International Comfort Products NH4A4 Installation Manual

INSTALLATION INSTRUCTIONS

R−410A Horizontal Split System Air Conditioner

NH4A4

These instructions must be read and understood completely before attempting installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory−authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes and

the current editions of the National Electrical Code (NEC)

NFPA70.

In Canada, refer to the current editions of the Canadian Electrical

Code CSA C22.1.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1........................

INSTALLATION 2−3.................................

Complete Pre−Installation Checks 2...................

Rig and Mount Unit 2..............................

Complete Refrigerant Piping Connections 3.............

Make Electrical Connections 3........................

START−UP 4........................................

SERVICE 4.........................................

MAINTENANCE 6...................................

Recognize safety information. This is the safety−alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

the signal words DANGER, WARNING, and CAUTION. These

words are used with the safety−alert symbol. DANGER identifies

the most serious hazards which will result in severe personal injury

or death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability, or operation.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

WARNING

.

!

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in environmental

pollution.

Remove and recycle all components or materials (i.e. oil,

refrigerant, etc.) before unit final disposal.

CAUTION

421 01 9703 01 02/25/15

INSTALLATION

IMPORTANT: Effective January 1, 2015, all split system and

packaged air conditioners must be installed pursuant to applicable

regional efficiency standards issued by the Department of Energy.

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when

handling parts.

!

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could result in personal injury

or equipment damage.

R−410A refrigerant systems operate at higher pressures than

standard R−22 systems. Do not use R−22 service equipment

or components on R−410A refrigerant equipment.

PERSONAL INJURY AND EQUIPMENT DAMAGE

HAZARD

Failure to follow this caution may result in personal injury

and / or equipment damage.

DO NOT operate the unit without a filter or with grille

removed.

COMPLETE PRE−INSTALLATION CHECKS

Unpack Unit

Move the unit to final location. Remove unit from carton, being

careful not to damage service valves and grilles.

Inspect Shipment

File a claim with the shipping company if shipment is damaged or

incomplete. Check the unit nameplates to ensure units match job

requirements.

Consider System Requirements

Consult local building codes and NEC for special installation

requirements.

Allow sufficient space for airflow clearance, wiring, refrigerant

piping, and servicing unit. Locate unit so that condenser airflow is

unrestricted on both sides.

Unit may be mounted on a level pad directly on base legs or

mounted on raised pads at support points.

RIG AND MOUNT UNIT

Mounting on Ground

Mount unit on a solid, level concrete pad. Position unit so water or

ice from roof does not fall directly onto unit. Use field−provided

snow stand or ice rack where prolonged subfreezing temperatures

or heavy snow occurs.

If conditions or local codes require unit be fastened to a pad, 6

field−supplied tie−down bolts should be used and fastened through

slots provided in unit mounting feet.

Mounting on Roof

Mount unit on a level platform or frame at least 6 in. (152.4 mm)

above roof surface. Isolate unit and tubing from structure.

WARNING

!

CAUTION

Clearance Requirements

Single Unit Applications: With coil facing wall: Allow 6” (152.4

mm) minimum clearance on coil side and coil end and 20” (504.0

mm) minimum clearance on fan side. Allow 24” (609.6 mm)

minimum clearance on compressor end for service.

With fan facing wall:

fan side and coil end and 20” (504.0 mm) minimum clearance on

coil side. Allow 24” (609.6 mm) minimum clearance on

compressor end for service when units are stacked or there is less

than 40” (1016 mm) of clearance above the unit. If there is 40”

(1016 mm) clearance above unit and the top panel is accessible for

removal allow 8” (203.2 mm) minimum clearance on compressor

end for service.

Multi−unit Applications:

clearance between fan and coil sides of multiple units. Arrange

units so discharge of one does not enter inlet of another. Allow 24”

(609.6 mm) minimum clearance on compressor end when units are

stacked or there is less than 40” (1016 mm) of clearance above the

unit. If there is 40” (1016 mm) clearance above unit and the top

panel is accessible for removal allow 8” (203.2 mm) minimum

clearance on compressor end for service.

When two units are installed end to end with the coil ends facing

each other allow 12” (304.8 mm) minimum clearance between

units.

IMPORTANT: When installing multiple units, ensure the

discharge air from one unit is not drawn into another unit. When

installing single or multiple units in an alcove, roof well, or

partially enclosed area, ensure there is adequate ventilation to

prevent recirculation of discharge air.

Operating Ambient

Minimum outdoor operating ambient in cooling mode is 55_F

(13_C), maximum 125_F (52_C).

