Page 1

Designjet SD Pro Scanner

Service manual

Page 2

© Copyright Hewlett-Packard Company 2014

Legal notices

For HP Internal Use Only

1st edition

This document contains proprietary

information that is protected by copyright. All

rights are reserved. No part of this document

may be photocopied, reproduced, or translated

to another language without the prior written

consent of Hewlett-Packard Company.

Page 3

Notices

Warranty

The information contained in this

document is subject to change without

notice.

Hewlett-Packard makes no warranty of

any kind with regard to this material,

including, but not limited to, the implied

warranties of merchantability and

fitness for a particular purpose.

Hewlett-Packard shall not be liable for

errors contained herein or for incidental or

consequential damages in connection with

the furnishing, performance, or use of this

material.

WARNING! The procedures described in

this manual are to be performed by HPqualified service personnel only.

Electrical Shock Hazard

Serious shock hazard leading to death or

injury may result if you do not take the

following precautions:

●

Ensure that the AC power outlet

(mains) has a protective earth

(ground) terminal.

●

Disconnect the product from the

power source prior to performing any

maintenance.

●

Prevent water or any other liquids

from running onto electrical

components or circuits, or through

openings in the enclosure.

Electrostatic Discharge

See

Electrostatic Discharge (ESD)

Precautions on page 48 for precautions

you should take to prevent damage to the

printer circuits from electrostatic

discharge.

WARNING! The Warning symbol calls

attention to a procedure, practice, or the

like, which, if not correctly performed or

adhered to, could result in personal injury.

Do not proceed beyond a Warning symbol

until the indicated conditions are fully

understood and met.

CAUTION: The Caution symbol calls

attention to an operating procedure,

practice, or the like, which, if not correctly

performed or adhered to, could result in

damage to or destruction of part or all of

the product. Do not proceed beyond a

Caution symbol until the indicated

conditions are fully understood and met.

Safety Symbols

General definitions of safety symbols are

given immediately after the table of

contents.

Content Management Department, Large Format Printing

Barcelona Division,

Hewlett-Packard Espanola, S.A.

Camí de Can Graells, 1–21

08174 Sant Cugat del Vallès

Spain

ENWW iii

Page 4

iv Notices ENWW

Page 5

Using this Manual

Purpose

This Service Manual contains information necessary to troubleshoot and service:

●

HP Designjet SD Scanner Pro

For information about using the product, see the corresponding user guide.

This Service Manual is about the Scanner and the integration with the printer as a copier. In order to

troubleshoot the printer, see the corresponding Service Manual for the printer.

Readership

The procedures described in this Service Manual are to be performed by HP Certified service personnel only.

Part Numbers

Part Numbers for service parts can be found in

Parts and Diagrams on page 43.

ENWW v

Page 6

vi Using this Manual ENWW

Page 7

Table of contents

1 Troubleshooting ........................................................................................................................................... 1

Troubleshooting tips ............................................................................................................................................. 2

Is the problem with the Printer or the Scanner? ................................................................................................... 2

Image-quality problems ........................................................................................................................................ 2

Output problems .................................................................................................................................................... 2

Troubleshooting System Error Codes ................................................................................................................... 3

Using the Service Tools from the Touchscreen .................................................................................................... 3

Troubleshooting Issues ......................................................................................................................................... 7

Troubleshooting print-quality and copy issues .................................................................................................... 8

Troubleshooting general scanner issues ............................................................................................................ 11

Troubleshooting Specific Scanner Issues ........................................................................................................... 17

Most common Image Quality issues ................................................................................................................... 19

Cleaning the Scanning Area ................................................................................................................................. 20

Troubleshooting Specific Panel PC Problems ..................................................................................................... 22

Touch screen fails ................................................................................................................................................ 26

Upgrade Scanner Software ................................................................................................................................. 26

2 System Error Codes ...................................................................................................................................... 28

System Error Codes for the Scanner Only ........................................................................................................... 29

Software Related Errors ...................................................................................................................................... 30

Error Codes for the JetImage Software RIP ........................................................................................................ 36

Error Messages for the Touch Screen ................................................................................................................. 40

3 Parts and Diagrams ..................................................................................................................................... 43

Scanner ................................................................................................................................................................ 44

Panel PC ............................................................................................................................................................... 45

4 Removal and Installation ............................................................................................................................. 47

Introduction ......................................................................................................................................................... 48

Safety Precautions .............................................................................................................................................. 48

Electrostatic Discharge (ESD) Precautions ......................................................................................................... 48

Required Tools ..................................................................................................................................................... 48

Open the CIS Unit ................................................................................................................................................. 49

Scanner Controller Board .................................................................................................................................... 50

ENWW vii

Page 8

Right Side Cover ................................................................................................................................................... 51

Power Supply ....................................................................................................................................................... 52

Left Side Cover ..................................................................................................................................................... 54

Stepper Motor Assembly ..................................................................................................................................... 55

Tacho Sensor ....................................................................................................................................................... 57

Paper and Lid Sensors ......................................................................................................................................... 58

Complete CIS Unit ................................................................................................................................................ 59

Power Entry Module ............................................................................................................................................ 60

Cable Interface ..................................................................................................................................................... 61

Spring for CIS Bridge ............................................................................................................................................ 62

Pressure Rollers .................................................................................................................................................. 63

viii ENWW

Page 9

1 Troubleshooting

●

Troubleshooting tips

●

Is the problem with the Printer or the Scanner?

●

Image-quality problems

●

Output problems

●

Troubleshooting System Error Codes

●

Using the Service Tools from the Touchscreen

●

Troubleshooting Issues

●

Troubleshooting print-quality and copy issues

●

Troubleshooting general scanner issues

●

Troubleshooting Specific Scanner Issues

●

Most common Image Quality issues

●

Cleaning the Scanning Area

●

Troubleshooting Specific Panel PC Problems

●

Touch screen fails

●

Upgrade Scanner Software

ENWW 1

Page 10

Troubleshooting tips

1. First record whether the problem is with the Printer, the Scanner, or the Touch Screen.

2. Make sure that the scanning area is completely clean.

3. Test 20: Noise Test can help you find where the scanning area is dirty.

4. The SCAN dump files can help you to understand the light profile of the affected scanner.

5. Remember, in order to cancel when copying, press the Cancel button on the Touch Screen and the

Cancel button on the printer.

Is the problem with the Printer or the Scanner?

If you experience the following symptoms, the problem could be related to the scanner:

●

System Error on the Touch Screen.

●

LED’s flashing on the Scanner Operator Panel.

●

WIDEsystem error message.

●

Vertical lines (either color or black) in the scanned image.

If you experience the following symptoms, then perform an Image Preview and send a Test Print:

●

Image Quality Problems.

●

No Output

●

Output is not as expected.

If the Image preview fails, this points to a problem with the Scanner. If the Test Print fails, this points to a

problem with the Printer.

Image-quality problems

If you have Image Quality problems in any prints, try the following:

1. Print out a file already stored or print out a demo file.

2. Once the print is finished, insert it into the Scanner.

3. Once scanned, print out the scanned image.

●

If the scanned image already shows the problem, then the problem is associated to the scanner.

●

If the scanned image looks fine, but the print looks incorrect, then the problem is most likely associated

to the printer

Output problems

If the output is not as you expected it to be, try the following:

●

Check all the settings in the Software: Color Settings and Margins.

●

Check media settings: Media profile (in software) and media loaded in the printer (front panel selection)

should be the same.

2 Chapter 1 Troubleshooting ENWW

Page 11

●

Perform Color Calibration (both Scanner and printer).

●

Check the Preview Image.

If there is no output at all, then try the following:

●

Check that both the scanner and the printer are correctly connected to the network.

●

Check the selected settings: List, Collate, Scan to file...

Troubleshooting System Error Codes

Chapter 2, System Error Codes on page 28, contains a list of system error codes and their respective

descriptions and recommended corrective actions. Only try one recommended action at a time and check if

the error code has disappeared.

Using the Service Tools from the Touchscreen

Here we briefly describe the various tests found in the software Service Tools menu (called SCANtest 6 in

previous systems).

The purpose of the Service Tools is to support the troubleshooting and adjustment of the Scanner.

To access the software you must go to the Setup tab and to: Options, System, Service (this part is password

protected, the password is ’support'.

When Service Tools has been started, the Scanner is switched ON in Test Mode, and the Diagnostic LED on the

Operator Panel is turned ON.

NOTE: The word camera is used in some service tests, and in this document to refer to the CIS elements.

Service Tools Menu

●

Test 1: Set Serial Number

●

Test 6: Motor Test

●

Test 9: Oscilloscope view cameras

●

Test 11: Manual Camera Alignment (Vertical alignment and stitching)

●

Test 12: Manual Scaling Adjustment

●

Test 20: Streak Test

●

Test 42: Backup Calibration and statistics

●

Test 43: Restore Calibration and statistics

●

Test 45: Operator Panel Key Test

●

Test 46: Paper Sensor Test

●

Test 47: Operator Panel LED Test

If Service Tools is started when the scanner is in Error Mode, the Error Code Number and a short description

of the error will be displayed on the screen.

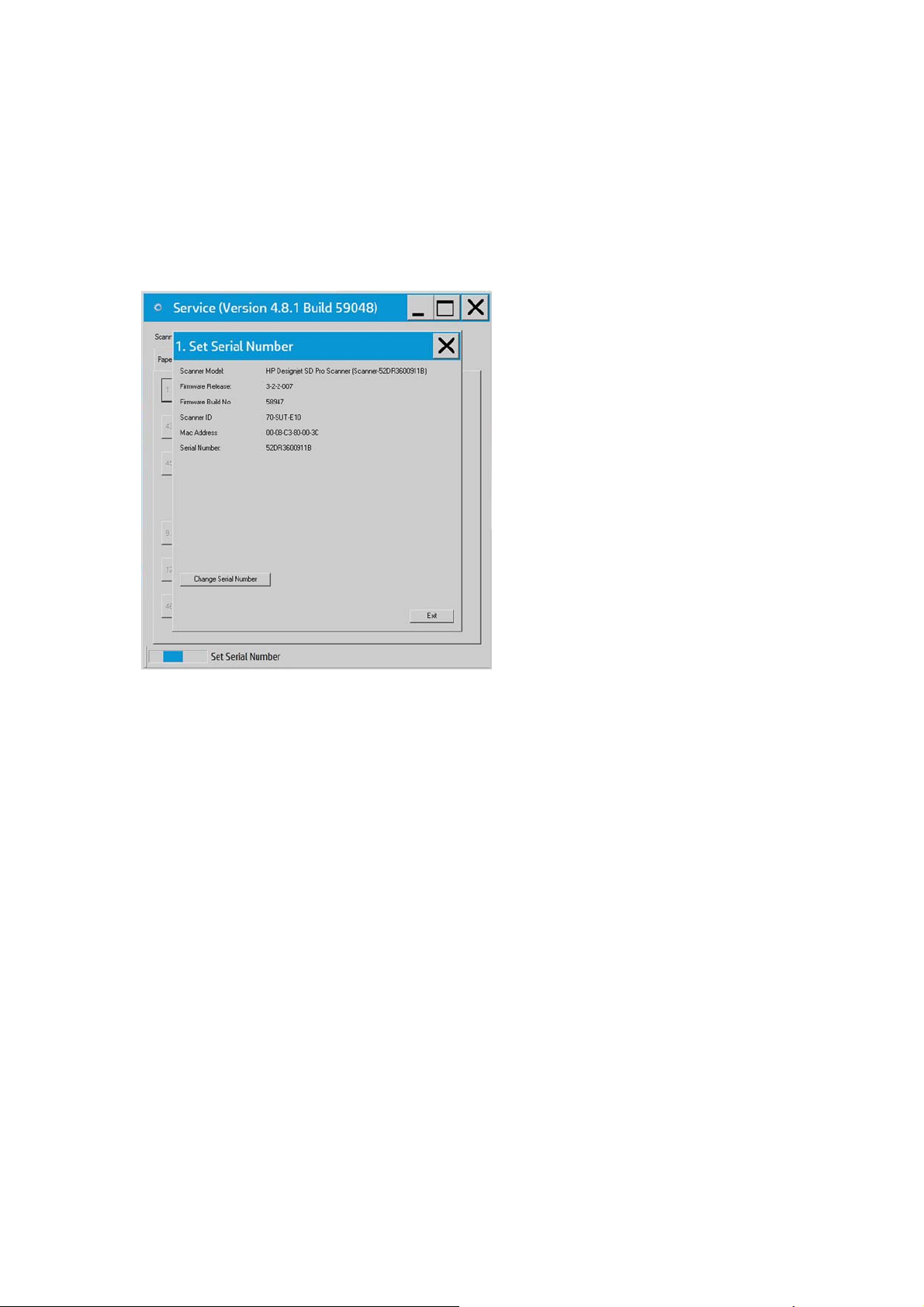

Test 1: Set Serial Number

This test displays general information regarding the scanner. When executed, the test displays the following:

ENWW Troubleshooting System Error Codes 3

Page 12

●

Scanner Model:

●

Firmware Release:

●

Firmware Build:

●

Scanner ID:

●

Mac Address:

●

Serial Number:

Test 6: Motor Test

This test checks the functionality of the Stepper Motor and any associated electronics.

When the test is executed, a menu appears that allows you to select the motor speed and the motor

direction.

If the Stepper Motor fails to run when the test is executed, then the Stepper Motor should be replaced.

Test 9: Oscilloscope View

This test contains a Software Oscilloscope that allows you to check the light profile of the CIS elements:

●

Uncorrected light profile shows the raw data from the CIS module.

●

Corrected light profile shows the calibrated data.

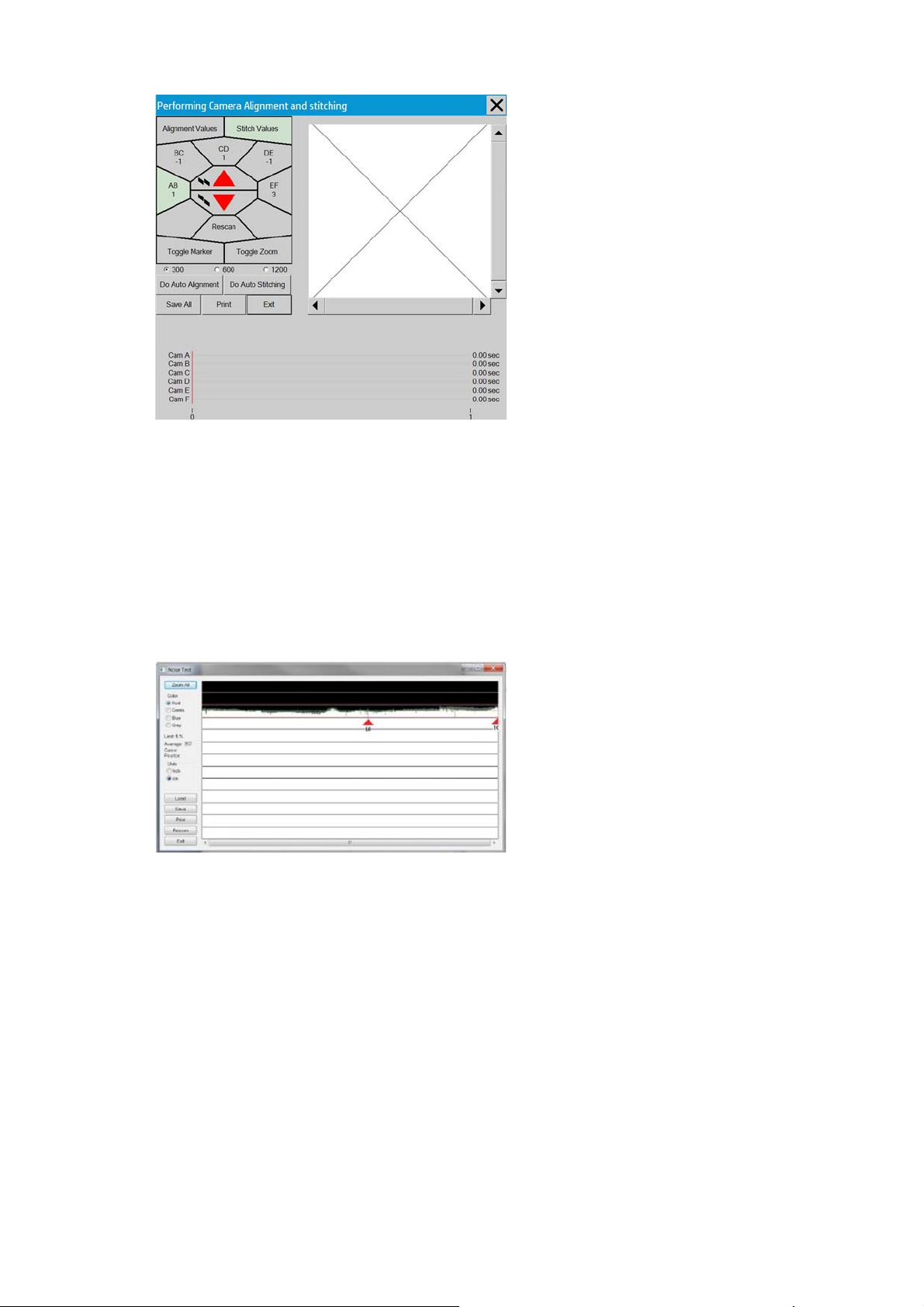

Test 11: Manual Camera Alignment

Allows you to adjust either Vertical Alignment or Stitching between 2 CIS modules:

1. Load the calibration sheet.

2. Select Alignment or Stitching.

3. Select the two CIS modules to adjust (AB, BC, etc...).

4. Use the arrows to either increase or decrease the value until the preview of the transition area between

both CIS modules look correctly aligned or stitched.

4 Chapter 1 Troubleshooting ENWW

Page 13

Test 12: Manual Scaling Adjustment

This test allows you to adjust the Y-Axis Scaling.

The scaling (dpi) in the mechanical scan direction (Y-Axis) depends on the speed of the stepper motor relative

to the scanline Exposure Time. The default motor speed can be changed ± 1%, either from Test 12 or by using

the ‘Scanner Setup/Correction factor …’ option of SW copying. The correction factor is stored in the Flash

Memory on the Scanner Controller Board.

Test 20: Streak test

The purpose of this test is to detect and locate the possible cause (dust, dirt, scratches,..) of vertical lines

running from top to bottom of the scanned image.

This test is very useful if there are image quality issues such as streaks throughout the scan (Scan direction).

It can be determined if the streaks are dust that are:

1. Present in the scanner (Dark streak that goes below the average line).

2. Present during Scanner Maintenance (white streak that goes above the average line).

Insert SM calibration sheet when asked.

Test 42: Backup Calibration and statistics

Use this option to backup the calibrations and the scanner accounting values onto a USB drive.

Test 43: Restore Calibration and Statistics

Use this option to restore the calibrations and accounting values previously backed up onto a USB drive.

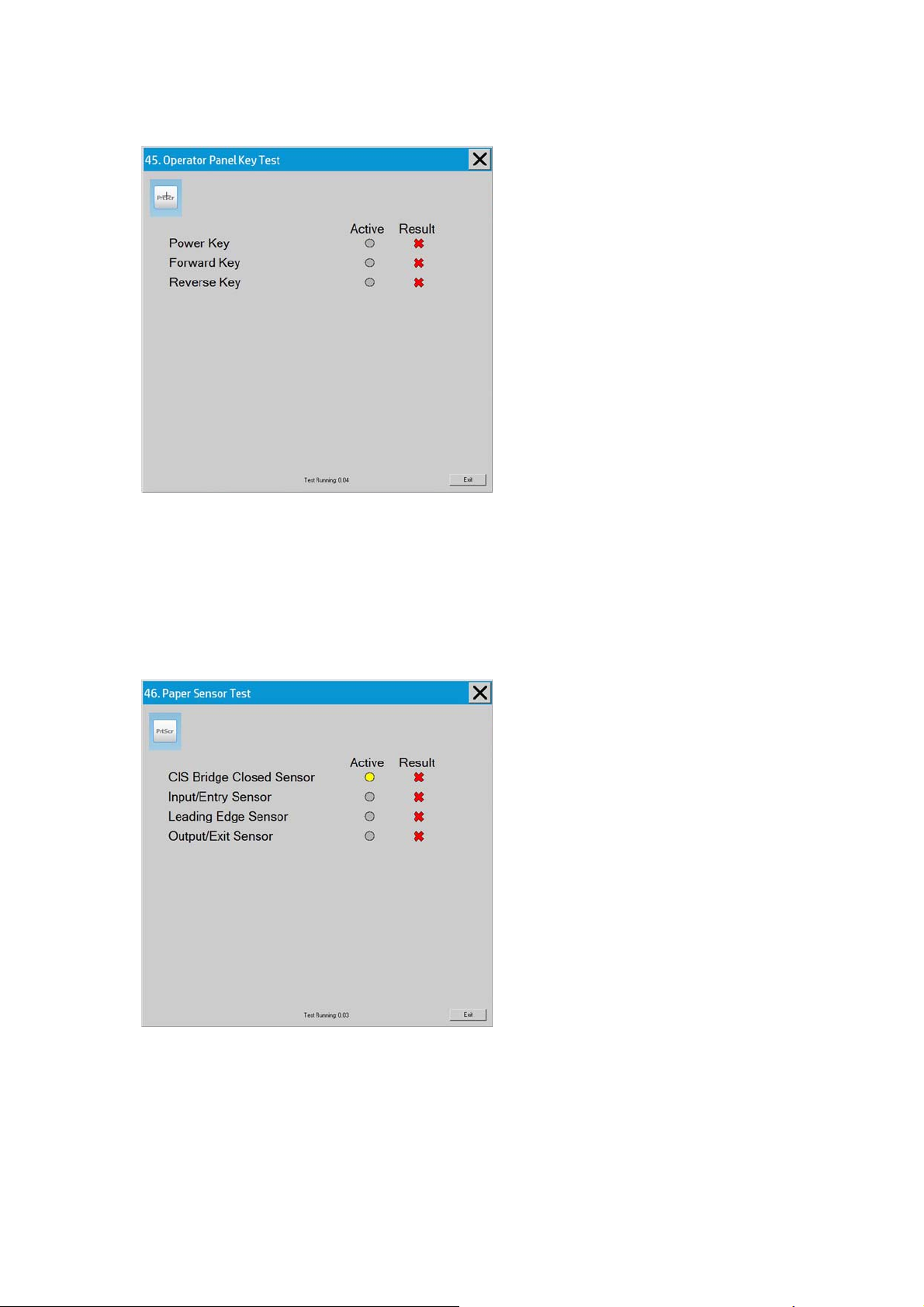

Test 45: Operator Panel Key Test

ENWW Using the Service Tools from the Touchscreen 5

Page 14

This test checks the functionality of the Keys on the Operator Panel. When pressing each of the keys, the test

will show that the key has been activated, and will show if the result is correct or not.

