For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Brush Cutters, Trimmers,

Pruners, Pruning saws,

Hedge trimmers, Ice drills,

Blowers

Workshop Manual

101 90 75-26

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Supplement to the workshop

manual for

brush cutters, trimmers

pruners, pruning saws, hedge

trimmers, ice drills, blowers

1999

Contents

General recommendations ______________________ 2

1. Starter ___________________________________ 3

2. Ignition system ___________________________ 11

3. Fuel system _____________________________ 19

4. Centrifugal clutch _________________________ 37

5. Angle gear_______________________________ 45

6. Cylinder and piston ________________________ 51

7. Crankshaft and crankcase __________________ 63

8. Hydraulic unit ____________________________ 75

9. Attachments _____________________________ 79

10. Tools ___________________________________ 91

The supplement includes new products and modifications to products after the

Workshop Manual was printed in March 1997.

For complete information when servicing we recommend that the supplement is

studied together with the Workshop Manual.

(Order number 101 90 74-26)

© Copyright Husqvarna AB, Sweden 1999

www.mymowerparts.com

1

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

General recommendations

The workshop used to carry out repairs must be equipped with

safety devices in accordance with local directives.

No one may carry out repairs without first having read and

understood the contents of this Workshop Manual.

The boxes below can be found in appropriate parts of this

manual.

WARNING!

!

NOTE!

This box warns of damage to material if the instructions are

not followed.

The machine is type approved for safety in accordance with

applicable legislative demands with the equipment specified in

the Operator’s Manual. The assembly of other equipment or

accessories or spare parts not approved by Husqvarna can

result in the failure to meet these safety demands and that the

person carrying out assembly bears responsibility for this.

The warning box warns of the risk for personal

injury if the instructions are not followed.

Bear in mind:

● Do not start the engine without the clutch drum and shaft

fitted. Otherwise there is a risk that the clutch can become

loose and cause personal injury.

● Do not touch hot components, e.g. the muffler and clutch

before they have cooled sufficiently to avoid burns.

● Avoid getting fuel or oil on your skin or in your mouth.

Use barrier cream on your hands. This reduces the risk of

infection and makes dirt easier to wash off.

Long term contact with engine oil can represent a health

hazard.

● Never start the engine indoors. Exhaust fumes are poisonous!

● Wipe up oil spills from the floor immediately to avoid

slipping.

● Do not use tools that are worn or fit badly, for example on

nuts and screws.

● Always work on a clean bench.

● Always work logically to ensure all parts are fitted correctly

and that nuts and screws are tightened.

● Use the special tools where recommended in order to

carry out the work correctly and efficiently.

Fire risk

Handle fuel with respect, as it is extremely inflammable.

Do not smoke and ensure there are no open flames or sparks

in the vicinity.

Make sure there is a working fire extinguisher close at hand.

Do not try to extinguish a petrol fire with water.

Poisonous fumes

When using cleaning agents read the instructions carefully.

Ensure there is good ventilation when handling petrol and other

volatile fluids.

The engine’s exhaust fumes are poisonous. Test run the engine

outdoors.

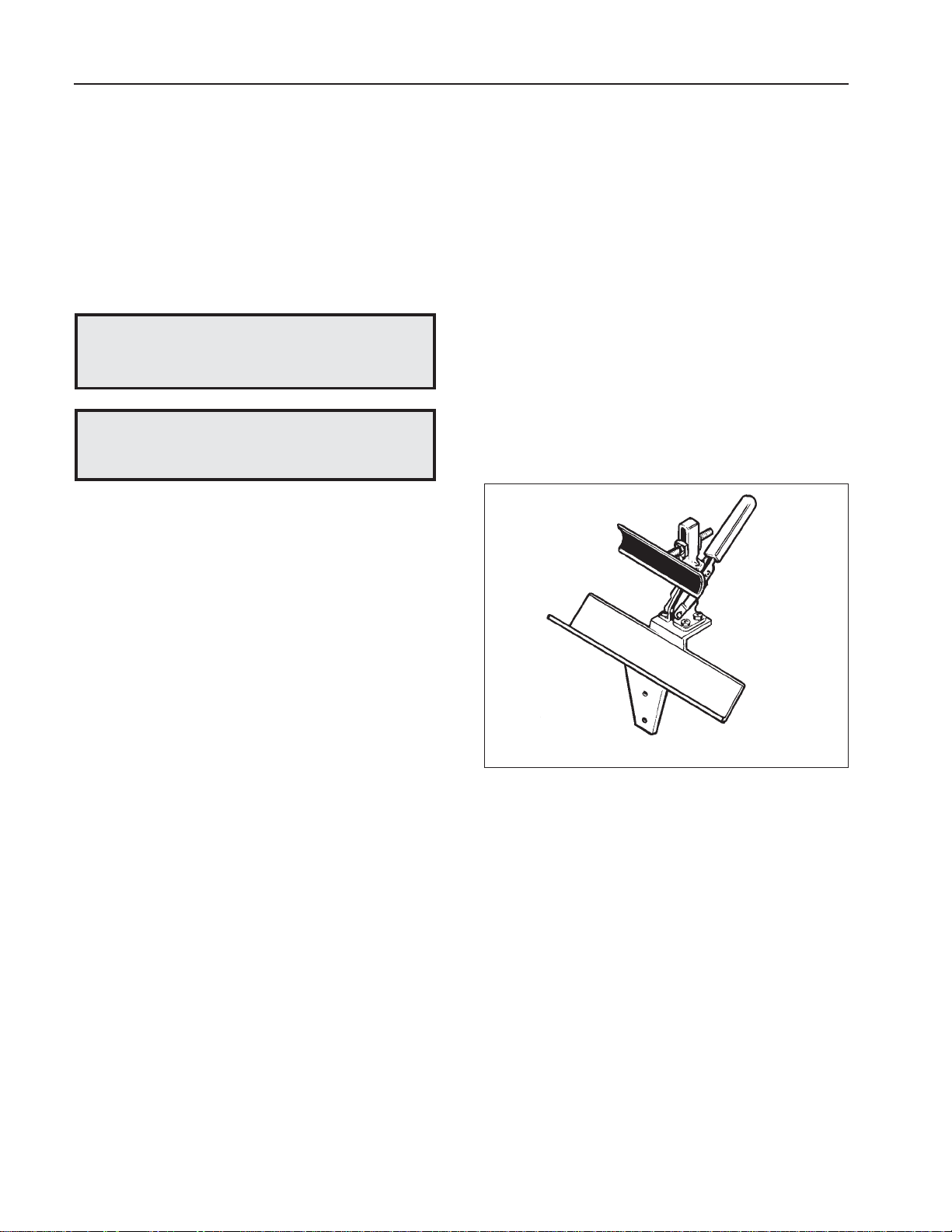

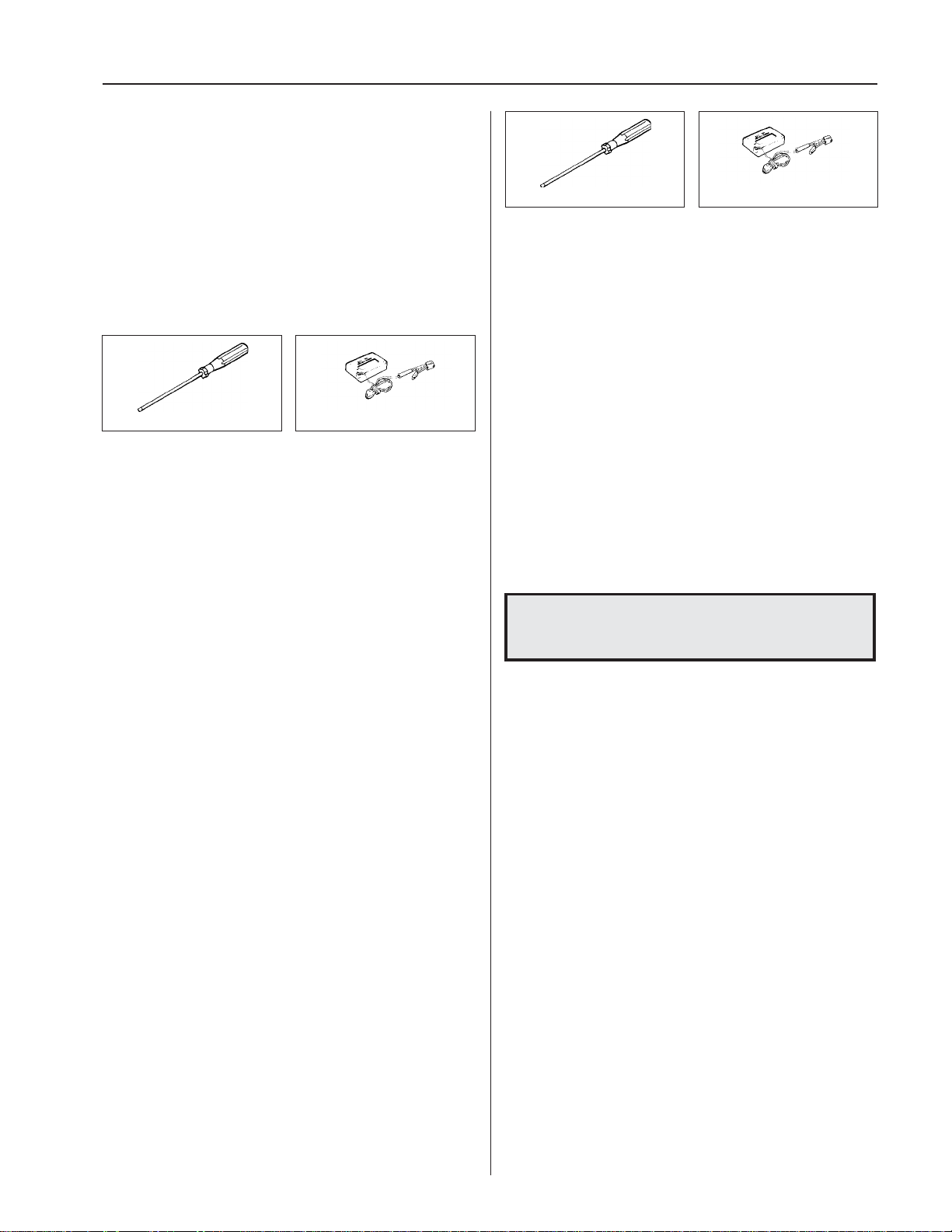

Special tools

Some of the work described in the Workshop Manual requires

special tools. In each section where this is necessary there is

a picture of the tool and an order number.

We recommend the use of special tools in order to avoid

personal injury and to eliminate expensive damage to the parts

in question.

502 51 03-01

Contact faces and gaskets

Ensure all surfaces are clean and free from gasket residue.

When cleaning use a tool that will not damage the contact face.

Any scratches or unevenness should be removed using a flat

fine cut file.

Sealing rings

Always replace a sealing ring that has been dismantled. The

sensitive sealing lip can easily be damaged resulting in inferior

sealing capacity. Surfaces that the seal shall seal against must

also be completely undamaged. Lubricate the sealing lip with

grease before it is fitted and ensure that it is not damaged e.g.

by shoulders and splines on a shaft. Use tape or a conical sleeve

as protection. It is important that the sealing ring faces in the

right direction for it to act as it is intended.

2

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Starter

1.

Contents

Models 322, 325

Dismantling, assembling___________________________ 4

Replacing the drive dogs __________________________ 5

Models 32, Mondo, Mondo Mega

Dismantling, assembling___________________________ 6

Model 18H

Dismantling _____________________________________ 6

Assembly ______________________________________ 7

Models 140B, 141B

Dismantling, assembling___________________________ 8

Assembly

General ________________________________________ 9

Replacing the drive dogs _______________________ 10

www.mymowerparts.com

3

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

Models 322, 325

Dismantling

Remove the 3 screws and lift off the starter.

NOTE!

Ensure the bushings (A) that guide the starter towards the fuel tank are not lost.

A

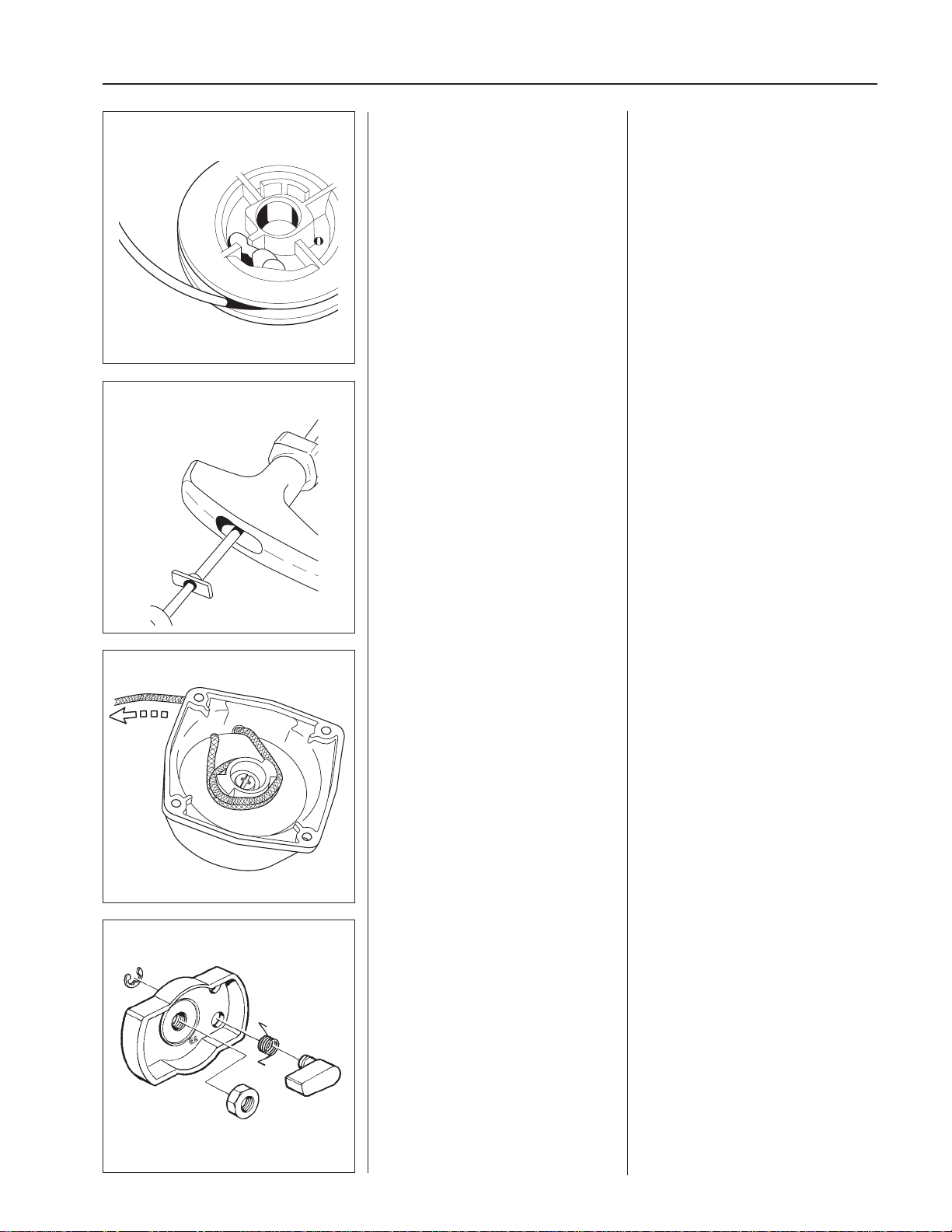

Offload the spring tension.

Remove the screw from the centre of the

starter pulley and lift off the starter pulley.

Offload the spring tension in the same

way as described for model 265.

Remove the screw in the centre of the

starter pulley. Carefully lift out the starter

pulley from the starter housing.

Assembly

Clean the component parts and assemble

in the reverse order as set out for dismantling.

Assemble the starter pulley.

Assemble a new starter cord.

NOTE!

A new starter cord can be fitted

without the need of dismantling

the starter!

