Husqvarna TC 250R (2013), TE 310R USA (2013), TXC 250R USA (2013), TE 310R (2013), TXC 310R USA (2013) Workshop Manual

...

TE 250R - 310R 2013 I.E.

TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

Workshop Manual Ed. 07-2012

Rev 00

HUSQVARNA MOTORCYCLES S.R.L. - Varese disclaims all liabilities for any errors or omissions in this manual and

reserves the right to make changes to reect on-going product development. Illustrations in the manual may differ from

actual components. No reproduction in full or in part without written authorisation.

1st edition (07-2012) - Rev. 00

a.1

simbolo

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

TE 250R - 310R 2013 I.E.

TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

TE 250R: ZKHA300AADV000001

TE 310R: ZKHA301AADV000001

TE 310R USA: ZKHKCEDG#DV000001

TC 250R: ZKHA300AADV050001

TC 250R USA: ZKHTC253#DV000001

TXC 250R USA: ZKHTX253#DV000001

TXC 310R USA: ZKHTX313#DV000001

H11268

1

Workshop Manual Ed. 07-2012

FOREWORD, TABLE OF CONTENTS

1st edition (07-2012) - Rev. 00

Printed in Italy

MODELS COVERED (from serial number onwards)

Copyright by

HUSQVARNA MOTORCYCLES S.R.L.

BMW Group

Technical Service

Via Nino Bixio, 8

21024

(Varese) - Italy

tel. ++39 0332 75.61.11

tel. ++39 0332 756 558

www.husqvarna-motorcycles.com

Workshop Manual

1. Chassis serial number

a.2

simbolo

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

FOREWORD, TABLE OF CONTENTS

Workshop Manual Ed. 07-2012

Foreword

This publication is designed for use by HUSQVARNA Service Centres to assist authorised personnel in the maintenance

and repair of the models covered in this manual. The technical information provided in this manual is a critical complement to operator training and operators should become thoroughly familiar with it.

For ease of understanding, diagrams and photographs are provided next to the text.

Notes with special signicance are identied as follows throughout the manual:

Accident-prevention rules for operator and persons working nearby.

Damage to vehicle and/or its components may result from incompliance with relevant instructions.

Additional information concerning the operation covered in the text.

Useful tips

To prevent problems and ensure effective service work, observe the following HUSQVARNA recommendations:

– before repair, evaluate the customer's description of the problem and ask the appropriate questions to clearly identify

problem symptoms;

– diagnose the problem and identify the causes clearly. This manual provides basic background information that must

be supplemented with the operator's expertise and specic training available through HUSQVARNA held at regular

periods;

– plan ahead before starting work: gather any spare parts and tools to avoid unnecessary delays;

– avoid unnecessary disassembly work to get to the part that needs repairing.

Always read the relevant instructions and follow the disassembly sequence outlined in this manual.

Recommended shop practices

1 Always replace gaskets, sealing rings and split pins with new ones.

2 When loosening or tightening nuts or bolts, always begin with the bigger ones or from the centre. Tighten to the speci-

ed torque and follow a cross pattern.

3 Always mark any parts or positions that might be confused upon assembly.

4 Use genuine HUSQVARNA parts and the recommended lubricant brands.

5 Use special tools where specied.

6 Technical Bulletins might contain more up-to-date setting data and procedures than this manual. Be sure to read

them.

a.3

simbolo

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

Workshop Manual Ed. 07-2012

FOREWORD, TABLE OF CONTENTS

Table of Contents

Title Section

Foreword, table of contents .................................................................................a

Important notices .................................................................................................b

General information

.............................................................................................A

Maintenance ........................................................................................................B

Troubleshooting

.................................................................................................. C

Settings and adjustments ................................................................................... D

General procedures .............................................................................................E

Engine disassembly.............................................................................................F

Engine overhaul.................................................................................................. G

Engine reassembly ............................................................................................. H

Front suspension ..................................................................................................I

Rear suspension.................................................................................................. J

Brakes .................................................................................................................L

Electrical system.................................................................................................M

Engine cooling .................................................................................................... N

Hydraulically controlled clutch .............................................................................P

Fuel injection system ...........................................................................................S

Special tools .......................................................................................................W

Tightening torque gures .....................................................................................X

Chassis and wheels.............................................................................................Y

NOTES

Unless otherwise specied, data and specications apply to all models.

b.1

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

b

Workshop Manual Ed. 07-2012

IMPORTANT NOTICES

Section

b.2

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

H11269

TE

H11270

TXC

H11271

TC

IMPORTANT NOTICES

Workshop Manual Ed. 07-2012

1) TC, TXC models are RACING motorcycles and are warranted to be free from

operating defects; a scheduled maintenance chart for racing use is provided in

Section B.

2) The TE model is for ROAD USE (DERATED); it is warranted to free from

defects and covered by legal warranty, provided that the STANDARD CONFIGURATION IS MAINTAINED and the maintenance chart provided in Section

B is observed. For TE models modied to RACING SPECIFICATIONS (FULL

POWER RATING), observe the scheduled maintenance chart for racing use

provided in Section B.

* This motorcycle has not been designed to travel over long distances with the

engine at top rpm, as in long-distance road or highway travel. Riding over long

distances at full throttle may result in severe engine damage.

* The geometry and setup of this motorcycle have been designed for racing

and to provide top performance when riding solo. We advise against riding

two-up, whether off-road or on the track.

* ALWAYS remember that these motorcycles are specically designed for

racing, i.e. for usage conditions signicantly different from those experienced

in regular road use.

IMPORTANT

VEHICLE CONFIGURATION as outlined below is a prerequisite for the warranty to remain valid:

A) STANDARD MOTORCYCLE, FOR ROAD USE: DERATED;

B) RACING MOTORCYCLE, FOR RACING USE: FULL POWER RATING.

* In order to maintain the vehicle’s “Guarantee of Functionality”, the client must

follow the maintenance programme indicated in Section B by having the required

maintenance inspections carried out at authorised HUSQVARNA dealers. The

cost for changing parts and for the labour necessary in order to comply with

the maintenance plan is charged to the Client. The warranty becomes NULL

AND VOID if the motorcycle is rented.

Notes

Left and right side is determined when seated on motorcycle.

Z: number of teeth

A: Austria

AUS: Australia

B: Belgium

BR: Brazil

CDN: Canada

CH: Switzerland

D: Germany

E: Spain

F: France

FIN: Finland

GB: Great Britain

I: Italy

J: Japan

USA: United States of America

Unless otherwise specied, data and instructions apply to all market variants.

A.1

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

A

Workshop Manual Ed. 07-2012

GENERAL INFORMATION

Section

A.2

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

GENERAL INFORMATION

Workshop Manual Ed. 07-2012

Sommario

Engine ..........................................................................................................A.3

Starting .........................................................................................................A.3

Timing system ..............................................................................................A.3

Lubrication ....................................................................................................A.3

Ignition ..........................................................................................................A.3

Fuel system ..................................................................................................A.3

Primary drive ................................................................................................A.3

Clutch ...........................................................................................................A.3

Transmission ................................................................................................A.4

Secondary drive............................................................................................A.4

Final ratios (TE) ............................................................................................A.4

Final ratios (TXC) .........................................................................................A.4

Final ratios (TC)

............................................................................................A.4

Frame ...........................................................................................................A.4

Front suspension ..........................................................................................A.4

Rear suspension...........................................................................................A.5

Front brake ...................................................................................................A.5

Rear brake

....................................................................................................A.5

Rims .............................................................................................................A.5

Tires ..............................................................................................................A.5

Cold tire pressure

.........................................................................................A.5

Electrical components location (TC)

.............................................................A.6

Electrical components location (TXC)

..........................................................A.6

Electrical components location (TE)

.............................................................A.6

Overall dimensions .......................................................................................A.7

Weight

..........................................................................................................A.8

Capacities

.....................................................................................................A.8

A.3

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

Workshop Manual Ed. 07-2012

GENERAL INFORMATION

Engine

Type .............................................................................. single cylinder, 4 stroke

TE-TXC 250R - 310R

Cooling ..........................................................liquid, with electric fan on models

TC 250R

Cooling ......................................................................................................liquid

TE-TXC 250R + TC 250R

Bore ..........................................................................................3,11 in. (79 mm)

Stroke .................................................................................. 2,00 in. (50,9 mm)

Displacement ...............................................................15,22 cu. in. (249,5 cm3)

Compression ratio

....................................................................................13,6:1

TE-TXC 310R

Bore

......................................................................................... 3,23 in. (82 mm)

Stroke ................................................................................... 2,26 in. (57,3 mm)

Displacement

.............................................................18,46 cu. in. (302,44 cm3)

Compression ratio ......................................................................................13:1

Starting

TE-TXC 250R - 310R ............................................................................ electric

TC 250R

............................................ kick start (with automatic decompressor)

Timing system

Type .......................................................................................4 titanium valves,

controlled by twin nger follower type camshafts, mixed chain/gear drive system

Valve clearance (with engine cold)

Intake .................................................................................. 0,006 in. (0,15 mm)

Exhaust............................................................................... 0,008 in. (0,20 mm)

