Page 1

HPE ProLiant MicroServer Gen10 User Guide

Abstract

This document is for the person who installs, administers, and troubleshoots servers and storage

systems. Hewlett Packard Enterprise assumes you are qualified in the servicing of computer

equipment and trained in recognizing hazards in products with hazardous energy levels.

Part Number: 872677-001

Published: June 2017

Edition: 1

Page 2

©

Copyright 2017

Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett Packard

Enterprise products and services are set forth in the express warranty statements accompanying such

products and services. Nothing herein should be construed as constituting an additional warranty. Hewlett

Packard Enterprise shall not be liable for technical or editorial errors or omissions contained herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession, use,

or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer Software

Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government under

vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard Enterprise

website.

Acknowledgments

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Linux® is the registered trademark of Linus Torvalds in the U.S. and other countries.

Page 3

Contents

Component identification........................................................................... 6

Setup...........................................................................................................14

Front panel components

Front panel LEDs and buttons.............................................................................................................7

Rear panel components...................................................................................................................... 8

Rear panel LEDs................................................................................................................................. 9

System board components................................................................................................................10

PCIe slot description............................................................................................................... 11

DIMM slot locations.................................................................................................................11

Drive numbering................................................................................................................................ 12

Drive screws......................................................................................................................................12

Optional services...............................................................................................................................14

Initial server setup overview.............................................................................................................. 14

Unpacking the server shipping carton............................................................................................... 14

Prerequisites for the initial server setup............................................................................................ 15

Optimum environment....................................................................................................................... 15

Site requirements....................................................................................................................15

Space and airflow requirements............................................................................................. 15

Temperature requirements......................................................................................................15

Power requirements................................................................................................................16

Electrical grounding requirements.......................................................................................... 16

Connecting the I/O devices............................................................................................................... 16

Connecting the network cable........................................................................................................... 17

Connecting the power cord................................................................................................................18

Powering on the server for the first time............................................................................................18

Installing an operating system...........................................................................................................18

Install the preloaded ClearOS image......................................................................................19

Install an OS from a bootable installation media.................................................................... 19

Installing the latest system software and firmware............................................................................ 19

Registering the server....................................................................................................................... 20

......................................................................................................................6

Operations..................................................................................................21

Server warnings and cautions........................................................................................................... 21

Electrostatic discharge...................................................................................................................... 21

Preventing electrostatic discharge..........................................................................................21

Grounding methods to prevent electrostatic discharge.......................................................... 22

Power up the server.......................................................................................................................... 22

Power down the server......................................................................................................................22

Prepare the server for hardware installation or removal....................................................................23

Prepare the server for operation........................................................................................................23

Remove the front bezel..................................................................................................................... 23

Removing a locked front bezel............................................................................................... 23

Removing an unlocked front bezel......................................................................................... 24

Install the front bezel......................................................................................................................... 25

Remove the chassis cover................................................................................................................ 26

Install the chassis cover.................................................................................................................... 27

Install the chassis cover..........................................................................................................27

Contents 3

Page 4

Install the system board assembly.................................................................................................... 27

Install the system board assembly..........................................................................................27

Remove the system board assembly

Remove the system board assembly......................................................................................29

................................................................................................ 28

Hardware options installation.................................................................. 31

Introduction........................................................................................................................................31

Drive support information.................................................................................................................. 31

Drive installation guidelines...............................................................................................................31

Installing an LFF drive....................................................................................................................... 31

Install the LFF drive................................................................................................................ 32

Installing an SFF drive.......................................................................................................................33

Install the SFF drive................................................................................................................34

Installing an SSD...............................................................................................................................36

Install the SSD........................................................................................................................37

Installing an optical drive................................................................................................................... 40

Install an optical drive............................................................................................................. 40

Memory support.................................................................................................................................44

DIMM identification................................................................................................................. 44

DIMM ranks ........................................................................................................................... 46

DIMM handling guidelines...................................................................................................... 46

DIMM installation guidelines................................................................................................... 46

Installing a DIMM....................................................................................................................46

Install the DIMM........................................................................................................... 47

Expansion board options...................................................................................................................47

Installing an expansion board.................................................................................................47

Remove the air baffle from the expansion board......................................................... 48

Install a low-profile bracket on the expansion board....................................................48

Install the expansion board..........................................................................................49

Internal USB device options.............................................................................................................. 50

Install an internal USB device.................................................................................................50

External HPE RDX Backup System option........................................................................................51

HP Trusted Platform Module............................................................................................................. 51

Trusted Platform Module (TPM) — China Import Restrictions................................................52

HP Trusted Platform Module installation guidelines............................................................... 52

Installing the Trusted Platform Module overview.................................................................... 52

Installing the Trusted Platform Module board......................................................................... 52

Install the Trusted Platform Module board................................................................... 53

Retaining the recovery key/password.....................................................................................54

Enabling the Trusted Platform Module....................................................................................54

4 Contents

Cabling........................................................................................................55

Cabling overview .............................................................................................................................. 55

Four-bay non-hot-plug drive cabling..................................................................................................55

Solid state drive cabling.....................................................................................................................56

Optical drive cabling.......................................................................................................................... 57

Fan cabling........................................................................................................................................57

Power supply cabling.........................................................................................................................58

Software and configuration utilities.........................................................59

Server mode......................................................................................................................................59

Product QuickSpecs..........................................................................................................................59

Aptio Setup Utility.............................................................................................................................. 59

Page 5

Using the Aptio Setup Utility .................................................................................................. 59

Boot option control..................................................................................................................60

Boot option

Selecting the boot mode ............................................................................................. 60

Restoring and customizing configuration settings.................................................................. 60

Clearing the BIOS configuration settings................................................................................60

Clearing the BIOS settings by using the Aptio Setup Utility.........................................61

Clearing the BIOS settings by using the CMOS header.............................................. 61

Embedded UEFI Shell ........................................................................................................... 62

Secure Boot configuration ..................................................................................................... 63

Utilities and features..........................................................................................................................63

HPE Smart Storage Administrator ......................................................................................... 63

Marvell Storage Utility ............................................................................................................63

Marvell BIOS Utility.................................................................................................................64

Accessing the Marvell BIOS Utility under legacy boot mode....................................... 64

Accessing the Marvell BIOS Utility under UEFI boot mode......................................... 64

USB support .......................................................................................................................... 64

Keeping the system current...............................................................................................................64

Firmware ................................................................................................................................64

Firmware update.....................................................................................................................65

Updating the system ROM using the EFI tool from within the Embedded UEFI

Shell ............................................................................................................................65

Online Flash components ........................................................................................... 66

Drivers, firmware, and software updates ............................................................................... 66

Operating System Version Support........................................................................................ 66

HPE Pointnext Portfolio.......................................................................................................... 66

Change control and proactive notification...............................................................................67

...................................................................................................................60

Troubleshooting.........................................................................................68

Troubleshooting resources................................................................................................................68

Specifications............................................................................................ 69

Environmental specifications.............................................................................................................69

Server specifications......................................................................................................................... 69

Power supply specifications.............................................................................................................. 69

200 W power supply specifications.........................................................................................70

Warranty and regulatory information.......................................................71

Warranty information......................................................................................................................... 71

Regulatory information...................................................................................................................... 71

Belarus Kazakhstan Russia marking...................................................................................... 71

Turkey RoHS material content declaration............................................................................. 72

Ukraine RoHS material content declaration............................................................................72

Support and other resources................................................................... 73

Accessing Hewlett Packard Enterprise Support................................................................................ 73

Accessing updates............................................................................................................................ 73

Customer self repair.......................................................................................................................... 73

Documentation feedback...................................................................................................................74

Acronyms and abbreviations................................................................... 75

Contents 5

Page 6

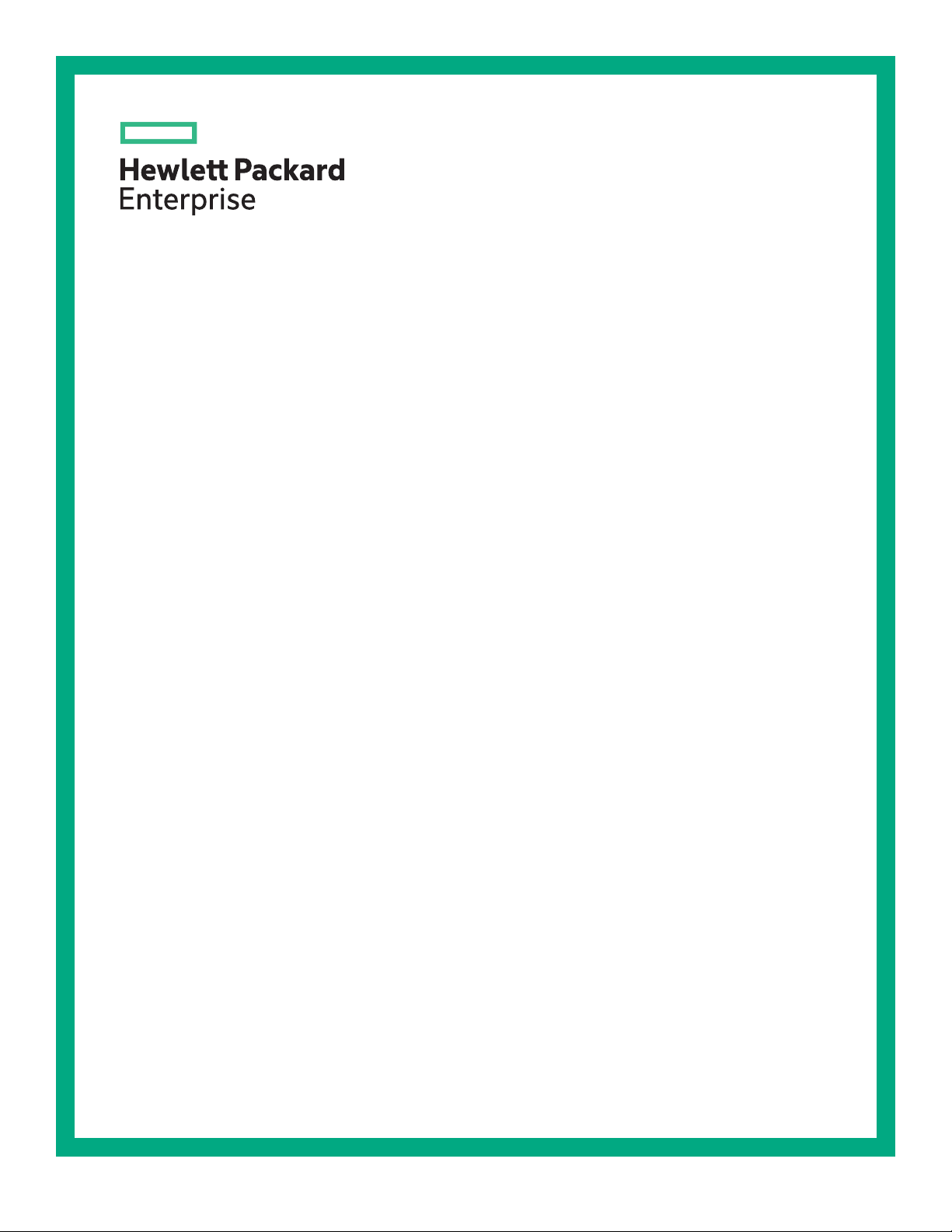

Component identification

5

6 1

2

3

4

This chapter describes the external and internal server features and components.

Front panel components

Item Component Description

1 Drive bays (4, behind the front

bezel)

2 Front bezel unlock indicator To remove the front bezel from the chassis, this groove must

3 Front bezel lock indicator To lock the front bezel in the chassis, this groove must show

4 Front bezel To access the front drive bays, remove this bezel.

5 USB 3.0 ports (2) Connect USB 3.0 devices to these ports. USB 3.0 support

6 Media bay When the relevant enablement options kits are installed, this

By default, the drive bays support 3.5-inch LFF SATA drives.

