Page 1

HP LaserJet M1005 MFP

Service Manual

Page 2

Page 3

HP LaserJet M1005 MFP

Service Manual

Page 4

Copyright and License

Trademark credits

© 2006 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained in this document

is subject to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number CB376-90929

Edition 1, 8/2006

Microsoft®, Windows®, and Windows NT®

are U.S. registered trademarks of Microsoft

Corporation.

Linux is a U.S. registered trademark of Linus

Torvalds.

PostScript® is a trademarks of Adobe

Systems Incorporated.

UNIX® is a registered trademark of The

Open Group.

Energy Star® and the Energy Star® logo are

U.S. registered marks of the United States

Environmental Protection Agency.

Page 5

Table of contents

1 Device information

Quick access to device information ...................................................................................................... 2

Model and serial number label ............................................................................................................. 3

Features at a glance ............................................................................................................................. 4

Walkaround .......................................................................................................................................... 5

General guidelines ............................................................................................................................... 6

Choosing paper and other media ......................................................................................................... 6

HP media ............................................................................................................................. 6

Media to avoid ..................................................................................................................... 6

Media that can damage the device ...................................................................................... 7

Guidelines for using media ................................................................................................................... 8

Paper ................................................................................................................................... 8

Colored paper ...................................................................................................................... 9

Custom-size media .............................................................................................................. 9

Labels .................................................................................................................................. 9

Label construction ............................................................................................... 9

Transparencies .................................................................................................................... 9

Envelopes .......................................................................................................................... 10

Envelope construction ....................................................................................... 10

Envelopes with double-side seams ................................................................... 10

Envelopes with adhesive strips or flaps ............................................................ 11

Envelope storage .............................................................................................. 11

Card stock and heavy media ............................................................................................. 11

Card stock construction ..................................................................................... 11

Card stock guidelines ........................................................................................ 11

Letterhead and preprinted forms ....................................................................................... 12

Supported media weights and sizes ................................................................................................... 13

Printing and storage environment ...................................................................................................... 14

2 Installation

What is in the box ............................................................................................................................... 16

Site requirements ............................................................................................................................... 17

Physical specifications ....................................................................................................... 17

Space requirements ........................................................................................................... 17

Loading media .................................................................................................................................... 18

Loading documents to copy or scan .................................................................................. 18

Loading input trays ............................................................................................................ 18

Main input tray (tray 1) ...................................................................................... 18

Priority input tray ............................................................................................... 19

ENWW iii

Page 6

Connect power ................................................................................................................................... 20

Minimum system requirements .......................................................................................................... 21

Supported operating systems ............................................................................................................. 21

Software installation ........................................................................................................................... 22

Printer driver ....................................................................................................................................... 23

Printer-driver Help .............................................................................................................. 23

Changing printer-driver settings ......................................................................................... 24

Software for Windows ........................................................................................................................ 25

HP LaserJet Scan software ............................................................................................... 25

Installing Windows device software ................................................................................... 25

Uninstalling Windows device software ............................................................................... 25

Uninstalling Macintosh device software ............................................................................. 25

3 Managing the device

Control panel ...................................................................................................................................... 28

Information pages ............................................................................................................................... 29

Managing supplies ............................................................................................................................. 30

Checking supplies status ................................................................................................... 30

Storing supplies ................................................................................................................. 30

Replacing and recycling supplies ...................................................................................... 30

HP policy on non-HP supplies ........................................................................................... 30

HP fraud hotline ................................................................................................................. 31

Supplies .............................................................................................................................................. 32

Cable and interface accessories ........................................................................................................ 32

User-replaceable parts ....................................................................................................................... 32

Paper and other print media ............................................................................................................... 32

4 Maintenance

Cleaning the device ............................................................................................................................ 36

To clean the exterior .......................................................................................................... 36

To clean the scanner glass ................................................................................................ 36

To clean the lid backing ..................................................................................................... 36

To clean the paper path ..................................................................................................... 37

Print cartridge ..................................................................................................................................... 38

Approximate print-cartridge replacement intervals ............................................................ 38

Managing the print cartridge .............................................................................................. 38

Replacing supplies and parts ............................................................................................................. 40

Supply replacement guidelines .......................................................................................... 40

Changing the print cartridge .............................................................................................. 40

5 Theory of Operation

Basic functions ................................................................................................................................... 44

Basic sequence of operation .............................................................................................................. 45

Formatter system ............................................................................................................................... 46

Central processing unit ...................................................................................................... 46

Print-cartridge life expectancy ........................................................................... 38

Print-cartridge storage ....................................................................................... 38

HP policy on non-HP print cartridges ................................................................ 38

HP fraud hotline ................................................................................................ 38

iv ENWW

Page 7

Standard boot process ....................................................................................................... 46

Device startup messages .................................................................................. 46

RAM ................................................................................................................................... 47

Universal serial bus (USB) interface .................................................................................. 47

Control panel ..................................................................................................................... 47

EconoMode ........................................................................................................................ 47

Device functions ................................................................................................................................. 48

Engine control system (engine control unit and power-supply assembly) ......................... 48

Device engine control system ........................................................................... 49

Device laser/scanner unit ................................................................................. 49

Power system on the power-supply assembly .................................................. 49

Image-formation system .................................................................................................... 51

The seven image-formation processes ............................................................ 52

Print cartridge .................................................................................................................... 53

Device paper-feed system ................................................................................................. 53

Jam detection in the device ............................................................................................... 54

Conditions of jam detection ............................................................................... 54

HP LaserJet M1005 MFP unique components ................................................................................... 56

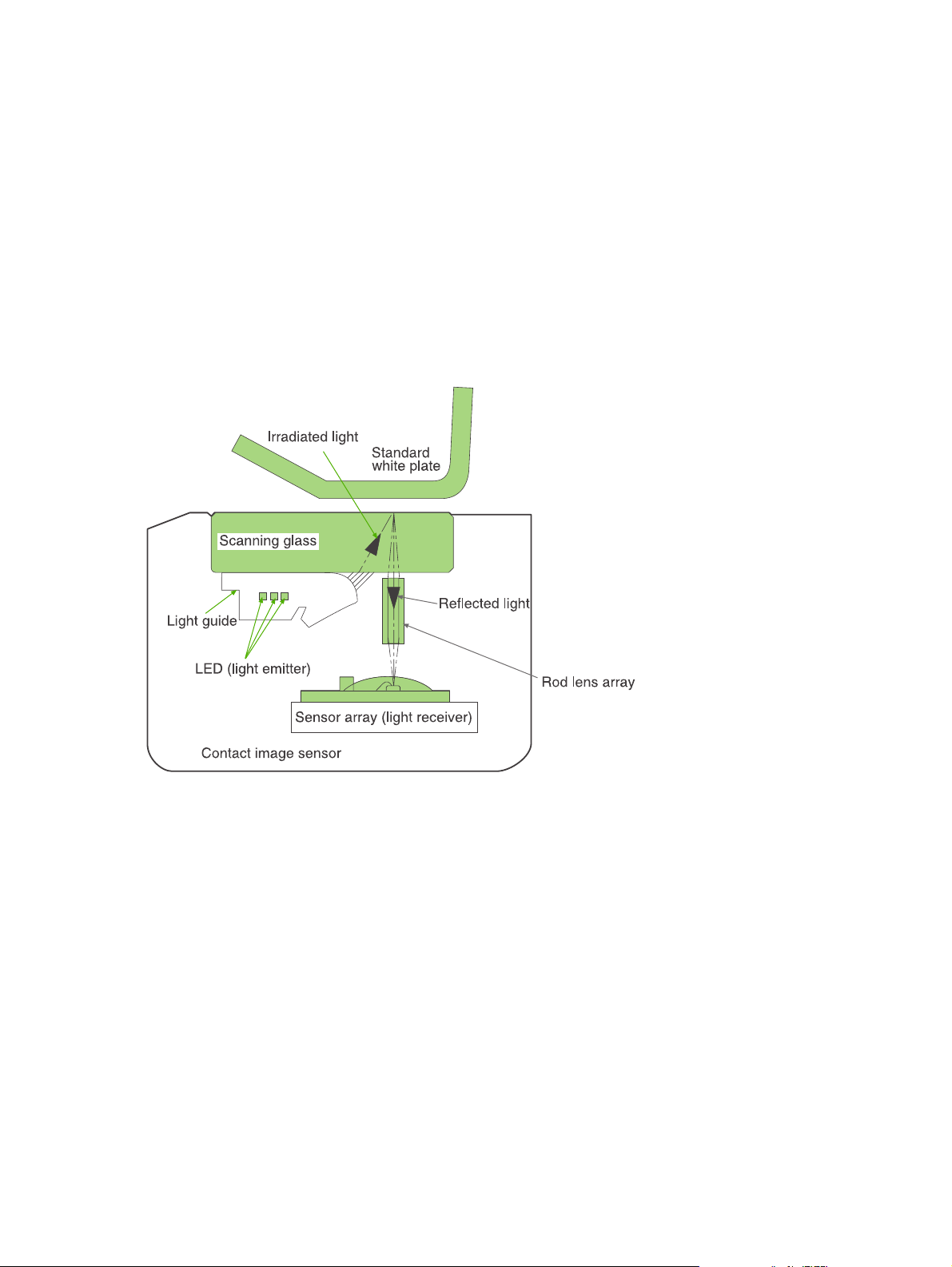

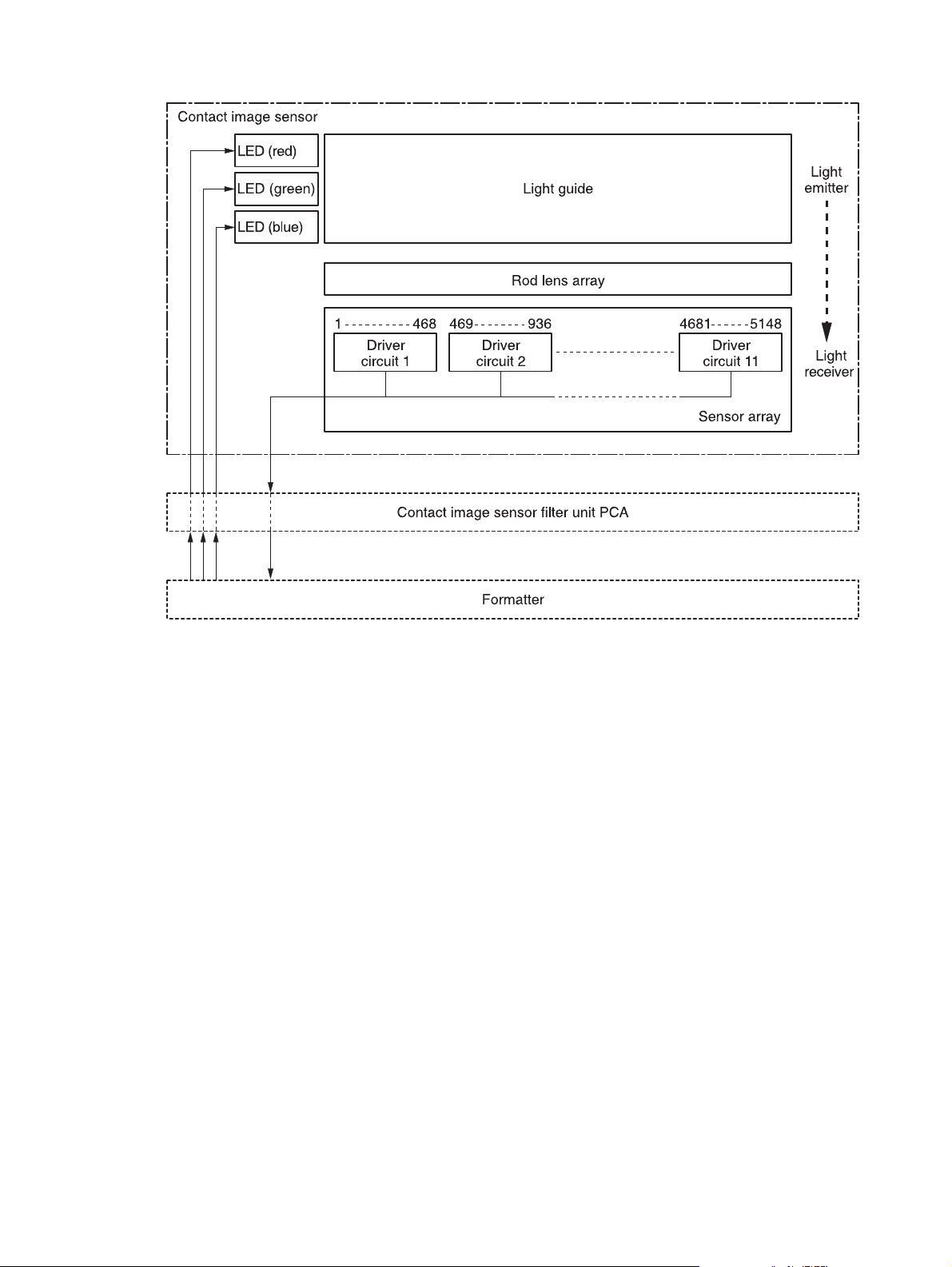

Scanner functions and operation ....................................................................................... 56