WARNING!

!

Assembly

Clean component parts before assembling.

Replace the return spring/starter pulley

and starter cord, if necessary.

NOTE!

The return spring and starter

pulley are supplied pre-assembled

and are fitted in the starter

housing as a single unit.

Exercise care when opening the

packaging so that the spring does

not fly out.

Lubricate the spindle with a little grease

and fit the starter pulley.

Position the washer and tighten the screw.

Assemble a new starter cord. Slide it into

the starter pulley’s slot as illustrated and

then out through the cord guide in the

starter housing.

Make sure the knot on the end of the cord

is as small as possible!

Wear protective glasses.

The return spring lies

tensioned in the starter

and can fly out and cause

personal injury with

careless handling.

4

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Starter

Assemble the starter handle. Assemble the starter handle in the same

way as described for model 265, but tie a

double knot, as the cord is lighter.

Tension the return spring.

Check the spring tension.

Fit the starter on the engine body.

Do not forget the guide sleeves for the fuel

tank.

Tension the return spring. Pull out the

starter cord fully and lift it out of the cutout in the starter pulley.

Now turn the starter pulley anticlock-

wise, 6 turns.

Check the spring tension. With the starter

cord fully extended it should still be possible to turn the starter pulley further,

least a half turn.

1

at

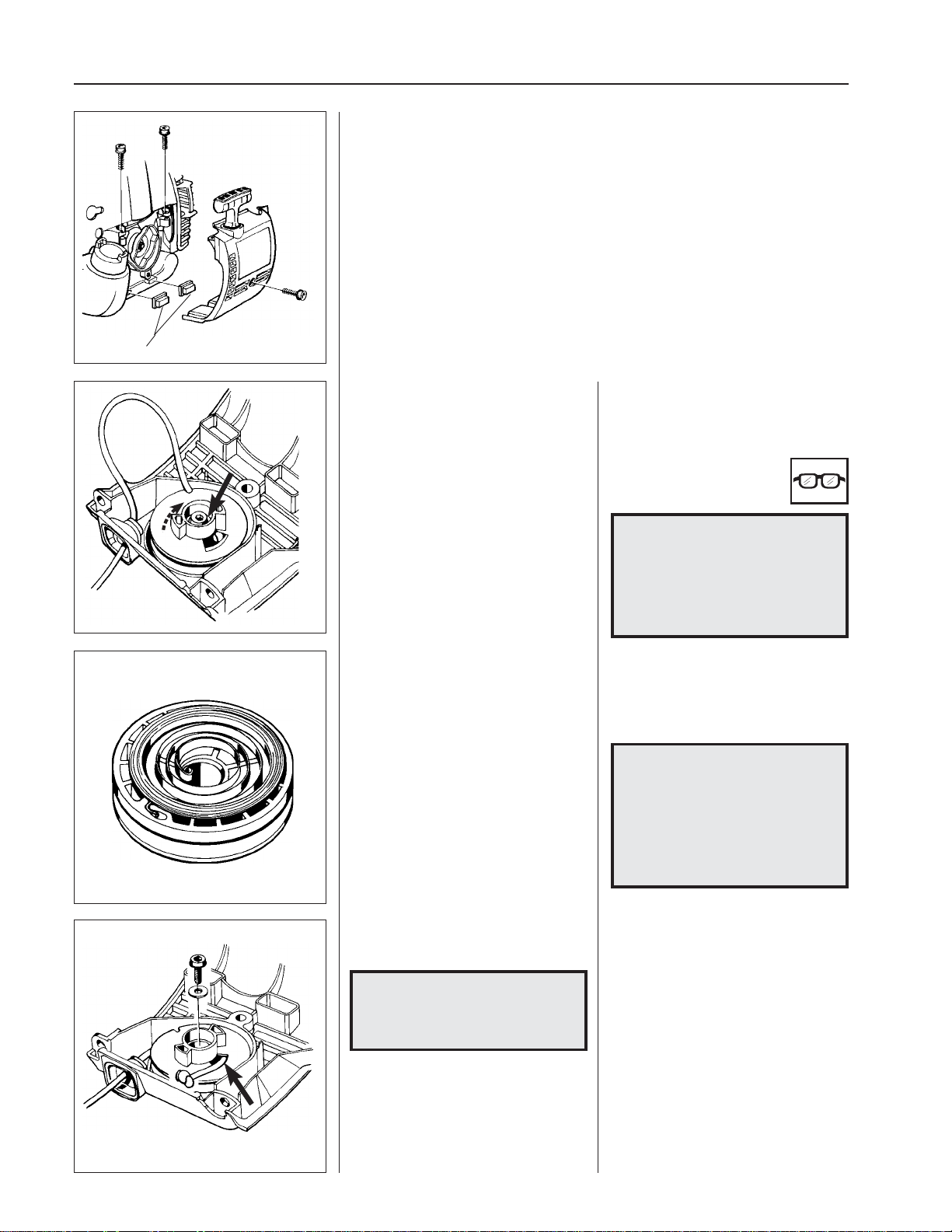

Replacing the drive dogs

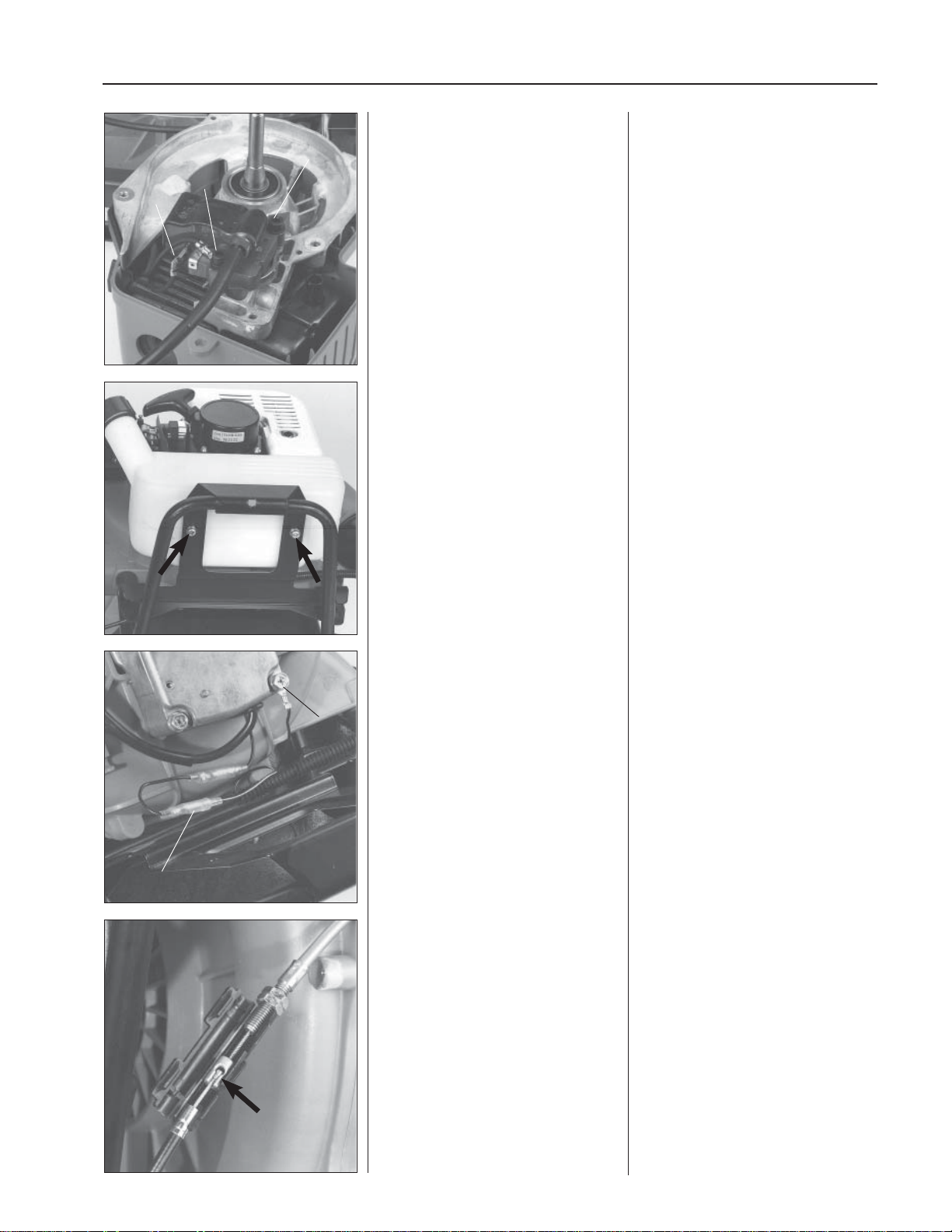

Dismantle the drive body.

504 91 06-05

Remove the circlip and replace any damaged drive dogs or springs, if necessary.

Replacing the drive dogs

Fit the piston stop no 504 91 06-05 in the

spark plug hole and loosen the nuts holding the drive body.

Remove the circlip holdings the drive

dog.

Lift out the drive dog and spring for replacement.

Assemble in the reverse order as set out

for dismantling.

www.mymowerparts.com

5

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

Models 32, Mondo,

Mondo Mega

Dismantling

Disconnect the electrical cables.

Remove the shaft complete with handle.

Dismantle the starter.

Models 32, Mondo,

Mondo Mega

Dismantling

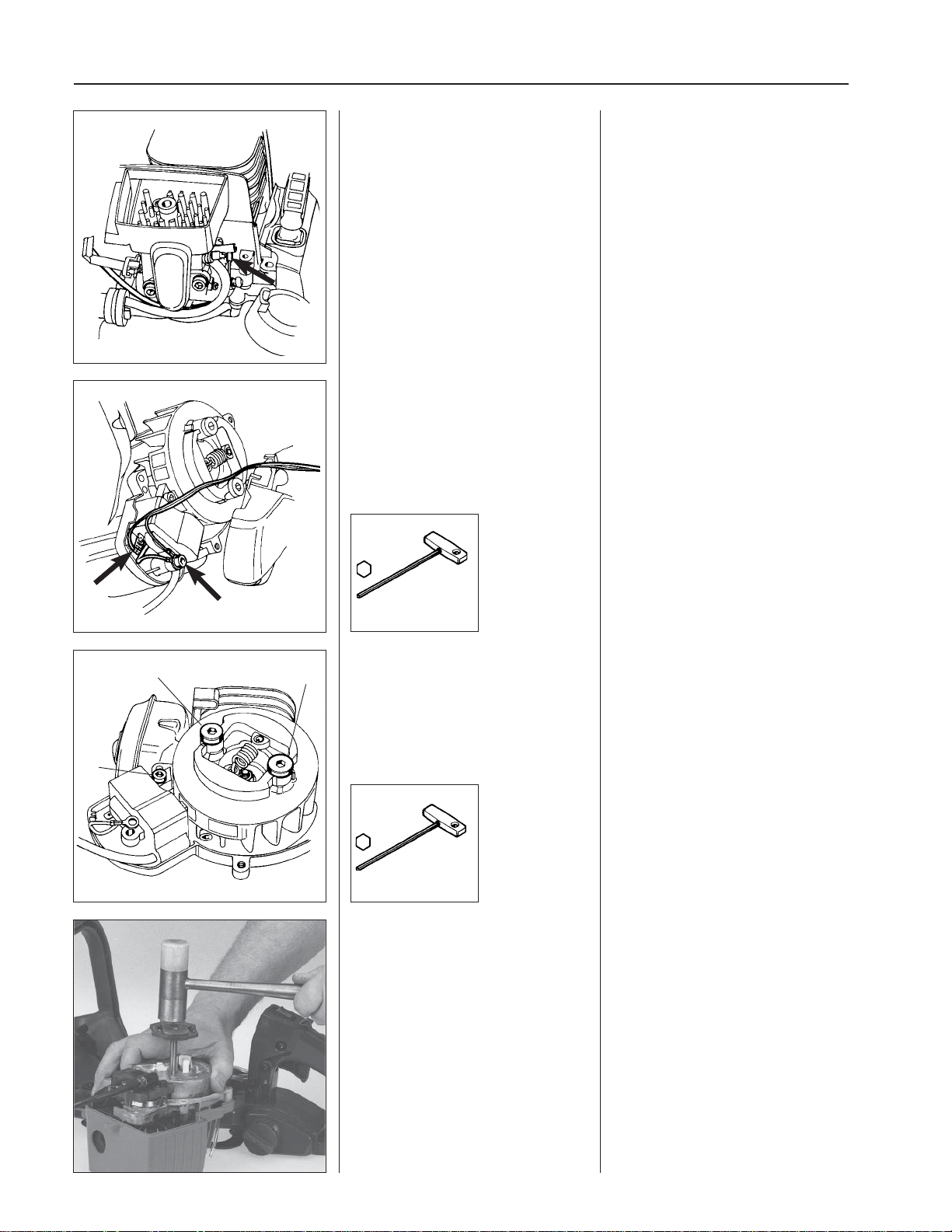

Disconnect the electrical cables by the

engine body and remove the 4 screws

(models Mondo and Mondo Mega have 3

screws) that hold the shaft and handle on

the starter housing.

Lift off the shaft.

Remove the 4 screws and lift off the

starter.

Model 32

Pull out the electrical cables from the starter

housing using flat nose pliers.

Model Mondo

Also dismantle the screw by the spark

plug.

Assembly

Assemble the starter handle.

Model 18H

Dismantling

Dismantle the air filter, throttle cable and

carburettor.

Remove the 4 screws holding the engine

body and gear housing.

Assembly

Assemble the starter handle in the same

way as described for model 265.

Tie a double knot, as the cord is lighter

than on model 265.

Model 18H

Dismantling

The starter is positioned between the

crankcase and the cutting equipment

drive.

First dismantle the spark plug, air filter,

throttle cable and carburettor.

Turn the trimmer upside down so that the

screws holding the engine body are accessible.

Remove the 4 screws.

6

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Starter

Dismantle the centrifugal clutch.

504 91 06-06

Dismantle the starter from the engine.

1

Assemble the piston stop no. 504 91 0605 in the cylinder.

Unscrew the centrifugal clutch. First

loosen it using a hammer and punch,

anticlockwise.

Dismantle the starter.

Remove the 5 screws holding the starter

housing

Lubricate the ignition cable with a few

drops of oil and remove the rubber grommet in the cover.

Lift off the starter housing.

The following procedures are the same as for models 32, Mondo:

Remove the locking plates holding the starter pulley axially.

Offload the spring tension.

Dismantle the starter pulley and spring cassette from the starter housing.

Assembly (also see model Mondo)

Place a new spring cassette in position in the starter housing.

Replace the cord and attach as illustrated.

Assemble the starter pulley.

Assemble the starter handle (see model 265).

Tension the return spring.

