HP LaserJet Pro 100 Color MFP M176n, LaserJet Pro 100 Color MFP M177fw Troubleshooting Manual

COLOR LASERJET PRO MFP

Troubleshooting Manual

OK

X

M176 M177

HP Color LaserJet Pro MFP M176, M177

Troubleshooting Manual

Copyright and License

Trademark Credits

© 2013 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or

omissions contained herein.

Part number: CZ165-90944

Edition 1, 9/2013

Microsoft®, Windows®, Windows® XP, and

Windows Vista® are U.S. registered trademarks

of Microsoft Corporation.

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging the

product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal injury,

catastrophic loss of data, or extensive damage to the product.

ENWW iii

Table of contents

1 Theory of operation ....................................................................................................................................... 1

Basic operation ...................................................................................................................................................... 2

Major product systems ........................................................................................................................ 2

Sequence of operation ........................................................................................................................ 3

Formatter-control system ..................................................................................................................................... 4

Sleep mode .......................................................................................................................................... 4

Input/output ........................................................................................................................................ 4

CPU ....................................................................................................................................................... 4

Memory ................................................................................................................................................ 4

NAND Flash memory ........................................................................................................................... 4

Firmware .............................................................................................................................................. 5

Memory use ......................................................................................................................................... 5

PJL overview ........................................................................................................................................ 5

LEDM overview .................................................................................................................................... 5

Control panel ....................................................................................................................................... 5

Engine-control system .......................................................................................................................................... 6

DC controller ........................................................................................................................................ 7

Low-voltage power supply ................................................................................................................. 8

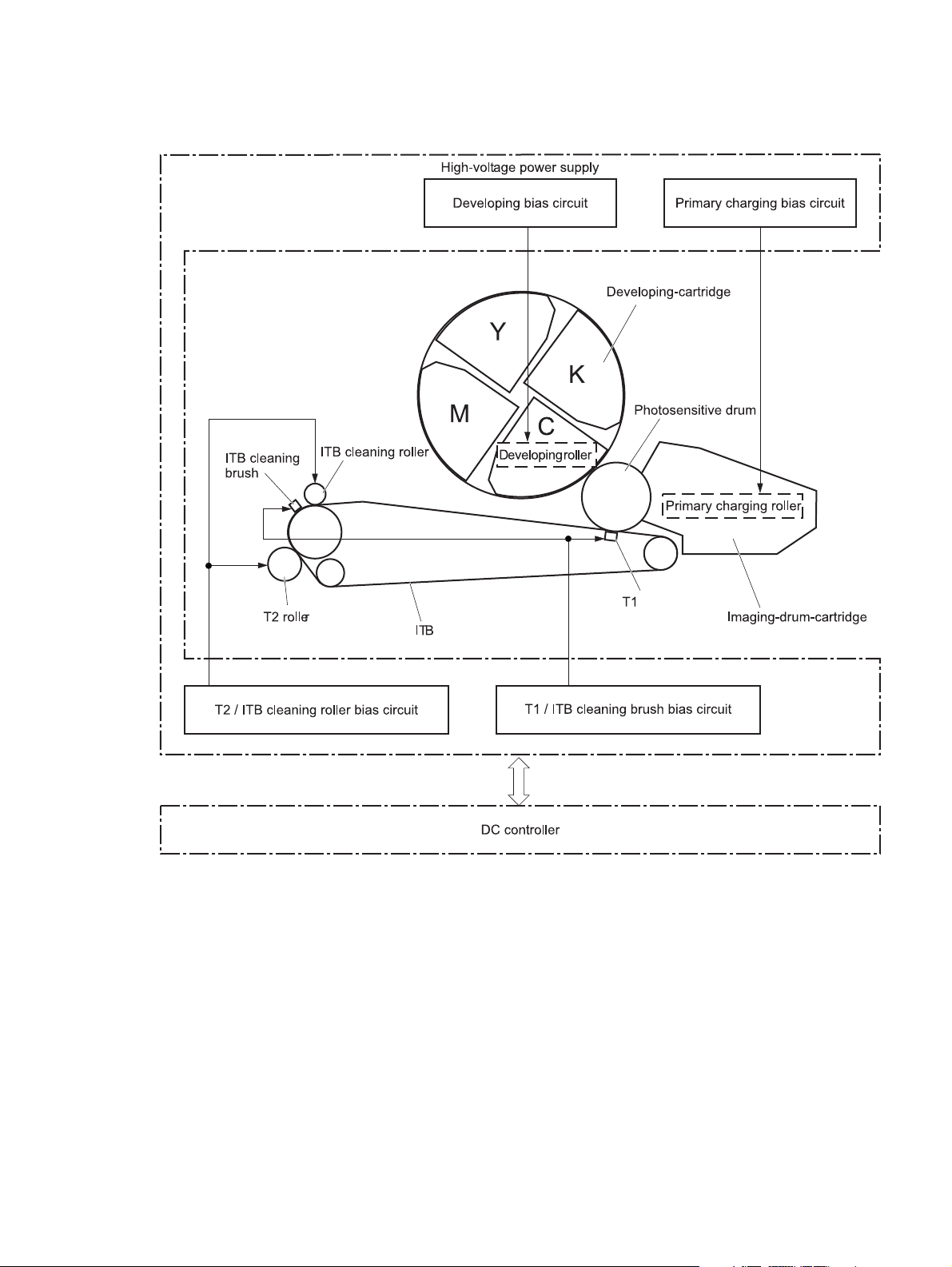

High-voltage power supply ................................................................................................................. 9

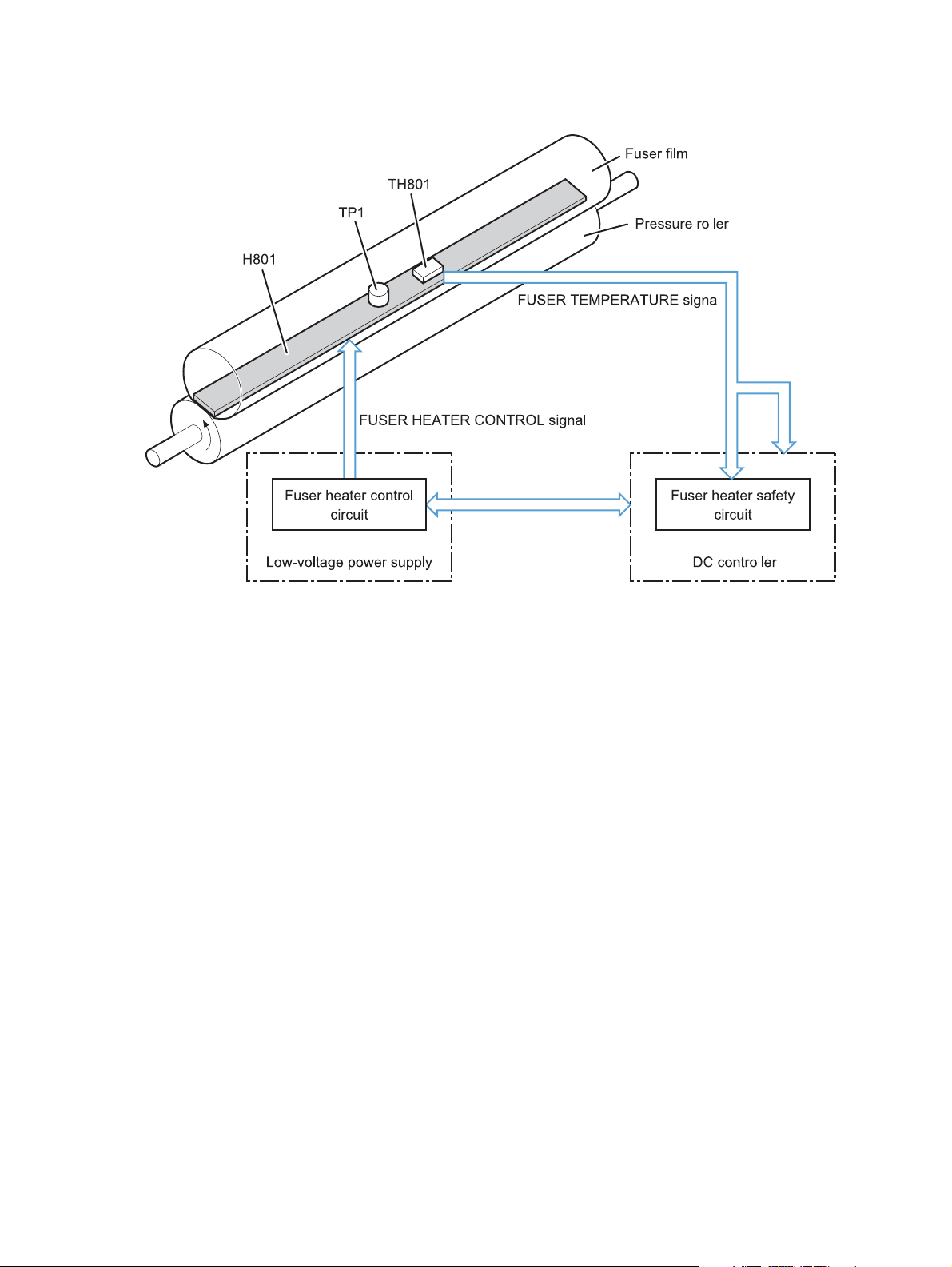

Fuser control ..................................................................................................................................... 10