Scanner functions ............................................................................................ 56

Scanner operation ............................................................................................. 57

6 Removal and replacement

Removal and replacement strategy .................................................................................................... 60

Admonitions ....................................................................................................................... 60

Required tools .................................................................................................................... 60

Before performing service .................................................................................................. 61

After performing service ..................................................................................................... 61

Parts removal order ........................................................................................................... 61

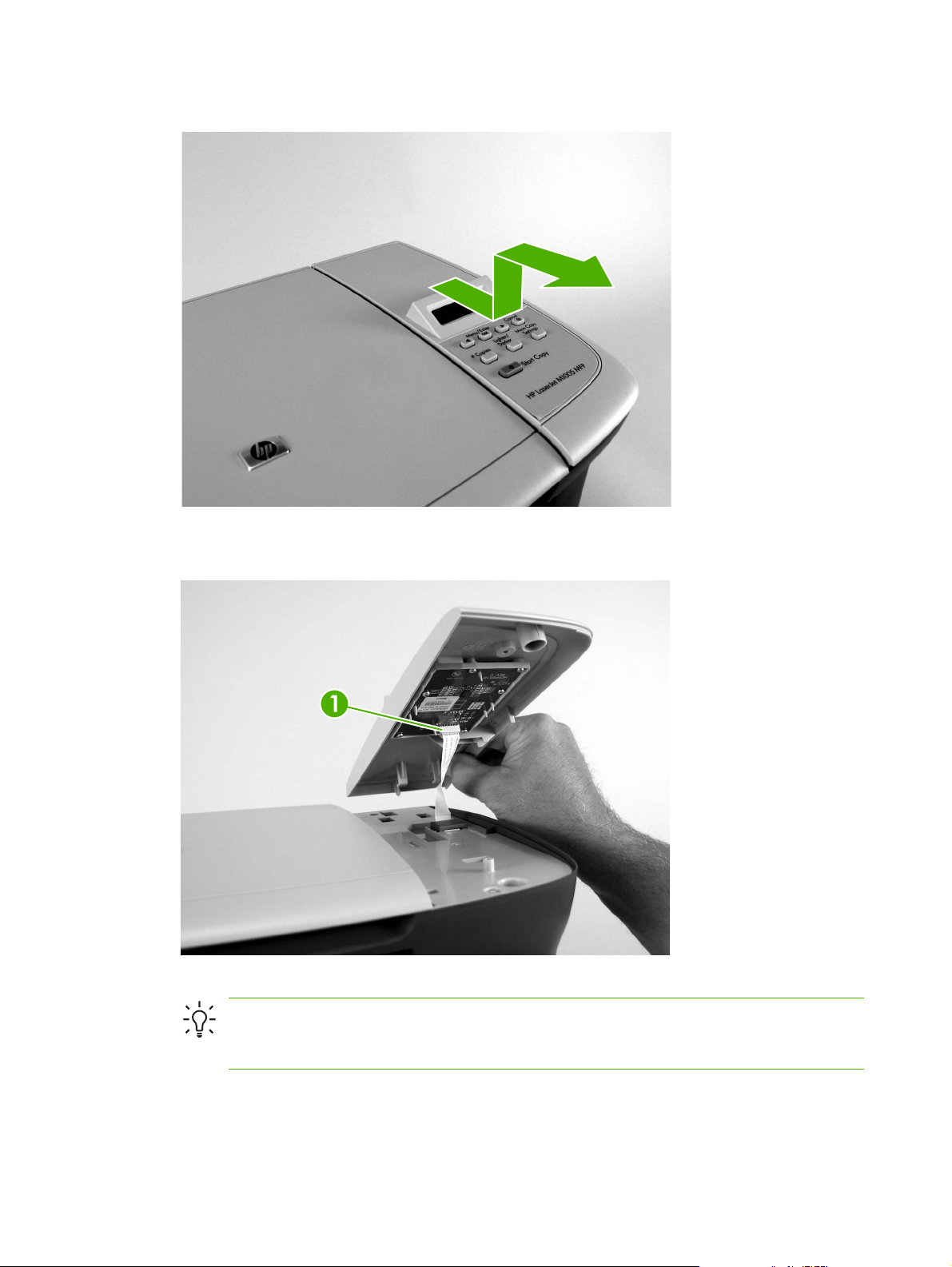

Flatbed lid .......................................................................................................................... 63

Control-panel overlay ......................................................................................................... 64

Control panel ..................................................................................................................... 65

Scanner assembly ............................................................................................................. 67

Device separation pad ....................................................................................................... 73

Print cartridge .................................................................................................................... 74

Device pickup roller ........................................................................................................... 75

Media input tray ................................................................................................................. 78

Transfer roller .................................................................................................................... 80

Device side covers ............................................................................................................. 82

Print-cartridge door ............................................................................................................ 85

Rear cover and fuser cover ............................................................................................... 86

Front cover ......................................................................................................................... 88

Installing the scanner cushions .......................................................................................... 90

Power supply ..................................................................................................................... 91

Formatter ........................................................................................................................... 94

Scanner support frame ..................................................................................................... 95

Engine controller unit ......................................................................................................... 98

Laser/scanner assembly .................................................................................................. 102

Main motor ....................................................................................................................... 103

Fuser ................................................................................................................................ 105

ENWW v

Page 8

7 Troubleshooting

Basic troubleshooting ....................................................................................................................... 110

Control-panel messages .................................................................................................................. 113

Solving image-quality problems ....................................................................................................... 116

Solving scanning (copying) image-quality problems ........................................................................ 124

Repetitive image defect ruler ............................................................................................................ 130

Solving paper-feed problems ........................................................................................................... 131

Functional checks ............................................................................................................................. 135

Firmware update using a flash executable file ................................................................................. 139

Troubleshooting tools ....................................................................................................................... 140

Service-mode functions .................................................................................................................... 141

Main wiring ....................................................................................................................................... 146

Component locations ........................................................................................................................ 148

Paper-pickup assembly ................................................................................................... 107

Alert and warning messages .......................................................................................... 113

Critical error messages ................................................................................................... 113

Event-log codes ............................................................................................................... 115

Checking the print cartridge ............................................................................................ 116

To redistribute the toner in the print cartridge ................................................. 116

Solving print image-quality problems ............................................................................... 116

Print image-quality problems ........................................................................... 116

Scanning (copying) image-quality problems .................................................................... 124

Jams occur in the device ................................................................................................. 131

To clear a jam ................................................................................................. 131

Solving print paper-feed problems ................................................................................... 132

Print paper-feed problems ............................................................................... 133

Half self-test functional check ......................................................................................... 135

To perform a half self-test check ..................................................................... 135

To perform other checks ................................................................................. 135

Drum rotation functional check ........................................................................................ 136

High-voltage contacts check ............................................................................................ 137

To check the print-cartridge contacts .............................................................. 137

To check the high-voltage connector pins ....................................................... 138

Printing a configuration report, demonstration page, or menu structure .......................... 140

Secondary service menu ................................................................................................. 141

To gain access to the secondary service menu .............................................. 141

Adjusting the country/region code parameters ................................................................ 142

To change the country/region from one location to another ............................ 142

To set the language and location if none is set ............................................... 142

NVRAM init ...................................................................................................................... 142

To perform NVRAM init ................................................................................... 143

System settings for localized products ............................................................................ 143

8 Parts and diagrams

Ordering parts and supplies ............................................................................................................. 152

Parts that wear ................................................................................................................ 152

Parts ................................................................................................................................ 152

World-wide customer support .......................................................................................... 152

Accessories ...................................................................................................................................... 153

vi ENWW

Page 9

Common hardware .......................................................................................................... 153

How to use the parts lists and diagrams .......................................................................... 154

Scanner assembly ............................................................................................................................ 156

Formatter .......................................................................................................................................... 158

Whole unit replacement part ............................................................................................................ 160

Alphabetical parts list ....................................................................................................................... 176

Numerical parts list ........................................................................................................................... 180

Appendix A Device specifications

Physical specifications ..................................................................................................................... 186

Electrical specifications .................................................................................................................... 186

Power consumption .......................................................................................................................... 186

Environmental specifications ............................................................................................................ 186

Acoustic emissions ........................................................................................................................... 187

Appendix B Product warranty

Hewlett-Packard Limited Warranty Statement ................................................................................. 190

Availability of support and service .................................................................................................... 191

HP maintenance agreements ........................................................................................................... 192

Next-Day Onsite Service ................................................................................................. 192

Appendix C Regulatory information

FCC compliance ............................................................................................................................... 194

Declaration of conformity ................................................................................................................. 195

Country-/region-specific safety statements ...................................................................................... 196

Laser safety statement .................................................................................................... 196

Canadian DOC statement ................................................................................................ 196

Korean EMI statement ..................................................................................................... 196

Finnish laser statement .................................................................................................... 197

Index ................................................................................................................................................................. 199

ENWW vii

Page 10

viii ENWW

Page 11

List of tables

Table 1-1 Device guides ..................................................................................................................................... 2

Table 1-2 Features ............................................................................................................................................. 4

Table 1-3 Priority input tray specifications ........................................................................................................ 13

Table 1-4 Tray 1 specifications ........................................................................................................................ 13

Table 2-1 Physical dimensions for the HP LaserJet M1005 MFP .................................................................... 17

Table 5-1 HP LaserJet M1005 MFP ................................................................................................................. 45

Table 5-2 Device startup messages ................................................................................................................. 46

Table 5-3 Dc power distribution ........................................................................................................................ 49

Table 7-1 Event-log codes ............................................................................................................................. 115

Table 7-2 System settings .............................................................................................................................. 143

Table 8-1 Technical support websites and related documentation ................................................................ 152

Table 8-2 Accessories .................................................................................................................................... 153

Table 8-3 Common fasteners ........................................................................................................................ 153

Table 8-4 Scanner assembly .......................................................................................................................... 157

Table 8-5 Formatter ........................................................................................................................................ 159

Table 8-6 Whole unit replacement part .......................................................................................................... 161

Table 8-7 Pickup- and delivery- tray assemblies ............................................................................................ 163

Table 8-8 External covers .............................................................................................................................. 165

Table 8-9 Internal components (1 of 3) .......................................................................................................... 167

Table 8-10 Internal components (2 of 3) ........................................................................................................ 169

Table 8-11 Internal components (3 of 3) ........................................................................................................ 171

Table 8-12 Paper-pickup assembly ................................................................................................................ 173

Table 8-13 Fuser (fixing assy) assembly ........................................................................................................ 175

Table 8-14 Alphabetical parts list ................................................................................................................... 176

Table 8-15 Numerical parts list ....................................................................................................................... 180

Table A-1 Physical specifications ................................................................................................................... 186

