Page 1

LASERJET PRO CP1020

COLOR PRINTER SERIES

Service Manual

Page 2

Copyright and License

Trademark Credits

© 2010 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is

prohibited, except as allowed under the

copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CE913-90943

Edition 1, 10/2010

Microsoft®, Windows®, Windows® XP,

and Windows Vista® are U.S. registered

trademarks of Microsoft Corporation.

Page 3

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging

the product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal

injury, catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 4

Table of contents

1 Removal and replacement ................................................................................................ 1

Introduction ............................................................................................................................. 2

Removal and replacement strategy ............................................................................................. 2

Electrostatic discharge .............................................................................................................. 3

Required tools .......................................................................................................................... 3

Service approach ..................................................................................................................... 4

Before performing service .......................................................................................... 4

After performing service ............................................................................................. 4

Post-service test ......................................................................................................... 4

Print-quality test .......................................................................................... 4

Parts removal order ................................................................................................... 5

Removal and replacement procedures ........................................................................................ 6

Replace the print cartridges ........................................................................................ 6

Replace the imaging drum .......................................................................................... 9

Input tray ............................................................................................................... 13

Secondary transfer roller .......................................................................................... 14

Separation pad assembly ......................................................................................... 15

Remove the separation pad assembly ......................................................... 15

Pickup roller ........................................................................................................... 16

Remove the pickup roller assembly ............................................................. 17

Covers ................................................................................................................... 18

Right cover assembly ................................................................................ 18

Remove the right cover assembly ................................................. 18

Left cover assembly ................................................................................... 19

Remove the left cover assembly ................................................... 19

Top door assembly ................................................................................... 20

Remove the top door assembly .................................................... 20

Rear top cover assembly ........................................................................... 22

Remove the rear top cover assembly ............................................ 22

Rear door assembly .................................................................................. 23

Remove the rear door assembly .................................................. 23

Rear lower cover assembly ........................................................................ 24

Remove the rear lower cover assembly ......................................... 24

Control panel .......................................................................................... 25

ENWW v

Page 5

Remove the control panel ........................................................... 25

Front door ............................................................................................... 27

Remove the front door ................................................................ 27

Main assemblies ..................................................................................................... 29

ITB assembly ............................................................................................ 29

Remove the ITB assembly ............................................................ 29

Fuser delivery assembly ............................................................................ 38

Remove the fuser delivery assembly ............................................. 39

Formatter PCA (base model) ...................................................................... 43

Remove the formatter PCA (base model) ....................................... 43

Formatter and wireless PCA (plus model) ..................................................... 44

Remove the formatter and wireless PCA (plus model) ..................... 44

Engine controller assembly ........................................................................ 46

Remove the engine controller assembly ........................................ 46

Low-voltage power supply assembly ........................................................... 49

Remove the low-voltage power supply assembly ............................ 49

2 Solve problems ............................................................................................................... 53

Solve problems checklist ......................................................................................................... 54

Step 1: Make sure that the product is set up correctly .................................................. 54

Step 2: Check the cabling or wireless connection (network models only) ........................ 54

Step 3: Check to see if any control-panel lights are lit .................................................. 54

Step 4: Check the paper .......................................................................................... 54

Step 5: Check the software ....................................................................................... 55

Step 6: Test print functionality ................................................................................... 55

Step 7: Check the supplies ....................................................................................... 55

Step 8: Try sending a print job from a computer ......................................................... 55

Troubleshooting process .......................................................................................................... 56

Determine the problem source ................................................................................... 56

Power subsystem ..................................................................................................... 57

Power-on checks ...................................................................................... 57

Tools for troubleshooting ......................................................................................................... 58

Component diagnostics ............................................................................................ 58

Engine diagnostics ................................................................................... 58

Engine test page ...................................................................................... 58

Diagrams ............................................................................................................... 59

Plug/jack locations ................................................................................... 59

Locations of connectors ............................................................................. 60

Locations of major components .................................................................. 61

General timing chart ................................................................................. 63

General circuit diagram ............................................................................ 64

Internal print-quality test pages .................................................................................. 65

Print quality troubleshooting page .............................................................. 65

vi ENWW

Page 6

Interpret the Print Quality Page .................................................... 65

Clean the paper path ............................................................................... 66

Print configuration page ............................................................................ 66

Print-quality troubleshooting tools .............................................................................. 67

Repetitive image defects ruler .................................................................... 67

Calibrate the product ................................................................................ 67

Interpret control panel light patterns ........................................................................... 68

Status alert messages ............................................................................................... 71

Clear jams ............................................................................................................................ 77

Prevent paper jams .................................................................................................. 77

Jam locations .......................................................................................................... 78

Clear jams from the input tray ................................................................................... 78

Clear jams from the output bin .................................................................................. 80

Clear jams from the rear door ................................................................................... 81

The product does not feed automatically ................................................................................... 82

The product feeds multiple sheets ............................................................................................. 82

Solve image-quality problems .................................................................................................. 83

Image defects table ................................................................................................. 83

Clean the product .................................................................................................................. 89

Clean the separation pad or pickup roller .................................................................. 89

Clean the paper path .............................................................................................. 90

Clean the exterior ................................................................................................... 90

Solve performance problems ................................................................................................... 91

The product does not print ........................................................................................ 91

The product prints slowly .......................................................................................... 91

Solve connectivity problems ..................................................................................................... 92

Solve direct-connect problems ................................................................................... 92

Solve network problems ........................................................................................... 92

Poor physical connection ........................................................................... 92

The computer is using the incorrect IP address for the product ........................ 92

The computer is unable to communicate with the product .............................. 93

The product is using incorrect link and duplex settings for the network ............ 93

New software programs might be causing compatibility problems .................. 93

The computer or workstation might be set up incorrectly ................................ 93

The product is disabled, or other network settings are incorrect ...................... 93

Solve wireless network problems (wireless models only) ............................................... 94

Wireless connectivity checklist ................................................................... 94

The product does not print after the wireless configuration completes .............. 94

The product does not print, and the computer has a third-party firewall

installed .................................................................................................. 95

The wireless connection does not work after moving the wireless router or

product ................................................................................................... 95

Cannot connect more computers to the wireless product ................................ 95

The wireless product loses communication when connected to a VPN ............. 95

ENWW vii

Page 7

The network does not appear in the wireless networks list ............................. 95

The wireless network is not functioning ........................................................ 95

Service mode functions ........................................................................................................... 97

Product resets ......................................................................................................... 97

Product updates ..................................................................................................................... 97

3 Parts and diagrams ........................................................................................................ 99

Order parts by authorized service providers ............................................................................ 100

Order replacement parts ........................................................................................ 100

Related documentation and software ....................................................................... 100

Supplies part numbers ........................................................................................... 100

Service parts ........................................................................................................ 100

Whole-unit replacement part numbers ...................................................................... 101

How to use the parts lists and diagrams .................................................................................. 102

Assembly locations ............................................................................................................... 103

Base product (no optional trays or accessories) ......................................................... 103

Covers, panels, and doors .................................................................................................... 104

Internal assembly ................................................................................................................. 106

Internal assembly .................................................................................................. 106

PCAs .................................................................................................................................. 108

Alphabetical parts list ........................................................................................................... 110

Numerical parts list .............................................................................................................. 112

Appendix A Service and support ..................................................................................... 115

Hewlett-Packard limited warranty statement ............................................................................. 116

HP's Premium Protection Warranty: LaserJet print cartridge limited warranty statement .................. 118

HP's LaserJet imaging drum limited warranty statement for replacement imaging drums ................ 119

Data stored on the print cartridge and imaging drum ............................................................... 120

End User License Agreement .................................................................................................. 121

OpenSSL ............................................................................................................................. 123

Customer self-repair warranty service ..................................................................................... 124

Customer support ................................................................................................................. 124

Repack the product .............................................................................................................. 125

Appendix B Specifications ................................................................................................ 127

Physical specifications .......................................................................................................... 128

Power consumption .............................................................................................................. 128

Acoustic specifications .......................................................................................................... 129

Environmental specifications .................................................................................................. 129

Appendix C Regulatory information ................................................................................. 131

FCC regulations ................................................................................................................... 132

Declaration of conformity (base models) ................................................................................. 133

viii ENWW

Page 8

Declaration of conformity (wireless models) ............................................................................. 135

Certificate of Volatility .......................................................................................................... 137

Safety statements ................................................................................................................. 139

Laser safety .......................................................................................................... 139

Canadian DOC regulations .................................................................................... 139

VCCI statement (Japan) .......................................................................................... 139

Power cord instructions .......................................................................................... 139

Power cord statement (Japan) ................................................................................. 139

EMC statement (Korea) .......................................................................................... 140

Laser statement for Finland ..................................................................................... 140

GS statement (Germany) ........................................................................................ 140

Substances Table (China) ....................................................................................... 141

Restriction on Hazardous Substances statement (Turkey) ............................................. 141

