Page 1

LASERJET PRO 200 COLOR MFP

Troubleshooting Manual

M276

Page 2

Page 3

HP LaserJet Pro 200 color MFP M276

Series

Troubleshooting Manual

Page 4

Copyright and License

Trademark Credits

© 2012 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is

prohibited, except as allowed under the

copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CF144-90996

Edition 1, 9/2012

Microsoft®, Windows®, Windows® XP,

and Windows Vista® are U.S. registered

trademarks of Microsoft Corporation.

ENERGY STAR and the ENERGY STAR mark

are registered U.S. marks.

Page 5

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging

the product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal

injury, catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 6

iv Conventions used in this guide ENWW

Page 7

Table of contents

1 Theory of operation .......................................................................................................... 1

Basic operation ........................................................................................................................ 2

Major product systems ............................................................................................... 2

Product components .................................................................................................. 3

Sequence of operation ............................................................................................... 4

Engine control system ............................................................................................................... 5

DC controller ............................................................................................................ 6

Low-voltage power supply .......................................................................................... 7

High-voltage power supply ......................................................................................... 8

Laser/scanner system ............................................................................................................... 9

Laser failure detection ................................................................................................ 9

Image-formation system ........................................................................................................... 10

Image-formation process .......................................................................................... 10

Latent-image formation stage .................................................................................... 11

Step 1: primary charging .......................................................................... 12

Step 2: laser-beam exposure ..................................................................... 12

Developing stage .................................................................................................... 12

Step 3: development ................................................................................. 13

Transfer stage ......................................................................................................... 14

Step 4: primary transfer ............................................................................ 14

Step 5: secondary transfer ......................................................................... 14

Step 6: separation from the ITB .................................................................. 15

Fusing stage ........................................................................................................... 15

Step 7: fusing .......................................................................................... 15

ITB cleaning stage ................................................................................................... 16

Step 8: ITB cleaning ................................................................................. 16

Drum cleaning stage ................................................................................................ 17

Step 9: drum cleaning .............................................................................. 17

Pickup-and-feed system ........................................................................................................... 18

Jam detection ......................................................................................................... 19

Scanner system (base models) ................................................................................................. 20

Scanner power-on sequence of events .......................................................................

20

ENWW v

Page 8

Copy or scan-to-computer sequence of events ............................................................. 21

Fax functions and operation (fax models only) ........................................................................... 22

Computer and network security features ..................................................................... 22

PSTN operation ...................................................................................................... 22

Receive faxes when you hear fax tones ...................................................................... 22

Distinctive ring function ............................................................................................ 23

Fax by using Voice over IP services ........................................................................... 23

The fax subsystem ................................................................................................... 24

Fax card in the fax subsystem ................................................................................... 24

Safety isolation ........................................................................................ 24

Safety-protection circuitry .......................................................................... 25

Data path ................................................................................................ 25

Hook state ............................................................................................... 25

Downstream device detection .................................................................... 26

Hook switch control .................................................................................. 26

Ring detect .............................................................................................. 26

Line current control ................................................................................... 26

Billing- (metering-) tone filters ..................................................................... 26

Fax page storage in flash memory ............................................................................ 26

Stored fax pages ...................................................................................... 27

Advantages of flash memory storage .......................................................... 27

USB Flash Drive ..................................................................................................................... 28

2 Solve problems ............................................................................................................... 29

Solve problems checklist ......................................................................................................... 30

Menu map ............................................................................................................................ 32

Troubleshooting process .......................................................................................................... 32

Pre-troubleshooting checklist ..................................................................................... 32

Power-on checks ..................................................................................................... 34

Tools for troubleshooting ......................................................................................................... 35

Component diagnostics ............................................................................................ 35

LED diagnostics ........................................................................................ 35

Networ

Control panel LEDs .................................................................... 36

Control-panel diagnostics .......................................................................... 37

Engine Diagnostics ................................................................................... 37

Engine test ................................................................................ 37

Diagrams ............................................................................................................... 38

Plug/jack locations ................................................................................... 38

DC controller PCA .................................................................................... 39

Locations of major components .................................................................. 41

k LEDs ........................................................................... 35

vi ENWW

Page 9

General timing charts ............................................................................... 43

General circuit diagram ............................................................................ 44

Internal print-quality test pages .................................................................................. 44

Interpret the Print Quality Page ................................................................... 44

Print a cleaning page ............................................................................... 45

Print a cleaning page ................................................................ 45

Configuration page .................................................................................. 46

Print a configuration page .......................................................... 46

Print-quality troubleshooting tools .............................................................................. 46

Repetitive image defects ............................................................................ 46

Calibrate the product to align the colors ...................................................... 47

Control panel menus ................................................................................................ 48

Setup Menu ............................................................................................. 48

HP Web Services ...................................................................... 48

Reports menu ............................................................................ 49

Self Diagnostics menu ................................................................ 50

Fax Setup menu ........................................................................ 50

System Setup menu .................................................................... 53

Service menu ............................................................................ 57

Network Setup menu ................................................................. 59

Quick Forms menu .................................................................... 60

Function specific menus ............................................................................. 61

USB Flash Drive ........................................................................ 61

Fax Menu ................................................................................. 61

Copy Menu .............................................................................. 63

Scan Menu ............................................................................... 65

Apps ....................................................................................... 66

Interpret control panel messages ............................................................................... 67

Control panel message types ..................................................................... 67

Control panel messages ............................................................................ 67

10.X00Y Supply Error ................................................................ 67

49 Error, Turn off then on ........................................................... 68

50.x Fuser Error ........................................................................ 68

51.XX Error .............................................................................. 68

54.XX Error .............................................................................. 68

55.X Error ................................................................................ 69

57 Fan Error, Turn off then on ..................................................... 69

59.X Error ................................................................................ 69

79 Error Turn off then on ............................................................ 70

Black Cartr

Black in wrong position .............................................................. 70

idge Low .................................................................. 70

ENWW vii

Page 10

Black Very Low ......................................................................... 70

Cleaning .................................................................................. 71

Cyan Cartridge Low .................................................................. 71

Cyan in wrong position .............................................................. 71

Cyan Very Low ......................................................................... 71

Device error, press OK .............................................................. 72

Door open ................................................................................ 72

Genuine HP supply installed ....................................................... 72

Incompatible <color> ................................................................. 72

Incorrect supplies ...................................................................... 72

Install <color> cartridge ............................................................. 73

Invalid driver Press [OK] ............................................................ 73

Jam in Tray 1, Clear jam and then press OK ................................ 73

Load tray 1 Press [OK] for available media .................................. 73

Load Tray 1 <TYPE> <SIZE>, Press OK to use available media ....... 73

Load Tray 1, <PLAIN> <SIZE> / Cleaning mode, OK to start ......... 73

Magenta Cartridge Low ............................................................. 74

Magenta in wrong position ........................................................ 74

Magenta Very Low .................................................................... 74

Manual Duplex Load Tray 1, Press OK ........................................ 74

Memory is low. Press OK. .......................................................... 75

Misprint, Press OK ..................................................................... 75

Print failure, press OK. If error repeats, turn off then on. ................. 75

Rear door open ......................................................................... 75

Remove shipping lock from <color> cartridge ............................... 76

Remove shipping locks from cartridges ........................................ 76

Replace <color> ....................................................................... 76

Supplies low ............................................................................. 76

Unexpected size in tray 1 Load <size> Press [OK] ........................ 76

Unsupported <color> Press [OK] to continue ................................. 77

Used <color> in use .................................................................. 77

Used <color> installed, to accept press OK .................................. 77

Used supplies in use .................................................................. 77

Yellow Cartridge Low ................................................................ 77

Yellow in wrong position ............................................................ 78

Yellow Very Low ....................................................................... 78

Event-log messages ................................................................................................. 79

Clear jams ............................................................................................................................ 85

Jam locations .......................................................................................................... 85

Clear jams from the document feeder ........................................................................ 86

Clear jams in the paper input tray ............................................................................. 87

viii ENWW

Page 11

Clear jams from the output bin .................................................................................. 89

Clear jams from the rear door ................................................................................... 89

Solve paper-handling problems ................................................................................................ 91

The product picks up multiple sheets of paper ............................................................. 91

The product does not pick up paper .......................................................................... 91

Solve image quality problems .................................................................................................. 92

Use the correct paper type setting in the printer driver ................................................. 92

Change the paper type setting for Windows ................................................ 92

Change the paper type setting for Mac ....................................................... 92

Adjust color settings in the printer driver ..................................................................... 93

Change the color theme for a print job ....................................................... 93

Change the color options .......................................................................... 94

Use paper that meets HP specifications ...................................................................... 94

Print a cleaning page .............................................................................................. 95

Calibrate the product to align the colors .................................................................... 95

Check the toner cartridges ........................................................................................ 96

Print the Supplies Status page .................................................................... 96

Inspect the print cartridge for damage ........................................................ 96

Repeating defects ..................................................................................... 97

Use the printer driver that best meets your printing needs ............................................. 97

Solve performance problems ................................................................................................... 99

Factors affecting print performance ........................................................................... 99

Print speeds ........................................................................................... 100

The product does not print or it prints slowly ............................................................. 101

The product does not print ....................................................................... 101

The product prints slowly ......................................................................... 102

Solve product connectivity problems ....................................................................................... 103

Solve direct-connect problems ................................................................................. 103

Solve network problems ......................................................................................... 103

Poor physical connection ......................................................................... 103

The computer is using the incorrect IP address for the product ...................... 103

The computer is unable to communicate with the product ............................ 104

The product is using incorrect link and duplex settings for the network .......... 104

New software programs might be causing compatibility problems ................ 104