Table A-2 Electrical specifications .................................................................................................................. 186

Table A-3 Power consumption (average, in watts), ...................................................................................... 186

Table A-4 Environmental specifications ........................................................................................................ 186

Table A-5 Acoustic emissions , ...................................................................................................................... 187

ENWW ix

Page 12

x ENWW

Page 13

List of figures

Figure 1-1 Model and serial number label .......................................................................................................... 3

Figure 1-2 Front view ......................................................................................................................................... 5

Figure 1-3 Back view .......................................................................................................................................... 5

Figure 2-1 What is in the shipping box ............................................................................................................. 16

Figure 2-2 Space requirements ........................................................................................................................ 17

Figure 2-3 Loading documents to copy or scan ............................................................................................... 18

Figure 2-4 Loading the main input tray (tray 1) (1 of 2) .................................................................................... 18

Figure 2-5 Loading the main input tray (tray 1) (2 of 2) .................................................................................... 19

Figure 2-6 Loading the priority input tray (1 of 2) ............................................................................................. 19

Figure 2-7 Loading the priority input tray (2 of 2) ............................................................................................. 19

Figure 2-8 Connect power ................................................................................................................................ 20

Figure 3-1 Control panel ................................................................................................................................... 28

Figure 4-1 Cleaning the scanner glass ............................................................................................................ 36

Figure 4-2 Cleaning the lid backing .................................................................................................................. 37

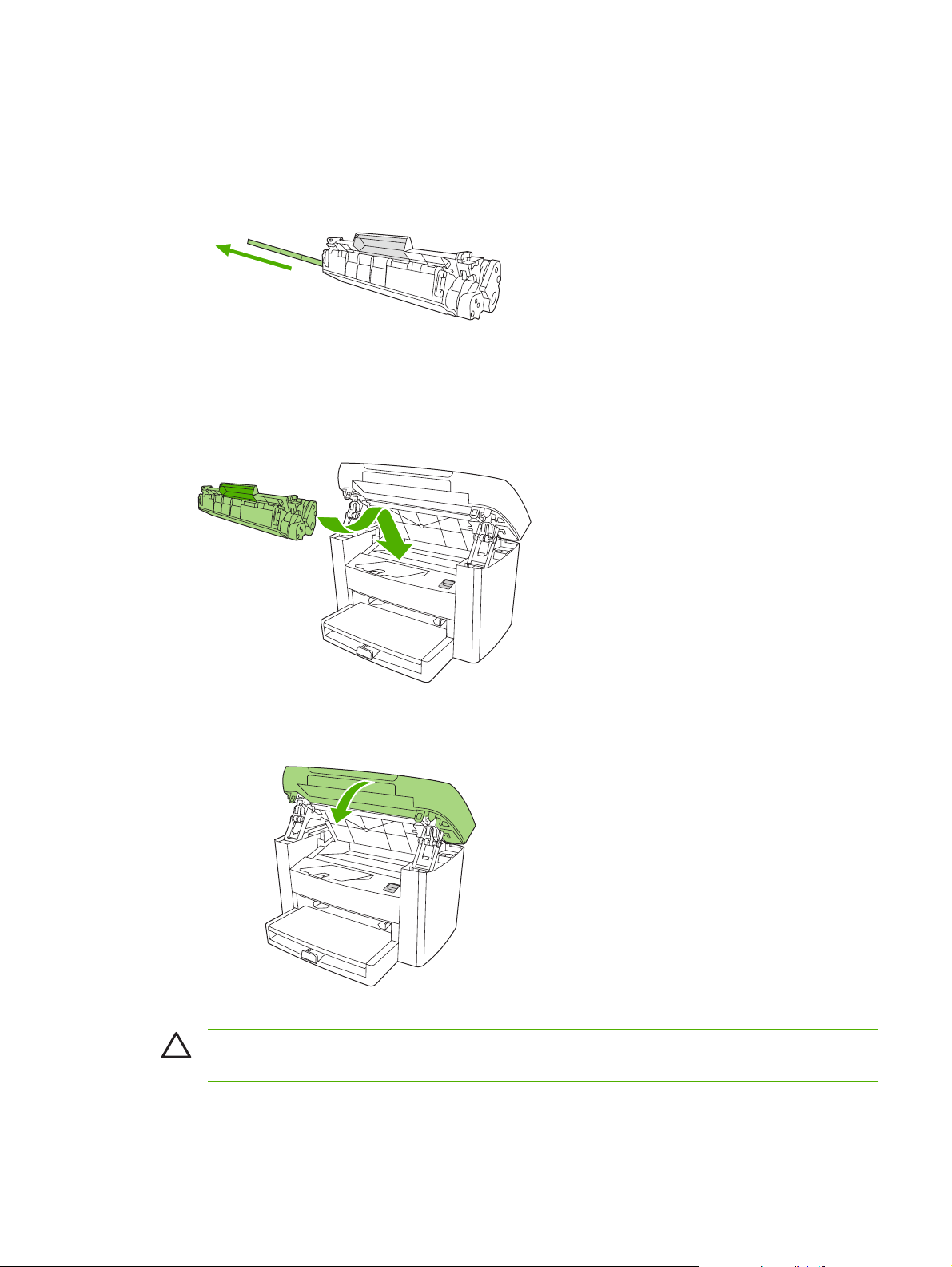

Figure 4-3 Changing the print cartridge (1 of 5) ............................................................................................... 40

Figure 4-4 Changing the print cartridge (2 of 5) ............................................................................................... 40

Figure 4-5 Changing the print cartridge (3 of 5) ............................................................................................... 41

Figure 4-6 Changing the print cartridge (4 of 5) ............................................................................................... 41

Figure 4-7 Changing the print cartridge (5 of 5) ............................................................................................... 41

Figure 5-1 Device configuration ....................................................................................................................... 44

Figure 5-2 Device functional block diagram ..................................................................................................... 48

Figure 5-3 High-voltage power supply circuit ................................................................................................... 51

Figure 5-4 Image-formation block diagram ..................................................................................................... 52

Figure 5-5 Device paper path .......................................................................................................................... 54

Figure 5-6 HP LaserJet M1005 MFP optical system (1 of 2) ........................................................................... 56

Figure 5-7 HP LaserJet M1005 MFP optical system (2 of 2) ........................................................................... 57

Figure 6-1 Parts removal order for the HP LaserJet M1005 MFP .................................................................... 62

Figure 6-2 Remove the flatbed lid (1 of 2) ........................................................................................................ 63

Figure 6-3 Remove the control-panel overlay .................................................................................................. 64

Figure 6-4 Remove the control panel (1 of 4) .................................................................................................. 65

Figure 6-5 Remove the control panel (2 of 4) .................................................................................................. 65

Figure 6-6 Remove the control panel (3 of 4) .................................................................................................. 66

Figure 6-7 Remove the control panel (4 of 4) .................................................................................................. 66

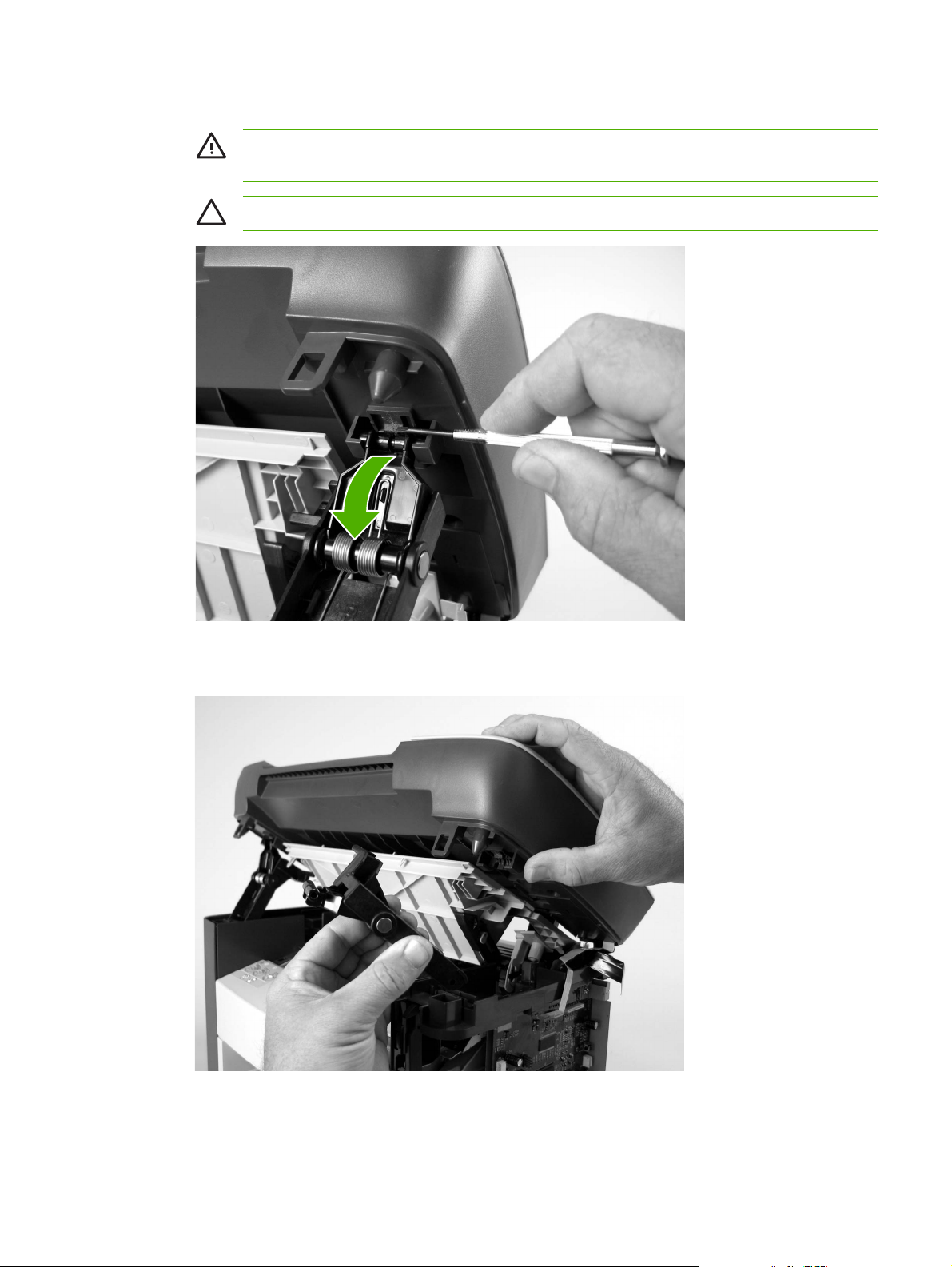

Figure 6-8 Remove the scanner assembly (1 of 11) ........................................................................................ 67

Figure 6-9 Remove the scanner assembly (2 of 11) ........................................................................................ 67

Figure 6-10 Remove the scanner assembly (3 of 11) ...................................................................................... 68

Figure 6-11 Remove the scanner assembly (4 of 11) ...................................................................................... 68

Figure 6-12 Remove the scanner assembly (5 of 11) ...................................................................................... 69

Figure 6-13 Remove the scanner assembly (6 of 11) ...................................................................................... 69

Figure 6-14 Remove the scanner assembly (7 of 11) ...................................................................................... 70

