HP Color LaserJet Enterprise M651, Color LaserJet Enterprise MFP M680 Troubleshooting Manual. Repair Manual

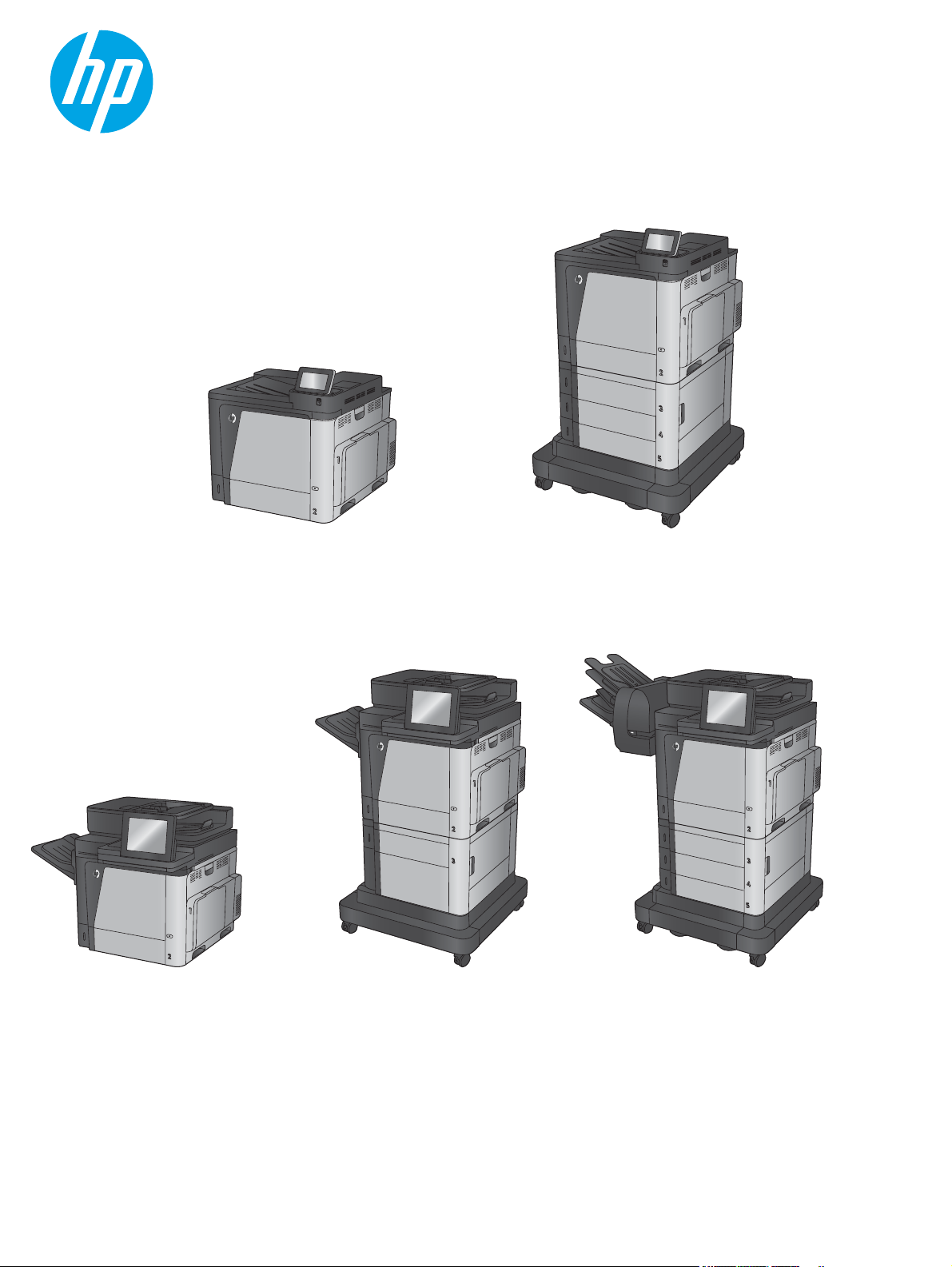

Color LaserJet Enterprise M651

Color LaserJet Enterprise MFP M680

Troubleshooting Manual

M651dn

M651xhM651n

M680zM680fM680dn

HP Color LaserJet Enterprise M651 and MFP

M680

Troubleshooting Manual

Copyright and License

© 2014 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or

omissions contained herein.

Edition 1, 4/2014

Conventions used in this guide

TIP: Helpful hints or shortcuts.

Reinstallation tip Reinstallation helpful hints, shortcuts, or considerations.

NOTE: Information that explains a concept or how to complete a task.

IMPORTANT: Information that help the user to avoid potential product error conditions.

CAUTION: Procedures that the user must follow to avoid losing data or damaging the product.

WARNING! Procedures that the user must follow to avoid personal injury, catastrophic loss of data, or

extensive damage to the product.

ENWW iii

Table of contents

1 Theory of operation ....................................................................................................................................... 1

Basic operation ...................................................................................................................................................... 2

Sequence of operation ........................................................................................................................ 4

Formatter-control system ..................................................................................................................................... 5

Formatter hardware ............................................................................................................................ 5

Sleep mode ....................................................................................................................... 6

Input/output ...................................................................................................................... 6

CPU .................................................................................................................................... 6

Memory ............................................................................................................................. 6

Firmware ........................................................................................................................... 6

Nonvolatile memory ......................................................................................................... 7

PJL overview ..................................................................................................................... 7

PML .................................................................................................................................... 7

Control panel ....................................................................................................................................... 7

