Ingersoll-Rand 300-301 User Manual

OPERATOR'S MANUAL 300-301

300-301 FLOW GUN 1/4 inch SEAT TUNGSTEN CARBIDE

IMPORTANT: READ THIS MANUAL CAREFULLY BEFORE INSTALLING, OPERATING,

OR SERVICING THIS EQUIPMENT

WARNING:

Always wear eye protection when operating this gun.

Do not use damaged, frayed or deteriorated material

hoses or fittings.

SERVICE KITS

Use only Johnstone replacement parts to insure

compatibility and longest life.

• 300-301RK Repair Kit

• 300-919 Valve Rod Assembly

WARNING:

DO NOT OPERATE FLOW GUN AT PRESSURES

ABOVE RECOMMENDED MAXIMUM OF 4000PSI

(272 BAR) MATERIAL AND 100PSI (6.8 BAR) AIR.

Material Inlet Port Size 3/8" NPT

Material Outlet 1/4” orifice

Nozzle connection 400-667 Collar

DAILY:

Check for material leakage.

Check for Frayed or damaged hoses.

Depressurize when not in use.

SPECIFICATIONS

MAINTENANCE SCHEDULE

OPERATION

Supply material to the flow gun.

Adjust Material Pressure to flow gun until desired

material flow is achieved. (Material Regulator)

Adjust the trigger spring pressure until the Flow Gun

closes while under pressure. Turn the Adjusting screw

clockwise to increase pressure and counter-clockwise

to decrease pressure.

