Page 1

Autodesk®

Visual Eff ects, Finishing, and

Color Grading

HP® Z800 Workstation

Hardware Setup Guide

Page 2

Autodesk® Visual Effects, Finishing and Grading 2010

©

2009 Autodesk, Inc. All rights reserved. Except as otherwise permitted by Autodesk, Inc., this publication, or

parts thereof, may not be reproduced in any form, by any method, for any purpose.

Certain materials included in this publication are reprinted with the permission of the copyright holder.

Portions relating to MD5 Copyright © 1991-2, RSA Data Security, Inc. Created 1991. All rights reserved. License to copy and use this software

is granted provided that it is identified as the "RSA Data Security, Inc. MD5 Message-Digest Algorithm" in all material mentioning or referencing

this software or this function. License is also granted to make and use derivative works provided that such works are identified as "derived from

the RSA Data Security, Inc. MD5 Message-Digest Algorithm" in all material mentioning or referencing the derived work. RSA Data Security, Inc.

makes no representations concerning either the merchantability of this software or the suitability of this software for any particular purpose. It

is provided "as is" without express or implied warranty of any kind. These notices must be retained in any copies of any part of this documentation

and/or software.

Trademarks

The following are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates in the USA and other countries:

3DEC (design/logo), 3December, 3December.com, 3ds Max, ADI, Algor, Alias, Alias (swirl design/logo), AliasStudio, Alias|Wavefront (design/logo),

ATC, AUGI, AutoCAD, AutoCAD Learning Assistance, AutoCAD LT, AutoCAD Simulator, AutoCAD SQL Extension, AutoCAD SQL Interface,

Autodesk, Autodesk Envision, Autodesk Intent, Autodesk Inventor, Autodesk Map, Autodesk MapGuide, Autodesk Streamline, AutoLISP, AutoSnap,

AutoSketch, AutoTrack, Backburner, Backdraft, Built with ObjectARX (logo), Burn, Buzzsaw, CAiCE, Can You Imagine, Character Studio, Cinestream,

Civil 3D, Cleaner, Cleaner Central, ClearScale, Colour Warper, Combustion, Communication Specification, Constructware, Content Explorer,

Create>what's>Next> (design/logo), Dancing Baby (image), DesignCenter, Design Doctor, Designer's Toolkit, DesignKids, DesignProf, DesignServer,

DesignStudio, Design|Studio (design/logo), Design Web Format, Discreet, DWF, DWG, DWG (logo), DWG Extreme, DWG TrueConvert, DWG

TrueView, DXF, Ecotect, Exposure, Extending the Design Team, Face Robot, FBX, Fempro, Filmbox, Fire, Flame, Flint, FMDesktop, Freewheel,

Frost, GDX Driver, Gmax, Green Building Studio, Heads-up Design, Heidi, HumanIK, IDEA Server, i-drop, ImageModeler, iMOUT, Incinerator,

Inferno, Inventor, Inventor LT, Kaydara, Kaydara (design/logo), Kynapse, Kynogon, LandXplorer, Lustre, MatchMover, Maya, Mechanical Desktop,

Moldflow, Moonbox, MotionBuilder, Movimento, MPA, MPA (design/logo), Moldflow Plastics Advisers, MPI, Moldflow Plastics Insight, MPX,

MPX (design/logo), Moldflow Plastics Xpert, Mudbox, Multi-Master Editing, NavisWorks, ObjectARX, ObjectDBX, Open Reality, Opticore,

Opticore Opus, Pipeplus, PolarSnap, PortfolioWall, Powered with Autodesk Technology, Productstream, ProjectPoint, ProMaterials, RasterDWG,

Reactor, RealDWG, Real-time Roto, REALVIZ, Recognize, Render Queue, Retimer,Reveal, Revit, Showcase, ShowMotion, SketchBook, Smoke,

Softimage, Softimage|XSI (design/logo), Sparks, SteeringWheels, Stitcher, Stone, StudioTools, Topobase, Toxik, TrustedDWG, ViewCube, Visual,

Visual Construction, Visual Drainage, Visual Landscape, Visual Survey, Visual Toolbox, Visual LISP, Voice Reality, Volo, Vtour, Wire, Wiretap,

WiretapCentral, XSI, and XSI (design/logo).

Adobe, Flash and Reader are either trademarks or registered trademarks in the United States and/or countries. Automatic Duck and the duck

logo are trademarks of Automatic Duck, Inc. FFmpeg is a trademark of Fabrice Bellard, originator of the FFmpeg project. Python is a registered

trademark of Python Software Foundation. All other brand names, product names or trademarks belong to their respective holders.

Disclaimer

THIS PUBLICATION AND THE INFORMATION CONTAINED HEREIN IS MADE AVAILABLE BY AUTODESK, INC. “AS IS.” AUTODESK, INC. DISCLAIMS

ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE REGARDING THESE MATERIALS.

Published by: Autodesk, Inc.

111 Mclnnis Parkway

San Rafael, CA 94903, USA

Title: Autodesk Visual Effects, Finishing, and Colour Grading HP Z800 Workstation Hardware Setup Guide

Document Version: 4

Date: November 23, 2009

Page 3

Contents

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Notation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Typical Configuration Overview for Autodesk Effects and Finishing Applications . . . . . . . . . . . . 5

Typical Configuration Overview for Autodesk Lustre . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hardware Configuration Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ensuring Proper Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power and Air Conditioning Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rack Mount Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Avoiding Damage from Static Electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Grounding Audio Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Receiving Your Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3 Connecting Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Workflow for Connecting Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connections Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connecting the Graphics Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connecting the Keyboard, Mouse, and Tablet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting the Graphics Monitor Calibration Device . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Visual Effects and Finishing Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Lustre Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting the Autodesk Control Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting the Slave Renderer to a Lustre Workstation . . . . . . . . . . . . . . . . . . . . . . . . . 16

iii

Page 4

Chapter 4 Setting Up Video Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Video Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Included Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wiring Your Video Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Setting Up VTR Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 5 Setting Up Audio Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

About Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Audio Wiring Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Audio Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Audio Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuring the Lucid ADA 88192 Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Understanding Remote vs. Local Control of the Lucid Converter . . . . . . . . . . . . . . . . . 25

Adjusting Lucid ADA 88192 Converter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Lucid ADA 88192 Converter Settings for Remote Control . . . . . . . . . . . . . . . . . . . . . 27

Lucid ADA 88192 Converter Settings for Local Control . . . . . . . . . . . . . . . . . . . . . . 27

Audio Keywords in the Visual Effects and Finishing Configuration File . . . . . . . . . . . . . . . . . 28

Chapter 6 Connecting Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting Media Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

About Autodesk Stone Direct Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the HP Z800 ATTO Fibre Channel Adapter . . . . . . . . . . . . . . . . . . . . . . 30

Connecting Storage Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

XR 6500 Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

XR 6412 Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

XR 5402 and XR 5412 Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connecting Archiving Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Filesystem Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SCSI Tape Drive Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 7 Configuring the Workstation BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

HP Z800 BIOS Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Restoring BIOS to Default Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Updating your System BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Appendix A VTR Control Cable Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Standard VTR Control Cable Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

VTR Emulation RS-422 Control Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Linux Master to Linux Emulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Third-Party Master to Linux Emulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

iv | Contents

Page 5

Introduction

Topics in this chapter:

■

About This Guide on page 1

■

Related Documentation on page 1

■

Notation Conventions on page 2

■

Contacting Customer Support on page 2

About This Guide

1

This guide describes how to set up the HP® Z800 workstation hardware and wiring for an Autodesk® Visual

Effects, Finishing, or Colour Grading application. This includes Autodesk® Lustre®, and the following Visual

Effects and Finishing applications: Autodesk® Inferno®, and Autodesk® Flame®, Autodesk® Flint®, Autodesk

Smoke®, and Autodesk® Backdraft® Conform.

NOTE In most cases, both hardware setup and application installation is done on delivery by an authorized

technician. If this is the case, please keep this guide as a reference, in case you decide to move the workstation,

change a peripheral, replace an adapter card, etc.

Related Documentation

This release has additional documentation to help you install, configure, and use the hardware and software.

At various places in this guide, references are made to other documents. Depending on your hardware and

software configuration and network topology, you may want to have additional documentation on hand

before you begin setting up the hardware:

■ Autodesk Visual Effects and Finishing Installation and Configuration Guide

■ Autodesk Lustre Installation and Configuration Guide for Linux Workstations

®

1

Page 6

■ Autodesk Lustre Colour Management User Guide

■ Autodesk Lustre User Guide

■ Autodesk Incinerator Installation and User Guide

■ Autodesk Control Surface User Guide

■ Autodesk System Central User Guide

For a list of all available documentation, visit http://www.autodesk.com/me-documentation. From there you

can access the complete documentation library and download PDF files. In addition, PDF files and an HTML

help system are installed with the software. For Lustre, documentation is also included on the application

CD.

NOTE Please refer to the product's release notes for late-breaking release information.

Notation Conventions

A number of style conventions are used throughout your documentation. These conventions and examples

of their use are shown as follows.

ExampleConvention

Text that you enter in a command line or shell appears

in Courier bold. Press the Enter key after each command.

Variable names appear in Courier, enclosed in angle

brackets.

Feedback from the command line or shell appears in

Courier.

utilities appear in italics.

install rpm -qa

<filename>

limit coredumpsize

/usr/discreetDirectory names, filenames, URLs, and command line

Contacting Customer Support

For Autodesk Media and Entertainment Customer Support, visit http://www.autodesk.com/support.

Customer support is also available through your Autodesk reseller. To find a reseller near you, consult the

reseller look-up database at http://www.autodesk.com/resellers.

2 | Chapter 1 Introduction

Page 7

Getting Started

2

Topics in this chapter:

■

General Workflow on page 3

■

Typical Configuration Overview for Autodesk Effects and Finishing Applications on page 5

■

Typical Configuration Overview for Autodesk Lustre on page 6

■

Hardware Configuration Guidelines on page 7

General Workflow

The following procedure provides the general workflow for connecting, configuring and installing an

Autodesk® Visual Effects, Finishing, or Colour Grading application on a workstation.

