Ingersoll-Rand 2XXX-XXX9-XXX User Manual

OPERATOR’S

MANUAL

2XXX-XXX9-XXX

INCLUDING: APPLICATION, LUBRICATION, INSTALLATION & SERVICE

ECONOMAIR

SERIES CYLINDERS

RELEASED: 9-14-92

REVISED: 5-25-10

(REV.

C)

READ THIS MANUAL CAREFULL

OPERA

It

is the responsibility of the employer to place this information in the hands of the operator

Rated Pressure: 200 PSI (14 Bar) Maximum Temperature Ratings: 0_ to 180_ F (-18_ to 82_ C)

MODEL

TING OR SER

VICING THIS EQUIPMENT

DESCRIPTION CHART

Y BEFORE INST

. Keep for future reference.

ALLING,

.

2X XX ĆX X X9 Ć XXX

SERIES NO.

23 Ć Noncushioned

24 Ć Cushioned, Both Ends

28 Ć Magnetic Piston, Cushioned Both Ends

BORE SIZE

18 Ć 1Ć1/8 in

15 Ć 1Ć1/2 in

20 Ć2in

25 Ć 2Ć1/2 in

30 Ć3in

40 Ć4in

STROKE LENGTH

WHOLE INCHES FRACTIONS

00=0in 0=None

01=1in 1=1/8in

02=2in 2=1/4in

03=3in 3=3/8in

04=4in 4=1/2in

05=5in 5=5/8in

06=6in 6=3/4in

7=7/8in

BB

99=99in

CYLINDER TYPE

1 Ć Double Acting, Rear Tang

5 Ć Double Acting, No Rear Tang

2 Ć Double Acting, Double Rod

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

© 2010

OPTIONS

09 Ć Standard Rod

89 Ć 303 Stainless Steel Rod

PACKING

0 Ć O" Ring, Nitrile

2 Ć O" Ring, Low Friction

3 Ć O" Ring, Viton

4 Ć Lip, Nitrile

5 Ć Lip, SelfĆLubricating

6 Ć Lip, Viton

CCN 99518706

Warnings

WARNINGS:

and Service Information

Improper application, installation, service or maintenance of

AROR

cylinders may create a hazardous condition,

turn

cause bodily injury

The

Aro Corporation for special applications.

ECONOMAIR

S Economair

cylinders designed for medium to heavy duty pneumatic

applications.

S

The operating pressures are 200 p.s.i.g. - pneumatic and

200 p.s.i.g. - non-shock hydraulic with hydraulic packing

option.

S

Economair cylinders are available in 6 bore sizes: 1-1/8”,

1-1/2”, 2”, 2-1/2”, 3” and 4”.

S

Options include : 6 mounting styles, magnetic pistons,

cushioned and non-cushioned and numerous packing options.

cylinders are a series of round line repairable

as well as shortened product life. Contact

CYLINDER APPLICA

which may in

TION

CUSHIONS

24 and 28 series cylinders

protective devices used to extend cylinder life and should not be

used to decelerate loads.

Cushioning on all bores, except the 1-1/8”, are equiped with an

adjustable needle valve in the head and cap to provide adjustment

of the cushion ef

ing, counterclockwise rotation decreases cushioning. After adjustment,

not

under

tighten retaining nut to

disengage cushion needle from head or cap

pressure.

OPERATION

Pneumatic cylinders should be lubricated to provide maximum

cycle life. Economair cylinders are lubricated with Shell

EP

grade, no. 2 grease during assembly at our factory in Angola,

Indiana.

cycle

ommend

you

in

Factory lubrication will provide a satisfactory amount of

life if no additional lubrication is provided.

lubrication for any pneumatic system and suggest that

follow the guidelines for types of lubricants

all of our catalogs (reference catalog 0020-M).

are cushioned models. Cushions are

fect - clockwise rotation increases cushion

lock into position. CAUTION: Do

while cylinder is

AND MAINTENANCE

Darina,

However

which are outlined

, we rec

and water. Cleaned parts should be rinsed and dried with low

pressure

placed.

air

. Any parts which are worn or damaged should be re

Selected parts and seals are available in repair kit form.