To support 2.5-inch SFF drives, install the SFF drive converter

option.

show the blue indicator.

the blue indicator.

after POST varies by operating system.

bay supports either a slim-type optical disc drive or solid state

drive option.

6 Component identification

Page 7

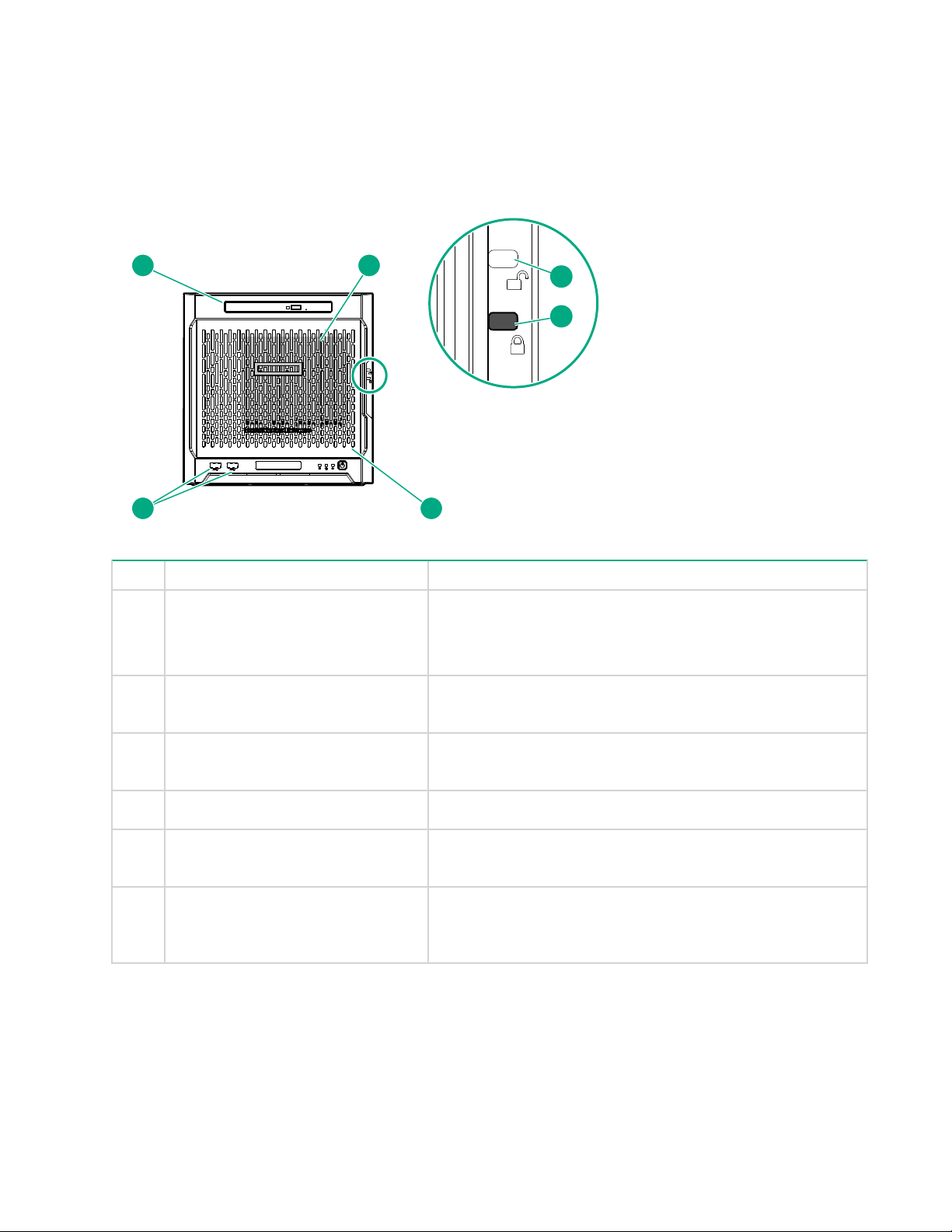

Front panel LEDs and buttons

1 2

3

4

Item Description Status

1 Drive activity LED Flashing green = Ongoing drive activity

Off = No drive activity

This LED only reflects the status of LFF/SFF drives and SSD that

are connected to the onboard SATA ports.

2 NIC status LED Solid green = Linked to network

Flashing green = Network active

Off = No network activity

This LED only reflects the status of Ethernet connections

managed by the embedded Broadcom BCM5720 Gigabit Ethernet

controller.

3 Health LED Solid green = Normal

Flashing amber = One or more component is in degraded

condition.

1

Flashing red = One or more component is in critical condition.

4 Power on/Standby button and

system power LED

Flashing green = Ongoing power-on sequence

Solid green = System on and normal operation

Amber = System in standby

Off = No power present

1

To identify which component is in the degraded or critical state, reboot the server. A POST error message

2

screen showing the affected component will appear for about 30 seconds. Depending on how critical the

component health status is, the system boot may or may not be completed. For troubleshooting information,

see the HPE ProLiant MicroServer Gen10 Troubleshooting Guide.

2

If the server does not power on, verify the following items:

1

Front panel LEDs and buttons 7

Page 8

Item Description Status

1

3

4

567

9

10

11

2

12

8

• The site power is available.

• The power cord is properly connected to the server power jack and to a working power source.

• The internal power supply cable is properly connected to the system board.

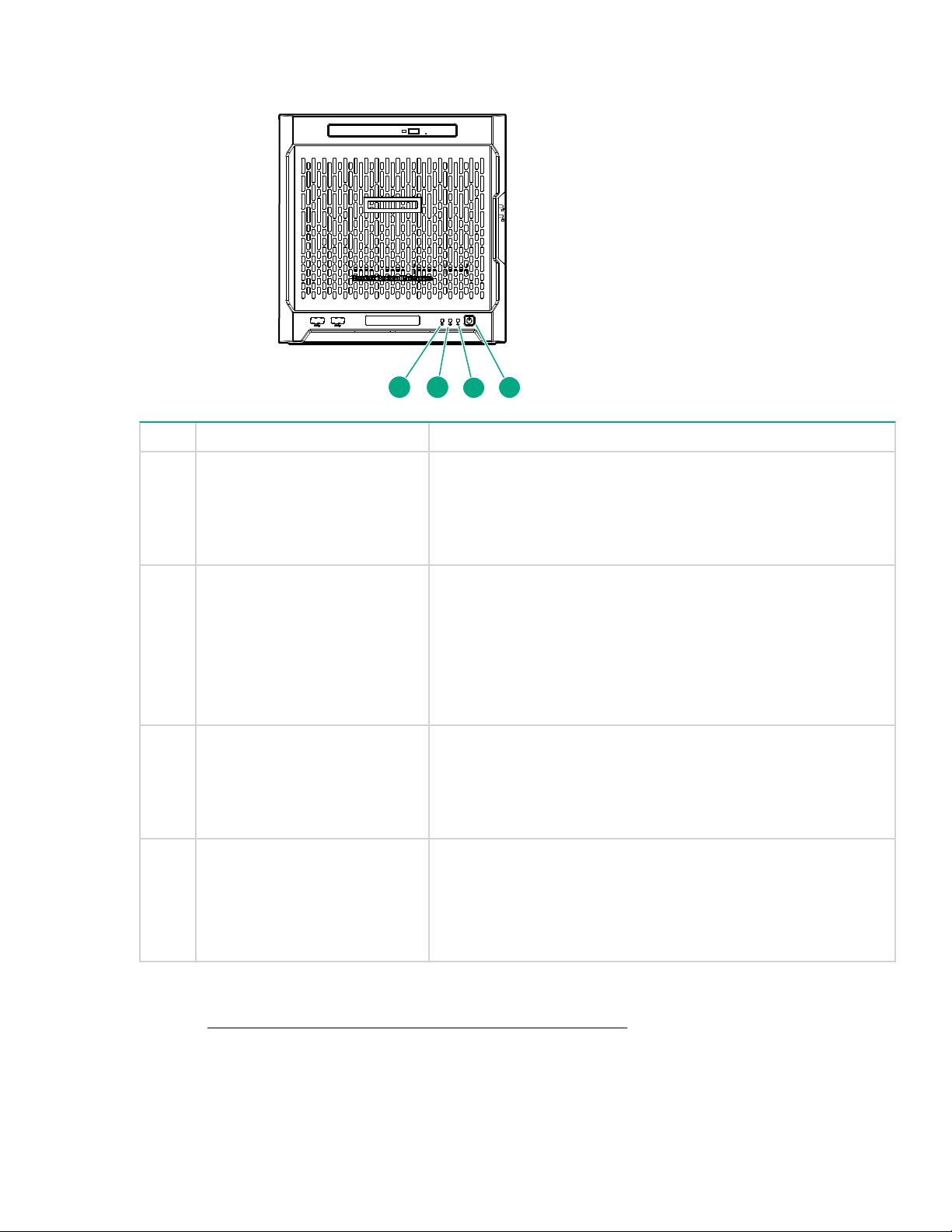

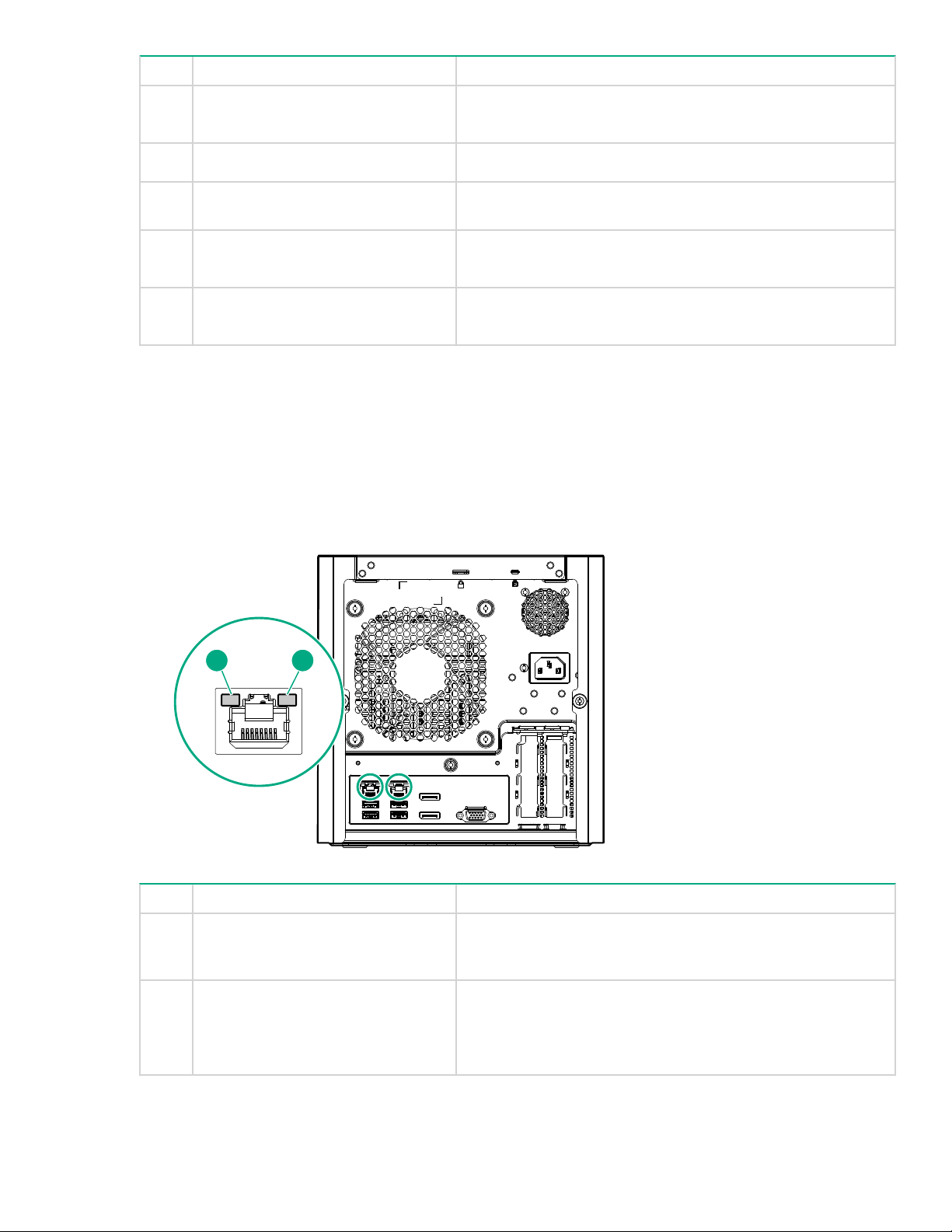

Rear panel components

Item Component Description

1 Padlock eye To lock the chassis cover and prevent access to the internal

components, attach a padlock here.

