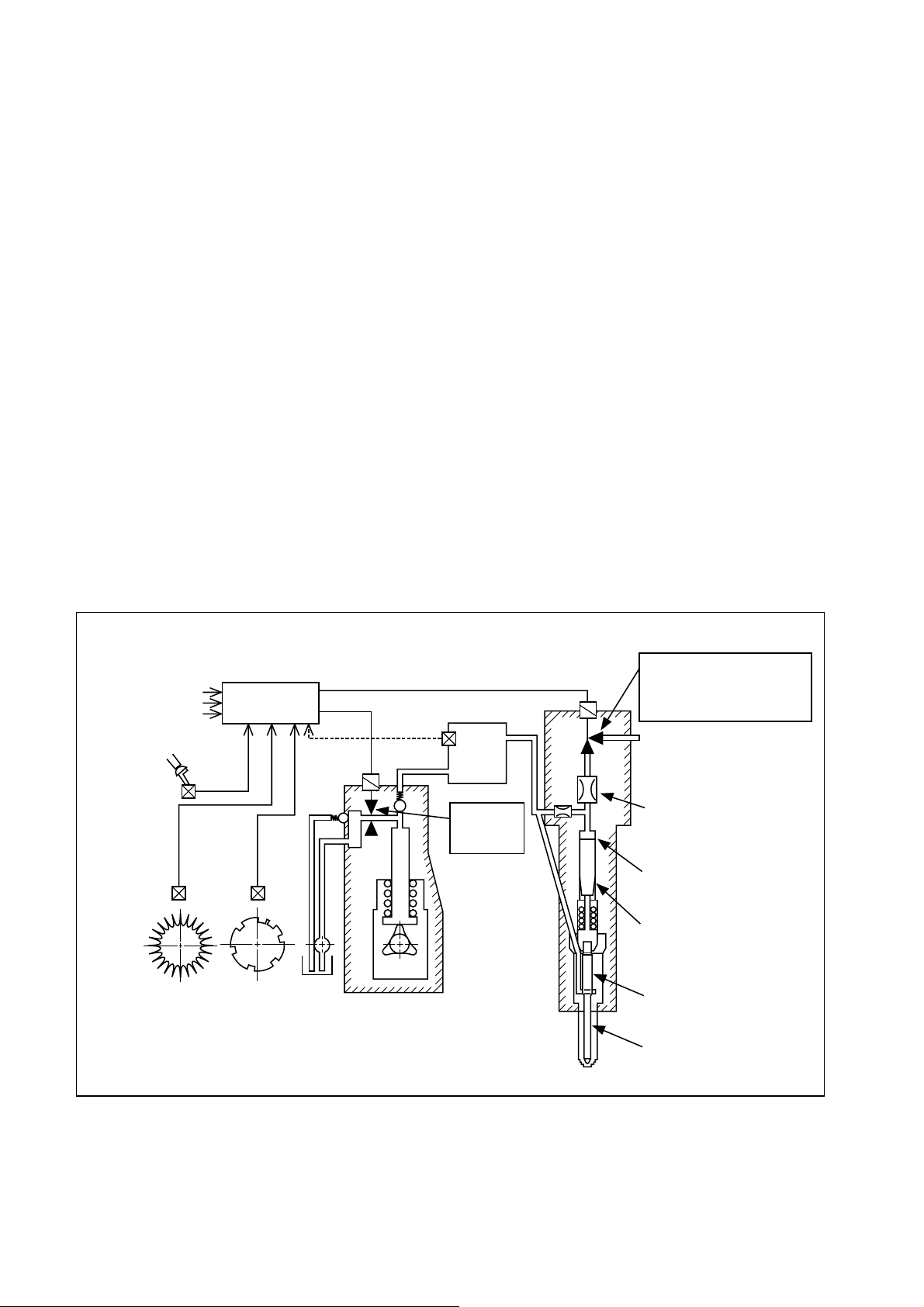

1.3 Construction and Operation of the System

The rail system is comprised of a supply pump, a rail, and injectors, and also includes an ECU

and sensors to regulate those components.

The supply pump generates the internal fuel pressure in the rail. Fuel pressure is regulated by

the quantity of fuel discharged by the supply pump. In turn, the fuel discharge quantity is regu-

lated by electronic signals from the ECU that turn the PCVs (pump control valves) ON and OFF.

Upon receiving fuel pressurized by the supply pump, the rail distributes the fuel to the cylinders.

The pressurized fuel is detected by the rail pressure sensor (installed in the rail) and undergoes

feedback control so that actual pressure will match the command pressure (designated accord-

ing to the engine speed and load).

Pressurized fuel in the rail passes through the injection pipes that lead to the cylinders, and applies

pressure to the injector nozzles and the control chamber.

The injector regulates injection quantity and timing by turning the TWV (two-way valve) ON and OFF.

When the TWV is ON (current applied), the fuel circuit switches over, causing the high-pressure

fuel in the control chamber to flow out via the orifice. As a result, the force of the high-pressure

fuel at the nozzle valve opening causes the needle valve to lift, thus starting the injection of fuel.

