HP PageWide Pro 352, PageWide Pro 377, PageWide Pro 452, PageWide Pro 477, PageWide Pro 552 Troubleshooting Manual

...Page 1

Troubleshooting Manual

PageWide Pro 352/377, 452/477, and 552/577

www.hp.com/support

377

477

577

352

452

552

Page 2

Page 3

HP PageWide Pro 352/377, 452/477, and

552/577

Troubleshooting Manual

Page 4

Copyright and License

Trademark Credits

© Copyright 2016 HP Development Company,

L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or

omissions contained herein.

Edition 1, 3/2016

ENERGY STAR® and the ENERGY STAR® mark are

registered U.S. marks.

Page 5

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging the

product.

WARNING! Warnings alert you to specic procedures that you should follow to avoid personal injury,

catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 6

iv Conventions used in this guide ENWW

Page 7

Table of contents

1 Theory of operation ....................................................................................................................................... 1

Basic operation ...................................................................................................................................................... 2

Function structure ............................................................................................................................... 2

Operation sequence ............................................................................................................................ 6

System control ....................................................................................................................................................... 8

Formatter and data path ..................................................................................................................... 8

Engine control ..................................................................................................................................... 9

Pen interface (I/F) .............................................................................................................................. 11

Power supply ..................................................................................................................................... 11

Print subsystem ................................................................................................................................................... 12

Printbar .............................................................................................................................................. 13

Printbar air management system ..................................................................................................... 14

Printbar lift ........................................................................................................................................ 15

Ink cartridges ..................................................................................................................................... 15

Optical scan carriage ......................................................................................................................... 15

Print system operational states ....................................................................................................... 15

Paper-handling system ....................................................................................................................................... 17

Input trays ......................................................................................................................................... 24

Paper path zones ............................................................................................................................... 24

Servicing system .................................................................................................................................................. 28

Service sled ........................................................................................................................................ 30

Transmission system ........................................................................................................................................... 31

Components ...................................................................................................................................... 32

States ................................................................................................................................................. 32

Aerosol management system ............................................................................................................................. 34

Document feeder system (377/477/577/P57750 models) ............................................................................... 36

Document feed system ..................................................................................................................... 36

Rollers and sensors in the document feeder .................................................................................... 36

Document feeder operation .............................................................................................................. 37

Deskew operation .............................................................................................................................. 38

Scanning and image capture system (377/477/577/P57750 models) .............................................................. 39

Fax functions and operation (377/477/577/P57750 models) ........................................................................... 40

ENWW v

Page 8

Computer and network security features ......................................................................................... 40

PSTN operation .................................................................................................................................. 40

The fax subsystem ............................................................................................................................ 40

Fax card in the fax subsystem ........................................................................................................... 40

Fax page storage in ash memory .................................................................................................... 42

2 Solve problems ............................................................................................................................................ 43

Restore the factory-set defaults ......................................................................................................................... 44

Menu access ......................................................................................................................................................... 44

Menu access on monochrome control panels .................................................................................. 45

Menu access on color control panels ................................................................................................ 47

Perform tap tests and interpret results .............................................................................................................. 49

10 tap test results (OOBE states) ...................................................................................................... 49

12 tap test results (REDI sensor values) ........................................................................................... 51

61 tap results (Align and color calibrations) ..................................................................................... 53

909 tap test results (BDD status) ...................................................................................................... 54

Verify that the pig tails have an adequate seal ................................................................................ 55

Troubleshooting owchart .................................................................................................................................. 56

Front-panel error codes ....................................................................................................................................... 57

Control-panel messages ...................................................................................................................................... 60

Error-related symptoms ...................................................................................................................................... 64

Check symptoms .................................................................................................................................................. 65

Power and electronics ....................................................................................................................... 65

Solve print quality problems ............................................................................................................. 67

Solve paper handling problems ........................................................................................................ 96

Solve connectivity problems ........................................................................................................... 113

Solve copy/scan problems .............................................................................................................. 119

Solve fax problems .......................................................................................................................... 126

Solve memory device problems ...................................................................................................... 138

Appendix A Event log codes ........................................................................................................................... 139

Interpret event log codes .................................................................................................................................. 140

Index ........................................................................................................................................................... 151

vi ENWW

Page 9

List of gures

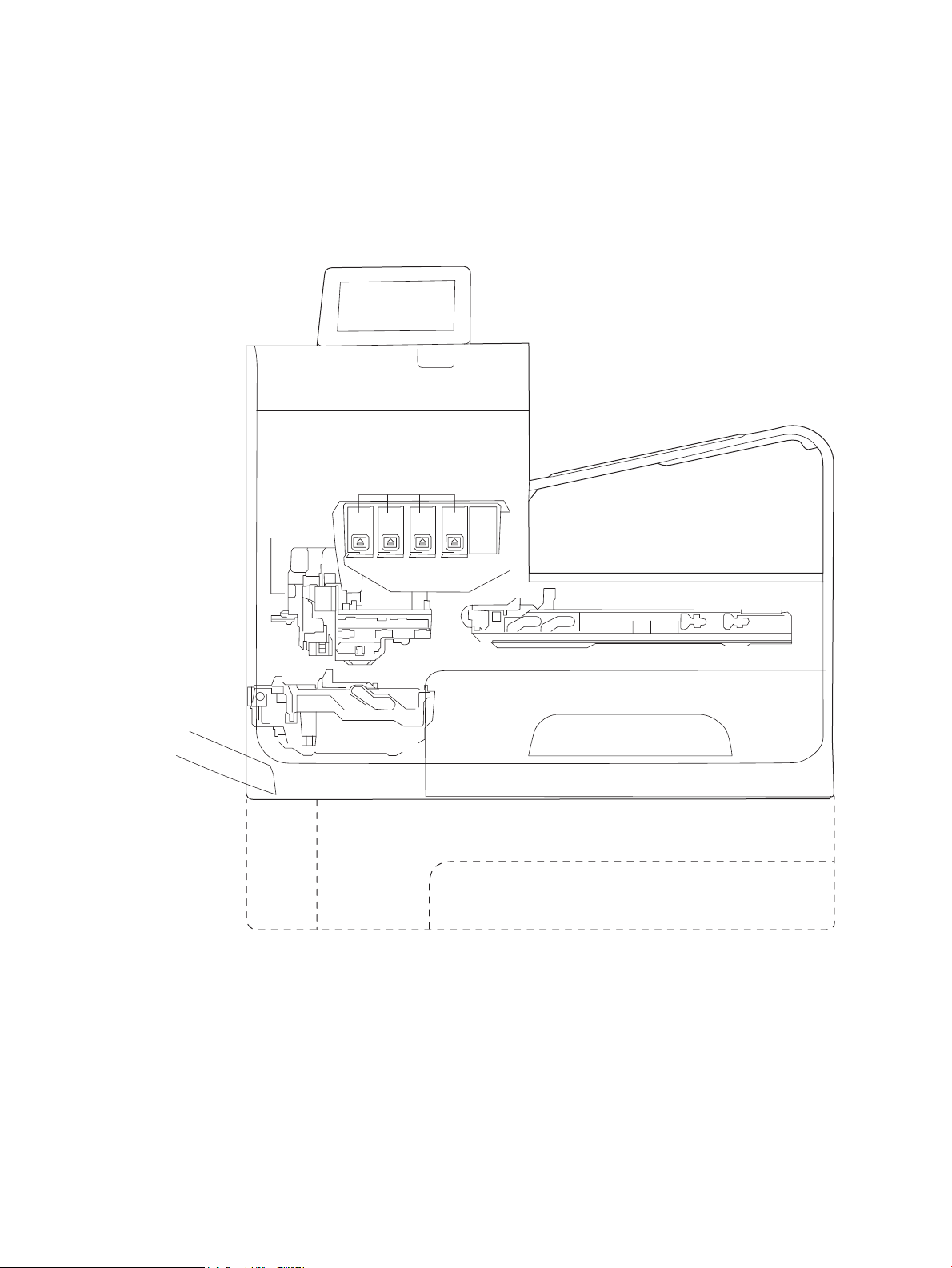

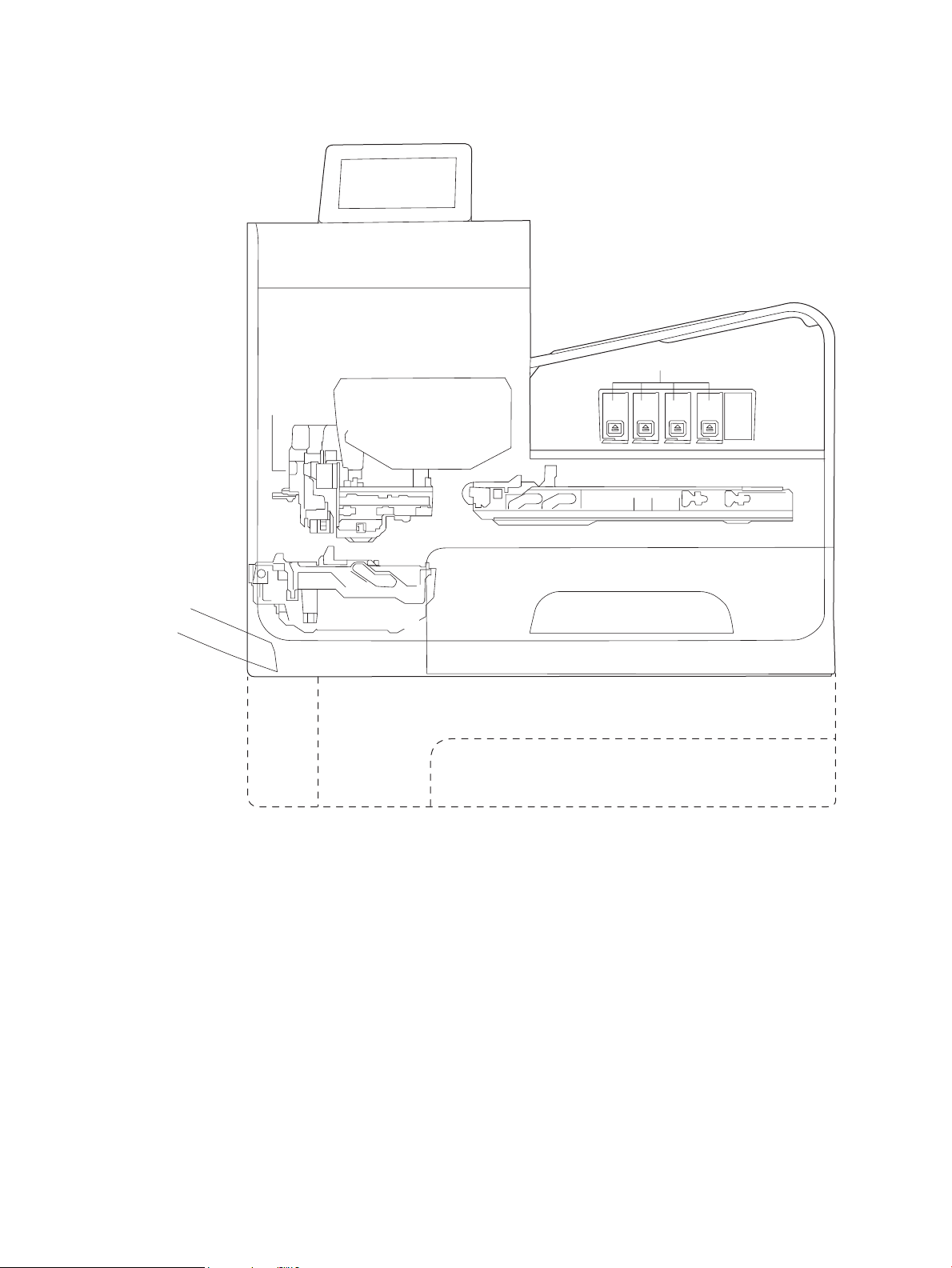

Figure 1-1 Main components (352/452 models) ................................................................................................................. 2

