Page 1

LASERJET PRO 100 COLOR MFP M175

Service Manual

Page 2

HP LaserJet Pro 100 color MFP M175

Service Manual

Page 3

Copyright and License

Trademark Credits

© 2011 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is

prohibited, except as allowed under the

copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CE865-90968

Edition 1, 4/2011

Microsoft®, Windows®, Windows® XP,

and Windows Vista® are U.S. registered

trademarks of Microsoft Corporation.

Page 4

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging

the product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal

injury, catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 5

Table of contents

1 Removal and replacement ................................................................................................ 1

Introduction ............................................................................................................................. 2

Removal and replacement strategy ............................................................................................. 2

Electrostatic discharge .............................................................................................................. 3

Required tools .......................................................................................................................... 3

Service approach ..................................................................................................................... 4

Before performing service .......................................................................................... 4

After performing service ............................................................................................. 4

Post-service test ......................................................................................................... 4

Product verification test ............................................................................... 4

Parts removal order ................................................................................................... 5

Removal and replacement procedures ........................................................................................ 7

Print cartridges .......................................................................................................... 7

Imaging drum ........................................................................................................... 9

Input tray ............................................................................................................... 11

Secondary transfer roller .......................................................................................... 12

Separation pad assembly ......................................................................................... 13

Pickup roller ........................................................................................................... 14

Remove the pickup roller assembly ............................................................. 15

Covers and document feeder .................................................................................... 16

Right cover .............................................................................................. 16

Left cover ................................................................................................ 17

Document feeder ...................................................................................... 18

Remove the document feeder ...................................................... 18

Document feeder hinges ............................................................................ 21

Remove the document feeder hinges ............................................ 21

Top door, rear-top cover, and delivery cover ............................................... 22

Remove the top door, rear-top cover, and delivery cover ................ 22

Reinstall the top door, rear-top cover, and delivery cover ............... 25

Rear door assembly .................................................................................. 27

Remove the rear door assembly .................................................. 27

Rear-lower cover ...................................................................................... 28

ENWW v

Page 6

Remove the rear-lower cover ....................................................... 28

Control panel .......................................................................................... 29

Remove the control panel ........................................................... 29

Left-front cover ......................................................................................... 31

Remove the left-front cover .......................................................... 31

Front door ............................................................................................... 33

Remove the front door ................................................................ 33

Inner cover .............................................................................................. 35

Remove the inner cover .............................................................. 35

Main assemblies ..................................................................................................... 38

Formatter PCA (base model) ...................................................................... 38

Remove the formatter PCA (base model) ....................................... 38

Formatter and wireless PCA (plus model) ..................................................... 40

Remove the formatter and wireless PCA (plus model) ..................... 40

Fuser power supply .................................................................................. 42

Remove the fuser power supply ................................................... 42

ITB assembly ............................................................................................ 43

Remove the ITB assembly ............................................................ 43

Fuser delivery assembly ............................................................................ 53

Remove the fuser delivery assembly ............................................. 54

Engine controller assembly ........................................................................ 58

Remove the engine controller assembly ........................................ 58

Low-voltage power supply assembly ........................................................... 63

Remove the low-voltage power supply assembly ............................ 63

Document feeder components ................................................................................... 69

Document feeder input tray ........................................................................ 69

Document feeder cover ............................................................................. 70

Document feeder core ............................................................................... 72

Remove the document feeder core ............................................... 72

Post scan pinch rollers .............................................................................. 74

Remove the post scan pinch rollers .............................................. 74

Document feeder base assembly ................................................................ 75

Remove the document feeder base assembly ................................ 75

2 Solve problems ............................................................................................................... 77

Solve problems checklist ......................................................................................................... 78

Step 1: Test print functionality ................................................................................... 78

Step 2: Test copy functionality .................................................................................. 78

Menu map ............................................................................................................................ 79

Troubleshooting processes ....................................................................................................... 80

Determine the problem source ................................................................................... 80

vi ENWW

Page 7

Power subsystem ..................................................................................................... 81

Power-on checks ...................................................................................... 81

Tools for troubleshooting ......................................................................................................... 82

Component diagnostics ............................................................................................ 82

Component tests ....................................................................................... 82

Control-panel tests ..................................................................... 82

Diagrams ............................................................................................................... 83

Locations of connectors ............................................................................. 83

Locations of major components .................................................................. 84

General timing chart ................................................................................. 86

General circuit diagram ............................................................................ 87

Internal print-quality test pages .................................................................................. 88

Print a Diagnostics Page ........................................................................... 88

Interpret the Print Quality Page ................................................................... 89

Print-quality troubleshooting tools .............................................................................. 90

Repetitive image defects ruler .................................................................... 90

Calibrate the product ................................................................................ 90

Control panel menus ................................................................................................ 91

Setup menu ............................................................................................. 91

Reports menu ............................................................................ 91

System Setup menu .................................................................... 91

Service menu ............................................................................ 94

Network Setup menu (network models only) ................................. 94

Function specific menus ............................................................................. 95

Copy Menu .............................................................................. 95

Service mode functions ........................................................................................................... 97

Service menu/Secondary service menu ...................................................................... 97

Service menu ........................................................................................... 97

Secondary service menu ........................................................................... 97

Open the secondary service menu ............................................... 97

Secondary service menu structure ................................................ 98

Product resets ......................................................................................................... 99

Restore factory settings .............................................................................. 99

NVRAM initialization ................................................................................ 99

Product updates ..................................................................................................................... 99

3 Parts and diagrams ...................................................................................................... 101

Order parts by authorized service providers ............................................................................ 102

Order replacement parts ........................................................................................ 102

Related documentation and software ....................................................................... 102

Supplies part numbers ........................................................................................... 102

ENWW vii

Page 8

Service parts ........................................................................................................ 103

Whole-unit replacement part numbers ...................................................................... 103

How to use the parts lists and diagrams .................................................................................. 104

Assembly locations ............................................................................................................... 105

Base product (no optional trays or accessories) ......................................................... 105

Covers, panels, and doors .................................................................................................... 106

Internal assembly ................................................................................................................. 108

Internal assembly .................................................................................................. 108

PCAs .................................................................................................................................. 110

Scanner and document feeder (ADF) main assemblies .............................................................. 112

Document feeder internal components .................................................................................... 114

Alphabetical parts list ........................................................................................................... 116

Numerical parts list .............................................................................................................. 119

Appendix A Service and support ..................................................................................... 123

Hewlett-Packard limited warranty statement ............................................................................. 124

HP's Premium Protection Warranty: LaserJet print cartridge limited warranty statement .................. 126

HP's LaserJet imaging drum limited warranty statement for replacement imaging drums ................ 127

Data stored on the print cartridge and imaging drum ............................................................... 128

End User License Agreement .................................................................................................. 129

OpenSSL ............................................................................................................................. 131

Customer self-repair warranty service ..................................................................................... 132

Customer support ................................................................................................................. 132

Repack the product .............................................................................................................. 133

Appendix B Specifications ................................................................................................ 135

Physical specifications .......................................................................................................... 136

Power consumption, electrical specifications, and acoustic emissions .......................................... 136

Environmental specifications .................................................................................................. 136

Appendix C Regulatory information ................................................................................. 137

FCC regulations ................................................................................................................... 138

Declaration of conformity (base models) ................................................................................. 139

Declaration of conformity (wireless models) ............................................................................. 141

Certificate of Volatility .......................................................................................................... 143

Safety statements ................................................................................................................. 144

Laser safety .......................................................................................................... 144

Canadian DOC regulations .................................................................................... 144

VCCI statement (Japan) .......................................................................................... 144

Power cord instructions .......................................................................................... 144

viii ENWW

Page 9

Power cord statement (Japan) ................................................................................. 144

EMC statement (Korea) .......................................................................................... 145

Laser statement for Finland ..................................................................................... 145

GS statement (Germany) ........................................................................................ 145

Substances Table (China) ....................................................................................... 146

Restriction on Hazardous Substances statement (Turkey) ............................................. 146

Additional statements for wireless products .............................................................................. 147

FCC compliance statement—United States ................................................................ 147

Australia statement ................................................................................................ 147

Brazil ANATEL statement ........................................................................................ 147

Canadian statements ............................................................................................. 147

European Union regulatory notice ........................................................................... 147

Notice for use in France ......................................................................................... 148

Notice for use in Russia ......................................................................................... 148

Korean statement .................................................................................................. 148

Taiwan statement .................................................................................................. 148

Index ............................................................................................................................... 149

ENWW ix

Page 10

List of tables

Table 2-1 External covers and doors (base) ............................................................................................ 85

Table 2-2 Service menu ..................................................................................................................... 97

Table 2-3 Secondary service menu ........................................................................................................ 98

Table 3-1 Order parts, accessories, and supplies .................................................................................. 102

Table 3-2 Related documentation and software .................................................................................... 102

Table 3-3 Supplies part numbers ......................................................................................................... 102

Table 3-4 Whole-unit replacement part numbers ................................................................................... 103

Table 3-5 Base product ..................................................................................................................... 105

Table 3-6 Covers, panels, and doors ................................................................................................... 107

Table 3-7 Internal assembly) ............................................................................................................... 109

Table 3-8 PCAs ................................................................................................................................ 111

Table 3-9 Scanner and document feeder main assemblies ..................................................................... 113

Table 3-10 Document feeder assembly parts ........................................................................................ 115

Table 3-11 Alphabetical parts list ....................................................................................................... 116

Table 3-12 Numerical parts list ........................................................................................................... 119

Table B-1 Physical specifications

Table B-2 Environmental specifications ................................................................................................ 136

1

........................................................................................................ 136

ENWW xi

Page 11

List of figures

Figure 1-1 Phillips and Pozidriv screwdriver comparison ............................................................................ 3

Figure 1-2 Parts removal order (base) ...................................................................................................... 5

Figure 1-3 Parts removal order (document feeder) ..................................................................................... 6

Figure 1-4 Remove the tray .................................................................................................................. 11

Figure 1-5 Remove the secondary transfer roller ...................................................................................... 12

Figure 1-6 Remove the separation pad assembly (1 of 1) ......................................................................... 13

Figure 1-7 Remove the pickup roller assembly (1 of 2) ............................................................................. 15

Figure 1-8 Remove the pickup roller assembly (2 of 2) ............................................................................. 15

Figure 1-9 Remove the right cover (1 of 2) ............................................................................................. 16

Figure 1-10 Remove the right cover (2 of 2) ........................................................................................... 16

Figure 1-11 Remove the left cover (1 of 2) ............................................................................................. 17

Figure 1-12 Remove the left cover (2 of 2) ............................................................................................. 17

Figure 1-13 Remove the document feeder (1 of 4) ................................................................................... 18

Figure 1-14 Remove the document feeder (2 of 4) ................................................................................... 19

Figure 1-15 Remove the document feeder (3 of 4) ................................................................................... 19

Figure 1-16 Remove the document feeder (4 of 4) ................................................................................... 20

Figure 1-17 Remove the scanner hinges (1 of 2) ..................................................................................... 21

Figure 1-18 Remove the scanner hinges (2 of 2) ..................................................................................... 21

Figure 1-19 Remove the top door, rear-top cover, and delivery cover (1 of 6) ............................................ 22

Figure 1-20 Remove the top door, rear-top cover, and delivery cover (2 of 6) ............................................ 23

Figure 1-21 Remove the top door, rear-top cover, and delivery cover (3 of 6) ............................................ 23

Figure 1-22 Remove the top door, rear-top cover, and delivery cover (4 of 6) ............................................ 24

Figure 1-23 Remove the top door, rear-top cover, and delivery cover (5 of 6) ............................................ 24

Figure 1-24 Remove the top door, rear-top cover, and delivery cover (6 of 6) ............................................ 25

Figure 1-25 Reinstall the top door, rear-top cover, and delivery cover (1 of 2) ............................................ 25

Figure 1-26 Reinstall the top door, rear-top cover, and delivery cover (1 of 2) ............................................ 26

Figure 1-27 Remove the rear door assembly (1 of 2) ............................................................................... 27

Figure 1-28 Remove the rear door assembly (2 of 2) ............................................................................... 27

Figure 1-29 Remove the rear-lower cover ............................................................................................... 28

Figure 1-30 Remove the control panel (1 of 3) ........................................................................................ 29

Figure 1-31 Remove the control panel (2 of 3) ......