Repeat tensioning the spring and fit the locking plates.

www.mymowerparts.com

7

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

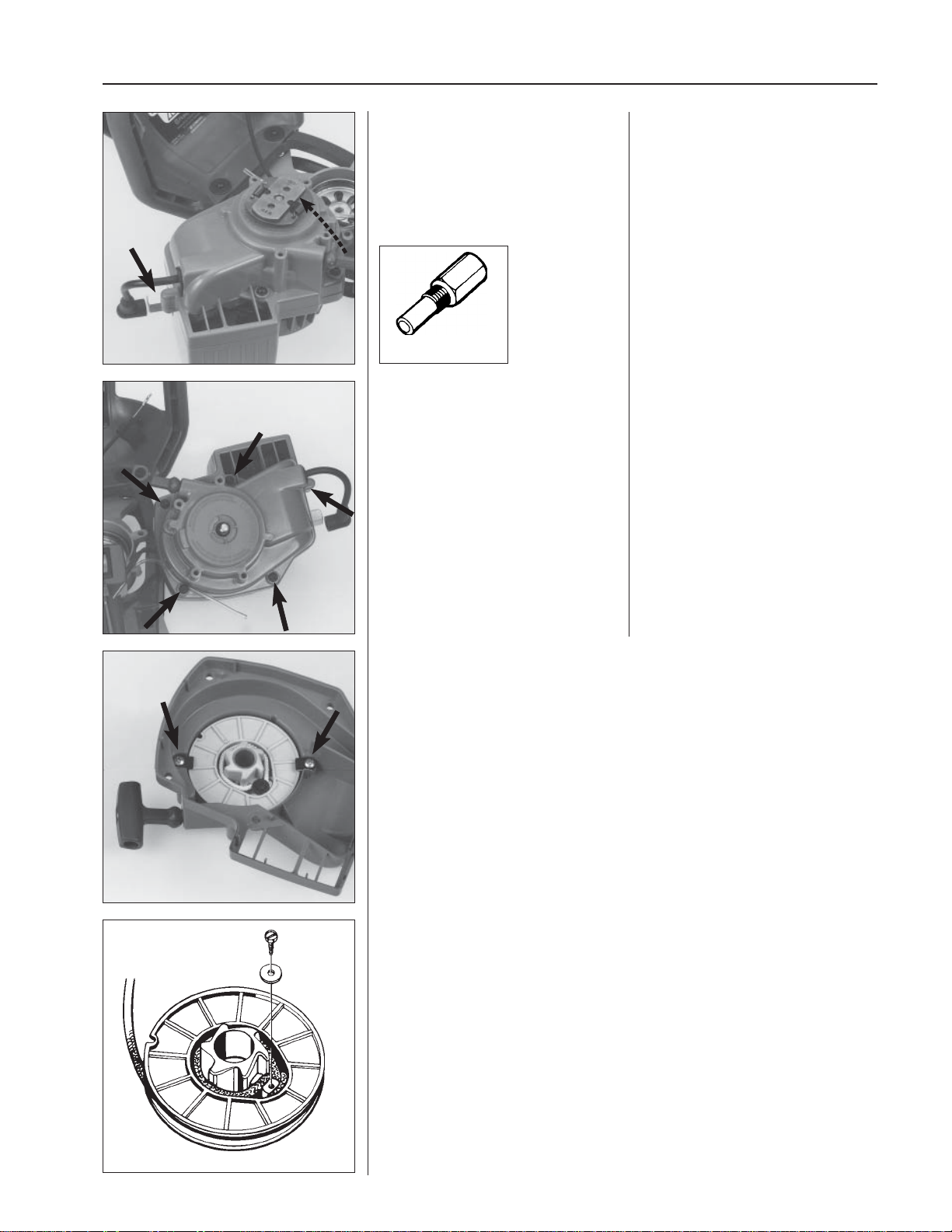

Models 140B, 141B

Dismantling

Remove the screws and lift off the starter.

Offload the spring tension and remove

the starter pulley from the starter housing.

Models 140B, 141B

Dismantling

Remove the 4 screws holding the starter

against the engine body.

Lift the starter cord out of the cut-out in

the starter pulley.

Offload the spring tension by allowing the

starter pulley to rotate backwards. Stop

the pulley using your thumb.

Remove the screw and washer from the

centre of the starter pulley.

Lift off the starter pulley.

Dismantle the return spring.

Clean and replace any damaged parts.

Assembly

Fit a new return spring in the starter

housing.

Carefully lift off the starter pulley and

return spring.

WARNING!

!

The return spring lies tensioned in the

starter housing and can fly out and cause

personal injury with careless handling.

Clean and replace any damaged parts.

Assembly

Fit a new return spring in the starter

housing. Exercise great care so that it

does not fly out.

!

Use protective

glasses.

WARNING!

Use protective

glasses.

Check that the spring’s mounting is facing the right way!

8

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Starter

Replace the starter cord and attach as

illustrated.

Wind the cord 4 turns clockwise around

the starter pulley.

Lubricate the spindle and return spring

and assemble the starter pulley.

Assemble the starter handle.

1

Attach a new starter cord in the starter

pulley as illustrated.

Wind the cord 4 turns clockwise around

the starter pulley.

Lubricate the spindle and return spring

with a few drops of oil.

Place the starter pulley in position and

tighten the screw in the centre. Do not

forget the washer.

Assemble the starter handle.

The collar on the washer should face

towards the starter handle.

Tension the return spring.

Check that the pulley can be turned a

further half turn with the starter cord fully

extended!

Models 140B, 141B

Drive dogs

Dismantle the drive from the crankshaft.

Replace the drive dogs if they are damaged or worn.

Tension the return spring.

● Pull out the cord approx. 30 cm and

stop the starter pulley using your

thumb.

● Lift the starter cord up in the cut-out in

the starter pulley.

● Wind the cord 2 turns anticlockwise

around the hub on the starter pulley.

● Pull out the starter cord fully.

www.mymowerparts.com

9

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

Assembly, general

Assemble the starter in the reverse order

as set out for dismantling.

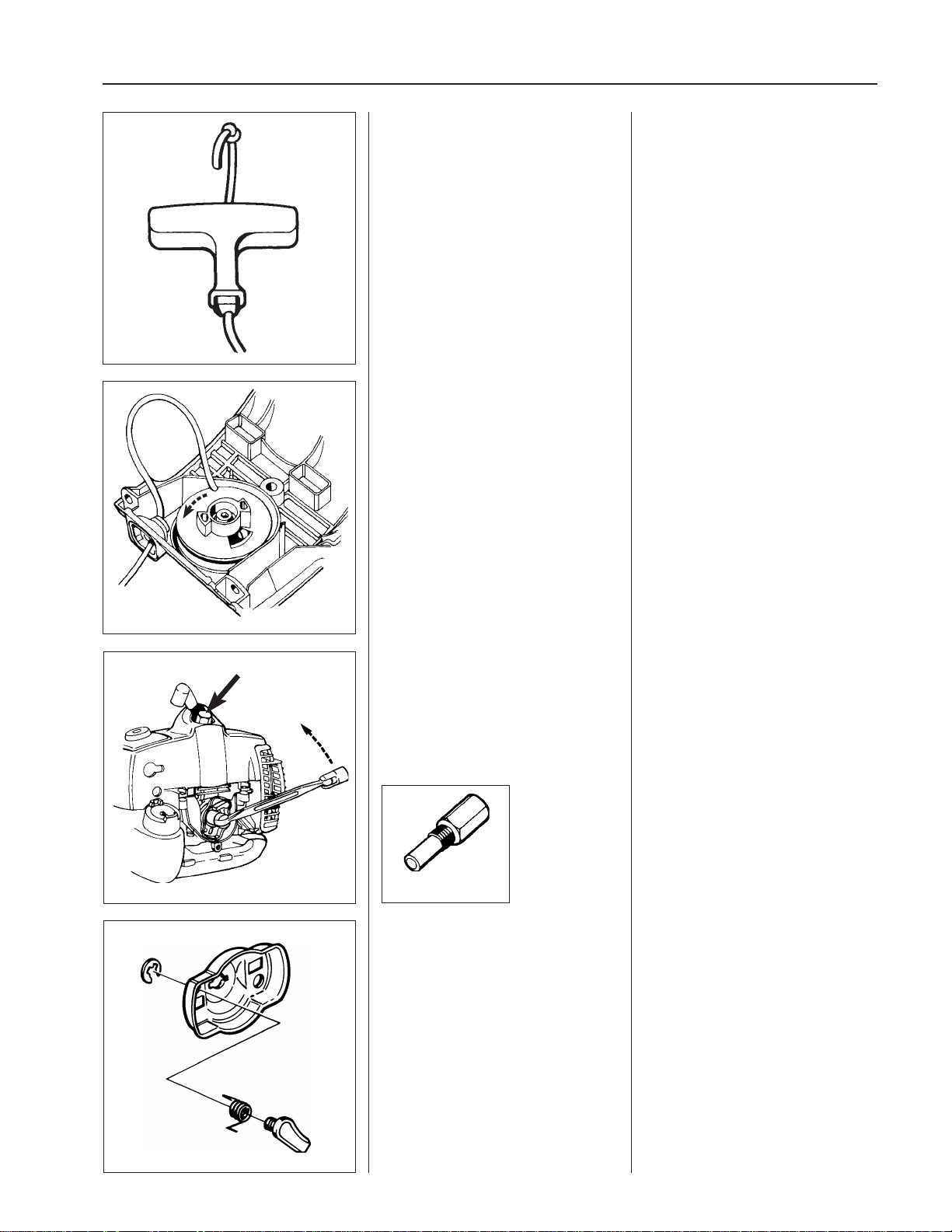

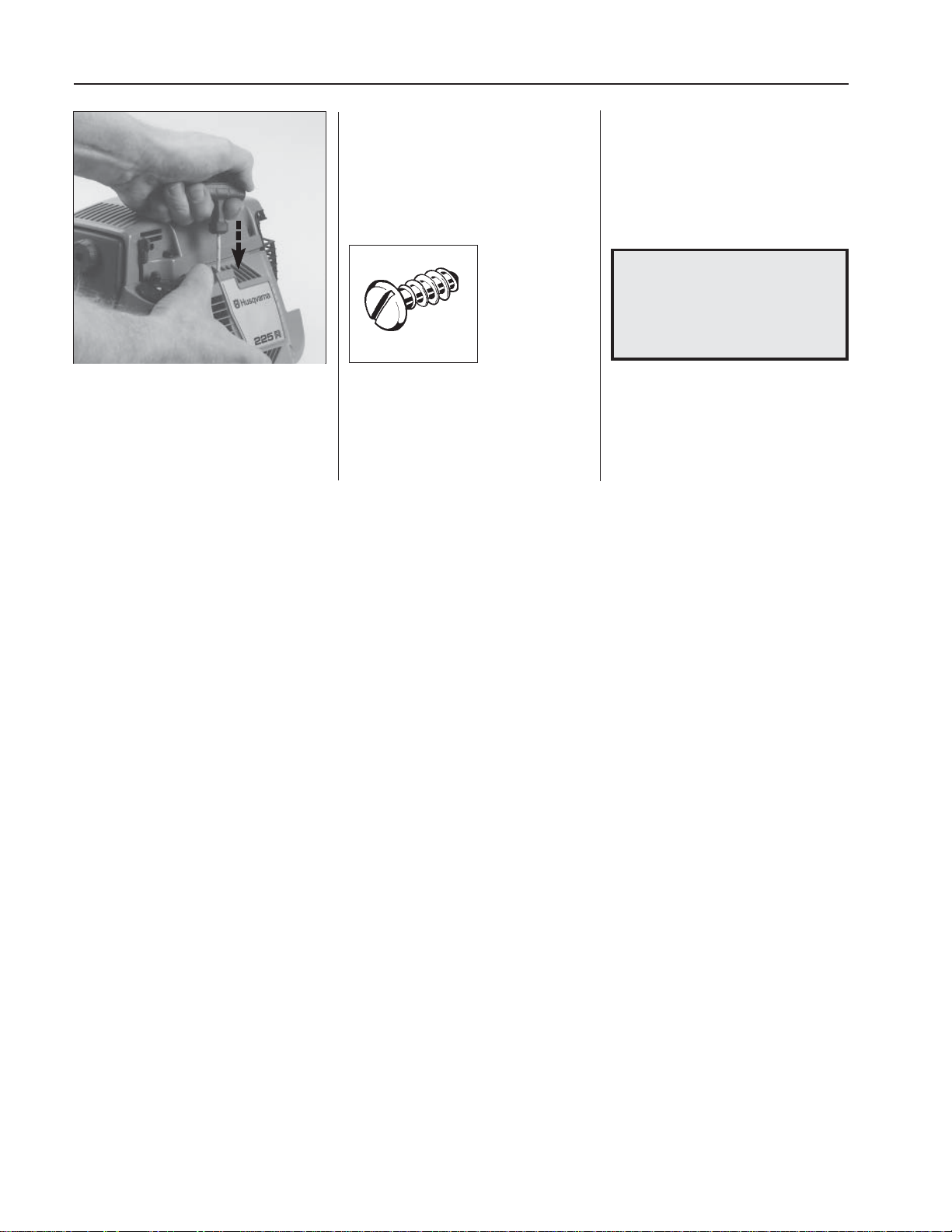

503 21 22-01

Replacing the drive

dogs

See chapter 2. “Ignition system, flywheel”

with regard to engines that have the drive

dogs fitted on the flywheel.

Assembly, general

Assemble the starter

Pull out the starter cord a little. Place the

starter in position. Release the starter

cord and check that the drive dogs engage in the starter pulley.

Tighten the screws.

NOTE!

We recommend the use of an over

dimensioned screw if the plastic

threads in the crankcase have

been damaged for some reason.

(no. 503 21 22-01).

Replacing the drive

dogs.

See chapter 2. “Ignition system, flywheel”

with regard to engines that have the drive

dogs fitted on the flywheel.

10

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Ignition system

2.

Contents

Dismantling

Models 322, 325, 18H __________________ 12

Models 140B, 141B ____________________ 13

Dismantling the flywheel ________________ 15

Assembly

Models 322, 325 ______________________ 16

Technical data _______________________ 18

www.mymowerparts.com

11

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

Ignition system

Dismantling

Models 322, 325

Dismantle the cylinder cover, guard over

the muffler and spark plug.

Unhook the throttle cable from the carburettor and remove the screws holding the

clutch cover.

Remove the clutch cover and loosen the

short-circuit cable from the ignition module.

Dismantling

Models 322, 325

The following components must be dismantled for the ignition system to be

accessible.

Cylinder cover, guard over the muffler

and spark plug.

Disconnect the throttle cable from the

carburettor.

Remove the three screws holding the

clutch cover.

Remove the clutch cover complete with

the shaft from the engine.

Loosen both ends of the short-circuit

cable from the ignition module.

504 90 00-02

B

A

B

Dismantle the ignition module and the

centrifugal clutch.

504 90 00-03

Model 18H

Remove the spacer and washer and screw

the clutch down on the crankshaft.

Hold the flywheel and sharply tap the

clutch a few times until the flywheel releases.

Remove the remaining screw (A) holding

the ignition module and both screws (B)

that hold the centrifugal clutch.

Lift off the clutch and ignition module.

Model 18H

Remove the long spacer and washer from

the crankshaft.

Screw down the clutch a few turns on the

shaft.

Hold the flywheel and sharply tap the

clutch a few times until the flywheel releases.

12

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Ignition system

Dismantle the ignition module. Dismantle the ignition module.

B

B

A

Models 140B, 141B

Dismantle the fuel tank.

Remove the short-circuit cable (A) and

both screws (B).

Models 140B, 141B

Empty the fuel tank and pull off the fuel

hoses from the carburettor.

Note how the hoses are connected.

Remove the screws and lift off the fuel

tank.

2

A

Pull apart the short-circuit cable connector and remove the earth cable.

B

Fold open the protective sleeve and separate the throttle cable.

Separate the connectors for the shortcircuit cable (A) and remove the earth

cable (B) by removing the crankcase

screw.