2 Kensington security slot To secure the server to a heavy or immovable object, connect

an anti-theft security cable here.

3 Power jack Connects the power cord.

4 Expansion slot 2, PCIe3 ×4 (1) For additional hardware capabilities, install a compatible

low‑profile PCIe expansion board here. This expansion slot

supports expansion boards with a physical connector link

widths of up to ×16.

1

5 Expansion slot 1, PCIe3 ×8 (8, 4, 1) For additional hardware capabilities, install a compatible

low‑profile PCIe expansion board here. This expansion slot

supports expansion boards with a physical connector link

widths of up to ×16.

6 Video port

7 Display port 1 Connects to a digital display device, such as a high-resolution

Connects to an analog VGA monitor or projector.

set top boxes or TV displays.

1

2

8 Rear panel components

Table Continued

Page 9

Item Component Description

21

8 Display port 2 Connects to a digital display device, such as a high-resolution

9 USB 2.0 ports (2)

10 USB 3.0 ports (2)

11 NIC port 1 (1 Gb) Connect an Ethernet cable here to connect the server to a

12 NIC port 2 (1 Gb) Connect an Ethernet cable here to connect the server to a

1

This expansion slot is open-ended, which enables down-plugging. Down-plugging means a larger

expansion board can be installed in a smaller

low-profile expansion boards with a physical connector link width of up to ×16. The board operates at the

highest common negotiable link width specified for the slot.

2

To support 4K resolution at a full 60 Hz frame rate, this Display port requires dual-channel memory

configuration. Single-channel memory configuration will only support up to 30 Hz frame rate.

3

This NIC port supports 10/100/1000 Mbps data transfer rate per port.

Rear panel LEDs

set top boxes or TV displays.

2

Connect USB 2.0 devices to these ports.

Connect USB 3.0 devices to these ports. USB 3.0 support

after POST varies by operating system.

wired network.

wired network.

3

3

-width

-width connector. For this server, the expansion slot supports

Item Description Status

1 NIC link LED Solid green = Link exists

Off = No link exists

2 NIC status LED Solid green = Linked to network

Flashing green = Network active

Off = No network activity

Rear panel LEDs 9

Page 10

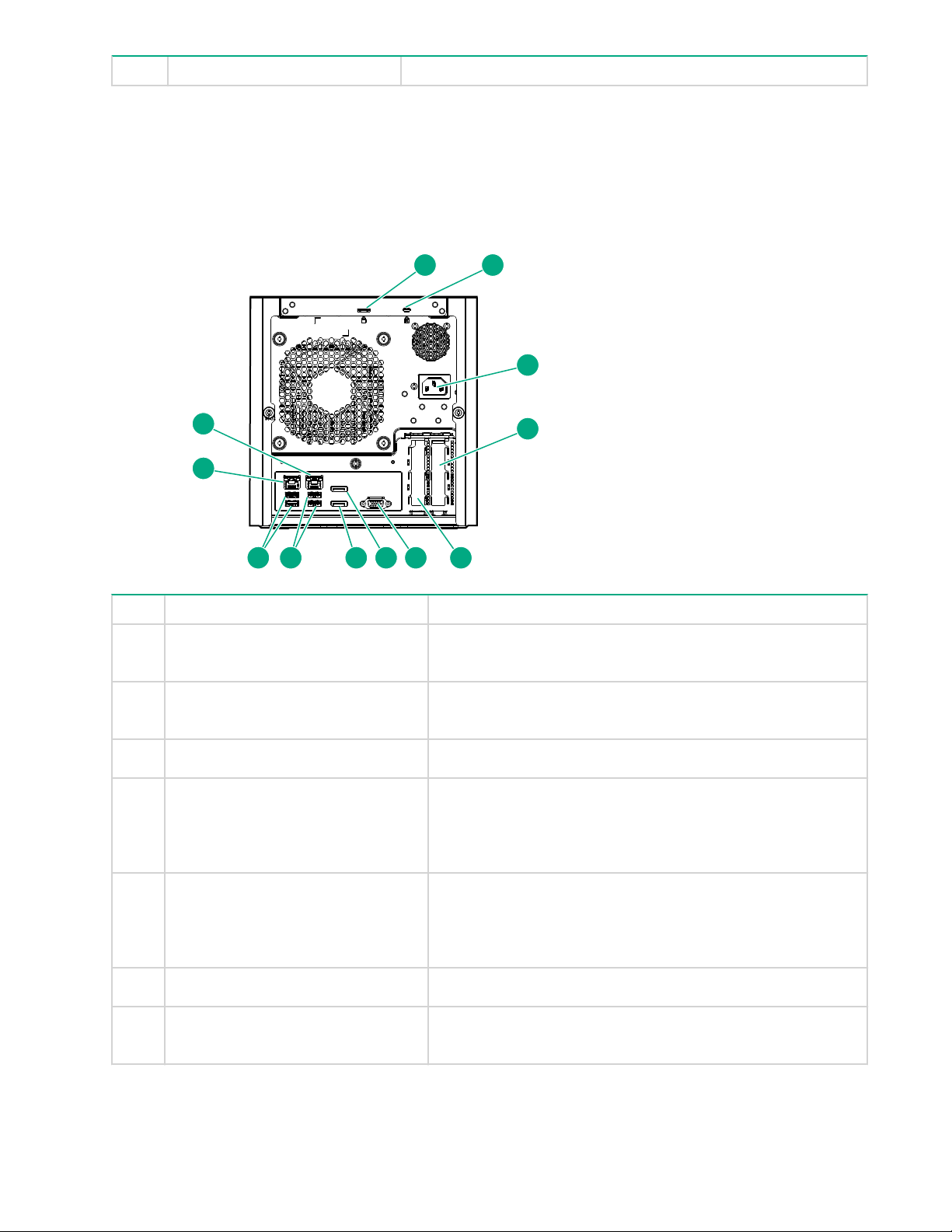

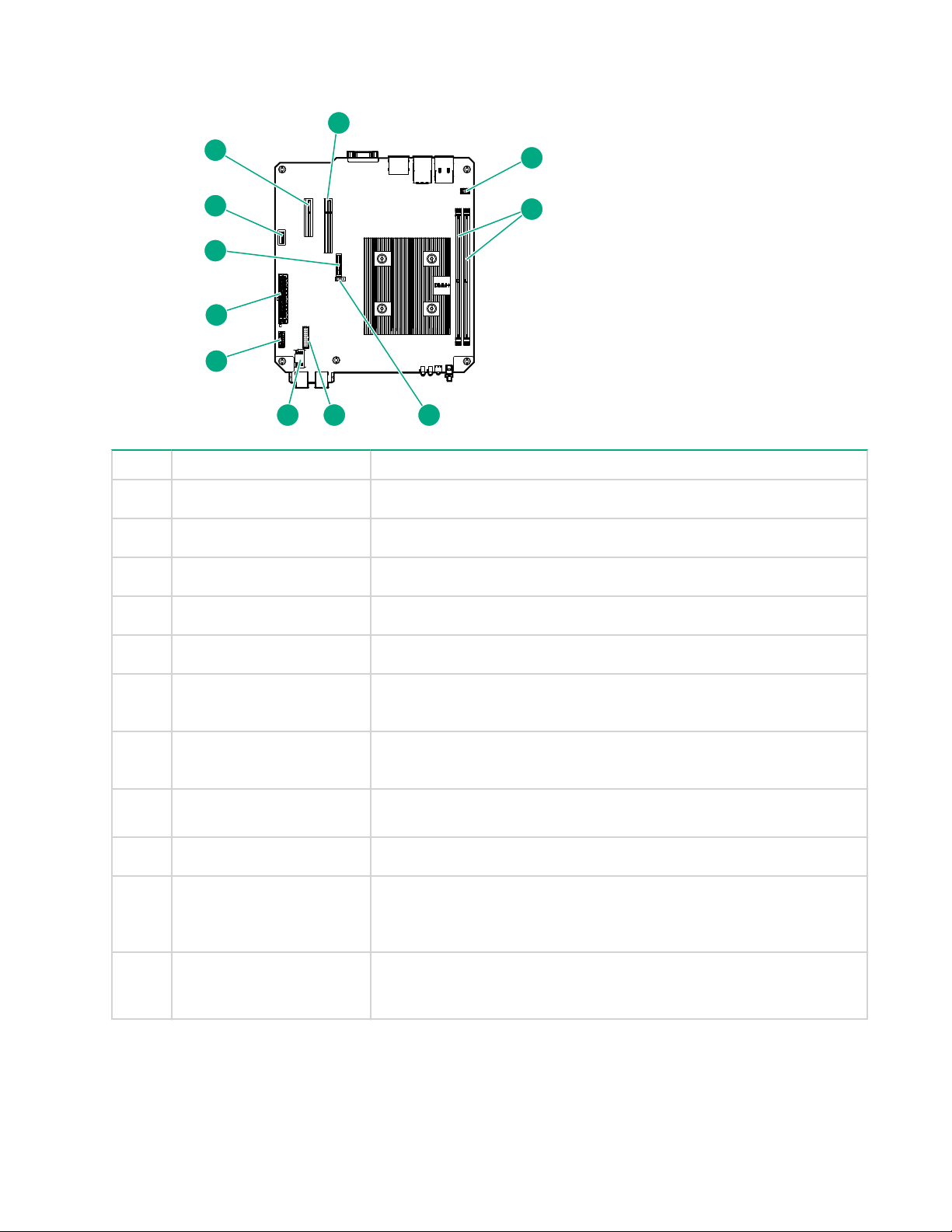

System board components

4

5

6

11

1

2

3

7

8

9

10

Item Component Description

1 Fan connector

2 DIMM slots

3 CMOS header

4 TPM connector

5 LFF/SFF drive SATA port

6 Optical drive or SSD SATA

Connects the fan cable.

These slots support standard UDIMMs with ECC only.

Use the jumper on this header to clear the CMOS.

This connector supports the TPM 2.0 option for data security solution.

Connects the LFF/SFF drive SATA cable.

Connects the optical drive or SSD SATA cable.

port

7 System board power

Connects the power supply cable.

connector

8 System battery

This battery provides power to the server real-time clock and BIOS

settings.

9 Internal USB 2.0 port

10 Expansion slot 2, PCIe3

×4 (1)

11 Expansion slot 1, PCIe3

1

This expansion slot is open-ended, which enables down-plugging. Down-plugging means a larger-width

expansion board can be installed in a smaller

×8 (8, 4, 1)

Connect internal USB devices to this port.

For additional hardware capabilities, install a compatible low-profile

PCIe expansion board here. This expansion slot supports expansion

boards with a physical connector link widths of up to ×16.

1

For additional hardware capabilities, install a compatible low-profile

PCIe expansion board here. This expansion slot supports expansion

boards with a physical connector link widths of up to ×16.