Figure 1-32 Remove the control panel (3 of 3) ........................................................................................ 30

.................................................................................. 30

ENWW xiii

Page 12

Figure 1-33 Remove the left-front cover (1 of 2) ...................................................................................... 31

Figure 1-34 Remove the left-front cover (2 of 2) ...................................................................................... 32

Figure 1-35 Remove the front door (1 of 2) ............................................................................................ 33

Figure 1-36 Remove the front door (2 of 3) ............................................................................................ 34

Figure 1-37 Remove the inner cover (1 of 4) .......................................................................................... 35

Figure 1-38 Remove the inner cover (2 of 4) .......................................................................................... 36

Figure 1-39 Remove the inner cover (3 of 4) .......................................................................................... 36

Figure 1-40 Remove the inner cover (4 of 4) .......................................................................................... 37

Figure 1-41 Remove the formatter PCA (base model; 1 of 2) .................................................................... 38

Figure 1-42 Remove the formatter PCA (base model; 2 of 2) .................................................................... 39

Figure 1-43 Remove the formatter and wireless PCA (plus model; 1 of 3) ................................................... 40

Figure 1-44 Remove the formatter and wireless PCA (plus mode; 2 of 3) ................................................... 40

Figure 1-45 Remove the formatter and wireless PCA (plus mode; 3 of 3) ................................................... 41

Figure 1-46 Remove the fuser power supply (1 of 2) ............................................................................... 42

Figure 1-47 Remove the fuser power supply (2 of 2) ............................................................................... 42

Figure 1-48 Remove the ITB assembly (1 of 17) ...................................................................................... 43

Figure 1-49 Remove the ITB assembly (2 of 17) ...................................................................................... 44

Figure 1-50 Remove the ITB assembly (3 of 17) ...................................................................................... 44

Figure 1-51 Remove the ITB assembly (4 of 17) ...................................................................................... 45

Figure 1-52 Remove the ITB assembly (5 of 17) ...................................................................................... 45

Figure 1-53 Remove the ITB assembly (6 of 17) ...................................................................................... 46

Figure 1-54 Remove the ITB assembly (7 of 17) ...................................................................................... 46

Figure 1-55 Remove the ITB assembly (8 of 17) ...................................................................................... 47

Figure 1-56 Remove the ITB assembly (9 of 17) ...................................................................................... 48

Figure 1-57 Remove the ITB assembly (10 of 17) .................................................................................... 48

Figure 1-58 Remove the ITB assembly (11 of 17) .................................................................................... 49

Figure 1-59 Remove the ITB assembly (12 of 17) .................................................................................... 49

Figure 1-60 Remove the ITB assembly (13 of 17) .................................................................................... 50

Figure 1-61 Remove the ITB assembly (14 of 17) .................................................................................... 50

Figure 1-62 Remove the ITB assembly (15 of 17) .................................................................................... 51

Figure 1-63 Remove the ITB assembly (16 of 17) .................................................................................... 51

Figure 1-64 Remove the ITB assembly (17 of 17) .................................................................................... 52

Figure 1-65 Remove the fuser delivery assembly (1 of 6) .......................................................................... 54

Figure 1-66 Remove the fuse

Figure 1-67 Remove the fuser delivery assembly (3 of 6) .......................................................................... 55

Figure 1-68 Remove the fuser delivery assembly (4 of 6) .......................................................................... 55

Figure 1-69 Remove the fuser delivery assembly (5 of 6) .......................................................................... 56

Figure 1-70 Remove the fuser delivery assembly (6 of 6) .......................................................................... 56

Figure 1-71 Reinstall the fuser delivery assembly (1 of 2) ......................................................................... 57

Figure 1-72 Reinstall the fuser delivery assembly (2 of 2) ......................................................................... 57

Figure 1-73 Remove the engine controller assembly (1 of 7) ..................................................................... 58

r delivery assembly (2 of 6) .......................................................................... 54

xiv ENWW

Page 13

Figure 1-74 Remove the engine controller assembly (2 of 7) ..................................................................... 59

Figure 1-75 Remove the engine controller assembly (3 of 7) ..................................................................... 59

Figure 1-76 Remove the engine controller assembly (4 of 7) ..................................................................... 60

Figure 1-77 Remove the engine controller assembly (5 of 7) ..................................................................... 60

Figure 1-78 Remove the engine controller assembly (6 of 7) ..................................................................... 61

Figure 1-79 Remove the engine controller assembly (7 of 7) ..................................................................... 61

Figure 1-80 Installing a replacement engine controller assembly ............................................................... 62

Figure 1-81 Remove the low-voltage power supply assembly (1 of 9) ........................................................ 63

Figure 1-82 Remove the low-voltage power supply assembly (2 of 9) ........................................................ 64

Figure 1-83 Remove the low-voltage power supply assembly (3 of 9) ........................................................ 64

Figure 1-84 Remove the low-voltage power supply assembly (4 of 9) ........................................................ 65

Figure 1-85 Remove the low-voltage power supply assembly (5 of 9) ........................................................ 65

Figure 1-86 Remove the low-voltage power supply assembly (6 of 9) ........................................................ 66

Figure 1-87 Remove the low voltage power supply assembly (7 of 9) ........................................................ 66

Figure 1-88 Remove the low-voltage power supply assembly (8 of 9) ........................................................ 67

Figure 1-89 Remove the low-voltage power supply assembly (9 of 9) ........................................................ 67

Figure 1-90 Reinstall the low-voltage power supply ................................................................................. 68

Figure 1-91 Installing a replacement low-voltage power supply ................................................................ 68

Figure 1-92 Remove the document feeder input tray (1 of 2) .................................................................... 69

Figure 1-93 Remove the document feeder input tray (2 of 2) .................................................................... 69

Figure 1-94 Remove the document feeder cover (1 of 3) .......................................................................... 70

Figure 1-95 Remove the document feeder cover (2 of 3) .......................................................................... 70

Figure 1-96 Remove the document feeder cover (3 of 3) .......................................................................... 71

Figure 1-97 Remove the document feeder core (1 of 4) ........................................................................... 72

Figure 1-98 Remove the document feeder core (2 of 4) ........................................................................... 72

Figure 1-99 Remove the document feeder core (3 of 4) ........................................................................... 73

Figure 1-100 Remove the document feeder core (4 of 4) ......................................................................... 73

Figure 1-101 Remove the post scan pinch rollers .................................................................................... 74

Figure 1-102 Remove the document feeder base assembly (1 of 3) ........................................................... 75

Figure 1-103 Remove the document feeder base assembly (2 of 3) ........................................................... 76

Figure 1-104 Remove the document feeder base assembly (3 of 3) ........................................................... 76

Figure 2-

Figure 2-2 Cross section view ............................................................................................................... 84

Figure 2-3 External covers and doors (base) ........................................................................................... 85

Figure 2-4 General timing diagram ....................................................................................................... 86

Figure 2-5 General circuit diagram ....................................................................................................... 87

Figure 2-6 Diagnostics Page ................................................................................................................. 88

Figure 3-1 Base product (no optional trays or accessories) ..................................................................... 105

Figure 3-2 Covers, panels, and doors ................................................................................................. 106

Figure 3-3 Internal assembly ............................................................................................................... 108

Figure 3-4 PCAs ............................................................................................................................... 110

1 Locations of connectors ........................................................................................................ 83

ENWW xv

Page 14

Figure 3-5 Scanner and document feeder main assemblies .................................................................... 112

Figure 3-6 Document feeder assembly parts ......................................................................................... 114

xvi ENWW

Page 15

1 Removal and replacement

Introduction

●

Removal and replacement strategy

●

Electrostatic discharge

●

Required tools

●

Service approach

●

Removal and replacement procedures

●

ENWW 1

Page 16

Introduction

This chapter describes the removal and replacement of field-replaceable units (FRUs) only.

Replacing FRUs is generally the reverse of removal. Occasionally, notes and tips are included to

provide directions for difficult or critical replacement procedures.

HP does not support repairing individual subassemblies or troubleshooting to the component level.

Note the length, diameter, color, type, and location of each screw. Be sure to return each screw to its

original location during reassembly.

Incorrectly routed or loose wire harnesses can interfere with other internal components and can become

damaged or broken. Frayed or pinched harness wires can be difficult to find. When replacing wire

harnesses, always use the provided wire loops, lance points, or wire-harness guides and retainers.

Removal and replacement strategy

WARNING! Turn the product off, wait 5 seconds, and then remove the power cord before

attempting to service the product. If this warning is not followed, severe injury can result, in addition to

damage to the product. The power must be on for certain functional checks during troubleshooting.

However, disconnect the power supply during parts removal.

Never operate or service the product with the protective cover removed from the laser/scanner

assembly. The reflected beam, although invisible, can damage your eyes.

The sheet-metal parts can have sharp edges. Be careful when handling sheet-metal parts.

CAUTION: Do not bend or fold the flat flexible cables (FFCs) during removal or installation. Also, do

not straighten pre-folds in the FFCs. You must fully seat all FFCs in their connectors. Failure to fully seat

an FFC into a connector can cause a short circuit in a PCA.

NOTE: To install a self-tapping screw, first turn it counterclockwise to align it with the existing thread

pattern, and then carefully turn it clockwise to tighten. Do not overtighten. If a self-tapping screw-hole

becomes stripped, repair the screw-hole or replace the affected assembly.

TIP: For clarity, some photos in this chapter show components removed that would not be removed to

service the product. If necessary, remove the components listed at the beginning of a procedure before

proceeding to service the product.