To install a Visual Effects, Finishing, and Colour Grading application on a workstation:

1 Review the guidelines for working with hardware components. See Hardware Configuration Guidelines

on page 7.

2 Connect all peripherals (mouse, keyboard, Wacom® tablet, graphics monitor) to the proper ports, and

connect the workstation to the Autodesk Wire® network. See Workflow for Connecting Peripherals on

page 11.

3 Connect the workstation to external storage. See Connecting Storage on page 29.

NOTE If repurposing existing storage, it is highly recommended you back up or archive the media and

projects before connecting it to the new workstation. For more information, see the application’s User Guide.

NOTE If you are installing or reinstalling the workstation’s Linux operating system, be sure to power-down

or disconnect any direct attached storage before booting from the Linux installation disk. If you do not, Linux

may attempt to reformat and install on the attached storage, destroying all stored media in the process.

3

Page 8

4 Connect a VTR and a broadcast monitor to the workstation. See Wiring Your Video Components on

page 20.

5 Set up the audio hardware. See Setting Up Audio Hardware on page 23.

6 Install the operating system, as instructed in the application’s Installation and Configuration Guide.

NOTE The Windows operating system is not supported by Lustre on the HP Z800 workstation.

7 Install and license the Visual Effects, Finishing, or Colour Grading application. As above, see the

application’s Installation and Configuration Guide.

4 | Chapter 2 Getting Started

Page 9

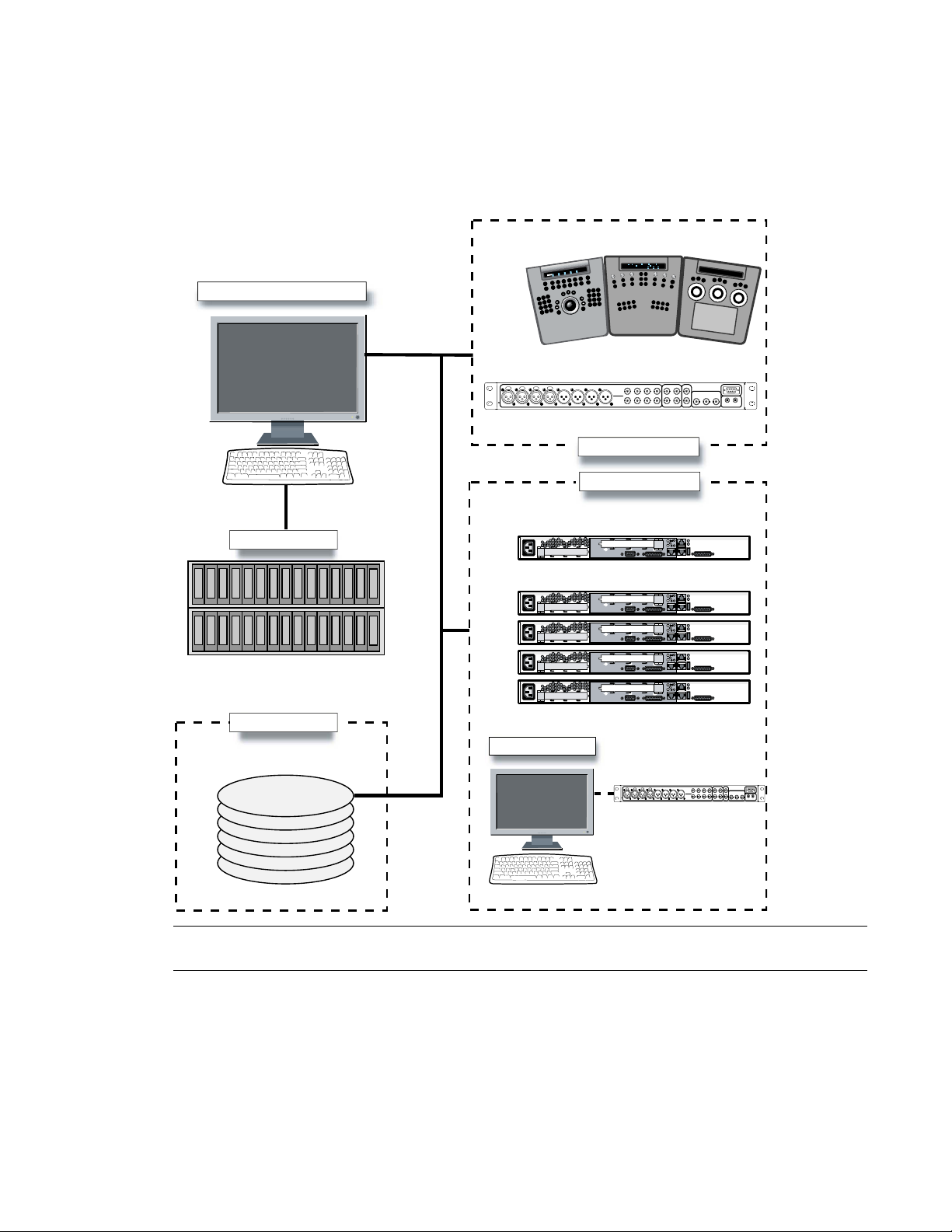

Typical Configuration Overview for Autodesk Effects and

AJA BOB (breakout box)

Background Rendering (Burn)

Workstation

Storage

Peripheral Options

Network Options

Stone Shared

SAN and Archive options

WACOM Tablet

POWER

SERIAL

INPUT

SERIAL

OUTPUT 4

SERIAL

OUTPUT 3

SERIAL

OUTPUT 2

SERIAL

OUTPUT 1

LOCK

MODELHD5DA

SERIALDISTRUBUTION

AMPLIFIER

HDTV

AJA HD5DA Distribution Amplifier

IN IN

OUT OUT

IN IN

OUT OUT

Video Tape Recorder

RefLoop

RS-422

SDI1/A SDI2/B

In

Out

Ch.1(L) Ch.2(R)

Y/G/CVBS Pb/B/Y Pr/R/C

VideoMonitorOut

Ch.1/2 Ch.3/4

In

Out

Ch.5/6

In

OutInOut

Ch.1/2Out Ch.3/4Out Ch.5/6 Out Ch.7/8 OutCh.1/2In

Ch.3/4In

Ch.5/6In

Ch.7/8In

AES/EBU

Audio

Ch.7/8

AJA BOB (Front)

Video Options

Finishing Applications

The following illustration shows a typical configuration, including the Wacom tablet, and other optional

components.

Typical Configuration Overview for Autodesk Effects and Finishing Applications | 5

Page 10

Lustre Station

Control Surface

Slave Renderer

Video I/O

Background Rendering (Burn)

Lustre Master Workstation

Lustre Storage

Peripheral Options

Network Options

High

Hue Brigh tness Saturation

G+ B+R+

R G B

ShMid

BrightBright

+

G- B-R - -

M

ulti

M

atte

O/P

S

til

l

ALT

W

i

p

e

S

pli

t

P

r

oxy

.

Cu

rv

e K

ey

P&S

Inside

Misc

Outside

#0001.000019

InPr

OutPr

Geom

Gr

ad

e

GRAD

E C

URVES

KE

Y G

EO

M P

&S

MISC

MOR

E

MOR

E

OUT

IN

1

+/

-

4

7

5

6

9

8

2

0

3

AL

T

ENTER

C

U

R

S

O

R

REVERT

CO

MP

UNDO

R

ED

O

DO

RECALL

O

FFSET

GRADE

CLIP

A/B

CUE

F

1

F

2

F

3

F

4

F

5

F

6

F

7

F

8

F

9

S

hado

w

C

on

tr

ast

Br

igh

tness

SAN options

RefLoop

RS-422

SDI1/A SDI2/B

In

Out

Ch.1(L) Ch.2(R)

Y/G/CVBS Pb/B/Y Pr/R/C

VideoMonitorOut

Ch.1/2 Ch. 3/4

In

Out

Ch.5/6

In

OutInOut

Ch.1/2Out Ch. 3/4Out Ch. 5/6Out Ch.7/8OutCh.1/2In

Ch.3/4In

Ch.5/6In

Ch.7/8In

AES/EBU

Audio

Ch.7/8

AJA BOB (Front)

AJA BOB (breakout box)

RefLoop

RS-422

SDI1/A SDI 2/B

In

Out

Ch.1(L) Ch.2(R)

Y/G/CVBS Pb/B/Y Pr/R/C

VideoMonitorOut

Ch.1/2 Ch. 3/4

In

Out

Ch.5/6

In

OutInOut

Ch.1/2Out Ch.3/4 Out Ch.5/6Out Ch. 7/8OutCh.1/2In

Ch.3/4In

Ch.5/6In

Ch.7/8In

AES/EBU

Audio

Ch.7/8

Typical Configuration Overview for Autodesk Lustre

The following illustration shows a typical configuration, including the Lustre Master Station, Station, and

other optional components.

NOTE For an Incinerator® system configuration overview, refer to the Autodesk Incinerator Installation and User

Guide.

6 | Chapter 2 Getting Started

Page 11

Hardware Configuration Guidelines

In most cases, hardware integration and application installation are done on delivery by an authorized

technician, and some of the procedures in this guide may not be necessary. Still, it is a good idea to read

through all chapters to familiarize yourself with the configuration procedures for the following reasons:

■ Many suspected problems with your system may be due to loosened connections or improperly configured

devices. This guide helps you troubleshoot problems by providing information about properly configured

systems.

■ If you need to call Customer Support, some familiarity with this guide will help you assist Customer

Support in diagnosing problems.

■ If you want to move your system at any time, or upgrade certain hardware components, this guide

contains crucial information.

NOTE It is recommended that all hardware configuration is performed by an experienced hardware integrator.