ENWW xi

Page 14

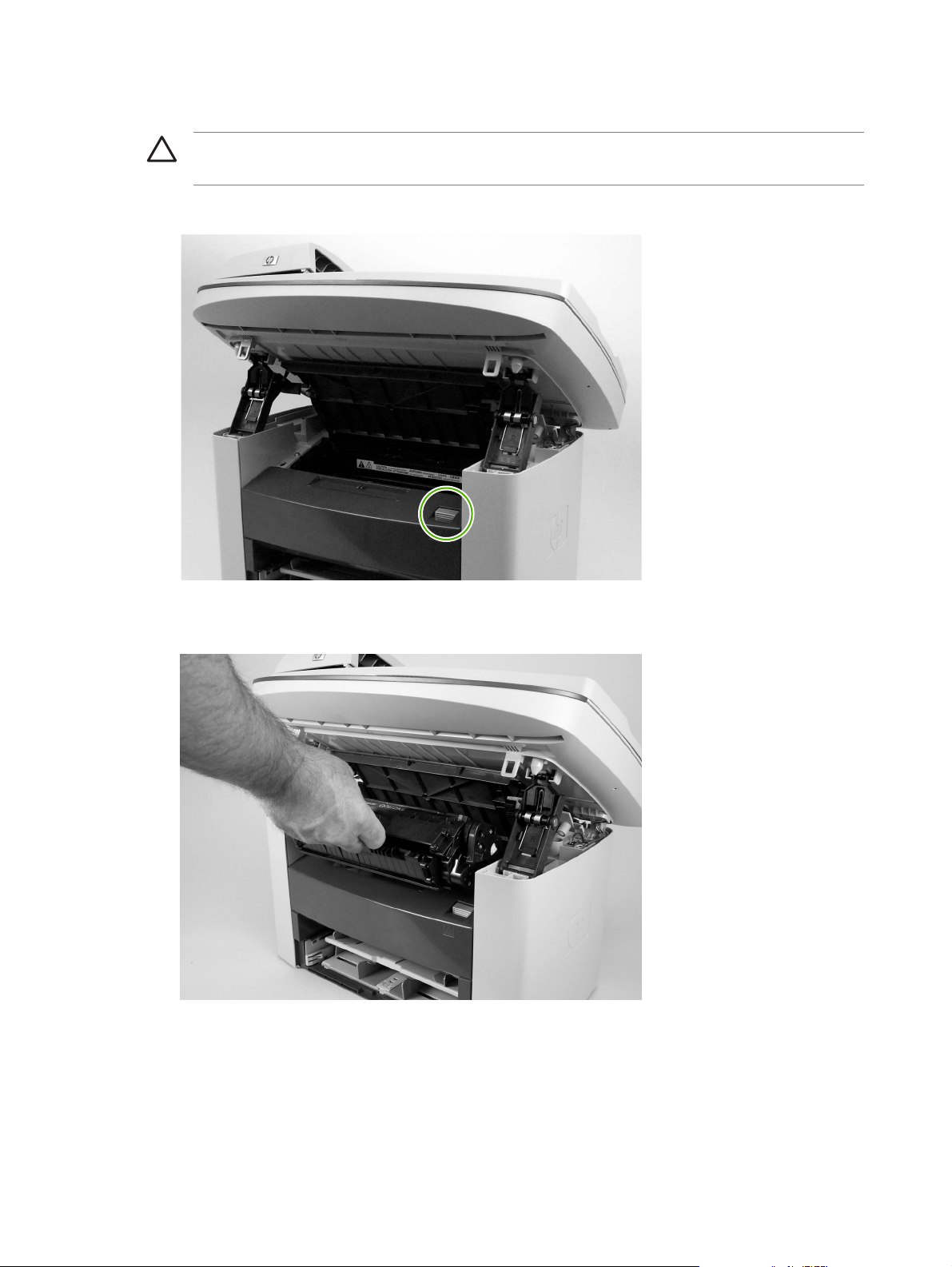

Figure 6-15 Remove the scanner assembly (8 of 11) ...................................................................................... 70

Figure 6-16 Remove the scanner assembly (9 of 11) ...................................................................................... 71

Figure 6-17 Remove the scanner assembly (10 of 11) .................................................................................... 71

Figure 6-18 Remove the scanner assembly (11 of 11) .................................................................................... 72

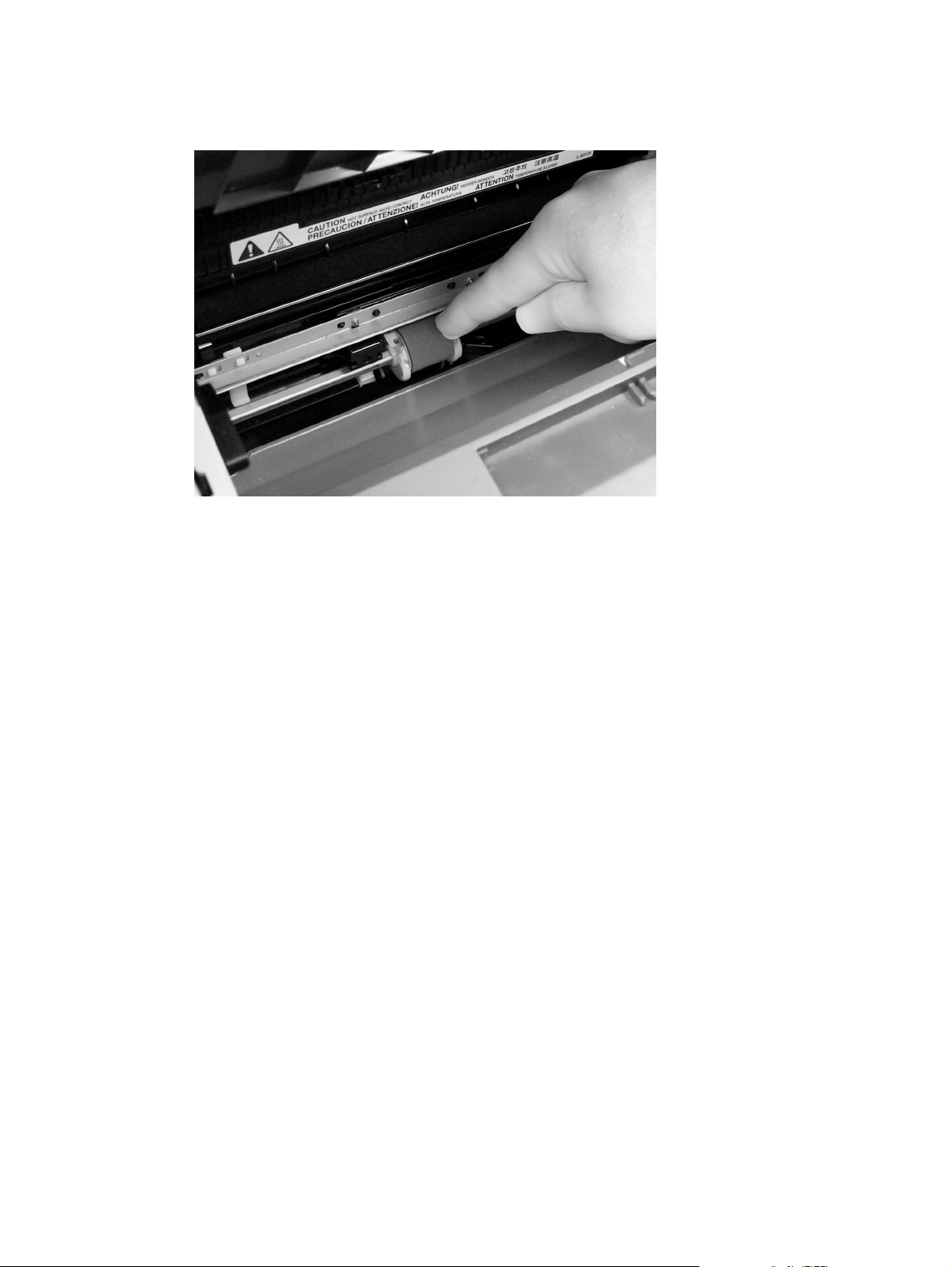

Figure 6-19 Remove the device separation pad (1 of 2) .................................................................................. 73

Figure 6-20 Remove the device separation pad (2 of 2) .................................................................................. 73

Figure 6-21 Remove the print cartridge (1 of 2) ............................................................................................... 74

Figure 6-22 Remove the print cartridge (2 of 2) ............................................................................................... 74

Figure 6-23 Remove the device pickup roller (1 of 5) ...................................................................................... 75

Figure 6-24 Remove the device pickup roller (2 of 5) ...................................................................................... 75

Figure 6-25 Remove the device pickup roller (3 of 5) ...................................................................................... 76

Figure 6-26 Remove the device pickup roller (4 of 5) ...................................................................................... 76

Figure 6-27 Remove the device pickup roller (5 of 5) ...................................................................................... 77

Figure 6-28 Remove the media input tray (1 of 3) ........................................................................................... 78

Figure 6-29 Remove the media input tray (2 of 3) ........................................................................................... 78

Figure 6-30 Remove the media input tray (3 of 3) ........................................................................................... 79

Figure 6-31 Remove the transfer roller (1 of 3) ................................................................................................ 80

Figure 6-32 Remove the transfer roller (2 of 3) ................................................................................................ 81

Figure 6-33 Remove the transfer roller (3 of 3) ................................................................................................ 81

Figure 6-34 Remove the device side covers (1 of 3) ....................................................................................... 82

Figure 6-35 Remove the device side covers (2 of 3) ...................................................................................... 83

Figure 6-36 Remove the device side covers (2 of 3) ...................................................................................... 83

Figure 6-37 Remove the device side covers (3 of 3) ....................................................................................... 84

Figure 6-38 Remove the print-cartridge door (1 of 2) ....................................................................................... 85

Figure 6-39 Remove the print-cartridge door (2 of 2) ....................................................................................... 85

Figure 6-40 Remove the rear cover and fuser cover (1 of 3) ........................................................................... 86

Figure 6-41 Remove the rear cover and fuser cover (2 of 3) ........................................................................... 86

Figure 6-42 Remove the rear cover and fuser cover (3 of 3) ........................................................................... 87

Figure 6-43 Remove the front cover (1 of 3) .................................................................................................... 88

Figure 6-44 Remove the front cover (2 of 3) .................................................................................................... 88

Figure 6-45 Remove the front cover (3 of 3) .................................................................................................... 89

Figure 6-46 Reinstalling the front cover ........................................................................................................... 89

Figure 6-47 Installing the scanner cushions ..................................................................................................... 90

Figure 6-48 Remove the power supply (1 of 3) ................................................................................................ 91

Figure 6-49 Remove the power supply (2 of 3) ................................................................................................ 92

Figure 6-50 Remove the power supply (3 of 3) ................................................................................................ 92

Figure 6-51 Remove the formatter (1 of 2) ....................................................................................................... 94

Figure 6-52 Remove the formatter (2 of 2) ....................................................................................................... 94

Figure 6-53 Remove the scanner support frame (1 of 3) ................................................................................. 95

Figure 6-54 Remove the scanner support frame (2 of 3) ................................................................................. 96

Figure 6-55 Remove the scanner support frame (3 of 3) ................................................................................. 96

Figure 6-56 Remove the ECU (1 of 6) .............................................................................................................. 98

Figure 6-57 Remove the ECU (2 of 6) .............................................................................................................. 99

Figure 6-58 Remove the ECU (3 of 6) .............................................................................................................. 99

Figure 6-59 Remove the ECU (4 of 6) ............................................................................................................ 100

Figure 6-60 Remove the ECU (5 of 6) ...........................................................................................

