TM

CORONA DISCHARGE

OZONE GENERATORS

CD-7 THRU CD-15

Main Power

Ozone Power

Vacuum

High Coolant Temperature

High Transformer Temperature

Water Backflow Detector

INSTALLATION & OPERATIONS MANUAL

DEL INDUSTRIES, INC. · SAN LUIS OBISPO, CA 93401 · USA · 800-676-1335 · Fax: 805-541-8459 012400 / 4-0401

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

TABLE OF CONTENTS

SECTION 1

General Information

1A. Description...........................................................1

1B. Specifications ......................................................1

1C. Warranty Summary...............................................1

SECTION 2

Installation

2A. Location...............................................................1

2B. Mounting..............................................................1

2C. Electrical ............................................................. 2

2D. Plumbing .............................................................2

2E. ORP Sensor Connection......................................2

SECTION 3

Operation

3A. General ................................................................3

3B. Initial System Start-Up ........................................3

3C. Normal Operation.................................................3

3D . Shut-Down ...........................................................3

3E. Water Chemistry ..................................................3

SECTION 4

Maintenance & Service

4A. System Electro-Mechanical Overview .................4

4B. PM Schedule .......................................................4

4C. Generator Servicing .............................................5

4D . T roub le Shooting ..................................................5

SECTION 5

Replacement Parts & Order Info

5A. Ordering Information ............................................6

5B. Standard Replacement P arts List.........................6

Warranty ...................................................... 7

Appendix

Appendix A (Safety)...................................................8

ALL Infinity CD Ozone Generators are

UL Classified and NSF Listed.

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLO W ALL INSTRUCTIONS.

· Read this manual completely before attempting installation.

· Install at least 5 feet (1.5meters) from wall of spa or pool water using nonmetallic plumbing. Install ozone generator

no less than one (1) foot above maximum water level to prevent water from contacting electrical equipment. Install

in accordance with the installation instructions.

· Connect to a grounded, grounding type receptacle only.

· Do not bury cord.

· Warning - To reduce the risk of electrical shock, replace damaged cord immediately .

· Follow all applicable electrical codes.

· Electric shock hazard. Be sure to turn power OFF and disconnect from power source before any service work is

performed. F ailure to do so could result in serious injury or death.

· Warning - Short term inhalation of high concentrations of ozone and long term inhalation of low concentrations of

ozone can cause serious harmful physiological effects. DO NO T inhale ozone gas produced b y this de vice.

· For y our safety, do not store or use gasoline, chemicals or other flammable liquids or v apors near this or any other

appliance.

· A spontaneous and violent ignition may occur if oil, grease or greasy substances come in contact with oxygen

under pressure. These substances m ust be kept a wa y from o xygen regulators, cylinder v alv es tubing and connections, and all other oxygen equipment.

SAVE THESE INSTRUCTIONS!

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

SECTION 1

General Information

1A. Description

The Infinity™ Corona Discharge series ozone generator

described in this manual is designed to provide the benefits of ozonated water in an environmentally safe and

effective manner. Infinity™generators are UL and NSF

listed. The high quality, specially engineered components

ensure efficient ozone output and reliable performance.

As a result of proper use of the Infinity™CD ozone generators, unpleasant effects of traditional chemical use,

(dry skin, red eyes, green hair) are virtually eliminated.

The Infinity CD ozone generator is safe and harmless to

your equipment if installed properly .

1B. Specifications

Ozone Output:

Ozone output (+10%):

Flow rate (max):

% weight O3: 2.5-3.0%

CD-7..........

CD-15 ........

CD-7..........

CD-15 ........

7 g/hr

15 g/hr

7 scfh (3.5 lpm)

15 scfh (7 lpm)

1C. Warranty Summary

Limited Warranty:

2 years on entire generator

In addition to the two (2) year warranty:

3 years on weldments

5 years on high voltage electrodes

2 years on compressors that are maintained

according to operation and maintenance manual.

SECTION 2

Installation

2A. Location

CD-7 and CD-15 are designed for either floor or wall mounting in a clean, protected area, either indoors or outdoors.

