Hyundai R290LC-7A User Manual

I

Photo may include optional equipment

CRAWLER EXCAVATOR Applied Tier III Engine

NEW 7A SERIES

R290LC-NLC-HC-LR-7A_new_en 10-01-2008 14:25 Pagina 1

R290LC-NLC-HC-LR-7A_new_en 10-01-2008 14:25 Pagina 2

Robex 290LC-7A

02 / 03

HYUNDAI CONSTRUCTION EQUIPMENT

Built for Maximum Power,

Performance and Reliability.

A new chapter in construction equipment has now begun.

Making the dream a reality.

I

Photo may include optional equipment

R290LC-NLC-HC-LR-7A_new_en 10-01-2008 14:25 Pagina 3

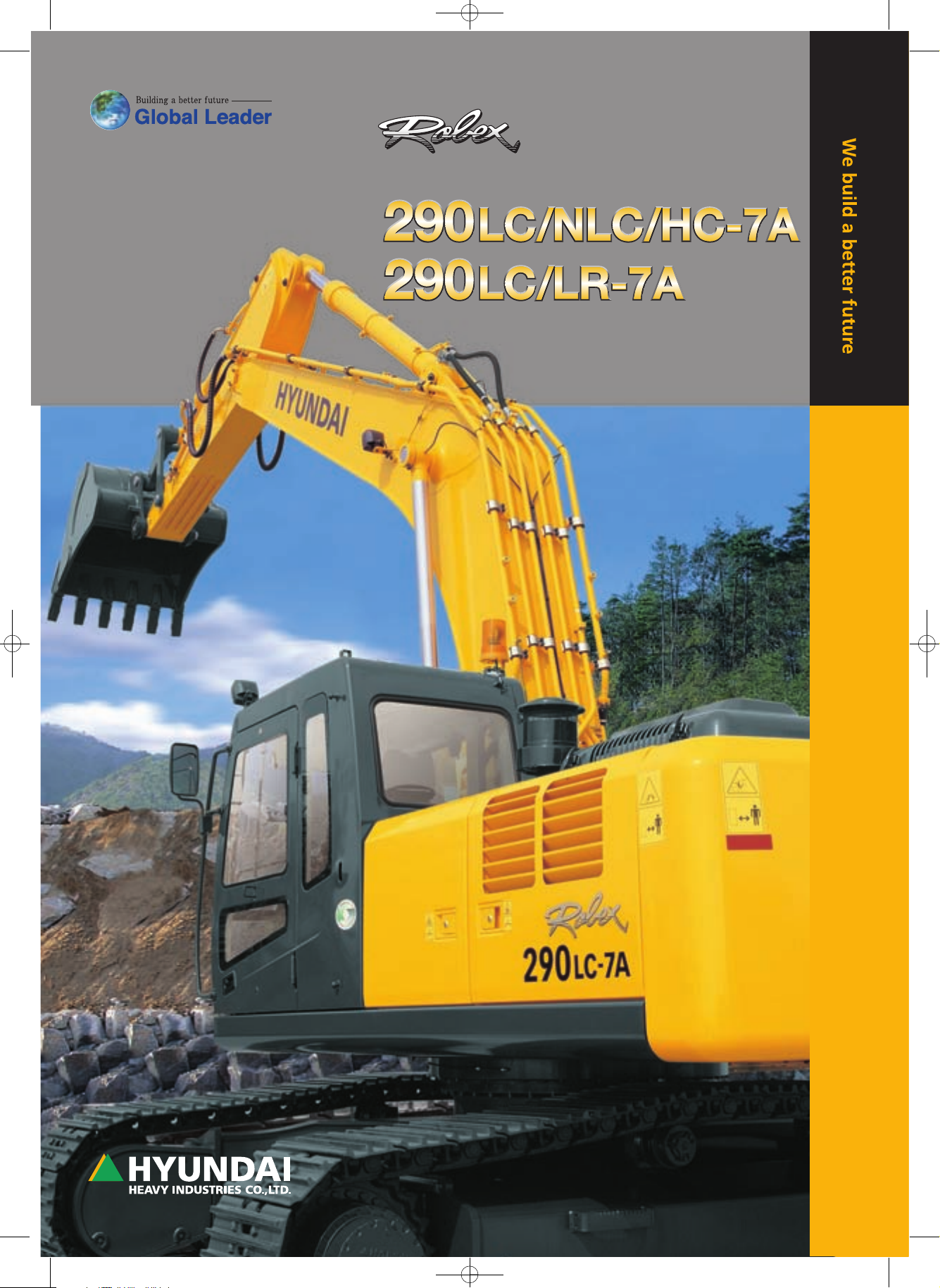

Operator’s Comfort is Our Main Concern.

Wide Cab Exceeding Industry Standards.

Technology in Cab Design

Visibility

.

Even more visibility than before, for safer, more efficient operation.

Excellent Ventilation

.

Ventilation has been improved by using a larger fresh air intake system,

and by providing additional air flow throughout the cab.

.

Sliding front and side windows provide improved ventilation.

.

A large sunroof offers upward visibility and additional ventilation.

Comfortable Operator Environment

.

The control levers and seat can be adjusted to provide maximum

operator comfort.

.

The seat is fully adjustable for optimum operating position, reducing

operator fatigue.

.

Console boxes slide forward and backward for improved accessibility.

.

The proportional pressure controls reduce unnecessary exertion while

ensuring precise operation.