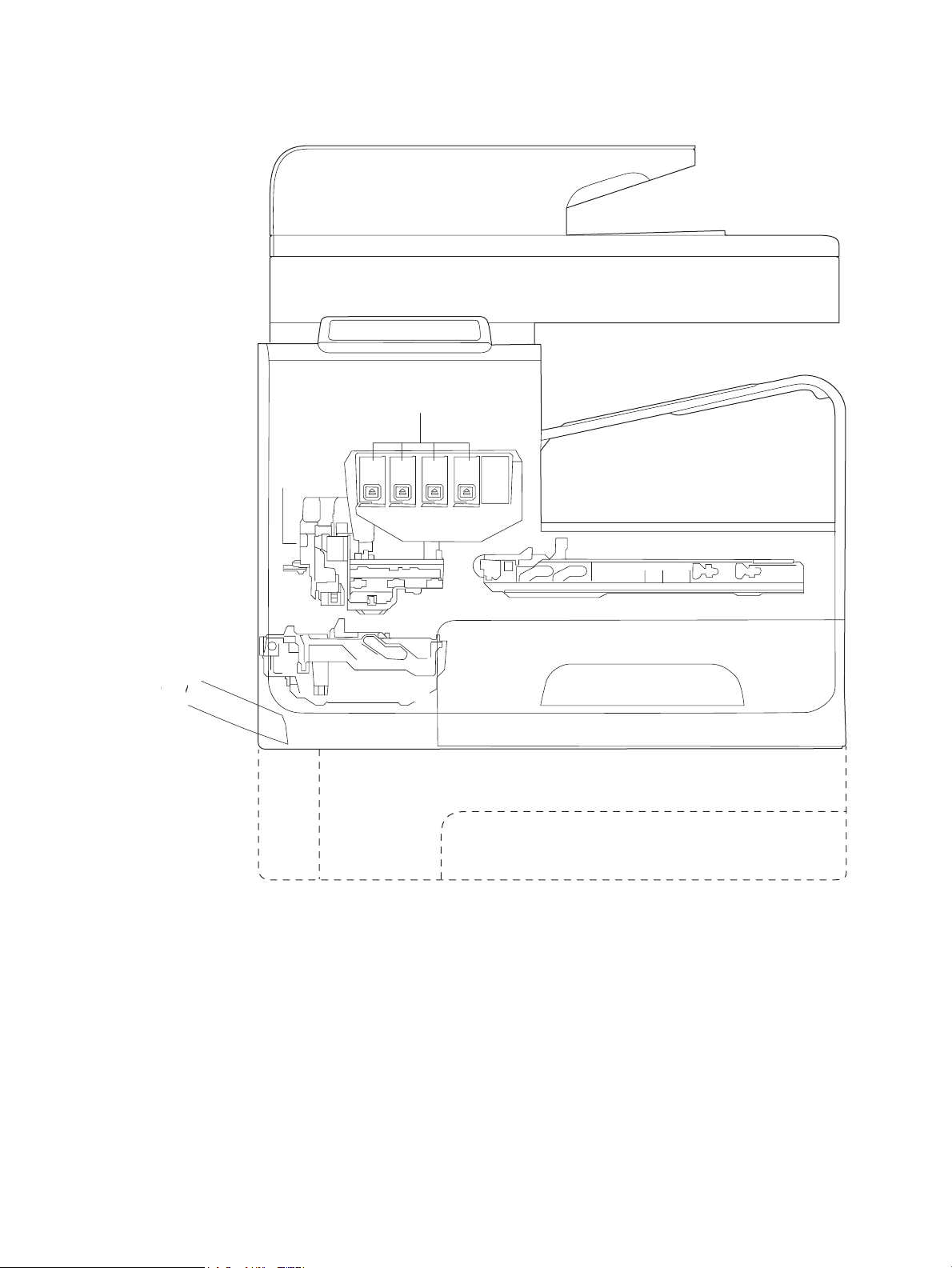

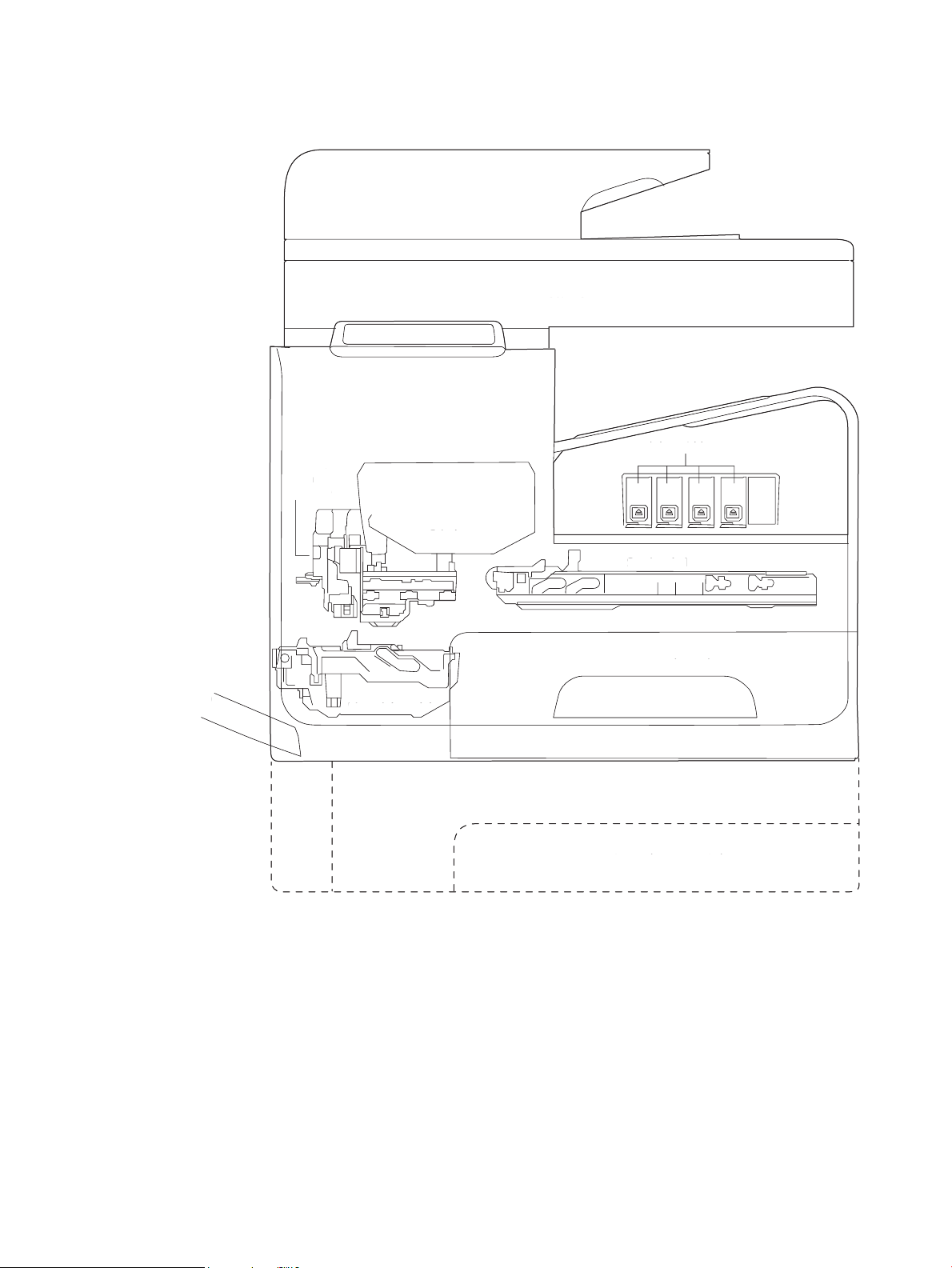

Figure 1-2 Main components (377/477 models) ................................................................................................................. 3

Figure 1-3 Main components (552/P55250 models) ........................................................................................................... 4

Figure 1-4 Main components (577/P57750 models) ........................................................................................................... 5

Figure 1-5 System control .................................................................................................................................................... 8

Figure 1-6 Print subsystem components (300/400 series) ............................................................................................... 12

Figure 1-7 Print subsystem components (500 series) ....................................................................................................... 13

Figure 1-8 Printbar components ........................................................................................................................................ 14

Figure 1-9 Paper-handling system paper path (300/400 series) ...................................................................................... 17

Figure 1-10 Paper-handling system paper path (500 series) ............................................................................................ 18

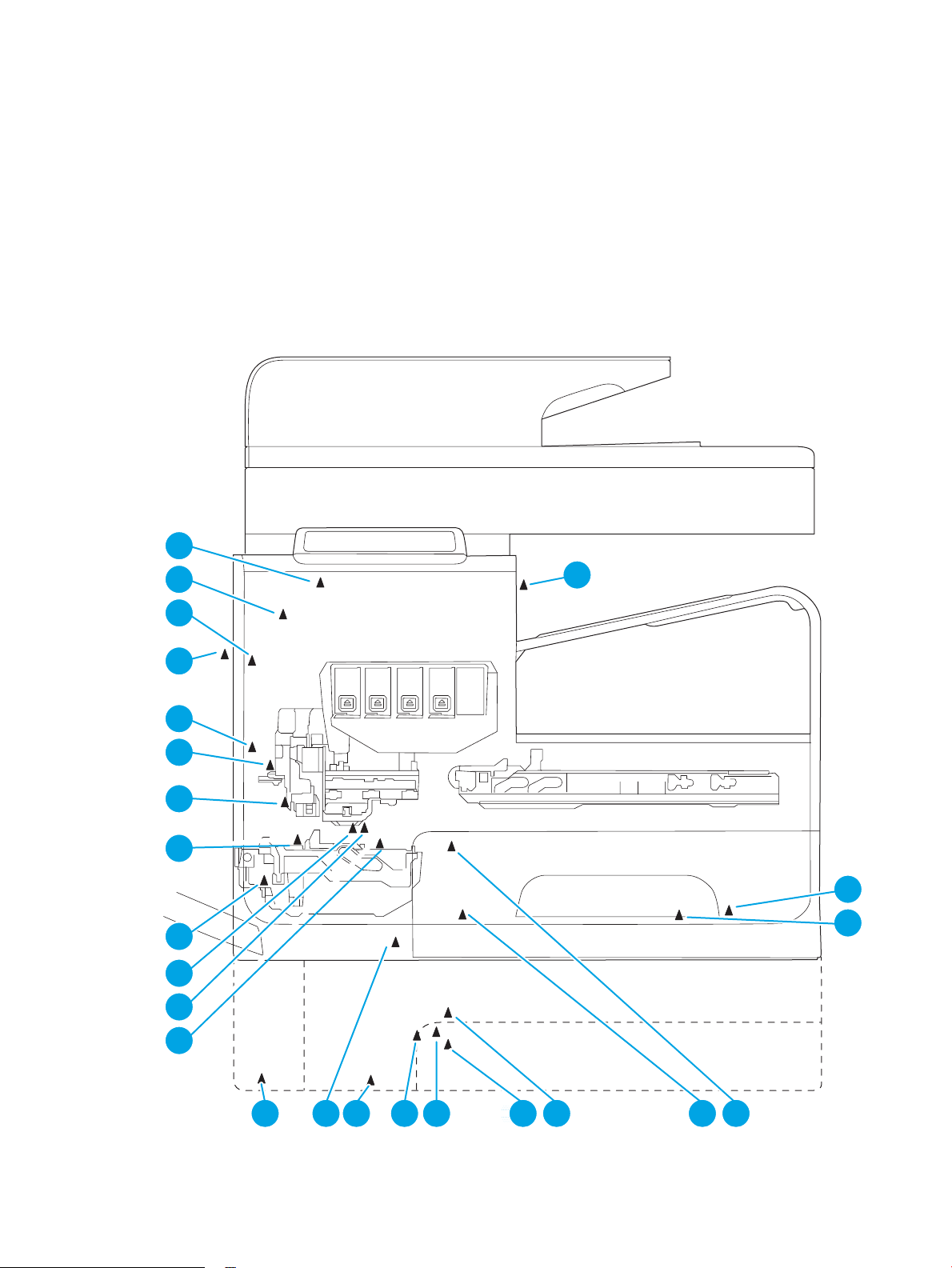

Figure 1-11 Printer sensors (300/400 series) .................................................................................................................... 19

Figure 1-12 Printer sensors (500 series) ............................................................................................................................ 20

Figure 1-13 Paper-handling-system motors (300/400 series) ......................................................................................... 22

Figure 1-14 Paper-handling-system motors (500 series) ................................................................................................. 23

Figure 1-15 Paper path zones (300/400 series) ................................................................................................................ 25

Figure 1-16 Paper path zones (500 series) ........................................................................................................................ 26

Figure 1-17 Servicing system components (300/400 series) ........................................................................................... 28

Figure 1-18 Servicing system components (500 series) ................................................................................................... 29

Figure 1-19 Service sled components ................................................................................................................................ 30

Figure 1-20 Transmission components, rear view ............................................................................................................. 31

Figure 1-21 Transmission main components ..................................................................................................................... 32

Figure 1-22 Aerosol management process ........................................................................................................................ 34

Figure 1-23 Aerosol management system components ................................................................................................... 35

Figure 1-24 Document feeder rollers and sensors ............................................................................................................ 36

Figure 1-25 Document feeder operation ........................................................................................................................... 37

Figure 1-26 Deskew operation ........................................................................................................................................... 38

Figure 2-1 Printer status report—determining genuine HP ink usage ............................................................................. 68

Figure 2-2 Mark the Web wipe ............................................................................................................................................ 90

Figure 2-3 Tray lift mechanism .......................................................................................................................................... 98

ENWW vii

Page 10

viii ENWW

Page 11

1 Theory of operation

●

Basic operation

●

System control

●

Print subsystem

●

Paper-handling system

●

Servicing system

●

Transmission system

●

Aerosol management system

●

Document feeder system (377/477/577/P57750 models)

●

Scanning and image capture system (377/477/577/P57750 models)

●

Fax functions and operation (377/477/577/P57750 models)

ENWW 1

Page 12

Basic operation

Control panel

Output bin

Printbar

Service sled

Main input tray (Tray 2)

Optional trays (Trays 3 and 4)

Multipurpose tray

(Tray 1)

Ink collection unit

Optical

scan

carriage

Ink cartridges

Function structure

The printer consists of the following components.

