Page 1

HP Designjet 3D Removal System

Service Guide

Page 2

Legal Notice

© 2012 Hewlett-Packard Development

Company, L.P.

The information contained herein is subject

to change without notice.

The only warranties for HP Products and services

are set forth in the express warranty statement

accompanying such products and services.

Nothing herein should be construed as

constituting an additional warranty.

HP shall not be liable for technical or editorial

errors or omissions contained herein.

Conforms to ANSI/UL std. 60950-1-2003

Certified to CAN/CSA C22.2 no. 60950-1-03

conform with the following standards, in accordance with the

EU Machinery, Low Voltage and Electromagnetic

HP Designjet 3D Removal System

Compatibility Directives.

.

Page 3

Introduction

The HP Designjet 3D Removal System is specifically developed to provide

efficient removal of support material from a model. The system removes support material by immersing models in a bath of water with a specific amount

of cleaning agent bags added to the cleaning agent receptacle.

Welcome to the new dimension of HP Designjet 3D Removal System!

How to use this guide

This Service Guide is laid out in easy to follow sections that cover Set-up,

Operation, Maintenance, and Troubleshooting. Read each section carefully

so that you will get the best performance from your HP Designjet 3D

Removal System.

3

Page 4

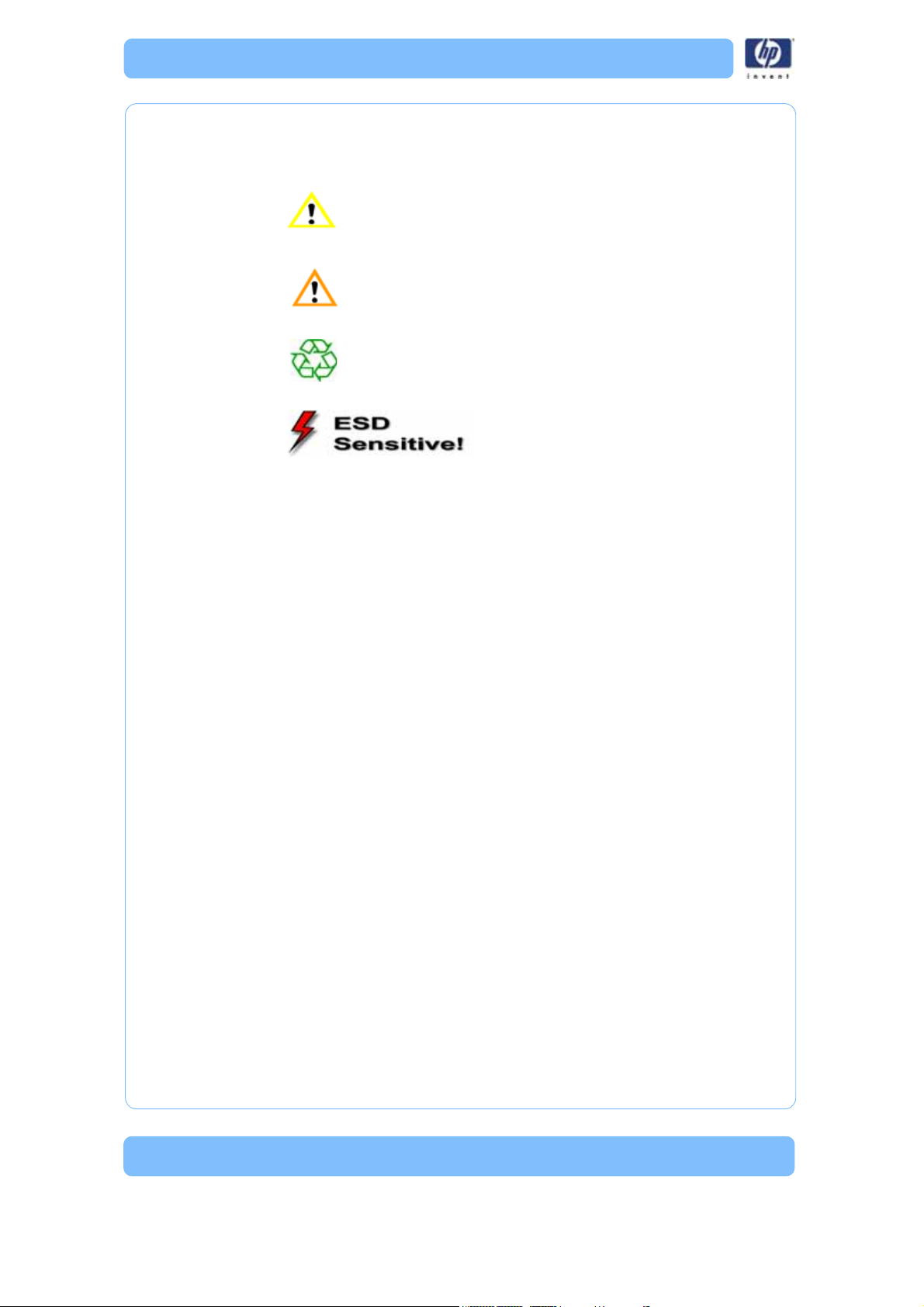

Safety

The following classifications are used throughout this guide.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in serious injury.

Recycle: Use proper recycling techniques for materials and

packaging.

ESD: Use standard electrostatic

discharge (ESD) precautions

when working on or near

electrical components.

4

Page 5

Table of Contents

Introduction

How to use this guide .....................................................................page 3

Safety ............................................................................................page 4

<> <>

System Overview

How the system works ...................................................................page 7

Setup

Connecting the system ....................................................................page 9

Operation

Cleaning Models ..........................................................................page 11

Other information ........................................................................page 15

Maintenance

Inspecting and cleaning the strainer ..............................................page 17

Cleaning .................................................................................... ..page 17

Model bag ...................................................................................page 17

Troubleshooting

Troubleshooting ...........................................................................page 19

Non-Coded Error Conditions ..........................................................page 19

Error Detection .............................................................................. page 21

Diagnostic and Test Specifications ................................................. page 25

Functional Description ....................................................................page 25

Subtest details ...............................................................................page 29

Service Procedures

Maintenance Preparation .............................................................page 32

Cabinet Components ....................... ....... ....... ....... ....... ........ ......... page 34

5

Page 6

System Lid ....................................................................................page 34

Lower Housing Assembly ................................................................page 36

Upper Housing Assembly ............................................................... page 38

Hardware Components ................................................................page 39

Back Panel ...................................................................................page 39

Line Filter ......................................................................................page 44

Thermostat .................................................................................... page 45

Thermometer Board ....................................................................... page 47

User Interface Board ...................................................................... page 49

Power Entry Module ......................................................................page 52

Main Control Board .......................................................................page 54

Cleaning Tank Assembly ................................................................page 60

Agitation Assembly ........................................................................page 65

Drive Belt .....................................................................................page 68

Induction Motor Assembly ..............................................................page 70

Float Level Sensor Assembly ...........................................................page 72

Lid Switch Assembly ......................................................................page 74

Lid Lock Assembly .........................................................................page 76

Appendix

System Components .....................................................................page 80

Upper Components ......................................................................page 81

Internal Components .................................................................. ..page 82

6

Page 7

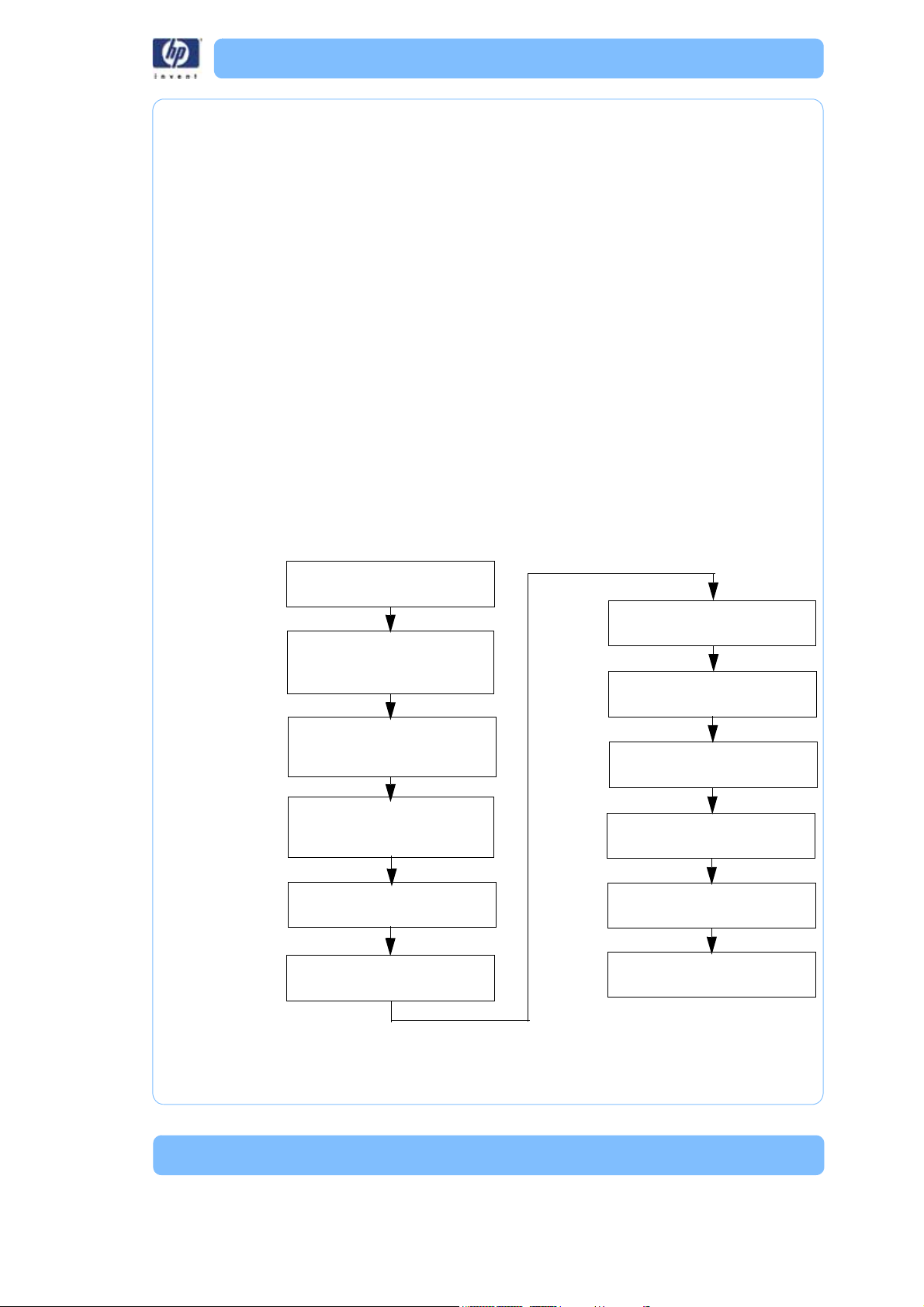

System Overvie w

Place model(s) in model basket

Select:

Cleaning tank level

Cycle length

Lid locks

Drain

Rinse cycle

Drain

Lid unlocks

Remove model(s)

Power on the System

Pour in all the contents of the

cleaning agent bag(s)

Press start cycle button

Wash cycle

How the system works

The system removes support material by immersing models in a bath of

water with a specific amount of cleaning agent bags added to the cleaning

agent receptacle. The system heats and circulates solution around the models

in the cleaning tank. The solution dissolves the support material without

harming the underlying model material. Over time, depending on geometry

and the amount of support material, all the support material is dissolved and

the models are ready to be removed, dried and used for their intended purpose.

The system incorporates the following functions:

•Automatic water fill

• User selectable cleaning tank level (half or full)

• Automatic water drain

• Automatic timing device for user selectable short, medium, or long cycles

• Automatic lock/unlock before and after cycling

• Automatic rinse and drain cycle

Figure 1: Sequence of Operation

7

Page 8

8

Page 9

Setup

Connec ting the system

Make sure the following preparations of the physical site are met:

• The system must be placed on a flat and stable surface able to support

36 kg (80 lbs.) to avoid the risk of falling.

• The work area for unpacking the system should be 76.2 cm (30 in.) high,

76.39 cm (28.5 in.) wide and 69.95 cm (27 in.) deep.

• The system must be located at least 20 cm (8 in.) higher than the wastewater drain.

• The drain facility must accept a drain pH level between 6.5 and 10.0.

• The drain must accept a wastewater temperature of at least 75°C (167°F).

• The water source connection must have a 3/4 in. hose thread.

• The water source temperature must be ≥15 ° C ( 59 ° F ) .

A hot water connection is highly recommended to speed up heating, but

is not required.

• The water pressure must be between 0.5 bars and 10 bars (7.25 psi and

145 p s i ) .

• The water source hardness should be ≤300 ppm.

• The grounded electrical outlet (220–240V~ 9A 50 Hz 1200W) must connect to either a Euro or a UK power cord plug provided and must be

located within 2 m (5 ft.) of the system.

• The operating environmental temperature must be between 15°C to 30°C

(59°F to 86°F).

• The operating environmental humidity must be between 20% to 80%,

non condensing.

• Consult your area's requirements regarding the disposal of the HP

Designjet 3D Removal System effluent prior to use. A permit or form of

pre-treatment may be required in your area.