If the Key test fails, replace the Operators Panel which is included in the Right Side Cover.

Test 46: Paper Sensor Test

This test checks the functionality of the Media Sensors.

To test the Media Sensors, use a sheet of media to activate the different sensors one by one. When activated,

the test will show that the sensor has been activated and will show if the result is correct or not.

For testing the CIS Bridge Sensors; open and close the scanner cover.

If the test fails, then the problem will be related to corresponding Sensor.

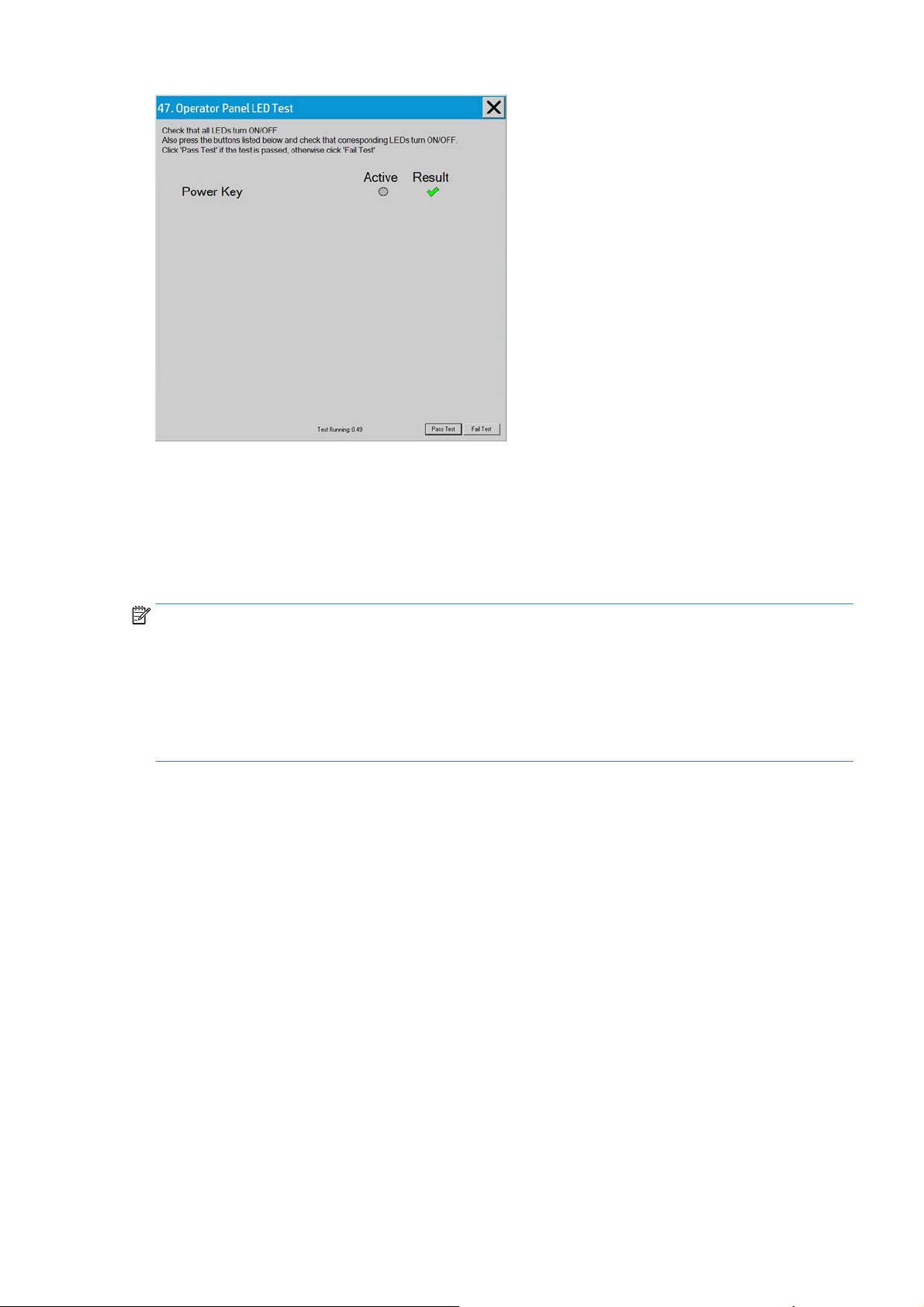

Test 47: Operator panel LED test

This test checks the functionality of the LED Indicators on the Operator Panel. When the test is executed, all

the LEDs are sequentially switched ON/OFF until Test 2 is terminated. If any of the LEDs fail, you will NOT get

an error message, instead the LED will NOT switch ON or OFF. Additionally you are requested to press the

Power button and see if the Power LED is switched ON. If the LED test fails, replace the Replace the Operators

panel which is included in the Right Side cover.

6 Chapter 1 Troubleshooting ENWW

Page 15

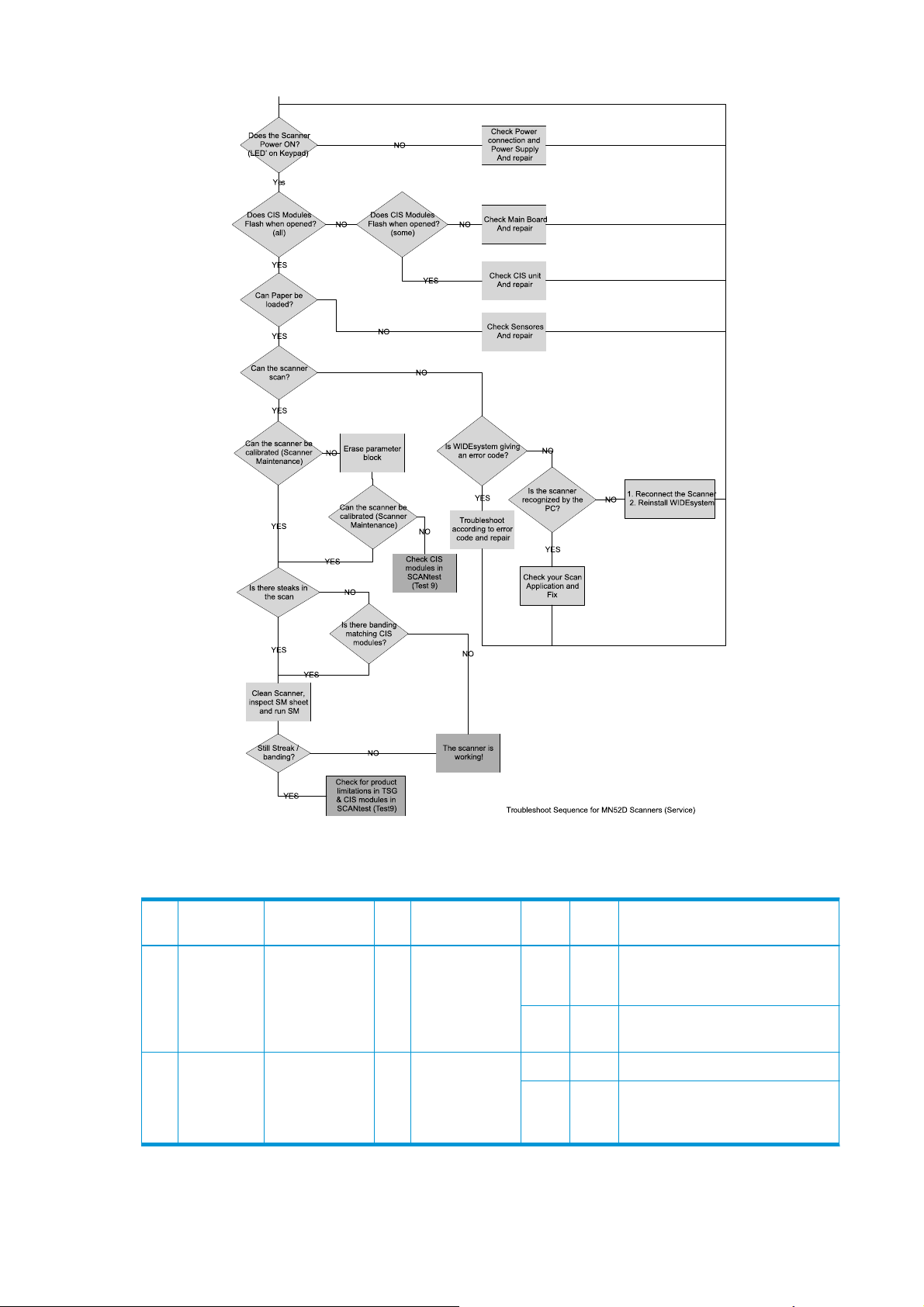

Troubleshooting Issues

The following guide will help you to find a solution to some typical problems that some customers may

experience. The problems (P#) that can be solved remotely through on-phone support and customer

intervention are marked C. The problems that require on-site intervention performed by a Support Technician

are marked T.

NOTE: Before sending a Support Technician to the customer, identify whether the problem is related to the

scanner or the Panel PC (PPC).

If the problem is scanner-related, erase the parameter block and run the scanner maintenance. Then perform

the system recover using the most recent version of the software.

If the problem is PPC-related, perform the system recovery using the most recent version of the software.

If the problem persists, try the solutions listed in the tables below.

