Page 1

N

S

T

R

U

C

T

I

O

N

S

I

Q SERIES

REACH-IN

FOOD STORAGE CABINETS

Q SERIES

REACH-IN

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 14580 Rev. L (Jan. 2002)

Page 2

Installation, Operation and Care of

Q SERIES REACH-IN FOOD STORAGE CABINETS

SAVE THESE INSTRUCTIONS

GENERAL

The Q Series Reach-In Food Storage Cabinets are available as low temperature (0°F), medium

temperature (38°F) refrigeration units or hot food storage cabinets (180°F maximum). They may be

ordered as one-, two-, or three-section cabinets.

A variety of optional cabinets is available. These include: Two- or three-section cabinets with a

combination of medium and low temperature sections or medium temperature and hot food storage

sections; two- or three section cabinets equipped with optional SAFE-T-THAW

rapid thawing at medium temperatures; convertible models which, by setting a selector switch, will

operate as either a low temperature or medium temperature unit; and single-section over/under

cabinets which feature a medium temperature and a low temperature unit, one on top of the other.

®

equipment for safe,

INSTALLATION

UNPACKING AND ASSEMBLY

Immediately after unpacking the reach-in, check for possible shipping damage. If this unit is found to

be damaged after unpacking, save the packaging material and contact the carrier within 15 days of

delivery.

Prior to installation, test the electrical service to assure that it agrees with the specifications on the

machine data plate located in the upper left corner inside the cabinet.

LOCATION

For optimum performance, the condensing unit of the reach-in (refrigeration models only) must have

an adequate supply of air for cooling purposes. The operating location must provide either a minimum

12

"

clearance overhead of the condensing unit or the unrestricted flow of air at the back of the reach-in.

– 2 –

Page 3

ASSEMBLY

Some components can be removed to allow the cabinet

to pass through short or narrow doorways.

The door handle can be removed as follows:

1. Remove the screw and bolt from the tumbler.

2. Remove the two mounting screws and the handle

assembly (Fig. 1)

3. Replace in reverse order of disassembly.

ASSEMBLY

MOUNTING

SCREW

SCREW

BOLT

DOOR

MOUNTING SCREW

HANDLE ASSEMBLY

KEY

Fig. 1

PLUG

BUTTON

PL-50949

Door(s) and hinges can be removed as follows:

1. Lift up and remove the front trim

panel (Fig. 1).

2. Remove the screws which secure

the trim rail cover (Fig. 1), unplug

the door switch lead wires, and

remove the screws which secure

the trim rail (Fig. 1). Carefully lay

the trim rail on top of the cabinet —

avoid damaging or kinking the

thermometer capillary tube.

3. Remove the three screws which

secure the upper hinge plate to the

cabinet (Fig. 2). This will remove

hinge tension. Remove the nut

underneath the lower hinge plate

which secures the bottom hinge.

PL-53615

Remove door. Remove lower hinge

plate (Fig. 2).

4. If the hinge mechanism should become

uncocked while changing the door, it will

be necessary to recock the hinge

mechanism. To do this, remove the door

from the cabinet and position the door

face down on a workbench or table. Using

5

/16" open end or adjustable wrench, turn

a

the hinge mechanism shaft 135° (Fig. 3).

5. Replace the hinge plates and door(s) in

the reverse order of disassembly.

FRONT TRIM PANEL

TRIM RAIL COVER

TRIM RAIL

Fig. 2 Fig. 3

UNCOCKED POSITION

TURN 135º

– POSITION 1 – (LEFT-HAND HINGED DOOR)

UNCOCKED POSITION COCKED POSITION

TURN 135º

COCKED POSITION

135º

SCREWS

135º

UPPER

HINGE

LOWER

HINGE

(3)

PL-53617

If cabinets are too tall, the refrigeration system

may need to be removed in order to pass

through short openings. Contact your dealer or

PL-50961

– POSITION 2 – (RIGHT-HAND HINGED DOOR)

POSITION DOOR IN ONE OF THE TWO POSITIONS SHOWN.

Fig. 4

authorized servicer if this becomes necessary.

Once the cabinet is in its final position, replace any components that may have been removed (door

handle, etc.) and then level the cabinet front-to-back and side-to-side by adjusting the legs as required.

Door Hinging

Should the doors need to be rehinged (from right to left or vice versa), contact a Hobart-authorized

Refrigeration Service Company.

