INTRODUCTION

Congratulations on your selection of a Honda trimmer/brush cutter!

We are certain you will be pleased with your purchase of one of the

finest trimmer/brush cutters on the market.

We want to help you get the best results from your new trimmer/brush

cutter and to operate it safely. This manual contains the information

on how to do that; please read it carefully.

We suggest you read the DISTRIBUTOR’S LIMITED WARRANTY

(page 30) and the EMISSION CONTROL SYSTEM WARRANTY

(page 31) to fully understand its coverage and your responsibilities of

ownership.

When your trimmer/brush cutter needs scheduled maintenance, keep

in mind that your Honda servicing dealer is specially trained in

servicing Honda trimmers/brush cutters. Your Honda servicing dealer

is dedicated to your satisfaction, and will be pleased to answer your

questions and concerns.

Keep this owner’s manual handy, so you can refer to it at any time.

This owner’s manual is considered a permanent part of the trimmer

and should remain with the trimmer if resold.

The information and specifications included in this publication were in

effect at the time of approval for printing. Honda Power Equipment

Mfg. Inc. reserves the right, however, to discontinue or change

specifications or design at any time without notice and without

incurring any obligation whatever. No part of this publication may be

reproduced without written permission.

OWNER’S MANUAL

HHT25S • HHT35S

B WARNING: B

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

CONTENTS

SAFETY MESSAGES

Your safety and the safety of others are very important. We have

provided important safety messages in this manual and on the

trimmer/brush cutter. This information alerts you to potential hazards

that could hurt you or others. Please read these messages carefully.

Of course, it is not practical or possible to warn you about all the

hazards associated with operating or maintaining a trimmer/brush

cutter. You must use your own good judgment.

You will find important safety information in a variety of forms:

• Safety Labels – on the trimmer/brush cutter.

• Instructions – how to use this trimmer/brush cutter correctly and

safely.

• Safety Messages – preceded by a safety alert A symbol and one

of three signal words: DANGER, WARNING, or CAUTION. These

signal words mean:

B DANGER

B WARNING

B CAUTION

Each message tells you what the hazard is, what can happen, and

what you can do to avoid or reduce injury.

• Damage Prevention Messages – You will also see other

important messages that are preceded by the word NOTICE. This

word means:

NOTICE

Your trimmer or other property can be

damaged if you don’t follow instructions.

You WILL be KILLED or SERIOUSLY

HURT if you don't follow instructions.

You CAN be KILLED or SERIOUSLY

HURT if you don't follow instructions.

You CAN be HURT if you don't follow

instructions.

INTRODUCTION...............................1

SAFETY MESSAGES........................1

TRIMMER SAFETY...........................2

IMPORTANT SAFETY

INFORMATION.............................2

ATTACHMENTS &

MODIFICATIONS .........................2

IMPORTANT MESSAGE TO

EMPLOYERS ...............................2

SAFETY LABEL LOCATIONS......3

ASSEMBLY .......................................3

U-TYPE HANDLEBAR..................4

CONTROLS AND EQUIPMENT........7

COMPONENT CONTROLS AND

LOCATIONS.................................7

CONTROLS..................................7

EQUIPMENT ................................8

BEFORE OPERATION......................9

ARE YOU READY TO OPERATE

THE TRIMMER?...........................9

IS YOUR WORKING AREA

READY? .......................................9

IS YOUR TRIMMER READY TO

GO?..............................................9

ARE YOUR SHOULDER HARNESS

AND TRIMMER CORRECTLY

ADJUSTED?...............................10

OPERATION....................................10

SAFE OPERATING

PRECAUTIONS..........................10

STARTING THE ENGINE...........10

STOPPING THE ENGINE ..........11

TRIMMER/HARNESS QUICK

DISCONNECTION......................11

TRIMMER OPERATION.............11

SAFE OPERATING PRACTICES12

OPERATING TIPS .....................13

SERVICING YOUR TRIMMER........14

MAINTENANCE SAFETY...........14

MAINTENANCE SCHEDULE.....14

ENGINE......................................15

FUEL SYSTEM...........................17

COOLING FIN INSPECTION .....18

RECOMMENDED CUTTING

ATTACHMENTS..............................18

CUTTING ATTACHMENT

APPLICATIONS .........................18

BLADES .....................................19

DEBRIS SHIELDS......................20

CUTTING-LINE HEADS............. 21

STORAGE.......................................24

TRANSPORTING............................25

TAKING CARE OF UNEXPECTED

PROBLEMS.....................................25

TECHNICAL INFORMATION..........26

EMISSION CONTROL SYSTEM27

SPECIFICATIONS......................27

CONSUMER INFORMATION .........28

QUICK REFERENCE

INFORMATION...........................29

DISTRIBUTOR'S LIMITED

WARRANTY............................... 30

ACCESSORIES, REPLACEMENT

PARTS, AND APPAREL

WARRANTY............................... 30

EMISSION CONTROL SYSTEM

WARRANTY............................... 31

© 2004-2009 American Honda Motor Co., Inc.—All Rights Reserved

31VL3D13

00X31-VL3-D130

EM5

POM31VL3D13

IPC.720.2009.04

PRINTED IN U.S.A.

1

TRIMMER SAFETY

IMPORTANT SAFETY INFORMATION

The Honda HHT25S and HHT35S trimmer/brush cutters are designed

to cut grass, weeds, brush, and/or wood if equipped with an

appropriate cutting attachment. Other uses can result in injury to the

operator or damage to the trimmer and other property.

These Honda trimmers are intended for use by gardening

professionals. Never allow children to operate the trimmer.

Most injuries or property damage can be prevented if you follow all

instructions in this manual and on the trimmer. The most common

hazards are discussed below, along with the best way to protect

yourself and others.

Keep the Trimmer Properly Maintained

• The cutting attachment should be examined for looseness, cracks,

broken parts, or excessive wear. Tighten or replace as needed

before operating the trimmer.

• Do not operate the trimmer without a debris shield properly

installed. Make sure you have the right shield installed for your

cutting attachment.

For more information, see page 20.

ATTACHMENTS & MODIFICATIONS

Modifying your trimmer/brush cutter, or installing non-Honda

attachments, can make your trimmer unsafe. Before you make any

modifications or install any attachments, be sure to read the following

information.

Always Wear Eye Protection and Protective Clothing

• The most frequent injuries associated with string trimmers are eye

injuries caused by thrown debris. Always wear safety glasses or

goggles that meet the ANSI Z87.1 rating whenever you use the

trimmer.

• The operator must wear hearing protectors when using this

trimmer. Hearing protectors will protect the operator's ears from

noise damage.

• Wearing protective clothing also reduces the risk and severity of

injury from thrown debris or contact with the cutting attachment.

Wear the trimmer harness, gloves, a long-sleeved shirt, long pants,

and sturdy boots with nonslip soles.

See page 9 for more information.

Keep Away From Cutting Lines and Blades

• A spinning cutting blade can cut through your clothes and skin just

as easily as it cuts through grass and dirt. Keep all parts of your

body away from a spinning cutting attachment.

• Even after the engine has stopped, the cutting attachment will spin

for several seconds. Do not touch it until it has stopped spinning, or

you may get cut.

Turn the Engine Off When Not Trimming

If you stop trimming or cutting for any reason, even to clean off the

cutting attachment, always shut off the engine.

Keep People Away From Your Working Area

To prevent injury to others, keep people at least 50 feet (15 meters)

away from the working area during operation.

Always Wear the Harness When Trimming

The harness keeps the trimmer away from your body, lowering your

chances of being cut by the trimmer’s blade or cutting line.

Read This Manual Before Using the Trimmer

Read the manual before operating the trimmer. Understand how to

use all the controls and obey all warnings.

Attachments

Your Honda trimmer servicing dealer has cutting attachments, debris

shields, barrier kits, and shoulder harnesses that have been designed

and approved for your trimmer and are covered by warranty. See

RECOMMENDED CUTTING ATTACHMENTS (page 18).

Non-Honda attachments are usually designed for universal

applications. Although aftermarket attachments may fit on your

trimmer, they may not meet factory specifications and could make

your trimmer unsafe.

Modifications

Do not remove the debris shield or modify your trimmer in any way

that would alter its design or operation. This could make your trimmer

unsafe.

IMPORTANT MESSAGE TO EMPLOYERS

As an employer, you have special responsibilities to the people who

work for you.

Before you ask anyone to operate this trimmer/brush cutter, you need

to determine whether the operator is old enough, large enough, and

strong enough to safely handle and control the trimmer/brush cutter.