Locate generator out of reach of sprinklers or drainage

spouts. Allow sufficient access for maintenance and all

tubing and electrical wires. Ozone generator should be

installed no less than one foot above maximum water

level.

Po wer Requirements:

Domestic:

Export*:

Cooling Water Requirements:

.1 GPM (.4 lpm) of clean, filtered, fresh water .

NOTE: Typical pool water may be used f or cooling.

Generator efficiency and life will be improved at inlet

temperatures of 80°F or less.

Inlet temperature: 50°F - 90°F (10°C - 32°C)

Inlet pressure: 15.0 - 40 psi (100 - 270 kPa)

Shipping Weight:

CD- 7 :Approx. 135 pounds / 61 kilos

CD-15: Approx. 150 pounds / 70 kilos

Location Requirements**:

Mounting: Floor or wall mount in a clean, protected

Ambient T emp: 40°F - 100°F (5°C - 40°C)

V entilation: 6 air changes per hour. (min)

* 230V/50Hz unit supplied with enclosed step down trans-

former

CD-7 .....

CD-15....

CD-7 .....

CD-15....

115VAC , 50/60 Hz, 1Ø, 6.0 Amp

115VAC , 50/60 Hz, 1Ø, 7.5 Amp

230VAC , 50 Hz, 1Ø, 3.5 Amp

230VAC , 50 Hz, 1Ø, 4.0 Amp

area using supplied brackets.

Figure 1: Wall Mount

**Protection from weather elements must be provided for

outdoor installations. Operating outside of the recommended temp. ranges may result in damage not covered

under the manufacturer’s warranty.

1

2B. Mounting

2B-1. Wall Mount Option

1. Attach two mounting brackets to wall using anchors

appropriate for mounting surface.

2. Using 1/4"-20 bolts (with washers as shown) secure generator to mounts.

2B-2. Floor Mount Option

1. Use the 4 1/4"-20 bolts with washers to secure feet

to bottom of cabinet.

2. Stand upright and securely fasten to concrete slab

using appropriate anchors and bolts.

See figure 1

2C. Electrical

Main power circuit: Unit is supplied with a standard

power cord. Plug cord into standard 110V grounded,

grounding type receptacle only. NOTE: The circuit must

be protected by a ground-fault circuit interrupter (GFCI)

installed in accordance with electrical codes.

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

.