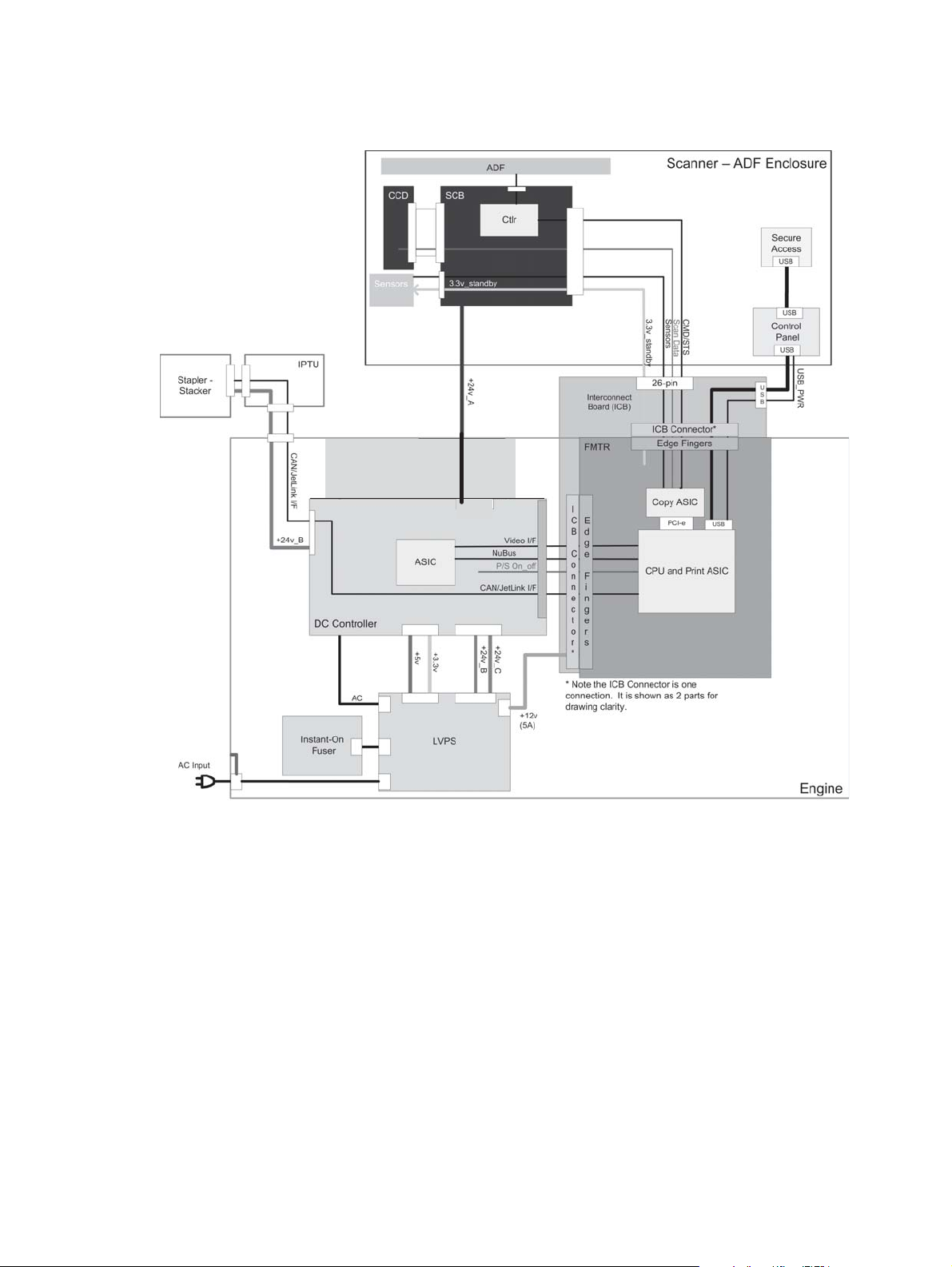

Engine-control system .......................................................................................................................................... 8

DC controller ........................................................................................................................................ 9

Solenoids ......................................................................................................................... 10

Clutches ........................................................................................................................... 10

Switches .......................................................................................................................... 10

Sensors ............................................................................................................................ 11

Motors ............................................................................................................................. 12

Fans ................................................................................................................................. 13

High-voltage power supply ............................................................................................ 14

Low-voltage power supply ............................................................................................. 16

Over-current/over-voltage protection ........................................................ 17

Safety ............................................................................................................ 17

Function ........................................................................................................ 18

Voltage detection ......................................................................................... 18

Sleep (power save) mode ............................................................................. 18

Low-voltage power supply failure ............................................................... 19

Fuser control ................................................................................................................... 19

Fuser temperature control ........................................................................... 20

ENWW v

Fuser sleeve temperature protection .......................................................... 20

Failure detection .......................................................................................... 21

Fuser unit identification ............................................................................... 22

Fuser unit life detection ............................................................................... 22

Laser/scanner system ......................................................................................................................................... 23

Laser/scanner failure ........................................................................................................................ 24

Protective-glass cleaners ................................................................................................................. 25

Image-formation system .................................................................................................................................... 26

Image formation process .................................................................................................................. 28

Step 1: Pre-exposure ...................................................................................................... 29

Step 2: Primary charging ................................................................................................ 29

Step 3: Laser-beam exposure ........................................................................................ 30

Step 4: Development ...................................................................................................... 30

Step 5: Primary transfer ................................................................................................. 31

Step 6: Secondary transfer ............................................................................................. 31

Step 7: Separation .......................................................................................................... 32

Step 8: Fusing .................................................................................................................. 32

Step 9: ITB cleaning ........................................................................................................ 33

Step 10: Drum cleaning .................................................................................................. 33

Toner cartridges ................................................................................................................................ 34

Memory tag ..................................................................................................................... 35

Developing unit engagement and disengagement control ........................................... 35

Intermediate transfer belt (ITB) unit ................................................................................................ 37

Primary transfer roller engagement and disengagement control ................................ 37

ITB cleaning mechanism ................................................................................................. 40

Calibration ......................................................................................................................................... 40

Color-misregistration control ........................................................................................ 41

Image stabilization control ............................................................................................. 42

Pickup, feed, and delivery system ...................................................................................................................... 43

Pickup-and-feed unit ........................................................................................................................ 48

Cassette pickup ............................................................................................................... 48

Cassette-presence detection ....................................................................... 49

Cassette lift operation and cassette paper-presence detection ................ 50

Cassette multiple-feed prevention .............................................................. 51

Multipurpose tray pickup ................................................................................................ 51

Paper feed ....................................................................................................................... 52

Skew-feed prevention .................................................................................. 54

Paper detection ............................................................................................ 55

Feed speed control ....................................................................................... 55

Fusing and delivery block ................................................................................................................. 56

Loop control .................................................................................................................... 57

vi ENWW

Pressure roller pressurization and depressurization control ....................................... 58

Duplex Block ...................................................................................................................................... 59

Duplex reverse and duplex feed control ........................................................................ 60

Duplex operation ............................................................................................................ 61

Jam detection .................................................................................................................................... 62

Optional paper feeders ........................................................................................................................................ 64

Motor control ..................................................................................................................................... 68

Paper-feeder pickup and feed operation ......................................................................................... 69

