Page 1

Quad-Core Intel® Xeon® Processor

5400 Series

Thermal/Mechanical Design Guidelines

November 2007

Reference Number: 318611 Revision: 001

Page 2

IINFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR

IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS

PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER,

AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING

LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY

PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life saving, or

life sustaining applications. Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel

reserves these for future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future

changes to them.

The Quad-Core Intel® Xeon® 5400 Series may contain design defects or errors known as errata, which may cause the product to

deviate from published specifications. Current characterized errata are available upon request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may be obtained

by calling1-800-548-4725, or by visiting Intel's website at http://www.intel.com.

Intel, Intel Inside, Xeon, Intel Core and the Intel logo are trademarks or registered trademarks of Intel Corporation or its

subsidiaries in the United States and other countries.

* Other brands and names may be claimed as the property of others.

Copyright © 2007, Intel Corporation. All rights reserved.

2 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 3

Contents

1Introduction..............................................................................................................9

1.1 Objective ...........................................................................................................9

1.2 Scope ................................................................................................................9

1.3 References .........................................................................................................9

1.4 Definition of Terms ............................................................................................ 10

2 Thermal/Mechanical Reference Design.................................................................... 13

2.1 Mechanical Requirements ................................................................................... 13

2.1.1 Processor Mechanical Parameters ............................................................. 13

2.1.2 Quad-Core Intel® Xeon® Processor 5400 Series Package............................ 14

2.1.3 Quad-Core Intel® Xeon® Processor 5400 Series Considerations................... 18

2.2 Processor Thermal Parameters and Features ......................................................... 19

2.2.1 Thermal Control Circuit and TDP............................................................... 19

2.2.2 Digital Thermal Sensor............................................................................ 20

2.2.3 Platform Environmental Control Interface (PECI) ........................................ 21

2.2.4 Multiple Core Special Considerations ......................................................... 21

2.2.5 Thermal Profile ...................................................................................... 24

2.2.6 TCONTROL Definition .............................................................................. 25

2.2.7 Thermal Profile Concepts for the Quad-Core Intel® Xeon®

2.2.8 Performance Targets............................................................................... 28

2.3 Fan Fail Guidelines ............................................................................................ 32

2.4 Characterizing Cooling Solution Performance Requirements..................................... 33

2.4.1 Fan Speed Control.................................................................................. 33

2.4.2 Processor Thermal Characterization Parameter Relationships........................ 34

2.4.3 Chassis Thermal Design Considerations ..................................................... 36

2.5 Thermal/Mechanical Reference Design Considerations ............................................ 37

2.5.1 Heatsink Solutions.................................................................................. 37

2.5.2 Thermal Interface Material....................................................................... 38

2.5.3 Summary .............................................................................................. 38

2.5.4 Assembly Overview of the Intel Reference Thermal Mechanical Design........... 39

2.5.5 Thermal Solution Performance Characteristics ............................................ 41

2.5.6 Thermal Profile Adherence....................................................................... 42

2.5.7 Components Overview ............................................................................ 45

2.5.8 Boxed Active Thermal Solution for the Quad-Core Intel®

A 1U Alternative Heatsink Thermal/Mechanical Design............................................... 53

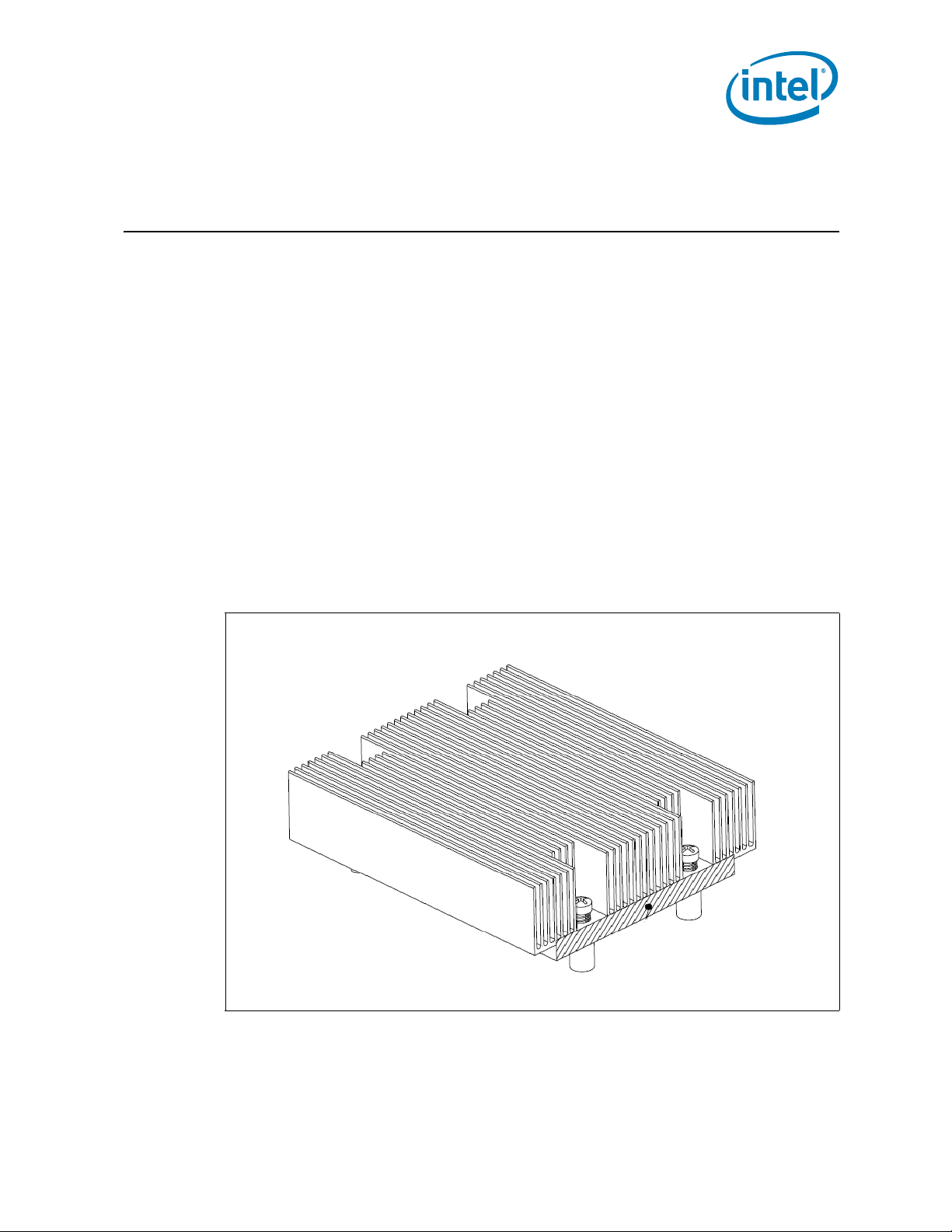

A.1 Component Overview......................................................................................... 53

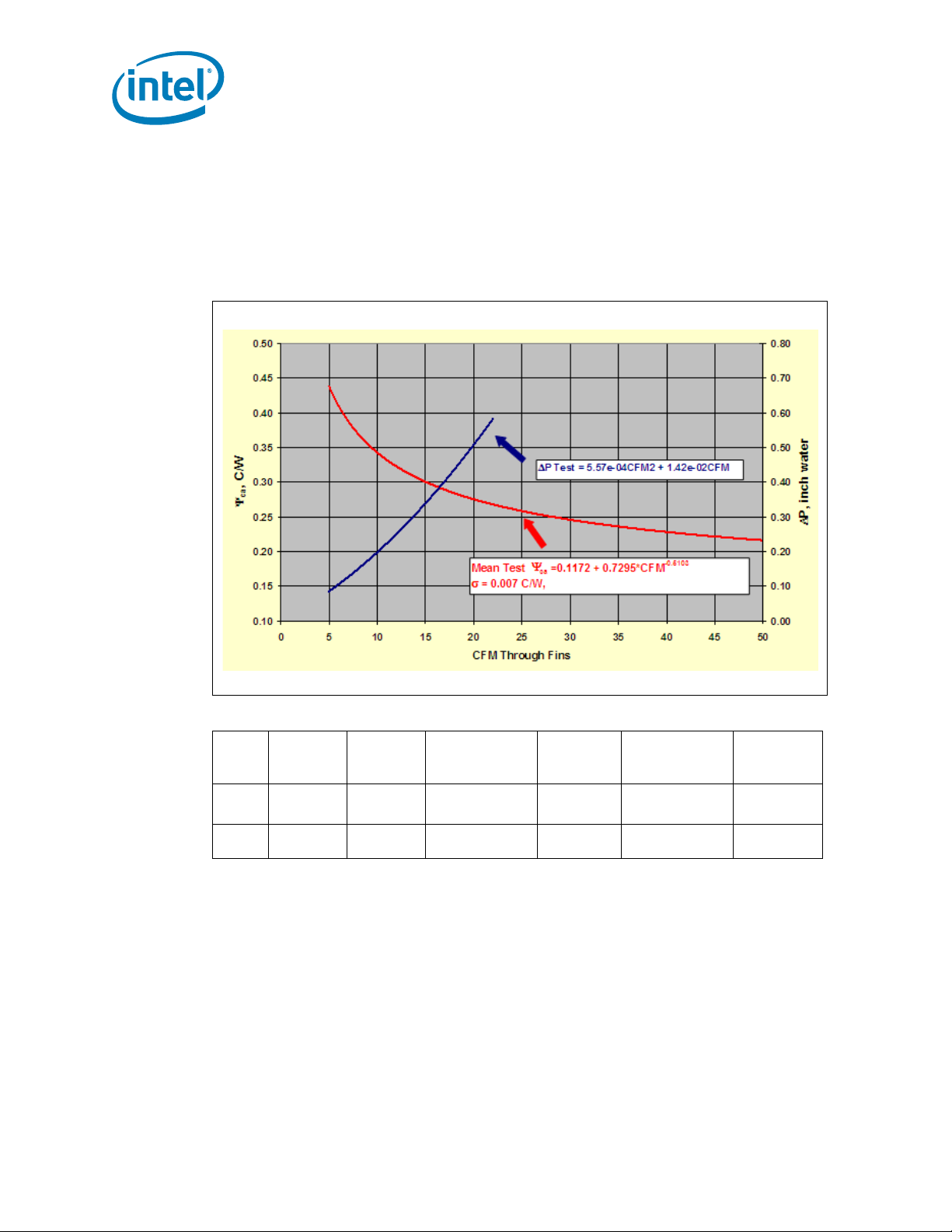

A.2 Thermal Solution Performance Characterics .......................................................... 54

A.3 Thermal Profile Adherence.................................................................................. 54

B Mechanical Drawings............................................................................................... 57

C Heatsink Clip Load Methodology .............................................................................. 83

C.1 Overview ......................................................................................................... 83

C.2 Test Preparation................................................................................................ 83

C.2.1 Heatsink Preparation .............................................................................. 83

C.2.2 Typical Test Equipment ........................................................................... 86

C.2.3 Test Procedure Examples ........................................................................ 86

C.2.4 Time-Zero, Room Temperature Preload Measurement ................................. 86

C.2.5 Preload Degradation under Bake Conditions ............................................... 87

Processor 5400 Series............................................................................. 26

Xeon® Processor 5400 Series Thermal Profile ............................................ 49

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 3

Page 4

D Safety Requirements................................................................................................89

E Quality and Reliability Requirements .......................................................................91

E.1 Intel Verification Criteria for the Reference Designs ................................................91

E.1.1 Reference Heatsink Thermal Verification ....................................................91

E.1.2 Environmental Reliability Testing ..............................................................91

E.1.3 Material and Recycling Requirements.........................................................93

F Enabled Suppliers Information.................................................................................95

F.1 Supplier Information ..........................................................................................95

F.1.1 Intel Enabled Suppliers............................................................................95

F.1.2 Additional Suppliers ................................................................................96

Figures

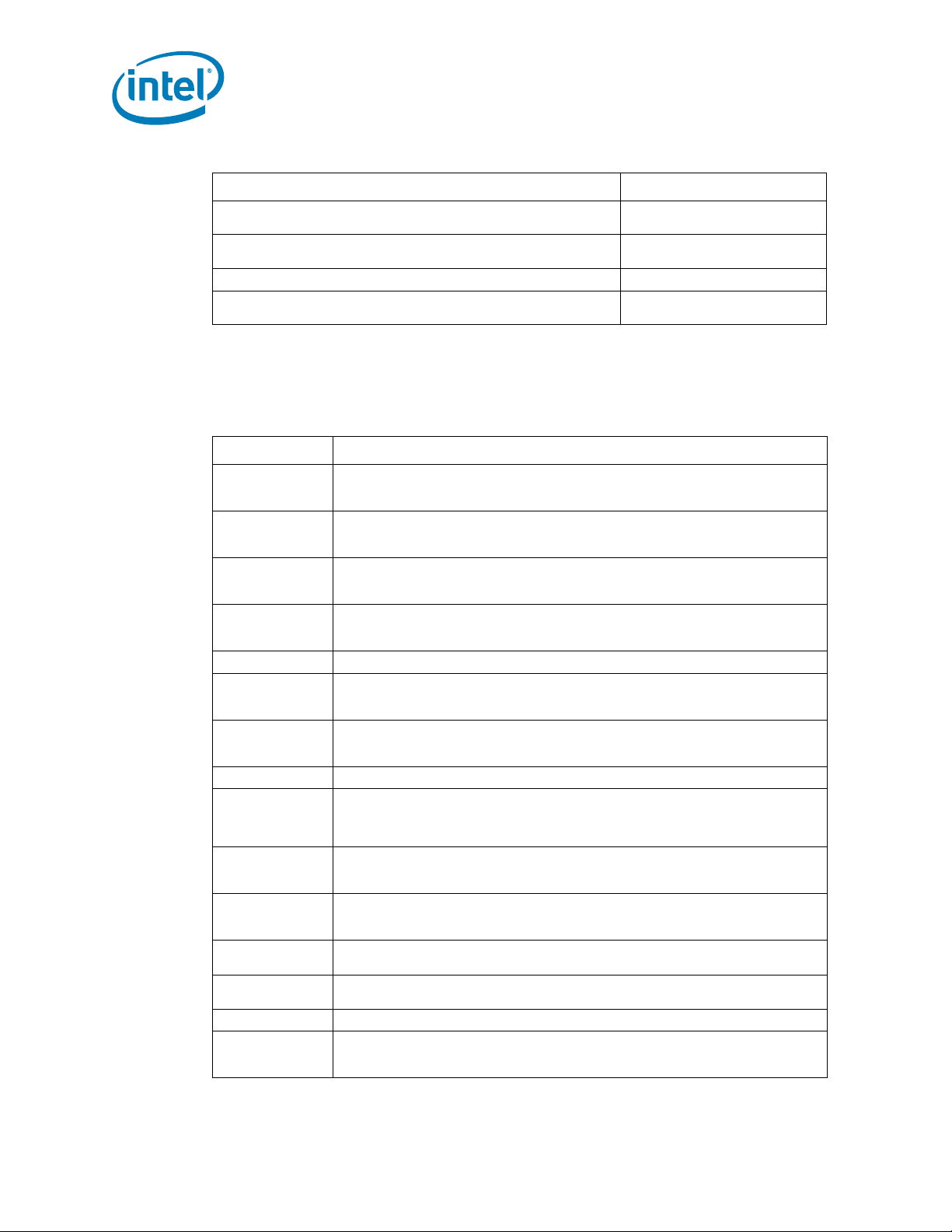

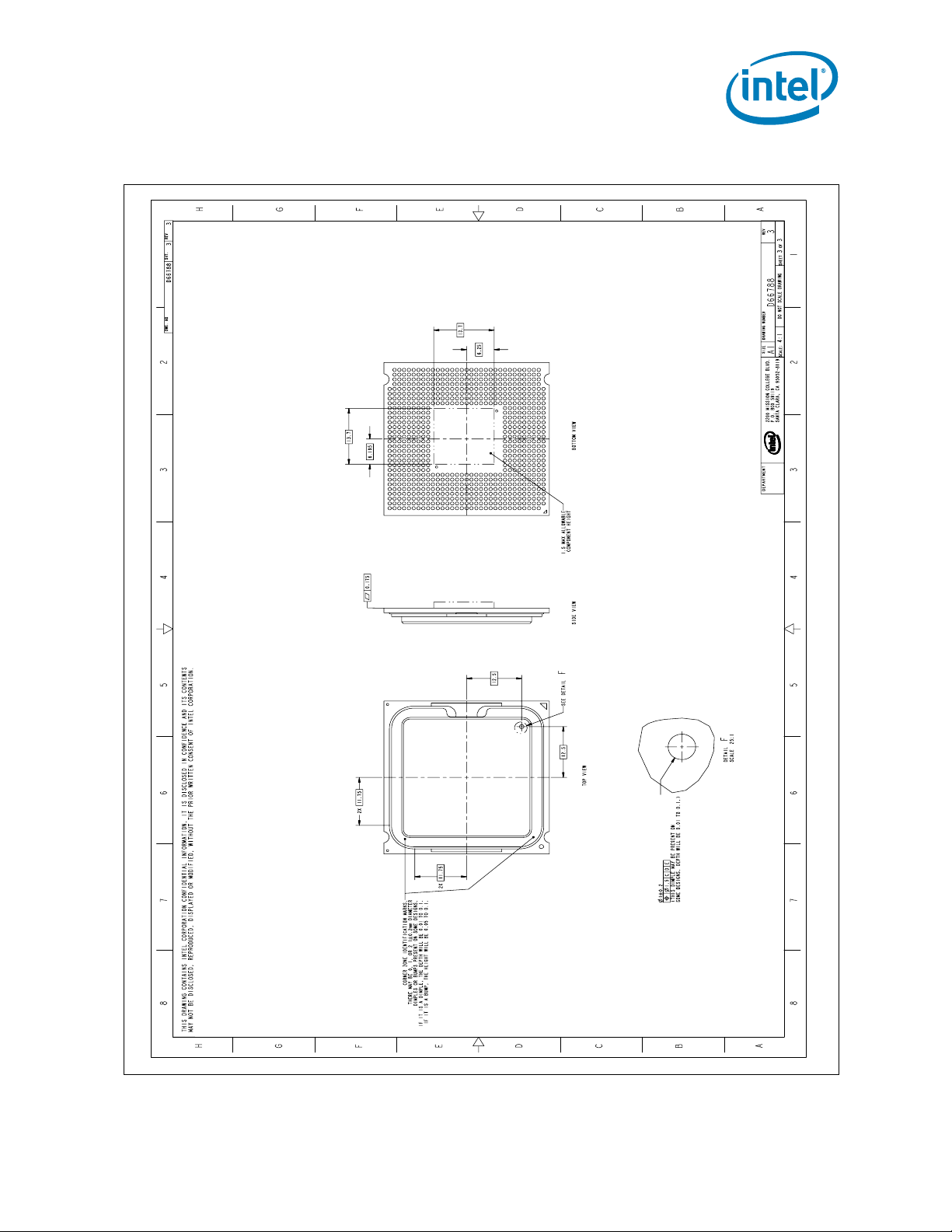

2-1 Quad-Core Intel® Xeon® Processor 5400 Series Mechanical Drawing (1 of 3)............15

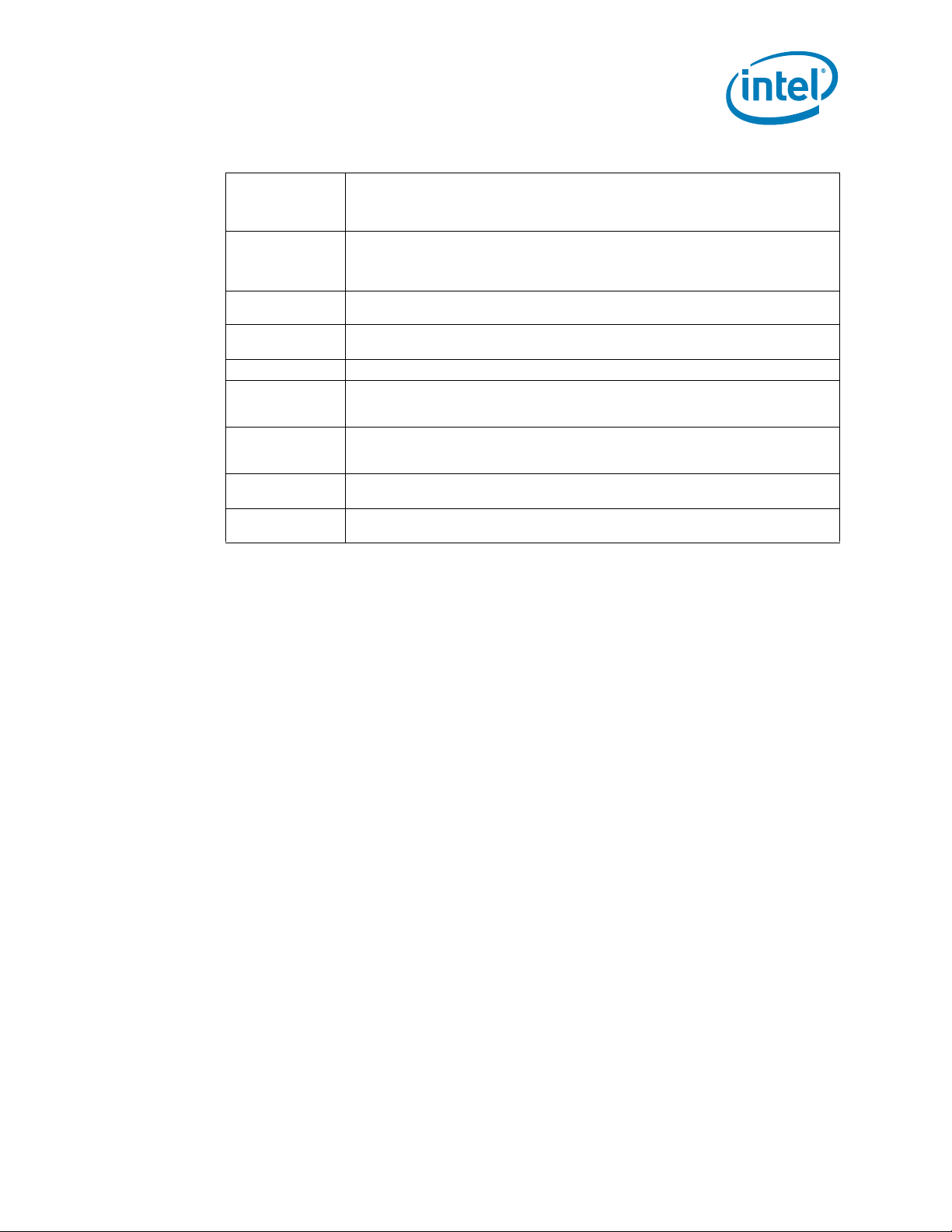

2-2 Quad-Core Intel® Xeon® Processor 5400 Series Mechanical Drawing (2 of 3)............16