Figure 6-61 Remove the ECU (6 of 6) ............................................................................................................ 101

Figure 6-62 Remove the laser/scanner assembly .......................................................................................... 102

Figure 6-63 Remove the main motor (1 of 2) ................................................................................................. 103

Figure 6-64 Remove the main motor (2 of 2) ................................................................................................. 104

................. 100

xii ENWW

Page 15

Figure 6-65 Remove the fuser assembly (1 of 2) ........................................................................................... 105

Figure 6-66 Remove the fuser assembly (2 of 2) ........................................................................................... 106

Figure 6-67 Fragile tab on fuser assembly ..................................................................................................... 106

Figure 6-68 Remove the paper-pickup assembly .......................................................................................... 107

Figure 7-1 Repetitive image defect ruler ........................................................................................................ 130

Figure 7-2 Clear a jam in the device base (1 of 3) ......................................................................................... 131

Figure 7-3 Clear a jam in the device base (2 of 3) ......................................................................................... 132

Figure 7-4 Clear a jam in the device base (3 of 3) ......................................................................................... 132

Figure 7-5 Check the fuser connectors on the fuser ...................................................................................... 136

Figure 7-6 Check the fuser connectors on the power supply ......................................................................... 136

Figure 7-7 Print-cartridge high-voltage contacts ............................................................................................ 137

Figure 7-8 High-voltage contacts ................................................................................................................... 138

Figure 7-9 Main wiring, HP LaserJet M1005 MFP scanner assembly ........................................................... 146

Figure 7-10 Main wiring, HP LaserJet M1005 MFP device base ................................................................... 147

Figure 7-11 HP LaserJet M1005 MFP component locations (1 of 2) ............................................................. 148

Figure 7-12 HP LaserJet M1005 MFP component locations (2 of 2) ............................................................. 149

Figure 8-1 Scanner assembly ........................................................................................................................ 156

Figure 8-2 Formatter ...................................................................................................................................... 158

Figure 8-3 Whole unit replacement part ......................................................................................................... 160

Figure 8-4 Pickup- and delivery-tray assemblies ........................................................................................... 162

Figure 8-5 External covers ............................................................................................................................. 164

Figure 8-6 Internal components (1 of 3) ......................................................................................................... 166

Figure 8-7 Internal components (2 of 3) ......................................................................................................... 168

Figure 8-8 Internal components (3 of 3) ......................................................................................................... 170

Figure 8-9 Paper-pickup assembly ................................................................................................................. 172

Figure 8-10 Fuser (fixing assy) assembly ...................................................................................................... 174

ENWW xiii

Page 16

xiv ENWW

Page 17

1 Device information

Quick access to device information

●

Model and serial number label

●

Features at a glance

●

Walkaround

●

General guidelines

●

Choosing paper and other media

●

Guidelines for using media

●

Supported media weights and sizes

●

Printing and storage environment

●

ENWW 1

Page 18

Quick access to device information

Several references are available for use with this device.

HP LaserJet M1005 MFP:

●

Table 1-1 Device guides

Guide Description

Getting started guide Provides step-by-step instructions for installing and setting up the device.

User guide Provides detailed information for using and troubleshooting the device. Available on the

Online Help Provides information about options that are available in the device drivers. To view a Help

www.hp.com/support/LJm_1005.

device CD.

file, open the online Help through the printer driver.

2 Chapter 1 Device information ENWW

Page 19

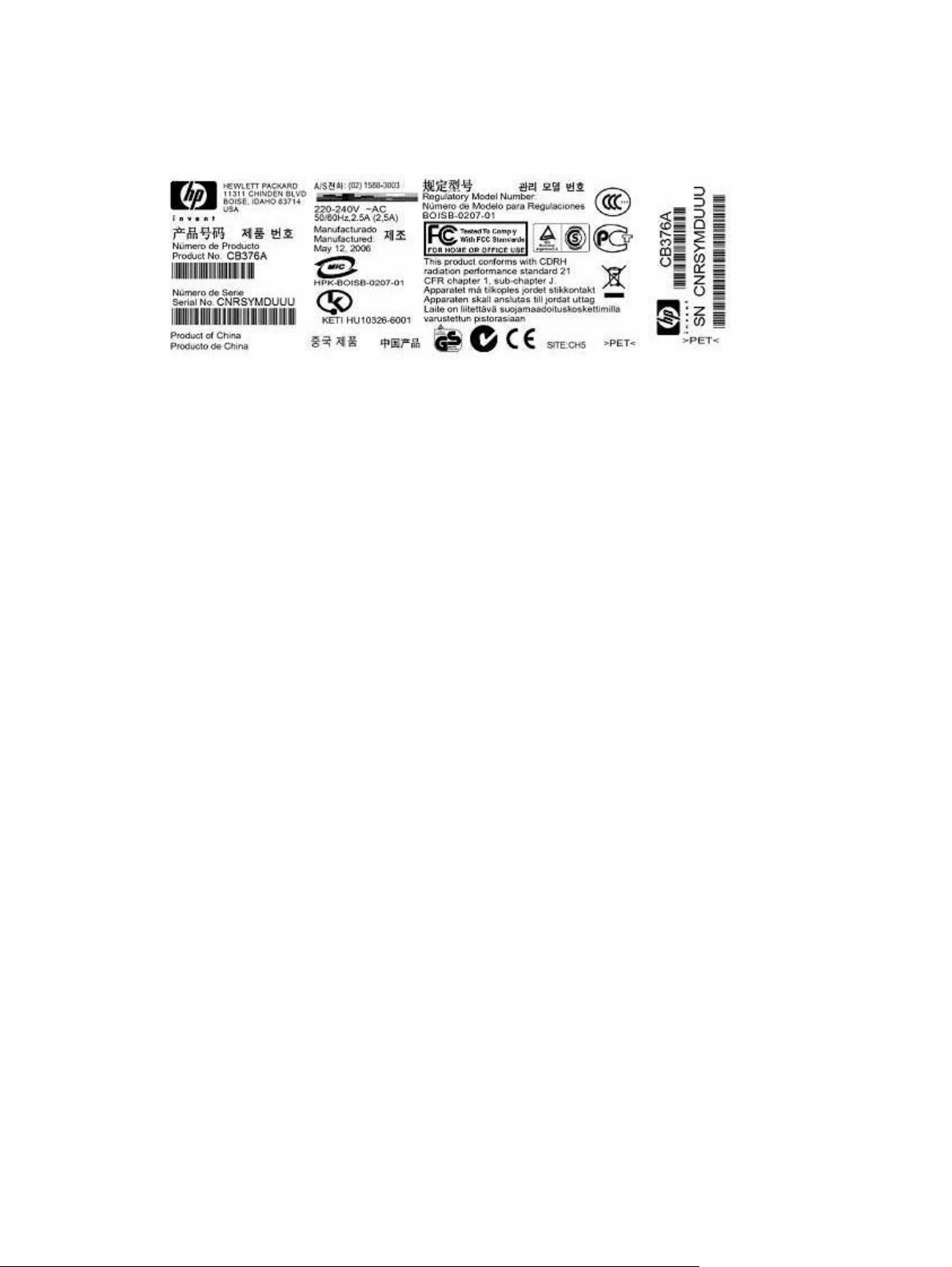

Model and serial number label

The model and serial number are located on a label found on the back of the device.

Figure 1-1 Model and serial number label

ENWW Model and serial number label 3

Page 20

Features at a glance

Table 1-2 Features

Feature Description

Print

Copy

Memory

Paper handling

Scan

Printer driver

Interface connections

Environmental features

Economical printing

Prints letter-size pages at speeds up to 15 pages per minute (ppm) and A4-size pages

●

at speeds up to 14 ppm

Prints at 600 dots per inch (dpi) and FastRes 1200 dpi

●

Includes adjustable settings to optimize print quality

●

Average yield for the standard black print cartridge is 2,000 pages in accordance with

●

ISO/IEC 19752. Actual yield depends on specific use.

Copies at 600 dots per inch (dpi)

●

Includes 32-megabyte (MB) random-access memory (RAM)

●

Priority input tray holds up to 10 pages

●

Tray 1 holds up to 150 sheets of print media or 10 envelopes

●

Output bin holds up to 100 sheets of print media

●

Provides 1200 pixels per inch (ppi) full-color scanning

●

FastRes 1200 produces 1200-dots-per-inch (dpi) print quality for fast, high-quality

●

printing of business text and graphics

Includes a Hi-Speed USB 2.0 port

●

ENERGY STAR®-qualified

●

Provides N-up printing (printing more than one page on a sheet)

●

Supplies

Accessibility

Provides an EconoMode setting, which uses less toner

●

Uses a print cartridge that has a no-shake design

●

Online user guide is compatible with text screen-readers

●

Print cartridge can be installed and removed by using one hand

●

All doors and covers can be opened by using one hand

●

4 Chapter 1 Device information ENWW

Page 21

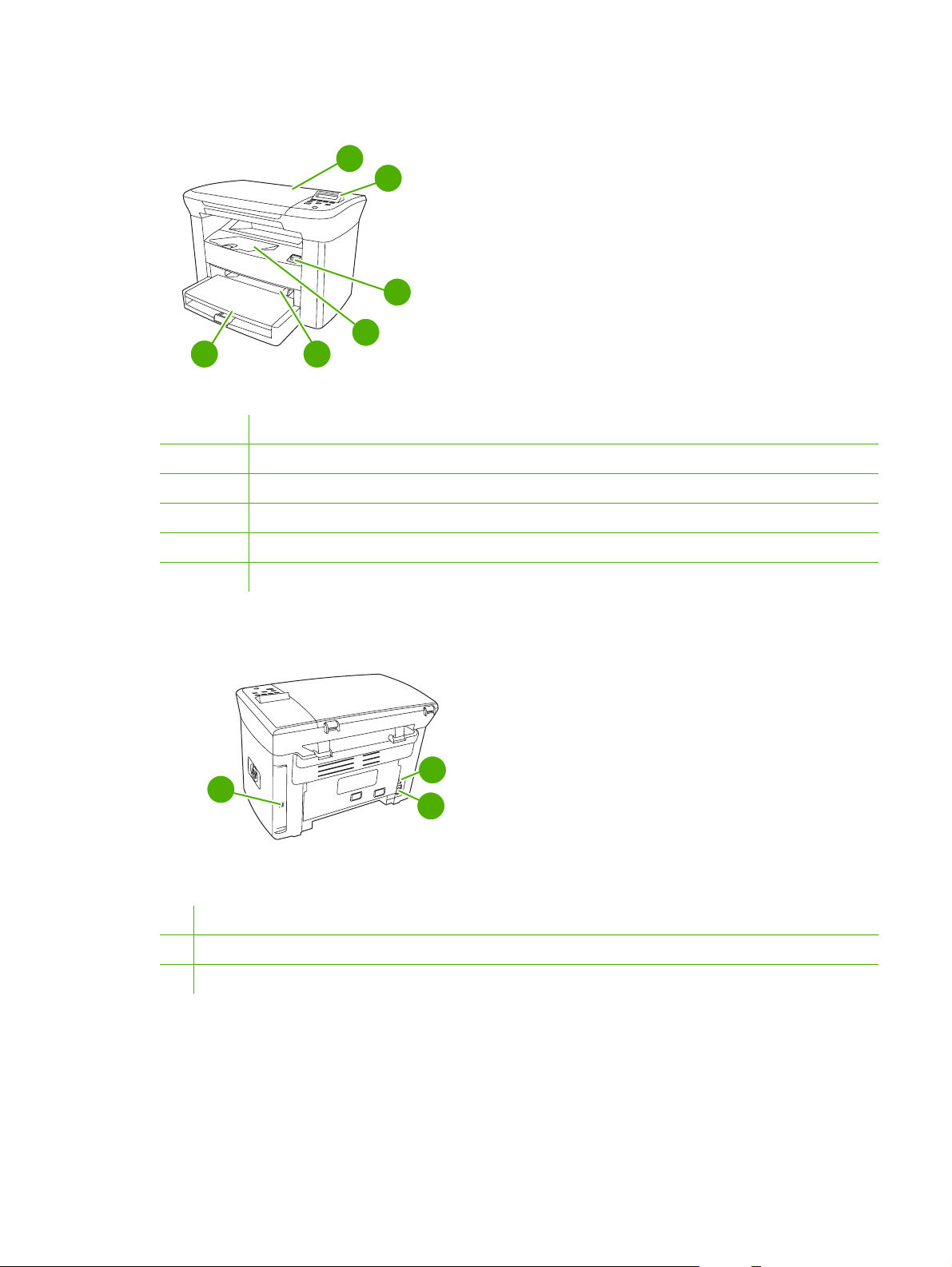

Walkaround

6

Figure 1-2 Front view

1 Flatbed scanner cover

2 Control panel

3 Cartridge-door release

4 Output bin

5 Priority input tray

6 Tray 1

1

2

3

4

5

8

7

9

Figure 1-3 Back view

7 Hi-Speed USB 2.0 port

8 Power switch

9 Power receptacle

ENWW Walkaround 5

Page 22

General guidelines

Some media might meet all of the guidelines in this manual and still not produce satisfactory results.