Memory Requirements

The HP Z800 workstation is equipped with 12 GB (base configuration) of DDR3 PC2-6400 ECC Unbuffered

DIMMs. The optimal RAM configuration depends on the resolution of your projects, and the type of work

you perform. For more information see:

■ Autodesk Visual Effects and Finishing Installation and Configuration Guide

■ Autodesk Lustre Installation and Configuration Guide for Linux Workstations

Ensuring Proper Environmental Conditions

You should consider the following environmental guidelines for all hardware configuration:

■ Place all components in an air-conditioned environment. All hardware components generate heat and

must be kept cool. See Power and Air Conditioning Requirements on page 7.

■ Make sure the rack on which hardware components are mounted is open or well ventilated. Follow the

ventilation specifications that apply to your system. See Rack Mount Requirements on page 8.

■ Keep all hardware components in a clean, dust-free location.

■ Minimize vibration and humidity.

■ Do not block the vents on the component housing.

■ Do not drape anything, such as a jacket or a blanket, over hardware components.

■ Minimize electromagnetic noise by separating digital data and power cables from analog audio cables

and running them in different cable ducts.

Power and Air Conditioning Requirements

The values for power consumption and heat output were recorded on an Autodesk certified system with all

of the required peripherals and certified components.

Hardware Configuration Guidelines | 7

Page 12

NOTE These values can fluctuate if uncertified hardware components or third party applications are added to

your system. The use of uncertified hardware components or third party applications is not supported. Please

consult the manufacturer's documentation for standardized minimum and maximum values.

The following table summarizes the peak (at startup) power consumed by the HP Z800 system and the heat

it generates under the maximum processing load produced by a Visual Effects, Finishing, or Colour Grading

application. For more detailed specifications, including noise output, see the documentation provided by

the manufacturer.

Heat (BTUs)WattsCont. Amps (120V

15564563.8 / 1.94.0 / 2.01HP Z800 (with cards)

205600.5 / 0.250.5 / 0.251Lucid ADA 88192

11403342.78 / 1.393.8 / 1.91

9422762.3 / 1.153.75 / 1.881Stone Direct XE expansion

21306245.2 / 2.66.41 / 3.21Stone Direct XR + Stone

4101201 / 0.51 / 0.51

Stone® Direct XR storage

chassis

chassis

Direct XE

Autodesk® Control Surface

(Lustre only)

QuantityComponent

Startup Amps

(120V / 240V)

/ 240V)

You must be able to meet the startup power requirement and have a climate control system with the capacity

to maintain the temperature of these components under the maximum processing load. The following table

shows standard conversion benchmarks and an example of how they can be used to determine climate

control requirements.

ExampleUnit Conversion

456 Watts = 1556.33 BTU1 Watt = 3.413 BTU

Rack Mount Requirements

If you plan to rack-mount your system, allow sufficient space for each component, as indicated in the

following table.

8 | Chapter 2 Getting Started

1556.33 BTU = 0.13 Tons of air conditioning12000 BTU = 1 Ton of air conditioning

Required Rack SpaceForm FactorQuantityComponent

5U5U1HP Z800 workstation

1U1U1AJA OEM-2K breakout box

2U2U1Stone Direct XR storage chassis

2U2U1Stone Direct XE expansion chassis (optional)

Page 13

Avoiding Damage from Static Electricity

Take precautions to prevent damage to sensitive components from static discharge:

■ Make sure power is turned off on the component you are working on. It is a good idea to unplug

components until all other connections are configured.

■ Wear a grounded static wrist strap. Attach the strap's alligator clip to any grounded metal surface on the

component's chassis that you are working on. Place the wristband around your wrist.

■ Do not handle any components unnecessarily, particularly boards and cards that slide in and out of PCI

slots on their parent hardware components.

Grounding Audio Hardware Components

It is important to properly ground the audio components. Otherwise, ground loops can occur, causing

humming in the system. To ensure proper grounding, use the XLR-3 cables shipped with your system. Other

cables may cause humming.

Receiving Your Shipment

Check all boxes for dents or other markings that might indicate damage during transport. If you suspect a

component is damaged, carefully inspect it before setting up the system. If you receive a damaged component,

call Customer Support. See Contacting Customer Support.

Use the packing checklist enclosed with the shipment to ensure you received all parts.

Avoiding Damage from Static Electricity | 9

Page 14

10

Page 15

Connecting Peripherals

Topics in this chapter:

■

Workflow for Connecting Peripherals on page 11

■

Connections Overview on page 12

■

Connecting the Graphics Monitor on page 12

■

Connecting the Keyboard, Mouse, and Tablet on page 13

■

Connecting the Graphics Monitor Calibration Device on page 13

■

Network Connections on page 14

■

Connecting the Autodesk Control Surface on page 15

■

Connecting the Slave Renderer to a Lustre Workstation on page 16

3

Workflow for Connecting Peripherals

This chapter explains how to connect all peripherals, other than video I/O, to the HP Z800 workstation. It

begins with an overview of the backplane, identifying the adapter cards. Next it provides instructions for

connecting the basic peripherals, including the graphics monitor, keyboard, and mouse. It also includes

instructions for connecting the workstation to the house network, and Wire network. For Lustre, it additionally

provides instructions on connecting to Autodesk Control Surfaces and the Slave Renderer. For information

on connecting video I/O, see Setting Up Video Hardware on page 19.

NOTE It is recommended you connect all hardware peripherals, as instructed in this guide, before booting the

workstation for the first time. However, if you are installing or reinstalling the Linux operating system, be sure to

power-down or disconnect any direct attached storage before booting. If you do not, Linux may attempt to

reformat and install on the attached storage, destroying all stored media in the process.

11

Page 16

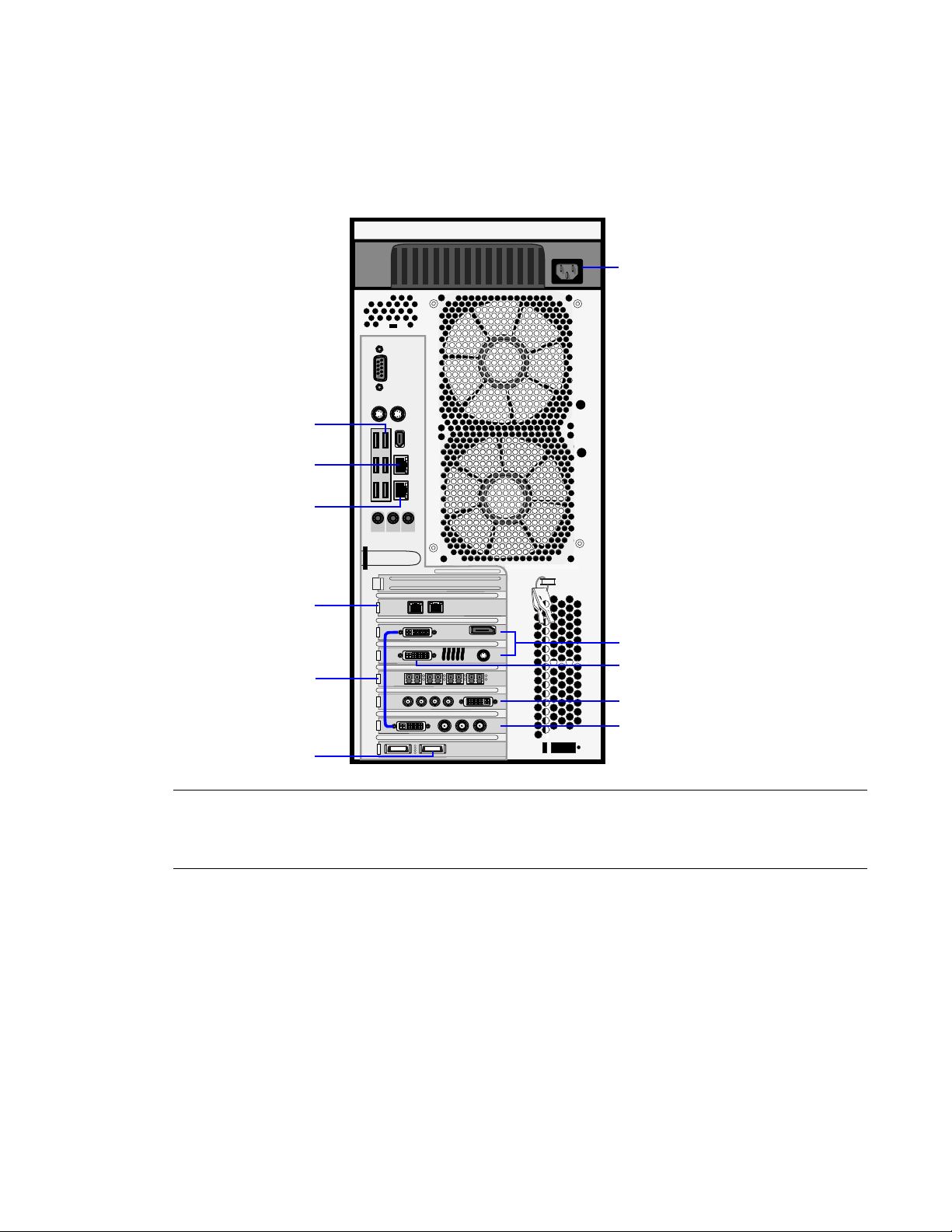

Connections Overview

HP Z800 Workstation

To keyboard, mouse,

tablet, monitor calibrator

To house network

GigE Adapter

to SAN and/or private

network, Incinerator node

Atto Celerity FC84-EN

to direct attached storage

Nvidia Quadro FX 5800

AJA OEM-2K

to video/audio i/o, VTR

Nvidia Quadro SDI Output

to reference monitor, RealTime Deliverables VTR,

sync generator

Power

Qlogic DDR InfinBand

to Wire network, Lustre

Media Server (optional)

To graphics monitor

To Lustre control surface

The following diagram provides an overview of the adapter card positions and general connection

requirements for the HP Z800 workstation.

12 | Chapter 3 Connecting Peripherals

NOTE This diagram illustrates a 2-port GigE adapter in slot 1. You also have the option of using a 10-GigE adapter

or a second ATTO Fibre Channel adapter in slot 1. On the HP Z800 workstation, the slots are numbered 1–7 from

top to bottom. Note also that a number of HP Z800 workstations shipped with a 4-port GigE adapter instead of

the 2-port adapter.