Lubrication

Type ......................... wet crankcase, lobe pump and cartridge and mesh lters

Ignition

Type ..................................................................Electronic, inductive discharge,

with adjustable advance (digital control)

Spark plug type..........................................................................NGK CR9EIA-9

Spark plug gap

....................................................0.031÷0,035 in. (0,8÷0,9 mm)

Fuel system

Type .............................................................................Electronic injection feed

Primary drive

Drive pinion gear- Clutch ring gear

................................................... Z 17- Z 54

Transmission ratio

....................................................................................3,176

Clutch

Type

.............................................oil bath multiple disc clutch, hydraulic control

A.4

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

GENERAL INFORMATION

Workshop Manual Ed. 07-2012

Transmission

Type ............................................................................ constant mesh gear type

TE-TXC 250R - 310R

Transmission ratio

1st gear...................................................................................... 2,142 (z 30/14)

2nd gear .................................................................................... 1,750 (z 28/16)

3rd gear ..................................................................................... 1,450 (z 29/26)

4th gear ..................................................................................... 1,227 (z 27/22)

5 th gear .................................................................................... 1,041 (z 25/24)

6 th gear .................................................................................... 0,884 (z 22/27)

TC 250R

Transmission ratio

1st gear. ..................................................................................... 2,142 (z 30/14)

2nd gear .................................................................................... 1,750 (z 28/16)

3rd gear .................................................................................... 1,450 (z 29/26)

4th gear...................................................................................... 1,227 (z 27/22)

5 th gear..................................................................................... 1,041 (z 25/24)

Secondary drive

Transmission sprocket- Rear wheel sprocket

TXC + TC...........................................................................................Z 13- Z 50

TE ......................................................................................................Z 13- Z 40

Transmission ratio

TXC + TC..................................................................................................3,846

TE ..............................................................................................................3,076

Final ratios (TE)

1st gear ...................................................................................................20,926

2nd gear ..................................................................................................17,096

3rd gear ..................................................................................................14,165

4th gear ..................................................................................................11,987

5th gear ..................................................................................................10,169

6th gear ....................................................................................................8,636

Final ratios (TXC)

1st gear....................................................................................................26,164

2nd gear .................................................................................................21,376

3rd gear ..................................................................................................17,251

4th gear ...................................................................................................14,987

5th gear ...................................................................................................12,715

6th gear ...................................................................................................10,797

Final ratios (TC)

1st gear....................................................................................................26,180

2nd gear ..................................................................................................21,380

3rd gear ...................................................................................................17,715

4th gear ...................................................................................................14,994

5th gear ...................................................................................................12,726

Frame

Type ................... Steel single tube cradle (roud, rectangular, ellipsoidal tubes);

light alloy rear frame

Front suspension

Type ............."Upside-down" telescopic hydraulic front fork with advanced axle

(adjustable in compression and rebound stroke);

stanchions tubes Ø 1.89 in. (Ø 48 mm)

Legs axis stroke......................................................................11.8 in. (300 mm)

A.5

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

Workshop Manual Ed. 07-2012

GENERAL INFORMATION

Rear suspension

Type ...................................... progressive with hydraulic single shock absorber

Wheel stroke...........................................................................11.6 in. (296 mm)

Front brake

Type ................................................. xed disc Ø 10.23 in. (Ø 260 mm) “Wave”

type with hydraulic control and oating caliper

Rear brake

Type .............................................. oating disc, Ø 9.45 in. (Ø 240 mm) “Wave”

type with hydraulic control and oating caliper

Rims

Front ..................................................................................in light alloy: 1,6x21”

TE-TXC 250R - 310R

Rear .................................................................................in light alloy: 2,15x18”

TC 250

Rear .................................................................................in light alloy: 1,85x19”

Tires

TE-TXC 250R- 310R

Front ...................................................................................................90/90x21”

TC 250R

Front ...............................................................................................80/100 x 21”

Rear TE - TXC ................................................................................. 120/90x18”

Rear TE USA ................................................................................... 140/90x18”

Rear TC ........................................................................................... 100/90x19”

Cold tire pressure

Front TE - TXC - TC (*) .............................................................. 0,9÷1,0 Kg/cm

2

Front TE - TXC (%) .......................................................................... 1,1 Kg/cm

2

Rear TE - TXC - TC (*) .............................................................. 0,8÷0,9 Kg/cm

2

Rear TE - TXC (%) .......................................................................... 1,0 Kg/cm

2

(*) In case of racing use - (%) Road use

A.6

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

GENERAL INFORMATION

Workshop Manual Ed. 07-2012

Electrical components location (TC)

The ignition system includes the following elements:

- Generator on the inner side of L.H. crankcase half cover;

- Integrated electronic ignition coil on the spark plug cap;

- Electronic control unit under the fuel tank;

- Spark plug on cylinder head;

- Throttle position sensor on the throttle body;

- MAP Sensor on the throttle body;

- Condenser on the left of rear chassis;

- Voltage regulator under the reservoir;

- Air temperature sensor on intake lter.

Electrical components location (TXC)

The ignition system includes the following elements:

- Generator on the inner side of L.H. crankcase half cover;

- Integrated electronic ignition coil on the spark plug cap;

- Electronic control unit under the fuel tank;

- Voltage regulator located to the left side of the motorcycle near the steering tube;

- Spark plug on cylinder head;

- 12V-450W starter motor behind the engine cylinder;

- Solenoid starter on the left of rear chassis;

- Throttle position sensor on the throttle body;

- MAP Sensor on the throttle body;

- Air temperature sensor on intake lter.

The electrical system includes the following elements:

- 12V-6Ah battery under the saddle;

- Electric fan;

- Two 15A and 20A fuses located to the right of the rear chassis, plus one 20A fuse on the starter relay;

- Coolant temperature sensor;

- Lambda sensor;

- Fuel pump inside the fuel tank.

- Fuel and reserve indicator.

Electrical components location (TE)

The ignition system includes the following elements:

- Generator on the inner side of L.H. crankcase half cover;

- Integrated electronic ignition coil on the spark plug cap;

- Electronic control unit under the fuel tank;

- Voltage regulator located to the left side of the motorcycle near the steering tube;

- Spark plug on cylinder head;

- 12V-450W starter motor behind the engine cylinder;

- Solenoid starter on the left of rear chassis;

- Throttle position sensor on the throttle body;

- MAP Sensor on the throttle body;

- Air temperature sensor on intake lter.

The electrical system includes the following elements:

- 12V-6Ah battery under the saddle;

- Turning indicator asher on left side of rear chassis;

- Injection and lighting system relay on the right side of the chassis;

- Electric fan;

- Three fuses (two 15A fuses and one 20A fuse), located to the right of the rear chassis, plus one 20A fuse on the starter relay;

- Coolant temperature sensor;

- Lambda sensor;

- Headlamp with 12V-35/35W twin halogen bulb and 12V-5W parking light bulb;

- LED tail light with stop light bulb;

- 12V-10W turning indicator bulbs;

- Fuel pump inside the fuel tank.

- Odometer.