Additional statements for wireless products .............................................................................. 142

FCC compliance statement—United States ................................................................ 142

Australia statement ................................................................................................ 142

Brazil ANATEL statement ........................................................................................ 142

Canadian statements ............................................................................................. 142

European Union regulatory notice ........................................................................... 142

Notice for use in France ......................................................................................... 143

Notice for use in Russia ......................................................................................... 143

Korean statement .................................................................................................. 143

Taiwan statement .................................................................................................. 143

Index ............................................................................................................................... 145

ENWW ix

Page 9

List of tables

Table 2-1 Status light legend ................................................................................................................ 68

Table 2-2 Control-panel light patterns .................................................................................................... 68

Table 2-3 Wireless light patterns ........................................................................................................... 70

Table 3-1 Order parts, accessories, and supplies .................................................................................. 100

Table 3-2 Related documentation and software .................................................................................... 100

Table 3-3 Supplies part numbers ......................................................................................................... 100

Table 3-4 Whole-unit replacement part numbers ................................................................................... 101

Table 3-5 Base product ..................................................................................................................... 103

Table 3-6 Covers, panels, and doors ................................................................................................... 105

Table 3-7 Internal assembly) ............................................................................................................... 107

Table 3-8 PCAs ................................................................................................................................ 109

Table 3-9 Alphabetical parts list ......................................................................................................... 110

Table 3-10 Numerical parts list ........................................................................................................... 112

Table B-1 Physical specifications

Table B-2 HP LaserJet Pro CP1020 Color Printer Series (average in watts)

Table B-3 HP LaserJet Pro CP1020 Color Printer Series

Table B-4 Environmental specifications ................................................................................................ 129

1

........................................................................................................ 128

123

............................................ 128

1,2

...................................................................... 129

ENWW xi

Page 10

List of figures

Figure 1-1 Phillips and Pozidriv screwdriver comparison ............................................................................ 3

Figure 1-2 Parts removal order ............................................................................................................... 5

Figure 1-3 Remove the tray .................................................................................................................. 13

Figure 1-4 Remove the secondary transfer roller ...................................................................................... 14

Figure 1-5 Remove the separation pad assembly (1 of 1) ......................................................................... 15

Figure 1-6 Remove the pickup roller assembly (1 of 2) ............................................................................. 17

Figure 1-7 Remove the pickup roller assembly (2 of 2) ............................................................................. 17

Figure 1-8 Remove the right cover (1 of 2) ............................................................................................. 18

Figure 1-9 Remove the right cover (2 of 2) ............................................................................................. 18

Figure 1-10 Remove the left cover (1 of 2) ............................................................................................. 19

Figure 1-11 Remove the left cover, duplex product (2 of 2) ...................................................................... 19

Figure 1-12 Remove the top door assembly (1 of 3) ................................................................................ 20

Figure 1-13 Remove the top door assembly (2 of 3) ................................................................................ 20

Figure 1-14 Remove the top door assembly (3 of 3) ................................................................................ 21

Figure 1-15 Remove the top door (1 of 2) .............................................................................................. 22

Figure 1-16 Remove the top door (2 of 2) .............................................................................................. 22

Figure 1-17 Remove the rear door assembly (1 of 2) ............................................................................... 23

Figure 1-18 Remove the rear door assembly (2 of 2) ............................................................................... 23

Figure 1-19 Remove the lower cover assembly ....................................................................................... 24

Figure 1-20 Remove the control panel (1 of 2) ........................................................................................ 25

Figure 1-21 Remove the control panel (2 of 2) ........................................................................................ 26

Figure 1-22 Remove the front door (1 of 2) ............................................................................................ 27

Figure 1-23 Remove the front door (2 of 3) ............................................................................................ 28

Figure 1-24 Remove the ITB assembly (1 of 16) ...................................................................................... 29

Figure 1-25 Remove the ITB assembly (2 of 16) ...................................................................................... 30

Figure 1-26 Remove the ITB assembly (3 of 16) ...................................................................................... 30

Figure 1-27 Remove the ITB assembly (4 of 16) ...................................................................................... 31

Figure 1-28 Remove the ITB assembly (5 of 16) ...................................................................................... 31

Figure 1-29 Remove the ITB assembly (6 of 16) ...................................................................................... 32

Figure 1-30 Remove the ITB assembly (7 of 16) ...................................................................................... 32

Figure 1-31 Remove the ITB assembly (8 of 16) ...................................................................................... 33

Figure 1-32

Figure 1-

Figure 1-34 Remove the ITB assembly (11 of 16) .................................................................................... 34

R

emove the ITB assembly (9 of 16) ...................................................................................... 33

33 Remove the ITB assembly (10 of 16) .................................................................................... 34

ENWW xiii

Page 11

Figure 1-35 Remove the ITB assembly (12 of 16) .................................................................................... 35

Figure 1-36 Remove the ITB assembly (13 of 16) .................................................................................... 35

Figure 1-37 Remove the ITB assembly (14 of 16) .................................................................................... 36

Figure 1-38 Remove the ITB assembly (15 of 16) .................................................................................... 36

Figure 1-39 Remove the ITB assembly (16 of 16) .................................................................................... 37

Figure 1-40 Remove the fuser delivery assembly (1 of 6) .......................................................................... 39

Figure 1-41 Remove the fuser delivery assembly (2 of 6) .......................................................................... 39

Figure 1-42 Remove the fuser delivery assembly (3 of 6) .......................................................................... 40

Figure 1-43 Remove the fuser delivery assembly (4 of 6) .......................................................................... 40

Figure 1-44 Remove the fuser delivery assembly (5 of 6) .......................................................................... 41

Figure 1-45 Remove the fuser delivery assembly (6 of 6) .......................................................................... 41

Figure 1-46 Reassemble the fuser delivery assembly (1 of 2) .................................................................... 42

Figure 1-47 Reassemble the fuser delivery assembly (2 of 2) .................................................................... 42

Figure 1-48 Remove the formatter PCA (base model; 1 of 2) .................................................................... 43

Figure 1-49 Remove the formatter PCA (base model; 2 of 2) .................................................................... 43

Figure 1-50 Remove the formatter and wireless PCA (plus model; 1 of 2) ................................................... 44

Figure 1-51 Remove the formatter and wireless PCA (plus mode; 2 of 2) ................................................... 45

Figure 1-52 Remove the engine controller assembly (1 of 5) ..................................................................... 46

Figure 1-53 Remove the engine controller assembly (2 of 5) ..................................................................... 47

Figure 1-54 Remove the engine controller assembly (3 of 5) ..................................................................... 47

Figure 1-55 Remove the engine controller assembly (4 of 5) ..................................................................... 48

Figure 1-56 Remove the engine controller assembly (5 of 5) ..................................................................... 48

Figure 1-57 Remove the low-voltage power supply assembly (1 of 6) ........................................................ 49

Figure 1-58 Remove the low-voltage power supply assembly (2 of 6) ........................................................ 50

Figure 1-59 Remove the low-voltage power supply assembly (3 of 6) ........................................................ 50

Figure 1-60 Remove the low-voltage power supply assembly (4 of 6) ........................................................ 51

Figure 1-61 Remove the low voltage power supply assembly (5 of 6) ........................................................ 51

Figure 1-62 Remove the low-voltage power supply assembly (6 of 6) ........................................................ 52

Figure 2-1 Engine test page ................................................................................................................. 58

Figure 2-2

Figure 2-

Figure 2-4 External view ...................................................................................................................... 61

Figure 2-5 Cross section view ............................................................................................................... 62

Figure 2-6 General timing diagram ....................................................................................................... 63

Figure 2-7 Circuit diagram ................................................................................................................... 64

Figure 3-1 Base product (no optional trays or accessories) ..................................................................... 103

Figure 3-2 Covers, panels, and doors ................................................................................................. 104

Figure 3-3 Internal assembly ............................................................................................................... 106

Figure 3-4 PCAs ............................................................................................................................... 108

Plug/jack locations ..............................................................................................................

3 Locations of connectors ........................................................................................................ 60

59

xiv ENWW

Page 12

1 Removal and replacement

Introduction

●

Removal and replacement strategy

●

Electrostatic discharge

●

Required tools

●

Service approach

●

Removal and replacement procedures

●

ENWW 1

Page 13

Introduction

This chapter describes the removal and replacement of field-replaceable units (FRUs) only.

Replacing FRUs is generally the reverse of removal. Occasionally, notes and tips are included to

provide directions for difficult or critical replacement procedures.

HP does not support repairing individual subassemblies or troubleshooting to the component level.

Note the length, diameter, color, type, and location of each screw. Be sure to return each screw to its

original location during reassembly.

Incorrectly routed or loose wire harnesses can interfere with other internal components and can become

damaged or broken. Frayed or pinched harness wires can be difficult to find. When replacing wire

harnesses, always use the provided wire loops, lance points, or wire-harness guides and retainers.