Connecting the Graphics Monitor

The graphics monitor connects to the Nvidia® Quadro® FX 5800 graphics adapter card. This is also an

opportunity to connect the graphics adapter to its add-on card, the Nvidia Quadro SDI Output adapter.

To connect the monitor:

1 Use the short DVI cable (included in TP.FX5800DI) to connect port 1 of the Nvidia Quadro FX 5800

graphics adapter card to the DVI port of the Nvidia Quadro SDI Output adapter (the add-on card).

Page 17

2 Use the longer DVI cable (F0-DVI-25-MN) to connect port 2 of the Nvidia Quadro FX 5800 graphics

adapter card to the DVI-D IN port of the monitor.

NOTE Although each end of the DVI cable appears to be identical, this is not the case. Ensure the connector

labeled Computer is connected to the workstation. Connect the one labeled Monitor to the monitor.

3 Optionally, extend the monitor cable to a machine room using the DVI extender cable

(DL.CAB-HDTV-FO82MM).

Connecting the Keyboard, Mouse, and Tablet

The keyboard, mouse and tablet connect to the workstation by way of the USB extender kit (TP.USB-EXT-410I).

The USB extender kit consists of a remote unit and a local unit, joined by an Ethernet cable

(DL.CAB-RJ45/RJ45).

To connect the keyboard, mouse, and tablet:

1 Connect the keyboard, mouse, and tablet to the remote unit of the USB extender kit.

NOTE For Lustre workstations, a “standalone” tablet can nevertheless be installed and used, even if you are

using an Autodesk Control Surface featuring a built-in tablet.

2 Connect the local unit of the USB extender kit to the workstation port indicated in the HP Z800

connections overview illustration.

3 Use the supplied Ethernet cable to connect the remote and local units. If using an alternate cable, ensure

it is of type Cat5.

To calibrate the tablet:

■ Visual Effects and Finishing: Calibrate all aspects of the tablet, including margins, in the Pointer area of

the creative application’s Preferences menu.

■ Lustre: In Lustre the tablet acts a mouse, and requires no particular calibration.

Connecting the Graphics Monitor Calibration Device

To ensure the graphics monitor accurately represents colors and other visual information, a monitor calibration

device (TP.MON-CAL-LCDCRT) has been supplied. This section explains how to connect the device to the

workstation. It also presents information for later use, once you begin installing the operating system and

application software.

NOTE This section applies only to workstations on which Autodesk Lustre will be installed. For non-Lustre

workstations, refer to the Lustre Color Management User Guide for all steps, including attaching the monitor

calibration device.

To connect the calibration device:

➤ Connect the monitor calibration device to port 4 on the remote unit of the USB extender

(TP.USB-EXT-410I).

Connecting the Keyboard, Mouse, and Tablet | 13

Page 18

To enable the Eye-One calibration utility driver:

■ Once the application software installation is complete, start the eyeone27 daemon on the workstation

by typing the following at the shell prompt: /etc/init.d/eyeone27 start

Network Connections

Network connections enable the workstation to gain access to a wide variety of possible networks. The

Gigabit Ethernet (GigE) ports built-in to the workstation, and those provided by the GigE adapter in slot 1,

can provide access to the following:

■ House network (e-mail, Internet, etc.)

■ Private network

■ Dedicated Autodesk Wire network

■ NAS/SAN storage network

■ Shared network mountpoints

■ Remote Visual Effects and Finishing workstation direct attached storage (via Wire network)

■ Background and/or network rendering

■ Lustre Control Surface

■ Link aggregation (port bonding) switch

The Qlogic™ DDR InfiniBand adapter (optional, slot 7) enables the workstation to gain access to a

high-performance InfiniBand network:

■ Visual Effects and Finishing: InfiniBand is used to enhance the Autodesk Wire network.

■ Lustre: InfiniBand is the high-performance option for connecting to an Incinerator node cluster.

NOTE Even though InfiniBand is point-to-point, an InfiniBand switch is nevertheless needed for any InfiniBand

network. It is not possible to simply connect two workstations together via their InfiniBand adapters, for example.

This section presents information on making the hardware connections to the available networks. The

connections presented here are offered as guidelines. The actual connections you make will depend upon

your particular network topology, including such factors as whether or not you have separate house and

Wire networks (highly recommended), how many network switches you have for each network, etc.

TIP It is recommended that you use Category 6 (Cat-6) cable for the GigE connections.

Visual Effects and Finishing Workstation

As you make the GigE network connections, be sure to take note of the port numbers used. You will need

these later, when configuring the network.

Connect the built-in GigE port as follows:

■ House network

14 | Chapter 3 Connecting Peripherals

Page 19

Connect the GigE adapter as follows:

■ SAN

■ Private and/or dedicated Wire network

■ Link aggregation ( port bonding) switch, etc.

Connect the optional Qlogic DDR InfiniBand adapter as follows:

■ Port one (right-most port) to InfiniBand network switch

For information on network configuration see the Autodesk Visual Effects and Finishing Installation and

Configuration Guide.

Lustre Workstation

As you make the GigE network connections, be sure to take note of the port numbers used. You will need

these later, when configuring the network.

Connect the built-in GigE ports as follows:

■ House network in port 0.

■ Autodesk Control Surface (via network switch) in port 1

Connect the GigE adapter as follows:

■ SAN

■ Private and/or dedicated Wire network

■ Incinerator private network. For more information, see the Autodesk Incinerator Installation and User Guide.

Connect the optional Qlogic DDR InfiniBand adapter as follows:

■ Port one (right-most port) to InfiniBand network switch. This port is also used by Incinerator, to transfer

frames.

For information on network configuration, see the Autodesk Lustre Installation Guide for Linux Workstations

and/or Autodesk Lustre User Guide.

Connecting the Autodesk Control Surface

The Autodesk Control Surface consists of three panels connected to the workstation’s on-board GigE port 1

by way of the supplied network switch. The central panel requires an additional connection to the remote

unit of the USB extender kit.

NOTE This section does not apply to Autodesk Visual Effects and Finishing applications.

This section provides information on making the physical connections needed to operate the Autodesk

Control Surface. For configuration information, see Configuring the Autodesk Control Surface. For user

information, see the Autodesk Control Surface User Guide.

Lustre Workstation | 15

Page 20

1 3 4 5 6 7 8

PWR

NETGEAR

2

Autodesk Control Surface

5V DC 4A Ethernet

Autodesk

Tablet

S

ystem

Power

Link

Activit y

-

+

Network Switch

To USB extender

Ports 3 and 4 to

additional panels

To port 1 on USB Extender

HP Z800 Workstation

NOTE The illustration shows the central panel only (the Colour Grading panel). This panel is easily identified,

since it has both an Ethernet network port and a USB connector. It is also the panel with the built-in tablet.

To connect the Autodesk Control Surface:

1 Connect each panel to a power supply using the AC power adapter cables.

2 Use network cables to connect each panel to the available ports in the network switch.

3 Additionally, connect the Colour Grading panel to the remote unit of the USB extender kit.

4 Use a network cable to connect an available port on the Netgear network switch to the workstation’s

Connecting the Slave Renderer to a Lustre Workstation

16 | Chapter 3 Connecting Peripherals

The Lustre Slave Renderer is a single render node that provides automatic background rendering on a

shot-by-shot basis. It is available for the Lustre Master Station, the Station, and the HD Station.

on-board GigE port 1, as illustrated.

Page 21

NOTE In comparison, Autodesk Incinerator provides “in-line” processing by several nodes at once. For more

information, see the Autodesk Incinerator Installation and User Guide.

Connect the Slave Renderer to a switch on your GigE house network. Note that the Slave Renderer can only

be used by one Lustre workstation.

Although the Lustre Slave Renderer uses a standard GigE network connection, it requires the higher-bandwidth

Cat-6 cable, to accommodate the increased data that is transmitted.

To connect the Slave Renderer:

1 Connect one end of the Cat-6 cable to an available GigE port on your house network switch.

2 Connect the other end to one of the on-board GigE ports of the Slave Renderer machine.

For information on configuring the IP addresses of the network ports that connect the two machines, see

the Autodesk Lustre Installation and Configuration Guide for Linux Workstations

Connecting the Slave Renderer to a Lustre Workstation | 17

Page 22

18

Page 23

Setting Up Video Hardware

Topics in this chapter:

■

Video Hardware Components on page 19

■

Wiring Your Video Components on page 20

■

Setting Up VTR Emulation on page 21

Video Hardware Components

4

This chapter explains how to set up video I/O by connecting the hardware components included in your

shipment. The only video hardware you must provide are a sync generator, VTR, HD/SDI-ready broadcast

monitor and patch panel (if desired).

Included Components

The following components are included in your shipment:

Nvidia Quadro FX 5800 graphics adapter The Nvidia Quadro FX 5800 graphics adapter drives the LCD

monitor directly, and a broadcast monitor via the Nvidia Quadro SDI Output adapter.

Nvidia Quadro SDI Output adapter The Nvidia Quadro SDI Output adapter supplies 2K, HD, or SD video

output to a broadcast monitor, VTR, or SDI projector. The card features a BNC genlock connector that

connects to your facility’s sync generator.

AJA OEM-2K adapter and breakout box The AJA OEM-2K adapter provides video and audio I/O, and VTR

control. The adapter connects to the breakout box, and handles SD (NTSC, PAL), and HD at a depth of 8

and 10 bits.

LCD graphics monitor The graphics monitor features a wide screen with a 16:9 aspect ratio, and a maximum

resolution of 1920x1200.

19

Page 24

AJA HD5DA video distribution amplifier The AJA distribution amplifier receives its signal from the Nvidia

SDI Output adapter and drives a VTR and broadcast monitor. The distribution amplifier is also necessary in

order to use the Real-Time Deliverables feature.