Figure 1-1 Main components (352/452 models)

2 Chapter 1 Theory of operation ENWW

Page 13

Figure 1-2 Main components (377/477 models)

Document feeder

Scanner

Control panel

Output bin

Printbar

Service sled

Main input tray (Tray 2)

Optional trays (Trays 3 and 4)

Multipurpose tray

(Tray 1)

Ink collection unit

Optical

scan

carriage

p

Ink cartridges

(

ENWW Basic operation 3

Page 14

Figure 1-3 Main components (552/P55250 models)

Control panel

Output bin

Printbar

Service sled

Main input tray (Tray 2)

Multipurpose tray

(Tray 1)

Duplex module\

Waste ink module

Optical

scan

carriage

Optional trays (Trays 3 and 4)

Ink cartridges

4 Chapter 1 Theory of operation ENWW

Page 15

Figure 1-4 Main components (577/P57750 models)

Control panel

Output bin

Printbar

Service sled

Main input tray (Tray 2)

Optional trays (Trays 3 and 4)

Multipurpose tray

(Tray 1)

Duplex module\

Waste ink module

Optical

scan

carriage

Document feeder

Scanner

Ink cartridges

C

ontrol pane

l

O

utput bi

n

Printbar

Se

rvice

sled

M

ain input tray (Tray 2

)

O

ptional trays (Trays 3 and 4

)

Mul

tipurpose tray

(

Tray 1

)

Duplex module

\

Waste ink module

le

O

ptica

l

scan

c

arriage

Document feeder

Sc

anner

nk cartr

idg

es

The printer contains the following systems:

●

Engine control system

●

Print subsystem

●

Paper-handling system

●

Servicing system

●

Aerosol management system

●

Scanner and document feeder system

ENWW Basic operation 5

Page 16

Two elements inuence the printer architecture:

●

The rst is the need to orient the printbar with its active face downwards and statically located above

the print media. This requires the printbar to move vertically to access its active face.

●

The second is producing face-down output. Rather than ejecting the page face-up immediately after the

ink is applied, the printer routes the printed page up and back over the printbar to eject face-down.

Operation sequence

The engine-control system on the formatter PCA controls the operational sequences. The following table

describes durations and operations for each period of a print operation from when the printer is turned on

until the motor stops rotating.

Table 1-1 Operation sequence

Period Duration Purpose

Initial startup and

calibrations

Servicing operations Performed when the printbar is

Print preparation From the time the printer

When the printer is set up for the

rst time from the factory.

entering the capping state after

printing, when leaving the

capping state after a print job is

initiated, or during extended

print jobs.

receives a printer command until

paper enters the print zone.

This period gets the printer ready to print for the rst time.

●

Fluid replacement—The printer ushes the shipping and

handling uid out of the printbar and replaces it with ink.

●

Die alignment—The printer aligns the 10 die on the printbar

active face.

●

Die density leveling—The printer measures and compensates

for the drop variation.

Servicing maintains print quality by removing debris and excess ink

and replacing missing nozzles.

●

Nozzle presence detection—The optical scan carriage detects

and disables inoperable nozzles, and replaces them with

operable nozzles.

●

Printbar servicing—The web wipe on the service sled moves

under the printbar to clean the active face and res the nozzles

into the ink collection unit to clear clogs.

Prepares the printer for a print job.

●

The printbar leaves the capping state as the service sled

moves away from the printbar.

●

If needed, some servicing occurs.

●

The printbar lowers to the printing position. The media type

and printing mode determine the print zone height.

●

The printer picks media from one of the input trays.

●

Every page from Tray 1 is scanned. For Tray 2 and optional

Trays 3 and 4, the printer performs media edge detection after

printing the rst sheet after the tray is loaded. The last sheet

of each job is also scanned if at least ve sheets have been

printed.

●

The printer monitors environmental conditions. The printer

can slow the print speed if conditions are signicantly dierent

than a normal oice environment (23° C (73.4° F), 50% relative

humidity).

●

The formatter PCA processes print data and transmits the data

to the printbar.

6 Chapter 1 Theory of operation ENWW

Page 17

Table 1-1 Operation sequence (continued)

Period Duration Purpose

Printing From the end of the preparation

period until the last sheet is

delivered.

End of print job Performed after the print job is

completed, and continues until

the next job is initiated.

Standby The printer is sitting idle, waiting

for the next print job to be

initiated.

Processes the print job.

●

As the page travels through the print zone, the printbar applies

ink to the page.

●

Simplex print job—the page moves up, over the printbar, and

out to the output bin (face-down).

●

Duplex print job—the page moves up until the trailing edge is

40 mm (1.5 in) past the star-wheel jam reective sensor. The

page reverses direction down through the duplex path and

underneath the ink collection unit. Then, it reenters the print

zone, where the printbar applies ink to the second side.

●

The process continues until all the pages of the print job are

completed. The process can be interrupted by occasional

nozzle presence detection and servicing events, if the job

includes many pages.

This period puts the printer in a state where it’s ready for the next

print job.

●

If needed, some servicing occurs.

●

The printbar moves to the capping position after a short dwell

interval.

●

The service sled moves to cap the printbar.

This period is intended to conserve energy when the printer is

sitting idle. Certain functions might be disabled to save power and

then re-started only when needed. The printer has two sleep

modes:

●

Idle mode—The printbar is capped and the printer is ready to

immediately start a new job

●

Sleep mode—After the printer is inactive for about 10 minutes

(a setting that can be adjusted from the control panel or the

Embedded Web Server), the control panel turns o and the

power LED blinks to indicate the unit is in Sleep mode. All

printer functions are available.

ENWW Basic operation 7

Page 18

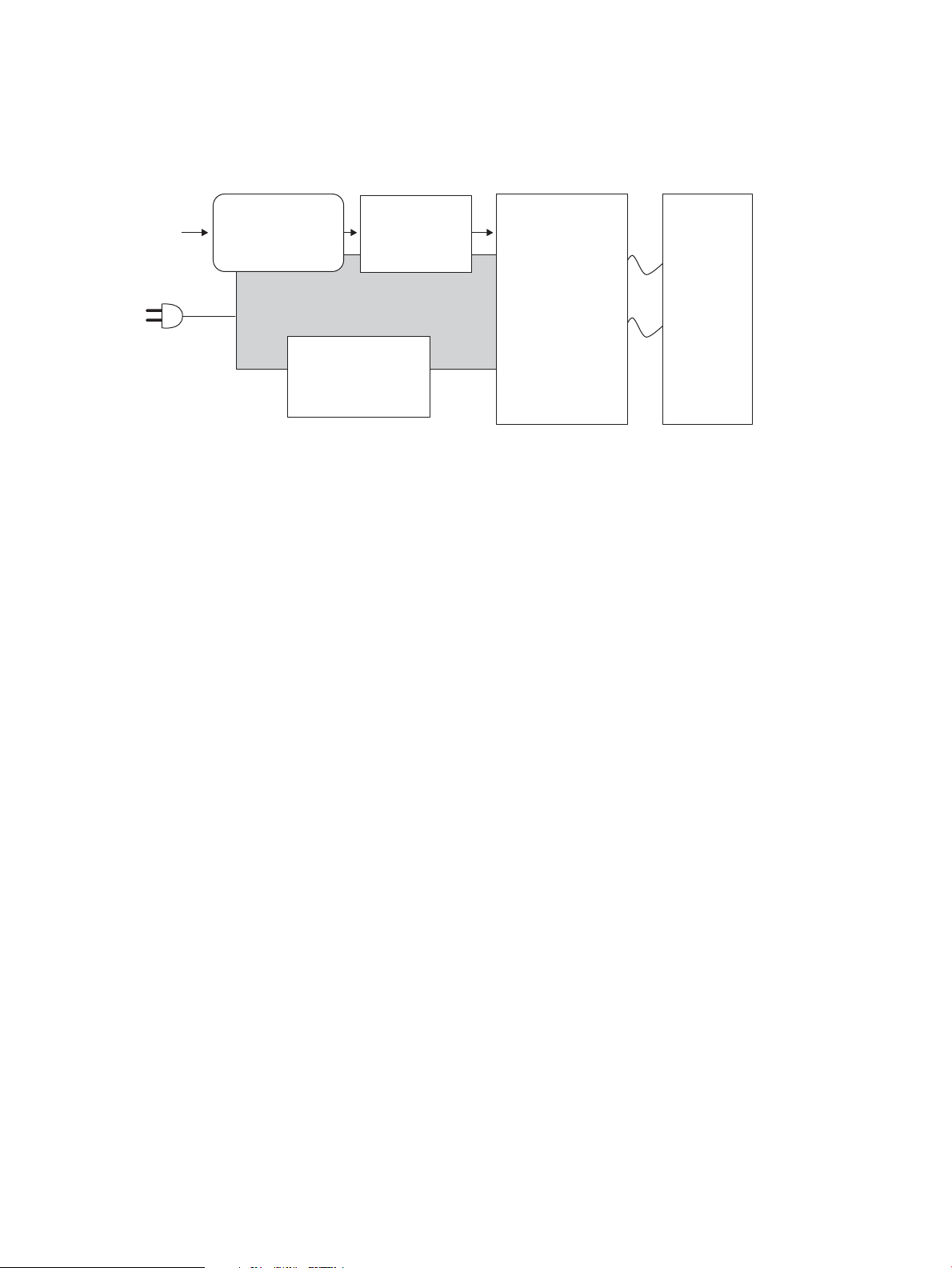

System control

Power supply

Engine control

Motor + sensor drive

Formatter

I/O, PDL, UI control

I/O

Datapath

ASIC +memory

Printbar

40,000 nozzles

Pen I/F

• Pen energy control

• Pen voltage

sequencing

• Signal integrity

• Ink-short protection

• Printhead

interconnects

• Ink supply

The system control coordinates all the other systems, according to commands from the formatter.

Figure 1-5 System control

The system consists of ve major sections.

●

Formatter

●

Data path

●

Engine control

●

Pen interface

●

Power supply

The engine PCA integrates both formatter and engine control electronics onto a single assembly. The wireless

radio unit (wireless models only) plugs into the back of the engine PCA, and the fax connects to the PCA via a

short at-exible cable (FFC).

Formatter and data path

The formatter controller ASIC controls the input/output (I/O) control, the user interface, and the rendering of

page description language les into printer-specic commands.

Input/output (I/O) control

The printers support 10/100 Ethernet, 802.11 wireless (HP wireless direct models), a rear USB host port, a

control panel USB host port (552/P55250/377/477/577/P57750 models), and an analog fax port

(377/477/577/P57750 models). For Ethernet networks, the formatter ASIC uses a separate integrated circuit

(Broadcom 5241) to provide the physical network layer.

The formatter ASIC controls the USB device and USB host as well.

Wireless I/O is provided via a separate radio module.

User interface

The printers contain either a 2-inch (352/452 models) monochrome display or an 4.3-inch (552/

P55250/377/477/577/P57750 models) color graphics display. An icon on the control panel of wireless

models denotes that the wireless feature is enabled. The 552, P55250, 377, 477, 577, and P57750 models

include a walk-up USB host port for connection to thumb drives.

8 Chapter 1 Theory of operation ENWW

Page 19

Formatter digital ASIC

The formatter digital ASIC contains dual ARM CPUs (1.2 GHz and 600MHz) that execute rmware code that

provides high-level device control. The digital ASIC uses a standard PCle interface to pass data to the engine

control ASIC.

Formatter analog ASIC

The formatter analog ASIC generates the system voltage for the formatter, drives the scanner and ADF

motors, manages the real-time clock, and drives the fax speaker. Also, the engine uses this ASIC to drive the

ISS pumps, solenoids, and aerosol fan.

Real-time clock

The real-time clock (RTC) allows the fax module to time-stamp outgoing faxes. In addition, it determines the

elapsed time between printhead and ISS calibration events. The RTC uses a special block inside the engine

analog ASIC, along with a crystal and a battery.

Engine control

The engine controller digital ASIC receives high-level commands from the formatter, and it then provides lowlevel control to the print mechanism. In particular, the engine controller digital ASIC and its rmware control

motors, system sensors, and the printbar. The engine controller analog ASIC integrates motor drivers, voltage

regulators, sensor interfaces, and supervisory circuits.

Engine controller digital ASIC

The engine controller digital ASIC has a high-performance 480 MHz ARM CPU and DSP co-processors that

execute rmware code to provide low-level engine control. It also drives the printbar via 15 high-speed LVDS

transmission lines, which are routed from the engine PCA to the printbar via two large FFC cables. The engine

controller digital ASIC receives pre-rendered data from the formatter digital ASIC over a standard PCle

interface.

When a product has entered sleep mode, many functions of the printer have gone into a low-power mode. If a

print job is received while the product is in sleep mode, the printer will take a short period of time to "wake

up". This can take up to 15 seconds, which will delay the rst page out (FPO) time accordingly.

Engine controller analog ASIC

The engine uses two analog ASICs to generate the system voltages for the engine, drive the engine motors,

control various engine sensors, and monitor printbar power delivery for correct operation.

The engine has seven motors, some of which are shared with other subsystems:

●

Pick motor

●

Feed motor

●

Duplex motor

●

Lift motor

●

Eject motor

●

Sensor carriage motor

●

Aerosol fan motor

ENWW System control 9

Page 20

Each one is a DC motor with encoder feedback, to provide precision servo control. These motors are driven

directly by one of the engine analog ASICs. Small DC motors also are used to drive the ISS pump and the

aerosol fan. There are solenoids that actuate the ejection ap and the ISS priming system.

The printer uses many sensors to track the media as it travels through the paper path. Most of these are

optical REDI sensors, which are used in conjunction with mirrors to sense the presence or absence of paper in

a particular location. These are carefully aligned and calibrated at the factory, so care must be taken when

servicing these sensors. See the Remove and Replace chapter in the repair manual for more details.

Other printed circuit-board assemblies (PCAs)

In addition to hosting the system ASICs, the engine PCA is home to many circuits needed to interface to

sensors and other sub-system components. In some cases, this circuitry is located on a smaller remote PCA

(SLB) to optimize cable interconnects.

●

Humidity sensor—The humidity sensor causes the printer to adjust printing speed if ambient conditions

are outside the optimal humidity range. This sensor is calibrated at the factory to ensure maximum

accuracy.

●

Temperature sensor—The temperature sensor causes the printer to adjust printing speed if ambient

conditions are outside the optimal temperature range. In some printers, this sensor resides on a

separate, remote PCA.