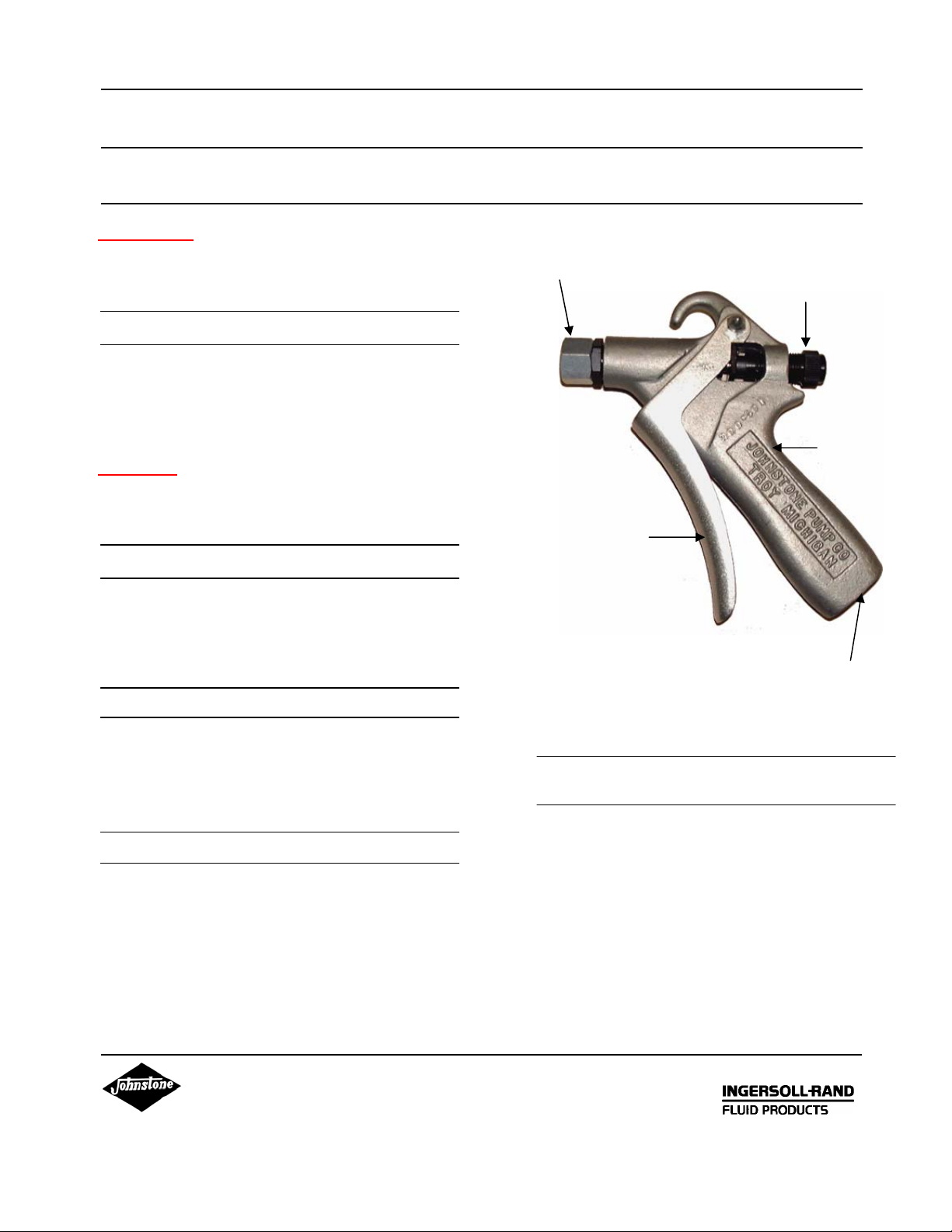

COLLAR

TRIGGER

REPLACEMENT PROCEDURE

Depressurize the Flow Gun

Disconnect the 3/8” NPT fitting from the Gun

inlet and remove the Nozzle.

Connect new Flow gun to the 3/8” NPT.

Install new nozzle.

To bleed air out of the Flow Gun- Operate the

Flow Gun until the air stops coming out.