2 Chapter 1 Removal and replacement ENWW

Page 17

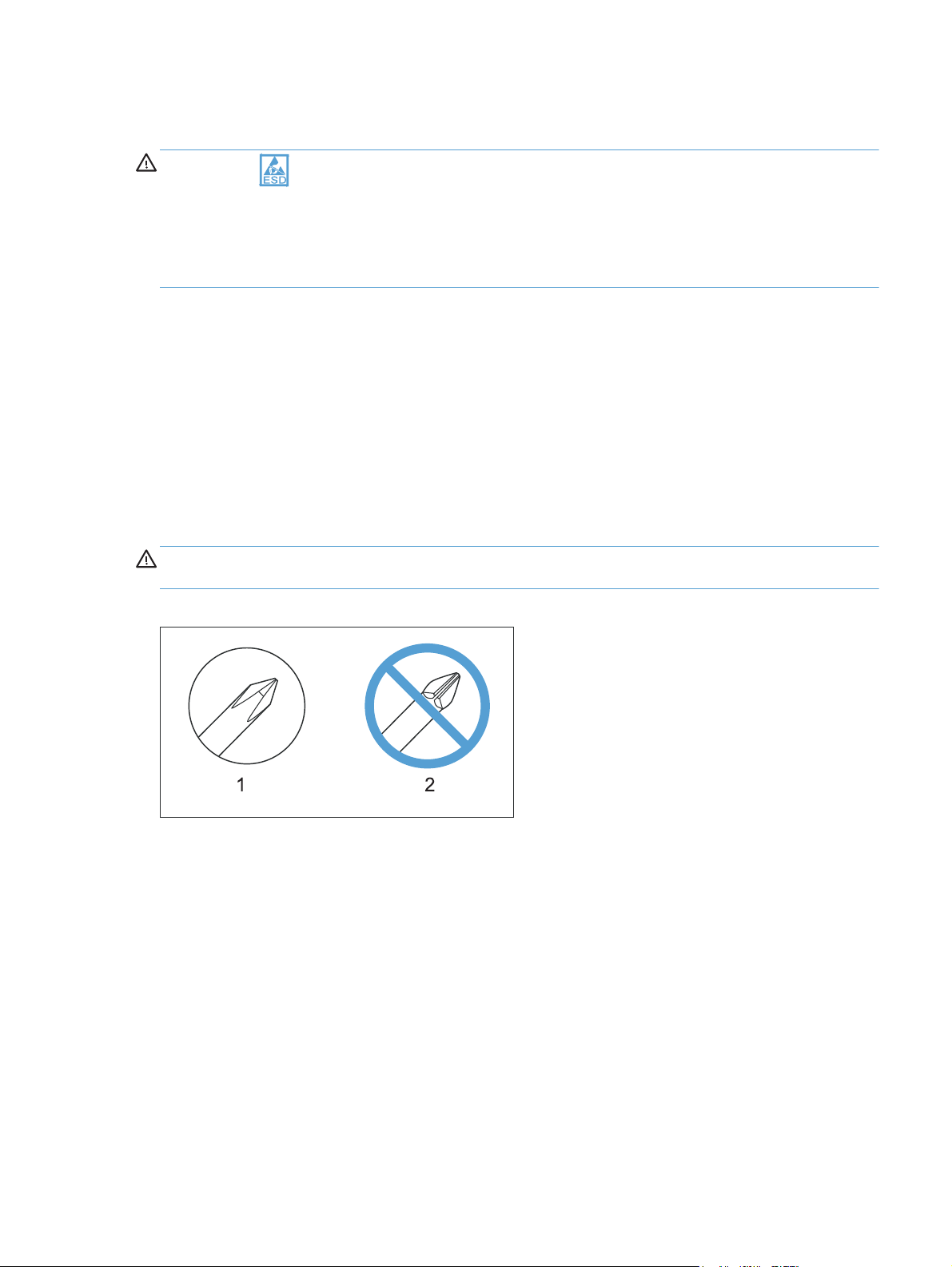

Electrostatic discharge

CAUTION: Some parts are sensitive to electrostatic discharge (ESD). Look for the ESD reminder

when removing product parts. Always perform service work at an ESD-protected workstation or mat, or

use an ESD strap. If an ESD workstation, mat, or strap is not available, ground yourself by touching the

sheet-metal chassis before touching an ESD-sensitive part.

Protect the ESD-sensitive parts by placing them in ESD pouches when they are out of the product.

Required tools

#2 Phillips screwdriver with a magnetic tip and a 152-mm (6-inch) shaft length

●

Small flat-blade screwdriver

●

Needle-nose pliers

●

ESD mat (if one is available) or ESD strap

●

Penlight (optional)

●

CAUTION: Always use a Phillips screwdriver (callout 1). Do not use a Pozidriv screwdriver

(callout 2) or any motorized screwdriver. These can damage screws or screw threads.

Figure 1-1 Phillips and Pozidriv screwdriver comparison

ENWW

Electrostatic discharge

3

Page 18

Service approach

Before performing service

Remove all paper from the product.

●

Turn off the power using the power button.

●

WARNING! The power button must be turned off before performing service. Failure to turn off

the power leaves the fuser engaged and prevents its removal.

Unplug the power cable and interface cable or cables.

●

Place the product on an ESD workstation or mat (if one is available), or use an ESD strap. If an

●

ESD workstation, mat, or strap is not available, ground yourself by touching the sheet-metal

chassis before touching an ESD-sensitive part.

Remove the print cartridges and imaging drum. See

●

drum on page 9

Remove the input tray. See

●

After performing service

Plug in the power cable.

●

Reinstall the print cartridges.

●

Load paper in the product.

●

Post-service test

Perform the following test to verify that the repair or replacement was successful.

Product verification test

1. Verify that you have completed the necessary reassembly steps.

2. Make sure that the tray contains clean, unmarked paper.

3. Attach the power cord and interface cable or interface cables, and then turn on the product.

Print cartridges on page 7 and Imaging

Input tray on page 11.

4. Verify that the expected startup sounds occur.

5. Print a configuration page, and then verify that the expected printing sounds occur.

6. Send a print job from the host computer, and then verify that the output meets expectations.

7. Use the document feeder to make a copy.

8. Clean the outside of the product with a damp cloth.

4 Chapter 1 Removal and replacement ENWW

Page 19

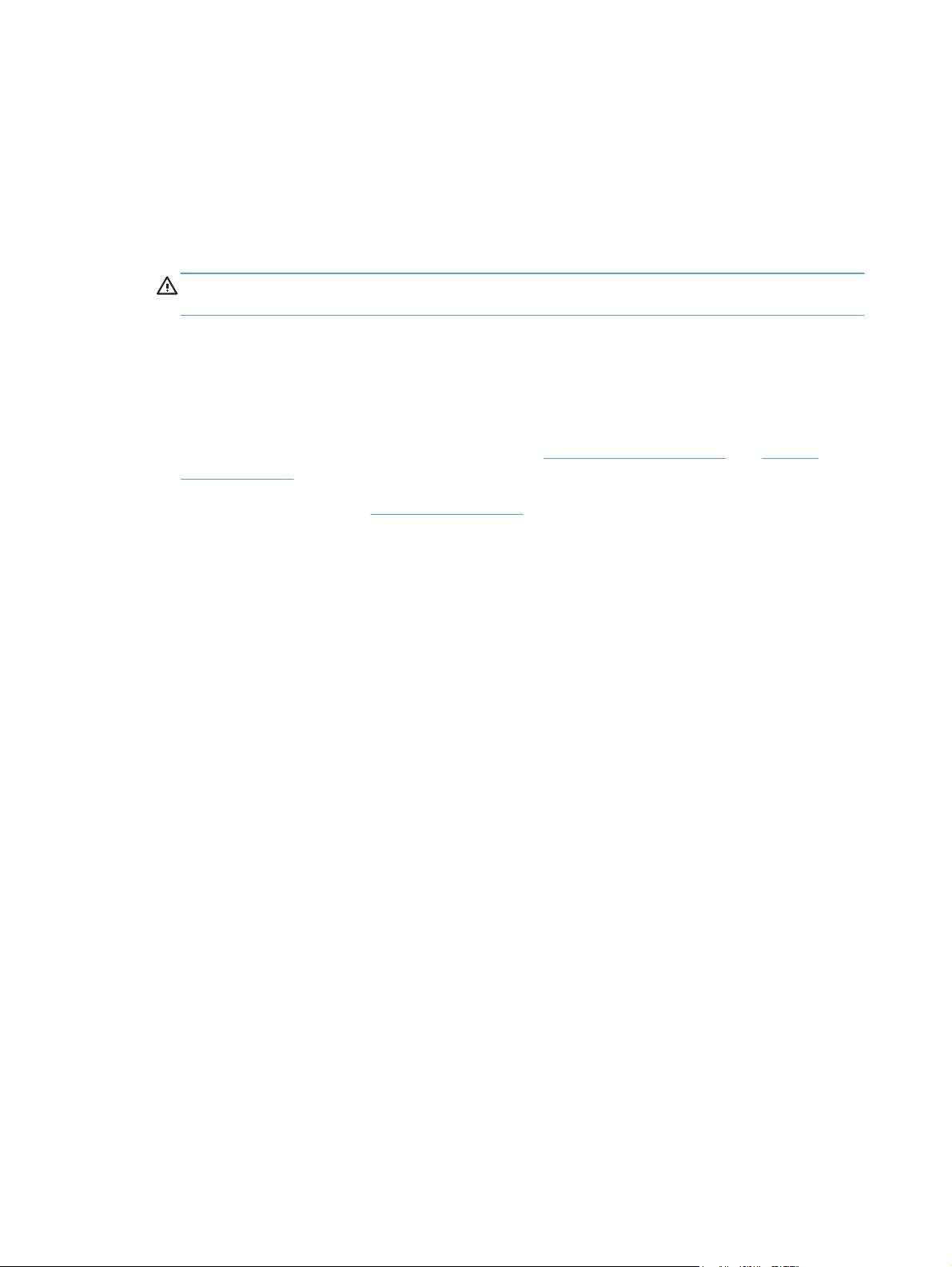

Parts removal order

Figure 1-2 Parts removal order (base)

Print cartridges

Imaging drum

Input tray

Secondary

transfer roller

Separation pad

Pickup roller

Right cover assembly

Left cover assembly

Document feeder

Document feeder

hinges

Separation

pad

Left cover

Left cover

Right cover

Document

feeder

Left cover

Top door, rear cover,

and delivery cover

Rear door assembly

Rear-lower cover

Control Panel

Left-front cover

Front door

Inner cover

Formatter PCA

(base model)

Formatter and

wireless PCA

(plus model)