●

Main tray presence sensor—The hall-eect sensor that detects if the main tray is properly engaged

resides on the back of the engine PCA. A small magnet on the back of the main tray actuates the sensor.

If the tray is fully engaged, the magnetic eld strength is suicient to trigger the sensor.

Additionally, the printer includes the following PCAs:

●

Front USB PCA—This PCA governs the control panel USB port.

●

Fax PCA—This PCA governs the printer fax module.

●

Duplex module presence sensor–This hall-eect sensor detects whether the duplex module is properly

seated.

●

Power button PCA—This PCA includes the power button and power LED, as well as interface cables to

the duplex module presence sensor and the MP tray empty REDI sensor.

●

Accessory tray interconnect PCA—This PCA provides communication to optional Tray 3.

●

Pick encoder distribution PCA—This PCA includes the pick motor encoder and the pick motor

interconnect cable.

●

Eject encoder distribution PCA—This PCA includes the eject motor encoder, plus the interconnect cables

to the eject motor and the aerosol fan.

●

Print zone distribution PCA—This PCA joins interconnect cables to the following sensors: separator REDI,

feed motion encoder, main tray empty sensor, Top of Form (TOF) REDI sensor, and the Print zone REDI

sensor.

●

REDI distribution PCA—This PCA includes hall-eect sensors that detect ink cartridge door and left door

positions. It also combines the interconnect cables for the eject REDI sensor, the upper paper path REDI

sensor, the lower paper path REDI sensor, and the eject ap opto ag sensor.

●

Sensor carriage PCA—This PCA includes a carriage motion encoder, a ZIM sensor, and the BDD sensor.

●

Printbar lift encoder distribution PCA—This PCA includes the printbar lift motion encoder and combines

interconnect cables to the printbar lift motor, carriage motor, and eject ap solenoid.

10 Chapter 1 Theory of operation ENWW

Page 21

●

Duplex encoder PCA—This PCA contains the motion encoder for the duplex motor.

●

SHAID PCA—This PCA contains interfaces to the out-of-ink sensors for the ink cartridges, and combines

the interface cables to the acumen PCA, the ISS pump, and the ISS solenoids.

●

Acumen PCA—This PCA contains interfaces to the acumen memory devices for the ink cartridges.

Pen interface (I/F)

The printbar is the key component that dierentiates these printers from other inkjet printers. The

conventional approach is to print a page in horizontal swaths by moving a “scanning” printhead horizontally

xed sheet of paper, advancing the paper a xed amount, and then printing the next swath. With these

over a

printers, the paper moves underneath a xed page-wide printhead in a single smooth motion.

Single pass page-wide printing requires that data and power be delivered to the printbar at a very high rate,

while also maintaining good control of paper position as it moves past the printhead nozzles.

The engine PCA sends power and data to the printbar via two large at exible cables (36 and 38 pins). The

printbar PCA routes power and data to 10 printhead die, which are attached to the PCA using a exible tab

circuit and wire-bonding process.

The printers also contain electronics to control the ink supply station (ISS). The SHAID PCA detects low-ink

conditions. It gauges ink levels by means of electrically sensing the presence of ink and/or ink foam in the Xchamber. The SHAID PCA also collects and distributes electrical signals that drive the push-prime pump(s),

engage the solenoids, and read the ink supply acumen data. All are routed through a single 17-pin FFC from

the SHAID PCA to the engine PCA.

Each ink supply has a memory tag that stores information about its type of ink, the amount of ink remaining,

and other critical data. It uses a special authentication scheme to ensure that only genuine HP supplies are

used and the printer is not damaged by using invalid supplies. Acumen uses a two-line serial bus, which,

along with 3.3 V and ground, is cabled via the SHAID PCA to the engine PCA and the engine control digital ASIC.

Power supply

The power supply module converts 100-240 VAC to 34 VDC to power the system. The power supply module

has a sleep mode that reduces power consumption in system low-power modes. When in its sleep mode, the

power supply generates less than 4 W.

The power supply module supplies 34 V to the engine PCA. The power supply module has two operating

modes, depending upon the state of its nSLEEP input pin:

●

Printing: = up to 13 W ( nSLEEP = high logic level)

●

Sleep mode: = < 4 W ( nSLEEP = low logic level)

The power supply is a self-contained module that can be replaced if it is determined to be defective (see the

Remove and Replace chapter of the Repair Manual).

To ensure safe operation, the power supply will “latch o” if a persistent over-current fault condition exists.

This would typically be caused by a short-circuit from 34 V to ground in the printer. Less severe faults can

cause the power supply to latch o, if present for an extended period of time, or if the printer is operated

above the recommended operating temperature range.

NOTE: In some countries/regions, the printer is equipped with a high-voltage power supply in order to

prevent power supply unit failures due to over-voltage conditions.

ENWW System control 11

Page 22

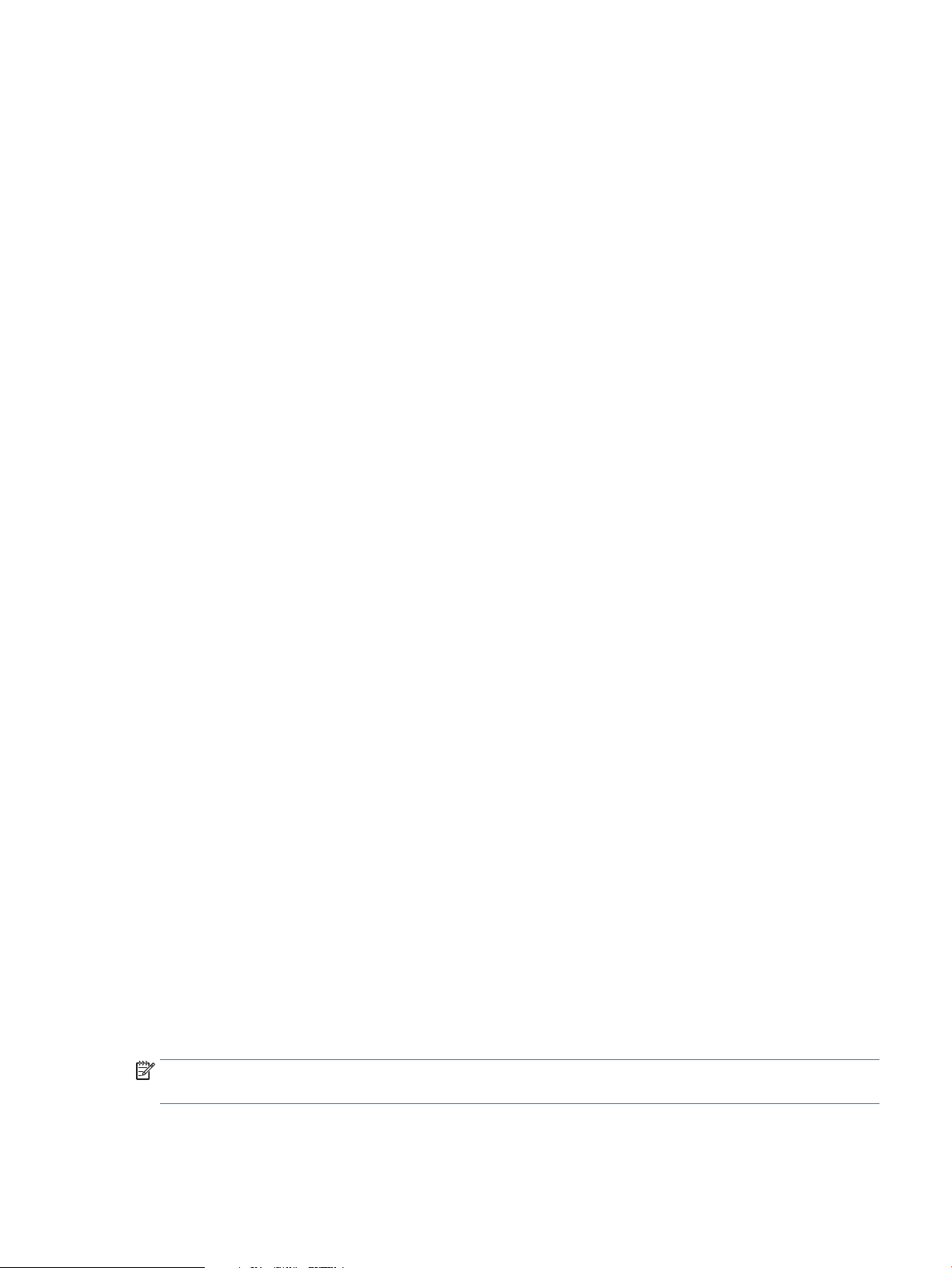

Print subsystem

Printbar lift

Ink cartridges

Printbar

Optical

scan

carriage

The print subsystem includes the following components.

●

Printbar

●

Printbar lift

●

Ink cartridges

●

Optical scan carriage

Figure 1-6 Print subsystem components (300/400 series)

12 Chapter 1 Theory of operation ENWW

Page 23

Figure 1-7 Print subsystem components (500 series)

Printbar

Optical

scan

carriage

Ink cartridges

Printbar lift

Printbar

The printbar’s fundamental purpose is to convert the digital ring instructions from the printer electronics

into properly formed and timed microscopic drops of the four ink colors. The printbar spans the full width of a

letter/A4-size sheet (216 mm (8.5 in)), which allows the printbar to be statically positioned within the printer

and have the media move underneath it, printing the entire page in a single motion.

ENWW Print subsystem 13

Page 24

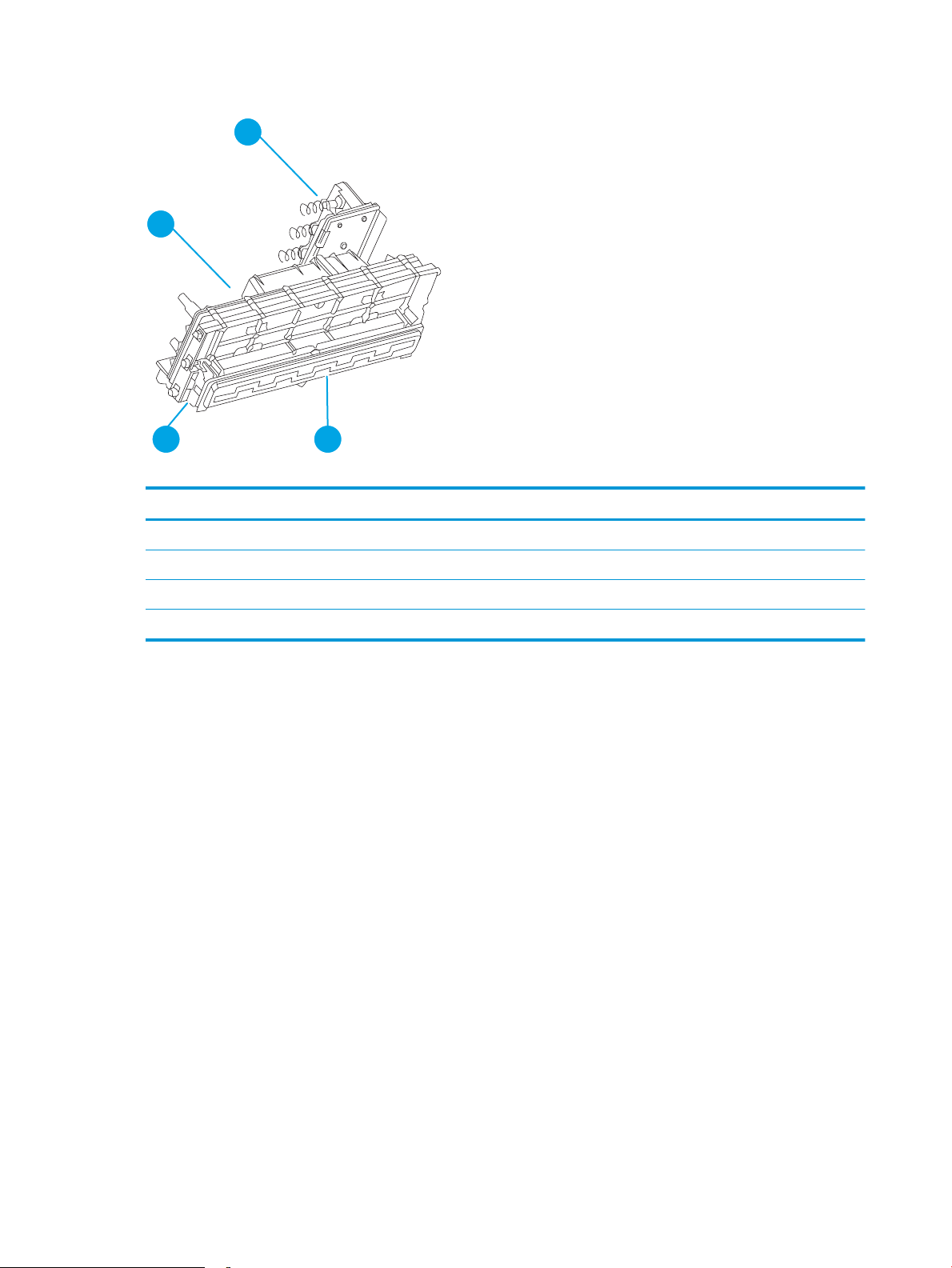

Figure 1-8 Printbar components

1

4

23

Table 1-2 Printbar components

Item Description

1 Ink cartridge connections

2 Thermal inkjet (TIJ) die array

3 Data/power ow and regulation

4 Inkow channels and pressure regulation

The printbar has a xed array of 10 thermal inkjet (TIJ) die oriented in two staggered rows. Each die contains

more than 1,000 nozzles for each of the four ink colors—black (K), cyan (C), magenta (M) and yellow (Y).

