Husqvarna 129R Manual

GB |

Operator’s manual 2-25 |

HU |

Használati utasítás 355-378 |

|

|

|

SE |

Bruksanvisning 26-47 |

PL |

Instrukcja obs∏ugi 379-403 |

|

|

|

DK |

Brugsanvisning 48-70 |

CZ |

Návod k pouÏití 404-426 |

|

|

|

NO |

Bruksanvisning 71-92 |

SK |

Návod na obsluhu 427-449 |

|

|

|

FI |

Käyttöohje 93-115 |

HR |

Priruãnik 450-471 |

|

|

|

DE |

Bedienungsanweisung 116-140 |

RS |

Priruãnik 472-494 |

|

|

|

FR |

Manuel d’utilisation 141-166 |

BA |

Uputstvo o upotrebi 495-517 |

A05328CBHV |

||

NL |

Gebruiksaanwijzing 167-191 |

RO |

Instrucöiuni de utilizare 518-542 |

|||

|

|

|||||

ES |

Manual de instrucciones 192-216 |

TR KULLANıM KıLAVUZU 543-565 |

|

|

||

PT |

Instruções para o uso 217-240 |

RU |

чуководствопо |

|

|

|

IT |

Istruzioni per l’uso 241-264 |

|

эксплуатации566-590 |

|

|

|

EE |

Käsitsemisõpetus 265-286 |

UA |

ос´бниккористувача 591-614 |

|

|

|

LV |

Lieto‰anas pamÇc¥ba 287-309 |

BG |

чъководствоза |

|

|

|

LT |

Naudojimosi instrukcijos 310-331 |

|

експлоатациЯ615-639 |

|

|

|

SI |

Navodila za uporabo 332-354 |

GR |

√‰ËÁ›Â˜ ¯Ú‹Ûˆ˜ 640-664 |

|

|

|

|

|

|

|

|||

WARNING: The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

WARNING: The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

Note the following before starting:

Please read the operator's manual carefully.

WARNING: Under no circumstances may the design of the machine be modified without the permission of the manufacturer. Always use genuine accessories. Non-authorized modifications and/or accessories can result in serious personal injury or the death of the operator or others.

WARNING: Under no circumstances may the design of the machine be modified without the permission of the manufacturer. Always use genuine accessories. Non-authorized modifications and/or accessories can result in serious personal injury or the death of the operator or others.

WARNING: A clearing saw, brushcutter or trimmer can be dangerous if used incorrectly or carelessly, and can cause serious or fatal injury to the operator or others. It is extremely important that you read and understand the contents of this operator's manual.

WARNING: A clearing saw, brushcutter or trimmer can be dangerous if used incorrectly or carelessly, and can cause serious or fatal injury to the operator or others. It is extremely important that you read and understand the contents of this operator's manual.

WARNING: Long-term exposure to noise can result in permanent hearing impairment. So always use approved hearing protection.

WARNING: Long-term exposure to noise can result in permanent hearing impairment. So always use approved hearing protection.

We have a policy of continuous product development and therefore reserve the right to modify the design and appearance of products without prior notice.

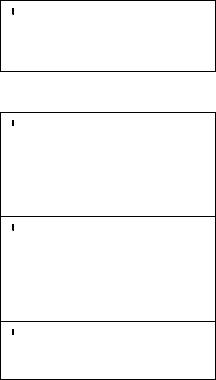

SYMBOL EXPLANATION

Symbols

WARNING: Clearing saws, brushcutters and trimmers can be dangerous.

WARNING: Clearing saws, brushcutters and trimmers can be dangerous.

Careless or incorrect use can result in serious or fatal injury to the operator or others.

Please read the operator's manual carefully and make sure you understand the instructions before using the machine.

Always use steel-toed safety footwear with non-slip soles; snugfitting clothing; heavy, long pants, and long sleeves; heavy-duty, non-slip gloves; eye protection such as non-fogging, vented goggles or face screen; an approved safety helmet; and sound barriers (ear plugs or mufflers) to protect your hearing.

Persons with long hair should (for personal safety) put their hair up.

The operator of the machine shall  ensure, while working, that no persons or animals come closer than 15 meters (50 feet).

ensure, while working, that no persons or animals come closer than 15 meters (50 feet).

Beware of thrown objects and ricochets.

Max speed of output axle, rpm

Machines fitted with grass blades can be thrown violently to the side when the blade comes into contact with a fixed object. The blade is capable of amputating an arm or leg. Always keep people and animals at least 15 meters (50 feet) from the machine.

Arrows which show limits for handle mounting.

Sound pressure level at 7,5 meters (25 feet) per Australian regulation.

Noise emission to the environment according to the European Community's Directive. The machine's emission is specified in the Technical data section and on label.

This product is in accordance with applicable EC directives.

This product is in accordance with applicable EAC directives.

This product is in accordance with the Australian electromagnetic compatibility (EMC) regulations.

Use unleaded gasoline and twostroke oil mixed at a ratio of 2% (50:1).

Other symbols/decals on the machine refer to special certification requirements for certain markets.

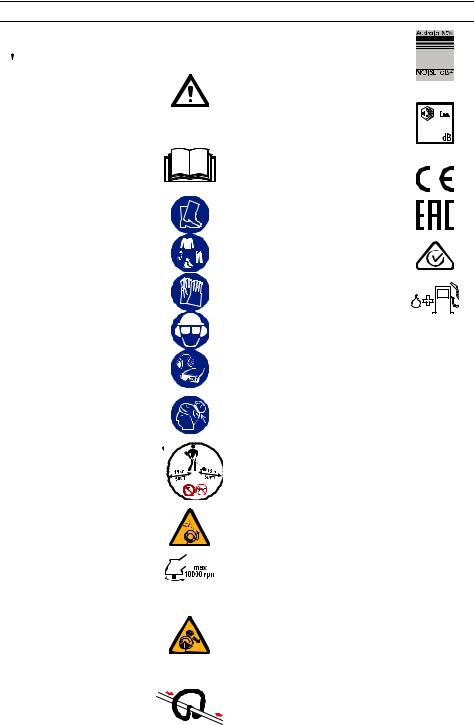

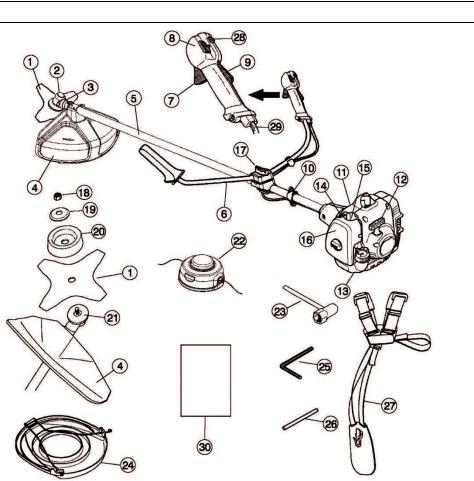

WHAT IS WHAT?

WHAT IS WHAT? |

21. |

Drive disc |

|

1. |

Blade |

22. |

Trimmer head |

2. |

Grease filler cap |

23. |

Socket wrench |

3. |

Bevel gear |

24. |

Transport guard |

4. |

Cutting attachment guard |

25. |

Hex wrench |

5. |

Shaft |

26. |

Locking pin |

6. |

Handlebar |

27. |

Harness |

7. |

Throttle control |

28. |

Start throttle button |

8. |

Stop switch |

29. |

Adjusting the throttle wire |

9. |

Throttle lock-out |

30. |

Operator's manual |

10.Harness clamp

11.Cylinder cover

12.Starter handle

13.Fuel tank

14.Choke control

15.Primer bulb

16.Air filter cover

17.Handle adjustment

18.Locking nut

19.Support flange

20.Support cup

GENERAL SAFETY PRECAUTIONS

Important

•A clearing saw, brushcutter or trimmer can be dangerous if used incorrectly or carelessly, and can cause serious or fatal injury to the operator or others. It is extremely important that you read and understand the contents of this operator's manual.

•The machine is only designed for trimming grass, grass clearing and/or forestry clearing.

•The only accessories you can operate with this engine unit are the cutting attachments we recommend in the “TECHNICAL DATA” section.

•Never use the machine if you are tired, if you have consumed alcohol, or if you are taking medication that could affect your vision, your judgment or your coordination.

•Never use the machine in extreme weather conditions such as severe cold, very hot and/or humid climates.

•Wear personal protective equipment. See instructions under the heading “Personal protective equipment”.

•Never use a machine that has been modified in any way from its original specification.

•Never use a machine that is faulty. Carry out the checks, maintenance and service instructions described in this manual. Some maintenance and service measures must be carried out by trained and qualified specialists. See instructions under the “MAINTENANCE” section.

•All covers and guards must be fitted before starting. Make sure the spark plug cap and lead are not damaged. Otherwise you could get an electric shock.

•The machine operator must ensure that no people or animals come closer than 15 meters (50 feet) while working. When several operators are working in the same area, the safety distance should be at least 15 meters (50 feet).

WARNING: This machine produces an electromagnetic field during operation. Under some circumstances, this field may interfere with active or passive medical implants. To reduce the risk of serious or fatal injury, we recommend persons with medical implants to consult their physician and the medical implant manufacturer before operating this machine.

WARNING: This machine produces an electromagnetic field during operation. Under some circumstances, this field may interfere with active or passive medical implants. To reduce the risk of serious or fatal injury, we recommend persons with medical implants to consult their physician and the medical implant manufacturer before operating this machine.

WARNING: Using an incorrect cutting attachment or an incorrectly filed blade can increase the risk of accidents.

WARNING: Using an incorrect cutting attachment or an incorrectly filed blade can increase the risk of accidents.

WARNING: Never allow children to use or be in the vicinity of the machine. As the machine is equipped with a spring-loaded stop switch and can be started by low speed and force on the starter handle, even small children under some circumstances can produce the force necessary to start the machine. This can mean a risk of serious personal injury. Therefore remove the spark plug cap when the machine is not under close supervision.