ENWW Troubleshooting Issues 7

Page 16

Troubleshooting print-quality and copy issues

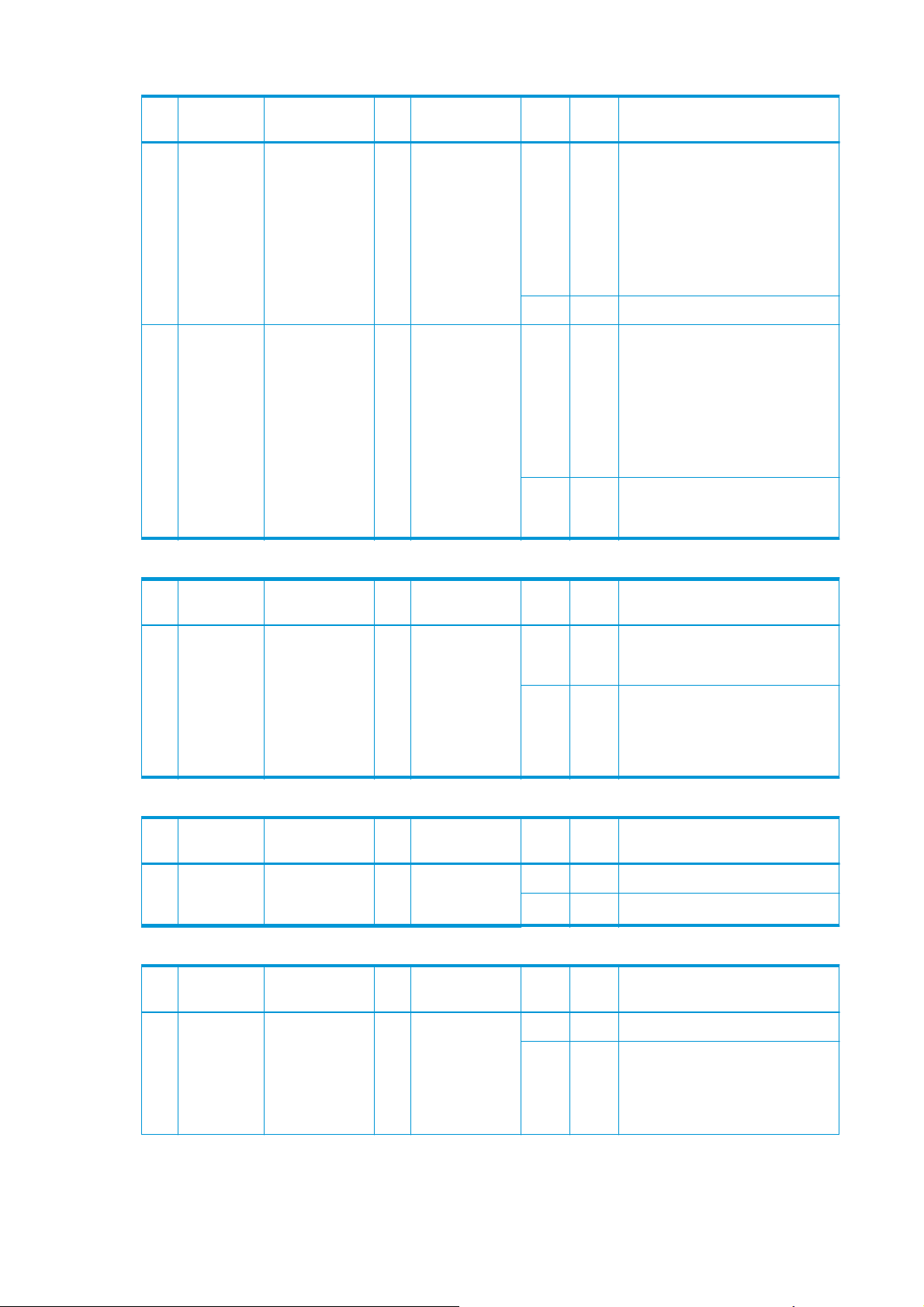

P# Category Problem Q# Question Yes/NoC/T Solution

1 Copy problem The colors on one

side of the copy do

not correspond to

the colors on the

other side of the

copy

2Have you

1 Have you cleaned

and calibrated

your scanner

recently?

upgraded the

system software

to the latest

version?

No C CIS modules differences - The scanner

needs to be cleaned and calibrated (see

P25 and P25).

Yes See Q2

No C Upgrade system software

Yes T CIS unit might need replacement

8 Chapter 1 Troubleshooting ENWW

Page 17

P# Category Problem Q# Question Yes/NoC/T Solution

2 Copy problem I get thin lines of

wrong colors in my

copy

2Are the lines

3Are the lines

4 Do you have a

1Are the lines

vertical and also

present in your

preview?

horizontal and

equally spaced?

horizontal, but

irregular (maybe

only 1 line)?

great number of

regular spaced

lines very close to

each other and

restricted to one

side (1 camera)

only?

Yes C Erase the parameter block. Then clean

and calibrate the scanner (see P25 and

P25).

No See Q2

Yes C Check printheads by starting printhead

test on Printer. By using the built-in test

print function in the Designjet Scan Copy

application, you can also get an idea

whether the Printer is performing OK

No See Q3

Yes C The lines could be caused by a data

error. Upgrade system software

No See Q4

Yes T You might have a CIS element error.

Replace CIS unit

P# Category Problem Q# Question Yes/NoC/T Solution

3 Copy problem I get thick lines of

slightly wrong

colors in my copy

2Are the lines

P# Category Problem Q# Question Yes/NoC/T Solution

4 Copy problem Some colors are

not the same

when I compare

the master print

with the copy

2 Do you use the

1Are the lines

vertical and also

present in your

preview?

horizontal and

equally spaced?

1 Is the scanner

clean and

calibrated?

correct media

profile for the

actual media?

Yes C The scanner needs to be cleaned and

calibrated (see P25 and P25).

No See Q2

Yes C Check printheads by starting printhead

test on Printer. By using the built-in test

print function in the Designjet Scan Copy

application, you can also get an idea

whether the Printer is performing OK

No See P2.

No C See P1. Clean and calibrate the scanner

(see P25 and P25).

Yes See Q2

No C If you are using e.g. Glossy Media for

this copy, the media profile selected

should also be for Glossy Media.

Yes See Q3

3Is the media

profile valid?

No C Create a new media profile (see P26)

Yes See Q4

ENWW Troubleshooting print-quality and copy issues 9

Page 18

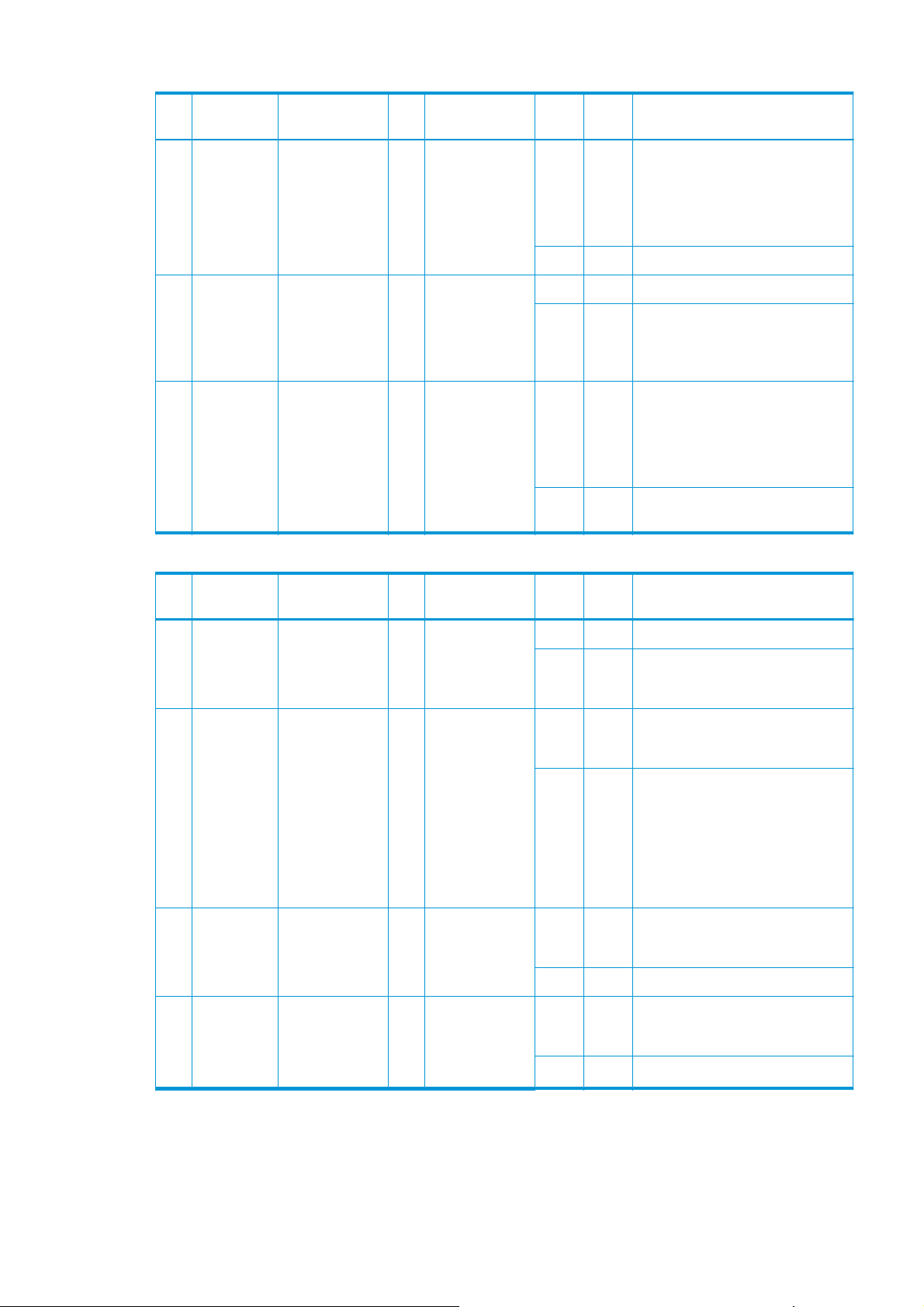

P# Category Problem Q# Question Yes/NoC/T Solution

4 Is the option 'Ink

5Is the media you

P# Category Problem Q# Question Yes/NoC/T Solution

5 Copy problem Only a part of the

master print is

being copied

No See Q3

2 Is the length too

Printer Original'

set in accordance

with your original?

are printing on the

same type as the

original?

1 Have you selected

'Auto size'?

short and the

width OK?

No C If original was printed using an Inkjet

Printer, set this option (see P27)

Yes See Q5

No C e.g. Use Glossy Media to reproduce a

Glossy original

Yes C Create a new media profile (see P26)

Yes C The scanner needs to be cleaned (see

P24)

Yes C The problem may be with the Printer

(not able to print close to the edges) or

Panel PC (Hard Disk is full).

No C Check that the margins that are set are

not too big. Also check Scanner Media

Offsets

P# Category Problem Q# Question Yes/NoC/T Solution

6 Copy problem Which setting will

give me the best

result when

copying?

P# Category Problem Q# Question Yes/NoC/T Solution

7 Copy Problem Nesting feature is

not working

2Is the Hard Disk

- - - C See section about media profile (P4).

1 Is the correct

printer selected?

close to being full?

No C Select the correct Printer

Yes See Q2

Yes C Free up some space, or try to run a

No C Make sure that Nesting is set: Select:

Use copy quality best. Choose the

correct Type of original ("Map" for maps,

"Photo" for photos, etc). Eventually go

to Original Setup to fine adjust colors

and sharpening. (See also online help

for more details - button with "?"

symbol)

nesting job with only 2 or 3 small

pictures. If that works, see P27.