Paper-size detection and cassette-presence detection .................................................................. 71

Paper-feeder cassette lift operation ................................................................................................ 73

Paper feeder jam detection .............................................................................................................. 74

Scanning/image capture system (M680) ............................................................................................................ 77

Scanner .............................................................................................................................................. 77

Document feed system ..................................................................................................................... 77

Sensors in the automatic document feeder ................................................................... 77

Automatic document feeder paper path ........................................................................ 79

Automatic document feeder simplex operation ............................................................ 79

Automatic document feeder e-duplex operation .......................................................... 80

Front-side and back-side background selector ............................................................. 81

Deskew operation ........................................................................................................... 82

Automatic document feeder hinges ............................................................................... 83

Stapling mailbox (M680) ..................................................................................................................................... 85

Motor control ..................................................................................................................................... 87

Failure detection ............................................................................................................................... 87

Delivery operation ............................................................................................................................. 88

Staple operation ............................................................................................................. 90

Stapler ............................................................................................................................. 94

Output bin 3 lift operation .............................................................................................. 95

Stacker mode .................................................................................................................................... 96

Mailbox/job separator mode ............................................................................................................ 97

Jam detection .................................................................................................................................... 98

Automatic delivery ............................................................................................................................ 99

2 Solve problems .......................................................................................................................................... 101

Solve problems checklist .................................................................................................................................. 102

Menu map .......................................................................................................................................................... 105

Current settings pages ...................................................................................................................................... 105

Event log ............................................................................................................................................................ 105

Pre-boot menu options ..................................................................................................................................... 107

Remote Admin ................................................................................................................................. 115

Required software and network connection ................................................................ 115

ENWW vii

Telnet client ................................................................................................ 116

Network connection ................................................................................... 117

Connect a remote connection ...................................................................................... 117

Disconnect a remote connection .................................................................................. 122

Troubleshooting process .................................................................................................................................. 124

Determine the problem source ....................................................................................................... 124

Troubleshooting flowchart .......................................................................................... 124

Power subsystem ............................................................................................................................ 125

Power-on checks .......................................................................................................... 125

Power-on troubleshooting overview ......................................................... 125

Scanning subsystem (M680) ........................................................................................................... 129

Control panel checks ....................................................................................................................... 129

Control panel diagnostic flowcharts ............................................................................ 133

Touchscreen black, white, or dim (no image) ............................................ 134

Touchscreen is slow to respond or requires multiple presses to

respond ....................................................................................................... 135

Touchscreen has an unresponsive zone .................................................... 136

No control panel sound .............................................................................. 137

Home button is unresponsive .................................................................... 138

Hardware integration pocket (HIP) is not functioning (control panel

functional) .................................................................................................. 139

Tools for troubleshooting ................................................................................................................................. 140

Individual component diagnostics .................................................................................................. 140

LED diagnostics ............................................................................................................. 140

Understand lights on the formatter .......................................................... 140

Engine diagnostics ........................................................................................................ 145

Defeating interlocks ................................................................................... 145

Disable cartridge check .............................................................................. 146

Engine test button ...................................................................................... 147

Paper path test ............................................................................................................. 148

Paper path sensors test ............................................................................................... 148

Manual sensor and tray/bin manual sensor tests ....................................................... 150

Manual sensor test ..................................................................................... 150

Tray/bin manual sensor test ...................................................................... 152

Print/stop test .............................................................................................................. 154

Component tests .......................................................................................................... 155

Component test (special-mode test) ......................................................... 155

Scanner tests (M680) .................................................................................................... 158

Scanner tests .............................................................................................. 158

Diagrams ......................................................................................................................................... 160

Block Diagrams ............................................................................................................. 160

viii ENWW

Sensors and switches ................................................................................. 160

Cross section diagrams .............................................................................. 165

Location of connectors ................................................................................................. 169

DC controller PCA ....................................................................................... 169

Intermediate paper transport unit (ITPU) driver PCA (M680) ................... 172

Accessories controller PCA ......................................................................... 173

3-bin stapling mailbox accessory (M680) ................................................. 174

Formatter connections ................................................................................................. 176

Location of major components .................................................................................... 178

Base product .............................................................................................. 178

1x500-sheet paper feeder ......................................................................... 181

1x500-sheet paper deck ............................................................................ 182

2,500-sheet high-capacity feeder (HCI) .................................................... 183

3-bin stapling mailbox accessory (M680) ................................................. 184

General timing chart ..................................................................................................... 185

Circuit diagrams ............................................................................................................ 186

Internal print-quality test pages .................................................................................................... 191

Print quality troubleshooting pages ............................................................................ 191

Print quality assessment page ..................................................................................... 194

Cleaning page ............................................................................................................... 196

Enable and configure auto cleaning .......................................................... 196

Print a configuration page ............................................................................................ 197

Configuration page ..................................................................................... 197

HP embedded Jetdirect page ..................................................................... 200

Finding important information on the configuration pages ..................... 202

Color band test ............................................................................................................. 202

Print quality troubleshooting tools ................................................................................................ 203

Print quality troubleshooting tools: repetitive defects ruler ...................................... 203

Calibrate the product to align the colors ..................................................................... 204

Control-panel menus ...................................................................................................................... 205

Administration menu .................................................................................................... 205

Reports menu ............................................................................................. 205

General Settings menu ............................................................................... 208

Copy Settings menu (M680 only) ............................................................... 222

Scan/Digital Send Settings menu (M680) .................................................. 229

Fax Settings menu (M680) ......................................................................... 240

General Print Settings menu ...................................................................... 253

Default Print Options menu ....................................................................... 256

Display Settings menu ............................................................................... 258

Manage Supplies menu .............................................................................. 260

Manage Trays menu ................................................................................... 266

ENWW ix

Network Settings menu ............................................................................. 268

Troubleshooting menu ............................................................................... 280

Device Maintenance menu ............................................................................................ 284

Backup/Restore menu ............................................................................... 284

Calibration/Cleaning menu (M680) ............................................................ 285

Calibration/Cleaning menu (M651) ............................................................ 288

USB Firmware Upgrade menu .................................................................... 289

Service menu .............................................................................................. 289

Print quality troubleshooting tools: interpret control-panel messages and event log entries . . . 290

Control-panel message types ...................................................................................... 290

Control-panel messages and event log entries ........................................................... 290

10.XX.YZ Error Messages ........................................................................... 290

11.XX.YZ Error Messages ........................................................................... 298