9

Page 10

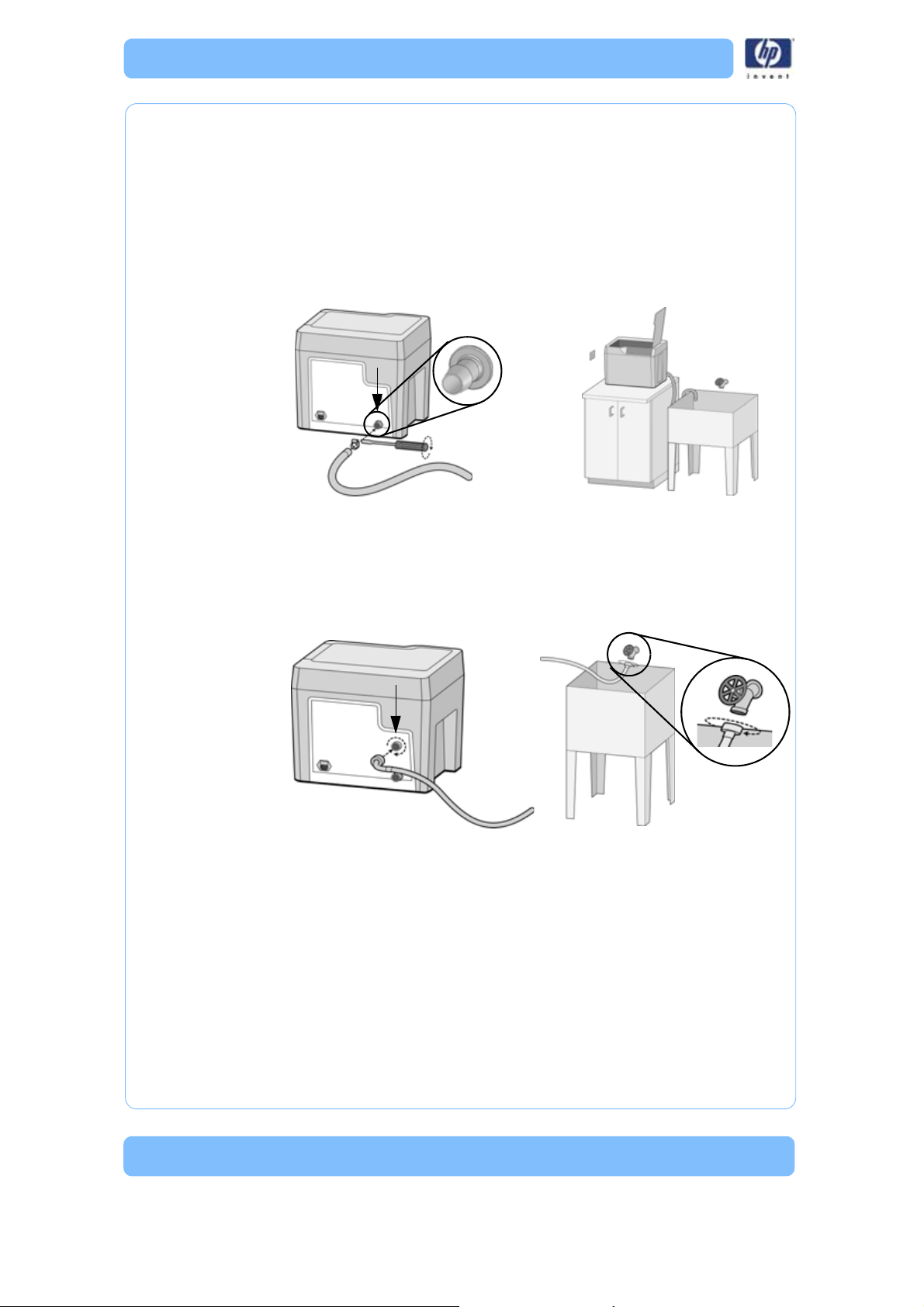

Connect the drain hose

Make sure the drain hose is attached by pushing the end of the drain hose

onto the barbed connection on the back panel of the system. Secure the

hose with the hose clamp using a flat bladed screwdriver. Route the free end

of the drain hose to the wastewater location. Make sure the system is at least

20 cm (8 in.) above the drain hose discharge and there are no kinks in the

hose. The system relies on gravity to drain the wastewater from the cleaning

tank.

Figure 2: Drain hose connections

Connect the water hose

Screw on the end of the water supply hose to the back panel of the system.

Securely tighten the fitting clockwise. Turn on the water and make sure there

are no leaks.

Figure 3: Water hose connections

Plug in the system

Securely plug one end of the supplied power cord into the receptacle at the

back of the system and the other end of the power cord into a grounded

receptacle. Only use the power cord provided.

10

Page 11

Operation

Upper Lid Position

Lower Lid Position

Cleaning Models

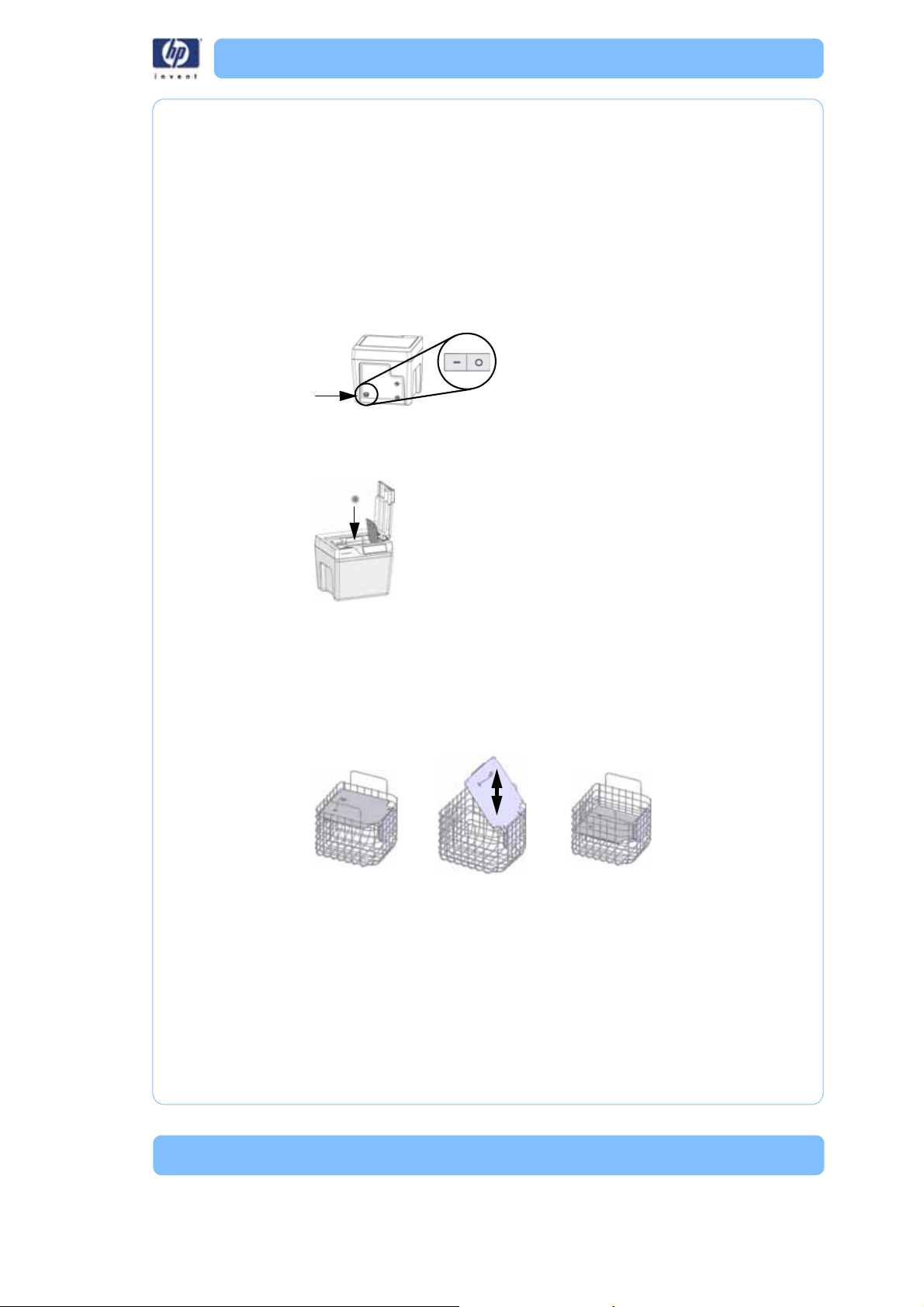

Power on the system

Power on the system using the On/Off switch above the power cord receptacle on the back of the system.

Add models

All models must be placed in the model basket and the model lid adjusted.

The model basket lid ensures the models remain submerged during the

cleaning process. The lid can be adjusted to two heights.

• Use the upper lid position for larger models > 8.89 cm (3.5 in.).

• Use the lower lid position for smaller size models ≤ 8.89 cm (3.5 in.).

• Many models may be cleaned at one time as long as they are submerged during the cleaning process with the model basket lid in either

position.

Delicate and flat models should be placed in the model bag on the model

basket lid. When using the model bag, always select the lower lid position

and do not add other models to the model basket.

• Delicate models have features with a cross sectional areas under 19

sq. mm (0.03 sq. in.).

• Flat models have large flat areas that are greater than 64 mm x 64

mm (2.5 in x 2.5 in) and less than 3 mm (1/8 in) thick).

11

Page 12

Cleaning tank level

Based on the model lid position, select either a full (upper lid position) or

half (lower lid position) cleaning tank level by pressing the cleaning tank

level button. A full cleaning tank level is approximately 15.14 L (4 gals.) and

a half cleaning tank level is approximately 7.57 L (2 gals).

Cleaning agent bag(s)

Select the number of cleaning agent bag(s) to be used based on Table 1

below.

Table 1: Cleaning Tank Level and Cleaning Agent Bags

Cleaning Tank Level Cleaning Agent Bag

Half cleaning tank level 1 cleaning agent bag

Full cleaning tank level 2 cleaning agent bags

Note:

Do not use more than the specified amount of cleaning agent

bags. Doing so will exceed pH levels for wastewater dis-

posal.

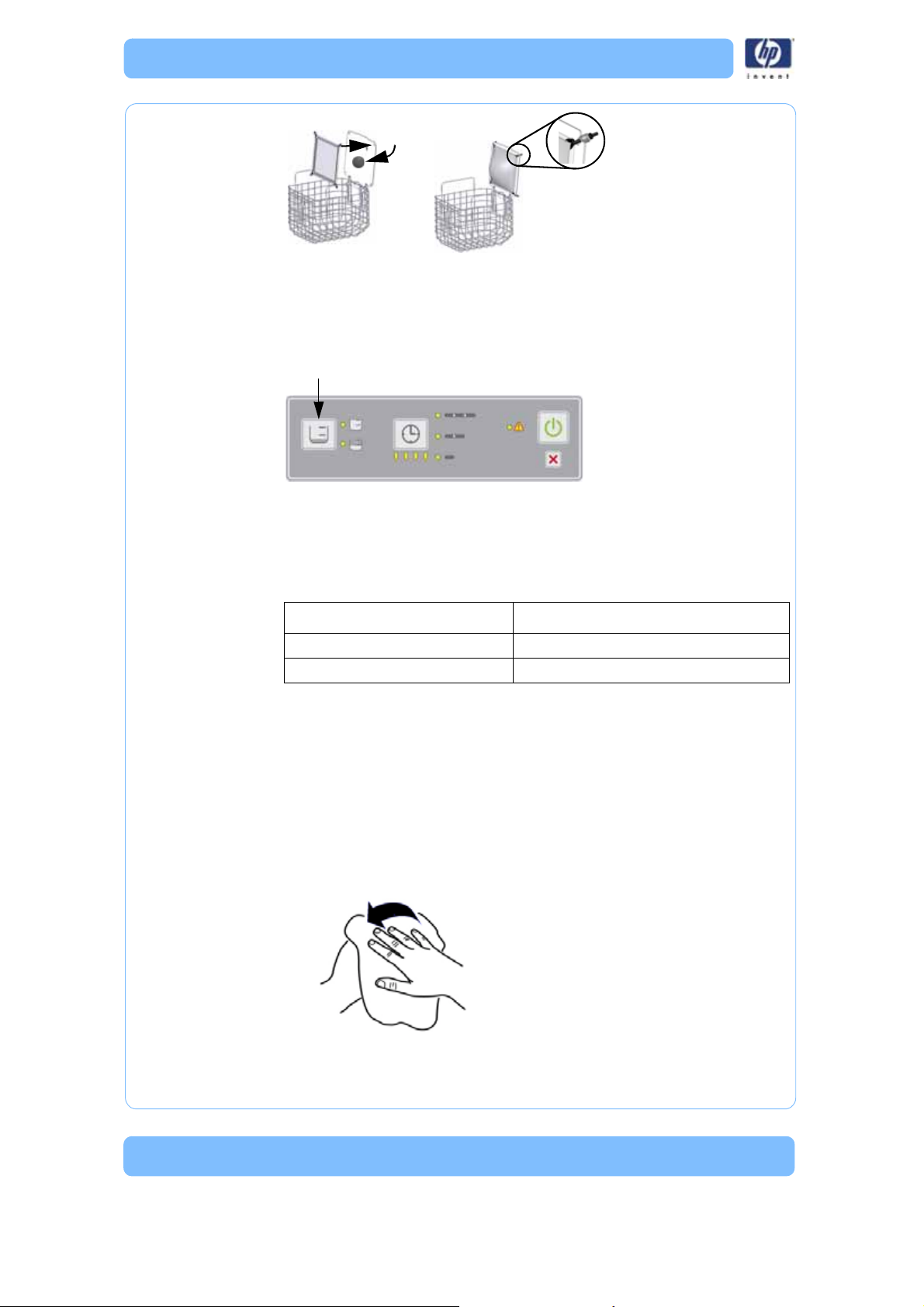

Add cleaning agent bag

Follow the instructions below for adding the contents of the cleaning agent

bag(s) to the cleaning agent receptacle.

1. Dry hands before opening the cleaning agent bag.

12

Page 13

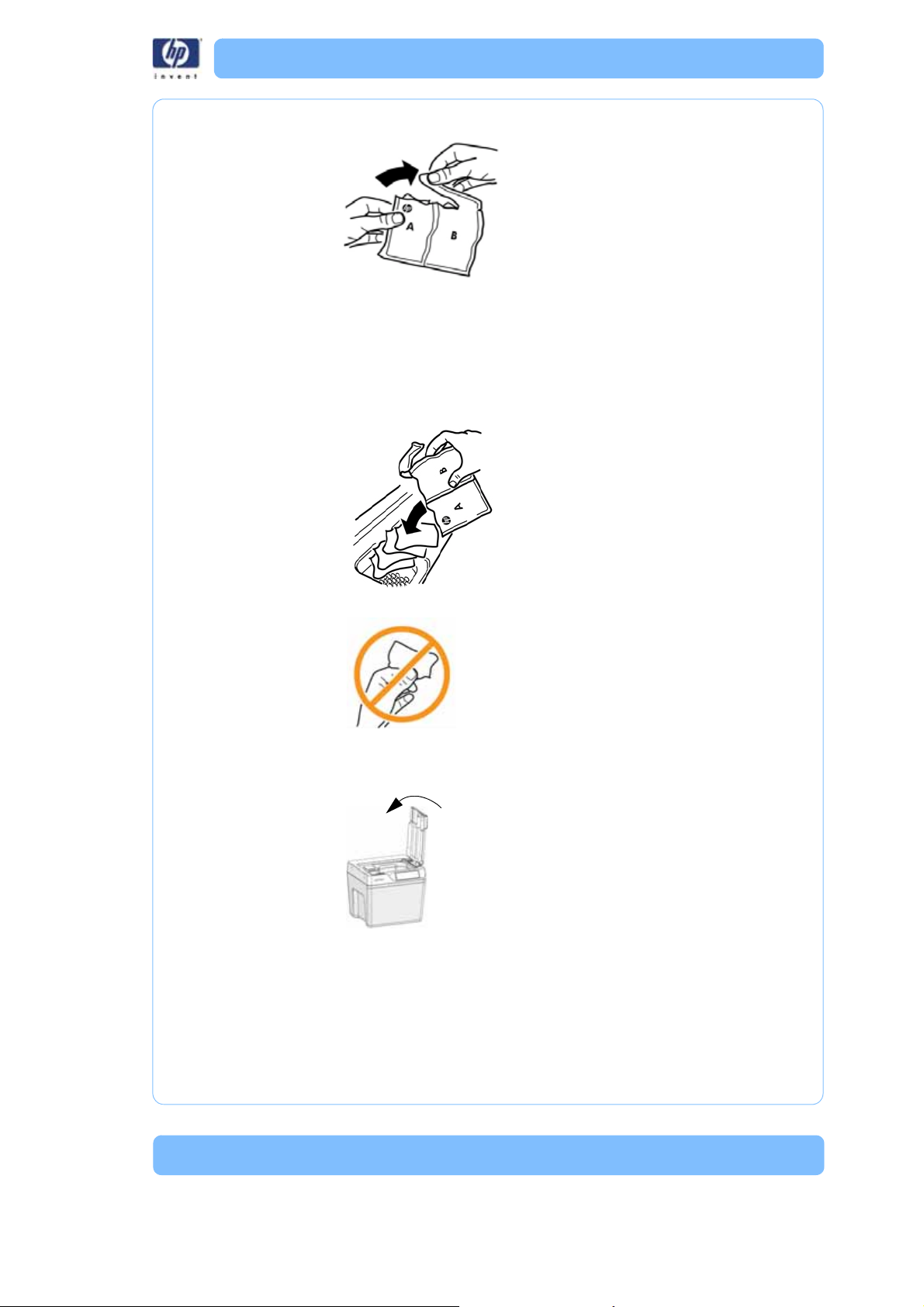

2. Open the cleaning agent bag as shown.

3. Empty all the contents of the specified number of cleaning agent

bag into the cleaning agent receptacle as directed (see

<Reference>Table 1).