The computer or workstation might be set up incorrectly .............................. 104

The product is disabled, or other network settin

Solve wireless network problems ............................................................................. 105

Wireless connectivity checklist ................................................................. 105

The control panel displays the message: The wireless feature on this product

has been turned off ................................................................................ 106

The product does not print after the wireless configuration completes ............ 106

gs are incorrect .................... 104

ENWW ix

Page 12

The product does not print, and the computer has a third-party firewall

installed ................................................................................................ 106

The wireless connection does not work after moving the wireless router or

product ................................................................................................. 106

Cannot connect more computers to the wireless product .............................. 107

The wireless product loses communication when connected to a VPN ........... 107

The network does not appear in the wireless networks list ........................... 107

The wireless network is not functioning ...................................................... 108

Service mode functions ......................................................................................................... 109

Secondary service menu ........................................................................................ 109

Open the secondary service menu ............................................................ 109

Secondary service menu structure ............................................................. 109

Product resets ....................................................................................................... 110

Restore the factory-set defaults ................................................................. 111

NVRAM initialization .............................................................................. 111

Solve fax problems ............................................................................................................... 112

Fax troubleshooting checklist .................................................................................. 112

Solve problems receiving faxes ............................................................................... 114

The fax does not respond ........................................................................ 114

The fax has a dedicated phone line ........................................... 114

An answering machine is connected to the product ..................... 114

A telephone handset is connected to the product ......................... 115

The Answer Mode setting is set to the Manual setting ................... 115

Voice mail is available on the fax line ........................................ 115

The product is connected to a DSL phone service ........................ 116

The product uses a fax over IP or VoIP phone service ................... 116

An error message displays on the control panel ......................................... 117

The No fax detected. message displays ..................................... 117

The Communication error. message displays .............................. 117

The Fax storage is full. message displays ................................... 118

The Fax is busy. message displays ............................................ 118

A fax is received but does not print .......................................................... 119

The Private Receive feature is on ............................................... 119

Sender receives a busy signal .................................................................. 119

A handset is connected to the product ........................................ 119

A phone line splitter is being used ............................................. 119

No dial tone .......................................................................................... 119

Fax cuts off or prints on two pages ........................................................... 120

Solve problems sending faxes ................................................................................. 120

An error message displays on the c

The Communication error. message displays .............................. 121

ontrol panel ......................................... 121

x ENWW

Page 13

No dial tone. .......................................................................... 121

The Fax is busy. message displays ............................................ 122

The No fax answer. message displays ....................................... 122

Document feeder paper jam ..................................................... 123

The Fax storage is full. message displays ................................... 123

Scanner error ......................................................................... 123

The control panel displays a Ready message with no attempt to send the fax . 124

The control panel displays the message "Storing page 1" and does not

progress beyond that message ................................................................. 124

Faxes can be received, but not sent .......................................................... 124

Unable to use fax functions from the control panel ...................................... 125

Unable to use speed dials ....................................................................... 125

Unable to use group dials ....................................................................... 125

Receive a recorded error message from the phone company when trying to

send a fax ............................................................................................. 126

Unable to send a fax when a phone is connected to the product .................. 126

Solve fax performance problems ............................................................................. 127

Faxes are sending slowly ........................................................................ 127

Fax quality is poor ................................................................................. 128

Solve DSL problems ............................................................................................... 128

Cannot send or receive a fax on a PBX line ............................................... 128

Product updates ................................................................................................................... 128

Appendix A Service and support ..................................................................................... 129

Hewlett-Packard limited warranty statement ............................................................................. 130

HP's Premium Protection Warranty: LaserJet print cartridge limited warranty statement .................. 132

Data stored on the print cartridge ........................................................................................... 133

End User License Agreement .................................................................................................. 134

OpenSSL ............................................................................................................................. 136

Customer support ................................................................................................................. 136

Repack the product .............................................................................................................. 137

Appendix B Product specifications ................................................................................... 139

Physical specifications .......................................................................................................... 140

Power consumption, electrical specifications, and acoustic emissions .......................................... 140

Environmental specifications .................................................................................................. 140

Appendix C Regulatory information .........

FCC regulations ................................................................................................................... 142

Environmental product stewardship program ........................................................................... 143

Protecting the environment ...................................................................................... 143

........................................................................ 141

ENWW xi

Page 14

Ozone production ................................................................................................. 143

Power consumption ............................................................................................... 143

Paper use ............................................................................................................. 143

Plastics ................................................................................................................. 143

HP LaserJet print supplies ....................................................................................... 143

Return and recycling instructions ............................................................................. 144

United States and Puerto Rico .................................................................. 144

Multiple returns (more than one cartridge) .................................. 144

Single returns .......................................................................... 144

Shipping ................................................................................ 144

Non-U.S. returns .................................................................................... 145

Paper .................................................................................................................. 145

Material restrictions ............................................................................................... 145

Disposal of waste equipment by users in private households in the European Union ...... 146

Chemical substances ............................................................................................. 146

Material Safety Data Sheet (MSDS) ......................................................................... 146

For more information ............................................................................................. 146

Declaration of conformity ...................................................................................................... 147

Declaration of conformity (wireless model) .............................................................................. 149

Certificate of Volatility .......................................................................................................... 151

Safety statements ................................................................................................................. 152

Laser safety .......................................................................................................... 152

Canadian DOC regulations .................................................................................... 152

VCCI statement (Japan) .......................................................................................... 152

Power cord instructions .......................................................................................... 152

Power cord statement (Japan) ................................................................................. 152

EMC statement (Korea) .......................................................................................... 153

Laser statement for Finland ..................................................................................... 153

GS statement (Germany) ........................................................................................ 153

Substances Table (China) ....................................................................................... 154

Restriction on Hazardous Substances statement (Turkey) ............................................. 154

Additional statements for telecom (fax) products ....................................................................... 155

EU Statement for Telecom Operation ....................................................................... 155

New Zealand Telecom Statements ........................................................................... 155

Additio

Telephone Consumer Protection Act (US) .................................................................. 156

Industry Canada CS-03 requirements ...................................................................... 156

Additional statements for wireless products .............................................................................. 158

FCC compliance statement—United States ................................................................ 158

Australia statement ................................................................................................ 158

Brazil ANATEL statement ........................................................................................ 158

nal FCC statement for telecom products (US) .................................................. 155

xii ENWW

Page 15

Canadian statements ............................................................................................. 158

European Union regulatory notice ........................................................................... 158

Notice for use in France ......................................................................................... 159

Notice for use in Russia ......................................................................................... 159

Korean statement .................................................................................................. 159

Taiwan statement .................................................................................................. 160

Index ............................................................................................................................... 161

ENWW xiii

Page 16

xiv ENWW

Page 17

List of tables

Table 1-1 Sequence of operation ............................................................................................................ 4

Table 2-1 DC controller connectors ....................................................................................................... 39

Table 2-2 Major components ............................................................................................................... 41

Table 2-3 Repetitive image defects ........................................................................................................ 46

Table 2-4 Event-log messages ............................................................................................................... 79

Table 2-5 Fax event log codes .............................................................................................................. 84

Table 2-6 Secondary service menu ...................................................................................................... 109

Table B-1 Physical specifications ......................................................................................................... 140

1

Table B-2 Environmental specifications

............................................................................................... 140