Removal and replacement strategy

WARNING! Turn the product off, wait 5 seconds, and then remove the power cord before

attempting to service the product. If this warning is not followed, severe injury can result, in addition to

damage to the product. The power must be on for certain functional checks during troubleshooting.

However, disconnect the power supply during parts removal.

Never operate or service the product with the protective cover removed from the laser/scanner

assembly. The reflected beam, although invisible, can damage your eyes.

The sheet-metal parts can have sharp edges. Be careful when handling sheet-metal parts.

CAUTION: Do not bend or fold the flat flexible cables (FFCs) during removal or installation. Also, do

not straighten pre-folds in the FFCs. You must fully seat all FFCs in their connectors. Failure to fully seat

an FFC into a connector can cause a short circuit in a PCA.

NOTE: To install a self-tapping screw, first turn it counterclockwise to align it with the existing thread

pattern, and then carefully turn it clockwise to tighten. Do not overtighten. If a self-tapping screw-hole

becomes stripped, repair the screw-hole or replace the affected assembly.

TIP: For clarity, some photos in this chapter show components removed that would not be removed to

service the product. If necessary, remove the components listed at the beginning of a procedure before

proceeding to service the product.

2 Chapter 1 Removal and replacement ENWW

Page 14

Electrostatic discharge

CAUTION: Some parts are sensitive to electrostatic discharge (ESD). Look for the ESD reminder

when removing product parts. Always perform service work at an ESD-protected workstation or mat, or

use an ESD strap. If an ESD workstation, mat, or strap is not available, ground yourself by touching the

sheet-metal chassis before touching an ESD-sensitive part.

Protect the ESD-sensitive parts by placing them in ESD pouches when they are out of the product.

Required tools

#2 Phillips screwdriver with a magnetic tip and a 152-mm (6-inch) shaft length

●

Small flat-blade screwdriver

●

Needle-nose pliers

●

ESD mat or ESD strap (if one is available)

●

Penlight (optional)

●

CAUTION: Always use a Phillips screwdriver (callout 1). Do not use a Pozidriv screwdriver

(callout 2) or any motorized screwdriver. These can damage screws or screw threads.

Figure 1-1 Phillips and Pozidriv screwdriver comparison

ENWW

Electrostatic discharge

3

Page 15

Service approach

Before performing service

Remove all paper from the product.

●

Turn off the power using the power button.

●

WARNING! The power button must be turned off before performing service. Failure to turn off

the power leaves the fuser engaged and prevents it removal.

Unplug the power cable and interface cable or cables.

●

Place the product on an ESD workstation or mat, or use an ESD strap (if one is available). If an

●

ESD workstation, mat, or strap is not available, ground yourself by touching the sheet-metal

chassis before touching an ESD-sensitive part.

Remove the print cartridges and imaging drum.

●

After performing service

Plug in the power cable.

●

Reinstall the print cartridge.

●

Load paper in the product.

●

Post-service test

Perform the following test to verify that the repair or replacement was successful.

Print-quality test

1. Verify that you have completed the necessary reassembly steps.

2. Make sure that the tray contains clean, unmarked paper.

3. Attach the power cord and interface cable or interface cables, and then turn on the product.

4. Verify that the expected startup sounds occur.

5. Print a configuration page, and then verify that the expected printing sounds occur.

6. Send a print job from the host computer, and then verify that the output meets expectations.

7. Clean the outside of the product with a damp cloth.

4 Chapter 1 Removal and replacement ENWW

Page 16

Parts removal order

Figure 1-2 Parts removal order

Print cartridges

Imaging drum

Input tray

Separation pad

Pickup roller

Right cover assembly

Left cover assembly

Top door assembly

Rear top cover assembly

Rear door assembly

Rear lower cover assembly

Control Panel

Front door

ITB

Fuser delivery assembly

Formatter PCA (base model)

Formatter and wireless PCA (plus model)

Engine controller assembly

Low-voltage power supply assembly

Separation pad

Right cover Left cover

Right cover Left cover

Right cover

Right cover Left cover

Right cover

Left cover

Imaging drum

Right cover

Left cover

Right cover Left cover

Left cover

Input tray Right cover Left cover

Control Panel

Rear top cover

Left cover

Rear door

Rear lower cover

Rear top cover

Top door

Rear lower cover

ENWW

Service approach

5

Page 17

Removal and replacement procedures

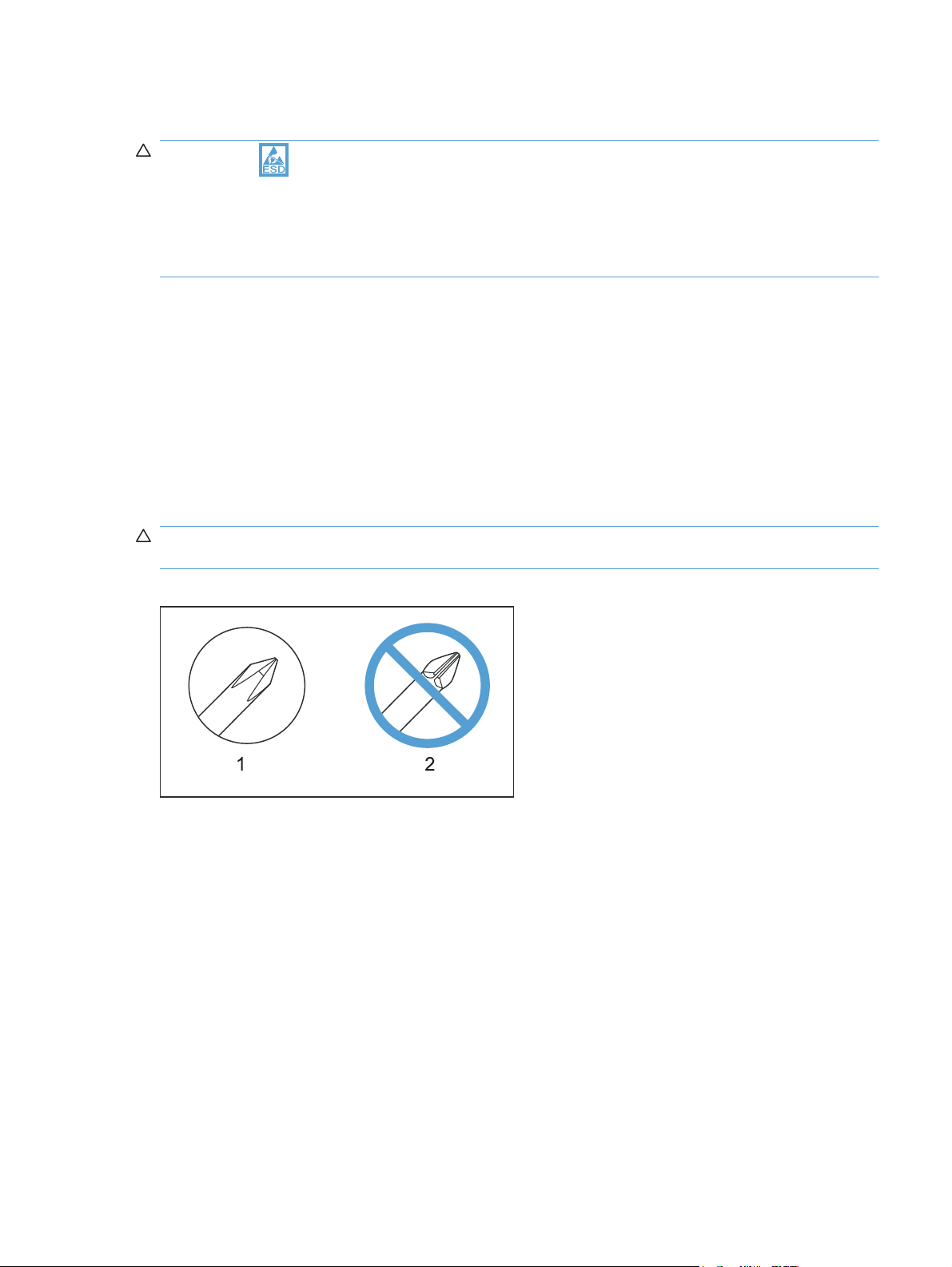

Replace the print cartridges

When a print cartridge approaches the end of its useful life, you can continue printing with the current

print cartridge until it no longer yields acceptable print quality.

Once an HP print cartridge has reached “very low’, HP’s Premium Protection Warranty on that supply

has ended. All print defects or print cartridge failures incurred when an HP supply is used in continue at

very low mode will not be considered to be defects in materials or workmanship in the supply under the

HP Print Cartridge Warranty Statement.

NOTE: Once an HP print cartridge has reached “very low’, the corresponding cartridge light on the

control panel turns on.

1. Press the Cartridge button of the print

cartridge that requires replacement to rotate

the print cartridge carousel for removal.

NOTE: All doors must be closed when

pressing the Cartridge

NOTE: Wait until the Cartridge

not flashing and the rotation sounds stops

before opening the print cartridge door.