WARNING: Never allow children to use or be in the vicinity of the machine. As the machine is equipped with a spring-loaded stop switch and can be started by low speed and force on the starter handle, even small children under some circumstances can produce the force necessary to start the machine. This can mean a risk of serious personal injury. Therefore remove the spark plug cap when the machine is not under close supervision.

Personal protective equipment

WARNING: You must use approved personal protective equipment whenever you use the machine. Personal protective equipment cannot eliminate the risk of injury but it will reduce the degree of injury if an accident does happen. Ask your dealer for help in choosing the right equipment.

WARNING: You must use approved personal protective equipment whenever you use the machine. Personal protective equipment cannot eliminate the risk of injury but it will reduce the degree of injury if an accident does happen. Ask your dealer for help in choosing the right equipment.

WARNING: Listen out for warning signals or shouts when you are wearing hearing protection. Always remove your hearing protection as soon as the engine stops.

WARNING: Listen out for warning signals or shouts when you are wearing hearing protection. Always remove your hearing protection as soon as the engine stops.

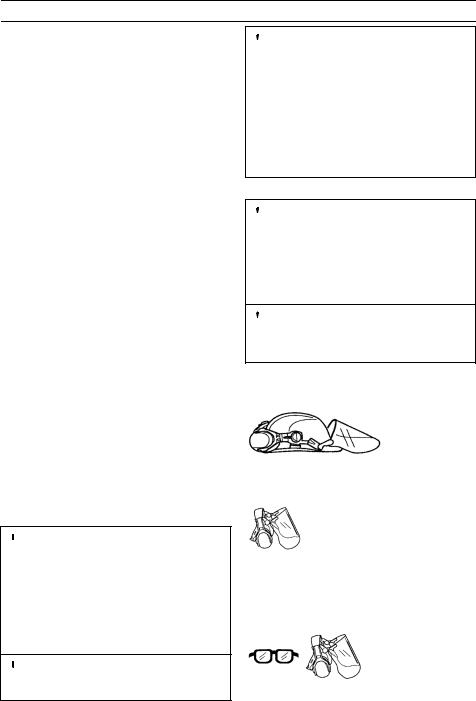

Helmet

A helmet should be worn if the brush being cleared is taller than 2 meters (6 feet).

Hearing Protection

Wear hearing protection that provides adequate noise reduction.

Eye Protection

Always wear approved eye protection. If you use a visor then you must also wear approved protective goggles. Approved protective goggles must comply with EN 166 in Europe, ANSI Z87 in the United States, and CSA Z94 in Canada.

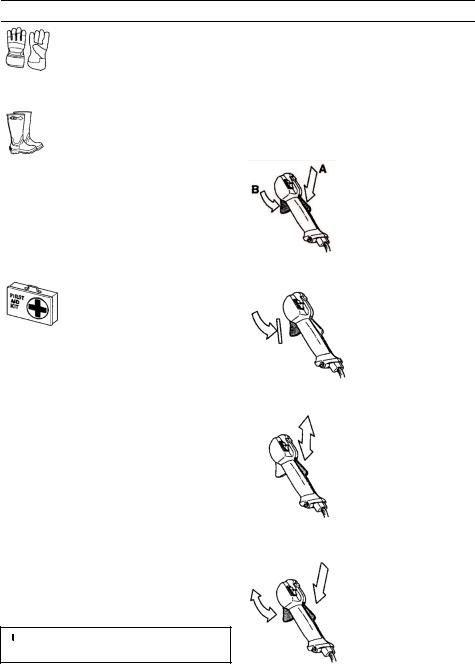

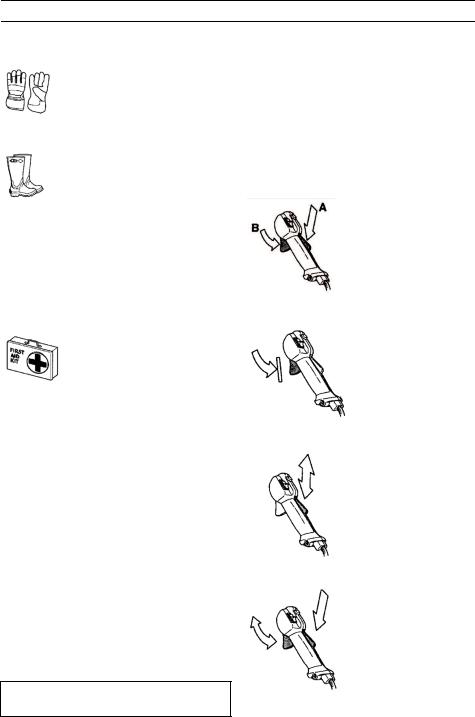

Gloves

Gloves should be worn when necessary, e.g., when fitting cutting attachments.

GENERAL SAFETY PRECAUTIONS

Boots

Wear anti-slip and stable boots.

Clothing

Wear clothes made of a strong fabric and avoid loose clothing that can catch on shrubs and branches. Always wear heavy, long pants. Do not wear jewelry, shorts sandals or go barefoot. Secure hair so it is above shoulder level.

First Aid Kit

A first aid kit should be carried by operators of clearing saws, brushcutters or trimmers.

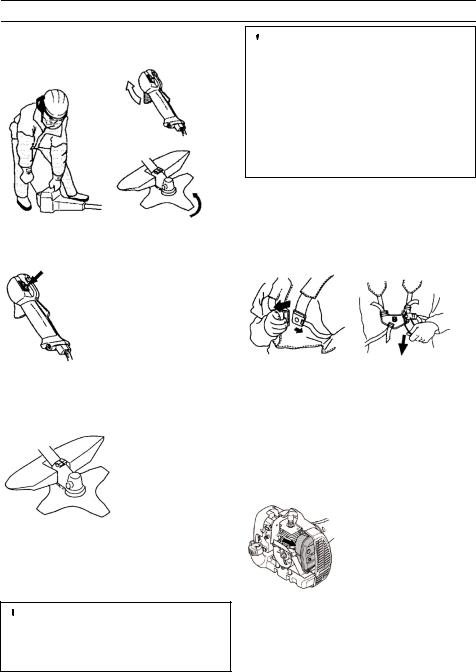

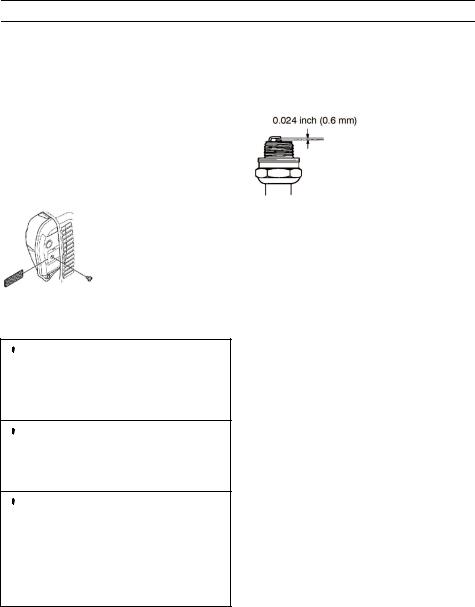

Throttle lock-out

The throttle lock-out is designed to prevent accidental operation of the throttle control. When you press the lock-out (A) (i.e. when you grasp the handle) it releases the throttle control (B). When you release the handle, the throttle control and the throttle lock-out both move back to their original positions. This movement is controlled by two independent return springs. This arrangement means that the throttle control is automatically locked at the idle setting.

Make sure the throttle control is locked at the idle setting when the throttle lock-out is released.

Machine's safety equipment

This section describes the machine's safety equipment, its purpose, and how checks and maintenance should be carried out to ensure that it operates correctly. See the "WHAT IS WHAT" section to locate where this equipment is positioned on your machine.

The life span of the machine can be reduced and the risk of accidents can increase if machine maintenance is not carried out correctly and if service and/or repairs are not carried out professionally. If you need further information please contact your nearest service workshop.

IMPORTANT! All servicing and repair work on the machine requires special training. This is especially true of the machine's safety equipment. If your machine fails any of the checks described below you must contact your service agent. When you buy any of our products we guarantee the availability of professional repairs and service. If the retailer who sells your machine is not a servicing dealer, ask him for the address of your nearest service agent.

WARNING: Never use a machine that has faulty safety equipment.

WARNING: Never use a machine that has faulty safety equipment.

Follow the control, maintenance and service instructions described in this section. If your machine fails any of these checks contact your service agent to get it repaired.

Press the throttle lock-out and make sure it returns to its original position when you release it.

Check that the throttle control and throttle lock-out move freely and that the return springs work properly.

See instructions under the heading “Start”. Start the machine and apply full throttle. Release the throttle and check that the cutting attachment stops and remains at a standstill. If the cutting attachment rotates with the throttle in the idle

GENERAL SAFETY PRECAUTIONS

position then the carburetor idle setting must be checked. See instructions under the “MAINTENANCE” section.

Stop switch

Make sure the engine stops when you push and release the stop switch.

Cutting attachment guard

This guard is intended to prevent loose objects from being thrown towards the operator. The guard also protects the operator from accidental contact with the cutting attachment.

Check that the guard is undamaged and not cracked. Replace the guard if it has been exposed to impact or is cracked.

Always use the recommended guard for the cutting attachment you are using. See the "TECHNICAL DATA" section.

WARNING: Never use a cutting attachment without an approved guard. See the “TECHNICAL DATA” section. If an incorrect or faulty guard is fitted this can cause serious personal injury.

WARNING: Never use a cutting attachment without an approved guard. See the “TECHNICAL DATA” section. If an incorrect or faulty guard is fitted this can cause serious personal injury.

Use of incorrectly wound trimmer line or an incorrect cutting attachment increases the level of vibration.

WARNING: Overexposure to vibration can lead to circulatory damage or nerve damage in people who have impaired circulation. Contact your doctor if you experience symptoms of overexposure to vibration. Such symptoms include numbness, loss of feeling, tingling, pricking, pain, loss of strength, changes in skin color or condition. These symptoms normally appear in the fingers, hands or wrists. The risk increases at low temperatures.

