International Comfort Products PGD324040, PGD324060, PGD330040, PGD330060, PGD336060 TECHNICAL MANUAL

...

21

Indoor Airflow and Airflow Adjustments

UNIT OPERATION HAZARD

Failure to follow this caution may result in unit damage.

For cooling operation, the recommended airflow is 350

to 450 cfm for each 12,000 BTU/h of rated cooling

capacity. For heating operation, the airflow must

produce a temperature rise that falls within the range

stamped on the unit rating plate.

CAUTION

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect electrical power to the unit and install lockout

tag before changing blower speed.

!

WARNING

NOTE: Be sure that all supply--and return--air grilles are

open, free from obstructions, and adjusted properly. Airflow

can be changed using the User Interface.

Table 8 shows the temperature rise in each heating mode.

Refer to these tables to determine the desired heating

airflow for the system being installed. (See Table 9 for wet

coil pressure drop).

Airflow can be changed by changing the lead connections

of the blower motor. Refer to Table 3 for motor lead color

coding (208/230V).

Model sizes 24, 36, 42 and 60 are factory wired for low

speed. Model sizes 30 and 48 are factory wired for medium

speed.

To change the speed of the indoor fan motor (IFM), remove

the fan motor speed leg lead from the blower relay (BR).

This wire is attached to terminal blower motor (BM) of the

integrated gas control (IGC) board for single--phase units.

To change the speed, remove and replace with lead for

desired blower motor speed. Insulate the removed lead to

avoid contact with chassis parts.

Table 3 -- Color Coding for 208/230V Motor Leads

Black = High Speed

Blue = Medium Speed

Red = Low Speed

Continuous Fan Operation

The continuous fan operates at the same fan speed as

cooling operation.

Cooling Sequence of

Operation

With the room thermostat SYSTEM switch in the COOL

position and the FAN switch in the AUTO position, the

cooling sequence of operation is as follows:

1. When the room temperature rises to a point that is

slightly above the cooling control setting of the

thermostat, the thermostat completes the circuit

between thermostat terminal R to terminals Y and G.

2. The normally open contacts of energized contactor (C)

close and complete the circuit through compressor

motor (COMP) to condenser (outdoor) fan motor

(OFM). Both motors start instantly.

NOTE: 3--phase, scroll compressors will run

backwards if not wired correctly. Unit must be checked

to ensure proper compressor 3--phase power lead

orientation. If not corrected within 5 minutes, the

internal protector will shut off the compressor. To

change the rotation of the compressor, swap any two of

the three power leads. When turning backwards, the

difference between compressor suction and discharge

pressures will be minimal.

3. The set of normally open contacts of energized relay

BM close and complete the circuit through evaporator

blower (indoor) fan motor (IFM).

NOTE:The cooling cycle remains on until the room

temperature drops to a point that is slightly below the

cooling control setting of the room thermostat. At this point,

the thermostat breaks the circuit between thermostat

terminal R to terminals Y and G. These open circuits

deenergize contactor coil C. The condenser and

compressor motors stop. After a 30 second delay, the

blower motor stops. The unit is in a standby condition,

waiting for the next call for cooling from the room

thermostat.

MAINTENANCE

To ensure continuing high performance and to minimize the

possibility of premature equipment failure, periodic

maintenance must be performed on this equipment. This

unit should be inspected at least once each year by a

qualified service person. To troubleshoot unit, refer to

Tables 11, 12, and 13 -- Troubleshooting Charts.

NOTE TOEQUIPMENT OWNER:Consult your localdealer

about the availability of a maintenance contract.

PERSONAL INJURY AND UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal

injury or death and unit component damage.

The ability to properly perform maintenance on this

equipment requires certain expertise, mechanical skills,

tools and equipment. If you do not possess these, do not

attempt to perform any maintenance on this equipment,

other than those procedures recommended in the

Owner’s Manual.

!

WARNING

22

ELECTRICAL SHOCK HAZARD

Failure to follow these warnings could result in personal

injury or death:

1. Turn off electrical power to the unit before performing

any maintenance or service on this unit. Install lock-

out tag.

