International Comfort Products FEM4X1800, FEM4X2400, FEM4X3000, FEM4X3500, FEM4X3600 Installation Manual

...

INSTALLATION INSTRUCTIONS

Fan Coils

FEM4X, FSM4X, FSU4X, FXM4X

These instructions must be read and understood completely before attempting installation.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING, CAUTION, and NOTE are used to identify levels of hazard seriousness. The signal word DANGER is only used on product labels to signify an immediate hazard. The signal words WARNING, CAUTION, and NOTE will be used on product labels and throughout this manual and other manuals that may apply to the product.

DANGER -- Immediate hazards which will result in severe personal injury or death.

WARNING -- Hazards or unsafe practices which could result in severe personal injury or death.

CAUTION -- Hazards or unsafe practices which may result in minor personal injury or product or property damage.

NOTE -- Used to highlight suggestions which will result in enhanced installation, reliability, or operation.

Signal Words in Manuals

The signal word WARNING is used throughout this manual in the following manner:

!WARNINGWAR ING

The signal word CAUTION is used throughout this manual in the following manner:

!CAUTION

Signal Words on Product Labeling

Signal words are used in combination with colors and/or pictures on product labels.

TABLE OF CONTENTS |

|

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Heater Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Position Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Air Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

Refrigerant Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

Refrigerant Metering Device . . . . . . . . . . . . . . . . . . . . |

11 |

Condensate Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

Start--up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

Airflow Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

R--410A Quick Reference Guide . . . . . . . . . . . . . . . . . |

18 |

!WARNING

PERSONAL INJURY, AND/OR PROPERTY DAMAGE HAZARD

Failure to carefully read and follow this warning could result in equipment malfunction, property damage, personal injury and/or death.

Installation or repairs made by unqualified persons could result in equipment malfunction, property damage, personal injury and/or death.

The information contained in this manual is intended for use by a qualified service technician familiar with safety procedures and equipped with the proper tools and test instruments.

Installation must conform with local building codes and with the National Electrical Code NFPA70 current edition.

INTRODUCTION

Models FEM4X, FSM4X, and FXM4X are designed for maximum flexibility and can be used for upflow, horizontal left or right, and downflow applications (accessory kit required for downflow or horizontal right).

496 01 5402 04 Mar/2016

INSTALLATION INSTRUCTIONS

Model FSU4X is designed for upflow installation, and can be field modified for downflow and horizontal left or right applications (accessory kits required for downflow or horizontal).

FEM4X and FXM4X models are available for system sizes 1--1/2 -- 5 tons (18,000 -- 60,000 BTUH) nominal cooling capacity.

FSM4X, and FSU4X models are available for system size 5 ton (60,000 BTUH) nominal cooling capacity.

FEM4X and FXM4X models use an ECM motor and have a factory installed and appropriately sized hard shut--off TXV metering device and are for R--410A refrigerant ONLY.

FSM4X and FSU4X models use a PSC motor and have a factory installed and appropriately sized hard shut--off TXV metering device and are for R--410A refrigerant ONLY.

Factory approved electric heater packages are available in sizes 3kW through 30kW. See Product Specification literature for available accessory kits.

LOCATION

Select the best position which suits the installation site conditions. The location should provide adequate structural support, space in the front of the unit for service access, clearance for return air and supply duct connections, space for refrigerant piping connections and condensate drain line connections. If heaters are being installed make sure adequate clearance is maintained from supply duct work.

Nuisance sweating may occur if the unit is installed in a high humidity environment with low airflow. On these installations a wrap of 2 (51mm) fiberglass insulation with a vapor barrier is recommended.

Fan Coils: FEM4X, FSM4X, FSU4X, FXM4X

POSITION UNIT

Unit can stand or lie on floor, or hang from ceiling or wall. Allow space for wiring, piping, and servicing unit.

!CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage

A field fabricated auxiliary drain pan, with a separate drain is REQUIRED for all installations over a finished living space or in any area that may be damaged by overflow from a restricted main drain pan. In some localities, local codes require an auxiliary drain pan for ANY horizontal installation.