Note:

Do not use more than the specified amount of cleaning agent

bags. Doing so will exceed pH levels for wastewater dis-

posal.

4. Avoid handling the contents of the cleaning agent bag.

After adding all the contents of the cleaning agent bag(s), properly dispose

of bag(s) and close the system lid.

13

Page 14

Cycle Length

Select one of the three cycle lengths by pressing the cycle length button.

Each press of the cycle length button increases from a short cycle to a

medium cycle or to a long cycle length. Pressing the cycle length button once

more returns to the short cycle length.

Table 2 should also be used as a general guideline for selecting cycle

lengths for most models.There are some factors that cause the support

removal process to take longer such as model geometry, small support filled

crevices, small blind holes, or low water temperature coming into the system.

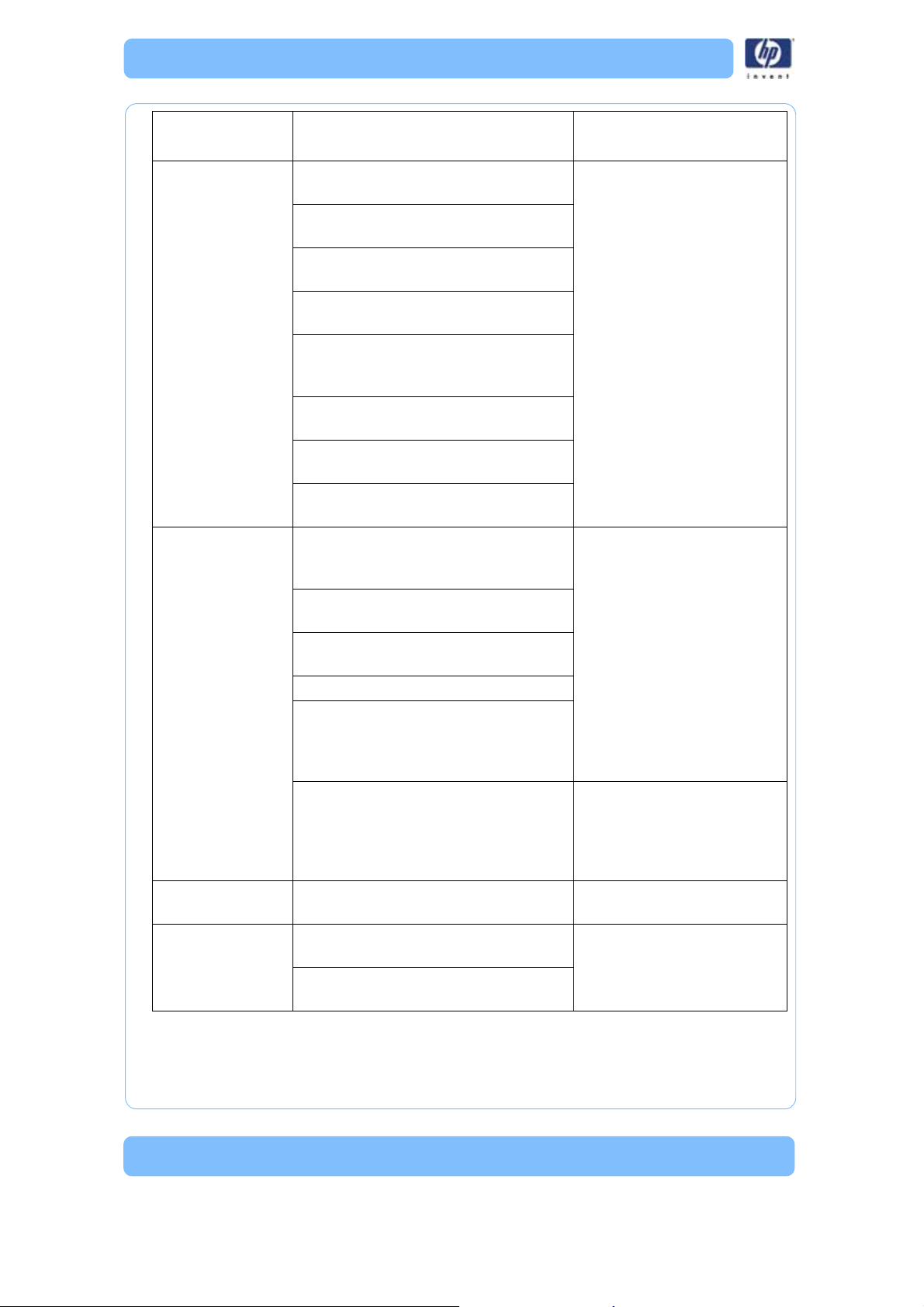

Table 2: Cycle Length Settings

Combined Build Times Cycle Selection Approximate Cycle Times

≤ 4 hrs. Short 3 hrs.

4 to 12 hrs. Medium 6 hrs.

> 12 hrs. Long 12 hrs.

Note:

When placing more than one model in the same cleaning

cycle, use the combined build times of all the models to deter-

mine the correct cycle length setting. Combined build time

means the sum of the individual build times of each model

put into the model basket.

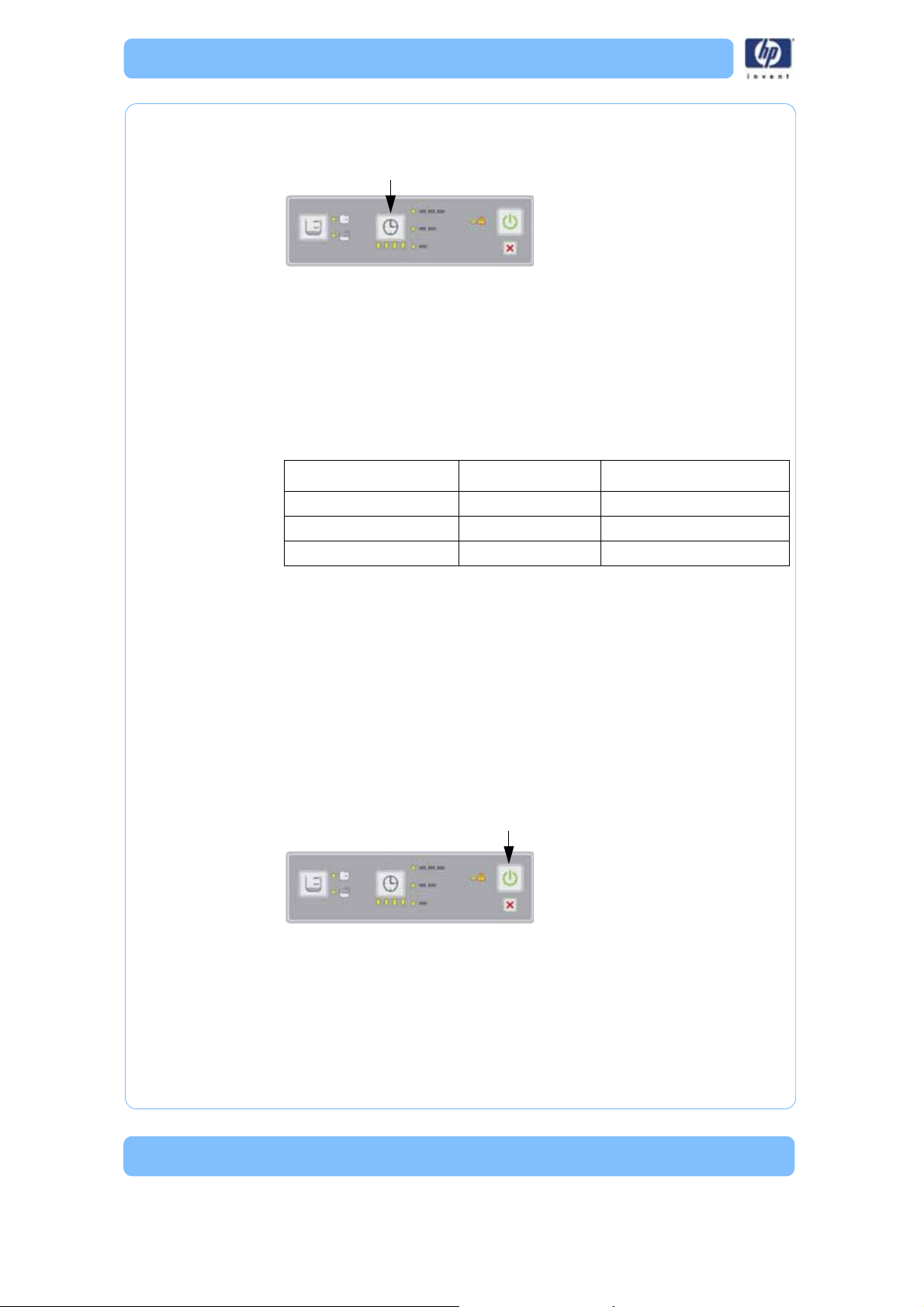

Start cycle

When the proper cleaning tank level and cycle length are set, press the start

cycle button. The system locks the lid and begins the process of filling the

cleaning tank, heating the solution, and starts the cleaning of models inside

the cleaning tank.

After the initial cleaning of the models, the system drains and then refills with

clean water for a final rinse and drain cycle. When the cleaning cycle completes, the left-hand progress LED will turn from yellow to green and the lid

unlocks.

14

Page 15

Remove the models

Cycle

complete

Let the solution drain off of the models for a few minutes then remove the

models, wash off any remaining solution and dry with a clean cloth or paper

towel.

Other informati on

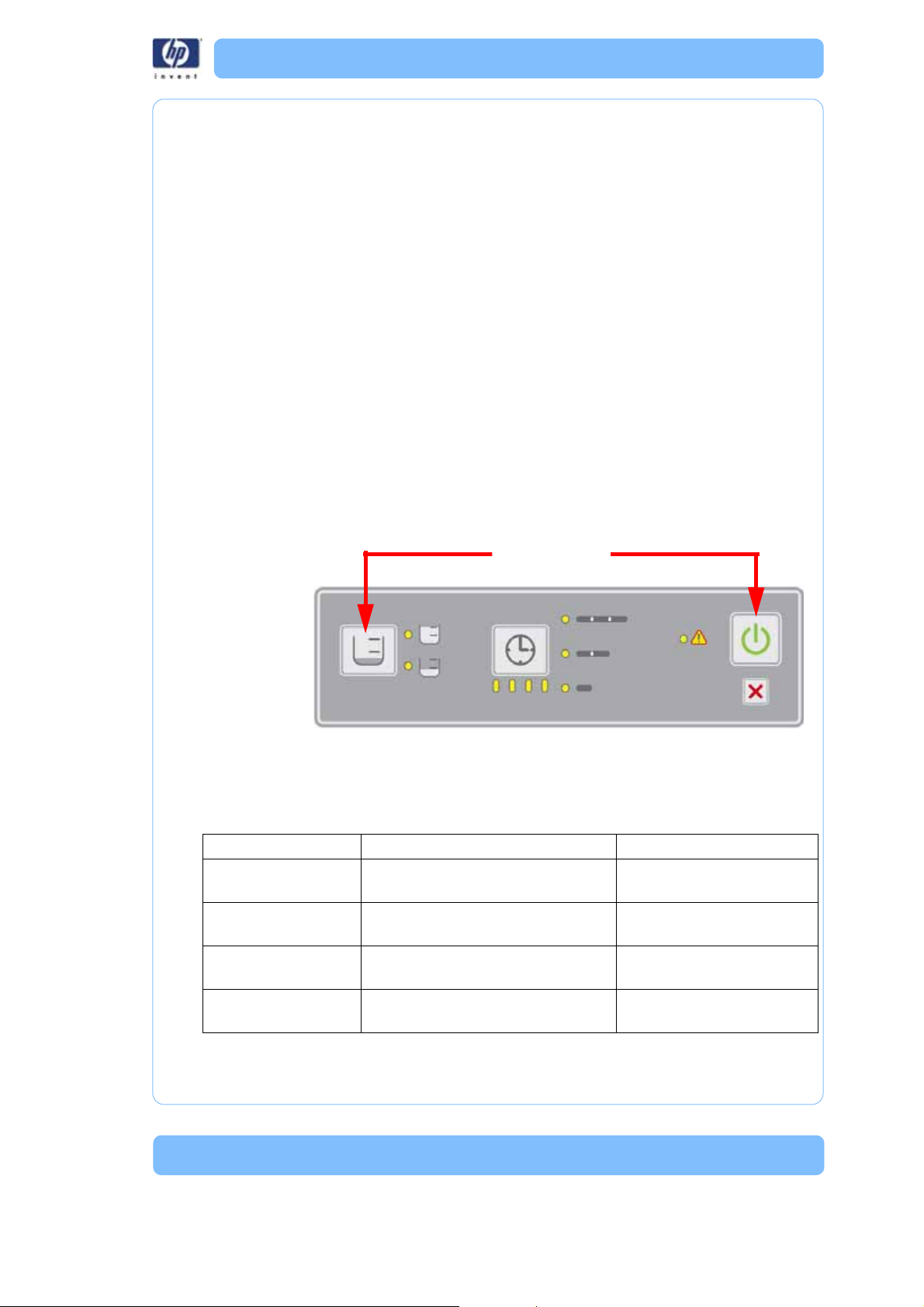

Progress LEDs

When the cleaning cycle is started, all the progress LEDs are illuminated in

yellow. Each progress LED from right to left will turn off as the cycle time progresses. When the cleaning cycle is complete, the left-hand progress LED will

turn from yellow to green.

