Page 1

PW10/PW20 PreP Washer

Lave-BaTTerIe PW10/PW20

LavavajILLas PW10 y PW20

MODEL

MODÈLE

MODELO

PW10 ML-130290

PW10ER ML-130291

PW20 ML-130292

PW20ER ML-130293

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

F-47575 (March 2016)

Page 2

© HOBART 2015

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL ....................................................................4

INSTALLATION ................................................................4

UNPACKING ..................................................................5

Unpacking From Pallet .......................................................6

Removing ER Section if Necessary ..............................................6

INSTALLATION CODES ........................................................10

LOCATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PLUMBING CONNECTIONS ....................................................15

Water Requirements ........................................................15

Water Supply Connection ....................................................15

Plumbing Connections .......................................................17

Drain ....................................................................17

Venting Requirements (PW10 / PW20) ..........................................17

Rate of Exhaust Flow Calculations .............................................17

Canopy Size and Location ....................................................18

Rate of Exhaust Flow Calculations .............................................18

Chemical Feeder Installations .................................................18

Detergent Feeder (Optional By Others) ..........................................19

Rinse Agent Feeder (Optional By Others) ........................................19

Delime Feeder (standard) on Advansys models only (PW10eR/ PW20eR) ..............19

Vent Exit (PW10 / PW20) .....................................................19

Vent Fan Control (Standard); Power Vent Fan (Optional) PW10/PW20 .................19

ELECTRICAL CONNECTION(S) ..................................................19

Rotation of Pump Motor(s) ....................................................20

EQUIPMENT CONNECTIONS ...................................................21

Vent Fan Control ...........................................................21

Detergent Feeder ...........................................................21

Rinse Aid Feeder ...........................................................21

OPERATION .................................................................22

CONTROLS ..................................................................22

Operating the PW Prep Washer ...............................................22

PROGRAMMING ..............................................................23

Manager Mode Programing ...................................................23

Programming Instructions ....................................................26

Menu Display Prompts .......................................................26

General Operating Instructions ................................................27

CLEANING ..................................................................27

For Models PW10eR and PW20eR .............................................30

MAINTENANCE ..............................................................32

WASH AND RINSE ARMS ...................................................32

DELIMING ................................................................32

TROUBLESHOOTING .........................................................34

– 3 –

Page 4

Installation, Operation and Care Of

Model PW10/PW20 Prep Washer

SAVE THESE INSTRUCTIONS

GENERAL

The PW10 and PW20 Prep Washer is the answer to volume utensil washing

problems in your kitchen, bakery or supermarket operation. The PW10/20 occupies

a minimum amount of oor space (under 48" x 43" with door open) and does not

require separate dish tables. The upper portion of the door raises, while the lower

portion swings out to provide a drain platform. The rack can then be pulled out for

easy loading and unloading.

The key pad lets you select a 2-, 4- or 6-minute cycle; each wash cycle is followed

by a dwell. After the dwell is a 10 (PW10, PW10eR, PW20) or 12 (PW20eR) second

rinse. Advansys models include a 1½ to 2½ minute condensing time following the

rinse cycle. The upper and lower wash arms provide thorough cleaning. Upper and

lower rinse arms provide a sanitizing rinse at the end of each cycle.

The PW10/20 is only available with electric tank heat and electric booster is standard.

A spray hose and nozzle is provided on the side of the machine.

UNPACKING

Features include: sloping strainer system, pumped drain, automatic ll, and rack

with inserts for trays. The at rack can accommodate a 140-quart Hobart mixer bowl.

INSTALLATION

Immediately after unpacking the PW10/PW20, check for possible shipping damage.

If the machine is found to be damaged, save the packaging material and contact

the carrier within 5 business days after delivery.

Prior to installation, test the electrical service to ensure that it agrees with the

specications on the data plate located on the bottom right of the upper door.

– 4 –

Page 5

Unpacking From Pallet

Carefully unpack the machine from the pallet.

1. Remove the shipping brackets from the machine/pallet.

Fig. 1

2. Remove the bottom pallet boards. This can be done using a pallet jack.

Proper care and personal equipment should be used when when handling

wood with exposed nails.

Fig. 2 Fig. 3

3. Screw out the feet.

4. With machine resting on the feet, slide pallet out from underneath the machine.

NOTE: On the PW20 machine the pallet sides might need to be removed to

make this easier.

– 5 –

Page 6

Removing ER Section if Necessary

Disconnect the electrical power to the machine and follow

lockout / tagout procedures. There may be multiple circuits. Be sure all circuits

are disconnected.

NOTE: One ER unit is shown in the following steps. If removing both from

PW20 Advansys, repeat steps 2 through 10 for each side.