ENWW xv

Page 18

xvi ENWW

Page 19

List of figures

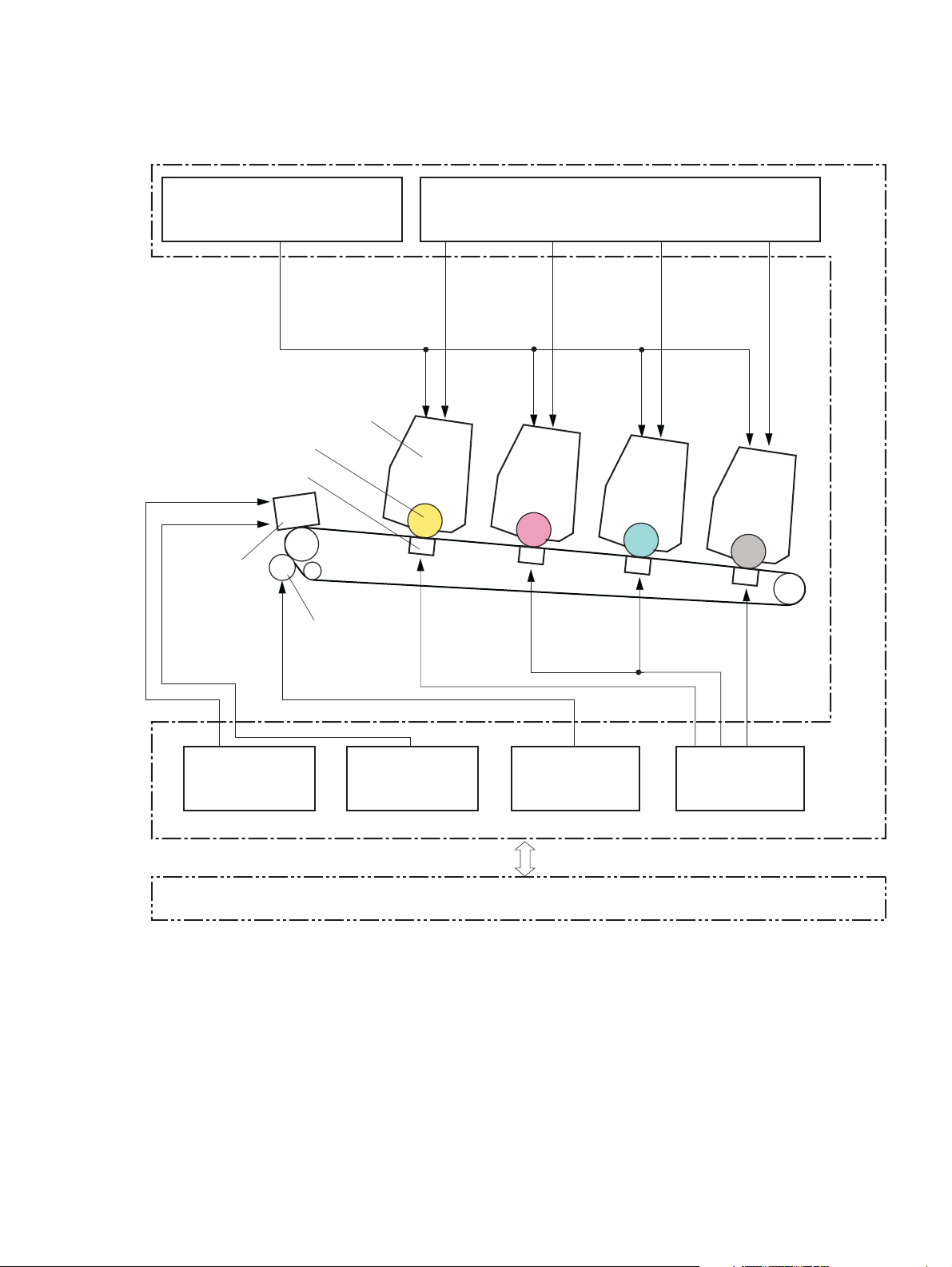

Figure 1-1 Product systems ..................................................................................................................... 2

Figure 1-2 Product components ............................................................................................................... 3

Figure 1-3 Engine control system components ........................................................................................... 5

Figure 1-4 DC controller circuit diagram .................................................................................................. 6

Figure 1-5 Low-voltage power supply ...................................................................................................... 7

Figure 1-6 High-voltage power supply ..................................................................................................... 8

Figure 1-7 Laser/scanner system ............................................................................................................. 9

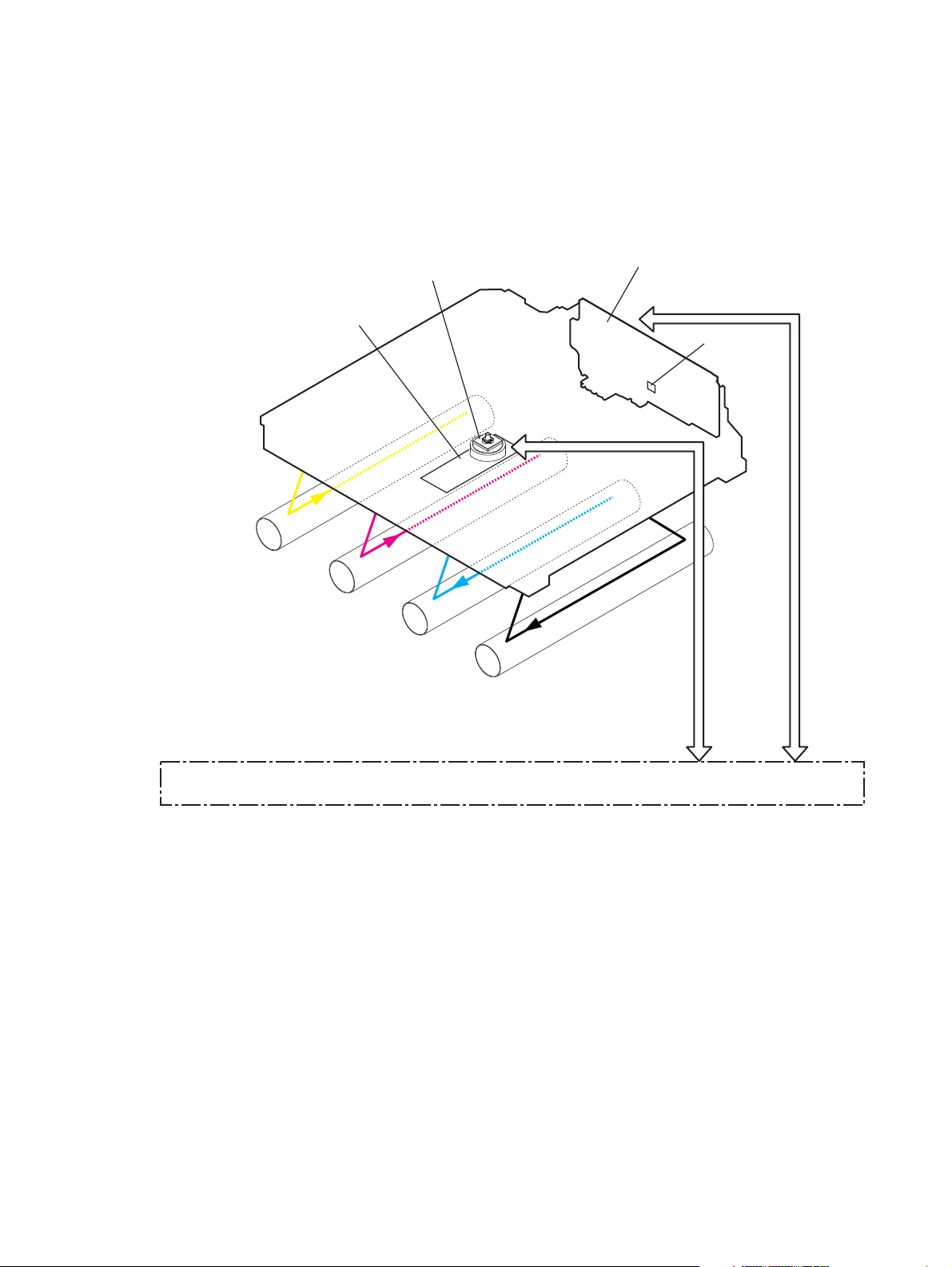

Figure 1-8 Image-formation system ........................................................................................................ 10

Figure 1-9 Image-formation process ...................................................................................................... 11

Figure 1-10 Primary charging ............................................................................................................... 12

Figure 1-11 Laser-beam exposure ......................................................................................................... 12

Figure 1-12 Development ..................................................................................................................... 13

Figure 1-13 Primary transfer ................................................................................................................. 14

Figure 1-14 Secondary transfer ............................................................................................................ 14

Figure 1-15 Separation from the ITB ...................................................................................................... 15

Figure 1-16 Fusing .............................................................................................................................. 15

Figure 1-17 ITB cleaning ...................................................................................................................... 16

Figure 1-18 Drum cleaning .................................................................................................................. 17

Figure 1-19 Pickup-and-feed system ..........................................................

Figure 2-1 DC controller connectors ...................................................................................................... 39

Figure 2-2 Major components .............................................................................................................. 41

Figure 2-3 Timing diagram ................................................................................................................... 43

Figure 2-4 Circuit diagram ................................................................................................................... 44

............................................. 18

ENWW xvii

Page 20

xviii ENWW

Page 21

1 Theory of operation

This chapter presents an overview of the major components of the product, and includes a detailed

discussion of the image-formation system.

Basic operation

●

Engine control system

●

Laser/scanner system

●

Image-formation system

●

Pickup-and-feed system

●

Scanner system (base models)

●

Fax functions and operation (fax models only)