Image-formation system .................................................................................................................................... 11

Image-formation process ................................................................................................................. 12

Latent-image formation stage ....................................................................................... 14

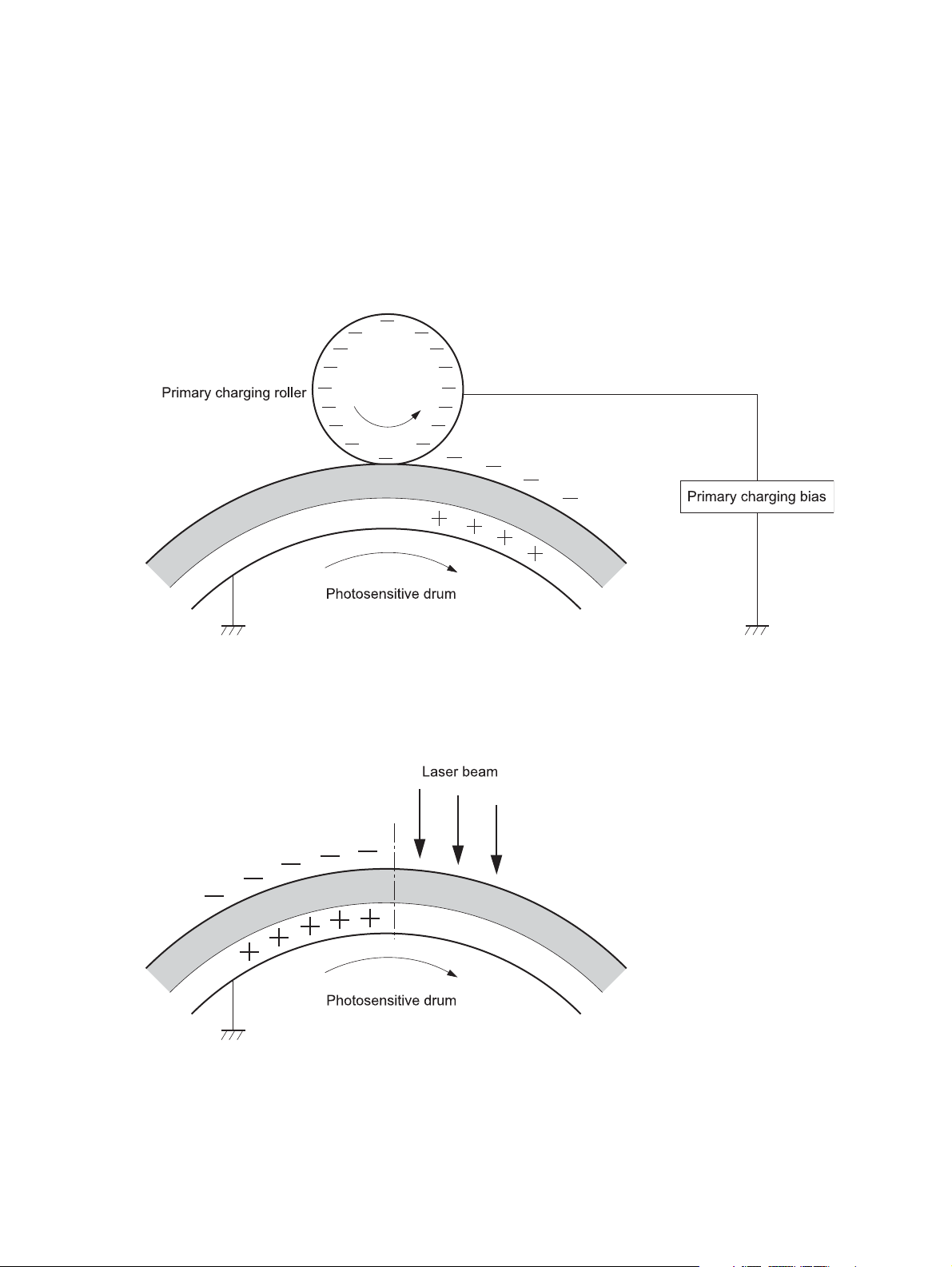

Step 1: Primary charging .............................................................................. 14

Step 2: Laser-beam exposure ...................................................................... 14

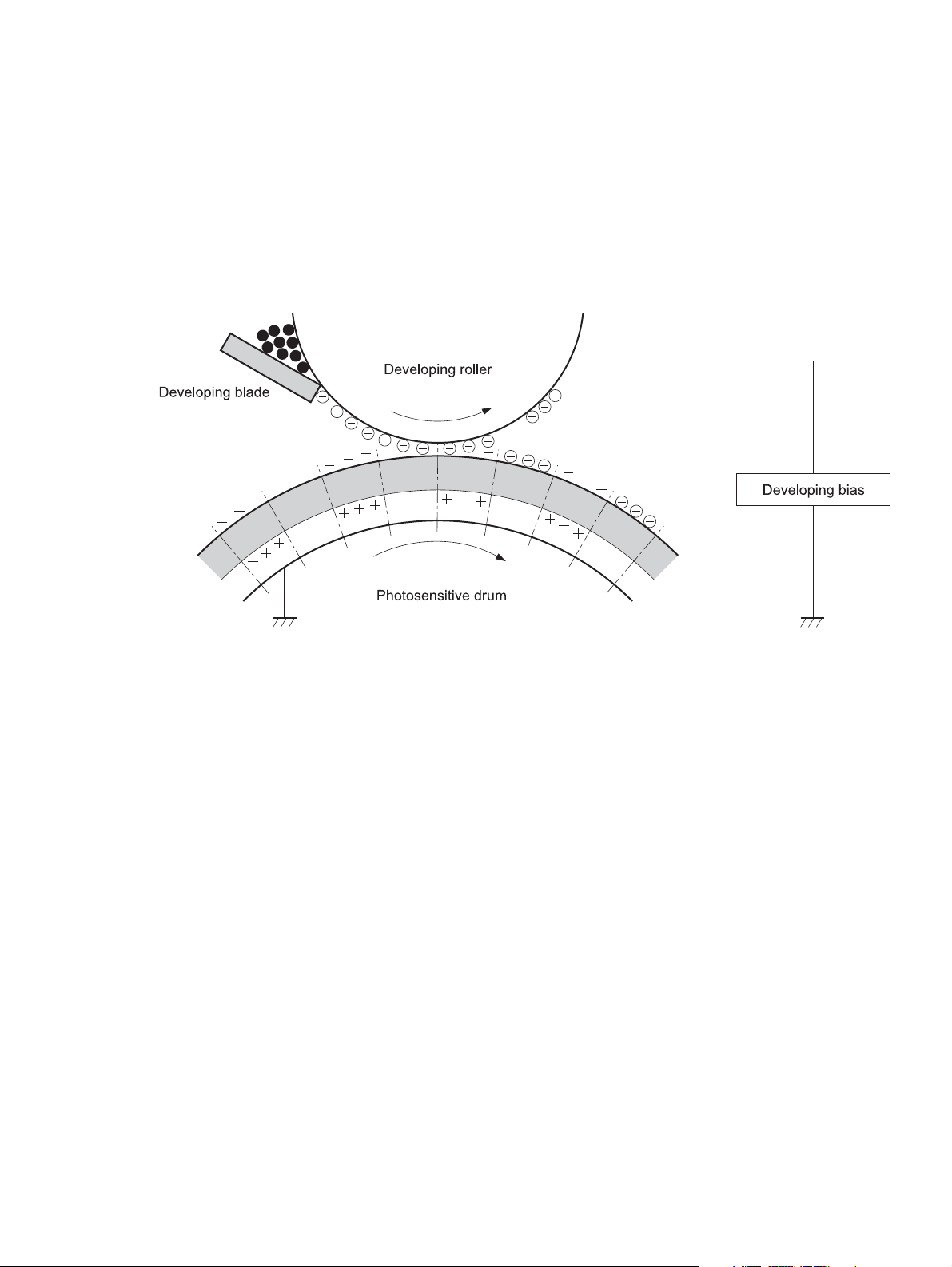

Developing stage ............................................................................................................ 15

Step 3: Development .................................................................................... 15