Wiring Your Video Components

Regarding connections to the Nvidia Quadro SDI Output adapter (slot 5), please note the following important

points:

■ Input port A of the VTR connects to the AJA HD5DA distribution amplifier (for 4:2:2 signal), and input

port B connects to the middle connector on the Nvidia SDI Output adapter (for dual link 4:4:4 signal).

The VTR output ports A and B connect to the SDI In A and B ports of the AJA breakout box.

NOTE The output of the AJA OEM-2K adapter, when ported through the AJA breakout box, can be used when

connected to a VTR that is not being used for Real-Time Deliverables. You can switch the output between the

AJA card and the SDI card though the application user interface.

■ VTR control is achieved through the RS-422 port on the AJA breakout box. See Standard VTR Control

Cable Pinouts on page 45.

■ Your facility’s sync source connects to the indicated connector on the Nvidia Quadro SDI Out adapter

card.

WARNING It is critical to connect the adapter card exactly as shown in the diagram to ensure the sync works

correctly.

■ Do not use an SD (NTSC or PAL) sync generator for HD projects. Always use a tri-level sync generator

for HD projects. Using the wrong sync generator for a project may impact the stability of your workstation.

20 | Chapter 4 Setting Up Video Hardware

Page 25

RefLoop

RS-422

SDI1/A SDI2/B

In

Out

Ch.1(L) Ch.2(R)

Y/G/CVBS Pb/B/Y Pr/R/C

VideoMonitorOut

Ch.1/2 Ch. 3/4

In

Out

Ch.5/6

In

OutInOut

Ch.1/2 Out Ch.3/4 Out Ch.5/6Out Ch. 7/8OutCh.1/2In

Ch.3/4In

Ch.5/6In

Ch.7/8In

AES/EBU

Audio

Ch.7/8

AJA

www.aja.com 102053

K3-Box

J1 In1/A In2/B Out1/A

Connectto Host

Out2/B

AJA BOB (Front)

AJA BOB (Back)

HD-SDI Out 1/A to 4:2:2 VTR (or 4:4:4 dual link)

HD-SDI In 2/B to 4:4:4 VTR (dual link 0:2:2)

HD-SDI In 1/A to 4:2:2 VTR (or 4:4:4 dual link)

HD-SDI Out 2/B to 4:4:4 VTR (dual link 0:2:2)

VGA

DVIVGA

(not included)

SD/HD SDI IN 2

Graphics Monitor

SD/HD/SDI Monitor

SD/HD SDI IN 1

AJA HD5DA

OUT 1 INPUT

OUT 2

For Real-Time Deliverables

To SD/HD SDI

Link A onVTR

"Key" to SD/HD SDI Link B,

on VTR (for dual link)

cnyS neG

cnyS neG

from house sync generation

(Trilevel/NTSC/PAL not included)

SD/HD SDI

In / Out

SD/HD SDI In / Out

to RS-422 VTR

machine control

HP Z800 Video I/O

Sync loop out to

NVIDIA Input

Control cable and power

"Fill" to Input

Setting Up VTR Emulation

You can configure your Autodesk Visual Effects, Finishing, and Colour Grading application to emulate a

VTR for both input and output in real time. You control the emulator from the application or device that

sees the Autodesk Visual Effects, Finishing, and Colour Grading application as a VTR.

The following procedure describes how to configure the hardware for VTR emulation. Consult the “VTR

Emulation” chapter in your application User Guide for more information.

Setting Up VTR Emulation | 21

Page 26

To configure hardware for VTR emulation:

1 Connect the video I/O cables between the devices involved in the VTR emulation process

(out-to-in/in-to-out). Make sure the connections support the video standard you want to work with.

If you intend to use the emulator as a Player, it is recommended that you connect one black or colour

bar SDI signal to the input of the system serving as the VTR emulator. This ensures the Player is stable

and correctly synced.

NOTE This applies to an Autodesk Visual Effects and Finishing application only: VTR emulation requires a

workstation with a video adapter card. The Video keyword for the corresponding device must be uncommented

in the software initialization configuration file, init.cfg. See the description of the Video keyword in the Autodesk

Visual Effects and Finishing Installation and Configuration Guide.

2 Connect the audio I/O cables between the devices involved in the VTR emulation process

(out-to-in/in-to-out).

If you intend to use the emulator as a Player, it is recommended that you connect an external AES signal

such as a tone to the input of the system serving as the VTR emulator. This ensures the Player is stable

and correctly synced.

NOTE Connect an RS-422 control cable to the serial ports between the devices used in the VTR emulation

process. This applies to an Autodesk Visual Effects and Finishing application only: Make sure that the serial

ports correspond to those defined by the Emulator keywords in the software initialization configuration file.

See the description of the Emulator keyword in the Autodesk Visual Effects and Finishing Installation and

Configuration Guide.

NOTE The RS-422 cables for VTR emulation require custom pinouts. See VTR Emulation RS-422 Control

Cables on page 46.

3 Make sure the appropriate video and audio sync setup is in place.

22 | Chapter 4 Setting Up Video Hardware

Page 27

Setting Up Audio Hardware

Topics in this chapter:

■

About Audio on page 23

■

Audio Wiring Workflow on page 23

■

Audio Hardware Components on page 24

■

Audio Wiring on page 24

■

Configuring the Lucid ADA 88192 Converter on page 25

■

Audio Keywords in the Visual Effects and Finishing Configuration File on page 28

5

About Audio

Your application uses the Discreet Native Audio subsystem. Discreet Native Audio offers eight audio input

and eight audio output channels. They all use 24-bit audio resolution.

Audio Wiring Workflow

The following procedure provides the general workflow for setting up the audio subsystem of your Visual

Effects, Finishing, and Colour Grading application.

To wire the audio subsystem:

1 Ensure that all of your workstation peripherals and video hardware components are properly connected.

If necessary, refer to Connecting Peripherals on page 11 and Setting Up Video Hardware on page 19.

2 Verify that you have all the required audio hardware components. See Audio Hardware Components

on page 24.

3 Determine whether you want to control the Lucid converter remotely or locally. This affects the way

you wire the audio hardware. See Understanding Remote vs. Local Control of the Lucid Converter on

page 25.

23

Page 28

4 Connect your audio hardware devices. See Audio Wiring on page 24.

5 Configure the Lucid converter for remote or local control. See Configuring the Lucid ADA 88192

Converter on page 25.

6 Set the appropriate keywords in the software initialisation file. See Audio Keywords in the Visual Effects

and Finishing Configuration File on page 28.

Audio Hardware Components

Discreet Native Audio uses the following hardware components, shipped with your system.

Lucid ADA 88192 Audio Converter Converts signals between the workstation and all digital or analog

audio I/O devices.

AJA Balanced Audio breakout box and AJA OEM-2K adapter card The Balanced Audio breakout box is the

audio component of the AJA breakout box. It provides connections for audio I/O. This breakout box connects

to the AJA OEM-2K adapter on your workstation. The OEM-2K adapter provides real-time input and output

of uncompressed SD and HD video signals as well as audio data at 24-bit resolution. The OEM-2K adapter

handles balanced AES/EBU audio signals from the Balanced Audio breakout box. The OEM-2K adapter

supports up to eight tracks of embedded audio.

Audio Wiring

To connect the Discreet Native Audio hardware components to the AJA breakout box, refer to the following

diagram.

24 | Chapter 5 Setting Up Audio Hardware

Page 29

Analog Inputs

AES/EBU Digital Outputs

Analog Outputs

3-4

1-2

1-25-67-8

3-45-67-8

12345678

12345678

AES/EBU Digital Inputs

RS-232

ADATIN 1-8

ADATOUT 1-8

WORD CLOCK

INPUT

OUTPUT

88192 A/D D/A CONVERTER

IN IN

OUT OUT

IN IN

OUT OUT

VTR

AUDIO

GPI

IN OUT

IN

DIGITAL AUDIO

OUT

1/2 3/4 7/85/6 1/2 3/4 5/6 7/8

WClk CVBS

RS.422D

LTC

RS 422C

RS.422B

RS 422A

RefLoop

RS-422

SDI1/A SDI 2/B

In

Out

Ch.1(L) Ch.2(R)

Y/G/CVBS Pb/B/Y Pr/R/C

VideoMonitorOut

Ch.1/2 Ch.3/4

In

Out

Ch.5/6

In

OutInOut

Ch.1/2 Out Ch.3/4 Out Ch. 5/6Out Ch.7/8 OutCh.1/2 In

Ch.3/4 In

Ch.5/6 In

Ch.7/8 In

AES/EBU

Audio

Ch.7/8

AJA

AJA BOB (Front)

Lucid ADA 88192

Converter

to serial port 1 on

Linux workstation

Required for remote

control of converter

Digital

outputs

Input from

analog source

Output to

analog destination

Digital

outputs

Alternative setup

converted from

analog source

Configuring the Lucid ADA 88192 Converter

You must manually configure the Lucid converter for either remote or local control. This section describes

how to use the controls on the front of the converter to adjust settings, and lists the proper settings for

remote control and for local control.

Understanding Remote vs. Local Control of the Lucid Converter

You can control the converter either remotely or locally. Remote control of the converter means that you

adjust converter settings through the audio preferences of the application. If you want to control the converter

Configuring the Lucid ADA 88192 Converter | 25

Page 30

remotely, you must connect the converter to the serial port of the HP Z800 workstation. Local control means

you adjust converter settings manually, using the controls on the front of the converter. Controlling the

converter remotely is the recommended method as it does not require physical access to the converter to

change settings.

Whether you control the converter remotely or locally, you should take any necessary precautions to prevent

inadvertent adjustments to settings via the controls on the front of the converter. For example, if the

converter is one of several in a machine room, you might label each with the name of the computer to

which it is connected, along with whether control is local or remote.

Adjusting Lucid ADA 88192 Converter Settings

You configure the converter through a series of setup menus that appear in the display on the front of the

converter. Use the encoder dial and button immediately to the right of the display to navigate these menus

and adjust settings.