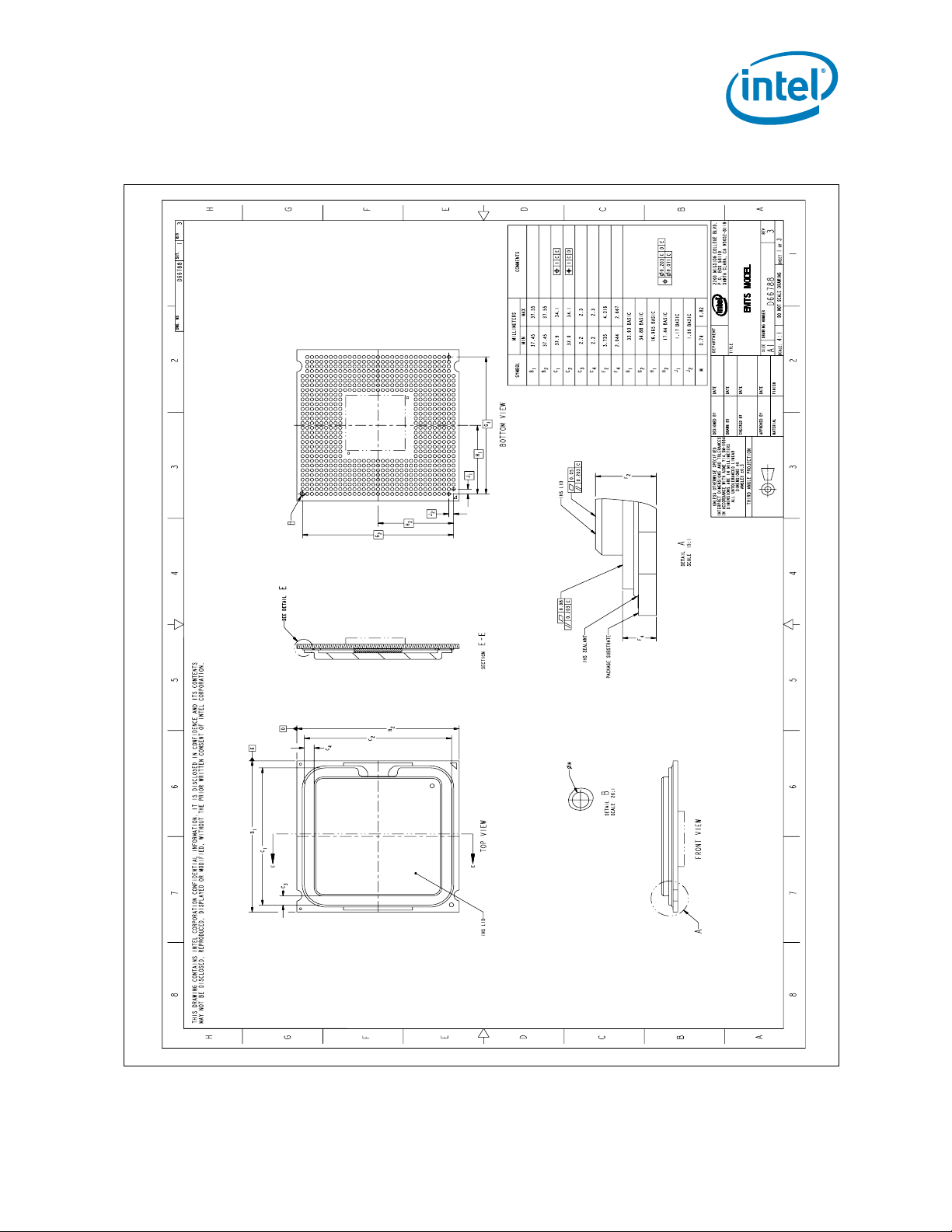

2-3 Quad-Core Intel® Xeon® Processor 5400 Series Mechanical Drawing (3 of 3)............17

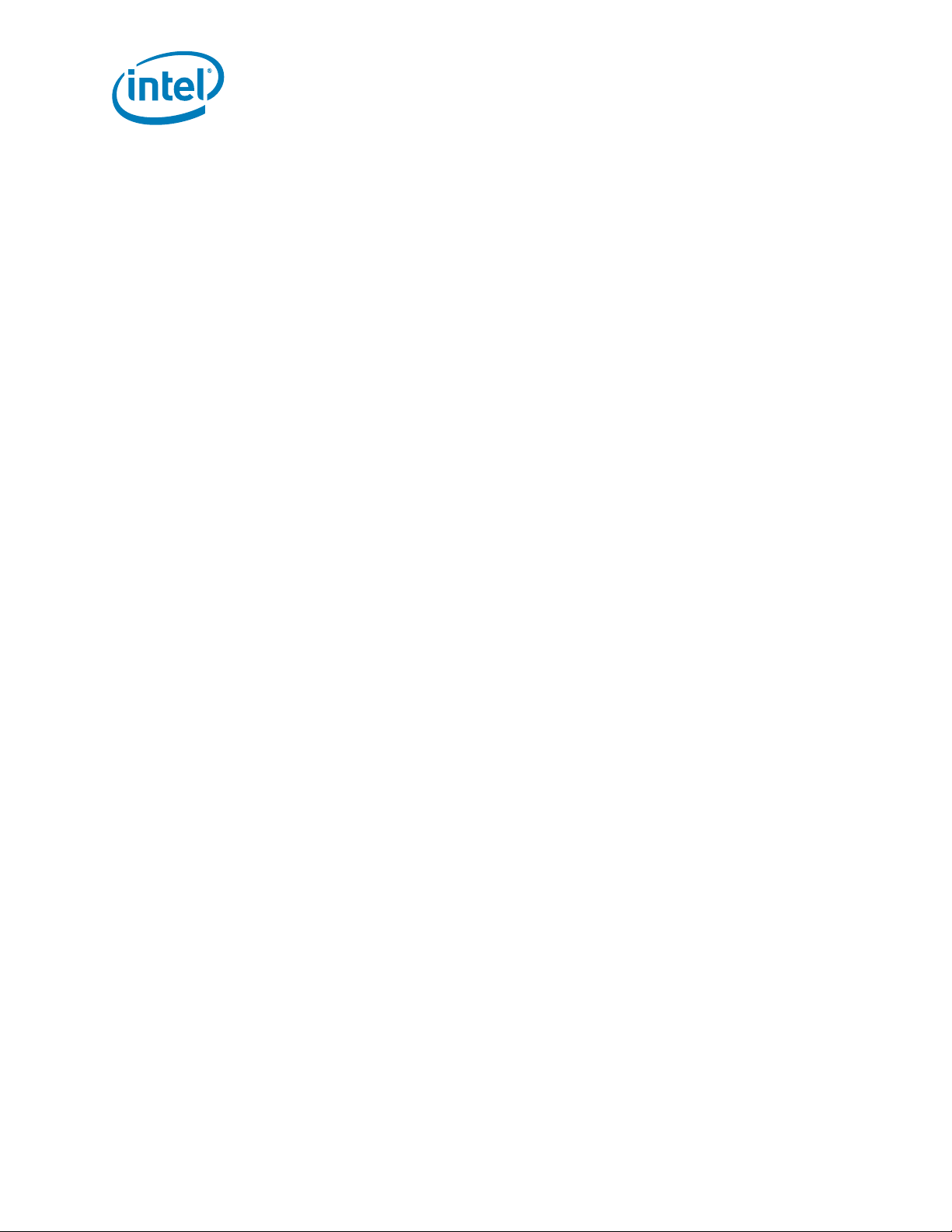

2-4 Processor Case Temperature Measurement Location ...............................................19

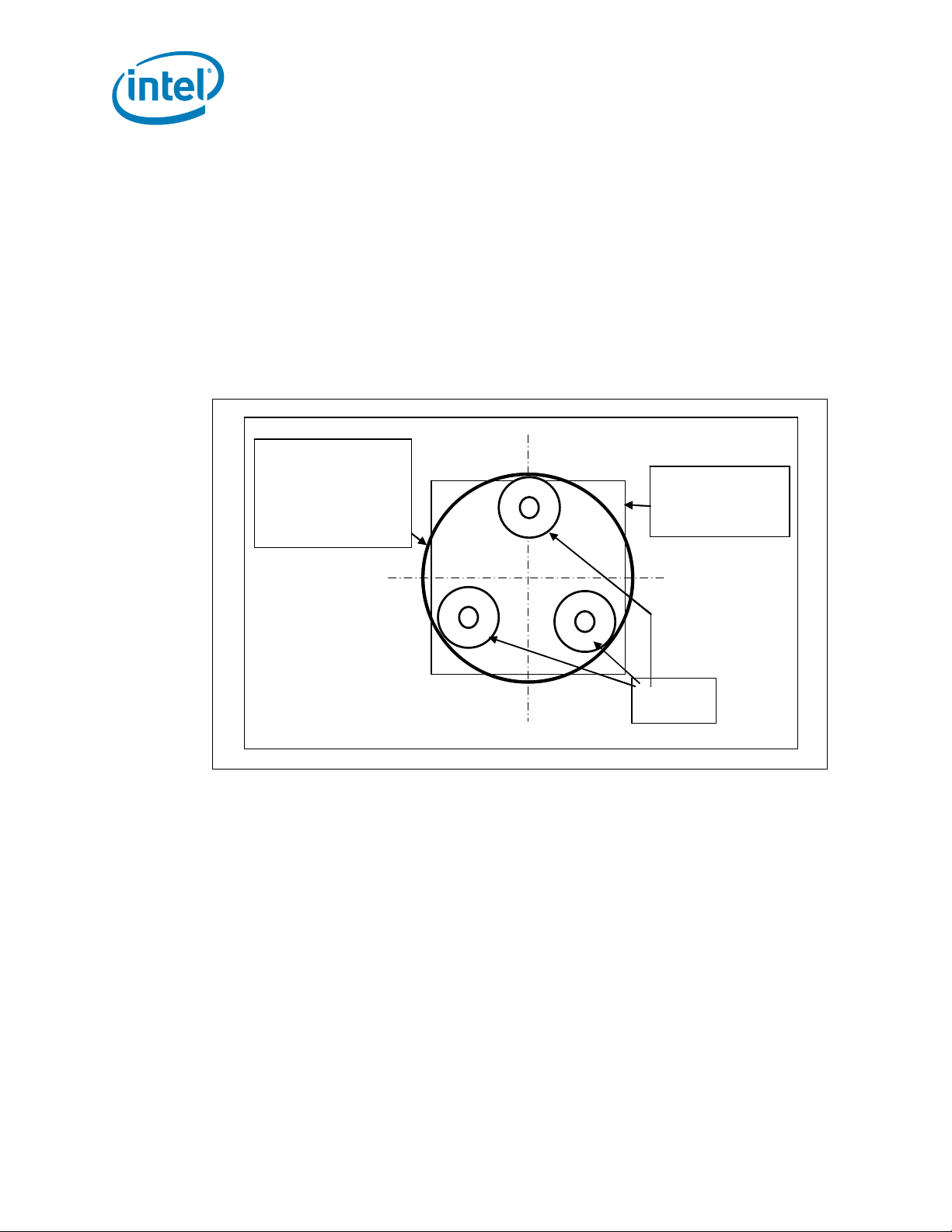

2-5 DTS Domain for Quad-Core Intel® Xeon® Processor 5400 Series ............................21

2-6 Processor Core Geometric Center Locations ...........................................................23

2-7 Thermal Profile Diagram .....................................................................................24

2-8 TCONTROL Value and Digital Thermal Sensor Value Interaction................................25

2-9 TCONTROL and Thermal Profile Interaction............................................................26

2-10 Dual Thermal Profile Diagram..............................................................................27

2-11 Thermal Profile for the Quad-Core Intel® Xeon® Processor X5400 Series..................29

2-12 Thermal Profile for Quad-Core Intel® Xeon® Processor E5400 Series .......................30

2-13 Thermal Profile for Quad-Core Intel® Xeon® Processor X5482 Series.......................31

2-14 TCONTROL and Fan Speed Control .......................................................................33

2-15 Processor Thermal Characterization Parameter Relationships ...................................35

2-16 Exploded View of CEK Thermal Solution Components..............................................39

2-17 2U+ CEK Heatsink Thermal Performance...............................................................41

2-18 1U CEK Heatsink Thermal Performance.................................................................42

2-19 2U+CEK Thermal Adherence to Quad-Core Intel® Xeon® Processor X5400

Series Thermal Profile A......................................................................................43

2-20 1U CEK Thermal Adherence to Quad-Core Intel® Xeon® Processor X5400

Series Thermal Profile B......................................................................................44

2-21 1U CEK Thermal Adherence to Quad-Core Intel® Xeon® Processor E5400

Series Thermal Profile ........................................................................................45

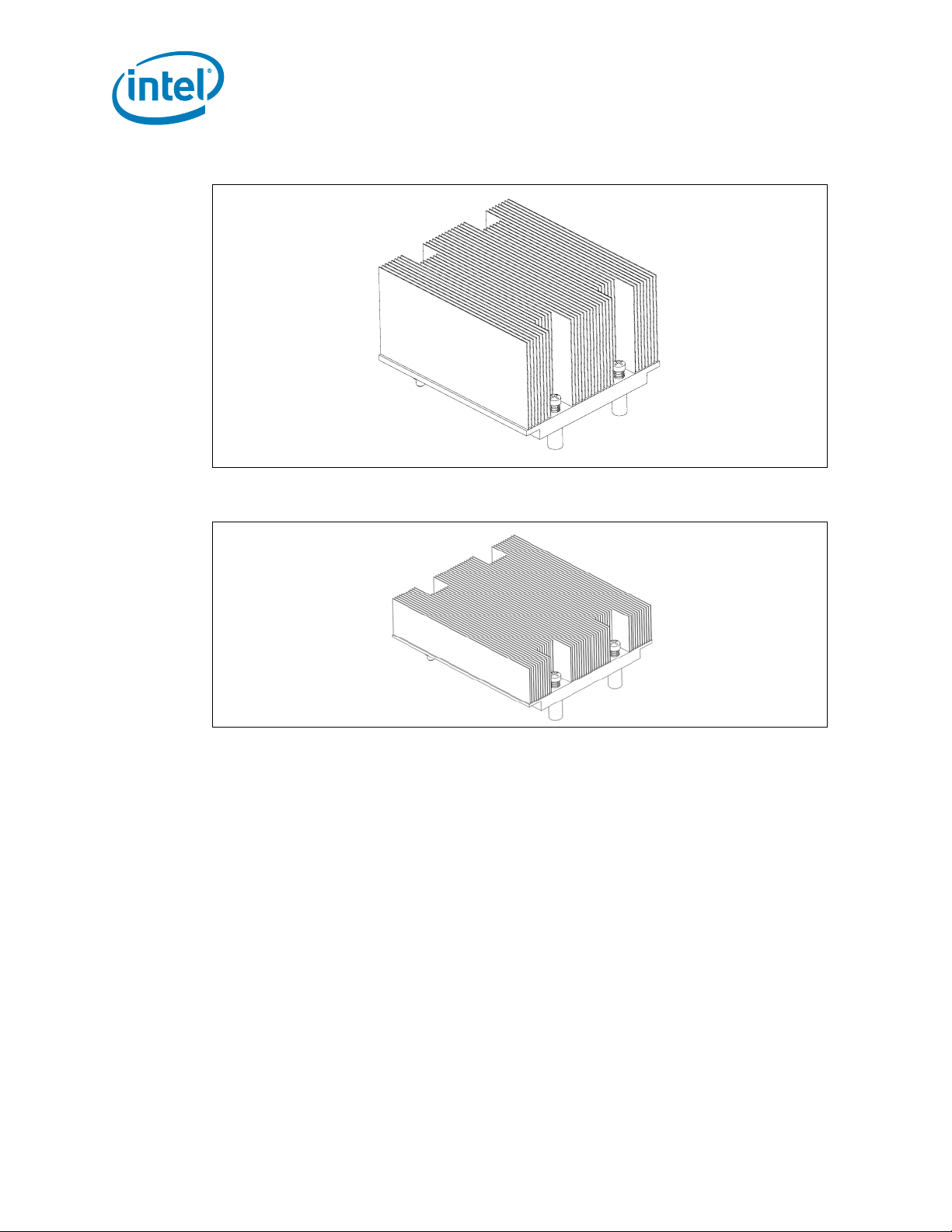

2-22 Isometric View of the 2U+ CEK Heatsink...............................................................46

2-23 Isometric View of the 1U CEK Heatsink .................................................................46

2-24 CEK Spring Isometric View..................................................................................48

2-25 Isometric View of CEK Spring Attachment to the Base Board ...................................48

2-26 Boxed Active CEK Heatsink Solutions with PWM/DTS Control

(Representation Only) ........................................................................................49

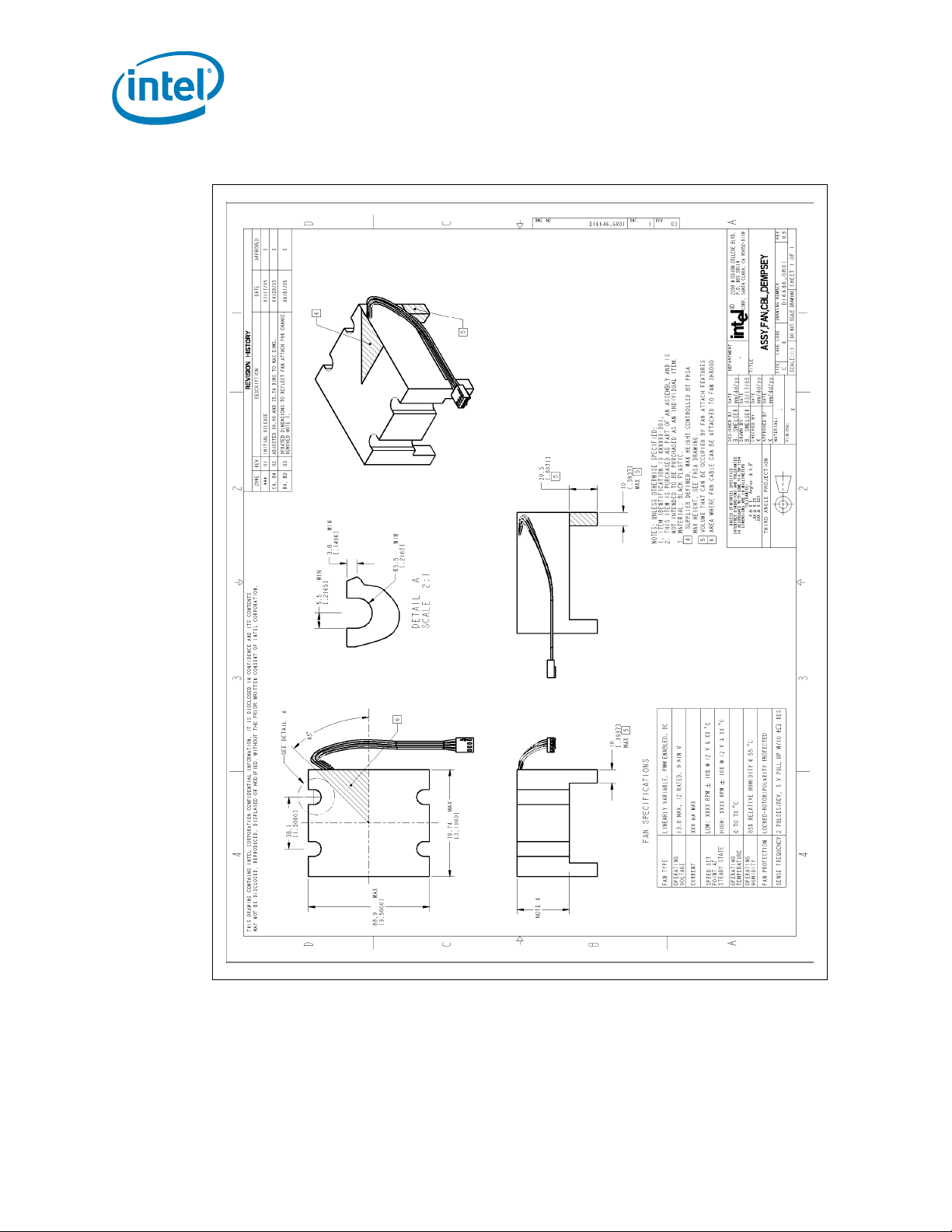

2-27 Fan Cable Connection (Active CEK) ......................................................................50

A-1 Isometric View of the 1U Alternative Heatsink........................................................53

A-2 1U Alternative Heatsink Thermal Performance .......................................................54

A-3 1U Alternative Heatsink Thermal Adherence to Quad-Core Intel® Xeon®

Processor L5400 Series Thermal Profile.................................................................55