Canceling the cleaning cycle

To cancel the cleaning cycle at anytime, press the cancel button on the control panel. The system will stop and drain the cleaning tank. Before the system completely turns off, the cleaning tank may refill with water for a final

rinse (depending on where the system is in the cleaning cycle) and then

drains again. After the cleaning tank has drained, the lid unlocks so the

model basket can be removed. The drained solution cannot be reused. Models may not be fully cleaned if you cancel the operation.

15

Page 16

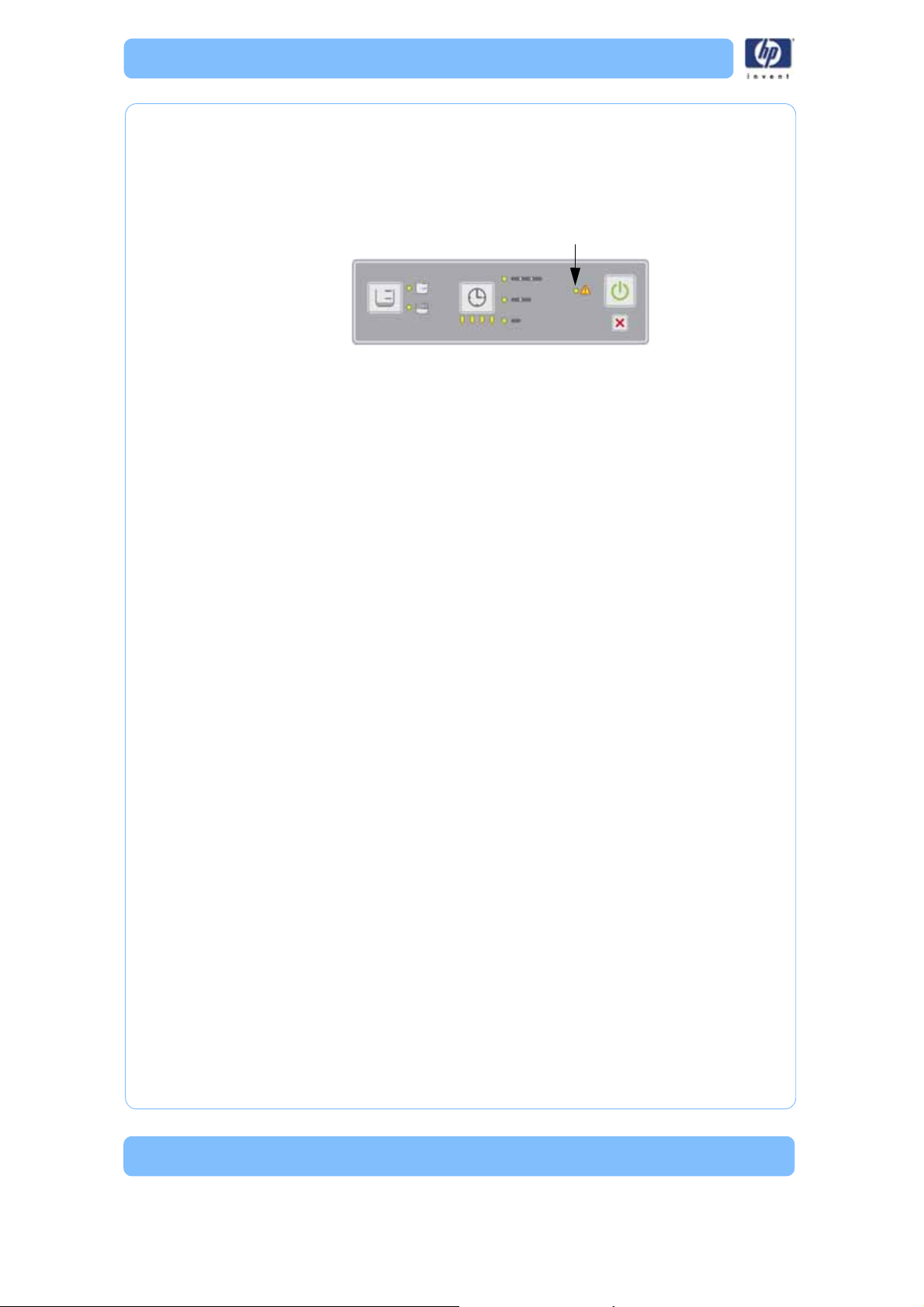

Process error LED

A flashing yellow process error LED indicates a warning. See “Troubleshoot-

ing” on page 19 for details.

A red process error LED indicates that the system is experiencing a system

error. See “Troubleshooting” on page 19 for details.

Turning the system off

Once the cleaning cycle is complete and the models have been removed,

the system should be turned off by toggling the power switch on the back

panel to the OFF position. If the system is not going to be used for an

extended period of time, remove all models from the model basket, make

sure the system is completely dry, and the power cord is disconnected from

the power cord receptacle.

16

Page 17

Maintenance

Inspecting and cleaning the strainer

The strainer at the bottom of the cleaning tank should be cleaned before

every use of the system to maintain optimal system performance. Remove the

strainer from the cleaning tank and rinse under water until the strainer is

clean. Place the strainer back in the cleaning tank after cleaning.

Cleaning

The system should be cleaned once a month or sooner as needed. Clean the

exterior and the interior of the cleaning tank with mild soap and water using

a sponge or cloth only. Hard to remove residue can be cleaned with isopropyl alcohol. Never immerse the system or use a spray nozzle or hose to

clean it. Any liquid in the electronics area behind the back panel of the system may damage the system and void the warranty.

Model bag

The model bag should be replaced after 40 cycles. Replace the bag if the

elastic cord starts to droop or the bag shows signs of wear.

17

Page 18

18

Page 19

Troubleshooting

In the presence of unusual electromagnet phenomena, such as strong electromagnetic fields or severe electrical disturbances, the system might behave

strangely, or even stop working. In this case, turn off the system, wait until the

electromagnetic environment has returned to normal and then turn it on

again.

The HP Designjet 3D Removal System has been designed to allow the end

user to resolve most operating problems. When a problem is encountered,

read through this troubleshooting section for possible solutions.

Troubleshooting

Non-Coded Error Conditions

Table 3: Non-Coded Error Conditions

Problem Recommendation

No power Verify that the power cord is securely

plugged in.

Verify that the power switch is in the

ON position.

Verify that AC power is present at the

power outlet.

Replacement Parts

* Part most likely to resolve issue

** Part less likely to resolve issue

* Main controller board

** Line filter

** Thermostat

19

Page 20

Problem Recommendation

Water has not

fully drained from

the cleaning tank

assembly

Verify that the strainer and cleaning

tank drain are not clogged.

Verify that the drain hose is not

clogged.

Verify that there are no kinks in the

drain hoses.

Make sure the system is at least 20 cm

(8 in.) above the drain hose discharge.

Make sure that no section of the drain

hose is higher than the system

discharge.

Verify that the power cord is securely

plugged in.

Verify that the power switch is in the

ON position.

Verify that AC power is present at the

power outlet.

Models not clean Make sure all the contents of the speci-

fied number of cleaning agent bag(s) is

used.

Make sure the correct cleaning tank

assembly level is selected.

Make sure the correct cycle length is

selected.

Repeat the cleaning cycle.

Make sure the model basket is used to

submerge models in the cleaning solution and the correct system lid position

is selected.

Cleaning tank assembly not heating. Note: Verify that the tank has

The system is

leaking

Yellow flashing

process error LED

Verify that the inlet and drain hose

connections are tight.

Open and close the system lid and then

make sure the lid is fully closed.

If recovering from a power loss, press

the cancel button.

Replacement Parts

* Part most likely to resolve issue

** Part less likely to resolve issue

* Agitation drive belt

** Induction motor

** Agitation assembly

** Cleaning tank assembly

failed to heat before

replacing the cleaning tank

assembly, by touching the

tank during unit operation.

*System lid

** System lid sensor

** Cleaning tank assembly

20

Page 21

Error Detection

Error Type

4

2

1

Value

Error Code

Value

8

4

2

1

Error Type

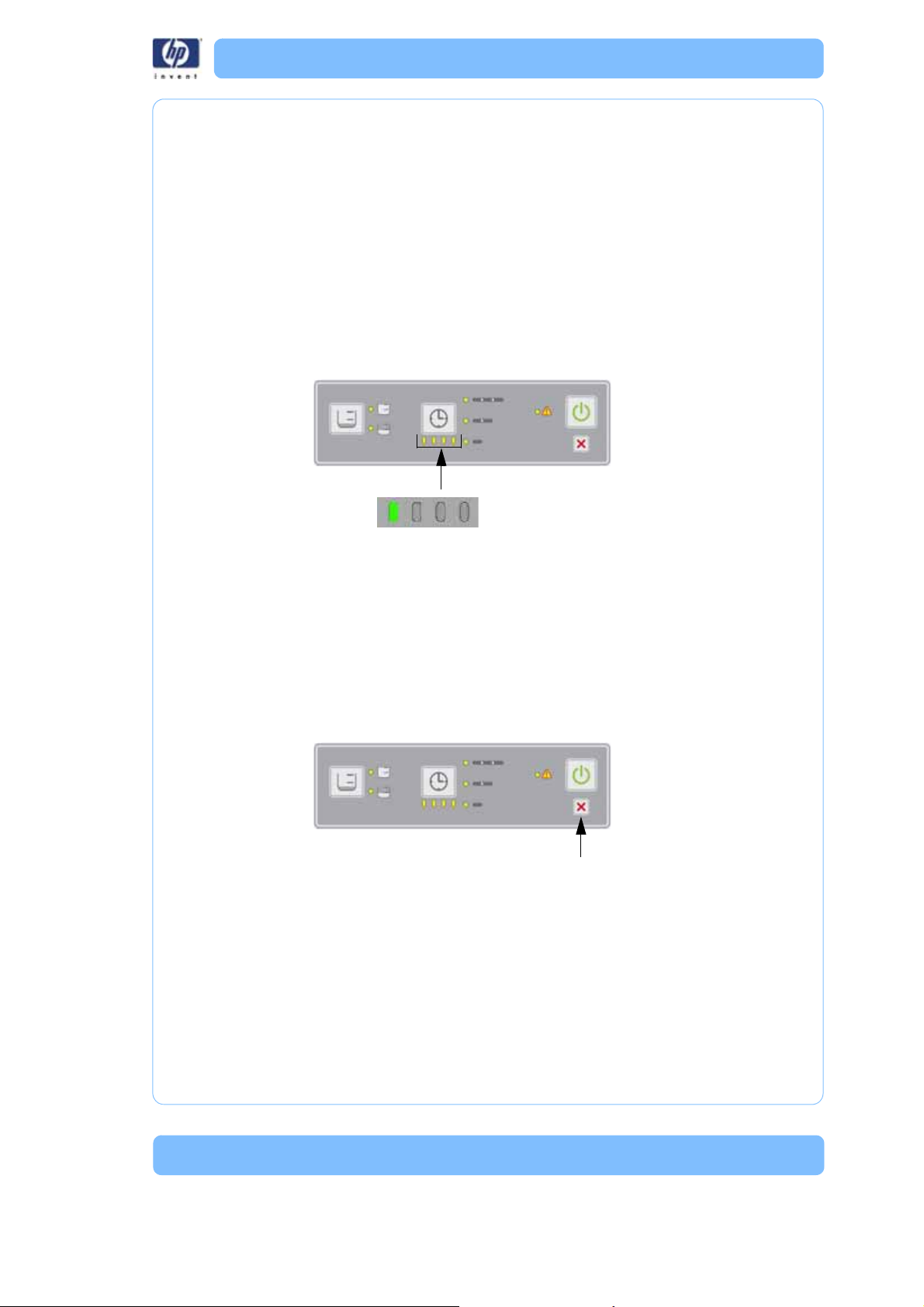

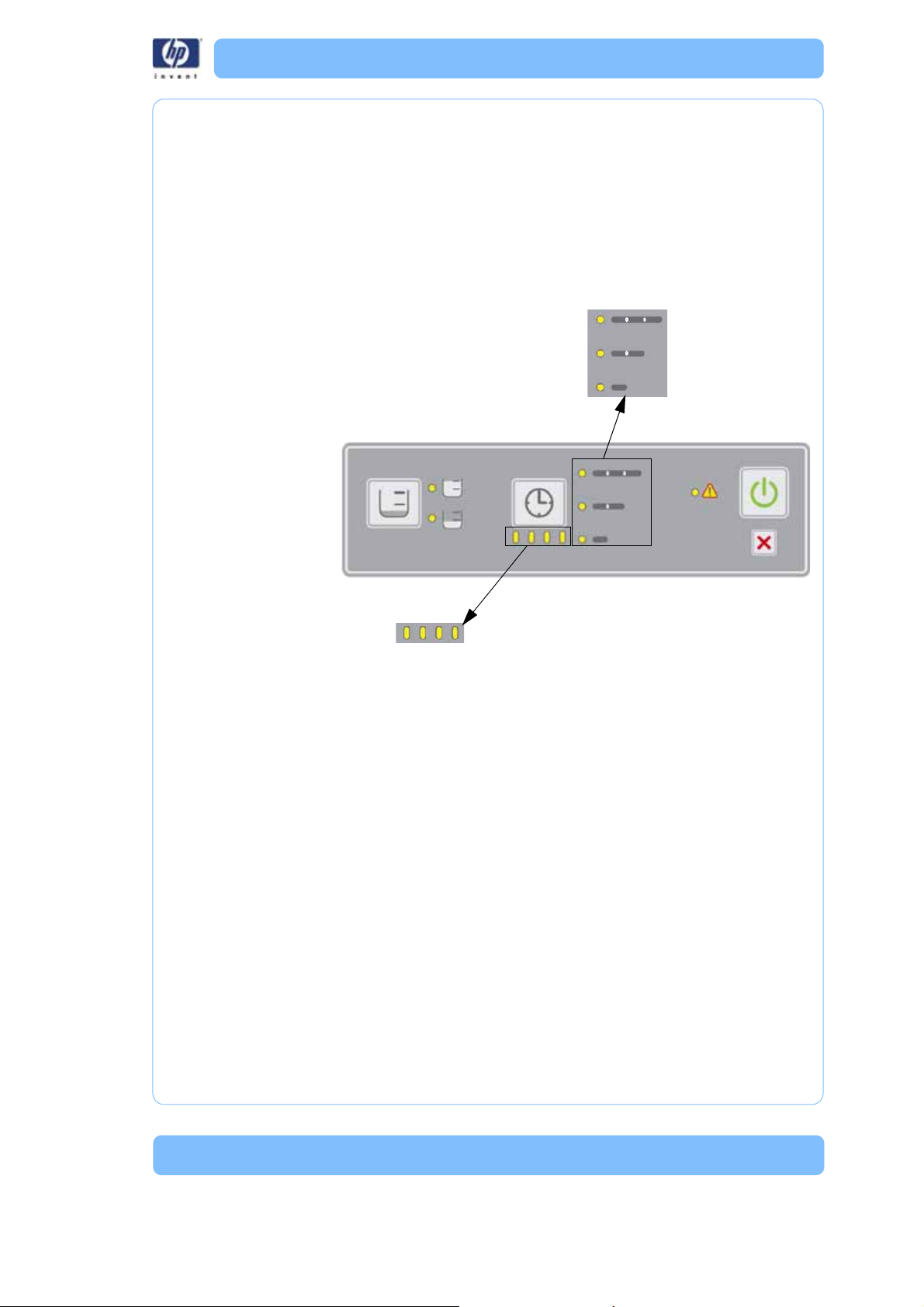

Each error type LED carries a weight value (4, 2, or 1). To obtain the error

type number, add up the weight value associated with the illuminated LED.