The top level setup menu contains the following menu items: ADAT, AES, Analog, Meter, Route, Sync, and

System. Each of these menu items takes you into a submenu, from which you can select and adjust settings.

The procedures below provide basic information on navigating and adjusting settings. If you require additional

information, refer to the Lucid ADA 88192 manual included with your shipment.

To navigate menus and adjust settings:

➤ Use the encoder dial and the button as follows.

Do this:To:

Select a menu option

menu tree

setup menu

To reset all settings to their factory defaults:

1 In the top level setup menu, select System, then select Miscellany.

2 In the Miscellany menu, select Defaults: RESET.

All settings are reset to their factory defaults.

NOTE The factory default for the items in the AES setup menu is SRC ON. Both local and remote control

require these items to be set to SRC OFF. If you reset to defaults, be sure to manually set these items back to

OFF (you cannot adjust these settings remotely).

Rotate the dial to highlight the option, then press the dial to select that option. If the option

you select has choices (as, for example, in the Route menu), rotate the dial again to move

through the choices, and press the dial to select an option.

Press the button.Back up one level in the

Press the button. Repeat until you are in the top level setup menu.Navigate to the top level

26 | Chapter 5 Setting Up Audio Hardware

Page 31

Lucid ADA 88192 Converter Settings for Remote Control

You must configure the following settings to control the converter remotely. Any setting not listed here

either has no effect with the application or can be set through the audio preferences of the application.

CommentMenu ItemMenu

ADAT

AES

Analog

Analog INs: SoftClip

Miscellany

ADAT INs: SRC ON

ADAT INs: SMUX OFF

AES IN1+2: SRC OFF

AES IN3+4: SRC OFF

AES IN5+6: SRC OFF

AES IN7+8: SRC OFF

IN1+2: SoftClip OFF

IN3+4: SoftClip OFF

IN5+6: SoftClip OFF

IN7+8: SoftClip OFF

3 is the recommended settingClip Detect: 3Meter

8 is the recommended settingRoute Unit: 8System

Lucid ADA 88192 Converter Settings for Local Control

You must configure the following settings to control the converter locally. Any setting not listed here either

has no effect with the application or can be set to any of the values available for it.

CommentMenu ItemMenu

ADAT

ADAT INs: SRC ON

ADAT INs: SMUX OFF

AES

Analog

Analog INs: SoftClip

Analog

Analog INs: Gain

Analog

Analog OUTs: Level

Route

AES IN1+2: SRC OFF

AES IN3+4: SRC OFF

AES IN5+6: SRC OFF

AES IN7+8: SRC OFF

IN1+2: SoftClip ON

IN3+4: SoftClip ON

IN5+6: SoftClip ON

IN7+8: SoftClip ON

set each input channel to a value in

the range -95.5 to +31.5 dB

set either -10 or +4 for each output

channel

For analog audio:

AES INs --> ADAT OUTs

Analog INs --> AES OUTs

AES INs --> Analog OUTs

3 is the recommended settingClip Detect: 3Meter

If these options do not appear, verify that Route Unit

(in the System, Miscellany menu) is set to 8.

Lucid ADA 88192 Converter Settings for Remote Control | 27

Page 32

CommentMenu ItemMenu

For digital audio:

AES INs --> ADAT OUTs

AES INs --> AES OUTs

AES INs --> ANALOG OUT

External AES 1+2 is the recommended setting.Internal OFFExternal AES 1+2Sync

Route Unit: 8System

Miscellany

Audio Keywords in the Visual Effects and Finishing Configuration File

There are two keywords in the software initialisation file (by default, init.cfg) that must be uncommented

and set to the correct values to ensure Discreet Native Audio works properly. The first, Audiodevice, enables

Discreet Native Audio. The second, MidiDevice, determines whether control of the Lucid converter is remote

or local.

NOTE This does not apply to Lustre.

Setting:Keyword:

AJAAudiodevice

MidiDevice

For additional information on these keywords and help setting them, see the Autodesk Visual Effects and

Finishing Installation and Configuration Guide.

If you are using local control of the converter, comment out this keyword.

If you are using remote control of the converter, uncomment the keyword, set the

serial port parameter to /dev/ttyS1 and leave all other parameters set to their default

value.

28 | Chapter 5 Setting Up Audio Hardware

Page 33

Connecting Storage

Topics in this chapter:

■

Connecting Media Storage on page 29

■

Connecting Archiving Storage on page 37

Connecting Media Storage

6

Overview

The workstation can be connected to two types of media storage.

■ Stone Direct XR-series disk arrays Autodesk's high-performance direct-attached storage (DAS) solution

designed to address the different real-time playback requirements of various workflows. Direct attached

storage devices provide storage to individual workstations, and can be made available to other Autodesk

Visual Effects and Finishing workstations via the Autodesk Wire network.

NOTE A Lustre workstation equipped with Incinerator does not use DAS storage. Incinerator storage is attached

to the Lustre Media Server, accessed by way of the InfiniBand network.

■ A SAN A storage infrastructure that allows multiple workstations to share simultaneous access to a

central storage enclosure.

About Autodesk Stone Direct Storage

Autodesk Stone Direct XR-series disk arrays provide two types of enclosures: a RAID enclosure (also called

an XR enclosure), and an EBOD enclosure (also called an XE enclosure). XR RAID enclosures contain two

RAID controllers.

29

Page 34

Autodesk Stone Direct uses hardware RAID to provide high performance, reliability, and protection against

data loss.

The following table outlines the drive sizes and maximum number of enclosures supported by each model

of Autodesk Stone Direct XR-series storage arrays.

Storage model

Disk sizeMax number of XE enclosures per

XR enclosure

146GB4XR 5402

146 GB or 300 GB4XR 5412

300 GB or 450 GB7XR 6412

450 GB7XR 6500

XR 6500 and XR 6412 arrays require a single XR RAID enclosure for 2-loop or 4-loop hardware RAID storage

configurations .

XR 5412 and XR 5402 arrays require a single XR RAID enclosure for 2-loop configurations, or two RAID

enclosures for 4-loop configurations.

These configurations may include additional XE expansion enclosures, up to the maximum number supported.

You can increase storage capacity by adding disk arrays.

A number of Stone Direct configurations will ensure optimal playback of the most demanding formats.

Expected PeformanceLoopsStorage Configuration

One 2-loop connectionStone Direct XR

■ One stream SD/HD 10-bit (32 channel/8-bits per channel audio), or

■ One stream 2K 12-bit unpacked (8

channel/8-bits per channel audio)

Stone Direct XR plus Stone Direct

XE

2 x Stone Direct XR

Two 2-loop connections (if permitted by

chassis)

– or –

One 2-loop connection

Two 2-loop connections (one per enclosure)

■ Two streams SD/HD 10-bit (32 channel/8-bits per channel audio), or

■ One stream 2K 12-bit unpacked (8

channel/8-bits per channel audio)

■ Two streams SD/HD 10-bit (32 channel/8-bits per channel audio), or

■ One stream 2K 12-bit unpacked (8

channel/8-bits per channel audio)

Connecting the HP Z800 ATTO Fibre Channel Adapter

On HP Z800 workstations or Lustre Media Servers, connections to media storage are made using the ATTO

Celerity FC84-EN fibre channel adapter, located in slot five (top to bottom).

NOTE If you need more storage connections, you can also have your HP Z800 workstation configured with a

second ATTO fibre channel adapter in slot 1, instead of the GigE adapter.

30 | Chapter 6 Connecting Storage

Page 35

The fibre channel adapter is equipped with four ports, called loops. You can connect your storage enclosure

FC port 1

FC port 2

FC port 3

FC port 0

To storage assembly

(Optional) To storage (4 loop),

archiving device or SAN

}

}

to the fibre channel cards using either 2 loops or 4 loops. A 2-loop device can be connected to either the

inner pair of ports or the outer pair of ports. A 4-loop device requires both the inner pair and the outer pair.

NOTE If you are not using all the ports of a fibre channel adapter, terminate the two unused ports with the FC

loopback couplers that shipped with your system. Terminating these ports significantly decreases the time required

to boot the system.

Connecting the HP Z800 ATTO Fibre Channel Adapter | 31

Page 36

Connecting Storage Enclosures

I

0

I

0

0

0

0

0

0

0

I

0

I

0

HOST1

8

4

1/2

HOST0

8

4

1/2

C

A

S

HOST1

8

4

1/2

HOST0

8

4

1/2

C

A

S

I

0

I

0

0

0

0

0

0

0

I

0

I

0

0

0

0

0

0

0

I

0

I

0

0

0

0

0

0

0

XR RAID Enclosure

XE (EBOD)_Expansion Enclosure

XE (EBOD) Expansion Enclosure

XE (EBOD) Expansion Enclosure

XE (EBOD) Expansion Enclosure

Single XR 6500 RAID enclosure, 2 loops

To FC adapter on workstation / LMS (port 1)

To FC adapter (port 2)

Cabling for additional enclosures

The following diagrams illustrate how to cable XR-series hardware RAID storage enclosures. Cable your

storage exactly as illustrated to ensure proper functionality.

Note that the XR 6500 series and XR 6412 series storage assemblies do not support configurations with two

XR RAID enclosures.

WARNING Do not power on your storage before installing Linux, otherwise the Red Hat installer might attempt

to format the storage array and use it as the system disk.

XR 6500 Wiring Diagrams

The following diagrams illustrate 2-loop and 4-loops connections for XR 6500 series storage assemblies.

A XR 6500 RAID enclosure supports a maximum of seven XE expansion enclosures.

32 | Chapter 6 Connecting Storage

Page 37

I

0

I

0

0

0

0

0

0

0

I

0

I

0

HOST1

8

4

1/2

HOST0

8

4

1/2

C

A

S

HOST1

8

4

1/2

HOST0

8

4

1/2

C

A

S

I

0

I

0

0

0

0

0

0

0

I

0

I

0

0

0

0

0

0

0

XR RAID Enclosure

XE (EBOD) Expansion Enclosure

XE (EBOD) Expansion Enclosure

XE (EBOD) Expansion Enclosure

Single XR 6500 RAID enclosure, 4 loops

To FC adapter (port 2)

To FC adapter (port 3)

Cabling for additional enclosures

To FC adapter on workstation / LMS (port 0)

To FC adapter (port 1)

NOTES:

■ In a 4-loop configuration, you need a minimum of one XE expansion enclosure attached to the XR 6500

RAID enclosure.