.

Large windows allow excellent visibility in all directions.

Low noise design

.

The Robex 7A series was designed with low operation noise in mind.

.

Hyundai’s engineers made efforts to keep interior and exterior noise levels

to a minimum.

.

The cab's noise levels have been additionally reduced by improving the

door seals for the cab and engine compartments.

.

The use of an insulated diesel engine compartment with sound-damping

material also reduces noise.

Wide, Comfortable Operating Space

Steel Cover Sunroof

Dial Type Engine Speed Switch and / Key Switch

Radio CD Control

R290LC-NLC-HC-LR-7A_new_en 10-01-2008 14:26 Pagina 4

Robex 290LC-7A

1

1

3

2

2

3

04 / 05

HYUNDAI CONSTRUCTION EQUIPMENT

I

Photo may include optional equipment

R290LC-NLC-HC-LR-7A_new_en 10-01-2008 14:26 Pagina 5

Improved Intelligent Display

The Instrument Panel is installed in front of the

RH console box. It is easy to check all critical

systems with easy-to-read indicators.

Minimization of Shock and Vibration through

Cab Mounting System

The application of the Viscous Mounting System to the cabin

support provides the operator with a smoother ride. The

operator’s work efficiency will increase as the shock and

noise level in the cabin decreases.

Operating Environment

Storage box and Cup Holder

An additional storage box and cup holder are located behind the

operator’s seat, the box keeps food and beverages cool or hot.