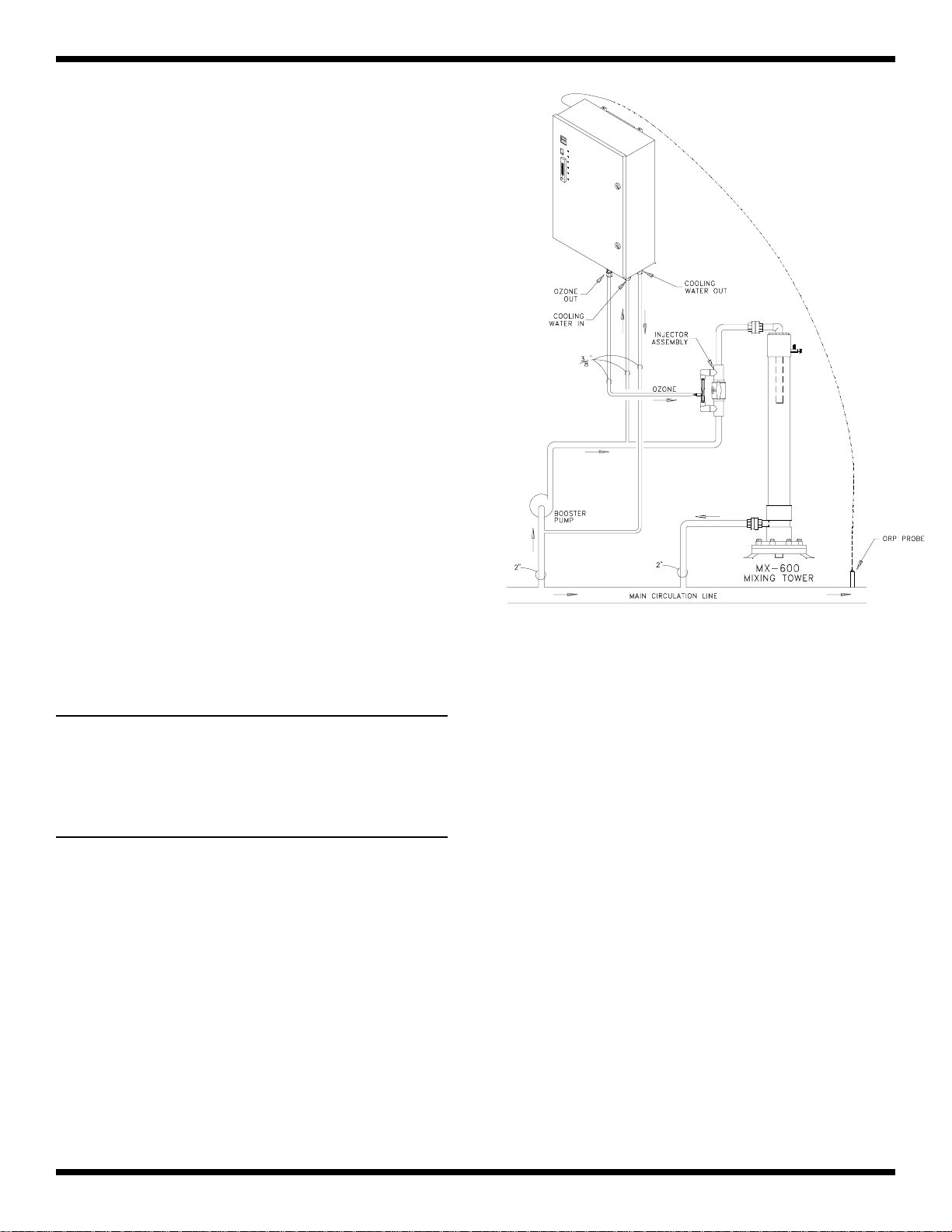

2D. Plumbing

Ozone gas is introduced to the pool circulation line using

a venturi injector . Suction developed b y the venturi allows

the CD to operate safely under vacuum.

manual for MX-600-CD for proper venturi installation

2D-1. Ozone Gas Line

1. Connect ozone tubing to generator outlet fitting.

(3/8" stainless steel compression fitting.)

2. Connect opposite end of ozone tubing to injector

suction port. (Suction port fitting: 3/8" stainless

steel compression fitting.)

NOTE: The ozone gas suppl y line must have a bac k flow

prevention device (such as a check valve) installed between the ozone generator cabinet and the point of

injection to prevent water from backing up into the

generator system. An ozone supply check valve is

included with the MX-600-CD system.

2D-2. Cooling W ater

Cooling water must be supplied as specified in section 1B.

1/4" FPT connections are supplied on the generator .

See figure 2

matched with the marked inlet and outlet ports. Carefully match and connect to water plumbing as shown

in figure 2. Alternate method using connections at injector may be used.

. Be sure that the tubing is appropriately

See figure 2

See installation

.

.

Figure 2: Plumbing Schematic

2E. ORP Sensor Connection

(For optional ORP Controller) Consists of mounting the

ORP probe and routing the sensor cables.

2E-1. ORP Probe Mounting

The sensor should be placed in the water stream at a

point downstream from the ozone injector .

1. Locate the point of insertion in the process pipe.

NOTE: Install the ORP probe in a location which

provides easy access for removal and cleaning of

the probe. The probe should be installed such that

the main stream ORP is measured. Locating the

ORP probe upstream of the ozone measures the

"pool" water . Locating the probe downstream of the

ozone measures the ORP of water returning to pool.

2. Install an appropriately sized tee in the process

line or drill and tap a 1/2" FPT hole in the process

pipe as shown in figure 3.

3. Remove the protective cap and apply Teflon tape

to the sensor threads. Thread the sensor into the

fitting or tapped hole. Save the protective sensor

cap for storage.

4. Start the circulation system and check for leaks

around the sensor.