For example; if the top LED (4) and the bottom LED (1) are both illuminated,

the value equals 5 (4+1=5).

Figure 4: Error Type

21

Page 22

Error Code

Each error code LED carries a weight value (8, 4, 2, or 1). To obtain the

error code number, add up the weight value associated with the illuminated

LED. For example; if the right LED (1) and the third from the right LED (4) are

both illuminated, the value equals 5 (1+4=5).

Note: To obtain error codes, see “Entering Diagnostic

Mode” on page 25 for details.

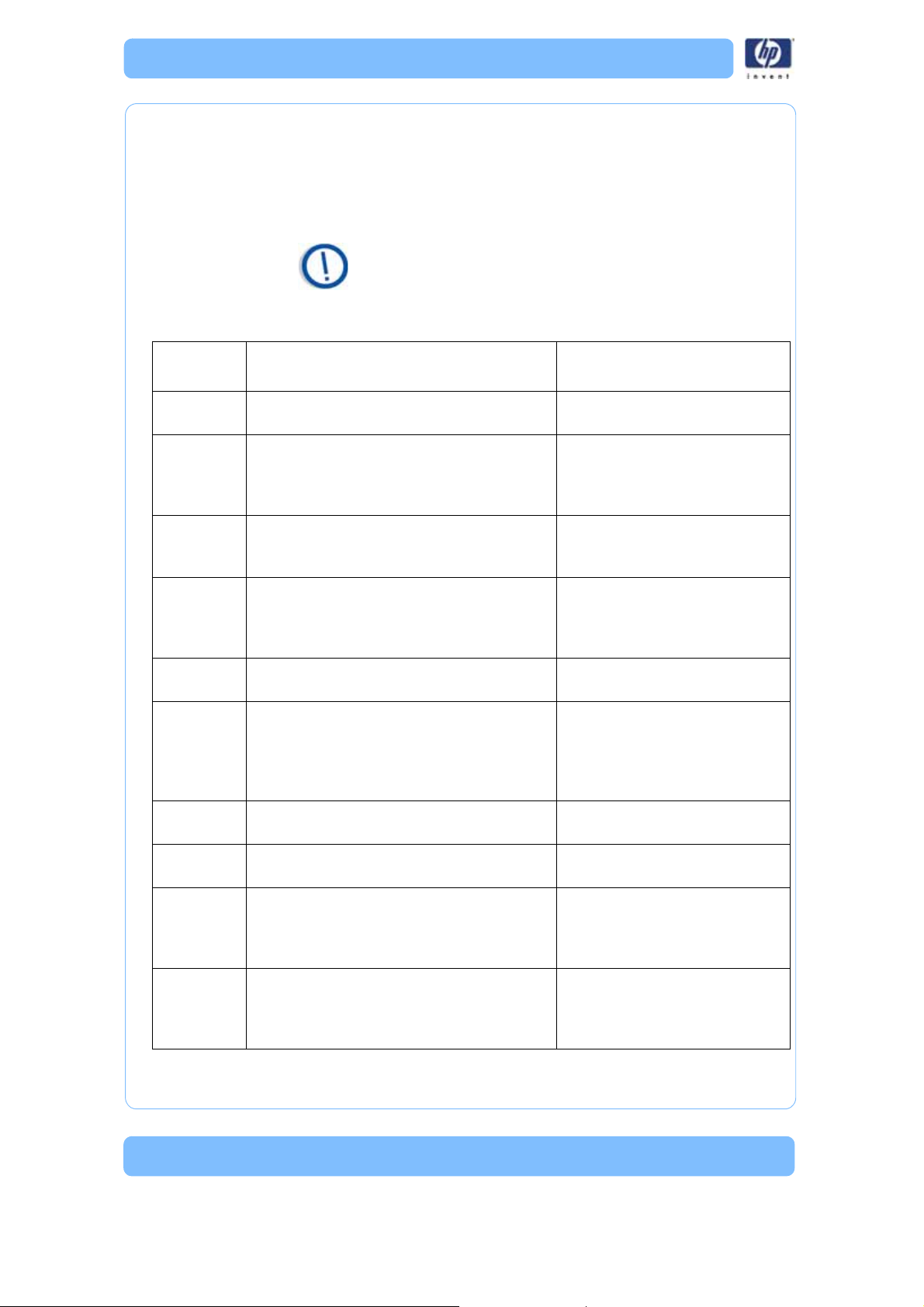

Table 4: Error Code Chart

Error

Type -Code Description

Replacement Parts

* Part most likely to resolve issue

** Part less likely to resolve issue

1-1 Failed or open thermometer * Thermometer board

** Main controller board

1-8 Set point temperature not reached * Cleaning Tank Assembly

* Main controller board

** Thermometer board

** User interface board

2-1 Ambient temperature error * Thermometer board

** User interface board

** Main controller board

2-2 Wait for high temperature failed * Cleaning Tank Assembly

* Main controller board

** Thermometer board

** User interface board

2-3 Wait for low temperature failed * Thermometer board

** Main controller board

2-4 Wait for the system lid to close failed

1. Check to see if the system lid is closed

2. Check to see if magnet is present in

system lid

CRU:

*System lid

FRU:

* Lid switch assembly

** User interface board

2-5 User interface to main controller

communication error

* User interface board

* Main controller board

2-6 Thermometer communication error * Thermometer board

* User interface board

2-7 Float level sensor assembly not empty

1. Check for drain hose blocked or

* Float level sensor assembly

** Cleaning tank assembly

mis-routed

2. Check to see if drain screen is clean

3-1 System lid open while washing

Check if magnet is secure in system lid

* System lid lock assembly

** System lid switch assembly

** User interface board

** Main controller board

22

Page 23

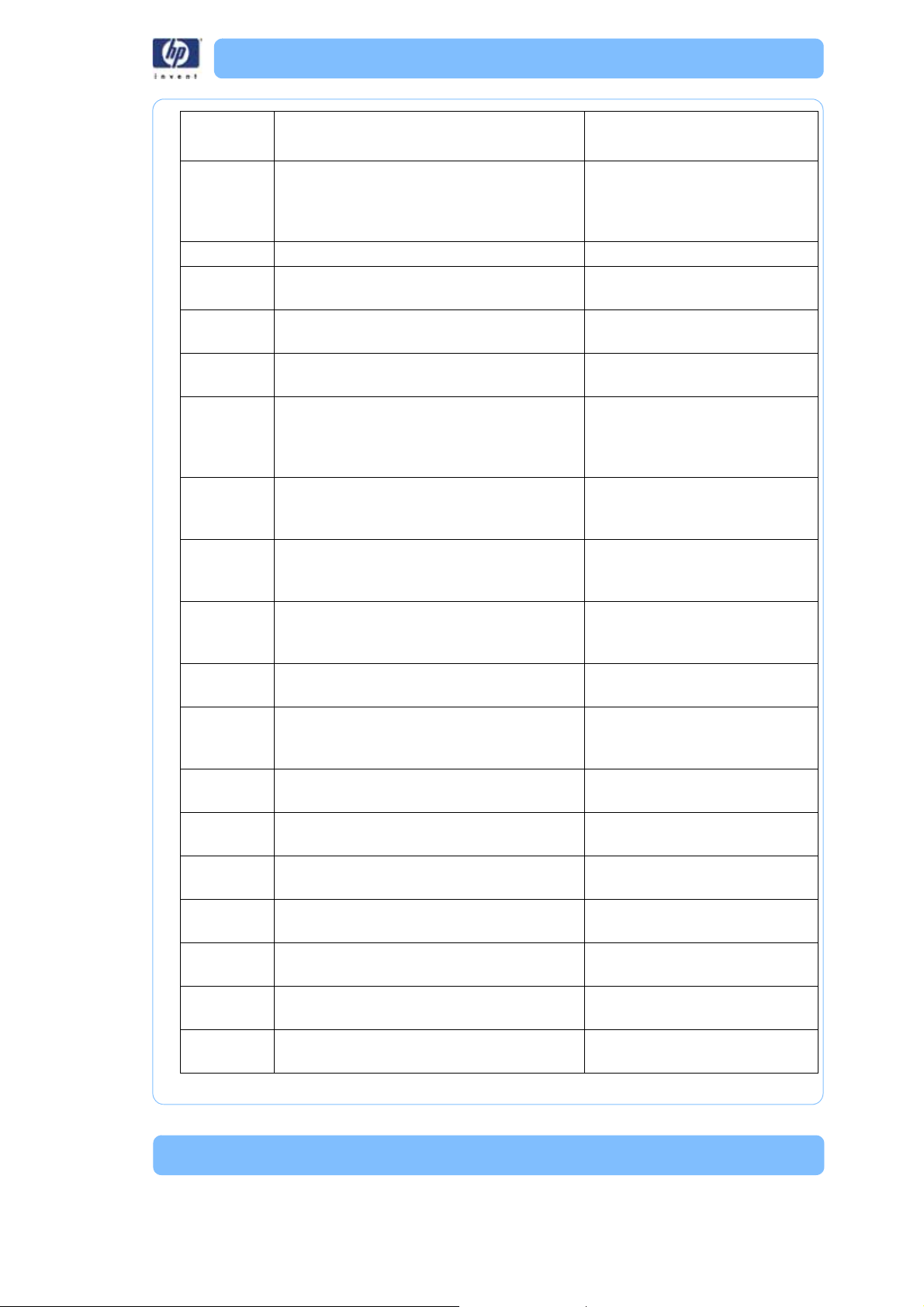

Error

Type -Code Description

3-2 System lid open while rinsing

Check if magnet is secure in system lid

Replacement Parts

* Part most likely to resolve issue

** Part less likely to resolve issue

* System lid lock assembly

** System switch assembly

** User interface board

** Main controller board

3-3 Power module fault detected * Main controller board

3-4 User interface to main controller

communication error

* User interface board

* Main control board

3-10 Invalid float level sensor assembly state * Float level sensor assembly

** Main controller board

4-1 Invalid float level sensor assembly state * Float level sensor assembly

** Main controller board

4-2 Timeout waiting for low water level

1. Check for water available at inlet

2. Check water pressure at inlet

* Cleaning tank assembly

** Inlet hose

** Main controller board

** Float level sensor assembly

4-3 Timeout waiting for mid water level

1. Check for water available at inlet

2. Check water pressure at inlet

* Cleaning tank assembly

** Float level sensor assembly

** Main controller board

4-4 Unexpected transition to overfill condition * Float level sensor assembly

** Cleaning tank assembly

** Main controller board

4-5 Timeout waiting for full water level

1. Check for water available at inlet

2. Check water pressure at inlet

4-6 Float level sensor assembly error - empty

switch stuck closed

4-7 Timeout waiting for full water level

1. Check for water available at inlet

2. Check water pressure at inlet

4-8 Overfill: Float level sensor assembly error -

mid switch stuck open

4-9 Float level sensor assembly error - mid

switch stuck open

4-10 Float level sensor assembly error - empty

switch stuck closed

* Float level sensor assembly

* Cleaning tank assembly

** Main controller board

* Float level sensor assembly

** Main controller board

* Float level sensor assembly

* Cleaning tank assembly

** Main controller board

* Float level sensor assembly

** Main controller board

* Float level sensor assembly

** Main controller board

* Float level sensor assembly

** Main controller board

4-11 Not empty at start of fill * Float level sensor assembly

** Main controller board

4-12 Float level sensor assembly error (full before

mid)