WARNING: Overexposure to vibration can lead to circulatory damage or nerve damage in people who have impaired circulation. Contact your doctor if you experience symptoms of overexposure to vibration. Such symptoms include numbness, loss of feeling, tingling, pricking, pain, loss of strength, changes in skin color or condition. These symptoms normally appear in the fingers, hands or wrists. The risk increases at low temperatures.

Harness quick release

There is an easily accessible, harness quick release fitted at the front in case of an emergency that requires you to free yourself from the machine and harness.

See instructions under the heading “Adjusting the harness”.

Check that the harness straps are correctly positioned. Once the harness and machine have been adjusted, check that the harness quick release works correctly.

Muffler

The muffler is designed to reduce the noise level and to direct the exhaust gases away from the operator.

CAUTION! Muffler is fitted with a catalytic converter designed to reduce harmful exhaust gases.

In countries that have a warm and dry climate there is a significant risk of fire. We therefore fit certain mufflers with a spark arrestor mesh. Check whether the muffler on your machine is fitted with this kind of mesh.

GENERAL SAFETY PRECAUTIONS

For mufflers, it is very important that you follow the instructions on checking, maintaining, and servicing your machine. Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to the machine.

WARNING: Mufflers fitted with catalytic converters get very hot during use and remain so for some time after stopping. This also applies at idle speed. Contact can result in burns to the skin. Remember the risk of fire.

WARNING: Mufflers fitted with catalytic converters get very hot during use and remain so for some time after stopping. This also applies at idle speed. Contact can result in burns to the skin. Remember the risk of fire.

WARNING: The inside of the muffler contain chemicals that may be carcinogenic. Avoid contact with these elements in the event of a damaged muffler.

WARNING: The inside of the muffler contain chemicals that may be carcinogenic. Avoid contact with these elements in the event of a damaged muffler.

WARNING: Engine exhaust fumes contain carbon monoxide, which can cause carbon monoxide poisoning. Do not start or run the machine indoors, or anywhere that is poorly ventilated.

WARNING: Engine exhaust fumes contain carbon monoxide, which can cause carbon monoxide poisoning. Do not start or run the machine indoors, or anywhere that is poorly ventilated.

WARNING: The exhaust fumes from the engine are hot and may contain sparks which can start a fire. Never start the machine indoors or near combustible material.

WARNING: The exhaust fumes from the engine are hot and may contain sparks which can start a fire. Never start the machine indoors or near combustible material.

Locking nut

A locking nut is used to secure some types of cutting attachment.

When fitting, tighten the nut in the opposite direction to the direction of rotation of the cutting attachment. To remove it, undo the nut in the same direction as the cutting attachment rotates. (The nut has a left-hand thread.) Tighten the nut using the socket wrench.

The nylon lining inside the locking nut must not be so worn that you can turn it by hand. The lining should offer a resistance of at least 1.5 Nm (1,1 ft lb). The nut should be replaced after it has been put on approximately 10 times.

Cutting equipment

This section describes how to choose and maintain your cutting equipment in order to:

•Reduce the risk of blade thrust.

•Obtain maximum cutting performance.

•Extend the life of cutting equipment.

IMPORTANT:

•Only use cutting attachments with the guards we recommend. See the “TECHNICAL DATA” section.

•Refer to the instructions for the cutting attachment to check the correct way to load the trimmer line and the correct line diameter.

•Keep the teeth of the blade correctly sharpened. Follow our recommendations. Also refer to the instructions on the blade packaging.

•Maintain the correct blade setting. Follow our instructions and use the recommended file gauge.

WARNING: Stop the engine before doing any work on the cutting attachment. Ensure the cutting attachment has stopped rotating completely. Disconnect the lead from the spark plug.

WARNING: Stop the engine before doing any work on the cutting attachment. Ensure the cutting attachment has stopped rotating completely. Disconnect the lead from the spark plug.

WARNING: Using an incorrect cutting attachment or an incorrectly sharpened blade increases the risk of kickback.

WARNING: Using an incorrect cutting attachment or an incorrectly sharpened blade increases the risk of kickback.

Cutting equipment

Grass blades and grass cutters are intended for cutting coarse grass.

A trimmer head is intended for trimming grass.

GENERAL SAFETY PRECAUTIONS

General rules

Only use cutting attachments with the guards we recommend. See the “TECHNICAL DATA” section.

Keep the teeth of the blade correctly sharpened. Follow our instructions and use the recommended file gauge. An incorrectly sharpened or damaged blade increases the risk of accidents.

Check the cutting attachment for damage or cracks. A damaged cutting attachment should always be replaced.

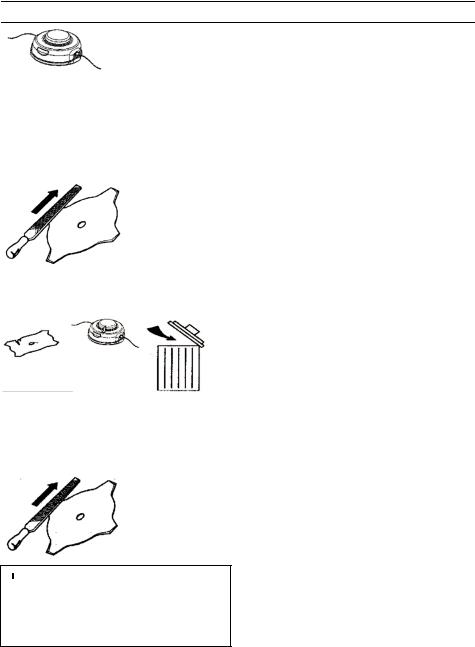

Sharpening grass cutters and grass blades

•See the cutting attachment packaging for correct sharpening instructions. Sharpen blades and cutters using a single-cut flat file.

•Sharpen all edges equally to maintain the balance of the blade.

WARNING: Always discard a blade that is bent, twisted, cracked, broken or damaged in any other way. Never attempt to straighten a twisted blade so that it can be reused. Only use original blades of the specified type.

WARNING: Always discard a blade that is bent, twisted, cracked, broken or damaged in any other way. Never attempt to straighten a twisted blade so that it can be reused. Only use original blades of the specified type.

Trimmer head

IMPORTANT: Always ensure the trimmer line is wound tightly and evenly around the drum; otherwise the machine may generate vibration which could be harmful.

•Only use the recommended cutting attachments. See the “TECHNICAL DATA” section.

•Smaller machines generally require small trimmer heads and vice versa. This is because when clearing using trimmer line the engine must throw out the trimmer line radially from the trimmer head and overcome the resistance of the grass being cleared.

•The length of the trimmer line is also important. A longer trimmer line requires greater engine power than a shorter trimmer line of the same diameter.

•Make sure that the cutter on the trimmer guard is intact. This is used to cut the trimmer line to the correct length.

•To increase the life of the trimmer line it can be soaked in water for a couple of days. This will make the line tougher so that it lasts longer.

ASSEMBLY

NOTE: Make sure unit is assembled correctly as shown in this manual.

Fitting the handlebar

1.Remove the screw at the rear of the throttle handle.

2.Slide the throttle handle onto the right side of the handlebar (see illustration).

3.Align the screw hole in the throttle handle with the hole in the handlebar.

4.Refit the screw in the hole in the rear of the throttle handle.

5.Screw the screw through the handle and handlebar. Tighten the screw.

6.Fit the mounting components as shown.

WARNING: The handlebar mounting parts must be fitted between the arrows on the shaft to maintain a safe operating position.

WARNING: The handlebar mounting parts must be fitted between the arrows on the shaft to maintain a safe operating position.

7. Tighten the screws with a hex wrench.

Fitting the harness

WARNING: When using a brushcutter, it must always be hooked securely to the harness. Otherwise, you will be unable to control the brushcutter safely. This can result in injury to yourself or others. Never use a harness with a defective quick release.

WARNING: When using a brushcutter, it must always be hooked securely to the harness. Otherwise, you will be unable to control the brushcutter safely. This can result in injury to yourself or others. Never use a harness with a defective quick release.

Proper harness and handlebar adjustments must be made with the engine completely stopped before using unit.

Fitting the harness clamp

1.Place the upper harness clamp over the shaft and position the lower harness clamp under the shaft. Align the upper and lower clamp screw

holes. Clamp must be fitted above the arrow on the shaft (see illustration).

NOTE: Fit throttle wire in groove of lower harness clamp before tightening screws.

2.Insert two screws into the screw holes.

3.Secure harness clamp by tightening screws with a hex wrench.

Adjusting the harness

At the front of the harness is an easily accessible quick release. Use the quick release in any emergency situation that requires you to free yourself from the machine and harness.

Spreading the load on your shoulders

A well-adjusted harness and machine makes work much easier.

Put on the harness. Adjust the harness for the best working position. Tension the side straps so that the weight is evenly distributed across both shoulders.

NOTE: It may be necessary to relocate the harness clamp on the shaft for proper balancing of unit.

Correct height

Adjust the harness so that the cutting attachment is parallel to the ground.

ASSEMBLY

Fitting a blade guard, grass blade and grass cutter

Correct balance

Let the cutting attachment rest lightly on the ground. If you use a grass blade, it should balance about 10 centimeters (4 inches) above the ground to prevent contact with stones and the like. Adjust the position of the harness clamp to balance the unit correctly.