●

USB Flash Drive

●

ENWW 1

Page 22

Basic operation

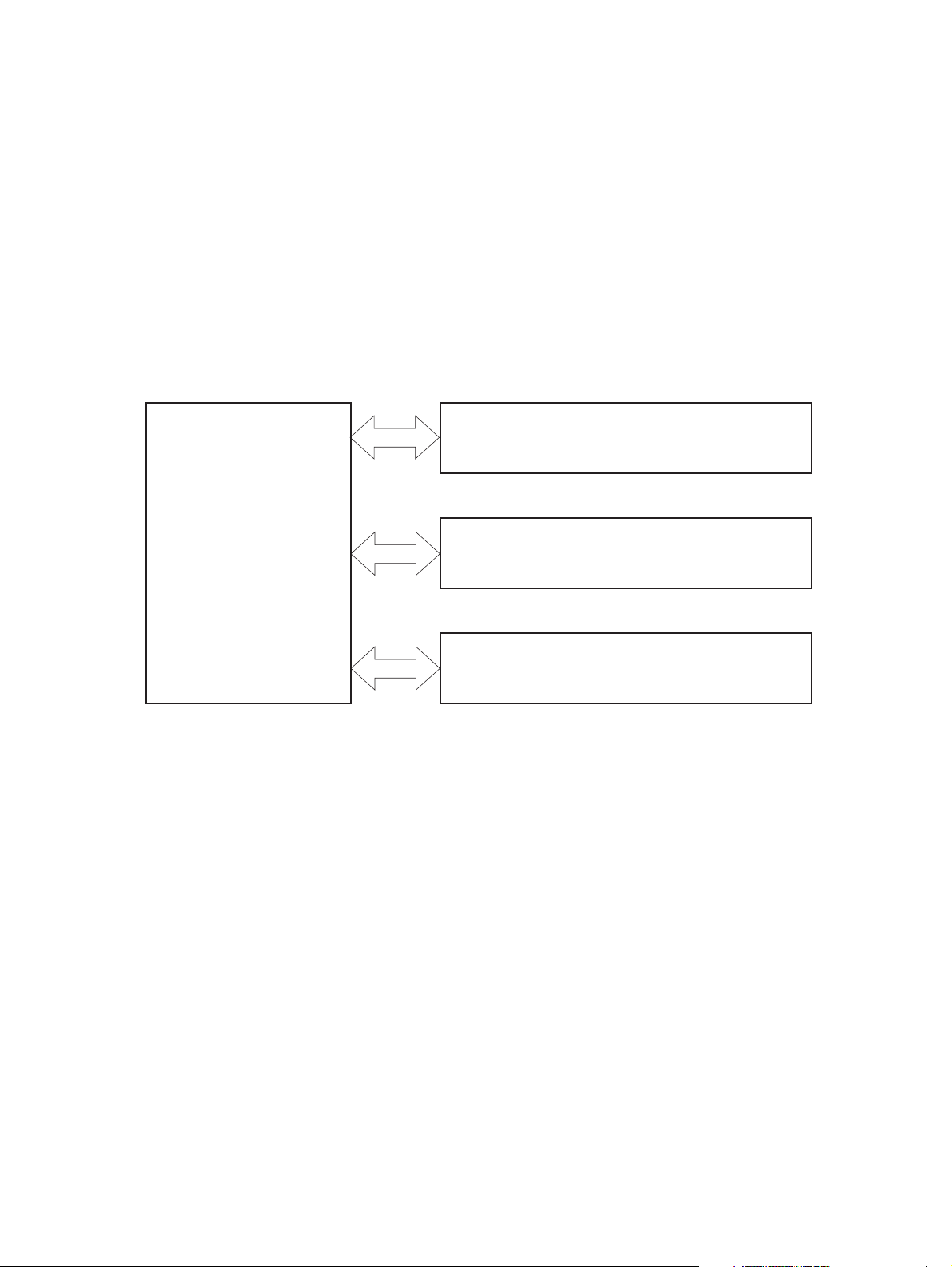

Major product systems

The product includes the following systems:

Engine control system

●

Laser/scanner system

●

Image-formation system

●

Pickup-and-feed system

●

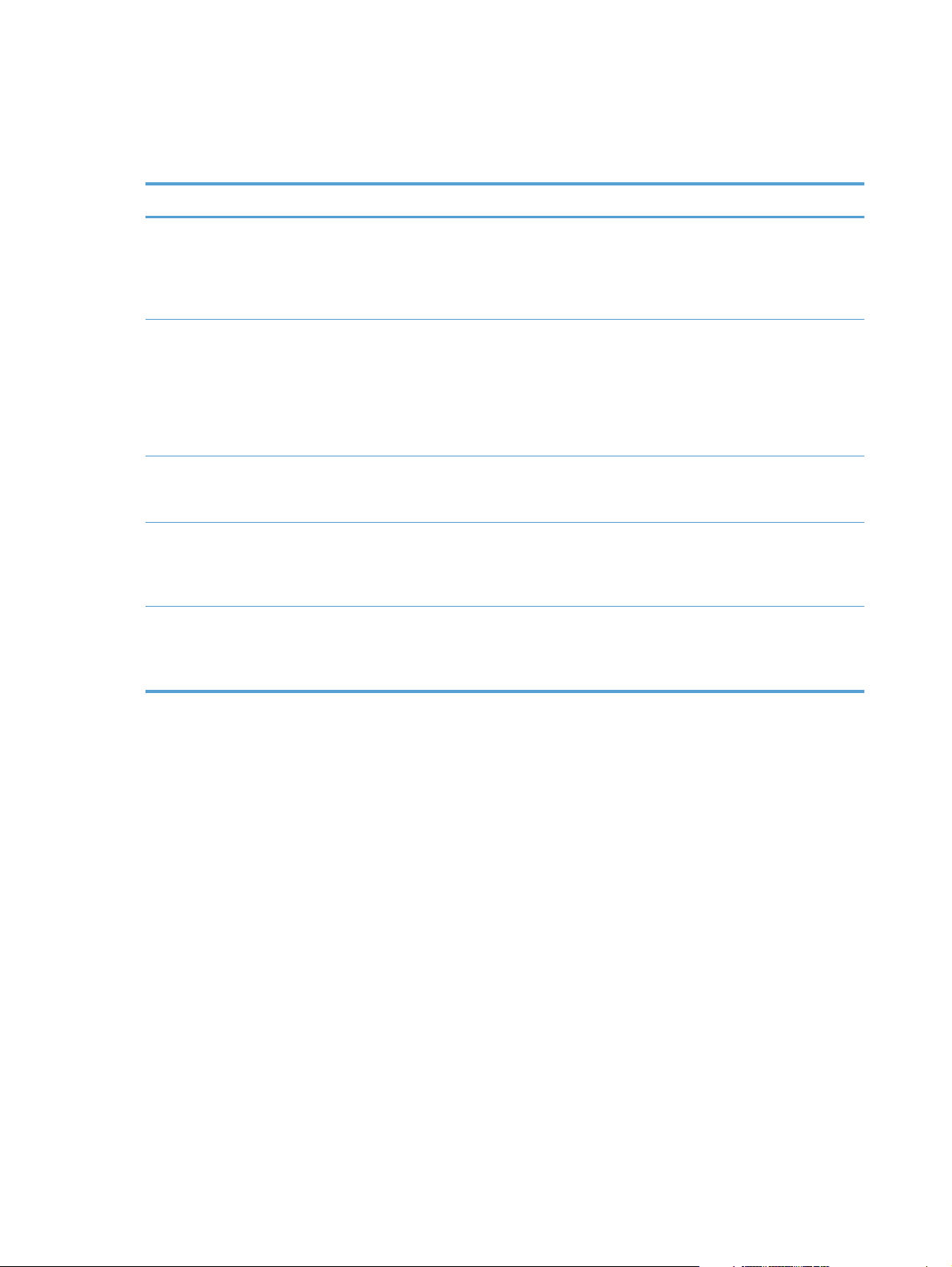

Figure 1-1 Product systems

LASER/SCANNER SYSTEM

ENGINE CONTROL

SYSTEM

IMAGE-FORMATION SYSTEM

PICKUP-AND-FEED SYSTEM

2 Chapter 1 Theory of operation ENWW

Page 23

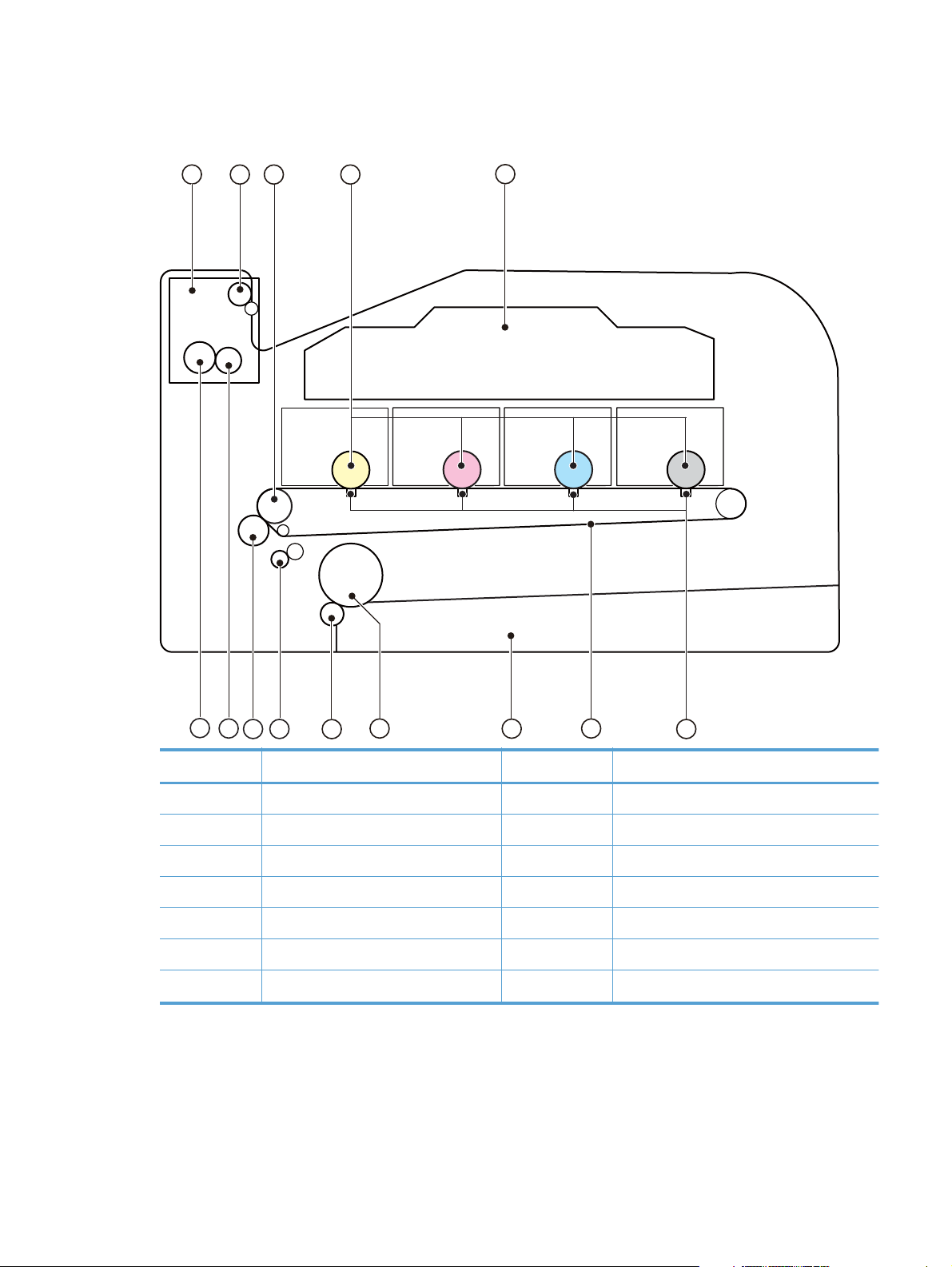

Product components

Figure 1-2 Product components

1

3 4

2

5

14

13

Item Description Item Description

1 Fuser unit 8 Cassette

2 Delivery roller 9 Pickup roller

3 ITB drive roller 10 Separation roller

4 Photosensitive drum 11 Registration roller

5 Laser scanner assembly 12 Secondary transfer roller

6 Transfer pad 13 Fusing film

7 Intermediate transfer belt (ITB) 14 Pressure roller

12

11

10

9

8

7

6

ENWW

Basic operation

3

Page 24

Sequence of operation

Table 1-1 Sequence of operation

Period Duration Purpose Remarks

WAIT From the time the power is

turned on or the door is

closed, until the printer is

ready for a print operation

STBY (Standby period) From end of the WAIT or

LSTR period until either the

print command is received

from the formatter or the

power is turned off

INTR (Initial rotation) From the time the print

command is received until the

media is picked up

PRINT From the end of INTR period

until the fuser paper sensor

detects the trailing edge of

paper

LSTR (Last rotation) From the end of the PRINT

period until the delivery motor

stops rotating

Clears the potential from the

drum surface, adjusts the

drum phase, and cleans the

ITB

Maintains the printer in

readiness for a print

command

Prepares the photosensitive

drum for printing

Forms the images on the

photosensitive drum and

transfers the toner image to

the print media

Moves the printed sheet out

of the printer

Detects the cartridge

presence and environment;

completes any required

calibration (color registration

control and image stability)

The printer enters sleep mode

when the formatter sends a

sleep command, and

performs color registration

and image stability control

when the formatter sends

those commands

Performs image stabilization

at a specified print interval or

at specified times

The printer enters the INTR

period as soon as the

formatter sends another print

command

4 Chapter 1 Theory of operation ENWW

Page 25

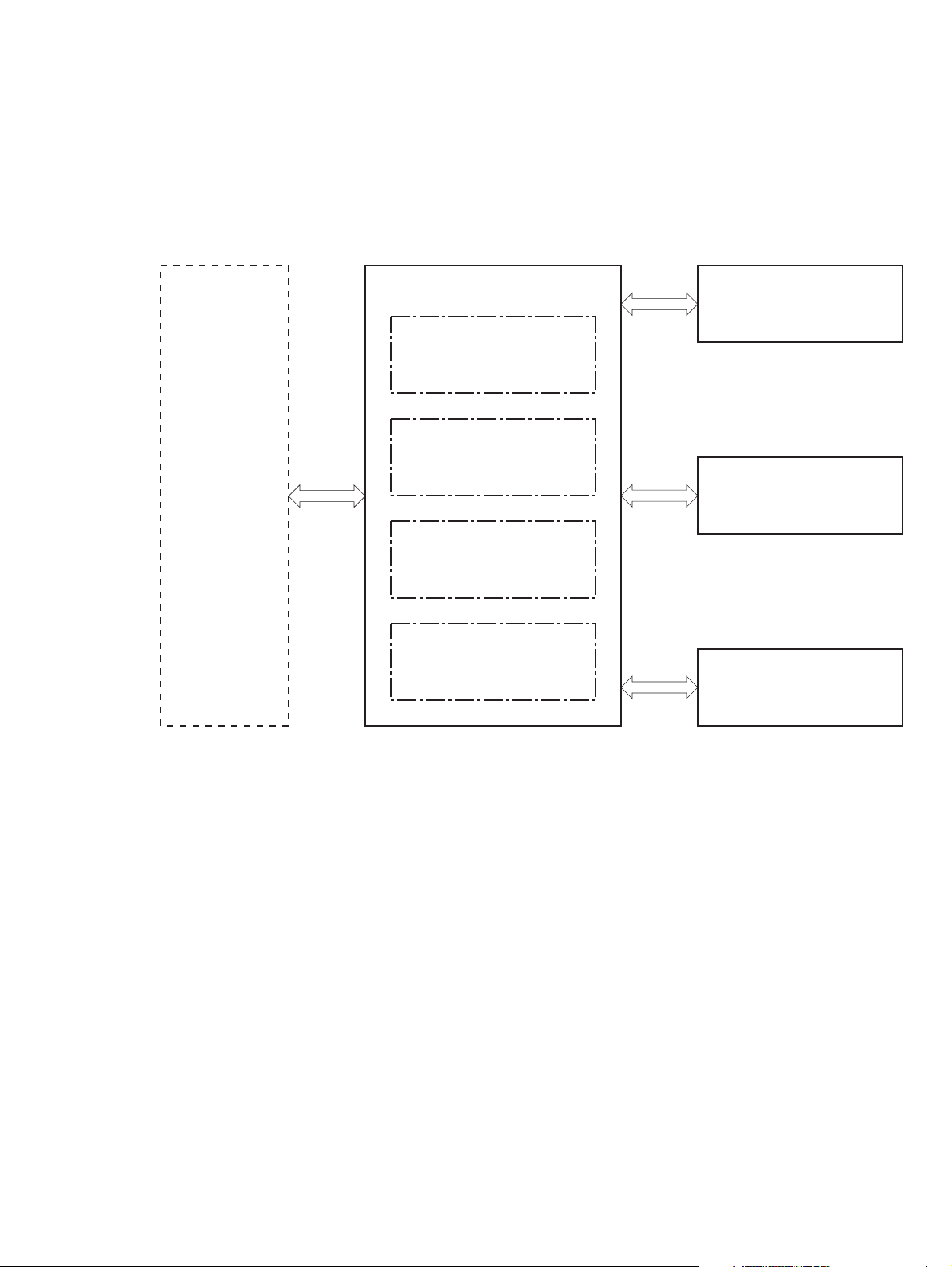

Engine control system

The engine control system coordinates all printer functions and drives the other three systems.

The engine control system contains the DC controller, high-voltage power-supply PCA, low-voltage

power-supply unit, and fuser control.

Figure 1-3 Engine control system components

Formatter

Engine-control system

Laser scanner system

DC controller

Low-voltage power supply

Image-formation system

High-voltage power supply

Fuser control

Pickup, feed and delivery

system

ENWW

Engine control system

5

Page 26

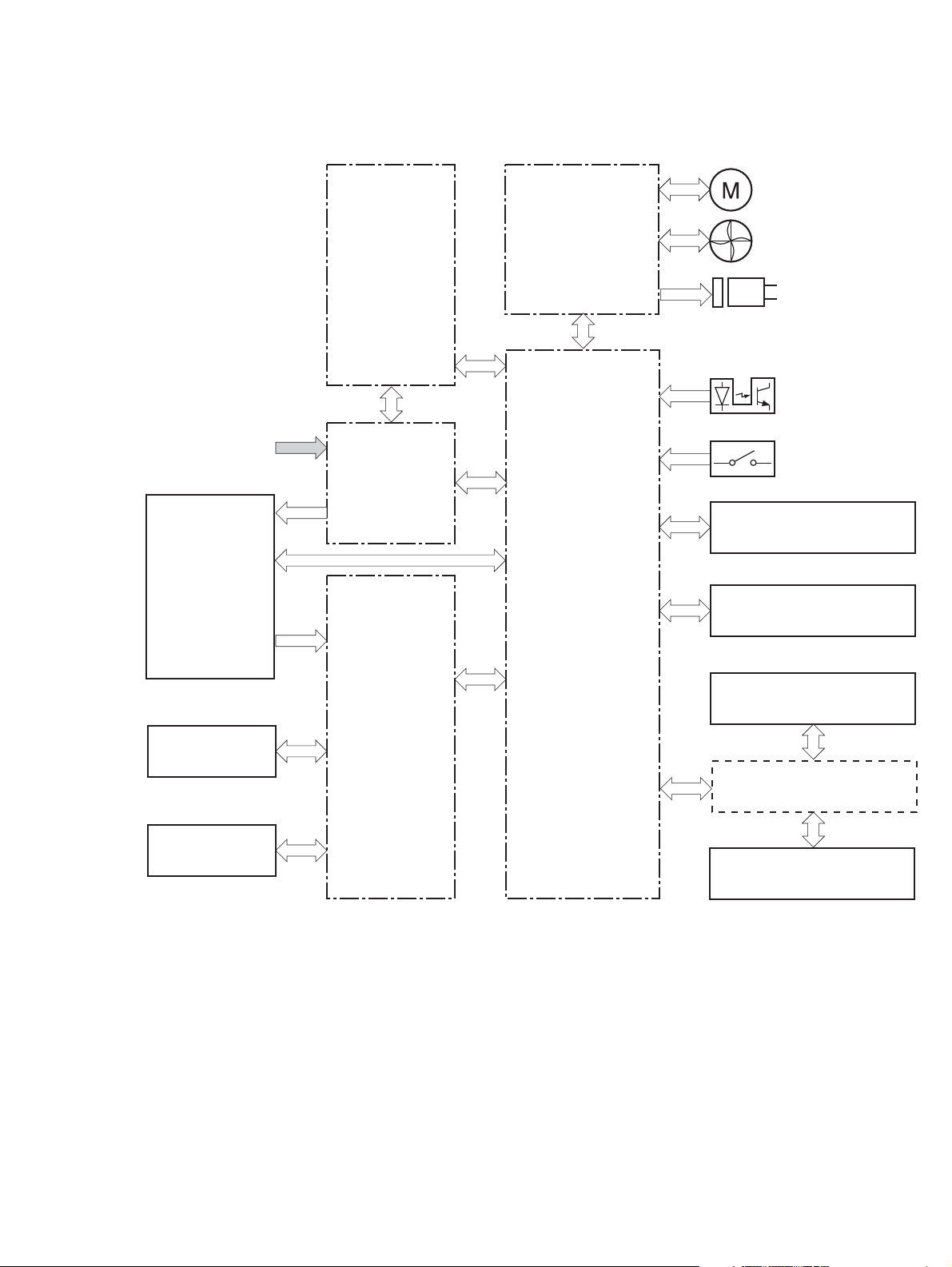

DC controller

Figure 1-4 DC controller circuit diagram

Motor

AC input

Fuser

Low-voltage

power supply

Fuser

power supply

Driver

DC controller

Fan

Solenoid

Photointerrupter

Switch

ITB assembly

Laser scanner assembly

USB (NOTE)