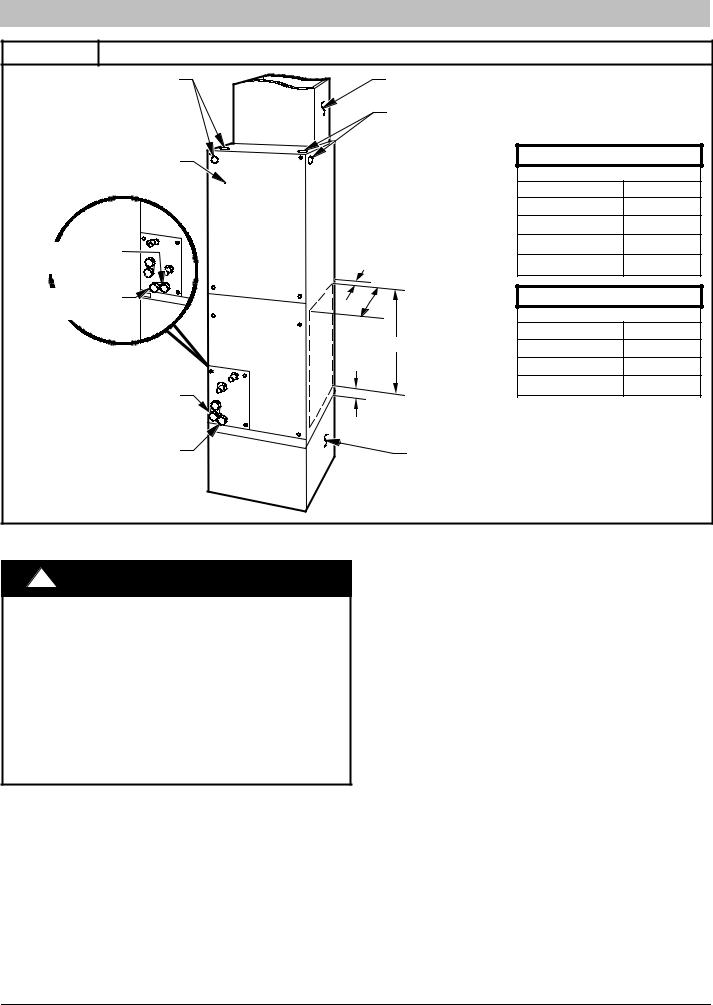

A. UPFLOW INSTALLATION

If return air is to be ducted through a floor, set unit on floor over opening and use 1/8 to 1/4 inch thick (3 to 6 mm thick) fireproof resilient gasket between duct, unit, and floor.

Side return is a field option on slope coil models. Cut opening per dimensions shown in Figure 2. A field--supplied bottom closure is required.