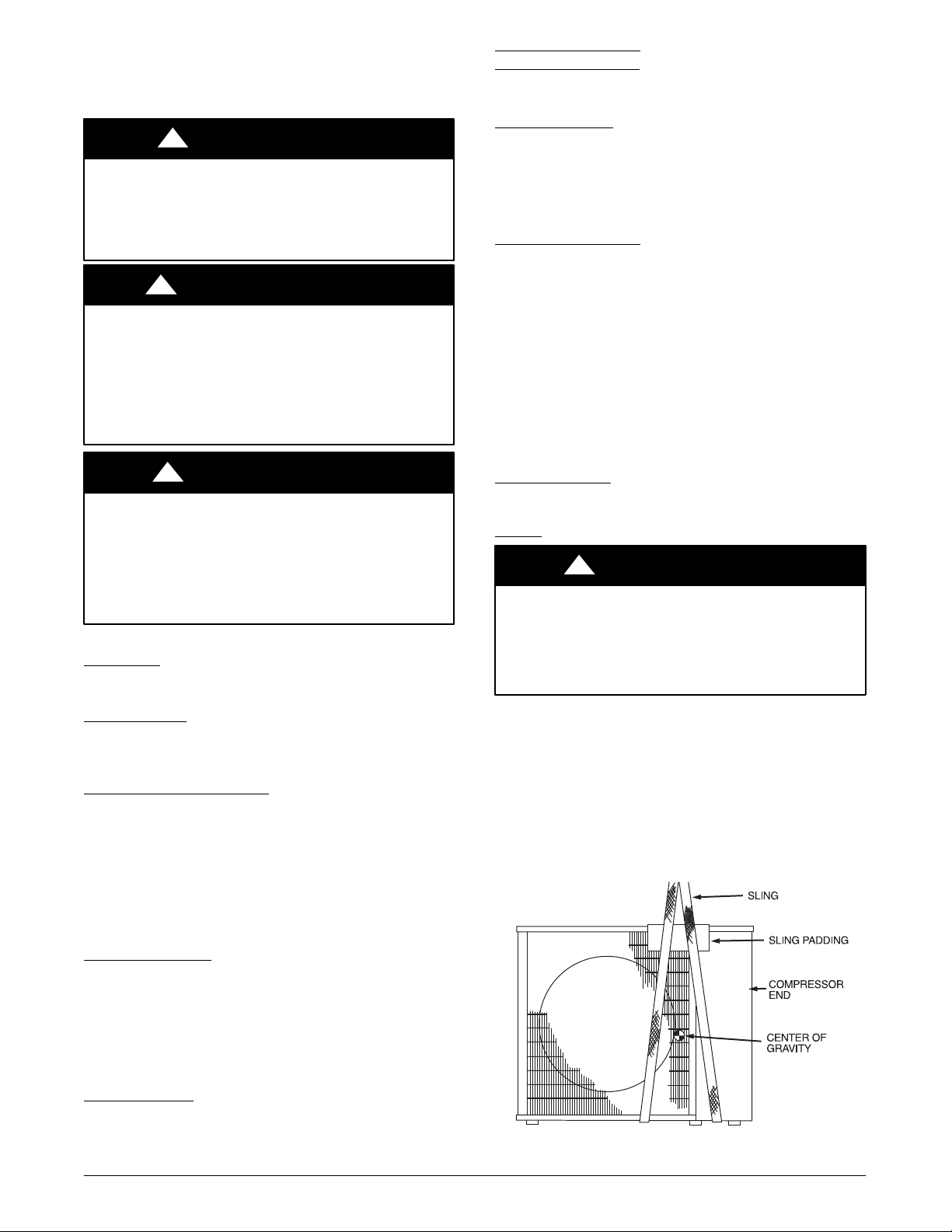

Rigging

PERSONAL INJURY AND/OR EQUIPMENT

DAMAGE HAZARD

Failure to follow this caution may result in personal injury

and/or equipment damage.

Be sure unit panels are securely in place prior to rigging.

Keep the unit upright and lift unit using a sling. Use cardboard or

padding under the sling, and spreader bars to prevent sling damage

to the unit. See Fig. 1. Install the unit so that the coil does not face

into prevailing winds. If this is not possible and constant winds

above 25 mph are expected, use accessory wind baffle. See

installation instructions provided with the accessory kit.

NOTE: Accessory wind baffles should be used on all units with

accessory low ambient temperature control.

Field−fabricated snow or ice stands may be used to raise unit when

operation will be required during winter months. Units may also be

wall mounted using the accessory wall mounting kit.

Allow 8” (203.2 mm) minimum clearance on

Allow 24” (609.6 mm) minimum

!

CAUTION

Fig. 1 - Lifting Unit with Sling

A07396

2 421 01 9703 01

Specifications subject to change without notice.

Loading...

Loading...