Page 1

BU80

BU80E

HTS-10

POWERED SUBWOOFER

SERVICE MANUAL

Infinity Systems, Inc.

250 Crossways Park Dr.

Woodbury, New York 11797 Rev H 11/2001

Page 2

Amplifier/Subwoofer BU-80/BU80E/HTS-10

2

SAFETY INFORMATION/VERSION DIFFERENCES

Warning

Any person performing service of this unit will be exposed

to hazardous voltages and the risk of electric shock. It is

assumed that any person who removes the amplifier from

this cabinet has been properly trained in protecting against

avoidable injury and shock. Therefore, any service

procedures are to be performed by qualified service

personal ONLY!

Caution

This unit does not have a power switch. Hazardous

voltages are present within the unit whenever it is

plugged in.

Before the amplifier is plugged in, be sure its rated voltage

corresponds to the voltage of the AC power source to be

used. Incorrect voltage could cause damage to the amplifier

when the AC power cord is plugged in. Do not exceed rated

voltage by more than 10%: operation below 90% of rated

voltage will cause poor performance or may shut the unit

off.

List of Safety Components Requiring

Exact Replacements

F1 ** Fuse SLO BLO 0.50A or 1.0A 250V

5 x 20mm.UL approved

See Bulletin (INF2000-02) page 16.

PWRCORD SPT-2 or better with polarized plug, UL

approved wired with the hot side to fused

side. Use with factory replacement panel

strain relief only.

T1 ** Transformer. Use only factory

Replacement.

DBR or D001 Bridge diode. Use only factory

replacement.

C1, 2 3300uF, 50V electrolytic filter caps. Be

sure replacement part is at least the same

working voltage and capacitance rating.

Also the lead spacing is important.

Incorrect spacing may cause premature

failure due to internal cabinet pressure

and vibration.

C6 * 10uF 50V electrolytic radial (BU80 and

HTS-10 version “A”,”B” only)

S53AMI Power output module. Use only factory

or CON101 replacement

Faceplate Use only factory replacement

Air leak cover Use only factory replacement

CMC1 Use only factory replacement

L1 Use only factory replacement

Fuse PCB Use only factory replacement

Main PCB Use only factory replacement

R29 470 ohm 1/4W METAL OXIDE, non

flammable

Leakage/Resistance Check

Before returning the unit to the customer, perform a leakage

or resistance test as follows:

Leakage Current. Note there is no power switch on this unit.

When the power plug is plugged in, the unit is live. Connect

the unit to its rated power source. Using an ammeter,

measure the current between the neutral side of the AC

supply and chassis ground of the unit under test. if leakage

current exceeds 0.5mA, the unit is defective. Reverse the

polarity of the AC supply and repeat.

Resistance. Measure the resistance from either side of the

line cord to chassis ground. If it is less than 500k ohms, the

unit is defective.

WARNING! DO NOT return the unit to the customer if it

fails one of these tests until the problem is located and

corrected.

* See Service Bulletin (INF2000-01) page 15.

** See Service Bulletin (INF2000-02) page 16.

Rev A version of the BU-80/HTS-10 subwoofer uses

the following SAFETY PARTS:

#80103 - T1 Power Transformer #4300

#80104 - F1 Line fuse 0.5A 250V T type slo-blo

Rev B version of the BU-80/HTS-10 subwoofer uses the

following SAFETY PARTS:

#80127 - T1 Power Transformer #4300F

#80111 - F1 Line fuse 1.0A 250V T type slo-blo

Either Rev A or Rev B can be identified by:

The correct fuse rating will be printed on the amplifier

label, also:

BU-80: Rev A version

serial #AM0011-29474 and below;

Rev B version serial #AM0011-29475 and

above.

HTS-10: Rev A version serial #AM0011-07400

and below;

Rev B version serial #AM0011-07401 and

above.

HTS-10 subwoofer only

There is a third version, “C”, with minor internal

differences.

Data for this ver s ion is inc luded, and differences ar e

noted in the manual.

Units can be identif ied for service as follows:

Amplifier fac eplate says “Made in Canada” on the “B ”

version.

Amplifier fac eplate says “Made in China” on the “C”

version.

BU80E = HTS-10 version, “C”

Page 3

TABLE OF CONTENTS

Amplifier/Subwoofer

BU-80/BU80E/HTS-10

3

SAFETY INFORMATION/VERSION DIFFERENCES....2

GENERAL SPECIFICATIONS........................................3

DETAILED SPECIFICATIONS........................................4

CONTROLS AND THEIR FUNCTION............................5

BU80/BU80E/HTS-10 CONNECTIONS ........................6

OPERATION ................................................................10

BU80/BU80E/HTS-10 TEST SET UP PROCEDURE...11

BU-80/HTS-10 POWER AMP TEST PROCEDURE

FLOW CHART..............................................................13

SERVICE BULLETIN INF9902 - APRIL 1999 ..............14

SERVICE BULLETIN INF2000-01rev2 -

FEBRUARY 2001 ........................................................15

SERVICE BULLETIN INF2000-02 - MARCH ..............16

TECH TIPS ..................................................................17

BU80/BU80E/HTS-10 AMPLIFIER ASSEMBLY

EXPLODED VIEW........................................................18

BU80/BU80E/HTS-10 PACKING & CABINET PARTS...20

BU-80/HTS-10 rev. A, B PCB (version 5) ....................21

BU-80/HTS-10 rev A, B PCB (version 5.1) ..................22

BU-80/HTS-10 rev A, B ELECTRICAL PARTS LIST....23

BU80/BU80E/HTS-10 INTEGRATED CIRCUIT/

TRANSISTORS DIAGRAM ..........................................24

BU-80/HTS-10 rev A, B SCHEMATIC 1 of 2 ................25

BU-80/HTS-10 rev A, B SCHEMATIC 2 of 2................26

BU80E/HTS-10 REV C

ELECTRICAL PARTS LIST ...27

BU80E/HTS-10 REV C CIRCUIT BOARDS ...............29

BU80E/HTS-10 REV C SCHEMATIC .........................32

BU80E/HTS-10 REV C POWER AMP

MODULE SCHEMATIC ................................................33

GENERAL SPECIFICATIONS

Frequency Response (± 3 db)..............45Hz - 150Hz

Output (RMS) ......................................75W

Driver....................................................8” Woofer

Crossover Frequency ..........................50Hz ~ 150Hz (continuously variable)

Dimensions (H x W x D) ......................11½” (29.2cm) x 11½” (29.2cm) x 11½” (29.2cm)

Add 1¾” (4.5cm) for feet.