Fuser power supply

ITB

Fuser delivery

assembly

Engine controller

assembly

Low-voltage power

supply assembly

Right cover

Right cover

Right cover

Right cover

Right cover

Right cover

Right cover

Left cover

Left cover

Left cover

Right cover

Right cover

Right cover

Right cover

Left cover

Left cover

Left cover

Left cover

Left cover

Left cover

Left cover

Left cover

Left cover

Left cover

Document

feeder

Rear door

Document

feeder

Document

feeder

Document

feeder

Document

feeder

Document

feeder

Document

feeder

Document

feeder

Document

feeder

Document

feeder hinges

Document

feeder hinges

Document

feeder hinges

Document

feeder hinges

Document

feeder hinges

Document

feederhinges

Document

feeder hinges

Document

feeder hinges

Document

feeder hinges

Top door,

rear cover,

and delivery cover

Top door,

rear cover,

and delivery cover

Top door,

rear cover,

and delivery cover

Top door,

rear cover,

and delivery cover

Top door,

rear cover,

livery cover

and de

Top door,

rear cover,

and delivery cover

Top door,

rear cover,

and delivery cover

Top door,

rear cover,

and delivery cover

Control

Pan el

Control

Pan el

Control

Pan el

Rear door

assembly

Rear door

assembly

Control

Pan el

Rear door

assembly

Left-front

cover

Left-front

cover

Rear-lower

cover

Rear-lower

cover

Left-front

cover

Rear-lower

cover

Formatter

PCA

Formatter

PCA

Inner

cover

Control

Pan el

Formatter

PCA

Left-front

cover

Inner cover

Formatter

PCA

ENWW

Service approach

5

Page 20

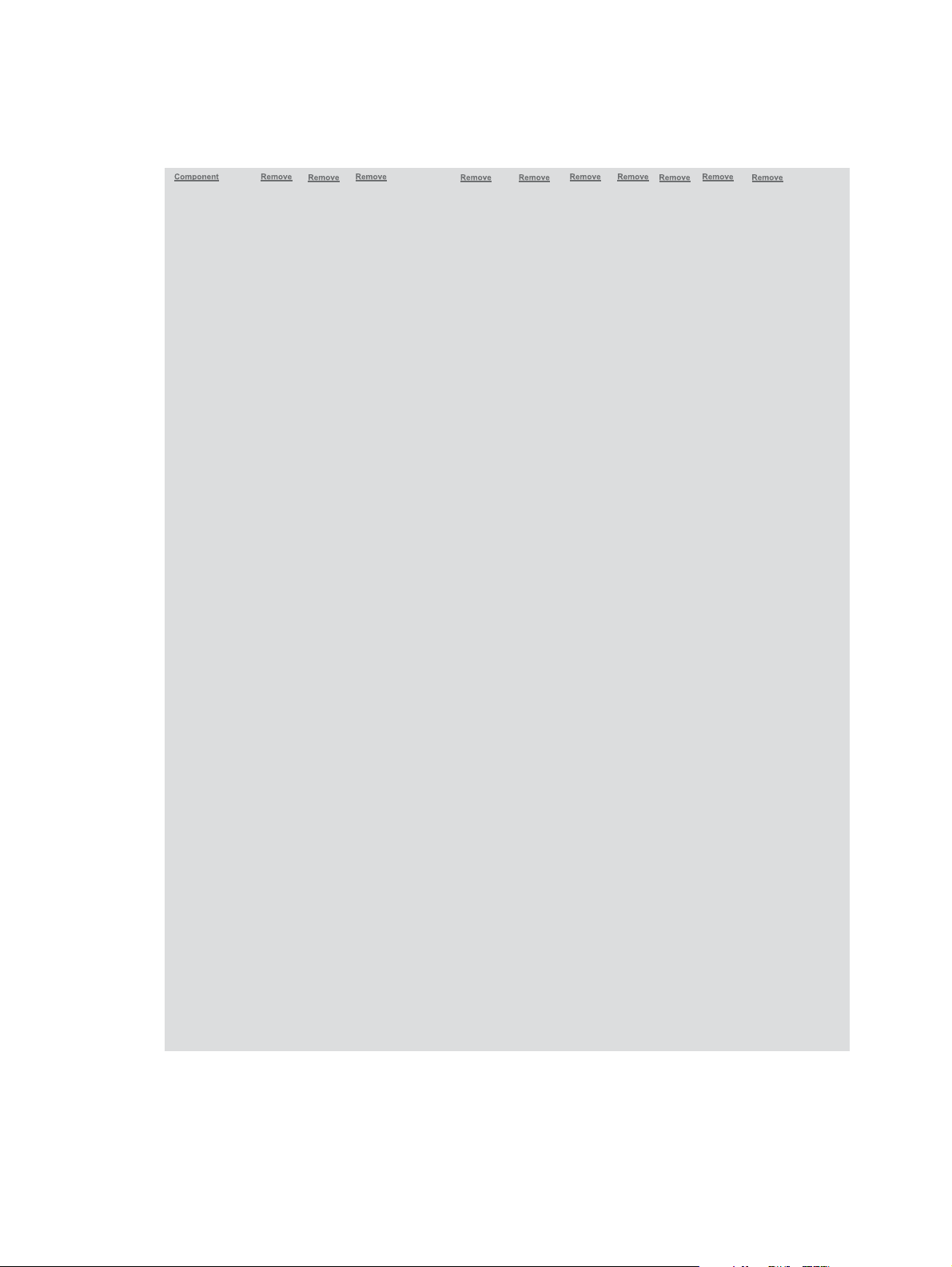

Figure 1-3 Parts removal order (document feeder)

Document feeder input tray

Document feeder cover

Document core

Post scan pinch rollers

Document feeder input tray

Document feeder cover

Document core

Document feeder base assembly

Document feeder input tray

Document feeder cover

6 Chapter 1 Removal and replacement ENWW

Page 21

Removal and replacement procedures

Print cartridges

When a print cartridge approaches the estimated end of its useful life, you can continue printing with

the current print cartridge until it no longer yields acceptable print quality.

Once an HP print cartridge has reached “very low’, the HP Premium Protection Warranty on that

supply has ended. All print defects or print cartridge failures incurred when an HP supply is used in

continue at very low mode will not be considered to be defects in materials or workmanship in the

supply under the HP Print Cartridge Warranty Statement.

1. Some error messages or status messages cause

the product to rotate the print cartridge

carousel to the affected cartridge

automatically. If the print cartridge that needs

to be replaced is not in the correct position,

press the Cartridge

cartridge carousel to the cartridge color that

you want to replace.

NOTE: All doors must be closed when

pressing the Cartridge

imaging drum must be installed for the

Cartridge

NOTE: Wait until the Rotating message

and the rotation sounds stop before opening

the print cartridge door.

button to work.

button to rotate the print

button. Also, the

ENWW

Removal and replacement procedures

7

Page 22

2. Open the print cartridge door.

3. Grasp the old print cartridge by the center

handle and remove it.

Close the doors, and then press the Cartridge

button to rotate the print cartridge carousel

to the next cartridge. Repeat to remove all

cartridges.

NOTE: Make sure that you store the

removed print cartridges away from strong

light. HP recommends that you cover the print

cartridges while servicing the product.

8 Chapter 1 Removal and replacement ENWW

Page 23

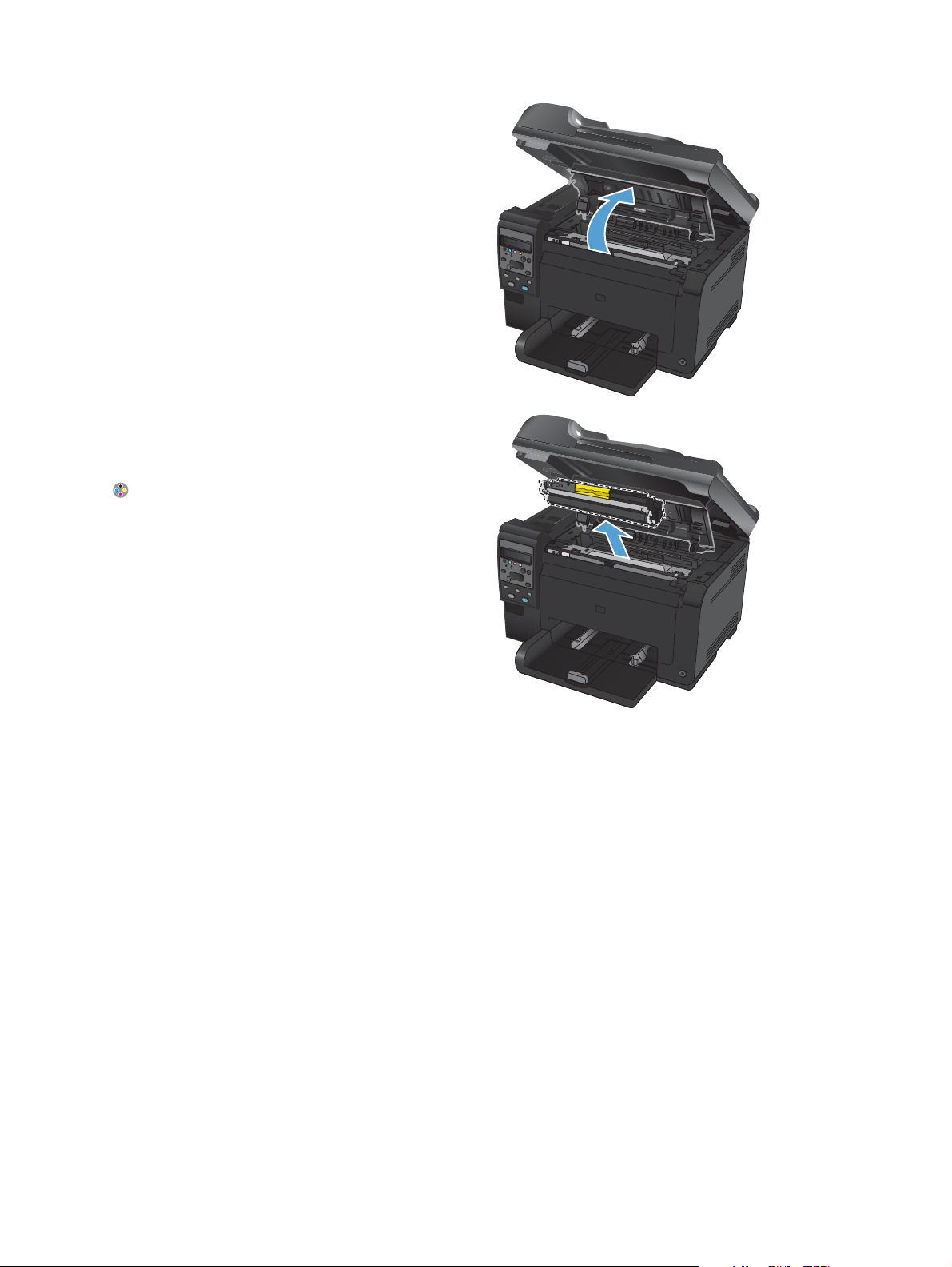

Imaging drum

NOTE: The imaging drum installed in this product is covered by the product warranty. Replacement

imaging drums have a one-year limited warranty from the date of installation. The imaging drum

installation date displays on the supplies status page. The HP Premium Protection Warranty applies only

to the print cartridges for the product.

1. Open the print cartridge door.

2. Open the front cover.

ENWW

Removal and replacement procedures

9

Page 24

3. Lift the two levers that hold the imaging drum.

4. Remove the old imaging drum.

NOTE: Make sure that you store the

removed imaging drum away from strong

light. HP recommends that you cover the

imaging drum while servicing the product.

10 Chapter 1 Removal and replacement ENWW

Page 25

Input tray

Pull the tray away from the printer to remove.

Figure 1-4 Remove the tray

ENWW

Removal and replacement procedures

11

Page 26

Secondary transfer roller

CAUTION: Do not touch the black spongy part of the roller. Skin oils might cause print-quality

problems.

1. Open the rear door.

2. Release two clips (callout 1), and then remove the roller from the product.

Figure 1-5 Remove the secondary transfer roller

1

12 Chapter 1 Removal and replacement ENWW

Page 27

Separation pad assembly

1. Turn the product face up.

WARNING! The ADF portion of the document feeder is not captive and can open when the

product is placed face up. Make sure that you support the ADF when handling the product.

NOTE: Dirt and debris can scratch the surface of the product. Make sure that you place the

product face up on a clean work space or on a clean soft cloth.

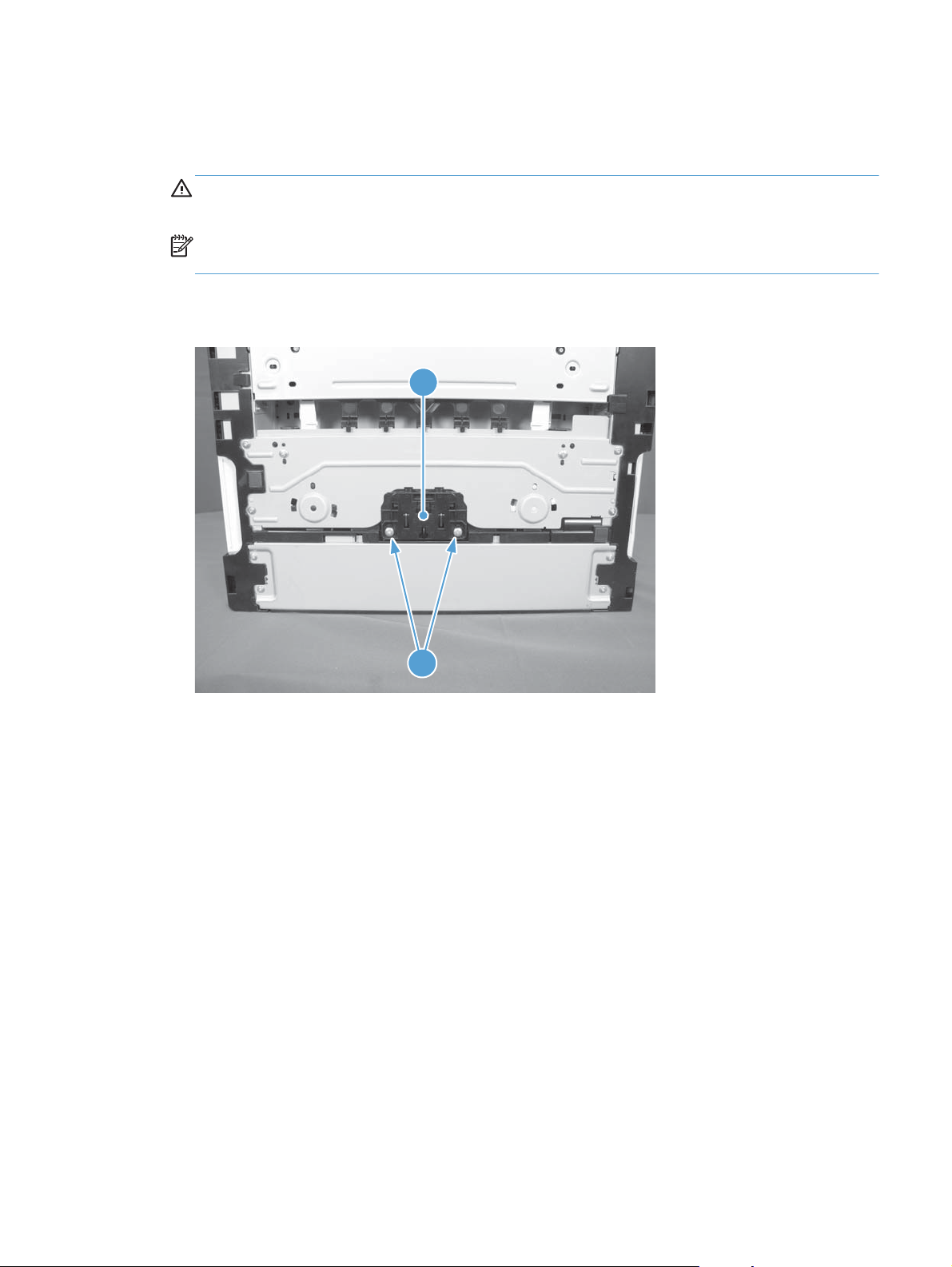

2. Remove two screws (callout 1) and the separation pad assembly (callout 2).

Figure 1-6 Remove the separation pad assembly (1 of 1)