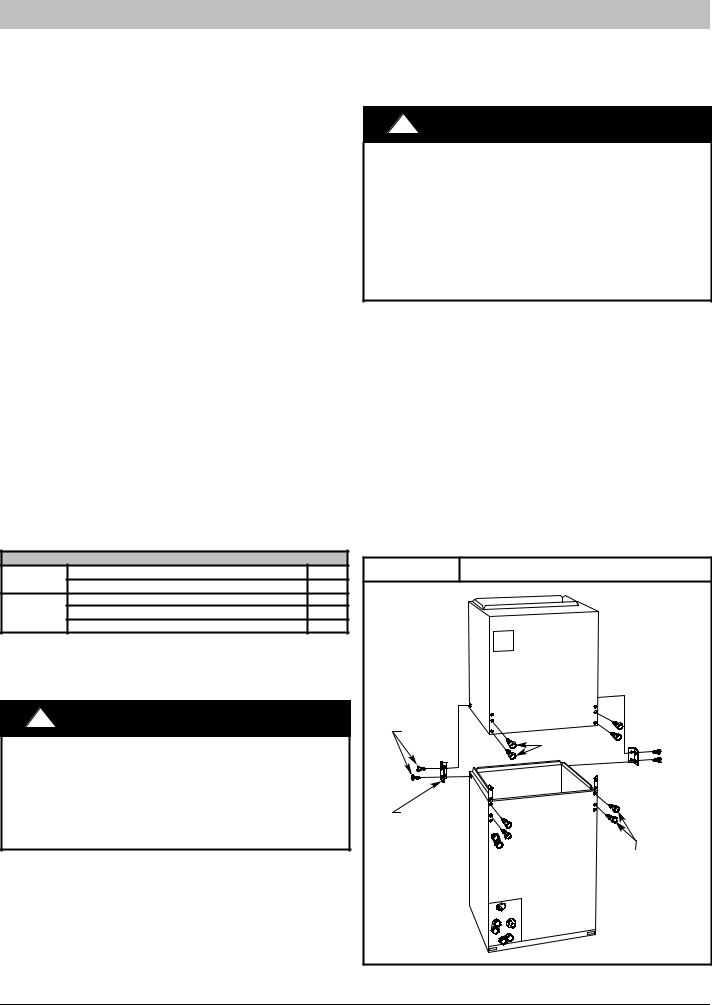

B. MODULAR UNITS

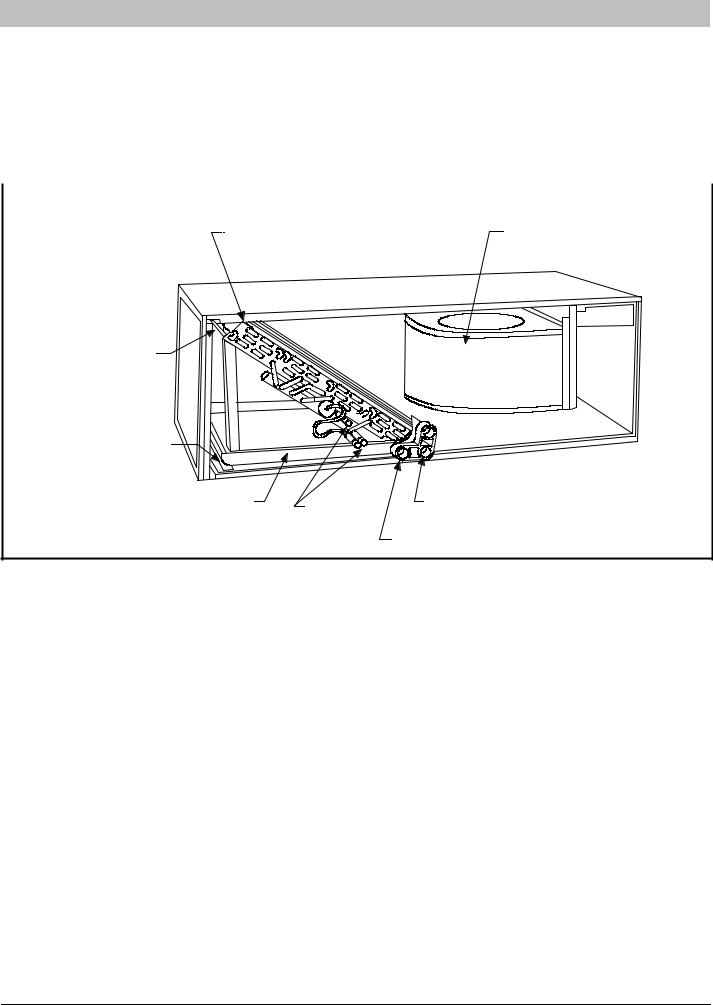

The FSU4X6000, FXM4X4800/6000, FEM4X4800/6000, and FSM4X4800/6000 fan coils are two--piece modular units. This allows for modular units to be disassembled and components moved separately to installation area for reassembly. This process accommodates small scuttle holes and limiting entrances to installation sites (refer to Figure 1).