If you decide he/she is, make sure the employee(s) read and

understand all instructions and warnings in this manual and on the

labels before operating the trimmer/brush cutter.

Allow adequate time for hands-on training by a qualified instructor,

and personally supervise practice sessions, until you feel sure the

employee is ready to operate the trimmer/brush cutter.

Also be sure employees wear proper clothing, eye and hearing

protection, and any other gear that may be required by local

ordinances or your insurance company.

Remember, too, that you are responsible for keeping the

trimmer/brush cutter properly maintained and in safe operating

condition.

Your commitment to safety on the job can help prevent injuries and

result in longer and more productive years of service.

Clear the Working Area First

Objects thrown by the trimmer can cause serious injury. Before

operating the trimmer, carefully inspect the area and remove any

broken glass, pieces of wire, and other loose objects.

2

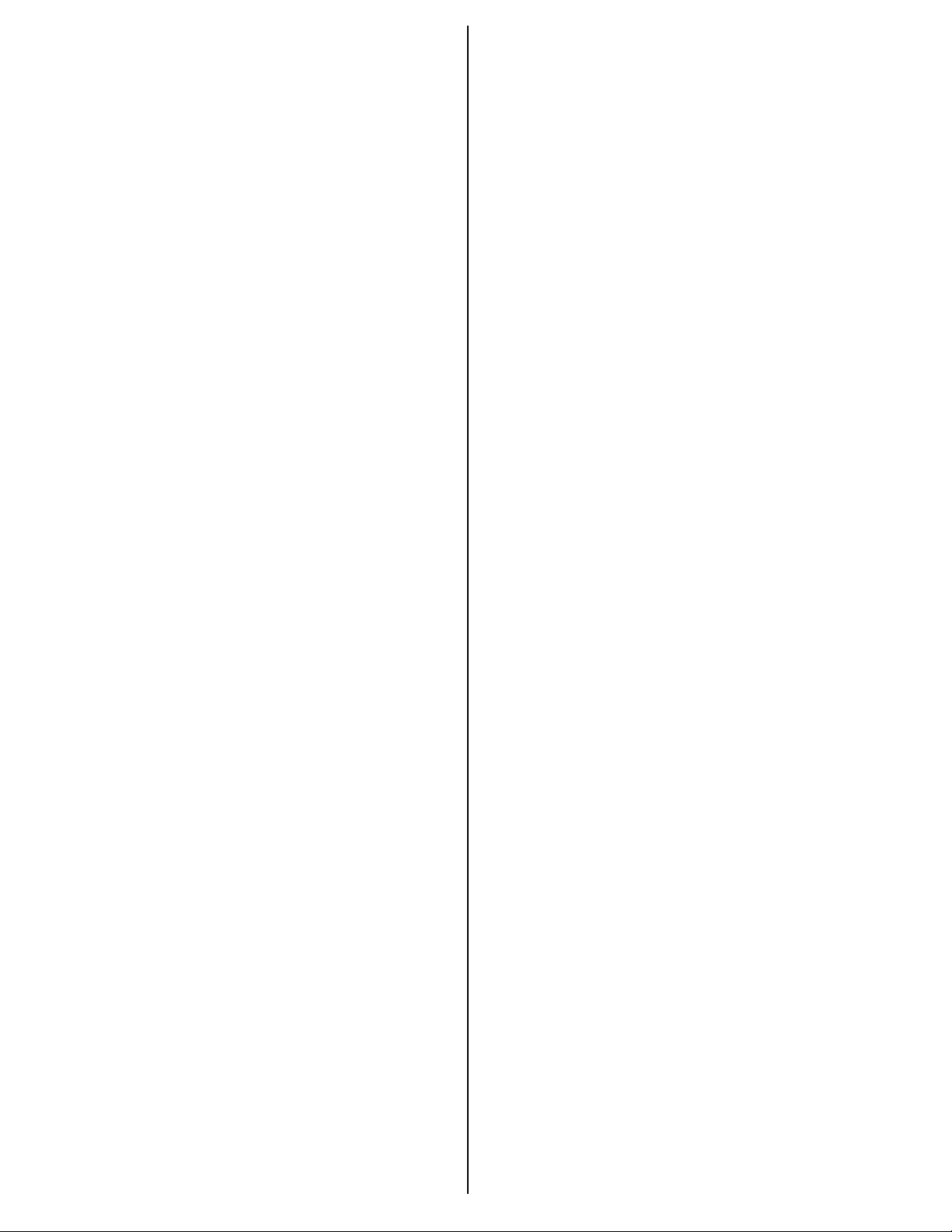

SAFETY LABEL LOCATIONS

The labels shown here contain important safety information. Please

read them carefully. These labels are considered permanent parts of

your trimmer/brush cutter. If a label comes off or becomes hard to

read, contact an authorized Honda servicing dealer for a replacement.

TYPE EQUIPPED WITH

LOOP HANDLE

ASSEMBLY

After assembly and before operation, review the SAFE OPERATING

PRECAUTIONS on page 10.

IMPORTANCE OF PROPER ASSEMBLY

Proper assembly is essential to operator safety and the reliability of

the machine. Any error or oversight made by the person assembling

and servicing a machine can result in faulty operation, damage to the

machine, or injury to the operator.

B WARNING

Improper assembly can cause an unsafe condition that

can lead to serious injury or death.

Follow the procedures and precautions in the assembly

instructions carefully.

Some of the most important safety precautions are given below.

However, we cannot warn you of every conceivable hazard that can

arise in performing this assembly. Only you can decide whether or not

you should perform a given task.

B WARNING

TYPE EQUIPPED WITH

U-TYPE HANDLEBAR

Failure to properly follow instructions and precautions

can cause you to be seriously hurt or killed.

Follow the procedures and precautions in this manual

carefully.

IMPORTANT SAFETY PRECAUTIONS

• Make sure you have a clear understanding of all basic shop safety

practices and that you are wearing appropriate clothing and safety

equipment.

• Read the instructions before you begin and be sure you have the

tools and skills required to perform the tasks safely.

• Make sure the engine is off before you begin any maintenance or

repairs. This will help eliminate several potential hazards:

T Carbon monoxide poisoning from engine exhaust. Be sure

there is adequate ventilation whenever you run the engine.

T Burns from hot parts. Let the engine and exhaust system

cool before touching.

T Injury from moving parts. Do not run the engine unless the

instruction tells you to do so. Even then, keep your hands,

fingers, and clothing away from moving parts. Do not run the

engine when any protective guard or shield is removed.

• To reduce the possibility of a fire or explosion, be careful when

working around gasoline. Use only a nonflammable solvent, not

gasoline, to clean parts. Keep all cigarettes, sparks, and flames

away from all fuel-related parts.

UNPACKING

Carefully remove the trimmer and loose parts from the carton and

compare the loose parts with the inventory list.

Tools Required (U-type handlebar only):

A 4 mm hex wrench, 8 and 17 mm sockets, 0 to 25 ft-lb torque

wrench.