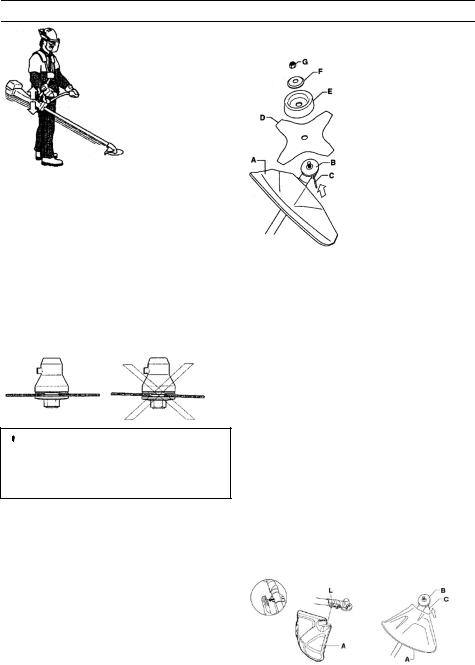

Fitting blades and trimmer heads

•When fitting the cutting attachment it is extremely important that the raised section on the drive disc/support flange engages correctly in the center hole of the cutting attachment. If the cutting attachment is fitted incorrectly it can result in serious and/or fatal personal injury.

WARNING: Never use a cutting attachment without an approved guard. See the “TECHNICAL DATA” section. If an incorrect or faulty guard is fitted this can cause serious personal injury.

WARNING: Never use a cutting attachment without an approved guard. See the “TECHNICAL DATA” section. If an incorrect or faulty guard is fitted this can cause serious personal injury.

IMPORTANT: If a grass blade is to be used, the machine must be equipped with the correct handlebar, blade guard and harness.

1.Hook the blade guard/combination guard (A) onto the fitting on the shaft and secure with the bolt.

CAUTION! Use the recommended blade guard. See the Technical data section.

2.Fit the drive disc (B) on the output shaft.

3.Turn the blade shaft until one of the holes in the drive disc aligns with the corresponding hole in the gear housing.

4.Insert the locking pin (C) in the hole to lock the shaft.

5.Place the blade (D), support cup (E) and support flange (F) on the output shaft.

6.Fit the nut (G). The nut must be tightened to a torque of 35-50 Nm (3.5-5 kpm). Use the socket wrench in the tool kit. Hold the shaft of the wrench as close to the blade guard as possible. To tighten the nut, turn the wrench in the opposite direction to the direction of rotation (NOTE: left-hand thread).

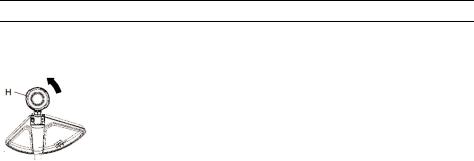

Fitting the trimmer guard and trimmer head

1.Fit the correct trimmer guard (A) for use with the trimmer head. Hook the trimmer guard/combination guard onto the fitting on the shaft and secure with the bolt (L).

2.Fit the drive disc (B) on the output shaft.

3.Turn the shaft until one of the holes in the drive disc aligns with the corresponding hole in the gear housing.

ASSEMBLY

4.Insert the locking pin (C) in the hole to lock the shaft.

5.Screw on the trimmer head (H) in the opposite direction to the direction of rotation.

6.To dismantle, follow the instructions in the reverse order.

FUEL HANDLING

Fuel safety

Never start the machine:

•If you have spilled fuel on it. Wipe off the spillage and allow remaining fuel to evaporate.

•If you have spilled fuel on yourself or your clothes, change your clothes. Wash any part of your body that has come in contact with fuel. Use soap and water.

•If the machine is leaking fuel. Check regularly for leaks from the fuel cap and fuel lines.

Transport and storage

•Store and transport the machine and fuel so that there is no risk of any leakage or fumes coming into contact with sparks or naked flames, for example, from electrical machinery, electric motors, electrical relays/switches or boilers.

•When storing and transporting fuel always use approved containers intended for this purpose.

•When storing the machine for long periods the fuel tank must be emptied. Contact your local gasoline station to find out where to dispose of excess fuel.

•Ensure the machine is cleaned and that a complete service is carried out before long-term storage.

•The transport guard must always be fitted to the cutting attachment when the machine is being transported or in storage.

•In order to prevent unintentional starting of the engine, the spark plug cap must always be removed during long-term storage, if the machine is not under close supervision and when performing all service measures.

•Secure the machine during transport.

WARNING: Take care when handling fuel. Bear in mind the risk of fire, explosion and inhaling fumes.

WARNING: Take care when handling fuel. Bear in mind the risk of fire, explosion and inhaling fumes.

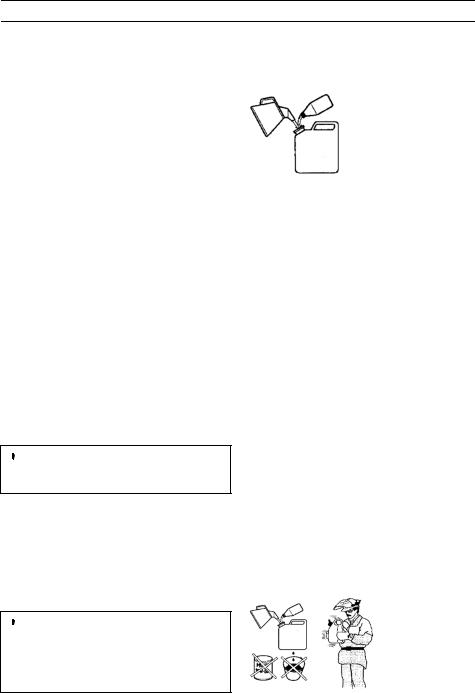

Fuel

CAUTION: The machine is equipped with a twostroke engine and must always be run using a mixture of gasoline and two-stroke engine oil. It is important to accurately measure the amount of oil to be mixed to ensure that the correct mixture is obtained. When mixing small amounts of fuel, even small inaccuracies can drastically affect the ratio of the mixture.

WARNING: Fuel and fuel fumes are highly inflammable and can cause serious injury when inhaled or allowed to come in contact with the skin. For this reason observe caution when handling fuel and make sure there is adequate ventilation.

WARNING: Fuel and fuel fumes are highly inflammable and can cause serious injury when inhaled or allowed to come in contact with the skin. For this reason observe caution when handling fuel and make sure there is adequate ventilation.

Gasoline

CAUTION: Always use a good quality gasoline/oil mixture (at least 90 octane). Use low-emission gasoline, also known as alkylate gasoline, if it is available.

•The lowest octane recommended is 90. If you run the engine on a lower octane than 90, it can result in knocking. This gives rise to a high engine temperature, which can result in serious engine damage.

•When working at continuous high revs, a higher octane rating is recommended.

Two-stroke oil

•To ensure best performance and engine durability, Husqvarna XP oil is preferred as it is specially formulated for our air-cooled two stroke-engines. Only use high quality full synthetic two-stroke oil when mixing fuel.

•Never use two-stroke oil intended for watercooled engines, sometimes referred to as outboard oil or marine oil (rated TCW).

•Never use oil intended for four-stroke engines.

Mixing

•Mixture is 50:1.

•Always mix the gasoline and oil in a clean container intended for fuel.

•Always start by filling half the amount of the gasoline to be used. Then add the entire amount of oil. Mix (shake) the fuel mixture. Add the remaining amount of gasoline.

•Mix (shake) the fuel mixture thoroughly before filling the machine's fuel tank.

Gasoline, liter (gal) |

Two-stroke oil, ml |

|

(oz) |

|

|

4 (1) |

77 (2,6) |

|

|

8 (2) |

154 (5,2) |

|

|

•Do not mix more than one month's supply of fuel at a time.

FUEL HANDLING

•If the machine is not used for some time, the fuel tank should be emptied and cleaned.

WARNING: The catalytic converter muffler gets very hot during and after use. This also applies during idling. Be aware of the fire hazard, especially when working near flammable substances and/or vapors.

WARNING: The catalytic converter muffler gets very hot during and after use. This also applies during idling. Be aware of the fire hazard, especially when working near flammable substances and/or vapors.

Fueling

WARNING: Taking the following precautions will lessen the risk of fire:

WARNING: Taking the following precautions will lessen the risk of fire:

•Do not smoke or place hot objects near fuel.

•Always shut off the engine before refueling.

•Always stop the engine and let it cool for a few minutes before refueling.

•When refueling, open the fuel cap slowly so that any excess pressure is released gently.

•Tighten the fuel cap carefully after refueling.

•Always move the machine away from the refueling area before starting.

•Clean the area around the fuel cap. Contamination in the tank can cause operating problems.

•Ensure that the fuel is well mixed by shaking the container before filling the tank.

STARTING AND STOPPING

Check before starting

•Check the blade to ensure that no cracks have formed at the bottom of the teeth or by the center hole. The most common reason why cracks are formed is that sharp corners have been formed at the bottom of the teeth while sharpening or that the blade has been used with dull teeth. Discard a blade if cracks are found.

•Check that the support flange is not cracked due to fatigue or due to being tightened too much. Discard the support flange if it is cracked.

•Ensure the locking nut has not lost its captive force. The nut lock should have a locking force of at least 1.5 Nm (1,1 ft lb). The tightening torque of the locking nut should be 35-50 Nm (26-36 ft lb).

•Check that the trimmer head and trimmer guard are not damaged or cracked. Replace the trimmer head or trimmer guard if they have been exposed to impact or are cracked.

•Never use the machine without a guard nor with a defective guard.

•All covers must be correctly fitted and undamaged before you start the machine.

Starting and stopping

WARNING: The complete clutch, clutch cover, and shaft must be fitted before the machine is started, otherwise parts could come loose and cause personal injury. Always move the machine away from the refueling area before starting. Place the machine on a flat surface. Ensure the cutting attachment cannot come into contact with any object.

WARNING: The complete clutch, clutch cover, and shaft must be fitted before the machine is started, otherwise parts could come loose and cause personal injury. Always move the machine away from the refueling area before starting. Place the machine on a flat surface. Ensure the cutting attachment cannot come into contact with any object.

Make sure no unauthorized persons are in the working area, otherwise there is a risk of serious personal injury. The safety distance is 15 meters (50 feet).

Cold engine

1.Primer bulb: Press the air purge diaphragm repeatedly until fuel begins to fill the diaphragm (about 10 times). The diaphragm need not be completely filled.

2.Choke: Set the choke control in the choke position.

WARNING: When the engine is started with the choke in choke position the cutting attachment will start to rotate immediately.