See figure 2

.

2

Figure 3: ORP Probe

2E-2. ORP Cable Routing:

Route the cable away from other power wires and protect

cable from damage. (i.e. Conduit or attached to plumbing.) Connect the sensor cable to the BNC connector located on the left exterior wall of the generator cabinet.

SECTION 3

Operation

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

Both (2) green indicator lights should be lit. If the optional

ORP Controller is installed, it should be displaying a reading from the sensor probe and will automatically cycle the

generator on and off as needed to maintain water quality.

A high ORP (650-750 mV) is necessary for biological control.

However , the system will not start under any of the following conditions:

1. If the optional ORP controller is installed the system

will not start up if the ORP level is already above

the setpoint of the ORP controller.

2. The system will not start up if the door is not secured. A door interlock switch is incorporated into

the system enclosure.

3. The system will not start up if there is not enough

vacuum being generated by water flow through

injector. Red v acuum light will go out when proper

vacuum is attained.

4. System will not operate if there is too much

vacuum. Red vacuum light will go out when

proper vacuum is attained.

3A. General

To achieve optimal performance from the ozone system,

the pool must be as clean as possible to start with.

1. Backwash or clean filters one day before starting

the ozone generator .

2. Superchlorinate pool water using a chlorine based

shock treatment.

3. Test pool chemistry and adjust pH between 7.4 and

7.6. Adjust total alkalinity between 80 and 120 ppm.

4. Run pool filtration continuously for 24 hours prior to

starting ozone system.

3B. Initial System Start-Up

Upon completing all of the generator system connections

and cleaning the pool as outlined above, you are ready to

begin start up procedures.

1. Check electrical fittings.

2. Check for proper voltage.

3. Turn on circulation pump.

4. Check for leaks.

5. Check cooling water .

6. Adjust injector by-pass to attain required vacuum.

(Red vacuum light will go out)

7. Turn main power switch to "ON" position.

3C. Normal Operation

At this point, the system’s cooling fans will start up. The

oxygen concentrator will begin operating and the output

solenoid valve will open. The ozone generator should be

producing ozone and injecting it into the process line.

If you experience complications, see TROUBLESHOO TING section 4C or call 800-676-1335 for assistance.

3D. System Shut-Down

The Infinity Corona Discharge ozone generator is a specialized water cooled device that must be properly protected

during shut-down/storage periods.The following sequence

of steps must be used for servicing or for storage.

1. Toggle the main system power switch to the “OFF”

position to shut down generator .

2. After the generator has been shut down, the process water circulation pump may be turned off.

3. If the system is going to be shutdown and stored

during freezing weather, it is very impor tant that

the cooling water jacket be drained to protect it from

rupture or damage.

NOTE: Process water flow

the ozone generator is operating. Doing so may cause

water to backflow into the system and damage the generator module and electrodes.

must not

be shut down when

3E. Water Chemistry

Regular chlorine/bromine testing should be performed as

normal. Ozone will be eliminating the majority of contaminants. Therefore, only a small amount of chemicals will

need to be added - just enough to maintain a minimum of

residual level of .5-1.0 ppm chlorine or 1.0-2.0 ppm bromine. Ozone has very little if any impact on pH, reducing

pH adjustments to a minimum.

3

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

SECTION 4

Maintenance and Service

4A. System Electro-Mechanical Overview

Refer to Figure 4

4A-1. Indicator Lights

1. Main Power: Green light indicates that power is

being supplied to the ozone generator .

2. Ozone Po wer: Green light indicates that power is

being supplied to the high voltage Corona Discharge

circuits and that ozone is being produced.

3. Vacuum: Red light indicates proper vacuum being

supplied from the venturi injector . Light will be lit for

either low or high vacuum conditions.

4. High Coolant Temperature: Red light indicates

coolant temperature is over 150°F - resulting from

loss of cooling water flow. (Refer to TROUBLESHOOTING section.)

5. High Transformer Temperature: Red light indicates

transformer temperature is over 150°F - resulting

from high current through the transformer . (Ref er to

TROUBLESHOO TING section.)