A.7

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

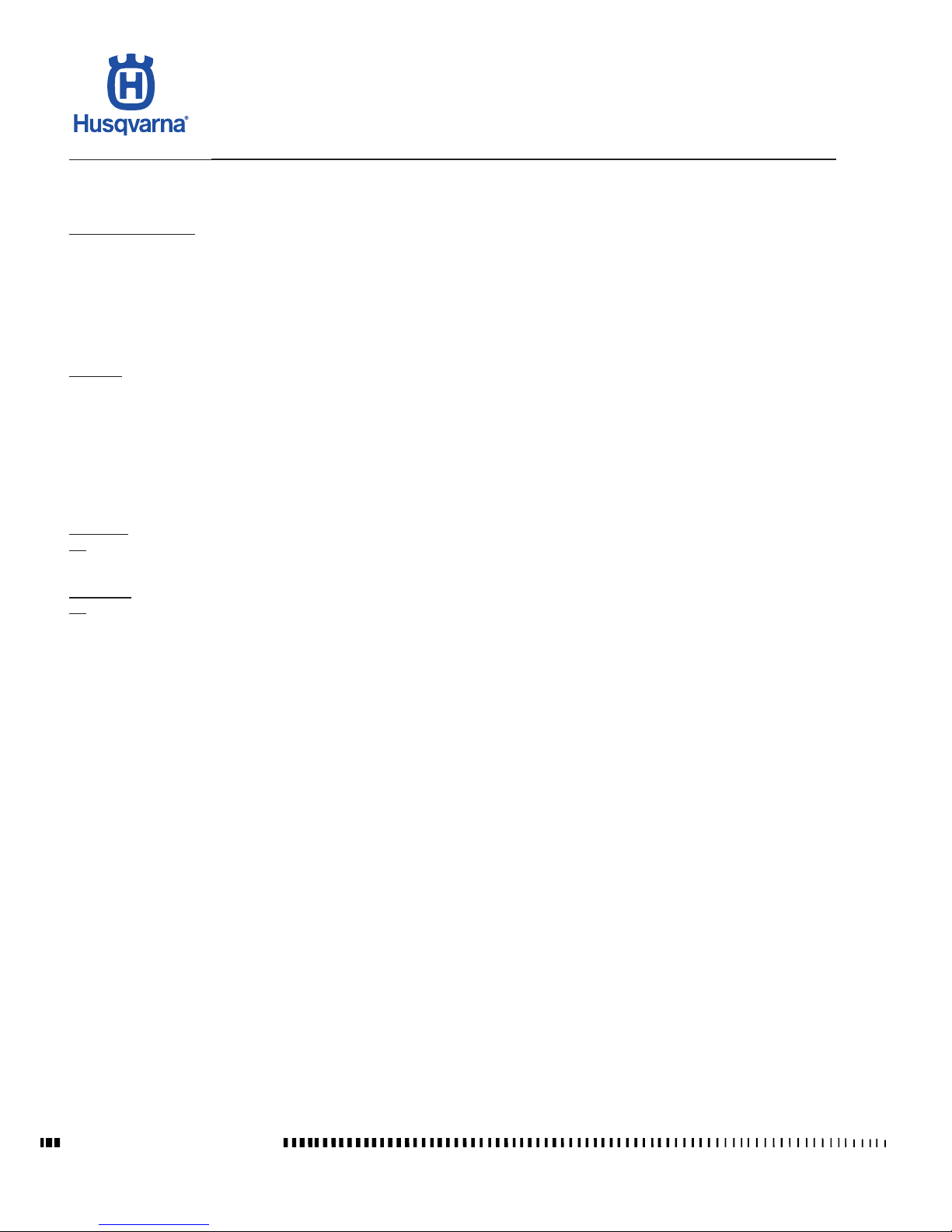

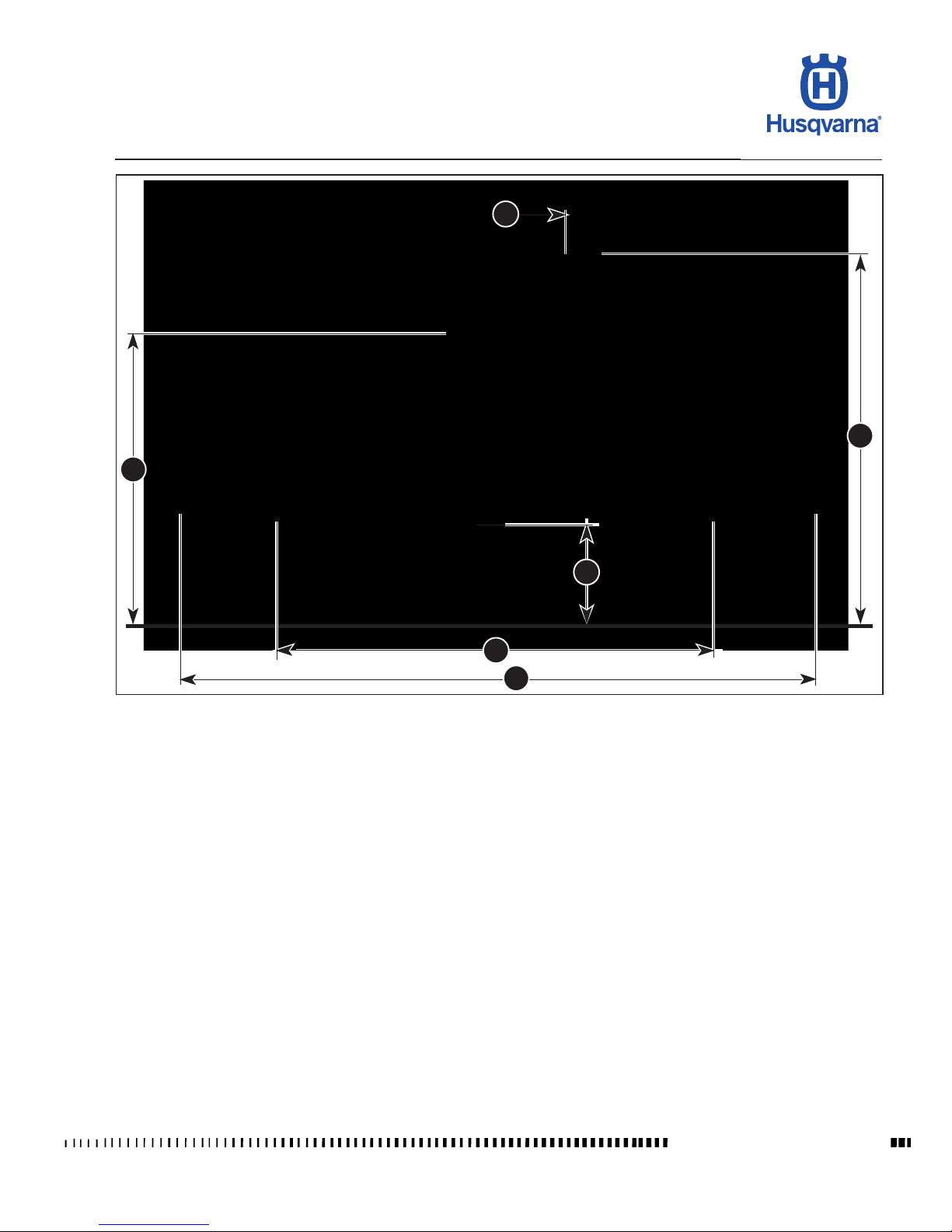

H11272

C

D

E

F

A

B

Workshop Manual Ed. 07-2012

GENERAL INFORMATION

Overall dimensions

Wheelbase A

(TE-TXC) ........................................................................... mm 1460 (57.47 in.)

(TC) ................................................................................... mm 1470 (57.87 in.)

Overall length B

(TC) ................................................................................... mm 2215 (87.20 in.)

(TE) .................................................................................... mm 2260 (88.97 in.)

(TXC) ................................................................................. mm 2176 (85.66 in.)

Overall width C .................................................................... mm 820 (32.28 in.)

Overall height D

(TE-TXC) ........................................................................... mm 1290 (50.78 in.)

(TC) ................................................................................... mm 1305 (51.37 in.)

Saddle height E

(TC) ..................................................................................... mm 985 (38.77 in.)

(TE-TXC) ............................................................................. mm 950 (37.40 in.)

Minimum ground clearance F

(TE-TXC) ..............................................................................mm 290 (11.41 in.)

(TC) ..................................................................................... mm 325 (12.79 in.)

A.8

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

GENERAL INFORMATION

Workshop Manual Ed. 07-2012

Weight

(TC)

Kerb weight, without fuel: .....................................................101,2 Kg (213,8 lb)

(TE)

Kerb weight, without fuel:

.........113 Kg (249,1 lb) 250 / 113,5 Kg (250,2 lb) 310

(TXC)

Kerb weight, without fuel:

.....108,6 Kg (239,4 lb) 250 / 109,1 Kg (240,5 lb) 310

Capacities Type Quantity

Fuel tank (TC) Premium grade unleaded fuel (R.O.N. 98) 6,5 liters

Imp. Gall. 1.43

U.S. Gall. 1.72

Fuel tank (TE-TXC) Premium grade unleaded fuel (R.O.N. 98) 8,5 liters

(2,3 liters - 0.51 Imp. Gall. - 0.61 U.S. Gall. reserve included)

Imp. Gall. 1.87

U.S. Gall. 2.25

Gearbox/engine oil CASTROL POWER 1 RACING (SAE 10W50) 900 cc

(oil change and oil lter

replacement)

850 cc

(oil change)

Front fork oil KAYABA KHL15-11 (SAE 7,5; SAE 5 for extremely cold weather)

Oil quantity in each fork leg (TC - TXC)

556 cm3 (33.93 in3)

Cartridge: 196 cm3 (11.96 in3)

Fork sleeve: 360 cm3 (21.97 in3)

Oil quantity in each fork leg (TE)

674 cm3 (41.13 in3)

Rear shock absorber oil CASTROL SYNTHETIC FORK OIL (5W)

Coolant CASTROL MOTORCYCLE COOLANT 0.9 litres

0,24 U.S. Gall.

0,2 Imp. Gall.

Front brake uid CASTROL RESPONSE SUPER (DOT 4)

Rear brake uid CASTROL RESPONSE SUPER (DOT 4)

Clutch uid CASTROL RESPONSE SUPER (DOT 4)

Drive chain lubrication CASTROL CHAIN LUBE RACING

Grease lubrication CASTROL PASTE TA GREASE

Electric contact protection CASTROL METAL PARTS CLEANER

CASTROL MOTORCYCLE DWF

Fillers for radiator AREXONS LIQUID FILLER

Front fork oil: Kayaba KHL15-11

Air lter oil AGIP FORMULA FILTER "Foam air lter protection oil"

Air lter detergent AGIP "Filter clean foam air detergent uid"

IMPORTANT - Do not add any additives to fuel or lubricants.