1. Disconnect incoming water hose at supply connection.

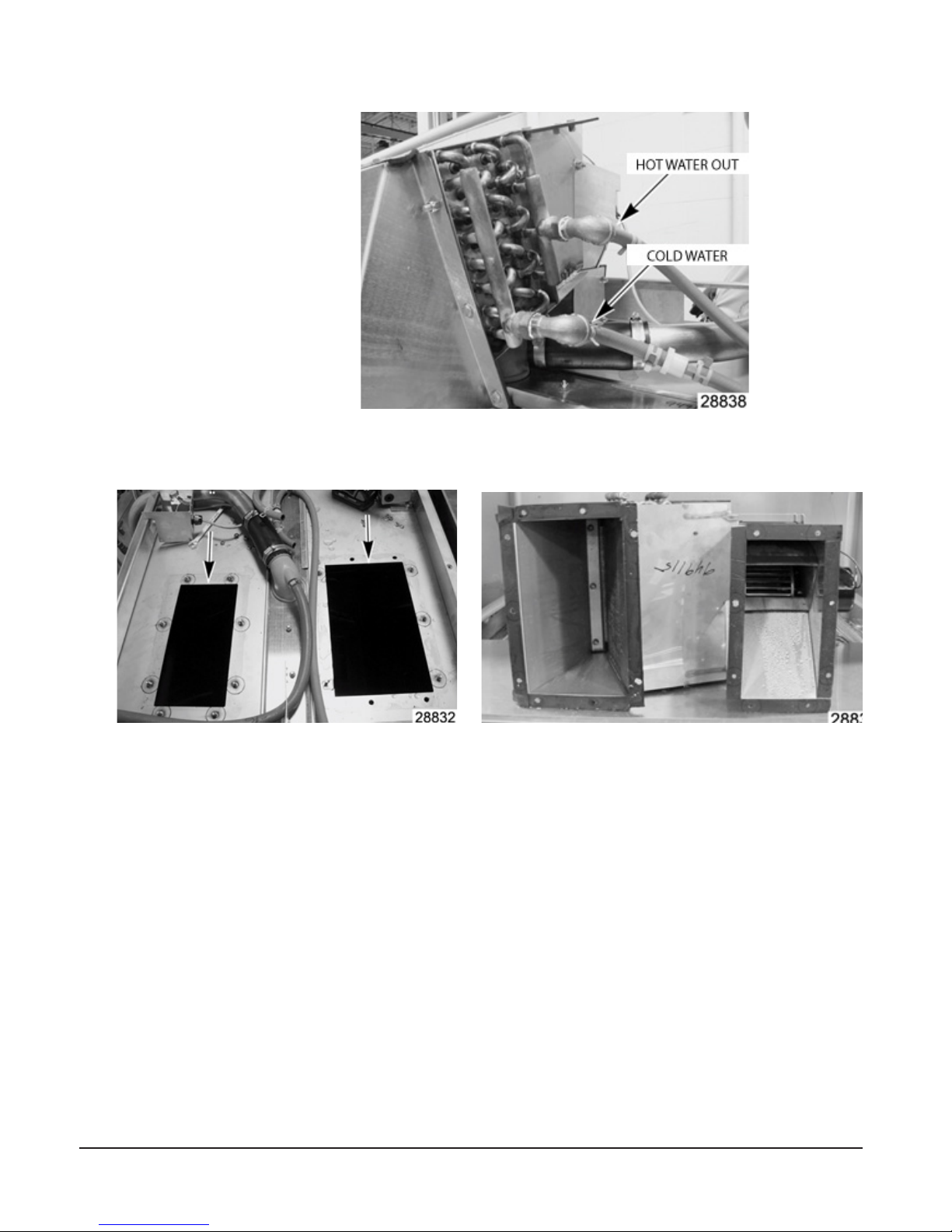

Fig. 4

NOTE: Drain out any excess water in hose.

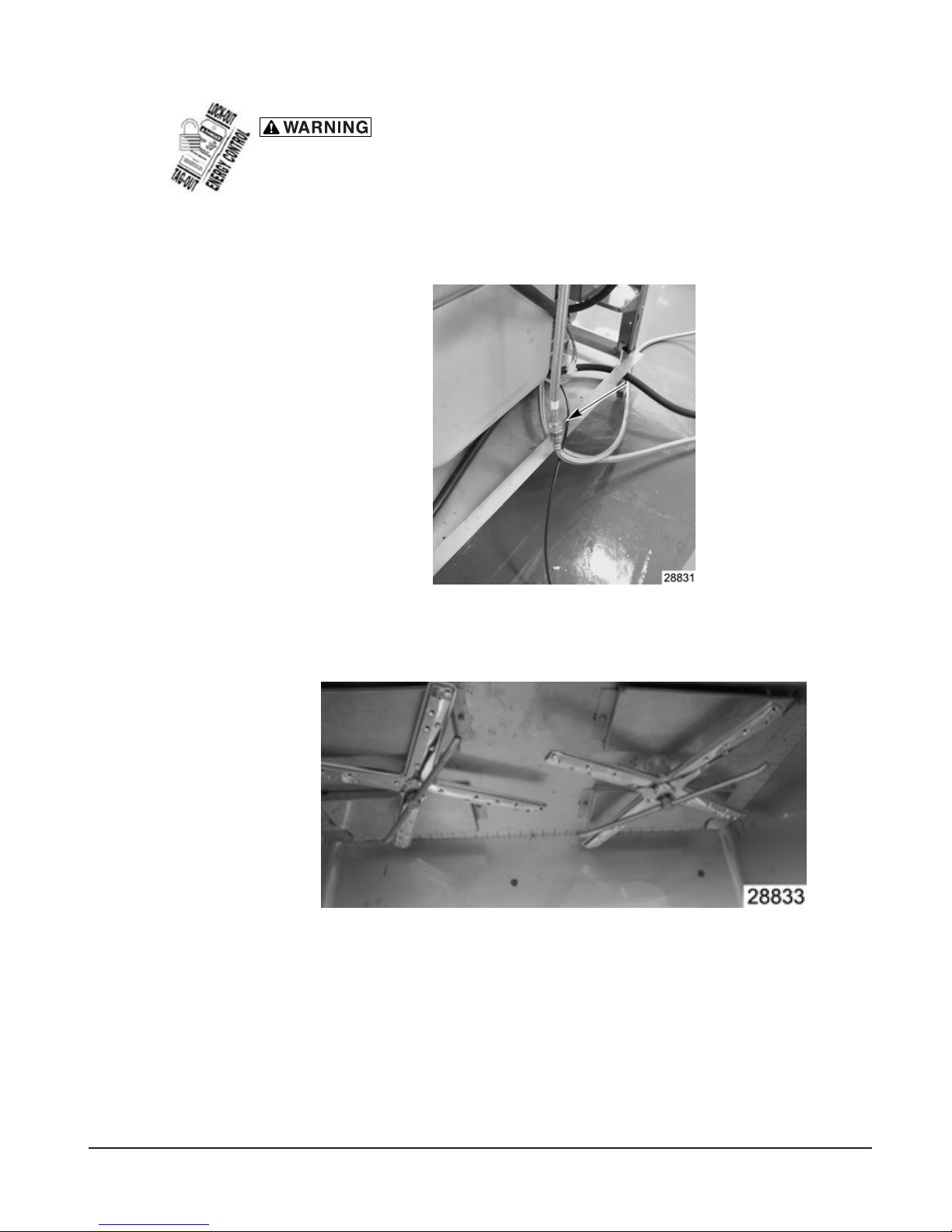

2. Remove upper wash and rinse arms.

Fig. 5

3. Remove bafes. (located under wash and rinse arms).

a. Remove bolt (1).

b. Side bafe to side to free from holding bracket (2) from opposite side of bafe.

c. Remove (Qty 4) nuts (3) that are holding ER assembly from inside wash area.