WARNING: When the engine is started with the choke in choke position the cutting attachment will start to rotate immediately.

3.Hold the body of the machine on the ground using your left hand (CAUTION! Not with your foot.). Grip the starter handle, slowly pull out the cord with your right hand until you feel some resistance (the starter pawls grip), then quickly and powerfully pull the cord. Never twist the starter cord around your hand.

NOTE! Do not squeeze the throttle control while attempting to start the engine.

NOTE! Do not pull the starter cord all the way out and do not let go of the starter handle when the cord is fully extended. This can damage the machine. Repeat pulling the cord

STARTING AND STOPPING

until engine attempts to start (or maximum 3 pulls).

4.If the engine starts or attempts to start, push the choke lever down to the run position.

5.Keep on pulling the cord powerfully until the engine starts.

6.Once the engine starts, allow the engine to warm up for 30 seconds before applying full throttle.

Warm engine

1.Primer bulb: Press the air purge diaphragm repeatedly until fuel begins to fill the diaphragm (about 10 times). The diaphragm need not be completely filled.

2.Repeat pulling the cord until engine attempts to start (or maximum 3 pulls).

For throttle handles with a start throttle lock-out:

Set the throttle to the start position by first pressing the throttle lock-out and the throttle trigger, then pressing the start throttle button (A). Then release the throttle lock-out and the throttle trigger, followed by the start throttle button. The throttle function is now activated. To return the engine to idle, press the throttle lock-out and throttle trigger again.

Stopping

Stop the engine by pushing and releasing the stop switch.

CAUTION! The stop switch automatically returns to the start position. In order to prevent unintentional starting, the spark plug cap must

be removed from the spark plug when assembling, checking and/or performing maintenance.

WARNING: When the engine is started with the choke in the closed position the cutting attachment will start to rotate immediately.

WARNING: When the engine is started with the choke in the closed position the cutting attachment will start to rotate immediately.

WORKING TECHNIQUES

IMPORTANT!

This section describes the basic safety precautions for working with trimmers. If you encounter a situation where you are uncertain how to proceed you should ask an expert. Contact your servicing dealer.

Avoid all usage which you consider to be beyond your capability.

You must understand the difference between forestry clearing, grass clearing and grass trimming before use.

Basic safety rules

•Look around you:

•To ensure that people, animals or other things cannot affect your control of the machine.

•To ensure that people, animals, etc., do not come into contact with the cutting attachment or loose objects that are thrown out by the cutting attachment.

CAUTION! Do not use the machine unless you are able to call for help in the event of an accident.

•Do not use the machine in bad weather, such as dense fog, heavy rain, strong wind, intense cold, etc. Working in bad weather is tiring and often brings added risks, such as icy ground, unpredictable felling direction, etc.

•Make sure you can move and stand safely. Check the area around you for possible obstacles (roots, rocks, branches, ditches, etc.) in case you have to move suddenly. Take great care when working on sloping ground.

•Switch off the engine before moving to another area. Fit the transport guard before carrying or transporting the equipment any distance.

•Never put the machine down with the engine running or while the cutting attachment is rotating.

The basics of clearing

•Always use the correct equipment.

•Make sure the equipment is well adjusted.

•Follow the safety precautions.

•Organize your work carefully.

•Always use full throttle when starting to cut with the blade.

•Always use sharp blades.

•Avoid stones.

•Always slow the engine to idle speed after each working operation. Long periods at full throttle without any load on the engine can lead to serious engine damage.

WARNING: Neither the operator of the machine nor anyone else may attempt to remove the cut material while the engine is running or the cutting equipment is rotating, as this can result in serious injury. Stop the engine and cutting equipment and disconnect the lead from the spark plug before you remove material that has wound around the blade shaft as otherwise there is a risk of injury. The bevel gear can get hot during use and may remain so for a while afterwards. Allow time to cool. You could get burned if you touch it.

WARNING: Neither the operator of the machine nor anyone else may attempt to remove the cut material while the engine is running or the cutting equipment is rotating, as this can result in serious injury. Stop the engine and cutting equipment and disconnect the lead from the spark plug before you remove material that has wound around the blade shaft as otherwise there is a risk of injury. The bevel gear can get hot during use and may remain so for a while afterwards. Allow time to cool. You could get burned if you touch it.

WARNING: Watch out for thrown objects. Always wear approved eye protection. Never lean over the cutting attachment guard. Stones, rubbish, etc. can be thrown up into the eyes causing blindness or serious injury. Keep unauthorized persons at a distance. Children, animals, onlookers and helpers should be kept outside the safety zone of 15 meters (50 feet). Stop the machine immediately if anyone approaches. Never swing the machine around without first checking behind you to make sure no one is within the safety zone.

WARNING: Watch out for thrown objects. Always wear approved eye protection. Never lean over the cutting attachment guard. Stones, rubbish, etc. can be thrown up into the eyes causing blindness or serious injury. Keep unauthorized persons at a distance. Children, animals, onlookers and helpers should be kept outside the safety zone of 15 meters (50 feet). Stop the machine immediately if anyone approaches. Never swing the machine around without first checking behind you to make sure no one is within the safety zone.

WARNING: Sometimes branches or grass get caught between the guard and cutting attachment. Always stop the engine before cleaning.

WARNING: Sometimes branches or grass get caught between the guard and cutting attachment. Always stop the engine before cleaning.

Grass clearing using a grass blade

•Grass blades and grass cutters must not be used on woody stems.

•A grass blade is used for all types of tall or coarse grass.

•The grass is cut down with a sideways, swinging movement, where the movement from right-to-left is the clearing stroke and the movement from left-to-right is the return stroke. Let the left-hand side of the blade (between 8 and 12 o'clock) do the cutting.

WORKING TECHNIQUES

•If the blade is angled to the left when clearing grass, the grass will collect in a line, which makes it easier to collect, e.g. by raking.

•Try to work rhythmically. Stand firmly with your feet apart. Move forward after the return stroke and stand firmly again.

•Let the support cup rest lightly against the ground. It is used to protect the blade from hitting the ground.

•Reduce the risk of material wrapping around the blade by following these instructions:

•Always work at full throttle.

•Avoid the previously cut material during the return stroke.

•Stop the engine, unclip the harness and place the machine on the ground before you start to collect the cut material.

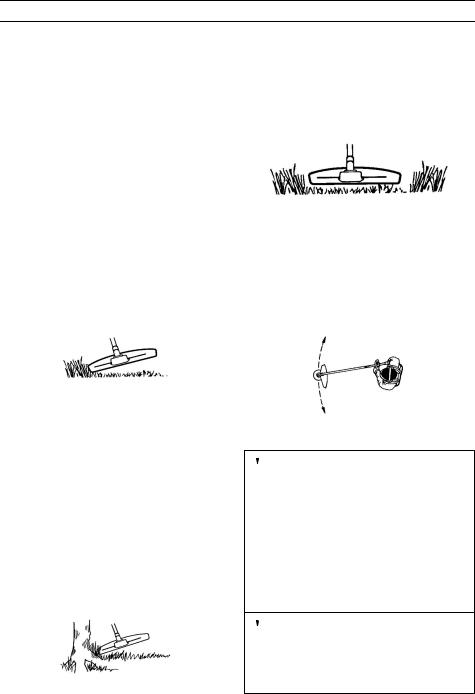

Grass trimming with a trimmer head

Trimming

•Hold the trimmer head just above the ground at an angle. It is the end of the trimmer line that does the work. Let the trimmer line work at its own pace. Never press the trimmer line into the area to be cut.

•The trimmer line can easily remove grass and weeds up against walls, fences, trees and borders; however it can also damage sensitive bark on trees and bushes, and damage fence posts.

•Reduce the risk of damaging plants by shortening the trimmer line to 10-12 cm (4-4,75 in) and reducing the engine speed.

•When trimming you should use less than full throttle so that the trimmer line lasts longer and to reduce the wear on the trimmer head.

Clearing

•The clearing technique removes all unwanted vegetation. Keep the trimmer head just above the ground and tilt it. Let the end of the trimmer line strike the ground around trees, posts, statues and the like. IMPORTANT! This technique increases the wear on the trimmer line.

•The trimmer line wears quicker and must be fed forward more often when working against stones, brick, concrete, metal fences, etc., than

when coming into contact with trees and wooden fences.

Cutting

•The trimmer is ideal for cutting grass that is difficult to reach using a normal lawn mower. Keep the trimmer line parallel to the ground when cutting. Avoid pressing the trimmer head against the ground as this can ruin the lawn and damage the tool.

•Do not allow the trimmer head to constantly come into contact with the ground during normal cutting. Constant contact of this type can cause damage and wear to the trimmer head.

Sweeping

•The fan effect of the rotating line can be used for quick and easy clearing up. Hold the trimmer line parallel to and above the area to be swept and move the tool back and forth.

•When cutting and sweeping you should use full throttle to obtain the best results.

WARNING: Neither the operator of the machine nor anyone else may attempt to remove the cut material while the engine is running or the trimmer line is rotating, as this can result in serious injury. Stop the engine and trimmer head and disconnect lead from spark plug before you remove material that has wound around the drive shaft as otherwise there is a risk of injury. The bevel gear can get hot during use and may remain so for a while afterwards. Allow time to cool. You could get burned if you touch it.

WARNING: Neither the operator of the machine nor anyone else may attempt to remove the cut material while the engine is running or the trimmer line is rotating, as this can result in serious injury. Stop the engine and trimmer head and disconnect lead from spark plug before you remove material that has wound around the drive shaft as otherwise there is a risk of injury. The bevel gear can get hot during use and may remain so for a while afterwards. Allow time to cool. You could get burned if you touch it.

WARNING: Watch out for thrown objects. Always wear eye protection. Never lean over the cutting attachment guard. Stones, rubbish, etc. can be thrown up into the eyes causing blindness or serious injury.