This problem might be the result of improper handling, unacceptable temperature and humidity levels,

or other variables over which Hewlett-Packard has no control.

Before purchasing large quantities of print media, always test a sample and make sure that the print

media meets the requirements specified in this service manual and in the HP LaserJet Printer Family

Print Media Guide, which you can view on the Web at

CAUTION Using media that does not meet HP specifications can cause problems for the

device, requiring repair. This repair is not covered by the Hewlett-Packard warranty or service

agreements.

The device accepts a variety of media, such as cut-sheet paper (including up to 100% recycled-fibercontent paper), envelopes, labels, transparencies, LaserJet glossy paper, HP LaserJet Tough paper,

and custom-size paper. Properties such as weight, composition, grain, and moisture content are

important factors that affect performance and output quality. Media that does not meet the guidelines

outlined in this manual can cause the following problems:

Poor print quality

●

Increased jams

●

Premature wear on the device, requiring repair

●

www.hp.com/support/ljpaperguide.

Choosing paper and other media

Properties such as weight, grain, and moisture content are important factors that affect performance

and quality. To achieve the best possible print quality, only use high-quality media that is designed for

laser printers.

NOTE Always test a sample of the media before you purchase large quantities. Your media

supplier should understand the requirements specified in the HP LaserJet Printer Family Print

Media Guide (HP part number 5963-7863).

HP media

HP recommends that you use HP LaserJet media in the device.

Media to avoid

The device can handle many types of media. Using media that is outside the specifications degrades

print quality and increases the chance of jams occurring. See

on page 8.

Do not use media that is too rough.

●

Do not use media that contains cutouts or perforations other than standard 3-hole punched paper.

●

Do not use multipart forms.

●

Guidelines for using media

Do not use paper that contains a watermark if you are printing solid patterns.

●

6 Chapter 1 Device information ENWW

Page 23

Media that can damage the device

In rare circumstances media can damage the device. Avoid the following types of media to prevent

possible damage:

Do not use media with staples or paper clips attached.

●

Do not use transparencies designed for inkjet printers or other low-temperature printers. Use only

●

transparencies that are specified for use with HP LaserJet devices.

Do not use photo paper intended for inkjet printers.

●

Do not use paper that is embossed or coated and is not designed for the temperature of the image-

●

fuser. Select media that can tolerate temperatures of 200°C (392°F) for 0.1 second.

HP manufactures a media that is designed for the device.

Do not use letterhead paper that was produced with low-temperature dyes or thermography.

●

Preprinted forms or letterhead must use inks that can tolerate temperatures of 200°C (392°F) for

0.1 second.

Do not use any media that produces emissions, or that melts, offsets, or discolors when exposed

●

to 200°C (392°F) for 0.1 second.

To order HP LaserJet printing supplies, go to

ghp/buyonline.html/ worldwide.

www.hp.com/go/ljsupplies in the U.S. or to www.hp.com/

ENWW Choosing paper and other media 7

Page 24

Guidelines for using media

The following sections provide guidelines and instructions for printing on transparencies, envelopes,

and other special media. Guidelines and specifications are included to help you select media that

optimizes print quality and avoid media that can cause jams or damage the device.

Paper

For best results, use conventional 80-g/m2 or 20-lb paper. Make sure that the paper is of good quality

and free of cuts, nicks, tears, spots, loose particles, dust, wrinkles, voids, and curled or bent edges.

If you are unsure about what type of paper you are loading (such as bond or recycled), check the label

on the package of paper.

Some paper causes print quality problems, jamming, or damage to the device.

Symptom Problem with paper Solution

Poor print quality or toner adhesion

Problems with feeding

Dropouts, jamming, or curl Stored improperly Store paper flat in its moisture-proof

Increased gray background shading Might be too heavy Use lighter paper.

Excessive curl

Problems with feeding

Jamming or damage to device Cutouts or perforations Do not use paper with cutouts or

Problems with feeding Ragged edges Use good quality paper.

Too moist, too rough, too smooth, or

embossed

Too moist, wrong grain direction, or

short-grain construction

Try another kind of paper that has a

smoothness rating of 100-250 Sheffield

and has 4-6% moisture content.

Check the device and make sure that the

appropriate media type has been

selected.

wrapping.

Use long-grain paper.

Check the device and make sure that the

appropriate media type has been

selected.

perforations.

NOTE The device uses heat and pressure to fuse toner to the paper. Make sure that any colored

paper or preprinted forms use inks that are compatible with the fuser temperature of 200°C (392°

F) for 0.1 second.

Do not use letterhead that is printed with low-temperature inks, such as those used in some types

of thermography.

Do not use raised letterhead.

Do not use transparencies that are designed for inkjet printers or other low-temperature printers.

Use only transparencies that are specified for use with HP LaserJet printers.

CAUTION Failure to follow these guidelines could cause jams or damage to the device.

8 Chapter 1 Device information ENWW

Page 25

Colored paper

Colored paper should be of the same high quality as white xerographic paper.

●

Pigments used must be able to withstand the fuser temperature of 200°C (392°F) for 0.1 second

●

without deterioration.

Do not use paper with a colored coating that was added after the paper was produced.

●

Custom-size media

Use the main input tray for multiple sheets.

CAUTION Make sure that the sheets are not stuck together before you load them.

Labels

HP recommends that you print labels from the priority input tray.

CAUTION Do not feed a sheet of labels through the device more than once. The adhesive

degrades and might damage the device.

Label construction

When selecting labels, consider the quality of the following components:

Adhesives: The adhesive material should be stable at 200°C (392°F), the maximum fuser

●

temperature.

Arrangement: Only use labels with no exposed backing between them. Labels can peel off sheets

●

that have spaces between the labels, causing serious jams.

Curl: Before printing, labels must lie flat with no more than 13 mm (0.5 inch) of curl in any direction.

●

Condition: Do not use labels with wrinkles, bubbles, or other indications of separation.

●

Transparencies

Transparencies must be able to withstand 200°C (392°F), the maximum fuser temperature.

CAUTION You can print transparencies from the 150-sheet tray (tray 1). However, do not load

more than 75 transparencies at one time into the tray.

ENWW Guidelines for using media 9

Page 26

Envelopes

HP recommends that you print envelopes from the priority input tray.

Envelope construction

Envelope construction is critical. Envelope fold lines can vary considerably, not only between

manufacturers, but also within a box from the same manufacturer. Successful printing on envelopes

depends upon the quality of the envelopes. When selecting envelopes, consider the following

components:

2

Weight: The weight of the envelope paper should not exceed 90 g/m

●

result.

Construction: Before printing, envelopes should lie flat with less than 6 mm (0.25 inch) of curl,

●

and should not contain air. Envelopes that trap air can cause problems. Do not use envelopes that

contain clasps, snaps, tie strings, transparent windows, holes, perforations, cutouts, synthetic

materials, stamping, or embossing. Do not use envelopes with adhesives that require pressure to

seal them.

Condition: Make sure that the envelopes are not wrinkled, nicked, or otherwise damaged. Make

●

sure that the envelopes do not have any exposed adhesive.

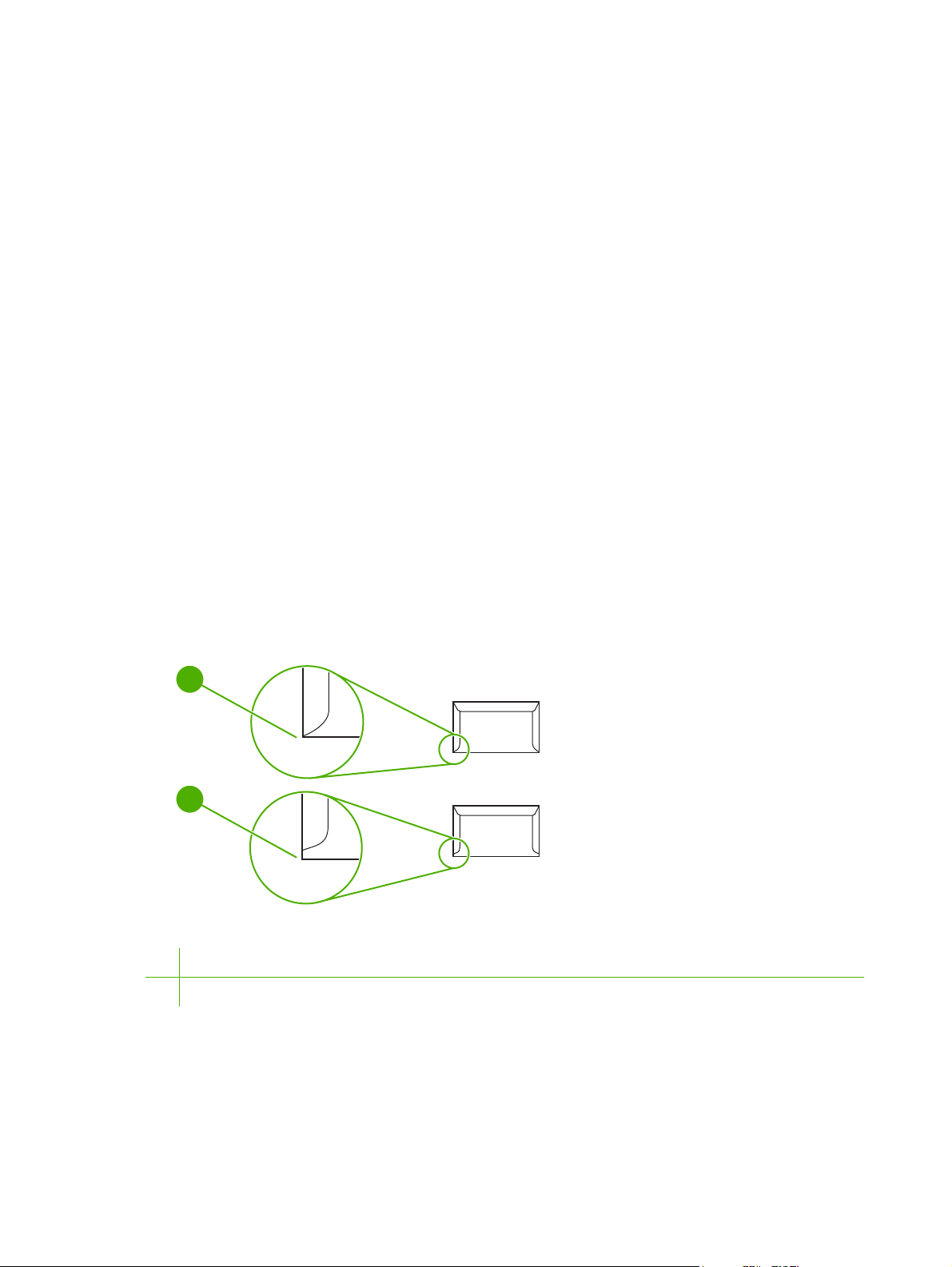

Envelopes with double-side seams

An envelope with double-side-seam construction has vertical seams at both ends of the envelope rather

than diagonal seams. This style might be more likely to wrinkle. Make sure that the seam extends all

the way to the corner of the envelope as shown in the following illustration:

(24 lb), or jamming might

1

2

1 Acceptable envelope construction

2 Unacceptable envelope construction

10 Chapter 1 Device information ENWW

Page 27

Envelopes with adhesive strips or flaps

Envelopes with a peel-off adhesive strip or with more than one flap that folds over to seal must use

adhesives compatible with the heat and pressure in the device: 200°C (392°F). The extra flaps and

strips might cause wrinkling, creasing, or jams.

Envelope storage

Proper storage of envelopes contributes to good print quality. You should store envelopes flat. If air is

trapped in an envelope, creating an air bubble, the envelope might wrinkle during printing.