– 3 –

Page 4

LEGS OR CASTERS

WARNING: THE CABINET MUST BE BLOCKED AND STABLE

BEFORE INSTALLING LEGS OR CASTERS.

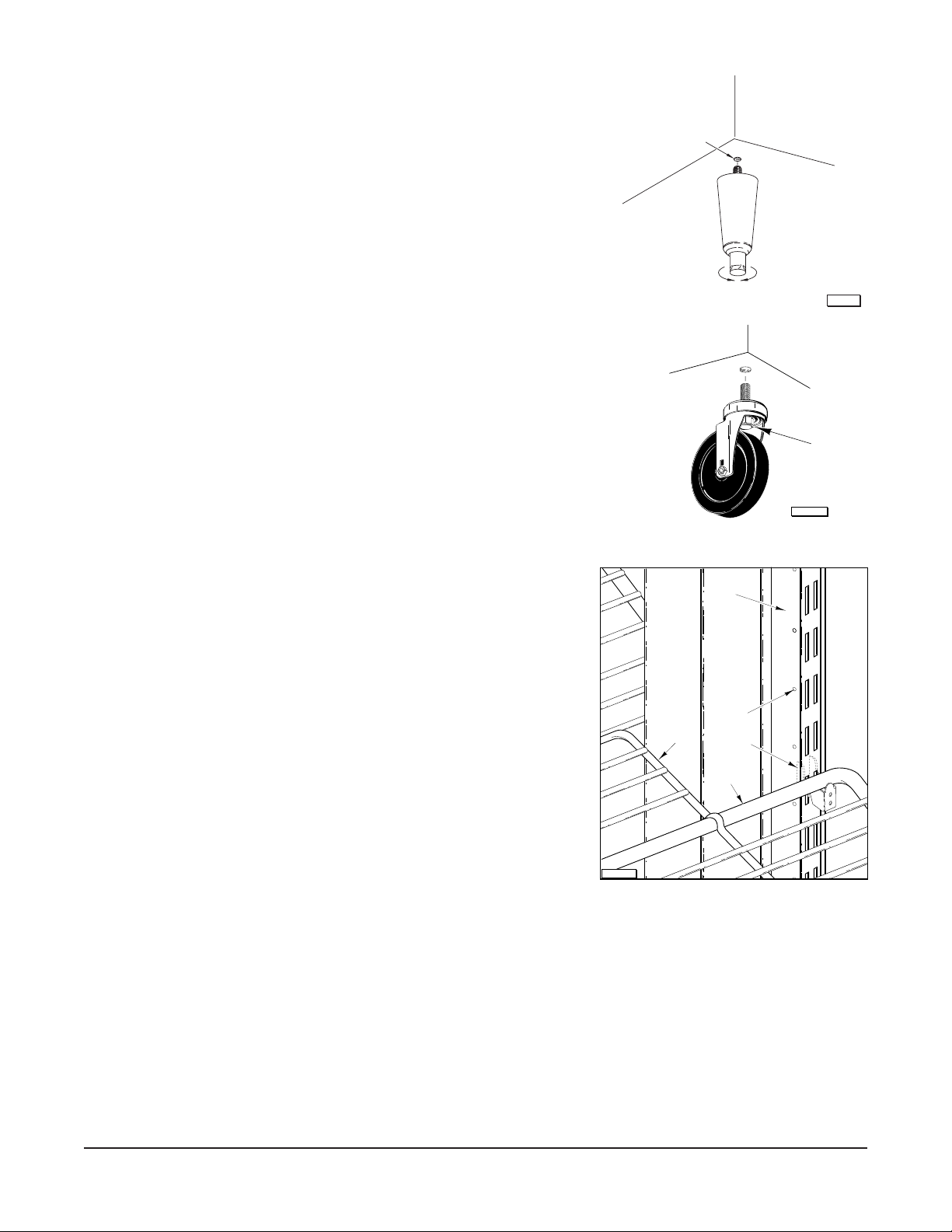

Legs (Fig. 5)

"

To install the legs, raise and block the reach-in a minimum of 7

from

the floor and thread the legs into the Threaded Holes on the bottom

of the cabinet. This unit must be level in order to operate properly.

Turn the adjustable feet in or out as required to level the unit

front-to-back and side-to-side.