Output Layout Nesting optimized

10 Chapter 1 Troubleshooting ENWW

Page 19

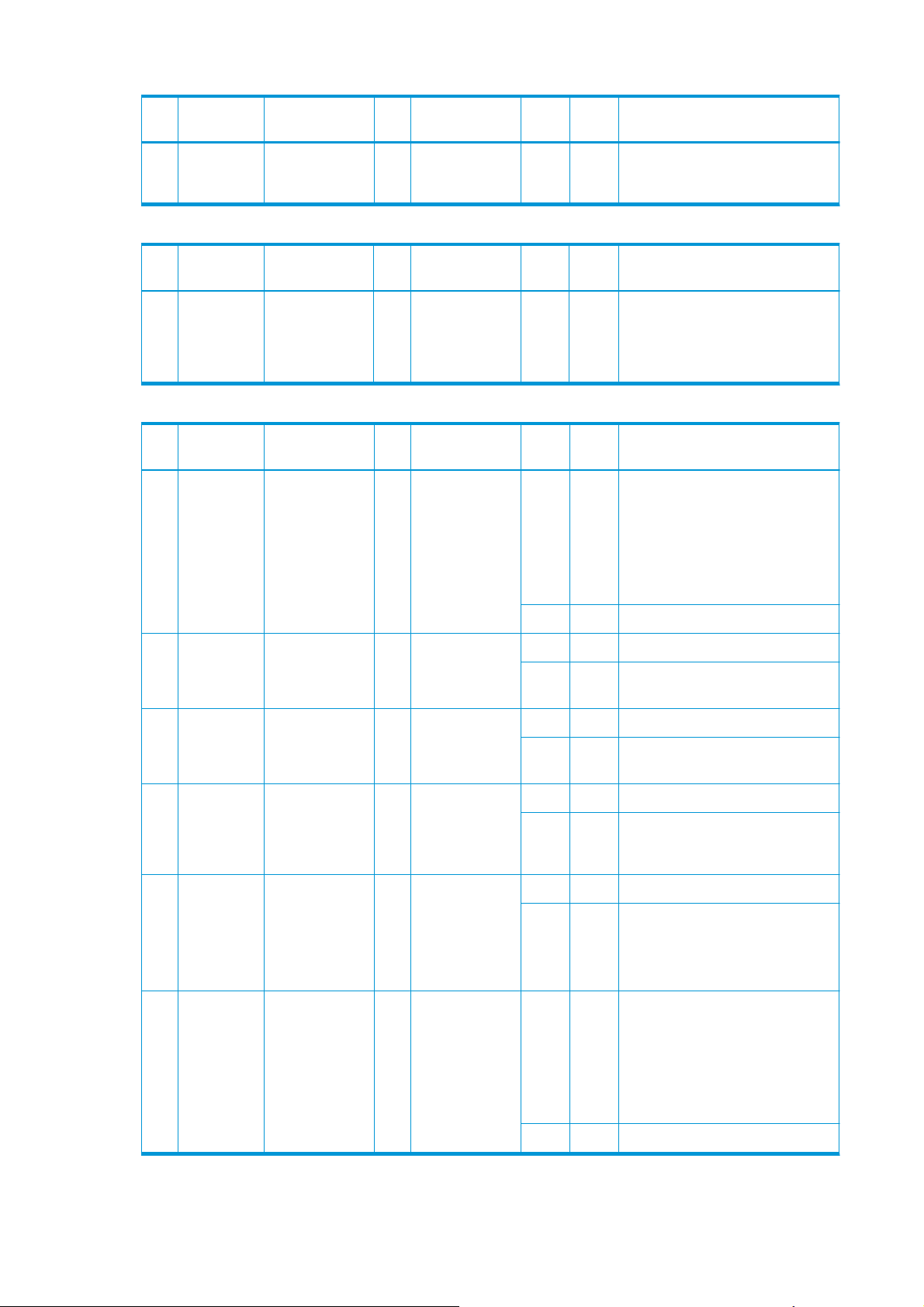

P# Category Problem Q# Question Yes/NoC/T Solution

8 Copy problem The Collate Copy

function does not

work

P# Category Problem Q# Question Yes/NoC/T Solution

9 Copy problem The lines are not

accurate

2Are the lines not

3Are the lines

1Is your Hard Disk

close to full?

1Are the lines wavy

and irregular?

sharp?

broken and the

errors situated in a

vertical column

between 2

columns?

Yes C Free up some space, or try to run a

collate job with a smaller picture.

No C Follow the step by step instructions in

the online help under Collate Copy.

Yes C/T C: The original could be curled or

crumpled. Try to flattten the original (in

case of very irregular waves there could

be a mechanical problem with the

scanner).

T: check motor and belt drive tension

No See Q2

Yes C/T C: Are you using the correct copy

method? Try sharpening.

No See Q3

Yes C You might have a visible stitching error

(see P28).

No C Check the dpi. In the case of too low

resolution, jagged diagonal lines will

appear.

P# Category Problem Q# Question Yes/NoC/T Solution

10 Copy Problem One side of the

preview is black

1Have you

upgraded the

system software

to the latest

version?

No C Upgrade system software.

Yes T Most likely a CIS module error. Replace

Troubleshooting general scanner issues

P# Category Problem Q# Question Yes/NoC/T Solution

12 System Error What should I do

when the program

hangs?

1 Are you running a

copy job?

Yes C Making a copy takes a lot of resources

No Restart the system. If the problem

the CIS unit.

according to the settings. Wait till the

copy is done before performing another

action.

comes back, reinstall the system.

ENWW Troubleshooting general scanner issues 11

Page 20

P# Category Problem Q# Question Yes/NoC/T Solution

13 File problem When I scan to file,

the file is very big

2 Are you scanning

P# Category Problem Q# Question Yes/NoC/T Solution

1 Are you scanning

in color?

in gray tones?

Yes C Scanning large drawings will generate

very big files. An A0 color drawing

scanned at 300 dpi will generate a file

size of approx. three Gigabytes when

scanned in an uncompressed format. In

order to reduce file size, select TIFF pack bits as format. You can reduce size

even more by selecting JPEG format, but

this format will reduce picture quality.

No See Q2

Yes C Scanning large drawings will generate

big files. An A0 gray tone drawing

scanned at 300 dpi will generate a file

size of approx. 300 Mbytes when

scanned in an uncompressed format. In

order to reduce file size, select TIFF pack bits as format. You can reduce size

even more by selecting JPEG format, but

this format will reduce picture quality.

No In order to reduce file size on scanned B/

W drawings, select TIFF group 4

compression.

14 File problem When I scan to file

P# Category Problem Q# Question Yes/NoC/T Solution

15 Network

Problem

P# Category Problem Q# Question Yes/NoC/T Solution

16 Scan to

network

my application

cannot read the

file

I cannot access the

system from the

network

I cannot access

network drivers

1Did you get an

error message

when creating the

file?

1Is the PC

connected to the

network?

1 With the Panel PC

connected to the

LAN, can you

access the Panel

PC from another

computer on the

network?

Yes C Check that you have enough disk space

and scan to file again, choosing TIFF

uncompressed as format

No C We only recommend to use the built-in

viewer for file viewing. Large format

drawing files may not load correctly in

other viewers due to file size. Try to

scan a smaller original (A4).

Yes C Do basic network troubleshooting.

No C Connect the PC to the Network.

Yes C Go to Q2

No C Check the network performance and

connection to the scanner Panel PC.

12 Chapter 1 Troubleshooting ENWW

Page 21

P# Category Problem Q# Question Yes/NoC/T Solution

2 Is the folder of the

server you are

trying to map

already mapped

by another user in

the Panel PC?

3 Do you have

permission to

access and write

to the network

folder you are

trying to map?

4Are you using the

correct user name

and password?

P# Category Problem Q# Question Yes/NoC/T Solution

Yes C Windows does not allow the same

server to be mapped by two different

users on one computer. Use the access

connection previously mapped or delete

the connection and map a new access

connection.

No C Go to Q3

Yes C Go to Q4

No C You cannot access this network folder.

Select a network folder for which you

have read and write permissions.

Yes C Try to map the network file from

another computer by selecting Windows

Explorer, Tools, Map network drive. If

you are able to map the drive in this

manner, you should also be able to map

through the Panel PC.

No C Use the correct user name and

password.

18 Scanner

Calibration

Problem

2 Error: Basic

3 Error: Sheet not

4Have you

Scanner

Calibration did not

succeed

1 Did any error occur

when performing

the Scanner?

calibration was

performed. but

failed to stitch

scanner or Could

not find

horizontal line or

Could not read

bar lines or Could

not recognize the

scanned IT8

picture.

recognized.

upgraded the

system software

to the latest

version?

Yes C See Q2

No C Clean and then run the scanner again

(see P24 and P 25). If that does not help,

see Q5.

Yes C Clean and then run the scanner again

(see P24 and P 25). If that does not help,

see Q5.

No See Q3.

Yes C Reinsert calibration sheet correctly and

run the scanner again. If that does not

help, see Q5.

No See Q4.

No C Upgrade system software. Clean the

scanner and then run Scanner

Maintenance again (see P24 and P 25).

Yes T Check the CIS modules.

ENWW Troubleshooting general scanner issues 13

Page 22

P# Category Problem Q# Question Yes/NoC/T Solution

19 System error I cannot install my

application on the

system.

P# Category Problem Q# Question Yes/NoC/T Solution

20 Updating How do I update

P# Category Problem Q# Question Yes/NoC/T Solution

21 Start-up

Problem

the system?

The system does

not power up

- - - C The copy system is only meant to

handle the factory installed software

and applications.

- - - C Download the new system file from the

1 Is the system dead

(no LEDs are lit,

the Panel PC

screen is black,

and no fan-noise

can be heard)?

Yes C 1. Check that all power switches on

the HP Support web site and copy into a

USB drive. Go to System Options >

Advanced > Update software, and follow

the instructions.

the equipment are ON.

2. Check if there is power at the wall

outlet.

3. Check power cables between wall

outlet and the individual units.

2 Does Panel PC

start with the

normal initial

screen?

3 Does Panel PC

start normally, but

the software does

not work?

4Is the Panel PC

dead (no fan noise

can be heard and

no screen image

appears)?

5 Is the Scanner

dead (no fan noise

can be heard and

no LEDs are lit)?

6 Does the scanner

hangup with all

LEDs lit?

No See Q2.

Yes C See Q5.

No See Q3.

Yes C Reinstall system software

No See Q4

Yes T Troubleshoot the Panel PC.

No See Q5.

No See Q6.

Yes T Check, and if necessary replace:

1. Power Supply Unit

2. Scanner controller board

Yes T Try the following:

1. Erase parameter block

2. Update the system software

3. Replace the Scanner controller

Board

No See P23.

14 Chapter 1 Troubleshooting ENWW

Page 23

P# Category Problem Q# Question Yes/NoC/T Solution

22 Mechanical

Problem

2 Can paper be

3 Does the Ready

P# Category Problem Q# Question Yes/NoC/T Solution

I cannot load the

original

1 Please try to load

a new piece of A4

paper at the

center of the

scanner. Does this

paper load?

loaded by pressing

the "Forward" key?

LED turn ON when

activating Original

Sensor (insert

paper)?

Yes C You have a problem with your original.

Please check that paper edges are not

bent or curled in any way.

No See Q2.

Yes C See Q3.

No T Try replacing the following:

1. Power Supply Unit

2. Feed motor (Stepper motor)

3. Scanner Controller Board

No T Check, and if necessary replace:

1. Paper/lid sensors

2. Scanner Controller Board

Yes C Check the settings in the software for

media loading.

23 Error code I get an Error

Code, what do I

do?

1Have you

P# Category Problem Q# Question Yes/NoC/T Solution

23a Error Code I still get an error

code, what do I

do?

"No scanner

found"

- - - - Re-power the system, and check if the

upgraded the

system software

to the latest

version?

Does the

Diagnostic LED

(and, in some

cases also other

LEDs) blink?

1 Does the scanner

start normally?

2 Are the interface

cables (Ethernet)

properly

connected to the

scanner and the

Panel PC?

No C Upgrade the system software. Check if

Yes C Lower Guide Plate to Normal position,

No C See P23.

Yes C See Q2.

Yes C See Q3.

error code reappears. If it does, see Q1.

Error Codes reappears. If it does, see

system errors list in chapter 2.

start Preview Scan to obtain an Error

Code or check if WIDEsystem gives an

Error Code. If it does, see system errors

list in chapter 2.

3Have you

upgraded your

system software?

Yes T 1. Replace network cable

2. Replace Scanner Controller Board

ENWW Troubleshooting general scanner issues 15

Page 24

P# Category Problem Q# Question Yes/NoC/T Solution

24 Cleaning How do I clean the

scanner?