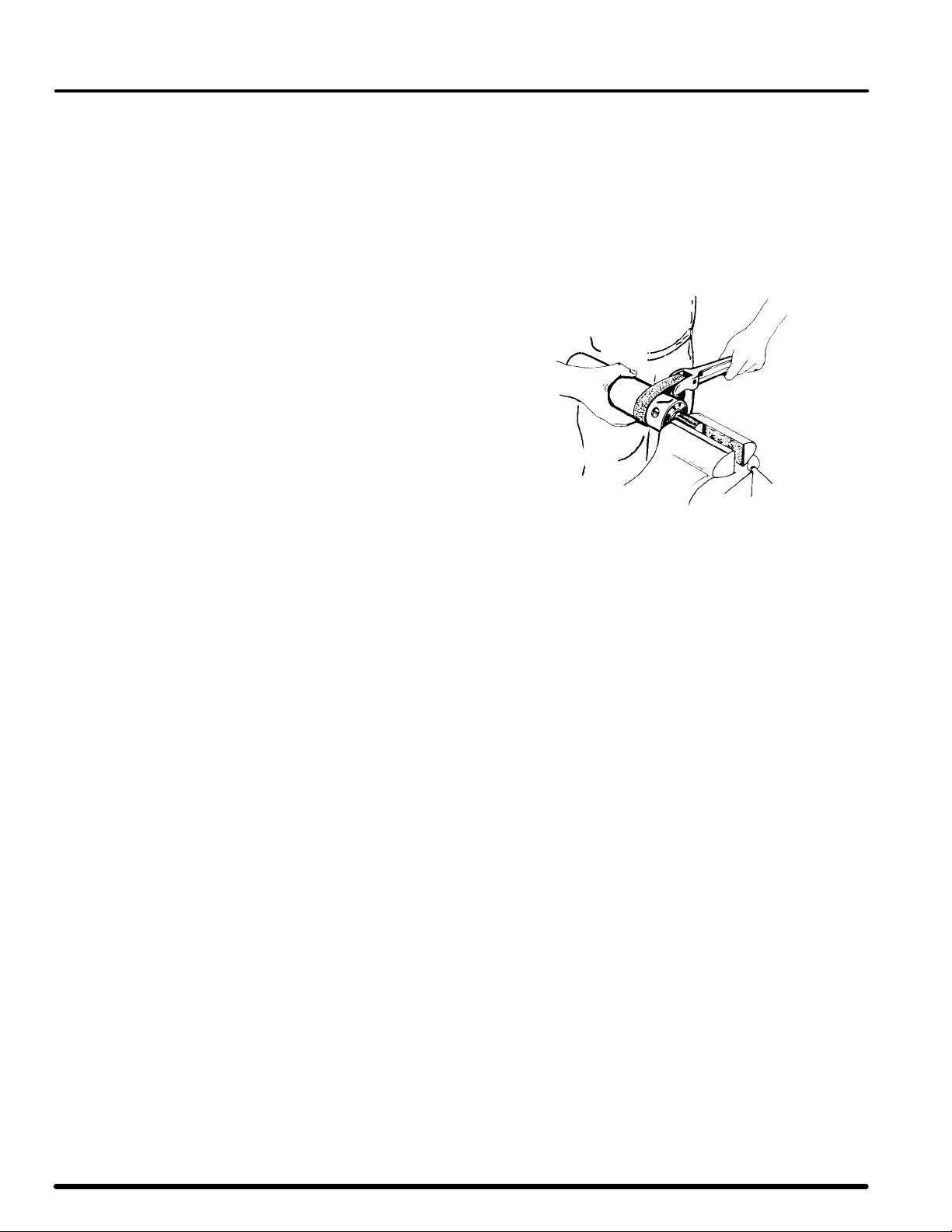

DISASSEMBLY

Clamp

head by nose or tang flats with port in a vertical position at

top

of cylinder

Remove all fittings, rotate barrel counterclockwise with a strap

wrench

ing.

At the completion of revolution, remove retaining wire, wiggle

barrel

and slide from head.

.

one

full turn. Locking wire will feed out of slot during turn

ASSEMBLY

-

Verify

that all

piston

grade no. 2 grease or equivalent.

Slide

then slide barrel over piston onto head. Avoid damaging piston

seals

port in a vertical position.

Align port and hole in barrel; insert retaining wire tap in hole in

head

revolution,

-

rel

turns.

The assembled cylinder can now be tested for

operation.

seals are in the correct position and that the rod and

seals have been properly lubricated with Shell Darina, Ep

piston rod in head (be sure not to damage “U” cup in head),

or head

in feed slot. Rotate barrel

“O” ring. Clamp head by nose or tang on flats with

with strap wrench clockwise one

until port and hole align; retaining wire will feed as bar

leaks and proper

-

-

-

Periodic maintenance must be performed to assure maximum

product

tion

of

solvent.

life. Disassembly for cleaning, inspection, and relubrica

can be performed any time equipment is idle for a short period

time.

All metal parts should be cleaned with a non-flammable

All rubber parts should be thoroughly washed with soap

1. Alternately

-

2. T

apply 90 p.s.i.g. air pressure to each of the cylinder

ports and test for internal leaks across

leaks

at the barrel seals and the rod seals.

est for proper cycling at 20 p.s.i.g. supply

the

piston and external

.