NOTE: Three-section front opening cabinets come with five legs,

the fifth leg should be placed in the front center threaded hole. In the

case of a three section pass through cabinet, a sixth leg is included

for the rear center hole. Failure to install these legs in the proper

location may result in damage to the cabinet.

Casters (Fig. 6)

THREADED HOLE

RAISE

Fig. 5

LOWER

PL-56125

Use casters only on reach-in models with self-contained refrigeration

systems that have cord and plug electrical connections. Raise and

block the cabinet a minimum of 7" from the floor. Thread the casters

into the holes in the bottom of the cabinet (Fig. 2). Casters with

brake should be installed at the front. Securely tighten the caster

with the octagon shaped Bolt head underneath — not the round

flange on top.

Shelves (Fig. 7)

If purchased, the shelves and shelf clips are shipped with the

cabinet. Insert the shelf clips into the pilaster and install the

shelves. Index holes are provided in the pilaster to help in

leveling the shelves.

Bonus shelves are provided to fill the space between the

shelves. These are positioned and supported by the shelves.

NOTE: Loosen all thumbscrews which secure shelf pilasters

and light cover(s) prior to placing product in cabinet.

Thumbscrews should be loose enough to remove with your

fingers so parts can be readily removed for cleaning without the

use of tools. Failure to comply with this request will invalidate

the NSF listing.

Utility Base (Optional)

PL-50910

COLD AIR

DUCT

BONUS

SHELF

Fig. 6

PILASTER

INDEX

HOLE

SHELF

CLIP

SHELF

Fig. 7

BOLT

PL-53353

If your unit comes with a utility base, we recommend securing the base to the floor to prevent damage

to the floor outlet due to accidental movement. The utility base is secured to the cabinet with four bolts,

one at each corner. The utility base is mounted at the factory. With the cabinet in its final installed and

leveled position, apply a bead of NSF approved sealant (not supplied) around the bottom. Access

covers, secured with screws, are provided on the left side and front for attaching the power supply cord

to a floor outlet underneath the cabinet.

Curb

The cabinet may be installed on a curb without legs or casters; the typical curb must be recessed a

3

minimum of 1

/8" from the front of the cabinet (and rear if it is a pass through) to allow room for the hinges.

– 4 –

Page 5

Compressor Mounts

TEMPERATURE

CONTROL

PL-56151

Some Q Series units have the compressor specially mounted to help prevent damage during shipment.

If the compressor is mounted on shipping blocks, remove the shipping blocks before operating the

compressor. If the compressor is mounted on springs, refer to the tag attached to the compressor.

Condensate Evaporator

Q Series cabinets, except for remote or over/under units, are equipped with an automatic condensate

evaporator and require no drain connection.

ELECTRICAL CONNECTIONS (Cord Connected Reach-Ins) 120 Volt, 60 Hertz, 1 Phase

WARNING: THIS MACHINE IS PROVIDED WITH A THREE-PRONGED GROUNDING PLUG. THE

OUTLET TO WHICH THIS PLUG IS CONNECTED MUST BE PROPERLY GROUNDED. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN.

ELECTRICAL CONNECTIONS (Permanently Connected Reach-Ins)

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT.

Make electrical connections per the wiring diagram supplied with the unit.

PRESTART CHECKS

REFRIGERANT LINES — Check for tubing shifts due to shipping that would cause operating noise,

wear or leaks.

SELECTOR SWITCH (Convertible Models Only) — The selector switch should be set to the proper

position. To gain access to the switch, remove the front trim panel (Fig. 2) by raising it up (to clear the

retaining slots) and out. Set the switch on the proper position (Refrigerator or Freezer) and replace the

trim panel.

OPERATIONAL CHECK — The refrigeration and defrost cycles should be checked for proper

operation and the thermometer(s) should also be checked for correct temperature indication — before

product is stored in the cabinet.

DEFROST TIMER — On freezer units, set the defrost timer as described in Operation.

OPERATION

CONTROLS (Refrigeration)

TEMPERATURE CONTROL — The temperature control is

set at the factory but local conditions may necessitate slight

adjustment. To adjust the temperature control, lift up and

remove the front trim panel (Fig. 2). Turn the control knob

(Fig. 8) a small amount at a time. Turning the control knob in

the direction of the arrow lowers the temperature. The control

knob has a marked OFF position which interrupts power to the

compressor and condenser fan only, not the entire reach-in.

NOTE: Over/under units have separate temperature controls

for each refrigeration system. They are located on the front of

each evaporator housing.