Weight ..................................................26 lbs/11.8 kg,

Refinements may be made on occasion to existing products without notice,

but will always meet of exceed original specifications unless otherwise stated.

IMPORTANT SERVICE NOTES: When testing the BU Series amplifier, a load must always

be connected to the output terminals, whether the woofer, or a 4 to 8 ohm resistive load.

All AC powered test instruments (meters, oscilloscopes, etc.) must have a floating

ground, i.e. be connected to an isolation transformer.

Page 4

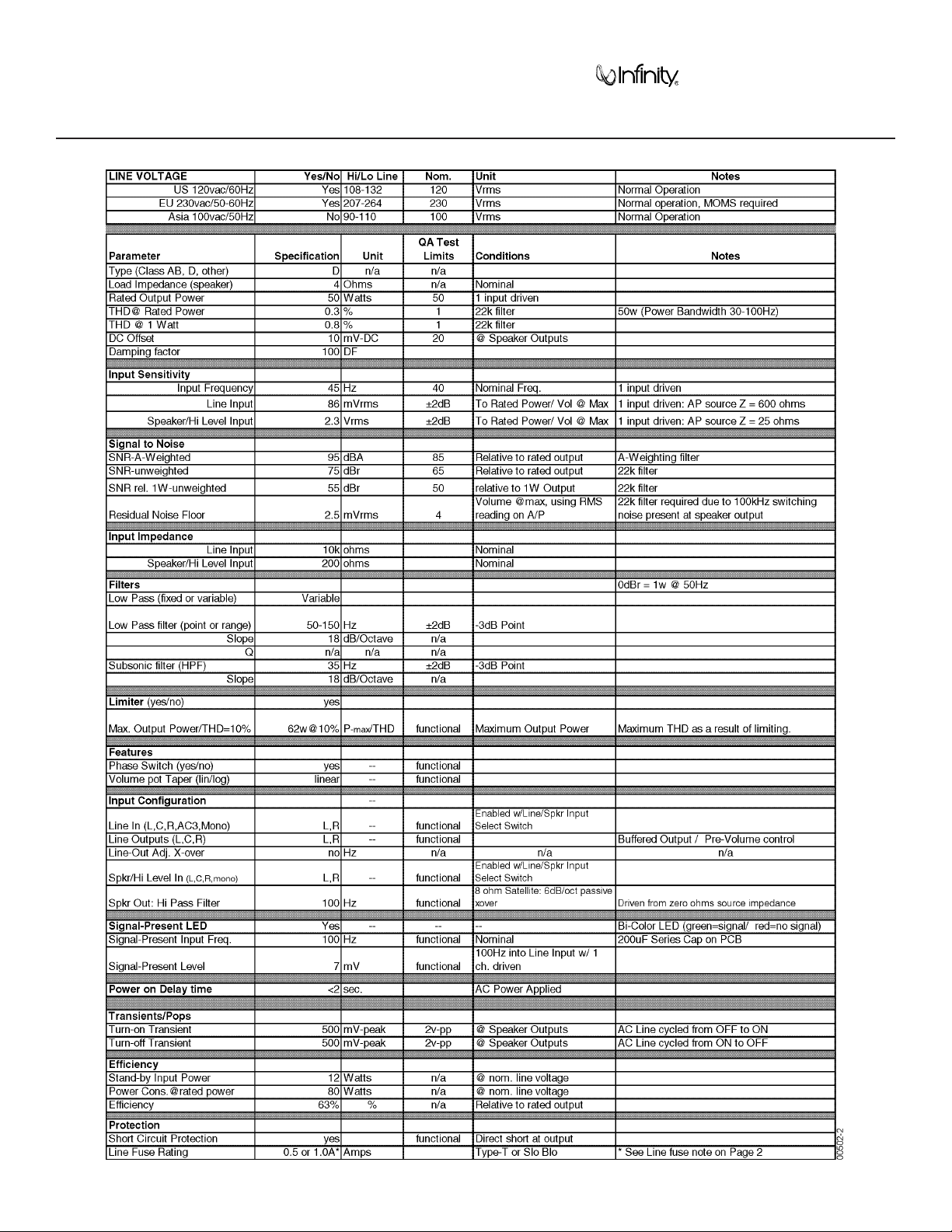

DETAILED SPECIFICATIONS

Amplifier/Subwoofer

BU-80/BU80E/HTS-10

4

Page 5

Amplifier/Subwoofer

BU-80/BU80E/HTS-10

5

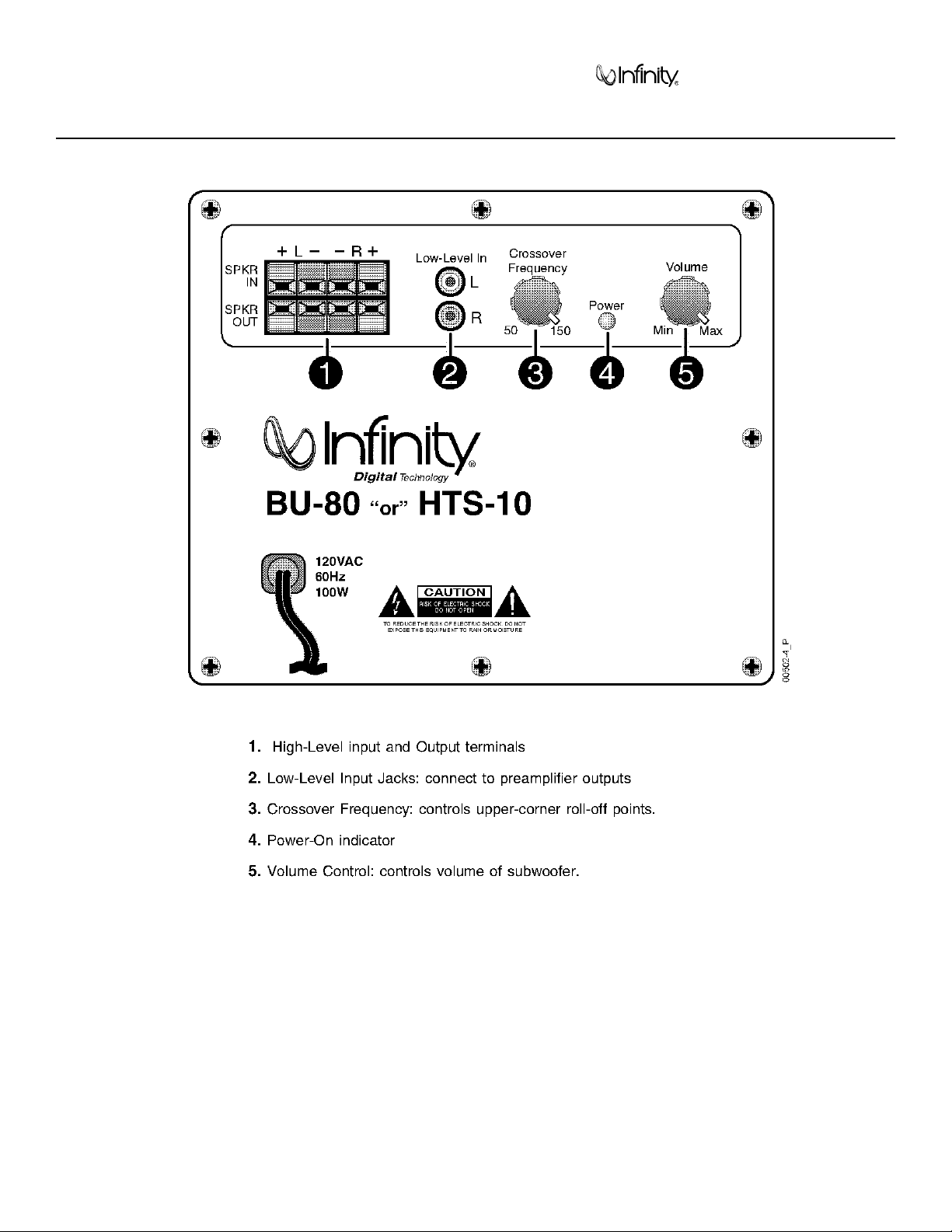

CONTROLS AND THEIR FUNCTION

Page 6

Amplifier/Subwoofer BU-80/BU80E/HTS-10

6

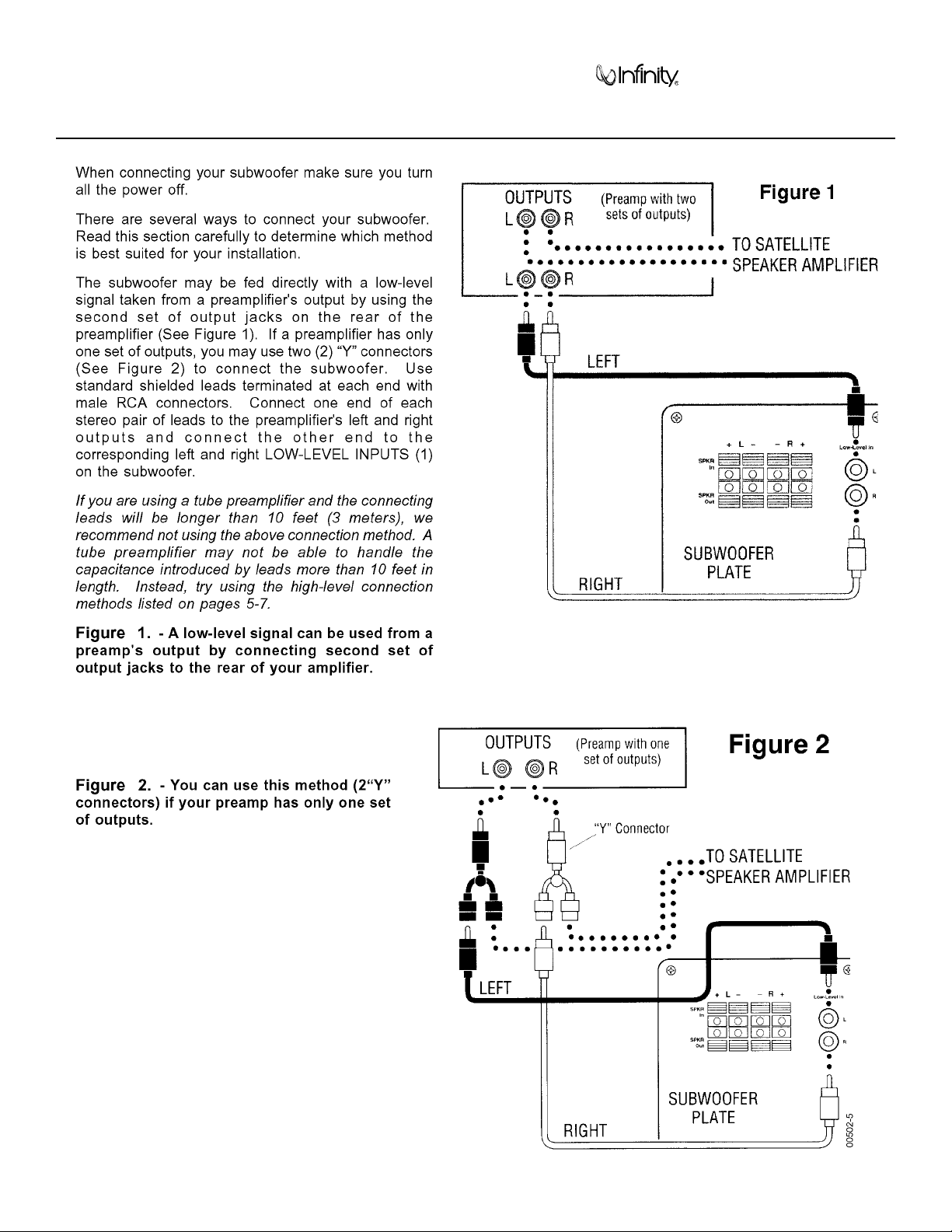

BU-80/BU80E/HTS-10 CONNECTIONS

Page 7

Amplifier/Subwoofer BU-80/BU80E/HTS-10

7

BU-80/BU80E/HTS-10 CONNECTIONS (Cont.)