Behind the die array are the ink ow channels and pressure regulation mechanisms that supply the die array

with ink at the proper pressure and ow. The die must also be fed power and data at the appropriate levels

and rates, which is the function of the onboard electronic circuitry. Finally, situated at the top of the printbar,

there are four ink cartridge receptacles, one for each color. These cartridges are linked by ow connections to

the rest of the printbar and supply the ink necessary for its operation.

A sensor technology called back-scatter drop detect (BDD) monitors printbar health and calibrations. This

system looks at the reection of the miniscule drops in ight, and then passes these signals through highspeed, high-gain, bandpass lters. A complex articial intelligence (AI) system decides which drop ejectors are

currently out of specications, and which are not.

After the AI system determines which drop ejectors are out of specication, the printer compensates for

them. Some ejectors use neighboring nozzles and at times even tiny amounts of other inks—whichever

combination of methods necessary to deliver the best print quality possible at that moment. In some cases,

fully half of the nozzles can be “out” without a noticeable degradation in quality. The compensation is done in

real time with a dedicated high-speed DSP. The system can scan portions of the system after print jobs, but it

is fully interruptible by new, incoming print jobs.

Printbar air management system

The printbar uses a passive air gain management system. Air can enter the printbar from the following

sources:

14 Chapter 1 Theory of operation ENWW

Page 25

●

Die outgassing (from air in the ink)

●

Air entering nozzles due to temperature or pressure variations

●

Air entry through the printbar structure

●

Air entry through the nozzles due to shipment vibration

Air that enters the printbar is warehoused. There is no mechanism to remove the air in the eld. Of the

various mechanisms for air entry, the rst three are generally benign, and rarely cause issues during the

expected life of the printer. The fourth mechanism generally occurs during shipment. New printers are

shipped with the printbar taped—which limits the amount of air gained. If the printbar isn’t well restrained

during shipment, then air gain can be

air gain can be reduced either by ensuring that the printer stays on its base, or that the printbar is restrained.

Both would be best.

Printbar lift

The printbar lift is responsible for positioning the printbar within the printer and moving it up and down as

required. This vertical motion is both to establish proper spacing to the paper during printing, and to raise it

to either access the active face or perform necessary calibrations.

During printing, the lift mechanism sets the printbar height and paper height depending on the type of paper.

Ink cartridges

signicant. If the printer is shipped after removal of the printbar tape,

These printers have new, state-of-the-art pigmented inks. They are ltered using proprietary processes to

prevent printhead contamination. These inks are designed to produce optimal print quality on ColorLok oice

papers, but also produce very good print quality on regular oice papers and specialty paper.

Optical scan carriage

The optical scan carriage has optical sensors used for calibration. Its motion is along the long axis of the

printbar. These sensors are used by a number of printer calibration features that are important for proper

subsystem function. The BDD sensor is located on the optical scan carriage.

Print system operational states

The print subsystem has a number of distinct operational states besides active printing.

Startup

As it comes from the factory, the printbar is initially lled with an inert ink-substitute called Shipping and

Handling Fluid (SHF). This uid, essential for the manufacture and transportation of the printbar, must be

ushed and replaced with actual ink. This is accomplished during the Startup phase. The ushing process

automatically commences when ink supplies are inserted and the unit is powered up for the rst time. The

SHF is removed by sustained printbar operation and replaced by ink from the supplies. The process

terminates once all the SHF has been ushed from the printbar.

Special host supplies are supplied with the printer prior to its rst use. These supplies contain additional ink

so that there will be 100 percent ink level after the SHF is replaced with ink. These supplies can be used only

to initialize the printer. You cannot use them in another printer that has been initialized.

NOTE: The initial startup time is noticeably longer than the following regular startup times.

ENWW Print subsystem 15

Page 26

Die alignment

Since 10 die comprise the printbar active face, each with associated positional tolerances, an active

calibration must be performed to prevent errors and allow a uniform ink application to the paper (without any

gaps or overlaps between adjacent die). This die alignment is done by printing a special diagnostic image on a

sheet of paper and then scanning it with the optical scan carriage. Die alignment is performed as part of

initial unit startup, and can be performed manually as part of the print quality recovery tool.

Die density leveling

Tolerances are also associated with the drops red by the individual printbar die. Another active calibration

measures and compensates for these variations to produce a visually uniform ink application to the paper.

Another set of diagnostic images is printed and scanned by the optical scan carriage to achieve this die

density leveling. Die alignment and die density leveling are usually paired together.

Nozzle presence detection

In printing, since all the ink is applied in a single smooth motion of the paper past the printbar, any inoperable

nozzle can show up as a noticeable streak. The operational state of each of the thousands of nozzles on the

printbar is periodically measured. The printbar lift raises the printbar, and the BDD assembly on the optical

scan carriage watches for drop presence as each nozzle is red. Inoperable nozzles are turned o and other

operable nozzles are used on subsequent printed pages to apply the missing ink. Nozzle presence detection is

fully interruptible by new, incoming print jobs.

Media edge position detection

The printer uses a learning algorithm to dene media center as a function of input source—Tray 1, Tray 2, or

optional Trays 3 and 4. The edge scan is located downstream of the print zone. As paper is scanned, the

media center database is updated. The image is registered to the page using the media center database.

Servicing and capping

When in the capped state, the printbar is fully raised, the service sled is positioned underneath, and the

printbar cap is engaged against the printbar active face. Servicing—the cleaning of the active face and the

ring of the nozzles—can occur either during Sleep2 mode or after extended time in storage. It can also occur

during extended print jobs.

Printing

The printing state begins by the printbar leaving the capping state, and lowering to the printing position after

the service sled moves out of the way. At the same time, a sheet of paper is picked from one of the three trays

and the leading edge staged at the entrance to the print zone. Once the print data has been sent, the sheet of

paper feeds at a constant velocity through the print zone and the printbar applies the ink.

In the case of one-sided printing, the inked sheet is moved up, over and out to the output tray. For two-sided

printing, the sheet is moved until its trailing edge is past the merge to the vertical path. The sheet is then

reversed down through the duplex path underneath the ink collection unit, and reintroduced into the print

zone for inking of the second side.

This process continues until all the pages of the print job are completed. If the print job is large enough, it can

be interrupted by servicing processes.

16 Chapter 1 Theory of operation ENWW

Page 27

Paper-handling system

The paper-handling system moves paper through the printer according to commands from the formatter.

The following gures show the printer paper path.

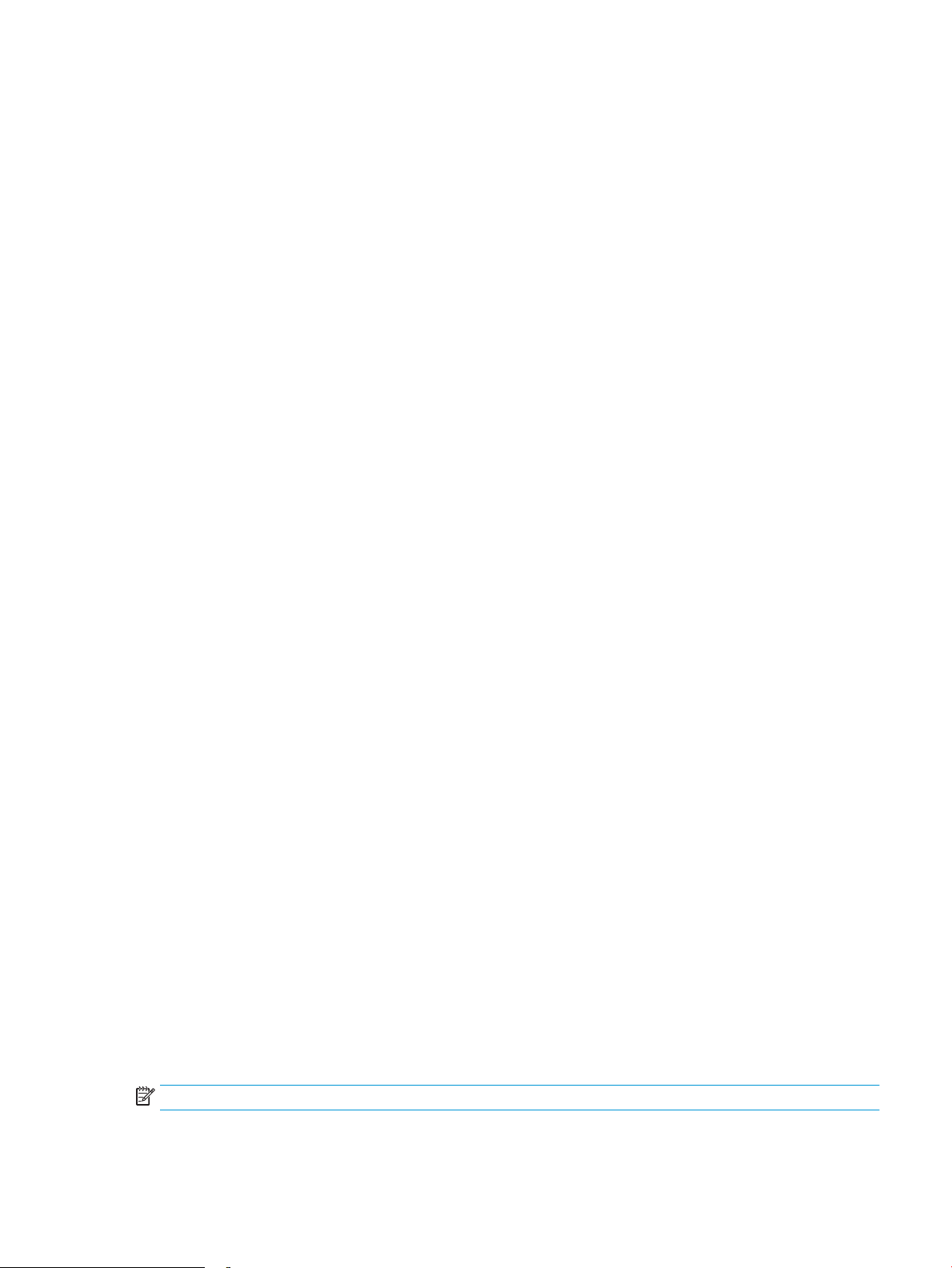

Figure 1-9 Paper-handling system paper path (300/400 series)

ENWW Paper-handling system 17

Page 28

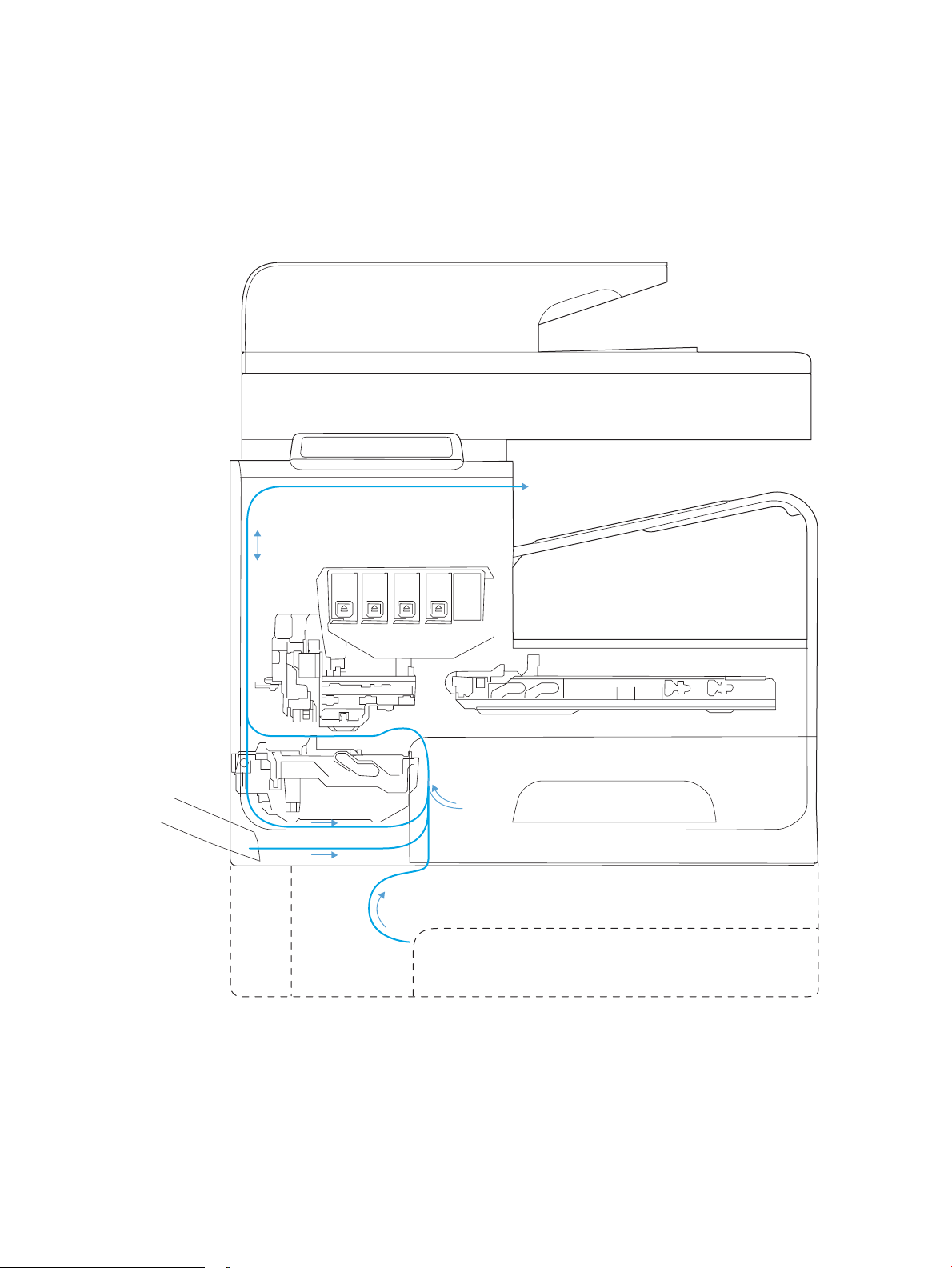

Figure 1-10 Paper-handling system paper path (500 series)

The paper path consists of the following major components:

●

Two integrated input trays plus one optional accessory tray

●

Four motors and a solenoid plus two more motors in the accessory tray

●

Duplex module

●

Sensors placed throughout the device, including the paper trays

18 Chapter 1 Theory of operation ENWW

Page 29

●

1

2

3

13

14

15

16

17

18

19

20

21

22

23

24

12 11 10 89

999997

6 45

Multiple feed rollers, pinch rollers, star wheels, and media guides

●

Transmission components (gears, shafts, levers, swingarms) that interface with other subsystems such

as the printbar and service sled.