2. Use extreme caution when removing panels and

parts.

3. Never place anything combustible either on or in

contact with the unit.

!

WARNING

UNIT OPERATION HAZARD

Failure to follow this caution may result in improper

operation.

Errors made when reconnecting wires may cause

improper and dangerous operation. Label all wires prior

to disconnecting when servicing.

CAUTION

!

The minimum maintenance requirements for this

equipment are as follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoor coil, drain pan, and condensate drain

each cooling season for cleanliness. Clean when

necessary.

3. Inspect blower motor and wheel for cleanliness at the

beginning of each heating and cooling season. Clean

when necessary. For first heating and cooling season,

inspect blower wheel bi--monthly to determine proper

cleaning frequency.

4. Check electrical connections for tightness and controls

for proper operation each heating and cooling season.

Service when necessary.

5. Ensure electric wires are not in contact with refrigerant

tubing or sharp metal edges.

6. Check and inspectheating section before each heating

season. Clean and adjust when necessary.

7. Check flue hood and remove any obstructions, if

necessary.

Air

Filter

NOTE: Never operate the unit without a suitable air filter in

the return--air duct system. Always replace the filter with the

same dimensional size and type as originally installed. See

Table 2 for recommended filter sizes.

Inspect air filter(s) at least once each month and replace

(throwaway--type) or clean (cleanable--type) at least twice

during each cooling season and twice during the heating

season, or whenever the filter becomes clogged with dust

and lint.

Evaporator (Indoor) Motor and

Blower

NOTE: All motors are pre--lubricated. Do not attempt to

lubricate these motors.

For longer life, operating economy, and continuing

efficiency, clean accumulated dirt and grease from the

blower wheel and motor annually.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect and tag electrical power to the unit before

cleaning and lubricating the blower motor and wheel.

!

WARNING

To clean the blower motor and wheel:

1. Remove and disassemble blower assembly as follows:

a. Remove unit access panel.

b. Disconnect motor lead from blower relay (BM).

Disconnect yellow lead from terminal L2 of the

contactor.

c. On all units remove blower assembly from unit.

Remove screwssecuring blower toblower partition

and slide assembly out. Be careful not to tear

insulation in blower compartment.

d. Ensure proper reassembly by marking blower

wheel and motor in relation to blower housing

before disassembly.

e. Loosen set screw(s) that secures wheel to motor

shaft, remove screws that secure motor mount

brackets to housing, and slide motor and motor

mount out of housing.

2. Remove and clean blower wheel as follows:

a. Ensure proper reassembly by marking wheel

orientation.

b. Lift wheel from housing. When handling and/or

cleaning blower wheel, be sure not to disturb

balance weights (clips) on blower wheel vanes.

c. Remove caked--on dirt from wheel and housing

with abrush. Remove lint and/or dirt accumulations

from wheel and housing with vacuum cleaner,

using soft brush attachment. Remove grease and

oil with mild solvent.

d. Reassemble wheel into housing.

e. Reassemble motor into housing. Be sure

setscrews are tightened on motor shaft flats and

not on round part of shaft.

f. Connect motor lead to blower relay (BM). Connect

yellow lead to terminal L2 of the contactor

g. Reinstall unit access panel.

3. Restore electrical power to unit. Start unit and checkfor

proper blower rotation and motor speeds during

heating and cooling cycles.

Induced Draft (Combustion Air)

Blower

Clean periodically to assure proper airflow and heating

efficiency. Inspect blower wheel every fall and periodically

during the heating season. For the first heating season,

inspect blower wheel bimonthly to determine proper

cleaning frequency.

To inspect blower wheel, remove draft hood assembly.

Shine a flashlight into opening to inspect wheel. If cleaning

is required, remove motor and wheel as follows:

1. Remove unit access panel (see Figure 17).

23

2. Remove the 5 screws that attach induced--draft motor

mounting plate to blower housing (see Figure 19).

3. Slide the assembly out of the blower housing (see

Figure 19). Clean the blower wheel. If additional

cleaning is required, continue with Steps 4 and 5.