ADJUSTING

SCREW

3/8” NPT

MATERIAL INLET

BODY

Johnstone Dispensing Systems 1872 Enerprise Drive PH (248) 293-5700

300-301.doc Rochester Hills MI 48309 FX (248 ) 293-5800 March15, 2000

300-301 FLOW GUN 1/4 inch SEAT TUNGSTEN CARBIDE

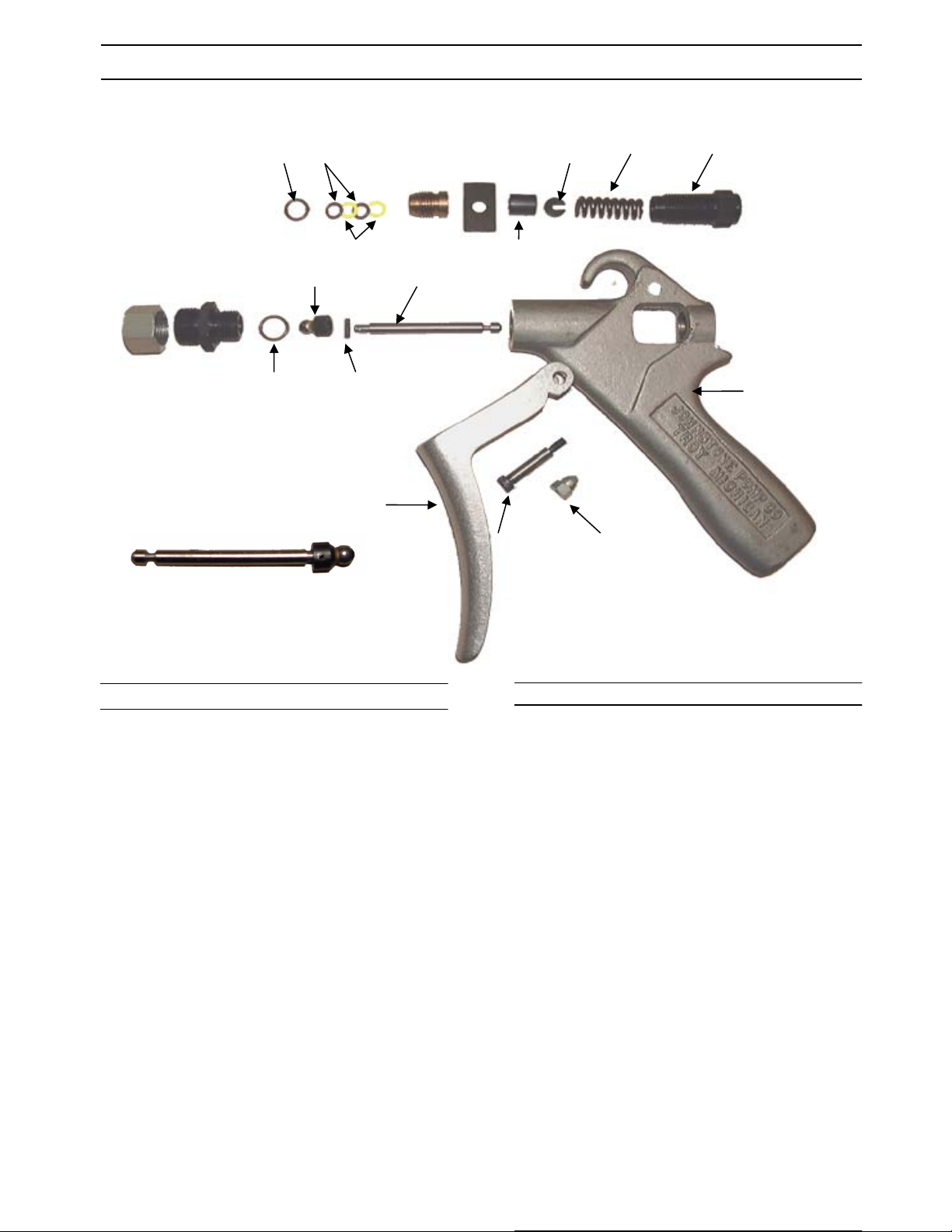

400-667

COLLAR

350-420

O’RING

400-690

VALVE SEAT

350-165 (2)

O’RING

400-691

VALVE-TC

350-167

O’RING

400-161

TRIGGER

300-919

VALVE ROD ASSEMBLY

400-160

PACKING

NUT

350-166 (2)

BACK UP

400-279

STEM

350-306

ROLL PIN

400-158

TRIGGER

PLATE

400-154

SPACER

SLEEVE

400-873

SHOULDER

SCREW

400-872

U-RING

400-164

SPRING

350-335

ACORN NUT

400-155

ADJUSTING

SCREW

400-153

BODY

DISASSEMBLY INSTRUCTIONS

1) Unbolt the Acorn nut and Shoulder screw and

remove the Trigger

2) Unscrew the adjustment screw and remove the

Spring.

3) Remove the Collar and Nozzle.

4) Remove the Valve Seat.

5) The U-ring can be pushed out from the side of

the body.

6) Push the Valve rod assembly out of the body.

7) Using a large flat screwdriver remove the

Packing nut and O’ring.

8) Clean and inspect all parts.

ASSEMBLY INSTRCTIONS

1) Align the holes between the Valve and Stem

and press the roll pin flush with the Valve.

2) Install a lubricated 350-420 O’ring into the

Packing Nut bore.

3) Install the back-up-rings and O’ring into the

Packing Nut and Lubricate.

4) Tighten the Packing Nut into the Body with a

large flat screwdriver.

5) Push the Valve Rod assembly though the

body. (see diagram above)

6) Slide the Trigger Plate and Spacer Sleeve over

the Stem.

7) Install the U-bolt on the Stem.

8) Place the Spring in the Adjusting Screw and

thread it into the Body.

9) Install the 350-167 O’ring on the Seat and

lubricate.

10) Thread the Valve Seat into the body and

tighten.

11) Install the Trigger and tighten the Acorn nut

and Shouder Screw.

12) Install Nozzle and Collar.

2

Loading...

Loading...