3

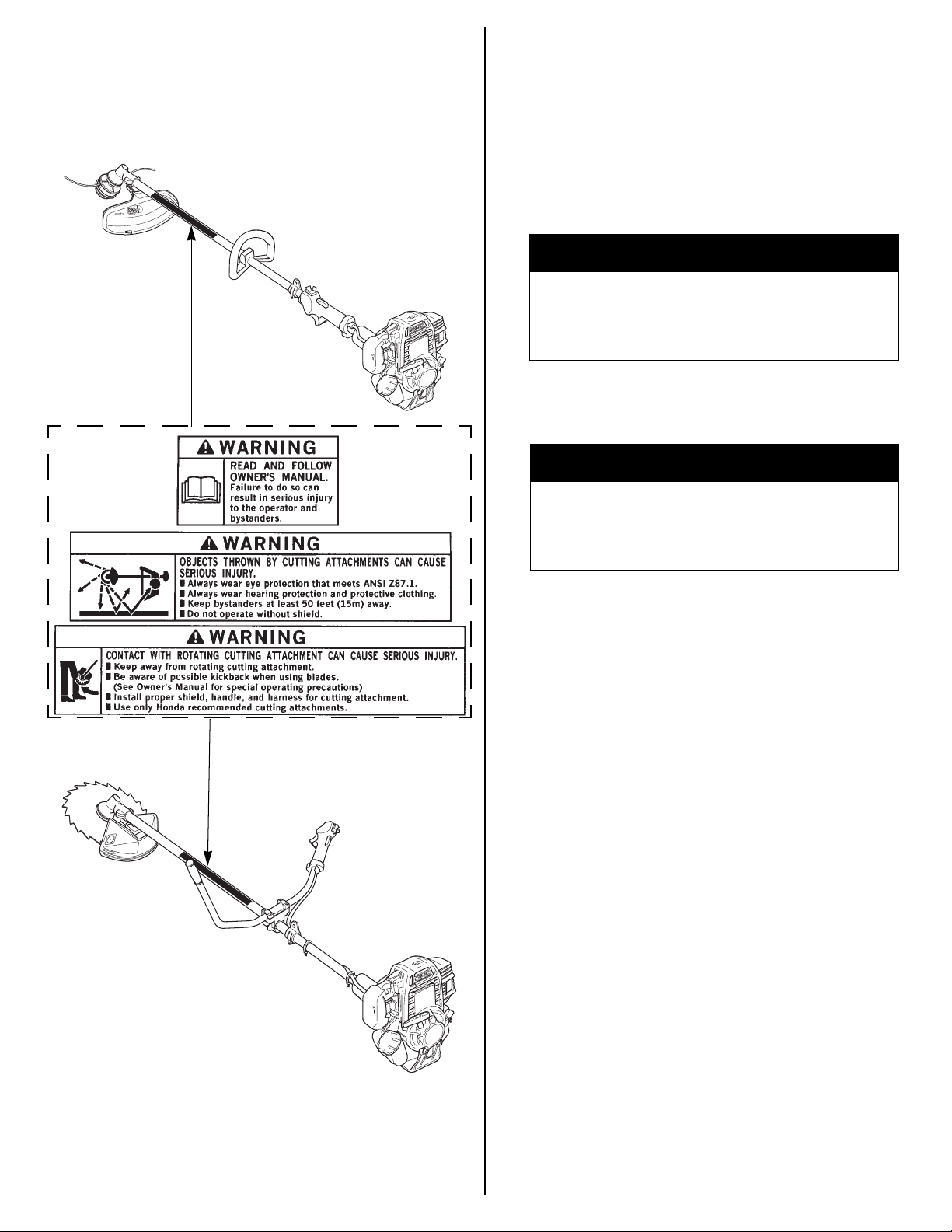

LOOSE PARTS

U-TYPE HANDLEBAR

Check all loose parts against the following list. Contact your

authorized Honda servicing dealer if any of the loose parts shown are

not included with your trimmer.

Ref.

No

Description

Loop

handle

U-type

handlebar

Qty.

1 Owner’s Manual ••1

2 Goggles ••1

3 Oil bottle ••1

Single-strap shoulder

4

harness

• 1

5 Full shoulder harness • 1

6 Brush/wood debris shield • 1

7 Cutting-line debris shield • 1

8 Cover • 1

10 mm left-hand thread lock

9

nut

• 1

10 Spacer • 2

11 5 x 28 mm bolt • 4

12 Spacer set (A & B) • 1

Brush/wood saw blade

13

(50-tooth/10 in)

• 1

14 Blade cover • 1

15 Cutting-line head • 1

4

3

standards.

100 cc / 3.4 oz

INTRODUCTION

Congratulations on your selection of a Honda trimmer/brush cutter!

We are certain you will be pleased with your purchase of one of the

finest trimmer/brush cutters on the market.

We want to help you get the best results from your new trimmer/brush

cutter and to operate it safely. This manual contains the information

on how to do that; please read it carefully.

As you read this manual, you will find information preceded by a

symbol. That information is intended to help you avoid

NOTICE

damage to your trimmer/brush cutter, other property, or the

environment.

We suggest you read the Distributor’s Limited Warranty (page30) and

the Emission Control System Warranty (page31) to fully understand

its coverage and your responsibilities of ownership.

When your trimmer/brush cutter needs scheduled maintenance, keep

in mind that your Honda servicing dealer is specially trained in

servicing Honda trimmers/brush cutters. Your Honda servicing dealer

is dedicated to your satisfaction, and will be pleased to answer your

questions and concerns.

SAFETY MESSAGES

Your safety and the safety of others are very important. We have

provided important safety messages in this manual and on the

trimmer/brush cutter. This information alerts you to potential hazards

that could hurt you or others. Please read these messages carefully.

Of course, it is not practical or possible to warn you about all the

hazards associated with operating or maintaining a trimmer/brush

cutter. You must use your own good judgment.

You will find important safety information in a variety of forms:

• Safety Labels – on the trimmer/brush cutter.

• Safety Messages – preceded by a safety alert symbol and one

of three signal words: DANGER, WARNING, or CAUTION. These

signal words mean:

You WILL be KILLED or SERIOUSLY

DANGER

HURT if you don't follow instructions.

You CAN be KILLED or SERIOUSLY

WARNING

HURT if you don't follow instructions.

You CAN be HURT if you don't follow

CAUTION

instructions.

• Safety Headings—such as IMPORTANT SAFETY

INFORMATION.

• Safety Section—such as TRIMMER SAFETY.

• Instructions – how to use this trimmer/brush cutter correctly and

safely.

This entire book is filled with important safety information—please

read it carefully.

© 2004-2006 American Honda Motor Co., Inc.—All Rights Reserved

31VL3D10

IPC

EM5

00X31-VL3-D100

1

CONTENTS

TRIMMER SAFETY........................................................................................................2

IMPORTANT SAFETY INFORMATION..................................................................2

ATTACHMENTS & MODIFICATIONS.....................................................................2

IMPORTANT MESSAGE TO EMPLOYERS...........................................................2

SAFETY LABEL LOCATIONS.................................................................................3

RECOMMENDED CUTTING ATTACHMENTS..............................................................3

CUTTING-LINE HEADS AND SHIELDS.................................................................3

BLADES AND SHIELDS..........................................................................................4

CUTTING ATTACHMENT APPLICATIONS............................................................5

ASSEMBLY.....................................................................................................................5

IMPORTANT SAFETY PRECAUTIONS..................................................................5

UNPACKING...........................................................................................................5

LOOSE PARTS.......................................................................................................6

U-TYPE HANDLEBAR.............................................................................................6

SAW BLADE............................................................................................................7

ENGINE OIL............................................................................................................8

CONTROLS AND EQUIPMENT.....................................................................................9

BEFORE OPERATION.................................................................................................11

OPERATION.................................................................................................................12

SAFE OPERATING PRECAUTIONS....................................................................12

STOPPING THE ENGINE.....................................................................................13

TRIMMER/HARNESS QUICK DISCONNECTION................................................14

TRIMMER OPERATION........................................................................................14

SAFE OPERATING PRACTICES..........................................................................15

OPERATING TIPS.................................................................................................15

SERVICING YOUR TRIMMER.....................................................................................16

MAINTENANCE SAFETY......................................................................................16

MAINTENANCE SCHEDULE................................................................................17

ENGINE.................................................................................................................17

CUTTING ATTACHMENTS...................................................................................18

FUEL SYSTEM......................................................................................................24

STORAGE.....................................................................................................................25

TRANSPORTING..........................................................................................................26

TAKING CARE OF UNEXPECTED PROBLEMS.........................................................26

TECHNICAL INFORMATION........................................................................................27

EMISSION CONTROL SYSTEM...........................................................................27

SPECIFICATIONS.................................................................................................28

CONSUMER INFORMATION.......................................................................................29

DISTRIBUTOR'S LIMITED WARRANTY..............................................................30

ACCESSORIES, REPLACEMENT PARTS, AND APPAREL WARRANTY..........30

POM53509-C

EMISSION CONTROL SYSTEM WARRANTY.....................................................31

XXXX.2006.12

PRINTED IN U.S.A.

OWNER’S MANUAL

HHT25S • HHT35S

Trimmer/Brush Cutter

WARNING:

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

2

1

10W-30

Genuine Honda Oil

Specially formulated and

blended for Honda engines.