P# Category Problem Q# Question Yes/NoC/T Solution

25 Color

Calibration

P# Category Problem Q# Question Yes/NoC/T Solution

26 Media

Validation

How do I color

calibrate the

scanner?

What is media

validation? How

do I validate?

- - - C Clean the Glass Plate on both sides with

mild detergent, and wipe thoroughly

with a lint-free cloth until dry. Check for

scratches. Deep scratches on the glass

plate or pressure rollers means

replacement of the part.

1 Do you have the

correct and "as

new" scanner

maintenance

sheet for the

scanner?

—— - C If the validate feature is chosen, a new

Yes C Clean scanner (see P24). Insert the

scanner maintenance sheet. Start

scanner calibration. The process is

automatic and will also include

stitching.

No C Get Correct/New Scanner Maintenance

Sheet.

color patch sheet is printed and can be

scanned for validation. In this way it can

be determined whether the produced

color map has passed.

P# Category Problem Q# Question Yes/NoC/T Solution

27 Ink Printer

Original

P# Category Problem Q# Question Yes/NoC/T Solution

28 Visible

stitching

Errors

What is Ink Printer

Original?

What is a visible

stitching error?

- — - C When the original has been printed on

an Inkjet printer this option should be

enabled.

- - - C A visible stitching error appears

typically as a column of broken lines

between 2 CIS modules. Normally it can

be solved by running Scanner

Calibration, which will perform an

automatic stitching adjustment. With

some curled or creased/crumpled

originals it is necessary to straighten

out the original to prevent it from lifting

from the glass plate.

16 Chapter 1 Troubleshooting ENWW

Page 25

Troubleshooting Specific Scanner Issues

P# Category Problem Q# Question Yes/NoC/T Solution

29 Vertical lines

(possible dust

problem)

P# Category Problem Q# Question Yes/NoC/T Solution

30 Firmware You are receiving

P# Category Problem Q# Question Yes/NoC/T Solution

31 Stepper

Motor

The image has a

vertical, white or

black line, which

could be caused by

dust. To verify

that the line is

caused by dust,

preview the image

and inspect the

preview using the

viewing section

buttons.

firmware-related

errors.

The Stepper Motor

does not work.

- - - C Perform Scanner Maintenance: Cleaning

and Scanner Calibration. Using Test 20

from Service Tools may help to identify

dusty/ dirty areas.

- - - C Try upgrading the System Software.

- - - C Try the following:

1. Use Test 6: Motor Test to check

the functionality of the Stepper

Motor.

2. Replace the Stepper Motor.

3. Replace the scanner controller

board.

P# Category Problem Q# Question Yes/NoC/T Solution

32 CIS unit The CIS modules

do not work

1Are some CIS

modules working

when opening the

scanner cover?

Yes - Replace CIS unit.

No - If none of the CIS modules work when

opening the scanner cover, replace

scanner controller board.

ENWW Troubleshooting Specific Scanner Issues 17

Page 26

P# Category Problem Q# Question Yes/NoC/T Solution

33 Skewing There is a skewing

problem

P# Category Problem Q# Question Yes/NoC/T Solution

34 Media

Loading

The media cannot

be loaded or there

are other media

loading problems.

- - - C Try the following:

1. Ensure that the Scanner Cover is

closed and latched.

2. Clean the rollers with isopropyl

alcohol.

3. Check the rollers.

4. Replace the CIS unit.

- - - C Try the following:

1. Check the Original Sensor (green

LED when loading media), or use

Test 46: Paper Sensor Test to

check the functionality of the

sensor.

2. Use Test 6: Motor Test to check

the functionality of the Stepper

Motor.

P# Category Problem Q# Question Yes/NoC/T Solution

36 Software You are

experiencing

problems with the

software

- - - C Try the following:

1. Reload the software.

2. After reloading the software, set-

up the system on the network

again (if necessary).

3. If the problems persist, reinstall

the software, and delete the user’s

files (press F12).

18 Chapter 1 Troubleshooting ENWW

Page 27

P# Category Problem Q# Question Yes/NoC/T Solution

37 Firmware All of the LEDs in

the scanner’s front

panel are flashing

when you turn on

the scanner (as

shown in the

image below),

indicating that

printer firmware

needs to be

upgraded.

NOTE: This

describes a

different situation

than when the

scanner is turned

on in special boot

mode, in which the

LEDs also flash.

- - - The most probable reason for this

Most common Image Quality issues

Banding Problems

Bad/no gray balance calibration (CIS module to module match).

situation is that the last system

software upgrade attempt was not

successful. To remedy this situation,

upgrade the system software.

Image Quality Problems

Scanning originals on a CIS scanner, that then have folds or are crumpled, is often perceived as a scanner

defect. In reality the defect is a technology limitation due to the original's very short distance from sensor to

surface, also called “Focal Length”. We also have a very short “Focus Depth”, meaning, if the original is NOT

in contact with the glass plate, it is very likely to be out of focus.

Dust Problems

There are image quality problems that are not related to hardware errors. These could be due to either

insufficient cleaning, bad calibration, or limitations in the CIS technology.

Streaks running in the scan direction which seem to appear and disappear during the scan are most likely

caused by dust. Clean the scanner and the original. The streaks are often a darker shade of color.

Streaks that run in the scan direction, that are color dependent or a lighter shade, are often calibration

related. Dust that was present in the scanner during calibration, but has been cleaned away since.

ENWW Most common Image Quality issues 19

Page 28

Stitching Problems

Other issues could be that the scanner simply needs to be calibrated, either because the parameter block has

been erased, never been calibrated, or that the scanner has been moved.

Cleaning the Scanning Area

The following parts must be cleaned using a soft lint-free cloth and a mild, streak-free, cleaning detergent.

Alternatively, the parts may be cleaned without the use of cleaning detergents by using a damp micro-fibre

cleaning cloth (soak the cloth with water and wring until damp):

●

Main scanner cover. Clean the main scanner cover to ensure that no dust is introduced into the scanning

area when you scan an original.

●

White pressure rollers

●

The Glass Plate. Do not recommend that customers clean the underside of the glass plate; it should only

be cleaned by an HP support technician.

●

The Feed Rollers. These may be cleaned with a damp micro-fibre cleaning cloth.

Once all these procedures have been completed, the scanner will be ready to work correctly.

The Cleaning Procedure

When cleaning any part of the scanning area DO NOT use abrasives, acetone, benzene or fluids that contain

these chemicals. Do not spray liquids directly onto the scanner glass plate or anywhere else in the scanner.

1. Turn the scanner power off.

2. Disconnect the scanner power cable.

20 Chapter 1 Troubleshooting ENWW

Page 29

3. Open the Guide Plate by pushing the left and right locking levers inwards, and flipping upwards to

expose the scan area.

4. Gently wipe the Glass Plate. Clean the glass with a lint-free cloth and a mild, streak-free, glass cleaner.

5. Dry the glass completely using a separate clean, dry lint-free cloth like the one provided with the

maintenance kit.

6. Clean the white pressure rollers. Wipe the white metal area with a lint-free cloth and a mild, streak-free,

glass cleaner.

ENWW Cleaning the Scanning Area 21

Page 30

7. Clean the platen rollers. Wipe the rollers with a lint-free cloth and a mild, streak-free, glass cleaner.

8. Dry the platen and rollers completely using a separate clean, dry lint-free cloth.

9. Close the Guide Plate.

10. Use the dust sheet to protect the Scanner when not in use.

CAUTION: Ensure that the scanner is turned off before covering it with the dust sheet. The scanner

will overheat if covered while turned on.

Troubleshooting Specific Panel PC Problems

●

Power failure

22 Chapter 1 Troubleshooting ENWW

Page 31

●

Boot up fails

●

LCD fails

●

No backlight and no display

●

With backlight but no display

●

The HDD fails

●

DDR DRAM fails

The following section is related to the PanelPC and it’s related components.

Power failure

If the power has been turned on, and there is no message on the screen, try the following:

●

Make sure the power cord is correctly connected.

●

Plug the power cord to another power outlet.

●

The system fan should start up if there is power in the PanelPC. If not, replace the External Power

Supply.

Boot up fails

LCD fails

The PanelPC issues a series of beeps which can be used to identify which part is failing.

●

One short beep: No error during POST (Power on Self-Test).

●

One long beep followed by two short beeps: Video initial error.

●

One long beep followed by nine short beeps: BIOS Bootblock error.

●

Single long beep repeatedly: DRAM error.

The failure of the LCD display can be divided into two issuses, the PanelPC has no backlight and no display, or

the Panel PC has the backlight but there is no display. Use the two troubleshooting flow charts to solve the

problem:

ENWW Troubleshooting Specific Panel PC Problems 23

Page 32

No backlight and no display

With backlight but no display

The HDD fails

The HDD is running, and the system configuration has identified the HDD’s ID while booting up. Try the

following:

24 Chapter 1 Troubleshooting ENWW

Page 33

●

Set the type of hard disk to AUTO in STANDARD CMOS SETUP.

●

Reconnect the cable between HDD and main board.

●

Change the HDD.

The HDD is not running, and the system configuration can not identify the HDD’s ID while booting up. Try the

following:

●

Reconnect the cable between HDD and main board.

●

Change the cable between HDD and main board.

●

Change the HDD.

DDR DRAM fails

If the computer repeatedly makes a long beep, and the display is blank when you power on, this indicates a

DDR DRAM error, replace the DDR DRAM.

ENWW Troubleshooting Specific Panel PC Problems 25

Page 34

Touch screen fails

Follow the steps in the flowchart below to quickly check if the touch screen fails:

Touch screen is working but can’t control the cursor

Try the following:

●

Run the calibration program.

●

Check that the cable between the LCD controller and the LCD is connected in the correct position.

●

Replace the LCD controller.

●

Replace the LCD.

Upgrade Scanner Software

Upgrade the HD Pro Scanner system software

System software on the web is divided in 5 packages to facilitate the download:

1. Download all 5 files (1 to 5) from

them to the same folder on your computer.

2. Extract part1; all of the parts extract one after the other to the selected folder.

3. After, the full System SW is located in the folder previously selected. The file size should be 3.32GB and

the extension is ".sif".

http://www.hp.com/go/designjethdproscanner/software. Save all of

4. Copy the System SW to a standard USB flash drive, formatted as FAT32,

26 Chapter 1 Troubleshooting ENWW

Page 35

5. Insert the USB drive into the PPC USB port.

6. Start the software update process as shown below:

ENWW Upgrade Scanner Software 27

Page 36

2 System Error Codes

●

System Error Codes for the Scanner Only on page 29

●

Error Codes for the JetImage Software RIP on page 36

●

Error Messages for the Touch Screen on page 40

28 Chapter 2 System Error Codes ENWW

Page 37

System Error Codes for the Scanner Only

Introduction

The following pages contain a list of system error codes and their respective descriptions and recommended

corrective actions. Only try one recommended action at a time and check if the error code has disappeared.

If you have an error code which is not documented in this Service Manual or you have an error which you

cannot resolve, then report the error to the HP Response Center or the nearest HP Support Office. When

reporting the error, have the following information ready:

●

Model and Serial Number of the scanner.

●

Which firmware revision the printer and the scanner is using.

●

SW version.

●

The complete error number.

●

ScanDump of Light Profiles.