Components of the paper path move the paper from the input tray to a position 1 to 2 mm (.04 to .08 in)

underneath the printbar, and then deliver the printed result to the output tray. The combined orientations and

actions of the printbar, the printbar lift, and the paper path establish the print-zone, where the ink drops

move from the active face of the printbar to the paper.

The following gures show the printer sensors.

Figure 1-11 Printer sensors (300/400 series)

ENWW Paper-handling system 19

Page 30

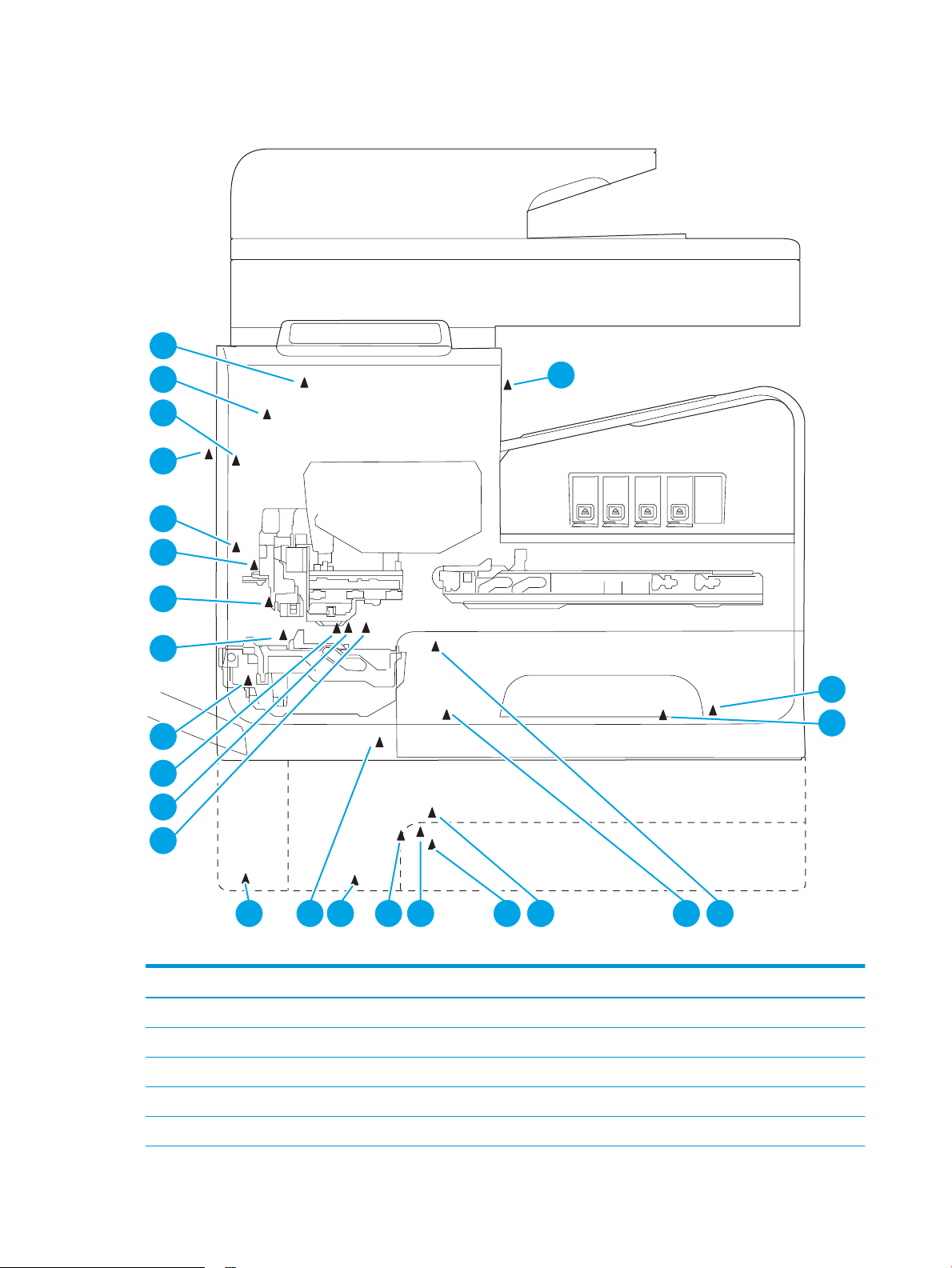

Figure 1-12 Printer sensors (500 series)

1

2

3

13

14

15

16

17

18

19

20

21

22

23

24

12 11 10 89 999997 6 45

Table 1-3 Printer sensors

Item Description Item Description

1 Output ap jam sensor 13 Top of Form (TOF) REDI sensor (located on platen)

2 Ambient temperature sensor 14 Feed roller encoder

3 Ambient humidity sensor 15 Feed roller home sensor

4 Tray 2 pickup tire home sensor 16 Duplex module presence sensor

5 Tray 2 tray presence sensor 17 Print zone REDI sensor (located on platen)

20 Chapter 1 Theory of operation ENWW

Page 31

Table 1-3 Printer sensors (continued)

Item Description Item Description

6 Tray 3 pickup tire home sensor 18 Back-scatter drop detect sensor

7 Tray 3 paper presence sensor 19 Print calibration/media edge detect sensor

8 Tray 3 separation sensor 20 Lower paper path REDI sensor

9 Tray 2 paper presence sensor 21 Left door open sensor

10 Tray 3 tray presence sensor 22 Upper paper path REDI sensor

11 Tray 1 paper presence sensor 23 Ink supply door open sensor

12 Tray 3 cleanout presence sensor 24 Eject REDI sensor

There are several motors in the printer for pick, feed, duplexing, printbar lift, delivery, and the scanning

sensor carriage.

ENWW Paper-handling system 21

Page 32

Figure 1-13 Paper-handling-system motors (300/400 series)

1

234

5

6

7

8

22 Chapter 1 Theory of operation ENWW

Page 33

Figure 1-14 Paper-handling-system motors (500 series)

1

234

5

6

7

8

Table 1-4 Paper-handling system motors

Item Description

1 Eject (or output drive) motor

2 Tray 2 pickup motor

3 Tray 3 pickup motor

4 Duplex Tray 1 motor

5 Tray 3 feed motor

ENWW Paper-handling system 23

Page 34

Table 1-4 Paper-handling system motors (continued)

Item Description

6 Feed motor

7 Optical carriage motor

8 Printbar lift motor

Input trays

The printer comes standard with two input trays, and also accepts two accessory trays.

●

●

50-page multipurpose (MP) tray—Tray 1: The tray shares a motor with the duplex module and has only

one sensor. It is a reective (REDI) sensor that determines if media is present in the tray. The feed roller

reective REDI sensor determines if a sheet of media is successfully picked from the tray.

500-sheet letter/A4 size main tray—Tray 2: The tray has a pick motor, which is also moves the service

sled. Similar to the accessory tray, both the main tray motor and the duplex MP tray motor will operate

at the same time when picking paper from the main tray. The main tray has three sensors:

◦

A hall eect sensor determines if the tray is closed.

◦

A ag/opto sensor determines if there is media in the tray.

◦

A ag/opto sensor determines if the pick roller is in home position.

The feed roller jam sensor is used to determine if a sheet of media is successfully picked from the main

tray.

●

Two optional 500-sheet legal size accessory trays—Trays 3 and 4: These optional trays each have two

motors, one for picking paper and one for the turn roller. This roller receives paper from the pickup roller

and transfers it to the multipurpose tray ITR, that is driven by the duplex module/MP tray motor. Both

the accessory tray motor and the duplex module/MP tray motor operate at the same time when picking

paper out of the accessory tray.

The accessory trays have the following sensors:

◦

A hall eect sensor determines if the tray is closed.

◦

A ag/opto sensor determines if there is media in the tray.

◦

A ag/opto sensor determines if the pickup roller is in the home position.

◦

A hall eect sensor determines if the left door is closed.

◦

A separation sensor determines if the printer successfully picked media.

Paper path zones

The printer paper path includes the following elements:

●

Deskew buckle

●

Print zone

●

Duplex

24 Chapter 1 Theory of operation ENWW

Page 35

●

1

2

4

5

3

Output

●

Eject

Figure 1-15 Paper path zones (300/400 series)

ENWW Paper-handling system 25

Page 36

Figure 1-16 Paper path zones (500 series)

2

1

5

4

3

Table 1-5 Paper path zones

Item Zone Description

1 Deskew buckle This is the area between the turn roller and feed roller. All paper passes through this zone. During the

deskew operation, the duplex module/MP tray motor rotates forward, driving the paper into the feed

roller nip while the feed roller is not moving. The feed roller REDI sensor determines the leading edge

for accurate deskew buckle size, detects jams, and senses whether the tray successfully picked paper.

26 Chapter 1 Theory of operation ENWW

Page 37

Table 1-5 Paper path zones (continued)

Item Zone Description

2 Print zone This is the path between the feed roller and output pinch 1 roller. The feed roller, which has an analog

3 Duplex By opening the left door, the duplex module can be removed to clear jams. The duplex module also

4 Output The output path begins at output pinch roller 1 and continues to output pinch roller 5. Four REDI

quadrature encoder, precisely controls the paper in the paper feed direction . In the vertical direction, a

combination of the platen, feed roller, and output pinch roller 1 controls the paper. The user can rotate

the platen down for jam access after removing the duplex module.

The print zone contains no paper path sensors. If a jam occurs in the print zone, it is not detected until

the leading edge of the paper is determined to be “late” in reaching the jam sensor in the output path.

When a user pulls on jammed paper in the print zone that is still partially in the feed roller nip, the

servo control detects a slight movement of the feed roller and assists the user by applying a forward

torque to the roller. Also, the motion control system disengages the duplex module rectier (swing

arm) so that the turn roller can spin freely. This feature reduces the pulling force needed by the user

and therefore reduces the chance of leaving torn pieces of paper in the path—especially in the deskew

buckle zone.

serves as an ink-collection unit for the printbar and will expose the user to waste ink when it is

removed. Therefore, the duplex module contains warnings to not touch certain areas.

When the user pulls on jammed paper from the duplex module (or any of the trays) that is partially in

the feed roller nip, the servo control detects a slight movement of the feed roller and assists the user

by applying a reverse torque to the feed roller and disengages. Also, the motion control system

disengages the duplex module rectier so the turn roller can spin freely. This feature reduces the

pulling force needed by the user and therefore reduces the chance of leaving torn pieces of paper in

the path—especially in the deskew buckle zone.

In order for the printer to determine the duplex module's presence, the duplex module has a magnet

that triggers a hall-eect sensor mounted to the structure.

sensors in this path detect leading and trailing edges and jams.

The feed motor drives the rollers in the output path, except output pinch roller 5. All the pinch rollers

in the output and exit path are star wheels to prevent roller tracking on wet/damp ink. However, the

turn roller pinch is solid and has a high amount of force for deskew buckle formation. Also, the feed

motor drives all output shafts except shafts 5 and 6.

The REDI dry path lower, REDI dry path upper, and eject jam REDI sensor in the output path all track

the leading and trailing edges of paper.

The outer and top portions of the vertical path are formed by paper guides molded in and attached to

the left door. The left door can be opened for jam clearance and has a hall-eect sensor to determine

if it is closed. Also when the left door is opened, drive rollers that form pinches 3 and 4 disengage from

the feed motor for safety purposes.

5 Eject The eject portion of the paper path includes the zone from output pinch roller 5 to the eject ap.

The eject motor powers output pinch roller 5 and eject pinch roller 6.

The eject ap has 3 positions:

●

Closed when not printing.

●

Partially open for heavy ink printing in dry environments to limit severe curl.

●

Open for all other printing. This position controls moderately curled paper.

The ap is opened and closed by a torque clutch on the eject roller shaft. The ap also has a locking

feature that is controlled by a solenoid. In order for the door to open all the way or move between

positions, the solenoid must be actuated.