– 5 –

Fig. 8

Page 6

STANDARD THERMOMETER (Fig. 9) — The standard digital

thermometer is calibrated at the factory and does not permit

recalibration.

OPTIONAL DIAL THERMOMETER — The optional dial

thermometer can be recalibrated. Compare the cabinet

Refrigerator

thermometer with an accurate test thermometer. If there is any

variation, contact a Hobart-authorized Refrigeration Service

Company.

CONTROLS (Safe-T-Thaw Only)

Fig. 9

PL-50767

The optional Safe-T-Thaw adaptation of the two- or three- section reach-in refrigerators significantly

reduces the defrost time of all frozen foods under a controlled environment without employing

temperatures over 45°F.

Safe-T-Thaw incorporates a two stage thermostat, a reversing valve on the refrigerant line, and multiple

fan units for increased internal air circulation. When non-frozen food is placed in the Safe-T-Thaw unit,

it operates as a normal refrigerator — the thermostat switches cooling on at 40°F and off at 36°F. When

a sufficient load of frozen food is placed in the cabinet to lower the temperature to 33°F, the heating mode

is activated. The two stage thermostat will switch the circulating fans on and reverse the refrigerant

valve so the warm refrigerant flows to the inside of the cabinet and the cool refrigerant goes to the

outside coil. When the cabinet has warmed to 40°F the thermostat turns off the warming. The cabinet

continues to cycle heat on at 36°F and off at 40°F.

When the frozen product has lost its ability to reduce the cabinet temperature to 36°F, heat from the fan

motors will gradually cause the cabinet temperature to climb to 45°F. At this point the thermostat will

reverse mode again to normal refrigeration cycle — cooling on at 40°F and off at 36°F.

Circulating fans do not work during normal refrigeration mode. All the apparatus works automatically

without adjusting the factory settings.

NOTE: To reduce the drying effect of the fans blowing air over foods, it is recommended that food

stored in the Safe-T-Thaw be covered.

CONTROLS (Hot Food Storage Units, Fig. 10)

The ON-OFF switch contains a pilot light which glows

whenever the switch is ON. Turn the switch OFF

whenever the cabinet is not in use. The ON-OFF

switch is not a disconnect switch — ALWAYS

DISCONNECT POWER AT THE SOURCE TO

SERVICE THE UNIT. The temperature control dial,

which has a marked OFF position (no heat), is used to

select the temperature at which the food will be held.

When this dial is OFF, the air circulating fans continue

to run.

The HUMIDITY control dial is used to regulate the

humidity level inside the cabinet. Three-section

cabinets have two HUMIDITY control dials.

– 6 –

Fig. 10

Page 7

ELECTRONIC DEFROST TIMER (when equipped)

If your freezer is equipped with an electronic Defrost Timer, it is

THUMBSCREW

located in a control box behind the trim rail at the top of the

Reach-In Freezer. To access the the Defrost Timer, remove the

Thumbscrew on the left side of the Control Box and slide the Lid

LID

to the left (Fig. 11). Save the Thumbscrew and Lid and put them

back in place after programming is done.

The Defrost Timer's clock is operating from the backup power

supply (battery) during shipping and before installation. Once the

freezer is plugged in, the Defrost Timer operates off of the AC

CONTROL BOX

power supply; the battery is only used during a power interruption

or outage. This battery is a permanent type that is not replaceable

PL-41628-1

Fig. 11

except by replacement of the defrost timer itself. For additional

information on behavior of the defrost timer if the battery loses

power, refer to page 11. When the AC power is plugged in, the

defrost time clock automatically switches the battery to a standby

condition.

When the Freezer is connected to the AC electrical power supply,

the SET CLOCK light on the Defrost Timer (Fig. 12) blinks rapidly

to indicate that the Defrost Timer is in normal Operation Mode.

The Defrost Time Clock is set at the factory to the current timeof-day for Central Standard Time. The Defrost Duration is preset

at the factory to run for 25 minutes. Also, the Defrost Schedule is

preset at the factory to start a defrost cycle four times each day,

AM, 8 AM, 2 PM and 8 PM. The factory preset defrost schedule

at 2

is active during normal Operation Mode if all 24 switches are OFF.

Switches are OFF when tabs are positioned to the left (Fig. 12).