2. Open the print cartridge door.

button.

light is

6 Chapter 1 Removal and replacement ENWW

Page 18

3. Grasp the old print cartridge by the center

handle and remove.

4. Remove the new print cartridge from the

packaging. Place the used print cartridge in

the bag and box for recycling.

CAUTION: To prevent damage to the print

cartridge, hold the print cartridge at each end.

Do not touch the roller on the print cartridge.

5. Remove the protective shielding from the new

print cartridge.

6. Grasp both sides of the print cartridge and

gently rock the print cartridge to distribute the

toner evenly inside the print cartridge.

7. Remove the tape from the print cartridge. Place

the tape in the print-cartridge box to return for

recycling.

ENWW

Removal and replacement procedures

7

Page 19

8. Grasp the print cartridge by the center handle

and insert into the product.

NOTE: Compare the color label on the print

cartridge to the color label in the carousel slot

to make sure the print cartridge color matches

the carousel position.

CAUTION: If toner gets on your clothing,

wipe it off with a dry cloth and wash the

clothing in cold water. Hot water sets toner

into the fabric.

9. Close the print cartridge door.

NOTE: After closing the print cartridge door,

the Ready

light and Attention light will

flash. Allow up to three minutes for the product

to calibrate.

NOTE: If replacing another print cartridge,

you must close the print cartridge door before

pressing the Cartridge

button of the next

print cartridge.

10. When printing, if you receive the status alert

message Wrong Cartridge in <Color>

Slot, remove the print cartridge from the

specified slot and compare the color label on

the print cartridge to the color label in the slot

to determine the correct print cartridge for the

slot.

8 Chapter 1 Removal and replacement ENWW

Page 20

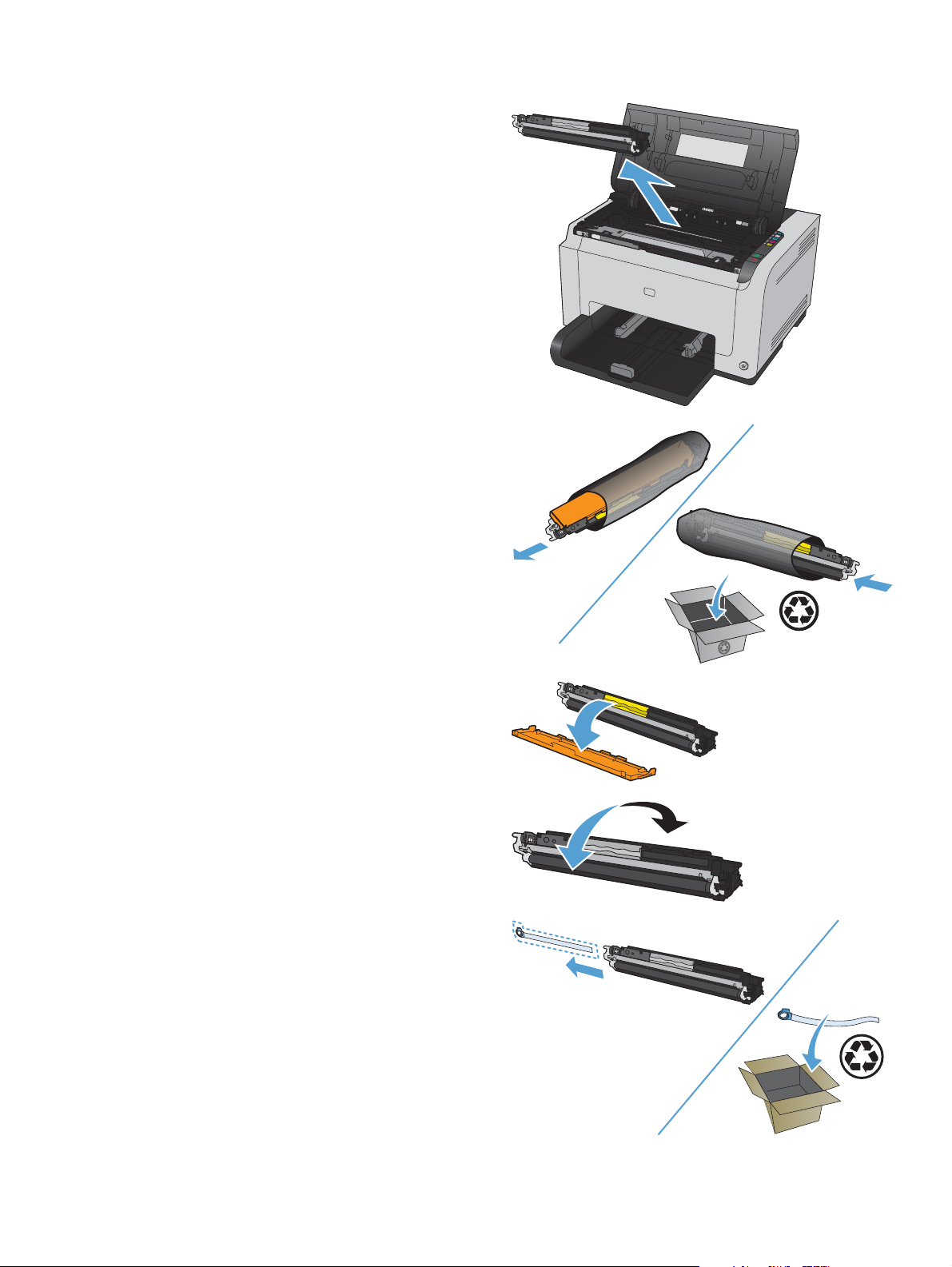

Replace the imaging drum

NOTE: The imaging drum installed in this product is covered by the product warranty. Replacement

imaging drums have a one-year limited warranty from the date of installation. The imaging drum

installation date displays on both the configuration page and on the supplies status page when the

imaging drum reaches approximately 30% of its estimated remaining life. HP's Premium Protection

Warranty applies only to the print cartridges for the product.

1. Open the print cartridge door.

2. Open the front cover.

ENWW

Removal and replacement procedures

9

Page 21

3. Lift the two levers that hold the imaging drum.

4. Remove the old imaging drum.

5. Remove the new imaging drum from the

packaging. Place the used imaging drum in

the bag and box for recycling.

10 Chapter 1 Removal and replacement ENWW

Page 22

6. Remove the protective shielding from the new

imaging drum.

CAUTION: To prevent damage, do not

expose the imaging drum to light for an

extended period of time. Cover the imaging

drum with a piece of paper if it can not be

installed immediately.

CAUTION: Do not touch the green drum.

Fingerprints on the imaging drum can cause

print-quality problems.

7. Insert the new imaging drum in the product.

8. Lower the two levers that hold the imaging

drum.

ENWW

Removal and replacement procedures

11

Page 23

9. Close the front cover.

10. Close the print cartridge door.

NOTE: After closing the print cartridge door,

the Ready

flash. Allow up to a minute for the product to

calibrate.

light and Attention light will

12 Chapter 1 Removal and replacement ENWW

Page 24

Input tray

Pull the tray away from the printer to remove.

Figure 1-3 Remove the tray

ENWW

Removal and replacement procedures

13

Page 25

Secondary transfer roller

CAUTION: Do not touch the black spongy part of the roller. Skin oils might cause print-quality

problems.

1. Open the rear door.

2. Release two clips (callout 1), and then remove the roller form the product.

Figure 1-4 Remove the secondary transfer roller

1

14 Chapter 1 Removal and replacement ENWW

Page 26

Separation pad assembly

Remove the separation pad assembly

1. Turn the product front side up.

2. Remove two screws (callout 1) and the separation pad assembly (callout 2).

Figure 1-5 Remove the separation pad assembly (1 of 1)