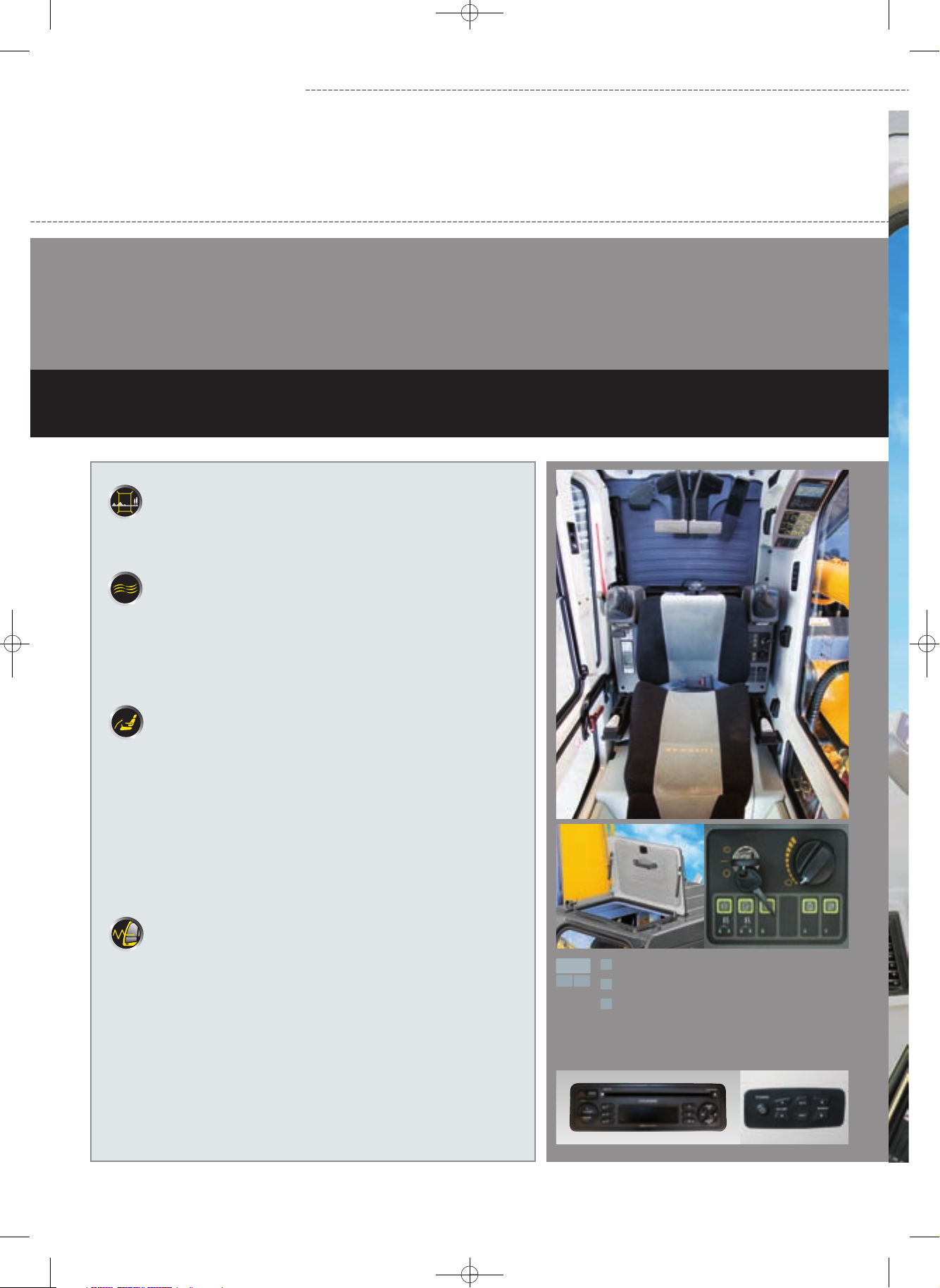

Wide Cab with Excellent Visibility

The cab is roomy and ergonomically designed with low noise level

and good visibility. A full view front window and large rear and side

windows provide excellent visibility in all directions.

Wide, Comfortable Operating Space

All the controls are designed and positioned

according to the latest ergonomic research.

Reinforced pillars have also been added for

greater cab rigidity.

Smooth Travel Pedal and Foot Rests

R290LC-NLC-HC-LR-7A_new_en 10-01-2008 14:26 Pagina 6

Robex 290LC-7A

06 / 07

HYUNDAI CONSTRUCTION EQUIPMENT

Maximum Protection

Highly Sensitive Joystick

and Easy Entrance

New joystick grips for precise

control have been equipped with

multiple switches.

Easy-to-Reach Control

Panels

Switches and other essential

controls are located near

the operator.

This helps to keep operator

movements to a minimum,

enhancing control with less

operator fatigue.

Rear Emergency

Exit Window

Rear Exit Window is

designed with easy exit

in emergency cases.

Raise-up Wiper and

Cabin Lights

Raise-up wiper installed to

enhance a better front view.