4. To remove blower wheel, remove 2 setscrews.

5. To remove motor and cooling fan assembly, remove 4

screws that hold blower housing to mounting plate.

6. To reinstall, reverse the procedure outlined above.

Flue Gas

Passageways

To inspect the flue collector box and upper areas of the heat

exchanger:

1. Remove the induced draft blower assembly according

to directions in the Induced Draft Blower Assembly

section.

2. Remove the 11 screws holding the flue collector box

cover (see Figure 18) to the heat exchanger assembly.

Inspect the heat exchangers.

3. Clean all surfaces, as required, using a wire brush.

Limit

Switch

Remove unit access panel. Limit switch is located on the

blower partition.

Burner

Ignition

Unit is equipped with a direct spark ignition 100 percent

lockout system. Ignition module is located in the control box

(see Figure 18). Module contains a self--diagnostic LED.

During servicing, refer to Table 5 or unit label diagram for

LED interpretation.

If lockout occurs, unit may be reset by either momentarily

interrupting power supply to unit or by turning selector

switch to OFF position at the thermostat.

Main

Burners

At the beginning of each heating season, inspect for

deterioration or blockage due to corrosion or other causes.

Observe the main burner flames and adjust, if necessary.

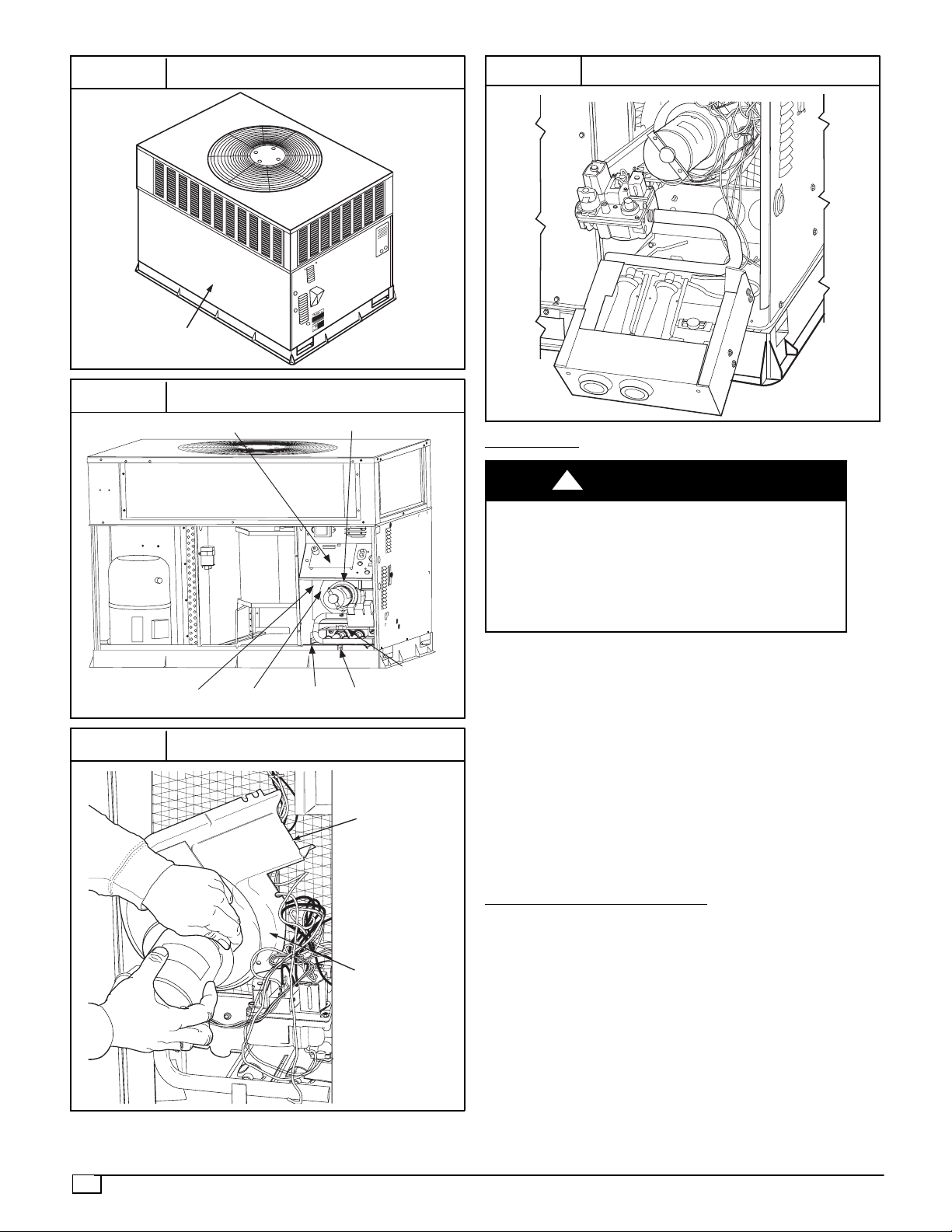

Removal of Gas T

rain

To remove the gas train for servicing:

1. Shut off main gas valve.

2. Shut off power to unit and install lockout tag.

3. Remove unit access panel (see Figure 17).

4. Disconnect gas piping at unit gas valve.

5. Remove wires connectedto gas valve. Mark each wire.