* Float level sensor assembly

** Main controller board

4-13 Not at target level at the end of fill * Float level sensor assembly

** Main controller board

5-1 Invalid float level sensor assembly state * Float level sensor assembly

** Main controller board

23

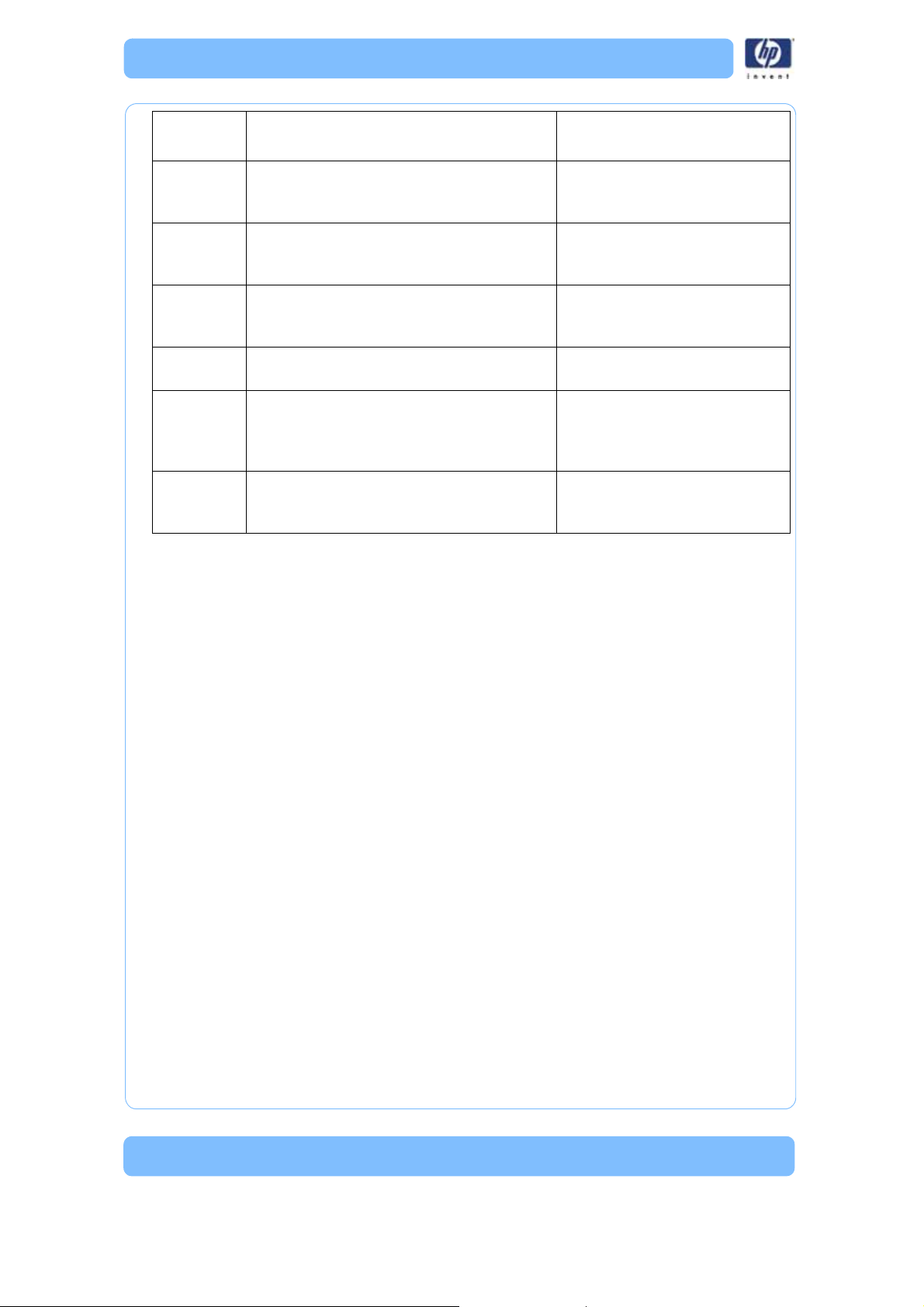

Page 24

Error

Type -Code Description

Replacement Parts

* Part most likely to resolve issue

** Part less likely to resolve issue

5-2 Unexpected loss of fluid * Cleaning tank assembly

** Float level board

** Main controller board

5-3 Overfill * Cleaning tank assembly

** Float level board

** Main controller board

5-4 Unexpected loss of fluid and invalid sensor

transition

* Float level sensor assembly

** Main controller board

** Cleaning tank assembly

6-1 Invalid float level sensor assembly state * Float level sensor assembly

** Main controller board

6-2 Timeout waiting for empty

1. Check for drain hose blocked or

* Float level sensor assembly

* Cleaning tank assembly

mis-routed

2. Check drain screen clean

6-3 Unexpected addition of fluid * Cleaning tank assembly

** Float level sensor assembly

** Main controller board

24

Page 25

Diagnostic and Test Specifications

Press Together

Functional Description

Overview

The diagnostic test feature is intended to allow the support engineer to confirm correct operation of a majority of the system’s hardware. Diagnostic testing does not require water be connected to the cleaning tank assembly for

the test sequence to complete successfully. The support engineer will be

required to verify certain hardware is operating properly where the cleaning

tank assembly itself is not capable of detecting it automatically.

Entering Diagnostic Mode

Diagnostic mode can only be entered when the system is initially powered

off. To enter diagnostic mode, the support engineer must simultaneously hold

down only the ‘start’ and ‘load select’ buttons (farthest apart) when power is

turned on. The system is now in diagnostic mode (indicated by both 'cycle

load' LEDs being ON simultaneously and all ‘cycle length’ and ‘progress status’ LEDs OFF, neither of which should ever occur during normal operating

mode). Normal operation cannot be resumed until this mode is exited. Note

that the input buttons have different functions when in diagnostic mode.

Input functions in Diagnostic Mode

The affect of pressing the interface panel buttons changes when diagnostic

mode is active.

Button Normal mode (for reference only) Diagnostic model

Cycle ‘Load Select’ Rotate though water level options

(FullHalfFull...)

Cycle ‘Length Select’ Rotate though cycle length options

(Long Med Short Long...)

‘Start’ Begin selected cleaning operation Run all diagnostic subtests

‘Cancel’ Abort any operation in progress Exit diagnostic mode(abort

Select subtest (sequential

Run selected subtest

(run remaining subtests)

current subtest)

25

Page 26

Exiting Diagnostic Mode

As long as no errors have been detected, diagnostic mode can be exited

simply by pressing the ‘cancel’ button. If a test sequence is in progress when

the ‘cancel’ button is pressed, the current subtest sequence is aborted, but

the system remains in diagnostic mode. Pressing ‘cancel’ a second time

would then exit diagnostic mode. LEDs should return to their default state for

normal operating mode. Diagnostic mode can also be exited by powering

the system off and on again (without holding down any input buttons).

Initiating the Diagnostic Sequence

The diagnostic subtests can be initiated in one of two ways: 1) “Run all”: run

all subtests with a single button press (with only a short delay between each

subtest), or 2) “Interactive mode”: run one subtest at a time, allowing the

user control over individual subtests. All ‘cycle length’, ‘progress status’, and

‘warning’ LEDs are OFF when diagnostics mode is ready to initiate subtesting.

Run all (entire sequence, no pausing)

To initiate the entire diagnostic test sequence, simply press the ‘start’ button

while in diagnostic mode. This starts a predetermined sequence of subtests

that exercise the system’s hardware. The entire test sequence runs until completion, an error has been detected, or the ‘cancel’ button is pressed. Pressing the ‘load select’ or ‘length select’ button has no affect once the ‘start’

button has initiated the sequence. Note that only a short delay occurs

between subtests; no other input is required to complete the sequence. It

may be helpful to note that diagnostics are best run with the system lid open.

Interactive mode (select subtest to run)

This mode allows individual tests to be selected and executed. To select a

particular test use the ‘load select’ button. Pressing this button selects the next

subtest which is displayed on the ‘cycle length’, ‘progress status’, and the

‘warning’ LEDs. Once the desired subtest is selected the ‘length select’ button

is used to execute that subtest. Pressing the ‘start’ button runs the currently

selected subtest as well as all the remaining subtests from that point on stopping at the final subtest (not looping back to run the first subtest). After successful completion of any subtest, another subtest can be selected using the

‘load select’ button or that same subtest can be run again by pressing the

‘length select’ button. When in the interactive mode, the operator must wait

30 seconds after powering on the system before running the heater subtest.

26

Page 27

Test Sequence

The test sequence has been designed to exercise the hardware one component at a time. Wherever possible, the system automatically detects proper

component operation. Where the system cannot detect component operation, the support engineer is required to confirm component operation (visually or audibly). The test sequence is described below along with a brief

description of each subtest. The sequence runs each subtest in order, unless

an error is detected, in which case the system jumps to the reporting phase

at the end of the test sequence, which displays the code for that error. The

‘cycle length’ and ‘progress status’ LEDs are used to indicate progress

through the test sequence. They should turn on one at a time, from top to bot-

tom, left to right, one for each subtest.

Subtest #

1 LEDs Visual Turn all LEDs ON, then OFF and repeat

2Electronics

Subtest

Name

self-test

Error

Detection Subtest Summary Status Display

once more. Return LEDs to their initial state.

This will display between every test (see

below)

Automatic Perform at any power-up, not just diagnostic

mode. The ‘warning’ LED is ON after

power-up if this subtest ever fails.

All LEDs blink

Topmost ’cycle

length’ LED

(long) ON and

’warning’ LED

is ON.

3 Inlet Valve Audible Open and close valve multiple times. 2 ‘cycle length’

LEDs (long +

medium) ON

and ‘warning’

LED is ON.

4Drain

Valve

Audible Open and close valve multiple times. All 3 ‘cycle

length’ LEDs

ON and ‘warning’ LED is

ON.

27

Page 28

Subtest #

5Motor/

6 Float Level

7 Door Lock Visual The system lid can be either open or shut for

8 Door

Subtest

Name

Propeller

Sensor

Assemblies

Switch

Error

Detection Subtest Summary Status Display

Visual Enable motor (propeller should rotate), then

disable motor.

Visual Verify all float level sensor assemblies can

change state.

this subtest. Door lock is activated 4 times.

Automatic Blink ‘warning’ LED until the support engi-

neer opens and closes the system lid to verify both switch states.

All 3 ‘cycle

length’ and

rightmost

‘progress status’ LEDs ON.

‘Warning’ LED

is ON.

All 3 ‘cycle

length’ and

right 2 ‘progress status’

LEDs ON.

‘Warning’ LED

is ON.

All 3 ‘cycle

length’ and

right 3 ‘progress status’

LEDs ON.

‘Warning’ LED

is ON.

All 3 ‘cycle

length’ and all

4 ‘progress status’ LEDs ON.

‘Warning’ LED

is blinking.

9 Heater Automatic Enable heater until test temperature is

reached (or timeout occurs), then disable

heater.

Sequence Reporting

While the ‘cycle load’ LEDs indicate whether the system is in normal or diagnostic mode, the ‘cycle length’, ‘progress status’, and ‘warning’ LEDs (all yellow) indicate diagnostic status. Reporting is very similar for the “entire

sequence” and “interactive” modes, but subtest completion and error status

are handled differently. For either mode, while a subtest is in progress, the

‘cycle length’, ‘progress status’, and ‘warning’ LEDs indicate which subtest is

active.

All 3 ‘cycle

length’, all 4

‘progress status’, and ‘warning’ LEDs ON

28

Page 29

Run all

Once the test sequence is complete, the ‘cycle complete’ LED turns ON. If no

errors were detected, then all ‘cycle length’, ‘progress status’, and ‘warning’

LEDs are OFF, as is the ‘error’ LED. If an error was detected, then the ‘cycle

length’, ‘progress status’, and ‘warning’ LEDs display an error code. The

‘cycle complete’ LED is OFF while the ‘error’ LED blinks.

Interactive mode

After each subtest completes, the ‘cycle length’, ‘progress status’, and ‘warning’ LEDs momentarily turn OFF while the ‘cycle complete’ LED turns ON.

Note that the ‘cycle complete’ LED is green, but is co-located with the left

most ‘progress status’ LED (yellow). The ‘cycle length’, ‘progress status’, and

‘warning’ LEDs continue to indicate the subtest that is selected; they do not

update unless the ‘load select’ (or ‘start’) button is pressed. After the last subtest, pressing ‘load select’ returns the ‘cycle length’, ‘progress status’, and

‘warning’ LEDs to all OFF.

If a failure was detected in interactive mode, then the ‘error’ LED blinks and

the ‘cycle complete’ LED is OFF while the ‘cycle length’ and ‘progress status’

LEDs display an error code. Note that the ‘error’ LED is red, but is co-located

with the ‘warning’ LED (yellow).

Subtest details

LED subtest

Two of the LED locations are bi-color LEDs. These two are easiest to verify if

only one of each pair of LEDs within the package is turned on at a time during testing. The LED test sequence is as follows: first, turn on all yellow LEDs

(‘cycle length’, ‘progress status’, and ‘warning’) ON for ~2 seconds, turn

those OFF while simultaneously turning the green and red LEDs (‘cycle complete’ and ‘error’) ON for ~2 seconds, then all LEDs OFF for ~2 seconds.

Repeat that ON/OFF cycle once more. Return LEDs to proper state for next

subtest (both ‘cycle load’ LEDs ON, etc.).

This should allow support engineers sufficient time to verify that all LEDs can

turn both ON and OFF.

Electronics Selftest

This subtest is performed at any power-up to normal mode as well as during

the diagnostic test sequence. This subtest should perform an internal check of

any and all possible electronic circuits than can be verified automatically.

Inlet Valve subtest

This subtest opens (default state is closed) and then closes the water inlet

valve at a 2 Hz. rate for a total of 5 cycles. This should allow support engineers an opportunity to hear the valve functioning. The valve must be left in

the default state at the end of the subtest. If the system is connected to a

water source, some water will enter the cleaning tank assembly during this

subtest.

29

Page 30

Drain Valve subtest

This subtest opens (default state is closed) and then closes the drain valve at

a 2 Hz. rate for a total of 5 cycles. This should allow support engineers an

opportunity to hear the valve functioning. The valve must be left in the default

state at the end of the subtest.

Motor/Propeller subtest

This subtest enables the agitation motor for a total of approximately 5 seconds, and then disables the motor. The support engineer should be able to

see the propeller rotating during this time.

Float Level Sensor Assemblies subtest

Since there is currently no manual or automatic way of activating the float

level sensor assemblies, this subtest simply checks that the sensors are in

their default state for an empty cleaning tank assembly.

System Lid Lock subtest

This subtest enables (default state is disabled) and then disables the system

lid lock at a 2 Hz. rate for a total of 5 cycles. This should allow support engineers an opportunity to both see (if the system lid is open) and hear the lock

functioning. The lock must be left disabled at the end of this subtest.

System Lid Switch subtest

This subtest necessarily involves support engineer interaction. The support

engineer must open and close the system lid so that the system can verify

that the system lid switch assembly can reach both states. The support engineer must do this within a specified time limit (10 seconds) or the test fails.

Once both states have been verified, the subtest is complete. In order to help

prompt the support engineer to move the system lid, the ‘warning’ LED

should be blinked at a 2 Hz. rate for the duration of this subtest.

Heater subtest

This subtest starts by verifying that the cleaning tank assembly temperature is

within normal operating limits (T

cleaning tank assembly heater (at ~10% duty cycle) until either the temperature rises T

occurs – whichever comes first. If the temperature limit is reached first, then

the heater is disabled. It is an error if the time limit expires before the temperature limit is reached. The heater should be immediately disabled in case of

an error. During this subtest, the support engineer is allowed to keep the system lid open in order to touch the inside of the sink for manual verification.

Therefore, the subtest temperature limit (T

There is no delay to wait for the system to cool back down after this subtest,

so repeated execution of this subtest will eventually cause a failure due to the

starting temperature being above T

run within 30 seconds of powering on the system.

subtest –limit

above the subtest’s starting temperature or a time-out

env-min

env-max

°C to T

subtest-limit

°C. The heater subtest will fail if

°C). If so, it enables the

env-max

) should be kept < 50°C.

30

Page 31

Service Procedures

Maintenance Preparation............................................................. page 32

Cabinet Components.................................................................... page 34

System Lid .................................................................................... page 34

Lower Housing Assembly................................................................ page 36

Upper Housing Assembly ............................................................... page 38

Hardware Components ................................................................ page 39

Back Panel ................................................................................... page 39

Line Filter...................................................................................... page 44

Thermostat.................................................................................... page 45

Thermometer Board ....................................................................... page 47

User Interface Board...................................................................... page 49

Power Entry Module ...................................................................... page 52

Main Control Board....................................................................... page 54

Cleaning Tank Assembly ................................................................ page 60

Agitation Assembly........................................................................ page 65

Drive Belt ..................................................................................... page 68

Induction Motor Assembly .............................................................. page 70

Float Level Sensor Assembly ........................................................... page 72

Lid Switch Assembly ...................................................................... page 74

Lid Lock Assembly ......................................................................... page 76

31

Page 32

Maintenanc e Preparati on

Read these warnings before performing service on the HP

Designjet 3D Remove System!

WARNING: Make sure the power is disconnected when

performing any of the disassembly or

assembly instructions in this section. Failure

to do so can cause severe personal injury or

damage to the electronics.