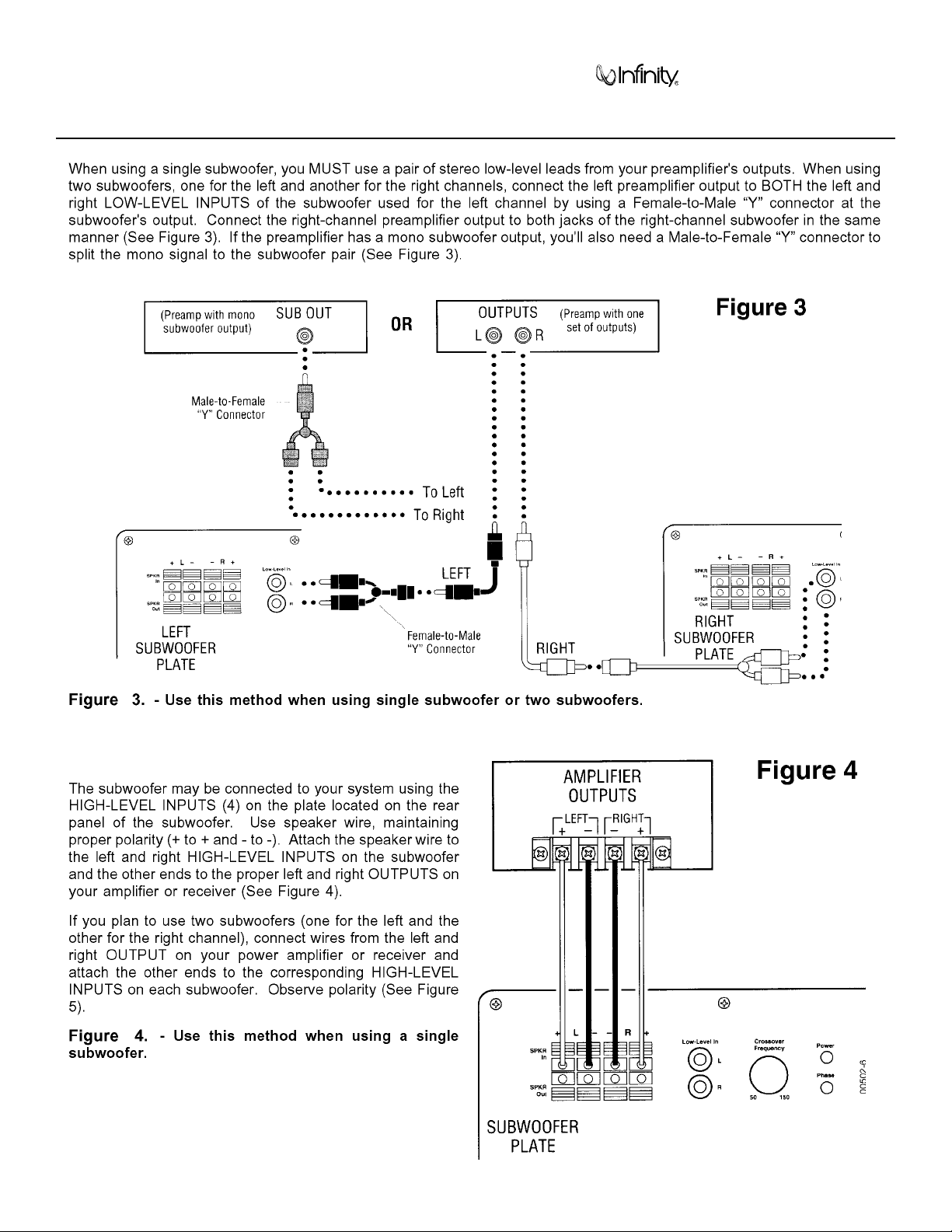

Page 8

Amplifier/Subwoofer BU-80/BU80E/HTS-10

8

BU-80/BU80E/HTS-10 CONNECTIONS (Cont.)