1

-width connector. For this server, the expansion slot supports

low-profile expansion boards with a physical connector link widths of up to ×16. The board operates at the

highest common negotiable link width specified for the slot.

10 System board components

Page 11

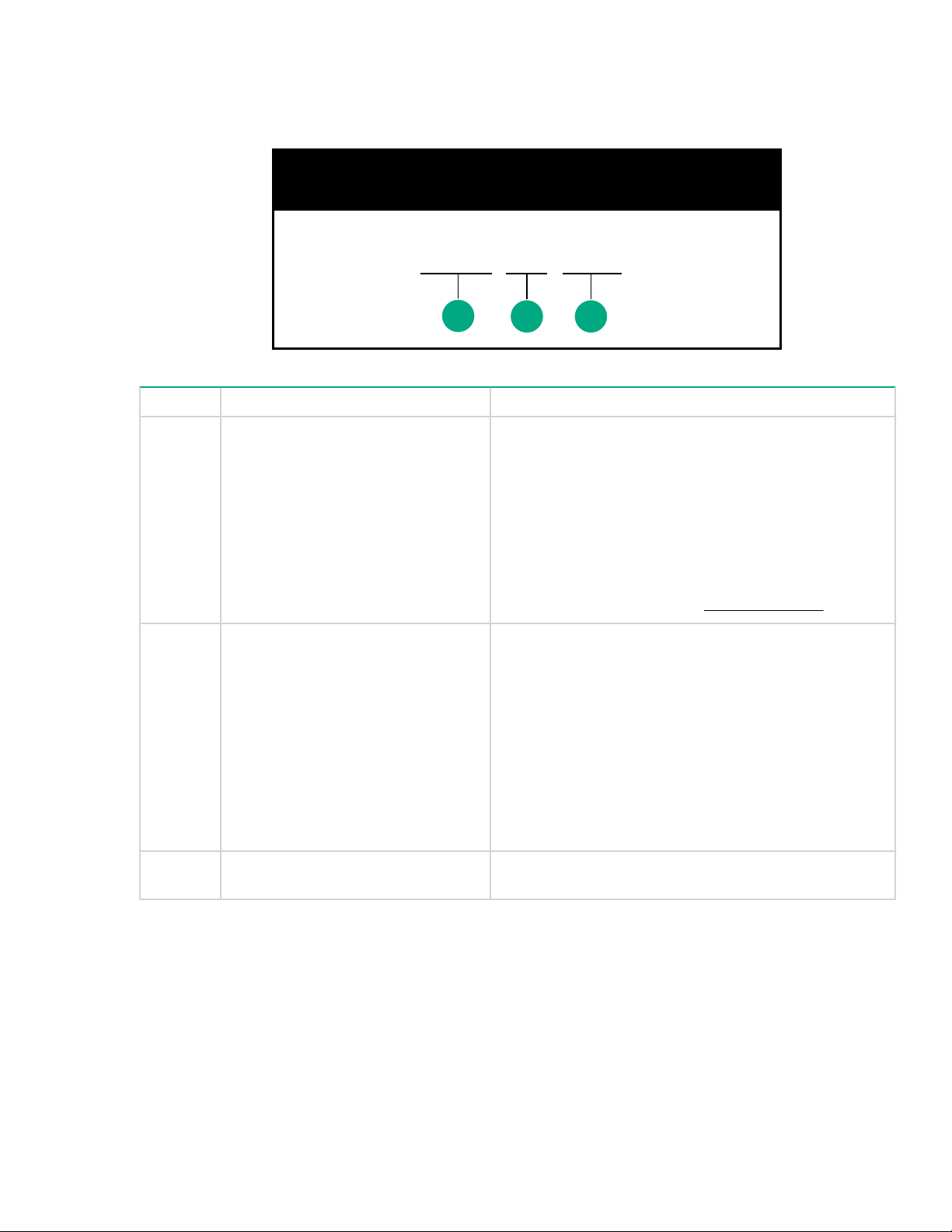

PCIe slot description

PCIe3 x8 (8,4,1)

PCIe slot description

1

2 3

Item Description Definition

1 PCI Express version

2 Physical connector link width PCIe devices communicate via a logical connection

3 Negotiable link width These numbers correspond to the maximum link

Each PCIe version corresponds to a specific data

transfer rate between the processor and peripheral

devices. Generally, a version update corresponds to an

increase in transfer rate.

• PCIe 1.x

• PCIe 2.x

• PCIe 3.x

The PCIe technology is under constant development. For

the latest information, see the PCI-SIG website.

called an interconnect or link. At the physical level, a link

is composed of one or more lanes. The number of lanes

is written with an "×" prefix with ×16 being the largest

size in common use.

• ×1

• ×2

• ×4

• ×8

• ×16

bandwidth supported by the slot.

DIMM slot locations

The DIMM slots are numbered 1 and 2. The arrow in the following illustration points to the front of the server.

PCIe slot description 11

Page 12

1A 2B

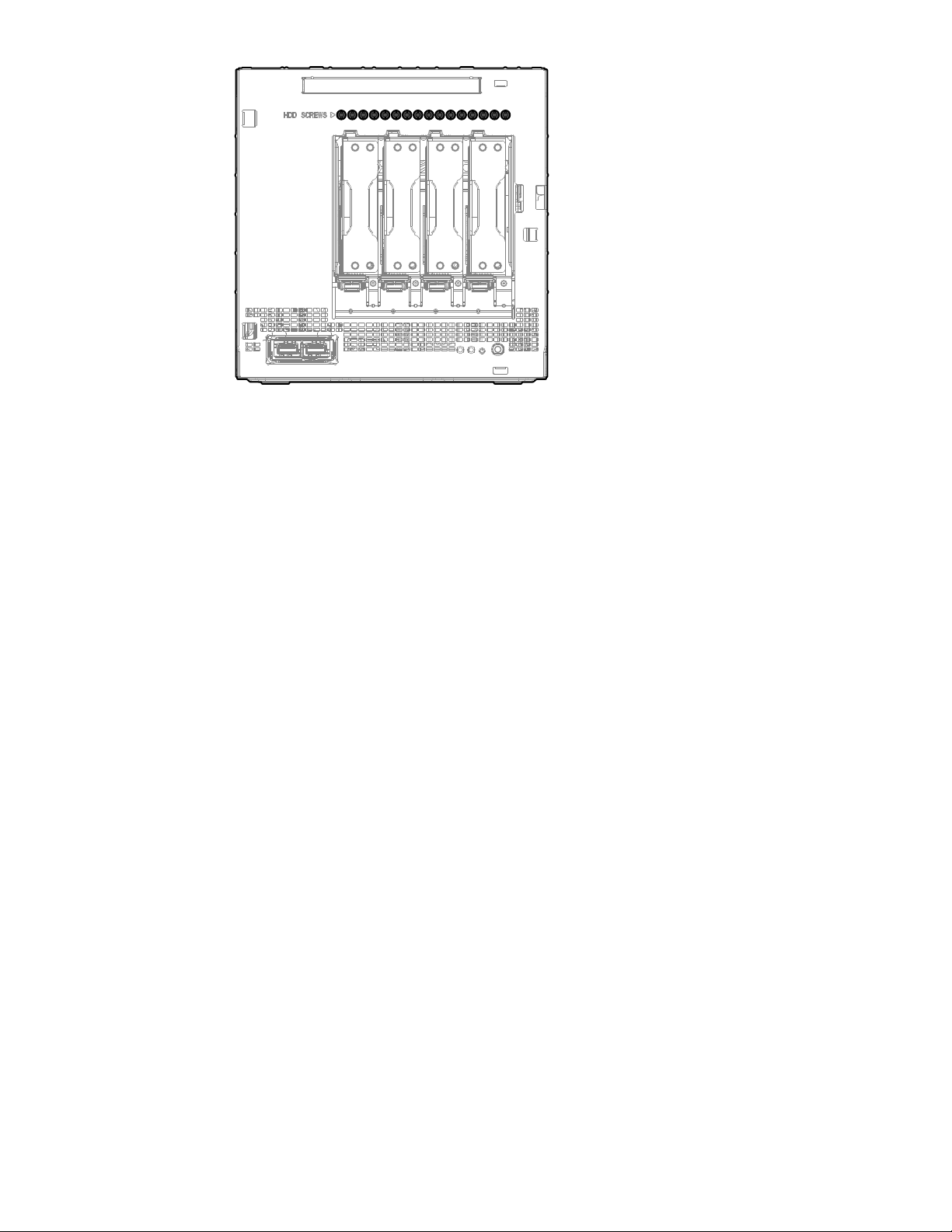

Drive numbering

1 2

5

3 4

Item Description

1-4 LFF/SFF drives

5 Solid state drive or optical disc drive

Drive screws

There are 16 T-15 T

the server.

12 Drive numbering

orx screws located above the drive bays. Use these screws to install LFF or SFF drives in

Page 13

Component identification 13

Page 14

Setup

This chapter describes the initial setup procedures to prepare the server for operation.

Optional services

Delivered by experienced, certified engineers, HPE support services help you keep your servers up and

running with support packages tailored specifically for HPE ProLiant systems. HPE support services let you

integrate both hardware and software support into a single package. A number of service level options are

available to meet your business and IT needs.

HPE support services offer upgraded service levels to expand the standard product warranty with

‑to‑buy, easy‑to‑use support packages that will help you make the most of your server investments.

easy

Some of the HPE support services for hardware, software, or both are:

• Foundation Care – Keep systems running.

The time commitment for this service might vary depending on the site's geographical region. For more

service information available at your site, contact your local

• Deployment service for both hardware and software.

HPE Education Services – Help train your IT staff.

•

For more information on HPE support services, see the HPE Pointnext website:

http://www.hpe.com/services

HPE support center.

Initial server setup overview

Procedure

1. Unpack the server shipping carton.

2. If applicable, install any hardware options that are shipped separately from the server.

For detailed option installation instructions, see the relevant section in Hardware options installation on

page 31.

3. Review the initial server setup prerequisites.

4. Connect the I/O devices.

5. Connect the network cable.

6. Connect the power cord.

7. Power on the server for the first time.

8. Install an operating system (OS).

9. As a best practice, Hewlett Packard Enterprise recommends that you install the latest firmware,

drivers, and system software before using the server for the first time.

10. Register the server.

Unpacking the server shipping carton

Unpack the server shipping carton. The contents of the server shipping carton include:

Server

•

•

Power cord

• Printed setup documentation

14 Setup

Page 15

Prerequisites for the initial server setup

Procedure

Verify that the optimum environmental requirements are satisfied.

Review and observe the server warnings and cautions.

Prepare the following items:

◦ Keyboard, mouse, and monitor

Ethernet cables of an appropriate length for each of the LAN and/or WAN connections.

◦

◦ Verify the network settings needed to integrate the server into the site network, in particular from an IP

addressing perspective and from a domain perspective.

◦ Verify that there are sufficient ports available on the devices to which the server will be connected (for

example, router, LAN switch).

Optimum environment

When installing the server, select a location that meets the environmental requirements described in this

section.

Site requirements

The server may be located in an office space or a purpose-made equipment room. The location must:

• Comply with local health and safety regulations.

• Be clean, tidy, and free of excessive dust and vibration.

• Be in an area in which the server cannot easily be disconnected from its power source.

• Not be adjacent to or underneath any area or piece of equipment where liquid is stored.

• Not be in a place where the server might be bumped, scratched, or disturbed.

• Be within an area that is ideally locked or at minimum not accessible to unauthorized personnel.

• Be within patching distance, directly or via cable management cross-patches, of the location of the WAN

connection and the switch that supplies the office/room floor network ports.

Space and airflow requirements

Leave at least a 10 cm (4 in) clearance space at the front and back of the server for proper ventilation.

CAUTION:

The server draws in cool air through the ventilation openings on the front side, and expels warm air

through the ventilation openings on the rear side. Do not block these openings. Failure to observe this

caution will result in improper airflow and insufficient cooling that can lead to thermal damage.