WARNING: Servicing instruc tions outlined in this section

are intended for use by qualified personnel

only. Failure to follow these guidelines can

cause severe injury.

WARNING: The Power Switch located on the rear of the

HP Designjet 3D Removal System MUST be

off before service is performed on the

system. It is recommended that the AC power

cord be disconnected before performing

maintenance outlined in this section.

NOTE: All references within this procedure to ‘Left’ or

‘Right’ are made assuming that the system is being

viewed from the ‘Front’ of the system.

NOTE: Before disassembling, make sure all liquid is

removed from the system to prevent trapped liquid from

dripping on the system electronics.

32

Page 33

Required Tool List

1. #1 standard screwdriver

2. #2 standard screwdriver

3. #1 phillips screwdriver

4. #2 phillips screwdriver

5. Pliers

6. Small wire cutters

7. Gr o u n d i n g s t r a p

8. 11/32” box wrench (PN 208853-0001)

9. Box wren ches

Prerequisite procedures

1. Cancel any pending jobs and wait for the system to drain. If the

system is inoperable, see “Inoperable system” on page 33.

2. After the system has drained toggle the On/Off switch at the

back of the system to Off.

3. Remove the AC power cord from the system.

4. Remove the inlet hose and the drain hose from the system.

5. Open the lid and make sure there is no liquid in the cleaning

tank. Drain any liquid from the system making sure that all

trapped liquid is removed from the cleaning tank.

NOTE: Before disassembling, make sure all liquid is

removed from the system to prevent trapped liquid from

dripping on the system electronics.

Inoperable system

If the system lid is in the locked position and cannot be opened, do the

following:

1. Using a #1 standard screwdriver, place the blade of the

screwdriver on the solenoid latch and then force the latch back

into the upper housing. See Figure 10.

2. After the solenoid latch has been moved back into the upper

housing, the lid will be free to open.

Figure 10: Door lock solenoid latch

3. After the lid has been opened, drain any liquid from the system

making sure that all trapped liquid is removed from the cleaning

tank.

33

Page 34

Center hinge pin

Cabinet Components

System Lid Removing th e system li d

1. Open the system lid and then move the lid beyond its natural

stopping point. Continue to move the lid until the lid snaps off

the housing hinges. See Figure 11.

2. Set the lid aside.

Figure 11: System Lid

Installing the system lid

1. Make sure that both lid hinge pins are centered in the hinges.

See Figure 12.

Figure 12: Center hinge pins

2. Position the lid so the lid hinges and the housing hinges line up.

See Figure 13.

34

Page 35

Figure 13: Attaching the lid

Snap lid hinges

onto housing hinges

3. Firmly press the lid hinges onto the housing hinges so the hinges

snap together. A sharp blow with the heel of your hand is sufficient to snap the hinges into place. See Figure 14.

Figure 14: Snapping the lid in place

4. Close the lid.

35

Page 36

Remove 5

screws

Remove 4 screws

Lower Housing Assembly

Required Tools

•#2 phillips screwdriver

Hardware

•10-32 x 1⁄2” phillips screw (x5)

Removing the lower housing assembly

NOTE: Before disassembling, make sure all liquid is

removed from the system to prevent trapped liquid from

dripping on the system electronics.

1. Using a #2 phillips screwdriver, remove the 5 screws that attach

the lower housing to back panel as shown in Figure 15.

Figure 15: Lower Housing screw locations

2. Remove the system lid so it won’t get in the way when servicing

the system. See “Removing the system lid” on page 34.

3. Flip the system upside down to gain access to the bottom of the

system.

4. Using a magnetized #2 phillips screwdriver, remove 4 screws

from the left side and right side of the lower housing. See Figure

16 .

Figure 16: Lower Housing screw locations

5. Lift up the lower housing and set the housing aside.

36

Page 37

Installing the lower housing assembly

NOTE: Prior to reassembling the system, check that

there is no liquid on the system electronics.

1. Place the lower housing in position and attach using 4 screws.

2. Flip the system right-side up.

3. Using a #2 phillips screwdriver, attach 5 screws to the back of

the housing. See Figure 15.

4. Attach the lid to the system. See “Installing the system lid” on

page 34.

37

Page 38

Upper Housing Assembly

Removing the upper housing assembly

1. Remove the back panel. See “Removing the back panel” on

page 39.

2. Remove the user interface board. See “Removing the user inter-

face board” on page 49.

3. Remove the cleaning tank assembly. See “Removing the clean-

ing tank assembly” on page 60.

4. Remove the agitation assembly. See “Removing the agitation

assembly” on page 65.

Figure 17: Upper housing assembly

Installing the upper housing assembly

1. Install the agitation assembly. See “Installing the agitation

assembly” on page 67.

2. Install the cleaning tank assembly. See “Installing the cleaning

tank assembly” on page 61.

3. Install the user interface board. See “Installing the user interface

board” on page 51.

4. Install the back panel. See “Installing the back panel” on

page 42.

38

Page 39

Hardware Co mponents

Remove 2

mounting screws

Remove 2

mounting screws

Back Panel

Required Tools

• #2 phillips screwdriver

•Grounding strap

Hardware

• 8-32 x 3/8” phillips screw (x3)

• 4-0.7 x 10 mm screw (x4)

Removing the back panel

1. Remove the lower housing. See “Removing the lower housing

assembly” on page 36.

2. Using a #2 screwdriver, remove 2 mounting screws that attach

the wastewater drain components to the back panel. See Figure

18 .

3. Using a #2 screwdriver, remove 2 mounting screws that attach

the water inlet components to the back panel.

Figure 18: Back panel screw location

39

Page 40

4. Using a #2 phillips screwdriver, remove 3 locking screws that

Remove 3

locking screws

attach the back panel to the upper housing See Figure 19.

Figure 19: Back panel screw locations

5. Tilt the back panel to gain access the connectors. Be careful not

to put stress on any wire cables.

6. Disconnect the following cable connectors from the main control

board: (see Figure 20)

• P10 Power Cable (PN 208700)

• P8 Motor Power (PN 208709)

•P7 Inlet Valve (PN 208701)

• P6 Drain Valve (PN 208702)

• P1A Heater (PN 208723) (black wire)

• P1B Heater (PN 208723) (white wire)

• P5 Data Cable (PN 208726)

• P4 Level Sensor (PN 208725)

7. Remove 1 grounding screw and remove 2 green grounding

wires. See Figure 20.

40

Page 41

Figure 20: Main board connector locations

P8

P7

P6

P1A

P1B

P5

P4

P10

Grounding

screw

AC GND

EMI P

EMI N

8. Disconnect 1 ground wire from the power entry module (AC

GND). See Figure 21.

9. Disconnect 2 wires from the line filter. (EMI P and EMI N).

10. Remove the back panel from the system.

Figure 21: Main control board connections

41

Page 42

Installing the back panel

Remove 3

locking screws

1. Place the back panel in position.

2. Using a #2 phillips screwdriver, attach 2 green grounding wires

using 1 grounding screw. See Figure 20.

3. Connect the following cables to the main control board: (see

Figure 20)

• P10 Power Cable (PN 208700)

• P8 Motor Power (PN 208709)

•P7 Inlet Valve (PN 208701)

• P6 Drain Valve (PN 208702)

• P1A Heater (PN 208723) (black wire)

• P1B Heater (PN 208723) (white wire)

• P5 Data Cable (PN 208726)

• P4 Level Sensor (PN 208725)

4. Connect 1 ground wire to the power entry module (AC GND).

See Figure 21.

5. Connect 2 wires to the line filter. (EMI P and EMI N).

6. Using a #2 phillips screwdriver, attach the back panel to the

upper housing using 3 screws.

Figure 22: Back panel screw locations

42

Page 43

7. Using a #2 screwdriver, attach wastewater drain components to

Remove 2

mounting screws

Remove 2

mounting screws

the back panel using 2 screws. See Figure 23.

8. Using a #2 screwdriver, attach the water inlet components to

the back panel using 2 screws. See Figure 23

Figure 23: Back panel screw location

9. Install the lower housing. See “Installing the lower housing

assembly” on page 37.

43

Page 44

Line Filter

Remove 2 mounting

screws and 2 star

EMI P

EMI N

AC L

AC N

washers

Required Tools

• #2 phillips screwdriver

Hardware

• 8-32 x 1/4” phillips screw (x2)

Removing the line filter

1. Remove the lower housing. See “Removing the lower housing

assembly” on page 36.

2. Disconnect 2 input wires from the line filter. See Figure 24.

3. Disconnect 2 output wires from the line filter.

4. Using a #2 phillips screwdriver, remove 2 mounting screws that

attach the line filter to the back panel.

5. Remove the line filter from the back panel.

Figure 24: Line filter

Installing the line filter

1. Place the line filter in position and attach the filter to the back

panel using 2 mounting screws.

2. Attach the AC L and the AC N wires to the input of the line filter.

3. Attach the EMI P and the EMI N wires to output of the line filter.

4. Install the lower housing. See “Installing the lower housing

assembly” on page 37.

44

Page 45

Thermostat

Remove 2

mounting nuts

Hot In

Hot Out

Required Tools

• 11/32” box wrench (PN 208853-0001)

Hardware

• 6-32” nut (x2)

Removing the thermostat

1. Remove the lower housing. See “Removing the lower housing

assembly” on page 36.

2. Disconnect 2 wires from the thermostat. See Figure 25.

3. Using the 11/32” box wrench (PN 208853-0001), remove 2

11/32” mounting nuts that attach the thermostat to the cleaning

tank.

Figure 25: Thermostat nut locatio n

45

Page 46

4. Remove the thermostat and the thermal heat sink pad from the

Thermostat

Heat sink

pad

system. See Figure 26.

Figure 26: Thermostat removal

Installing the thermostat

1. Place the heat sink pad in position on the cleaning tank.

2. Place the thermostat in position over the heat sink pad.

3. Using the 11/32” box wrench (PN 208853-0001), attach the

thermostat to the cleaning tank using 2 11/32” mounting nuts.

Make sure the thermal heat sink pad is between the thermostat

and the cleaning tank and has not shifted.

4. Connect 2 wires on the thermostat. See Figure 25.

5. Install the lower housing. See “Installing the lower housing

assembly” on page 37.

46

Page 47

Thermometer Board

Remove 2

mounting nuts

J20

Required Tools

•5/16” wrench

•Grounding strap

Hardware

• 6-32” nut (x2)

Removing the thermometer board

1. Remove the lower housing. See “Removing the lower housing

assembly” on page 36.

2. Disconnect J20 from the thermometer board. See Figure 27.

3. Using a 5/16” wrench, remove the 2 mounting nuts that secure

the thermometer board to the cleaning tank.

Figure 27: Thermometer board

47

Page 48

4. Remove the thermometer board and the heat sink pad from the

Heat sink

pad

Thermometer

board

Stud spacers

remain in place

cleaning tank. Make sure the stud spacers remain in place. See

Figure 28.

Figure 28: Thermometer board removal

Installing the thermometer

1. Place the heat sink pad between the thermometer board and

the cleaning tank.

2. Using the 5/16” box wrench, attach the thermometer board to

the cleaning tank using 2 5/16” nuts. Make sure the heat sink

pad is positioned properly between the board and the cleaning

tank. Do not over tighten the 5/16” nuts.

3. Connect J20 to the thermometer board. See Figure 27

4. Install the lower housing. See “Installing the lower housing

assembly” on page 37.

48

Page 49

User Interface Board

P37

P33

P32

P31

P34

Required Tools

• #2 phillips screwdriver

• Ground strap

Hardware

• 6-32 3/16” phillips screw (x4)

Removing the user interface board

1. Remove the lower housing. See “Removing the lower housing

assembly” on page 36.

2. Disconnect the following cable connectors (see Figure 32) from

the user interface board:

• P33 Door sensor (PN 208705)

•P32 Door solenoid (PN 208704)

• P31 Thermal sensor (208706-0001)

•P34 Power strip

• P37 Data and power (PN 208726)

Figure 29: Connector locations

49

Page 50

3. To unlock connector bracket on P36, squeeze and pull up on

Pull up on the

data cable

P36

Squeeze and pull up

ends of connector bracket

Remove 3 mounting screws

Remove 1 mounting

screw and 1 grounding

wire

the ends of the connector bracket. See Figure 30.

4. Disconnect the flexible data cable by pulling the cable out of

connector P36. See Figure 30.

Figure 30: Flexible data cable removal

5. Using a #2 phillips screwdriver, remove 3 mounting screws that

attach the user interface board to the board mounting bracket.

See Figure 31.

6. Using a #2 phillips screwdriver, remove 1 mounting screw

along with 1 grounding wire. See Figure 31.

Figure 31: User interface board screw locations

7. Remove the user interface board.

50

Page 51

Installing the user interface board

1. Place the user interface board in position over the standoffs.

2. Using a #2 phillips screwdriver, attach the board to the stand-

offs using 3 mounting screws.

3. Using a #2 phillips screwdriver, attach 1 grounding wire and 1

mounting screw to secure the board to the system.

4. Connect the flexible data cable (P36) to the interface board.

Make sure to securely lock the connector bracket in position by

pushing down on the bracket.

5. Connect the following cable connectors to the interface board:

(see Figure 29)

• P33 Door sensor (PN 208705)

• P32 Door solenoid ( 208704)

• P31 Thermal sensor (208706-0001)

•P34 Power strip

• P37 Data and power (PN 208726)

6. Install the lower housing. See “Installing the lower housing

assembly” on page 37.

51

Page 52

Power Entry Module

Green wire

White wire

Black wire

(L)

(N)

(Ground)

Metal tab

Required Tools

• #2 standard screwdriver

Removing the power entry module

1. Remove the lower housing. See “Removing the lower housing

assembly” on page 36.

2. Disconnect 3 wires from the back of the power entry module.

See Figure 32.

Figure 32: Power Entry Module Wires

3. Using a #2 standard screwdriver, press the metal tabs on the

power entry module in and remove the module from the back

panel. See Figure 33.

Figure 33: Power Entry Module

52

Page 53

Installing the power entry module

1. Press the power entry module into the back panel making sure

the metal tabs lock in place.

2. Attach 3 wires to the back of the power entry module. See Fig-

ure 32 for wiring details.

3. Install the lower housing. See “Installing the system lid” on

page 34.

53

Page 54

Main Control Board

Required Tools

• #2 phillips screwdriver

•Grounding strap

Hardware

• 8-32 x 1-3/8” nylon phillips screw (x3)

• 6-32 x 3/16” phillips screw (x7)

• 8-32 x 3/8” phillips screw (x3)

• 4-0.7 x 10 mm screw (x4)

Removing the main control board

1. Remove the lower housing. See “Removing the lower housing

assembly” on page 36.

2. Using a #2 screwdriver, remove 2 mounting screws that attach

the wastewater drain components to the back panel. See Figure

34.

3. Using a #2 screwdriver, remove 2 mounting screws that attach

the water inlet components to the back panel.