WARNING: Watch out for thrown objects. Always wear eye protection. Never lean over the cutting attachment guard. Stones, rubbish, etc. can be thrown up into the eyes causing blindness or serious injury.

WORKING TECHNIQUES

Keep unauthorized persons at a distance. Children, animals, onlookers and helpers should be kept outside the safety zone of 15 meters (50 feet). Stop the machine immediately if anyone approaches.

Keep unauthorized persons at a distance. Children, animals, onlookers and helpers should be kept outside the safety zone of 15 meters (50 feet). Stop the machine immediately if anyone approaches.

MAINTENANCE

The life span of the machine can be reduced and the risk of accidents can increase if machine maintenance is not carried out correctly and if service and/or repairs are not carried out professionally. If you need further information, please contact your nearest authorized service dealer.

Unit/Maintenance Safety

Disconnect the spark plug before performing maintenance, except carburetor adjustments.

WARNING: The complete clutch, clutch cover, and shaft must be fitted before the machine is started, otherwise parts could come loose and cause personal injury.

WARNING: The complete clutch, clutch cover, and shaft must be fitted before the machine is started, otherwise parts could come loose and cause personal injury.

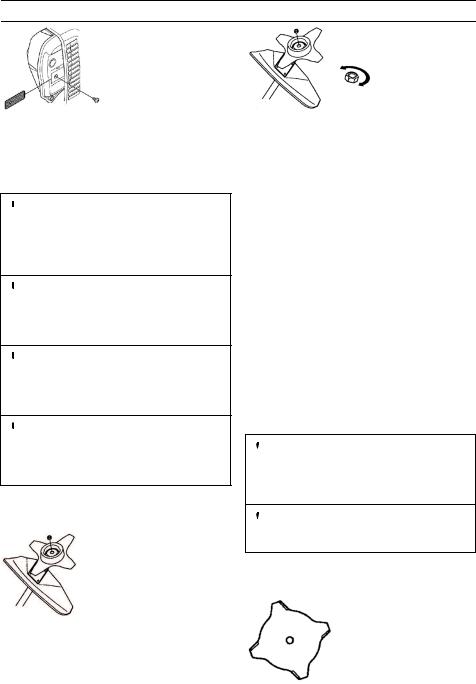

Carburetor

Function

The carburetor governs the engine's speed via the throttle control. Air and fuel are mixed in the carburetor.

The T-screw regulates the throttle setting at idle speed. If the T-screw is turned clockwise this gives a higher idle speed; turning it counterclockwise gives a lower idle speed.

Basic setting

The basic carburetor settings are adjusted during testing at the factory. Fine adjustment should be carried out by a trained technician.

WARNING: The cutting attachment may be spinning during carburetor adjustments. Wear your protective equipment and observe all safety instructions. Be sure the cutting attachment stops turning when the engine idles. When the unit is turned off, make sure the cutting attachment has stopped before the unit is set down.

WARNING: The cutting attachment may be spinning during carburetor adjustments. Wear your protective equipment and observe all safety instructions. Be sure the cutting attachment stops turning when the engine idles. When the unit is turned off, make sure the cutting attachment has stopped before the unit is set down.

CAUTION! If the cutting attachment rotates when the engine is idling the idle adjustment screw T should be turned counterclockwise until the cutting attachment stops.

Recommended idle speed:

See "Technical data" section.

Recommended max. speed:

See "Technical data" section.

Fine adjustment of the idle speed-T

Adjust the idle speed using the idle adjustment screw-T if it is necessary to readjust. First, turn the idle adjustment screw-T clockwise until the cutting attachment starts to rotate. Then, turn the screw counterclockwise until the cutting attachment stops. The idle speed is correctly adjusted when the engine will run smoothly in every position. The

idle speed should also be well below the speed at which the cutting attachment starts to rotate.

Adjusting the start throttle speed

The correct start throttle speed is set by means of an adjuster on the rear of the handle next to the cable. Use this screw (4 mm Allen screw) to increase or decrease the start throttle speed.

Proceed as follows:

1.Run the machine at idle.

2.Press the start throttle lock as described under the heading Starting and stopping.

3.If the start throttle speed is too low (below 4000 rpm), turn adjuster screw (A) clockwise until the cutting attachment starts to rotate. Then turn adjuster screw (A) clockwise an additional 1/2 turn.

4.If the start throttle speed is too high, turn adjuster screw (A) counterclockwise until the cutting attachment stops. Then turn adjuster screw (A) clockwise an additional 1/2 turn.

WARNING: If the idle speed cannot be adjusted so that the cutting attachment stops, contact your servicing dealer. Do not use the machine until it has been correctly adjusted or repaired.

WARNING: If the idle speed cannot be adjusted so that the cutting attachment stops, contact your servicing dealer. Do not use the machine until it has been correctly adjusted or repaired.

Muffler

CAUTION! Muffler is fitted with a catalytic converter designed to reduce harmful exhaust gases.

(Starter housing removed for clarity)

MAINTENANCE

The muffler is designed to reduce the noise level and to direct the exhaust gases away from the operator. The exhaust gases are hot and can contain sparks, which may cause fire if directed against dry and combustible material.

Mufflers are equipped with a special spark arrestor mesh. The mesh should be checked and, if necessary, cleaned by a servicing dealer. If the mesh is damaged, it should be replaced.

If the mesh is frequently blocked, this can be a sign that the performance of the catalytic converter is impaired. Contact your servicing dealer to inspect the muffler. A blocked mesh will cause the machine to overheat and result in damage to the cylinder and piston.

CAUTION: Never use a machine that has a faulty or loose muffler. Ensure the muffler bolts are tight.

WARNING: Mufflers fitted with catalytic converters get very hot during use and remain so for some time after stopping. This also applies at idle speed. Contact can result in burns to the skin. Remember the risk of fire!

WARNING: Mufflers fitted with catalytic converters get very hot during use and remain so for some time after stopping. This also applies at idle speed. Contact can result in burns to the skin. Remember the risk of fire!

WARNING: The inside of the muffler contain chemicals that may be carcinogenic. Avoid contact with these elements in the event of a damaged muffler.

WARNING: The inside of the muffler contain chemicals that may be carcinogenic. Avoid contact with these elements in the event of a damaged muffler.

WARNING: Engine exhaust fumes contain carbon monoxide, which can cause carbon monoxide poisoning. Do not start or run the machine indoors, or anywhere that is poorly ventilated.

WARNING: Engine exhaust fumes contain carbon monoxide, which can cause carbon monoxide poisoning. Do not start or run the machine indoors, or anywhere that is poorly ventilated.

The exhaust fumes from the engine are hot and may contain sparks which can start a fire. Never start the machine indoors or near combustible material!

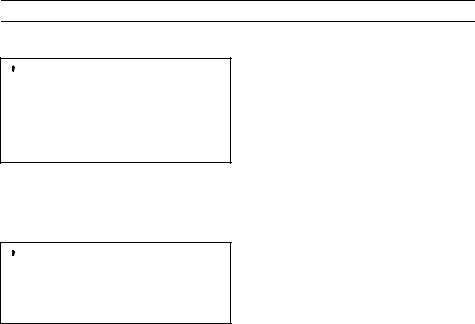

Spark plug

The spark plug condition is influenced by:

•incorrect carburetor adjustment.

•an incorrect fuel mixture (too much or incorrect type of oil).

•a dirty air filter.

These factors cause deposits on the spark plug electrodes, which may result in operating problems and starting difficulties.

If the machine is low on power, difficult to start or runs poorly at idle speed always check the spark plug first before taking any further action.

If the spark plug is dirty, clean it and check that the electrode gap is 0.024 inch (0.6 mm). The spark plug should be replaced after about a month in operation or earlier if necessary.

CAUTION: Always use the recommended spark plug type. Use of the wrong spark plug can damage the piston/cylinder.

Air filter

The air filter must be regularly cleaned to remove dust and dirt in order to avoid:

•carburetor malfunctions

•starting problems

•loss of engine power

•unnecessary wear to engine parts

•excessive fuel consumption

Clean the filter every 25 hours, or more regularly if conditions are exceptionally dusty.

Cleaning the air filter

Remove the air filter cover and take out the filter. Wash it clean in warm, soapy water. Rinse thoroughly. Ensure that the filter is dry before refitting it.

An air filter that has been in use for a long time cannot be cleaned completely. The filter must therefore be replaced with a new one at regular intervals. A damaged air filter must always be replaced.

Bevel gear

The bevel gear is filled with the right quantity of grease at the factory. However, before using the machine you should check that the bevel gear is filled three-quarters full with grease. Use special grease. The grease in the bevel gear does not normally need to be changed except if repairs are carried out.

MAINTENANCE

Sharpening grass cutters and grass blades

WARNING: Always stop the engine before doing any work on the cutting attachment. This continues to rotate even after the throttle has been released. Ensure that the cutting attachment has stopped completely and disconnect the lead from the spark plug before you start to work on it.

WARNING: Always stop the engine before doing any work on the cutting attachment. This continues to rotate even after the throttle has been released. Ensure that the cutting attachment has stopped completely and disconnect the lead from the spark plug before you start to work on it.

•See the cutting attachment packaging for correct sharpening instructions.

•Sharpen blades and cutters using a single-cut flat file.

•Sharpen all edges equally to maintain the balance of the blade.

WARNING: Always discard a blade that is bent, twisted, cracked, broken or damaged in any other way. Never attempt to straighten a twisted blade so that it can be reused. Only use original blades of the specified type.

WARNING: Always discard a blade that is bent, twisted, cracked, broken or damaged in any other way. Never attempt to straighten a twisted blade so that it can be reused. Only use original blades of the specified type.

Maintenance schedule

The following is a list of the maintenance that must be performed on the machine. Most of the items are described in the Maintenance section. The user must only carry out the maintenance and service work described in this Operator's Manual. More extensive work must be carried out by an authorized service workshop.

Weekly Maintenance:

•Clean the outside of the machine.

•Make sure the throttle trigger lock and the throttle function correctly from a safety point of view.

•Check that the stop switch works correctly.