6. Remove ignitor and sensor wires a t the ignitor module.

7. Remove the mounting screw that attaches the burner

rack to the unit base (see Figure 18).

8. Slide the burner rackout of the unit (see Figures 18 and

20).

9. To reinstall, reverse the procedure outlined above.

Outdoor Coil, Indoor Coil, and Condensate Drain

Pan

Inspect the condenser coil, evaporator coil, and

condensate drain pan at least once each year.

The coils are easily cleaned when dry; therefore, inspect

and clean the coils either before or after each cooling

season. Remove all obstructions, including weeds and

shrubs, that interfere with the airflowthrough the condenser

coil.

Straighten bent fins with a fin comb. If coated with dirt or lint,

clean the coils with a vacuum cleaner, using the soft brush

attachment. Be careful not to bend the fins. If coated with oil

or grease, clean the coils with a mild detergent and water

solution. Rinse coils with clear water, using a garden hose.

Be careful not to splash water on motors, insulation, wiring,

or air filter(s). For best results, spray condenser coil fins

from inside to outside the unit. On units with an outer and

inner condenser coil, be sure to clean between the coils. Be

sure to flush all dirt and debris from the unit base.

Inspect the drain pan and condensate drain line when

inspecting the coils. Clean the drain pan and condensate

drain by removing all foreign matter from the pan. Flush the

pan and drain trough with clear water. Do not splash water

on the insulation, motor, wiring, or air filter(s). If the drain

trough is restricted, clear it with a “plumbers snake” or

similar probe device.