54

Page 55

Figure 34: Back panel screw location

Remove 2

mounting screws

Remove 2

mounting screws

55

Page 56

4. Using a #2 phillips screwdriver, remove 3 locking screws that

Remove 3

locking screws

attach the back panel to the upper housing.

Figure 35: Back panel screw locations

5. Tilt the back panel to gain access the connectors. Be careful not

to put stress on any wire cables.

6. Disconnect the following cable connectors from the main control

board: (see Figure 36)

• P10 Power Cable (PN 208700)

• P8 Motor Power (PN 208709)

•P7 Inlet Valve (PN 208701)

• P6 Drain Valve (PN 208702)

• P1A Heater (PN 208723) (black wire)

• P1B Heater (PN 208723) (white wire)

• P5 Data Cable (PN 208726)

• P4 Level Sensor (PN 208725)

7. Remove 1 grounding screw and remove 2 green grounding

wires. See Figure 36.

56

Page 57

Figure 36: Main board connector locations

P8

P7

P6

P1A

P1B

P5

P4

P10

Grounding

screw

AC GND

EMI P

EMI N

8. Disconnect 1 ground wire from the power entry module (AC

GND). See Figure 37.

9. Disconnect 2 wires from the line filter. (EMI P and EMI N).

Figur e 37: Main control board connections

57

Page 58

Remove 3

nylon screws

Remove 7 mounting screws

Remove 3 wing

nuts and 3 nylon

screws

10. Remove 7 mounting screws that attach the main control board

to the back panel. See Figure 38.

11. Remove 3 nylon screw that attach the main control board to the

back panel.

Figure 38: Main control board mounting screws

12. Remove the main control board from the back panel.

Installing the main control board

1. Remove the 3 shipping wing nuts and 3 nylon screws before

installing the control board.

2. Place the main control board in position and using a #2 phillips

screwdriver, attach but do not tighten 7 mounting screws that

attach the main control board to the back panel.

3. Using a #2 phillips screwdriver, attach but do not tighten 3

nylon mounting screws to secure the main control board to the

back panel.

4. After all 7 screws and the 3 nylon screws are installed, go back

and tighten all the screws.

58

Page 59

5. Using a #2 phillips screwdriver, attach 2 green grounding wires

using 1 grounding screw. See Figure 36.

6. Connect the following cables to the main control board: (see

Figure 36)

• P10 Power Cable (PN 208700)

• P8 Motor Power (PN 208709)

•P7 Inlet Valve (PN 208701)

• P6 Drain Valve (PN 208702)

• P1A Heater (PN 208723) (black wire)

• P1B Heater (PN 208723) (white wire)

• P5 Data Cable (PN 208726)

• P4 Level Sensor (PN 208725)

7. Connect 1 ground wire to the power entry module (AC GND).

See Figure 37.

8. Connect 2 wires to the line filter. (EMI P and EMI N).

9. Install the lower housing. See “Installing the lower housing

assembly” on page 37.

59

Page 60

Cleaning Tank Assembly

Tank holding

clamps (X4)

Required Tools

• #2 phillips screwdriver

•Anti-seize compound

• Tank chassis seal

• Alcohol wipes

Hardware

• 8-32 x 3/8” phillips screw (x12)

Removing the cleaning tank assembly

1. Remove the back panel. See “Removing the back panel” on

page 39.

2. Remove the user interface board. See “Removing the user inter-

face board” on page 49.

3. Using a #2 phillips screwdriver, remove the 4 tank holding

clamps. Each clamp has 3 mounting screws securing each

clamp to the upper housing. See Figure 39.

Figure 39: Cleaning tank clamp removal

4. Disconnect the 2 spade connectors from the drain solenoid. See

Figure 40.

5. Disconnect the 2 spade connectors from the thermostat.

6. Remove 5 screws that attach the cleaning tank to the agitation

assembly and remove the agitation assembly.

60

Page 61

Figure 40: Cleaning tank removal locations

Drain solenoid

spade connectors

Thermostat spade

connectors

Remove 5 mounting screws

Remove and discard

the tank chassis

seal

7. Remove the cleaning tank from the system by slightly twisting

the cleaning tank to clear the agitation assembly.

8. Remove and discard the tank chassis seal from the upper hous-

ing. See Figure 41.

Figure 41: Cleaning tank assembly removal

Installing the cleaning tank assembly

1. Use alcohol wipes to clean any remnants left by the tank chassis

seal.

2. Position the tank chassis gasket over the agitation assembly as

show in Figure 42. Make sure the holes in the tank chassis gasket aligned over the threaded holes on the agitator assembly.

3. Install the cleaning tank on top of the lower housing making

sure to not wrinkle the tank chassis seal.

61

Page 62

Alignment holes (5X)

Figure 42: Agitation assembly tank chassis gasket alignment

4. Using a #2 phillips screwdriver, attach the cleaning tank to the

upper housing using 5 screws. Make sure to use anti-seize compound on the screws before installing.

5. Using a #2 phillips screwdriver, loosely attach 4 tank holding

clamps. Each holding clamp is secured to the upper housing by

3 screws each. The tank holding clamps are all a unique size so

make sure they are in their proper location.

62

Page 63

Tighten 3 screws on this tank clamp last.

Tighten 3 screws on this tank clamp next.

Tighten 3 screws on this tank clamp next.

Tighten 3 screws on this tank clamp first.

6. After all 4 tank clamps are in and their screws are holding the

cleaning tank in position, tighten the 4 tank clamps in the

sequence show in Figure 43.

Figure 43: Cleaning tank tightening sequence

63

Page 64

7. Install the user interface board. See “Installing the user interface

board” on page 51.

8. Install the back panel. See “Installing the back panel” on

page 42.

64

Page 65

Agitation Assembly

Remove

1 screw

Required Tools

• #2 phillips screwdriver

•Anti-seize compound

Hardware

• 8-32 x 3/8” phillips screw (x1)

• #8 lock washer (x1)

Removing the agitation assembly

1. Remove the back panel. See “Removing the back panel” on

page 39.

2. Remove the user interface board. See “Removing the user inter-

face board” on page 49.

3. Remove the cleaning tank assembly. See “Removing the clean-

ing tank assembly” on page 60.

4. Using a #2 phillips screwdriver, remove 1 mounting screw and

1 lock washer that attach the agitation assembly to the upper

housing. See Figure 44.

Figure 44: Agitation assembly removal

5. Lift up and remove the agitation assembly from the upper hous-

ing.

65

Page 66

Tension idler

pulley

Move to

relieve

tension

Remove 1

motor grounding

screw and 1

Remove 4

mounting screws

grounding wire

6. Move the tension idler pulley to relieve tension on the drive belt

and then remove the drive belt. See Figure 45.

Figur e 45: Drive belt replacement

7. Using a #2 screwdriver, remove 1 grounding screw and 1

grounding wire.

8. Using a #2 screwdriver, remove the 4 mounting screws.

Figure 46: Induction motor assembly

n

9. Remove the induction motor from the agitation assembly for

installation on the new agitation assembly.

66

Page 67

Installing the agitation assembly

1. Install the induction motor removed from the old agitation

assembly onto the new agitation assembly.

2. Move the tension idler pulley up and then install the drive belt

as shown in Figure 47.

Figur e 47: Drive belt installation

3. Place the agitation assembly in position on the upper housing.

4. Using a #2 phillips screwdriver, attach 1 screw and 1 lock

washer to secure the agitation assembly to the upper housing.

Make sure to use anti-seize compound on the screw before

installing.

5. Install the cleaning tank assembly. See “Installing the cleaning

tank assembly” on page 61.

6. Install the user interface board. See “Installing the user interface

board” on page 51.

7. Install the lower housing. See “Installing the lower housing

assembly” on page 37.

8. Install the back panel. See “Installing the back panel” on

page 42.

67

Page 68

Tension idler

pulley

Move to

relieve

tension

Drive Belt

Removing the drive belt

1. Remove the back panel. See “Removing the back panel” on

page 39.

2. Remove the user interface board. See “Removing the user inter-

face board” on page 49.

3. Remove the cleaning tank assembly. See “Removing the clean-

ing tank assembly” on page 60.

4. Remove the agitation assembly. See “Removing the agitation

assembly” on page 65.

5. Move the tension idler pulley to relieve tension on the drive belt

and then remove the belt. See Figure 48.

Figure 48: Drive belt replacement

Installing the drive belt

1. Move the tension idler pulley up and then install the drive belt

as shown in Figure 49.

Figure 49: Drive belt installation

68

Page 69

2. Install the agitation assembly. See “Installing the agitation

assembly” on page 67.

3. Install the cleaning tank assembly. See “Installing the cleaning

tank assembly” on page 61.

4. Install the user interface board. See “Installing the user interface

board” on page 51.

5. Install the back panel. See “Installing the back panel” on

page 42.

69

Page 70

Tension idler

pulley

Move to

relieve

tension

Induction Motor Assembly

Required Tools

• #2 phillips screwdriver

Hardware

• #10 lock washer (x4)

• #10 flat washer (x4)

• 10-32 x 3/4” phillips screw (x4)

Removing the induction motor assembly

1. Remove the back panel. See “Removing the back panel” on

page 39.

2. Remove the user interface board. See “Removing the user inter-

face board” on page 49.

3. Remove the cleaning tank assembly. See “Removing the clean-

ing tank assembly” on page 60.

4. Remove the agitation assembly. See “Removing the agitation

assembly” on page 65.

5. Move the tension idler pulley to relieve tension on the drive belt

and then remove the belt. See Figure 50.

Figur e 50: Drive belt replacement

70

Page 71

6. Using a #2 screwdriver, remove 1 grounding screw and 1

Remove 1

motor grounding

screw and 1

Remove 4

mounting screws

grounding wire

grounding wire.

7. Using a #2 screwdriver, remove the 4 mounting screws.

Figure 51: Induction motor assembly

8. Remove the induction motor from the agitation assembly.

Installing the induction motor assembly

n

1. Place the induction motor assembly in position and using a #2

phillips screwdriver, attach 4 screws to secure the motor to the

agitation assembly.

2. Using a #2 phillips screwdriver, attach 1 grounding wire to the

induction motor assembly.

3. Install the drive belt. See “Installing the drive belt” on page 68.

4. Install the agitation assembly. See “Installing the agitation

assembly” on page 67.

5. Install the cleaning tank assembly. See “Installing the cleaning

tank assembly” on page 61.

6. Install the user interface board. See “Installing the user interface

board” on page 51.

7. Install the back panel. See “Installing the back panel” on

page 42.

71

Page 72

Float Level Sensor Assembly

Required Tools

• #2 phillips screwdriver

•Anti-seize compound

Hardware

• #8 lock washer (x2)

• 8-32 x 3/8” phillips screw (x7)

Removing the float level sensor assembly

1. Remove the back panel. See “Removing the back panel” on

page 39.

2. Remove the user interface board. See “Removing the user inter-

face board” on page 49.

3. Remove the cleaning tank assembly. See “Removing the clean-

ing tank assembly” on page 60.

4. Remove the agitation assembly. See “Removing the agitation

assembly” on page 65.

5. Using a #2 phillips screwdriver, remove 5 cable routing clamps.

See Figure 52.

6. Lift the float level sensor assembly out of the agitation assembly.

7. Using a #2 phillips screwdriver, remove the 2 screws that attach

the float level sensor assembly to the agitation assembly.

8. Remove the float level sensor assembly from the agitation

assembly.

72

Page 73

Figure 52: Float level sensor assembly

Remove 5 screws

Remove

2 screws

and 2 lock

washers

Installing the float level sensor assembly

1. Place the float level sensor assembly in the agitation assembly.

2. Using a #2 phillips screwdriver, secure the float level sensor

assembly to the agitation assembly with 2 screws. Make sure to

use anti-seize compound on the screws before installing.

3. Using a #2 phillips screwdriver, secure 5 cable routing clamps

to the agitation assembly standoffs. Make sure to use anti-seize

compound on the screws before installing.

4. Install the agitation assembly. See “Installing the agitation

assembly” on page 67.

5. Install the cleaning tank assembly. See “Installing the cleaning

tank assembly” on page 61.

6. Install the user interface board. See “Installing the user interface

board” on page 51.

7. Install the lower housing. See “Installing the lower housing

assembly” on page 37.

8. Install the back panel. See “Installing the back panel” on

page 42

73

Page 74

Lid Switch Assembly

Remove 1 screw and 1 flat washer

Lid switch

Required Tools

• #2 phillips screwdriver

Hardware

• 0.174 x 0.375 flat washer (x1)

• 8-32 x 5/8” phillips screw (x1)

Removing the lid switch assembly

1. Remove the back panel. See “Removing the back panel” on

page 39.

2. Remove the user interface board. See “Removing the user inter-

face board” on page 49.

3. Remove the cleaning tank assembly. See “Removing the clean-

ing tank assembly” on page 60.

4. Remove the agitation assembly. See “Removing the agitation

assembly” on page 65.

5. Using a #2 phillips screwdriver, remove 1 screw that attaches

the lid switch assembly to the agitation assembly. See Figure

53.

Figure 53: Lid switch assembly

74

Page 75

Installing the lid switch assembly

Wire routing

1. Place the lid switch assembly in position and using a #2 phillips

screws, attach the lid switch assembly to the agitation assembly

2. Route the wiring as shown in Figure 54. Make sure no wiring is

pinched during installation.

Figure 54: Lid lock assembly wire routing

3. Install the agitation assembly. See “Installing the agitation

assembly” on page 67.

4. Install the cleaning tank assembly. See “Installing the cleaning

tank assembly” on page 61.

5. Install the user interface board. See “Installing the user interface

board” on page 51.

6. Install the back panel. See “Installing the back panel” on

page 42.

75

Page 76

Lid Lock Assembly

Remove 3

screws

Required Tools

• #2 phillips screwdriver

Hardware

• 8-32 x 3/8” phillips screw (x3)

• #8 lock washer (x3)

• 0.174 x 0.375 flat washer (x3)

Removing the lid lock assembly

1. Remove the back panel. See “Removing the back panel” on

page 39.

2. Remove the user interface board. See “Removing the user inter-

face board” on page 49.

3. Remove the cleaning tank assembly. See “Removing the clean-

ing tank assembly” on page 60.

4. Remove the agitation assembly. See “Removing the agitation

assembly” on page 65.

5. Using a #2 phillips screwdriver, remove 3 screws that attach the

lid lock assembly to the agitation assembly. See Figure 55

Figure 55: Lid lock assembly removal

6. Remove the lid lock assembly from the agitation assembly.

76

Page 77

Installing the lid lock assembly

Wire routing

1. Using a #2 phillips screwdriver, loosely attach the lid lock

assembly to the agitation assembly.

2. Temporarily place the agitation assembly in position and adjust

the lid lock assembly for smooth operation and with no binding.

Using a #2 phillips screwdriver, tighten 3 screws to secure the

solenoid to the agitation assembly.