•Check that the cutting attachment does not rotate at idle.

•Clean the air filter. Replace if necessary.

•Check that the cutting attachment guard is undamaged and not cracked. Replace the cutting attachment guard if it has been exposed to impact or is cracked.

•Check that the trimmer head is undamaged and not cracked. Replace the trimmer head if necessary.

•Check that the locking nut of the cutting equipment is tightened correctly.

•Check that nuts and screws are tight.

•Check that there are no fuel leaks from the engine, tank or fuel lines.

Monthly Maintenance:

• Check the starter and starter cord.

Annual Maintenance:

•Clean the outside of the spark plug. Remove it and check the electrode gap. Adjust the gap to 0,6 mm (1/32 inch) or replace the spark plug.

Check that the spark plug is fitted with a suppressor.

•Clean the outside of the carburetor and the space around it.

•Check that the bevel gear is filled threequarters full with lubricant. Fill if necessary using special grease.

•Check the fuel filter from contamination and the fuel hose from cracks or other defects. Replace if necessary.

•Check all cables and connections.

•Check the clutch, clutch springs and the clutch drum for wear. Replace if necessary by an authorized service workshop.

•Replace the spark plug. Check that the spark plug is fitted with a suppressor.

•Clean or replace the spark arrestor mesh on the muffler.

TECHNICAL DATA |

|

|

|

Engine |

|

Cylinder displacement, cm3 |

28 |

Cylinder bore, mm |

35 |

Stroke, mm |

28,7 |

Idle speed, rpm |

2800-3200 |

Recommended max. fast idle speed, rpm |

11000 |

Speed of output shaft, rpm |

8000 |

Max. engine output, acc. to ISO 7293, kW |

0,8 |

Catalytic converter muffler |

Yes |

Speed-regulated ignition system |

Yes |

Ignition system |

|

Spark plug |

NGK BPMR6A |

Electrode gap, mm |

0,6 |

Fuel and lubrication system |

|

Fuel tank capacity, cm3 |

343 |

Weight |

|

Weight without fuel, cutting attachment and guard, kg |

5,21 |

Noise emissions (see Note 1) |

|

Sound power level, measured dB(A) |

106 |

Sound power level, guaranteed LWA dB(A) |

114 |

Noise levels (see Note 2) |

|

Equivalent sound pressure level at the operator’s ear, measured according to |

|

EN/ISO 11806 and ISO 22868, dB(A) |

|

Equipped with grass blade (original) |

94 |

Equipped with trimmer head (original) |

95 |

Vibration levels (see Note 3) |

|

Equivalent vibration levels (ahv,eq) at handles, measured according to EN ISO |

|

11806 and ISO 22867, m/s2 |

|

Equipped with grass blade (original), left/right |

4,21 / 4,23 |

Equipped with trimmer head (original), left/right |

5,89 / 4,61 |

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/EC. Reported sound power level for the machine has been measured with the original cutting attachment that gives the highest level. The difference between guaranteed and measured sound power is that the guaranteed sound power also includes dispersion in the measurement result and the variations between different machines of the same model according to Directive 2000/14/EC.

Note 2: Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion (standard deviation) of 1 dB(A).

Note 3: Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s2.

Model 129R (M10 LH arbor shaft thread) - center hole in blades/cutters, Ø 25,4 mm

Approved accessories |

Type |

Cutting attachment / guard, |

|

|

part. no. |

Grass blade/grass cutter |

Grass 255-4 1 inch (Ø 250 4- |

504001303 / 580446606 |

|

teeth) |

|

Trimmer head |

T25 (Ø 2,4 - 2,7 mm line) |

537338306 / 580446606 |

DECLARATION OF CONFORMITY

Issuer's name: Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel: +46-36-146500.

Husqvarna AB claims sole responsibility for the object of this declaration: Trimmer and/or Brushcutter, platform(s) A05328CBHV representing model 129R from 2014 serial numbers and onwards.

The platform number and Model number are clearly stated in plain text on the type plate along with the year with subsequent serial numbers.

The object of the declaration described above is in conformity with the requirements of the Council's Directives:

•2006/42/EC "relating to machinery" 17 May 2006.

•2004/108/EC "relating to electromagnetic compatibility" 15 Dec 2004

•2000/14/EC "relating to noise emissions in the environment" 08 May 2000

In accordance with Annex V, the declared sound values are stated in the technical data sheet of the operator's manual.

The following standards have been applied:

EN ISO 12100:2010, EN ISO 11806-1:2011, ISO 14982:1998, CISPR 12:2007

TUV Rheinland N.A. has carried out a voluntary examination on behalf of Husqvarna AB, providing AM72140165 - Certificate of conformity to EC Council directive 2006/42/EC for machinery. This certificate is applicable to all manufacturing locations and Countries of Origin, as stated on the product. The supplied grass trimmer and/or brushcutter conforms to the example that underwent examination.

Signed on behalf of: Husqvarna AB, Huskvarna, Sweden, 2013-12-27.

Ronnie E. Goldman, Director of Engineering. (Authorized representative for Husqvarna AB and responsible for technical documentation.)

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA EMISSION CONTROL WARRANTY STATEMENT

IMPORTANT: This product is compliant with U.S. EPA Phase 3 regulations for exhaust and evaporative emissions. To ensure EPA Phase 3 compliance, we recommend using only genuine replacement parts. Use of non-compliant replacement parts is a violation of federal law.

YOUR WARRANTY RIGHTS AND OBLIGATIONS: The U.S. Environmental Protection Agency, California Air Resources Board, Environment Canada and Husqvarna Consumer Outdoor Products N.A., Inc. (HCOP) are pleased to explain the emissions control system warranty on your year 2014 and later off-road engine. In California, all small off-road engines must be designed, built, and equipped to meet the State’s stringent antismog standards. HCOP must warrant the emission control system on your small off-road engine for the periods of time listed below provided there has been no abuse, neglect, or improper maintenance of your small off-road engine. Your emission control system includes parts such as the carburetor, the ignition system and the fuel tank, line, and cap. Where a warrantable condition exists, HCOP will repair your small off-road engine at no cost to you. Expenses covered under warranty include diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE: If any emissions related part on your engine (as listed under Emissions Control Warranty Parts List) is defective or a defect in the materials or workmanship of the engine causes the failure of such an emission related part, the part will be repaired or replaced by HCOP.

OWNER’S WARRANTY RESPONSIBILITIES: As the small off-road engine owner, you are responsible for the performance of the required maintenance listed in your instruction manual. HCOP recommends that you retain all receipts covering maintenance on your small off-road engine, but HCOP cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance. As the small off-road engine owner, you should be aware that HCOP may deny you warranty coverage if your small off-road engine or a part of it has failed due to abuse, neglect, improper maintenance, unapproved modifications, or the use of parts not made or approved by the original equipment manufacturer. You are responsible for presenting your small offroad engine to a HCOP authorized repair center as soon as a problem exists. Warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have any questions regarding your warranty rights and responsibilities, you should contact your nearest authorized service center.

Please call HCOP at 1-800-487-5951 (USA) or 1-800-805-5523 (Canada) or send e-mail correspondence to emission.warranty@us.hvwan.net.

WARRANTY COMMENCEMENT DATE: The warranty period begins on the date the small off-road engine is purchased.

LENGTH OF COVERAGE: This warranty shall be for a period of two years from the initial date of purchase, or until the end of the product warranty (whichever is longer).

WHAT IS COVERED: REPAIR OR REPLACEMENT OF PARTS. Repair or replacement of any warranted part will be performed at no charge to the owner at an approved HCOP servicing center. If you have any questions regarding your warranty rights and responsibilities, you should contact your nearest authorized service center.

Please call HCOP at 1-800-487-5951 (USA) or 1-800-805-5523 (Canada) or send e-mail correspondence to emission.warranty@us.hvwan.net.

WARRANTY PERIOD: Any warranted part which is not scheduled for replacement as required maintenance, or which is scheduled only for regular inspection to the effect of “repair or replace as necessary” shall be warranted for 2 years. Any warranted part which is scheduled for replacement as required maintenance shall be warranted for the period of time up to the first scheduled replacement point for that part.

DIAGNOSIS: The owner shall not be charged for diagnostic labor which leads to the determination that a warranted part is defective if the diagnostic work is performed at an approved HCOP servicing center. CONSEQUENTIAL DAMAGES: HCOP may be liable for damages to other engine components caused by the failure of a warranted part still under warranty.

WHAT IS NOT COVERED: All failures caused by abuse, neglect, or improper maintenance are not covered. ADD-ON OR MODIFIED PARTS: The use of add-on or modified parts can be grounds for disallowing a warranty claim. HCOP is not liable to cover failures of warranted parts caused by the use of add-on or modified parts. HOW TO FILE A CLAIM: If you have any questions regarding your warranty rights and responsibilities, you should contact your nearest authorized HCOP service center.

Please call HCOP at 1-800-487-5951 (USA) or 1-800-805-5523 (Canada) or send e-mail correspondence to emission.warranty@us.hvwan.net.

WHERE TO GET WARRANTY SERVICE: Warranty services or repairs shall be provided at all HCOP service centers. Please call HCOP at 1-800-487-5951 (USA) or 1-800-805-5523 (Canada) or send e-mail correspondence to emission.warranty@us.hvwan.net.

MAINTENANCE, REPLACEMENT AND REPAIR OF EMISSION RELATED PARTS: Any HCOP approved replacement part used in the performance of any warranty maintenance or repair on emission related parts will be provided without charge to the owner if the part is under warranty.

EMISSION CONTROL WARRANTY PARTS LIST: Carburetor, air filter (covered up to maintenance schedule), ignition system: spark plug (covered up to maintenance schedule), ignition module, muffler including catalyst (if equipped), fuel tank, line, and cap.

MAINTENANCE STATEMENT: The owner is responsible for the performance of all required maintenance as defined in the instruction manual.

VARNING: Avgaserna från maskinens motor innehåller kemikalier som i Kalifornien anses orsaka cancer och fosterskador eller andra fortplantningsskador.