– 6 –

Page 7

2. Remove shroud.

3. Remove door lock assembly cover.

Fig. 6

Fig. 7

Fig. 8

– 7 –

Page 8

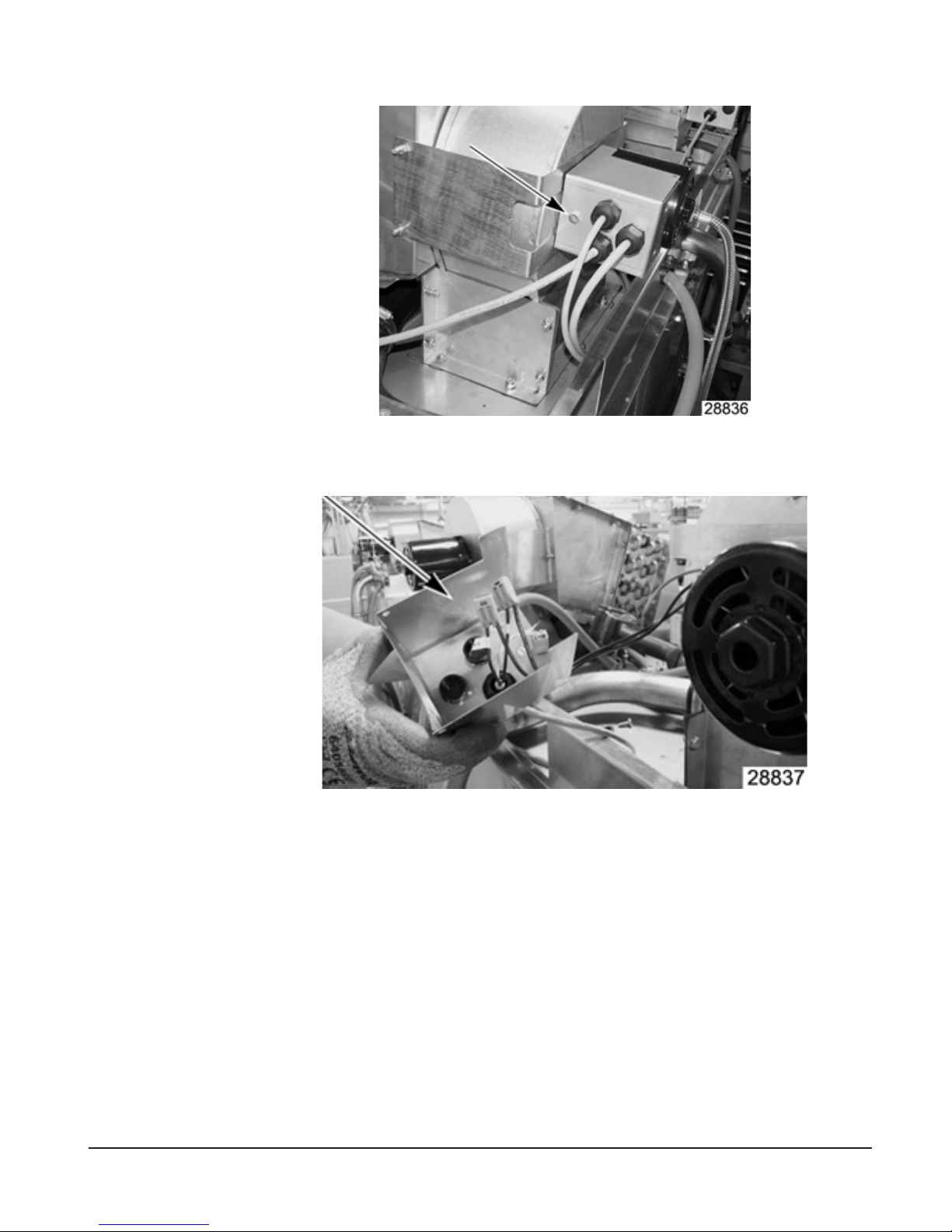

4. Remove motor junction box cover.

Fig. 9

5. Label motor wires for reconnecting later.

6. Disconnect motor wires.

Fig. 10

– 8 –

Page 9

7. Disconnect water hoses connected at ER assembly.

Fig. 11

8. Remove (Qty 13) mounting nuts around ER assembly.

Fig. 12 Fig. 13

– 9 –

Page 10

9. Lift ER assembly off of machine.

10. Reverse procedure to install.

NOTE: If ER units were removed to get thru a door opening, when re-installing,

remove, clean surface, and install new foam tape to the housing to ensure a

proper seal.

INSTALLATION CODES

Installation must be in accordance with state and local codes, and the National

Electrical Code ANSI/NFPA70 (latest edition). In Canada, the installation code is

CSA 22.1 (latest edition).