■ The total number of enlcosures must be an even number.

Connecting Storage Enclosures | 33

Page 38

XR 6412 Wiring Diagrams

Cabling for additional enclosures

XE (EBOD) Expansion Enclosure

0

1

0

ID

0

1

0

ID

XR RAID Enclosure

0

!

0

!

FACTORY

USEONLY

FACTORY

USEONLY

XE (EBOD) Expansion Enclosure

0

1

0

ID

0

1

0

ID

XE (EBOD) Expansion Enclosure

0

1

0

ID

0

1

0

ID

XE (EBOD) Expansion Enclosure

0

1

0

ID

0

1

0

ID

To FC adapter on workstation / LMS (port 1)

To FC adapter (port 2)

Single XR 6412 RAID enclosure, 2 loops

The following diagrams illustrate 2-loop and 4-loops connections for XR 6412 series storage assemblies.

NOTE A XR 6412 RAID enclosure supports a maximum of seven XE expansion enclosures.

34 | Chapter 6 Connecting Storage

Page 39

Cabling for additional enclosures

XE (EBOD) Expansion Enclosure

0

1

0

ID

0

1

0

ID

XR RAID Enclosure

0

!

0

!

FACTORY

USEONLY

FACTORY

USEONLY

XE (EBOD) Expansion Enclosure

0

1

0

ID

0

1

0

ID

XE (EBOD) Expansion Enclosure

0

1

0

ID

0

1

0

ID

XE (EBOD) Expansion Enclosure

0

1

0

ID

0

1

0

ID

To FC adapter on workstation / LMS (port 0)

To FC adapter (port 3)

To FC adapter (port 1)

To FC adapter (port 2)

Single XR 6412 RAID enclosure, 4 loops

NOTE In a 4-loop configuration with a XR 6412 RAID enclosure, you need a minimum of one XE expansion

enclosure attached to the XR RAID enclosure.

Connecting Storage Enclosures | 35

Page 40

XR 5402 and XR 5412 Wiring Diagrams

To FC adapter on workstation / LMS (port 1)

To FC adapter (port 2)

XR RAID Enclosure

XE (EBOD) Expansion Enclosure

XE (EBOD) Expansion Enclosure

XE (EBOD) Expansion Enclosure

XE (EBOD) Expansion Enclosure

Cabling for additional enclosures

Single XR 5402 / 5412 RAID enclosure, 2 loops

The following digrams illustrate 2-loop and 4-loop connections for XR 5402 and XR 5412 series storage

assemblies.

XR 5402 and XR 5412 series storage assemblies support 2-loop configurations with one XR RAID enclosure,

and 4-loop configurations with two XR RAID enclosures.

NOTE The XR 5402 and XR 5412 RAID enclosures support a maximum of four XE expansion enclosures.

36 | Chapter 6 Connecting Storage

Page 41

XR RAID Enclosure XR RAID Enclosure

XE (EBOD) Expansion Enclosure XE (EBOD) Expansion Enclosure

XE (EBOD) Expansion EnclosureXE (EBOD) Expansion Enclosure

Cabling for additional enclosures

To FC adapter on workstation / LMS (port 1)

To FC adapter (port 2)

To FC adapter on workstation / LMS (port 0)

To FC adapter (port 3)

First storage assembly Second storage assembly

Two XR 5402 / 5412 RAID enclosures, 4 loops

NOTE In a configuration with two XR RAID enclosures, the number of XE extension enclosures per XR RAID

enclosure must be the same. The total number of enclosures in the storage assembly must be an even number.

Connecting Archiving Storage

NOTE This section does not apply to Autodesk Lustre.

Visual Effects and Finishing applications support archiving to USB 2.0, FireWire® (IEEE 1394) and fibre

channel devices. This includes filesystems, VTRs and tape drives. This section discusses the requirements for

filesystem and tape drive devices. For information on connecting a VTR, see Connecting Video Components.

Filesystem Devices

USB 2.0 and FireWire (IEEE 1394) attached devices must be formatted with one of the following filesystems:

XFS, ext2, ext3, or HFS (Mac®). NTFS is not supported.

NOTE Care must be taken to ensure that the filesystems used to store archives are reliable, stable and properly

backed up so as to protect the archive integrity. This functionality is not provided by the application.

SCSI Tape Drive Devices

SCSI tape drives can be connected to a fibre channel port of the workstation by way of a fibre-channel-to-SCSI

bridge, such as the Atto FibreBridge 2390D. The tape drive device must meet two criteria. First, the device’s

Connecting Archiving Storage | 37

Page 42

driver must accept standard UNIX tape device calls. Second, the device must be certified for use with the

currently supported version of the workstation operating system and kernel.

While Autodesk Media and Entertainment makes no certification statement about any tape drive device,

you can use the “Tape Drive Test” plug-in in Autodesk SystemCentral to test SCSI tape drives for compatibility.

For more information, see the Autodesk System Central User Guide.

38 | Chapter 6 Connecting Storage

Page 43

SCSI Tape Drive Devices | 39

Page 44

40

Page 45

Configuring the Workstation BIOS

Topics in this chapter:

■

HP Z800 BIOS Settings on page 41

■

Restoring BIOS to Default Factory Settings on page 42

■

Updating your System BIOS on page 43

HP Z800 BIOS Settings

7

After wiring the workstation and before installing Linux, turn the workstation on and check the BIOS version

and BIOS settings.

WARNING If BIOS settings are not set up correctly before installing Linux, you will need to reinstall the OS.

The certified BIOS version for your workstation is 1.06.

Make sure the BIOS version number that appears on screen while booting the workstation matches the

certified version. If the versions do not match, update the BIOS to the certified version, after configuring

BIOS settings. BIOS update instructions are at the end of this chapter.

To adjust system BIOS settings, press F10 while booting the workstation.

The following table lists the Autodesk certified BIOS settings. Items not listed are set to their default factory

settings. See Restoring BIOS to Default Factory Settings on page 42 for instructions on restoring your BIOS

settings to factory defaults.

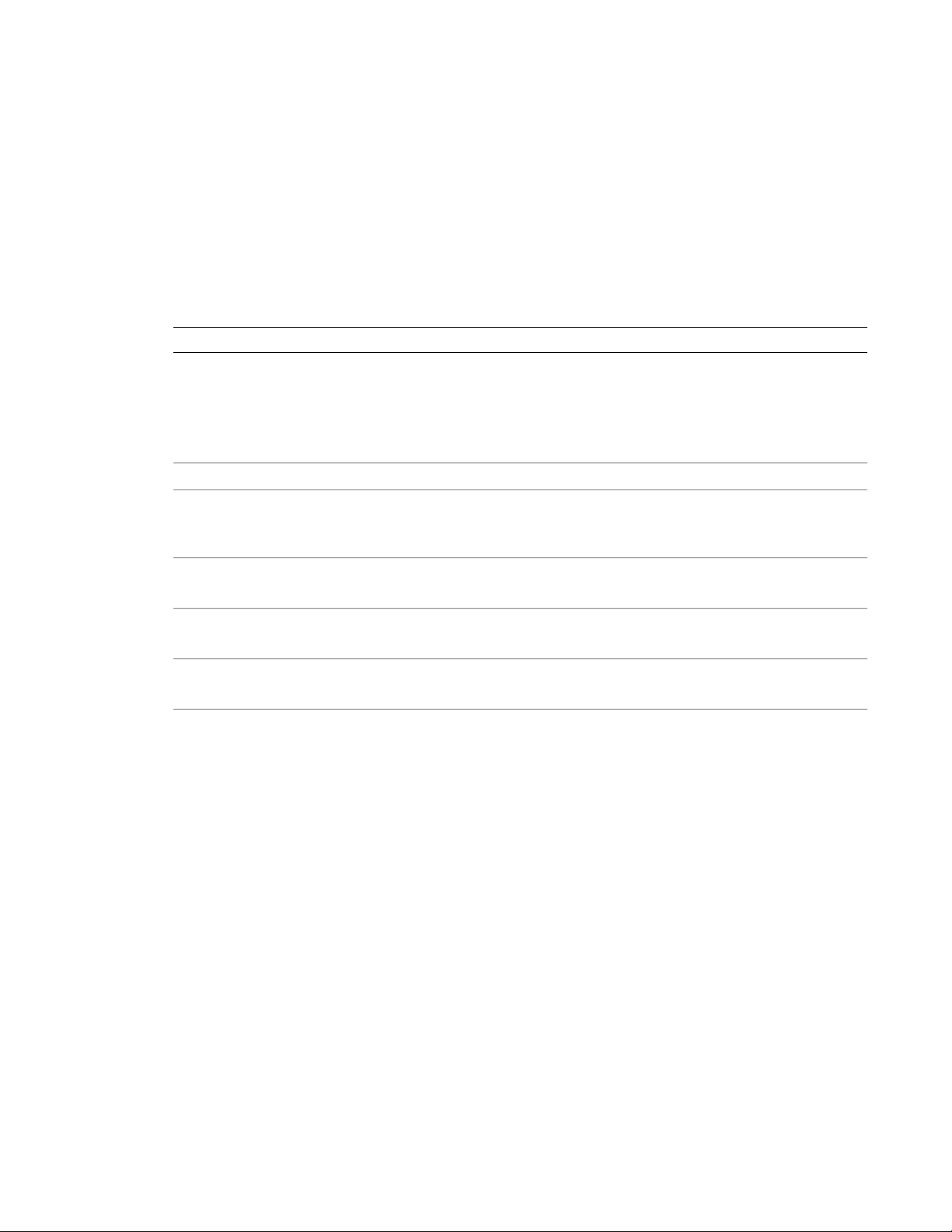

ValueItemSubmenuBIOS Menu

RAID+AHCISATA EmulationStorage OptionsStorage

41

Page 46

Optical DriveBoot Order

USB Device

ValueItemSubmenuBIOS Menu

<hard drive model>Hard Drive

Integrated SATA

DisableRuntime Power ManagementOS Power ManagementPower

NormalIdle Power Saving

DisableMWAIT Aware OS

DisableACPI S3 Hard Disk Reset

DisableSATA Power ManagementHardware Power Management

DisableIntel Turbo Boost Technology

EnableHyper-ThreadingProcessorsAdvanced

EnableMemory Node InterleaveChipset/Memory

DisableNUMA Split Mode

DisableS5 Wake on LANDevice Options

DisableInternal Speaker

DisableNIC PXE Option ROM Download

DisableOption ROM DownloadSlot 1 PCIe2 x8(4)

DisableOption ROM DownloadSlot 3 PCIe2 x8(4)

DisableOption ROM DownloadSlot 4 PCIe2 x16(8)

DisableOption ROM DownloadSlot 6 PCI32

Restoring BIOS to Default Factory Settings

If necessary, perform the following procedure to restore the BIOS settings to factory defaults.