2

1

ENWW

Removal and replacement procedures

15

Page 27

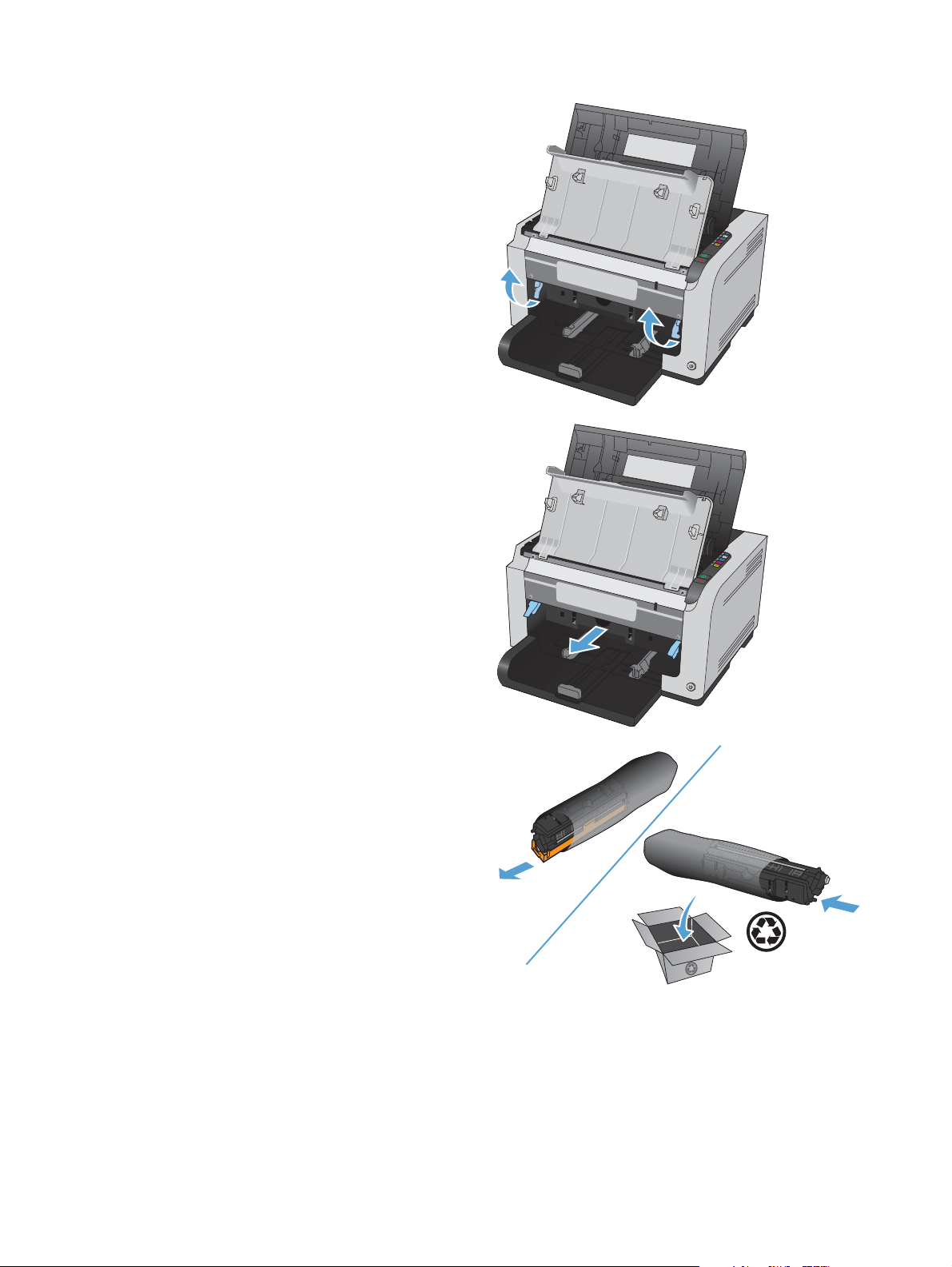

Pickup roller

Rotate the pickup roller to the service position

To gain access to the roller locking tabs you must rotate the roller to the correct position for removal.

1. When the product is in the Ready state, press and hold the Auto-On/Auto-Off (power) button for

about seven seconds or until the Ready

TIP: Optionally, unplug the power cord, and then plug the cord back in.

2. Make sure that one sheet of paper is loaded in the input tray.

NOTE: If more than one sheet of paper is loaded in the tray, this procedure will not be

successful.

3. Press and release the Auto-On/Auto-Off (power) button and within two seconds press and hold

down the cyan cartridge button. Hold the cyan button down for about five seconds, or until the

initialization process begins.

NOTE: Immediately after the Auto-On/Auto-Off (power) button is pressed, all of the control

panel lights illuminate briefly (for about two seconds). You must press the cyan cartridge button

while the lights are illuminated.

4. When the product finishes initializing, the roller rotates into the removal position. Turn the product

off. Unplug the product before removing any components.

light turns off.

NOTE: When the roller is in the removal position, the sheet of paper will have been pulled into

the paper path by about 12 mm (.5 in). This is visual confirmation that the roller has rotated to the

removal position.

Before proceeding, remove the following components:

Right cover assembly. See

●

Left cover assembly. See

●

Separation pad assembly. See

●

Right cover assembly on page 18.

Left cover assembly on page 19.

Separation pad assembly on page 15.

16 Chapter 1 Removal and replacement ENWW

Page 28

Remove the pickup roller assembly

1. Remove four screws (callout 1) and the lower stay part (callout 2).

Figure 1-6 Remove the pickup roller assembly (1 of 2)

2

1

2. Release two tabs (callout 1) and remove the pickup roller (callout 2).

Figure 1-7 Remove the pickup roller assembly (2 of 2)

1

2

ENWW

Removal and replacement procedures

17

Page 29

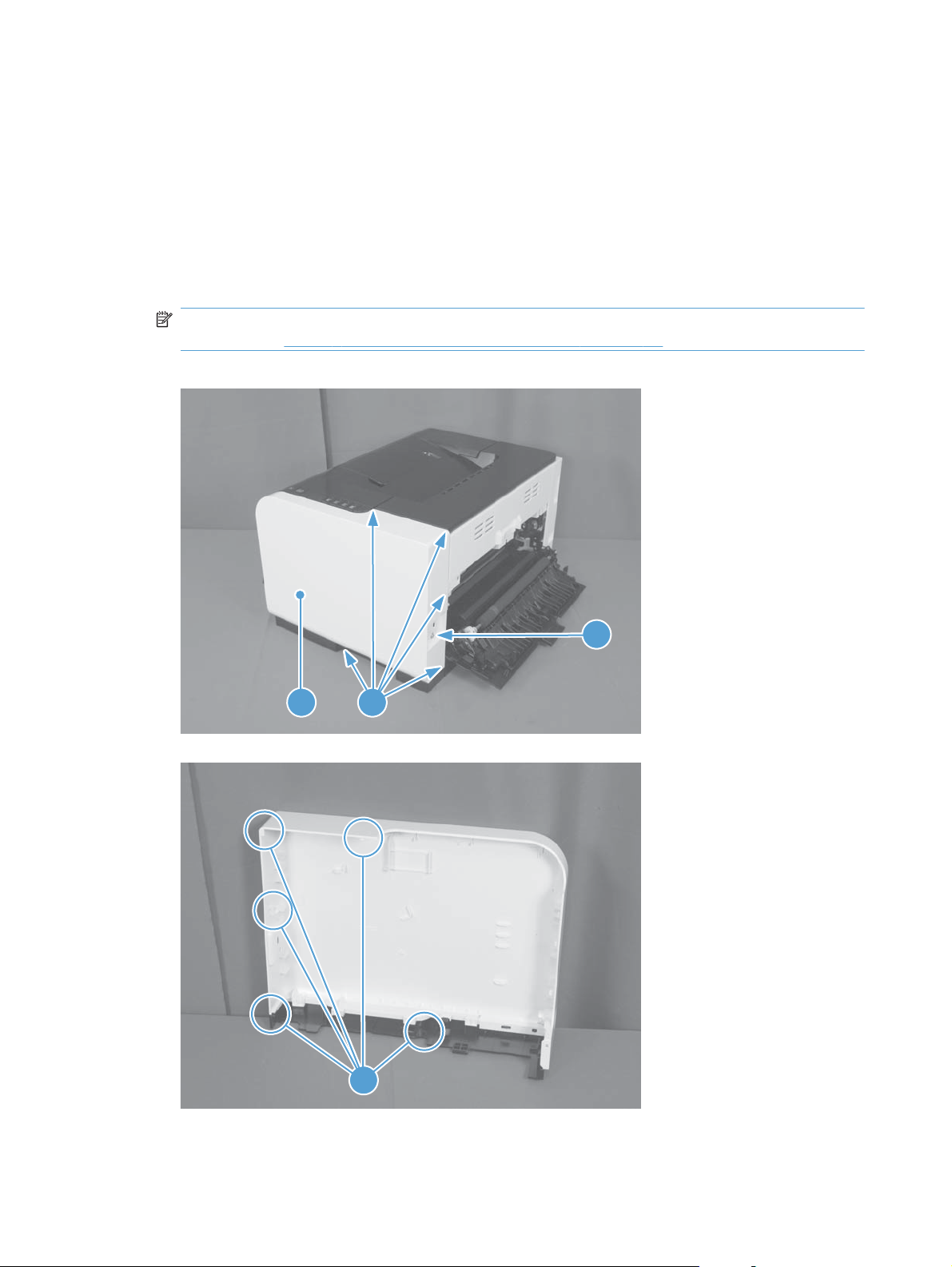

Covers

Right cover assembly

Remove the right cover assembly

1. Open the top and rear door assemblies.

2. Remove one screw (callout 1), and then starting at the rear vertical edge, release five tabs (callout

2) and remove the right cover assembly (callout 3).

NOTE: Before proceeding, take note of the locations of the tabs (callout 1) on the back side of

the cover. See

Figure 1-8 Remove the right cover (1 of 2)

Figure 1-9 Remove the right cover (2 of 2) on page 18.