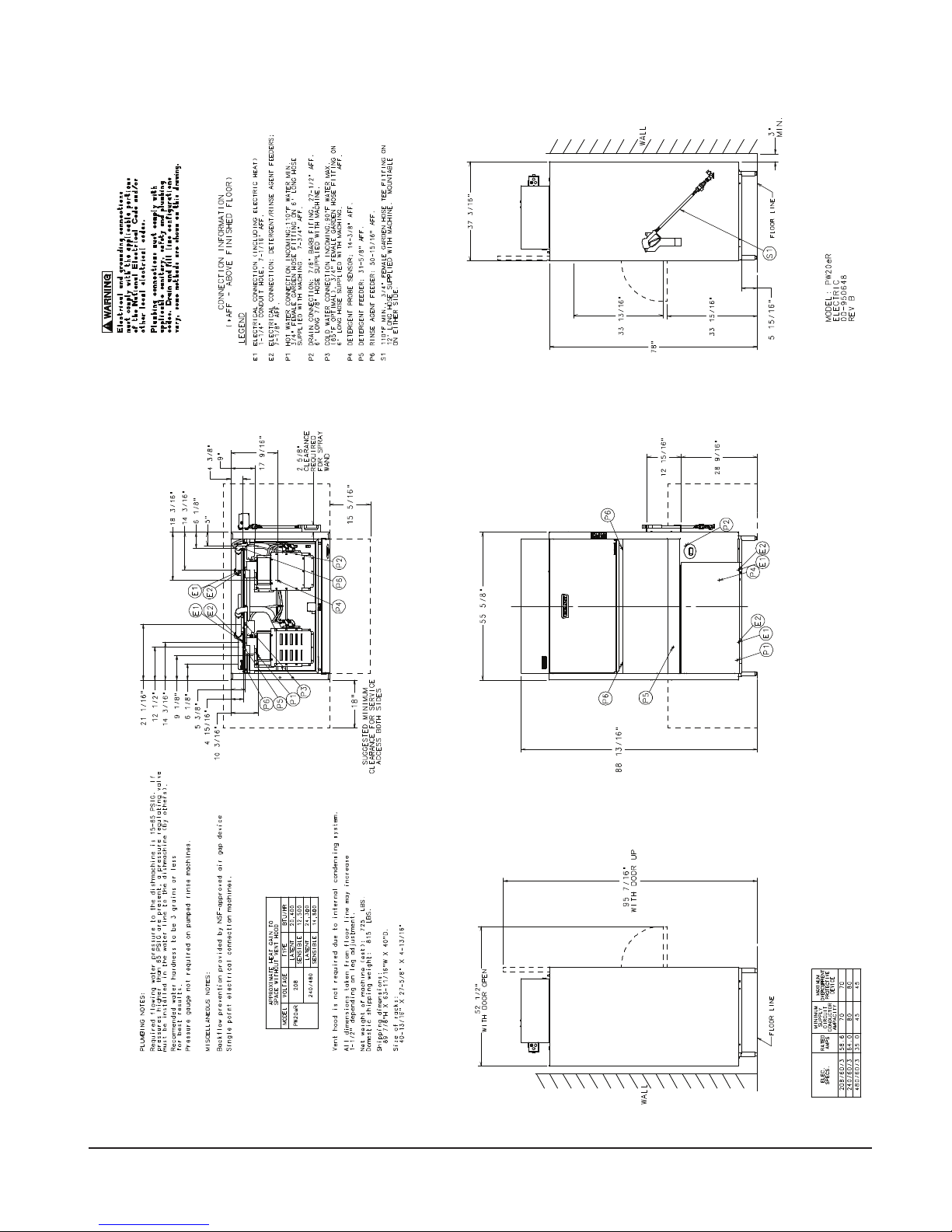

LOCATION

Set the machine in place after the nal oor covering is installed. Make sure the

machine is level before making any plumbing connections. Allow at least 3" at the

rear and 18" at the sides of the machine for service access. Allow 16" in front of the

machine for the door to lower and sufcient additional space for the operator to work.