B.1

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

B

Workshop Manual Ed. 07-2012

MAINTENANCE

Section

B.2

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

MAINTENANCE

Workshop Manual Ed. 07-2012

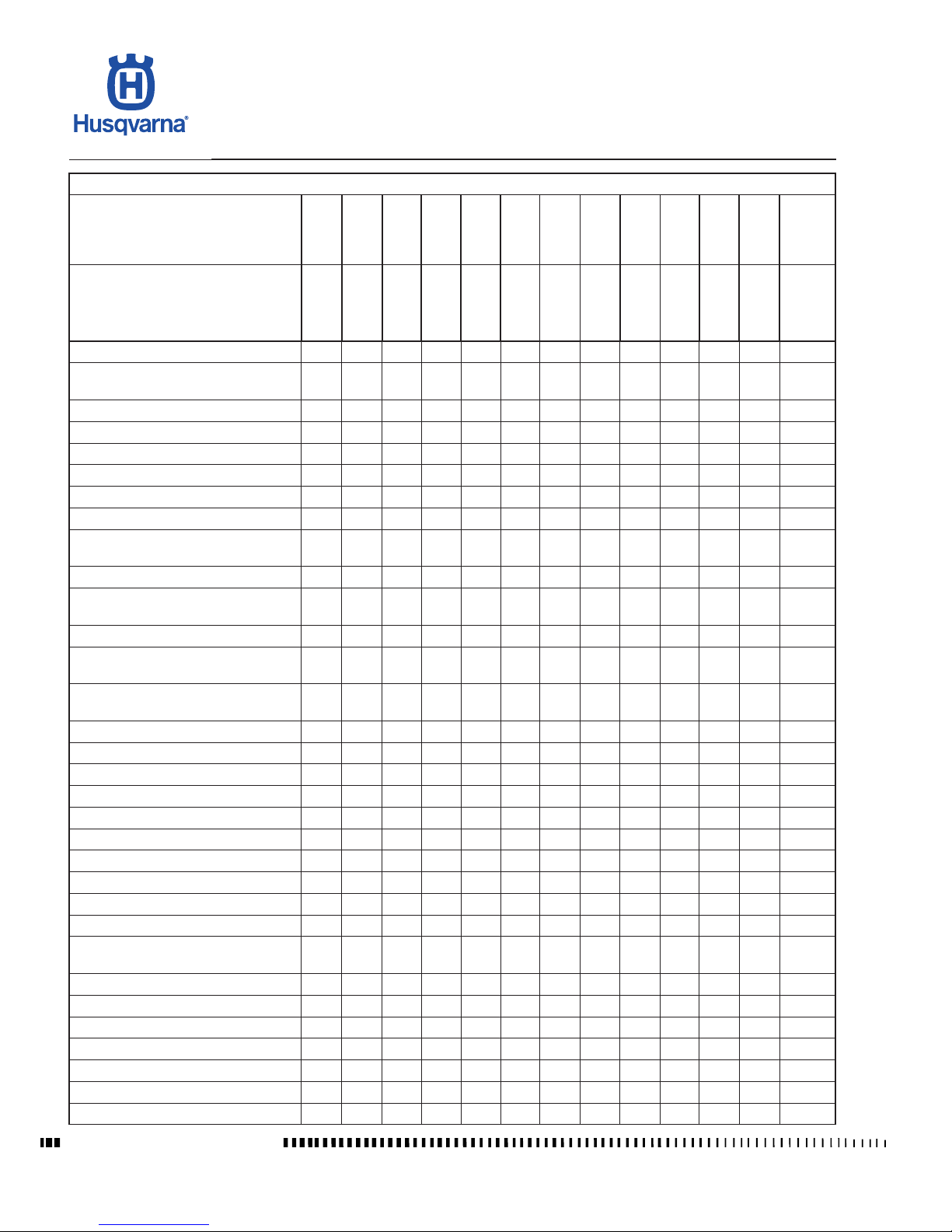

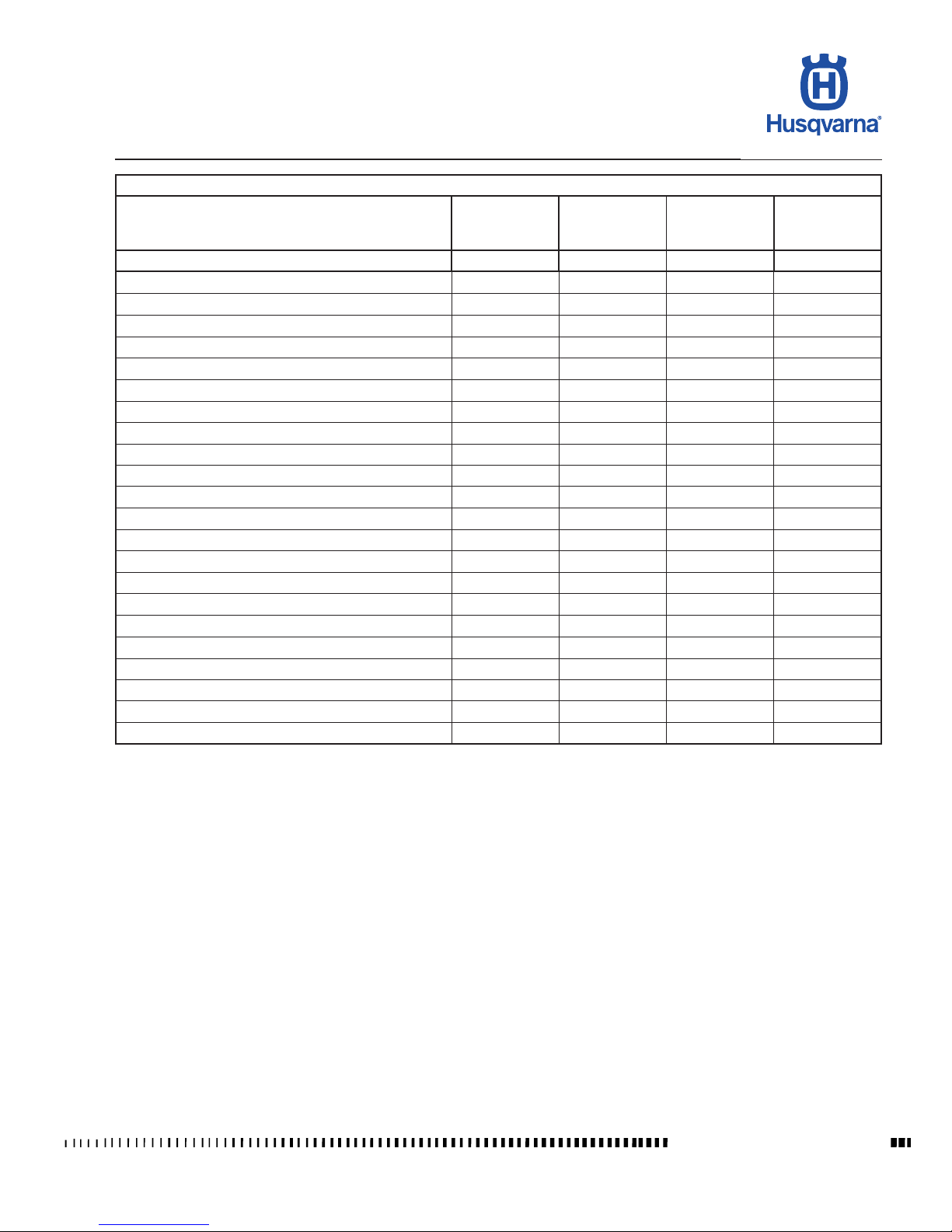

SCHEDULED MAINTENANCE CHART (TO BE CARRIED OUT AT THE HUSQVARNA DEALER)

TXC - TE 250R / TXC - TE 310R

RACING MOTORCYCLE, FOR RACING USE: FULL POWER RATING

AFTER THE

FIRST 2,5 h

EVERY 5 h

EVERY 10 h

EVERY 20 h

EVERY 30 h

EVERY 40 h

EVERY 50 h

EVERY 60 h

EVERY 70 h

EVERY 80 h

EVERY 90 h

EVERY

100 h

REPLACE

AS

REQUIRED

PARTICOLARE

CHECK

CHECK

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

AIR FILTER

P,L P,L

REAR CHASSIS MNTG BOLTS, ENGINE MNTG BOLTS

C C

WHEEL SPOKE TENSION

C C

SPROCKET BOLT TIGHTENING

C C

TORQUE OF NUTS AND BOLTS

C C

COOLANT

C X,

*

BRAKE PADS

C X

REAR CHAIN SPROCKET

C X

HANDLEBAR MOUNTS AND FASTENERS

C

REAR SWINGING ARM BUSHING

L

REAR SUSPENSION LINKAGE BUSHINGS

L

CHAIN GUIDE/CHAIN GUARD

C X

SWINGING ARM AXLE ROLLER

CAGES

L

ROLLER CAGES, LINKAGE PINS OF

REAR SUSP.