Open the protective sleeve over the cable

joint and lift out the throttle cable running

to the throttle.

www.mymowerparts.com

13

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

Ignition system

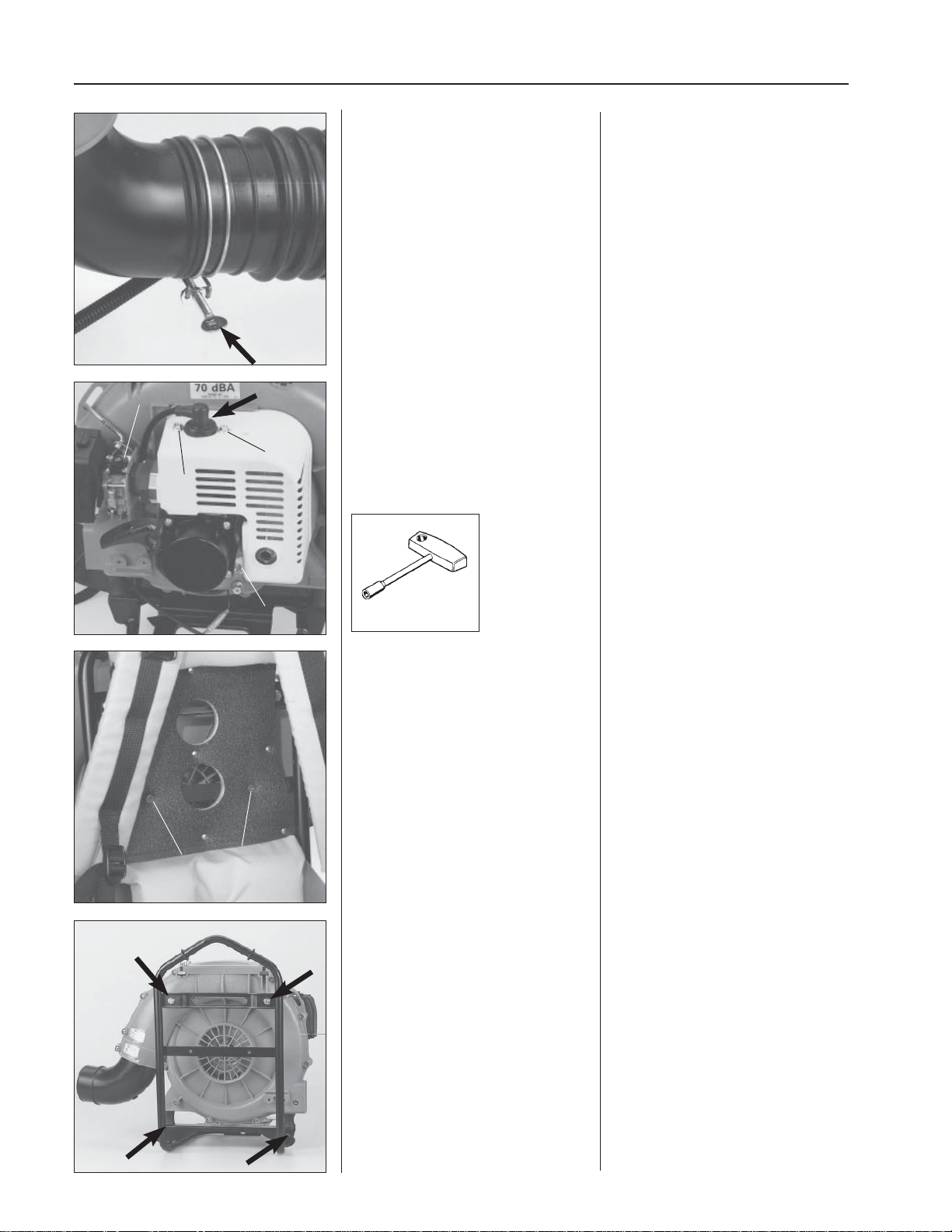

Remove the blower pipe.

B

A

A

Dismantle the cylinder cover, heat guard

around the cylinder and the rotary valve

from the carburettor.

Loosen the hose clip and remove the

blower pipe.

Lift off the spark plug cap and unscrew the

spark plug.

Remove the 3 screws (A) holding the

cylinder cover and remove this and the

heat guard from around the cylinder.

Dismantle the rotary valve (B) from the

carburettor by removing the 2 screws

holding the cover. Let the throttle hang

from the throttle cable.

A

A

A

502 50 22-01

Dismantle the harness. Remove the harness from the tubular

frame by removing both screws (A).

Remove the pipe bend.

Remove all screws and separate both

halves of the fan housing.

Remove the pipe bend.

Remove the cleaning cover and all the

screws (12) holding both halves of the fan

housing.

Separate the halves.

14

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Ignition system

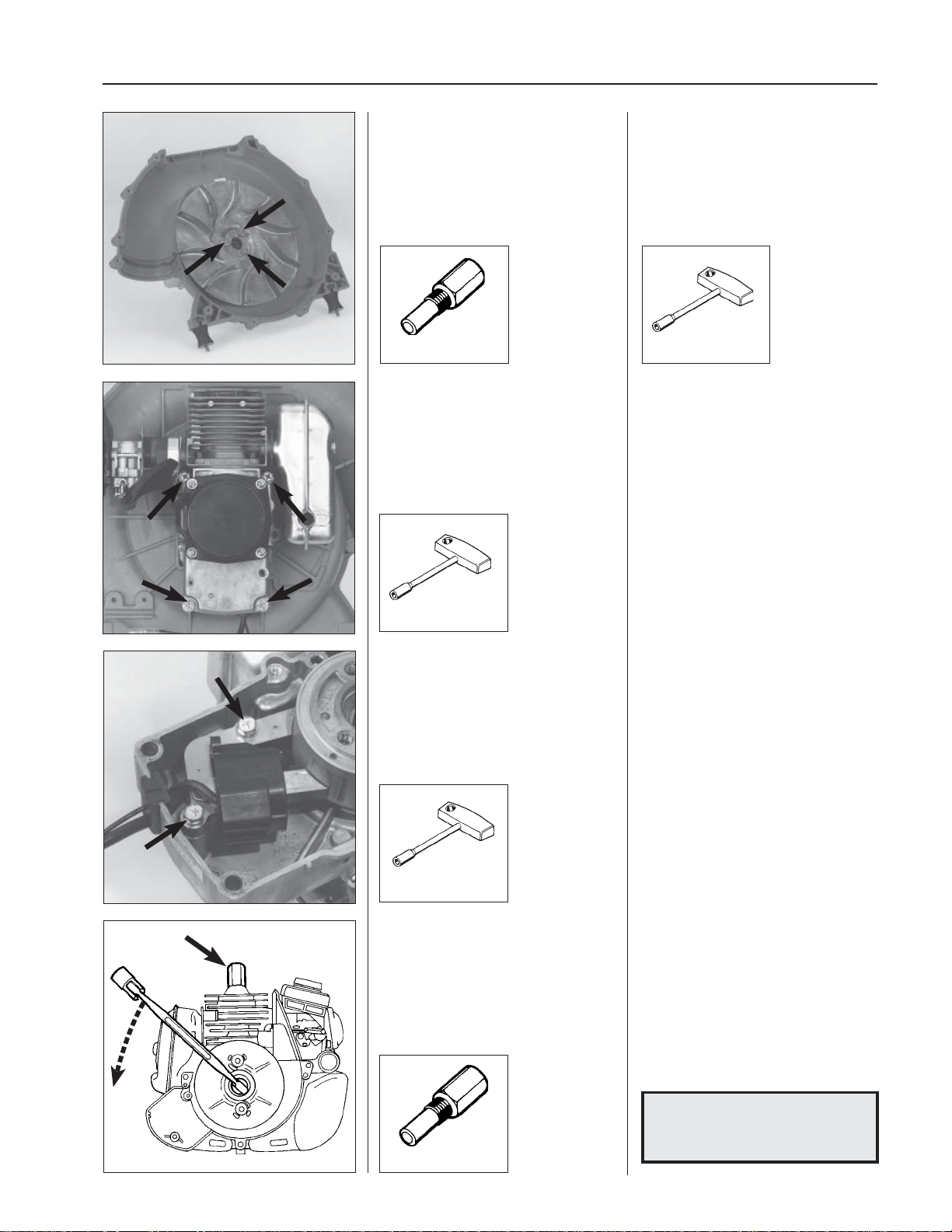

Dismantle the impeller

504 91 06-05 502 50 23-01

Dismantle the engine from the fan housing.

Screw in the piston stop no. 504 91 06-5

in the spark plug hole and remove the 3

screws holding the impeller using tool no.

502 50 23-01.

Remove the 4 screws holding the engine

against the fan housing.

Lift off the engine.

2

502 50 23-01

Remove the screws and lift off the ignition

module.

502 50 22-01

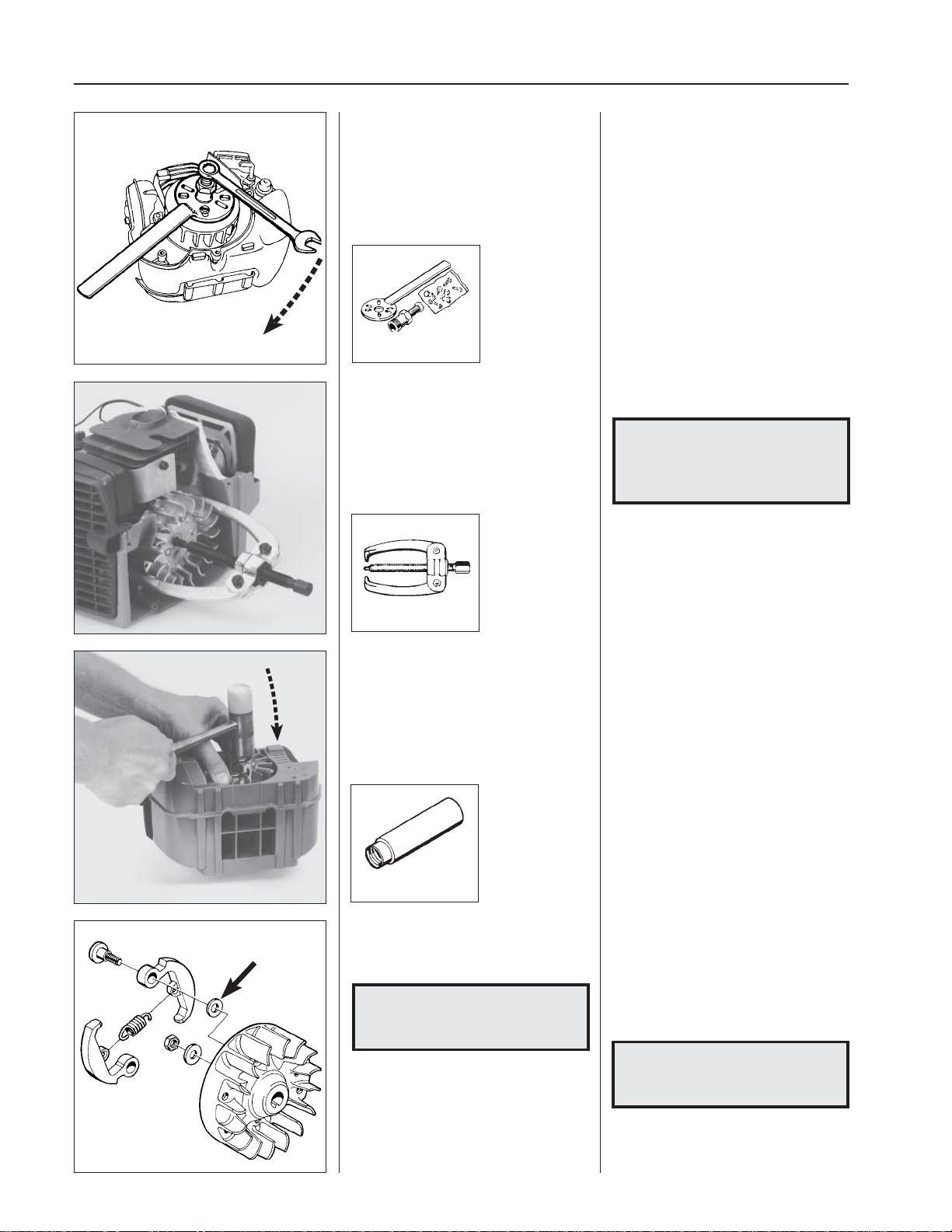

Dismantling the

flywheel

Fit the piston stop no. 504 91 06-05 and

remove the nut holding the flywheel and

where appropriate the plate with drive

dogs.

Remove the screws and lift off the ignition

module with the ignition lead, short-circuit cable and grommet.

Dismantling the

flywheel

Assemble the piston stop no. 504 91 0605 in the spark plug hole.

Ensure the piston stop is screwed down

to the bottom.

Remove the nut holding the flywheel and

where appropriate the plate with drive

dogs.

504 91 06-05

www.mymowerparts.com

NOTE!

The piston stop cannot be used on

model 122.

15

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

Ignition system

Dismantle the flywheel by using the flywheel puller.

502 51 49-01

Dismantle the flywheel by using the bearing puller.

Dismantle the flywheel from the crankcase using the puller no. 502 51 49-01.

Gently knock the puller screw with a hammer, if the flywheel sits tightly on the

crankshaft.

Select a suitable screwdriver and align

the puller so that it does not pull at an

angle.

Pull off the flywheel by using the bearing

puller no. 504 90 90-01.

NOTE!

The puller arms should be placed by

and opposite the magnet on the flywheel to avoid damaging it.

504 90 90-01

Dismantle the flywheel by using a hammer and push bar.

502 51 94-01

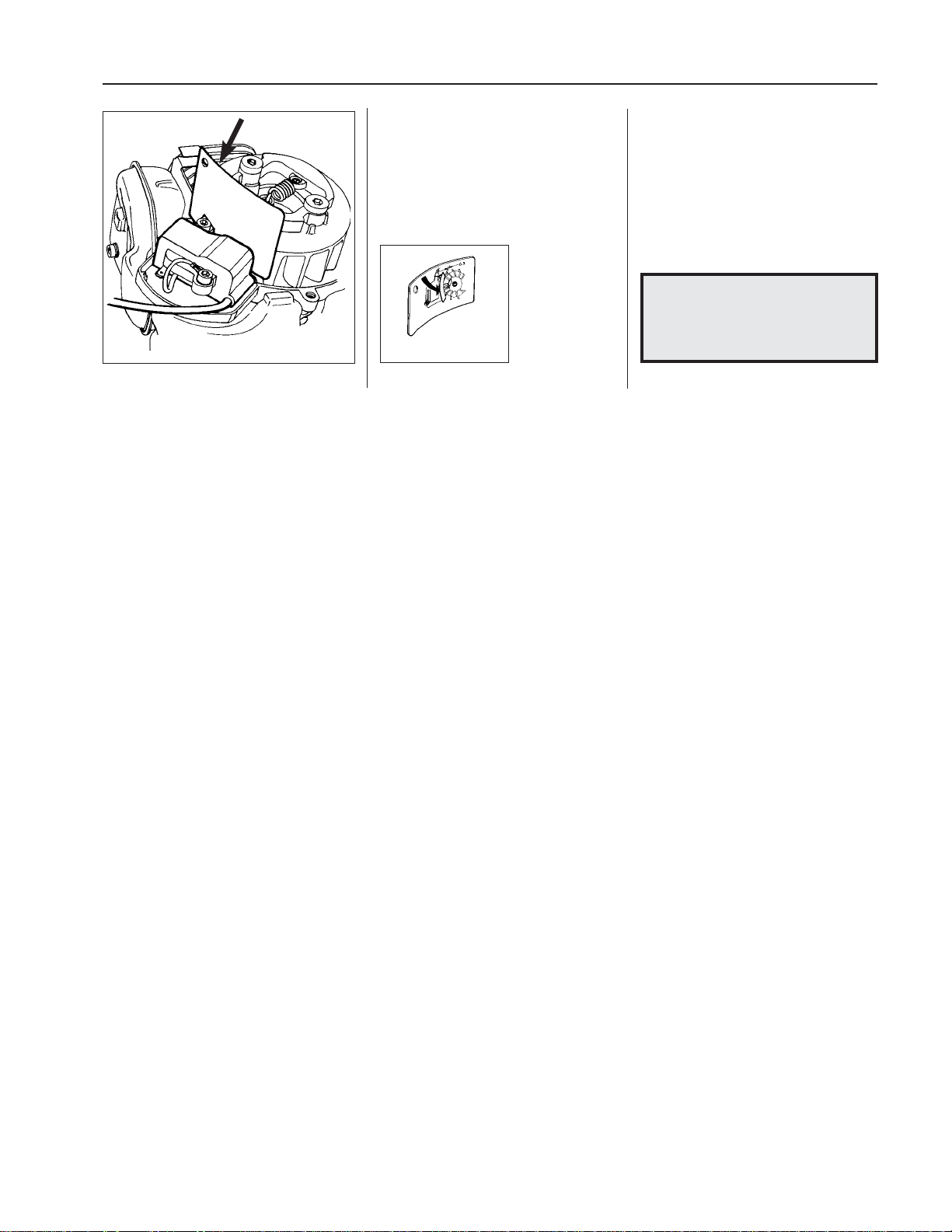

Assembly

Models 322, 325

Assemble the centrifugal clutch.