Meets or exceeds American

Petroleum Institute SJ

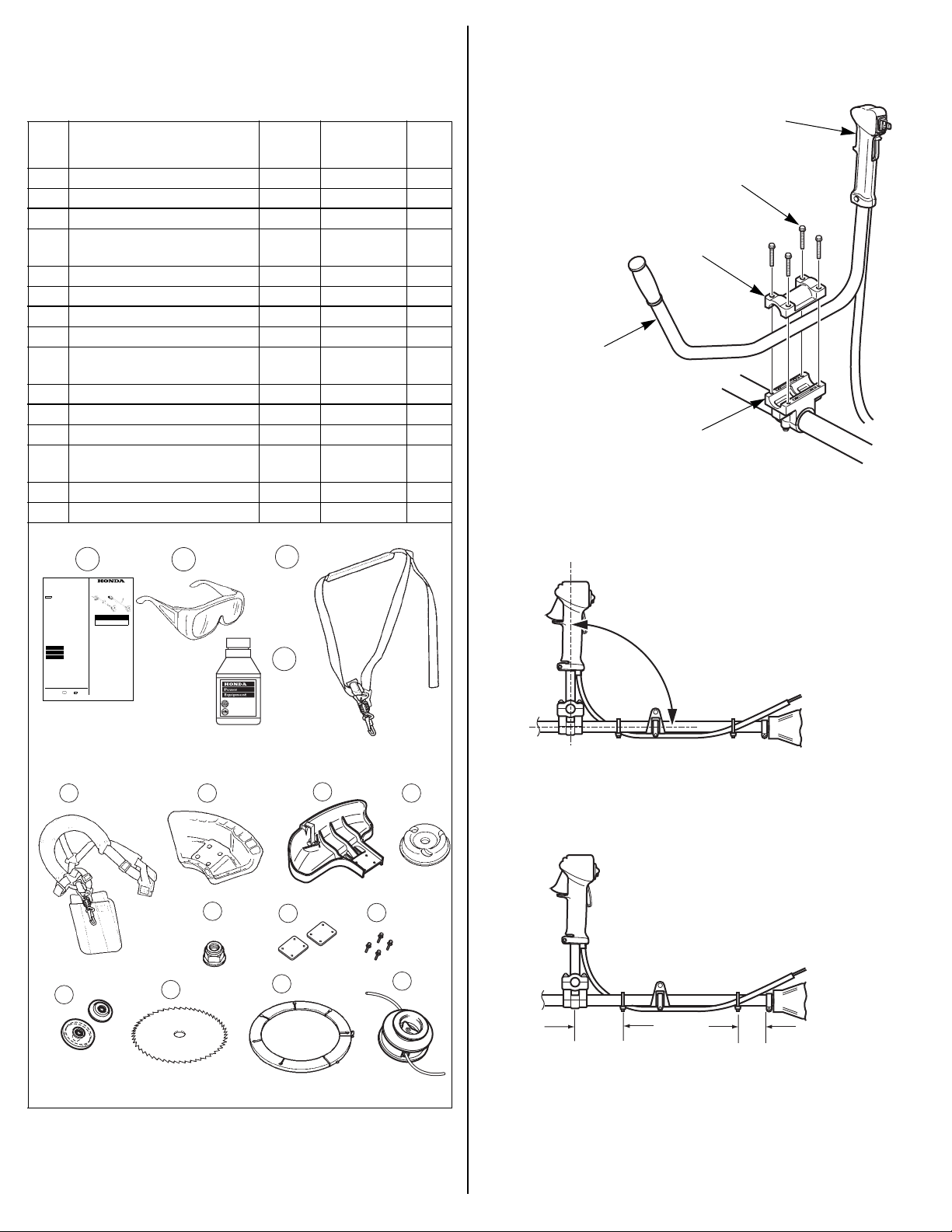

Installation

1. Remove the four 5 x 28 mm bolt/washers and handlebar holder A.

THROTTLE TRIGGER

5 x 28 mm

BOLT/WASHER (4)

HANDLEBAR

HOLDER A

U-SHAPED

HANDLEBAR

HANDLEBAR

HOLDER B

2. Set the U-shaped handle into handlebar holder B with the throttle

trigger facing to the right.

3. Adjust the handlebar position as shown.

90°

U-Type Handlebar Only

5 6 8

9

12

13

7

10

14

4

4. Tighten the four 5 x 28 mm bolt/washers.

TORQUE: 3.6 ft-lb (5 N·m)

5. Make sure the tie straps are positioned as shown.

11

15

3.9 in (100 mm) 2.4 in (60 mm)

6. Operate the throttle trigger and make sure the throttle operates

smoothly.

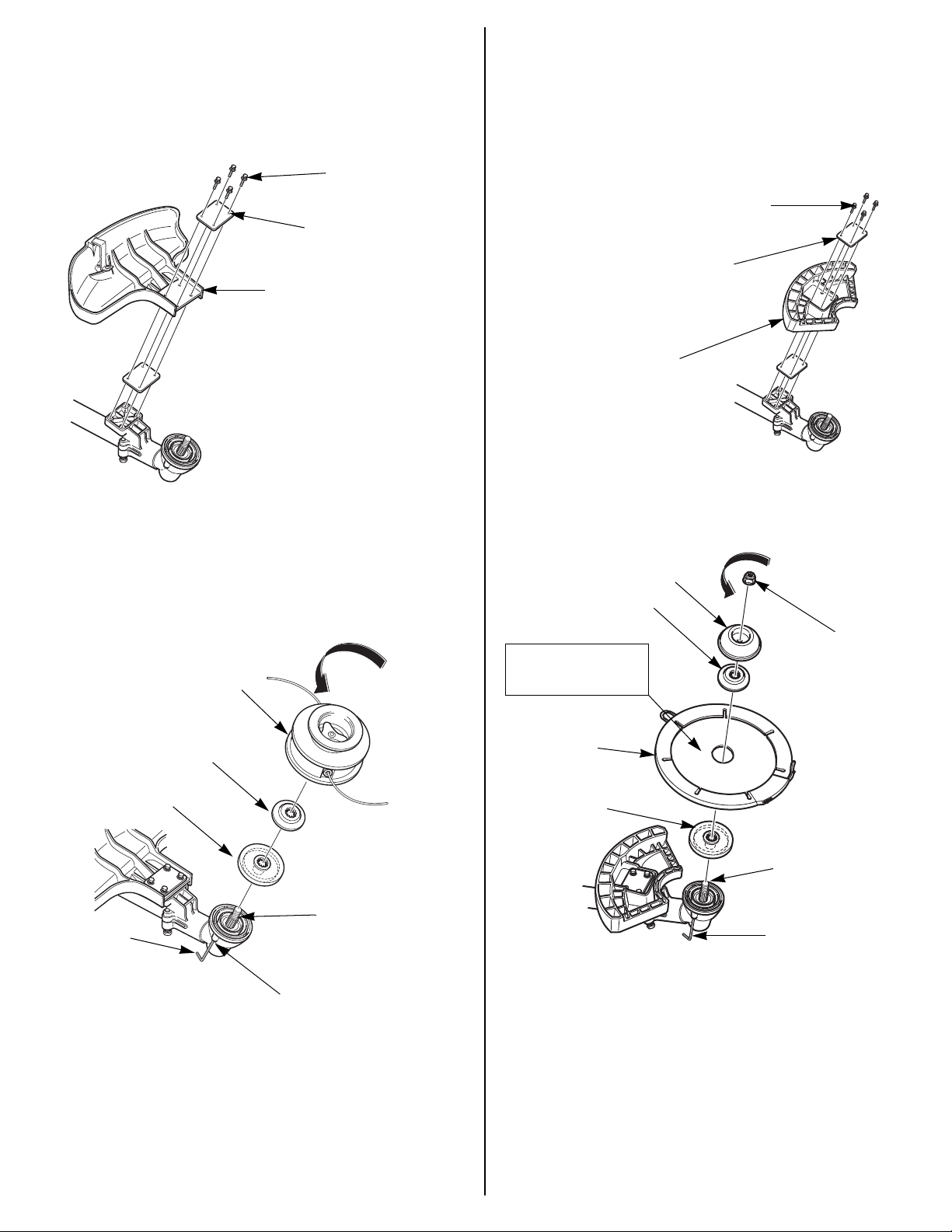

Cutting-line Head and Shield Installation

Prior to installation, move the ignition switch to the STOP (O) position

and disconnect the spark plug cap from the spark plug.

1. Install the cutting-line head debris shield as shown below.

2. Tighten the 5 x 28 mm bolt/washers:

TORQUE: 2.5 ft-lb (3.4 N·m)

5 x 28 mm

BOLT/WASHER (4)

SPACER (2)

[3/32" (2.3 mm) thick]

CUTTING-LINE

DEBRIS SHIELD

(with cutoff knife)

3. Insert the tip of a 4 mm hex wrench, or equivalent, fully into the

gear case hole.

4. Turn the output shaft until you feel the tool drop into the hole in the

cover plate/spacer A. Verify the trimmer head does not turn.

5. All output shafts use left-hand threads. Make sure the tool remains

in the hole, then grasp the trimmer head and turn in the direction of

the arrow to install.

CUTTING-LINE HEAD

Brush/Wood (50-tooth) Blade and Shield Installation

Prior to installation, move the ignition switch to the STOP (O) position

and disconnect the spark plug cap from the spark plug. Wear

protective gloves when working around the cutting-line head and saw

blade.