REQUIRED CLEARANCES -- ALL MODELS (inches) |

|

Figure 1 |

Modular Unit Assembly |

|

No |

All Sides |

0 |

||

Heaters |

From Supply Duct |

0 |

|

|

With |

All Sides |

0 |

|

|

From First 3 feet of Supply Duct to Combustibles |

1 |

|

|

|

Heaters |

|

|

||

From Supply Duct to Combustibles after 3 feet |

0 |

|

|

|

|

|

|

||

NOTE: Internal filter can be accessed from separate filter |

|

|

||

door. If the filter can NOT be easily accessed, a remote filter |

|

|

||

is recommended. Refer to ACCA Manual D for remote filter |

|

|

||

sizing. |

|

|

|

BLOWER BOX |

|

|

|

|

|

! |

WARNING |

|

2 SCREWS |

|

FIRE HAZARD |

|

|

2 SCREWS |

|

|

|

|

|

|

Failure to maintain proper clearances could result in per- |

|

|

||

sonal injury, death, and/or property damage. |

|

|

|

|

When heaters are installed, maintain clearances from |

REAR CORNER |

|

||

combustible materials as specified on unit rating plate. |

|

|||

BRACKET |

|

|||

Do not use plastic lined or combustible flexible ducting |

|

|||

|

|

|||

within 36 inches (1m) of the supply end of the fan coil. |

|

|

COIL BOX |

|

HEATER PACKAGES |

|

|

||

|

|

|

|

2 SCREWS |

Factory approved, field installed, UL listed heater packages |

|

|

||

are available from the equipment supplier. See unit rating |

|

|

||

plate for a list of factory approved heaters. Heaters that are |

|

|

||

not factory approved could cause damage which would not |

|

|

||

be covered under the equipment warranty. |

|

|

|

|

2 |

|

|

|

496 01 5402 04 |

INSTALLATION INSTRUCTIONS |

|

|

Fan Coils: FEM4X, FSM4X, FSU4X, FXM4X |

||

Figure 2 |

Upflow Installation |

|

|

||

POWER ENTRY |

|

FIELD SUPPLIED |

|

|

|

OPTIONS |

|

SUPPLY DUCT |

|

|

|

|

|

LOW VOLT |

|

|

|

|

|

ENTRY |

|

|

|

|

|

OPTIONS |

|

|

|

FRONT SERVICE CLEARANCE |

|

|

|

SLOPE COIL UNITS |

|

60 model = 24” (610 mm) |

|

|

|

||

|

|

|

FEM4X |

|

|

|

|

|

|

|

|

|

|

|

|

MODEL SIZE |

A |

A-COIL |

|

|

|

18 |

12" (305mm) |

UNITS |

|

|

|

24 |

17" (432mm) |

|

|

|

|

||

UPFLOW/DOWNFLOW |

1--1/2” |

|

30 |

17" (432mm) |

|

|

|

19" (483mm) |

|||

SECONDARY DRAIN |

|

35 |

|||

|

|

|

|||

UPFLOW/DOWNFLOW |

19” |

(483mm) |

SLOPE COIL UNITS |

||

PRIMARY DRAIN |

FXM4X |

|

|||

|

|

|

|

|

|

|

|

|

FIELD MODIFIED |

MODEL SIZE |

A |

|

|

A |

SIDE RETURN |

18 |

17" (432mm) |

|

2--- 1/2” |

LOCATION FOR |

|||

|

|

SLOPE COIL |

24 |

17" (432mm) |

|

|

(64mm) |

|

UNITS ONLY |

||

|

|

30 |

19" (483mm) |

||

UPFLOW/DOWNFLOW |

|

|

|

||

|

|

|

|

|

|

SECONDARY DRAIN |

|

|

|

|

|

UPFLOW/DOWNFLOW |

|

|

FIELD SUPPLIED |

|

|

PRIMARY DRAIN |

|

|

RETURN PLENUM |

|

|

B. DOWNFLOW INSTALLATION

!CAUTION

PRODUCT OR PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in product or property damage

The conversion of the fan coil to downflow requires special procedures for the condensate drains on both A--coil and Slope--coil units. The vertical drains have an overflow hole between the primary and secondary drain holes. This hole is plugged for all applications except downflow, and must be used for downflow.

Failure to follow instructions could result in personal injury or product and property damage.

In this application, field conversion of the evaporator coil is required using accessory Downflow Kit along with an accessory Base Kit. Set unit on floor over opening and use 1/8” to 1/4” thick fireproof resilient gasket between duct, unit, and floor. Refer to installation instructions packaged with accessory kit. See Product Specification literature for kit part numbers.

During the conversion process, removed the plastic cap covering the vertical drains only and discard.

Remove the plug from the overflow hole and discard.

At completion of the downflow installation, caulk around the vertical pan fitting to door joint to retain low air leak performance of the unit.

NOTE: Gasket kit number (EBAC01GSK) is also required for all downflow applications to maintain low air leak/low sweat performance.