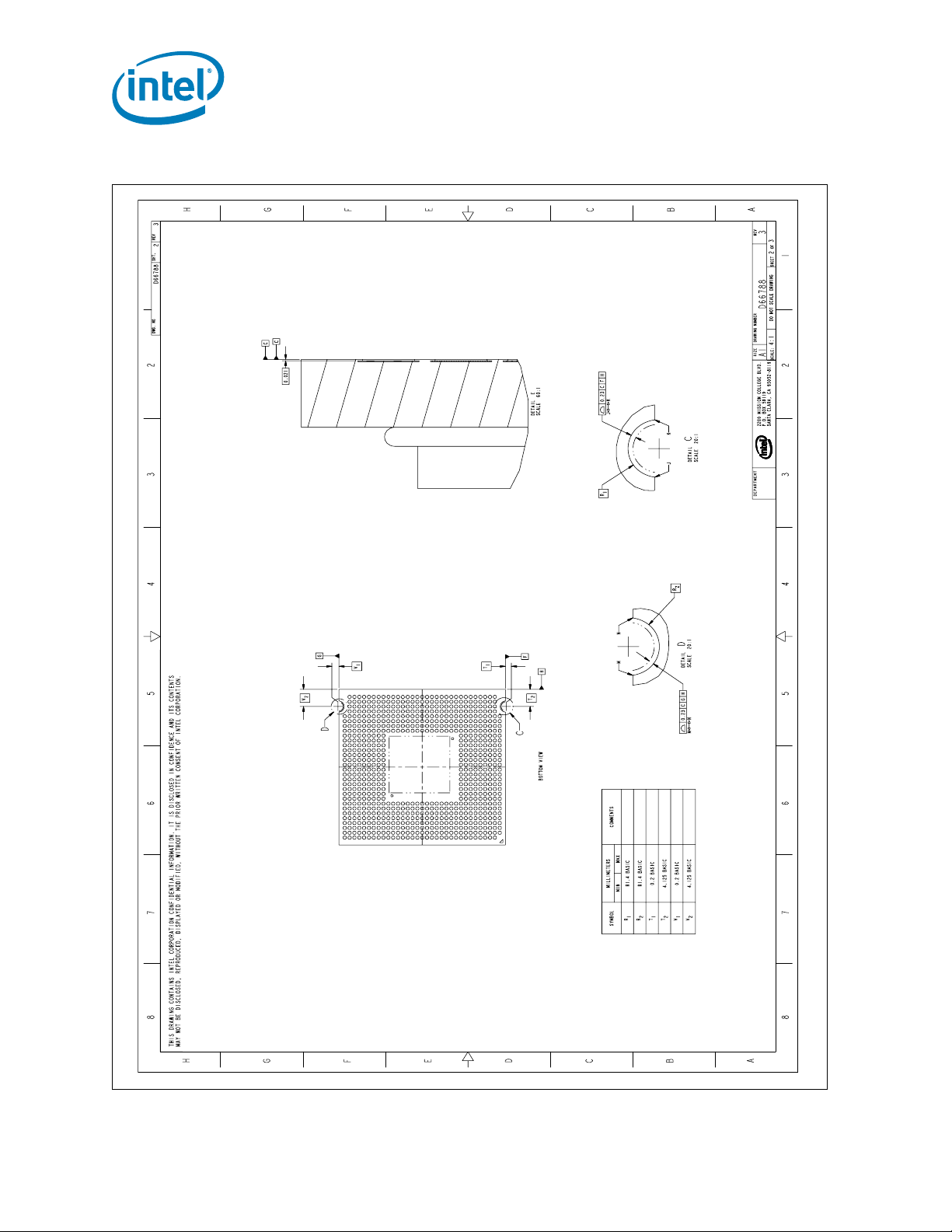

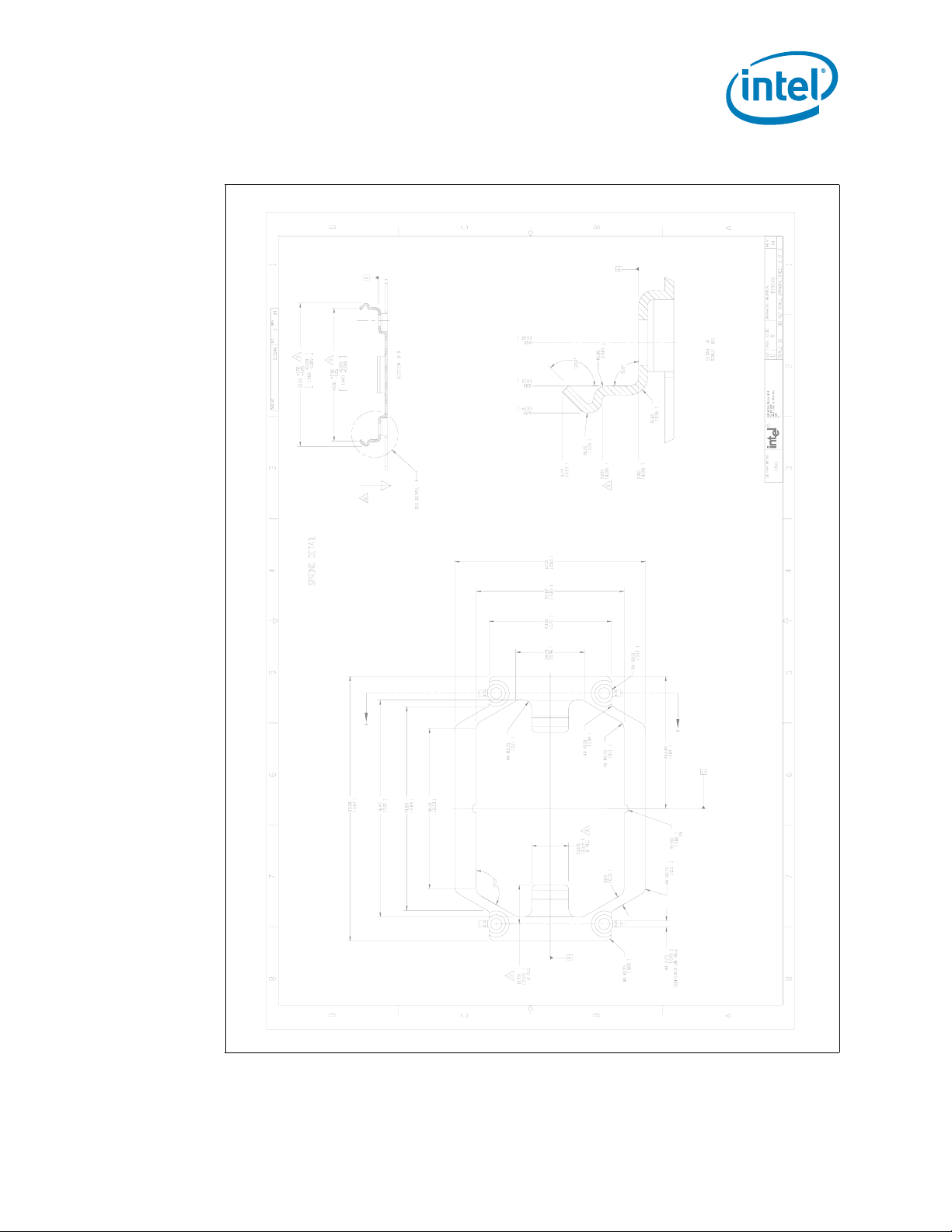

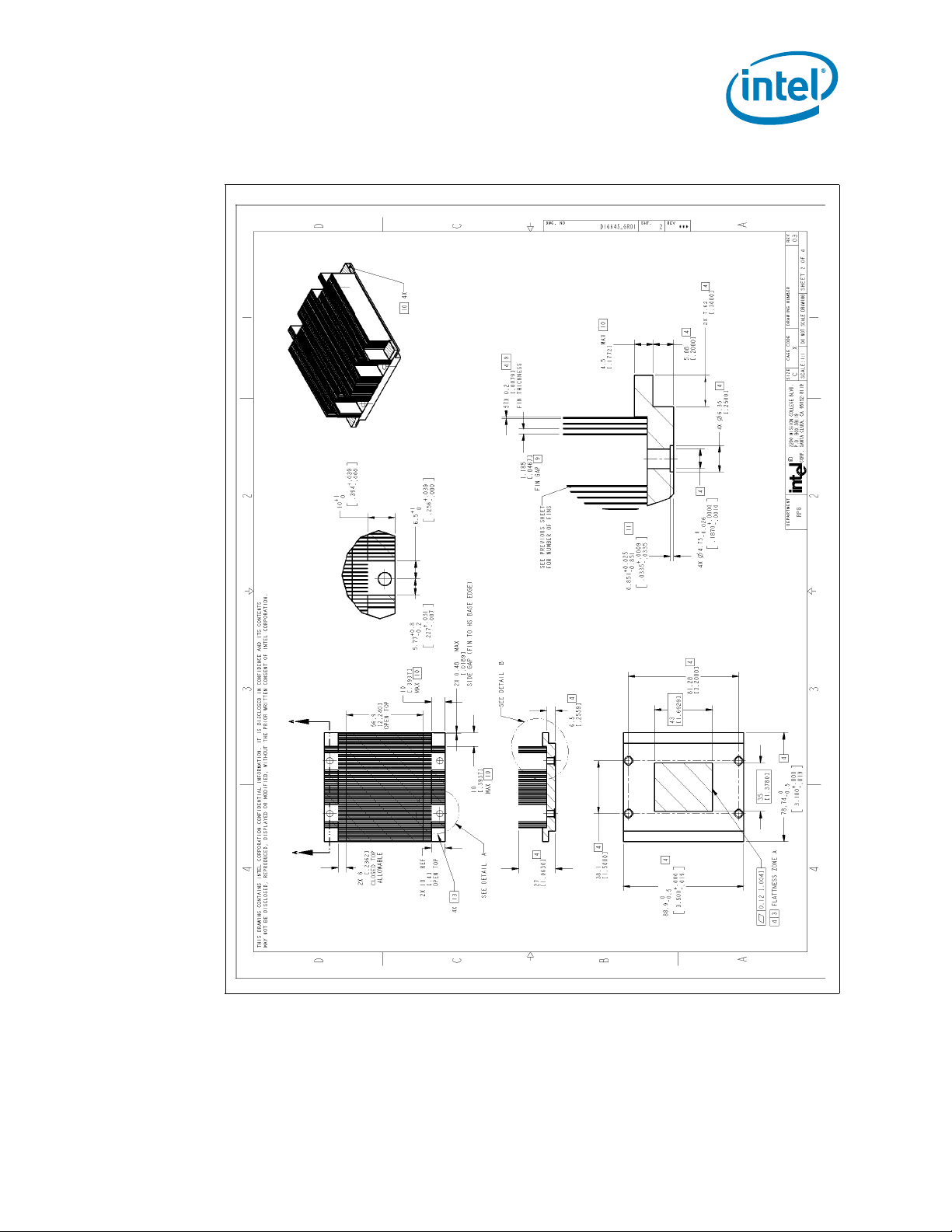

B-1 2U CEK Heatsink (Sheet 1 of 4) ...........................................................................58

B-2 2U CEK Heatsink (Sheet 2 of 4) ...........................................................................59

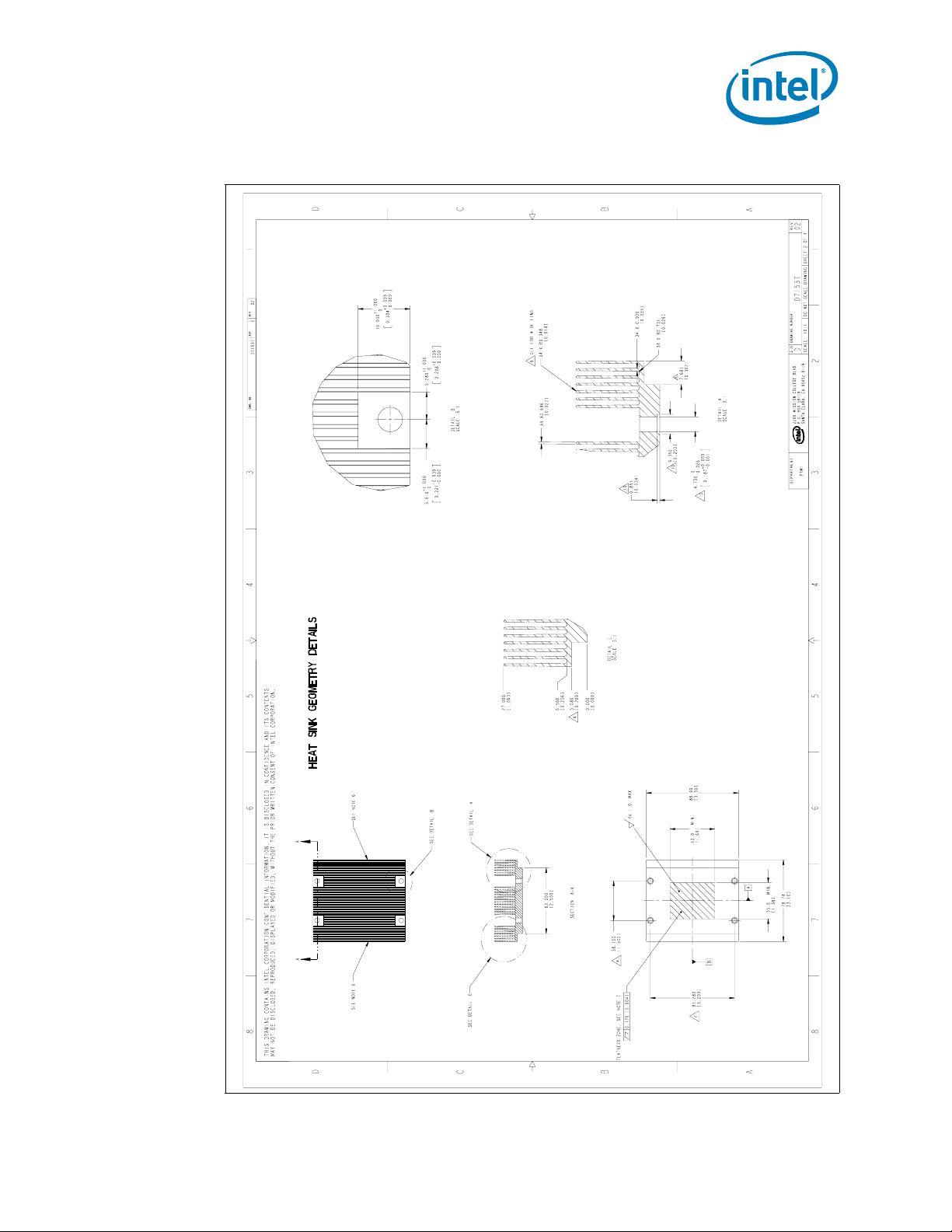

B-3 2U CEK Heatsink (Sheet 3 of 4) ...........................................................................60

B-4 2U CEK Heatsink (Sheet 4 of 4) ...........................................................................61

4 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 5

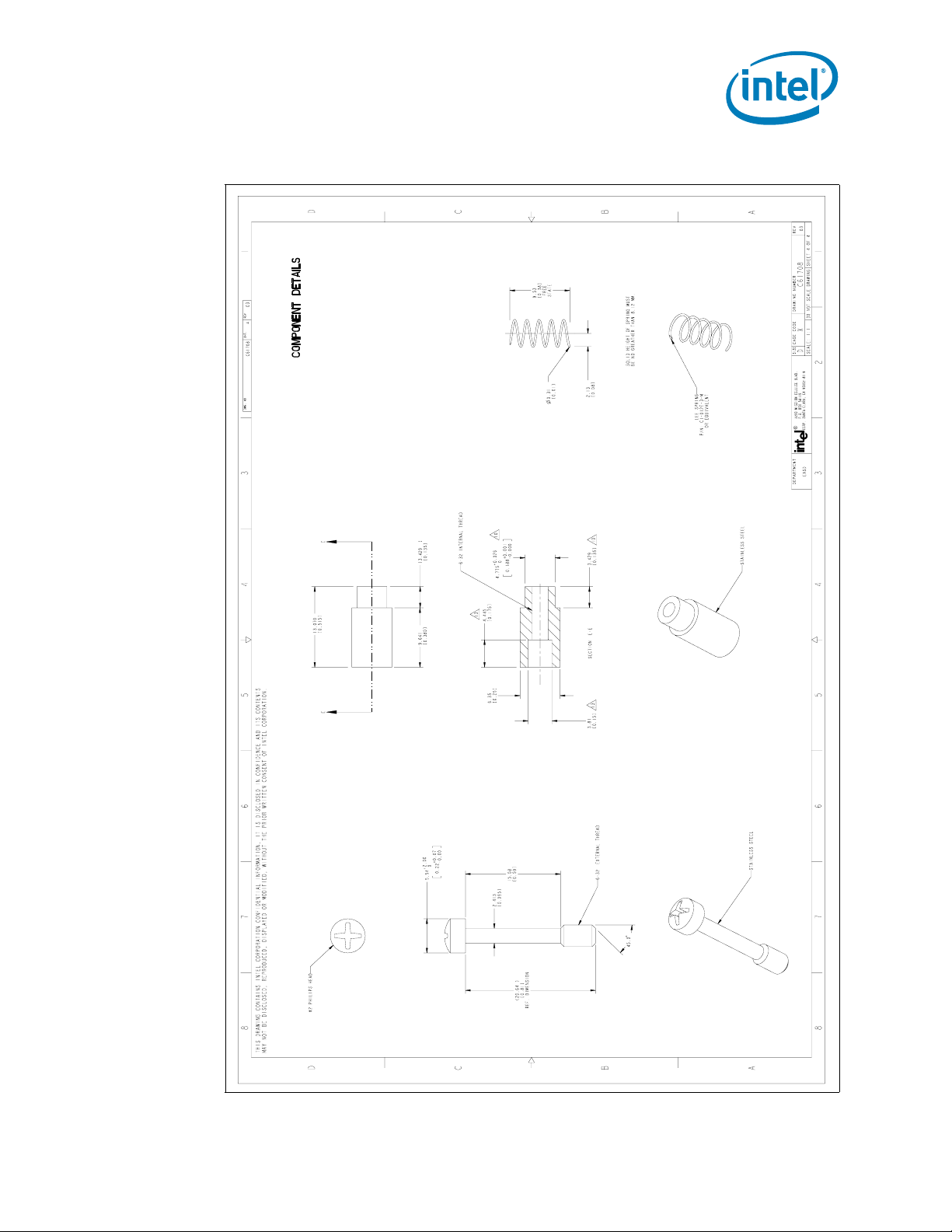

B-5 CEK Spring (Sheet 1 of 3) .................................................................................. 62

B-6 CEK Spring (Sheet 2 of 3) .................................................................................. 63

B-7 CEK Spring (Sheet 3 of 3) .................................................................................. 64

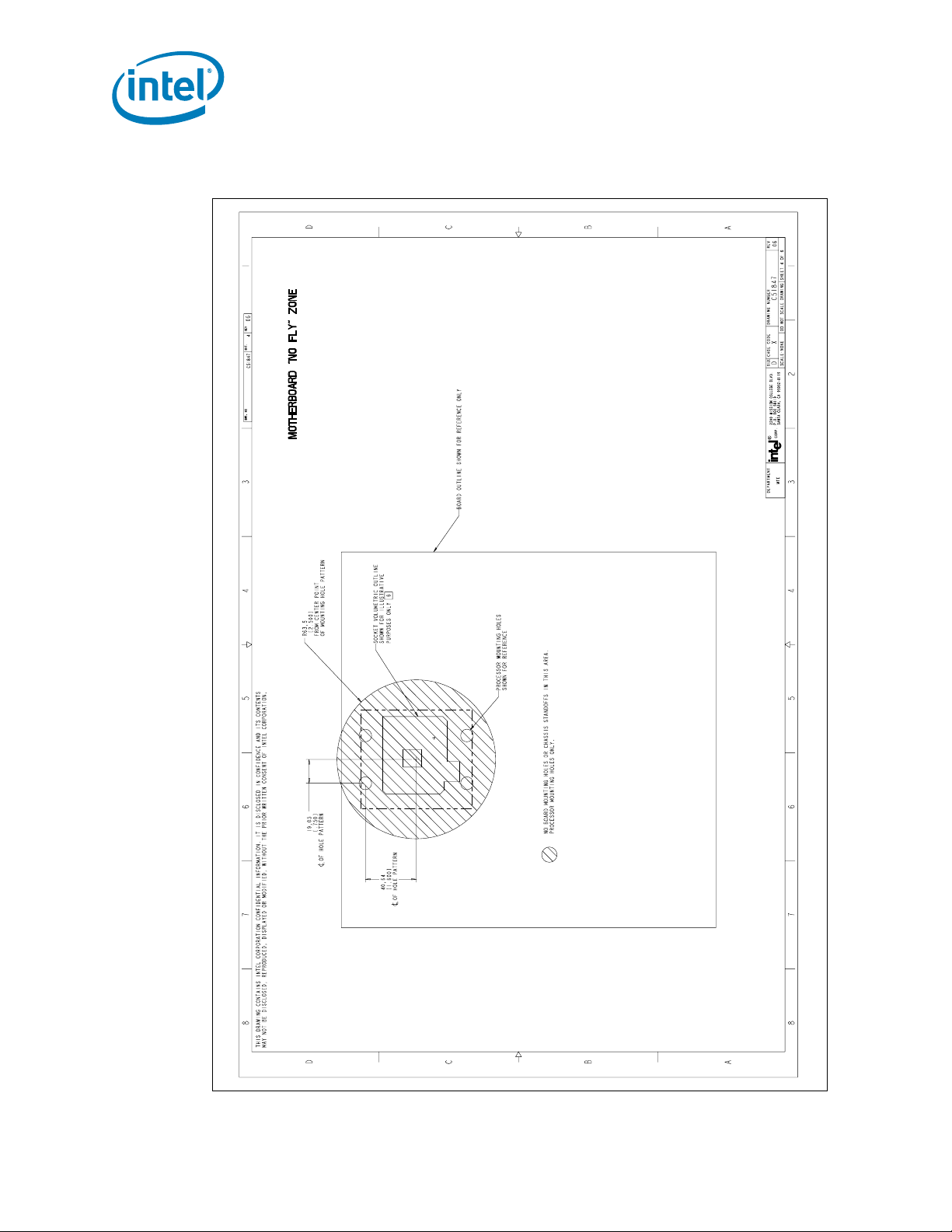

B-8 Baseboard Keepout Footprint Definition and Height Restrictions for

Enabling Components (Sheet 1 of 6).................................................................... 65

B-9 Baseboard Keepout Footprint Definition and Height Restrictions for

Enabling Components (Sheet 2 of 6).................................................................... 66

B-10 Baseboard Keepout Footprint Definition and Height Restrictions for

Enabling Components (Sheet 3 of 6).................................................................... 67

B-11 Baseboard Keepout Footprint Definition and Height Restrictions for

Enabling Components (Sheet 4 of 6).................................................................... 68

B-12 Baseboard Keepout Footprint Definition and Height Restrictions for

Enabling Components (Sheet 5 of 6).................................................................... 69

B-13 Baseboard Keepout Footprint Definition and Height Restrictions for

Enabling Components (Sheet 6 of 6).................................................................... 70