T2 roller

Cartridge

High-voltage

power supply

Formatter

Control panel

6 Chapter 1 Theory of operation ENWW

Page 27

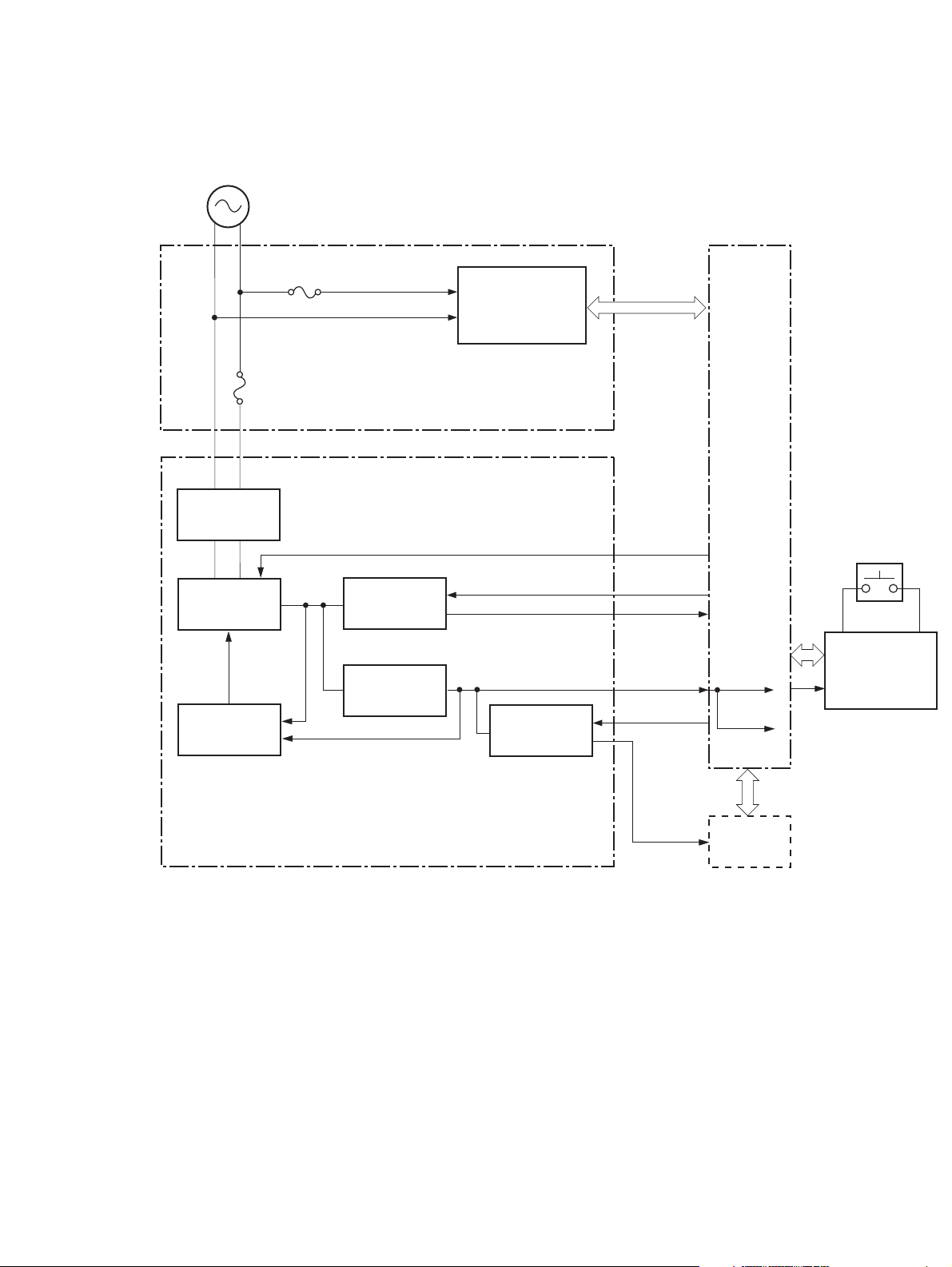

Low-voltage power supply

Figure 1-5 Low-voltage power supply

AC input

Fuse

FU901

Fuse

FU801

Rectifying

circuit

Fuser control

circuit

Fuser power supply

PWSV

DC controller

Power switch

SW801

+24V

generation

circuit

Protection

circuit

+24VR

+24V

control circuit

+3.3V

generation

circuit

+3.3V

control circuit

Low-voltage power supply

REM24V

+24VA

VCTRLOFF

+3.3VC

+3.3VA+3.3VA

+3.3VB

Formatter

+24VA

Power switch

control circuit

ENWW

Engine control system

7

Page 28

High-voltage power supply

Figure 1-6 High-voltage power supply

Primary charging bias circuit

Cartridge

Photosensitive drum

T1 pad

ITB cleaning

ass’y

T2 roller

Developing bias circuit

ITB

ITB cleaning brush

bias circuit

ITB cleaning roller

bias circuit

T2 bias circui

DC controller

T1 bias circuit

High-voltage power supply

8 Chapter 1 Theory of operation ENWW

Page 29

Laser/scanner system

The formatter sends video signals to the DC controller, which controls the laser/scanner. When the

laser/scanner system receives those signals, it converts them to latent images on the photosensitive

drum.

Figure 1-7 Laser/scanner system

Scanner mirror

Scanner motor assembly

Laser assembly

BD sensor

Photosensitive drum

(Y)

Photosensitive drum

(M)

Photosensitive drum

Laser failure detection

The optical unit failure detection sensor manages the laser/scanner unit failure-detection functions. The

DC controller identifies the laser/scanner unit failure and notifies the formatter if the laser/scanner unit

encounters the following conditions:

Scanner motor failure

●

BD failure

●

(C)

Photosensitive drum

(K)

DC controller

ENWW

Laser/scanner system

9

Page 30

Image-formation system

The image-formation system forms a toner image on media. The product includes four toner cartridges

that contain the toner. Toner is applied in the following order, using only the colors necessary for a

specific image: yellow (Y), magenta (M), cyan (C), and black (K).

Figure 1-8 Image-formation system

High-voltage power supply

Fuser

DC controller

Laser scanner assembly

Cartridge

T2 roller

Image-formation process

Laser printing requires the interaction of several different technologies including electronics, optics, and

electrographics to provide a printed page. Each process functions independently and must be

coordinated with the other processes. Image formation consists of the following processes:

Latent-image formation

●

Development

●

Transfer

●

MCYK

T1 pad

Photosensitive drum

ITB

10 Chapter 1 Theory of operation ENWW

Page 31

Fuser

●

ITB cleaning

●

Drum cleaning

●

These processes are divided into nine steps, which are shown in

on page 11 and described in the following sections.

Figure 1-9 Image-formation process

Delivery

Latent image formation

7. Fusing

Fuser

3. Development

Development

Transfer

6. Separation

5. Secondary transfer

Registration

2. Laser beam exposure

1. Primary charging

Photosensitive drum cleaning

9. Drum cleaning

4. Primary transfer

8. ITB cleaning

ITB cleaning

Figure 1-9 Image-formation process

: Media path

: Direction of drum rotation

: Block

: Step

Pickup

Latent-image formation stage

During the two steps that comprise this stage, a latent image is formed by applying a negative charge

to the photosensitive drum. You cannot see this image on the drum.

ENWW

Image-formation system

11

Page 32

Step 1: primary charging

A high-voltage DC bias is applied to the primary charging roller, which is made of conductive rubber

and is in contact with the drum surface. As the roller moves across the drum, it applies the negative

charge to that surface.

Figure 1-10 Primary charging

Primary charging roller

Photosensitive drum

Step 2: laser-beam exposure

The laser beam scans the photosensitive drum to neutralize the negative charge on portions of the drum

surface. An electrostatic latent image is formed where the negative charge was neutralized.

DC bias

Figure 1-11 Laser-beam exposure

Unexposed area Exposed area

Developing stage

The developer roller comes in contact with the photosensitive drum and deposits toner on the

electrostatic latent image.

Laser beam

12 Chapter 1 Theory of operation ENWW

Page 33

Step 3: development

Toner acquires a negative charge as a result of the friction from the developer roller rotating against the

developer blade. When the negatively charged toner comes in contact with the drum, it adheres to the

electrostatic latent image. When the toner is on the drum, the image becomes visible.

Figure 1-12 Development

Developer blade

Exposed area

Unexposed area

Developer roller

DC negative bias

Unexposed area

Exposed area

Photosensitive drum

ENWW

Image-formation system

13

Page 34

Transfer stage

Step 4: primary transfer

The toner image on the photosensitive drum is transferred to the ITB. The DC positive bias is applied to

the primary transfer pad. The negatively charged toner transfers to the ITB from the drum surface.

Figure 1-13 Primary transfer

Photosensitive

T1 pad

drum

ITB

T1 bias

Step 5: secondary transfer

The toner image on the ITB is transferred to the print media. The DC positive bias is applied to the

secondary transfer roller. As the media passes between the secondary transfer roller and the ITB, the

toner image is transferred to the media.