13.WX.YZ Error Messages .......................................................................... 298

20.XX.YY and 21.XX.YY .............................................................................. 318

30.XX.YZ Error Messages ........................................................................... 319

31.XX.YZ Error Messages ........................................................................... 326

32.08.XX Error Messages ........................................................................... 332

33.XX.YZ Error Messages ........................................................................... 337

41.XX.YZ Error Messages ........................................................................... 340

42.XX.YY Error Messages ........................................................................... 348

44.XX.XX Error Messages ........................................................................... 349

47.XX.XX Error Messages ........................................................................... 350

48.XX.YY Error Messages ........................................................................... 352

49.XX.YY Error Messages ........................................................................... 353

50.WX.YZ Error Messages .......................................................................... 354

51.XX.YZ, 52.XX.YZ Error Messages .......................................................... 360

54.XX.YZ Error Messages ........................................................................... 361

55.XX.YZ, 56.XX.YZ Error Messages .......................................................... 364

57.XX.YZ Error Messages ........................................................................... 365

58.XX.YY & 59.XX.YZ Error Messages ........................................................ 367

60.00.0Y, 62.00.00 Error Messages .......................................................... 371

65.X0.AZ Error Messages ........................................................................... 373

70.XX.YY Error Messages ........................................................................... 374

80.XX.YY, 82.XX.YY Error Messages .......................................................... 374

98.0X.0Y Error Messages ........................................................................... 375

99.XX.YY Error Messages ........................................................................... 376

Alpha Error Messages ................................................................................. 384

Print quality troubleshooting tools: event log messages ............................................................. 430

Print or view an event log ............................................................................................. 431

Clear the event log ........................................................................................................ 431

x ENWW

Clear jams .......................................................................................................................................................... 432

Auto-navigation for clearing jams .................................................................................................. 432

Experiencing frequent or recurring paper jams? ............................................................................ 432

Jam sensor locations ...................................................................................................................... 433

Paper path sensor locations ......................................................................................... 433

Jam locations (M680) ...................................................................................................................... 438

Jam locations (M651) ...................................................................................................................... 439

Clear jams in Tray 1 ......................................................................................................................... 440

Clear jams in Tray 2 and the 500-sheet trays ................................................................................ 442

Clear jams in the 1,500-sheet high-capacity input tray and the lower-right door ....................... 447

Clear jams in the lower-right door .................................................................................................. 451

Clear jams in the right door and the fuser area .............................................................................. 452

Clear jams from under the top cover (M680) ................................................................................. 455

Clear jams in the document feeder (M680) .................................................................................... 456

Clear jams in the output bin (M680) ............................................................................................... 460

Clear jams in the output bin (M651) ............................................................................................... 460

Clear jams in the stapling mailbox accessory (M680) .................................................................... 461

Clear staple jams in the stapling mailbox accessory (M680) ......................................................... 463

Change jam recovery ....................................................................................................................... 466

Paper feeds incorrectly or becomes jammed ................................................................................................... 467

The product does not pick up paper ............................................................................................... 467

The product picks up multiple sheets of paper .............................................................................. 467

The document feeder jams, skews, or picks up multiple sheets of paper (M880) ........................ 468

Prevent paper jams ......................................................................................................................... 468

Use manual print modes ................................................................................................................................... 469

Solve image quality problems .......................................................................................................................... 473

Image defects table ........................................................................................................................ 473

Clean the product .............................................................................................................................................. 491

Print a cleaning page ...................................................................................................................... 491

Check the scanner glass for dirt or smudges (M680) ..................................................................... 492

Clean the pickup rollers and separation pad in the document feeder (M680) .............................. 494

Clean the pickup, feed, and separation rollers in the 1x500-sheet paper-feeder and 1x500-

sheet paper-feeder with storage cabinet ...................................................................................... 496

Clean the pickup, feed, and separation rollers in the 2,500-sheet high-capacity feeder (HCI) .... 497

Solve performance problems ............................................................................................................................ 498

Solve connectivity problems ............................................................................................................................. 499

Solve USB connection problems ..................................................................................................... 499

Solve wired network problems ....................................................................................................... 499

Poor physical connection ............................................................................................. 499

The computer is using the incorrect IP address for the product ................................. 499

The computer is unable to communicate with the product ........................................ 500

ENWW xi

The product is using incorrect link and duplex settings for the network ................... 500

New software programs might be causing compatibility problems ........................... 500

The computer or workstation might be set up incorrectly .......................................... 500

The product is disabled, or other network settings are incorrect ............................... 500

Service mode functions ..................................................................................................................................... 501

Service menu ................................................................................................................................... 501

Product resets ................................................................................................................................. 506

Restore factory-set defaults ........................................................................................ 506

Restore the service ID ................................................................................................... 507

Product cold reset ........................................................................................................ 507

Format Disk and Partial Clean functions ........................................................................................ 508

Active and repository firmware locations .................................................................... 508

Partial Clean .................................................................................................................. 508

Execute a Partial Clean ............................................................................... 509

Format Disk ................................................................................................................... 509

Execute a Format Disk ................................................................................ 510

Solve fax problems (M680) ............................................................................................................................... 511

Checklist for solving fax problems ................................................................................................. 511

What type of phone line are you using? ....................................................................... 511

Are you using a surge-protection device? .................................................................... 511

Are you using a phone company voice-messaging service or an answering

machine? ....................................................................................................................... 511

Does your phone line have a call-waiting feature? ..................................................... 511

Check fax accessory status .......................................................................................... 512

General fax problems ...................................................................................................................... 513

The fax failed to send ................................................................................................... 513

An Out of Memory status message displays on the product control panel ................ 513

Print quality of a photo is poor or prints as a gray box ............................................... 513

You touched the Stop button to cancel a fax, but the fax was still sent ..................... 513

No fax address book button displays ........................................................................... 513

Not able to locate the Fax settings in HP Web Jetadmin ............................................. 513

The header is appended to the top of the page when the overlay option is enabled 513

A mix of names and numbers is in the recipients box ................................................. 513

A one-page fax prints as two pages ............................................................................. 514

A document stops in the document feeder in the middle of faxing ............................ 514

The volume for sounds coming from the fax accessory is too high or too low .......... 514

Use Fax over VoIP networks ........................................................................................................... 515

Problems with receiving faxes ........................................................................................................ 516

Problems with sending faxes ......................................................................................................... 518