C. HORIZONTAL INSTALLATION

Unit must NOT be installed with access panels facing up or down. Access panels must only face to the side.

FEM4X, FSM4X, and FXM4X models are factory built for horizontal left installation (refer to Figure 3 and Figure 4). They can be field converted to horizontal right (accessory Gasket Kit required, see Product Specification literature for part number). Refer to Figure 5 and Figure 6.

FSU4X models require accessory kits for any horizontal installation (see Product Specification literature for required accessory kits).

NOTE: When suspending unit from ceiling, dimples in casing indicate suitable location of screws for mounting metal support straps.

NOTE: For optimum condensate drainage performance in horizontal installations, unit should be leveled along its length and width.

496 01 5402 04 |

3 |

INSTALLATION INSTRUCTIONS |

Fan Coils: FEM4X, FSM4X, FSU4X, FXM4X |

|

|

|

|

|

|

|

|

|

|

Figure 3 |

Horizontal Left Application (Slope Coil) (FXM4X factory configuration) |

|

|

|

|

|

|

FIELD

SUPPLIED

HANGING

STRAPS

SECONDARY

DRAIN

LOW VOLT

ENTRY

OPTIONS

POWER |

PRIMARY |

ENTRY |

DRAIN |

OPTIONS |

|

A-COIL

HORIZONTAL LEFT

SECONDARY |

PRIMARY |

|

DRAIN |

||

DRAIN |

||

|

FRONT SERVICE CLEARANCE (FULL FACE OF UNIT)

18 -- 48 models = 21” (533mm)

60 model = 24” (610mm)

1--3/4” (45mm) FILTER ACCESS CLEARANCE

Figure 4 |

Horizontal Left Application (A--Coil) (FEM4X, FSM4X, and FXM4X factory configuration) |

|

|

A |

|

FACTORY SHIPPED |

|

COIL |

|

BRACKET |

|

HORIZONTAL LEFT |

|

|

|

|

|

APPLICATION |

|

|

|

|

COIL |

|

|

SUPPORT |

|

B |

RAIL |

|

|

|

|

C |

DRAIN PAN |

|

|

SUPPORT |

|

|

BRACKET |

|

|

COIL |

|

|

BRACKET |

|

HORIZONTAL |

|

|

DRAIN PAN |

PRIMARY DRAIN |

|

AIR SEAL |

HORIZONTAL LEFT |

|

|

|

|

ASSEMBLY |

SECONDARY DRAIN |

|

|

HORIZONTAL LEFT |

REFRIGERANT

CONNECTIONS

4 |

496 01 5402 04 |

INSTALLATION INSTRUCTIONS

Horizontal Right Conversion of Units With Slope Coils

1.Remove blower and coil access panel and fitting panel (refer to Figure 5).

2.Remove coil mounting screw securing coil assembly to right side casing flange.

3.Remove coil assembly.

4.Lay fan coil unit on its right side and reinstall coil assembly with condensate pan down (refer to Figure 5).

Fan Coils: FEM4X, FSM4X, FSU4X, FXM4X

5.Attach coil to casing flange using coil mounting screw previously removed.

6.Align holes with tubing connections and condensate pan connections, and reinstall access panels and fitting panel. After brazing, make sure liquid and suction tube grommets are in place to prevent air leaks and cabinet sweating.