Error Codes displayed on the Keypad

An error condition is indicated by a flashing Diagnostic Indicator. The error may be identified by an Error Code

Number being displayed on the screen and/or by the following combinations of flashing (F) indicators on the

Operator Panel: See

codes that follow after for details.

Flash Code Diagnostic Paper

BOOT F F

ERR_GENERAL F OFF

ERR_SU F F

ERR_CB F 2 X F

ERR_SMC F 5 X F

1 X F, 2 X F, means that the Paper Indicator flashes 1, 2, times every time the Diacnostic Indicator is turned

on. F, F, means that both indicators are flashing simultaneously.

The Software Modules

The first set of numbers in the error code refer to a part of the Scanner software or the Scanner.

The Software Modules on page 29 for an overview, and the lists of individual error

ENWW System Error Codes for the Scanner Only 29

Page 38

Software Modules Comments/Notes

51 - Scanner API Low level scanner control library. All scanner communication goes

52 - Image Format Library Printer and file formatting. All printing and file read/write is formatted/

53 - Copy Engine The central processing engine in the (JETimage) software.

54 - Closed Loop Calibration Color Management math library that calculates the media profiles.

55 - Test Software Scanner Maintenance / SCANtest.

56 - Jetimage container All user interface and business logic except for Scanner Maintenance /

57 - WIDEsystem (WS) Scanner surveillance utility

100 - Scanner Mechanical part of the Scanner.

Software Related Errors

System Error: 100-00119

Description:

Invalid SCSI command.

though this API.

decoded by this library.

SCANtest and WIDEsystem.

Corrective Action:

1. PC (cable, PC hardware/software etc.)

2. Update system software

System Error: 100-00120

Description:

Invalid value in SCSI CDB.

Corrective Action:

1. PC (cable, PC hardware/software etc.)

2. Update system software

System Error: 100-00121

Description:

Invalid SCSI parameter list length.

Corrective Action:

1. PC (cable, PC hardware/software etc.)

2. Update system software

System Error: 100-00123

Description:

30 Chapter 2 System Error Codes ENWW

Page 39

Unsupported SCSI parameter.

Corrective Action:

1. PC (cable, PC hardware/software etc.)

2. Update system software

System Error: 100-00124

Description:

Invalid SCSI parameter value.

Corrective Action:

1. PC (cable, PC hardware/software etc.)

2. Update system software

System Error: 100-00125

Description:

Incorrect scanner status. Please check the paper path and reload the media.

Corrective Action:

1. PC (cable, PC hardware/software etc.)

2. Update system software

System Error: 100-00126

Description:

SCSI time-out.

Corrective Action:

1. PC (cable, PC hardware/software etc.)

2. Update system software

System Error: 100-00127

Description:

The scanner keyboard was used during communication with the scanner.

Corrective Action:

▲

User interaction

System Error: 100-00128

Description:

The scanner has paper jam. Please reload the media.

ENWW Software Related Errors 31

Page 40

Corrective Action:

1. User interaction

2. Related mechanical parts

3. Lamp and Motor driver board

4. Switch Mode Power Supply

5. Main controller board

System Error: 100-00129

Description:

The scanner does not support this test command in normal mode. Please restart test program.

Corrective Action:

▲

User interaction

System Error: 100-00131

Description:

The scanner is initializing. Please retry the operation when the scanner has finished initializing.

Corrective Action:

▲

User interaction

System Error: 100-00132

Description:

The scanner is warming up. Please retry the operation when the scanner has finished warming up.

Corrective Action:

▲

User interaction

System Error: 100-50122

Description:

Pop request failed, position unknown.

Corrective Action:

1. PC (cable, PC hardware/software etc.)

2. Update system software

System Error: 100-50123

Description:

Pop request failed, invalid command.

32 Chapter 2 System Error Codes ENWW

Page 41

Corrective Action:

1. PC (cable, PC hardware/software etc.)

2. Update system software

System Error: 100-50218

Description:

Data never arrives in the Image.

Corrective Action:

▲

Update system software

System Error: 100-50231

Description:

System software download is in progress.

Corrective Action:

▲

Update system software

System Error: 100-50232

Description:

System software is incomplete. Please download new system software.

Corrective Action:

▲

User interaction

System Error: 100-50234

Description:

Scanner is in safe mode. Please reboot scanner or download new system software.

Corrective Action:

1. User interaction

2. Main controller board

System Error: 100-50237

Description:

Host PC does not support SSE2 calculations.

Corrective Action:

▲

User interaction

System Error: 100-50259

Description:

System software unable to identify controller board id.

ENWW Software Related Errors 33

Page 42

Corrective Action:

▲

Main controller board

System Error: 100-50260

Description:

System software unable to identify controller board variant.

Corrective Action:

▲

Main controller board

System Error: 100-50268

Description:

ETH PHY loopback error.

Corrective Action:

▲

Main controller board

System Error: 100-50269

Description:

Flash error.

Corrective Action:

▲

Main controller board

System Error: 100-50270

Description:

RAM error.

Corrective Action:

▲

Main controller board

System Error: 100-50271

Description:

Scanner has no MAC address.

Corrective Action:

▲

Main controller board

System Error: 100-50600

Description:

Main controller board error.

34 Chapter 2 System Error Codes ENWW

Page 43

Corrective Action:

1. Main controller board

2. Switch Mode Power Supply

System Error: 100-50601

Description:

CIS unit error.

Corrective Action:

1. CIS Unit

2. Main controller board

System Error: 100-50602

Description:

System software error. Please download latest system software.

Corrective Action:

1. Update system software

2. Main controller board

System Error: 100-50603

Description:

Unrecoverable scanner state. Please reboot the scanner. Download of the latest system software and PC

application/driver may be required.

Corrective Action:

1. Reboot scanner

2. Update system software

3. PC driver/software

ENWW Software Related Errors 35

Page 44

Error Codes for the JetImage Software RIP

-13 Unable to rename the folder.

Cause Solution

Unable to rename the folder. Occurs during file browsing operations, usually due to a share

-12 Unable to delete the folder.

Cause Solution

Unable to delete the folder (occurs during file browsing

operations, typically if a folder is shared).

-11 The folder must be empty.

Cause Solution

The folder must be empty (occurs during file browsing

operations).

-2 No media profile selected for current printer.

Cause Solution

No media profile selected for current printer. Prepare a Media Profile before performing the operation.

issue.

Close all the applications and try again.

Check that the folder is empty before deleting it.

-1 No printer selected.

Cause Solution

No printer selected. Select a printer. A printer must be configured in the application

02 Invalid scan coordinates. The paper frame was placed fully outside the scan image.

Cause Solution

Invalid scan coordinates. The paper frame was placed fully

outside the scan image.

06 Not enough disk space for spool file.

Cause Solution

Not enough disk space for spool file. Make sure that the environment TEMP (or secondary TMP) points

before trying to print.

Try repositioning the paper frame so that it covers some of the

scannable area.

to a folder with plenty of space.

36 Chapter 2 System Error Codes ENWW

Page 45

08 The scanner is currently on standby. Please press the soft power button on the scanner to activate it.

Cause Solution

The scanner is currently on standby. Press the soft Power button on the scanner to activate it.

00003 Scanning invalid size of area requested for scanning.

Cause Solution

Negative scan-width specified. Reselect the scan area and try again.

01003 Error printing colorsheet.

Cause Solution

Error printing colorsheet. Try the following:

●

Check the printer to make sure it is switched ON and

connected to the scanner.

●

Try printing a test print to make sure that the printer is

working.

01013 Error detecting index-mark.

Cause Solution

Skew: Error detecting the index mark. Try the following:

●

Try restarting the system.

●

If the problem persists, view the scandump.tif file for

further diagnosis.

01014 Sheet bad aligned.

Cause Solution

Sheet badly aligned. Try the following:

●

Reinsert the sheet, making sure that it is straight and at the

right position.

●

If the problem persists, view the scandump.tif file for

further diagnosis.

01015 Error detecting left margin.

Cause Solution

Error detecting the left margin of the sheet. Try the following:

●

Try reinserting the sheet.

●

If the problem persists, view the scandump.tif file for

further diagnosis.

ENWW Error Codes for the JetImage Software RIP 37

Page 46

01016 Error detecting right margin.

Cause Solution

Error detecting the right margin of the sheet. Try the following:

●

Try reinserting the sheet.

●

If the problem persists, view the scandump.tif file for

further diagnosis.

01017 Error reading colorsheet.

Cause Solution

Error reading the colorsheet. The end of the sheet is reached

before expected.

01018 CLC aborted.

Cause Solution

The Close Loop Calibration (CLC) has been aborted. The user has cancelled the color map operation.

01019 Wrong insert position.

Cause Solution

The sheet has been inserted in the wrong position. Try the following:

01020 Can’t find top of sheet.

Check that the correct colorsheet is being used.

●

Reinsert the sheet, making sure that it is at the right

position.

●

If the problem persists, view the scandump.tif file for

further diagnosis.

Cause Solution

The top of the sheet couldn’t be found. Reinsert the sheet, making sure that it is at the right position.

01021 Can’t find bottom of sheet.

Cause Solution

The bottom of the sheet couldn’t be found. Reinsert the sheet, making sure that it is at the right position.

02004 Unable to open device for reading.

Cause Solution

Unable to open the device for reading. Check that the device (file) is available.

38 Chapter 2 System Error Codes ENWW

Page 47

02005 Unable to open device for writing.

Cause Solution

Unable to open the device for writing. Check that the device (file or printer) is available.

02006 Unable to read from device.

Cause Solution

Unable to read from the device. Try the operation again.

02007 Unable to write to device.

Cause Solution

Unable to write to the device. Try the operation again.

02013 Destination already exists.

Cause Solution

Destination already exists. Try the operation again with a different file name.

03008 Device not available.

Cause Solution

Scanner not found. Try the following:

●

Check that the scanner is turned ON.

●

Check the connection to the scanner.

13496 The scanner is initializing or warming up.

Cause Solution

The scanner is initializing. This happens if you try to scan too quickly after powering ON the

17977 Media is present in scanner, but command was aborted by user.

Cause Solution

User interfered with the scanner. Try the operation again.

scanner. Wait a short while and then try scanning again.

17980 Paper jam.

Cause Solution

Paper jam. Check rollers and mechanical paper detectors for any paper jam.

Once paper jam is cleared, try the operation again.

ENWW Error Codes for the JetImage Software RIP 39

Page 48

Error Messages for the Touch Screen

BIOS ROM checksum error - system halted.

Cause Solution

Error during initialization. Reboot the system and enter the BIOS setting. Load Setup

CMOS battery failed.

Cause Solution

The battery life is approximately three years before it requires

replacement.

CMOS checksum error - defaults loaded.

Cause Solution

Error detected in the CMOS. Reboot the system and enter the BIOS setting. Load Setup

Display switch is set incorrectly

Cause Solution

Problem found with the Touch Screen. Connect the Touch Screen to a CRT Monitor and check the

Default and save the BIOS setting.

Replace the CMOS Battery.

Default and save the BIOS setting.

resolution setting for the display. If the CRT Monitor is working

well then it seems there is an LCD problem.

Hard Disk install failure.

Cause Solution

No Hard Disk detected, error related to Hard Disk Drive. Try the following:

●

In the BIOS setup select Standard CMOS Features and check

if the IDE/SATA detection method is set to AUTO (password

to access the BIOS is bigcoco)?