Fax error messages on the product control panel ......................................................................... 519

Send-fax messages ...................................................................................................... 520

xii ENWW

Receive-fax messages .................................................................................................. 521

Service settings ............................................................................................................................... 522

Settings in the Troubleshooting menu ........................................................................ 522

Firmware upgrades ........................................................................................................................................... 523

Determine the installed revision of firmware ................................................................................ 523

Perform a firmware upgrade .......................................................................................................... 523

HP Embedded Web Server ............................................................................................ 523

USB flash drive (Pre-boot menu) ................................................................................. 524

USB flash drive (control-panel menu) .......................................................................... 525

Appendix A Product specifications ................................................................................................................. 527

Product dimensions ........................................................................................................................................... 528

Product space requirements ............................................................................................................................. 529

Power consumption, electrical specifications, and acoustic emissions .......................................................... 530

Environmental specifications ............................................................................................................................ 530

Certificate of Volatility ...................................................................................................................................... 531

Index ........................................................................................................................................................... 535

ENWW xiii

List of tables

Table 1-1 Sequence of operation ......................................................................................................................................... 4

Table 1-2 Formatter hardware components ....................................................................................................................... 5

Table 1-3 Solenoids ............................................................................................................................................................ 10

Table 1-4 Clutches .............................................................................................................................................................. 10

Table 1-5 Switches ............................................................................................................................................................. 10

Table 1-6 Sensors ............................................................................................................................................................... 11

Table 1-7 Motors ................................................................................................................................................................ 12

Table 1-8 Fans .................................................................................................................................................................... 13

Table 1-9 High-voltage power supply circuits ................................................................................................................... 14

Table 1-10 Converted DC voltages ..................................................................................................................................... 17

Table 1-11 Low-voltage power supply functions .............................................................................................................. 18

Table 1-12 Fuser components ........................................................................................................................................... 19

Table 1-13 Image formation process ................................................................................................................................. 28

Table 1-14 Primary-transfer roller engagement states ................................................................................................... 38

Table 1-15 Image-stabilization controls ........................................................................................................................... 42

Table 1-16 Switches and sensors for the pickup, feed, and delivery system ................................................................... 45

Table 1-17 Motors and solenoids for the pickup, feed, and delivery system ................................................................... 46

Table 1-18 Cassette-presence detection ........................................................................................................................... 49

Table 1-19 Print mode and feed speed .............................................................................................................................. 55

Table 1-20 Paper sizes ....................................................................................................................................................... 61

Table 1-21 Jams that the product detects ......................................................................................................................... 63

Table 1-22 Electrical components for the paper feeder ................................................................................................... 65

Table 1-23 Electrical components for the 2,500-sheet paper feeder HCI ........................................................................ 67

Table 1-24 Motor control (1x500-sheet paper feeder) ..................................................................................................... 68

Table 1-25 Motor control (2,500-sheet paper feeder HCI) ................................................................................................ 68

Table 1-26 Pickup feed components (1x500-sheet paper feeder) ................................................................................... 69

Table 1-27 Pickup feed components (2,500-sheet paper feeder HCI) .............................................................................. 70

Table 1-28 Paper-size detection and cassette-presence detection (1 x 500 paper feeder) ............................................ 71

Table 1-29 Paper-size detection and cassette-presence detection (2,500-sheet paper feeder HCI) ............................. 72

Table 1-30 Automatic document feeder sensors .............................................................................................................. 78

Table 1-31 Automatic document feeder paper path ......................................................................................................... 79

Table 1-32 Automatic document feeder deskew features ................................................................................................ 82

ENWW xv

Table 1-33 Electrical components for the stapling mailbox ............................................................................................. 86

Table 1-34 Motor control (stapling mailbox) ..................................................................................................................... 87

Table 1-35 Delivery components (stapling mailbox) ........................................................................................................ 88

Table 2-1 Pre-boot menu options (1 of 7) ....................................................................................................................... 107

Table 2-2 Pre-boot menu options (2 of 7) ....................................................................................................................... 109

Table 2-3 Pre-boot menu options (3 of 7) ....................................................................................................................... 110

Table 2-4 Pre-boot menu options (4 of 7) ....................................................................................................................... 111

Table 2-5 Pre-boot menu options (5 of 7) ....................................................................................................................... 111

Table 2-6 Pre-boot menu options (6 of 7) ....................................................................................................................... 113

Table 2-7 Pre-boot menu options (7 of 7) ....................................................................................................................... 114

Table 2-8 Troubleshooting flowchart .............................................................................................................................. 124

Table 2-9 Control panel diagnostic functions .................................................................................................................. 130

Table 2-10 Connectivity LED, product initialization ........................................................................................................ 141

Table 2-11 Connectivity LED, product operational .......................................................................................................... 143

Table 2-12 Paper-path sensors diagnostic tests ............................................................................................................ 148

Table 2-13 Manual sensor diagnostic tests ..................................................................................................................... 150

Table 2-14 Tray/bin manual sensors ............................................................................................................................... 152

Table 2-15 Component test details ................................................................................................................................. 155

Table 2-16 Sensors and switches (product; M651) ......................................................................................................... 160

Table 2-17 Sensors and switches (product; M680) ......................................................................................................... 161

Table 2-18 1x500-sheet paper-feeder and 1x500-sheet paper-feeder with storage cabinet sensors and switches .. 162

Table 2-19 2,500-sheet paper deck (HCI) sensors and switches .................................................................................... 163

Table 2-20 3-bin stapling mailbox accessory sensors and switches (M680) ................................................................. 164

Table 2-21 Product base .................................................................................................................................................. 165

Table 2-22 1x500-sheet paper-feeder and 1x500-sheet paper-feeder with storage cabinet

1

.................................... 166

Table 2-23 2,500-sheet high-capacity feeder (HCI) sensors and switches .................................................................... 167

Table 2-24 3-bin stapling mailbox accessory (M680) ..................................................................................................... 168

Table 2-25 DC controller connectors ............................................................................................................................... 169

Table 2-26 Intermediate paper transport unit (ITPU) driver PCA (M680) ....................................................................... 172

Table 2-27 Accessories controller PCA ............................................................................................................................ 173

Table 2-28 3-bin stapling mailbox accessory (M680) ..................................................................................................... 174

Table 2-29 Formatter connections (M651) ...................................................................................................................... 176

Table 2-30 Formatter connections (M680) ...................................................................................................................... 176