24

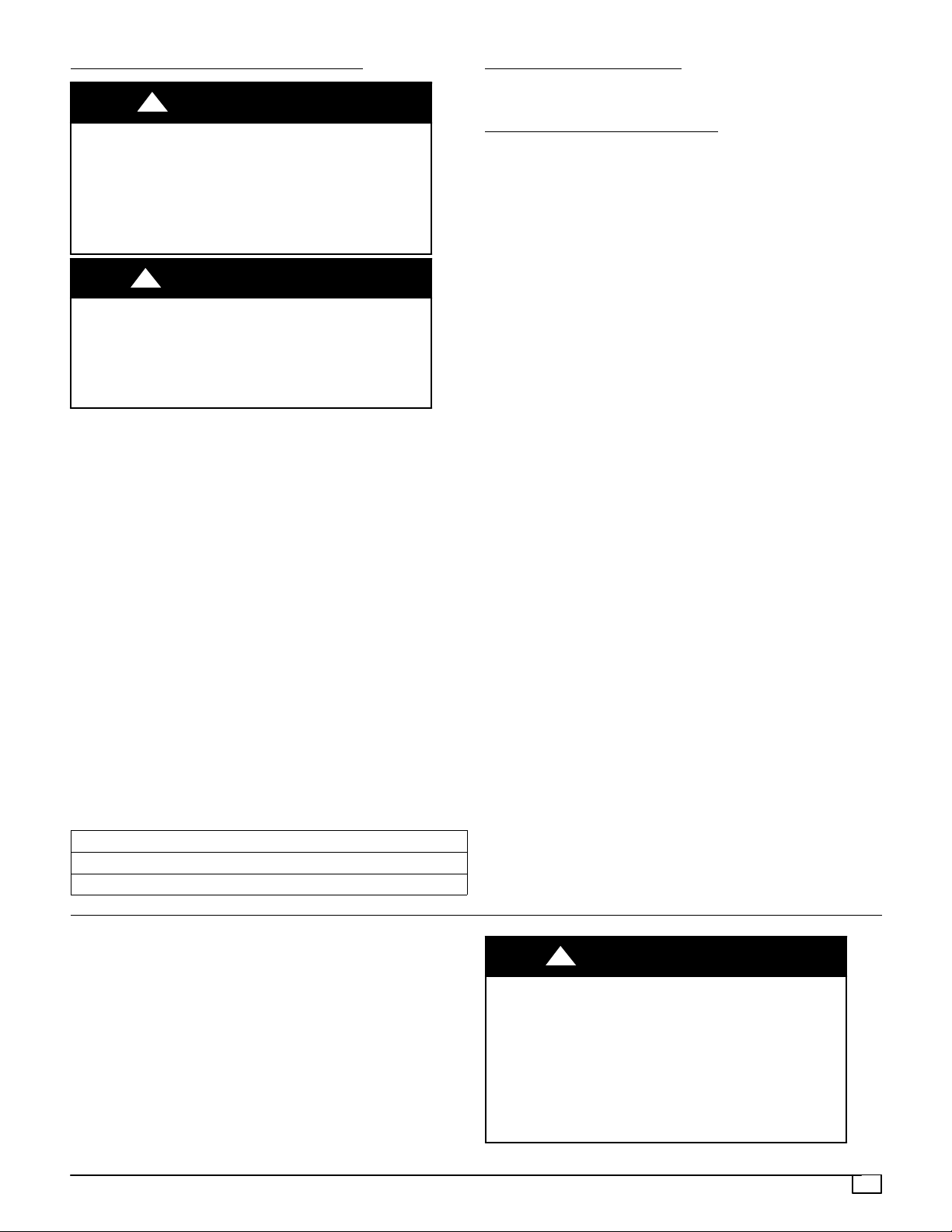

FIGURE 17

Unit Access Panel

FRONT

ACCESS PANEL

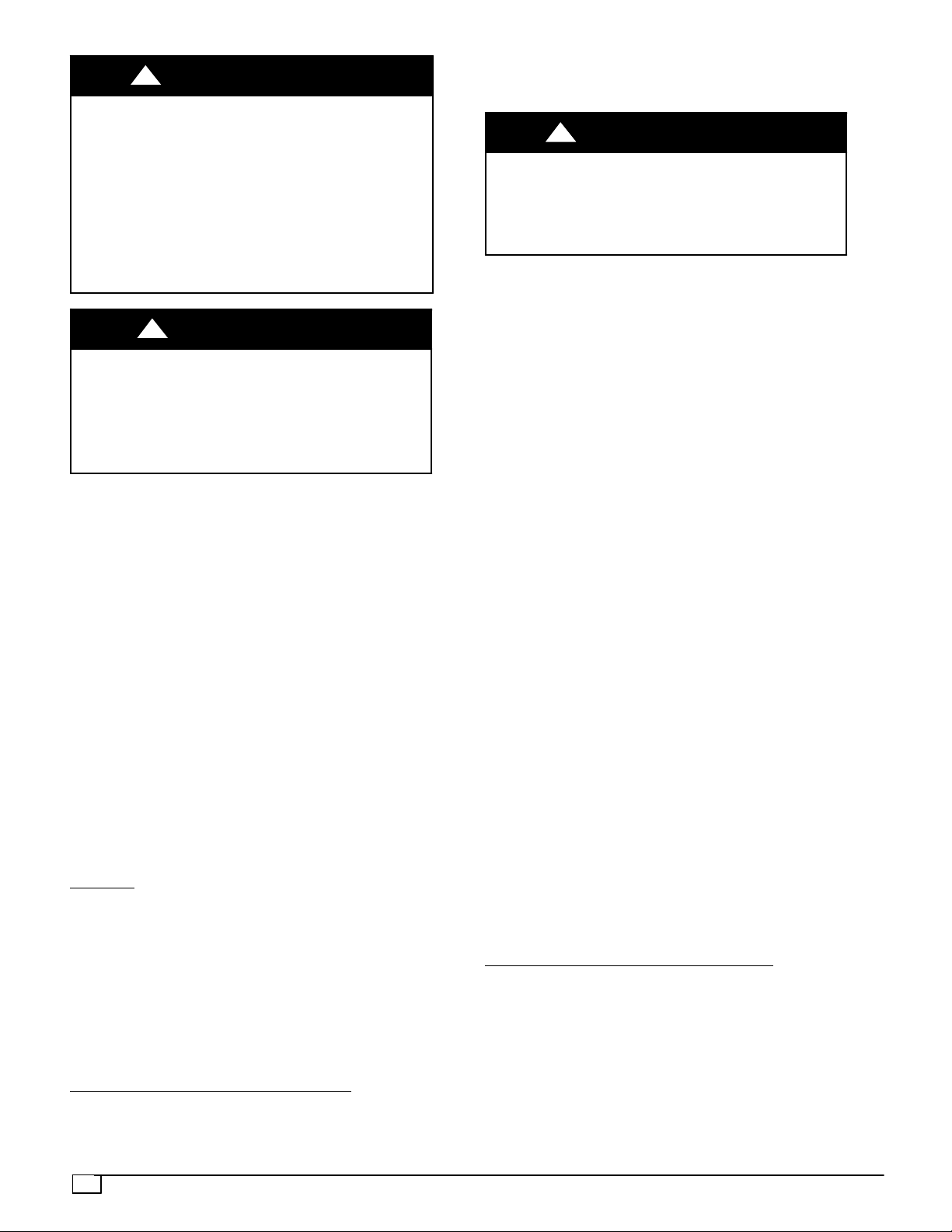

FIGURE 18

Blower Housing and Flue Collector Box

INDUCED DRAFT MOTOR MOUNT

FLUE

COLLECTOR

BOX

BLOWER

HOUSING

BURNER

RACK

MOUNTING

SCREW

ROLLOU

T

SWITCH

IGNITION MODULE

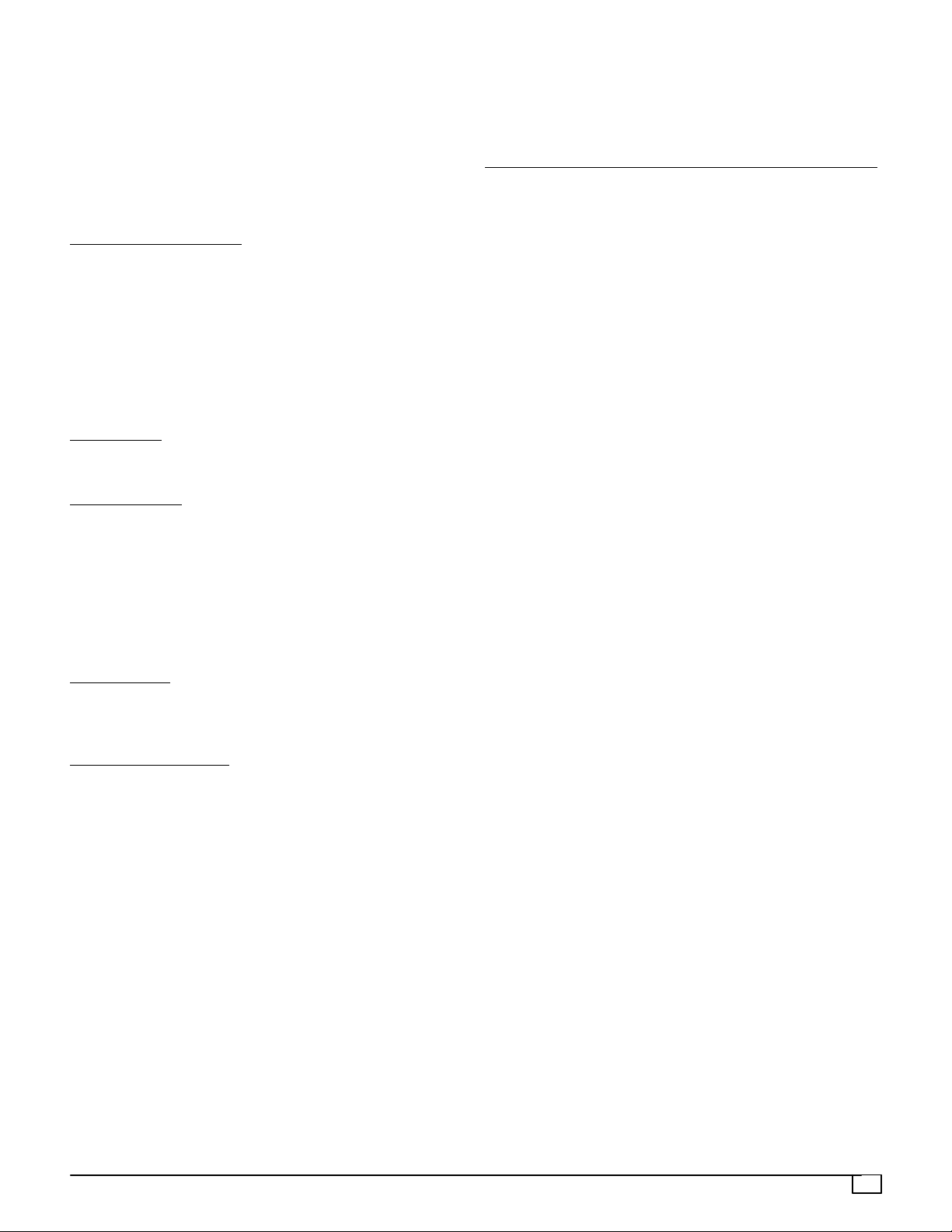

FIGURE 19

Removal of Motor and Blower Wheel

BLOWER

HOUSING

2 SETSCREWS

(HIDDEN)

FIGURE 20

Burner Rack Removed

Outdoor Fan

UNIT OPERATION HAZARD

Failure to follow this caution may result in damage to

unit components.

Keep the condenser fan free from all obstructions to

ensure proper cooling operation. Never place articles

on top of the unit.

CAUTION

!