ENWW Paper-handling system 27

Page 38

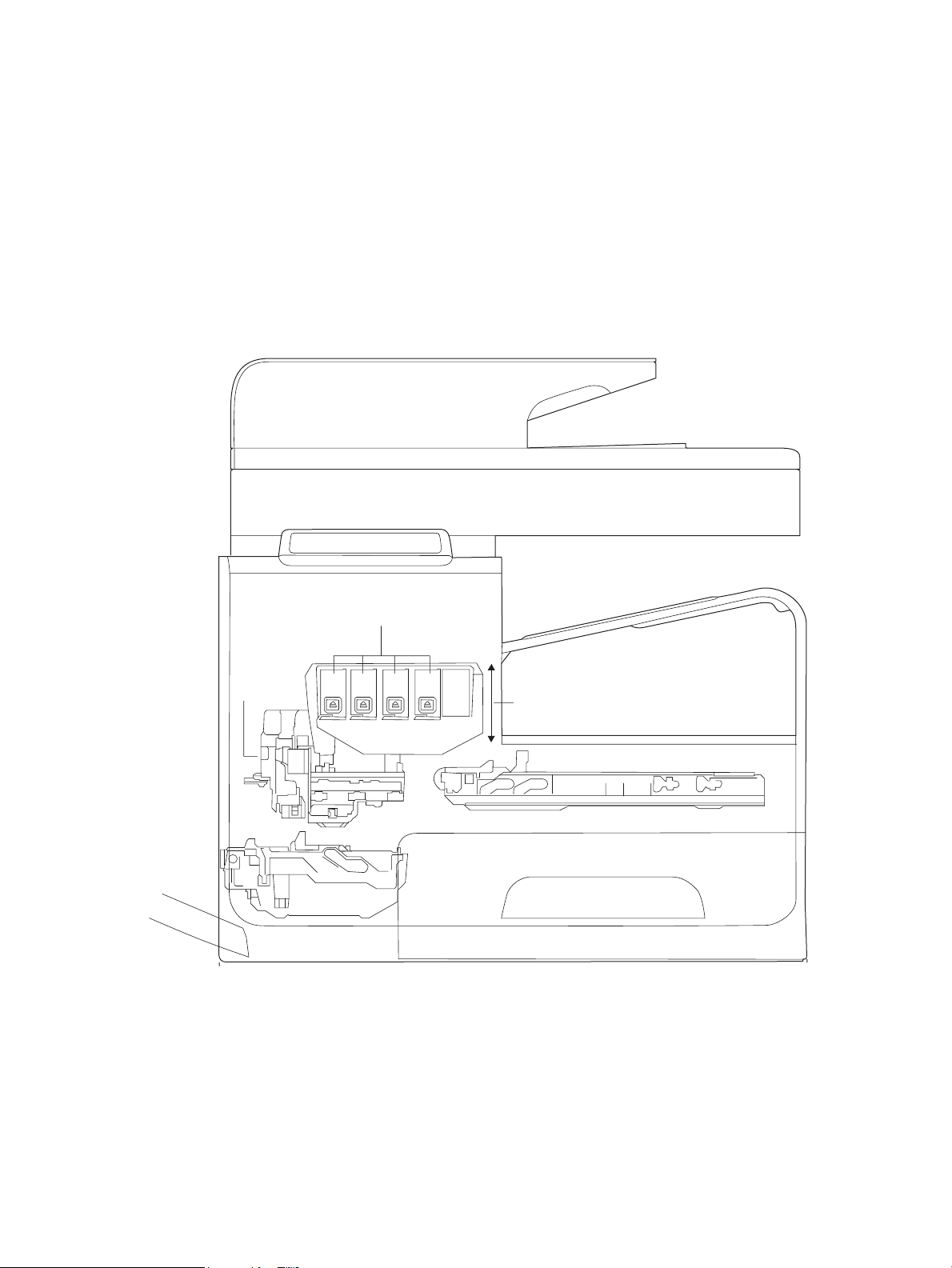

Servicing system

Duplex module/

Ink collection unit

Service sled

The servicing system comprises the service sled, which maintains print quality by wiping debris and ink o

the print nozzles, and the ink collection unit, where maintenance ink is deposited.

Figure 1-17 Servicing system components (300/400 series)

28 Chapter 1 Theory of operation ENWW

Page 39

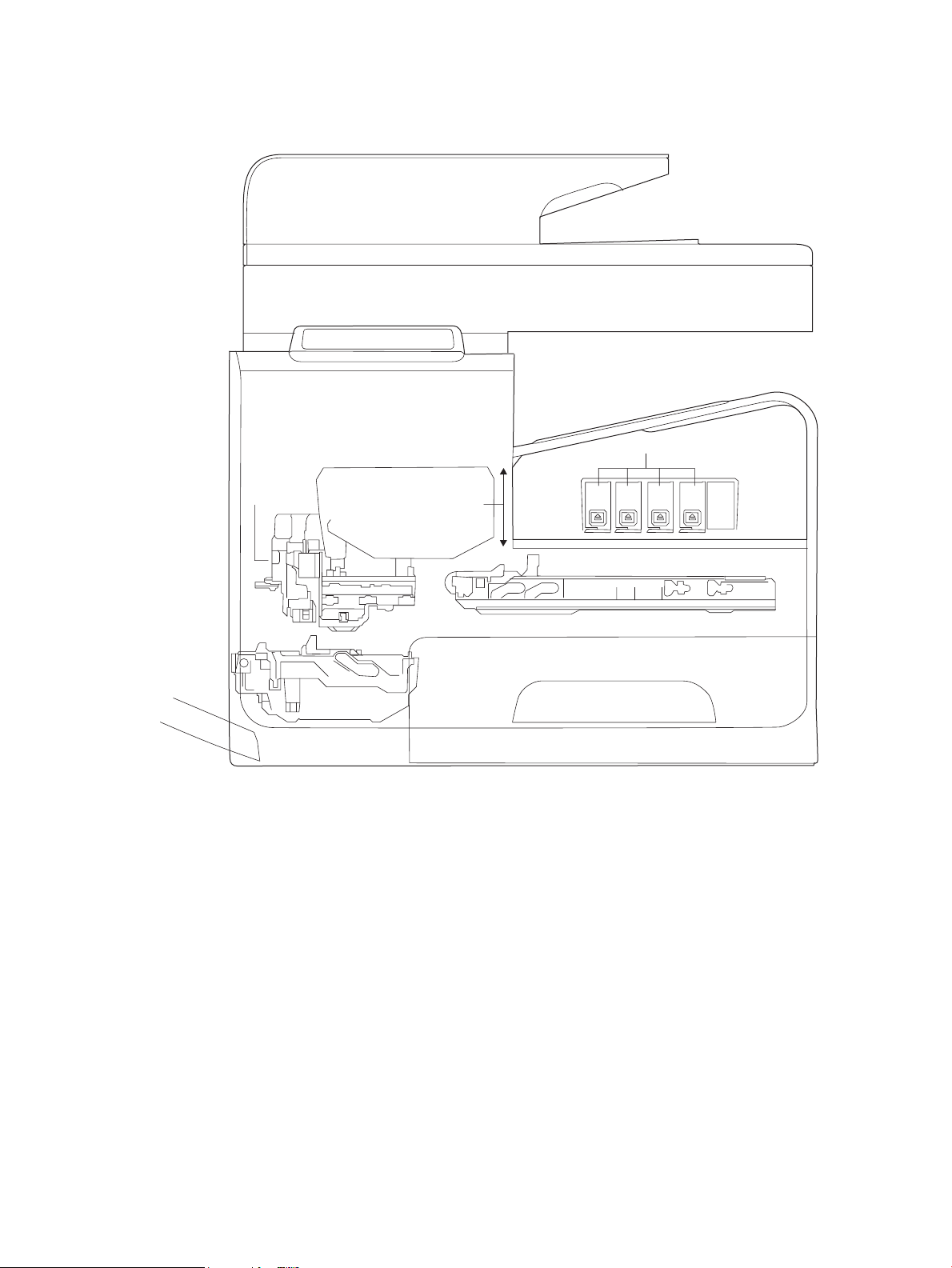

Figure 1-18 Servicing system components (500 series)

Service sled

Duplex module/

Ink collection unit

ENWW Servicing system 29

Page 40

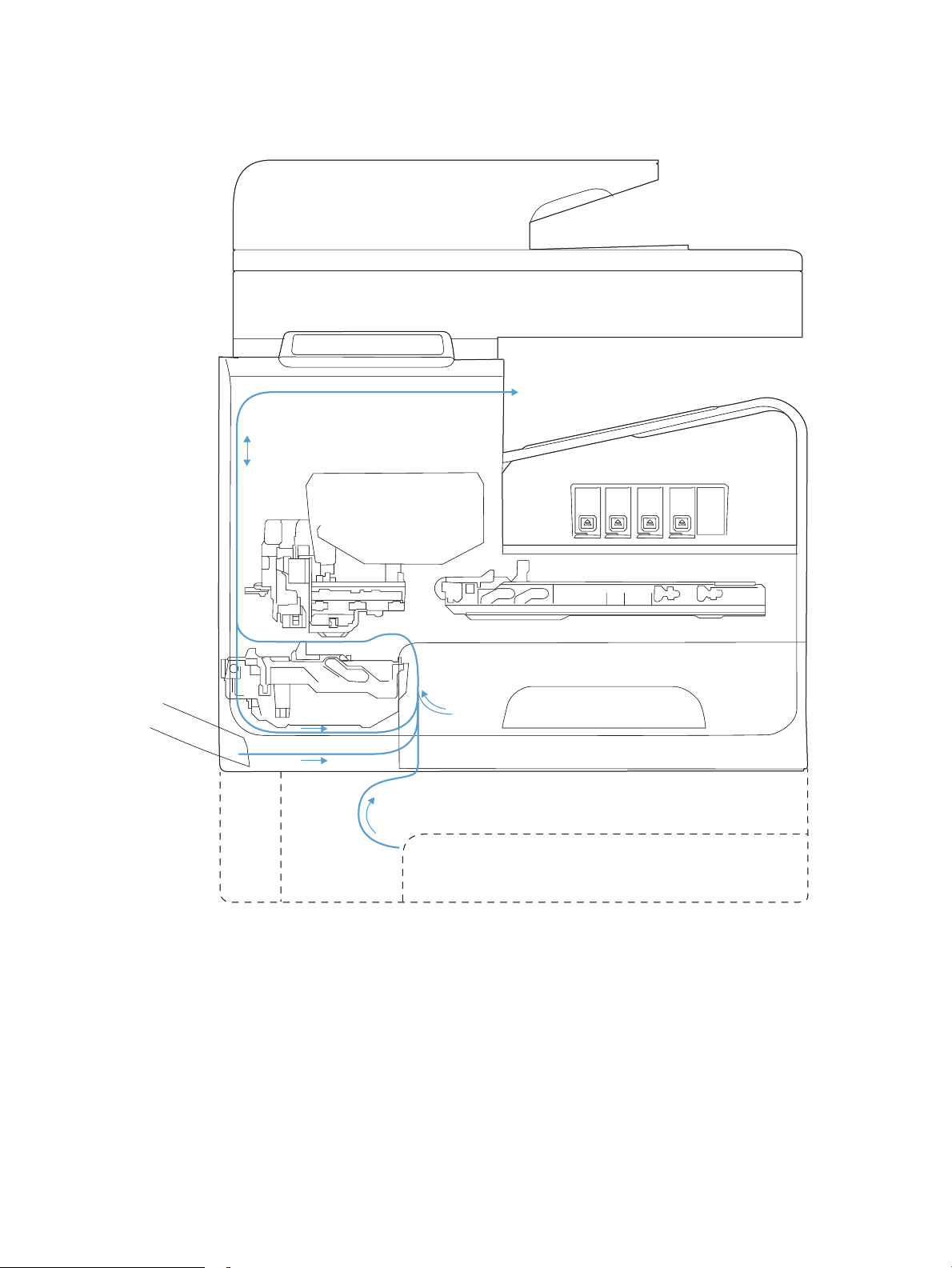

Service sled

1

2

3

4

Figure 1-19 Service sled components

Table 1-6 Service sled components

Item Description

1 Service sled cap

2 Service sled wiping surface

3 Service sled web fabric loop

4 Printbar support posts

The service sled system keeps the printbar nozzles ring correctly throughout the life of the printer as it

performs the wiping and capping functions.

●

The wiping function cleans the nozzles of ink residue and particulates.

●

The capping function keeps the nozzles moist during storage and when the printer is idle.

The service sled system uses the pick drive system (a component of the paper path) for horizontal motion to

perform its functions.

To perform the wiping function, the printer moves the service sled underneath the printbar (which is elevated

from the print position) so that the web fabric makes contact with the ink nozzles. The web fabric is a looped

belt that advances after every wipe. Since the belt is a nite loop, it will eventually reuse previously used

material. The web advances when the web wipe module moves to the right and out of the print zone. A

mechanism located on the rear wall of the unit triggers the advance mechanism..

To perform the capping function, the service sled moves underneath the printbar (which is elevated from the

print position), allowing the rubber cap to seal the print nozzles from the environment.

30 Chapter 1 Theory of operation ENWW

Page 41

Transmission system

The pick/service motor uses a multi-state transmission to power the following three functions:

●

Move the service sled

●

Pick paper from the main tray

●

Lift the main tray paper stack

The transmission has the following states:

●

Service sled (forward/reverse)

●

Pick (forward direction)/tray lift (reverse direction)

Printbar movement to a specic location releases the transmission lock, and enables the pick/service motor

to select the transmission state. The general location of the transmission parts is in Figure 1-20 Transmission

components, rear view on page 31.

NOTE: The transmission components are behind the main PCA electronics and are diicult to access.

Figure 1-20 Transmission components, rear view

The printer will not function with the transmission in the main tray pick/main tray lift state if the service

station has been manually capped.