NOTE!

Do not forget the washers between

the flywheel and centrifugal clutch.

Is the flywheel extremely tight?

Lift up the engine body by holding the

puller and then hit the puller screw a few

times with a hammer.

Screw the nut on to the axle to protect the

threads.

Snap off the springs and move the drive

dogs to make space for the hammer.

Hold the flywheel and lift up the engine

body.

Use a hammer to hit the flywheel nut

sharply a few times until the flywheel

becomes loose on the axle.

Tip!

Use the push bar to protect the threads on

the axle and at the same time as it will be

easier to use the hammer.

Do not screw the push bar against the

flywheel – leave approx. 2 mm.

Assembly

Models 322, 325

If the crankshaft has two keyways, the

flywheel should be fitted in the right-hand

keyway seen from the axle end.

Assemble the centrifugal clutch.

NOTE!

Do not forget the washers between

the flywheel and centrifugal clutch.

16

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Ignition system

Assemble the ignition module and adjust

the air gap to 0.3 mm.

502 51 34-02

2

Assemble the ignition module.

Wait to connect the short-circuit cable to

facilitate the adjustment of the air gap. It

should be 0.3 mm between the permanent magnets in the flywheel and the

ignition module.

Now fit the short-circuit cable and the

remaining parts in the reverse order as

set out for dismantling.

NOTE!

Do not forget the rubber bushings

between the clutch cover and the

fuel tank.

www.mymowerparts.com

17

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

Technical data

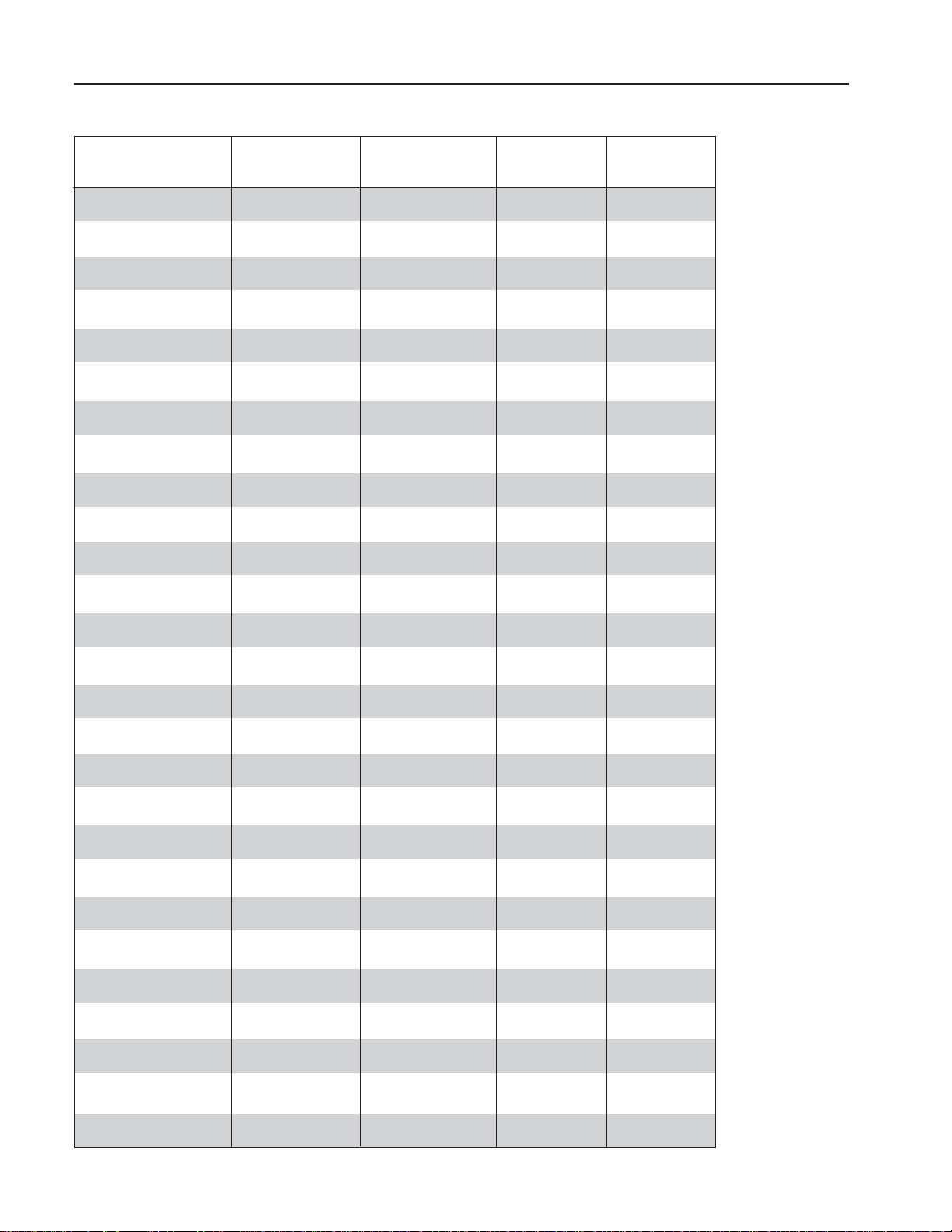

Model Spark plug Electrode gap Ignition system Air gap

Mondo

122L

Mondo Max

225L/LD

232L

Mondo Mega

225R/RD

232R

322

325

235R

240R

245R

250R

245RX

250RX

252RX

265RX

240RBD

235P

250PS

225E

18H

225H60/75

140B, 141B

132HBV

225BV/225HBV

Ignition system

mm/inch mm/inch

Champion RCJ8Y 0.5/0.02 Phelon 0.3/0.012

NGK BPM 6A CD

NGK BPM 6Y 0.6/0.024 Ikeda Denso 0.3/0.012

Solid State

Champion 0.5/0.02 Phelon 0.3/0.012

RCJ 8Y CD

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

Champion 0.5/0.02 Phelon 0.3/0.012

RCJ 8Y CD

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

Champion 0.5/0.02 Electrolux 0.3/0.012

RCJ 7Y ET

Champion 0.5/0.02 Electrolux 0.3/0.012

RCJ 7Y ET

Champion 0.5/0.02 Electrolux 0.3/0.012

RCJ 7Y ET

Champion 0.5/0.02 Electrolux 0.3/0.012

RCJ 7Y ET

Champion 0.5/0.02 Electrolux 0.3/0.012

RCJ 7Y ET

Champion 0.5/0.02 Electrolux 0.3/0.012

RCJ 7Y ET

Champion 0.5/0.02 SEM 0.3/0.012

RCJ 7Y GA6 CD

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

Champion 0.5/0.02 Electrolux 0.3/0.012

RCJ 7Y ET

Champion 0.5/0.02 Walbro 0.3/0.12

RCJ 7Y CD

Champion 0.5/0.02 Phelon 0.3/0.012

RCJ 8Y Solid State

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

NGK 0.6–0.7/ Kawasaki 0.4/0.016

BPM 7A 0.024–0.028 Transistor

Champion 0.6/0.024 Phelon 0.25–0.35/

CJ 8Y CD 0.010–0.014

Champion 0.5/0.02 Walbro 0.3/0.012

RCJ 7Y CD

18

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Fuel system

3.

Contents

Air filter __________________________________ 20

Tank venting ______________________________ 20

Primer pump ______________________________ 20

Carburettor _______________________________ 20

Assembly ________________________________ 25

Carburettor settings ________________________ 26

CARB-designed carburettor __________________ 28

Throttle cable _____________________________ 31

Throttle __________________________________ 33

Technical data _____________________________ 36

www.mymowerparts.com

19

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

Fuel system

Air filter

A

Remove the air filter cover and lift out the

air filter for cleaning.

Tank venting

Model 141B

The tank ventilation is integrated in the

fuel cap’s gasket

Blow through the flat hose to check that it

A

is open.

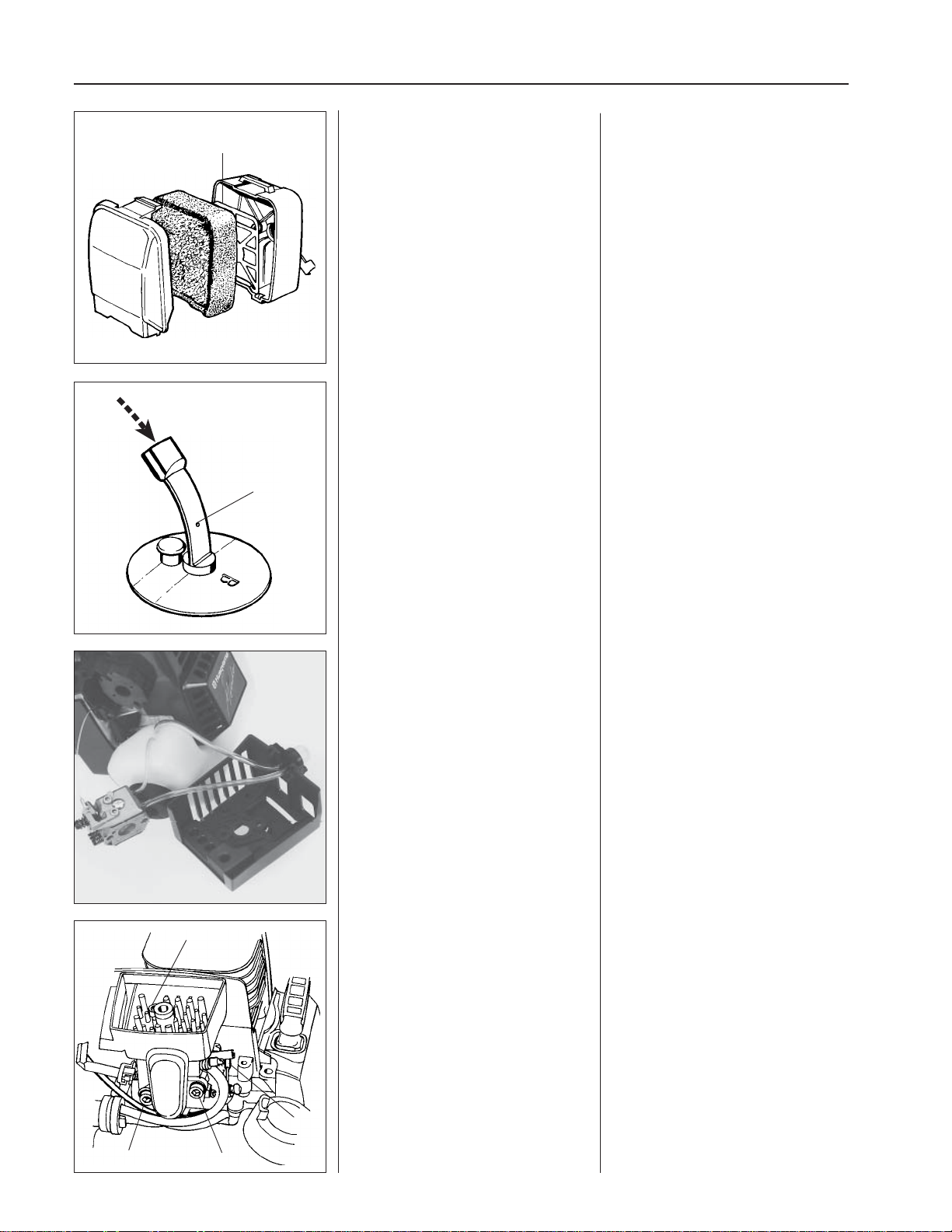

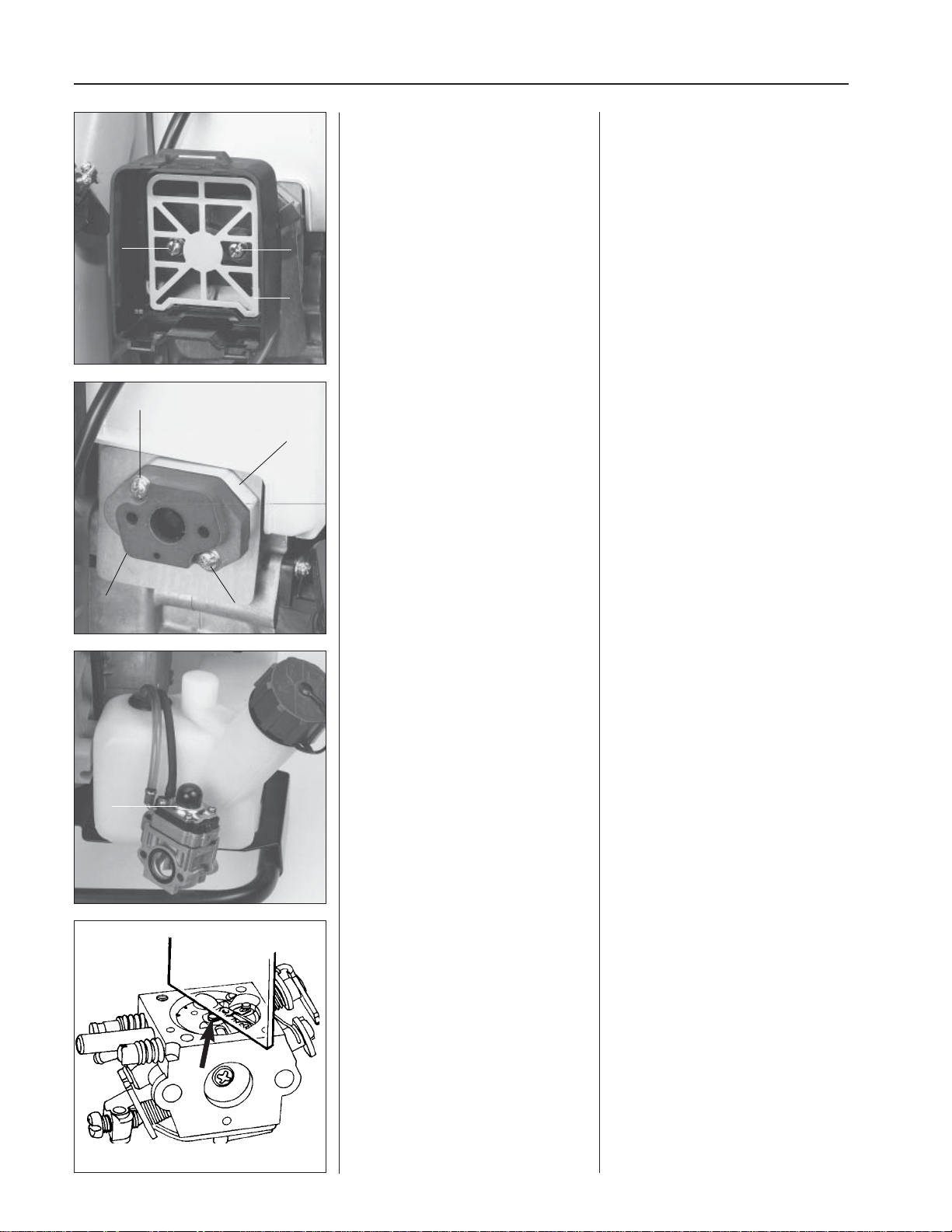

Air filter

Model 141B

Press down the catch on the cover over

the air filter housing and remove the cover

and the air filter for cleaning.

Clean the filter in the same way as described above.

Fit the filter with the smooth side facing in

towards the carburettor.

Ensure the support grille (A) is in position.

Tank venting

Model 141B

The tank ventilation is integrated in the

fuel cap’s gasket and can easily be dismantled for replacement.

Pull off the flat hose from the pin on the

rubber washer and blow through the hose

to check that it is not blocked.

Check that the hole (A) is open.

Primer pump

Models 322, 325, Mondo, 18H

The primer pump facilitates cold starts.

The pump cannot be repaired and must

be replaced if it stops working.

Note how the fuel hoses are connected to

simplify assembly.