1. Install the brush/wood blade debris shield as shown below.

2. Tighten the 5 x 28 mm bolt/washers:

TORQUE: 2.5 ft-lb (3.4 N·m)

5 x 28 mm

BOLT/WASHER (4)

SPACER (2)

[3/32" (2.3 mm) thick]

BRUSH/WOOD BLADE

DEBRIS SHIELD

3. Insert a 4 mm hex wrench or equivalent into the gear case hole to

prevent the output shaft from turning.

4. Install cover plate/spacer A onto the output shaft as shown.

TIGHTEN

COVER

SPACER B

BLADE

Install with the white

markings facing the

debris shield.

10 mm LOCK NUT

(left-hand thread)

4 mm hex

wrench

SPACER B

COVER PLATE/

SPACER A

OUTPUT SHAFT

(left-hand thread)

GEAR CASE HOLE

BLADE

COVER

COVER PLATE/

SPACER A

OUTPUT SHAFT

(left-hand thread)

4 mm HEX TOOL

5. With the blade cover installed on the blade, install the blade by

aligning the center of the blade with the shoulder on cover plate/

spacer A.

6. Install spacer B, the cover, and the 10 mm lock nut as shown.

Be sure to install the blade with the cutting edges of the saw teeth

in the direction of rotation; the side with the white markings must

face the debris shield.

The output shaft has left-hand threads. Tighten the 10 mm lock nut

counterclockwise.

TORQUE: 14 ft-lb (20 N•m)

7. Remove the 4 mm hex wrench or equivalent from the gear case.

5

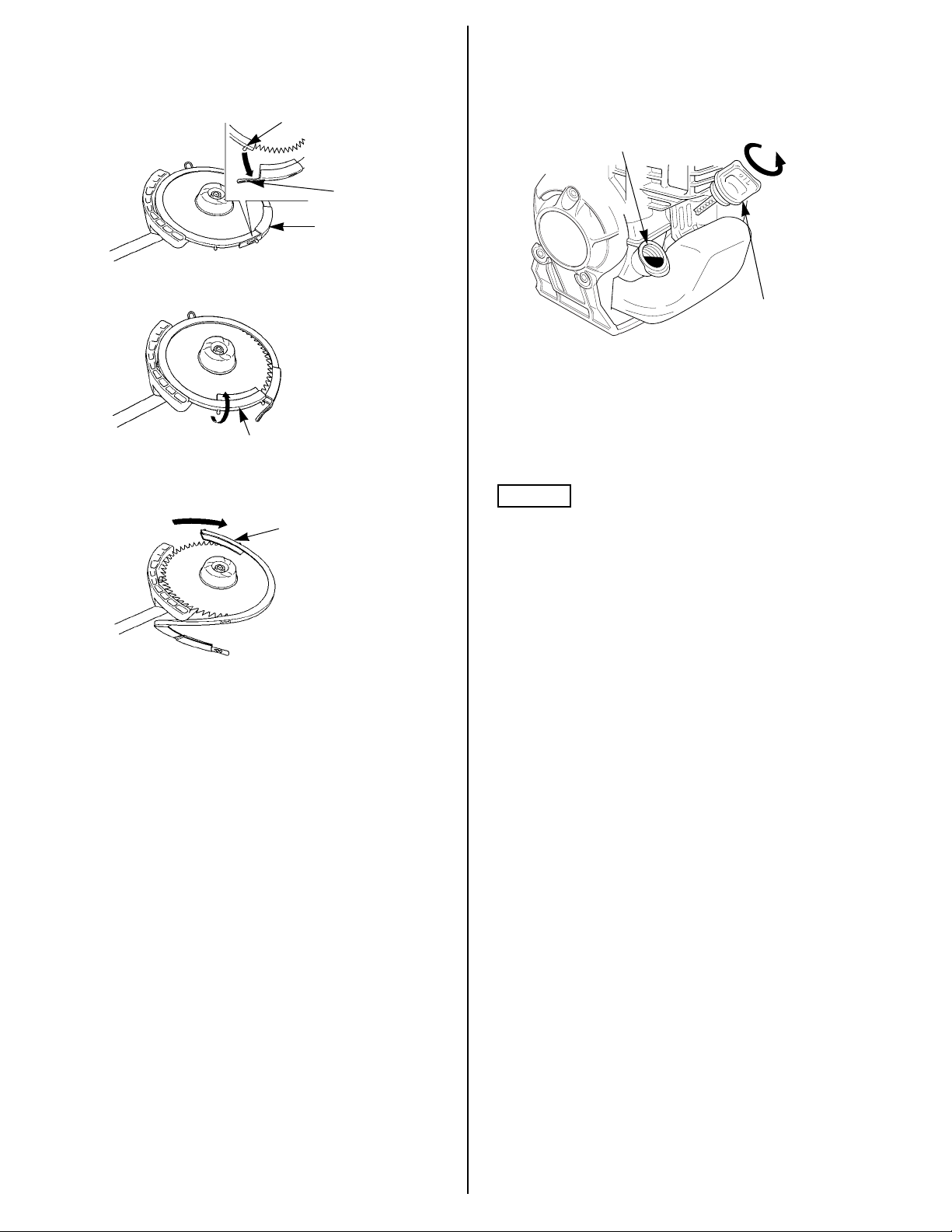

Blade Cover Removal

1. Turn the blade cover slowly until the cover latch is clear of the

debris shield.

Unfasten the latch by lifting the tab off the post.

POST

TAB

BLADE COVER

2. Pull the post end away from the blade and set it on top of the blade

as shown.

POST END

3. Turn the blade cover slowly until the post end is clear of the debris

shield, then remove the blade cover from the blade.

POST END

ENGINE OIL

The trimmer is shipped WITHOUT OIL in the engine.

1. Place the trimmer on a level surface, and then remove the oil filler

cap/dipstick.

OIL FILLER OPENING

OIL FILLER CAP/DIPSTICK

2. Slowly add the recommended oil (included in the box) to the

bottom edge of the oil filler opening. Do not overfill, as the engine

oil tank capacity is small.

3. If the supplied oil is not used, add enough SAE 10W-30 API

service category SJ or later oil. Add oil until the oil level is to the

bottom edge of the oil filler opening.

NOTICE

Running the engine with too little or too much oil can cause engine

damage.

4. Screw in the oil filler cap/dipstick securely.

Blade Cover Installation

1. Install the blade cover over the blade so half of the blade is

covered.

To prevent the post end from interfering with the debris shield, pull

the post end away from the blade and set it on top of the blade as

shown above.

2. Turn the blade cover slowly until the post end clears the debris

shield.

3. Reposition the post end over the blade.

4. With the blade cover fully seated on the blade, latch the tab over

the post.

FUEL

See page 17.

BEFORE USING YOUR TRIMMER

On blade equipped models, always remove the blade cover before

starting the engine. If the cover is not removed, the blade cover may

fly off at high speed during test operation. Reinstall the blade cover

when the trimmer is not being used.

Before using the trimmer, all trimmer operators must read the

following sections.

• TRIMMER SAFETY (page 2)

• CONTROLS & EQUIPMENT (page 7)

• BEFORE OPERATION (page 9)

• OPERATION (page 10)

• MAINTENANCE SCHEDULE (page 14)