Temperature requirements

To ensure continued, safe, and reliable equipment operation, install or position the system in a well-ventilated,

climate-controlled environment.

The maximum recommended TMRA for most server products is 35°C (95°F). The temperature in the room

where the server is located must not exceed 35°C (95°F).

Prerequisites for the initial server setup 15

Page 16

CAUTION:

To reduce the risk of damage to the equipment when installing third-party options:

Do not permit optional equipment to impede airflow around the server beyond the maximum

•

allowable limits.

• Do not exceed the manufacturer’s TMRA.

Power requirements

Installation of this equipment must comply with local and regional electrical regulations governing the

installation of information technology equipment by licensed electricians. This equipment is designed to

operate in installations covered by NFPA 70, 1999 Edition (National Electric Code) and NFP

for Protection of Electronic Computer/Data Processing Equipment). For electrical power ratings on options,

see the product rating label or the user documentation supplied with that option.

CAUTION:

Protect the server from power fluctuations and temporary interruptions with a regulating uninterruptible

power supply. This device protects the hardware from damage caused by power surges and voltage

spikes and keeps the system in operation during a power failure.

When installing more than one server, you might have to use additional power distribution devices to safely

provide power to all devices. Observe the following guidelines:

• Balance the server power load between available AC supply branch circuits.

Do not allow the overall system AC current load to exceed 80% of the branch circuit AC current rating.

•

• Do not use common power outlet strips for this equipment.

• Provide a separate electrical circuit for the server.

A-75, 1992 (code

Electrical grounding requirements

The server must be grounded properly for proper operation and safety. In the United States, you must install

the equipment in accordance with NFP

local and regional building codes. In Canada, you must install the equipment in accordance with Canadian

Standards Association, CSA C22.1, Canadian Electrical Code. In all other countries, you must install the

equipment in accordance with any regional or national electrical wiring codes, such as the International

Electrotechnical Commission (IEC) Code 364, parts 1 through 7. Furthermore, you must be sure that all

power distribution devices used in the installation, such as branch wiring and receptacles, are listed or

certified grounding-type devices.

Because of the high ground-leakage currents associated with multiple servers connected to the same power

source, Hewlett Packard Enterprise recommends the use of a PDU that is either permanently wired to the

building’s branch circuit or includes a nondetachable cord that is wired to an industrial-style plug. NEMA

locking-style plugs or those complying with IEC 60309 are considered suitable for this purpose. Using

common power outlet strips for the server is not recommended.

A 70, 1999 Edition (National Electric Code), Article 250, as well as any

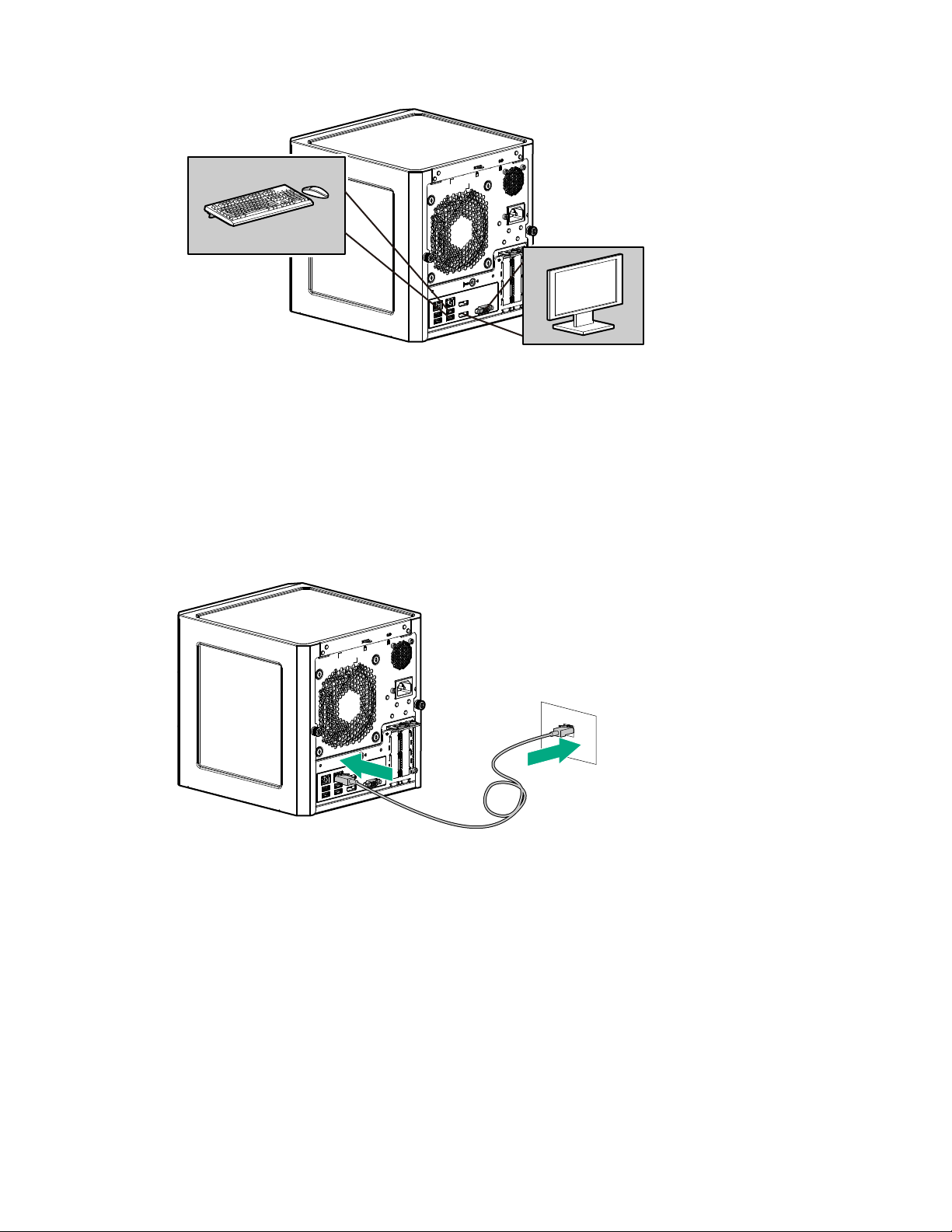

Connecting the I/O devices

About this task

To view and navigate the initial server setup screens, connect I/O devices to the server.

Procedure

1. Connect a keyboard and mouse to the USB ports.

2. Connect a monitor to the VGA or Display port.

16 Power requirements

Page 17

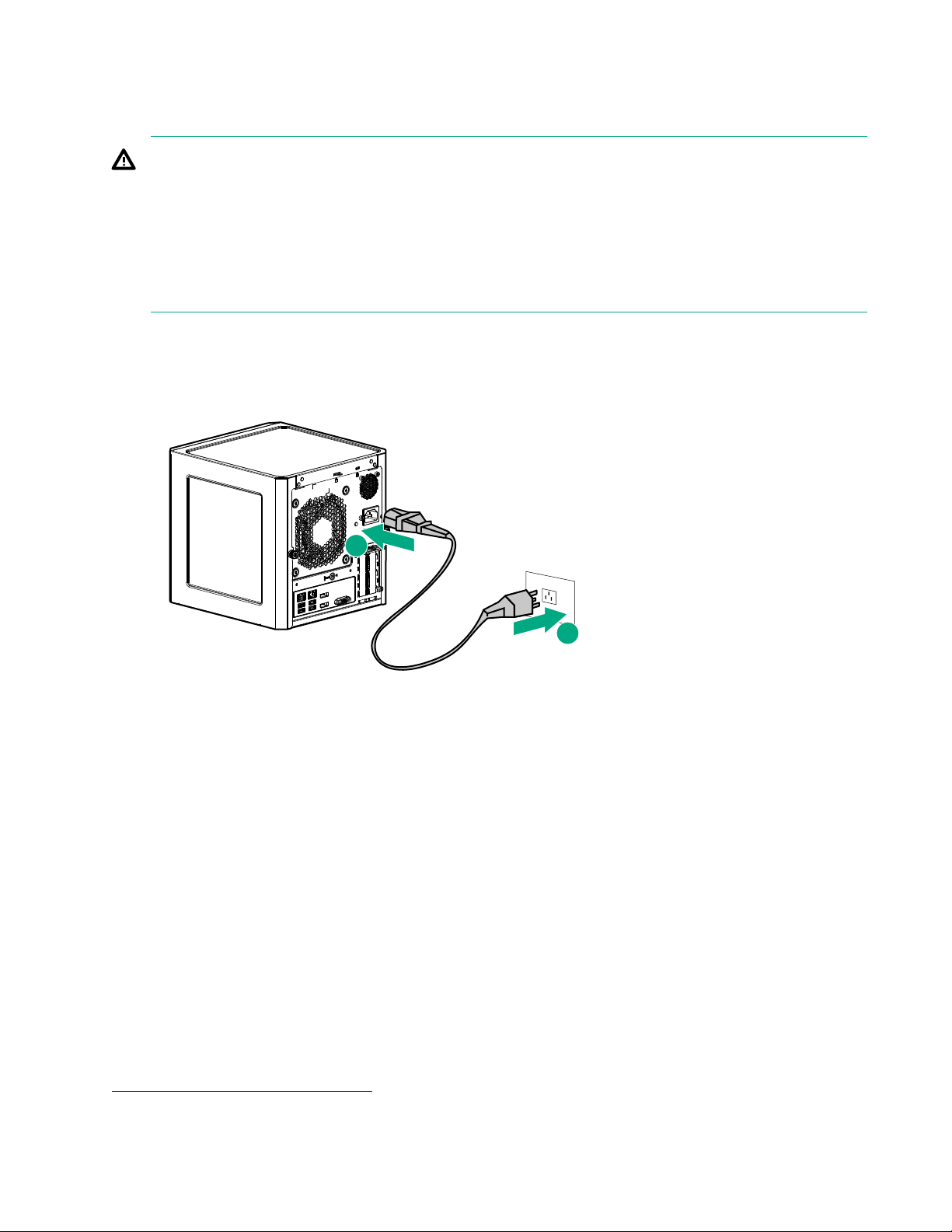

Connecting the network cable

Procedure

1. Connect one end of the network cable to the NIC port.

2. Connect the other end of the network cable to a network jack or a network device such as router or LAN

switch.