3

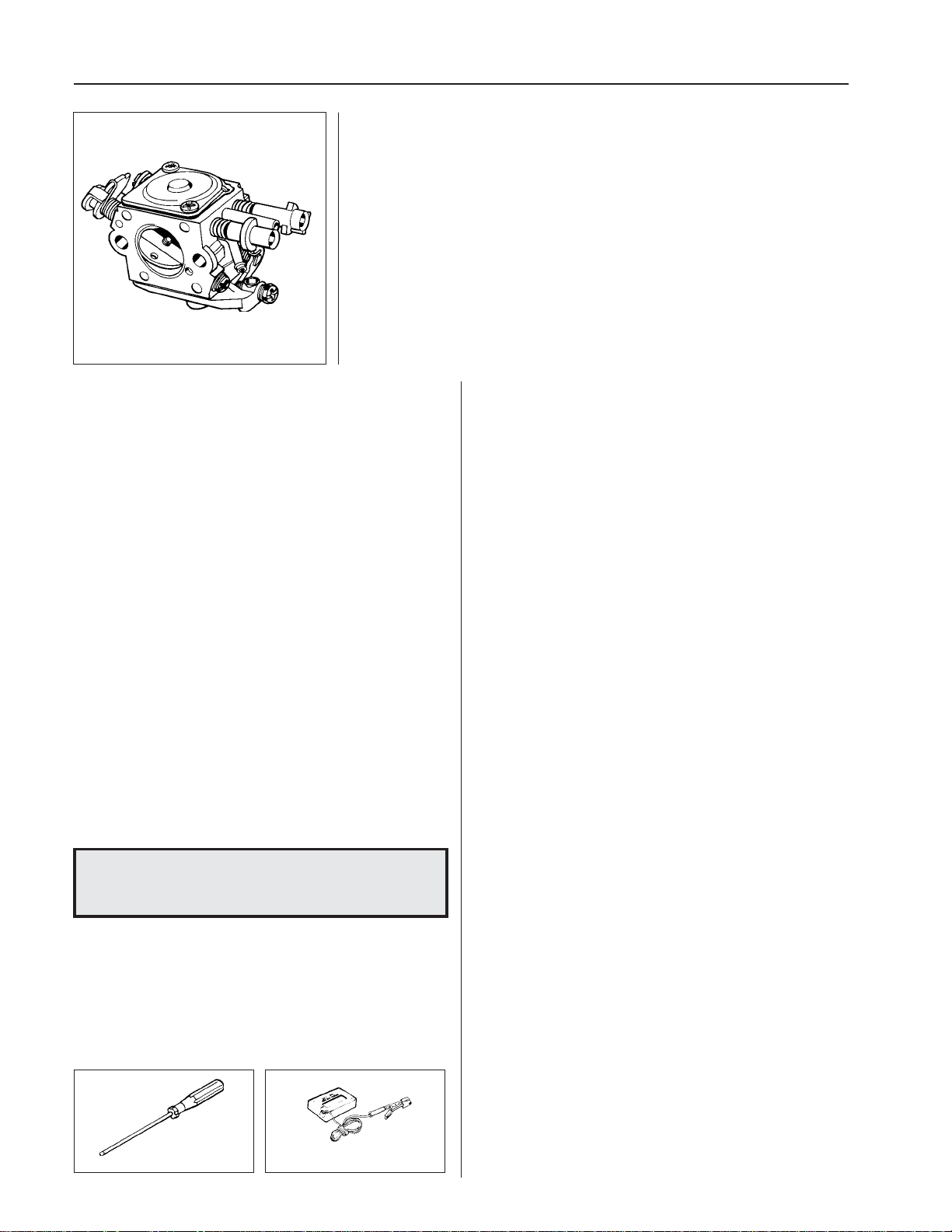

Carburettor

Models 322, 325

Disconnect the throttle cable from the

carburettor.

Dismantle the carburettor.

Primer pump

Models 322, 325, Mondo, 18H

The primer pump has the task of facilitating the start of the engine when cold. The

pump fills the carburettor with fuel before

attempting to start the engine. This also

prevents vapour bubbles from blocking

the narrow fuel channels.

If the pump does not work it must be

replaced.

Note how the fuel hoses are connected to

simplify assembly.

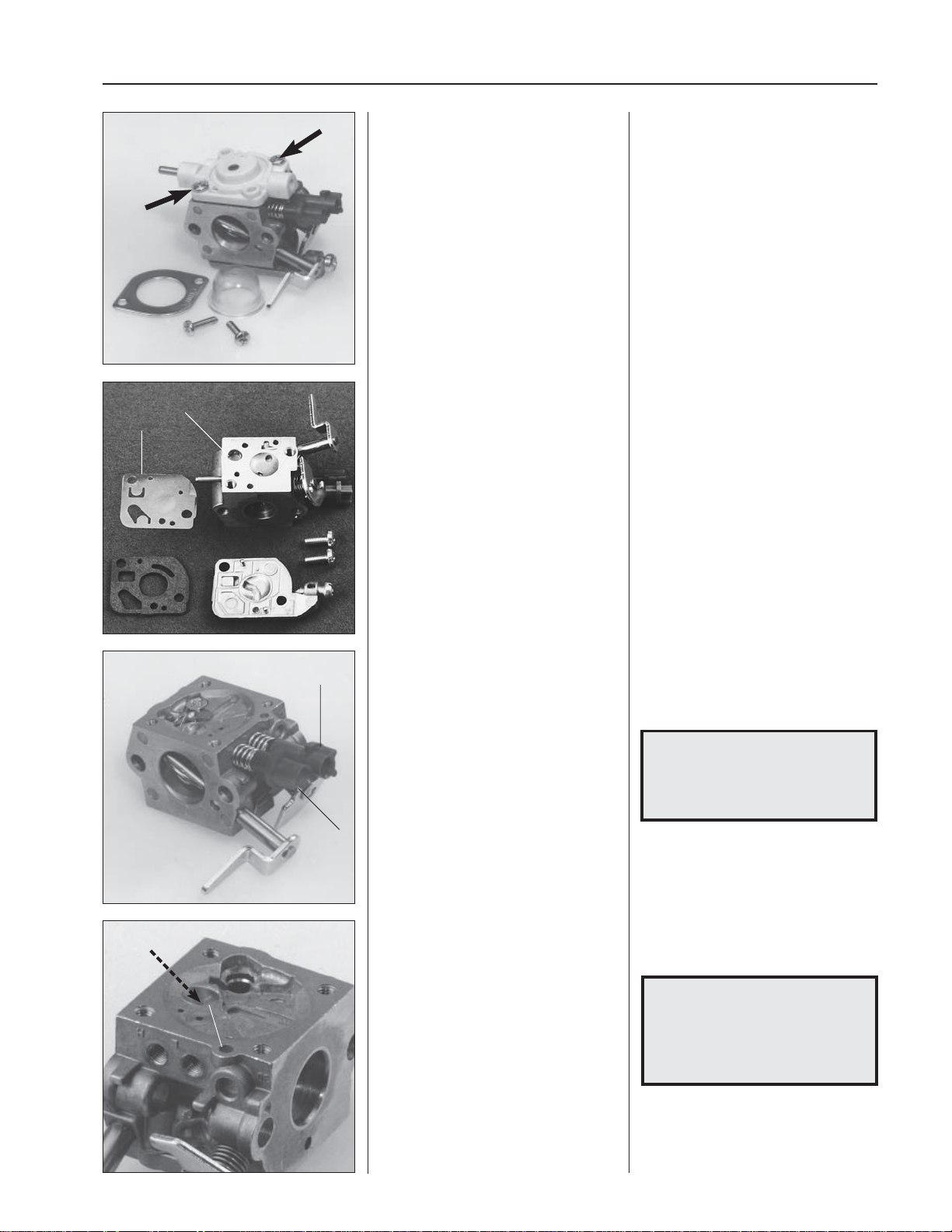

Carburettor

Models 322, 325

1. Disconnect the throttle cable from the

lever arm on the carburettor.

2. Loosen the carburettor screws.

3. Remove the screws holding the air

filter holder.

20

1

2

2

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Fuel system

Lift off the carburettor and note how the

fuel hoses are connected.

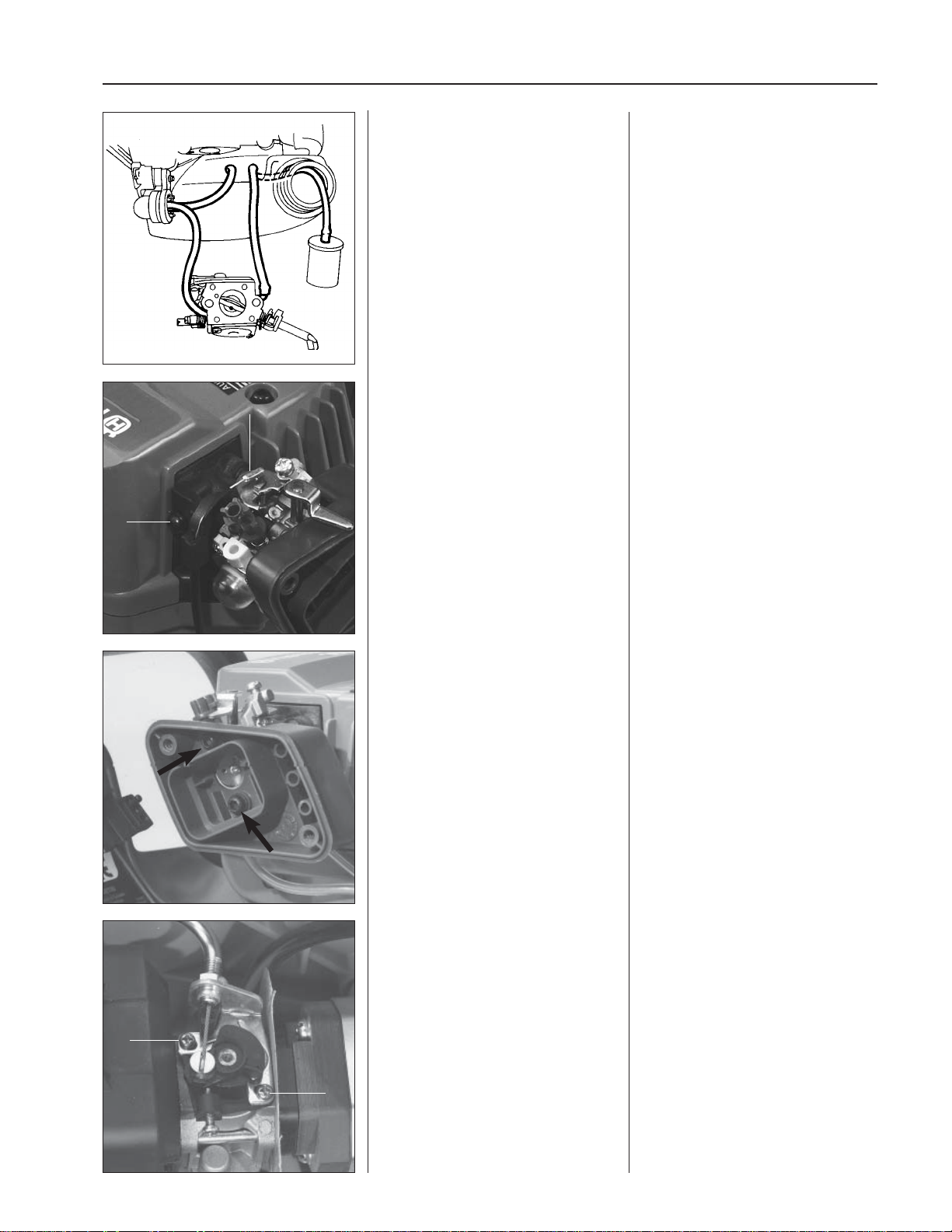

Model 18H

A

B

Disconnect the throttle cable from the

carburettor.

Lift off the carburettor and note how the

fuel hoses are connected.

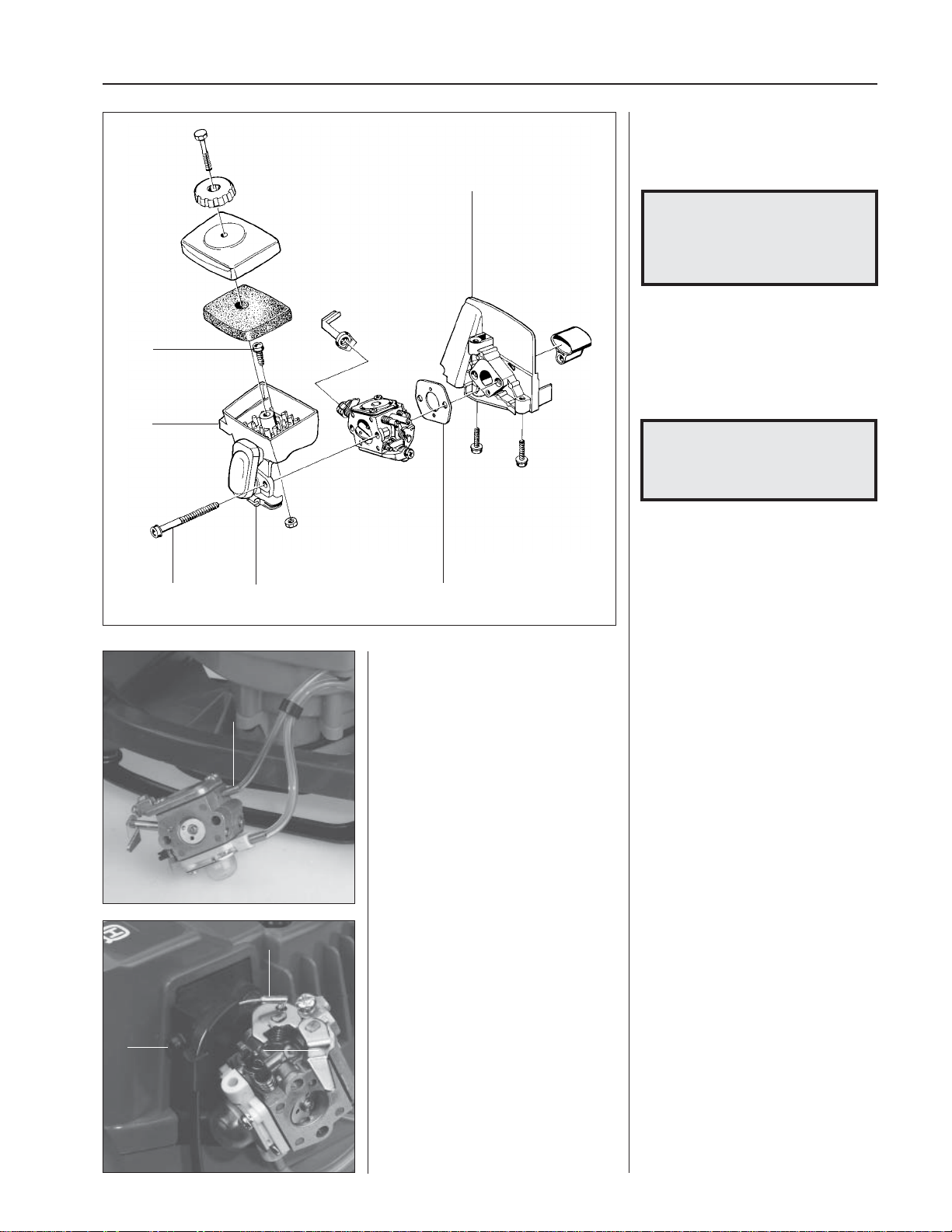

Model 18H

Disconnect the throttle cable from the

carburettor.

Remove the screw (B) and unhook the

throttle cable from the lever arm on the

carburettor (A).

3

A

Dismantle the carburettor from the cylinder.

Model 141B

Dismantle the cover together with the

rotary valve and cable bracket.

A

Loosen the carburettor screws and lift out

the air filter holder and carburettor.

Remove the fuel hoses from the carburettor.

Model 141B

Loosen both screws (A) and lift off the

cover together with the rotary valve and

cable bracket.