Cabin Lights enhances safety by

brightly lighting the surroundings

in dark environments. (optional)

Centralized control panel

Horn button

Option button

Remote Radio control

Travel lever

Cluster

One touch decel button

Hour meter

Travel pedal

Fully adjustable suspension seat

Safety lever

Power boost button

Joystick control lever

Air Conditioner and Heater controller

쐅

쐈

쐉

씈

씉

The better working conditions in a pleasant environment

Left

•

Power boost

•

One touch deceleration

•

Optional (2)

Right

•

Horn

•

Optional (3)

R290LC-NLC-HC-LR-7A_new_en 10-01-2008 14:26 Pagina 7

B

A

C

B

A

C

Automatic Engine Overheat

Prevention

If the engine coolant temperature

gets too high, the CPU controller

lowers the engine speed and cools

the engine.

Anti Restart System

The new system protects the starter

from re-starting during engine

operation, even if the operator

accidentally turns the start key again.

Power boost control System

When the power boost system is

activated, digging power increases

about 10%.

It is especially useful when extra

power is temporarily needed, for

instance, when digging hard earth

and rock.

Automatic Warming-up System

After the engine is started, if the

engine coolant temperature is low,

the CPU controller increases the

engine speed and pump flow

automatically so to warm up the

engine more effectively.