2

1

ENWW

Removal and replacement procedures

13

Page 28

Pickup roller

Before proceeding, remove the following components:

Separation pad assembly. See

●

Right cover assembly. See

●

Left cover assembly. See

●

Rotate the pickup roller to the service position

To gain access to the roller locking tabs you must rotate the roller to the correct position for removal.

1. When the product is in the Ready state, press and hold the Auto-On/Auto-Off (power) button for

about seven seconds or until the Ready light turns off.

TIP: Optionally, unplug the power cord, and then plug the cord back in.

2. Make sure that one sheet of paper is loaded in the input tray.

NOTE: If more than one sheet of paper is loaded in the tray, this procedure will not be

successful.

3. Press and release the Auto-On/Auto-Off (power) button and within two seconds press and hold

down the cyan cartridge button. Hold the cyan button down for about five seconds, or until the

initialization process begins.

NOTE: Immediately after the Auto-On/Auto-Off (power) button is pressed, all of the control

panel lights illuminate briefly (for about two seconds). You must press the cyan cartridge button

while the lights are illuminated.

Separation pad assembly on page 13.

Right cover on page 16.

Left cover on page 17.

4. When the product finishes initializing, the roller rotates into the removal position. Turn the product

off. Unplug the product before removing any components.

NOTE: When the roller is in the removal position, the sheet of paper will have been pulled into

the paper path by about 12 mm (.5 in). This is visual confirmation that the roller has rotated to the

removal position.

14 Chapter 1 Removal and replacement ENWW

Page 29

Remove the pickup roller assembly

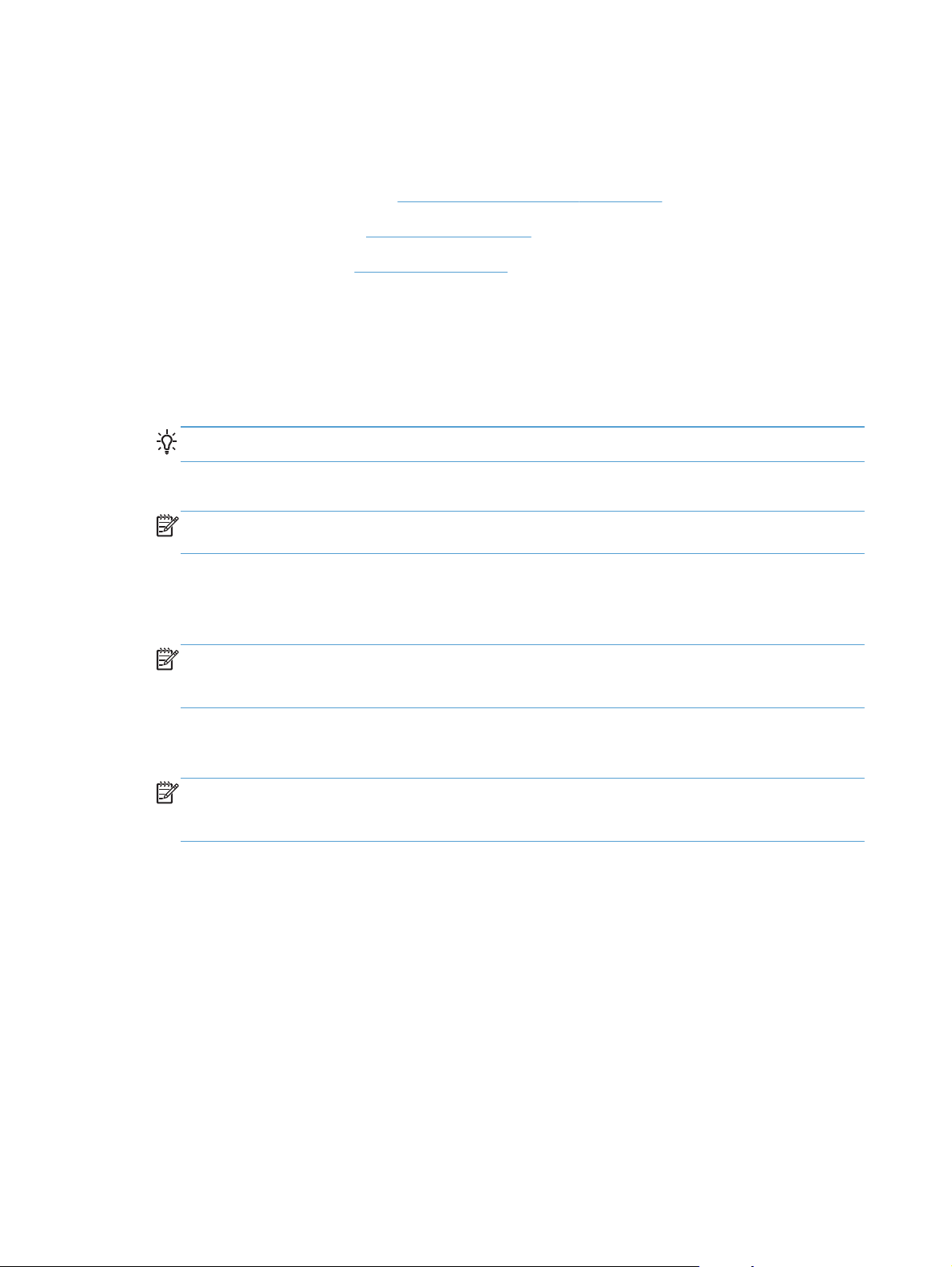

1. Remove four screws (callout 1) and the lower stay part (callout 2).

Figure 1-7 Remove the pickup roller assembly (1 of 2)

2

1

2. Release two tabs (callout 1) and remove the pickup roller (callout 2).

Figure 1-8 Remove the pickup roller assembly (2 of 2)

1

2

ENWW

Removal and replacement procedures

15

Page 30

Covers and document feeder

Right cover

1. Open the document feeder.

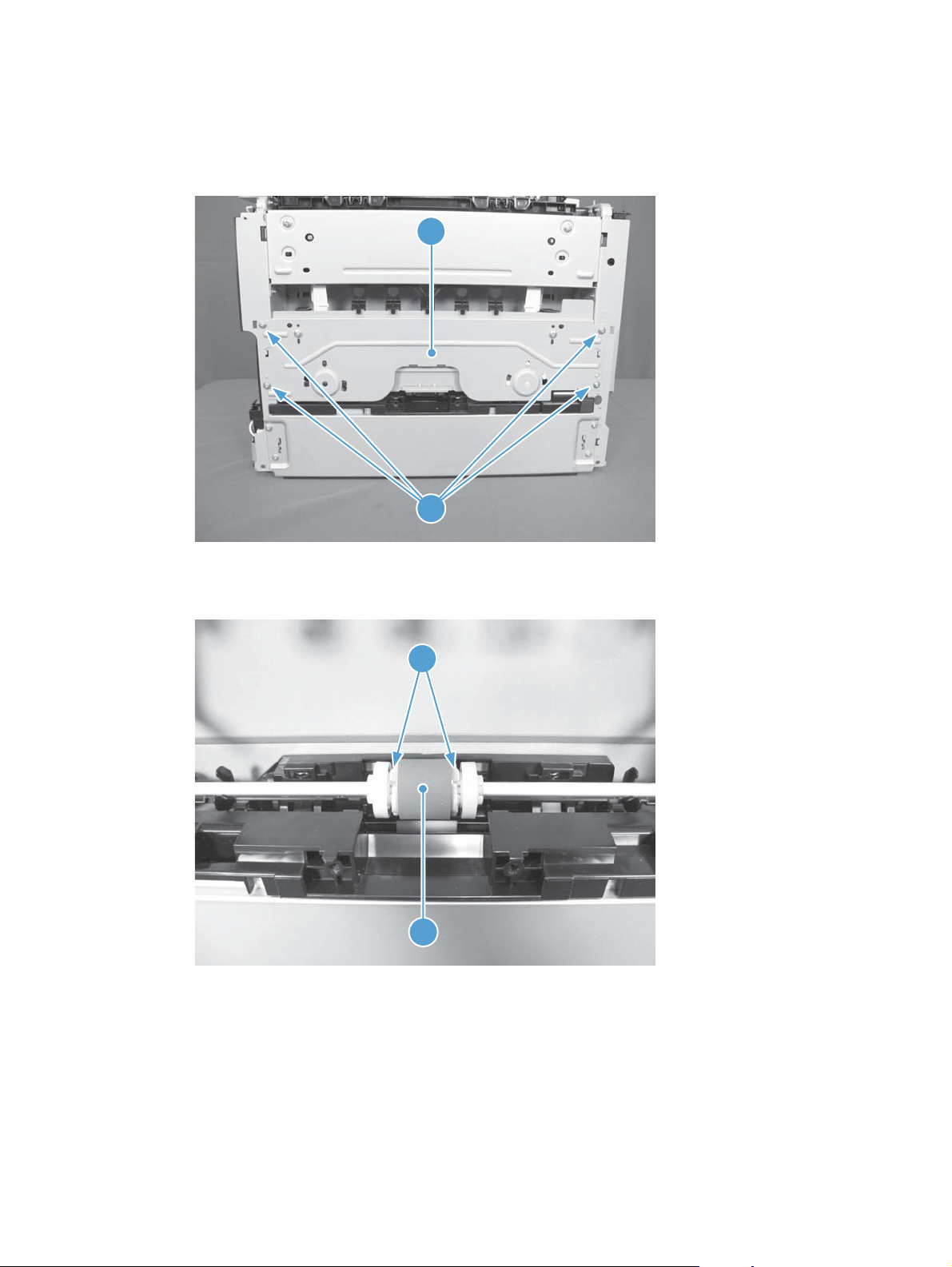

2. Remove one screw (callout 1), and then starting at the rear vertical edge, release six tabs

(callout 2) and remove the right cover.

NOTE: Before proceeding, take note of the locations of the tabs (callout 1) on the back side of

the cover. See

Figure 1-9 Remove the right cover (1 of 2)

Figure 1-10 Remove the right cover (2 of 2) on page 16.