6. Water Bac kflow Detected: Red light indicates water backflow from injector into generator. (Refer to

TROUBLESHOO TING section.)

4A-2. Remaining External Components

1. Main Po wer Switch: P ower switch is used f or system start-up and shut-down. Switch activates the

control system allowing the generator to start up.

2. Flowmeter: Flowmeter controls and indicates the

oxygen flow through the system.

3. Circuit Breaker: Circuit breaker protects the gen-

erator from over current conditions. Push the breaker

button to reset.

4. ORP Controller (optional): ORP controller receives

a millivolt (mV) signal from the ORP sensor mounted

in the process water line. ORP (Oxidation-Reduction Potential) is a measure of the relative oxidation strength of the water . As ozone is added to the

water system the ORP level will rise. As ozone is

used up in the water system the ORP level will

drop. The ORP controller continuously analyses the

sensor signal, compares it to the setpoint that has

been programmed, indicates the ORP level on the

digital display, and relays the signal to the ozone

generator .

5. V ariac (Optional): Variac adjusts high voltage

power supplied to the ozone generator module

controlling ozone output concentration.

for component locations.

4A-3. Internal Components

1. Corona Discharge (CD) Module: Generator

module consists of stainless steel water jacket

and ground tubes and two end housings.

Enclosed inside the module are the high voltage

glass tube electrodes. The top end housing (the

cylindrical glass chamber) encloses the high

voltage connection for the electrodes and allows

for visual inspection.

2. High Voltage T ransformer(s): T r ansformer raises

supplied voltage up to the voltage necessary for

ozone production. T r ansformer is thermally

protected by a temperature switch attached to the

transformer casing.

3. Air Compressor: Compressor produces and

supplies compressed air to oxygen concentrator .

4. Oxygen Concentrator: Supplies concentrated,

dry , o xygen feed gas to the oz one generator .

5. Lo Limit Vacuum Switch: If the vacuum in the

ozone output supply line falls below 2 in. Hg the

switch will open causing the system to shut down.

6. Hi Limit Vacuum Switch: If the vacuum in the

ozone output supply line rises above 10 in. Hg the

switch will open causing the system to shut down.

7. Water Bac kflow Detector: Backflow detector

senses water present in ozone tubing in generator .

If water is detected, system will close solenoid

valve to prevent additional water backflow from

occuring. W ater in the generator will cause severe

damage to the high voltage electrodes.

8. V entilation Fan: Cooling fan operates when main

power switch is “ON”.

9. Air Filter: Filter cleans ventilation air entering the

enclosure.

10. Door Interlock Switch: Interlock switch will shut

down entire system if door is opened. Securing

the door will bring the system back into operation.

11. Relay Panel: Contains control relays for system

interlocks, indicator lights and main power control.

4B. Preventative Maintenance Schedule

The Infinity™ Corona Discharge ozone system requires very

little maintenance beyond general housekeeping practices.

DAILY:

1. Check ozone generator for proper operation.

- Make sure no red indicator lights are lit.

- Make sure flow meter is indicating proper air flow .

2. Practice normal pool maintenance.

MONTHLY:

1. Remove and clean ORP probe.

- Remove from water stream.

- Clean tip of probe with non-abrasive cleanser to

remove any contaminant build up on probe.

- If there is a heavy build up on probe surface,

clean with a mild muriatic solution.

- Rinse and return to water stream.

4

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

Figure 4: Component Locations

2. Remov e and clean air filter .

- Remove filter housing to access filter.

- Rinse filter in warm, soapy water and blo w dry.

- Replace filter.

3. P erform general cleaning of cabinet interior .

ANNUALLY:

1. Remove, disassemble and clean CD module.

See GENERA T OR SER VICING section 4C.

BIANNUALLY:

1. Rebuild compressor .

See GENERA T OR SER VICING section 4C.

4C. Generator Servicing

Before performing any servicing to the ozone generator ,

make sure the power is off by disconnecting electrical

plug from wall socket.

4C-1. Corona Discharge (CD) Module

1. Disconnect the wires from the thermostat switch and

ground terminal attached to the generator housing.