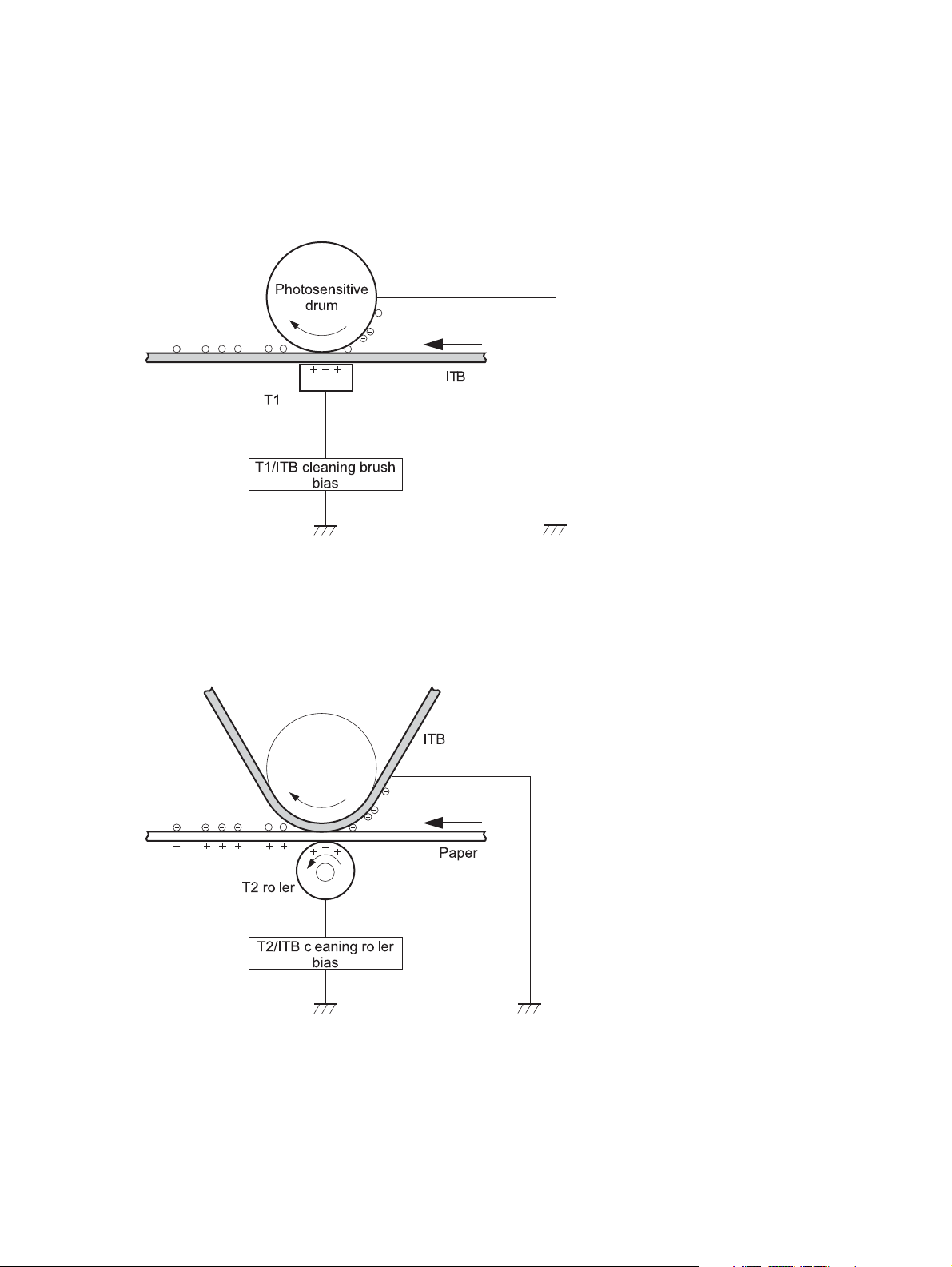

Transfer stage ................................................................................................................. 16

Step 4: Primary transfer ............................................................................... 16

Step 5: Secondary transfer .......................................................................... 16

Step 6: Separation from the drum ............................................................... 17

Fusing stage .................................................................................................................... 17

ENWW v

Step 7: Fusing ............................................................................................... 17

Drum cleaning stage ....................................................................................................... 18

Step 8: Drum cleaning .................................................................................. 18

ITB cleaning mechanism ................................................................................................. 18

Pickup, feed, and delivery system ...................................................................................................................... 20

Photo sensors and switches ............................................................................................................. 21

Main-input tray .................................................................................................................................................... 22

Jam detection .................................................................................................................................... 22

Scanner system ................................................................................................................................................... 23

Electrical system ............................................................................................................................... 23

Scanner power-on sequence of events .......................................................................... 23

Copy or scan-to-computer sequence of events ............................................................. 24

Document feeder functions and operation ......................................................................................................... 25

Document feeder operation .............................................................................................................. 25

Document feeder paper path and document feeder sensors .......................................................... 25

Document feeder jam detection ....................................................................................................... 26

Fax functions and operation ............................................................................................................................... 27

Computer and network security features ........................................................................................ 27

PSTN operation ................................................................................................................................. 27

The fax subsystem ............................................................................................................................ 27

Fax card in the fax subsystem .......................................................................................................... 27

Safety isolation ............................................................................................................... 28

Safety-protection circuitry ............................................................................................. 28

Data path ......................................................................................................................... 28

Hook state ....................................................................................................................... 28

Downstream device detection ........................................................................................ 29

Hook switch control ........................................................................................................ 29

Ring detect ...................................................................................................................... 29

Line current control ........................................................................................................ 29

Billing- (metering-) tone filters ...................................................................................... 29

Fax page storage in flash memory ................................................................................................... 29

Stored fax pages ............................................................................................................. 30

Advantages of flash memory storage ............................................................................ 30

2 Solve problems ........................................................................................................................................... 31

Solve problems checklist ..................................................................................................................................... 32

Step 1: Test print functionality ......................................................................................................... 32

Step 2: Test copy functionality ......................................................................................................... 32

Menu map ............................................................................................................................................................ 33

Troubleshooting processes ................................................................................................................................. 34

Determine the problem source ......................................................................................................... 34

vi ENWW

Power subsystem .............................................................................................................................. 35

Power-on checks ............................................................................................................ 35

Tools for troubleshooting ................................................................................................................................... 36

Component diagnostics .................................................................................................................... 36

Engine-test page ............................................................................................................ 36

LCD control-panel tests .................................................................................................. 36

Touchscreen control-panel tests ................................................................................... 36

Diagrams ........................................................................................................................................... 38

Plug/jack locations ......................................................................................................... 38

Locations of connectors ................................................................................................. 39

Locations of major components ..................................................................................... 41

General timing chart ....................................................................................................... 43

General circuit diagram .................................................................................................. 44

Internal print-quality test pages ...................................................................................................... 45

Clean the paper path ....................................................................................................... 45

Print Configuration page ................................................................................................ 45

Print-quality troubleshooting tools ................................................................................................. 46

Repetitive image defects ruler ....................................................................................... 46

Calibrate the product ...................................................................................................... 47

Control panel menus ......................................................................................................................... 48

Touchscreen control panel ............................................................................................. 48

Setup menu .................................................................................................. 48

Fax Menu ....................................................................................................... 55

Copy Menu .................................................................................................... 57

LCD control panel ............................................................................................................ 59

Setup menu .................................................................................................. 59

Interpret control-panel messages .................................................................................................... 66

Control-panel message types ........................................................................................ 66

Control-panel messages ................................................................................................ 66

Clear jams ............................................................................................................................................................ 73

Solve paper feed or jam problems .................................................................................................... 73

The product does not pick up paper ............................................................................... 73

The product picks up multiple sheets of paper .............................................................. 73

Frequent or recurring paper jams .................................................................................. 73

Prevent paper jams ......................................................................................................... 74

Clear jams from the input tray .......................................................................................................... 75

Clear jams in the output bin .............................................................................................................. 79

Clear jams in the document feeder ................................................................................................... 81

Solve paper-handling problems .......................................................................................................................... 83

Solve image-quality problems ............................................................................................................................ 84

General print-quality issues ............................................................................................................. 84

ENWW vii

Color image defects .......................................................................................................................... 88

Copy print-quality problems ............................................................................................................. 93

Scan-quality problems ...................................................................................................................... 94

Prevent scan-quality problems ...................................................................................... 94

Solve scan-quality problems .......................................................................................... 94

Clean the product ................................................................................................................................................ 95

Print a cleaning page ......................................................................................................................... 95

Check the scanner glass for dirt and smudges ................................................................................. 95

Clean the pickup rollers and separation pad in the document feeder ............................................. 96

Solve performance problems .............................................................................................................................. 97