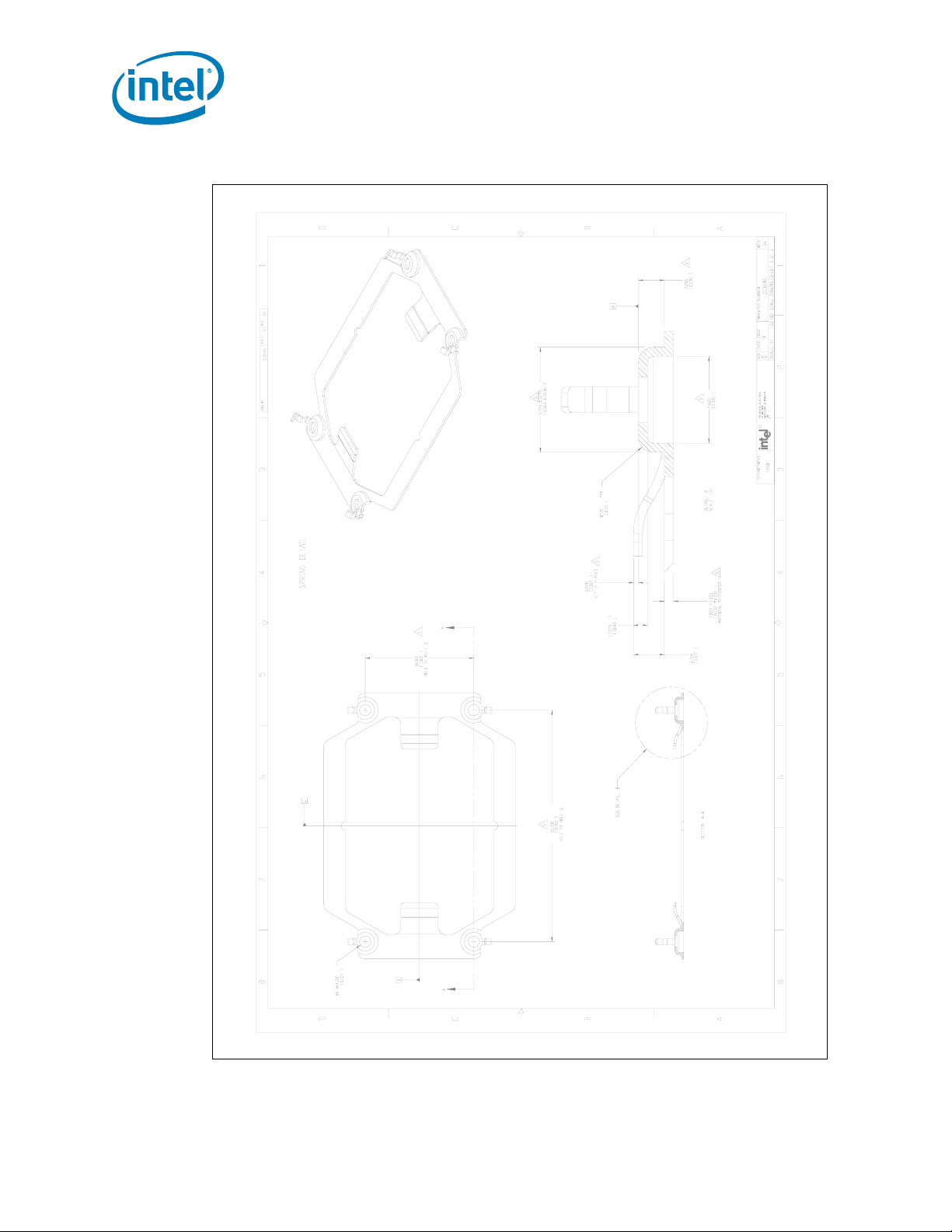

B-14 1U CEK Heatsink (Sheet 1 of 4)........................................................................... 71

B-15 1U CEK Heatsink (Sheet 2 of 4)........................................................................... 72

B-16 1U CEK Heatsink (Sheet 3 of 4)........................................................................... 73

B-17 1U CEK Heatsink (Sheet 4 of 4)........................................................................... 74

B-18 Active CEK Thermal Solution Volumetric (Sheet 1 of 3)........................................... 75

B-19 Active CEK Thermal Solution Volumetric (Sheet 2 of 3)........................................... 76

B-20 Active CEK Thermal Solution Volumetric (Sheet 3 of 3)........................................... 77

B-21 1U Alternative Heatsink (1 of 4) .......................................................................... 78

B-22 1U Alternative Heatsink (2 of 4) .......................................................................... 79

B-23 1U Alternative Heatsink (3 of 4) .......................................................................... 80

B-24 1U Alternative Heatsink (4 of 4) .......................................................................... 81

C-1 Load Cell Installation in Machined Heatsink Base Pocket - Bottom View..................... 84

C-2 Load Cell Installation in Machined Heatsink Base Pocket - Side View......................... 85

C-3 Preload Test Configuration.................................................................................. 85

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 5

Page 6

Tables

1-1 Reference Documents.......................................................................................... 9

1-2 Terms and Descriptions ......................................................................................10

2-1 Processor Mechanical Parameters Table ................................................................13

2-2 Input and Output Conditions for the Quad-Core Intel® Xeon® Processor 5400

Series Thermal Management Features ..................................................................22

2-3 Processor Core Geometric Center Dimensions........................................................23

2-4 Intel Reference Heatsink Performance Targets for the Quad-Core Intel®

Xeon® Processor X5400 Series............................................................................31

2-5 Intel Reference Heatsink Performance Targets for the Quad-Core Intel®

Xeon® Processor E5400 Series............................................................................32

2-6 Fan Speed Control, TCONTROL and DTS Relationship..............................................34

2-7 CEK Heatsink Thermal Mechanical Characteristics...................................................47

2-8 Recommended Thermal Grease Dispense Weight ...................................................47

2-9 Fan Specifications (Boxed 4-wire PWM/DTS Heatsink Solution) ................................50

2-10 Fan Cable Connector Pin Out (Active CEK).............................................................51

A-1 1U Alternative Heatsink Thermal Mechanical Characteristics ....................................54

B-1 Mechanical Drawing List......................................................................................57

C-1 Typical Test Equipment.......................................................................................86

E-1 Use Conditions Environment................................................................................92

F-1 Suppliers for the Quad-Core Intel® Xeon® Processor 5400 Series Intel

Reference Solution.............................................................................................95

F-2 Additional Suppliers for the Quad-Core Intel® Xeon® Processor 5400 Series

Intel Reference Solution .....................................................................................97

6 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 7

Revision History

Reference

Number

318611 001 Initial release of the document. November 2007

Revision

Number

Description Date

§

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 7

Page 8

8 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 9

Introduction

1 Introduction

1.1 Objective

The purpose of this guide is to describe the reference thermal solution and design

parameters required for the Quad-Core Intel® Xeon® Processor 5400 Series.

It is also the intent of this document to comprehend and demonstrate the processor

cooling solution features and requirements. Furthermore, this document provides an

understanding of the processor thermal characteristics, and discusses guidelines for

meeting the thermal requirements imposed over the entire life of the processor. The

thermal/mechanical solutions described in this document are intended to aid

component and system designers in the development and evaluation of processor

compatible thermal/mechanical solutions.

1.2 Scope

The thermal/mechanical solutions described in this document pertain to a solution(s)

intended for use with the Quad-Core Intel® Xeon® Processor 5400 Series in 1U, 2U,

2U+ and workstation form factors systems. This document contains the mechanical

and thermal requirements of the processor cooling solution. In case of conflict, the data

in the Quad-Core Intel® Xeon® Processor 5400 Series Datasheet supersedes any data

in this document. Additional information is provided as a reference in the appendices.

1.3 References

Material and concepts available in the following documents may be beneficial when

reading this document.

Table 1-1. Reference Documents (Sheet 1 of 2)

Document Comment

European Blue Angel Recycling Standards http://www.blauer-engel.de

®

Intel

Xeon® Dual- and Multi- Processor Family Thermal Test Vehicle

User's Guide

LGA771 Socket Mechanical Design Guide See Note following table.

LGA771 SMT Socket Design Guidelines See Note following table.

LGA771 Daisy Chain Test Vehicle User Guide See Note following table.

Stoakley Platform Design Guide (PDG) See Note following table.

Dual-Core Intel

Guide (PDG)

Dual-Core Intel

Guide (PDG)

Clovertown, Harpertown & Wolfdale-DP Processors Compatibility Design

Guide for Bensley, Bensley-VS, and Glidewell Platforms

PECI Feature Set Overview See Note following table

Platform Environment Control Interface(PECI) Specification See Note following table

Quad-Core Intel® Xeon® Processor 5400 Series Datasheet See Note following table.

Clovertown_Harpertown_Wolfdale-DP Processor Enabled CEK and

Package Mechanical Models (in IGES and ProE* format)

®

Xeon® Processor-Based Servers Platform Design

®

Xeon® Processor-Based Workstation Platform Design

See Note at bottom table.

See Note following table.

See Note following table.

See Note following table.

Available electronically

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 9

Page 10

Table 1-1. Reference Documents (Sheet 2 of 2)

Document Comment

Clovertown_Harpertown_Wolfdale-DP Processor Enabled Components

CEK Thermal Models (in Flotherm* and Icepak*)

Clovertown_Harpertown_Wolfdale-DP Processor Package Thermal

Models (in Flotherm and Icepak)

RS - Wolfdale Processor Family BIOS Writers Guide (BWG) See Note following table.

Thin Electronics Bay Specification (A Server System Infrastructure (SSI)

Specification for Rack Optimized Servers

Note: Contact your Intel field sales representative for the latest revision and order number of this document.

1.4 Definition of Terms

Table 1-2. Terms and Descriptions (Sheet 1 of 2)

Term Description

Bypass Bypass is the area between a passive heatsink and any object that can act to form a

DTS Digital Thermal Sensor replaces the Tdiode in previous products and

MSR The processor provides a variety of model specific registers that are used to control and

FMB Flexible Motherboard Guideline: an estimate of the maximum value of a processor

FSC Fan Speed Control

IHS Integrated Heat Spreader: a component of the processor package used to enhance the

LGA771 Socket The Quad-Core Intel® Xeon® Processor 5400 Series interfaces to the baseboard

P

MAX

PECI A proprietary one-wire bus interface that provides a communication channel between

Ψ

CA

Ψ

CS

Ψ

SA

T

CASE

T

CASE_MAX

TCC Thermal Control Circuit: Thermal monitor uses the TCC to reduce the die temperature

duct. For this example, it can be expressed as a dimension away from the outside

dimension of the fins to the nearest surface.

sensor as the PROCHOT# sensor to indicate the on-die temperature. The temperature

value represents the number of degrees below the TCC activation temperature.

report on processor performance. Virtually all MSRs handle system related functions and

are not accessible to an application program.

specification over certain time periods. System designers should meet the FMB values to

ensure their systems are compatible with future processor releases.

thermal performance of the package. Component thermal solutions interface with the

processor at the IHS surface.

through this surface mount, 771 Land socket. See the LGA771 Socket Mechanical

Design Guide for details regarding this socket.

The maximum power dissipated by a semiconductor component.

Intel processor and chipset components to external thermal monitoring devices, for use

in fan speed control. PECI communicates readings from the processors Digital Thermal

Sensor. PECI replaces the thermal diode available in previous processors.

Case-to-ambient thermal characterization parameter (psi). A measure of thermal

solution performance using total package power. Defined as (T

Package Power. Heat source should always be specified for Ψ measurements.

Case-to-sink thermal characterization parameter. A measure of thermal interface

material performance using total package power. Defined as (T

Package Power.

Sink-to-ambient thermal characterization parameter. A measure of heatsink thermal

performance using total package power. Defined as (T

The case temperature of the processor, measured at the geometric center of the topside

of the IHS.

The maximum case temperature as specified in a component specification.

by using clock modulation and/or operating frequency and input voltage adjustment

when the die temperature is very near its operating limits.

Introduction

Available electronically

Available electronically

www.ssiforum.com

uses the same

– TLA) / Total

CASE

– TS) / Total

CASE

– TLA) / Total Package Power.

S

10 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 11

Introduction

Table 1-2. Terms and Descriptions (Sheet 2 of 2)

T

CONTROL

T

OFFSET

TDP Thermal Design Power: Thermal solution should be designed to dissipate this target

Thermal Monitor A feature on the processor that can keep the processor’s die temperature within factory

Thermal Profile Line that defines case temperature specification of a processor at a given power level.

TIM Thermal Interface Material: The thermally conductive compound between the heatsink

T

LA

T

SA

U A unit of measure used to define server rack spacing height. 1U is equal to 1.75 in, 2U

A processor unique value for use in fan speed control mechanisms. T

temperature specification based on a temperature reading from the processor’s Digital

Thermal Sensor. T

implementation. T

An offset value from the TCC activation temperature value programmed into each

processor during manufacturing and can be obtained by reading the

IA_32_TEMPERATURE_TARGET MSR. This is a static and a unique value. Refer to the

can be described as a trigger point for fan speed control

CONTROL

= -T

CONTROL

RS - Wolfdale Processor Family BIOS Writers Guide (BWG) for further details.

power level. TDP is not the maximum power that the processor can dissipate.

specifications under normal operating conditions.

and the processor case. This material fills the air gaps and voids, and enhances the

transfer of the heat from the processor case to the heatsink.

The measured ambient temperature locally surrounding the processor. The ambient

temperature should be measured just upstream of a passive heatsink or at the fan inlet

for an active heatsink.

The system ambient air temperature external to a system chassis. This temperature is

usually measured at the chassis air inlets.

equals 3.50 in, etc.

OFFSET

is a

CONTROL

.

§

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 11

Page 12

Introduction

12 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 13

Thermal/Mechanical Reference Design

2 Thermal/Mechanical Reference

Design

This chapter describes the thermal/mechanical reference design for Quad-Core Intel®

Xeon® Processor 5400 Series. Both Quad-Core Intel® Xeon® Processor X5400 Series

and Quad-Core Intel® Xeon® Processor E5400 Series are targeted for the full range of

form factors (2U, 2U+ and 1U). The Quad-Core Intel® Xeon® Processor X5482 sku is

an ultra performance version of the Quad-Core Intel® Xeon® Processor 5400 Series

with 150W TDP and is use only in workstation platforms.

2.1 Mechanical Requirements

The mechanical performance of the processor cooling solution must satisfy the

requirements described in this section.

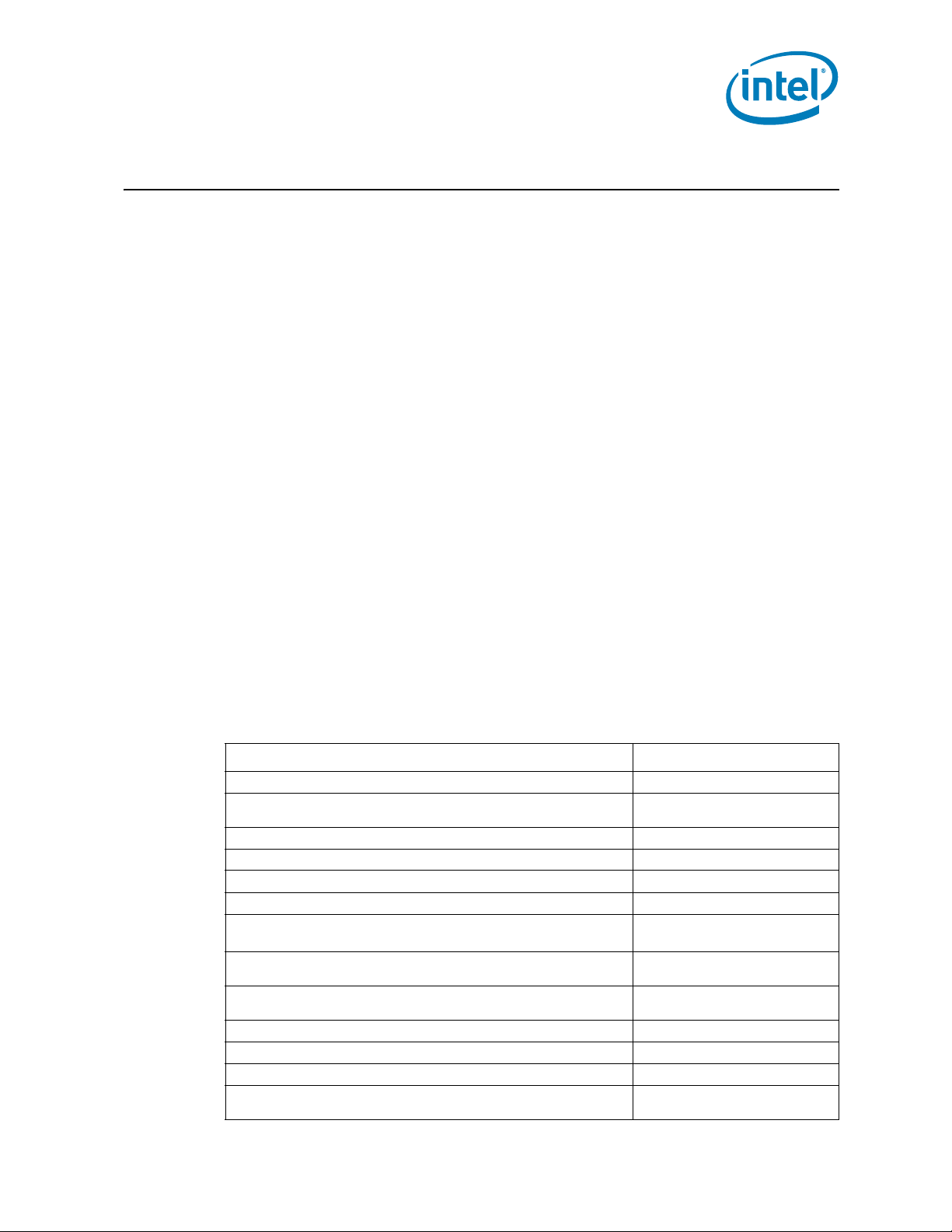

2.1.1 Processor Mechanical Parameters

Table 2-1. Processor Mechanical Parameters Table

Parameter Minimum Maximum Unit Notes

Volumetric Requirements and Keepouts 1

Static Compressive Load 3

Static Board Deflection 3

Dynamic Compressive Load 3

Tra n s ient B e n d 3

Shear Load 70

Tensile Load 25

Torsi on L o a d 35

Notes:

1. Refer to drawings in Appendix B.

2. In the case of a discrepancy, the most recent Quad-Core Intel® Xeon® Processor 5400 Series Datasheet

and LGA771 Socket Mechanical Design Guide supersede targets listed in Ta bl e 2 -1 above.

3. These socket limits are defined in the LGA771 Socket Mechanical Design Guide.

4. These package handling limits are defined in the Quad-Core Intel® Xeon® Processor 5400 Series

Datasheet.

5. Shear load that can be applied to the package IHS.

6. Tensile load that can be applied to the package IHS.

7. Torque that can be applied to the package IHS.

311

111

3.95

lbf

N

lbf

N

in*lbf

N*m

2,4,5

2,4,6

2,4,7

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 13

Page 14

Thermal/Mechanical Reference Design

2.1.2 Quad-Core Intel® Xeon® Processor 5400 Series Package

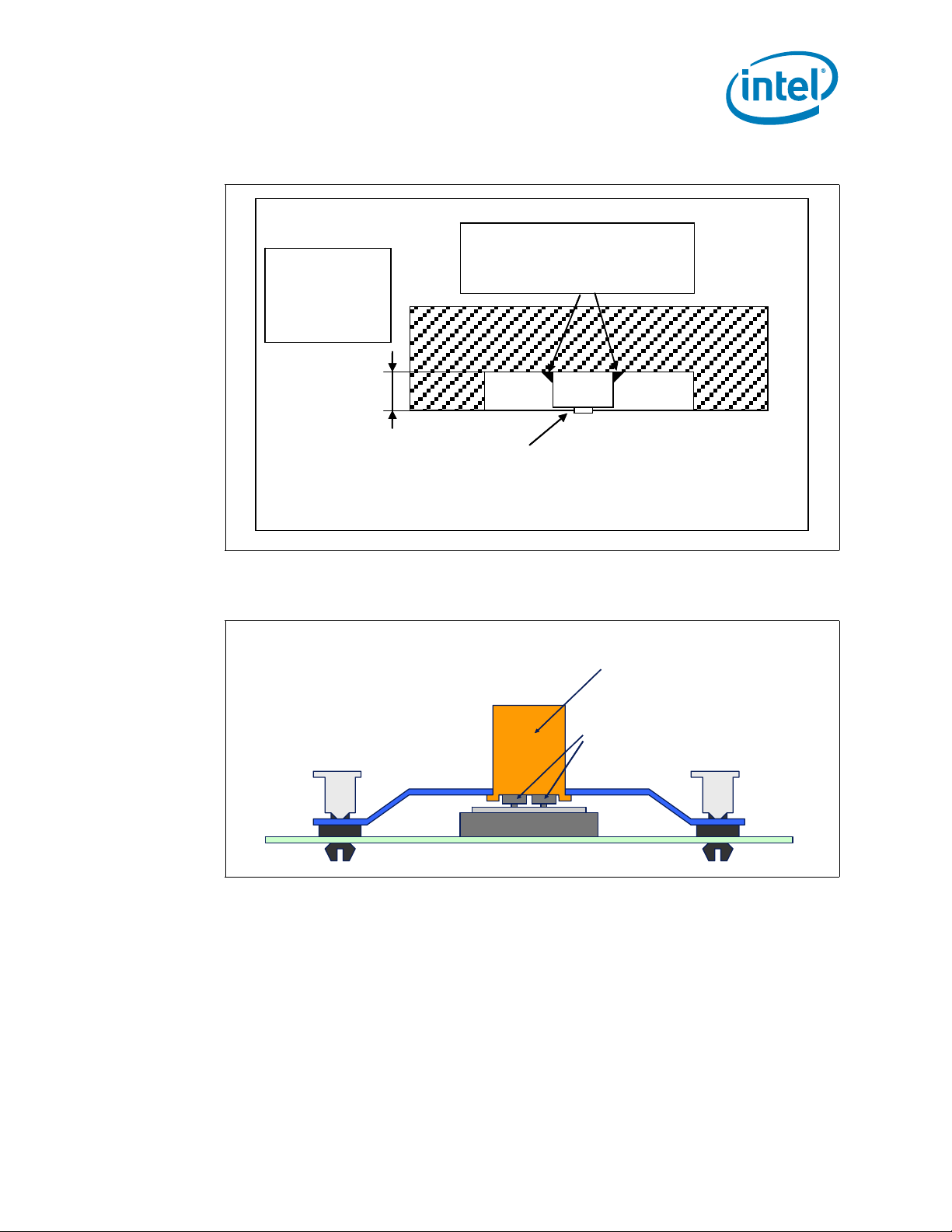

The Quad-Core Intel® Xeon® Processor 5400 Series is packaged using the flip-chip

land grid array (FC-LGA) package technology. Please refer to the Quad-Core Intel®

Xeon® Processor 5400 Series Datasheet for detailed mechanical specifications. The

Quad-Core Intel® Xeon® Processor 5400 Series mechanical drawing shown in

Figure 2-1, Figure 2-2, and Figure 2-3 provide the mechanical information for the

Quad-Core Intel® Xeon® Processor 5400 Series. The drawing is superseded with the

drawing in the processor datasheet should there be any conflicts. Integrated package/

socket stackup height information is provided in the LGA771 Socket Mechanical Design

Guide.