2. Unplug high voltage cable(s) from the top end of

the CD module.

3. Ver y carefully disconnect the oxygen feed and

ozone output lines by removing the stainless steel

compression nuts.

4. Drain cooling water from ozone module and disconnect cooling water lines.

5. Remove module from cabinet.

6. Carefully remove glass end housing, inspect for

damaged glass or retainer springs, and set aside.

7. Remove the opposite end (aluminum discharge end)

taking care not to lose retainer springs. Inspect for

damage and set aside.

8. Gently glide glass tube electrodes out from module.

Inspect for damage.

9. Wipe down electrodes using a solvent such as denatured alcohol and set in a safe area.

10. Swab out the stainless steel tubes using a solvent

such as denatured alcohol or acetone.

11. Replace electrodes -

prints

, and reassemble module in rev erse order .

4C-2. Air Compressor

be sure to wipe off any finger-

Air compressor requires a rebuild every two (2) years

or 15,000 hours of operation.

1. Purchase rebuild kit from DEL Industries, Inc.

See Section 5 for ordering information.

2. Follo w instructions in kit to rebuild compressor.

4D. Trouble Shooting

Knowledge of electrical applications is required for

trouble shooting. Contact a certified electrician if you

are unsure of your ability to service the equipment.

If any condition persists, call 800-676-1335 for

technical assistance.

Symptom: “

in the "ON" position.

1. No power to the generator module from the power supply:

a. Check the circuit breaker at the facility power disb . Check for loose connections or wiring breaks

Main power

tribution box.

from the power distribution bo x to the generator .

” light out when system switch is

5

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

2. G.F.C.I. has tripped.*

a. Check pow er cord and reset G.F.C.I.

3. Circuit breaker has tripped.*

a. Reset breaker .

*If G.F.C.I. or breaker continue to trip after reset, call

for technical assistance.

Symptom: “

Ozone power

” indicator light out.

1. If optional ORP is installed, ORP may have shut down

the generator when ORP level reached setpoint.

a. W ait for ORP to come down. Generator will

restart when ORP level is below set point.

2. Abnormal operating condition exists.

a. Check red fault indicator lights. Refer to corre-

sponding symptom and corrective action.

Symptom: “

range vacuum being supplied.

Vacuum

” indicator light is on indicating out of

1. Injector not supplying adequate suction.

a. Check pump and ensure water is flowing through

injector.

b. Check by-pass valve and adjust if necessary to

obtain proper pressure differential in order to

reestablish suction.

2. Injector supplying too much suction.

a. Check by-pass valve and adjust to obtain proper

suction.

b . Check system back pressure and increase to

reduce suction.

3. Another abnormal condition exists causing ozone output solenoid valve to be closed.

a. Check red fault indicator lights. Refer to corre-

sponding symptom and corrective action.

b . Solenoid valve may be stuck in closed position.

Free solenoid plunger and return system to

normal operation.

Symptom: “

on indicating ozone module temperature over 150°F.

High coolant temperature

” indicator light is

1. Coolant water flow has been interupted.

a. Check all tubing connections, ensureing tight,

leak free connections.

b. Trace tubing and look for b lockage of flow.

c. Re-establish proper coolant water flo w .

Symptom: “

is on indicating high voltage transformer temperature over

150°F.

High transformer temperature

” indicator light

1. Enclosure ventilation is blocked.

a. Check air filter on bottom left-hand side of

enclosure for blockage.

b. Clear bloc kage or clean filter .

c. Restart system and allow transformer to cool.

When temperature returns to normal system will

return to normal operation.

2. Excessive ambient temperatures in installation area.

a. Generator should not be exposed to ambient

temperatures above 100°F. Higher temperatures

may damage generator components.

Symptom: “

Water bac kflow detected

” indicator light is on.

1. Water has back ed into generator from injector .

a. Establish proper water flow through injector and

correct suction.

b. Drain Back Flo w Pre v enter b y first routing dr ain

tubing out of cabinet.opening cabinet and opening

1/4" stainless steel ball valve.

c. After water has completly drained close drain

valve , secure cabinet door and restart system.