Let the parts remain hanging from the

throttle cable if they are not damaged and

do not need to be replaced.

www.mymowerparts.com

21

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

Fuel system

Dismantle the carburettor from the cylinder.

B

A

B

A

Remove the screws and lift out both distance pieces.

C

Inspect the fibre distance piece with regard to crack formation.

Replace the distance piece if necessary.

Remove the air filter support (A) and both

screws (B) that hold the carburettor on

the cylinder.

Lift off the air filter holder and carburettor

from the cylinder.

Remove the screws (A), the fibre distance piece (B) and the aluminium distance piece (C).

Inspect the fibre distance piece with regard to crack formation. Replace the distance piece if necessary.

B

A

Pull off the fuel hoses and lift out the

carburettor.

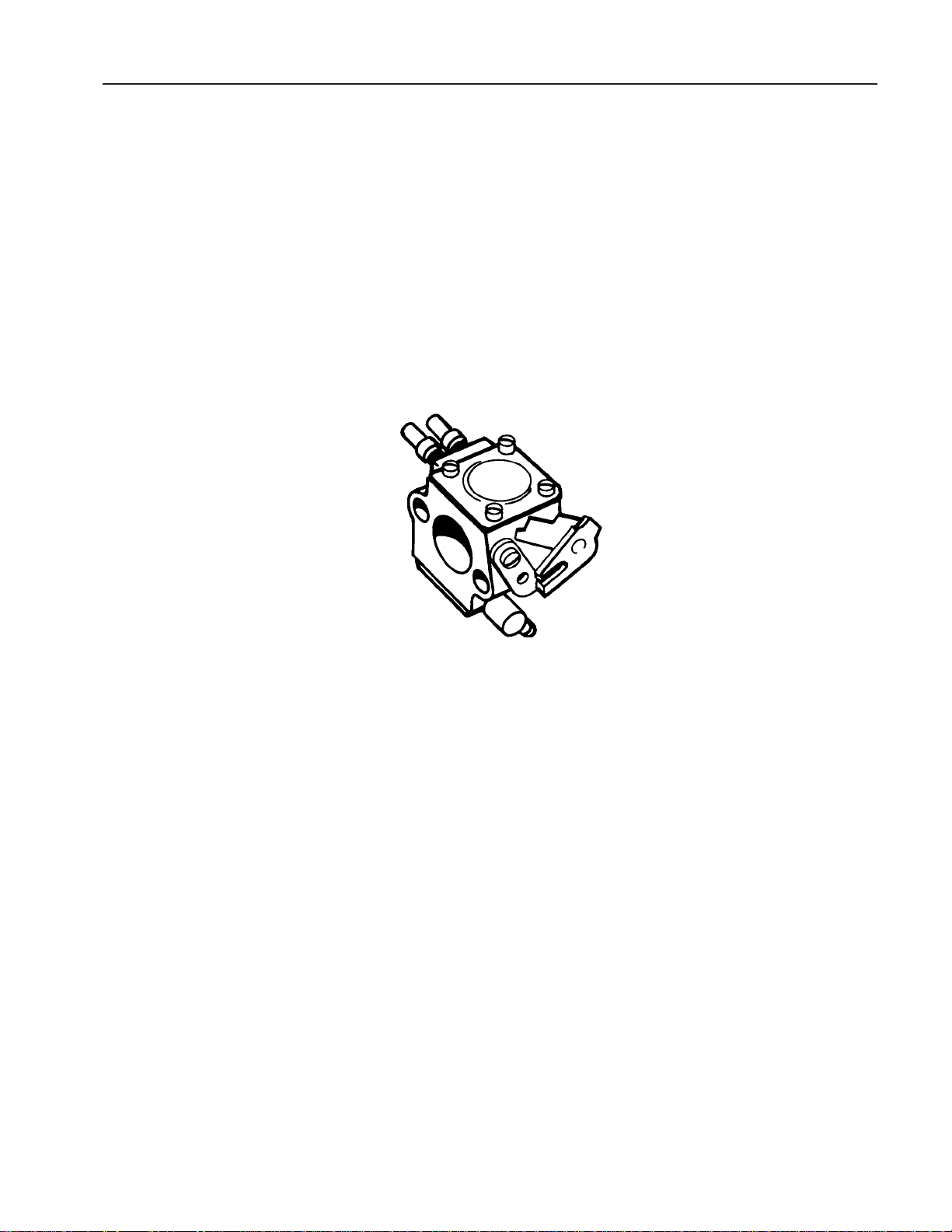

Assembling the carburettor –

Zama

Design, function and servicing correspond

with the Walbro carburettor.

Lift out the carburettor and note how both

fuel hoses are connected to the carburettor (rubber hose on the straight nipple).

Assembling the carburettor –

Zama

Zama has the same design and function

as the Walbro carburettor, which means

that servicing is also carried out in the

same way.

The lever arm should lie flush with the

carburettor housing’s contact face.

22

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Fuel system

Dismantling, assembling

Model 18H

The carburettor is made by Zama.

Dismantle the primer pump’s bellows and

cover over the control diaphragm.

Dismatle te pump diaphragm and the fuel

2

1

screen.

Dismantling, assembling

Model 18H

The carburettor is made by Zama.

It has the same principle design as the

Tillotson and Walbro carburettors.

Dismantle the primer pump’s bellows and

then the cover over the control diaphragm.

Inspect the control diaphragm and needle valve in the same way as previously

described.

Remove the screws holding the cover

over the pump diaphragm.

Lift off the cover, pump diaphragm and

gasket.

Check the diaphragm (1) as described in

the workshop manual.

Carefully remove the fuel screen (2) using, e.g. a needle.

3

Unscrew the jet needles. Unscrew the jet needles.

L

H

Press out the main jet for possible replacement using a suitable punch.

1

The plastic sleeves must first be removed

using a screwdriver on carburettors with

movement limiters.

NOTE!

Note how the needles are

positioned.

(For example, the H-needle is a

little shorter than the L-needle).

The main jet can be pressed out for

possible replacement using a suitable

punch.

NOTE!

When the new jet is fitted it must

not be pressed in further than so

that the edge (1) on the jet lies

flush with the carburettor

housing.

www.mymowerparts.com

23

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

Fuel system

Assemble the carburettor and pressure

test it.

Wait to fit the movement limiters on the jet

needles.

Dismantling, assembling

Model 141B

Remove the screws and lift off cover with

the pump bellows.

Assemble the carburettor in the reverse

order as set out for dismantling.

The needle valve lever arm should be

adjusted to a level flush with the carburettor housing’s contact face.

NOTE!

The control diaphragm and pump

diaphragm should lie closest to

the carburettor housing!

Wait to fit the movement limiters on the jet

needles.

Dismantling, assembling

Model 141B

This carburettor has a rotary valve instead of a throttle valve.

Remove the 4 screws and lift off cover

with the pump bellows.

Lift off the cover above the control diaphragm and carefully remove the non–

return valve. Check that it opens and

closes.

Continue to dismantle and assemble the

carburettor in the same way as described

for model 122.

Lift off the cover over the control diaphragm.

Carefully remove the non-return valve

and check that it opens and closes by

pressing together the valve’s short sides

with you thumb nail.

Hold the valve against a light to make it

easier to see whether it closes fully.

Continue to dismantle and assemble the

carburettor in the same way as described

for model 122.

24

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Fuel system

3

Assembly

Models 322, 325

1. First assemble the fuel hoses on the

4

5

1

2

6

3

carburettor.

NOTE!

The hose, with the fuel filter in the

tank, should be fitted on the

carburettor’s inlet side (pump

chamber).

2. Keep the air filter holder (1) in position

on the carburettor.

3. Slide in the carburettor screws (2).

4. Position the gasket (3) and screw together the entire carburettor assembly

against the distance piece (4). Tighten

the carburettor screws crosswise.

NOTE!

Do not forget the screw (5) that

holds the air filter holder against

the distance piece.

5. Connect the throttle cable to the lever

arm on the carburettor.

Make sure the cable enters the correct slot in the clutch cover and in the

guide on the air filter holder (6).

Assemble the remaining parts in the reverse order as set out for dismantling.

Model 18H

Connect the fuel hoses.

A

A

B

Connect the throttle cable.

Tighten the air filter holder.

Clean or replace the air filter.

Model 18H

Connect the fuel hoses on the carburettor.

The thin hose (A) is connected to the

nipple on the carburettor body (pump

diaphragm).

Connect the throttle cable (A) to the throttle valve’s lever arm.

Secure the cable guide (B) on the distance piece.

Tighten the air filter holder.

Do not forget the gasket between the

carburettor and the distance piece!

Clean or replace the air filter before assembly.

Clean in tepid soapy water.

Fit the air filter cover.

www.mymowerparts.com

25

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

A

Fuel system

Model 141B

Fit the distance piece on the cylinder.

Turn the carburettor so that the recessed

sealing ring (A) comes against the air

filter holder.

Tighten the carburettor and air filter holder

against the cylinder.

Slide down the rotary valve in the carburettor and screw on the cover.

Check that the throttle works.

Model 141B

Pay special attention that the distance

pieces and gaskets face the right way

and do not block the impulse channel

when fitted on the cylinder.

Secure the distance piece closest to the

carburettor with a little grease. This facilitates carburettor assembly.

Turn the carburettor so that the recessed

sealing ring (A) comes against the air

filter holder.

Place the carburettor screws in the air

filter holder (do not forget the choke valve)

and then slide the carburettor on the

screws.

Tighten the carburettor against the cylinder.

Slide down the rotary valve in the carburettor housing. Tighten the cover and

check that the throttle is turned easily

when accelerating and that it rests against

the idling screw when the throttle is released.

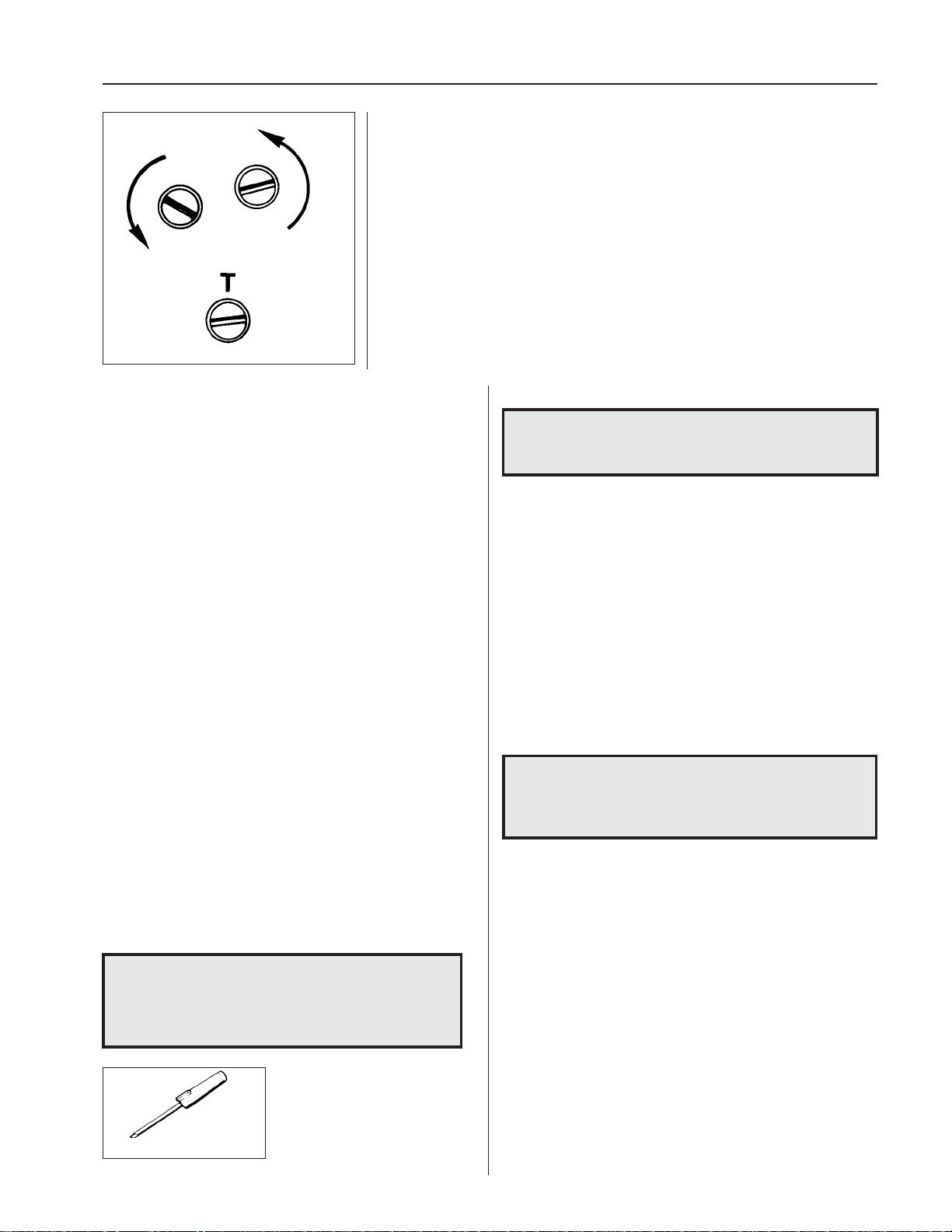

H

L

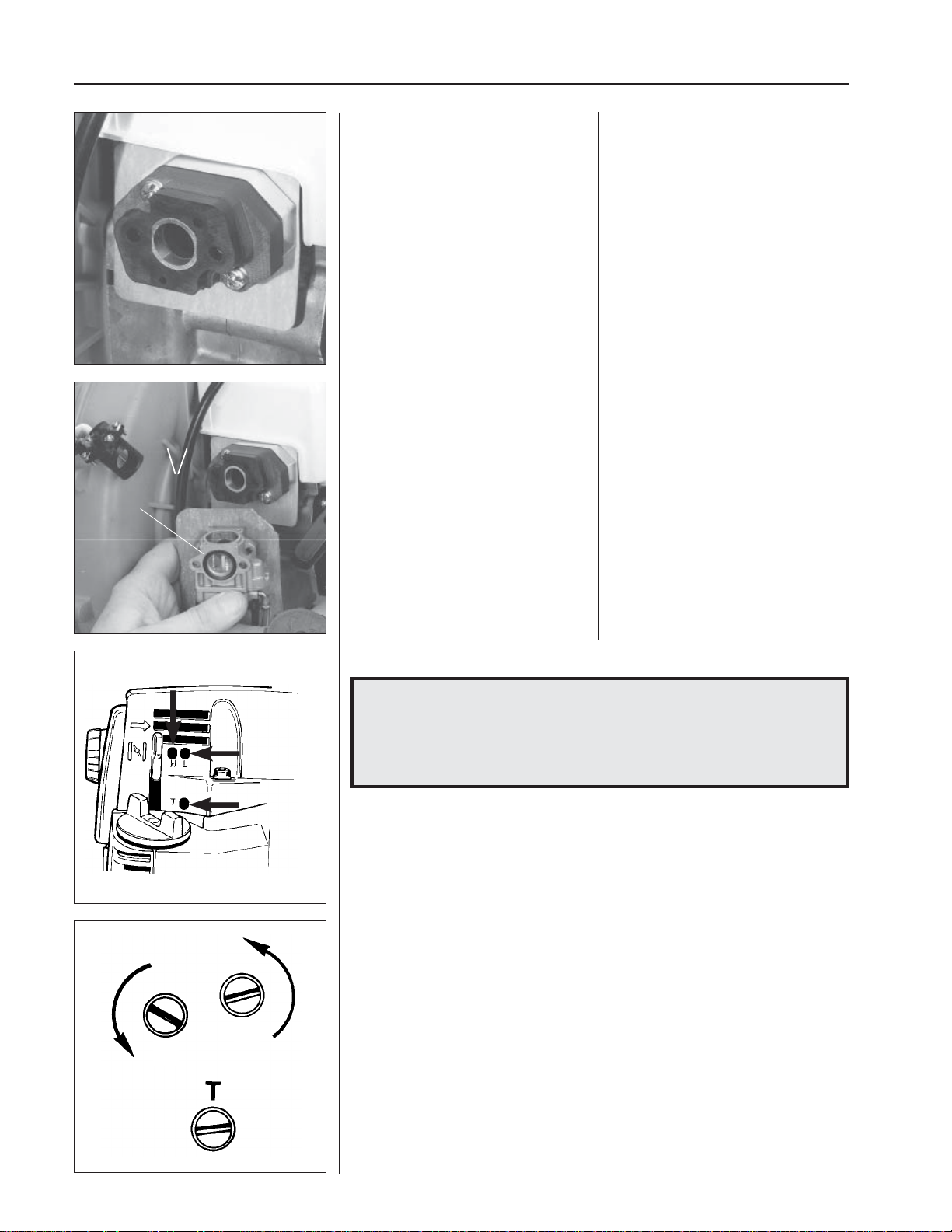

Carburettor settings

WARNING!