Solve connectivity problems ............................................................................................................................... 98

Solve direct-connect problems ......................................................................................................... 98

Solve wired network problems ......................................................................................................... 98

Poor physical connection ................................................................................................ 98

The computer is using the incorrect IP address for the product ................................... 98

The computer is unable to communicate with the product ........................................... 99

The product is using incorrect link and duplex settings for the network ...................... 99

New software programs might be causing compatibility problems ............................. 99

The computer or workstation might be set up incorrectly ............................................ 99

The product is disabled, or other network settings are incorrect ................................. 99

Solve wireless network problems .................................................................................................... 99

Wireless connectivity checklist .................................................................................... 100

The product does not print after the wireless configuration completes .................... 100

The product does not print, and the computer has a third-party firewall installed ... 101

The wireless connection does not work after moving the wireless router or

product .......................................................................................................................... 101

Cannot connect more computers to the wireless product .......................................... 101

The wireless product loses communication when connected to a VPN ...................... 101

The network does not appear in the wireless networks list ....................................... 101

The wireless network is not functioning ...................................................................... 101

Perform a wireless network diagnostic test ................................................................ 102

Reduce interference on a wireless network ................................................................ 102

Service mode functions ..................................................................................................................................... 103

Secondary service menu ................................................................................................................. 103

Open the secondary service menu ............................................................................... 103

Secondary service menu structure .............................................................................. 103

Product resets ................................................................................................................................. 105

Restore factory settings ............................................................................................... 105

NVRAM initialization ..................................................................................................... 105

Solve fax problems ............................................................................................................................................ 106

Check the hardware setup .............................................................................................................. 106

viii ENWW

Faxes are sending slowly ................................................................................................................ 107

Fax quality is poor ........................................................................................................................... 108

Fax cuts off or prints on two pages ................................................................................................ 109

Product updates ................................................................................................................................................ 110

Appendix A Service and support .................................................................................................................... 111

Hewlett-Packard limited warranty statement ................................................................................................. 112

HP's Premium Protection Warranty: LaserJet toner cartridge limited warranty statement ........................... 113

HP policy on non-HP supplies ........................................................................................................................... 114

HP anticounterfeit Web site .............................................................................................................................. 115

Data stored on the toner cartridge ................................................................................................................... 116

End User License Agreement ............................................................................................................................ 117

OpenSSL ............................................................................................................................................................. 119

Customer self-repair warranty service ............................................................................................................. 120

Customer support .............................................................................................................................................. 121

Appendix B Product specifications ................................................................................................................. 123

Physical specifications ...................................................................................................................................... 124

Power consumption, electrical specifications, and acoustic emissions .......................................................... 124

Environmental specifications ............................................................................................................................ 124

Appendix C Regulatory information ............................................................................................................... 125

FCC regulations .................................................................................................................................................. 126

Environmental product stewardship program ................................................................................................. 127

Protecting the environment ........................................................................................................... 127

Ozone production ............................................................................................................................ 127

Power consumption ........................................................................................................................ 127

Toner consumption ......................................................................................................................... 127

Paper use ......................................................................................................................................... 127

Plastics ............................................................................................................................................ 127

HP LaserJet print supplies .............................................................................................................. 127

Return and recycling instructions ................................................................................................... 128

United States and Puerto Rico ...................................................................................... 128

Multiple returns (more than one cartridge) ............................................... 128

Single returns ............................................................................................. 128

Shipping ...................................................................................................... 128

Non-U.S. returns ........................................................................................................... 129

Paper ............................................................................................................................................... 129

Material restrictions ........................................................................................................................ 129

Disposal of waste equipment by users ........................................................................................... 13 0

ENWW ix

Electronic hardware recycling ........................................................................................................ 130

Chemical substances ....................................................................................................................... 130

Material Safety Data Sheet (MSDS) ................................................................................................ 130

For more information ...................................................................................................................... 130

Declaration of conformity (M176n model) ....................................................................................................... 131

Declaration of conformity (M177fw model) ..................................................................................................... 133

Safety statements ............................................................................................................................................. 135

Laser safety ..................................................................................................................................... 135

Canadian DOC regulations .............................................................................................................. 135

VCCI statement (Japan) ................................................................................................................... 135

Power cord instructions .................................................................................................................. 135

Power cord statement (Japan) ....................................................................................................... 135

EMC statement (Korea) ................................................................................................................... 136

Laser statement for Finland ........................................................................................................... 136

GS statement (Germany) ................................................................................................................ 137

Substances Table (China) ................................................................................................................ 137

Restriction on Hazardous Substances statement (Turkey) ........................................................... 137

Restriction on Hazardous Substances statement (Ukraine) .......................................................... 137

Eurasian Conformity (Belarus, Kazakhstan, Russia) ...................................................................... 138

Additional statements for telecom (fax) products ........................................................................................... 139

EU Statement for Telecom Operation ............................................................................................ 139

New Zealand Telecom Statements ................................................................................................. 139

Additional FCC statement for telecom products (US) .................................................................... 139

Telephone Consumer Protection Act (US) ...................................................................................... 140

Industry Canada CS-03 requirements ............................................................................................ 140

Vietnam Telecom wired/wireless marking for ICTQC Type approved products ............................ 141

Additional statements for wireless products ................................................................................................... 142

FCC compliance statement—United States ................................................................................... 142

Australia statement ........................................................................................................................ 142

Brazil ANATEL statement ................................................................................................................ 142

Canadian statements ...................................................................................................................... 142

Products with 5 GHz Operation Industry of Canada ....................................................................... 142

Exposure to Radio Frequency Radiation (Canada) ......................................................................... 142

European Union regulatory notice .................................................................................................. 143

Notice for use in France .................................................................................................................. 143

Notice for use in Russia ................................................................................................................... 143

Mexico statement ........................................................................................................................... 143

Taiwan statement ........................................................................................................................... 144

Korean statement ........................................................................................................................... 144

Vietnam Telecom wired/wireless marking for ICTQC Type approved products ............................ 141

x ENWW

Index ........................................................................................................................................................... 145

ENWW xi

List of tables

Table 1-1 Sequence of operation ......................................................................................................................................... 3

Table 1-2 Photo sensors and switches .............................................................................................................................. 21

Table 1-3 Document feeder sensors .................................................................................................................................. 25

Table 2-1 Determine the problem source .......................................................................................................................... 34

Table 2-2 Plug/jack locations ............................................................................................................................................. 38

Table 2-3 Engine control unit PCA connectors .................................................................................................................. 39

Table 2-4 Cross section view .............................................................................................................................................. 41

Table 2-5 External covers and doors (base) ...................................................................................................................... 42

Table 2-6 Repetitive image defects ruler .......................................................................................................................... 46

Table 2-7 HP Web Services menu (touchscreen control panel) ........................................................................................ 48

Table 2-8 Reports menu (touchscreen control panel) ....................................................................................................... 49

Table 2-9 Self Diagnostics menu (touchscreen control panel) ......................................................................................... 49

Table 2-10 Fax Setup menu (touchscreen control panel) ................................................................................................. 49

Table 2-11 System Setup menu (touchscreen control panel) ........................................................................................... 52

Table 2-12 Service menu (touchscreen control panel) ...................................................................................................... 54

Table 2-13 Network Setup menu (touchscreen control panel) ......................................................................................... 55

Table 2-14 Fax Menu (touchscreen control panel) ............................................................................................................ 55

Table 2-15 Copy Menu (touchscreen control panel) .......................................................................................................... 57

Table 2-16 HP Web Services menu (LCD control panel) .................................................................................................... 48

Table 2-17 Copy Setup menu (LCD control panel) ............................................................................................................. 57

Table 2-18 ID Copy menu (LCD control panel) ................................................................................................................... 60

Table 2-19 Reports menu (LCD control panel) .................................................................................................................. 60

Table 2-20 Self Diagnostics menu (LCD control panel) ..................................................................................................... 61

Table 2-21 System Setup menu (LCD control panel) ......................................................................................................... 52

Table 2-22 Service menu (LCD control panel) .................................................................................................................... 54

Table 2-23 Network Setup menu (LCD control panel) ....................................................................................................... 55

Table 2-24 Control-panel messages .................................................................................................................................. 66

Table 2-25 Solve paper-handling problems ...................................................................................................................... 83

Table 2-26 General print-quality issues ............................................................................................................................ 84

Table 2-27 Color image defects ......................................................................................................................................... 88

Table 2-28 Copy print-quality problems ............................................................................................................................ 93

Table 2-29 Scan-quality problems ..................................................................................................................................... 94

ENWW xiii

Table 2-30 Solve performance problems .......................................................................................................................... 97

Table 2-31 Secondary service menu ................................................................................................................................ 103

Table B-1 Physical specifications ..................................................................................................................................... 124