Symptom: CD Module is not operating. Ozone output

has dropped.

1. No power to the generator module from the power supply:

a. Check H.V. cab les for breaks or loose connections,

replace if necessary .

b . Check for power at input terminals of the H.V.

transformers.*

c. Check ozone power relay for loose connections

or faulty operation.

*CA UTION: HIGH V OL TAGE.

Symptom: No air flow through the generator. The air flow

meter indicates 0 scfh flow.

1. Flowmeter control valve is improperly set:

a. Open flowmeter valve until proper air flow is

indicated (~8 scfh for CD-7, ~14 scfh for CD-15).

2. Air compressor is not operating properly.

a. Listen for air compressor operation.

b. Check all tubing connections from the air compres-

sor through the system for leaks.

SECTION 5

Replacement Parts and Order Information

5A. Ordering information:

For replacement parts call DEL at 1-800-676-1335.

Be prepared with the following information:

· Customer Name · Customer Address

· DEL Model Number · DEL Serial Number

· Date Purchased · Proof of Purchase

5B. Standard replacement parts list:

1. Compressor rebuild kit, CD-7 .................. 9-1007

2. Compressor rebuild kit, CD-15 ................ 9-1015

3. Ventilation air filter................................... 7-0401

4. High voltage electrode............................. 9-0540

5. Ozone tubing, Teflon ............................... 7-0126

6. Ozone tubing, Stainless Steel................. 8-0098

7. Ozone module gasket (1 ea.) .................. 7-0801

8. Installation & Operations Manual ............ 4-0401

6

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

DEL INDUSTRIES, INC.

LIMITED WARRANTY

The limited warranty set forth below applies to products manufactured by DEL INDUSTRIES, Inc. - 3428

Bullock Lane, San Luis Obispo , California 93401, and sold by DEL INDUSTRIES and its authorized dealers.

This limited warranty is given only to the first retail purchaser of such products and is not transferable to any

subsequent owners or purchasers of such products.

DEL INDUSTRIES warrants that it or its authorized dealers will repair or replace, at its option, any part of

such products proven to be defective in materials or workmanship within two (2) years of the date of final

commissioning by DEL INDUSTRIES or its authorized agent. W arranties on systems not commissioned b y

an authorized DEL INDUSTRIES representative shall be deemed null and void. DEL INDUSTRIES reserves

all rights to determine and authorize DEL INDUSTRIES representatives. This policy pertains to ALL instal-

lations. This w arranty is e xtended to three (3) years on w eldments and five (5) y ears on high v oltage

electrodes. Compressors shall be covered under the two (2) year warranty when, and only when, maintained

per operation and maintenance manual. Required maintenance includes a compressor rebuild after one (1)

year . W arranty does not include parts for reb uild kit. This warranty specifically excludes any components

not manufactured by DEL INDUSTRIES that are external to the products covered, such as pumps, air

compressors, monitors or related components. DEL INDUSTRIES will assist with all warranty claims for

such components purchased through DEL INDUSTRIES; limited to the e xtent of the manuf acturer’s stan-

dard warranty. ANY REPAIR OR REPLACEMENT WILL BE W ARRANTED ONLY FOR THE BALANCE OF

THE ORIGINAL W ARRANTY PERIOD .

NOTE : USE ONLY DEL AUTHORIZED REPLACEMENT PARTS. USE OF ANY OTHER PART(S) WILL

AUTOMA TICALLY VOID THIS WARRANTY .

Any replaced parts must be returned to DEL Industries for evaluation.

THIS LIMITED W ARRANTY DOES NO T INCLUDE ANY OF THE FOLLO WING: (a) any repair or replace-

ment of such parts necessitated by faulty installation, improper maintenance, improper operation, misuse,

abuse, negligence, accident, fire, repair materials, and/or unauthorized accessories; (b) any such products

installed without regard to required local codes and accepted trade practices; (c) ANY IMPLIED W AR-

RANTY OF MERCHANT ABILITY OR IMPLIED W ARRANTY OF FITNESS FOR PARTICULAR PURPOSE,

AND SUCH W ARRANTIES ARE HEREBY DISCLAIMED; AND (d) DEL INDUSTRIES SHALL NOT BE

LIABLE UNDER ANY CIRCUMSTANCES FOR LOSS OF USE OF SUCH PRODUCTS, LOST PROFITS,

DIRECT DAMA GES, INDIRECT D AMAGES, CONSEQUENTIAL D AMAGES AND/OR INCIDENTAL

DAMAGES.