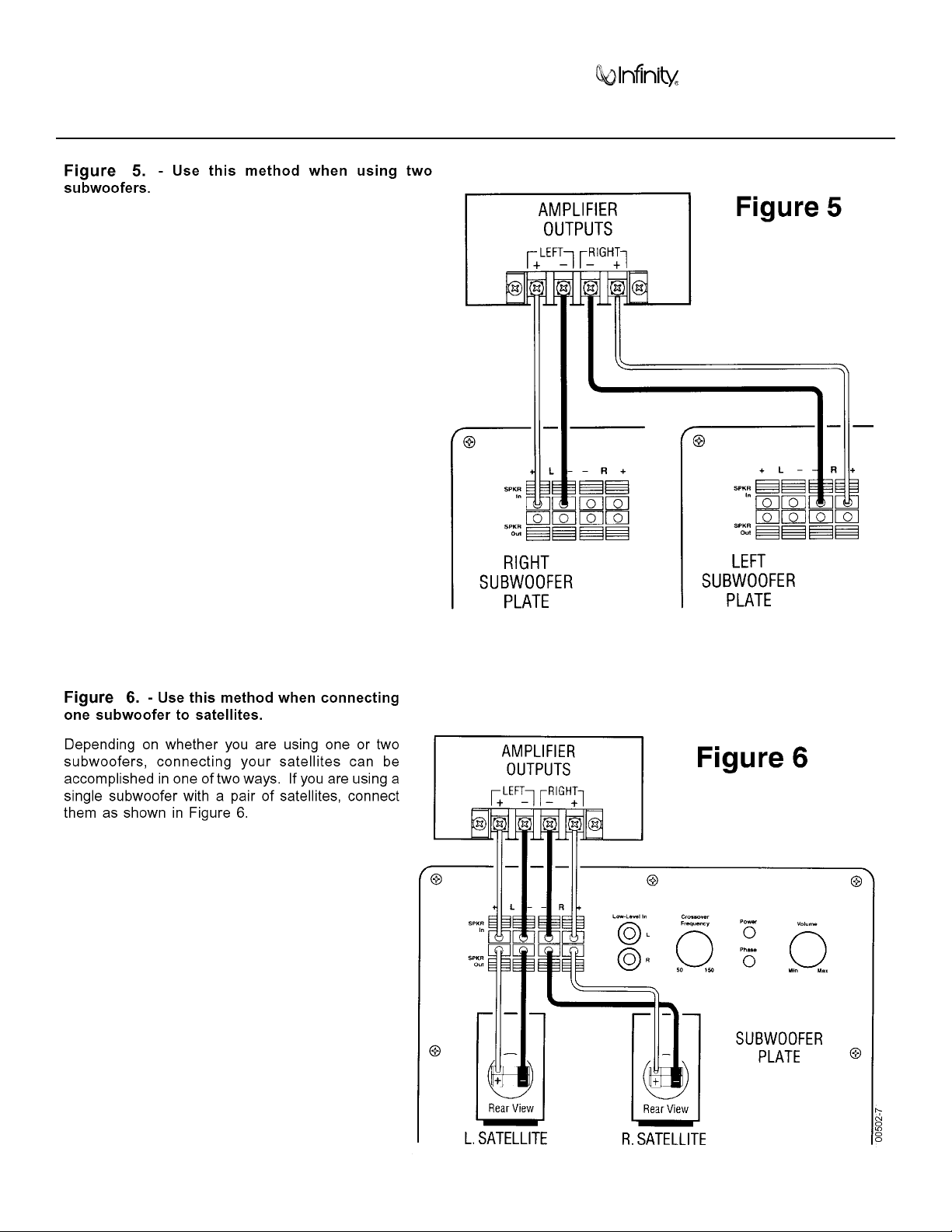

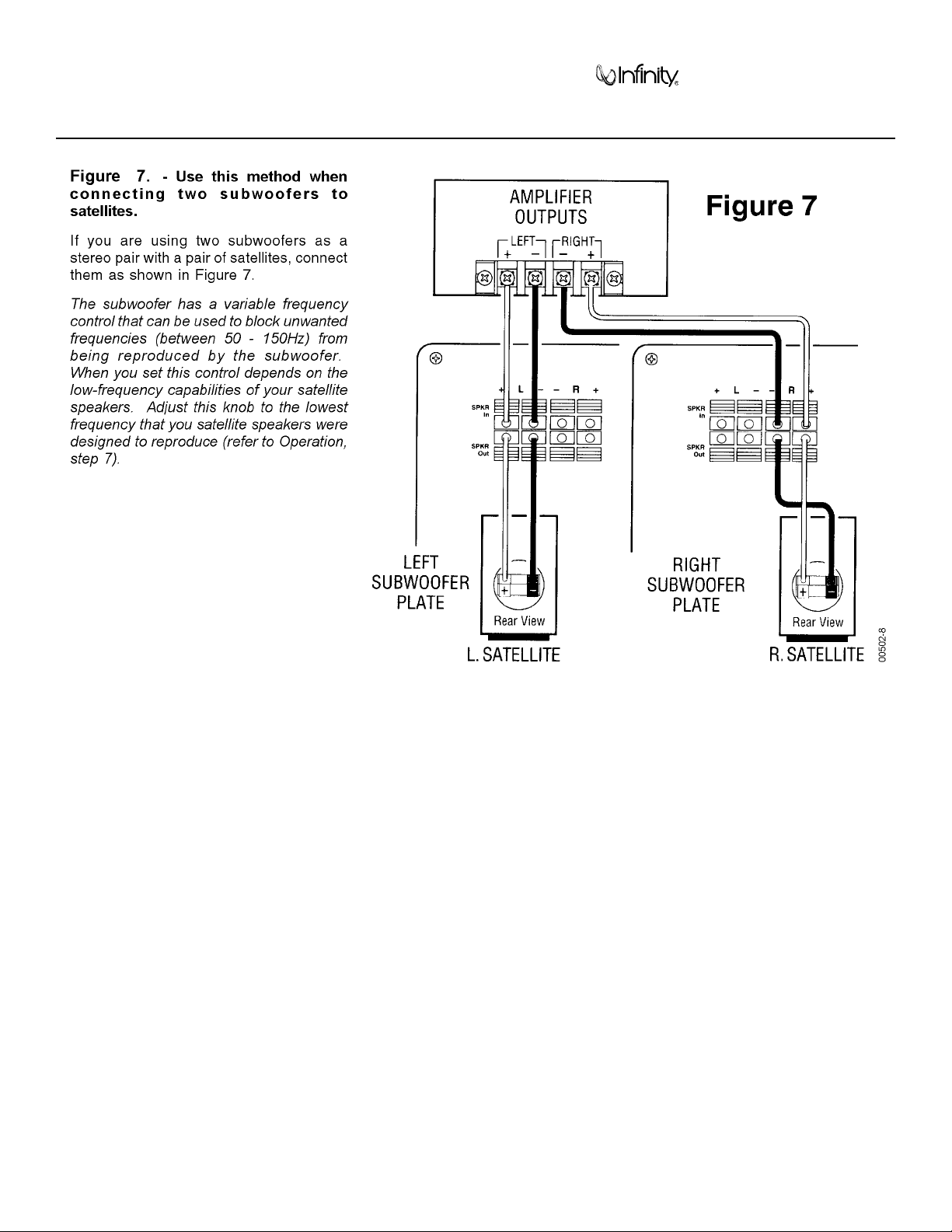

Page 9

Amplifier/Subwoofer BU-80/BU80E/HTS-10

9

BU-80/BU80E/HTS-10 CONNECTIONS (Cont.)