Card stock and heavy media

You can print many types of card stock from the input tray, including index cards and postcards. Some

card stock performs better than others because its construction is better suited for feeding through a

laser printer.

2

For optimum performance, do not use paper heavier than 157 g/m

cause misfeeds, stacking problems, jams, poor toner fusing, poor print quality, or excessive mechanical

wear.

NOTE You might be able to print on heavier paper if you do not fill the input tray to capacity

and if you use paper with a smoothness rating of 100-180 Sheffield.

(42 lb). Paper that is too heavy might

In either the software program or the printer driver, select Heavy (106 g/m2 to 163 g/m2; 28- to 43-lb

bond) or Cardstock (135 g/m

2

to 216 g/m2; 50- to 80-lb cover) as the media type, or print from a tray

that is configured for heavy paper. Because this setting affects all print jobs, it is important to return the

device back to its original settings after the job has printed.

Card stock construction

Smoothness: 135-157 g/m

●

100-180 Sheffield. 60-135 g/m

100-250 Sheffield.

Construction: Card stock should lie flat with less than 5 mm (0.2 inch) of curl.

●

Condition: Make sure that the card stock is not wrinkled, nicked, or otherwise damaged.

●

2

(36-42 lb) card stock should have a smoothness rating of

2

(16-36 lb) card stock should have a smoothness rating of

Card stock guidelines

Set margins at least 2 mm (0.08 inch) away from the edges.

●

Use tray 1 for card stock (135 g/m2 to 216 g/m2; 50- to 80-lb cover).

●

ENWW Guidelines for using media 11

Page 28

Letterhead and preprinted forms

Letterhead is premium paper that often has a watermark, sometimes uses cotton fiber, and is available

in a wide range of colors and finishes with matching envelopes. Preprinted forms can be made of a

broad spectrum of paper types ranging from recycled to premium.

Many manufacturers now design these grades of paper with properties optimized for laser printing and

advertise the paper as laser compatible or laser guaranteed. Some of the rougher surface finishes, such

as cockle, laid, or linen, might require the special fuser modes that are available on some device models

to achieve adequate toner adhesion.

NOTE Some page-to-page variation is normal when printing with laser printers. This variation

cannot be observed when printing on plain paper. However, this variation is obvious when printing

on preprinted forms because the lines and boxes are already placed on the page.

To avoid problems when using preprinted forms, embossed paper, and letterhead, observe the following

guidelines:

Avoid using low-temperature inks (the kind used with some types of thermography).

●

Use preprinted forms and letterhead paper that have been printed by offset lithography or

●

engraving.

Use forms that have been created with heat-resistant inks that will not melt, vaporize, or release

●

emissions when heated to 200°C (392°F) for 0.1 second. Typically, oxidation-set or oil-based inks

meet this requirement.

When the form is preprinted, be careful not to change the moisture content of the paper, and do

●

not use materials that change the paper's electrical or handling properties. Seal the forms in

moisture-proof wrap to prevent moisture changes during storage.

Avoid processing preprinted forms that have a finish or coating.

●

Avoid using heavily embossed or raised-letterhead papers.

●

Avoid papers that have heavily textured surfaces.

●

Avoid using offset powders or other materials that prevent printed forms from sticking together.

●

NOTE To print a single-page cover letter on letterhead, followed by a multiple-page document,

feed the letterhead face up in the priority input tray, and load the standard paper in the main input

tray (tray 1). The device automatically prints from the priority input tray first.

12 Chapter 1 Device information ENWW

Page 29

Supported media weights and sizes

For optimum results, use conventional 80 to 90 g/m2 (20 to 24 lb) photocopy paper. Verify that the paper

is of good quality and is free of cuts, nicks, tears, spots, loose particles, dust, wrinkles, curls, and bent

edges.

NOTE The device supports a wide range of standard and custom sizes of print media. The

capacity of trays and bins can vary depending on media weight and thickness and on

environmental conditions. Use only transparencies that are designed for use with HP LaserJet

printers. Inkjet and monochrome transparencies are not supported for the device.

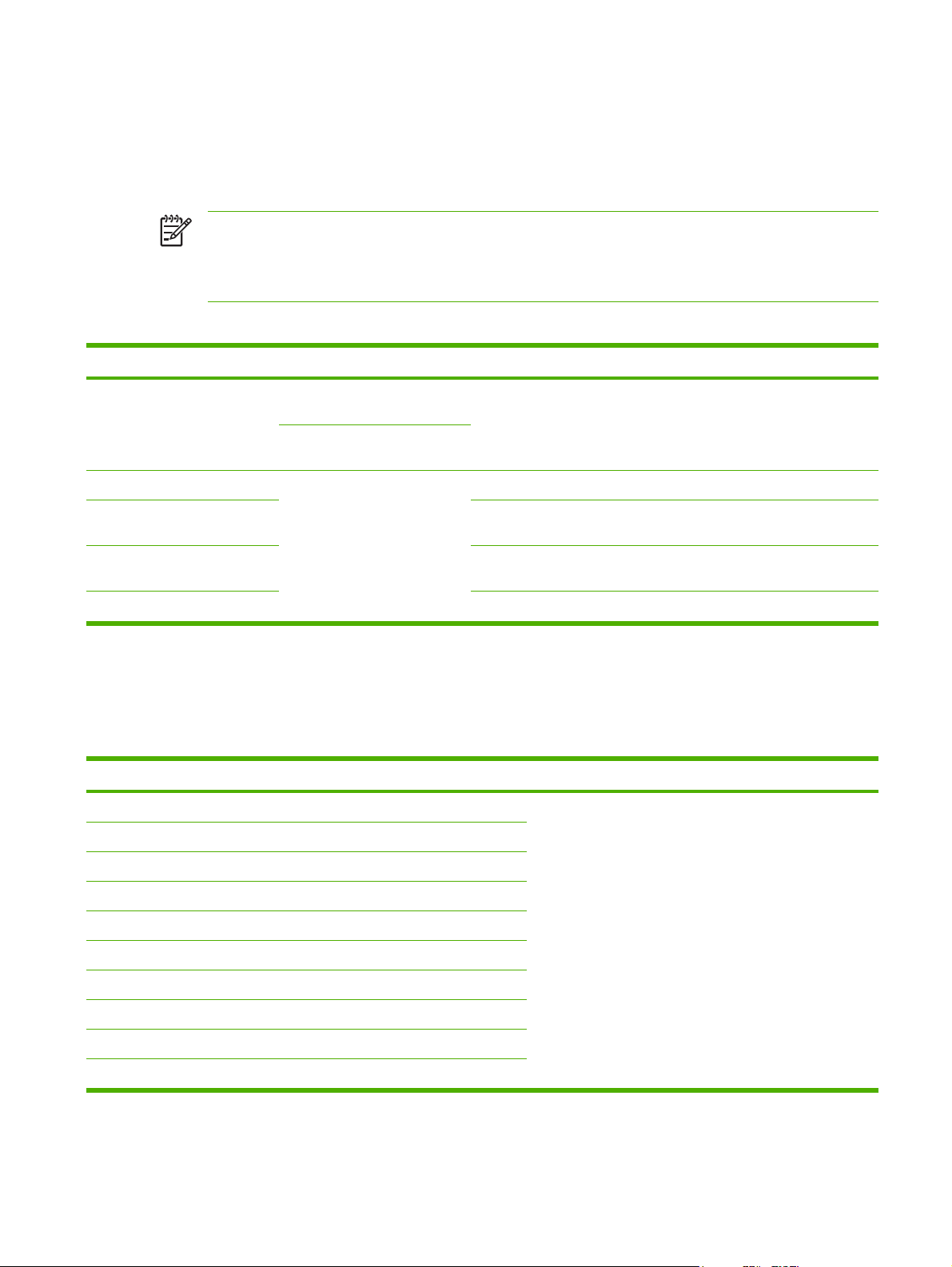

Table 1-3 Priority input tray specifications

Media Dimensions

1

Paper Minimum: 89 x 44 mm (3.5 x

1.75 inches)

Weight Capacity

42 to 260 g/m2 (11 to 69 lb) Up to 10 sheets of 80 g/m2 or 20 lb

paper

2

Maximum: 216 x 356 mm (8.5 x

14 inches)

HP Cover paper

3

Same as the preceding listed

203 g/m2 (75 lb cover)

1 sheet

minimum and maximum sizes

Transparencies and opaque

film

4

Labels

Thickness: 0.10 to 0.13 mm (3.9

to 5.1 mils)

Thickness: up to 0.23 mm (up to

1 transparency

1 sheet of labels

9 mils)

Envelopes

1

The device supports a wide range of standard and custom sizes of print media. Check the printer driver for supported sizes.

2

Capacity can vary depending on media weight and thickness, and environmental conditions.

3

Hewlett-Packard does not guarantee results when printing with other types of heavy paper.

4

Smoothness: 100 to 250 (Sheffield).

Up to 90 g/m2 (16 to 24 lb)

Up to 10

Table 1-4 Tray 1 specifications

Media Dimensions

Minimum size 76 x 127 mm (3 x 5 inches)

Maximum size 216 x 356 mm (8.5 x 14 inches)

1

Weight Capacity

60 to 163 g/m2 (16 to 43 lb) 150 sheets of 80 g/m2 (20 lb)

paper

2

Letter 216 x 279 mm (8.5 x 11 inches)

A4 210 x 297 mm (8.3 x 11.7 inches)

Legal 216 x 356 mm (8.5 x 14 inches)

A5 148 x 210 mm (5.8 x 8.3 inches)

B5 (ISO) 176 x 250 mm (6.9 x 9.9 inches)

B5 (JIS) 182 x 257 mm (7.2 x 10 inches)

Executive 191 x 267 mm (7.3 x 10.5 inches)

8.5 x 13 inches 216 x 330 mm (8.5 x 13 inches)

1

The device supports a wide range of standard sizes of print media. Check the printer driver for supported sizes.

2

Capacity can vary depending on the media weight and thickness, and environmental conditions.

ENWW Supported media weights and sizes 13

Page 30

Printing and storage environment

Ideally, the printing and media-storage environment should be at or near room temperature, and not too

dry or too humid. Remember that paper absorbs and loses moisture rapidly.

Heat works with humidity to damage paper. Heat causes the moisture in paper to evaporate, while cold

causes it to condense on the sheets. Heating systems and air conditioners remove most of the humidity

from a room. As paper is opened and used, it loses moisture, causing streaks and smudging. Humid

weather or water coolers can cause the humidity to increase in a room. As paper is opened and used

it absorbs any excess moisture, causing light print and dropouts. Also, as paper loses and gains moisture

it can distort. This issue can cause jams.

As a result, paper storage and handling are as important as the paper-making process itself. Paper

storage environmental conditions directly affect the feed operation and print quality.

Care should be taken not to purchase more paper than can be easily used in a short time (about three

months). Paper stored for long periods can experience heat and moisture extremes, which can cause

damage. Planning is important to prevent damage to a large supply of paper.

Unopened paper in sealed reams can remain stable for several months before use. Opened packages

of paper have more potential for environmental damage, especially if they are not wrapped with a

moisture-proof barrier.

The media-storage environment should be maintained to ensure optimum performance. The required

condition is 20° to 24°C (68° to 75°F), with a relative humidity of 45% to 55%. The following guidelines

are helpful when evaluating the storage environment:

Print media should be stored at or near room temperature.

●

The air should not be too dry or too humid.

●

The best way to store an opened ream of paper is to rewrap it tightly in its moisture-proof wrapping.

●

If the device environment is subject to extremes, unwrap only the amount of paper to be used

during the day's operation to prevent unwanted moisture changes.

Avoid storing paper and print media near heating and air conditioning vents or near windows and

●

doors that are frequently open.