!

Function

The carburettor has the task of supplying a combustible fuel/air mixture to the cylinder.

The amount

The mixture’s composition

needles “H” and “L”.

The needles must be correctly adjusted in order for the engine to give maximum power

at different speeds, run steadily while idling and to react quickly when accelerating.

The setting of the carburettor can vary a little depending on the humidity, temperature

and air pressure.

L = Low speed needle

H = High speed needle

T = Adjuster screw for idling

The fuel quantity in relation to the air flow permitted by the throttle opening is

adjusted by the L and H-needles. Turning the needles clockwise gives a leaner fuel

mixture (less fuel) and turning them anticlockwise gives a richer fuel mixture (more

fuel).

● The T-screw regulates the position of the throttle while the engine is idling. Turning

the screw clockwise gives a higher idling speed while turning it anticlockwise gives

a lower idling speed.

The clutch and clutch cover must be fitted under all

circumstances when testing the engine in connection with

carburettor adjustment.

Otherwise there is a risk of the clutch becoming loose resulting in

serious personal injury.

of this mixture is controlled by the throttle.

of fuel and air is controlled by means of the adjustable

A leaner

mixture gives

higher

revs while

a richer

mixture gives

less

revs.

26

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Fuel system

Basic setting

The carburettor is set to its basic setting when test run at the factory. The basic setting is

“richer” than the optimal setting (the max speed is 600–800 rpm under the recommended

max. speed) and should be kept during the engine’s first working hours. Thereafter the

carburettor should be finely adjusted. The basic setting can vary between:

H = 1 to 1 1/4 turns (model 235 P: 3/4 – 1 turn, Mondo + Mega + Max, 18 H: 2 turns,

L

H

Fine adjustment

Fine adjustment of the carburettor should be carried out after the

engine has been “run-in”.

● The air filter should be clean and the cylinder cover fitted

when adjustments are made.

First adjust the L-needle, then the H-needle and finally the

idling speed's T-screw.

The following speed recommendations apply:

Idling speed = 2,500 rpm.

322, 325: 2 1/2 turns)

L = 1 to 1 1/4 turns (model 235 P: 3/4 – 1 turn, Mondo + Mega + Max, 18H: 2 turns)

Basic setting model 235 P

The pruner’s engine can not be revved to the max speed as the cutting head’s blades

go against the stop and the engine slows. Consequently, the engine revs at max under

load. The high speed needle H should not be changed from the basic settings (3/4 – 1

turn open). If the muffler smokes heavily, at the same time as the engine 4 strokes

a,great deal the setting is too rich. Turn the H-needle clockwise until you find the setting

that sounds right.

Max. speed

Model During running in After running in

265 10,900 11,500

252, 250 RX (R) 12,900 (11,900) 13,500 (12,500)

240 11,900 12,500

245 11,900 12,500

225 10,500 11,000

232 10,300 10,800

235 10,500 11,000

240 RBD 10,500 11,000

322, 325 12,500 12,500

122 10,800

32 7,000

Mondo 9,000

Mega / Max 9,000

250PS

235 P — —

225 H60 / H75 10,500 11,000

18H 9,500 10,000

132HBV 7,100 7,600

140B, 141B

225HBV 7,700 8,200

NOTE!

The max. recommended speed must not be exceeded.

When checking the speed on a trimmer no part of the

cord should be extended.

Check the speed using the tachometer 502 71 14-01.

● Carefully screw in (clockwise) the

L and H-needles until they bottom. Now screw out (anticlockwise) the needles 1 turns. The

501 60 02-02

carburettor now has the setting H

= 1 and L = 1. Use the special

screwdriver 501 60 02-02.

www.mymowerparts.com

3

● Start the engine and run warm for 10 minutes.

NOTE!

If the cutting equipment rotates while idling the T-screw

should be turned anticlockwise until it stops.

Low speed needle L

Find the highest idling speed by slowly turning the low speed

needle clockwise and anticlockwise. When the highest speed has

been found, turn the L-needle 1/4 turn anticlockwise.

High speed needle H

The high speed needle H affects the engine’s power and speed.

A too lean H-needle setting (H-needle screwed in too far) gives

too little fuel to the engine resulting in damage to the engine.

Run the engine at full throttle for about 10 seconds. The H-needle

is set correctly when the engine “splatters” a little.

If the muffler smokes heavily, at the same time as the engine

splatters a great deal the setting is too rich. Turn the H-needle

clockwise until you find the setting that sounds right.

NOTE!

A tachometer should always be used to find the

optimal setting.

The recommended max. speed must not be exceeded.

Idling speed T-screw

Let the engine idle for about 30 seconds or until the speed has

stabilised. Adjust the idling speed T-screw until the engine idles

without stopping.

● Turn the screw clockwise if the engine stops.

● Turn the speed anticlockwise to lower the speed.

Correctly adjusted carburettor

A correctly adjusted carburettor means that the engine accelerates without hesitation and it 4 strokes a little at full throttle.

● A too lean adjusted L-needle can cause starting difficulties

and bad acceleration.

● A too lean adjusted H-needle results in lower power, bad

acceleration and/or damage to the engine.

● A too rich setting of the “L” and “H” needles give acceleration

problems or a too low working speed.

27

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

Fuel system

Carburettors in E-TECH and CARB-EPA designs

(CARB-EPA only applies to USA)

On these types of carburettor the H and L-needles can be adjusted within extremely

tight limits, to among others, comply with the stringent demands with regard to the

hydrocarbon and nitrogen oxide content in the exhaust fumes.

The carburettor needles on these carburettors are fitted with plastic sleeves with

movement limiters

To carry out adjustment when replacing needles or the entire carburettor the engine

must be under load. This is achieved by fitting a Trimmy Fix with the specified length and

diameter of trimmer cord. Consequently, the stated speed will be much lower than with

“normal” carburettor adjustment when the motor may run freely.

After replacing the needles or the entire carburettor on a CARB-EPA approved engine,

adjustment must be carried out according to the instructions below.

The combiguard or trim guard must be fitted when adjusting the H-needle.

After replacing the complete

carburettor

1. Check that the plastic sleeve on the H-needle is turned as far

as possible anticlockwise (richest fuel mixture). The sleeve

sits freely on the needle and can be turned without affecting

the needle’s setting.

Do not change the L-needle setting. This is adjusted at the

factory and the plastic sleeve is already fixed on the needle.

2. Fit four trimmer cords Ø 3.3 mm on a Trimmy Fix.

(Trimmy Fix M10, 531 00 38-69 for models 225, 232, 322L,

322R, 325L, 325L-X, 325R-X. Trimmy Fix M12, 502 13 87-02

for model 235).

Maybe the hole needs to be enlarged a little to make fitting the

trimmer cords easier.

(Does not apply to models 225H60/H75 and 18H).

3. Cut the trimmer cord to the right length (measure the length

to the edge of the Trimmy Fix).

Model 225: 145 mm

Model 232: 155 mm

Model 235: 170 mm

Models 322L/R, 325L/L-X/R-X: 142 mm

Fit the Trimmy Fix on the machine.

Model 322C must be run with Trimmy Hit VI and its standard

cord (Ø 2.0 mm). Cut off the cord ends so that they are

146 mm long.

(Does not apply to models 225H60/H75 and 18H).

NOTE!

The spray guard must be removed from model 235.

Exercise care when the trimmer cord is rotating.

4. Start the engine. Adjust the idling speed T-screw if necessary.

5. Use screwdriver 531 00 48-63 to adjust the H-needle. The

blade is 2 mm wide and goes through the plastic sleeve and

only adjusts the needle.

Adjust the H-needle so that the max. speed 8400 ± 200 rpm

is set.

Use the tachometer 502 71 14-01 to check the speed.

(Does not apply to models 225H60/H75 and 18H).

531 00 48-63

28

502 71 14-01

www.mymowerparts.com

6. Run the engine warm for 2–3 minutes.

7. Check that the max speed is still 8400 ± 200 rpm. Adjust the

H-needle if necessary.

8. Check that the plastic sleeve on the H-needle is turned as far

as possible anticlockwise (richest fuel mixture).

9. Press in the plastic sleeve using a punch (Ø 5 mm).

The basic setting of the carburettor is now complete. Further fine

adjustment, within the limits that the plastic sleeves on the needles

permit, can be necessary.

Departures for models 225H60/H75, 18H

5A. Adjust the H-needle until the max speed is reached.

Then turn the needle anticlockwise until the speed drops by

500 rpm.

6A. Run the engine warm at full throttle for 2–3 min.

7A. Check the idling speed and that the engine reacts quickly

when accelerating.

7B. Adjust the H-needle until the max speed is reached. Then turn

the needle anticlockwise until the speed drops by 500 rpm.

After replacing only the H-needle

1. Turn the L-needle as far as possible anticlockwise (richest fuel

mixture).

2. Remove the plastic sleeve on the H-needle and unscrew the

needle.

3. Carefully screw the new H-needle to the bottom and then

loosen it a 1/2 turn. On models 322/325 the needle should be

loosened approx.2 1/2 turns.

4. Press a new plastic sleeve on the H-needle down to the first

stop. The sleeve can now be turned without turning the needle.

5. Turn the plastic sleeve as far as possible anticlockwise (richest fuel mixture) without turning the needle.

6. Fit four trimmer cords Ø 3.3 mm on a Trimmy Fix.

(Trimmy Fix M10, 531 00 38-69 for models 225, 232, 322L,

322R, 325L, 325L-X, 325R-X. Trimmy Fix M12, 502 13 87-02

for model 235).

Maybe the hole needs to be enlarged a little to make fitting the

trimmer cords easier.

(Does not apply to models 225H60/H75).

7. Cut the trimmer cord to the right length (measure the length

to the edge of the Trimmy Fix).

Mod. 225: 145 mm Mod. 232: 155 mm

Mod. 235: 170 mm Mod. 322L/R, 325L/L-X/R-X: 142 mm

Fit the Trimmy Fix on the machine.

Model 322C must be run with Trimmy Hit VI and its standard cord

(Ø 2.0 mm). Cut off the cord ends so that they are 146 mm long.

(Does not apply to models 225H60/H75 and 18H).

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Fuel system

The spray guard must be removed from model 235. Exercise

care when the trimmer cord is rotating.

8. Start the engine. Adjust the idling speed T-screw if necessary.

9. Use screwdriver 531 00 48-63 to adjust the H-needle. The

blade is 2 mm wide and goes through the plastic sleeve and

only adjusts the needle.

Adjust the H-needle so that the max. speed 8400 ± 200 rpm

is set.

Use the tachometer 502 71 14-01 to check the speed.

(Does not apply to models 225H60/H75 and 18H).

10. Run the engine warm for 2–3 minutes.

531 00 48-63

11. Check that the max speed is still 8400 ± 200 rpm. Adjust the

H-needle if necessary.

12. Check that the plastic sleeve on the H-needle is turned as far

as possible anticlockwise (richest fuel mixture).

13. Press in the plastic sleeve using a punch (Ø 5 mm).

The basic setting of the carburettor is now complete. Further fine

adjustment, within the limits that the plastic sleeves on the

needles permit, can be necessary.

502 71 14-01

3

531 00 48-63

Now turn the L-needle as far as possible anticlockwise (richest fuel mixture).

9. Turn the plastic sleeve on the H-needle as far as possible

anticlockwise (richest fuel mixture).

10. Fit four trimmer cords Ø 3.3 mm on a Trimmy Fix.

(Trimmy Fix M10, 531 00 38-69 for models 225, 232, 322L,

322R, 325L, 325L-X, 325R-X. Trimmy Fix M12, 502 13 87-02

for model 235).

Maybe the hole needs to be enlarged a little to make fitting the

trimmer cords easier.

(Does not apply to models 225H60/H75 and 18H).

11. Cut the trimmer cord to the right length (measure the length to

the edge of the Trimmy Fix).

Model 225: 145 mm Model 232: 155 mm

Model 235: 170 mm

Models 322L/R, 325L/L-X/R-X: 142 mm

Fit the Trimmy Fix on the machine.

Model 322C must be run with Trimmy Hit VI and its standard cord

(Ø 2.0 mm). Cut off the cord ends so that they are 146 mm long.

(Does not apply to models 225H60/H75 and 18H).

502 71 14-01

Departures for models 225H60/H75, 18H

9A. Adjust the H-needle until the max speed is reached.

Then turn the needle anticlockwise until the speed drops by

500 rpm.

10A.Run the engine warm at full throttle for 2–3 min.

11A.Check the idling speed and that the engine reacts quickly

when accelerating.

11B. Adjust the H-needle until the max speed is reached. Then turn

the needle anticlockwise until the speed drops by 500 rpm.

After replacing the H- and L-needles

1. Remove the plastic sleeves from both needles and screw out

the needles.

2. Carefully screw the new needles in until they bottom.

Screw out the L-needle 2 turns. On models 322/325 the

needle should be screwed out approx. 1 turn.

Screw out the H-needle 1/2 turn. On models 322/325 the

needle should be screwed out approx. 2 1/2 turns.

3. Press the new plastic sleeves on the needles until the first stop.

The sleeves can still be turned without the needles turning.

4. Turn the plastic sleeve on the L-needle as far as possible

clockwise (leanest fuel mixture).

5. Start the engine and let it idle.

6. Use screwdriver 531 00 48-63 to adjust the L-needle. The

blade is 2 mm wide and goes through the plastic sleeve and

only adjusts the needle.

Adjust the L-needle so that the highest idling speed is obtained.

Use the tachometer 502 71 14-01 to check the speed.

7. Check that the plastic sleeve on the L-needle is still turned as

far as possible clockwise (leanest fuel mixture).

8. Press the plastic sleeve on the L-needle using a punch (Ø 5 mm).

NOTE!

The spray guard must be removed from model 235.

Exercise care when the trimmer cord is rotating.

12. Start the engine. Adjust the idling speed T-screw if necessary.

13. Use screwdriver 531 00 48-63 to adjust the H-needle. The

blade is 2 mm wide and goes through the plastic sleeve and

only adjusts the needle.

Adjust the H-needle so that the max. speed 8400 ± 200 rpm

is set.

Use the tachometer 502 71 14-01 to check the speed. (Does

not apply to models 225H60/H75).

14. Run the engine warm for 2–3 minutes.

15. Check that the max speed is still 8400 ± 200 rpm. Adjust the

H-needle if necessary.

16. Check that the plastic sleeve on the H-needle is turned as far

as possible anticlockwise (richest fuel mixture).

17. Press in the plastic sleeve using a punch (Ø 5 mm).

The basic setting of the carburettor is now complete. Further fine

adjustment, within the limits that the plastic sleeves on the

needles permit, can be necessary.

Departures for models 225H60/H75, 18H

13A. Adjust the H-needle until the max speed is reached.

Then turn the needle anticlockwise until the speed drops by

500 rpm.

14A. Run the engine warm at full throttle for 2–3 min.

15A. Check the idling speed and that the engine reacts quickly

when accelerating.

15B. Adjust the H-needle until the max speed is reached. Then turn

the needle anticlockwise until the speed drops by 500 rpm.

www.mymowerparts.com

29

Loading...

Loading...