Table B-2 Product dimensions with document feeder opened ....................................................................................... 124

Table B-3 Operating-environment specifications ........................................................................................................... 124

xiv ENWW

List of figures

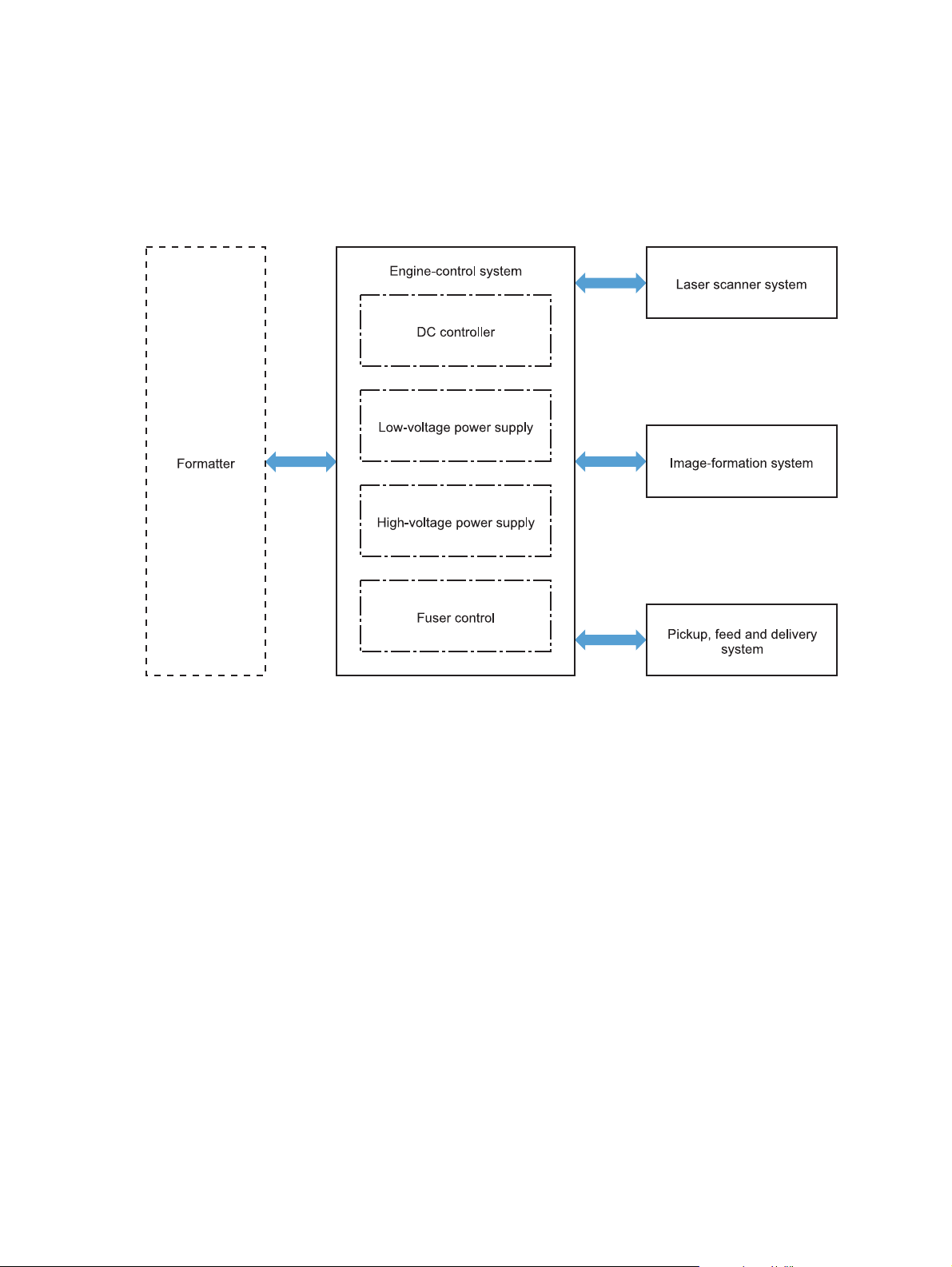

Figure 1-1 Product systems ................................................................................................................................................. 2

Figure 1-2 Engine control system components ................................................................................................................... 6

Figure 1-3 DC controller circuit diagram .............................................................................................................................. 7

Figure 1-4 Low-voltage power supply ................................................................................................................................. 8

Figure 1-5 High-voltage power supply ................................................................................................................................ 9

Figure 1-6 Image-formation system .................................................................................................................................. 12

Figure 1-7 Image-formation process ................................................................................................................................. 13

Figure 1-8 Primary charging ............................................................................................................................................... 14

Figure 1-9 Laser-beam exposure ....................................................................................................................................... 14

Figure 1-10 Development .................................................................................................................................................. 15

Figure 1-11 Primary transfer ............................................................................................................................................. 16

Figure 1-12 Secondary transfer ......................................................................................................................................... 16

Figure 1-13 Separation from the drum .............................................................................................................................. 17

Figure 1-14 Fusing .............................................................................................................................................................. 17

Figure 1-15 Drum cleaning ................................................................................................................................................. 18

Figure 1-16 ITB cleaning mechanism ................................................................................................................................. 18

Figure 1-17 Pickup, feed, and delivery system block diagram ......................................................................................... 20

Figure 1-18 Photo sensors and switches ........................................................................................................................... 21

Figure 1-19 Document feeder paper path and document feeder sensors ........................................................................ 25

Figure 2-1 Plug/jack locations ........................................................................................................................................... 38

Figure 2-2 Locations of connectors ................................................................................................................................... 39

Figure 2-3 Cross section view ............................................................................................................................................. 41

Figure 2-4 External covers and doors (base) ..................................................................................................................... 42

Figure 2-5 General timing diagram .................................................................................................................................... 43

Figure 2-6 General circuit diagram ..................................................................................................................................... 44

ENWW xv

1 Theory of operation

This chapter presents an overview of the major components of the product, and it includes a detailed

discussion of the image-formation system.