The backup power supply (battery) maintains the correct time-ofday during shipping. If the freezer stays in the Central Time Zone,

the time-of-day does not need to be reset. If the freezer is installed

Fig. 12

in a different time zone, the time clock can be reset to the correct

time-of-day if desired. Refer to Setting the Time Clock to the

Current Time-of-Day (page 8).

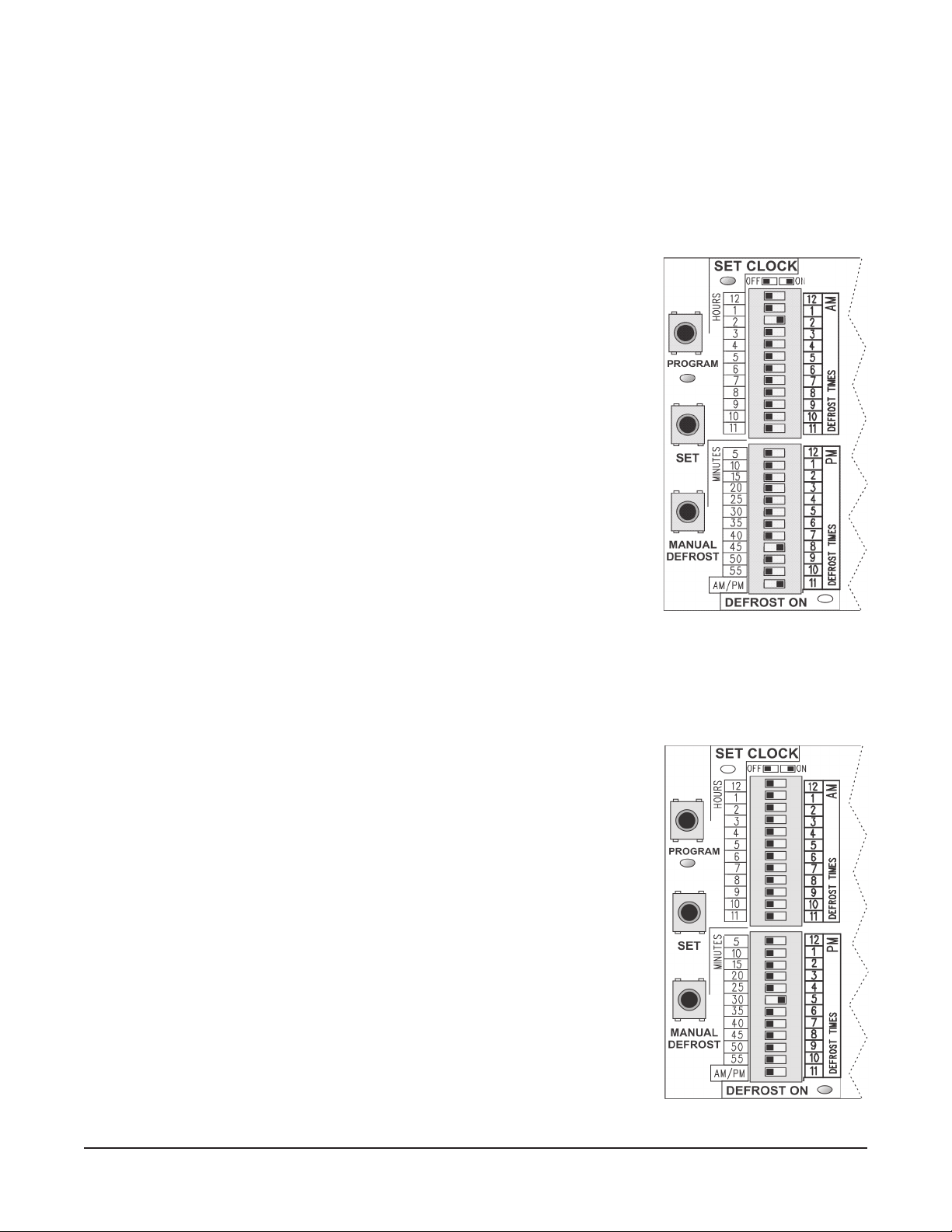

PROGRAMMING THE ELECTRONIC DEFROST TIMER

Use a small probe such as a pen, pencil or screwdriver to move the switches during programming.

Switches are OFF when the tab is left, ON when tab is moved to the right.