To restore default factory BIOS settings:

1 Press F10 while booting the workstation to enter the system BIOS.

2 In the File menu, select Default setup, then Restore Factory Settings as Default.

3 Press F10 to accept the changes.

4 In the File menu, select Apply Defaults and Exit, then press F10 to confirm.

The factory system defaults are restored.

5 When the workstation reboots, press F10 again to re-enter the BIOS, and configure the recommended

Autodesk settings.

42 | Chapter 7 Configuring the Workstation BIOS

Page 47

Updating your System BIOS

The BIOS version installed on your system appears on the screen while booting the workstation. The following

procedure describes how to update a workstation to the certified BIOS version required by your application.

NOTE Before attempting to update the system BIOS, make sure the SATA Emulation option is properly set,

otherwise your optical drive is not detected.

To update the BIOS on your workstation:

1 Download the latest version of the DKU from Autodesk and extract the tar file into a temporary directory.

2 Go to the /Utils/BIOS subdirectory of the DKU directory.

In the BIOS directory there is a subdirectory for each platform supported by the current version of your

Visual Effects, Finishing, and Colour Grading application.

3 Go to the directory that corresponds to your hardware platform.

The directory contains an .iso disc image file for each supported BIOS version, as well as a README text

file that describes each file, and provides information on updating the BIOS.

4 Burn the correct .iso file to a CD and place it in the DVD-ROM drive on the workstation.

5 Reboot your workstation and press F10 to enter the system BIOS.

6 Optional: Press F8 to select a language.

7 In the Storage menu, select Storage Options, and set SATA Emulation to IDE. This option allows the

BIOS to be updated from a CD.

8 Press F10 to confirm the change.

9 In the File menu, select Save Changes and Exit.

The workstation reboots.

10 Press F10 to enter the BIOS again.

11 In the File menu, select Flash System ROM.

A dialog box prompts you to select between USB and CD-ROM.

NOTE If the CD-ROM option does not appear, SATA emulation was not set correctly. Reboot your machine

and redo this procedure from step 4.

12 Select CD-ROM and press F10 to confirm.

13 Select the .bin file.

A confirmation dialog box appears.

14 Press F10 to confirm.

15 Press any key.

A message stating that the system ROM flash was successful appears.

16 In the Storage menu, select Storage Options and set SATA Emulation back to the value documented in

the previous table. This setting is required for Linux to work properly.

17 Press F10 to confirm the change.

18 Verify all the BIOS settings again to make sure they correspond to the recommended settings.

19 In the File menu, select Save Changes and Exit.

Updating your System BIOS | 43

Page 48

The workstation reboots.

44 | Chapter 7 Configuring the Workstation BIOS

Page 49

VTR Control Cable Pinouts

Topics in this chapter:

■

Standard VTR Control Cable Pinouts on page 45

■

VTR Emulation RS-422 Control Cables on page 46

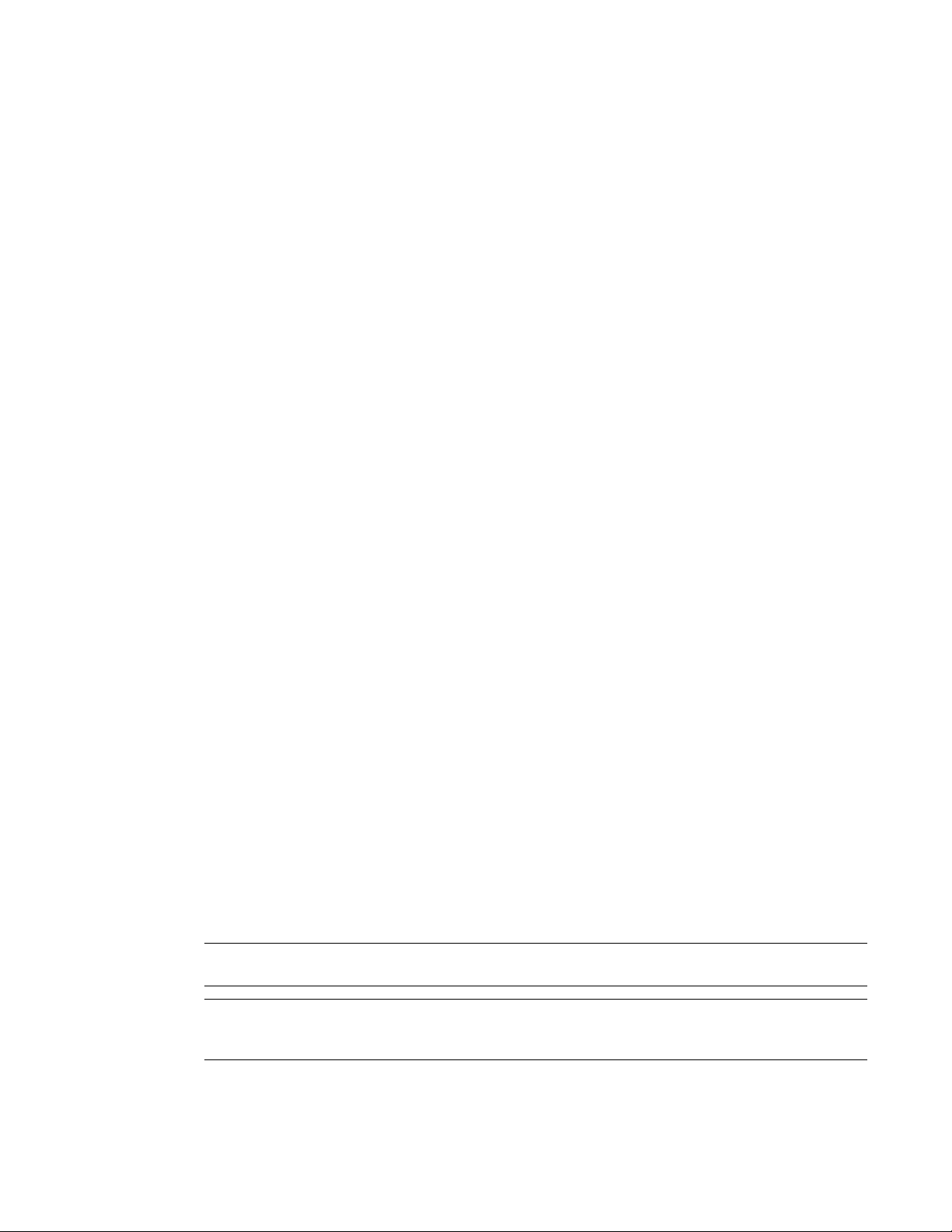

Standard VTR Control Cable Pinouts

The following diagram depicts the RS-422 control cable pinouts for the standard VTR control cable.

A

45

Page 50

1

6

2

7

3

8

4

9

5

1

6

2

7

3

8

4

9

5

WHT

BLK

BLK

RED

GND

OEM-2K: MALE DB9

OEM-LH: FEMALE DB9

MALE DB9

2 - RX -

7 - RX +

3 - TX -

8 - TX +

2 - TX -

7 - TX +

3 - RX -

8 - RX +

4 - GND (SHIELD) 4 - GND (SHIELD)

PAIR 1

PAIR 2

Standard VTR Control Cable:

Linux(AJA) Controlling VTR (Normal Video I/O Control Cable)

Linux(AJA)

VTR

RS-422

VTR Emulation RS-422 Control Cables

Custom cables are required to control the VTR emulator. The pinouts required by the cable depend on the

workstation and device involved in the VTR emulation process. The following diagrams depict the control

cable pinouts required for the most common VTR emulation setups.

46 | Appendix A VTR Control Cable Pinouts

Page 51

Linux Master to Linux Emulator

1

6

2

7

3

8

4

9

5

1

6

2

7

3

8

4

9

5

WHT

BLK

BLK

RED

GND

2 -RX-

7 -RX+

8 -TX-

3 -TX+

8 -TX-

3 -TX+

2 -RX-

7 -RX+

4 - GND (SHIELD)

4 - GND (SHIELD)

PAIR1

PAIR2

VTR-Emulation Control Cable

Linux(AJA) Master Controlling Linux(AJA) Emulator

Linux(AJA) Master Linux(AJA) Emulator

OEM-2K: MALE DB9

OEM-LH: FEMALE DB9

OEM-2K: MALE DB9

OEM-LH: FEMALE DB9

RS-422

Linux Master to Linux Emulator | 47

Page 52

Third-Party Master to Linux Emulator

WHT

BLK

BLK

RED

GND

MALE DB9

2 -RX -

7 -RX +

8 -TX-

3 -TX+

8 -TX -

3 -TX+

2 -RX -

7 -RX+

4 - GND (SHIELD)

4 - GND (SHIELD)

PAIR 1

PAIR 2