Connecting the network cable 17

Page 18

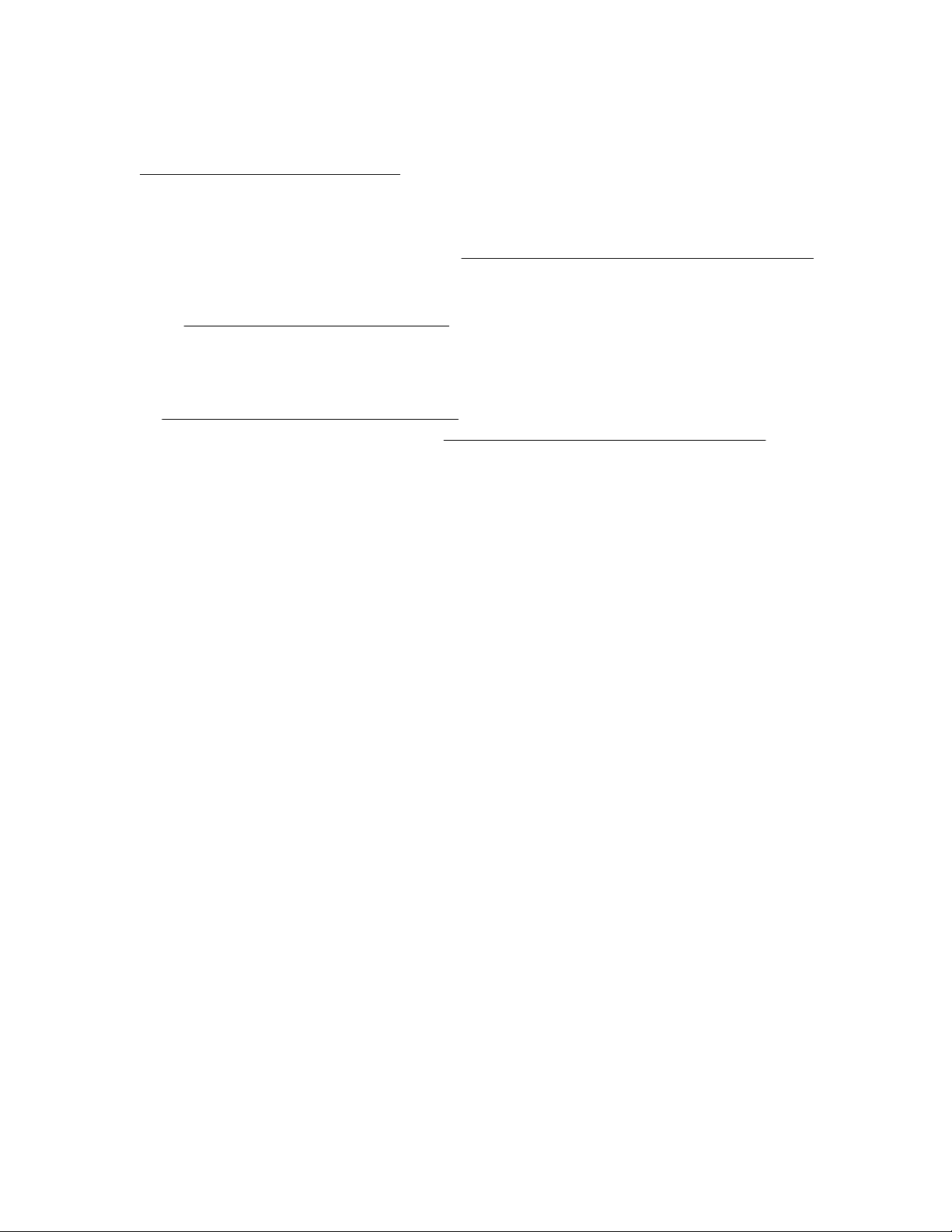

Connecting the power cord

1

2

About this task

WARNING:

To reduce the risk of electric shock or damage to the equipment:

Do not disable the power cord grounding plug. The grounding plug is an important safety feature.

•

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

• Do not route the power cord where it can be walked on or pinched by items placed against it. Pay

particular attention to the plug, electrical outlet, and the point where the cord extends from the server.

Procedure

1. Connect the power cord to the server power jack.

2. Connect the power cord to the AC power source.

Powering on the server for the first time

Procedure

1. If you are installing an operating system from a bootable media, insert the media into the server.

2. Press the Power On/Standby button.

3. Verify that the system power LED changes to green.

4. During the initial boot, on the enter setup prompt, press the F2 or Del key to access the Aptio Setup Utility

and do one of the following:

• Modify the default BIOS configuration settings.

• Access the preloaded ClearOS image.

• Adjust the boot order to select the OS bootable media.

Installing an operating system

To operate properly

operating systems, see the Hewlett Packard Enterprise website:

http://www.hpe.com/info/supportos

18 Connecting the power cord

, the server must have a supported operating system. For information on supported

Page 19

This server supports Class 2 UEFI implementation. UEFI Class 2 implementation supports both UEFI boot

mode and legacy BIOS boot mode. The boot mode is configured in the Aptio Setup Utility. When the server is

configured for UEFI boot mode, observe the appropriate operating system, boot mode, network device, and

controller requirements. For more information on these requirements, see the Important UEFI Requirements

(for the HPE ProLiant MicroServer Gen10) on the Hewlett Packard Enterprise Information Library:

http://www.hpe.com/info/UEFI/docs

To install an operating system on the server

• If you are planning to install ClearOS, there are two install scenarios:

◦ For a server that shipped with ClearOS,

◦ For a server that does not have ClearOS preloaded, download the software from the Hewlett Packard

Enterprise website:

http://www.hpe.com/servers/clearos

ClearOS is a Linux-based OS with a web-based interface with its own application marketplace for small to

medium businesses. For detailed ClearOS installation instructions, see the ClearOS 7 on HPE ProLiant

Servers Installation Guide at:

http://www.hpe.com/support/ClearOS-IG

• If you are planning to install another OS, boot directly from the OS installation media.

This installation media can either be an optical disc or a USB drive. If you are using an OS installation disc

and the server does not have an internal optical drive installed, an external USB optical drive is required.

, use one of the following methods:

Install the preloaded ClearOS image

Procedure

1. On the Aptio Setup Utility screen, select the Boot menu.

2. Under Boot Option Priorities, verify that Boot Option #1 is set as [ClearOS Utilities].

If it is not set, select Boot Option #1, press the Enter key, and then change the setting to [ClearOS

Utilities].

o confirm the change and exit the utility, press the F4 key.

3. T

boot the server to the preloaded ClearOS image.

The server automatically reboots to the selected device.

4. Follow the OS installation wizard instructions.

Install an OS from a bootable installation media

Procedure

1. On the Aptio Setup Utility screen, select the Boot menu.

2. Under Boot Option Priorities, verify that Boot Option #1 is set to the OS installation media device.

If it is not set, select Boot Option #1, press the Enter key, and then change the setting.

o confirm the change and exit the utility, press the F4 key.

3. T

The server automatically reboots to the selected device.

4. Follow the OS installation wizard instructions.

Installing the latest system software and firmware

As a best practice, Hewlett Packard Enterprise recommends that you install the latest firmware, drivers, and

system software before using the

see the server download page:

server for the first time. T

o get the latest firmware and software updates,

Install the preloaded ClearOS image 19

Page 20

http://www.hpe.com/downloads/microservergen10

Registering the server

To experience quicker service and more ef

https://myenterpriselicense.hpe.com/

ficient support, register the server at the My License Portal website:

20 Registering the server

Page 21

Operations

This chapter describes the hardware operations carried out prior to and after installing or removing a

hardware option, or performing a server maintenance or troubleshooting procedure.

Before performing these hardware operations, review and observe the server warnings and cautions.

Server warnings and cautions

WARNING:

To reduce the risk of personal injury

cord to remove power from the server. Pressing the Power On/Standby button does not shut off system

power completely. Portions of the power supply and some internal circuitry remain active until AC power

is removed.

WARNING:

To reduce the risk of personal injury from hot surfaces, allow the drives and the internal system

components to cool before touching them.

CAUTION:

Protect the server from power fluctuations and temporary interruptions with a regulating UPS. This

device protects the hardware from damage caused by power surges and voltage spikes and keeps the

server in operation during a power failure.

CAUTION:

To prevent improper cooling and thermal damage, do not operate the server with the media bay blank,

chassis cover

CAUTION:

To prevent damage to electrical components, properly ground the

installation procedure. Improper grounding can cause electrostatic discharge.

, or the front bezel removed.

, electric shock, or damage to the equipment, disconnect the power

server before beginning any

CAUTION:

To avoid data loss, Hewlett Packard Enterprise recommends that you back up all server data before

installing or removing a hardware option, or performing a server maintenance or troubleshooting

procedure.

Electrostatic discharge

Preventing electrostatic discharge

About this task

To prevent damaging the system, be aware of the precautions you must follow when setting up the system or

handling parts. A discharge of static electricity from a finger or other conductor may damage system boards or

other static-sensitive devices. This type of damage may reduce the life expectancy of the device.

Operations 21

Page 22

Procedure

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

Place parts on a grounded surface before removing them from their containers.

•

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

Grounding methods to prevent electrostatic discharge

Several methods are used for grounding. Use one or more of the following methods when handling or

installing electrostatic-sensitive parts:

• Use a wrist strap connected by a ground cord to a grounded workstation or computer chassis. Wrist straps

are flexible straps with a minimum of 1 megohm ±10 percent resistance in the ground cords. To provide

proper ground, wear the strap snug against the skin.

•

Use heel straps, toe straps, or boot straps at standing workstations. Wear the straps on both feet when

standing on conductive floors or dissipating floor mats.

• Use conductive field service tools.

• Use a portable field service kit with a folding static-dissipating work mat.

If you do not have any of the suggested equipment for proper grounding, have an authorized reseller install

the part.

For more information on static electricity or assistance with product installation, contact an authorized reseller.

Power up the server

Press the Power On/Standby button.

The server exits standby mode and applies full power to the system. The system power LED changes to

green.

Power down the server

Prerequisites

Before powering down the server for any upgrade or maintenance procedures, perform a backup of critical

server data and programs.

Procedure

• Press and release the Power On/Standby button.

This method initiates a controlled shutdown of applications and the OS before the server enters standby

mode.

• Press and hold the Power On/Standby button for more than 4 seconds to force the server to enter standby

mode.

This method forces the server to enter standby mode without properly exiting applications and the OS. If

an application stops responding, you can use this method to force a shutdown.

The system power LED changes to red indicating that the server is in standby mode. Auxiliary power is still

present in the system in this mode.

22 Grounding methods to prevent electrostatic discharge

Page 23

Prepare the server for hardware installation or removal

Procedure

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server.

3. Disconnect all peripheral cables from the server

4. If installed, unlock and remove the security padlock and/or the Kensington security lock.

For more information, see the lock documentation.

.

Prepare the server for operation

Procedure

1. If removed, attach the security padlock and/or the Kensington security lock.

For more information, see the lock documentation.

2. Connect all peripheral cables to the server.

3. Connect the power cord to the server power jack, and then to the AC source.

4. Secure the power cord and rear panel cables based on the standard cable management practices.

5. Power up the server on page 22.

Remove the front bezel

o access the drive bays, remove the front bezel.

T

Removing a locked front bezel

Prerequisites

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server

3. Disconnect all peripheral cables from the server.

4.

Remove the chassis cover on page 26.

Procedure

1. To unlock the front bezel from the chassis, slide the release tab upward.

.

Prepare the server for hardware installation or removal 23

Page 24

1

2. Open the front bezel.

1

2

3. To completely detach the bezel from the front panel, release the bezel hinges from the chassis.

Retain the bezel for later use.

Removing an unlocked front bezel

Prerequisites

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server

3. Disconnect all peripheral cables from the server.

Procedure

1. Open the front bezel.

2. To completely detach the bezel from the front panel, release the bezel hinges from the chassis.

Retain the bezel for later use.

24 Removing an unlocked front bezel

.

Page 25

1

2

Install the front bezel

1

2

About this task

To cover the drive bays, install the front bezel.

Procedure

1. Attach the bezel to the front panel, and then close it.

2. If you prefer to secure the bezel to the chassis, do the following:

a. If installed, remove the chassis cover.

b. Slide the release tab downwards to lock the bezel to the chassis.

Install the front bezel 25

Page 26

c. Install the chassis cover on page 27.

1

1

2

Remove the chassis cover

About this task

To access the front bezel lock and the internal components, remove the chassis cover.

Procedure

1. If installed, unlock and remove the security padlock and/or the Kensington security lock.

For more information, see the lock documentation.

2. Remove the chassis cover thumbscrews.

If the thumbscrews are too tight, use a T-15 screwdriver to remove it.

3. Slide the chassis cover toward the rear panel, and then lift it from the server.

26 Remove the chassis cover

Page 27

Install the chassis cover

1

1

3

3

2

To prevent access to the front bezel lock and the internal components, install the chassis cover.

Install the chassis cover

Prerequisites

1. Verify that all internal cables are properly connected and are secured in their respective cable ties.

erify that the drive cables are not blocking the fan blades.

2. V

Procedure

1. Insert the tabs on the bottom left and right sides of the chassis cover into the corresponding slots on the

chassis.