Reusing caps or pushing the caps too far onto the printbar lift guide rods while servicing the printer can result

in the transmission not shifting reliably.

ENWW Transmission system 31

Page 42

Components

Service Station (PHSA)

Service Station

Drive Shaft (PHSA)

Link Pivot Arm

Shift Swing Arm

Pick Shaft (LPP)

Lower Swing Arm

MT Lift

Transmission (LPP)

Encoder PCA

Upper

Swing Arm

Belt

Motor

Figure 1-21 Transmission main components

States

1. State 1–Main tray lift

●

Link pivot arm and shift swing arm in locked

position

●

Upper swing arm down, engaged with lower

swing arm

●

Lower swing arm down, engaged with main

tray lift transmission

●

Printbar either up or down

2. State 1–Main tray pick

●

Link pivot arm and shift swing arm in locked

position

●

Upper swing arm down, engaged with lower

swing arm

●

Lower Swing arm up, engaged with pick shaft

●

Printbar either up or down

32 Chapter 1 Theory of operation ENWW

Page 43

3. State 1–Mid - Switch

●

Link pivot arm and shift swing arm in unlocked position

●

Upper swing arm in mid switch position

●

Printbar in middle position

4. State 2–Service Station

●

Link pivot arm and shift swing arm in locked

position

●

Upper swing arm up, engaged with service

sled drive shaft

●

Printbar either up or down

ENWW Transmission system 33

Page 44

Aerosol management system

Printbar

Platen

Duct

Duplex

module

Absorbers

Spit

Roller

Aerosol filter

Aerosol blower

Service ink capture (in duplex module)

Paper

The aerosol management system consists of a fan module and lter box to keep ink aerosol from building up

inside the printer. The following gure shows the service ink and aerosol capture system components.

Figure 1-22 Aerosol management process

In between pages, printed aerosol is drawn though the platen openings. Service ink travels directly through

the platen, impacting and collecting on the spit roller. Aerosol from the service spitting is also collected via

the same system. Service ink collects in the duplex module, and a porous lter element captures the aerosol

as aerosol-laden air passes through it. The aerosol blower mounted to the lter housing creates the air

motion (suction—lower pressure—in the print zone).

Most of printbar servicing ink (maintenance ink) is captured by the spit roller and scraped into the bottom of

the bucket on the duplex module. The service ink spit roller is indexed slowly by the motion of paper though

the printer, specically driven by the swingarm and turn-roller gear train, with power provided by the duplex

motor.

The printer purges the printbar of its shipping uid at initial startup, and then absorbers in the base of the

duplex module collect the uid. These absorbers allow much of the initial water to evaporate from the

shipping uid over time. Also, they allow service ink coming into contact with the absorbers to leach some of

their uids into them, assisting with drying and thickening of the sludge.

The blower remains active as long as the printbar is uncapped, and it continues to operate for a few seconds

after capping is complete.

34 Chapter 1 Theory of operation ENWW

Page 45

Figure 1-23 Aerosol management system components

1

2

3

4

Table 1-7 Aerosol management system components

Item Description

1 Blower

2 Aerosol lter housing

3 Duplex module/ink collection unit

4 Platen

ENWW Aerosol management system 35

Page 46

Document feeder system (377/477/577/P57750 models)

23

1

4

5

6

7

8

9

10

11

Document feed system

This section describes the following:

●

Rollers and sensors in the document feeder

●

Document feeder operation

●

Deskew operation

The printer supports single-pass electronic duplexing (e-duplex) copy jobs. Two separate scan modules scan

the front-side and back-side of an e-duplex copy job page in a single pass through the document feeder.

Rollers and sensors in the document feeder

The document feeder contains the following rollers and sensors:

Figure 1-24 Document feeder rollers and sensors

Table 1-8 Document feeder rollers and sensors

Item Description

1 Pre-pick Roller

2 Document ag

3 Separation roller

4 Pre-scan feed roller

5 Pre-scan pinch roller

6 TOF ag

7 E-duplex sensor

8 Post-scan feed roller

9 Post-scan pinch roller

10 Post-scan drive O-ring

11 Post-scan kicker roller

36 Chapter 1 Theory of operation ENWW

Page 47

Document feeder operation

1

2

3

Following is the basic sequence of operation for a document feeder job:

Figure 1-25 Document feeder operation

1. When the original pages to be copied are loaded in the document feeder input tray, the document ag

(callout 1) activates (state switches to 1). A Document loaded message appears on the control panel.

With this ag activated, the document feeder becomes the default copy or scan source. This ag

remains activated until all pages feed through the document feeder.

2. When copy or scan is initiated, the pick system engages and begins feeding the rst page. The leading

edge of the page triggers the TOF ag (callout 2) (state switches to 1) and the page feeds through the

scan-zone.

3. The atbed scan sensor collects the image of the front of the page. For duplex or two-sided scans, the

e-duplex scan sensor (callout 3) collects the scanned image of the back of the page. For a multiple-page

document, the document ag (callout 1) remains triggered (state remains at 1).

4. The trailing edge of the rst page disengages the TOF ag (callout 2) (state switches to 0). The leading

edge of the next page engages the TOF ag (callout 2) (state switches to 1), initiating the scan of the

second page. All of the originals feed through the document feeder with the leading and trailing edges

of the pages engaging and disengaging the TOF ag in this manner.

5. When the last page feeds through the document feeder, the document ag (callout 1) disengages (state

switches to 0). This signals that the job is complete. After the TOF ag (callout 2) sees the last trailing

edge (state switches to 0), the last sheet ejects, the pick system lifts, and the scan or copy job

completes.

6. A pick failure occurs if the page doesn’t reach the TOF ag (callout 2) within a certain time frame. If this

failure occurs, the pick system will make two more attempts to pick the page before displaying a Reload

original message on the control panel.

7. The TOF ag (callout 2) expects to see the trailing edge of the page within approximately 43.18 cm

(17 in) from the beginning of the page. If this does not happen, a document jam message displays on the

control panel.

ENWW Document feeder system (377/477/577/P57750 models) 37

Page 48

Deskew operation

Sliding side guides on the document feeder input tray ensure that the paper stack is correctly aligned at the

center of the input tray when paper is loaded in the tray. The correct position of the loaded paper is parallel

with the direction of travel into the document feeder paper path.

The document feeder further reduces paper skew due to improper loading of paper in the input tray by

buckling the paper to create a paper buer.

The document feeder aligns the leading edge of the paper parallel with the deskew drive rollers before the

paper is driven further into the document feeder paper path.

NOTE: If the page to be copied is smaller than the minimal sliding guide setting, do not use the document

feeder for the copy job. Attempting to copy too small of a page using the document feeder can result in

document feeder jams and/or damage to the original page. Instead, use the atbed glass to copy the page.

Figure 1-26 Deskew operation

38 Chapter 1 Theory of operation ENWW

Page 49

Scanning and image capture system (377/477/577/P57750 models)

The scanner is a carriage-type platen scanner that includes the frame, glass, scan module, and a scan control

board (SCB). The scanner has a sensor to detect legal-sized paper and a switch to indicate when the document

feeder is opened.

ENWW Scanning and image capture system (377/477/577/P57750 models) 39

Page 50

Fax functions and operation (377/477/577/P57750 models)

The following sections describe the printer fax capabilities.

Computer and network security features

The printer can send and receive fax data over telephone lines that conform to public switch telephone

network (PSTN) standards. The secure fax protocols make it impossible for computer viruses to be

transferred from the telephone line to a computer or network.

The following printer features prevent virus transmission:

●

No direct connection exists between the fax line and any devices that are connected to the USB or

Ethernet ports.

●

The internal rmware cannot be modied through the fax connection.

●

All fax communications go through the fax subsystem, which does not use Internet data-exchange

protocols.

PSTN operation

The PSTN operates through a central oice (CO) that generates a constant voltage on the TIP and RING wires

(usually 48 V). A device goes o-hook by connecting impedance (such as 600 ohms for the U.S.) across the TIP

and RING so that a line current can ow. The CO can detect this current and send impulses like dial tones. The

printer generates more signaling tones, such as dialing digits, to tell the CO how to connect the call. The

printer can also detect tones, such as a busy tone from the CO, that tell it how to behave.

When the call is connected, the CO behaves like a wire connecting the sender and receiver. This is the period

during which all of the fax signaling and data transfer occurs. When a call is completed, the circuit opens

again and the line-current ow ceases, removing the CO connection from both the sender and the receiver.

On most phone systems, the TIP and RING signals appear on pins 3 and 4 of the RJ-11 modular jack (the one

on the fax card, as dened in the common 6-wire RJ standard). These two signals do not have to be polarized

because all the equipment works with TIP on one pin and RING on the other pin. This means that cables of

either polarity can interconnect and still work.

These basic functions of PSTN operation are assumed in the design of the fax subsystem. The printer

generates and detects the signaling tones, currents, and data signals that are required to transmit and

receive faxes using the PSTN.

The fax subsystem

The formatter, fax card, rmware, and software all contribute to the printer fax functionality. The designs of

the formatter and fax card, along with parameters in the rmware, determine the majority of the regulatory

requirements for telephony on the printer.

The fax subsystem is designed to support V.34 fax transmission, medium speeds (such as V.17 fax), and the

lower speeds of older fax machines.

Fax card in the fax subsystem

The fax card contains the modem chipset (DSP and CODEC) that controls the basic fax functions of tone

generation and detection, along with channel control for fax transmissions. The CODEC and its associated

circuitry act as the third-generation silicon data access arrangement (DAA) to comply with worldwide

regulatory requirements.

40 Chapter 1 Theory of operation ENWW

Page 51

Safety isolation

The fax card provides safety isolation between the high-voltage, transient-prone environment of the

telephone network (TNV—telephone network voltage) and the low-voltage analog and digital circuitry of the

formatter (SELV—secondary extra-low voltage). This safety isolation provides both customer safety and

printer reliability in the telecom environment.

Any signals that cross the isolation barrier do so magnetically. The breakdown voltage rating of barriercritical components is greater than 5 kV.

Safety-protection circuitry

In addition to the safety barrier, the fax card protects against overvoltage and overcurrent events.

Telephone overvoltage events can be either dierential mode or common mode. The event can be transient in

nature (a lightning-induced surge or ESD) or continuous (a power line crossed with a phone line). The fax card

protection circuitry provides a margin of safety against combinations of overvoltage and overcurrent events.

Common mode protection is provided by the selection of high-voltage, barrier-critical components

(transformer and relay). The safety barrier of the fax card PCA and the clearance between the fax card and

surrounding components also contribute to common mode protection.

A voltage suppressor (a crowbar-type thyristor) provides dierential protection. This device becomes low

impedance at approximately 300 V dierential, and crowbars to a low voltage.

Data path

TIP and RING are the two-wire paths for all signals from the telephone network. All signaling and data

information comes across them, including fax tones and fax data.

The telephone network uses DC current to determine the hook state of the telephone, so line current must be

present during a call. The silicon DAA provides a DC holding circuit to keep the line current constant during a

fax call.

The silicon DAA converts the analog signal to a digital signal for DSP processing, and also converts the digital

signal to an analog signal for transmitting data through a telephone line.

The magnetically coupled signals that cross the isolation barrier go through a transformer.

The DSP in the fax card communicates with the ASIC on the formatter using the high-speed serial interface.

Ring detect

Ring detect is performed by the line voltage monitoring module of the silicon DAA, and is a combination of

voltage levels and cadence (time on and time o). Both must be present to detect a valid ring. The CODEC

works with DSP and the rmware to determine if an incoming signal is an answerable ring.

Line current control

The DC current from the CO needs to have a path to ow from TIP to RING. The DC impedance emulation line

modulator and DC termination modules in the silicon DAA act as a DC holding circuit, and work with the

rmware to achieve the voltage-current characteristic between TIP and RING. The impedance (the currentvoltage characteristic) changes in correspondence to certain special events, such as pulse dialing or when the

printer goes on-hook.

ENWW Fax functions and operation (377/477/577/P57750 models) 41

Page 52

Fax page storage in ash memory

Fax pages are the electronic images of the document page. They can be created in one of three ways: scanned

to be sent to another fax machine, generated to be sent by the computer, or received from a fax machine to be

printed.

The printer automatically stores all fax pages in ash memory. After these pages are written into ash

memory, they are stored until the pages are sent to another fax machine, printed on the printer, transmitted

to the computer, or erased by the user.

These pages are stored in ash memory, which is the nonvolatile memory that can be repeatedly read from,

written to, and erased. The printer has 512 MB of total

settings, job storage and fax storage.

Advantages of ash memory storage

Fax pages that are stored in ash memory are persistent. They are not lost as a result of a power failure, no

matter how long the power is o. Users can reprint faxes if an ink cartridge runs out of ink or the printer

experiences other errors while printing faxes.

The printer also has scan-ahead functionality that makes use of ash memory. Scan-ahead automatically

scans pages into ash memory before a fax job is sent. This allows the sender to pick up the original

document immediately after it is scanned, eliminating the need to wait until the fax transmission is complete.

Because fax pages are stored in ash memory rather than RAM, more RAM is available to handle larger and

more complicated copy and print jobs.

ash memory, shared between rmware, customer

42 Chapter 1 Theory of operation ENWW

Page 53

2 Solve problems

●

Restore the factory-set defaults

●

Menu access

●

Perform tap tests and interpret results

●

Troubleshooting owchart

●

Front-panel error codes

●

Control-panel messages

●

Error-related symptoms

●

Check symptoms

ENWW 43

Page 54

Restore the factory-set defaults

CAUTION: Restoring the factory-set defaults returns all of the printer and network settings to the factory