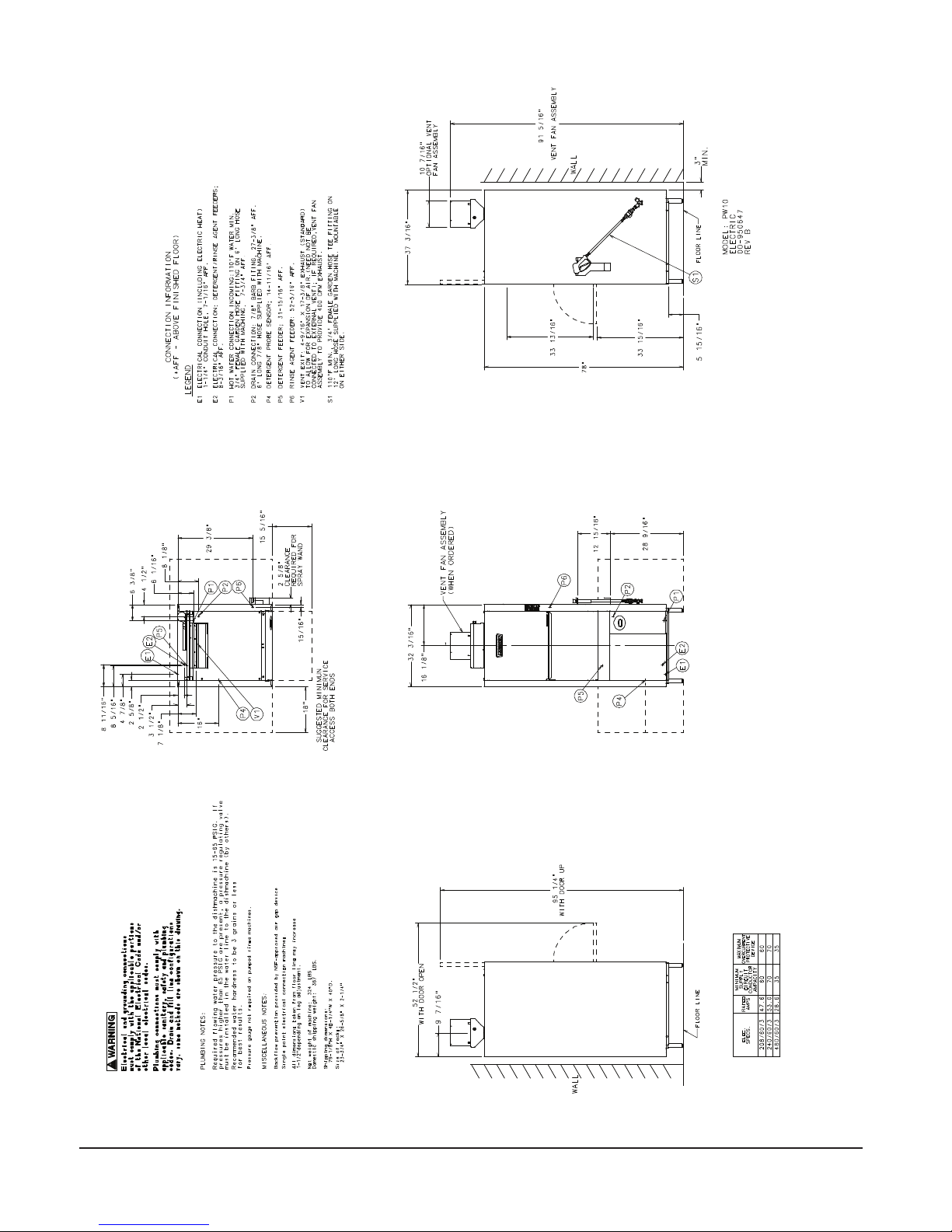

Fig. 14

– 10 –

Page 11

OPTIONAL

PW10

– 11 –

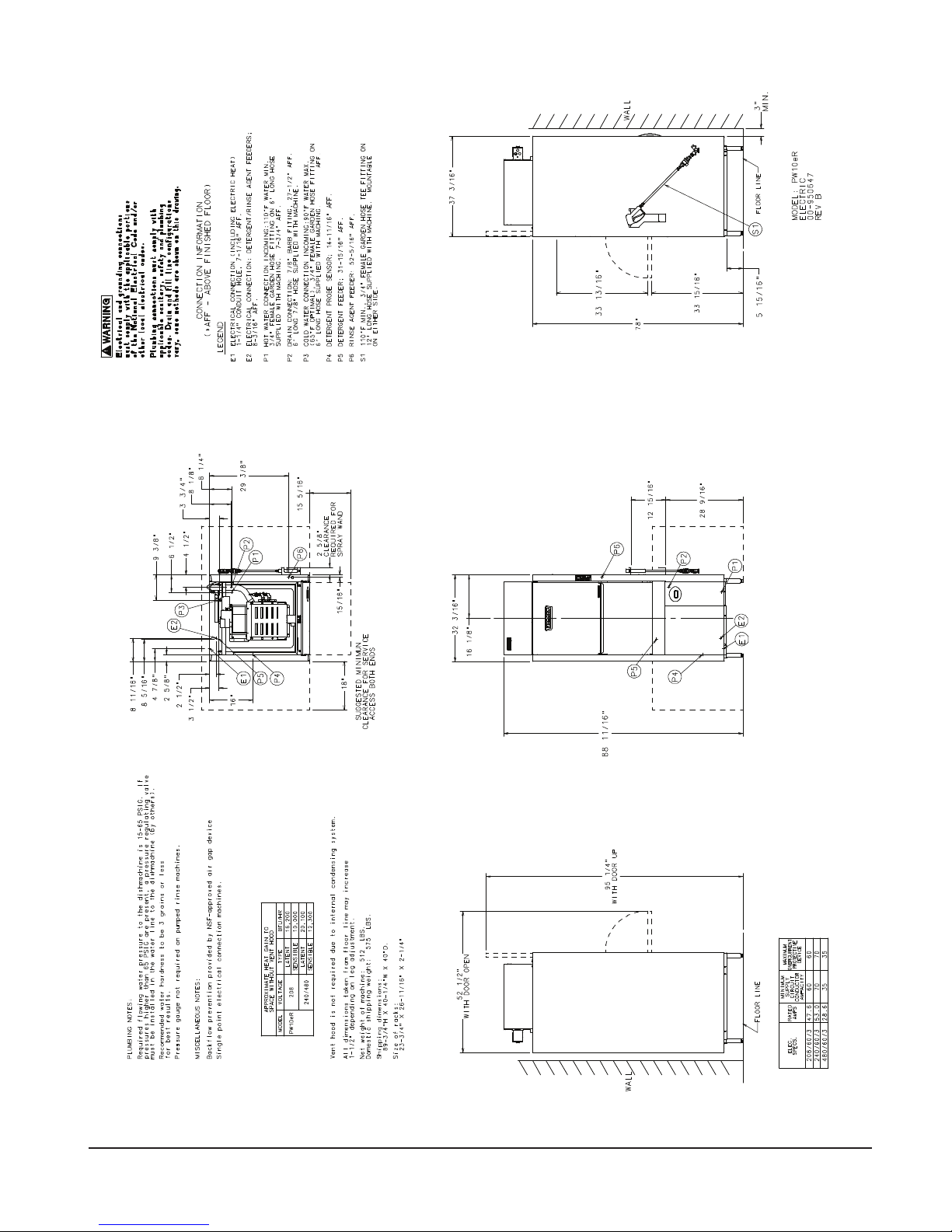

Page 12

76-7/16”