L

COMPLETE THROTTLE CONTROL

C, L

EXHAUST PIPE AND SILENCER

C X

FUEL PIPES

C S X

SECONDARY DRIVE CHAIN

C, L C, L X

KICK START PEDAL

L

GEAR SHIFT PEDAL

C

RADIATORS

C

WATER HOSES AND CLAMPS

C

RADIATORS TO WATER PUMP HOSE

C

FOOTPEGS, PINS, SPRINGS

C X

STEERING HEAD, BOTTOM YOKE

WITH STEM

L

REAR CHAIN SLIDER

C X

FRONT BRAKE DISC

C X

REAR BRAKE DISC

C X

CHAIN GUIDE ROLLER, BEARINGS

C

SIDESTAND

C

COMPLETE CLUTCH CONTROL

R

THROTTLE CABLES

C/L X

B.3

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

Workshop Manual Ed. 07-2012

MAINTENANCE

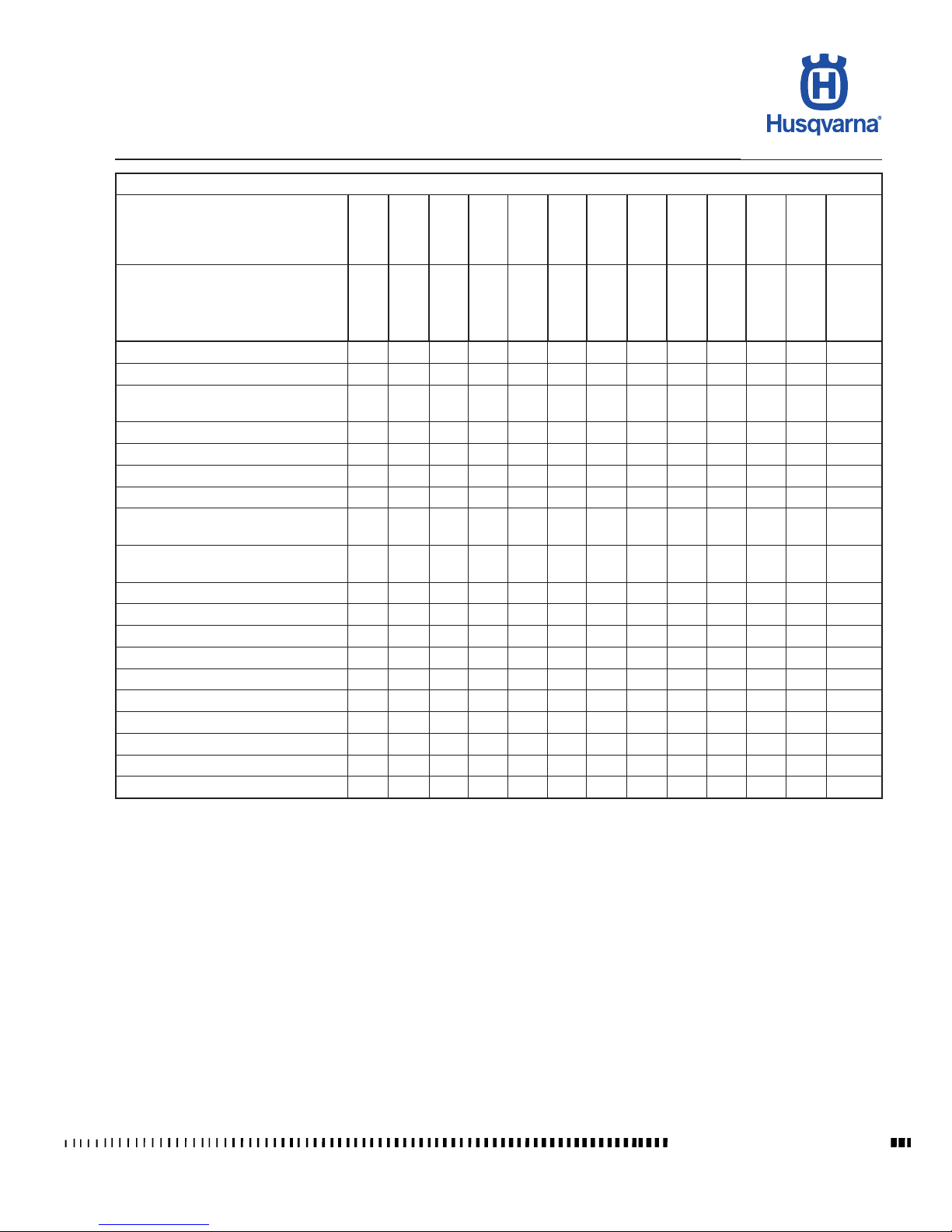

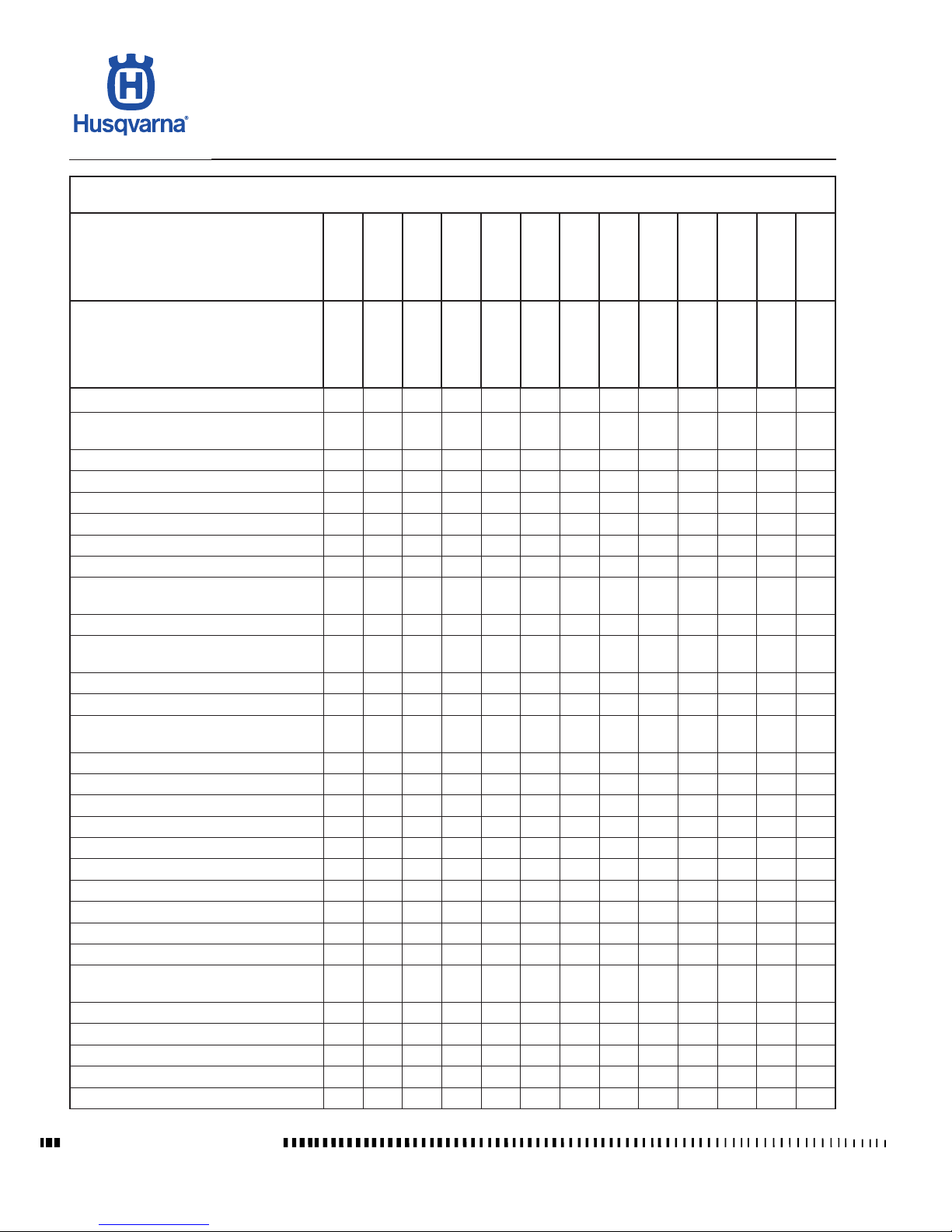

SCHEDULED MAINTENANCE CHART (TO BE CARRIED OUT AT THE HUSQVARNA DEALER)

TXC - TE 250R / TXC - TE 310R

RACING MOTORCYCLE, FOR RACING USE: FULL POWER RATING

AFTER THE

FIRST 2,5 h

EVERY 5 h

EVERY 10 h

EVERY 20 h

EVERY 30 h

EVERY 40 h

EVERY 50 h

EVERY 60 h

EVERY 70 h

EVERY 80 h

EVERY 90 h

EVERY

100 h

REPLACE

AS

REQUIRED

PARTICOLARE

CHECK

CHECK

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

FRONT BRAKING SYSTEM FLUID

C S

REAR BRAKING SYSTEM FLUID

C S

MASTER CYLINDER TO BRAKE

CALLIPER HOSES

C X

WHEEL HUB BEARINGS

C X

ENGINE OIL AND FILTER

S

SPARK PLUG

S

VALVES

C (•) S

VALVE SPRINGS, ROCKER ARMS

AND PLATES

C

TIMING CHAIN / TIMING CHAIN

SLIDER

C

TIMING CHAIN GEARS

C

TIMING CHAIN TENSIONER

C

OIL PUMP

C X

CRANKSHAFT OIL SEALS

S

PISTON

S

CYLINDER

C S X

CLUTCH HUB

C X

CRANKCASE BEARINGS

C S

CRANKSHAFT

S

PRIMARY DRIVE GEAR PAIR

C X

LEGEND:

h: HOURS

S: REPLACE

C: CHECK

(•): CHECK CLEARANCE

P: CLEAN

R: OVERHAUL

L: GREASE/LUBRICATE

*

: CHANGE AND/OR ADD IF NECESSARY

NOTES:

- REPLACE GASKETS AND SEALS AFTER EACH REMOVAL

- REPLACE SCREWS AND BOLTS IF DAMAGED

- PERFORM A GENERAL INSPECTION AFTER RIDING ON MUDDY OR SANDY TERRAIN

B.4

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

MAINTENANCE

Workshop Manual Ed. 07-2012

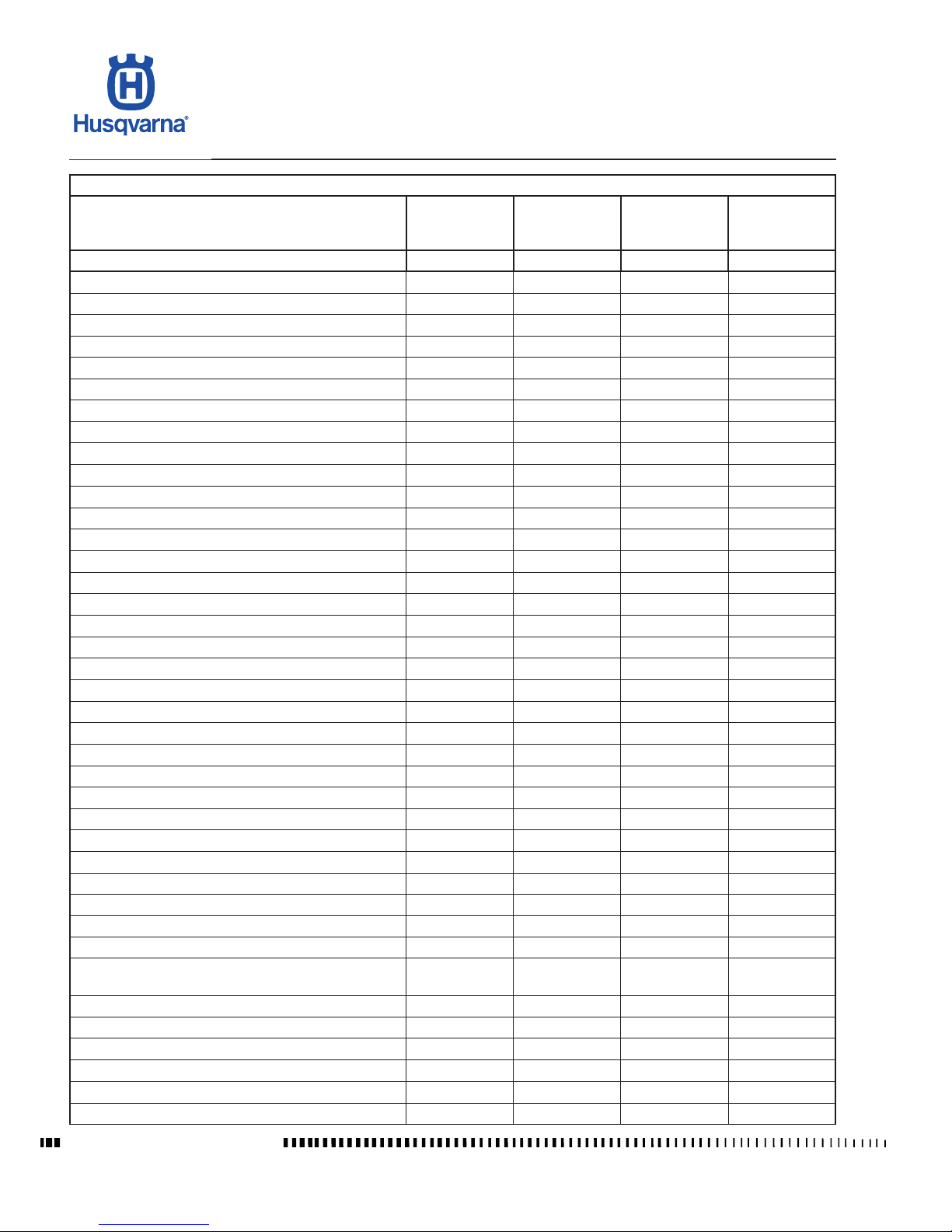

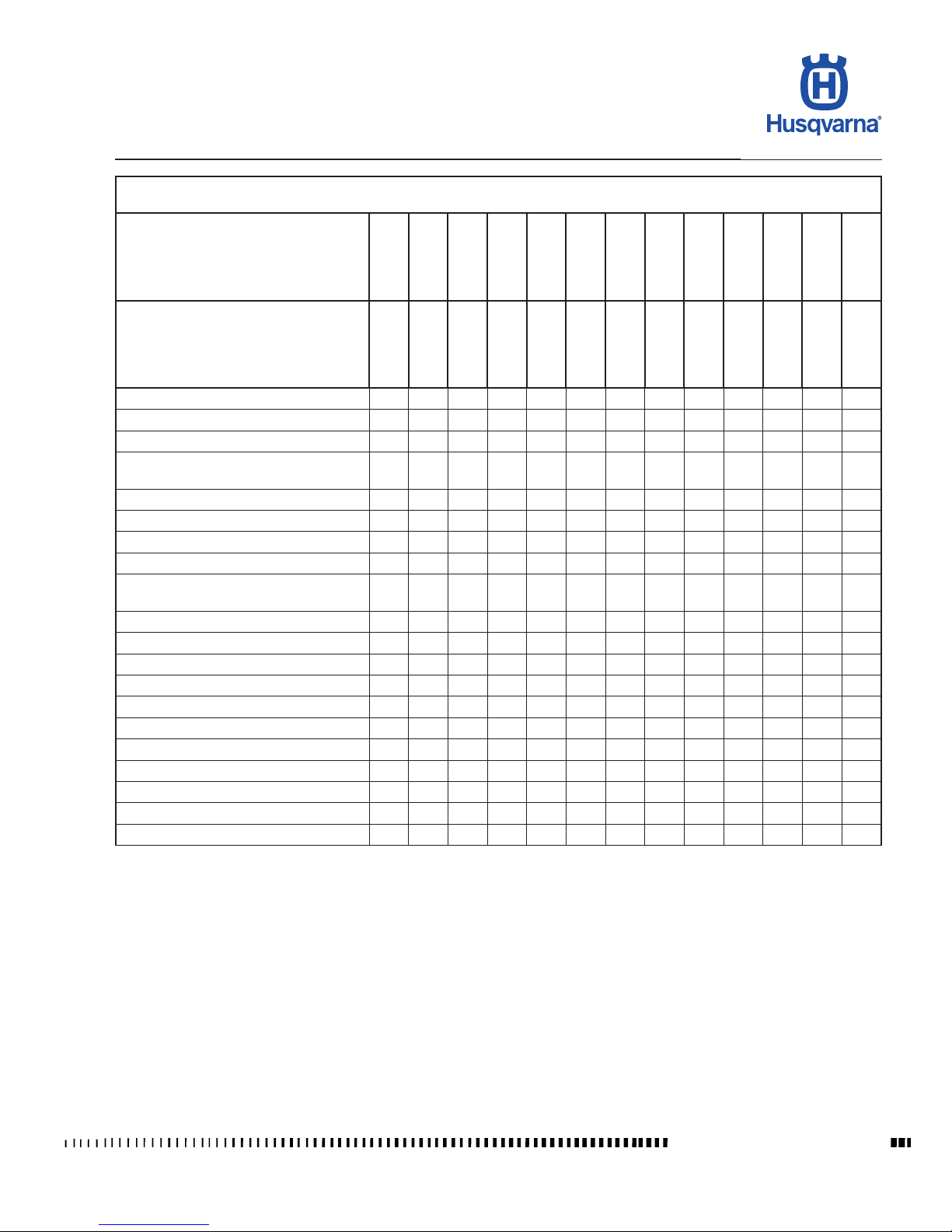

SCHEDULED MAINTENANCE CHART (TO BE CARRIED OUT AT THE HUSQVARNA DEALER)

TE 250R / TE 310R

STANDARD MOTORCYCLE, FOR ROAD USE

(DERATED)