6

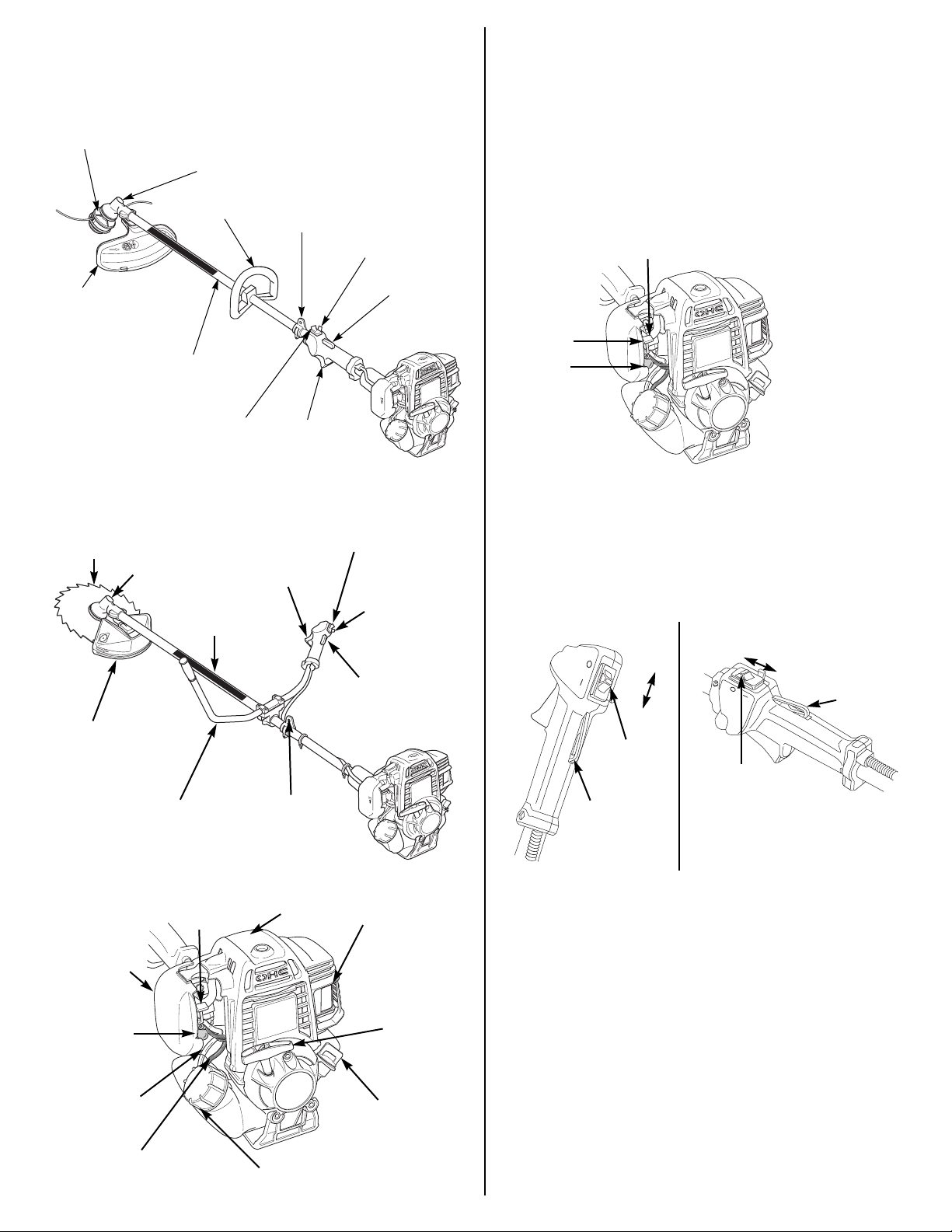

CONTROLS AND EQUIPMENT

COMPONENT CONTROLS AND LOCATIONS

Loop Type Handle

CUTTING-LINE HEAD

GEAR CASE

LOOP HANDLE

HARNESS HANGER

THROTTLE SET BUTTON

CONTROLS

The location and operation of the controls are similar on both the

HHT25S and HHT35S models.

Choke Lever

The choke lever opens and closes the choke valve.

The CLOSED position enriches the fuel mixture for starting a cold

engine.

The OPEN position provides the correct fuel mixture for operation

after starting, and for restarting a warm engine.

CHOKE LEVER

DEBRIS SHIELD

WITH CUTOFF KNIFE

DRIVE CABLE

FRAME PIPE

IGNITION SWITCH

THROTTLE

TRIGGER

OPERATOR PRESENCE LEVER

U-Type Handlebar

This type is supplied with a cutting-line head, a saw blade, and two

debris shields.

SAW BLADE

GEAR CASE

DEBRIS SHIELD

FOR BRUSH/

WOOD BLADE

U-TYPE

HANDLEBAR

THROTTLE

TRIGGER

DRIVE CABLE

FRAME PIPE

HARNESS

HANGER

IGNITION SWITCH

THROTTLE

SET BUTTON

OPERATOR

PRESENCE

LEVER

CLOSED

OPEN

Ignition Switch

The ignition switch controls the ignition system.

The ignition switch must be in the ON (I) position for the engine to

start and run.

Moving the ignition switch to the STOP (O) position stops the engine.

U-type Handle:

STOP

(O)

ON (I)

IGNITION

SWITCH

OPERATOR

PRESENCE

LEVER

STOP (O)

IGNITION

SWITCH

Loop Handle:

ON (I)

OPERATOR

PRESENCE

LEVER

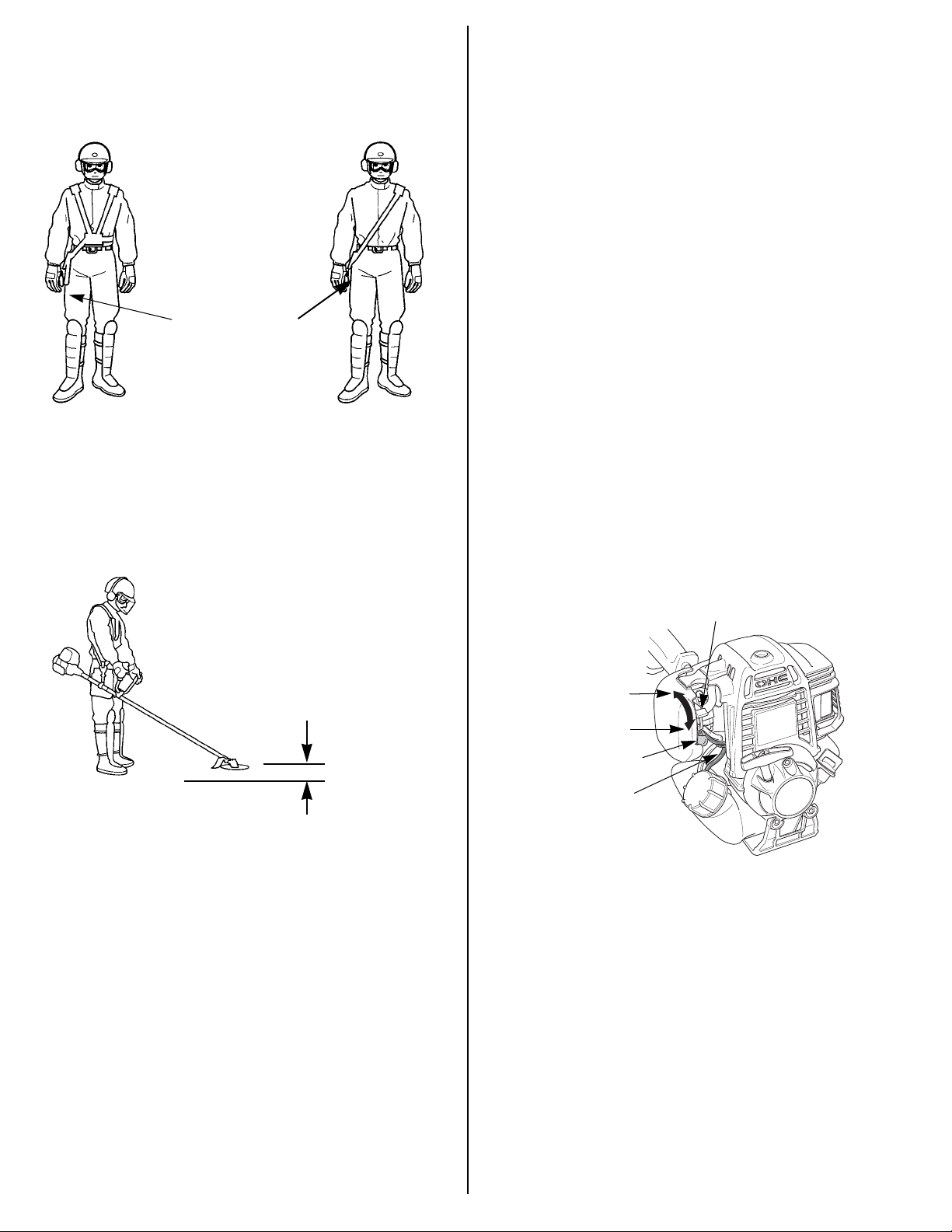

Engine

AIR

CLEANER

COVER

PRIMING

BULB

FUEL RETURN

TUBE (CLEAR)

FUEL SUPPLY

TUBE (BLACK)

CHOKE LEVER

SPARK PLUG

OIL FILLER CAP

FUEL TANK CAP

SPARK

ARRESTER

STARTER

GRIP

Operator Presence Lever

The operator presence lever blocks the throttle trigger. This safety

feature prevents unintentional throttle operation if the trimmer is

bumped while the operator’s hand is not on the control handle.

When the operator presses the presence lever by gripping the control

handle, the trigger moves freely.