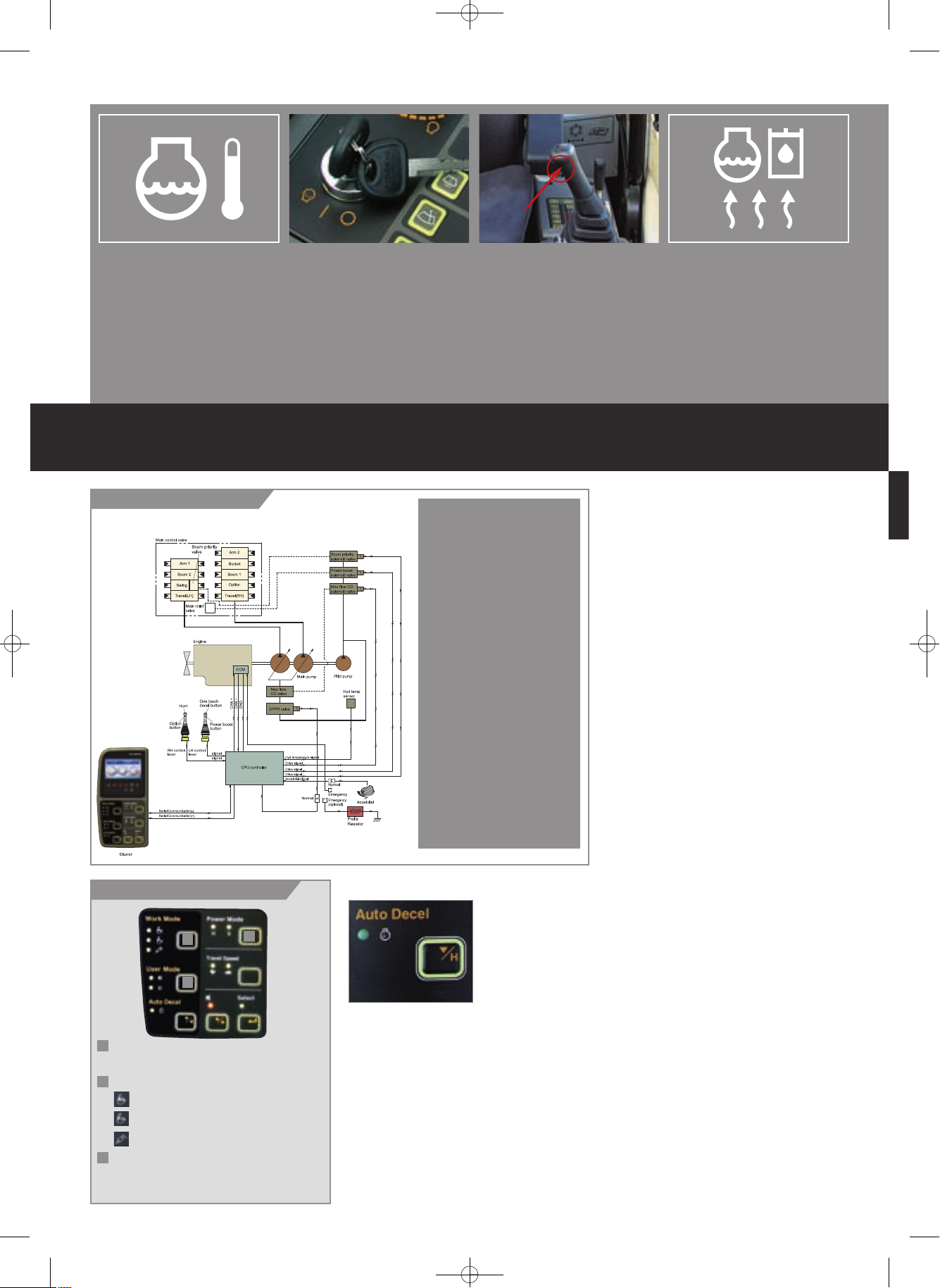

Advanced Hydraulic System

The advanced CAPO(Computer

Aided Power Optimization)

system maintains engine and

mutual pump power at optimum

levels. Mode selections are

designed for various work

loads and maintaining high

performance while reducing

fuel consumption. Features

such as auto deceleration and

power boost are included in the

system. The system monitors

engine speed, coolant and

hydraulic oil temperature.

Contained within the system

are self diagnostic capabilities

which are displayed by error

codes on the cluster.

POWER MODE

H mode: High power

S mode: Standard power

WORK MODE

: Heavy duty work

: General work

: Breaker

USER MODE

M mode: Maximum Power

U mode : Memorizing Operator’s Preferable Power Setting

Auto Deceleration System

When the remotecontrol valves are in

neutral position more

than 4 seconds, the

CPU controller

instructs the

accelerator actuator

to reduce engine

speed to 1050 rpm. This decreases fuel

consumption and reduces cab noise levels.

Max. Flow Cut-off System

For precise control and finishing work, the Max.

Flow Cut-off System reduces pump flow, allowing

smooth operation.

Self Diagnostic System

The CPU controller diagnoses problems in the

CAPO system caused by electric and hydraulic

malfunctions and displays them on the LCD

monitor of the cluster through error codes.

This controller has the capacity to identify 48

distinct types of errors. The information from this

device, such as engine rpm, main pump delivery

pressure, battery voltage, hydraulic temperature,

and the state of all types of electric switches,

provides the operator with the exact condition

of his machine. This instrument makes it easier

to troubleshoot the machine in case of failure.

One Touch Deceleration System

When the one touch deceleration switch is

pressed, the CPU controller controls the

acceleration actuator to reduce engine speed to

800 rpm. Once this switch is pressed again, the

engine speed recovers to its preset RPM

Pump Flow Control System

In neutral position: Pump flow is reduced to a

minimum to eliminate power loss. In operation:

Maximum pump flow is delivered to the actuator

to increase the speed. With movement of the

control lever, pump flow is automatically adjusted

and the actuator speed can be proportionally

controlled.

Boom & Arm Holding System

The holding valves in the main control valve

prevents the boom & arm from lowering over an

extended period in neutral position.

Arm Flow Regeneration System

Arm flow regeneration valve provides smooth

arm-in operation without cavitation.

Hydraulic Damper in Travel Pedal

Improved controllability & feeling during

movement of the machine by use of shock

reducing material.

ADVANCED CAPO SYSTEM

NEW MODE CONTROL SYSTEM

R290LC-NLC-HC-LR-7A_new_en 10-01-2008 14:26 Pagina 8

2

3

1

1

2

3

1

Loading...

Loading...