PW10eR

– 12 –

Page 13

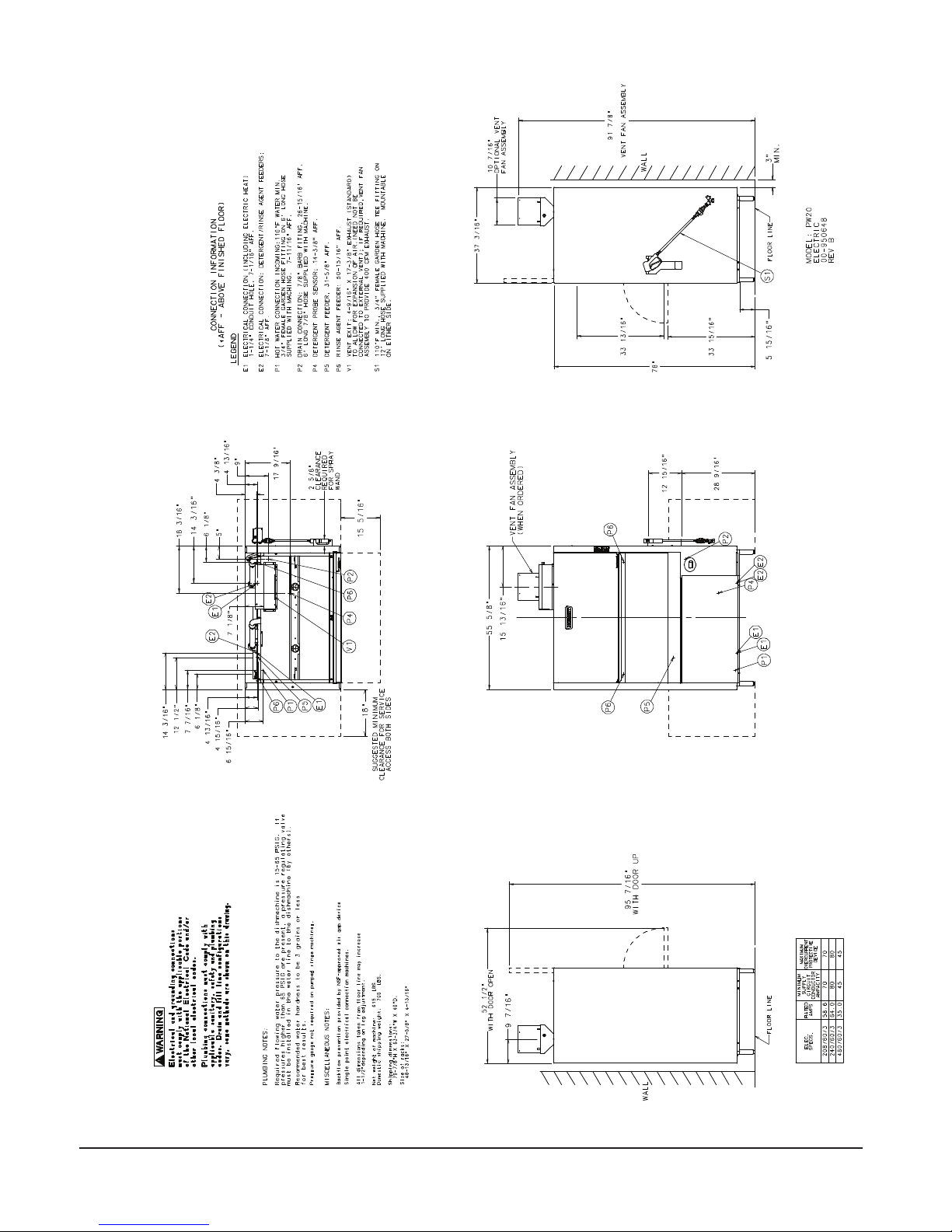

OPTIONAL

PW20

– 13 –

Page 14

76-5/8”

PW20eR

– 14 –

Page 15

PLUMBING CONNECTION(S)

applicable portions of the National Electrical Code (NFPA No. 70, CSA 22.1

latest edition) and/or other local electrical codes.

Water Requirements

Proper water quality can improve ware washing performance by reducing spotting,

enhancing effectiveness of labor and extending equipment life. Water conditions

vary from one location to another. The recommended proper water treatment for

effective and efcient use of this equipment will also vary depending on the local

water conditions. Ask your municipal water supplier for details about your local water

conditions prior to installation.

Recommended water hardness is 3 grains of hardness per gallon or less. Higher

hardness may cause excessive formation of lime scale. Water hardness above 3

grains per gallon requires water treatment. Water treatment has been shown to

reduce costs associated with machine cleaning, reduce deliming of the dishwasher,

and reduce detergent usage in the dishwasher. Chlorides must not exceed 50 ppm.

require an iron lter. High chloride levels in the water supply can cause

pitting and may require a chloride removal system. Contact your local water

treatment professional for proper water treatment.

Electrical and grounding connections must comply with

High iron levels in the water supply can cause staining and may

Sediment may require a particulate lter. Dissolved solids may require water treatment

such as a water softener, reverse osmosis system, etc. Contact your local water

treatment professional for proper water treatment.

If an inspection of the dishwasher or booster heater reveals lime buildup after the

equipment has been in service, water treatment is recommended. If a water softener

is already in place, ensure there is a sufcient level of salt. Contact your local Hobart

Service ofce for specic recommendations.

Water Supply Connection

The water supply line should be a ¾” male garden hose (supplied by others).

The plumber connecting this machine is responsible for making certain that water

lines are THOROUGHLY FLUSHED OUT BEFORE connecting to the dishwasher.

This "ush-out" is necessary to remove all foreign matter, such as chips (resulting

from cutting or threading of pipes) pipe joint compound from the lines; or, if soldered

ttings are used, bits of solder or cuttings from the tubing. Debris, if not removed,

may lodge in the dishwasher's plumbing components and render them inoperative.

Manual valves or solenoid valves fouled by foreign matter and any expenses resulting

from this fouling are NOT the responsibility of the manufacturer and associated

repair costs are not covered under warranty.