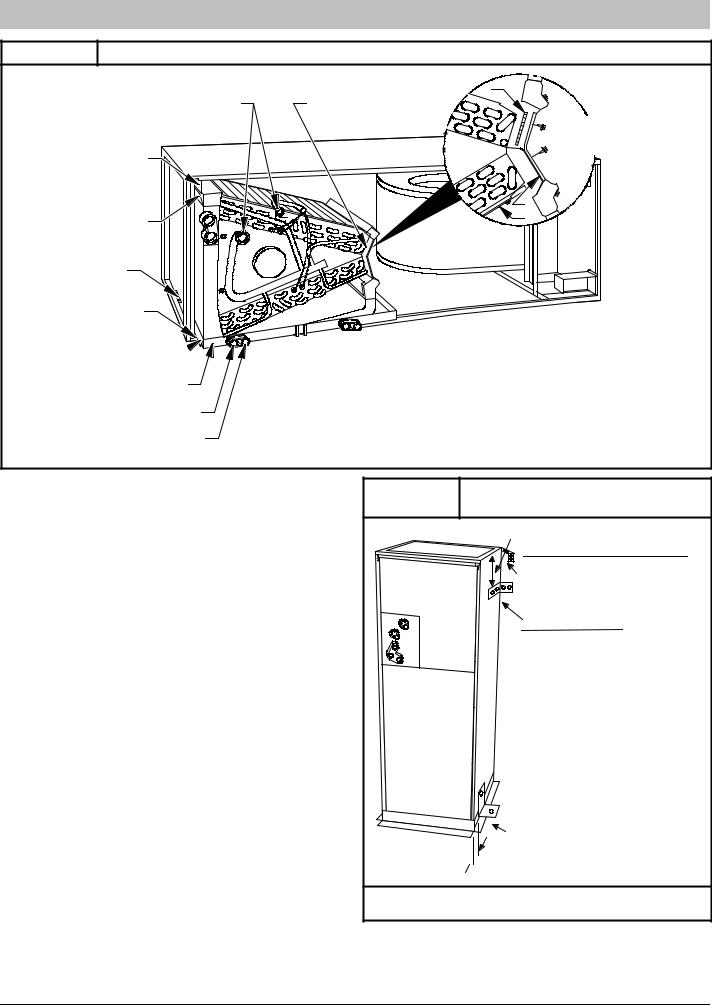

Figure 5 |

Horizontal Right Conversion Applications (Slope Coil) (FXM4X) |

|

|

|

|

|

COIL MOUNTING |

BLOWER |

|

SCREW |

ASSEMBLY |

COIL SUPPORT RAIL

SLOPE COIL

DRAINPAN |

PRIMARY DRAIN |

|

REFRIGERANT |

|

CONNECTIONS |

|

SECONDARY DRAIN |

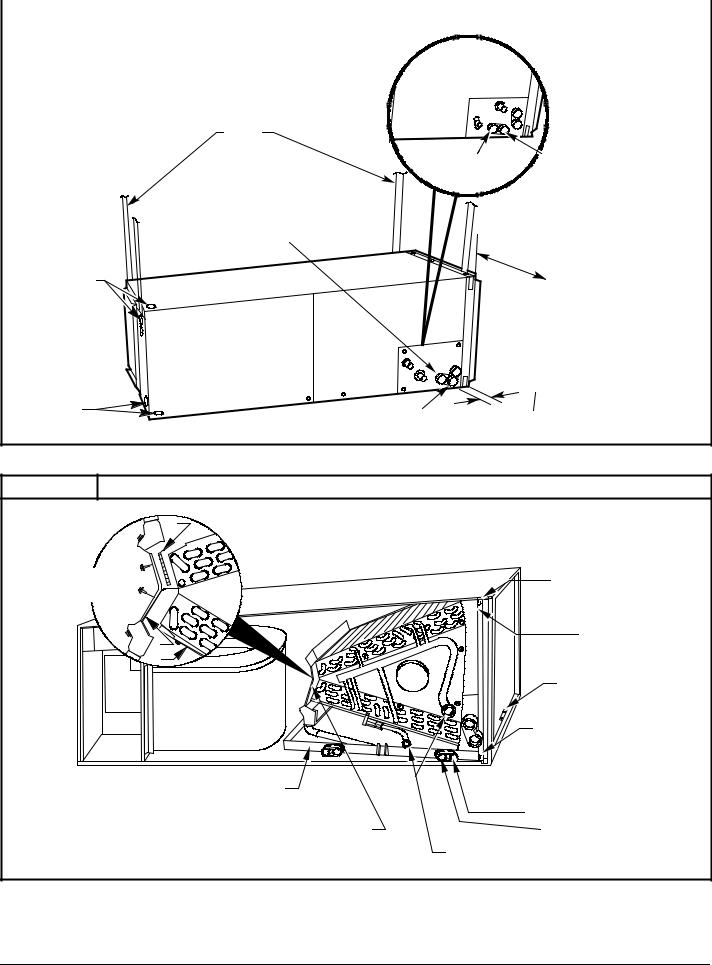

Horizontal Right Conversion of Units With A--Coils

1.Remove blower and coil access panel and fitting panel (refer to Figure 6).