●

Basic operation

●

Formatter-control system

●

Engine-control system

●

Image-formation system

●

Pickup, feed, and delivery system

●

Main-input tray

●

Scanner system

●

Document feeder functions and operation

●

Fax functions and operation

ENWW 1

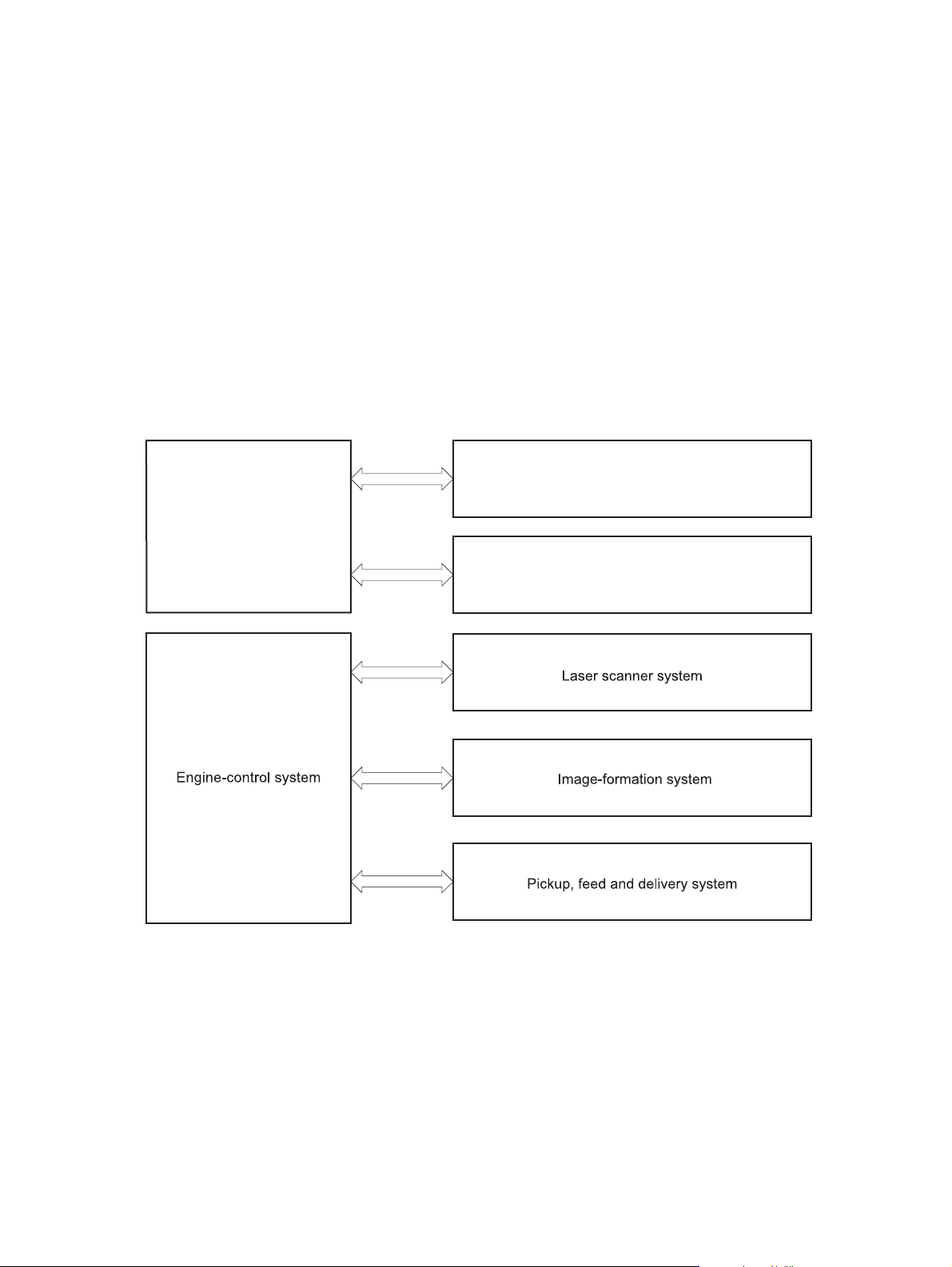

Basic operation

Major product systems

The product includes the following systems:

●

Document feeder

●

Document scanner

●

Engine control system

●

Laser/scanner system

●

Image-formation system

●

Pickup-and-feed system

Figure 1-1 Product systems

Formatter

Document feeder

Document scanner

2 Chapter 1 Theory of operation ENWW

Sequence of operation

Table 1-1 Sequence of operation

Period Duration Purpose Remarks

WAIT From the time the power is

turned on or the door is closed

until the drum-phase

adjustment is complete

STBY (Standby period) From end of the WAIT or LSTR

period until either the print

command is received from the

formatter or the power is

turned off

INTR (Initial rotation) From the time the print

command is received until the

paper is picked up

PRINT From the end of INTR period

until the fuser paper sensor

detects the trailing edge of

paper

LSTR (Last rotation) From the end of the PRINT

period until the motor stops

rotating

Clears the potential from the

drum surface, adjusts the drum

phase, and cleans the

intermediate transfer belt (ITB)

Maintains the product in

readiness for a print command

Prepares the photosensitive

drum for printing

Forms the images on the

photosensitive drum and

transfers the toner image to

the paper

Moves the printed sheet out of

the product

Detects the toner level,

cartridge presence, and

environment; completes any

required calibration (color

registration control and image

stability)

The product enters STBY mode

when the formatter sends a

sleep command; the product

performs color registration and

the image stability control

when the formatter sends

those commands

Performs image stabilization at

a specified print interval or at

specified times

The product enters the INTR

period as soon as the formatter

sends another print command

ENWW Basic operation 3

Formatter-control system

The formatter is responsible for the following procedures:

●

Controlling Sleep mode

●

Receiving and processing print data from the various product interfaces

●

Monitoring control-panel functions and relaying product-status information (through the control panel

and the network or bidirectional interface)

●

Developing and coordinating data placement and timing with the DC controller PCA

●

Storing font information

●

Communicating with the host computer through the network or the bidirectional interface

The formatter receives a print job from the network or bidirectional interface and separates it into image

information and instructions that control the printing process. The DC controller PCA synchronizes the imageformation system with the paper-input and -output systems, and then signals the formatter to send the

print-image data.

Sleep mode

After a user-specified time, the Sleep mode feature automatically conserves electricity by substantially

reducing power consumption when the product is not printing. After a user-specified time, the product

automatically reduces its power consumption (Sleep mode). The product returns to the ready state when a

button is pressed, a print job is received, or a door is opened. When the product is in Sleep mode, all of the

control-panel LEDs and the power button backlight LED are off.

Input/output

The product receives print data primarily from the following:

●

Hi-Speed USB 2.0 port

●

10/100/1000 Ethernet LAN connection

●

802.11b/g/n wireless networking

CPU

The formatter incorporates a 600 MHz Arm processor.

Memory

The random access memory (RAM) on the formatter PCA contains the page, I/O buffers, and the font storage

area. RAM stores printing and font information received from the host system, and can also serve to

temporarily store a full page of print-image data before the data is sent to the print engine.

NAND Flash memory

The Smart Install CD image (ISO) is stored in the NAND Flash non-volatile memory. This memory can be

reprogrammed through the firmware.

4 Chapter 1 Theory of operation ENWW

Firmware

The product has 128 MB of DDR-2 SDRAM, which is used for run-time firmware imaging and print, scan and

copy job information during printing.

Memory use

The product has a 16 KB EEPROM and 16 MB of SPI NOR Flash Memory, which is used for product

configuration information and print driver firmware.

PJL overview

The print job language (PJL) is an integral part of configuration, in addition to the standard print command

language (PCL). With standard cabling, the product can use PJL to perform a variety of functions such as

these:

●

Two-way communication with the host computer through a network connection or a USB connection.

The product can inform the host about such things as the control-panel settings, and the control-panel

settings can be changed from the host.

●

Dynamic I/O switching. The product uses this switching to be configured with a host on each I/O. The

product can receive data from more than one I/O simultaneously, until the I/O buffer is full. This can

occur even when the product is offline.

●

Context-sensitive switching. The product can automatically recognize the personality (PS or PCL) of

each job and configure itself to serve that personality.

●

Isolation of print environment settings from one print job to the next. For example, if a print job is sent

to the product in landscape mode, the subsequent print jobs print in landscape mode only if they are

formatted for landscape printing.

LEDM overview

The low-end data model (LEDM) provides one consistent data representation method and defines the

dynamic and capabilities tickets shared between clients and devices, as well as the access protocol, event,

security, and discovery methods.

Control panel

The formatter sends and receives product status and command data to and from the control-panel PCA.

ENWW Formatter-control system 5

Engine-control system

The engine control system coordinates all product functions and drives the other three systems.

The engine control system contains the DC controller, low-voltage power supply PCA, high-voltage power

supply PCA, and fuser control PCA.