3

Figure 1-9 Remove the right cover (2 of 2)

2

2

1

18 Chapter 1 Removal and replacement ENWW

Page 30

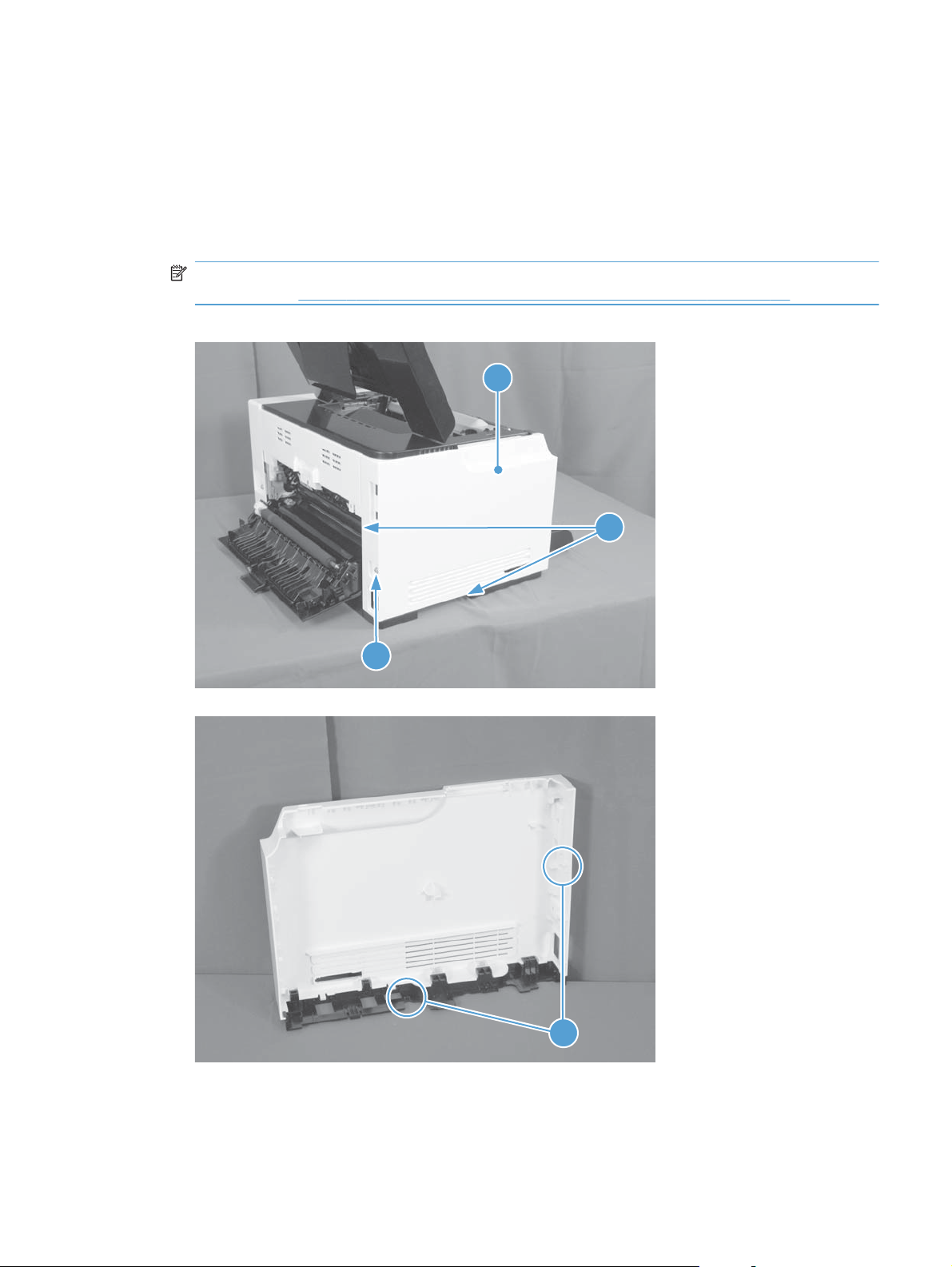

Left cover assembly

Remove the left cover assembly

1. Open the top door.

2. Remove one screw (callout 1), and then starting at the rear vertical edge, release two tabs (callout

2) and remove the left cover assembly (callout 3).

NOTE: Before proceeding, take note of the locations of the tabs (callout 2) on the back side of

the cover. See

Figure 1-10 Remove the left cover (1 of 2)

Figure 1-11 Remove the left cover, duplex product (2 of 2) on page 19.

3

2

1

Figure 1-11 Remove the left cover, duplex product (2 of 2)

2

ENWW

Removal and replacement procedures

19

Page 31

Top door assembly

Before proceeding, remove the following components:

Right cover assembly. See

●

Left cover assembly. See

●

Remove the top door assembly

1. Remove one screw (callout 1).

Figure 1-12 Remove the top door assembly (1 of 3)

Right cover assembly on page 18.

Left cover assembly on page 19.

1

2. Use a small, flat blade screwdriver to release the five tabs between the top door assembly and the

rear top cover.

Figure 1-13 Remove the top door assembly (2 of 3)

20 Chapter 1 Removal and replacement ENWW

Page 32

3. Lift the top door and rear edge, then slide the top door assembly forward to release the two tabs

from the drive shaft at the top of the product.

Figure 1-14 Remove the top door assembly (3 of 3)

ENWW

Removal and replacement procedures

21

Page 33

Rear top cover assembly

Before proceeding, remove the following components:

Right cover assembly. See

●

Left cover assembly. See

●

Top door assembly. See

●

Remove the rear top cover assembly

Release one tab (callout 1) and remove the rear top cover (callout 2).

▲

Figure 1-15 Remove the top door (1 of 2)

Left cover assembly on page 19.

Top door assembly on page 20.

Right cover assembly on page 18.

2

1

Figure 1-16 Remove the top door (2 of 2)

1

22 Chapter 1 Removal and replacement ENWW

Page 34

Rear door assembly

Before proceeding, remove the following components:

Right cover assembly. See

●

Remove the rear door assembly

1. Remove one screw (callout 1) and the bushing (callout 2).

Figure 1-17 Remove the rear door assembly (1 of 2)

Right cover assembly on page 18.

1

2

2. Pull out the shaft (callout 1) and remove the rear door assembly (callout 2).

Figure 1-18 Remove the rear door assembly (2 of 2)

1

2

ENWW

Removal and replacement procedures

23

Page 35

Rear lower cover assembly

Before proceeding, remove the following components:

Right cover assembly. See

●

Left cover assembly. See

●

Rear door assembly. See

●

Remove the rear lower cover assembly

Remove two screws (callout 1) and the rear lower cover assembly (callout 2).

Figure 1-19 Remove the lower cover assembly

Right cover assembly on page 18.

Left cover assembly on page 19.

Rear door assembly on page 23.

1

2

24 Chapter 1 Removal and replacement ENWW

Page 36

Control panel

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Right cover assembly. See

●

Remove the control panel

1. Open the top door assembly.

2. Remove two screws (callout 1) and disconnect one connector (callout 2).

Figure 1-20 Remove the control panel (1 of 2)

Right cover assembly on page 18.

1

4

2

ENWW

Removal and replacement procedures

25

Page 37

3. Release one tab (callout 3) and remove the control panel (callout 4).

Figure 1-21 Remove the control panel (2 of 2)

3

26 Chapter 1 Removal and replacement ENWW

Page 38

Front door

Before proceeding, remove the following components:

Right cover assembly. See

●

Left cover assembly. See

●

Control panel. See

●

Remove the front door

1. Open the front door.

2. Remove four screws (callout 1) and the scanner cover (callout 2).

Figure 1-22 Remove the front door (1 of 2)

Right cover assembly on page 18.

Left cover assembly on page 19.

Control panel on page 25.

1

2

ENWW

Removal and replacement procedures

27

Page 39

3. Release one tab (callout 1) and slide the front door (callout 2) in the direction that the arrow

indicates to remove it.

Figure 1-23 Remove the front door (2 of 3)

2

1

28 Chapter 1 Removal and replacement ENWW

Page 40

Main assemblies

ITB assembly

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Imaging drum. See

●

Rear top cover assembly. See

●

Rear lower cover assembly. See

●

Remove the ITB assembly

1. For wireless products, follow these steps to remove the wireless PCA.

a. Release one tab (callout 1) and disconnect one connector (callout 2) on the back of the

wireless PCA.

Figure 1-24 Remove the ITB assembly (1 of 16)

Replace the imaging drum on page 9.

Rear top cover assembly on page 22.

Rear lower cover assembly on page 24.

1

2

ENWW

b. Remove three screws (callout 1).

NOTE: Base products have only two screws and the appearance of the formatter may be

slightly different from what appears in

on page 29.