– 15 –

Page 16

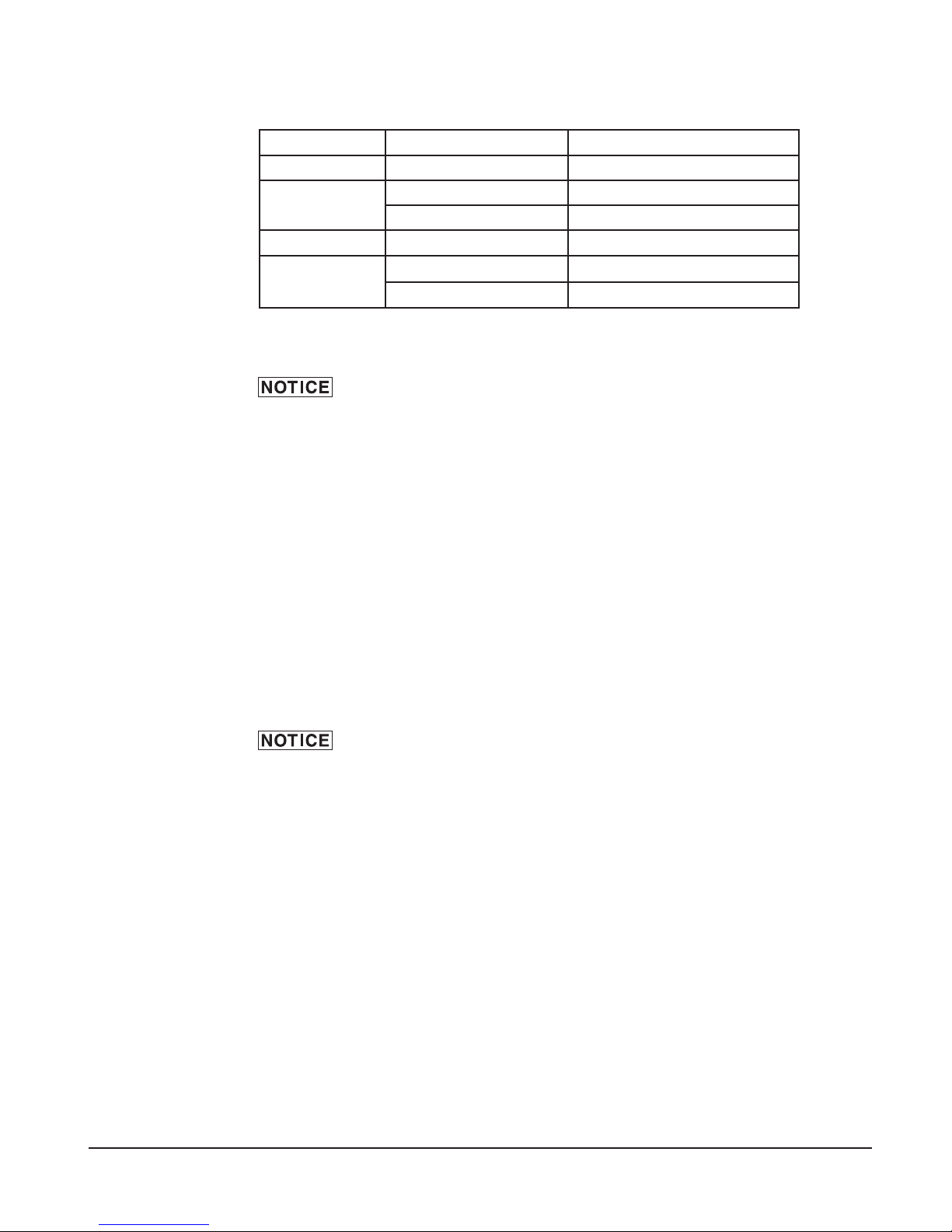

Water supply requirements are as follows:

WATER SUPPLY REQUIREMENTS

Model Supply Temperature

PW10 Hot Water 110°F Minimum

PW10eR Cold Water 55°F Minimum, 80°F Maximum

Hot Water 110°F Minimum

PW20 Hot Water 110°F Minimum

PW20eR Cold Water 55°F Minimum, 80°F Maximum

Hot Water 110°F Minimum

PW10eR and PW20eR models require both a cold water supply connection and a

hot water supply connection.

On PW10eR and PW20eR installations, the cold water supply must

not exceed 80°F (27°C) for proper operation. Optimal results are obtained

when cold water supply temperature is below 65°F (18°C). For best results,

it may be necessary to use ½” pipe for cold water pipe size and minimize

the distance between the dishwasher and the entrance into the building.

Pipe insulation will also improve results.

If cold water supply temperature is consistently above 80°F (27°C) or if excessive

water vapor or steam is entering the room after the condensing cycle is complete,

contact Hobart Service to increase condensing time.

Required owing water pressure to the dishmachine is 15-65 PSIG. If pressures

higher than 65 PSIG are present, a pressure regulating valve must be installed in

the water line to the dishmachine (by others). If owing pressure is less than 15

psi, improper machine operation may result. All PW models are equipped with a

pumped rinse system; therefore, a water pressure gauge is not required and is not

supplied with the machine.

The water pressure regulator must have a relief bypass. Failure to

use the proper type of pressure regulator may result in damage to the unit.

A manual shutoff valve (not supplied) should be installed upstream of the ll hose

to accommodate servicing the machine.

It is recommended that a line strainer (not supplied) be installed in the supply line

between the manual shutoff valve (not supplied) and the connection point on the

machine. Make plumbing connections with ½” minimum copper piping OD (¾”

recommended), with a ¾” male garden hose tting (not supplied). See installation

diagrams, pages 11-14.

– 16 –

Page 17

Plumbing Connections

Plumbing connections must comply with applicable sanitary,

safety, and plumbing codes.

Drain

A drain hose, 7⁄8" inside diameter and 6' long, is provided. This should be securely

plumbed into a drain. Use care not to kink hose. See installation diagrams, pages

11-14. Drain must have a minimum ow capacity of 18 gallons per minute for PW10/

PW10eR and 26 gallons per minute for PW20/PW20eR.

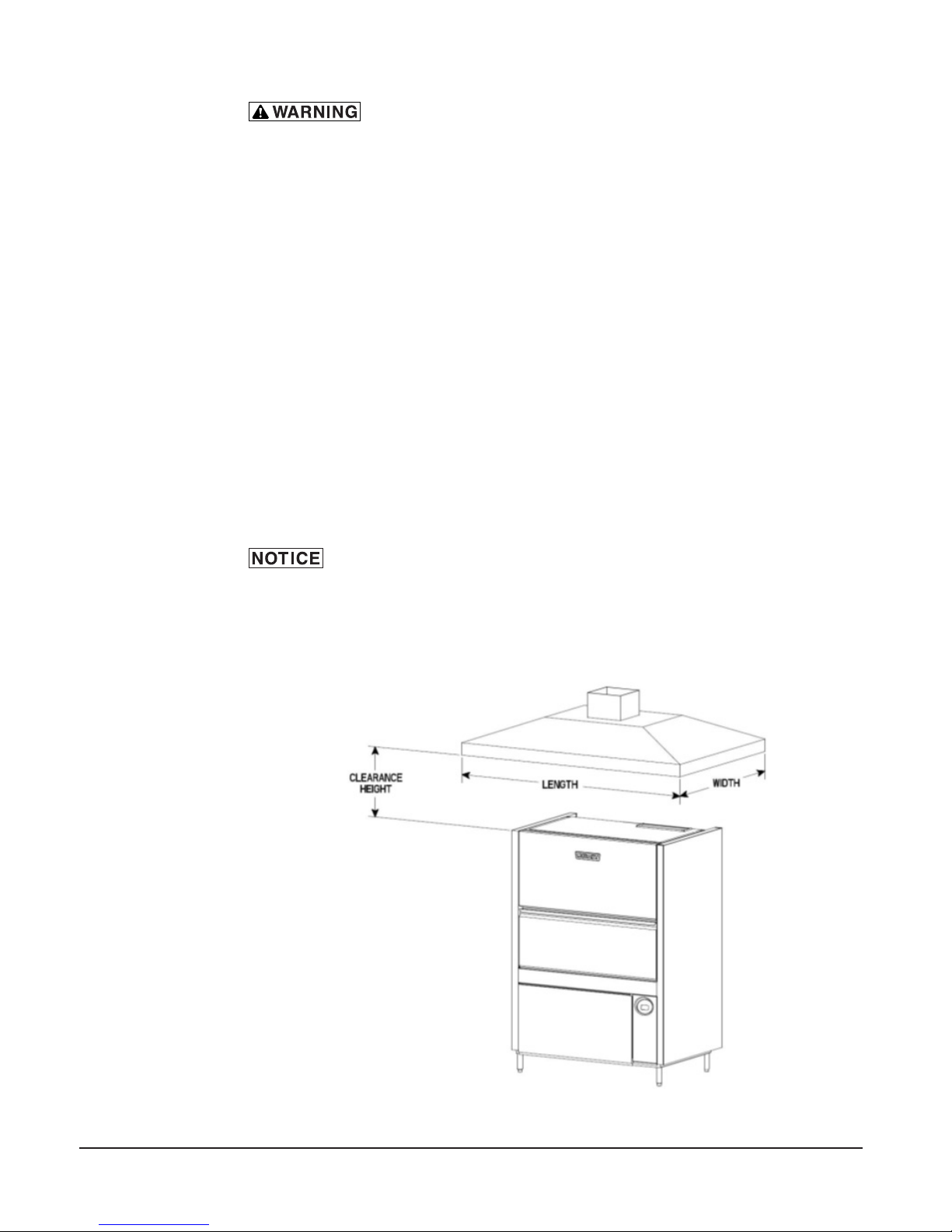

Venting Requirements (PW10 / PW20)