Table 2-31 M680 product integrated scanner assembly (ISA) ........................................................................................ 178

Table 2-32 Base product external view M651 ................................................................................................................. 179

Table 2-33 Base product external view M680 ................................................................................................................. 180

Table 2-34 1x500-sheet paper feeder ............................................................................................................................. 181

Table 2-35 1x500-sheet paper deck ................................................................................................................................ 182

Table 2-36 2,500-sheet high-capacity feeder (HCI) ........................................................................................................ 183

Table 2-37 3-bin stapling mailbox accessory (M680) ..................................................................................................... 184

Table 2-38 Configuration page ........................................................................................................................................ 198

xvi ENWW

Table 2-39 HP embedded Jetdirect page ......................................................................................................................... 200

Table 2-40 Important information on the configuration pages ...................................................................................... 202

Table 2-41 Reports menu ................................................................................................................................................. 206

Table 2-42 General Settings menu .................................................................................................................................. 208

Table 2-43 Copy Settings menu (M680) .......................................................................................................................... 222

Table 2-44 Scan/Digital Send Settings menu (M680) ..................................................................................................... 229

Table 2-45 Fax Settings menu (M680) ............................................................................................................................. 240

Table 2-46 General Print Settings menu ......................................................................................................................... 253

Table 2-47 Default Print Options menu ........................................................................................................................... 256

Table 2-48 Display Settings menu ................................................................................................................................... 258

Table 2-49 Manage Supplies menu .................................................................................................................................. 260

Table 2-50 Manage Trays menu ....................................................................................................................................... 266

Table 2-51 Network Settings menu ................................................................................................................................. 268

Table 2-52 Jetdirect Menu ................................................................................................................................................ 268

Table 2-53 Troubleshooting menu .................................................................................................................................. 280

Table 2-54 Backup/Restore menu ................................................................................................................................... 284

Table 2-55 Calibration/Cleaning menu (M680) ............................................................................................................... 285

Table 2-56 Calibration/Cleaning menu (M651) ............................................................................................................... 288

Table 2-57 Sensors and switches (product; M651) ......................................................................................................... 433

Table 2-58 Sensors and switches (product; M680) ......................................................................................................... 434

Table 2-59 1x500-sheet paper-feeder and 1x500-sheet paper-feeder with storage cabinet sensors and

switches ............................................................................................................................................................................... 435

Table 2-60 2,500-sheet paper deck (HCI) sensors and switches .................................................................................... 436

Table 2-61 3-bin stapling mailbox accessory sensors and switches (M680) ................................................................. 437

Table 2-62 Print modes

1

under the Adjust Paper Types submenu ................................................................................. 470

Table 2-63 Print modes under the Optimize submenu ................................................................................................... 471

Table 2-64 Image defects table ....................................................................................................................................... 473

Table 2-65 Solve performance problems ........................................................................................................................ 498

Table 2-66 Service menu (M651 and M680) .................................................................................................................... 501

Table 2-67 Service menu (M680 only) ............................................................................................................................. 505

Table 2-68 Send-fax messages ....................................................................................................................................... 520

Table 2-69 Receive-fax messages ................................................................................................................................... 521

Table A-1 Physical specifications, with toner cartridges (M680) .................................................................................... 528

Table A-2 Physical specifications, with toner cartridge (M651) ...................................................................................... 528

Table A-3 Product dimensions with all doors, trays, and document feeder fully opened (M680) ................................. 528

Table A-4 Product dimensions with all doors and trays fully opened (M651) ................................................................ 528

Table A-5 Accessory dimensions ...................................................................................................................................... 528

Table A-6 Product space requirements ........................................................................................................................... 529

Table A-7 Operating-environment specifications ........................................................................................................... 530