Figure 1-24 Remove the ITB assembly (1 of 16)

Removal and replacement procedures

29

Page 41

2. Disconnect three connectors (callout 2) and remove the formatter (callout 3).

Figure 1-25 Remove the ITB assembly (2 of 16)

3

2

1

3. Release one tab (callout 1) and remove the cable cover (callout 2).

Figure 1-26 Remove the ITB assembly (3 of 16)

2

1

4. Disconnect one connector (callout 1).

30 Chapter 1 Removal and replacement ENWW

Page 42

5. Release cables (callout 4) from the cable clips (callout 2) and the cable guide (callout 3).

Figure 1-27 Remove the ITB assembly (4 of 16)

4

1

3

2

6. Release one tab (callout 1) and remove the left side arm (callout 2) of the rear door.

Figure 1-28 Remove the ITB assembly (5 of 16)

ENWW

2

1

Removal and replacement procedures

31

Page 43

7. Release the hook (callout 1) of the ITB fuser spring and turn the spring (callout 2) frontward.

Figure 1-29 Remove the ITB assembly (6 of 16)

3

2

Figure 1-30 Remove the ITB assembly (7 of 16)

2

32 Chapter 1 Removal and replacement ENWW

Page 44

8. Turn the ITB fuser part (callout 1) frontward (callout 2).

Figure 1-31 Remove the ITB assembly (8 of 16)

1

Figure 1-32 Remove the ITB assembly (9 of 16)

2

ENWW

Removal and replacement procedures

33

Page 45

9. Release two tabs (callout 1) and remove the spring cover (callout 2).

Figure 1-33 Remove the ITB assembly (10 of 16)

1

2

10. Release one tab (callout 1) and remove the right side arm (callout 2) of the rear door.

Figure 1-34 Remove the ITB assembly (11 of 16)

1

2

34 Chapter 1 Removal and replacement ENWW

Page 46

11. Pull out the cables (callout 1), release the hook (callout 2) of the ITB fuser spring, and then turn the

spring (callout 3) frontward.

Figure 1-35 Remove the ITB assembly (12 of 16)

1

2

3

Figure 1-36 Remove the ITB assembly (13 of 16)

ENWW

2

Removal and replacement procedures

35

Page 47

12. Turn the ITB fuser part (callout 1) frontward.

Figure 1-37 Remove the ITB assembly (14 of 16)

Figure 1-38 Remove the ITB assembly (15 of 16)

1

1

36 Chapter 1 Removal and replacement ENWW

Page 48

13. Pull out the ITB assembly (callout 1).

CAUTION: Avoid touching the black plastic transfer belt. Skin oils on the belt might cause print-

quality problems.

Figure 1-39 Remove the ITB assembly (16 of 16)

1

ENWW

Removal and replacement procedures

37

Page 49

Fuser delivery assembly

NOTE: For this product, the fuser and the paper delivery components are one assembly.

Position the fuser pressure roller for removal

You must rotate the pressure roller to the correct position before removing the fuser delivery assembly.

1. When the product is in the Ready state, press and hold the Auto-On/Auto-Off (power) button for

about seven seconds or until you hear subtle movement within the product and the Ready

turns off.

2. Release the Auto-On/Auto-Off (power) button. The product power will be off and the fuser

pressure roller is in the removal position. Unplug the product before removing any components.

Before proceeding, remove the following components:

light

●

Left cover assembly. See

●

Top door assembly. See

●

Rear top cover assembly. See

●

Formatter (base model) or formatter and wireless PCA (plus model). See

●

model) on page 43 or Formatter and wireless PCA (plus model) on page 44.

Left cover assembly on page 19.

Top door assembly on page 20.

Rear top cover assembly on page 22.

Right cover assembly. See

Right cover assembly on page 18 .

Formatter PCA (base

38 Chapter 1 Removal and replacement ENWW

Page 50

Remove the fuser delivery assembly

CAUTION: ESD sensitive.

1. Release one tab (callout 1) and disconnect one connector (callout 2) on the back of the wireless

PCA.

Figure 1-40 Remove the fuser delivery assembly (1 of 6)

2

1

2. Remove three screws (callout 1).

3. Disconnect three connectors (callout 2) and the formatter (callout 3).

Figure 1-41 Remove the fuser delivery assembly (2 of 6)

3

2

1

ENWW

Removal and replacement procedures

39

Page 51

4. Release one tab (callout 1) and remove the cable cover (callout 2).

Figure 1-42 Remove the fuser delivery assembly (3 of 6)

2

1

5. Disconnect four connectors (callout 1).

6. Release cables (callout 4) from the cable clips (callout 2) and the cable guide (callout 3).

Figure 1-43 Remove the fuser delivery assembly (4 of 6)

2

3

4

1

40 Chapter 1 Removal and replacement ENWW

Page 52

7. Remove two screws (callout 1) and the carousel cover (callout 2).

Figure 1-44 Remove the fuser delivery assembly (5 of 6)

2

1

8. Remove six screws (callout 1) and the fuser delivery assembly (callout 2).

Figure 1-45 Remove the fuser delivery assembly (6 of 6)

1

2

ENWW

Removal and replacement procedures

41

Page 53

Reassemble the fuser delivery assembly

When reassembling the fuser delivery assembly, be sure the drive cam (callout 1) for fuser

▲

pressure release is positioned as shown in the figures below.

Figure 1-46 Reassemble the fuser delivery assembly (1 of 2)

1

Figure 1-47 Reassemble the fuser delivery assembly (2 of 2)

1

42 Chapter 1 Removal and replacement ENWW

Page 54

Formatter PCA (base model)

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Left cover assembly. See

●

Remove the formatter PCA (base model)

1. Disconnect three connectors (callout 1).

Figure 1-48 Remove the formatter PCA (base model; 1 of 2)

Left cover assembly on page 19.

1

ENWW

2. Remove three screws (callout 1), and then remove the formatter PCA.

Figure 1-49 Remove the formatter PCA (base model; 2 of 2)

1

Removal and replacement procedures

43

Page 55

Formatter and wireless PCA (plus model)

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Right cover assembly. See

●

Left cover assembly. See

●

Top door assembly. See

●

Remove the formatter and wireless PCA (plus model)

1. Release two tabs (callout 1), and then remove the wireless PCA (callout 2).

Figure 1-50 Remove the formatter and wireless PCA (plus model; 1 of 2)

Right cover assembly on page 18.

Left cover assembly on page 19.

Top door assembly on page 20.

2

1

44 Chapter 1 Removal and replacement ENWW

Page 56

2. Disconnect three connectors (callout 1), remove three screws (callout 2), and then remove the

formatter PCA.

Figure 1-51 Remove the formatter and wireless PCA (plus mode; 2 of 2)

2

1

ENWW

Removal and replacement procedures

45

Page 57

Engine controller assembly

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Left cover assembly. See

●

Remove the engine controller assembly

1. Release one tab (callout 1) and disconnect one connector (callout 2) on the back of the wireless

PCA.

Figure 1-52 Remove the engine controller assembly (1 of 5)

Left cover assembly on page 19.

1

2

2. Remove three screws (callout 1).

46 Chapter 1 Removal and replacement ENWW

Page 58

3. Disconnect three connectors (callout 2) and the formatter (callout 3).

Figure 1-53 Remove the engine controller assembly (2 of 5)

3

2

1

4. Release one tab (callout 1) and remove the cable cover (callout 2).

Figure 1-54 Remove the engine controller assembly (3 of 5)

ENWW

2

1

Removal and replacement procedures

47

Page 59

5. Disconnect all of eleven connectors (callout 1) on the engine controller assembly.

Figure 1-55 Remove the engine controller assembly (4 of 5)

1

6. Remove six screws (callout 1).

7. Release two tabs (callout 2) and the engine controller assembly (callout 3).

Figure 1-56 Remove the engine controller assembly (5 of 5)

1

2

3

48 Chapter 1 Removal and replacement ENWW

Page 60

Low-voltage power supply assembly

CAUTION: ESD sensitive.

Before proceeding, remove the following components:

Input tray. See

●

Right cover assembly. See

●

Left cover assembly. See

●

Rear lower cover assembly. See

●

Remove the low-voltage power supply assembly

1. Remove two screws (callout 1) and disconnect one connector (callout 2).

Figure 1-57 Remove the low-voltage power supply assembly (1 of 6)

Input tray on page 13.

Right cover assembly on page 18.

Left cover assembly on page 19.

Rear lower cover assembly on page 24.

1

ENWW

2

2. Release the cables (callout 1).

Removal and replacement procedures

49

Page 61

3. Release two tabs (callout inlet part (callout 3).

Figure 1-58 Remove the low-voltage power supply assembly (2 of 6)

2

3

4. Disconnect one connector (callout 1).

5. Release the cables (callout 3) from the cable guide (callout 2).

Figure 1-59 Remove the low-voltage power supply assembly (3 of 6)

1

1

3

2

6. Turn the product rear side up.

50 Chapter 1 Removal and replacement ENWW

Page 62

7. Remove four screws (callout 1).

Figure 1-60 Remove the low-voltage power supply assembly (4 of 6)

1

8. Remove three screws (callout 1).

9. Disconnect one connector (callout 2) and pull out the low-voltage power supply assembly

(callout 3).