Page 10

Amplifier/Subwoofer BU-80/BU80E/HTS-10

10

OPERATION

Page 11

Amplifier/Subwoofer BU-80/BU80E/HTS-10

11

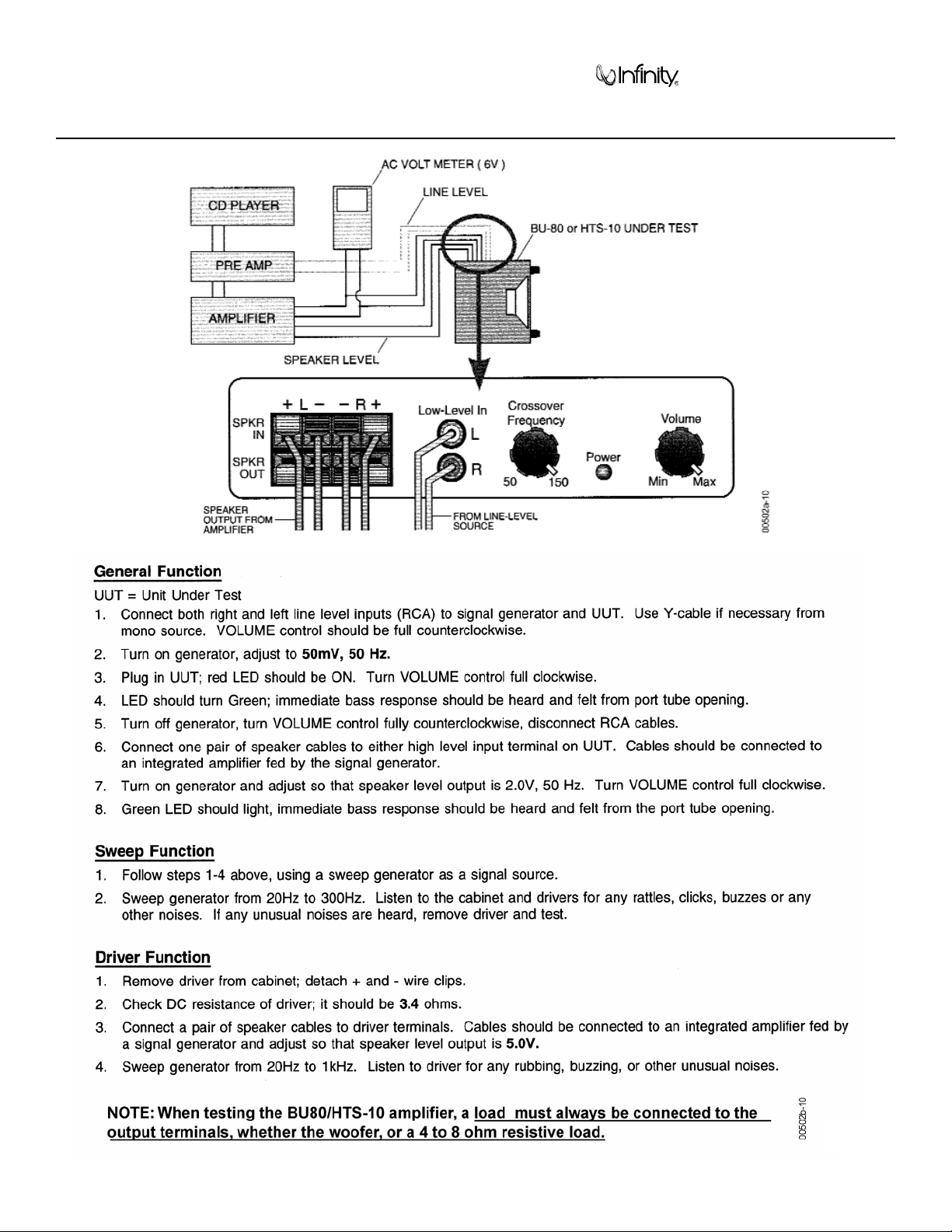

BU-80/BU80E/HTS-10 TEST SET UP AND PROCEDURE

Page 12

Amplifier/Subwoofer BU-80/HTS-10

12

BU80/HTS rev. “A, B”

Page 13

Amplifier/Subwoofer

BU-80/HTS-10

13

Power Amp Test Procedure Flow Chart BU80/HTS-10 rev. “A, B”

Page 14

Amplifier/Subwoofer

BU-80/HTS-10

14

Service Bulletin INF9902 - APRIL 1999

Page 15

Amplifier/Subwoofer

BU-80/HTS-10

15

Page 16

Amplifier/Subwoofer

BU-80/HTS-10

16

Page 17

Amplifier/Subwoofer

BU-80/HTS-10

17

TECH TIPS

Page 18

Amplifier/Subwoofer BU-80/BU80E/HTS-10

18

BU-80/BU80E/HTS-10 AMPLIFIER ASSEMBLY EXPLODED VIEW

BU80/BU80E/HTS-10

Page 19

Amplifier/Subwoofer BU-80/BU80E/HTS-10

19

BU-80/BU80E/HTS-10 AMPLIFIER ASSEMBLY EXPLODED VIEW (Cont.)

Page 20

Amplifier/Subwoofer

BU-80/BU-80EHTS-10

20

BU-80/BU-80E/HTS-10 PACKING & CABINET PARTS

FEET (SET OF 4)

BU-80/HTS-10

(rev. "A,B") 200210

BU-80E/HTS-10 (rev. "C")

061-403005-000

SCREWS (4)

8" WOOFER

BU-80/HTS-10

(rev. "A,B") 200200

BU-80E/HTS-10 (rev. "C")

090-308000-000

CABINET

NOT FOR

SALE

BU-80/BU-80E/HTS-10

CABINET ASSEMBLY

SCREWS (4)

AMPLIFIER

ASSEMBL

Y

SCREWS (8)

FEET PAD (4)

STICKERS

#200252

WARRANTY

CARD

#333715-001

OWNER'S

MANUAL

BU-80

“or”

HTS-10

OWNER'S

MANUAL

BU-80 - #200230

HTS-10 - #HTS10GUIDE

BU-80E - #008-042228-020

BU-80/BU-80E/HTS-10 PACKING

CARTON

BU-80 - #200220

HTS-10 - #HTS10CTN

BU-80E- #005-003838-000

BOTTOM STYROFOAM

RAILPADS

(2 per carton)

#200260

BU-80 "or"

HTS-10

SUBWOOFER

PLASTIC BAG

TOP

STYROFOAM

PADS

(4 per carton)

#200270

00502-19

NOTE:

The HTS-10

speakers;

subwoofer

the master carton

is part of the HTS-10

is not shown.