VARNING: Avgaserna från maskinens motor innehåller kemikalier som i Kalifornien anses orsaka cancer och fosterskador eller andra fortplantningsskador.

Innan start måste följande observeras:

Läs igenom bruksanvisningen noggrant.

VARNING: Under inga förhållanden får maskinens ursprungliga utformning ändras utan tillstånd från tillverkaren. Använd alltid originaltillbehör. Icke auktoriserade ändringar och/eller tillbehör kan medföra allvarliga personskador eller dödsfall för föraren eller andra.

VARNING: Under inga förhållanden får maskinens ursprungliga utformning ändras utan tillstånd från tillverkaren. Använd alltid originaltillbehör. Icke auktoriserade ändringar och/eller tillbehör kan medföra allvarliga personskador eller dödsfall för föraren eller andra.

VARNING: En röjsåg, buskröjare eller trimmer kan felaktigt eller slarvigt använd vara ett farligt redskap, som kan orsaka allvarliga skador eller dödsfall för användaren eller andra. Det är mycket viktigt att du läser och förstår innehållet i denna bruksanvisning.

VARNING: En röjsåg, buskröjare eller trimmer kan felaktigt eller slarvigt använd vara ett farligt redskap, som kan orsaka allvarliga skador eller dödsfall för användaren eller andra. Det är mycket viktigt att du läser och förstår innehållet i denna bruksanvisning.

VARNING: Långvarig exponering för buller kan ge bestående hörselskador. Använd därför alltid godkända hörselskydd.

VARNING: Långvarig exponering för buller kan ge bestående hörselskador. Använd därför alltid godkända hörselskydd.

Vi arbetar ständigt med att vidareutveckla våra produkter och förbehåller oss därför rätten till ändringar beträffande bl.a. form och utseende utan föregående meddelande.

SYMBOLFÖRKLARING

Symboler

VARNING: Röjsågar, buskröjare och trimmers kan vara farliga. Slarvigt eller felaktigt användande kan resultera i allvarliga skador eller dödsfall för föraren eller andra.

VARNING: Röjsågar, buskröjare och trimmers kan vara farliga. Slarvigt eller felaktigt användande kan resultera i allvarliga skador eller dödsfall för föraren eller andra.

Läs igenom bruksanvisningen noggrant och se till att du förstår instruktionerna innan du använder maskinen.

Bär alltid arbetsskor med stålhätta och halkfri sula, åtsittande kläder, kraftiga långbyxor, skjorta med långa ärmar; kraftiga och halksäkra handskar, skyddsglasögon (gärna ventilerade och dimfria) eller ansiktsmask, godkänd skyddshjälm och hörselskydd (öronproppar eller ljuddämpare).

Personer som har långt hår bör (för sin personliga säkerhet) fästa upp håret.

Användare av maskinen ska  under arbetets gång se till att inga människor eller djur kommer närmare än 15 meter.

under arbetets gång se till att inga människor eller djur kommer närmare än 15 meter.

Se upp för utslungade föremål och rikoschetter.

Den utgående axelns maximala varvtal (varv/minut)

Maskiner utrustade med gräsklingor kan rycka våldsamt i sidled när klingan kommer i kontakt med fasta föremål. Klingan kan amputera både armar och ben. Håll alltid människor och djur minst 15 meter bort från maskinen.

Pilmarkeringar som anger gränser för handtagsfästet.

Ljudtrycksnivå vid 7,5 meter enligt föreskrifter i Australien.

Emission av buller till omgivningen enligt EU:s direktiv. Maskinens emission anges i avsnittet Tekniska data och på dekal.

Denna produkt överensstämmer med gällande EG-direktiv.

Denna produkt överensstämmer med gällande EAC-direktiv.

Denna produkt överensstämmer med föreskrifter i Australien gällande elektromagnetisk kompatibilitet (EMC).

Använd blyfri bensin och tvåtaktsolja blandad i proportionen 2 % (50:1).

Övriga på maskinen angivna symboler/dekaler avser specifika krav för certifieringar på vissa marknader.

VAD ÄR VAD

Vad är vad |

20. Stödkopp |

|||

1. |

Kniv |

21. Medbringare |

||

22. |

Trimmerhuvud |

|||

2. |

Påfyllning av smörjmedel |

|||

23. |

Hylsnyckel |

|||

3. |

Vinkelväxel |

|||

24. |

Transportskydd |

|||

4. |

Skärutrustningens skydd |

|||

25. |

Insexnyckel |

|||

5. |

Riggrör |

|||

26. |

Låspinne |

|||

6. |

Handtag |

|||

27. |

Kablage |

|||

7. |

Gasreglage |

|||

28. |

Startgasknapp |

|||

8. |

Stoppkontakt |

|||

29. |

Justering av gasvajer |

|||

9. |

Gasreglagespärr |

|||

30. |

Bruksanvisning |

|||

|

|

|||

10.Selfäste

11.Cylinderkåpa

12.Startsnörets handtag

13.Bränsletank

14.Chokereglage

15.Bränslepump

16.Luftfilterlock

17.Handtagsinställning

18.Låsmutter

19.Stödfläns

ALLMÄNNA SÄKERHETSINSTRUKTIONER

Viktigt

•En röjsåg, buskröjare eller trimmer kan felaktigt eller slarvigt använd vara ett farligt redskap, som kan orsaka allvarliga skador eller dödsfall för användaren eller andra. Det är mycket viktigt att du läser och förstår innehållet i denna bruksanvisning.

•Maskinen är endast konstruerad för grästrimning, gräsröjning och/eller skogsröjning.

•De enda tillbehör du får använda motorenheten som drivkälla till är de skärutrustningar vi rekommenderar i avsnittet "TEKNISKA DATA".

•Använd aldrig maskinen om du är trött, om du har druckit alkohol eller om du tar mediciner som kan påverka din syn, ditt omdöme eller din kroppskontroll.

•Använd aldrig maskinen vid extrema klimatförhållanden såsom sträng kyla eller mycket varmt och/eller fuktigt klimat.

•Använd personlig skyddsutrustning. Se anvisningar under rubrik "Personlig skyddsutrustning".

•Använd aldrig en maskin som modifierats så att den ej längre överensstämmer med originalutförandet.

•Använd aldrig en maskin som är defekt. Följ underhålls-, kontrolloch serviceinstruktioner i denna bruksanvisning. Vissa underhållsoch serviceåtgärder skall utföras av utbildade och kvalificerade specialister. Se anvisningar under avsnitt "UNDERHÅLL".

•Samtliga kåpor och skydd måste vara monterade före start. Se till att tändhatt och kabel är oskadade. Det finns risk för elektrisk stöt.

•Användare av maskinen ska se till att inga människor eller djur kommer närmare än 15 meter under arbetet. När flera användare arbetar på samma område ska säkerhetsavståndet vara minst 15 meter.

VARNING: Denna maskin alstrar under drift ett elektromagnetiskt fält. Under vissa omständigheter kan det här fältet ge påverkan på aktiva eller passiva medicinska implantat. För att reducera risken för allvarliga eller livshotande skador rekommenderar vi därför personer med implantat att rådgöra med läkare samt tillverkaren av det medicinska implantatet innan denna maskin används.

VARNING: Denna maskin alstrar under drift ett elektromagnetiskt fält. Under vissa omständigheter kan det här fältet ge påverkan på aktiva eller passiva medicinska implantat. För att reducera risken för allvarliga eller livshotande skador rekommenderar vi därför personer med implantat att rådgöra med läkare samt tillverkaren av det medicinska implantatet innan denna maskin används.

VARNING: En felaktig skärutrustning eller en felaktigt filad klinga ökar risken för olyckor.

VARNING: En felaktig skärutrustning eller en felaktigt filad klinga ökar risken för olyckor.

VARNING: Tillåt aldrig barn att använda eller vara i närheten av maskinen. Eftersom maskinen är utrustad med återfjädrande stoppkontakt och kan startas med låg hastighet och kraft på starthandtaget, kan även små barn under vissa omständigheter åstadkomma den kraft som behövs för att starta maskinen. Detta kan innebära risk för allvarlig personskada. Avlägsna därför tändhatten när maskinen inte är under uppsikt.

VARNING: Tillåt aldrig barn att använda eller vara i närheten av maskinen. Eftersom maskinen är utrustad med återfjädrande stoppkontakt och kan startas med låg hastighet och kraft på starthandtaget, kan även små barn under vissa omständigheter åstadkomma den kraft som behövs för att starta maskinen. Detta kan innebära risk för allvarlig personskada. Avlägsna därför tändhatten när maskinen inte är under uppsikt.

Personlig skyddsutrustning

VARNING: Godkänd personlig skyddsutrustning skall användas då du använder maskinen. Personlig skyddsutrustning kan inte eliminera skaderisken, men den reducerar effekten av en skada vid ett eventuellt olyckstillbud. Be din återförsäljare om hjälp vid val av utrustning.

VARNING: Godkänd personlig skyddsutrustning skall användas då du använder maskinen. Personlig skyddsutrustning kan inte eliminera skaderisken, men den reducerar effekten av en skada vid ett eventuellt olyckstillbud. Be din återförsäljare om hjälp vid val av utrustning.

VARNING: Var alltid uppmärksam på varningssignaler eller tillrop när hörselskydd används. Tag alltid av hörselskydden så snart du stängt av motorn.

VARNING: Var alltid uppmärksam på varningssignaler eller tillrop när hörselskydd används. Tag alltid av hörselskydden så snart du stängt av motorn.

Hjälm

Hjälm ska användas om buskarna som avverkas är högre än 2 meter.

Hörselskydd

Hörselskydd med tillräcklig dämpeffekt ska användas.

Ögonskydd

Godkända ögonskydd skall alltid användas. Används visir måste även godkända skyddsglasögon användas. Godkända skyddsglasögon måste uppfylla standarden EN 166 i Europa, ANSI Z87 i USA och CSA Z94 i Kanada.