Figure 1-14 Secondary transfer

Media

Secondary transfer roller

DC bias

ITB

ITB drive roller

14 Chapter 1 Theory of operation ENWW

Page 35

Step 6: separation from the ITB

The elasticity of the print media and the curvature of the ITB drive roller cause the media to separate

from the ITB.

Figure 1-15 Separation from the ITB

Media

Secondary transfer roller

Fusing stage

Until the fusing stage is complete, the image is not permanently affixed to the print media. The toner

can be easily smudged until the heat and pressure of the fusing process fix the image to the sheet.

Step 7: fusing

ITB

ITB drive roller

The product uses an on-demand fixing method to fix the toner image onto the media. The toner image

is permanently affixed to the print media by heat and pressure.

Figure 1-16 Fusing

Fuser film

Fuser heater

Toner

Paper

Pressure roller

ENWW

Image-formation system

15

Page 36

ITB cleaning stage

Step 8: ITB cleaning

The ITB cleaning roller and the cleaning brush are applied with the DC positive bias to charge the

residual toner positive. Because the primary transfer pad is also applied with the DC positive bias, the

positively charged residual toner is reverse-transferred to the photosensitive drum from the ITB surface.

Figure 1-17 ITB cleaning

Positive potential waste toner

Negative potential waste toner

Partition sheet

ITB cleaning brush

Sweeper strip

DC bias

Cartridge

Photosensitive drum

ITB cleaning roller

IT B

DC bias

16 Chapter 1 Theory of operation ENWW

Page 37

Drum cleaning stage

Not all of the toner is removed from the photosensitive drum during the transfer stage. During the

cleaning stage, the residual, or waste, toner is cleared from the drum surface to prepare the surface for

the next latent-image formation.

Step 9: drum cleaning

The cleaning blade scrapes the residual toner off the surface of the photosensitive drum and deposits it

in the waste-toner container. The drum is now clear and is ready for the next image-formation process.

Figure 1-18 Drum cleaning

Cleaning blade Blowout seal

Photosensitive

drum

ENWW

Image-formation system

17

Page 38

Pickup-and-feed system

The pickup-and-feed system picks up and feeds the print media. It consists of several types of feed

rollers.

Figure 1-19 Pickup-and-feed system

SR610 SR611

SR609

SR607

SR603

SR602

SR601

Number Description Number Description

Cassette paper out sensor SR601 CASSETTE PAPER OUT signal

Registration sensor SR602 REGISTRATION signal

Loop sensor SR603 LOOP signal

SW1

Fuser output sensor SR609 FUSER OUTPUT signal

Rear door open detection sensor SR607 REAR DOOR OPEN DETECTION signal

Paper width sensor (L) SR610 PAPER WIDTH (L) signal

Paper width sensor (R) SR611 PAPER WIDTH (R) signal

Front door open detection switch SW1 FRONT DOOR OPEN DETECTION signal

18 Chapter 1 Theory of operation ENWW

Page 39

Jam detection

The product uses the following sensors to detect the presence of media and to check whether media is

being fed correctly or has jammed:

Cassette media-presence sensor

●

Top-of-page sensor

●

Loop sensor

●

Fuser delivery sensor

●

The product detects the following jams:

Pickup delay jam

●

Pickup stationary jam

●

Delivery delay jam

●

Delivery stationary jam

●

Fixing wrapping jam

●

Residual media jam

●

ENWW

Pickup-and-feed system

19

Page 40

Scanner system (base models)

The flatbed image scanner captures an electronic image of the document on the glass. The scanner

does this by illuminating the document with LEDs (red, green, and blue) and capturing the image in the

image sensor to create an electronic format of the document. The flatbed scanner consists of three main

elements

CIS scanner. The CIS (contact image sensor) scanner captures an image using the product's

●

optical path. Red, green, and blue LEDs sequentially illuminate a small strip of the document (often

called a raster line), and the optical system captures each color in a single row of CCD sensors

that cover the entire page width. Because only one color is captured for each line per exposure,

the three colors are recombined electronically to create the full color image. For monochromatic

scans or copies, all three LEDs are illuminated to create a white light for the scan so the raster line

can be captured in one exposure.

Mechanical carriage drive. The carriage drive moves the CIS scan head along the document

●

length to create the image. In this product, a small DC motor with an optical encoder creates this

motion. The speed of the carriage drive is proportional to the scan resolution (300 ppi is much

faster than 1200 ppi) and also proportional to the type of scan (color scans are three-times slower

than monochromatic scans). A 1200 ppi color scan moves so slowly that the product may appear

to not be working, whereas a monochromatic copy scan moves at 50 times that speed and will be

somewhat noisy.

Image processing system (formatter). The formatter processes the scanner data into either

●

a copy or a scan to the computer. For copies, the image data is sent directly to the product

without being transmitted to the computer. Depending on user selections for the copy settings, the

formatter enhances the scanner data significantly before sending it to the product. Image data is

captured at 300 ppi for copies and is user selectable for scans to the computer. Each pixel is

represented by 8 bits for each of the three colors (256 levels for each color), for a total of 24 bits

per pixel (24-bit color).

Scanner power-on sequence of events

When the product is turned on, it performs the following tests:

Motor test. The product moves the motor left and right to confirm operation. It reports a scanner

●

error 12 if no motion is detected in the motor encoder system.

Wall find. The scan carriage moves slowly to the left while watching an encoder on the carriage

●

motor to determine when the carriage has found the side wall or stop. This enables the product to

identify the document origin (position of the original). If the document origin cannot be located, a

default position is used instead.

LED check. The product moves the carriage to the white calibration label under the left side of

●

the flatbed image scanner, and it verifies that the minimum and maximum response is acceptable.

It reports a scanner error 14 if the response is unacceptable.

Home find. The scan carriage uses the optical scanner to find physical reference features that

●

relate to the document origin at the left side of the image glass. This process ensures accurate

location of the first document pixels so that the user documents will have an accurate placement of

20 Chapter 1 Theory of operation ENWW

Page 41

the image on scans and copies. It reports a scanner error 6 message if the reference features are

not found.

Calibration. This test, also known as scanner color calibration, enables the product to identify

●

the black and white on every pixel in the CCD. Calibration occurs in two major processes: a

broad (analog) adjustment of all pixels to bring them into the target output range, and a pixel-bypixel adjustment (digital) to fine tune the actual black and white response. The calibration process

occurs under the left side of flatbed image scanner where there is a special white calibration

label.

Calibration is the most important step in creating a high quality image. Calibration problems can

include color and brightness inaccuracies, and vertical streaks through the image. The calibration

process identifies any bad pixels and enables the image formatter to recreate the lost information

from adjacent pixels. Extreme cases of this problem can appear as large vertical streaks or image

smears. The user has no control over the calibration process itself or this pixel-replacement

process.

Copy or scan-to-computer sequence of events

To create an accurate rendition of a document, the scanner must be calibrated for the requested

operation. If the user selects a scan at 600 ppi color, the flatbed image scanner calibrates for that

specific operational mode. Subsequently, the flatbed image scanner automatically re-calibrates for the

next requested operation. Calibration does not occur for every new copy request.

Normal sequence of operation for a flatbed copy or scan includes:

1. LEDs illuminate.

2. Carriage motion begins moving the CIS scanner toward the right.

3. Image capture continues for the entire page or length requested in a scan-to-computer operation.

4. Carriage returns to the home position on the left.

ENWW

Scanner system (base models)

21

Page 42

Fax functions and operation (fax models only)

The following sections describe the product fax capabilities.

Computer and network security features

The product can send and receive fax data over telephone lines that conform to public switch telephone

network (PSTN) standards. The secure fax protocols make it impossible for computer viruses to be

transferred from the telephone line to a computer or network.

The following product features prevent virus transmission:

No direct connection exists between the fax line and any devices that are connected to the USB or

●

Ethernet ports.

The internal firmware cannot be modified through the fax connection.

●

All fax communications go through the fax subsystem, which does not use Internet data-exchange

●

protocols.

PSTN operation

The PSTN operates through a central office (CO) that generates a constant voltage on the TIP and RING

wires (48 V, usually). A device goes on-hook by connecting impedance (such as 600 ohms for the

U.S.) across the TIP and RING so that a line current can flow. The CO can detect this current and can

send impulses like dial tones. The product generates more signaling tones, such as dialing digits, to tell

the CO how to connect the call. The product can also detect tones, such as a busy tone from the CO,

that tell it how to behave.

When the call is finally connected, the CO behaves like a piece of wire connecting the sender and

receiver. This is the period during which all of the fax signaling and data transfer occurs. When a call

is completed, the circuit opens again and the line-current flow ceases, removing the CO connection

from both the sender and the receiver.

On most phone systems, the TIP and RING signals appear on pins 3 and 4 of the RJ-11 modular jack

(the one on the fax card, as defined in the common 6 wire RJ standard). These two signals do not have

to be polarized because all of the equipment works with either TIP or RING on one pin and the other

signal on the other pin. This means that cables of either polarity can interconnect and still work.

These basic functions of PSTN operation are assumed in the design of the fax subsystem. The product

generates and detects the signaling tones, currents, and data signals that are required to transmit and

receive faxes using the PSTN.

Receive faxes when you hear fax tones

In general, incoming faxes to the product are automatically received. However, if other devices are

connected to the same phone line, the product might not be set to answer automatically.

22 Chapter 1 Theory of operation ENWW

Page 43

If the product is connected to a phone line that receives both fax and phone calls, and you hear fax

tones when you answer the extension phone, receive the fax in one of two ways:

If you are near the product, press Start Fax on the control panel.