14 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 15

Thermal/Mechanical Reference Design

Figure 2-1. Quad-Core Intel® Xeon® Processor 5400 Series Mechanical Drawing (1 of 3)

Note: Guidelines on potential IHS flatness variation with socket load plate actuation and installation of the cooling solution are

available in the processor Thermal/Mechanical Design Guidelines.

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 15

Page 16

Thermal/Mechanical Reference Design

Figure 2-2. Quad-Core Intel® Xeon® Processor 5400 Series Mechanical Drawing (2 of 3)

16 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 17

Thermal/Mechanical Reference Design

Figure 2-3. Quad-Core Intel® Xeon® Processor 5400 Series Mechanical Drawing (3 of 3)

Note: The optional dimple packing marking highlighted by Detail F from the above drawing may only be found on initial

processors.

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 17

Page 18

Thermal/Mechanical Reference Design

The package includes an integrated heat spreader (IHS). The IHS transfers the nonuniform heat from the die to the top of the IHS, out of which the heat flux is more

uniform and spreads over a larger surface area (not the entire IHS area). This allows

more efficient heat transfer out of the package to an attached cooling device. The IHS

is designed to be the interface for contacting a heatsink. Details can be found in the

Quad-Core Intel® Xeon® Processor 5400 Series Datasheet.

The processor connects to the baseboard through a 771-land surface mount socket. A

description of the socket can be found in the LGA771 Socket Mechanical Design Guide.

The processor package and socket have mechanical load limits that are specified in the

Quad-Core Intel® Xeon® Processor 5400 Series Datasheet and the LGA771 Socket

Mechanical Design Guide. These load limits should not be exceeded during heatsink

installation, removal, mechanical stress testing, or standard shipping conditions. For

example, when a compressive static load is necessary to ensure thermal performance

of the Thermal Interface Material (TIM) between the heatsink base and the IHS, it

should not exceed the corresponding specification given in the LGA771 Socket

Mechanical Design Guide.

The heatsink mass can also add additional dynamic compressive load to the package

during a mechanical shock event. Amplification factors due to the impact force during

shock must be taken into account in dynamic load calculations. The total combination

of dynamic and static compressive load should not then exceed the processor/socket

compressive dynamic load specified in the LGA771 Socket Mechanical Design Guide

during a vertical shock. It is not recommended to use any portion of the processor

substrate as a mechanical reference or load-bearing surface in either static or dynamic

compressive load conditions.

2.1.3 Quad-Core Intel® Xeon® Processor 5400 Series Considerations

An attachment mechanism must be designed to support the heatsink since there are no

features on the LGA771 socket to directly attach a heatsink. In addition to holding the

heatsink in place on top of the IHS, this mechanism plays a significant role in the

robustness of the system in which it is implemented, in particular:

• Ensuring thermal performance of the TIM applied between the IHS and the

heatsink. TIMs, especially ones based on phase change materials, are very

sensitive to applied pressure: the higher the pressure, the better the initial

performance. TIMs such as thermal greases are not as sensitive to applied

pressure. Refer to Section 2.5.2 and Section 2.5.7.2 for information on tradeoffs

made with TIM selection. Designs should consider possible decrease in applied

pressure over time due to potential structural relaxation in enabled components.

• Ensuring system electrical, thermal, and structural integrity under shock and

vibration events. The mechanical requirements of the attach mechanism depend on

the weight of the heatsink and the level of shock and vibration that the system

must support. The overall structural design of the baseboard and system must be

considered when designing the heatsink attach mechanism. Their design should

provide a means for protecting LGA771 socket solder joints as well as preventing

package pullout from the socket.

Note: The load applied by the attachment mechanism must comply with the package and

socket specifications, along with the dynamic load added by the mechanical shock and

vibration requirements, as identified in Section 2.1.1.

18 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 19

Thermal/Mechanical Reference Design

A potential mechanical solution for heavy heatsinks is the direct attachment of the

heatsink to the chassis pan. In this case, the strength of the chassis pan can be utilized

rather than solely relying on the baseboard strength. In addition to the general

guidelines given above, contact with the baseboard surfaces should be minimized

during installation in order to avoid any damage to the baseboard.

The Intel reference design for Quad-Core Intel® Xeon® Processor 5400 Series is using

such a heatsink attachment scheme. Refer to Section 2.5 for further information

regarding the Intel reference mechanical solution.

2.2 Processor Thermal Parameters and Features

2.2.1 Thermal Control Circuit and TDP

The operating thermal limits of the processor are defined by the Thermal Profile. The

intent of the Thermal Profile specification is to support acoustic noise reduction through

fan speed control and ensure the long-term reliability of the processor. This

specification requires that the temperature at the center of the processor IHS, known

as (T

Figure 2-4 shows the measurement location for the Quad-Core Intel® Xeon®

Processor 5400 Series package. Compliance with the T

achieve optimal operation and long-term reliability (See the Intel® Xeon® Dual- and

Multi- Processor Family Thermal Test Vehicle User's Guide for Case Temperature

definition and measurement methods).

Figure 2-4. Processor Case Temperature Measurement Location

) remains within a certain temperature specification. For illustration,

CASE

specification is required to

CASE

To ease the burden on thermal solutions, the Thermal Monitor feature and associated

logic have been integrated into the silicon of the processor. One feature of the Thermal

Monitor is the Thermal Control Circuit (TCC). When active, the TCC lowers the

processor temperature by reducing power consumption. This is accomplished through a

combination of Thermal Monitor and Advanced Thermal Monitor (TM2). Thermal

Monitor modulates the duty cycle of the internal processor clocks, resulting in a lower

effective frequency. When active, the TCC turns the processor clocks off and then back

on with a predetermined duty cycle. Thermal Monitor 2 activation adjusts both the

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 19

Page 20

Thermal/Mechanical Reference Design

processor operating frequency (via the bus multiplier) and input voltage (via the VID

signals). Please refer to the Quad-Core Intel® Xeon® Processor 5400 Series Datasheet

for further details on TM and TM2.

PROCHOT# is designed to assert at or a few degrees higher than maximum T

CASE

(as

specified by the thermal profile) when dissipating TDP power, and can not be

interpreted as an indication of processor case temperature. This temperature delta

accounts for processor package, lifetime, and manufacturing variations and attempts to

ensure the Thermal Control Circuit is not activated below maximum T

CASE

when

dissipating TDP power. There is no defined or fixed correlation between the PROCHOT#

assertion temperature and the case temperature. However, with the introduction of the

Digital Thermal Sensor (DTS) on the Quad-Core Intel® Xeon® Processor 5400 Series,

the DTS reports a relative offset below the PROCHOT# assertion (see Section 2.2.2 for

more details on the Digital Thermal Sensor). Thermal solutions must be designed to the

processor specifications (i.e Thermal Profile) and can not be adjusted based on

experimental measurements of T

, PROCHOT#, or Digital Thermal Sensor on

CASE

random processor samples.

By taking advantage of the Thermal Monitor features, system designers may reduce

thermal solution cost by designing to the Thermal Design Power (TDP) instead of

maximum power. TDP should be used for processor thermal solution design targets.

TDP is not the maximum power that the processor can dissipate. TDP is based on

measurements of processor power consumption while running various high power

applications. This data set is used to determine those applications that are interesting

from a power perspective. These applications are then evaluated in a controlled

thermal environment to determine their sensitivity to activation of the thermal control

circuit. This data set is then used to derive the TDP targets published in the processors

datasheet. The Thermal Monitor can protect the processors in rare workload excursions

above TDP. Therefore, thermal solutions should be designed to dissipate this target

power level. The thermal management logic and thermal monitor features are

discussed in extensive detail in the Quad-Core Intel® Xeon® Processor 5400 Series

Datasheet.

In addition, on-die thermal management features called THERMTRIP# and FORCEPR#

are available on the Quad-Core Intel® Xeon® Processor 5400 Series. They provide a

thermal management approach to support the continued increases in processor

frequency and performance. Please see the Quad-Core Intel® Xeon® Processor 5400

Series Datasheet for guidance on these thermal management features.

2.2.2 Digital Thermal Sensor

The Quad-Core Intel® Xeon® Processor 5400 Series include on-die temperature

sensor feature called Digital Thermal Sensor (DTS). The DTS uses the same sensor

utilized for TCC activation. Each individual processor is calibrated so that TCC activation

occurs at a DTS value of 0. The temperature reported by the DTS is the relative offset

in PECI counts below the onset of the TCC activation and hence is negative. Changes in

PECI counts are roughly linear in relation to temperature changes in degrees Celsius.

For example, a change in PECI count by '1' represents a change in temperature of

approximately 1°C. However, this linearity cannot be guaranteed as the offset below

TCC activation exceeds 20-30 PECI counts. Also note that the DTS will not report any

values above the TCC activation temperature, it will simply return 0 in this case.

The DTS facilitates the use of multiple thermal sensors within the processor without the

burden of increasing the number of thermal sensor signal pins on the processor

package. Operation of multiple DTS will be discussed in more detail in Section 2.2.4.

Also, the DTS utilizes thermal sensors that are optimally located when compared with

thermal diodes available with legacy processors. This is achieved as a result of a

20 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 21

Thermal/Mechanical Reference Design

smaller foot print and decreased sensitivity to noise. These DTS benefits will result in

more accurate fan speed control and TCC activation.The DTS application in fan speed

control will be discussed in more detail in Section 2.4.1.

2.2.3 Platform Environmental Control Interface (PECI)

The PECI interface is designed specifically to convey system management information

from the processor (initially, only thermal data from the Digital Thermal Sensor). It is a

proprietary single wire bus between the processor and the chipset or other health

monitoring device. The PECI specification provides a specific command set to discover,

enumerate devices, and read the temperature. For an overview of the PECI interface,

please refer to PECI Feature Set Overview. For more detailed information on PECI,

please refer to Platform Environment Control Interface (PECI) Specification and Quad-

Core Intel® Xeon® Processor 5400 Series Datasheet.

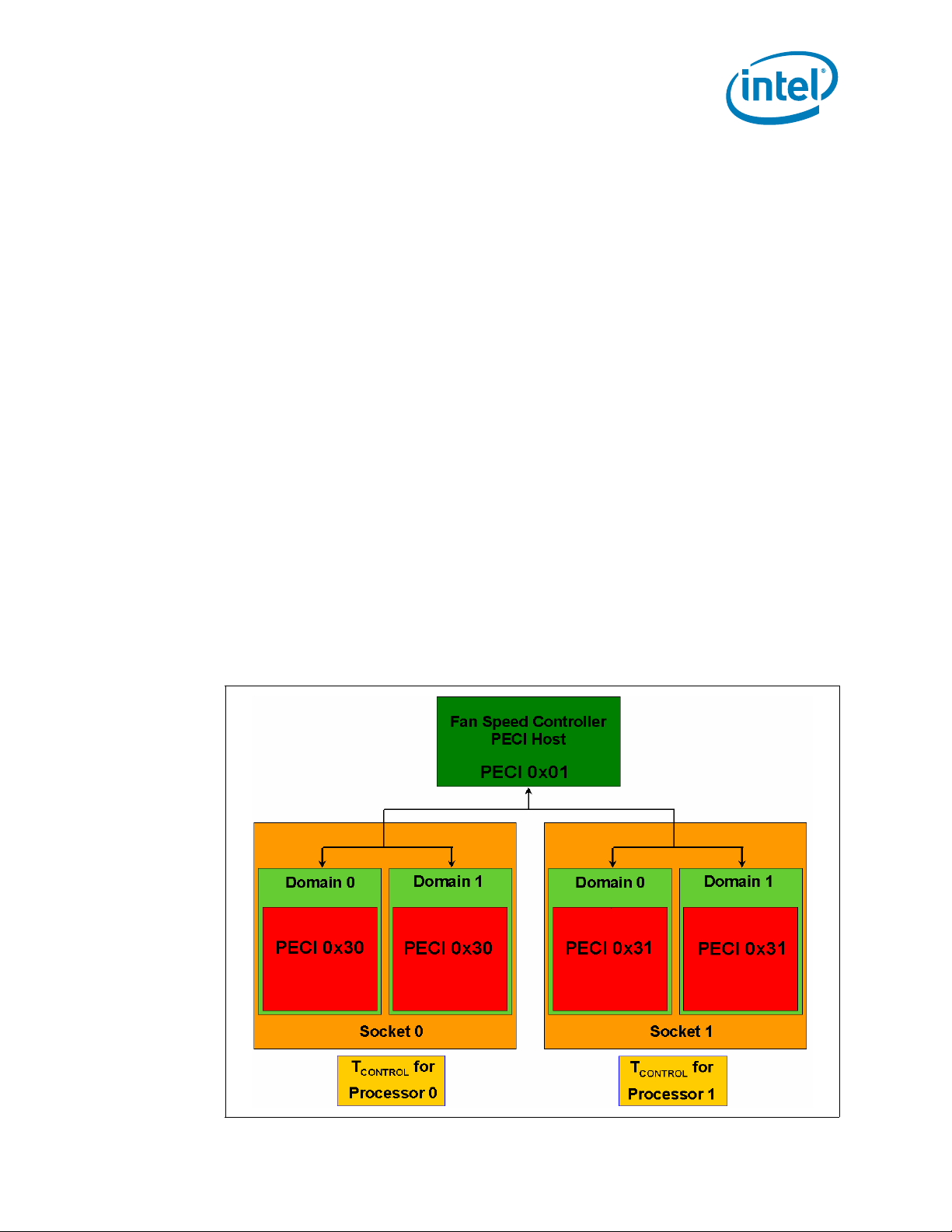

2.2.4 Multiple Core Special Considerations

2.2.4.1 Multiple Digital Thermal Sensor Operation

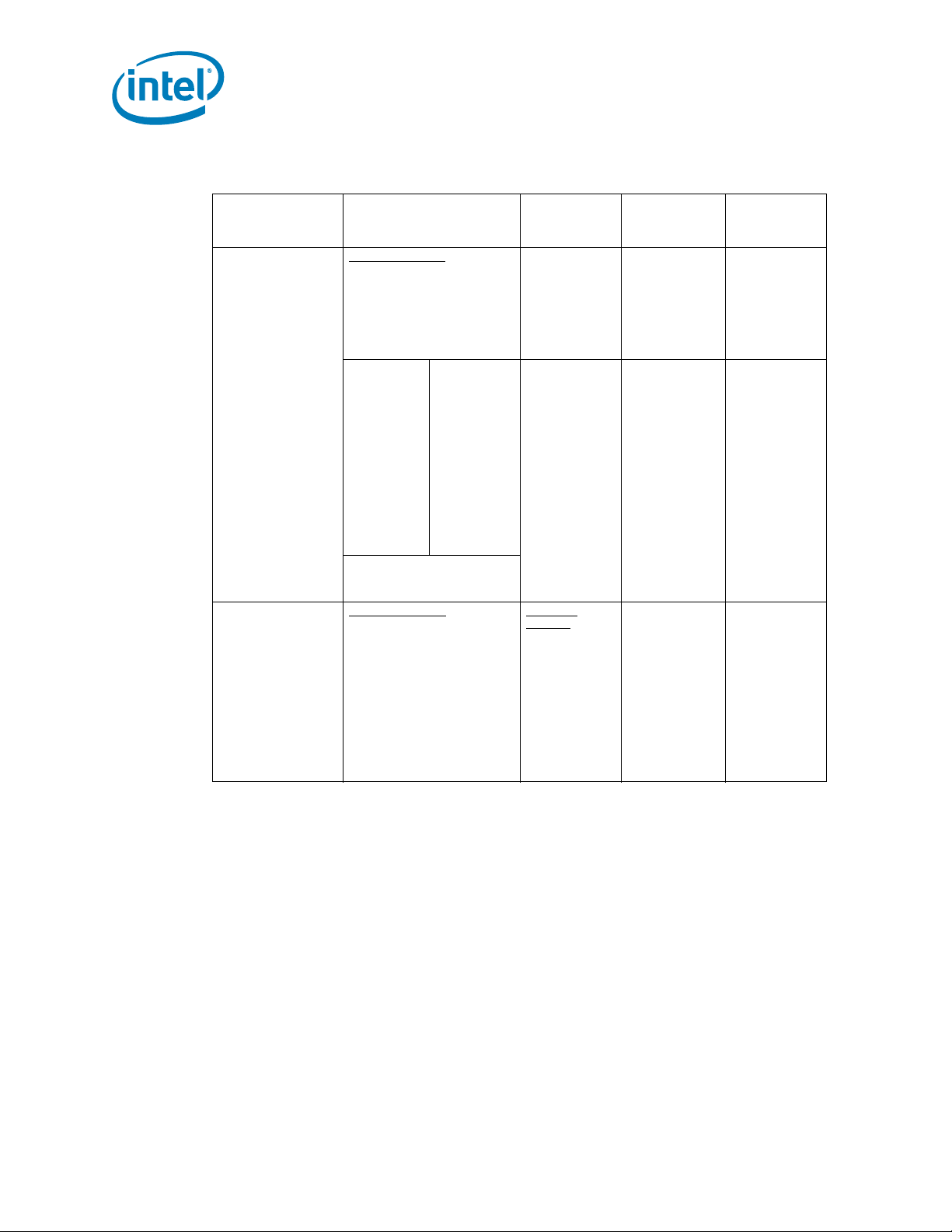

Each Quad-Core Intel® Xeon® Processor 5400 Series can have multiple Digital

Thermal Sensors located on the die. Each die within the processor currently maps to a

PECI domain. The Quad-Core Intel® Xeon® Processor 5400 Series contains two cores

per die (domain) and two domains (die) per socket. BIOS will be responsible for

detecting the proper processor type and providing the number of domains to the

thermal management system. An external PECI device that is part of the thermal

management system polls the processor domains for temperature information and

currently receives the highest of the DTS output temperatures within each domain.

Figure 2-5 provides an illustration of the DTS domains for the Quad-Core Intel® Xeon®

Processor 5400 Series.

Figure 2-5. DTS Domain for Quad-Core Intel® Xeon® Processor 5400 Series

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 21

Page 22

2.2.4.2 Thermal Monitor for Multiple Core Products

Thermal/Mechanical Reference Design

The thermal management for multiple core products has only one T

processor. The T

CONTROL

for processor 0 and T

CONTROL

for processor 1 are independent

CONTROL

value per

from each other. If the DTS temperature from any domain within the processor is

greater than or equal to T

CONTROL

, the processor case temperature must remain at or

below the temperature as specified by the thermal profile. See Section 2.2.6 for

information on T

CONTROL

. The PECI signal is available through CPU pin (G5) on each

LGA771 socket for the Quad-Core Intel® Xeon® Processor 5400 Series. Through this

pin, the two domains provide the current hottest value received from all the

temperature sensors, to an external PECI device such as a thermal management

system.

2.2.4.3 PROCHOT#, THERMTRIP#, and FORCEPR#

The PROCHOT# and THERMTRIP# outputs will be shared by all cores on a processor.

The first core to reach TCC activation will assert PROCHOT#. A single FORCEPR# input

will be shared by every core. Tabl e 2- 2 provides an overview of input and output

conditions for the Quad-Core Intel® Xeon® Processor 5400 Series thermal

management features.

Table 2-2. Input and Output Conditions for the Quad-Core Intel® Xeon® Processor 5400

Series Thermal Management Features

Item Processor Input Processor Output

DTS

TM1/TM2

PROCHOT#

Core X > TCC Activation Temperature

Core X > TCC Activation Temperature

DTS

All Cores TCC Activation

PROCHOT# Asserted

Core X > THERMTRIP # Assertion

THERMTRIP#

FORCEPR#

Note:

1. X=1,2,3,4; represents any one of the core1, core2, core3 and core4 in the Quad-Core Intel® Xeon® Processor 5400

Series.

2. For more information on PROCHOT#, THERMTRIP#, and FORCEPR# see the Quad-Core Intel® Xeon® Processor 5400

Series Datasheet.

DTS

Tem p era t ur e

FORCEPR# Asserted All Cores TCC Activation

THERMTRIP# Asserted,

all cores shut down

2.2.4.4 Heatpipe Orientation for Multiple Core Processors

Thermal management of multiple core processors can be achieved without the use of

heatpipe heatsinks, as demonstrated by the Intel Reference Thermal Solution discussed

in Section 2.5.