14 Chapter 1 Device information ENWW

Page 31

2 Installation

What is in the box

●

Site requirements

●

Loading media

●

Connect power

●

Minimum system requirements

●

Supported operating systems

●

Software installation

●

Printer driver

●

Software for Windows

●

ENWW 15

Page 32

What is in the box

The following items come in the box with the device.

Figure 2-1 What is in the shipping box

1. HP LaserJet M1005 MFP

2. Output bin support

3. Main input tray (tray 1)

4. Print cartridge

5. Software and documentation CD-ROM

6. Readiris CD-ROM

7. Getting started guide

8. Control panel overlay

9. Power cord

16 Chapter 2 Installation ENWW

Page 33

Site requirements

Select a sturdy, well-ventilated, dust-free area that is away from direct sunlight to position the device.

Allow enough space around the device to open the doors and trays.

Physical specifications

NOTE Device weight does not include the print cartridge, which weighs 0.7 kg (1.5 lb).

Table 2-1 Physical dimensions for the HP LaserJet M1005 MFP

Device model Height Depth Width Weight

HP LaserJet M1005 MFP 308 mm (12.1 in) 363 mm (14.3 in) 437 mm (19.3 in) 8.3 kg (18.4 lb)

Space requirements

The device must have the following amount of space above and around it for proper access and

ventilation.

Width: 500 mm (19.7 in)

●

Depth: 480 mm (19 in)

●

Height: 560 mm (22 in)

●

Figure 2-2 Space requirements

ENWW Site requirements 17

Page 34

Loading media

The following sections describe how to load media into the different input trays.

CAUTION Printing on wrinkled, folded, or damaged media can cause jams.

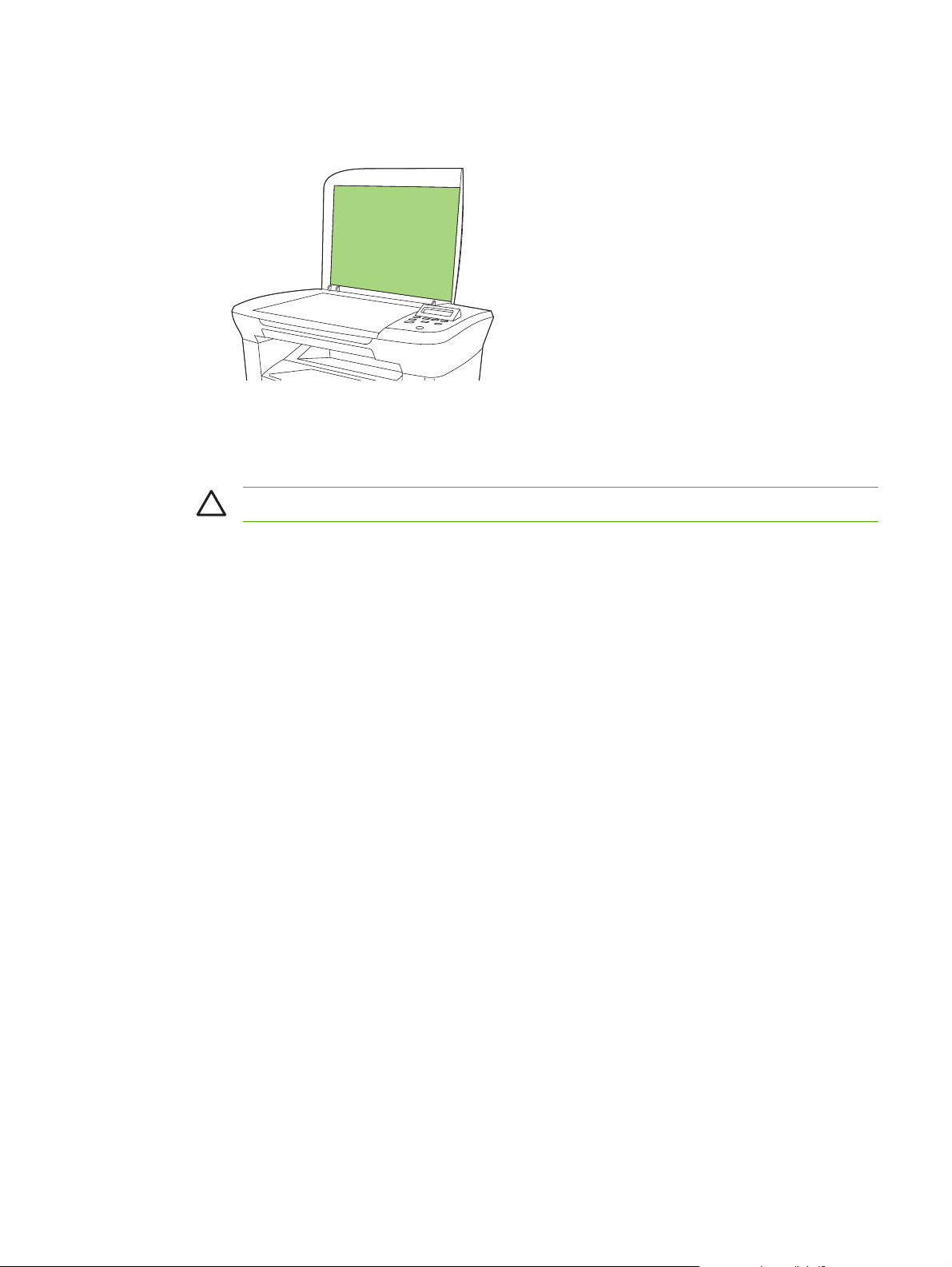

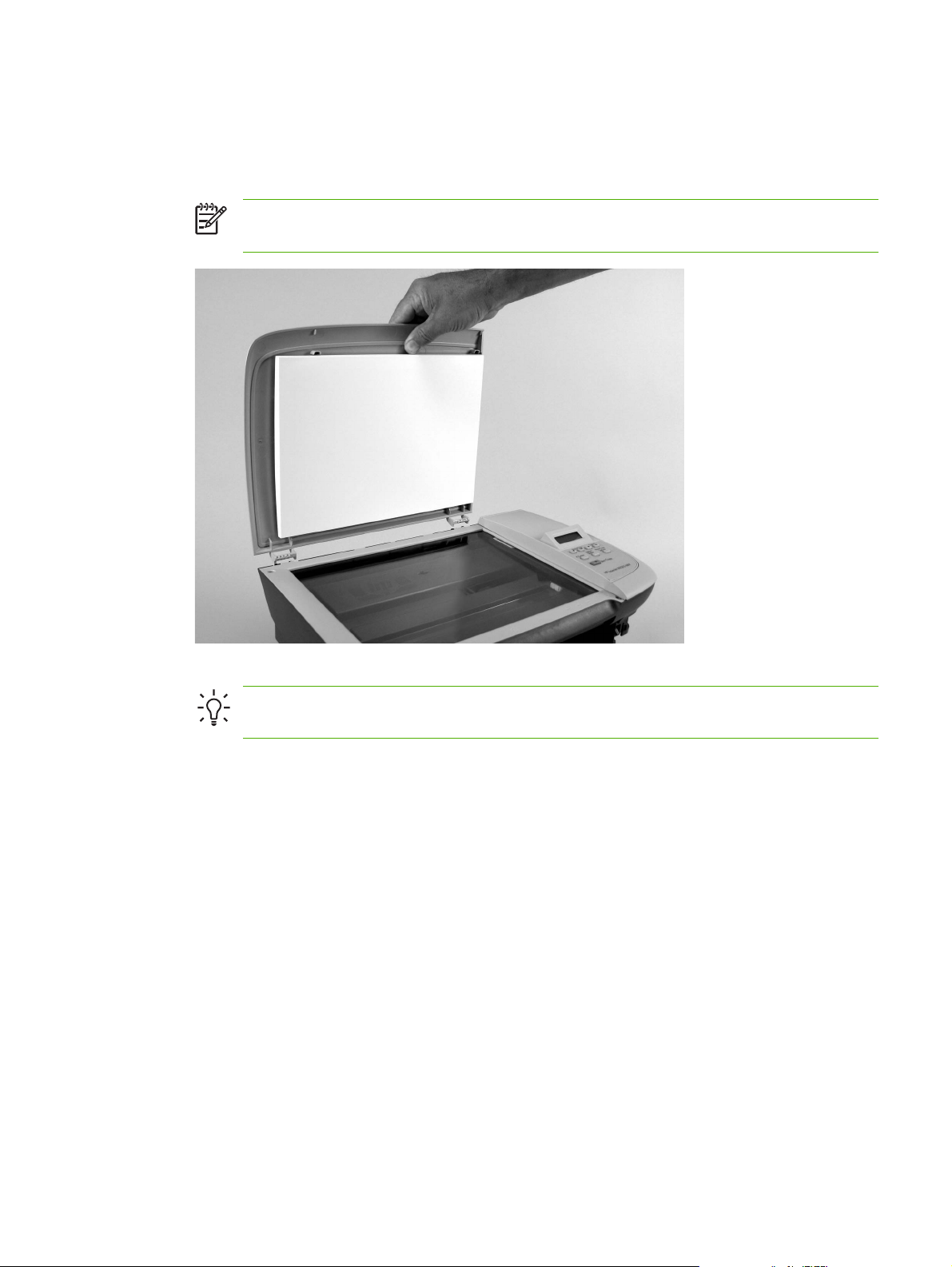

Loading documents to copy or scan

Use these instructions to load originals into the device for scanning.

1. Lift the flatbed scanner cover.

2. Place the original document face-down on the flatbed scanner with the upper-left corner of the

document at the lower-right corner of the glass.

Figure 2-3 Loading documents to copy or scan

3. Gently close the lid.

The document is ready to be copied or scanned.

Loading input trays

Main input tray (tray 1)

Figure 2-4 Loading the main input tray (tray 1) (1 of 2)

2

The main input tray holds up to 150 pages of 80 g/m

(15 mm (0.6 in) or less stack height). Load media with the top forward and the side to be printed facing

down. To prevent jams and skewing, always adjust the side and rear media guides.

or 20 lb paper or fewer pages of heavier media

18 Chapter 2 Installation ENWW

Page 35

Figure 2-5 Loading the main input tray (tray 1) (2 of 2)

NOTE When you add new media, make sure that you remove all of the media from the input

tray and straighten the stack of new media. This helps to prevent multiple sheets of media from

feeding into the device, which can cause jams.

Priority input tray

Figure 2-6 Loading the priority input tray (1 of 2)

The priority input tray on the HP LaserJet M1005 MFP holds up to 10 sheets of media up to 80 g/m

2

(20 lb) in weight or one envelope, transparency, or card. Load media with the top forward and the side

to be printed facing up. To prevent jams and skewing, always adjust the side media guides before

feeding the media.

Figure 2-7 Loading the priority input tray (2 of 2)

ENWW Loading media 19

Page 36

Connect power

Make sure that the power cord is connected to the device and to a power supply.

Figure 2-8 Connect power

20 Chapter 2 Installation ENWW

Page 37

Minimum system requirements

In order to install and use the device software, your computer must meet the following minimum

requirements:

Windows requirements

Pentium II (233 MHz) processor

●

64 MB of RAM

●

35 MB of disk space

●

SVGA 800x600 16-bit color monitor

●

Macintosh requirements

G3, G4, or G5 PowerPC processor

●

128 MB of RAM

●

30 to 50 MB of disk space

●

Supported operating systems

The device comes with software for the following operating systems:

Windows XP

●

Windows 2000

●

Windows Server 2003

●

Mac OS X V10.3 and later (print/twain drivers only)

●

ENWW Minimum system requirements 21

Page 38

Software installation

If the computer meets the recommended minimum requirements, the installation process includes the

following software.

Windows

HP LaserJet Scan software program and driver (twain)

●

Readiris OCR (not installed with other software; separate installation is required)

●

Printer drivers (Windows and Mac)

●

Macintosh

Readiris OCR (not installed with other software; separate installation is required)

●

Printer drivers (Windows and Mac)

●

TWAIN driver (Mac)

●

22 Chapter 2 Installation ENWW

Page 39

Printer driver