●

Press 1-2-3 in sequence on the extension phone keypad, listen for fax transmission sounds, and

●

then hang up.

NOTE: In order for the 1-2-3 sequence to work, the extension phone setting must be set to On in the

Fax Setup menu.

Distinctive ring function

Distinctive ring is a service that a telephone company provides. The distinctive ring service allows three

phone numbers to be assigned to one phone line. Each phone number has a distinctive ring. The first

phone number has a single ring, the second phone number has a double ring, and the third phone

number has a triple ring.

NOTE: The product has not been tested with all of the distinctive-ring services that telephone

companies provide in all countries/regions. HP does not guarantee that the distinctive-ring function will

operate correctly in all countries/regions. Contact the local phone service provider for assistance.

Set up the distinctive ring function

1. Press Setup

2. Use the arrow buttons to select Fax Setup, and then press Enter.

3. Use the arrow buttons to select Basic Setup, and then press Enter.

4. Use the arrow buttons to select Distinctive Ring, and then press Enter.

5. Use the arrow buttons to select one of the following options:

NOTE: The control-panel display might show some of these options as abbreviations.

All Rings (default setting)

●

Single

●

Double

●

Triple

●

Double and Triple

●

Press Enter to save the setting.

.

Fax by using Voice over IP services

ENWW

Voice over IP (VoIP) services provide normal telephone service, including long distance service through

a broadband Internet connection. These services use packets to break up the voice signal on a

telephone line and transmit it digitally to the receiver, where the packets are reassembled. The VoIP

Fax functions and operation (fax models only)

23

Page 44

services are often not compatible with fax machines. The VoIP provider must state that the service

supports fax over IP services.

Because the installation process varies, the VoIP service provider will have to assist in installing the

product fax component.

Although a fax might work on a VoIP network, it can fail when the following events occur:

Internet traffic becomes heavy and packets are lost.

●

Latency (the time it takes for a packet to travel from its point of origin to its point of destination)

●

becomes excessive.

If you experience problems using the fax feature on a VoIP network, ensure that all of the product

cables and settings are correct. Configuring the Fax Speed setting to Medium(V.17) or Slow(V.

29) can also improve your ability to send a fax over a VoIP network.

If you continue to have problems faxing, contact your VoIP provider.

The fax subsystem

The formatter, fax card, firmware, and software all contribute to the fax functionality. The designs of the

formatter and fax card, along with parameters in the firmware, determine the majority of the regulatory

requirements for telephony on the product.

The fax subsystem is designed to support V.34 fax transmission, low speeds (such as V.17 fax), and

older fax machines.

Fax card in the fax subsystem

Two versions of the fax card are used in the product. One is used in the North American, South

American, and Asian countries/regions. The other is used primarily in European countries/regions.

The fax card contains the modem chipset (DSP and CODEC) that controls the basic fax functions of tone

generation and detection, along with channel control for fax transmissions. The CODEC and its

associated circuitry act as the third-generation silicon data access arrangement (DAA) to comply with

worldwide regulatory requirements.

The only difference between the two versions is that each version is compliant with the 2/4-wire phone

jack system from the respective country/region.

Safety isolation

The most important function of the fax card is the safety isolation between the high-voltage, transientprone environment of the telephone network (TNV [telephone network voltage]) and the low-voltage

analog and digital circuitry of the formatter (SELV [secondary extra-low voltage]). This safety isolation

provides both customer safety and product reliability in the telecom environment.

Any signals that cross the isolation barrier do so magnetically. The breakdown voltage rating of barriercritical components is greater than 5 kV.

24 Chapter 1 Theory of operation ENWW

Page 45

Safety-protection circuitry

In addition to the safety barrier, the fax card protects against over-voltage and over-current events.

Telephone over-voltage events can be either differential mode or common mode. The event can be

transient in nature (a lightning-induced surge or ESD) or continuous (a power line crossed with a phone

line). The fax card protection circuitry provides margin against combinations of over-voltage and overcurrent events.

Common mode protection is provided by the selection of high-voltage-barrier critical components

(transformer and relay). The safety barrier of the fax card PCB traces and the clearance between the

fax card and surrounding components also contribute to common mode protection.

A voltage suppressor (a crowbar-type thyristor) provides differential protection. This device becomes

low impedance at approximately 300 V differential, and crowbars to a low voltage. A series thermal

switch works in conjunction with the crowbar for continuous telephone line events, such as crossed

power lines.

All communications cross the isolation barrier magnetically. The breakdown voltage rating of barriercritical components is greater than 5 kV.

Data path

TIP and RING are the two-wire paths for all signals from the telephone network. All signaling and data

information comes across them, including fax tones and fax data.

The telephone network uses DC current to determine the hook state of the telephone, so line current

must be present during a call. The silicon DAA provides a DC holding circuit to keep the line current

constant during a fax call.

The silicon DAA converts the analog signal to a digital signal for DSP processing, and also converts the

digital signal to an analog signal for transmitting data through a telephone line.

The magnetically coupled signals that cross the isolation barrier go through either a transformer or a

relay.

The DSP in the fax card communicates with the ASIC in the formatter using the high-speed serial

interface.

Hook state

Another magnetically coupled signal is the control signal that disconnects the downstream telephone

devices (such as a phone or answering machine). A control signal originating on the DSP can change

the relay state, causing the auxiliary jack (downstream jack) to be disconnected from the telephone

circuit.

The product takes control of calls that it recognizes as fax calls. If the product does not directly pick up

the call, it monitors incoming calls for the fax tone or for the user to direct it to receive a fax. This idle

mode is also called eavesdropping. This mode is active when the product is on-hook but current exists

in the downstream phone line because another device is off-hook. During eavesdropping, the receive

circuit is enabled but has a different gain from the current that is generated during normal fax

transmissions.

ENWW

Fax functions and operation (fax models only)

25

Page 46

The product does not take control of the line unless it detects a fax tone or the user causes it to connect

manually. This feature allows the user to make voice calls from a phone that is connected to the product

without being cut off if a fax is not being received.

Downstream device detection

The line voltage monitoring module of the silicon DAA can detect the line state as well as the

downstream device. It tells DSP via DIB that an active device (telephone, modem, or answering

machine) is connected to the auxiliary port on the product (the right side of the dual RJ-11 jack). The

DSP uses the signal to ensure that the product does not go off-hook (and disconnects a downstream

call) until it has been authorized to do so (by a manual fax start or the detection of the appropriate

tones).

Hook switch control

In the silicon DAA the CODEC controls the hook switch directly. The CODEC is activated when it

receives commands from the DSP. When the circuit is drawing DC current from the central office it is

considered off-hook. When no DC current flows the state is considered on-hook.

Ring detect

Ring detect is performed by the line voltage monitoring module of the silicon DAA, and is a

combination of voltage levels and cadence (time on and time off). Both must be present to detect a

valid ring. The CODEC works with DSP as well as the firmware to determine if an incoming signal is an

answerable ring.

Line current control

The DC current from the CO needs to have a path to flow from TIP to RING. The DC impedance

emulation line modulator and DC terminations modules in the silicon DAA act as a DC holding circuit,

and work with the firmware to achieve the voltage-current characteristic between TIP and RING. The

impedance (the current-voltage characteristic) changes corresponding to certain special events, such as

pulse dialing or when the product goes on-hook.

Billing- (metering-) tone filters

Switzerland and Germany provide high-frequency AC signals on the phone line in order to bill

customers.

A filter in a special fax cable (for certain countries/regions), can filter these signals. Because these

billing signals are not used in the U.S., these filters are not present in the U.S. fax cable.

To obtain a special fax cable, contact your local telephone service provider.

Fax page storage in flash memory

Fax pages are the electronic images of the document page. They can be created in any of three ways:

scanned to be sent to another fax machine, generated to be sent by the computer, or received from a

fax machine to be printed.

26 Chapter 1 Theory of operation ENWW

Page 47

The product stores all fax pages in flash memory automatically. After these pages are written into flash

memory, they are stored until the pages are sent to another fax machine, printed on the product,

transmitted to the computer, or erased by the user.

These pages are stored in flash memory, which is the nonvolatile memory that can be repeatedly read

from, written to, and erased. The product has 8 MB of flash memory, of which 7.5 MB is available for

fax storage. The remaining 0.5 MB is used for the file system and reclamation. Adding RAM does not

affect the fax page storage because the product does not use RAM for storing fax pages.

Stored fax pages

The user can reprint stored fax receive pages in case of errors. For a fax send, the product will resend

the fax in case of errors. The product will resend stored fax pages after a busy signal, communication

error, no answer, or power failure. Other fax devices store fax pages in either normal RAM or shortterm RAM. Normal RAM immediately loses its data when power is lost, while short-term RAM loses its

data about 60 minutes after power failure. Flash memory maintains its data for years without any

applied power.

Advantages of flash memory storage

Fax pages that are stored in flash memory are persistent. They are not lost as a result of a power

failure, no matter how long the power is off. Users can reprint faxes in case the print cartridge runs out

of toner or the product experiences other errors while printing faxes.

The product also has scan-ahead functionality that makes use of flash memory. Scan-ahead

automatically scans pages into flash memory before a fax job is sent. This allows the sender to pick up

the original document immediately after it is scanned, eliminating the need to wait until the fax

transmission is complete.

Because fax pages are stored in flash memory rather than RAM, more RAM is available to handle

larger and more complicated copy and print jobs.

ENWW

Fax functions and operation (fax models only)

27

Page 48

USB Flash Drive

This product features printing the following types of files from the USB flash drive.

PDF

●

RGB JPEG

●