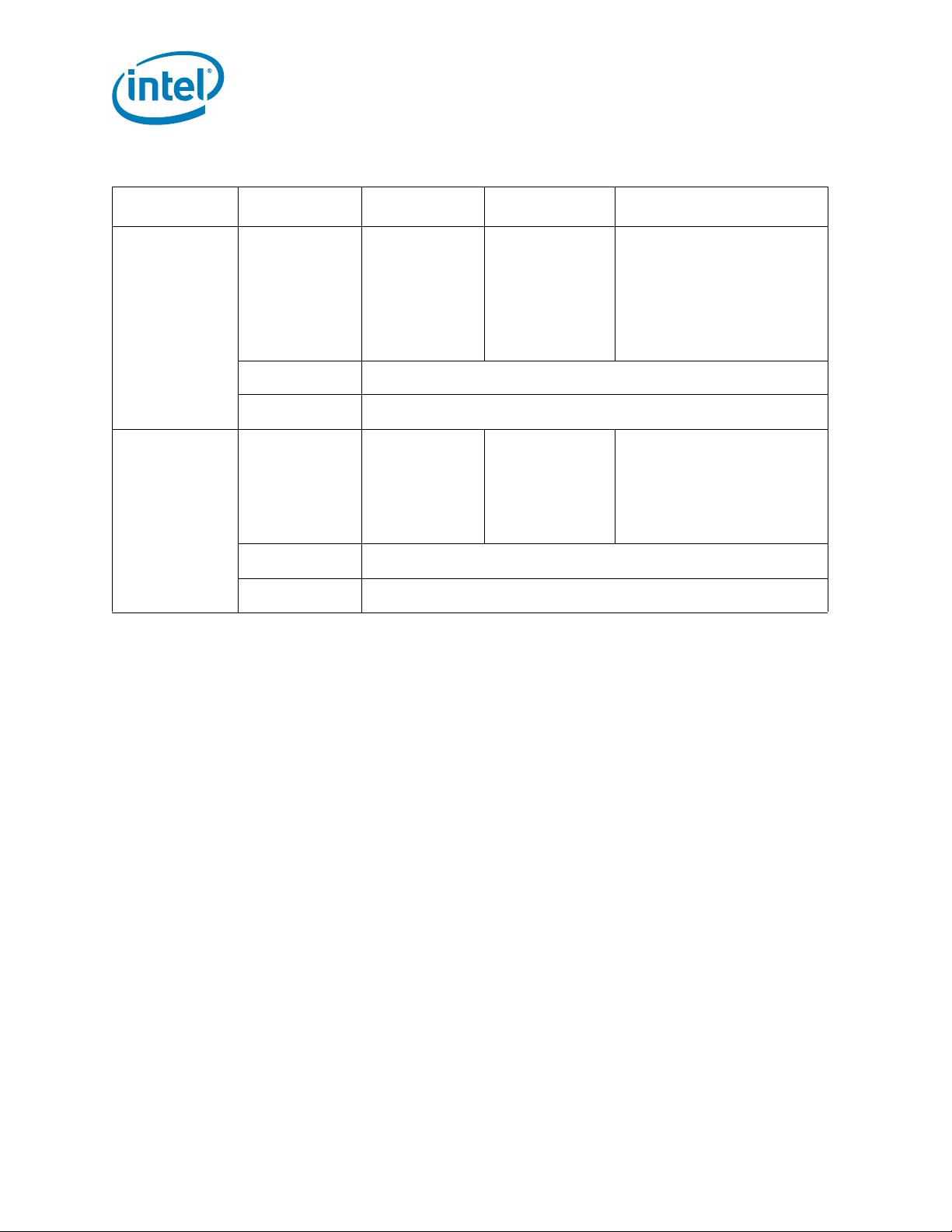

To assist customers interested in designing heatpipe heatsinks, processor core

locations have been provided. In some cases, this may influence the designer’s

selection of heatpipe orientation. For this purpose, the core geometric center locations,

as illustrated in Figure 2-6, are provided in Tab l e 2 - 3 . Dimensions originate from the

vertical edge of the IHS nearest to the pin 1 fiducial as shown in Figure 2-6.

22 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 23

Thermal/Mechanical Reference Design

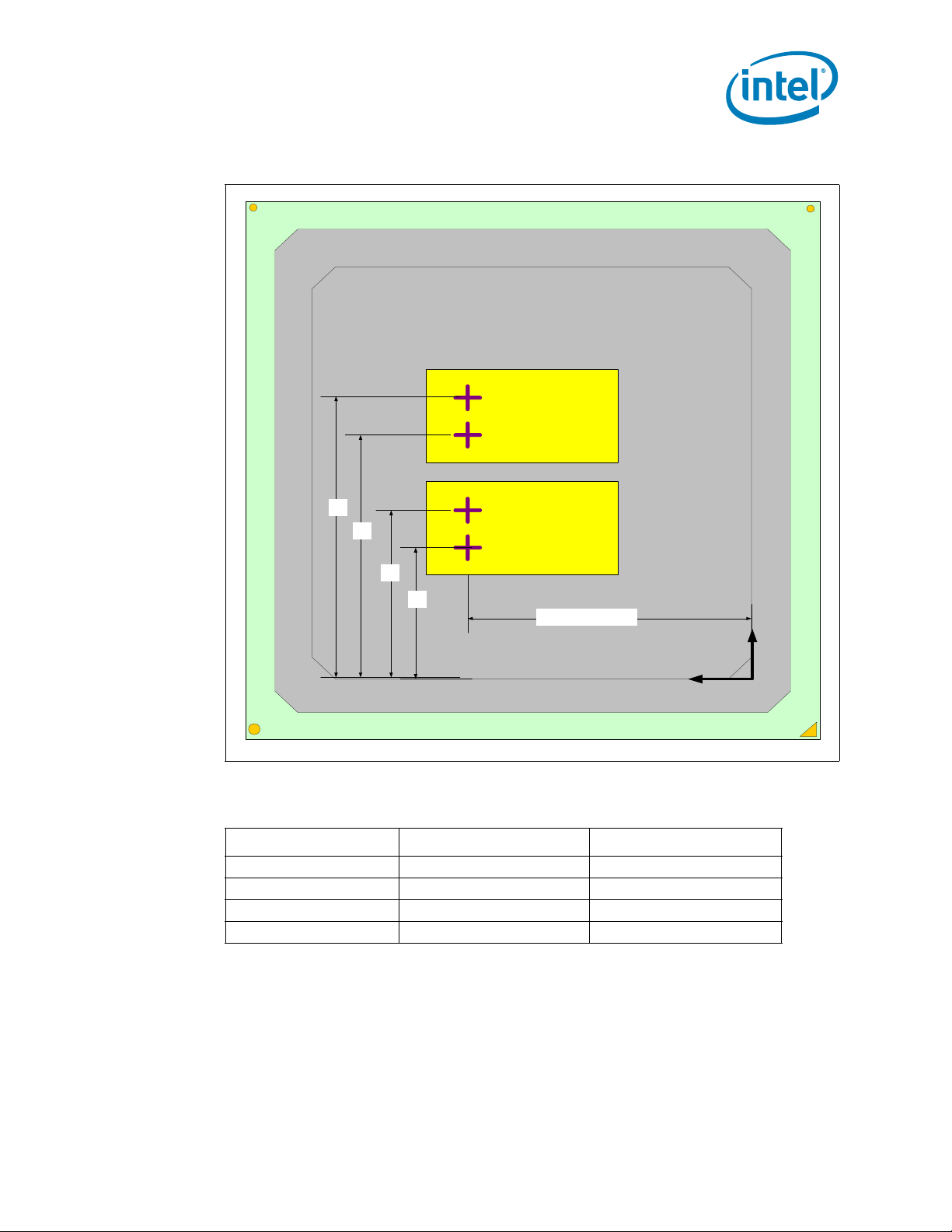

Figure 2-6. Processor Core Geometric Center Locations

Core4

Core4

Core3

Core3

Y4

Y4

Y3

Y3

Core2

Core2

Core1

Y2

Y2

Y1

Y1

Table 2-3. Processor Core Geometric Center Dimensions

Feature X Dimension Y Dimension

Core 1 18.15 mm 6.15 mm

Core 2 18.15 mm 10.35 mm

Core 3 18.15 mm 18.85 mm

Core 4 18.15 mm 23.05 mm

Core1

X1, X2, X3, X4

X1, X2, X3, X4

Y

Y

X

X

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 23

Page 24

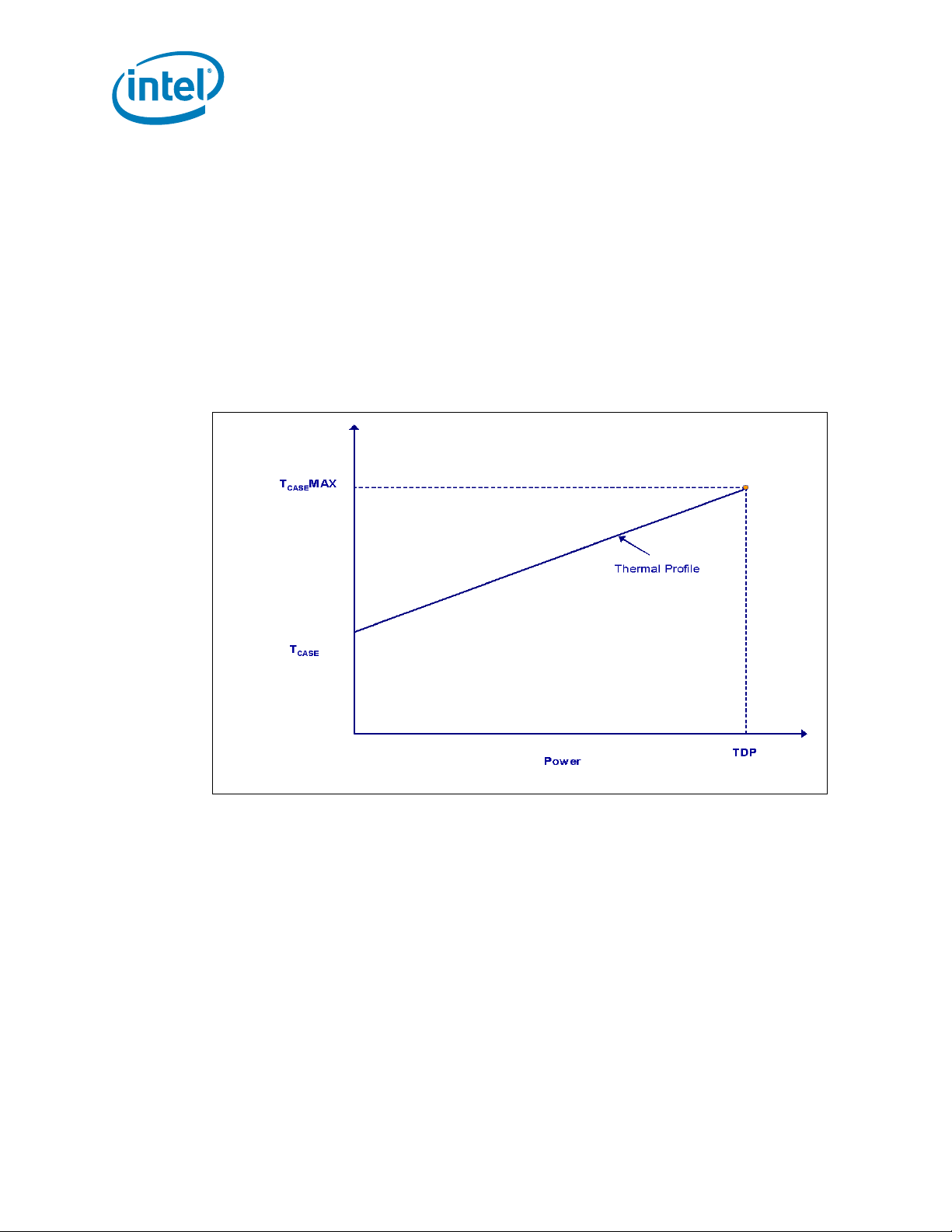

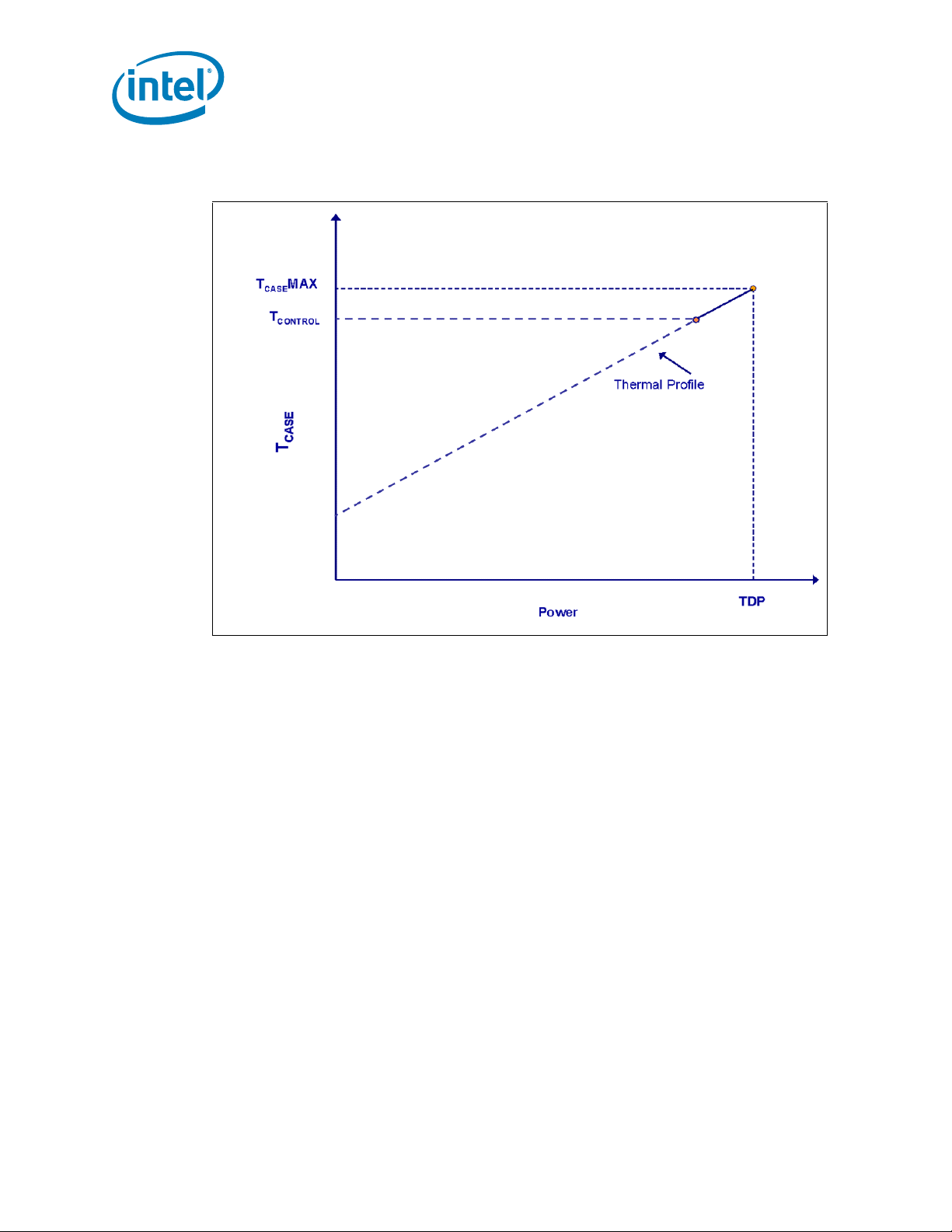

2.2.5 Thermal Profile

The thermal profile is a line that defines the relationship between a processor’s case

temperature and its power consumption as shown in Figure 2-7. The equation of the

thermal profile is defined as:

Equation 2-1.y = ax + b

Where:

y = Processor case temperature, T

x = Processor power consumption (W)

a = Case-to-ambient thermal resistance, ΨCA (°C/W)

b = Processor local ambient temperature, TLA (°C)

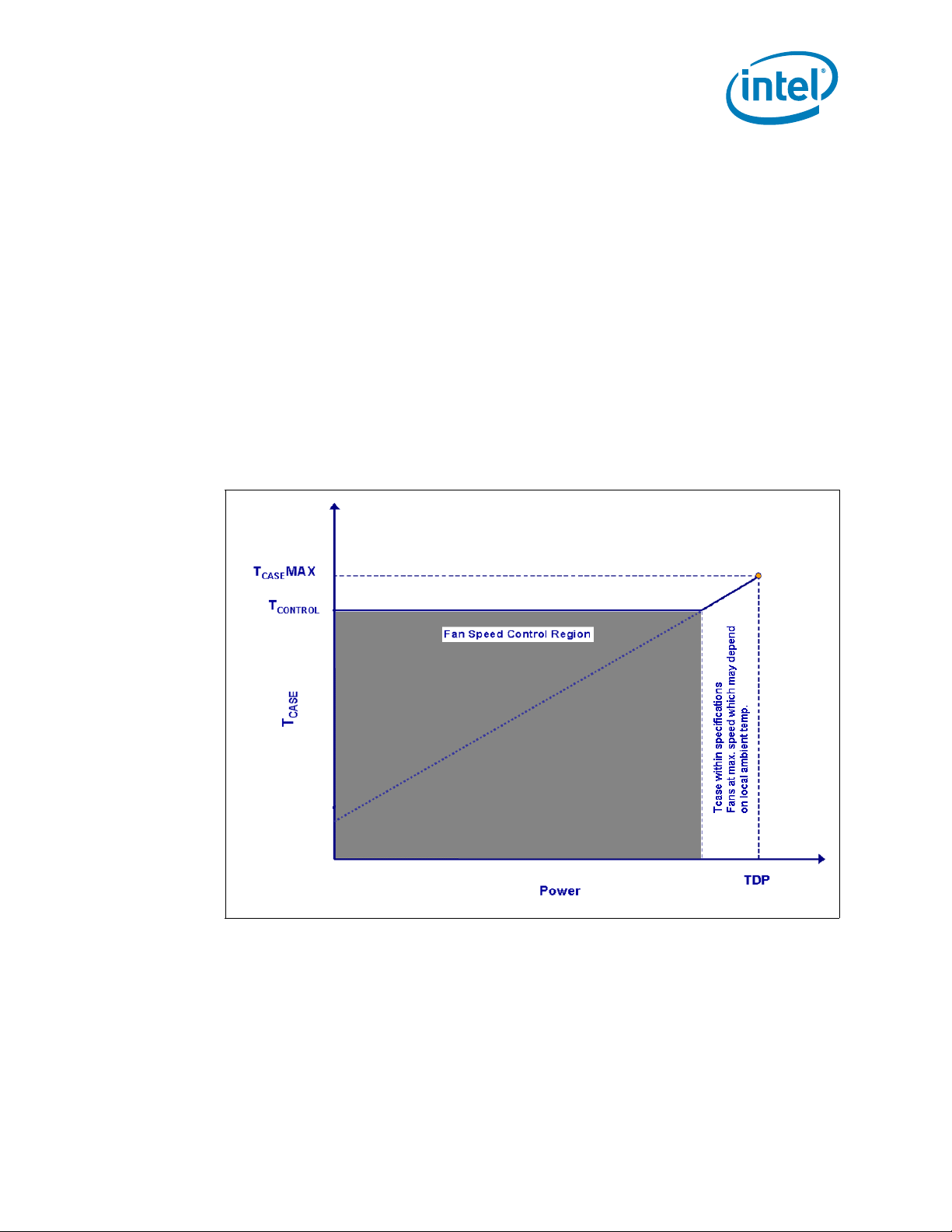

Figure 2-7. Thermal Profile Diagram

CASE

Thermal/Mechanical Reference Design

(°C)

The high end point of the Thermal Profile represents the processor’s TDP and the

associated maximum case temperature (T

CASE_MAX

) and the lower end point represents

the local ambient temperature at P = 0W. The slope of the Thermal Profile line

represents the case-to-ambient resistance of the thermal solution with the y-intercept

being the local processor ambient temperature. The slope of the Thermal Profile is

constant, which indicates that all frequencies of a processor defined by the Thermal

Profile will require the same heatsink case-to-ambient resistance.

In order to satisfy the Thermal Profile specification, a thermal solution must be at or

below the Thermal Profile line for the given processor when its DTS temperature is

greater than T

CONTROL

(refer to Section 2.2.6). The Thermal Profile allows the

customers to make a trade-off between the thermal solution case-to-ambient

resistance and the processor local ambient temperature that best suits their platform

implementation (refer to Section 2.4.3). There can be multiple combinations of thermal

solution case-to-ambient resistance and processor local ambient temperature that can

meet a given Thermal Profile. If the case-to-ambient resistance and the local ambient

temperature are known for a specific thermal solution, the Thermal Profile of that

solution can easily be plotted against the Thermal Profile specification. As explained

24 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 25

Thermal/Mechanical Reference Design

above, the case-to-ambient resistance represents the slope of the line and the

processor local ambient temperature represents the y-axis intercept. Hence the

T

CASE_MAX

determined, the line can be extended to Power (P) = 0W representing the Thermal

Profile of the specific solution. If that line stays at or below the Thermal Profile

specification, then that particular solution is deemed as a compliant solution.

value of a specific solution can be calculated at TDP. Once this point is

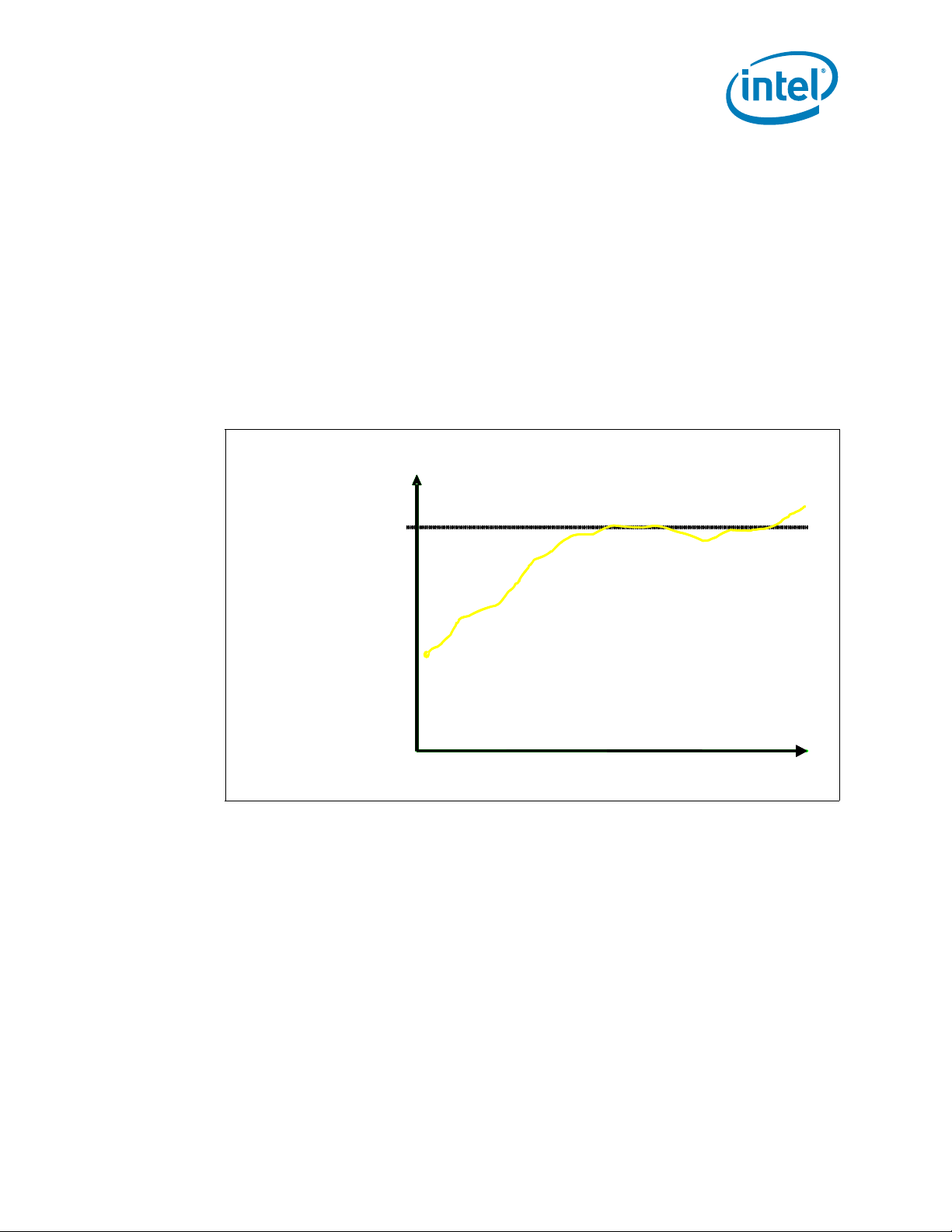

2.2.6 T

T

processor T

longer absolute. The T

activation set point (i.e. PECI Count = 0), as indicated by PROCHOT#. Figure 2-8

depicts the interaction between the T

Figure 2-8. T

CONTROL

CONTROL

CONTROL

Digital Thermal Sensor Temperature

Digital Thermal Sensor Temperature

Tcontrol = -5

Tcontrol = -5

Definition

can be described as a trigger point for fan speed control implementation. The

CONTROL

Value and Digital Thermal Sensor Value Interaction

value provided by the Digital Thermal Sensor is relative and no

CONTROL

-10

-10

-10

-20

-20

-20

-30

-30

-30

-40

-40

-40

value is now defined as a relative value to the TCC

CONTROL

0

0

0

value and Digital Thermal Sensor value.