7

Throttle Trigger

The throttle trigger controls engine speed.

Pulling the throttle trigger toward the control handle grip increases

engine speed. The trimmer will have the greatest cutting force at

maximum engine speed.

Releasing the throttle trigger reduces engine speed. At idle, the

cutting attachment should coast to a stop.

THROTTLE TRIGGER

IDLE

(cutting attachment stops)

FAST

(cutting attachment rotates)

THROTTLE SET BUTTON

Throttle Set Button

The throttle set button is used to hold the throttle trigger at the fast idle

position for starting. Do not allow the cutting line or blade to contact

any obstruction when starting the engine with the throttle set button

engaged.

To engage the throttle set button, press the operator presence lever

by gripping the control handle, pull the throttle trigger, then press and

hold the throttle set button while releasing the throttle trigger.

To disengage the throttle set button, simply pull the throttle trigger.

The throttle set button automatically disengages when the throttle

trigger is pulled.

Do not use the throttle set button while operating the trimmer. The

trimmer will not return to idle, and the cutting-line head or blade will

continue to spin until the throttle set button is disengaged and the

throttle trigger is released.

Priming Bulb

Pressing the priming bulb pumps fuel from the fuel tank to the

carburetor. This procedure is necessary for starting the engine.

To ensure fuel has reached the carburetor, press the priming bulb

repeatedly until fuel can be seen in the clear plastic fuel return tube.

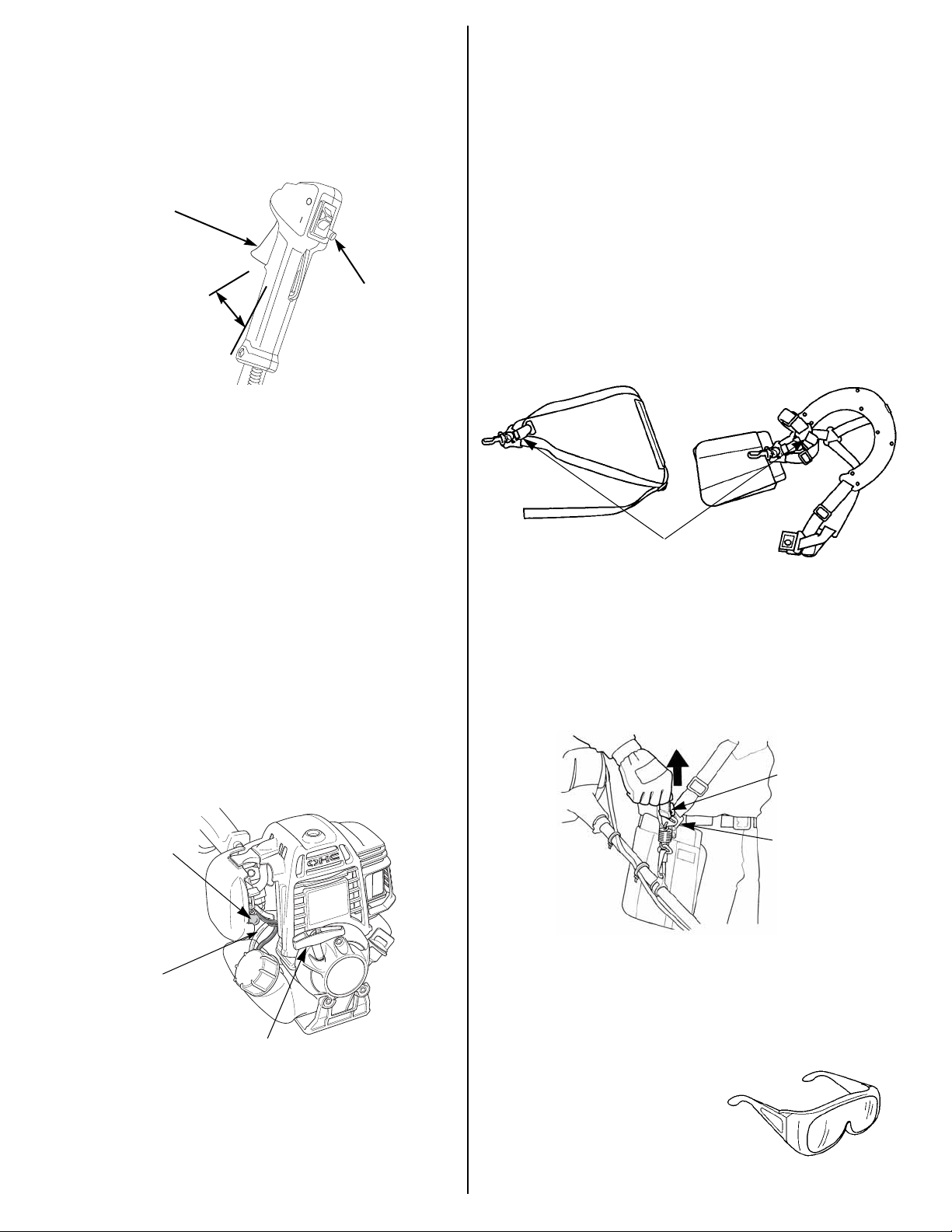

EQUIPMENT

The Honda HHT25S and HHT35S trimmer/brush cutters are supplied

with a shoulder harness and safety glasses. Refer to page 9 for a

description of other equipment and protective clothing you will need.

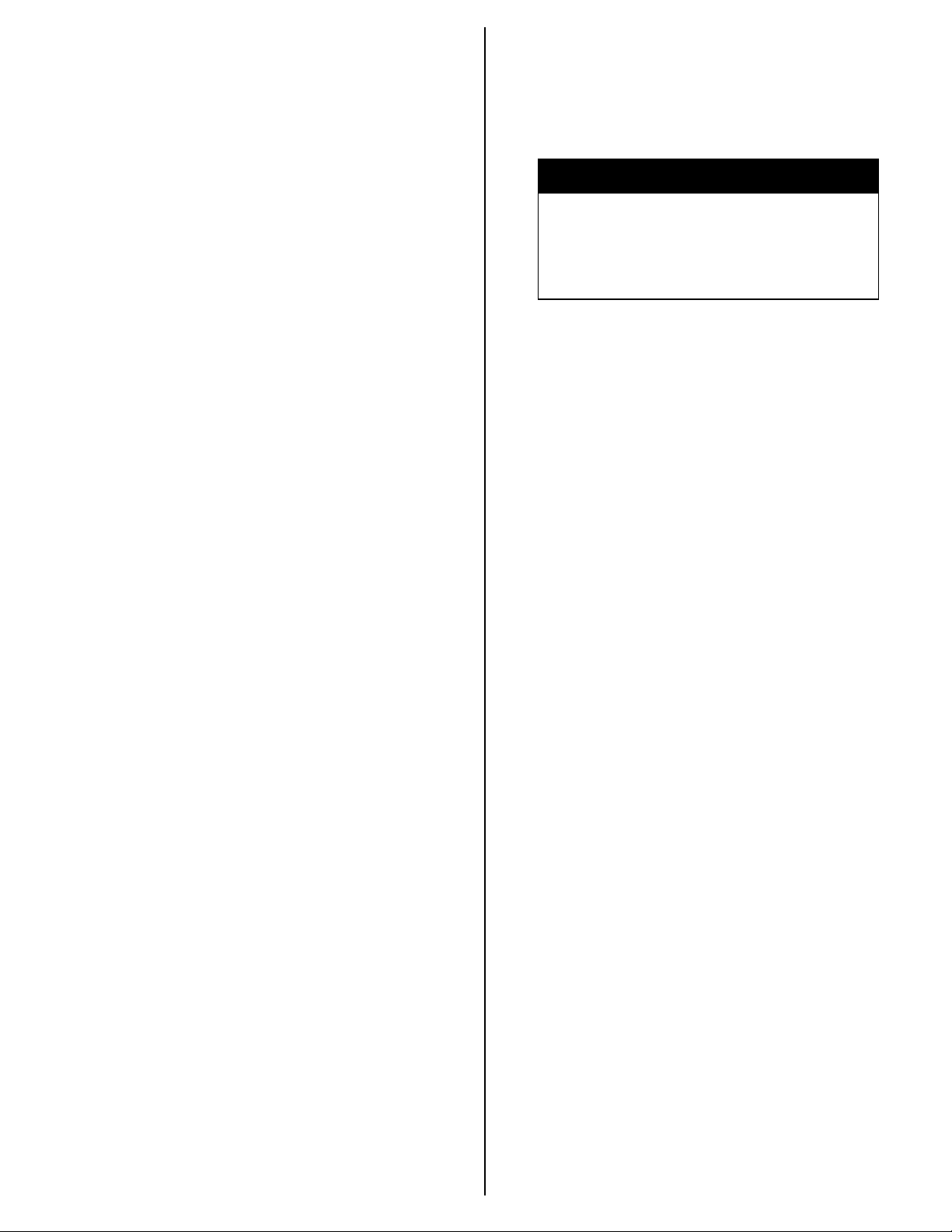

Shoulder Harness

A full shoulder harness must be worn by the operator of these Honda

trimmers/brush cutters when equipped with a blade and debris shield.