When the TWV is turned OFF (current not applied), the fuel circuit switches over so that high-

pressure fuel, traveling via the orifice, is introduced to the control chamber. As a result, the nee-

dle valve lowers, thus ending the injection of fuel.

Thus, through electronic control, the timing of the current applied to the TWV determines the

injection timing, and the duration in which current is applied to the TWV determines the injection

quantity.

Q000084E

Additional information

(temperature, pressure)

Engine load

ECU

Supply Pump

· Injection quantity control

· Injection timing control

· Injection rate control

TWV

Leak

Orifice

Control chamber

Hydraulic piston

Nozzle

Needle

Injector

TWV control pulse

Rail pressure sensor

Rail

Injection

pressure

control

5

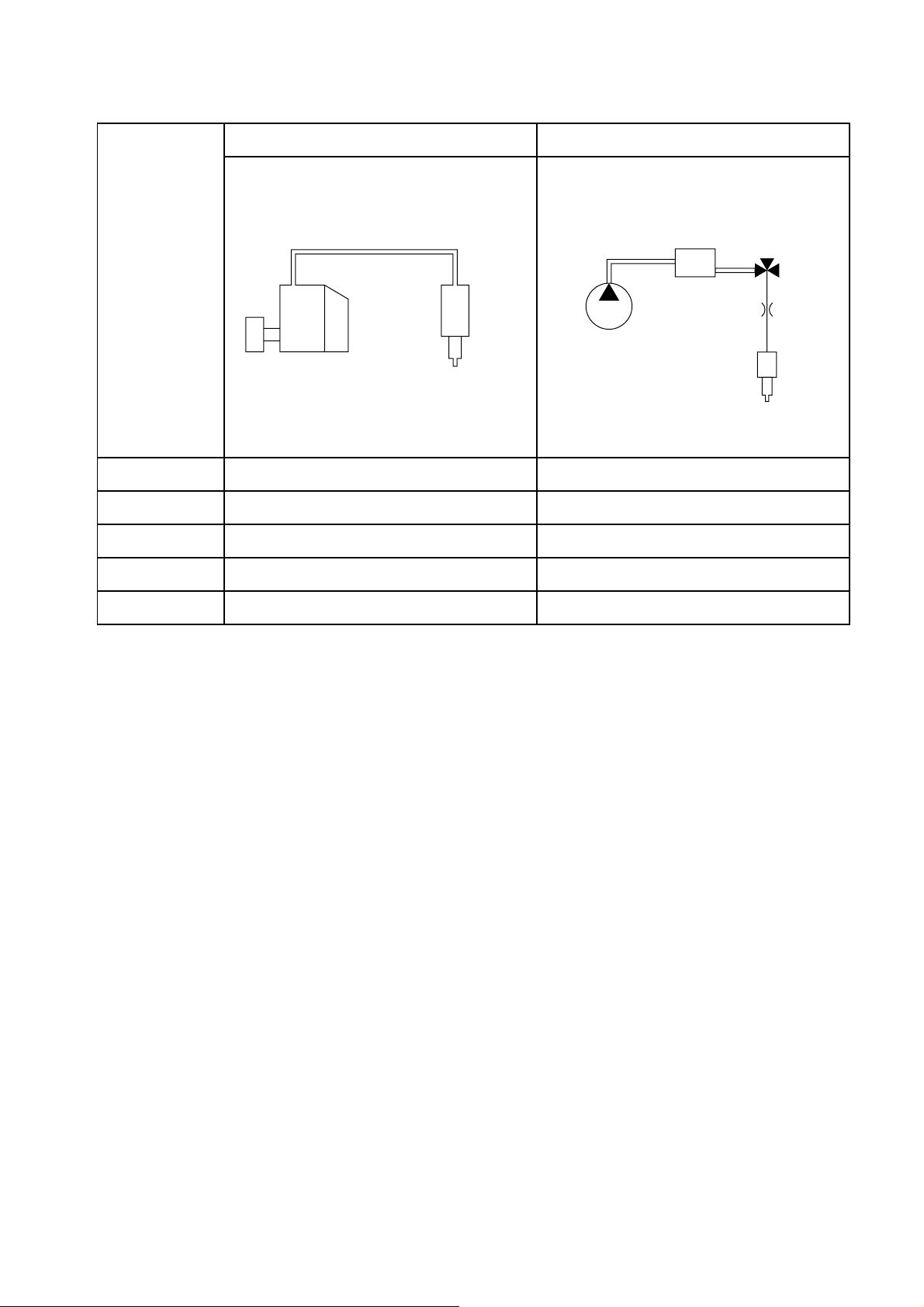

1.4 Comparison to Conventional Pump

Inline Type Common Rail System

System

Injection quantity

regulation

Injection timing

regulation

Distribution of

generated pressure

Distribution

Injection pressure

regulation

Pump (governor)

Pump (timer)

Pump

Pump

(Dependent on engine speed and injection volume)

ECU, injector (TWV)

ECU, injector (TWV)

Supply pump

Supply pump (PCV)

Rail

Q000085E

Pipe

Instantaneous high

pressure

Timer

Pump

Governor

Nozzle

Supply pump

Rail

Constant high

pressure

Injector

Loading...

Loading...