Temperature

Temperature

Time

Time

The value for T

individually. For the Quad-Core Intel® Xeon® Processor 5400 Series, the T

value is obtained by reading the processor model specific register

(IA32_TEMPERATURE_TARGET MSR).

Note: There is no T

The fan speed control device only needs to read the T

the DTS value from the PECI interface. The equation for calculating T

Equation 2-2.T

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 25

CONTROL

Where:

T

OFFSET

CONTROL

CONTROL_BASE

= -T

OFFSET

= A DTS-based value programmed into each processor during

manufacturing that can be obtained by reading the

IA32_TEMPERATURE_TARGET MSR. This is a static and a unique value.

Refer to the RS - Wolfdale Processor Family BIOS Writer’s Guide (BWG)

for further details.

is calibrated in manufacturing and configured for each processor

CONTROL

value to sum as previously required on legacy processors.

OFFSET MSR

and compare this to

CONTROL

is:

Page 26

Thermal/Mechanical Reference Design

Figure 2-9. T

Figure 2-9 depicts the interaction between the Thermal Profile and T

CONTROL

and Thermal Profile Interaction

CONTROL

.

If the DTS temperature is less than T

CONTROL

, then the case temperature is permitted

to exceed the Thermal Profile, but the DTS temperature must remain at or below

T

CONTROL

T

CASE

T

CASE_MAX

Refer to Section 2.4.1 for the implementation of the T

. The thermal solution for the processor must be able to keep the processor’s

at or below the Thermal Profile when operating between the T

CONTROL

and

at TDP under heavy workload conditions.

CONTROL

value in support of fan

speed control (FSC) design to achieve better acoustic performance.

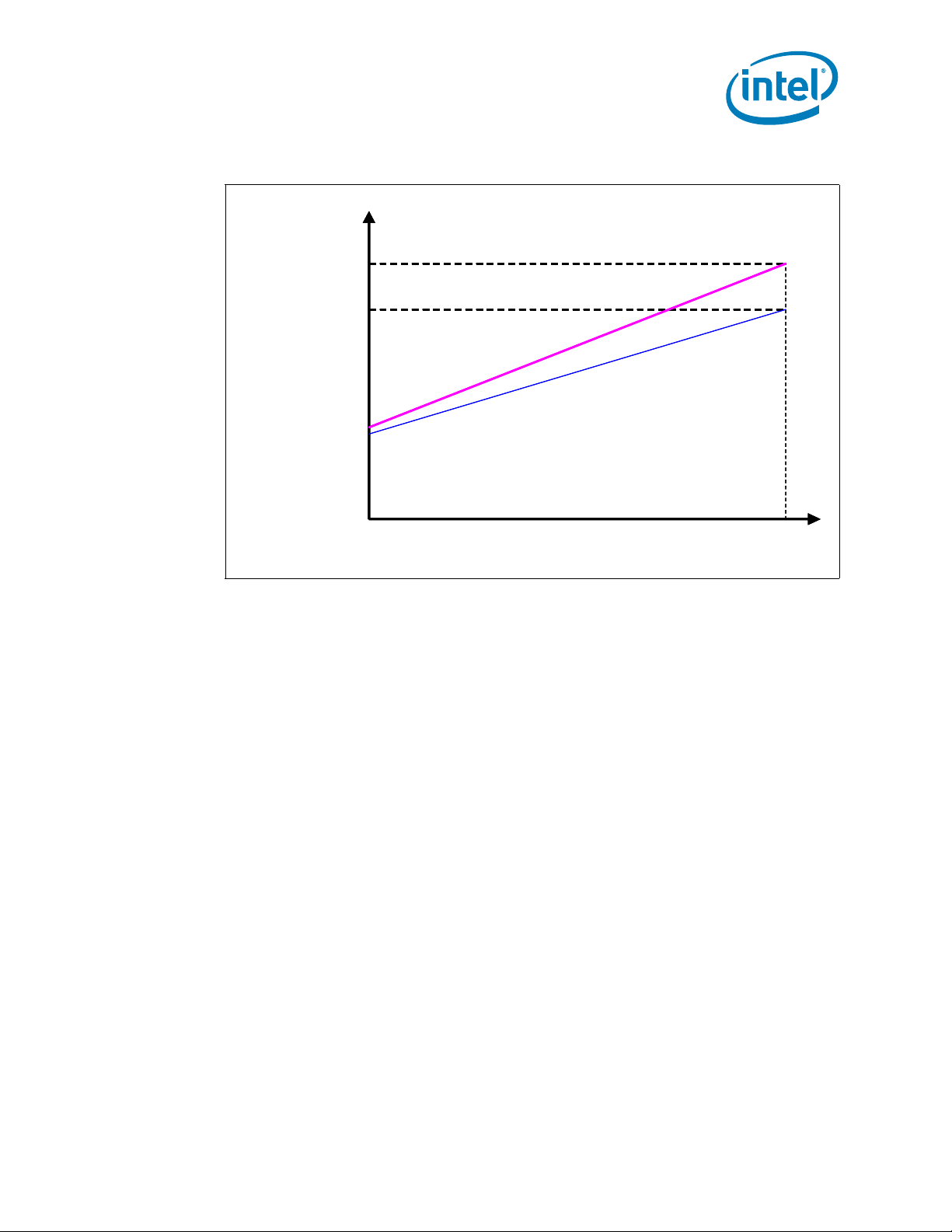

2.2.7 Thermal Profile Concepts for the Quad-Core Intel® Xeon® Processor 5400 Series

2.2.7.1 Dual Thermal Profile Concept for the Quad-Core Intel® Xeon® Processor

X5400 Series

The Quad-Core Intel® Xeon® Processor X5400 Series is designed to go into various

form factors, including the volumetrically constrained 1U and custom blade form

factors. Due to certain limitations of such form factors (i.e. airflow, thermal solution

height), it is very challenging to meet the thermal requirements of the processor. To

mitigate these form factor constraints, Intel has developed a dual Thermal Profile

specification, shown in Figure 2-10.

26 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 27

Thermal/Mechanical Reference Design

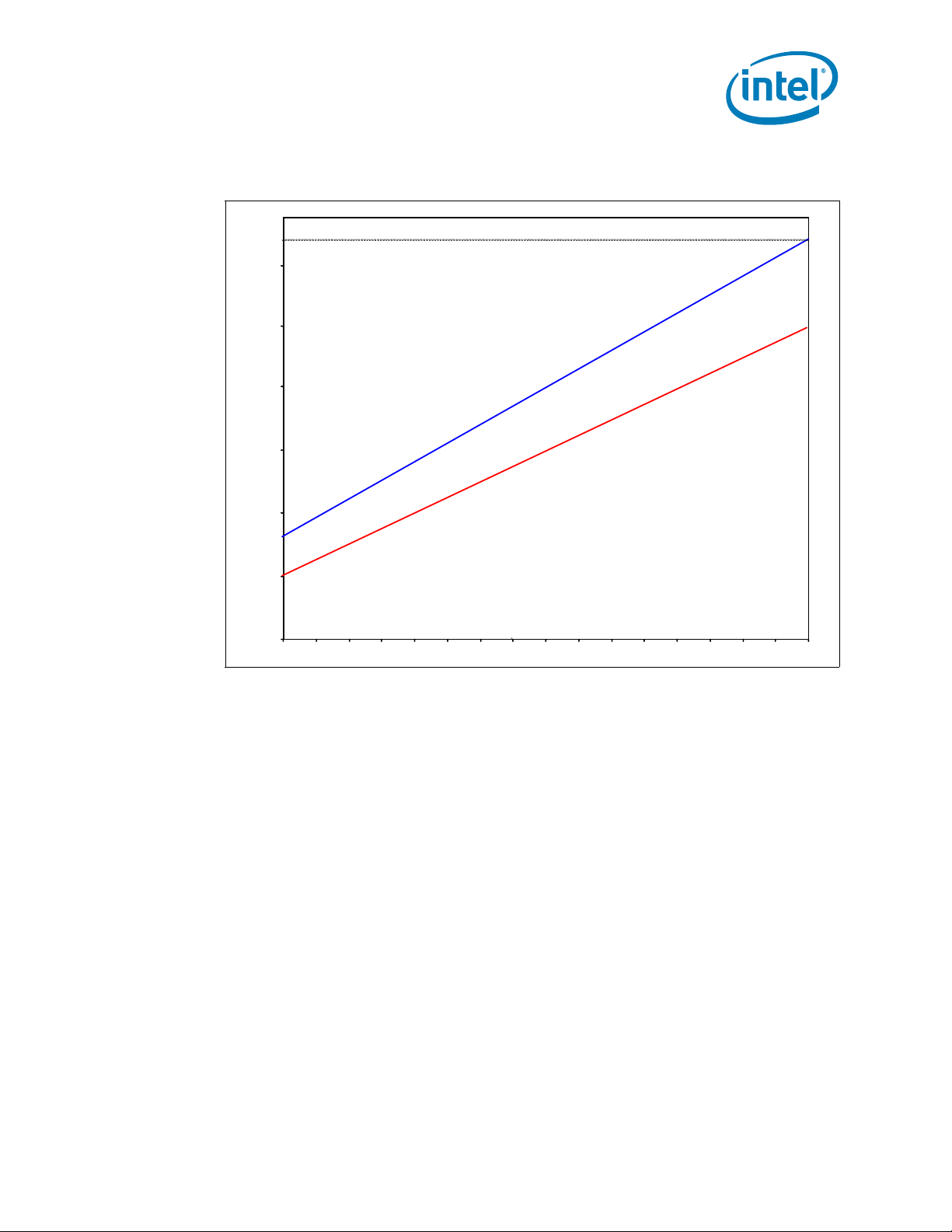

Figure 2-10. Dual Thermal Profile Diagram

T

T

case_max_B

case_max_B

T

T

case_max_A

case_max_A

Thermal Profile B

Thermal Profile B

Thermal Profile A

Thermal Profile A

TDP

Power

Power

The Thermal Profile A is based on Intel’s 2U+ air cooling solution. Designing to Thermal

Profile A ensures that no measurable performance loss due to Thermal Control Circuit

(TCC) activation is observed in the processor. It is expected that TCC would only be

activated for very brief periods of time when running a worst-case real world

application in a worst-case thermal condition. These brief instances of TCC activation

are not expected to impact the performance of the processor. A worst case real world

application is defined as a commercially available, useful application which dissipates a

power equal to, or above, the TDP for a thermally relevant timeframe. One example of

a worst-case thermal condition is when a processor local ambient temperature is at or

above 42.8°C for Quad-Core Intel® Xeon® Processor X5400 Series Thermal Profile A.

Thermal Profile B supports volumetrically constrained platforms (i.e. 1U, blades, etc.),

and is based on Intel’s 1U air cooling solution. Because of the reduced capability

represented by such thermal solutions, designing to Thermal Profile B results in an

increased probability of TCC activation and an associated measurable performance loss.

Measurable performance loss is defined to be any degradation in the processor’s

performance greater than 1.5%. The 1.5% number is chosen as the baseline since the

run-to-run variation in a given performance benchmark is typically between 1 and 2%.

Although designing to Thermal Profile B results in increased T

compared to Thermal Profile A at a given power level, both of these Thermal Profiles

ensure that Intel’s long-term processor reliability requirements are satisfied. In other

words, designing to Thermal Profile B does not impose any additional risk to Intel’s

long-term reliability requirements. Thermal solutions that exceed Thermal Profile B

specification are considered incompliant and will adversely affect the long-term

reliability of the processor.

temperatures

CASE

TDP

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 27

Page 28

Thermal/Mechanical Reference Design

Refer to the Quad-Core Intel® Xeon® Processor 5400 Series Datasheet or

Section 2.2.8 for the Thermal Profile A and Thermal Profile B specifications. Section 2.5

of this document also provides details on the 2U+ and 1U Intel reference thermal

solutions that are designed to meet the Quad-Core Intel® Xeon® Processor X5400

Series Thermal Profile A and Thermal Profile B respectively.

2.2.7.2 Thermal Profile Concept for the Quad-Core Intel® Xeon® Processor

E5400/X5482 Series

The Quad-Core Intel® Xeon® Processor E5400 Series is designed to go into various

form factors, including the volumetrically constrained 1U and custom blade form

factors. The Quad-Core Intel® Xeon® Processor X5482 is designed to go into

volumetrically unconstrained workstation platforms only. Intel has developed single

thermal profile for E5400/X5482 Series.

Designing to the Thermal Profile ensures that no measurable performance loss due to

Thermal Control Circuit (TCC) activation is observed in the processor. It is expected

that TCC would only be activated for very brief periods of time when running a worstcase real world application in a worst-case thermal condition. These brief instances of

TCC activation are not expected to impact the performance of the processor. A worst

case real world application is defined as a commercially available, useful application

which dissipates a power equal to, or above, the TDP for a thermally relevant

timeframe. One example of a worst-case thermal condition is when a processor local

ambient temperature is at or above 43.2°C for Quad-Core Intel® Xeon® Processor

E5400 Series Thermal Profile.

Thermal solutions that exceed the Thermal Profile specification are considered

incompliant and will adversely affect the long-term reliability of the processor.

Refer to the Quad-Core Intel® Xeon® Processor 5400 Series Datasheet or

Section 2.2.8 for the Quad-Core Intel® Xeon® Processor 5400 Series Thermal Profile

specifications. Section 2.5 and Appendix A of this document provide details on 1U Intel

reference thermal solutions that are designed to meet the Quad-Core Intel® Xeon®

Processor E5400 Series Thermal Profile.

2.2.8 Performance Targets

The Thermal Profile specifications for this processor are published in the Quad-Core

Intel® Xeon® Processor 5400 Series Datasheet. These Thermal Profile specifications

are shown as a reference in the subsequent discussions.

28 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 29

Thermal/Mechanical Reference Design

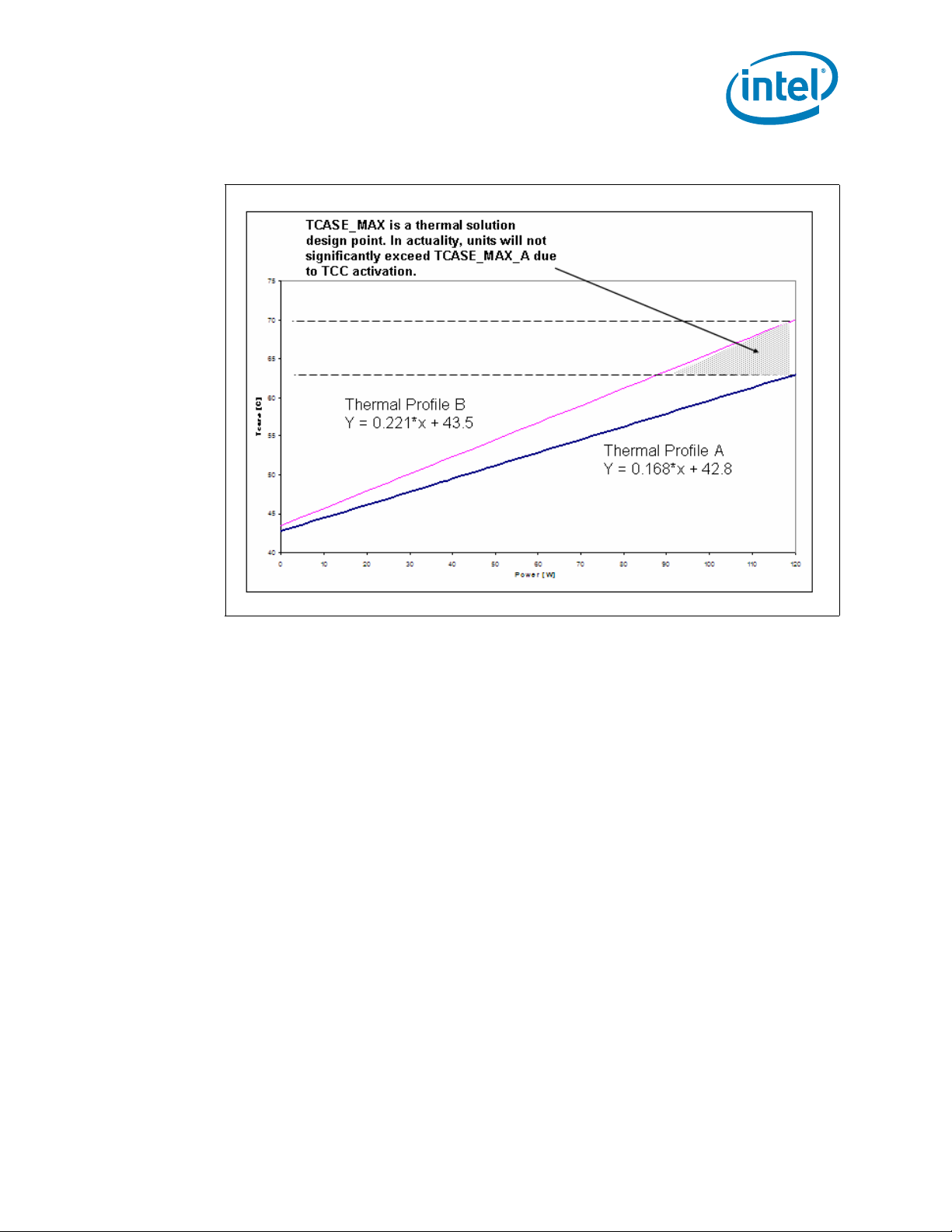

Figure 2-11. Thermal Profile for the Quad-Core Intel® Xeon® Processor X5400 Series

Notes:

1. The The thermal specifications shown in this graph are for Quad-Core Intel® Xeon® Processor X5400

Series except the Quad-Core Intel® Xeon® Processor X5482 sku.

2. Refer to the Quad-Core Intel® Xeon® Processor 5400 Series Datasheet for the Thermal Profile

specifications. In case of conflict, the data information in the datasheet supersedes any data in this figure.

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 29

Page 30

Thermal/Mechanical Reference Design

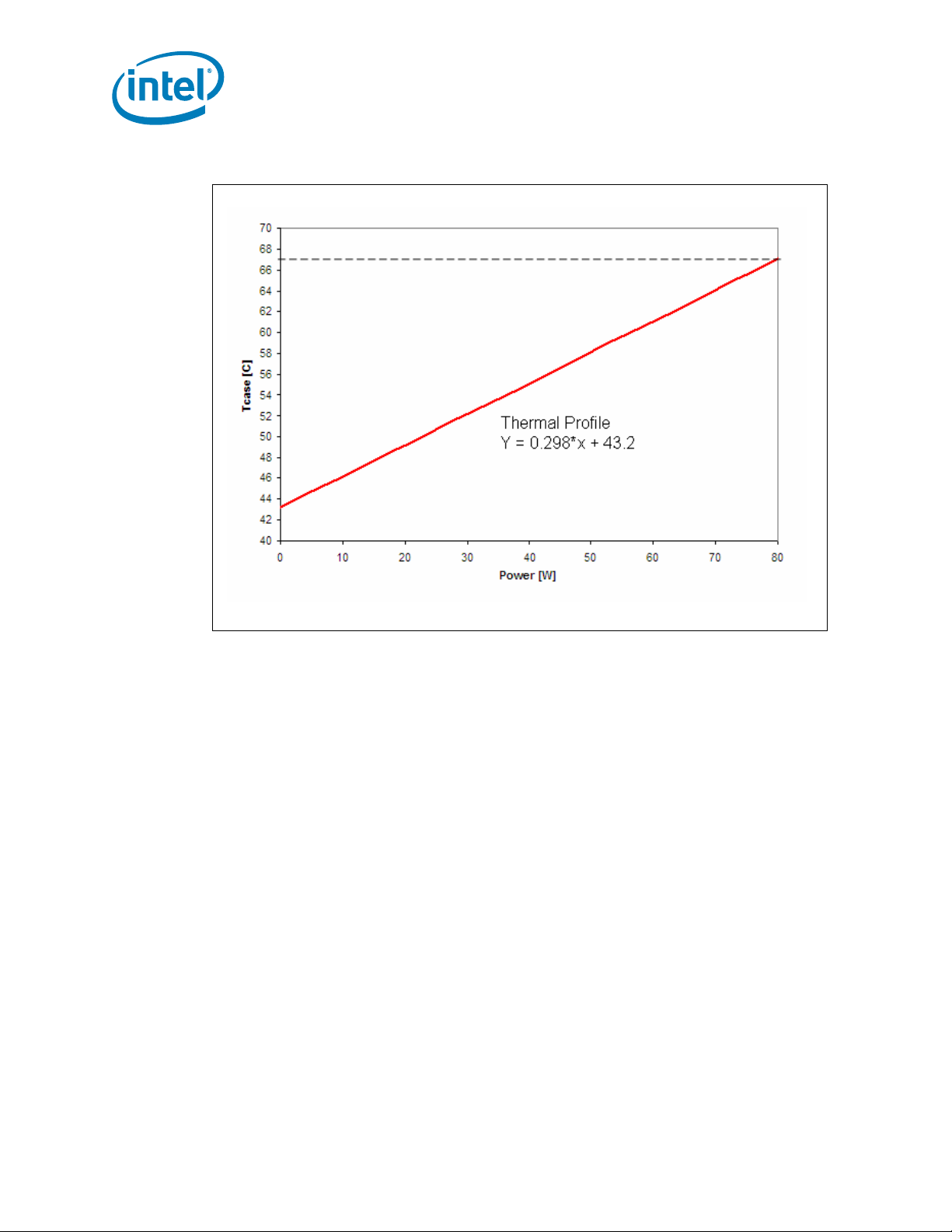

Figure 2-12. Thermal Profile for Quad-Core Intel® Xeon® Processor E5400 Series

Note: The thermal specifications shown in this graph are for reference only. Refer to the Quad-Core Intel®

Xeon® Processor 5400 Series Datasheet for the Thermal Profile specifications. In case of conflict, the

data information in the datasheet supersedes any data in this figure.