ENWW xvii

List of figures

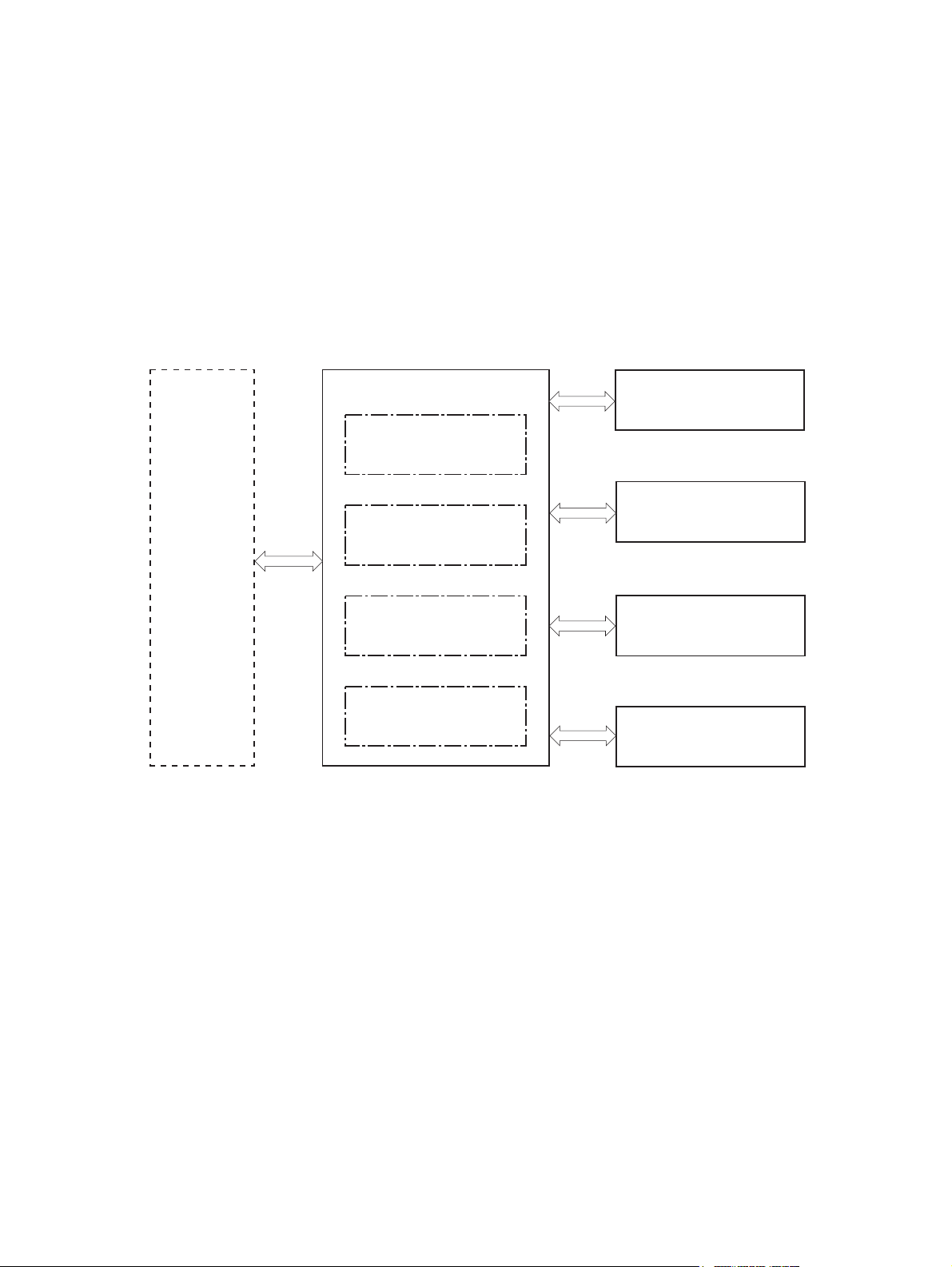

Figure 1-1 Relationship between the main product systems .............................................................................................. 2

Figure 1-2 System block diagram ........................................................................................................................................ 3

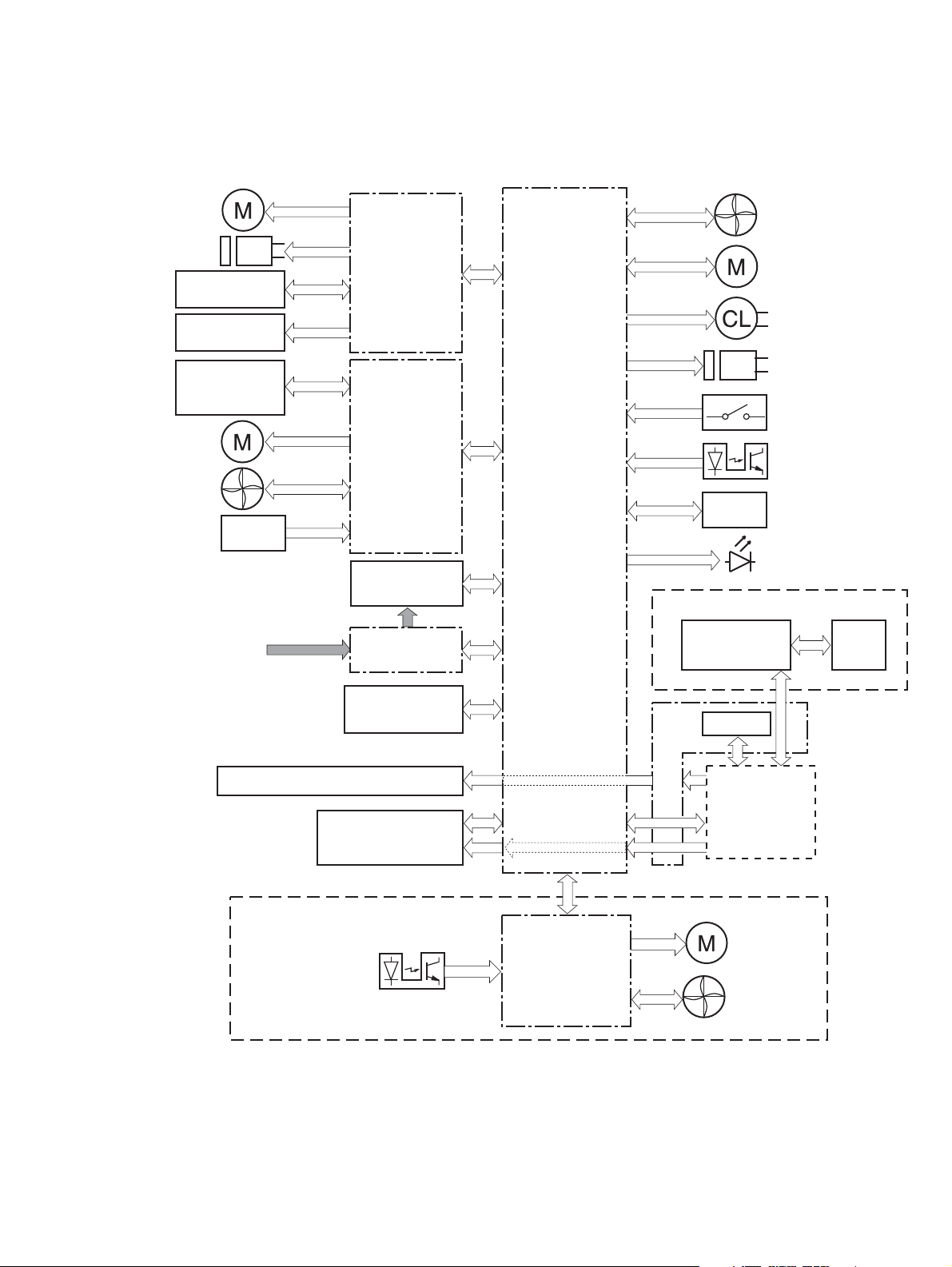

Figure 1-3 Engine-control system ........................................................................................................................................ 8

Figure 1-4 DC controller block diagram ............................................................................................................................... 9

Figure 1-5 High-voltage power supply circuits .................................................................................................................. 14

Figure 1-6 Low-voltage power-supply circuit ................................................................................................................... 16

Figure 1-7 Fuser components ............................................................................................................................................ 19

Figure 1-8 Fuser temperature-control circuit .................................................................................................................... 20

Figure 1-9 Laser/scanner system ...................................................................................................................................... 23

Figure 1-10 Protective-glass cleaners (PGCs) ................................................................................................................... 25

Figure 1-11 Image-formation system ............................................................................................................................... 26

Figure 1-12 Image-formation drive system ...................................................................................................................... 27

Figure 1-13 Image-formation process ............................................................................................................................... 28

Figure 1-14 Pre-exposure .................................................................................................................................................. 29

Figure 1-15 Primary charging ............................................................................................................................................ 29

Figure 1-16 Laser-beam exposure ..................................................................................................................................... 30

Figure 1-17 Development .................................................................................................................................................. 30

Figure 1-18 Primary transfer ............................................................................................................................................. 31