Economair Cylinders2OF8

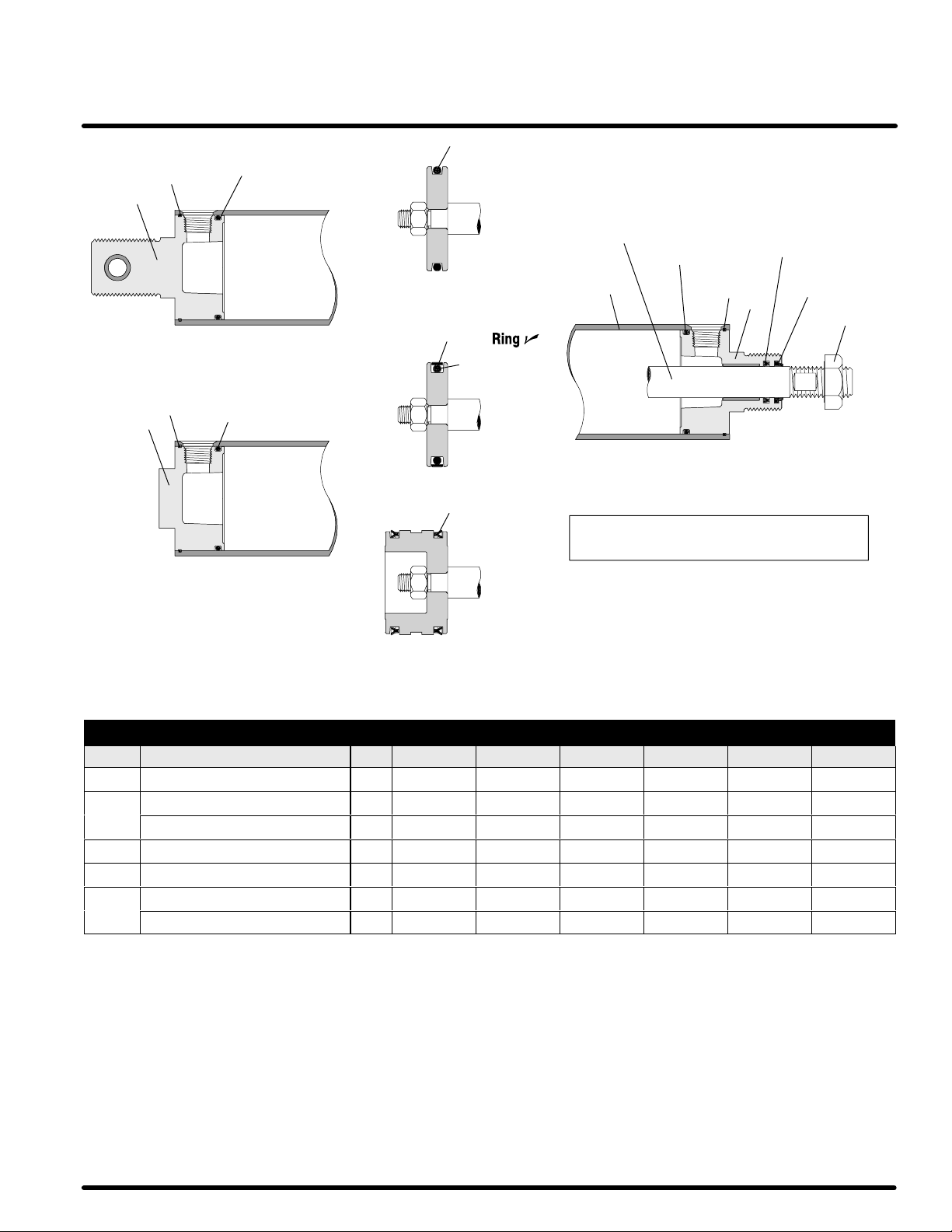

PARTS LIST

PTFE

3

2

MODELS: 23XX-1XX9-XXX

3

2

Barrel Seal n

Barrel Seal n

SERIES

23 CYLINDERS

DOUBLE ACTING, SINGLE ROD END

O" Ring n

Reciprocating

Assembly

(see page 7)

MODELS:

23XX-X0X9-XXX

23XX-X3X9-XXX

O" Ring n

MODELS:

23XX-X2X9-XXX

U" Cup (2) n

5

k Moderately lubricate barrel I.D. and all seals

with Shell Darina EP Grade #2 Grease.

Barrel Seal n

3

Rod Seal n

Wiper n

1

4

MODELS: 23XX-5XX9-XXX

MODELS:

23XX-X4X9-XXX

23XX-X5X9-XXX

23XX-X6X9-XXX

n Included in Seal Kit (see page 7)

PARTS LIST

ITEM DESCRIPTION QTY 1Ć1/8" 1Ć1/2" 2" 2Ć1/2" 3" 4"

1 Head (1) 5002 118308 118319 118330 118340 118350

2 Cap (23XXĆ1) (1) 5003 5105 5205 118334 118344 118354

Cap (23XXĆ5) (1) 5058 5158 5258 118337 118347 118357

3 Feed Ring Wire (2) 5012 5112 5212 116750 5312 5412

4 Nut (1) Y12Ć106ĆC Y12Ć108ĆC Y12Ć110ĆC Y12Ć112ĆC Y12Ć112ĆC Y12Ć116ĆC

*5 Barrel (23XXĆX0, 23XXĆX2, 23XXĆX3) (1) 5501ĆXXX 5608ĆXXX 5708ĆXXX 6008ĆXXX 5808ĆXXX 5908ĆXXX

Barrel (23XXĆX4, 23XXĆX5, 23XXĆX6) (1) 20866ĆXXX 20867ĆXXX 20868ĆXXX 20869ĆXXX 20870ĆXXX 20871ĆXXX

* Specify Stroke Length

Economair Cylinders 3OF8

Loading...

Loading...