system

and packaged

with 5 satellite

Page 21

Amplifier/Subwoofer BU-80/HTS-10

21

BU-80/HTS-10 (rev. A, B) PCB

Page 22

Amplifier/Subwoofer

BU-80/HTS-10

22

BU-80/HTS-10 (rev. A, B) PCB

Page 23

Amplifier/Subwoofer

BU-80/HTS-10

23

BU-80/HTS-10 (rev. A, B) ELECTRICAL PARTS LIST

Page 24

Amplifier/Subwoofer

BU-80/BU-80EHTS-10

24

BU-80/HTS-10 INTEGRATED CIRCUIT/TRANSISTORS DIAGRAM

S53AM/S64AMI - Power Amp module SAFETY PART

BU-80 and HTS-10 rev “A, B” ONLY

+6V 15

16

V+

17

18

O/P

19

20

V- V-

21

22

1+6V

2

3

V+

4

O/P

5

6

7

8

+15V 23 9 +15V

SD 24

10 SD

FR 25 11 FR

I/P 26 12 I/P

GND 27 13 GND

-15V 28 14 -15V

NOTE: THE FOLLOWING PROCEDURES MUST BE FOLLOWED WHEN

INSTALLING NEW AMP MODULES:

FAILURE TO FOLLOW ONE OR MORE OF THESE STEPS MAY

RESULT IN THE INSTANT DESTRUCTION OF THE MODULE WHEN

POWERED UP.

1) Align white indent marker on Amp Module with indent marker on main

PCB; alternately position of label on the top of the module; incorrectly

0

replacing the Module 180

in the PCB slot will result in its destruction.

2) All AC powered test instruments (meters, oscilloscopes, etc.) must

have a floating ground, i.e. be connected to an isolation transformer.

3) Align and position the Amp Module before soldering.

4) Attach the amp Module with the mounting screws before soldering

powering up.

5) Use only rosin-core or non-acid core solder; thoroughly de-flux the

surfaces after soldering.

If the new Amp Module has larger mounting hole(s) in the case, and

the stock screws no longer will fit, and screws of the proper type cannot be obtained locally order:

00228

(2) part# 60301S (screws)

or

QUAD OP AMP,

LM324, TL074

U1, IC101

MOSFET TRANS

IRF530

Q2, 3

1. DRAIN

2. GATE

3. SOURCE

TRANS, PNP, 2SA1015

Q101, 104, 105

TRANS, PNP, 2N3906

MPS A56

Q2, 4, 5

(2) part# 60301N (nuts)

146V13

15

LIM

IT

V

+

TRANS, NPN, KSP113

2SC1815

Q102, 103

TRANS, NPN, 2N5551

2N3904

Q1, 3

BU-80E & HTS-10 rev “C” ONLY

12

V

+

O

V

+

/

P

V

V

-

-

+15V

V

-

5

6

7

8

9

10

11

PWR MODULE

CN101

IC 74HC14N HEX SCHMITT

TRIGGER INVERTER

U2, 3

V

A6

CC

14

13

A5

Y6

12

3

21

S/D

11

4

4IN3

Y6

10

5

2

G

-15V

N

D

A4

Y4

98

6

GNDA3Y2A2 Y3Y1A1

TRANS, NPN

MPS A13 (Darl)

1

FB

7

Q1

2

BASE

00370

JFET DUAL OPAMP

LF353N U1

1

OUT1

IN1 (–)

2

IN1 (+)

3

V

4

EE

3 COLLECTOR

1 EMITTE R

8

7

6

5

V

CC

OUT2

IN2 (–)

IN2 (+)

12

3

Page 25

Amplifier/Subwoofer

BU-80/HTS-10

25

BU-80/HTS-10 (rev. A, B) SCHEMATIC 1 OF 2

Page 26

Amplifier/Subwoofer

BU-80/HTS-10

26

BU-80/HTS (rev. A, B) SCHEMATIC 2 OF 2

Page 27

Amplifier/Subwoofer infinity BU-80/BU80E/HTS-10

27

HTS-10 ELECTRICAL PARTS LIST (Rev C version)