2

1

Figure 1-10 Remove the right cover (2 of 2)

1

16 Chapter 1 Removal and replacement ENWW

Page 31

Left cover

1. Open the document feeder.

2. Remove one screw (callout 1), and then starting at the rear vertical edge, release two tabs

(callout 2) and remove the left cover.

NOTE: Before proceeding, take note of the locations of the tabs (callout 1) on the back side of

the cover. See

Figure 1-11 Remove the left cover (1 of 2)

Figure 1-12 Remove the left cover (2 of 2) on page 17.

2

1

Figure 1-12 Remove the left cover (2 of 2)

1

ENWW

Removal and replacement procedures

17

Page 32

Document feeder

Before proceeding, remove the following components:

Left cover. See

●

Remove the document feeder

1. Release two tabs (callout 1), and then remove the cover (callout 2).

Figure 1-13 Remove the document feeder (1 of 4)

Left cover on page 17.

2

1

18 Chapter 1 Removal and replacement ENWW

Page 33

2. Disconnect two FFCs (callout 1), and then release them from the guides (callout 2).

CAUTION: Do not bend or fold the flat flexible cables (FFCs) during removal or installation.

Also, do not straighten pre-folds in the FFCs.

Figure 1-14 Remove the document feeder (2 of 4)

2

1

3. Release the tabs inside the hinges (callout 1) to allow the scanner assembly to slide down on the

hinges.

Figure 1-15 Remove the document feeder (3 of 4)

1

ENWW

Removal and replacement procedures

19

Page 34

4. Lift and rotate the scanner assembly up and away from the hinges.

Figure 1-16 Remove the document feeder (4 of 4)

1

2

20 Chapter 1 Removal and replacement ENWW

Page 35

Document feeder hinges

Left cover. See

●

Document feeder. See

●

Remove the document feeder hinges

1. Remove one screw (callout 1) from each hinge.

Figure 1-17 Remove the scanner hinges (1 of 2)

Left cover on page 17.

Document feeder on page 18.

1

2. Lift each hinge up to remove it.

Figure 1-18 Remove the scanner hinges (2 of 2)

ENWW

Removal and replacement procedures

21

Page 36

Top door, rear-top cover, and delivery cover

Before proceeding, remove the following components:

Right cover. See

●

Left cover. See

●

Document feeder. See

●

Document feeder hinges. See

●

Remove the top door, rear-top cover, and delivery cover

1. Remove two screws (callout 1 and callout 2).

NOTE: When facing the product, the screw on the right is black (callout 2), and the one on the

left (callout 1) is silver.

Figure 1-19 Remove the top door, rear-top cover, and delivery cover (1 of 6)

Right cover on page 16.

Left cover on page 17.

Document feeder on page 18.

1

Document feeder hinges on page 21.

2

22 Chapter 1 Removal and replacement ENWW

Page 37

2. Open the top door, release the door retainer arm (callout 1), and then close the top door.

Figure 1-20 Remove the top door, rear-top cover, and delivery cover (2 of 6)

1

3. Open the rear door, and then release two tabs on the rear-top cover (callout 1).

Figure 1-21 Remove the top door, rear-top cover, and delivery cover (3 of 6)

1

ENWW

Removal and replacement procedures

23

Page 38

4. Push up on the rear-top cover (callout 1) to slightly raise the delivery cover (callout 2) to release

two rear-top cover tabs (callout 3) along the rear edge of the product.

Figure 1-22 Remove the top door, rear-top cover, and delivery cover (4 of 6)

2

1

3

5. Open the top door (callout 1), rotate the delivery cover and rear-top cover (callout 2) away from

the product, and then slide the door and covers towards the front of the product to release the

assembly.

Figure 1-23 Remove the top door, rear-top cover, and delivery cover (5 of 6)

1

2

24 Chapter 1 Removal and replacement ENWW

Page 39

6. Remove the top door (callout 1) , delivery cover (callout 2), and rear-top cover (callout 3)

assembly.

Figure 1-24 Remove the top door, rear-top cover, and delivery cover (6 of 6)

1

Reinstall the top door, rear-top cover, and delivery cover

Before reassembly, make sure that the two cartridge lock springs (callout 1; located to the right and left

of the print-cartridge opening) are not damaged.

Figure 1-25 Reinstall the top door, rear-top cover, and delivery cover (1 of 2)

2

3

ENWW

1

Removal and replacement procedures

25

Page 40

Figure 1-26 Reinstall the top door, rear-top cover, and delivery cover (1 of 2)

1

26 Chapter 1 Removal and replacement ENWW

Page 41

Rear door assembly

Before proceeding, remove the following components:

Right cover. See

●

Remove the rear door assembly

1. Remove one screw (callout 1) and the bushing (callout 2).

Figure 1-27 Remove the rear door assembly (1 of 2)

Right cover on page 16.

1

2

2. Pull out the shaft (callout 1) and remove the rear door assembly (callout 2).

Figure 1-28 Remove the rear door assembly (2 of 2)

1

2

ENWW

Removal and replacement procedures

27

Page 42

Rear-lower cover

Before proceeding, remove the following components:

Right cover assembly. See

●

Left cover assembly. See

●

Rear door assembly. See

●

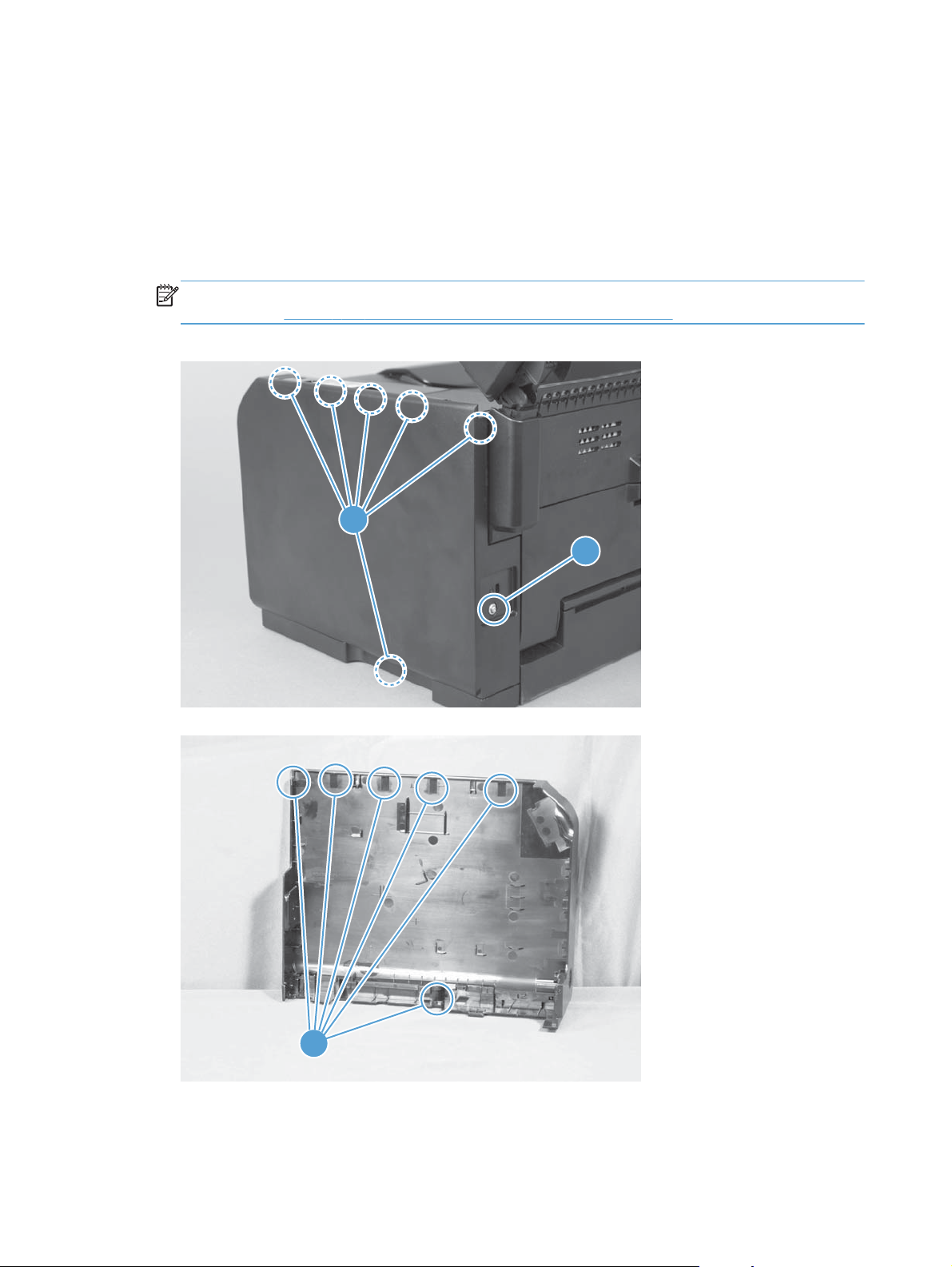

Remove the rear-lower cover

Remove two screws (callout 1) and the rear lower cover assembly (callout 2).

Figure 1-29 Remove the rear-lower cover

Right cover on page 16.

Left cover on page 17.

Rear door assembly on page 27.

1

2

28 Chapter 1 Removal and replacement ENWW

Page 43

Control panel

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Right cover. See

●

Left cover. See

●

Document feeder. See

●

Document feeder hinges. See

●

Top door, rear-top cover, and delivery cover. See

●

on page 22.

Remove the control panel

1. Disconnect one FFC (callout 1), and then release the FFC from the guide (callout 2).

CAUTION: Do not bend or fold the flat flexible cables (FFCs) during removal or installation.

Also, do not straighten pre-folds in the FFCs.

Figure 1-30 Remove the control panel (1 of 3)

Right cover on page 16.

Left cover on page 17.

Document feeder on page 18.

Document feeder hinges on page 21.

Top door, rear-top cover, and delivery cover

2

ENWW

1

Removal and replacement procedures

29

Page 44

2. Remove two screws (callout 1).

Figure 1-31 Remove the control panel (2 of 3)

1

3. Carefully separate the control panel from the product.

NOTE: Guide the FFC through the opening in the product chassis (callout 1) to prevent it from

being damaged when the control-panel is removed.

Figure 1-32 Remove the control panel (3 of 3)

1

30 Chapter 1 Removal and replacement ENWW

Page 45

Left-front cover

Before proceeding, remove the following components:

Right cover. See

●

Left cover. See

●

Document feeder. See

●

Document feeder hinges. See

●

Top door, rear-top cover, and delivery cover. See

●

on page 22.

Control panel. See

●

Remove the left-front cover

1. Remove one screw (callout 1), and then release two tabs (callout 2).

Figure 1-33 Remove the left-front cover (1 of 2)

Left cover on page 17.

Right cover on page 16

Document feeder on page 18.

Document feeder hinges on page 21.

Control panel on page 29.

1

Top door, rear-top cover, and delivery cover

2

ENWW

Removal and replacement procedures

31

Page 46

2. Release on tab (callout 1) by slightly rotating the top of the cover (callout 2) away from the

product.

Figure 1-34 Remove the left-front cover (2 of 2)

2

1

32 Chapter 1 Removal and replacement ENWW

Page 47

Front door

Before proceeding, remove the following components:

Right cover. See

●

Left cover. See

●

Document feeder. See

●

Document feeder hinges. See

●

Top door, rear-top cover, and delivery cover. See

●

on page 22.

Control panel. See

●

Left-front cover. See

●

Remove the front door

1. Open the front door.

2. Remove four screws (callout 1) and the laser/scanner cover (callout 2).

Figure 1-35 Remove the front door (1 of 2)

Right cover on page 16

Left cover on page 17.

Document feeder on page 18.

Document feeder hinges on page 21.

Top door, rear-top cover, and delivery cover

Control panel on page 29.

Left-front cover on page 31.