Figure 1-2 Engine control system components

6 Chapter 1 Theory of operation ENWW

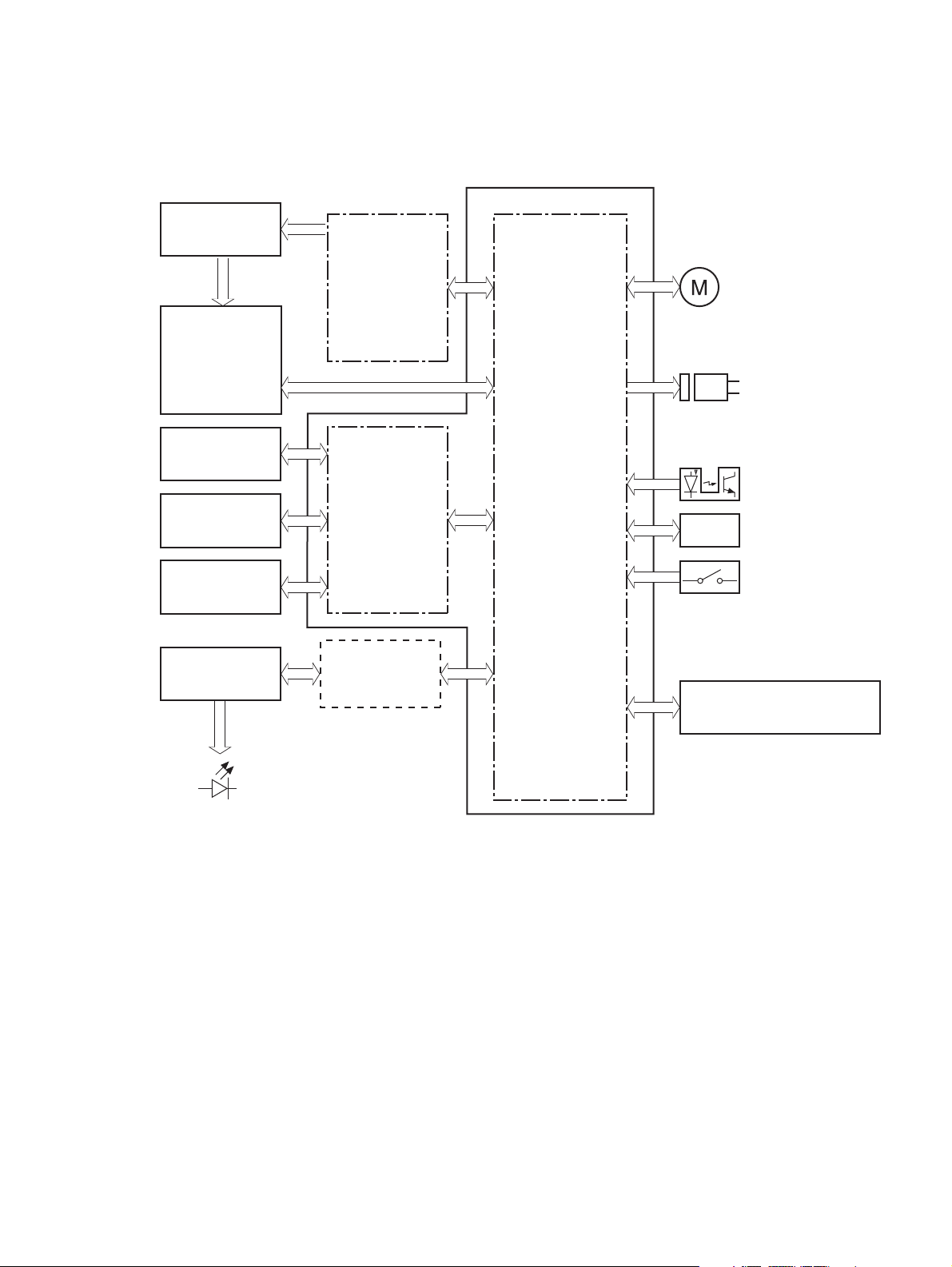

DC controller

The DC controller controls the operational sequences of the product.

Figure 1-3 DC controller circuit diagram

Connector PCA

Engine controller

Fuser

ITB ass’y

T2 roller

Cartridge

Control panel

Low-voltage

power supply

High-voltage

power supply

Formatter

Motor

Solenoid

Photointerruptor

DC controller

Sensor

Switch

Laser scanner ass’y

LED

ENWW Engine-control system 7

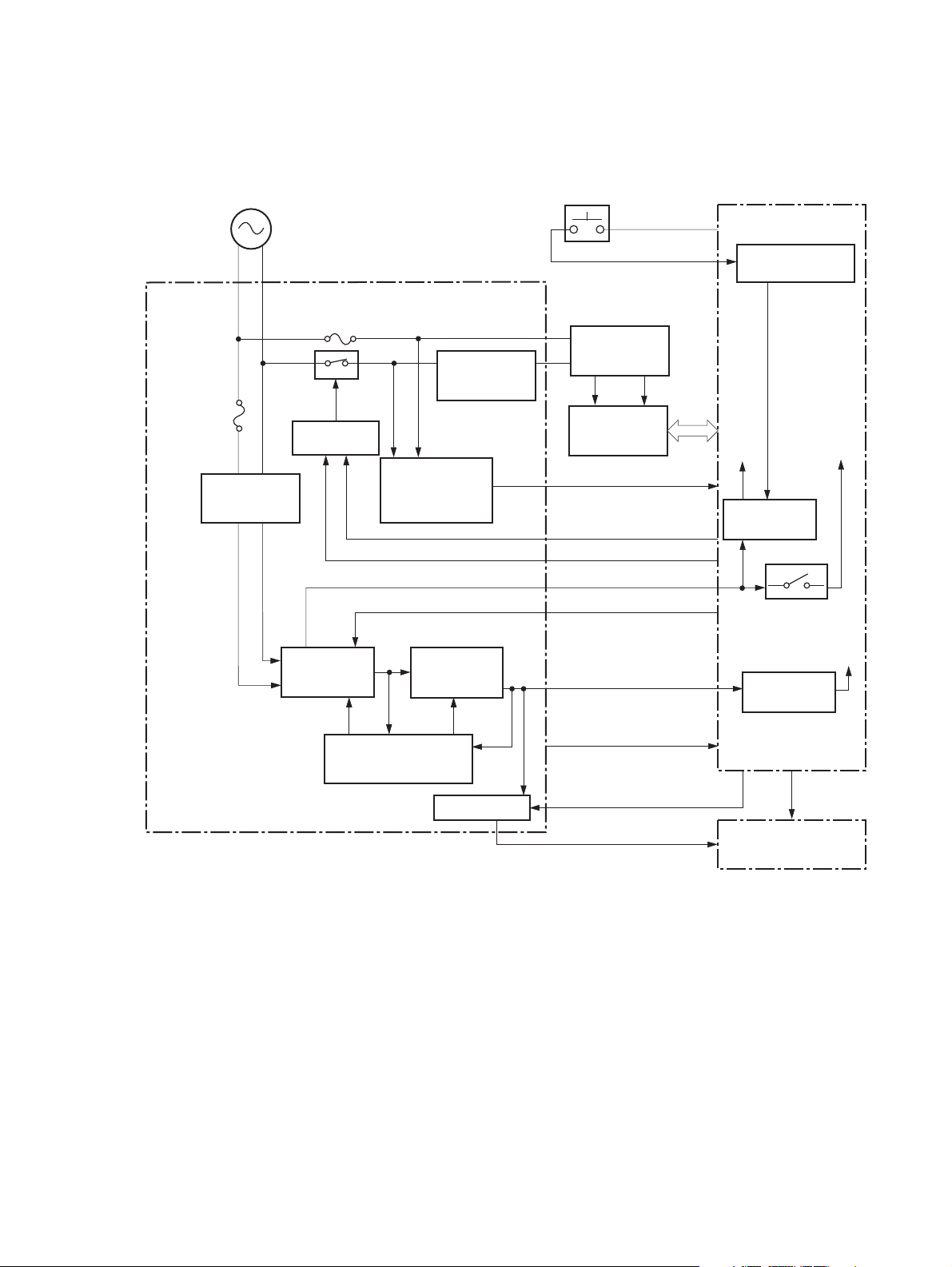

Low-voltage power supply

The low-voltage power supply converts AC power from the wall receptacle into DC voltage power.