AFTER FIRST

1000 KM

EVERY 5000 KM EVERY 10000 KM

REPLACE AS

REQUIRED

PART

SERVICE COUPON SERVICE COUPON SERVICE COUPON

VALVES

C (•) C (•) S

VALVE SPRINGS C X

TIMING CHAIN

S

TIMING CHAIN SLIDER C S

TIMING DRIVEN GEAR C X

TIMING DRIVE GEAR

C

TIMING CHAIN TENSIONER

C

INTAKE MANIFOLD AND CLAMPS C C S X

COMPLETE CYLINDER

C X

COMPLETE PISTON

S

COMPLETE CRANKSHAFT

S

CRANKCASE BEARINGS

S

CRANKSHAFT OIL SEAL

C X

ENGINE OIL AND OIL FILTER S S S

OIL PUMP

C

PRIMARY DRIVE GEAR PAIR

C X

CLUTCH HUB

C X

CLUTCH PLATES C C X

CLUTCH PRESSURE PLATE

C X

CLUTCH SPRINGS

C X

CLUTCH PUSHROD

C X

TRANSMISSION SPROCKET C C X

STARTER GEARS

C X

KICK START PEDAL

L

GEAR SHIFT PEDAL

C X

SPARK PLUG P S

AIR FILTER P, L P, L X

RADIATORS

C

WATER HOSES AND CLAMPS C C

RADIATORS TO WATER PUMP HOSE C C

CRANKSHAFT OIL SEAL C C

FOOTPEGS, PINS, SPRINGS

C X

REAR CHASSIS MNTG BOLTS, ENGINE MNTG

BOLTS

C C

SIDE STAND

C

CHAIN GUIDE ROLLER, BEARING C C X

STEERING HEAD, BOTTOM YOKE WITH STEM

L

FRONT FORK

R

HANDLEBAR MOUNTS WITH FASTENERS

C C

REAR SWINGING ARM BUSHING

C

B.5

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

Workshop Manual Ed. 07-2012

MAINTENANCE

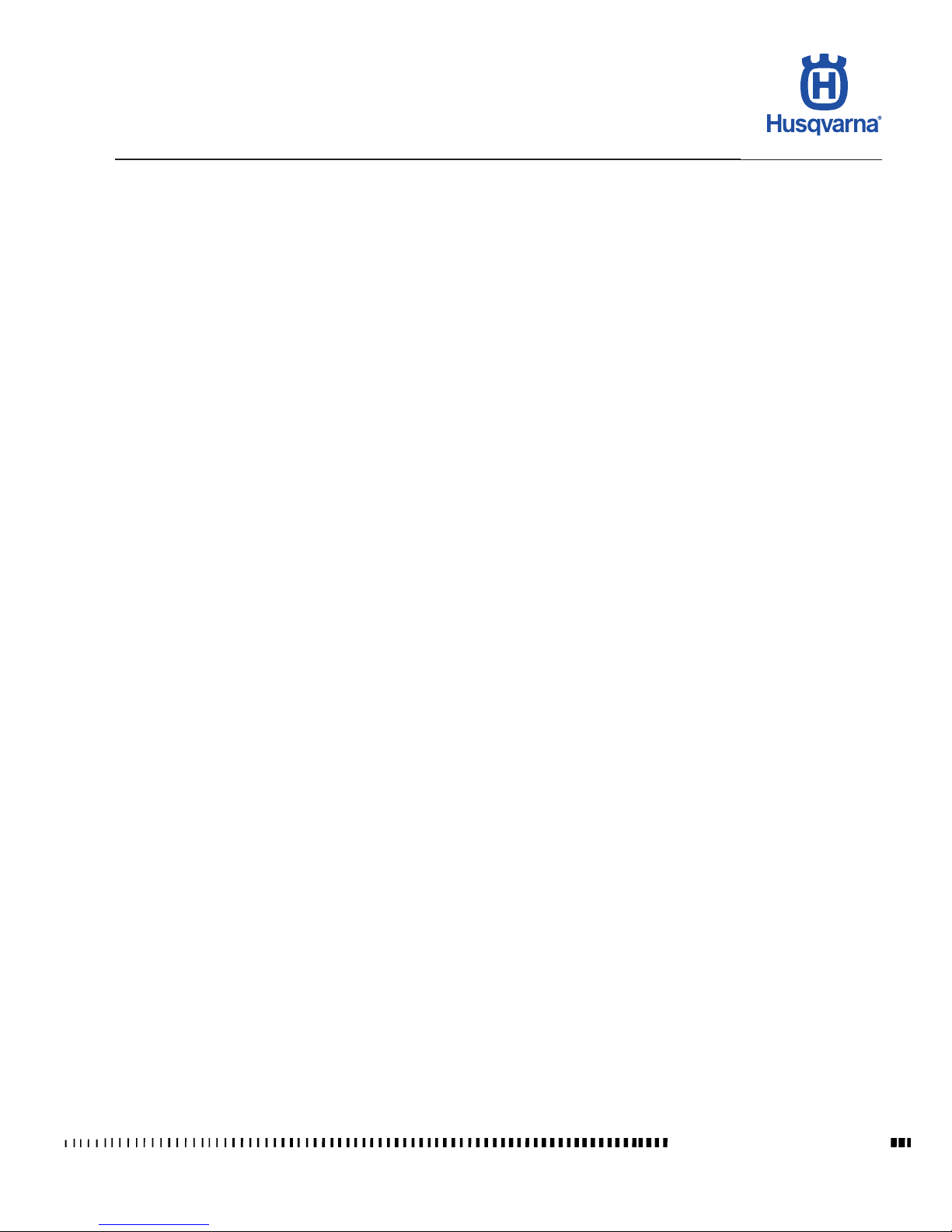

SCHEDULED MAINTENANCE CHART (TO BE CARRIED OUT AT THE HUSQVARNA DEALER)

TE 250R / TE 310R

STANDARD MOTORCYCLE, FOR ROAD USE

(DERATED)

AFTER FIRST

1000 KM

EVERY 5000 KM EVERY 10000 KM

REPLACE AS

REQUIRED

PART

SERVICE COUPON SERVICE COUPON SERVICE COUPON

REAR CHAIN SLIDER

C C X

REAR SUSPENSION LINKAGE BUSHINGS

C X

CHAIN GUIDE/CHAIN GUARD

C C X

ROLLER CAGES, LINKAGE PINS OF REAR SUSP.

L

REAR SHOCK ABSORBER

C

COMPLETE THROTTLE CONTROL

C, L

COMPLETE CLUTCH CONTROL C R

THROTTLE CABLES C L X

FRONT BRAKE DISC C X

FRONT BRAKING SYSTEM FLUID C S

REAR BRAKE DISC

C X

REAR BRAKING SYSTEM FLUID C S

BRAKE PADS C C C X

MASTER CYLINDER TO BRAKE CALLIPER HOSES

C X

FUEL PIPES

C X

EXHAUST PIPE AND SILENCER

C X

WHEEL SPOKE TENSION

C C

WHEEL HUB BEARINGS

C X

REAR CHAIN SPROCKET C S

SPROCKET BOLT TIGHTENING C C C

SECONDARY DRIVE CHAIN C, L C, L C, L X

TORQUE OF NUTS AND BOLTS

C C

LÉGENDE:

S: REMPLACEMENT

C: CONTRÔLE

(•): CONTRÔLE JEU

P: NETTOYAGE

R: CONTRÔLE TECHNIQUE

L: GRAISSAGE/LUBRIFICATION

REMARQUES:

- REMPLACER LES JOINTS À CHAQUE DÉPOSE

- REMPLACER LA VISSERIE SI ENDOMMAGÉE

- APRÈS CHAQUE PARCOURS SUR TERRAIN BOUEUX OU SUR SABLE, FAIRE UN CONTRÔLE GÉNÉRAL

B.6

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

MAINTENANCE

Workshop Manual Ed. 07-2012

SCHEDULED MAINTENANCE CHART

(TO BE CARRIED OUT AT THE HUSQVARNA DEALER)

TC 250R

RACING MOTORCYCLE, FOR RACING

USE: FULL POWER RATING

EVERY 2,5 h

EVERY 5 h

EVERY 10 h

EVERY 20 h

EVERY 30 h

EVERY 40 h

EVERY 50 h

EVERY 60 h

EVERY 70 h

EVERY 80 h

EVERY 90 h

EVERY 100 h

REPLACE AS

REQUIRED

PART

CHECK

CHECK

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

AIR FILTER

P,L

REAR CHASSIS MNTG BOLTS,

ENGINE MNTG BOLTS

C

WHEEL SPOKE TENSION C

SPROCKET BOLT TIGHTENING C

TORQUE OF NUTS AND BOLTS C

COOLANT C X,

*

BRAKE PADS C X

REAR CHAIN SPROCKET C X

HANDLEBAR MOUNTS AND FASTEN-

ERS

C

REAR SWINGING ARM BUSHING L

REAR SUSPENSION LINKAGE BUSH-

INGS

L

CHAIN GUIDE/CHAIN GUARD C X

SWINGING ARM AXLE ROLLER CAGES L

ROLLER CAGES, LINKAGE PINS OF

REAR SUSP.