Figure 1-61 Remove the low voltage power supply assembly (5 of 6)

2 3

1

ENWW

Removal and replacement procedures

51

Page 63

10. Disconnect three connectors (callout 1) and remove the low-voltage power supply assembly

(callout 2).

Figure 1-62 Remove the low-voltage power supply assembly (6 of 6)

1

2

52 Chapter 1 Removal and replacement ENWW

Page 64

2 Solve problems

Solve problems checklist

●

Troubleshooting process

●

Tools for troubleshooting

●

Clear jams

●

The product does not feed automatically

●

The product feeds multiple sheets

●

Solve image-quality problems

●

Clean the product

●

Solve performance problems

●

Solve connectivity problems

●

Service mode functions

●

Product updates

●

ENWW 53

Page 65

Solve problems checklist

Follow these steps when trying to solve a problem with the product.

Step 1: Make sure that the product is set up correctly

●

Step 2: Check the cabling or wireless connection (network models only)

●

Step 3: Check to see if any control-panel lights are lit

●

Step 4: Check the paper

●

Step 5: Check the software

●

Step 6: Test print functionality

●

Step 7: Check the supplies

●

Step 8: Try sending a print job from a computer

●

Step 1: Make sure that the product is set up correctly

Make sure that the product is set up correctly.

1. Press the power button to turn on the product or to deactivate the Auto-On\Auto-Off mode.

2. Check the power-cable connections.

3. Make sure that the line voltage is correct for the product power configuration. (See the label that is

on the back of the product for voltage requirements.) If you are using a power strip and its voltage

is not within specifications, plug the product directly into the wall. If it is already plugged into the

wall, try a different outlet.

4. Make sure that the imaging-drum-cartridges are installed correctly.

5. Print an engine test page to verify the engine is functioning.

Step 2: Check the cabling or wireless connection (network models

only)

1. Check the cable connection between the product and the computer. Make sure that the connection

is secure.

2. Make sure that the cable itself is not faulty by using a different cable, if possible.

Step 3: Check to see if any control-panel lights are lit

The control panel should indicate ready status. If an error message appears, resolve the error.

Step 4: Check the paper

1. Make sure that the paper that you are using meets specifications.

2. Make sure that the paper is loaded correctly in the input tray.

54 Chapter 2 Solve problems ENWW

Page 66

Step 5: Check the software

1. Make sure that the product software is installed correctly.

2. Verify that you have installed the printer driver for this product. Check the program to make sure

that you are using the printer driver for this product.

Step 6: Test print functionality

1. Print a configuration page. Select Print configuration page on the Services tab in the Printer

Preferences.

2. If the page does not print, verify that the input tray contains paper.

3. If the page jams in the product, clear the jam.

Step 7: Check the supplies

Print a supplies status page and check remaining life of the print cartridges and imaging drum.

Step 8: Try sending a print job from a computer

1. Try printing the job from another computer that has the product software installed.

2. Check the USB cable connection. Direct the product to the correct port, or reinstall the software,

selecting the connection type that you are using.

3. If the print quality is unacceptable, complete the following steps:

Verify that the print settings are correct for the media that you are using.

●

ENWW

Solve problems checklist

55

Page 67

Troubleshooting process

Determine the problem source

The following table includes basic questions to ask the customer to quickly help define the problem or

problems.

General topic Questions

Environment

Paper

Input tray

Is the product installed on a solid, level surface (± 1°)?

●

Is the power-supply voltage within ± 10 volts of the specified power source?

●

Is the power-supply plug inserted in the product and the outlet?

●

Is the operating environment within the specified parameters?

●

Is the product exposed to ammonia gas, such as that produced by diazo

●

copiers or office cleaning materials?

NOTE: Diazo copiers produce ammonia gas as part of the coping

processes. Ammonia gas (from cleaning supplies or a diazo copier) can have

an adverse affect on some product components (for example, the imaging

drum).

Is the product exposed to direct sunlight?

●

Does the customer use only supported paper?

●

Is the paper in good condition (no curls, folds, or distortion)?

●

Is the paper stored correctly and within environmental limits?

●

Is the amount of paper in the tray within specifications?

●

Is the paper correctly placed in the tray?

●

Are the paper guides aligned with the stack?

●

Cartridge

Transfer roller and fuser

Covers

Condensation

Miscellaneous

Are the developing cartridges and the imaging-drum installed correctly and

●

firmly seated?

Are the transfer roller and fuser installed correctly?

●

Are the top, front and rear doors firmly closed?

●

Does condensation occur following a temperature change (particularly in

●

winter following cold storage)? If so, wipe affected parts dry or leave the

product on for 90 to 120 minutes.

Was a cartridge opened soon after being moved from a cold to a warm

●

room? If so, allow the cartridge to sit at room temperature for 1 to 2 hours.

Check for and remove any non-HP components (for example, a print cartridge)

●

from the product.

Remove the product from the network and make sure that the failure is with the

●

product before beginning troubleshooting.

56 Chapter 2 Solve problems ENWW

Page 68

Power subsystem

Power-on checks

Turn on the power. If the control-panel LEDs do not illuminate, perform the power-on checks to find the

cause of the problem.

1. Verify that the product is plugged into an active electrical outlet that delivers the correct voltage.

2. Verify that the power button is in the on position.

3. Make sure that the product makes the expected start up sounds.

NOTE: The overcurrent/overvoltage protection circuit in the low-voltage power supply unit might

be functioning. Turn the product off, unplug the power cord, and turn the product on. If the

product does not function, the fuse melts, or the power supply is malfunctioning, replace the

engine controller unit. See

Engine controller assembly on page 46.

ENWW

Troubleshooting process

57

Page 69

Tools for troubleshooting

Component diagnostics

Engine diagnostics

Printing an engine test page helps determine if the product engine is functioning. Use the following

procedure to print a test page to make sure that the product engine is functioning

Engine test page

NOTE: The product does not have a test-print switch.

1. When the product is in the Ready state, press and hold the Auto-On/Auto-Off (power) button for

about seven seconds or until the Ready

TIP: Optionally, unplug the power cord, and then plug the cord back in.

2. Make sure that at least one sheet of paper is loaded in the input tray.

3. Open the top door (print-cartridge door).

4. Release the rear door and allow it to open to its first stop position; open about 19 mm (.75 in).

light turns off.

5. Press and hold the Auto-On/Auto-Off (power) button.

NOTE: The control-panel lights cycle on and off sequentially twice, starting with the black-

cartridge light (top) and ending with the Ready

6. When the black-cartridge light turns on for the second time—the beginning of the second cycle—

close the rear door, and then within five seconds close the top door (print-cartridge door).

7. When the product finishes initializing, an engine test page prints.

Figure 2-1 Engine test page

light.

58 Chapter 2 Solve problems ENWW

Page 70

Diagrams

Plug/jack locations

Figure 2-2 Plug/jack locations

1

1 Kensington lock

2 Rear jam-access door

2

3

4

5

3 HP internal network port (network models only)

4 USB port

5 Power receptacle

ENWW

Tools for troubleshooting

59

Page 71

Locations of connectors

Figure 2-3 Locations of connectors

J103

Item Description Item Description Item Description

J128

J130

J106

J107

J119

J102

J108

J101

J109

J152

J104

J110

J112

J140

J101 Not used J107 Media width

sensor (SR1)

Delivery sensor

(SR2)

J102 Not used J108 Low-voltage power

supply

TOP sensor (SR6)

J103 Formatter J109 Memory tag

Scanner motor

(M5)

Power switch PCA

Carousel home

sensor (SR7)

J104 Scanner assembly

(laser drive PCA)

J110 Carousel motor

(M1)

Fuser motor (M2)

J106 Loop sensor (SR3) J112 Pickup motor (M3)

T2 roller and ITB

cleaner solenoid

(SL1)

J119 Fuser pressure

release sensor

(SR4)

J128 Rear door open

detection switch

(SW1)

J130 ITB

J140 Low-voltage power

supply

J152 Not used

60 Chapter 2 Solve problems ENWW

Page 72

Locations of major components

Figure 2-4 External view

1

9

8

7

6

5

2

3

4

ENWW

Item Description Item Description

1 Top door assembly 6 Rear door assembly

2 Control panel 7 Rear top cover

3 Right cover 8 Input tray

4 Left cover 9 Front door

5 rear bottom cover

Tools for troubleshooting

61

Page 73

Figure 2-5 Cross section view

Item Description Item Description

1 Pressure roller 10 T1 pad

2 Delivery roller 11 ITB

3 Fuser film assembly 12 Pickup roller

4 Density ITB_TOP sensor 13 Separation pad

5 Developing-cartridge 14 Feed roller

6 Imaging drum 15 T2 roller

7 Imaging-drum 16 ITB drive roller