Before programming, if the initial switch settings are not all off (Fig. 12), make a record of the current

switch settings on a piece of paper; this indicates the current defrost schedule. Then slide all 24

switches to the left or OFF position (Fig. 12).

During programming, all settings must be completed within 4 minutes or the timer will return to normal

Operation Mode. Once programming is done, restore the previous defrost schedule by returning the

switches to the same positions noted on your record.

– 7 –

Page 8

To Change the Defrost Duration and Bypass the Setting of the Time Clock

Begin with the SET CLOCK light blinking rapidly, indicating normal Operation Mode . . .

If you want to change the Defrost Duration but not reset the time-of-day, press and hold the PROGRAM

button for about 3 seconds until the PROGRAM light starts blinking. Release the PROGRAM button

and the PROGRAM light and the SET CLOCK light remain lit. Press and hold the PROGRAM button

again until the DEFROST ON light starts blinking. Release the PROGRAM button and the DEFROST

ON light remains lit. Skip the section titled Setting the Time Clock to the Current Time-of-Day (below)

and continue with Setting the Defrost Duration (bottom of this page).

Setting the Time Clock to the Current Time-of-Day

Begin with the SET CLOCK light blinking rapidly, indicating normal

Operation Mode . . .

• Begin with all switches OFF (Fig. 12).

• Press and hold the PROGRAM button for about 3 seconds until the

PROGRAM light starts blinking. Release the PROGRAM button and

the PROGRAM and the SET CLOCK lights remain lit.

• The upper set of switches sets the HOUR. Slide the switch that

corresponds to the current hour to the right. The 11 other switches

remain OFF.

• The lower set of switches sets the MINUTES. Find the switch that

is within 5 minutes of the current minutes and move it to the right. At

least 10 of the other switches in the lower set remain OFF. If the time

is 0 to 3 minutes after the hour, all 11 switches can remain OFF.

• The last switch of the lower set of switches selects AM or PM. Leave

the tab on the left for AM. Slide the tab to the right for PM.

The example, Fig. 13, sets the Time Clock at 2:45

PM.

Fig. 13

Press and hold the SET button until the SET CLOCK light starts blinking. Release the SET button; the

SET CLOCK light goes off and the DEFROST ON light begins to blink and then remains on. Continue

with Setting the Defrost Duration. To exit without setting the Defrost Duration, return all switches to the

left, press the PROGRAM button for three seconds and release the PROGRAM button — normal

Operation Mode returns with the SET CLOCK light blinking rapidly.

Setting the Defrost Duration

The Defrost Duration was preset at the factory for 25 minutes. Depending

on freezer usage and your defrost schedule, you may choose to customize

the Defrost Duration. The usual and recommended Defrost Duration

setting is 25 minutes.

Complete either the section titled To Change the Defrost Duration and

Bypass the Setting of the Time Clock or complete the section titled Setting

the Time Clock to the Current Time-of-Day before continuing.

With the PROGRAM and the DEFROST ON lights lit . . .

• Move all 24 switches to the left or OFF position.

• In the lower set of switches, move the one switch to the right that

corresponds to the desired Defrost Duration (nearest 5 minutes).

The example, Fig. 14, sets the Defrost Duration at 30 minutes.

Press and hold the SET button until the DEFROST ON light starts

blinking. Release the SET button and the SET CLOCK light flashes

rapidly indicating that the timer has returned to normal Operation Mode.

To verify that the clock and the defrost duration are set properly, perform

Program Review (page 10).

– 8 –

Fig. 14

Page 9

How to Set a Custom Defrost Schedule

Begin with the defrost timer on normal Operation Mode: The SET CLOCK light is blinking rapidly and

the PROGRAM and DEFROST ON lights are off. If all switches are OFF (Fig. 15), the factory preset

defrost schedule is enabled: 2

AM, 8 AM, 2 PM, 8 PM.

• Determine your own best defrost schedule. The upper set of switches represents the AM hours;

the lower switches represent the PM hours. Allow a minimum of 2 hours between the start of any

two defrost cycles.

• To customize your defrost schedule, begin with all switches OFF (Fig. 15).

• With the SET CLOCK light blinking rapidly, as in normal Operation Mode, slide the switches to the

right that correspond to the hour when each defrost cycle should begin.

• If you want a defrost cycle to begin on the half-hour, slide the two adjacent switches to the right.

For example, to start a defrost cycle at 2:30

PM, Slide switches 2 and 3 to the right in the lower set

of switches.