L

COMPLETE THROTTLE CONTROL C, L

EXHAUST PIPE AND SILENCER C X

FUEL PIPES C S X

SECONDARY DRIVE CHAIN C, L X

KICK START PEDAL L

GEAR SHIFT PEDAL C

RADIATORS C

WATER HOSES AND CLAMPS C

RADIATORS TO WATER PUMP HOSE C

FOOTPEGS, PINS, SPRINGS C X

STEERING HEAD, BOTTOM YOKE

WITH STEM

L

REAR CHAIN SLIDER C X

FRONT BRAKE DISC C S X

REAR BRAKE DISC C S X

CHAIN GUIDE ROLLER, BEARINGS C

COMPLETE CLUTCH CONTROL

R (#)

B.7

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

Workshop Manual Ed. 07-2012

MAINTENANCE

SCHEDULED MAINTENANCE CHART

(TO BE CARRIED OUT AT THE HUSQVARNA DEALER)

TC 250R

RACING MOTORCYCLE, FOR RACING

USE: FULL POWER RATING

EVERY 2,5 h

EVERY 5 h

EVERY 10 h

EVERY 20 h

EVERY 30 h

EVERY 40 h

EVERY 50 h

EVERY 60 h

EVERY 70 h

EVERY 80 h

EVERY 90 h

EVERY 100 h

REPLACE AS

REQUIRED

PART

CHECK

CHECK

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

SERVICE

COUPON

THROTTLE CABLES C X

FRONT BRAKING SYSTEM FLUID S

REAR BRAKING SYSTEM FLUID S

MASTER CYLINDER TO BRAKE CALLI-

PER HOSES

C X

WHEEL HUB BEARINGS C

ENGINE OIL AND FILTER S

PLUG S

VALVES C (•) S

VALVE SPRINGS, ROCKER ARMS AND

PLATES

C

TIMING CHAIN / TIMING CHAIN SLIDER C

TIMING CHAIN GEARS C

TIMING CHAIN TENSIONER C

OIL PUMP C X

CRANKSHAFT OIL SEALS S

PISTON S

CYLINDER S

CLUTCH HUB C X

CRANKCASE BEARINGS S

CRANKSHAFT S

PRIMARY DRIVE GEAR PAIR C X

LEGEND:

h: HOURS

P: CLEAN

L: GREASE/LUBRICATE

C: CHECK

R: OVERHAUL

S: REPLACE

(•): CHECK CLEARANCE

*

: CHANGE AND/OR ADD IF NECESSARY

NOTES:

- REPLACE GASKETS AND SEALS AFTER EACH REMOVAL

- REPLACE SCREWS AND BOLTS IF DAMAGED

- PERFORM A GENERAL INSPECTION AFTER RIDING ON MUDDY OR SANDY TERRAIN

C.1

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

C

Workshop Manual Ed. 07-2012

TROUBLESHOOTING

Section

C.2

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

TROUBLESHOOTING

Workshop Manual Ed. 07-2012

ENGINE

Trouble Cause Remedy

Engine does not start or Insufcient compression

has starting trouble 1. Piston seized Replace

2. Connecting rod small or big end seized Replace

3. Worn piston rings Replace

4. Worn cylinder Replace

5. Cylinder head loosely tightened Tighten

6. Head gasket leaking Replace

7. Spark plug loose Tighten

8. Incorrect valve clearances Adjust

9. Weak or seized valve springs Replace

10. Seized valves Replace

Weak or no spark

1. Spark plug faulty Replace

2. Fouled or wet spark plug Clean or dry

3. Spark plug electrode gap too wide Adjust

4. Ignition coil faulty Replace

5. High-tension cables open circuit or shorted Check

6. Electronic control unit faulty Replace

7. Right-hand switch faulty (TE - TXC) Replace

Engine stalls 1. Fouled spark plug Clean

easily 2. Electronic control unit faulty Replace

3. Carburettor jets clogged Clean

4. Low idle Adjust

Engine is noisy Noise seems to come from piston

1. Too much piston-to-cylinder clearance Replace

2. Worn piston rings or piston grooves Replace

3. Too much carbon build-up in

combustion chamber or on piston crown Clean

4. Valve clearances too large Adjust

5. Weak or seized valve springs Replace

6. Worn timing chain Replace

7. Incorrect timing chain tension Adjust

Noise seems to come from crankshaft

1. Worn main bearings Replace

2.

Connecting rod big end has too much side clearance or end oat

Replace

3. Crankshaft gear damaged Replace

4. Crankshaft locknut loose Tighten

Noise seems to come from the clutch

1. Worn plates Replace

2.

Too much clearance between clutch housing and friction plates

Replace

Noise seems to come from gearbox

1. Worn gears Replace

2. Worn gear grooves Replace

Noise seems to come 1. Chain stretched (worn) or improperly adjusted Replace or adjust

from secondary drive 2. Worn transmission sprocket and rear chain sprocket Replace

chain

C.3

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

Workshop Manual Ed. 07-2012

TROUBLESHOOTING

Trouble Cause Remedy

Clutch slips 1. Weak clutch springs Replace

2. Worn clutch plates Replace

Clutch is hard to operate 1. Uneven spring load Replace

2. Bent clutch plates Replace

Gears do not engage 1. Bent or seized shifter forks Replace

2. Worn gear ratchets Replace

3. Damaged shifter fork shafts Replace

Gear shift pedal

does not return to original position

1. Weak or broken selector return spring Replace

2. Worn shifter forks Replace

Transmission jumps out of gear 1. Worn sliding gear dogs Replace

2. Worn gear grooves Replace

3. Worn dog slots in gears Replace

4. Worn selector shaft splines Replace

5. Damaged shifter fork shafts Replace

Engine has low power 1. Dirty air lter Clean

2. Poor fuel quality Replace

3. Intake coupling loose Tighten

4. Spark plug electrode gap too wide Adjust

5. Insufcient compression Identify cause

6. Incorrect valve clearances Adjust

7. Valve seats or guides faulty Replace

8. Weak or seized valve springs Replace

Engine overheats 1. Combustion chamber and/or piston crown fouled

with carbon deposits Clean

2. Insufcient oil in engine or

wrong oil Top up or change

3. Obstructions blocking air ow on radiator Clean

4. Cylinder head gasket leaking Replace

5. Clutch slips Adjust

6. Cooling fan faulty (TE-TXC) Replace the fan

7. Faulty thermostatic valve (TE-TXC) Replace the valve

8. Faulty fan thermal switch Replace

C.4

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

TROUBLESHOOTING

Workshop Manual Ed. 07-2012

CHASSIS

Trouble Cause Remedy

Handlebar turns hard 1. Insufcient tyre pressure Inate

2. Bearing adjuster ring nut or steering stem nut overtightened Adjust

3. Bent steering stem Replace bottom yoke

4. Worn or seized steering bearings Replace

Handlebar vibration 1. Bent fork legs Replace

2. Bent front wheel axle Replace

3. Warped chassis Replace

4. Bent front wheel rim Replace

5. Worn front wheel bearings Replace

Damping is 1. Too much oil in fork legs Remove excess oil

too hard 2. Fork oil viscosity too high Change

3. Overinated tyres Deate

4. Improperly set rear shock absorber Adjust

Damping is 1. Insufcient oil in fork legs Top up

too soft 2. Fork oil viscosity too low Change

3. Weak fork springs Replace

4. Weak rear shock absorber spring Replace

5. Improperly set rear shock absorber Adjust

(Front / rear) wheel 1. Bent wheel rim Replace

shakes 2. Worn wheel hub bearings Replace

3. Incorrect spoke tension Adjust

4. Wheel axle nut loose Tighten

5. Worn rear swinging arm bearings Replace

6. Improperly adjusted chain tensioners Adjust

7. Improperly balanced wheel Balance

Rear suspension is 1. Worn link rod spacers or bearings Replace

noisy 2. Worn shock absorber ball joints Replace

3. Shock absorber faulty Replace

Poor braking 1. Air in brake system Bleed

(front and rear) 2. Insufcient uid in tank Top up

3. Worn brake pad and/or disc Replace

4. Damaged disc Replace

5. Improperly adjusted brake pedal Adjust

6. Water in brake system Change uid

C.5

TE 250R - 310R 2013 I.E. / TE 310R 2013 I.E. USA

TC 250R 2013 - TC 250R 2013 I.E. USA

TXC 250R - 310R 2013 I.E. USA

Workshop Manual Ed. 07-2012

TROUBLESHOOTING

ELECTRICAL SYSTEM (see also Section M)

Trouble Cause Remedy

Spark plug fouls 1. Dirty air lter Clean

easily 2. Worn piston rings Replace

3. Worn piston or cylinder liner Replace

Spark plug electrodes 1. Spark plug electrode gap too close Adjust

overheat 2. Heat rating too high Replace with recommended

spark plug

Generator does not charge or 1.

Cables running to voltage regulator improperly connected or

Connect correctly or

is not providing enough charge shorted replace

2. Voltage regulator faulty Replace

3. Generator coil faulty Replace

Generator overcharges battery 1. Voltage regulator faulty Replace

Battery does not hold charge 1. Battery terminals dirty Clean

(TE-TXC)

Starter motor 1. Battery is at Charge

does not start or slips 2. Control on R.H. switch faulty Replace

(TE-TXC) 3. Starter relay faulty Replace

4. Starter motor faulty Repair or replace

5. Worn starter gears Replace

6. Worn or damaged freewheel rollers Replace freewheel

Loading...

Loading...