1

ENWW

2

Removal and replacement procedures

33

Page 48

3. Release one tab (callout 1) and slide the front door (callout 2) to the right to remove it.

Figure 1-36 Remove the front door (2 of 3)

2

1

34 Chapter 1 Removal and replacement ENWW

Page 49

Inner cover

Before proceeding, remove the following components:

Right cover. See

●

Left cover. See

●

Document feeder. See

●

Document feeder hinges. See

●

Top door, rear-top cover, and delivery cover. See

●

on page 22.

Control panel. See

●

Left-front cover. See

●

Remove the inner cover

1. Remove one spring (callout 1), and then remove the door retainer arm (callout 2).

Figure 1-37 Remove the inner cover (1 of 4)

Right cover on page 16

Left cover on page 17.

Document feeder on page 18.

Document feeder hinges on page 21.

Top door, rear-top cover, and delivery cover

Control panel on page 29.

Left-front cover on page 31.

2

1

ENWW

Removal and replacement procedures

35

Page 50

2. Remove three machine screws (callout 1), and then remove one self-tapping screw (callout 2).

Figure 1-38 Remove the inner cover (2 of 4)

1

2

3. Release one tab (callout 1).

Figure 1-39 Remove the inner cover (3 of 4)

1

36 Chapter 1 Removal and replacement ENWW

Page 51

4. Remove the inner cover (callout 1).

Figure 1-40 Remove the inner cover (4 of 4)

1

ENWW

Removal and replacement procedures

37

Page 52

Main assemblies

Formatter PCA (base model)

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Left cover assembly. See

●

Remove the formatter PCA (base model)

1. Disconnect three connectors (callout 1).

Figure 1-41 Remove the formatter PCA (base model; 1 of 2)

Left cover on page 17.

1

38 Chapter 1 Removal and replacement ENWW

Page 53

2. Remove two screws (callout 1), and then remove the formatter PCA.

Figure 1-42 Remove the formatter PCA (base model; 2 of 2)

1

ENWW

Removal and replacement procedures

39

Page 54

Formatter and wireless PCA (plus model)

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Left cover. See

●

Remove the formatter and wireless PCA (plus model)

1. Remove one screw (callout 1), and then remove the wireless PCA (callout 2).

Figure 1-43 Remove the formatter and wireless PCA (plus model; 1 of 3)

Left cover on page 17.

2

1

2. Disconnect two connectors (callout 1), and then disconnect four FFCs (callout 2).

Figure 1-44 Remove the formatter and wireless PCA (plus mode; 2 of 3)

2

1

40 Chapter 1 Removal and replacement ENWW

Page 55

3. Remove four screws (callout 1), and then remove the formatter PCA.

Figure 1-45 Remove the formatter and wireless PCA (plus mode; 3 of 3)

1

ENWW

Removal and replacement procedures

41

Page 56

Fuser power supply

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Left cover. See

●

Remove the fuser power supply

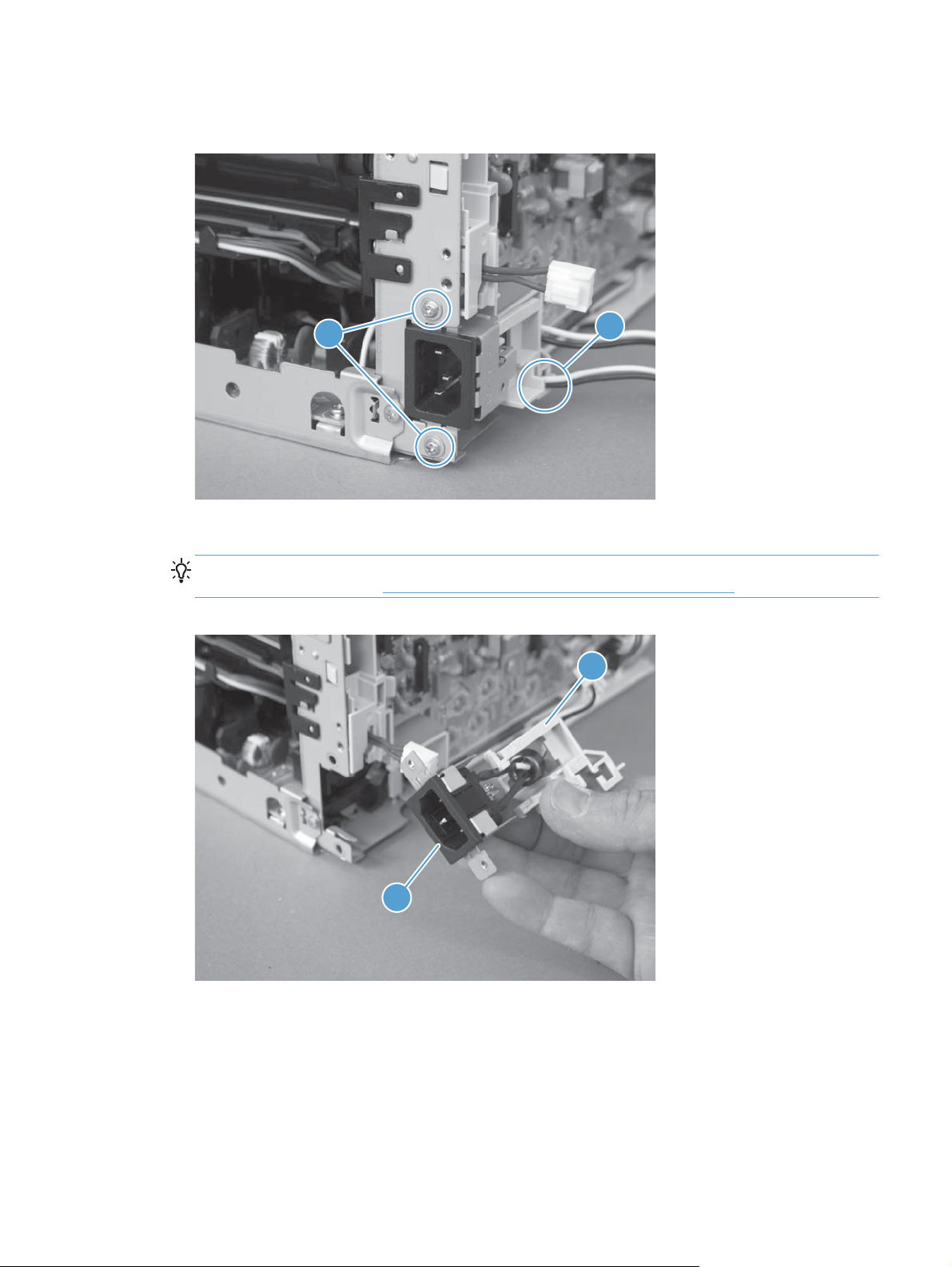

1. Disconnect four connectors (callout 1)

Figure 1-46 Remove the fuser power supply (1 of 2)

Left cover on page 17.

1

2. Remove three screws (callout 1), and then remove the fuser power supply.

Figure 1-47 Remove the fuser power supply (2 of 2)

1

42 Chapter 1 Removal and replacement ENWW

Page 57

ITB assembly

CAUTION: ESD sensitive.

NOTE: If you have not removed the image drum before servicing the product, remove it now. See

Imaging drum on page 9.

Before proceeding, remove the following components:

Right cover. See

●

Left cover. See

●

Document feeder. See

●

Document feeder hinges. See

●

Top door, rear-top cover, and delivery cover. See

●

on page 22.

Rear door. See

●

Rear-lower cover. See

●

Formatter PCA or formatter and wireless PCA. See

●

Formatter and wireless PCA (plus model) on page 40.

Remove the ITB assembly

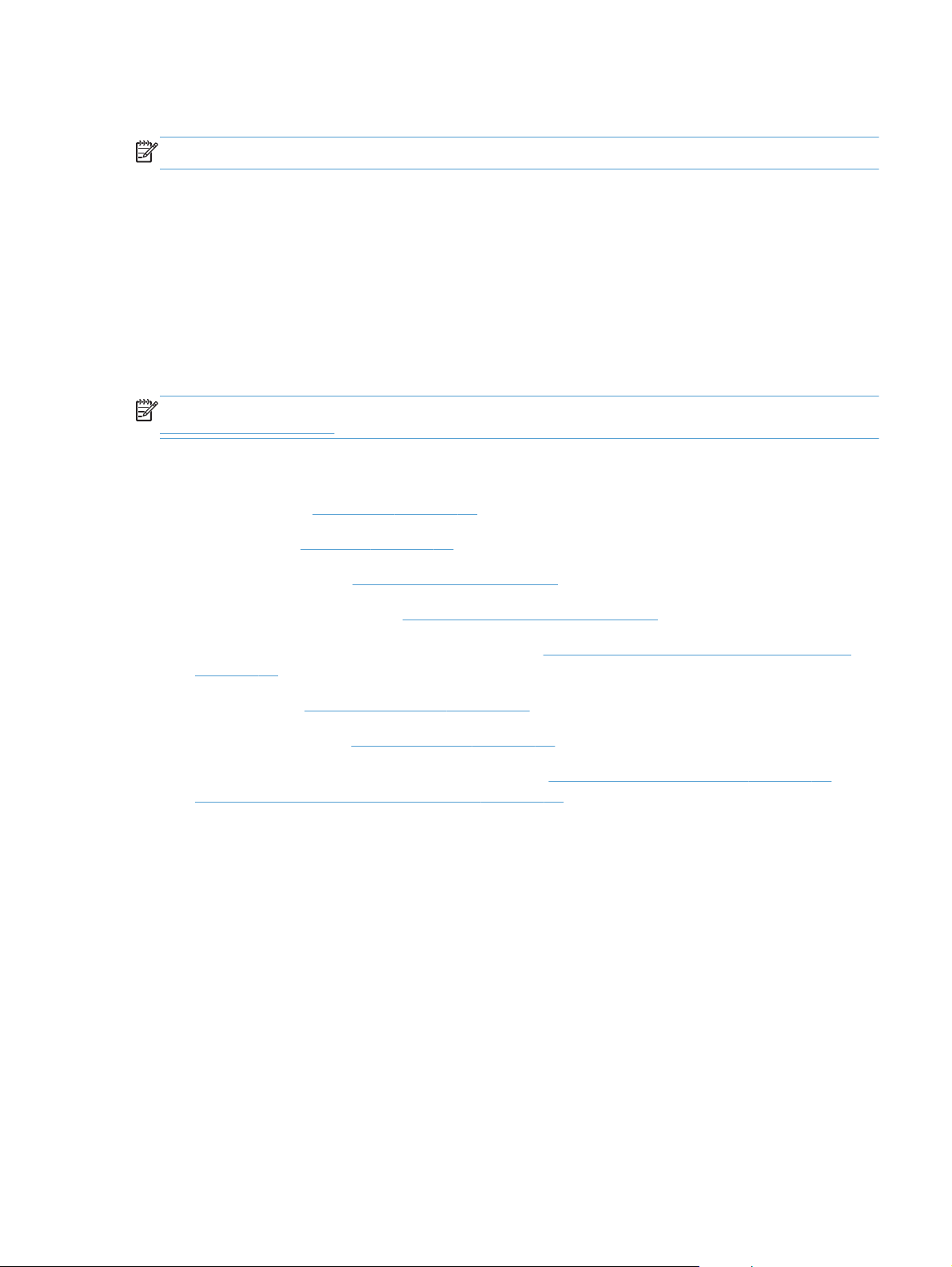

1. Disconnect four connectors.

Figure 1-48 Remove the ITB assembly (1 of 17)

Right cover on page 16

Left cover on page 17.

Document feeder on page 18.

Document feeder hinges on page 21.

Top door, rear-top cover, and delivery cover

Rear door assembly on page 27.

Rear-lower cover on page 28.