Figure 1-4 Low-voltage power supply

AC power

Fuse

FU102

Rectifying

Relay

RL401

Relay control

circuit

Fuse

FU101

circuit

Power switch

SW7001

Low-voltage power supply

Fuser control

circuit

Frequency

detection circuit

200V model only

PWSW

Connector

PCA

Fuser

FREQSNS

RLD+

RLD-

+24V

DC controller

Remote switch

control circuit

+24V

Switching

circuit

+24B

+24V

generation

circuit

Protection circuit

+3.3V

generation

circuit

Switch

+24R

PWSV

+3.3R

LVT100V

/REM3V_V

+3.3V

Interlock switch

SW501

+3.3T

Switching

circuit

+24V

Formatter

8 Chapter 1 Theory of operation ENWW

High-voltage power supply

Figure 1-5 High-voltage power supply

brush

ENWW Engine-control system 9

Fuser control

10 Chapter 1 Theory of operation ENWW

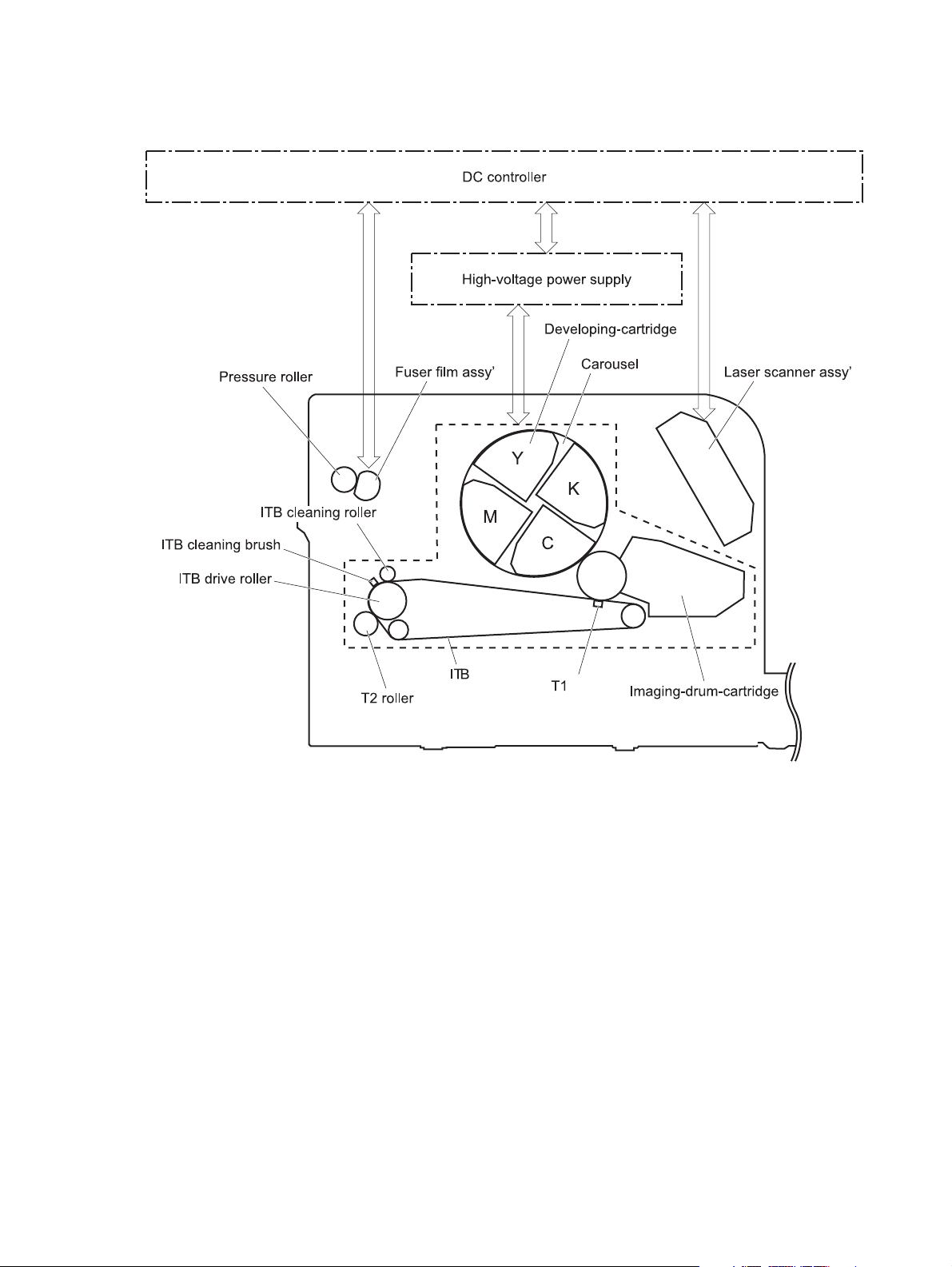

Image-formation system

The DC controller controls the image-formation system according to commands from the formatter.

The DC controller controls the internal components of the image scanner system to form the toner image on

the photosensitive drum surface. The toner image is transferred to the paper and fused.

The following are the main components of the image-formation system.

●

Imaging drum

●

Laser scanner assembly

●

Carousel

●

Four toner cartridges

●

ITB

●

ITB drive roller

●

T1 pad

●

ITB cleaning brush

●

ITB cleaning roller

●

T2 roller

●

Fuser film assembly

●

Pressure roller

●

High-voltage power supply

ENWW Image-formation system 11

The following image shows the components of the image-formation system.

Figure 1-6 Image-formation system

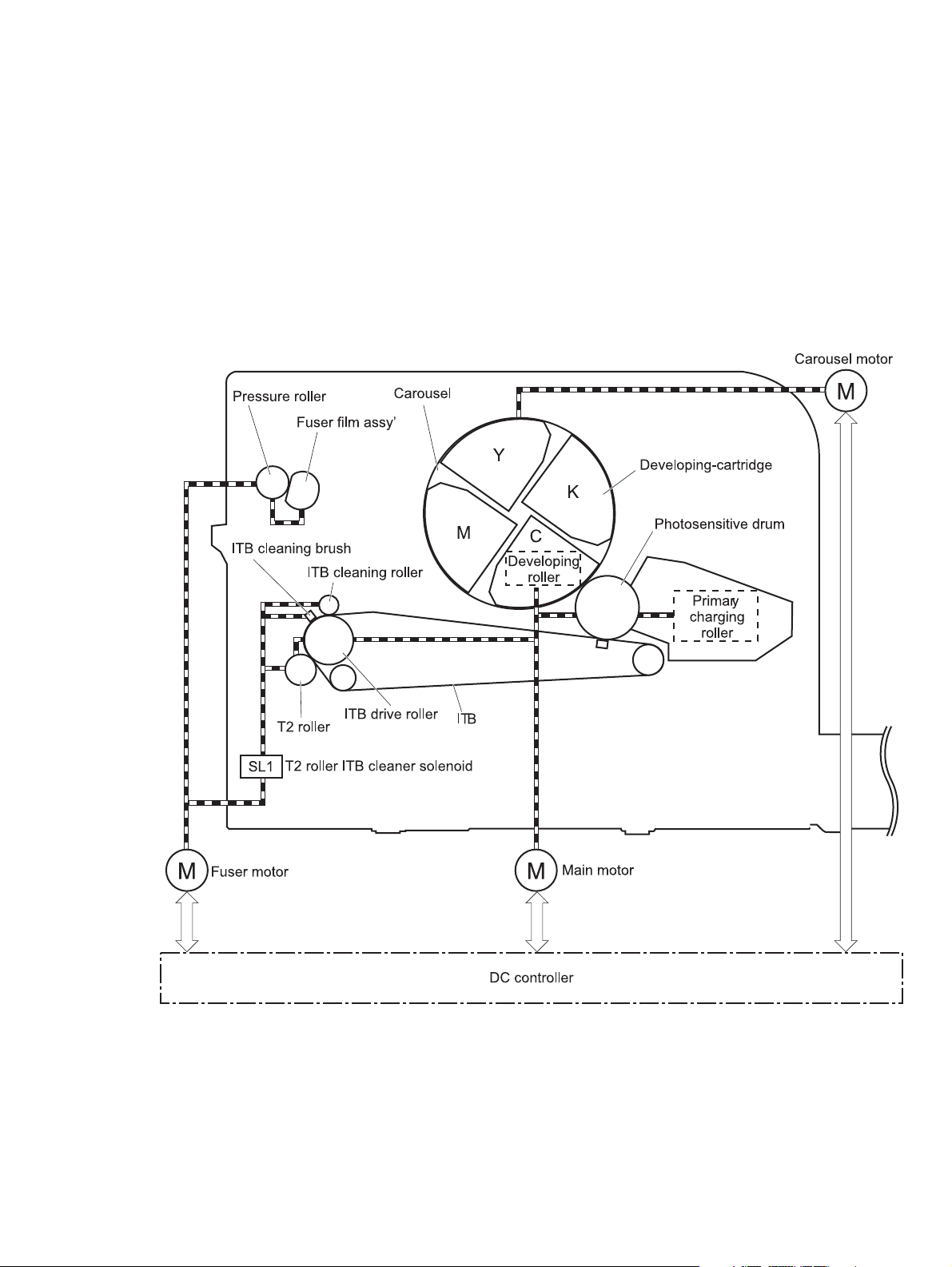

Image-formation process

The DC controller rotates the following motors to drive each component.

Main motor

●

ITB drive roller

●

ITB (follows the ITB drive roller)

●

T2 roller (follows the ITB)

●

Imaging drum

●

Primary charging roller (part of the imaging drum)

●

Developing roller (part of the toner cartridge)

brush

12 Chapter 1 Theory of operation ENWW

Carousel motor

●

●

Fuser motor

●

●

●

Figure 1-7 Image-formation process

Carousel

Engagement/Disengagement of the developing-cartridge (follows the carousel)

Pressure roller

Fuser film (follows the pressure roller)

Engagement/Disengagement of the T2 roller, ITB cleaning roller and ITB cleaning brush

ENWW Image-formation system 13

Latent-image formation stage

During the two steps that comprise this stage, a latent image is formed by applying a negative charge to the

photosensitive drum. This image is not visible on the drum.

Step 1: Primary charging

A high-voltage DC bias is applied to the primary charging roller, which is made of conductive rubber and is in

contact with the drum surface. As the roller moves across the drum, it applies the negative charge to that

surface.

Figure 1-8 Primary charging

Step 2: Laser-beam exposure

The laser beam scans the photosensitive drum to neutralize the negative charge on portions of the drum

surface. An electrostatic latent image is formed where the negative charge was neutralized.

Figure 1-9 Laser-beam exposure

14 Chapter 1 Theory of operation ENWW

Developing stage

The developing cylinder comes in contact with the photosensitive drum and deposits toner on the

electrostatic latent image.

Step 3: Development

The toner acquires a negative charge as a result of the friction from the developing cylinder rotating against

the developing blade. When the negatively charged toner comes in contact with the drum, it adheres to the

electrostatic latent image. When the toner is on the drum, the image becomes visible.

Figure 1-10 Development

ENWW Image-formation system 15

Transfer stage

Step 4: Primary transfer

The toner image on the photosensitive drum is transferred to the ITB. The DC positive bias is applied to the

primary transfer pad. The negatively charged toner transfers to the ITB from the drum surface.

Figure 1-11 Primary transfer

brush

Step 5: Secondary transfer

The toner image on the ITB is transferred to the paper. The DC positive bias is applied to the secondary

transfer roller. As the paper passes between the secondary transfer roller and the ITB, the toner image is

transferred to the paper.

Figure 1-12 Secondary transfer

16 Chapter 1 Theory of operation ENWW

Loading...

Loading...