30 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 31

Thermal/Mechanical Reference Design

Figure 2-13. Thermal Profile for Quad-Core Intel® Xeon® Processor X5482 Series

Thermal Profile (2U)

75

70

65

60

55

Tcase [C]

50

45

40

Thermal P r ofile

Y = 0.187*x + 35

35

0 102030405060708090100110120130140150

Pow er [W]

Ta b le 2 - 4 and Ta bl e 2- 5 describe the thermal performance target for the Quad-Core

Intel® Xeon® Processor 5400 Series cooling solution enabled by Intel.

Table 2-4. Intel Reference Heatsink Performance Targets for the Quad-Core Intel®

Xeon® Processor X5400 Series

Parameter Maximum Unit Notes

Altitude Sea-level m Heatsink designed at 0 meters

T

LA

TDP 120 W

T

CASE_MAX_A

Airflow 27

Pressure Drop 0.182

ψ

CA

T

CASE_MAX_B

Airflow 15

Pressure Drop 0.331

ψ

CA

40 °C

2U+ CEK, Thermal Profile A

63 °C

CFM

3

45.9

45.3

0.187 °C/W Mean + 3σ

1U CEK, Thermal Profile B

70 °C

25.5

82.4

0.246 °C/W Mean + 3σ

/ hr

m

Inches of H

Pa

CFM

3

m

/ hr

Inches of H

Pa

O

2

O

2

Airflow through the heatsink fins

Airflow through the heatsink fins

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 31

Page 32

Thermal/Mechanical Reference Design

Table 2-5. Intel Reference Heatsink Performance Targets for the Quad-Core Intel®

Xeon® Processor E5400 Series

Parameter Maximum Unit Notes

Altitude Sea-Level m Heatsink designed at 0 meters

T

LA

TDP

40 °C

80 W

1U CEK

T

CASE_MAX

Airflow

Pressure Drop

ψ

CA

T

CASE_MAX

Airflow

Pressure Drop

ψ

CA

67 °C

15

25.5

0.331

82.4

0.246 °C/W Mean + 3σ

1U Alternative Heatsink

67 °C

15

25.5

0.331

82.4

0.331 °C/W Mean + 3σ

CFM

3

/ hr

m

Inches of H

Pa

CFM

3

m

/ hr

Inches of H

Pa

2

2

Airflow through the heatsink fins

O

Airflow through the heatsink fins

O

Note: Intel does not enable reference heatsink for the Quad-Core Intel® Xeon®

Processor X5482 with 150W TDP. The Intel 2U CEK is capable of meeting the

thermal specification when local ambient temperature (TLA) is maintained at

or below 35°C.

2.3 Fan Fail Guidelines

Under fan failure or other anomalous thermal excursions, Tcase may exceed Thermal

Profile [Thermal Profile B for Quad-Core Intel® Xeon® Processor X5400 Series] for a

duration totaling less than 360 hours per year without affecting long term reliability

(life) of the processor. For more typical thermal excursions, Thermal Monitor is

expected to control the processor power level as long as conditions do not allow the

Tcase to exceed the temperature at which Thermal Control Circuit (TCC) activation

initially occurred. Under more severe anomalous thermal excursions when the

processor temperature cannot be controlled at or below this Tcase level by TCC

activation, then data integrity is not assured. At some higher threshold THERMTRIP#

will enable a shut down in an attempt to prevent permanent damage to the processor.

Thermal Test Vehicles (TTVs) may be used to check anomalous thermal excursion

compliance by ensuring that the processor Tcase value, as measured on the TTV, does

not exceed Tcase_max [Tcase_max_B for Quad-Core Intel® Xeon® Processor X5400

Series] at the anomalous power level for the environmental condition of interest. This

anomalous power level is equal to 80% of the TDP limit for Quad-Core Intel® Xeon®

Processor X5400 Series with 120W TDP and 90% of the TDP limit for Quad-Core Intel®

Xeon® Processor E5400 Series with 80W TDP.

Note: Fan Failure Guidelines apply only to SKUs which have Thermal Monitor2 enabled.

32 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 33

Thermal/Mechanical Reference Design

2.4 Characterizing Cooling Solution Performance Requirements

2.4.1 Fan Speed Control

Fan speed control (FSC) techniques to reduce system level acoustic noise are a

common practice in server designs. The fan speed is one of the parameters that

determine the amount of airflow provided to the thermal solution. Additionally, airflow

is proportional to a thermal solution’s performance, which consequently determines the

of the processor at a given power level. Since the T

T

CASE

important parameter in the long-term reliability of a processor, the FSC implemented in

a system directly correlates to the processor’s ability to meet the Thermal Profile and

hence the long-term reliability requirements. For this purpose, the parameter called

T

CONTROL

as explained in Section 2.2.6, is to be used in FSC designs to ensure that the

long-term reliability of the processor is met while keeping the system level acoustic

noise down. Figure 2-14 depicts the relationship between T

methodology.

of a processor is an

CASE

CONTROL

and FSC

Figure 2-14. T

CONTROL

and Fan Speed Control

Once the T

CONTROL

reading from the processor can be compared to this T

value is determined as explained earlier, the DTS temperature

CONTROL

value. A fan speed

control scheme can be implemented as described in Tabl e 2 - 6 without compromising

the long-term reliability of the processor.

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 33

Page 34

Thermal/Mechanical Reference Design

Table 2-6. Fan Speed Control, T

Condition FSC Scheme

DTS ≤ T

CONTROL

DTS >T

CONTROL

CONTROL

FSC can adjust fan speed to maintain DTS ≤ T

FSC should adjust fan speed to keep T

specification (increased acoustic region).

and DTS Relationship

CASE

(low acoustic region).

CONTROL

at or below the Thermal Profile

There are many different ways of implementing fan speed control, including FSC based

on processor ambient temperature, FSC based on processor Digital Thermal Sensor

(DTS) temperature or a combination of the two. If FSC is based only on the processor

ambient temperature, low acoustic targets can be achieved under low ambient

temperature conditions. However, the acoustics cannot be optimized based on the

behavior of the processor temperature. If FSC is based only on the Digital Thermal

Sensor, sustained temperatures above T

CONTROL

drives fans to maximum RPM. If FSC is

based both on ambient and Digital Thermal Sensor, ambient temperature can be used

to scale the fan RPM controlled by the Digital Thermal Sensor. This would result in an

optimal acoustic performance. Regardless of which scheme is employed, system

designers must ensure that the Thermal Profile specification is met when the processor

Digital Thermal Sensor temperature exceeds the T

CONTOL

value for a given processor.

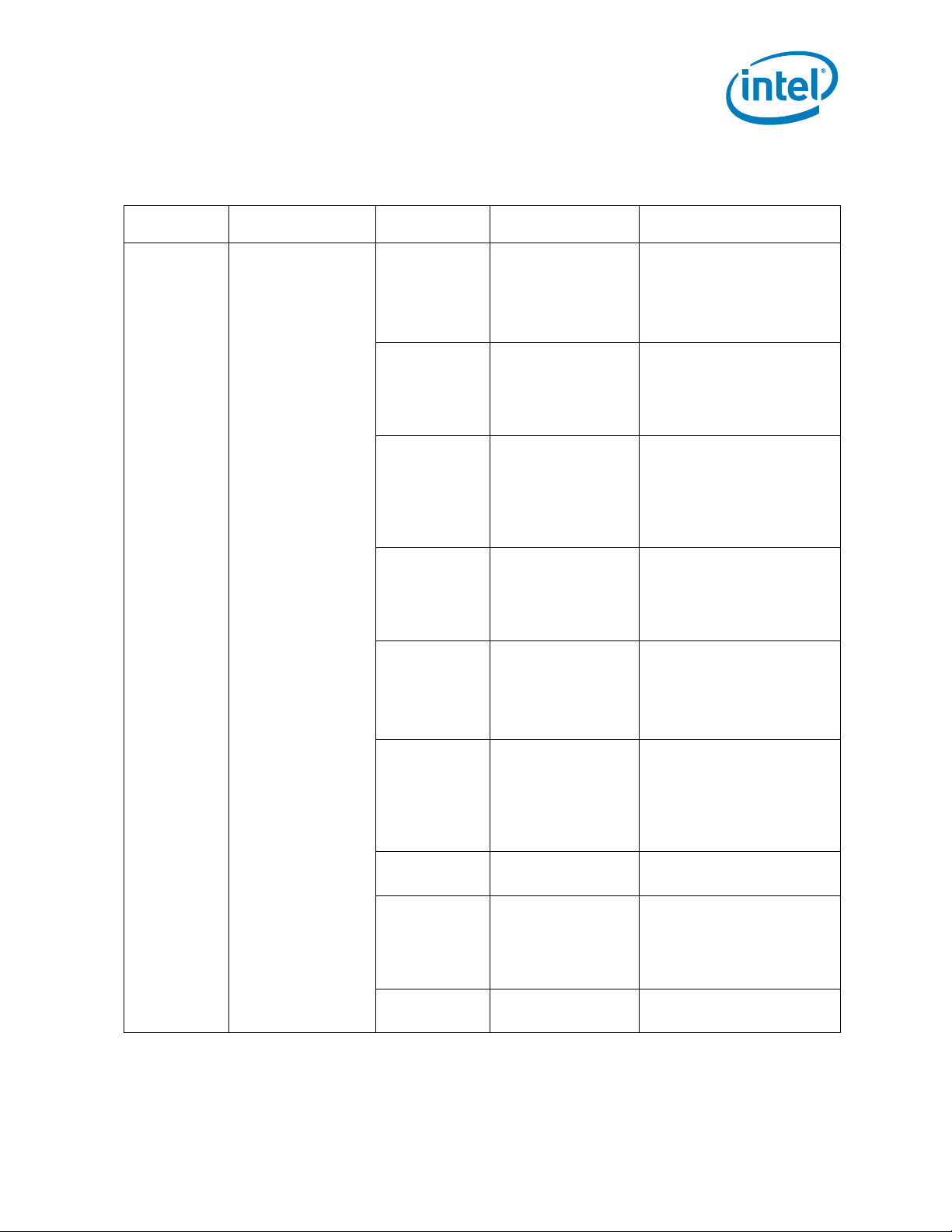

2.4.2 Processor Thermal Characterization Parameter Relationships

The idea of a “thermal characterization parameter”, Ψ (psi), is a convenient way to

characterize the performance needed for the thermal solution and to compare thermal

solutions in identical conditions (heating source, local ambient conditions). A thermal

characterization parameter is convenient in that it is calculated using total package

power, whereas actual thermal resistance, θ (theta), is calculated using actual power

dissipated between two points. Measuring actual power dissipated into the heatsink is

difficult, since some of the power is dissipated via heat transfer into the socket and

board. Be aware, however, of the limitations of lumped parameters such as Ψ when it

comes to a real design. Heat transfer is a three-dimensional phenomenon that can

rarely be accurately and easily modeled by lump values.

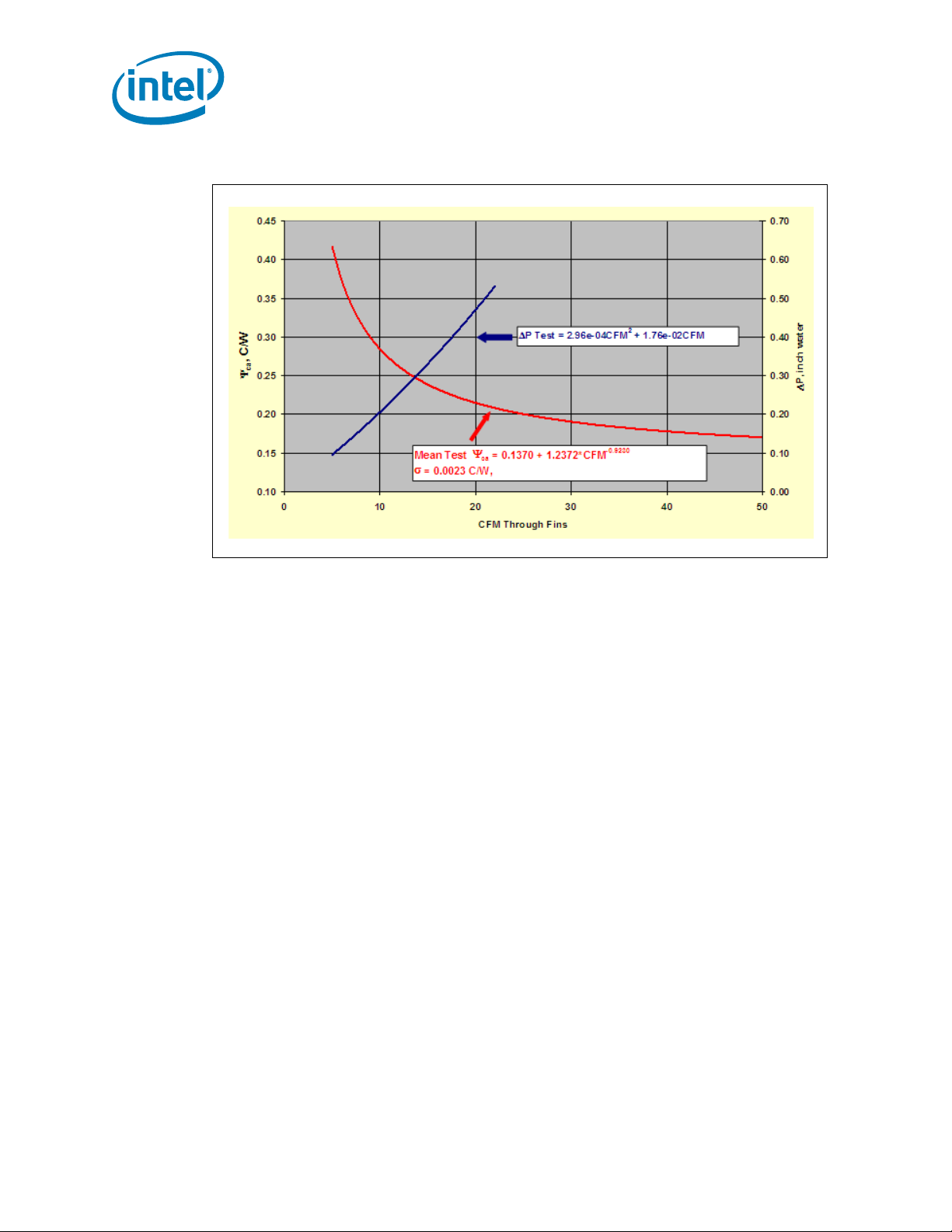

The case-to-local ambient thermal characterization parameter value (Ψ

) is used as a

CA

measure of the thermal performance of the overall thermal solution that is attached to

the processor package. It is defined by the following equation, and measured in units of

°C/W:

Equation 2-3.Ψ

CA

= (T

CASE

- TLA) /

TDP

Where:

Ψ

T

T

= Case-to-local ambient thermal characterization parameter (°C/W).

CA

= Processor case temperature (°C).

CASE

= Local ambient temperature in chassis at processor (°C).

LA

TDP = TDP dissipation (W) (assumes all power dissipates through the

integrated heat spreader (IHS)).

34 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 35

Thermal/Mechanical Reference Design

The case-to-local ambient thermal characterization parameter of the processor, ΨCA, is

comprised of ΨCS, the TIM thermal characterization parameter, and of ΨSA, the sink-tolocal ambient thermal characterization parameter:

Equation 2-4.Ψ

= ΨCS + ΨSA

CA

Where:

Ψ

Ψ

= Thermal characterization parameter of the TIM (°C/W).

CS

= Thermal characterization parameter from heatsink-to-local ambient

SA

(°C/W).

is strongly dependent on the thermal conductivity and thickness of the TIM

Ψ

CS

between the heatsink and IHS.

is a measure of the thermal characterization parameter from the bottom of the

Ψ

SA

heatsink to the local ambient air. ΨSA is dependent on the heatsink material, thermal

conductivity, and geometry. It is also strongly dependent on the air velocity through

the fins of the heatsink.

Figure 2-15 illustrates the combination of the different thermal characterization

parameters.

Figure 2-15. Processor Thermal Characterization Parameter Relationships

2.4.2.1 Example

The cooling performance, Ψ

characterization parameter described above:

• Define a target case temperature T

processor datasheet.

• Define a target local ambient temperature at the processor, TLA.

The following provides an illustration of how one might determine the appropriate

performance targets. The example power and temperature numbers used here are not

related to any Intel processor thermal specifications, and are for illustrative purposes

only.

Quad-Core Intel® Xeon® Processor 5400 Series TMDG 35

is then defined using the principle of thermal

CA,

CASE_MAX

and corresponding TDP, given in the

Page 36

Thermal/Mechanical Reference Design

Assume the datasheet TDP is 85 W and the case temperature specification is 68 °C.

Assume as well that the system airflow has been designed such that the local processor

ambient temperature is 45°C. Then the following could be calculated using equation

(2-3) from above:

Equation 2-5.Ψ

CA

= (T

– TLA) / TDP = (68 – 45) / 85 = 0.27 °C/W

CASE

To determine the required heatsink performance, a heatsink solution provider would

need to determine Ψ

performance for the selected TIM and mechanical load

CS

configuration. If the heatsink solution was designed to work with a TIM material

performing at ΨCS ≤ 0.05 °C/W, solving for equation (2-4) from above, the performance

of the heatsink would be:

Equation 2-6.Ψ

= ΨCA − ΨCS = 0.27 − 0.05 = 0.22 °C/W

SA

If the local processor ambient temperature is assumed to be 40°C, the same

calculation can be carried out to determine the new case-to-ambient thermal

resistance:

Equation 2-7.ΨCA = (T

– TLA) / TDP = (68 – 40) / 85 = 0.33 °C/W

CASE

It is evident from the above calculations that, a reduction in the local processor

ambient temperature has a significant positive effect on the case-to-ambient thermal

resistance requirement.

2.4.3 Chassis Thermal Design Considerations

2.4.3.1 Chassis Thermal Design Capabilities and Improvements

One of the critical parameters in thermal design is the local ambient temperature

assumption of the processor. Keeping the external chassis temperature fixed, internal

chassis temperature rise is the only component that can affect the processor local

ambient temperature. Every degree gained at the local ambient temperature directly

translates into a degree relief in the processor case temperature.

Given the thermal targets for the processor, it is extremely important to optimize the

chassis design to minimize the air temperature rise upstream to the processor (T

rise

),

hence minimizing the processor local ambient temperature.

The heat generated by components within the chassis must be removed to provide an

adequate operating environment for both the processor and other system components.

Moving air through the chassis brings in air from the external ambient environment and

transports the heat generated by the processor and other system components out of

the system. The number, size and relative position of fans, vents and other heat

generating components determine the chassis thermal performance, and the resulting

ambient temperature around the processor. The size and type (passive or active) of the

thermal solution and the amount of system airflow can be traded off against each other

to meet specific system design constraints. Additional constraints are board layout,

spacing, component placement, and structural considerations that limit the thermal

solution size.

In addition to passive heatsinks, fan heatsinks and system fans, other solutions exist

for cooling integrated circuit devices. For example, ducted blowers, heat pipes and

liquid cooling are all capable of dissipating additional heat. Due to their varying

attributes, each of these solutions may be appropriate for a particular system

implementation.

36 Quad-Core Intel® Xeon® Processor 5400 Series TMDG

Page 37

Thermal/Mechanical Reference Design

To develop a reliable, cost-effective thermal solution, thermal characterization and

simulation should be carried out at the entire system level, accounting for the thermal

requirements of each component. In addition, acoustic noise constraints may limit the

size, number, placement, and types of fans that can be used in a particular design.

2.5 Thermal/Mechanical Reference Design Considerations

2.5.1 Heatsink Solutions

2.5.1.1 Heatsink Design Considerations

To remove the heat from the processor, three basic parameters should be considered:

• The area of the surface on which the heat transfer takes place - Without any

enhancements, this is the surface of the processor package IHS. One method used

to improve thermal performance is by attaching a heatsink to the IHS. A heatsink

can increase the effective heat transfer surface area by conducting heat out of the

IHS and into the surrounding air through fins attached to the heatsink base.

• The conduction path from the heat source to the heatsink fins - Providing a

direct conduction path from the heat source to the heatsink fins and selecting

materials with higher thermal conductivity typically improves heatsink

performance. The length, thickness, and conductivity of the conduction path from

the heat source to the fins directly impact the thermal performance of the heatsink.

In particular, the quality of the contact between the package IHS and the heatsink

base has a higher impact on the overall thermal solution performance as processor

cooling requirements become strict. Thermal interface material (TIM) is used to fill

in the gap between the IHS and the bottom surface of the heatsink, and thereby

improves the overall performance of the thermal stackup (IHS-TIM-Heatsink). With

extremely poor heatsink interface flatness or roughness, TIM may not adequately

fill the gap. The TIM thermal performance depends on its thermal conductivity as

well as the pressure load applied to it. Refer to Section 2.5.2 for further information

on the TIM between the IHS and the heatsink base.

• The heat transfer conditions on the surface on which heat transfer takes

place - Convective heat transfer occurs between the airflow and the surface

exposed to the flow. It is characterized by the local ambient temperature of the air,

, and the local air velocity over the surface. The higher the air velocity over the

T

LA

surface, the resulting cooling is more efficient. The nature of the airflow can also

enhance heat transfer via convection. Turbulent flow can provide improvement over

laminar flow. In the case of a heatsink, the surface exposed to the flow includes the

fin faces and the heatsink base.

An active heatsink typically incorporates a fan that helps manage the airflow through

the heatsink.

Passive heatsink solutions require in-depth knowledge of the airflow in the chassis.

Typically, passive heatsinks see slower air speed. Therefore, these heatsinks are