1. Remove 6 screws holding discharge grille and motor to

top cover.

2. Turn motor/grille assembly upside down on top cover to

expose fan blade.

3. Inspect the fan blades for cracks or bends.

4. If fan needs to be removed, loosen setscrew and slide

fan off motor shaft.

5. When replacing fan blade, position blade so that the

hub is 8” (3.2mm) away from the motor end (8”

(3.2mm) of motor shaft will be visible).

6. Ensure that setscrew engages the flat area on the

motor shaft when tightening.

7. Replace grille.

Electrical Controls and W

iring

Inspect and check the electrical controls and wiring

annually. Be sure to turn off the electrical power to the unit.

Remove access panel to locate all the electrical controls

and wiring. Check all electrical connections for tightness.

Tighten all screw connections. If any smoky or burned

connections are noticed, disassemble the connection,

clean all theparts, re--strip the wireend and reassemble the

connection properly and securely.

After inspecting the electrical controls and wiring, replace

all the panels. Start the unit, and observe at least one

complete cooling cycle to ensure proper operation. If

discrepancies are observed in operating cycle, or if a

suspected malfunction has occurred, check each electrical

25

component withthe proper electricalinstrumentation. Refer

to the unit wiring label when making these checks.

NOTE: Refer to the Cooling Sequence of Operation in this

document to understand proper control operation.