Custom Defrost Schedule Example #1 (Fig. 16) shows five defrost cycles that begin at 1

PM and 8 PM.

2:30

Custom Defrost Schedule Example #2 (Fig. 17) shows six defrost cycles that begin at 1

PM, 6 PM and 9:30 PM.

2:30

AM, 6 AM, 10 AM,

AM, 4 AM, 10 AM,

During normal operation, leave these switches set on the desired defrost schedule if it is other than the

factory preset schedule.

ALL S WITCHES OFF GIVES Y OU T HE

FACTORY P RESET D EFROST S CHEDULE:

2:00 AM, 8:00 AM, 2:00 PM, 8:00 PM

USTOM DEFROST SCHEDULE EXAMPLE #1:

C

1:00 AM, 6:00 AM, 10:00 AM, 2:30 PM,

8:00

PM

CUSTOM D EFROST S CHEDULE E XAMPLE #2:

1:00 AM, 4:00 AM, 10:00 AM, 2:30 PM,

6:00

PM, 9:30 PM

Fig. 15

Fig. 16

– 9 –

Fig. 17

Page 10

Program Review

During normal Operation Mode, with the SET CLOCK light blinking rapidly . . .

Current Clock Time = HH:MM

# Blinks = HH

# Blinks (times 5) = MM

# Blinks (times 5) =

DEFROST DURATION

Fig. 18

Press the SET button until the SET CLOCK, PROGRAM, and

DEFROST ON lights are lit; then release the SET button and all

three lights go off for two seconds. After that, all three lights begin

to blink. The number of blinks of a light corresponds to the

programmed value for that light. A three second pause follows the

last blink before the cycle repeats. The Review Mode's sequence

of blinking lights (Fig. 18) repeats ten times to give you plenty of

chances to count the number of blinks for each light. Review Mode

can be stopped at any time by pressing the SET button for 3

seconds; when the SET button is released, normal Operation

Mode returns with the SET CLOCK light blinking rapidly.

The SET CLOCK light blinks from 1 to 12 times to indicate the

TIME CLOCK HOUR. If the final blink for the hour count

remains on for two seconds, it indicates PM; if the final blink

for the hour count is a normal blink, it indicates AM.

While the SET CLOCK light is blinking the HOUR, the PROGRAM

light blinks from 0 to 11 times to indicate the TIME CLOCK

MINUTES to the nearest 5 minutes after the hour: 0 blinks =

0 minutes, 1 blink = 5 minutes, 2 blinks = 10 minutes, . . .

11 blinks = 55 minutes.

While the SET CLOCK light is blinking the HOUR and the

PROGRAM light is blinking the MINUTES, the DEFROST ON

light blinks from 0 to 11 times to indicate the DEFROST

DURATION setting to the nearest 5 minutes: 0 blinks = 0

minutes, 1 blink = 5 minutes, 2 blinks = 10 minutes, . . .

11 blinks = 55 minutes.

Initiating a Manual Defrost

During normal Operation Mode, with the SET CLOCK light blinking rapidly . . .

Cancelling a Defrost Cycle

After the ten blinking sequences are done or after Review Mode

has been stopped, normal Operation Mode returns with the

SET CLOCK light blinking rapidly.

Press the MANUAL DEFROST button for about 3 seconds until

the DEFROST ON light comes on. The Defrost Cycle is started

and continues for the amount of time programmed for DEFROST

DURATION (page 8).

While a Defrost Cycle is in progress, the DEFROST ON light is lit.

A Defrost Cycle that is in progress can be terminated by pressing

the MANUAL DEFROST button for 3 seconds. The DEFROST

ON light goes off.

The normal DEFROST SCHEDULE continues to operate as

programmed.

– 10 –

Page 11

If the Defrost Timer's Battery Loses Power

If the SET CLOCK, PROGRAM and DEFROST ON lights are all blinking, the backup power supply

(battery) to the Defrost Timer has weakened. Estimated battery life is 10 years. The timer can

continue to function normally after the battery has weakened if the timer is reprogrammed.

If a power outage occurs and is later restored after the battery has weakened, the following three

things happen:

• The defrost clock resumes as if it were 12:00 midnight.

• The position of the switches dictates the defrost schedule. If all switches are OFF, the factory

preset times of 2

AM, 8 AM, 2 PM and 8 PM will initiate deftost cycles 2, 8, 14 and 20 hours after

power was restored.