If the trimmer is equipped with a cutting-line head and shield with

cutoff knife, the operator may wear a single-strap harness.

A suitable shoulder harness is supplied with each new Honda

HHT25S and HHT35S trimmer/brush cutter. Replacement shoulder

harnesses may be purchased through any authorized Honda

trimmer/brush cutter servicing dealer.

Before operation, adjust your shoulder harness as described on

page 10.

SINGLE-STRAP SHOULDER HARNESS

(Loop type handle)

QUICK-RELEASE LATCH

Quick-Release Latch

The shoulder harnesses supplied with these trimmers are equipped

with a quick-release latch.

Pull the latch tab upward to detach the trimmer from the harness.

Insert the latch tongue in the slot of the quick-release latch to reattach

the trimmer to the harness.

FULL SHOULDER HARNESS

(U-type handlebar)

LATCH TAB

PRIMING

BULB

FUEL RETURN TUBE

(clear plastic tube)

RECOIL STARTER GRIP

Recoil Starter Grip

Pulling the starter grip operates the recoil starter to turn the engine for

starting.

8

QUICK-RELEASE

LATCH

Safety Glasses

Safety glasses or goggles that comply with ANSI (American National

Standards Institute) standard Z87.1 must be worn by the operator of

any Honda trimmer/brush cutter. The safety glasses supplied with

each new Honda HHT25S and HHT35S trimmer/brush cutter comply

with this ANSI standard.

SAFETY GLASSES (ANSI Z87.1)

BEFORE OPERATION

ARE YOU READY TO OPERATE THE TRIMMER?

Your safety is your responsibility. A little time spent in preparation will

significantly reduce your risk of injury.

Read and understand this manual. Know what the controls do and

how to operate them.

Familiarize yourself with the trimmer and its operation before you

begin to use it. Know what to do in case of emergencies.

You must be alert and in good physical condition to operate the

trimmer. Do not operate the trimmer if you are tired, ill, or under the

influence of alcohol, medication, or any substance that might impair

your vision, dexterity, or judgment.

If you have any physical problem that may be aggravated by

strenuous work, consult your physician before operating the trimmer.

Wearing protective clothing will reduce your risk of injury. Do not wear

loose clothing, jewelry, short pants, sandals, or go barefoot. Secure

hair so it is above shoulder level.

Always wear safety glasses or goggles that comply with ANSI

standard Z87.1 to protect your eyes from thrown objects. Prescription

glasses may be worn under the safety glasses or goggles.

A helmet with a face shield is recommended for further protection.

However, safety glasses or goggles should always be worn under the

face shield. Do not rely on a face shield alone to protect your eyes.

Wearing a dust mask will help to reduce the amount of pollen and dust

inhaled.

Hearing protectors will help to protect your ears from noise.

Earmuff-style hearing protectors can also protect your ears from

thrown objects.

Wear gloves, a long-sleeved shirt, and long pants made of heavy

material. Clothing should fit closely but allow freedom of movement,

and should have no strings, straps, etc. that could catch on brush or

the trimmer. Keep clothing fastened.

Wear sturdy work boots with good toe protection and nonslip soles.

IS YOUR WORKING AREA READY?

Objects thrown by the trimmer can cause serious injury. Before

operating the trimmer, carefully inspect the area and remove all

objects that could be thrown by, or entangled in, the cutting

attachment, such as rocks, broken glass, nails, wire, or string.

Clear the area of children, bystanders, and pets. Keep all children,

bystanders, and pets at least 50 feet (15 meters) away from where the

trimmer is being operated.

Even outside a 50-foot (15-meter) radius of the trimmer, there may be

a risk of injury from thrown objects, so bystanders should be

encouraged to wear eye protection.

If anyone approaches you while you are operating the trimmer,

release the throttle trigger and stop the engine.

IS YOUR TRIMMER READY TO GO?

For your safety, and to maximize the service life of your equipment, it

is very important to take a few moments before you operate the

trimmer to check its condition. Be sure to take care of any problem

you find, or have your servicing dealer correct it, before you operate

the trimmer.

B WARNING

Improperly maintaining this trimmer, or failing to

correct a problem before operation, could cause a

malfunction in which you could be seriously injured.

Always perform a pre-operation inspection before

each operation, and correct any problem.

Safety Inspection

• Look around the engine for signs of oil or gasoline leaks. Wipe up

any spills before starting the engine.

• Replace any damaged parts.

• Check that all fasteners are in place and secure. Tighten as

necessary.

Cutting Attachment Inspection

• Look for signs of damage to the cutting attachment (see page 21

and page 19). Replace any cutting attachment and parts that are

worn out, bent, cracked, chipped, or damaged in any way.

• If using a metal blade, be sure it is sharp. A dull blade is more likely

to snag and thrust.

• If using a metal blade on a trimmer equipped with a loop handle, be

sure the barrier bar (optional part) is installed beneath the loop

handle.

• Make sure the cutting attachment is properly installed and securely

fastened (see page 24 and page 21).

• Check that the debris shield is the correct shield for the cutting

attachment (see page 21), and that it is securely installed and in

good condition.

Maintenance Inspection

• Check the oil level (see page 15). Running the engine with a low oil

level can cause engine damage.

• Check the air filter (see page 15). A dirty air filter will restrict air flow

to the carburetor, reducing engine and trimmer performance.

• Check throttle cable free play (see page 16). The cable must be

correctly adjusted and operate smoothly for good throttle control.

• Check the fuel level (see page 17). Starting with a full tank will help

to eliminate or reduce operating interruptions for refueling.

9

ARE YOUR SHOULDER HARNESS AND TRIMMER CORRECTLY ADJUSTED?

Adjusting the Harness

Adjust the harness so the quick-release latch is at your right hip, as

shown.

QUICK-RELEASE

LATCH

FULL SHOULDER

HARNESS

Balancing the Trimmer on the Shoulder Harness

Hang the trimmer on the harness hook, and see how it balances.

Adjust the shoulder harness, the harness hanger on the frame pipe,

and the loop handle or U-type handlebar, so the handle or handlebars

are in a comfortable operating position, and the trimmer hangs with its

cutting attachment a few inches above the ground (see page 11).

SINGLE-STRAP

SHOULDER HARNESS

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the trimmer for the first time, please review the

IMPORTANT SAFETY INFORMATION section on page 2 and

BEFORE OPERATION section starting on page 9.

Even if you have operated other trimmers, take time to become

familiar with the operation of this trimmer’s controls and handling.

For your safety, avoid starting or operating the engine in an enclosed

area, such as a garage. Your engine's exhaust contains poisonous

carbon monoxide gas which can collect rapidly in an enclosed area

and cause illness or death.

If the trimmer starts to shake or vibrate, stop the engine immediately.

After the cutting head has completely stopped, inspect it to determine

the cause of the vibration. Sudden vibration is a sign of a hazardous

problem, such as a loose or damaged blade. Do not operate the

trimmer until the problem is corrected.

Prolonged exposure to vibration may cause Hand-Arm Vibration

Syndrome (HAVS). Symptoms include loss of skin color in the hands

and numbness or a painful tingling sensation in the fingers, hands,

and arms. Regular users of any power equipment may feel the

numbness or pain spontaneously, at any time, not just after using the

equipment. If any of these symptoms occur, see a physician

immediately.

STARTING THE ENGINE

1. To start a cold engine, move the choke lever to the CLOSED

position.

To restart a warm engine, leave the choke lever in the OPEN

position.

CHOKE LEVER

A few inches above the

ground

GROUND

CLOSED

OPEN

PRIMING

BULB

FUEL RETURN

TUBE

(clear plastic

tube)

2. To start a cold engine, or after refueling an engine that has run out

of fuel, press the priming bulb repeatedly until fuel can be seen in

the clear plastic fuel return tube.

To restart a warm engine, it is not necessary to press the priming

bulb.

3. Set the throttle trigger in the starting position, using the throttle set

button.

10

Loading...

Loading...