Refrigeration

Circuit

Annually inspect all refrigerant tubing connections and

the unit base for oil accumulations. Detecting oil generally

indicates a refrigerant leak.

EXPLOSION, SAFETY AND ENVIRONMENT AL

HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

System under pressure. Relieve pressure and recover all

refrigerant before system repair or final unit disposal. Use

all service ports and open all flow--control devices,

including solenoid valves.

!

WARNING

If oil is detected or if low cooling performance is

suspected, leak--test all refrigerant tubing using an

electronic leak--detector, halide torch, or liquid--soap

solution. If a refrigerant leak is detected, refer to the

Check for Refrigerant Leaks section.

If no refrigerant leaks are found and low cooling

performance is suspected, refer to the Checking and

Adjusting Refrigerant Charge section.

Gas

Input

The gas input does not require checking unless improper

heating performance is suspected. If a problem exists,

refer to the Start--Up section.

Evaporator Airflow

The heating and/or cooling airflow does not require

checking unless improper performance is suspected. If a

problem exists, be sure that all supply-- and return --air

grilles are open and free from obstructions, and that the

air filter is clean. When necessary, refer to the Indoor

Airflow and Airflow Adjustments section to check the

system airflow.

R--410A

Items

Metering Device (Thermostatic Expansion Valve

)

This metering device is a hard shutoff, balance port TXV.

The TXV maintains a constant superheat at the

evaporator exit resulting in higher overall system

efficiency.

Pressure Switches

Pressure switches are protective devices wired into

control circuit (low voltage). They shut off compressor if

abnormally high or low pressures are present in the

refrigeration circuit. These pressure switches are

specifically designed to operate with R--410A systems.

R--22 pressure switches must not be used as

replacements for the R--410A system.

Loss of Charge Switch

This switch is located on the liquid line and protects

against low suction pressures caused by such events as

loss of charge, low airflow across indoor coil, dirty filters,

etc. It opens on a pressure drop at about 20 psig. If

system pressure is above this, switch should be closed.

To check switch:

1. Turn off all power to unit.

2. Disconnect leads on switch.

3. Apply ohm meter leads across switch. You should have

continuity on a good switch.

NOTE:Because these switches are attached to

refrigeration system under pressure, it is not advisable to

remove this device for troubleshooting unless you are

reasonably certain that a problem exists. If switch must

be removed, remove and recover all system charge so

that pressure gauges read 0 psi. Never open system

without breaking vacuum with dry nitrogen.

High--Pressure

Switch

The high--pressure switch is located in the discharge line

and protects against excessive condenser coil pressure.

It opens at 650 psig.

High pressure may be caused by a dirty outdoor coil,

failed fan motor, or outdoor air recirculation. To check

switch:

1. Turn off all power to unit.

2. Disconnect leads on switch.

3. Apply ohm meter leads across switch. You should have

continuity on a good switch.

Copeland Scroll Compressor (R--410A

Refrigerant)

The compressor used in this product is specifically

designed to operate with R--410A refrigerant and cannot

be interchanged.

The compressor is an electrical (as well as mechanical)

device. Exercise extreme caution when working near

compressors. Power should be shut off, if possible, for

most troubleshooting techniques. Refrigerants present

additional safety hazards.

FIRE/EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury or death and/or property damage.

Wear safety glasses and gloves when handling

refrigerants. Keep torches and other ignition sources

away from refrigerants and oils.

!

WARNING

The scroll compressor pumps refrigerant throughout the

system by the interaction of a stationary and an orbiting

scroll. The scroll compressor has no dynamic suction or

discharge valves, and it is more tolerant of stresses

caused by debris, liquid slugging, and flooded starts. The

compressor is equipped with an anti--rotational device

and an internal pressure relief port. The anti--rotational

device prevents the scroll from turning backwards and

replaces the need for a cycle protector. The pressure

relief port is a safety device, designed to protect against

extreme high pressure. The relief port has an operating

range between 550 psi (26.34 kPa) and 625 psi (29.93

kPa) differential p ressure.

Loading...

Loading...