◦

If Yes: In Advanced BIOS features, set HDD to first boot

device.

◦

If No: Choose auto for all IDE/SATA detection.

●

Check if HDD can be detected in the boot-up system

configuration table:

◦

If Yes: check the boot up files in HDD, recover it if

necessary.

◦

If No: replace HDD.

40 Chapter 2 System Error Codes ENWW

Page 49

Primary master hard disk fail.

Cause Solution

No Hard Disk detected, error related to Hard Disk Drive. Try the following:

●

In the BIOS setup select Standard CMOS Features and check

if the IDE/SATA detection method is set to AUTO (password

to access the BIOS is bigcoco)?

◦

If Yes: In Advanced BIOS features, set HDD to first boot

device.

◦

If No: Choose auto for all IDE/SATA detection.

●

Check if HDD can be detected in the boot-up system

configuration table:

◦

If Yes: check the boot up files in HDD, recover it if

necessary.

◦

If No: replace HDD.

Secondary master hard disk fail.

Cause Solution

No Hard Disk detected, error related to Hard Disk Drive. Try the following:

●

In the BIOS setup select Standard CMOS Features and check

if the IDE/SATA detection method is set to AUTO (password

to access the BIOS is bigcoco)?

◦

If Yes: In Advanced BIOS features, set HDD to first boot

device.

◦

If No: Choose auto for all IDE/SATA detection.

●

Check if HDD can be detected in the boot-up system

configuration table:

◦

If Yes: check the boot up files in HDD, recover it if

necessary.

◦

If No: replace HDD.

Primary slave hard disk fail.

Cause Solution

No Hard Disk detected, error related to Hard Disk Drive. Try the following:

●

In the BIOS setup select Standard CMOS Features and check

if the IDE/SATA detection method is set to AUTO (password

to access the BIOS is bigcoco)?

◦

If Yes: In Advanced BIOS features, set HDD to first boot

device.

◦

If No: Choose auto for all IDE/SATA detection.

●

Check if HDD can be detected in the boot-up system

configuration table:

ENWW Error Messages for the Touch Screen 41

Page 50

Primary slave hard disk fail.

Cause Solution

◦

If Yes: check the boot up files in HDD, recover it if

necessary.

◦

If No: replace HDD.

Secondary slave hard disk fail.

Cause Solution

No Hard Disk detected, error related to Hard Disk Drive. Try the following:

●

In the BIOS setup select Standard CMOS Features and check

if the IDE/SATA detection method is set to AUTO (password

to access the BIOS is bigcoco)?

◦

If Yes: In Advanced BIOS features, set HDD to first boot

device.

◦

If No: Choose auto for all IDE/SATA detection.

●

Check if HDD can be detected in the boot-up system

configuration table:

◦

If Yes: check the boot up files in HDD, recover it if

necessary.

◦

If No: replace HDD.

Memory test fail.

Cause Solution

Memory test has failed. Try the following:

●

Re-install the SDRAM and check if the problem is solved:

◦

If Yes: There was a poor connection between the Main

Board and the SDRAM Memory Module.

◦

If No: Replace the SDRAM Memory Module.

42 Chapter 2 System Error Codes ENWW

Page 51

3 Parts and Diagrams

●

Scanner on page 44

●

Panel PC on page 45

ENWW 43

Page 52

Scanner

Number in photo Description HP Part Number

1-01 Left Side Cover G6H50-67009

1-02 Glass Plate CM719-60013

1-03 Paper/LID Sensor G6H51-67016

1-04 Pressure Rollers (6 pcs) G6H50-67008

1-05 Right Side Cover including operators panel G6H50-67013

2-01 Controller Board G6H50-67004

2-02 CIS Unit 44" except controller board G6H50-67005

3-01 Power Supply G6H50-67003

3-02 Optointerrupter (Tacho sensor, ATAC sensors) G6H51-67015

3-03 Stepper Motor Assembly G6H51-67010

3-04 Power Entry Module with EMI Filter G6H50-67006

3-05 Cable Interface G6H50-67012

3-06 Spring for CIS bridge G6H50-67011

N/A Paper guide (2 pcs) G6H50-67014

N/A Return Guide G6H50-67015

N/A Calibration Sheet G6H50-67002

N/A Castors G6H51-67026

N/A Europe Power Cord SV KIT CQ533-60001

N/A America Power Cord SV KIT CQ533-60002

N/A Asia Power Cord SV KIT CQ533-60003

44 Chapter 3 Parts and Diagrams ENWW

Page 53

Panel PC

HP Part Number Description Image

G6H51-67035 PPC Cable Harness

G6H51-67035 PPC Cable Harness

G6H51-67035 PPC Cable Harness

G6H51-67035 PPC Cable Harness

G6H51-67035 PPC Cable Harness

G6H51-67035 PPC Cable Harness

G6H51-67035 PPC Cable Harness

G6H51-67035 PPC Cable Harness

G6H51-67035 PPC Cable Harness

G6H51-67042 PPC External PSU

G6H51-67046 PPC Front Bezel Module

G6H51-67051 PPC Panel Module

G6H51-67048 Rear Cover

ENWW Panel PC 45

Page 54

G6H51-67047 PPC Motherboard cover

G6H51-67044 PPC Touch Screen Controller

G6H51-67049 PPC LED light board

G6H51-67041 PC Main Board

G6H51-67039 PPC HDD

G6H51-67043 PPC SDRAM

G6H51-67045 PPC Cooler module

46 Chapter 3 Parts and Diagrams ENWW

Page 55

4 Removal and Installation

●

Introduction

●

Safety Precautions

●

Electrostatic Discharge (ESD) Precautions

●

Required Tools

●

Open the CIS Unit

●

Scanner Controller Board

●

Right Side Cover

●

Power Supply

●

Left Side Cover

●

Stepper Motor Assembly

●

Tacho Sensor

●

Paper and Lid Sensors

●

Complete CIS Unit

●

Power Entry Module

●

Cable Interface

●

Spring for CIS Bridge

●

Pressure Rollers

ENWW 47

Page 56

Introduction

This chapter is a step-by-step guide to the removal and installation of the key components in the product.

You may find it useful to tick off the steps as they are performed. Use the illustration at each procedure to

identify the parts referred to in the text.

The procedures appear in order of removal. So the whole product can be stripped down by starting at the

beginning of this chapter and working through the subsequent procedures.

Safety Precautions

Review WARNING and CAUTION instructions before you service the product. Follow these warnings and

cautions for your protection and to avoid damaging the product.

NOTE: Serious shock hazard leading to death or injury may result if you do not take the following

precautions:

Ensure that the AC power outlet (mains) has a protective earth (ground) terminal.

Switch off the printer, the scanner, and the PC, and then disconnect them from the power source prior to

performing any maintenance.

Prevent water or other liquids from running onto electrical components or circuits, or through openings in

the module.

Electrostatic Discharge (ESD) Precautions

To prevent damage to the product circuits from high-voltage electrostatic discharge (ESD):

1. Do not wear clothing that is subject to static build-up.

2. Do not handle integrated circuits (ICs) in carpeted areas.

3. Do not remove an IC or a printed circuit assembly (PCA) from its conductive foam pad or conductive

packaging until you are ready to install it.

4. Ground (earth) your body while disassembling and working on the Scanner. This can be done by

touching any metallic part of the Scanner.

5. After removing a cover from the Scanner, attach an earthing (ground) lead between the PCA common

and earth ground. Touch all tools to earth ground to remove static charges before using them on the

Scanner.

6. After removing any PCA from the Scanner, place it on a conductive foam pad or into its conductive

packaging to prevent ESD damage to any ICs on the PCA.

Required Tools

The following Common Hand Tools are required to disassemble and repair the Scanner:

●

Torx 10 Straight

●

Torx 15 Straight & Angled

●

Torx 20 Straight & Angled

NOTE: Before replacing any electrical parts such as the Scanner Control Unit or CIS Unit, try calibrating the

scanner in order to get the scanner to recreate the content of the parameter block. This will solve the

problem in most cases.

48 Chapter 4 Removal and Installation ENWW

Page 57

Open the CIS Unit

1. Remove the screws (x2, Torx 15)

2. Remove the screws (x5, Torx 15).

3. Remove the cover from the CIS unit.

ENWW Open the CIS Unit 49

Page 58

Scanner Controller Board

Removal

Prerequisites: Turn off the scanner, disconnect the power cord, and

1. Disconnect the cables (A), release the lock (X) on the ribbon cables, and pull the cable out (B).

NOTE: If required; remove the screws on the wire bracket (C).

2. Remove the screws (x3, Torx 10):

Open the CIS Unit on page 49.

Installation

▲

Replace the Scanner Controller Board and reverse the removal steps.

50 Chapter 4 Removal and Installation ENWW

Page 59

Right Side Cover

Removal

Prerequisites: Turn off the scanner, disconnect the power cord, and

1. Remove the screws (x2, Torx 20).

2. Carefully remove the cover.

CAUTION: The keypad ribbon is attached to the cover.

3. Disconnect the keypad ribbon cable.

Open the CIS Unit on page 49.

4. Disconnect the keypad ribbon cable.

5. Pull the cable out though the side cover.

Installation

▲

Replace the Right Side Cover and reverse the removal steps.

ENWW Right Side Cover 51

Page 60

Power Supply

Removal

Prerequisites: Turn off the scanner, and disconnect the power cord.

CAUTION: The power supply is double pole/neutral fusing.

1. Remove the screws (x2, Torx 20).

2. Carefully remove the cover.

CAUTION: The keypad ribbon is attached to the cover.

3. Disconnect the keypad ribbon cable.

4. Disconnect the cables (x2).

5. Remove the screws (x4, Torx 10), and lift the Power Supply out.

Installation

52 Chapter 4 Removal and Installation ENWW

Page 61

▲

Replace the Power Supply and reverse the removal steps.

ENWW Power Supply 53

Page 62

Left Side Cover

Removal

1. Remove the screws (x2, Torx 20).

2. Remove the cover.

Installation

▲

Replace the Left Side Cover and replace the screws.

54 Chapter 4 Removal and Installation ENWW

Page 63

Stepper Motor Assembly

Removal

Prerequisites: Turn off the scanner, disconnect the power cord, and

1. Remove the

2. Disconnect the motor cable.

3. To release belt tension; loosen the screw (Torx 10) (don’t remove).

Right Side Cover on page 51.

Open the CIS Unit on page 49.

4. Push the tension wheel upwards, and tighten the screw again.

ENWW Stepper Motor Assembly 55

Page 64

5. Remove the screws (x2, Torx 20).

6. Remove the Stepper Motor Assembly.

Installation

▲

Replace the Stepper Motor Assembly, and reverse the removal steps.

56 Chapter 4 Removal and Installation ENWW

Page 65

Tacho Sensor

Removal

Prerequisites: Turn off the scanner, disconnect the power cord, and

1. Remove the

2. Disconnect the sensor cable.

3. Loosen, but don't remove, the Torx 10 screw (A). Hold in place with the 8mm wrench (B), and remove

the tacho wheel (C).

Right Side Cover on page 51.

Open the CIS Unit on page 49.

4. Gently push together the lock flaps, and remove sensor.

Installation

▲

Replace the Tacho Sensor, and reverse the removal steps.

ENWW Tacho Sensor 57

Page 66

Paper and Lid Sensors

Removal

Prerequisites: Turn off the scanner, disconnect the power cord, and