2. Slide the chassis cover towards the front panel.

3. Install the chassis thumbscrews.

4. If removed, install the security padlock and/or the Kensington security lock.

For more information, see the lock documentation.

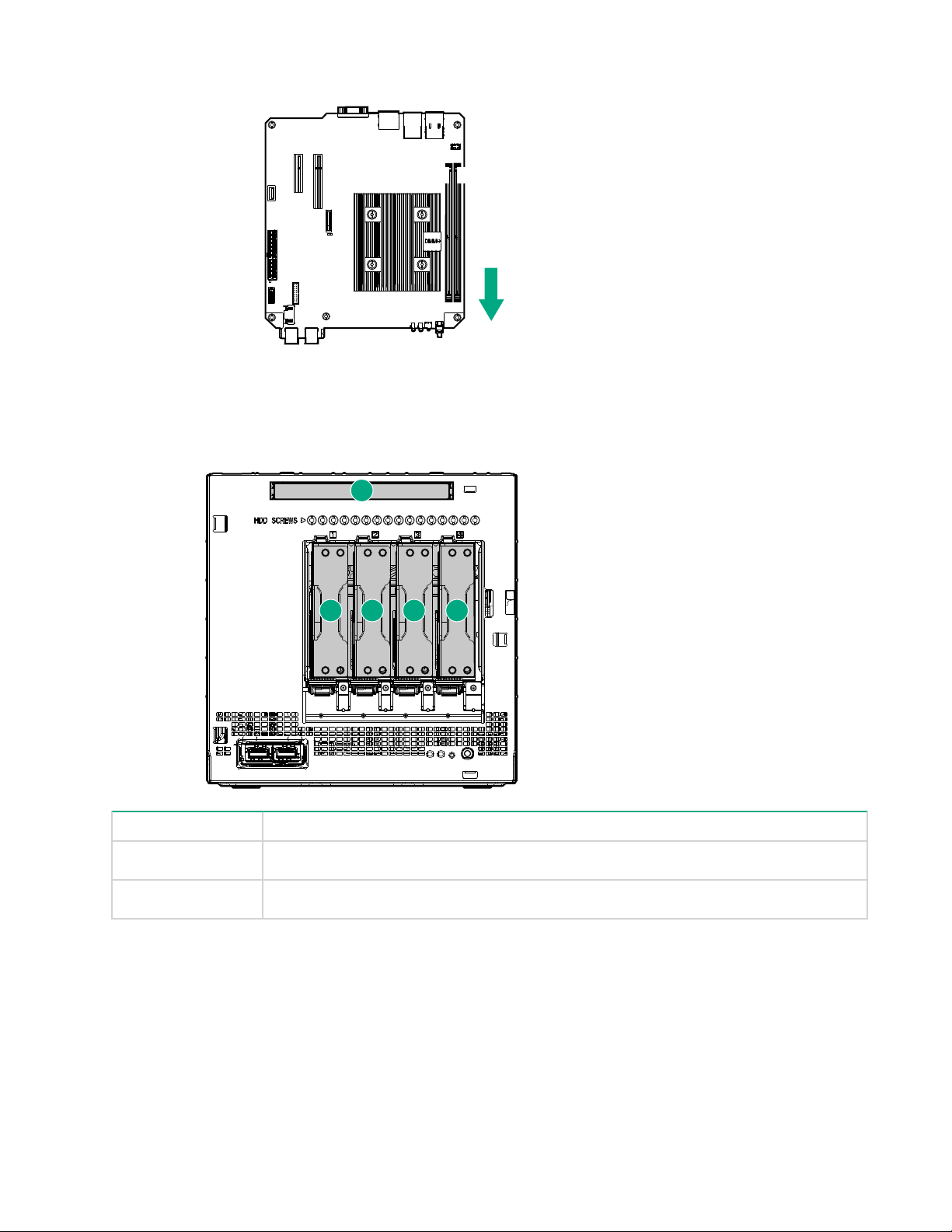

Install the system board assembly

To secure the system board inside the chassis, install the system board assembly.

Install the system board assembly

Prerequisites

Procedure

Before you perform this procedure, make sure that you have a T-15 T

1. Slide the system board assembly into the chassis.

2. Press against the system board assembly until it clicks into place.

3. Install the system board assembly screw.

orx screwdriver available.

Install the chassis cover 27

Page 28

1

1

2

3

4. Connect the following system cables:

• Power supply cable

• Optical drive or SSD SATA cable (optional)

• LFF/SFF drive SATA cable – This cable can either be connected to the system board or to an installed

HBA.

• Fan cable

5. If removed, install the internal USB device.

Remove the system board assembly

To install or remove hardware components on the system board or to access the CMOS header, remove the

system board assembly

28 Remove the system board assembly

.

Page 29

Remove the system board assembly

1

2

2

1

1

2

Prerequisites

Before you perform this procedure, make sure that you have a T-15 T

Procedure

1. If installed, remove the internal USB device.

2. To serve as a reference for system cable connections when the system board assembly is installed back

3. Disconnect the following system cables:

orx screwdriver available.

into the server

, take a picture of the current system board cable connections.

• Power supply cable

• Optical drive or SSD SATA cable (optional)

• LFF/SFF drive SATA cable – This cable can either be connected to the system board or to an installed

HBA.

• Fan cable

4. Remove the system board assembly screw.

5. Place a finger in the notch on both sides of the system board assembly, and then pull out the assembly.

Remove the system board assembly 29

Page 30

1

2

2

30 Operations

Page 31

Hardware options installation

This chapter provides detailed instructions on how to install hardware options.

For more information on supported options, see the product QuickSpecs on the HPE ProLiant MicroServer

Gen10 website at:

http://www.hpe.com/server/microserver

To view the warranty for your server and supported options, see Warranty information.

Introduction

If more than one option is being installed, read the installation instructions for all the hardware options and

identify similar steps to streamline the installation process.

WARNING:

To reduce the risk of personal injury from hot surfaces, allow the drives and the internal system

components to cool before touching them.

CAUTION:

To prevent damage to electrical components, properly ground the server before beginning any

installation procedure. Improper grounding can cause electrostatic discharge.

Drive support information

This server only supports non-hot-plug drives. These drives are not designed to be installed or removed from

the server while the system is still powered on. Power of

option.

From a drive interface standpoint, the embedded Marvell 88SE9230 PCIe to SAT

SATA drives.

From a form factor standpoint, the server drive bays support 3.5-inch LFF drives. To support 2.5-inch SFF

drives,

To support a 7-mm SA

install the SFF-to-LFF drive converter option.

TA solid state drive in the media bay,

Drive installation guidelines

Populate drive bays based on the drive numbering sequence. Start from the

•

device number.

• All drives grouped into the same drive array must meet the following criteria:

They must be either all hard drives or all solid state drives.

◦

◦ Drives should be the same capacity to provide the greatest storage space efficiency when drives are

grouped together into the same drive array.

• The system automatically sets all device numbers.

Installing an LFF drive

f the server before installing or removing a drive

A 6Gb/s Controller supports

install the SSD enablement kit.

drive bay with the lowest

About this task

To add internal data storage to the server

, install one or more LFF drives in the drive bays.

Hardware options installation 31

Page 32

Procedure

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server.

3. Disconnect all peripheral cables from the server

4.

5. Install the LFF drive on page 32.

6. Install the front bezel on page 25.

7. Connect all peripheral cables to the server

8. Connect the power cord to the server power jack, and then to the AC source.

9.

10. Determine the status of the server drives from the drive LED definitions.

11. T

.

Remove the front bezel on page 23.

.

Power up the server on page 22.

o configure drive arrays, do one of the following:

• If the drives are connected to the LFF/SFF drive SATA port, use the

or the

63

If the drives are connected to an HPE Smart HBA or Smart Array controller option, use the

•

Smart Storage Administrator on page 63.

Marvell BIOS Utility on page 64.

Install the LFF drive

Prerequisites

Before you perform this procedure, make sure that you have the following items available:

-15 Torx screwdriver

• T

• LFF drive option

Procedure

1. Remove four drive screws from the front panel.

Marvell Storage Utility on page

HPE

2. Install the screws in the drive.

32 Install the LFF drive

Page 33

3. Slide the drive into the drive bay until it clicks into place.

Installing an SFF drive

About this task

To install SFF drives in the drive bays, install the SFF drive converter option. In general, SFF drives give

greater power and space savings. SFF drives can require as little as half the power and generate significantly

less heat than LFF drives.

Procedure

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server.

3. Disconnect all peripheral cables from the server

4.

5. Install the SFF drive on page 34.

6. Install the front bezel on page 25.

7. Connect all peripheral cables to the server

8. Connect the power cord to the server power jack, and then to the AC source.

9.

10. Determine the status of the server drives from the drive LED definitions.

11. T

.

Remove the front bezel on page 23.

.

Power up the server on page 22.

o configure drive arrays, do one of the following:

Installing an SFF drive 33

Page 34

• If the drives are connected to the LFF/SFF drive SATA port, use the Marvell Storage Utility on page

or the

63

If the drives are connected to an HPE Smart HBA or Smart Array controller option, use the

•

Smart Storage Administrator on page 63.

Marvell BIOS Utility on page 64.

Install the SFF drive

Prerequisites

Before you perform this procedure, make sure that you have the following items available:

-10 Torx screwdriver

• T

• T-15 Torx screwdriver

• SFF drive converter option kit. This kit includes:

◦ Drive converter tray

◦ T-10 screws (4)

• SFF drive option

Procedure

1. Install the SFF drive in the drive converter tray.

HPE

2. Follow the callout sequence in the following illustration to install the screws included in the converter kit on

the bottom side of the converter tray.

34 Install the SFF drive

Page 35

1

3

2

4

3. Remove three drive screws from the front panel.

4. Install the three screws removed from the front panel on the left and right sides of the converter tray.

Hardware options installation 35

Page 36

5. Slide the drive into the drive bay until it clicks into place.

Installing an SSD

About this task

The media bay supports a 7-mm slim-type SAT

Information is stored in microchips. Traditional hard disk drives use a mechanical arm with a read/write head

to move around and read information from the right location on a rotating storage platters. This lack of rotating

media in SSDs:

• Greatly reduces the SSD’s power consumption

• Enable SSDs to tolerate significantly higher operating shock and vibration levels

SSDs are suitable for server workloads with highly random data under a variety of write-workload

applications.

36 Installing an SSD

A solid state drive option. SSDs have no moving parts.

Page 37

Procedure

1

2

2

2

2

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server.

3. Disconnect all peripheral cables from the server

4.

Remove the chassis cover on page 26.

5. Install the SSD on page 37.

6. Install the chassis cover on page 27.

7. Connect all peripheral cables to the server

8. Connect the power cord to the server power jack, and then to the AC source.

9.

Power up the server on page 22.

Install the SSD

Prerequisites

Before you perform this procedure, make sure that you have the following items available:

-10 Torx screwdriver

• T

• T-15 Torx screwdriver

• SSD enablement option kit. This kit includes:

◦ SSD tray

◦ SSD power cable

◦ SSD SATA cable

◦ T-10 screws (4, for securing the SSD)

◦ T-15 Torx screw (1, for securing the SSD tray)

• SSD option

.

.

Procedure

1. Place the SSD in the SSD tray, and then install the SSD screws.

2. Install the SSD assembly in the media bay, and then secure it with the screw.

Install the SSD 37

Page 38

1

2

3. Connect the SSD power cable:

2

1

a. Open the cable ties.

b. Connect the power cable to the SSD, and then to the power supply cable labeled P3.

38 Hardware options installation

Page 39

1

2

4. Connect the SSD SATA cable:

3

2

2

1

a. Connect the SATA cable to the SSD.

b. Route the SATA cable through the left side chassis opening down to the system board.

c. Connect the SATA cable to the SATA port.

5. Bundle the extra length of the SSD power and SAT

A cables, and then secure them in the cable ties.