This warranty gives you specific legal rights. You may have other rights which vary from state to state.

TO OBTAIN W ARRANTY SER VICE: DEL Industries, Inc. CD Department

3428 Bullock Lane, San Luis Obispo , CA 93401

Customer Service Number: 800-676-1335

Fax Number: 805-541-8459

PRO VIDE: 1. Project, contact name, mailing address and telephone number .

2 . Installer/Mechanical Contractor .

3 . Serial # and date of commissioning.

4 . The date of failure.

5. A description of the failure.

7

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

APPENDIX “A”

SAFETY

8

CD-7 thru CD-15 Infinity Corona Discharge Ozone Generator

HEALTH HAZARDS OF OZONE

Detection Levels

Ozone can be detected in air by its distinctive odor at

concentrations of about 0.02 ppm. Although each nose

varies, olfactory fatigue occurs quickly. As a result, DO

NOT RELY ON ODOR AS A WARNING OF HIGH

OZONE CONCENTRA TIONS .

The permissible exposure level (PEL) or time weighted

concentration for ozone to which workers may be

exposed os 0.1 ppm averaged over 8 hours, 5 days a

week (OSHA). The short term exposure limit is 0.3 ppm

average o ver 15 minutes . The concentration of 10 ppm

ozone in air is generally accepted as immediately

Dangerous to Life or Health (DLH).

Effects on Humans

Ozone acts as a primary irritant, affecting mainly the

eyes, upper respiratory tract and the lungs. Onset of

pulmonary edema (fluid buildup in the lungs) may be

delayed for a few hours after exposure. Inhaling ozone

at concentrations of 50 ppm for 30 minutes can be fatal.

Many people exposed to airborne ozone rapidly develop

a headache, which often disappears after a few minutes

in fresh air.

Reduction in lung function due to scar tissue forming in

the lung may occur due to long-term exposure to ozone

at concentrations above 0.2 ppm, or a single high

exposure. Although medical studies show no evidence

of ozone causing cancer or lung allergies or harming the

unborn, there is some evidence that the oxidizing power

of ozone could lead to premature aging of the body as a

whole.

The owner of any ozone installation should advise any

person who may be exposed to ozone that those with a

history of heart or respiratory disease should take e v ery

precaution to avoid exposure to ozone.

FIRST AID

General

First Action

1. If exposure to ozone causes headache or shortness

of breath, immediately remove the patient to a fresh

air environment.

Second Action

1. Workers who have been exposed to low concentrations of ozone should be given oxygen to breathe

while under the observation of trained personnel.

2. If exposure is sever, send for medical assistance

immediately.

Inhalation

First Action

1. Assess patient's breathing.

2. All unconscious patients must be placed in the

drainage position (on their sides), so that fluids can

drain from the airways once breathing has been

restored.

3. Check pulse.

Second Action

1. If breathing has ceased, start artificial respiration

(rescue breathing is the most effective) method until

breathing has been restored.

2. Send for medical assistance immediately.

3. If absent, begin cardiopulmonary resuscitation

(CPR).

Eye Contact

First Action

1. Effective irrigation should start immediately. Eyes

should be irrigated for 30 minutes by the clock with

running tap water or preferably normal saline.

Second Action

1. Effective irrigation must be continued while en route

to hospital.

Precautions

Workers with a pre vious cardiopulmonary (heart and

lung) condition must consult their physician prior to

working in an area in which they may be exposed to

ozone. Significant alterations in cardiopulmonary

functions have been documented when such workers

have been exposed to low concentration of ozone.

END OF DOCUMENT.

9

Loading...

Loading...