Figure 1-19 Secondary transfer ......................................................................................................................................... 31

Figure 1-20 Separation ....................................................................................................................................................... 32

Figure 1-21 Fusing .............................................................................................................................................................. 32

Figure 1-22 ITB cleaning ..................................................................................................................................................... 33

Figure 1-23 Drum cleaning ................................................................................................................................................. 33

Figure 1-24 Toner cartridge system .................................................................................................................................. 34

Figure 1-25 Developing-roller engagement and disengagement control ........................................................................ 35

Figure 1-26 ITB unit ............................................................................................................................................................ 37

Figure 1-27 Three states of primary-transfer roller engagement and disengagement .................................................. 39

Figure 1-28 ITB cleaning process ....................................................................................................................................... 40

Figure 1-29 Toner patterns for calibration ........................................................................................................................ 41

Figure 1-30 Paper path ....................................................................................................................................................... 43

Figure 1-31 Switches and sensors for the pickup, feed, and delivery system (M651 only) ............................................. 44

Figure 1-32 Switches and sensors for the pickup, feed, and delivery system (M680 only) ............................................. 44

ENWW xix

Figure 1-33 Motors and solenoids for the pickup, feed, and delivery system .................................................................. 46

Figure 1-34 Three main units of the pickup, feed, and delivery system ........................................................................... 47

Figure 1-35 Pickup-and-feed unit ...................................................................................................................................... 48

Figure 1-36 Cassette-pickup mechanism .......................................................................................................................... 49

Figure 1-37 Cassette lift mechanism ................................................................................................................................. 50

Figure 1-38 Multiple-feed prevention ................................................................................................................................ 51

Figure 1-39 Multipurpose tray pickup mechanism ............................................................................................................ 52

Figure 1-40 Paper-feed mechanism .................................................................................................................................. 53

Figure 1-41 Skew-feed prevention .................................................................................................................................... 54

Figure 1-42 Fuser and delivery unit ................................................................................................................................... 56

Figure 1-43 Loop-control mechanism ............................................................................................................................... 57

Figure 1-44 Pressure-roller pressurization control .......................................................................................................... 58

Figure 1-45 Duplexing unit ................................................................................................................................................. 59

Figure 1-46 Duplex reverse and feed control .................................................................................................................... 60

Figure 1-47 Jam detection sensors .................................................................................................................................... 62

Figure 1-48 1 x 500 optional paper feeder ........................................................................................................................ 64

Figure 1-49 Signals for the paper feeder ........................................................................................................................... 65

Figure 1-50 2,500-sheet paper feeder HCI ........................................................................................................................ 66

Figure 1-51 Signals for 2,500-sheet paper feeder HCI ...................................................................................................... 67

Figure 1-52 Paper-feeder pickup and feed operation (1x500-sheet paper feeder) ........................................................ 69

Figure 1-53 Paper-feeder pickup and feed operation (2,500-sheet paper feeder HCI) ................................................... 70

Figure 1-54 Paper-feeder cassette lift .............................................................................................................................. 73

Figure 1-55 Jam detection (1x500-sheet paper feeder) ................................................................................................... 74

Figure 1-56 2,500-sheet paper feeder HCI media feed sensors ....................................................................................... 75

Figure 1-57 Automatic document feeder sensors ............................................................................................................. 78

Figure 1-58 Automatic document feeder paper path ........................................................................................................ 79

Figure 1-59 Automatic document feeder deskew features .............................................................................................. 82

Figure 1-60 Automatic document feeder open (book mode) ............................................................................................ 83

Figure 1-61 Automatic document feeder open (60º to 80º) .............................................................................................. 84

Figure 1-62 Stapling mailbox ............................................................................................................................................. 85

Figure 1-63 Signals for the stapling mailbox ..................................................................................................................... 85

Figure 1-64 Stapling mailbox delivery operation .............................................................................................................. 88

Figure 1-65 Stapling mailbox stapler operation (1 of 4) ................................................................................................... 90

Figure 1-66 Stapling mailbox stapler operation (2 of 4) ................................................................................................... 91

Figure 1-67 Stapling mailbox stapler operation (3 of 4) ................................................................................................... 92

Figure 1-68 Stapling mailbox stapler operation (4 of 4) ................................................................................................... 93

Figure 1-69 Stapling mailbox sensors for the stapler ....................................................................................................... 94

Figure 1-70 Stapling mailbox sensors for output bin 3 lift operation .............................................................................. 95

Figure 1-71 Stapling mailbox sensors for stacker mode .................................................................................................. 96

Figure 1-72 Stapling mailbox sensors for mail

Figure 1-73 Stapling mailbox sensors for jam detection .................................................................................................. 98

box/jam separation ................................................................................. 97

xx ENWW

Figure 2-1 Open the Control Panel ................................................................................................................................... 116

Figure 2-2 Turn Windows features on or off .................................................................................................................... 116

Figure 2-3 Enable the telnet client feature ..................................................................................................................... 117

Figure 2-4 Select the +3:Administrator item ................................................................................................................... 118

Figure 2-5 Select the +A:Remote Admin item ................................................................................................................. 118

Figure 2-6 Select the 1:Start Telnet item ........................................................................................................................ 118

Figure 2-7 Telnet connecting message ............................................................................................................................ 118

Figure 2-8 Telnet error message ..................................................................................................................................... 119

Figure 2-9 Telnet server function initialized ................................................................................................................... 119

Figure 2-10 Open a command window ............................................................................................................................ 120

Figure 2-11 Start a telnet session .................................................................................................................................... 120

Figure 2-12 Establish a telnet connection ....................................................................................................................... 120

Figure 2-13 Enter the PIN ................................................................................................................................................. 121

Figure 2-14 Remote Admin window ................................................................................................................................. 121

Figure 2-15 Access the administrator menu ................................................................................................................... 122

Figure 2-16 Access the remote admin menu ................................................................................................................... 122

Figure 2-17 Terminate the telnet connection ................................................................................................................. 123

Figure 2-18 M650 control-panel test button location .................................................................................................... 130

Figure 2-19 Touchscreen blank, white, or dim (no image) .............................................................................................. 134

Figure 2-20 Touchscreen is slow to respond or requires multiple presses to respond ................................................. 135

Figure 2-21 Touchscreen has an unresponsive zone ...................................................................................................... 136

Figure 2-22 No control panel sound ................................................................................................................................ 137

Figure 2-23 Home button is unresponsive ...................................................................................................................... 138