• The factory preset defrost duration of 25 minutes is re-invoked.

Because the clock resumed at 12:00 midnight, it must be reset to the current time-of-day to avoid

inconvenient defrost cycles. Refer to Setting the Time Clock to the Current Time-of-Day (page 8).

If the Defrost Duration was set at a value other than the factory preset 25 minutes, reset it. If power

is lost again, reset again. Refer to Setting the Defrost Duration (page 8).

If you are using a custom Defrost Schedule, the switches must be reset after resetting the time and

Defrost Duration. Any defrost start times that are set by the positions of the program switches will

override the factory preset defrost start times even if the battery is weakened.

If the battery has weakened and reprogramming the time-of-day, defrost duration and schedule after

a power interruption is too inconvenient, the Electronic Defrost Timer can be replaced.

In the event of a power surge or lightning, the SET CLOCK, PROGRAM and DEFROST ON lights will

all blink the same as for a weak battery but the battery may not have weakened. First, try to reprogram

the Defrost Timer. If the Defrost Timer fails to function normally, contact service.

MECHANICAL DEFROST TIMER (Fig. 19)

When equipped on Freezers or on Convertible Models with Freezer Chambers, when power is initially

applied to the cabinet, the exterior dial of the defrost time clock must be set to the correct time of day.

To access the defrost timer, remove the front

trim panel (Fig. 2) by lifting up and out. Open

TIME-OF-DAY POINTER

EXTERIOR DIAL (24 HOUR)

door on the defrost timer box. Turn the inside

knob counterclockwise until the exterior dial is

positioned so the correct time of day is at the

time of day pointer. Replace the front trim

panel when done.

TURN KNOB

COUNTERCLOCKWISE

DEFROST CYCLE PINS

The defrost timer (Fig. 19) is set at the factory

for four 26-minute defrost cycles per day (2

AM, 2 PM and 8 PM). Depending on local

8

AM,

conditions, it may be necessary to change the

frequency or duration of defrost cycles.

If the power supply is interrupted, the defrost

timer must be reset to the correct time of day.

END DEFROST

(26 MINUTES)

– 11 –

BEGIN DEFROST

PL-41397-1

Fig. 19

Page 12

MAINTENANCE

CLEANING

Cabinet

Clean the inside of the cabinet and the doors weekly with a warm water solution of mild household liquid

dishwashing detergent (such as Palmolive green or Ivory). Do not use anything containing grit,

abrasive materials, bleach or harsh chemicals. Be cautious with new or improved formulas; use only

after being well tested. Rinse thoroughly and dry with a clean soft cloth.

Gaskets

Door gaskets should be cleaned weekly using a warm water solution of mild household liquid

dishwashing detergent (such as Palmolive green or Ivory). Never allow gaskets to contact concentrated

cleaners or disinfectants. This can cause premature failure of the gasket material.

Condenser Coil

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING THE CONDENSING

UNIT.

Check the condenser coil weekly. This surface must be kept free of dirt and grease for proper system

operation. Remove the front trim panel and carefully vacuum or brush dirt and lint from the condenser

coil. Replace the trim panel.

Evaporator Coil, Drain Pan, Condensate Loop and Condensate Dish

When needed, flush these components with fresh water. This should be a part of any routine

maintenance program and can prolong the life of the equipment.

Light Bulb Replacement (when equipped)

Replace light bulb(s) with 40 watt incandescent appliance type bulb(s) ONLY. The protective cover

can easily be removed and replaced.

Florescent Light Bulb Replacement (when equipped)

Remove protective cover. Replace florescent tube with same size and type: 40 watt, 48" long.

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE

Unit fails to operate. Power failure.

Plug loose in receptacle.

Blown fuse or tripped circuit breaker.

If a freezer model is in a deftost cycle, wait 30 minutes and recheck.

Check the Temperature Control (page 5 or 6) to make sure it is not OFF.

If the suggestions above fail to remedy the situation, contact service.

WARRANTY

The Q series cabinet warranty is for two years. It includes parts, labor and travel during normal working

hours in the continental United States. The non-prorated compressor warranty is for an additional three

years and does not include labor.

For additional information or to discuss a maintenance program, contact your local authorized

refrigeration servicer.

FORM 14580 Rev. L (Jan. 2002) PRINTED IN U.S.A.

– 12 –

Loading...

Loading...