Hardware options installation 39

Page 40

1

2

Installing an optical drive

About this task

The media bay supports a slim-type SATA optical drive option. This option allows you to retrieve or store data

on optical discs like CDs and DVDs.

Procedure

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server.

3. Disconnect all peripheral cables from the server.

4. Remove the chassis cover on page 26.

5. Remove the front bezel on page 23.

6. Install an optical drive on page 40.

7. Install the front bezel on page 25.

8. Install the chassis cover on page 27.

9. Connect all peripheral cables to the server.

10. Connect the power cord to the server power jack, and then to the AC source.

11. Power up the server on page 22.

Install an optical drive

Prerequisites

Before you perform this procedure, make sure that you have the following items available:

• T

-15 Torx screwdriver

• Phillips No. 2 screwdriver

• Optical drive option kit. This kit includes:

40 Installing an optical drive

◦ Optical drive

◦ Optical drive bracket

◦ Phillips No. 2 screws (2, for securing the optical drive bracket)

◦ T-15 screw (1, for securing the optical drive)

Page 41

Procedure

2

1

1

1

2

2

1. Facing the server, press and hold the release latches on both sides of the optical drive blank, and then

2. Attach the bracket to the optical drive.

push the blank out of the media bay

Retain the blank for future use.

.

3. Slide the optical drive into the media bay.

4. Install the optical drive screw

.

Hardware options installation 41

Page 42

1

2

5. Connect the optical drive SATA Y-cable:

a. Connect the common end of the cable to the optical drive.

b. Open the cable tie.

42 Hardware options installation

Page 43

2

1

c. Connect the power end of the SATA cable to the power supply cable labeled P3.

d. Route the data end of the SAT

A Y-cable through the left side chassis opening down to the system

board.

e. Connect the data end of the cable to the SATA port.

Hardware options installation 43

Page 44

1

1

2

f. Bundle the extra length of the SATA Y-cable and the power supply P3 cable, and then secure them in

1

2

the cable tie.

Memory support

The server has two DIMM slots supporting standard UDIMMs with ECC for a maximum memory capacity of

32 GB.

For more information on the server memory support, see the Gen10 memory user guide on the Hewlett

Packard Enterprise Information Library:

http://www.hpe.com/info/enterprise-docs

DIMM identification

o determine DIMM characteristics, see the label attached to the DIMM. The information in this section helps

T

you to use the label to locate specific information about the DIMM.

44 Memory support

Page 45

8GB 1R x8 PC 4-240 0T-E

8GB 1 Rx8 PC4 -2400T-E

1 2 43 5 6 7

Item Description Definition

1 Capacity

2 Rank

3 Data width on DRAM

4 Memory generation

5 Maximum memory speed

8 GB

16 GB

32 GB

64 GB

128 GB

1R = Single-rank

2R = Dual-rank

4R = Quad-rank

8R = Octal-rank

x4 = 4-bit

x8 = 8-bit

x16 = 16-bit

PC4 = DDR4

2133 MT/s

2400 MT/s

6 CAS latency

7 DIMM type

2666 MT/s

P = CAS 15-15-15

T = CAS 17-17-17

U = CAS 20-18-18

V = CAS 19-19-19 (for RDIMM, LRDIMM)

V = CAS 22-19-19 (for 3DS TSVLRDIMM)

R = RDIMM (registered)

L = LRDIMM (load reduced)

E = UDIMM (unbuffered ECC)

Hardware options installation 45

Page 46

DIMM ranks

To understand and configure memory protection modes properly

Some DIMM configuration requirements are based on these classifications.

A single-rank DIMM has one set of memory chips that is accessed while writing to or reading from the

memory. A dual-rank DIMM is similar to having two single-rank DIMMs on the same module, with only one

rank accessible at a time. A quad-rank DIMM is, effectively, two dual-rank DIMMs on the same module. Only

one rank is accessible at a time. The server memory control subsystem selects the proper rank within the

DIMM when writing to or reading from the DIMM.

Dual- and quad-rank DIMMs provide the greatest capacity with the existing memory technology. For example,

if current DRAM technology supports 8 GB single-rank DIMMs, a dual-rank DIMM would be 16 GB, and a

quad-rank DIMM would be 32 GB, and an octal-rank LRDIMM would be 64 GB.

LRDIMMs are labeled as quad- and octal-rank DIMMs. There are four and eight ranks of DRAM on the DIMM,

but the LRDIMM buffer creates an abstraction that allows the DIMM to appear as a logical dual-rank DIMM to

the system. This is called Rank Multiplication. The LRDIMM buffer also isolates the electrical loading of the

DRAM from the system to allow for faster operation. These two changes allow the system to support up to

three LRDIMMs per memory channel, providing for greater memory capacity and higher memory operating

speed compared to quad-rank RDIMMs.

DIMM handling guidelines

When handling a DIMM, observe the following guidelines.

• A

void electrostatic discharge.

• Always hold DIMMs by the side edges only.

• Avoid touching the connectors on the bottom of the DIMM.

• Never wrap your fingers around a DIMM.

• Avoid touching the components on the sides of the DIMM.

• Never bend or flex the DIMM.

, an understanding of DIMM rank is helpful.

CAUTION:

Failure to properly handle DIMMs can cause damage to the components on the DIMM, as well as the

system board connector.

DIMM installation guidelines

When installing a DIMM, observe the following guidelines.

• Before seating the DIMM, open the DIMM slot and align the DIMM with the slot.

•

To align and seat the DIMM, use two fingers to hold the DIMM along the side edges.

• To seat the DIMM, use two fingers to apply gentle pressure along the top of the DIMM.

For more information, see the

Hewlett Packard Enterprise website.

Installing a DIMM

About this task

The server uses memory to perform almost all of its operations. Upgrading the server memory capacity leads

to faster boot-up, processing period, and timely responses to promote optimum system performance.

Procedure

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server

.

46 DIMM ranks

Page 47

3. Disconnect all peripheral cables from the server.

2

2

1

4. Remove the chassis cover on page 26.

5. Install the DIMM on page 47.

6. Install the chassis cover on page 27.

7. Connect all peripheral cables to the server

8. Connect the power cord to the server power jack, and then to the AC source.

9.

Power up the server on page 22.

o configure the memory, use the

10. T

Memory Configuration.

Install the DIMM

Procedure

1. Open the DIMM slot latches.

2. Align the notch on the bottom edge of the DIMM with the keyed surface of the DIMM slot, and then fully

press the DIMM into the slot until the latches snap back into place.

The DIMM slots are structured to ensure proper installation. If you try to insert a DIMM but it does not fit

easily into the slot, you might have positioned it incorrectly. Reverse the orientation of the DIMM and insert

it again.

.

Aptio Setup Utility on page 59. Select

Chipset > South Bridge >

Expansion board options

The server has two low-profile, open-ended PCIe3 expansion slots. Use these slots to install additional

hardware capabilities such as:

• An HBA to enable advanced drive features.

A GPU to accelerate the processing speed of your applications.

•

• A network adapter with advanced Ethernet connectivity features.

Installing an expansion board

Procedure

1. Power down the server on page

2. Disconnect the power cord from the AC source, and then from the server.

3. Disconnect all peripheral cables from the server.

4.

22.

Remove the chassis cover on page 26.

Install the DIMM 47

Page 48

5. Remove the system board assembly on page 28.

6. If the expansion board is shipped with an air baffle attached, remove this baffle from the board.

7. If the expansion board is shipped with a full-height bracket attached, replace it with a low-profile one.

8. Install the expansion board.

9. Install the system board assembly on page 27

10. Connect all necessary internal cabling to the expansion board.

For more information on these cabling requirements, see the documentation that ships with the option.

11. Install the chassis cover on page 27.

12. Connect all peripheral cables to the server.

13. Connect the power cord to the server power jack, and then to the AC source.

14. Power up the server on page 22.

Remove the air baffle from the expansion board

Remove the air baffle from the expansion board.

The number and location of the latches that secure the baffle to the board will vary depending on the

expansion board. The illustration below is an example image only. See the expansion board

documentation for model-specific information.

Install a low-profile bracket on the expansion board

About this task

The number and location of the bracket screws will vary depending on the expansion board. The illustrations

below are example images only. See the expansion board documentation for model-specific information.

Procedure

1. Remove the full-height bracket from the expansion board.

48 Remove the air baffle from the expansion board

Page 49

1

2

1

2. Install the low-profile bracket on the expansion board.

1

2

2

Install the expansion board

Prerequisites

Before you perform this procedure, make sure that you have T-15 T

orx screwdriver available.

Procedure

1. Identify the expansion slot compatible with the expansion board, and then remove the blank opposite that

slot.

Retain the blank for future use.

Install the expansion board 49

Page 50

1

2

2. Verify that any switches or jumpers on the expansion board are set properly.

1

2

For more information, see the expansion board documentation.

3. Install the expansion board. Verify that the board is firmly seated in the slot.

Internal USB device options

The server has an internal USB 2.0 port that you can use to install internal USB devices such as:

• USB flash media devices for booting up from flash solutions or for data backup/redundancy.

USB devices that are intended to be rarely removed such as a USB dongle for Bluetooth or Wi‑Fi support.

•

Install an internal USB device

Procedure

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server

3. Disconnect all peripheral cables from the server.

Remove the chassis cover on page 26.

4.

50 Internal USB device options

.

Page 51

5. Plug in the USB device into the internal USB port.

6. Install the chassis cover on page 27.

7. Connect all peripheral cables to the server.

8. Connect the power cord to the server power jack, and then to the AC source.

9. Power up the server on page 22.

For more information on any required setup or configuration procedure, see the USB device documentation.

External HPE RDX Backup System option

To install a simple, inexpensive, and reliable way to securely store your data backups, install an external HPE

RDX Backup System. The backup system is a removable, ruggedized, hard disk drive system.

The backup system consists of two components:

RDX cartridge

•

• RDX docking station

Hewlett Packard Enterprise recommends that no more than one HPE RDX Removable Disk Backup System

be connected to a system at a time.

For more information on installing and configuring the external HPE RDX Removable Disk Backup System,

see the Storage section of the Hewlett Packard Enterprise Information Library:

http://www.hpe.com/info/storage/docs

HP Trusted Platform Module

The TPM is a hardware-based system security feature that can securely store information, such as

passwords and encryption keys, which can be used to authenticate the platform.

The TPM works with Microsoft Windows BitLocker which is a data protection feature available in Microsoft

Windows Server 2008 R2 SP1 and later operating systems. BitLocker helps protect user data and helps

ensure that a server running Windows Server has not been tampered with while the system was offline.

This server supports TPM 2.0. T

cannot be removed from the board once it has been installed.

o prevent possible damage to the TPM or to the system board, the TPM

External HPE RDX Backup System option 51

Page 52

Trusted Platform Module (TPM) — China Import Restrictions

HPE

Special Reminder: Before enabling TPM functionality on this system, you must ensure that your

intended use of TPM complies with relevant local laws, regulations and policies, and approvals or licenses

must be obtained if applicable.

For any compliance issues arising from your operation/usage of the TPM which violates the above mentioned

requirement, you shall bear all the liabilities wholly and solely. HPE will not be responsible for any related

liabilities.

HP Trusted Platform Module installation guidelines

CAUTION:

Always observe the guidelines in this document. Failure to follow these guidelines can cause hardware

damage or halt data access.

When installing or replacing a TPM, observe the following guidelines:

• Do not remove an installed TPM. Once installed, the TPM becomes a permanent part of the system board.

•

When installing or replacing hardware, Hewlett Packard Enterprise service providers cannot enable the

TPM or the encryption technology. For security reasons, only the customer can enable these features.

• When returning a system board for service replacement, do not remove the TPM from the system board.

When requested, HPE Service provides a TPM with the spare system board.

• Any attempt to remove an installed TPM from the system board breaks or disfigures the TPM security