2.Remove coil mounting screw securing coil assembly to right side casing flange.

3.Remove coil assembly.

4.Lay fan coil unit on its right side and reinstall coil assembly with condensate pan down (refer to Figure 6).

5.Remove horizontal drain pan support bracket from coil support rail on left side of unit and reinstall on coil support rail on right side of unit.

6.Convert air--seal assembly for horizontal right (refer to Figure 6).

a.Remove air--seal assembly from coil by removing 4 screws.

b.Remove coil drip flanges from A--coil and reinstall on right side of coil (same side as horizontal drain pan).

c.Remove filler plate (A) and install air splitter (B) in place of filler plate.

d.Install filler plate (A) as shown in horizontal right application.

e.Remove condensate troughs (C) and install on opposite tube sheets.

f.Install hose onto plastic spout.

7.Install horizontal pan on right side of coil assembly.

8.Slide coil assembly into casing. Be sure coil bracket on each corner of vertical pan engages coil support rails.

9.Reinstall 2 snap--in clips to correctly position and secure coil assembly in unit. Be sure clip with large offsets is used on right side of unit to secure horizontal pan.

10.Remove 2 oval coil access panel plugs and reinstall into holes on left side of coil access panel and fitting panel.

11.Remove insulation knockouts on right side of coil access panel

12.Reinstall access fitting panels, aligning holes with tubing connections and condensate pan connections. Be sure to reinstall metal clip between fitting panel and vertical condensate pan.

13.After brazing, make sure liquid and suction tube grommets are in place to prevent air leaks and cabinet sweating.

496 01 5402 04 |

5 |

INSTALLATION INSTRUCTIONS |

Fan Coils: FEM4X, FSM4X, FSU4X, FXM4X |

Figure 6 |

Horizontal Right Conversion Applications (A--Coil) |

|

A |

REFRIGERANT |

AIR SEAL |

CONNECTIONS |

ASSEMBLY |

|

HORIZONTAL |

|

RIGHT |

COIL |

APPLICATION |

|

|

SUPPORT |

|

RAIL |

|

|

B |

COIL |

C |

|

|

BRACKET |

|

DRAIN PAN

SUPPORT

BRACKET

COIL

SUPPORT

RAIL

COIL

BRACKET

HORIZONTAL

DRAIN PAN

PRIAMRY DRAIN

HORIZONTAL RIGHT

SECONDARY DRAIN

HORIZONTAL RIGHT

D.MANUFACTURED HOUSING AND MOBILE HOME APPLICATIONS

1.Fan coil unit must be secured to the structure using field--supplied hardware.

2.Allow a minimum of 24 inches (610mm) clearance from access panels.

3.Recommended method of securing for typical applications:

a.If fan coil is away from wall, attach pipe strap to top of fan coil using No. 10 self tapping screws. Angle strap down and away from back of fan coil, remove all slack, and fasten to wall stud of structure using 5/16” lag screws. Typical both sides of fan coil.

b.If fan coil is against wall, secure fan coil to wall stud using 1/8” (3mm) wide right--angle brackets. Attach brackets to fan coil using No. 10 self tapping screws and to wall stud using 5/16” lag screws (refer to Figure 7).

NOTE: Modular units can be disassembled and components moved separately to installation area for reassembly. This process accommodates small scuttle holes and limiting entrances to installation sites (refer to Figure 8).

Figure 7 |

Mobile Home or Manufactured Hous- |

|

ing Applications |

||

|

4” (102mm) MAX

SECURE FAN COIL TO STRUCTURE

UNIT AWAY FROM WALL

PIPE STRAP (TYPICAL BOTH SIDES)

OR

UNIT AGAINST WALL

11/8” (3mm) INCH THICK ANGLE MOUNTING BRACKET (TYPICAL BOTH SIDES)

DOWN FLOW

BASE KIT

BASE KIT

SECURE UNIT TO FLOOR

ANGLE BRACKET OR PIPE STRAP

4” (102mm) MAX

4” (102mm) MAX

6 |

496 01 5402 04 |

Loading...

Loading...