Part Number Description Ref. Designator Qty

MAIN PCB

Semiconductors

050-002400-100 ZENER DIODE 24V D103 1

050-003000-100 ZENER DIODE 30V D104 1

050-006200-100 ZENER DIODE 6.2V D002 1

050-414802-100 1N4148 DIODE D101,102,105,106 4

050-524500-200 ZENER DIODE 15V/1W D003,004 2

051-001300-100 TRANSISTOR KSP113 Q102 1

051-101501-000 TRANSISTOR 2SA1015 Q101,104,105 3

051-181501-100 TRANSISTOR 2SC1815 Q103 1

052-401001-000 KBU4A/100V Bridge Regulator D001 1

053-007400-000 IC TL074 Dual Op-Amp IC101 1

Resistors

020-100497-120 Carbon resistor 1K 1/4W J R132,139,140 3

020-100597-120 Carbon resistor 10K 1/4W J R107,108,R131,133,136 5

020-100697-120 Carbon resistor 100K 1/4W J R105,106,114,122,124,134,137 7

020-100797-120 Carbon resistor 1M 1/4W J R128 1

020-220797-120 Carbon resistor 2M2 1/4W J R138 1

020-330397-120 Carbon resistor 330R 1/4W J R118,119 2

020-330497-120 Carbon resistor 3K3 1/4W J R130 1

020-330597-120 Carbon resistor 33K 1/4W J R135 1

020-430497-121 Carbon resistor 4K3 1/4W J R125 1

020-470197-121 Carbon resistor 4R7 1/4W J R002 1

020-470497-120 Carbon resistor 4K7 1/4W J R117 1

020-470597-120 Carbon resistor 47K 1/4W J R123 1

020-470697-120 Carbon resistor 470K 1/4W J R129 1

020-680597-120 Carbon resistor 68K 1/4W J R109,143 2

021-100096-120 MOF RESISTOR 0R1 1/2W R141,142 2

021-100301-120 MOF RESISTOR 100R/1W R101-104 4

021-220401-021 MOF RESISTOR 2K2 1W R120,121 2

021-220402-020 MOF RESISTOR 2K2 2W R001 1

021-221597-100 MF RESISTOR 221K 1/4W F R112 1

021--249597-100 MF RESISTOR 24K9 1/4W F R115 1

021-270697-100 MF RESISTOR 270K 1/4W F R127 1

021-274697-100 MF RESISTOR 274K 1/4W F R116 1

021-280597-100 MF RESISTOR 28K 1/4W F R110 1

021-470497-100 MF RESISTOR 4K7 1/4W F R126 1

021-499597-100 MF RESISTOR 49K9 1/4W F R113 1

021-820302-020 MO 820OHM/2W R003,004 2

021-820497-100 MO 8K2 OHM/1W R111 1

026-100695-251 VR 100KB Crossover Frquency Pot VR102 1

026-500495-252 VR 5K ohm Volume Pot VR101 1

Capacitors

030-100247-300 Ceramic capacitor 0u1/50V Z P:5 C114,115,006,009,010 5

032-100163-300 mylar capacitor 0u001/100V J P:5 C103 1

032-100263-301 mylar capacitor 0u01/100V J P:5 C110 1

032-100364-300 mylar capacitor 0u1/100V K R C001,002,003,007,008, 11

104105106107108, 118

032-180364-300 mylar capacitor 0u18/100V J P:5 C116 1

032-220163-300 mylar capacitor 0u0022/100V J P:5 C109,111 2

033-220543-200 elec capacitor 22uF/50V J6R 1020 C117 1

033-220644-281 NPE capacitor 220uF/50V K10R1326 VIE C101,102 2

Page 28

Amplifier/Subwoofer infinity BU-80/BU80E/HTS-10

28

Part Number Description Ref. Designator Qty

034-100635-300 elec capacitor 100uF/35V MR 0811 P5 C113 1

034-330745-310 elec capacitor 3300uF/50V MR 1840 P7.5 C004,005 2

034-470425-300 elec capacitor 4u7/25V MR 0511 P5 C112 1

POWER AMP MODULE 1

050-414802-100 1N4148 DIODE D1-D9 9

051-530000-100 MOSFET N-CHANNEL IRF530 Q2,3 2

051-555100-000 TRANSISTOR 2N5551 Q1 1

053-035301-000 IC LF353N Dual Op-Amp U1 1

053-741400-000 IC 74HC14N Hex Schmitt Trigger Inverter U2,3 2

020-100297-120 Carbon resistor 10R 1/4W J R11,12 2

020-100397-120 Carbon resistor 100R 1/4W J R7 1

020-100497-120 Carbon resistor 1K 1/4W J R3,4,5,9 4

020-100697-120 Carbon resistor 100K 1/4W J R2 1

020-100797-120 Carbon resistor 1M 1/4W J R10 1

020-220397-121 Carbon resistor 220R 1/4W J R6 1

020-330497-120 Carbon resistor 3K3 1/4W J R8 1

020-680497-120 Carbon resistor 6K8 1/4W J R1 1

032-100394-302 MND mylar capacitor 0u1/100V K P:7.5 C9 1

034-100525-303 elec capacitor 10uF/25V M SM 4*7 C7 1

039-100343-100 mylar capacitor(axial) 100pF/50V J NPO C1,2,3,5 4

039-100345-100 mylar capacitor(axial) 0u1/50V M Z5U C4 1

039-100464-100 mylar capacitor(axial) 0u001/50V K X7R C8 1

039-330344-101 mylar capacitor(axial) 330pF/50V K X7R C6 1

072-040170-000 CONNECTOR 15PIN 1

073-014023-900 SHIELD 103.9*14*0.3t 1

073-032050-000 HEAT SINK 102.3*58mm 1

061-700012-000 Silicon Sleeves for Q2, Q3 2

FUSE PCB ASS’y

011-080203-000 FUSE PCB BOARD SWD80 82*21*1.6m/m

072-040039-000 Terminal (PCB TYPE) PC205 (t=0.8mm) J3,4,5,6 4

091-000097-000 FUSE T1A/250V 5*20mm 1

091-000130-000 FUSE HOLDER CQ-203SP(C) (0)

Miscellaneous

042-017607-004 Transformer YT-9161-2 75W-120Vac 1

073-014026-000 Metal Shield Plate

061-020000-000 knob 20x15mm ul94V-0 1

061-314002-000 cord bushing P/N SB4F-2 1

062-160400-001 Rear cover 168.6x36.8x19.9mm 1

062-211800-000 Front cover 213x178x31.5mm 1

083-041802-017 power cord spt-2 blk #18 1

043-240130-010 CHOKE COIL 2.4mH YT-8719 L001 1

043-260330-001 CHOKE COIL 0.11mH YT-8713-1 L104 1

050-505200-001 LED LT-2402-25 LED101 1

008-061007-200 GASKET MODULE BLK CR C4305 1x7x80mm 1

008-061610-201 GASKET PCB PU FOAM SM-55 3x6x200mm 1

062-050800-000 PUSH TERMINAL 8P JK101 1

070-560891-108 SCREW BTS-3 2.6x8m/m

072-010058-000 RCA JACK 2P P/N:052000W1G (Red,Wht) JK102 1

072-040032-000 Terminal P:3.96 3P CN001 1

072-040039-000 Terminal PCB TYPE PC205 (t=0.8mm) J101,102 2

091-000143-000 EMI BEAD 2

1

Page 29

Amplifier/Subwoofer BU80E/HTS-10

29

BU80E/HTS-10 REV C POWER AMP MODULE PCB

Page 30

Amplifier/Subwoofer

BU-80E/HTS-10

30

BU80E/HTS-10 REV C CIRCUIT BOARD (Cont.)

Page 31

Amplifier/Subwoofer BU80E/HTS-10

31

BU80E/HTS-10 REV C CIRCUIT BOARD (Cont.)

Page 32

Amplifier/Subwoofer

BU-80E/HTS-10

32

BU80E/HTS-10 REV C SCHEMATIC

Page 33

Amplifier/Subwoofer

BU-80E/HTS-10

33

BU80E/HTS-10 rev C POWER AMP MODULE SCHEMATIC

(IRF640)

(IRF640)

E

D

F

321

C

B

A

4321

A

B

C

8765

D

E

F

876

00503

Page 34

Loading...

Loading...