Formatter PCA (base model) on page 38 or

ENWW

1

Removal and replacement procedures

43

Page 58

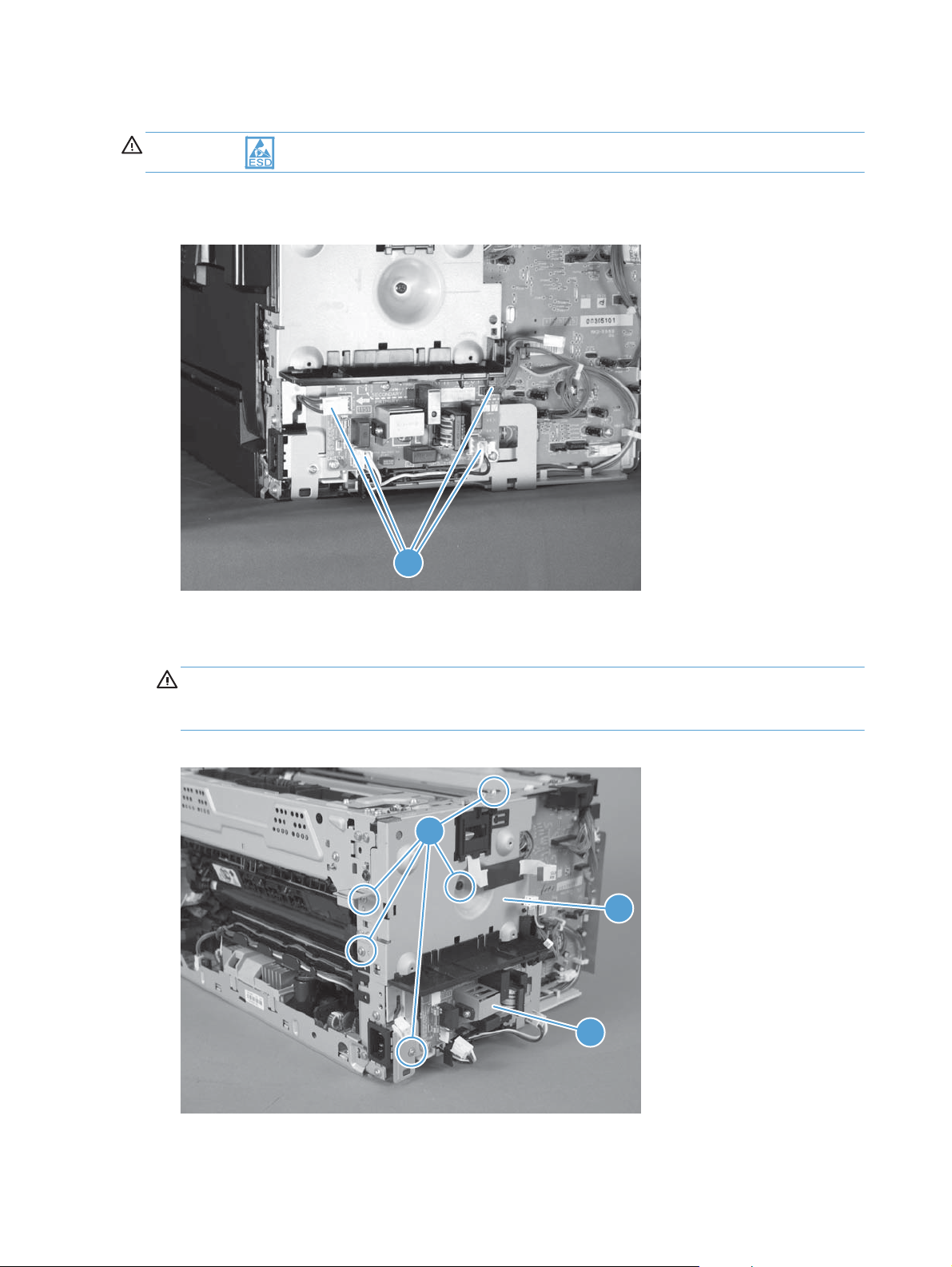

2. Remove five screws (callout 1), and then separate the sheet-metal plate (callout 2) and fuser power

supply (callout 3) from the product.

CAUTION: The sheet-metal plate and fuser power supply assembly is still attached to the

product by a FFC connected to the engine controller assembly. Do not attempt to completely

remove the assembly.

Figure 1-49 Remove the ITB assembly (2 of 17)

1

2

3

3. Disconnect one FFC (Callout 1), and then remove the sheet-metal plate and fuser power supply

assembly.

Figure 1-50 Remove the ITB assembly (3 of 17)

1

44 Chapter 1 Removal and replacement ENWW

Page 59

4. Release one tab (callout 1), and then remove the cable cover (callout 2).

Figure 1-51 Remove the ITB assembly (4 of 17)

2

1

5. Disconnect one connector (callout 1), release the wire harnesses (callout 2) from the guide (callout

3).

Figure 1-52 Remove the ITB assembly (5 of 17)

1

2

3

ENWW

Removal and replacement procedures

45

Page 60

6. Release one tab (callout 1), and then remove the rear-door left-side arm (callout 2).

Figure 1-53 Remove the ITB assembly (6 of 17)

2

1

7. Release the hook end (callout 1) of the ITB fixing spring (callout 2).

Figure 1-54 Remove the ITB assembly (7 of 17)

1

2

46 Chapter 1 Removal and replacement ENWW

Page 61

8. Rotate the spring (callout 1) so that it faces out of the product.

Figure 1-55 Remove the ITB assembly (8 of 17)

1

ENWW

Removal and replacement procedures

47

Page 62

9. Rotate the ITB fixing part (callout 1) so that it faces out of the product.

Figure 1-56 Remove the ITB assembly (9 of 17)

1

Figure 1-57 Remove the ITB assembly (10 of 17)

1

48 Chapter 1 Removal and replacement ENWW

Page 63

10. Release two tabs (callout 1), and then remove the spring cover (callout 2).

Figure 1-58 Remove the ITB assembly (11 of 17)

1

2

11. Release one tab (callout 1), and the remove the rear-door right-side arm (callout 2).

Figure 1-59 Remove the ITB assembly (12 of 17)

1

2

ENWW

Removal and replacement procedures

49

Page 64

12. Release the hook end (callout 1) of the ITB fixing spring (callout 2), and then pull the wire harness

(callout 3) through the hole in the chassis.

Figure 1-60 Remove the ITB assembly (13 of 17)

3

1

2

13. Rotate the spring (callout 1) so that it faces out of the product.

Figure 1-61 Remove the ITB assembly (14 of 17)

1

50 Chapter 1 Removal and replacement ENWW

Page 65

14. Rotate the ITB fixing part (callout 1) so that it faces out of the product.

Figure 1-62 Remove the ITB assembly (15 of 17)

1

Figure 1-63 Remove the ITB assembly (16 of 17)

1

ENWW

Removal and replacement procedures

51

Page 66

15. Pull the ITB assembly (callout 1) straight out of the product.

CAUTION: Avoid touching the black plastic transfer belt. Skin oils on the belt might cause print-

quality problems.

Figure 1-64 Remove the ITB assembly (17 of 17)

1

52 Chapter 1 Removal and replacement ENWW

Page 67

Fuser delivery assembly

NOTE: For this product, the fuser and the paper delivery components are one assembly.

Position the fuser pressure roller for removal

You must rotate the pressure roller to the correct position before removing the fuser delivery assembly.

1. When the product is in the Ready state, press and hold the Auto-On/Auto-Off (power) button for

about seven seconds or until you hear subtle movement within the product and the Ready light

turns off.

2. Release the Auto-On/Auto-Off (power) button. The product power will be off and the fuser

pressure roller is in the removal position. Unplug the product before removing any components.

NOTE: If you have not removed the image drum before servicing the product, remove it now. See

Imaging drum on page 9.

Before proceeding, remove the following components:

Right cover. See

●

Left cover. See

●

Document feeder. See

●

Document feeder hinges. See

●

Top door, rear-top cover, and delivery cover. See

●

on page 22.

Rear door. See

●

Rear-lower cover. See

●

Formatter PCA or formatter and wireless PCA. See

●

Formatter and wireless PCA (plus model) on page 40.

Right cover on page 16

Left cover on page 17.

Document feeder on page 18.

Document feeder hinges on page 21.

Rear door assembly on page 27.

Rear-lower cover on page 28.

Top door, rear-top cover, and delivery cover

Formatter PCA (base model) on page 38 or

ENWW

Removal and replacement procedures

53

Page 68

Remove the fuser delivery assembly

CAUTION: ESD sensitive.

1. Disconnect four connectors.

Figure 1-65 Remove the fuser delivery assembly (1 of 6)

1

2. Remove five screws (callout 1), and then separate the sheet-metal plate (callout 2) and fuser power

supply (callout 3) from the product.

CAUTION: The sheet-metal plate and fuser power supply assembly is still attached to the

product by a FFC connected to the engine controller assembly. Do not attempt to completely

remove the assembly.

Figure 1-66 Remove the fuser delivery assembly (2 of 6)

1

2

3

54 Chapter 1 Removal and replacement ENWW

Page 69

3. Disconnect one FFC (Callout 1), and then remove the sheet-metal plate and fuser power supply

assembly.

Figure 1-67 Remove the fuser delivery assembly (3 of 6)

1

4. Release one tab (callout 1), and then remove the cable cover (callout 2).

Figure 1-68 Remove the fuser delivery assembly (4 of 6)

2

1

ENWW

Removal and replacement procedures

55

Page 70

5. Disconnect four connectors (callout 1), Release the wire harnesses (callout 2) from the guide

(callout 3).

Figure 1-69 Remove the fuser delivery assembly (5 of 6)

2

3

1

6. Remove six screws (callout 1), and then remove the fuser delivery assembly (callout 2).

Figure 1-70 Remove the fuser delivery assembly (6 of 6)

1

2

56 Chapter 1 Removal and replacement ENWW

Page 71

Reinstall the fuser delivery assembly

When reassembling the fuser delivery assembly, be sure the drive cam (callout 1) for fuser

▲

pressure release is positioned as shown below.

Figure 1-71 Reinstall the fuser delivery assembly (1 of 2)

1

Figure 1-72 Reinstall the fuser delivery assembly (2 of 2)

1

ENWW

Removal and replacement procedures

57

Page 72

Engine controller assembly

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Right cover. See

●

Left cover. See

●

Document feeder. See

●

Document feeder hinges. See

●

Top door, rear-top cover, and delivery cover. See

●

on page 22.

Control panel. See

●

Left-front cover. See

●

Inner cover. See

●

Formatter PCA or formatter and wireless PCA. See

●

Formatter and wireless PCA (plus model) on page 40.

Remove the engine controller assembly

1. Disconnect four connectors.

Figure 1-73 Remove the engine controller assembly (1 of 7)

Right cover on page 16

Left cover on page 17.

Document feeder on page 18.

Document feeder hinges on page 21.

Control panel on page 29.

Left-front cover on page 31.

Inner cover on page 35.

Top door, rear-top cover, and delivery cover

Formatter PCA (base model) on page 38 or

1

58 Chapter 1 Removal and replacement ENWW

Page 73

2. Remove five screws (callout 1), and then separate the sheet-metal plate (callout 2) and fuser power

supply (callout 3) from the product.

CAUTION: The sheet-metal plate and fuser power supply assembly is still attached to the

product by a FFC connected to the engine controller assembly. Do not attempt to completely

remove the assembly.

Figure 1-74 Remove the engine controller assembly (2 of 7)

1

2

3

3. Disconnect one FFC (Callout 1), and then remove the sheet-metal plate and fuser power supply

assembly.

Figure 1-75 Remove the engine controller assembly (3 of 7)

1

ENWW

Removal and replacement procedures

59

Page 74

4. Release one tab (callout 1) and remove the cable cover (callout 2).

Figure 1-76 Remove the engine controller assembly (4 of 7)

2

1