Type I or type II canopy hoods are recommended. Hoods must be installed according

to the manufacturer's instructions. Make-up air must be provided so that the exhaust

ow rate results in a negative building pressure in the room where the unit is located

(more exhaust air than outside air). Factory-built hoods not tested to UL standard

710 and custom-built hoods must comply with the following specications: Stainless

steel should have a minimum thickness of 0.037 in. (0.94 mm) [No. 20 Gauge] or

copper sheet weighing at least 24 ounces per square foot (7 Kg/m2); the hood

must be secured in place by noncombustible supports and must meet the RATE of

EXHAUST FLOW CALCULATIONS.

Make sure the installation meets the local code for your area.

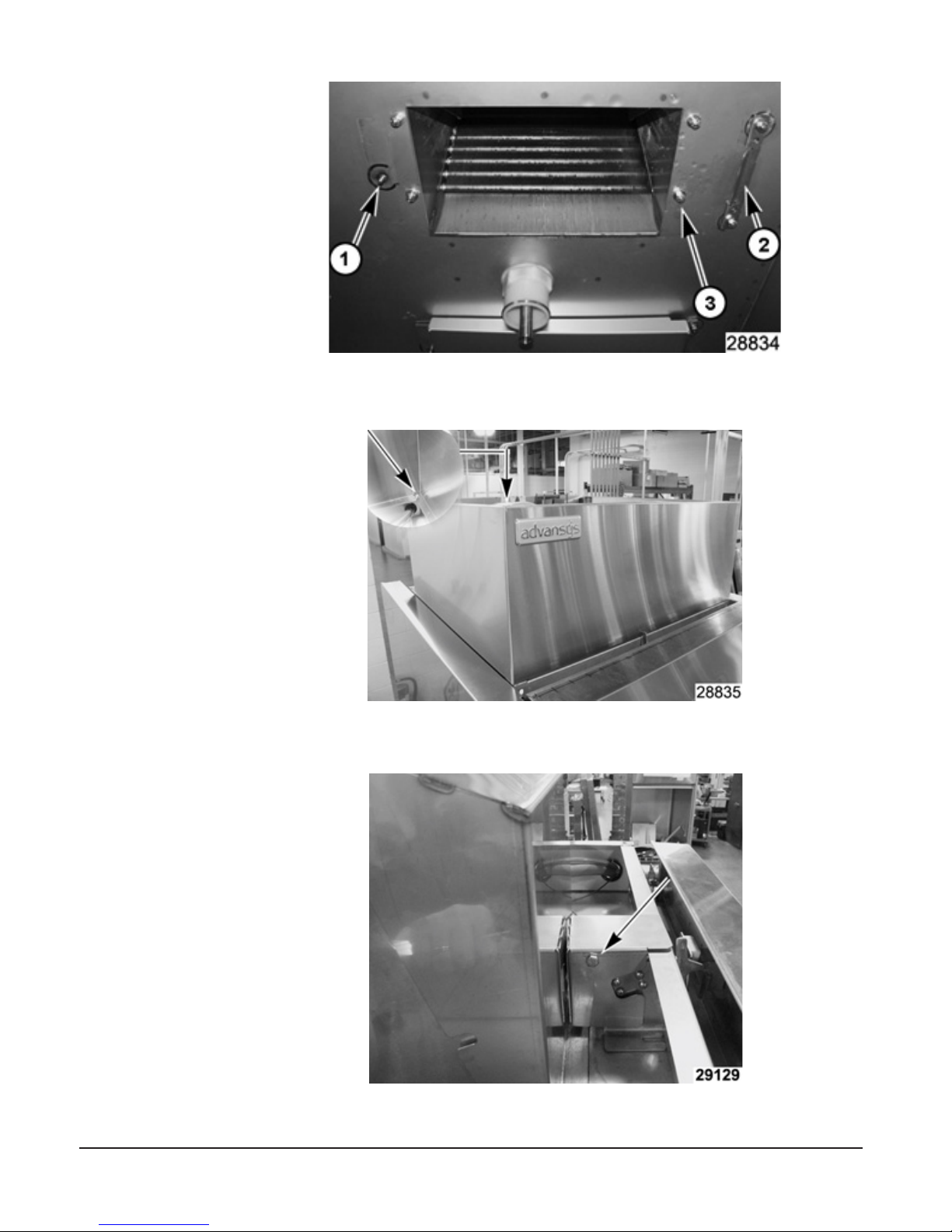

Rate of Exhaust Flow Calculations (FIG. 14)

Based on the 2015 International Mechanical Code.

Fig. 15

– 17 –

Page 18

Canopy Size and Location

The inside lower edge of canopy-type type I and II commercial hoods shall overhang

or extend a horizontal distance of not less than 6 inches (152 mm) beyond the edge

of the top horizontal surface of the appliance on all open sides. The vertical distance

between the front lower lip of the hood and such surface shall not exceed 4 feet

(1219 mm) with a minimum of 1 foot (305 mm).

18” min overhang of the front opening.

The RATE of air ow required for a vent hood is a minimum of 100 CFM per linear

foot of hood length.

Rate of Exhaust Flow Calculations

Based on the 2015 International Mechanical Code.

The minimum net airow for Type II hoods used for dishwashing appliances shall

be 100 cfm per linear foot of hood length. The net quantity of exhaust air shall be

calculated by subtracting any airow supplied directly to a hood cavity form the total

exhaust ow rate of a hood.

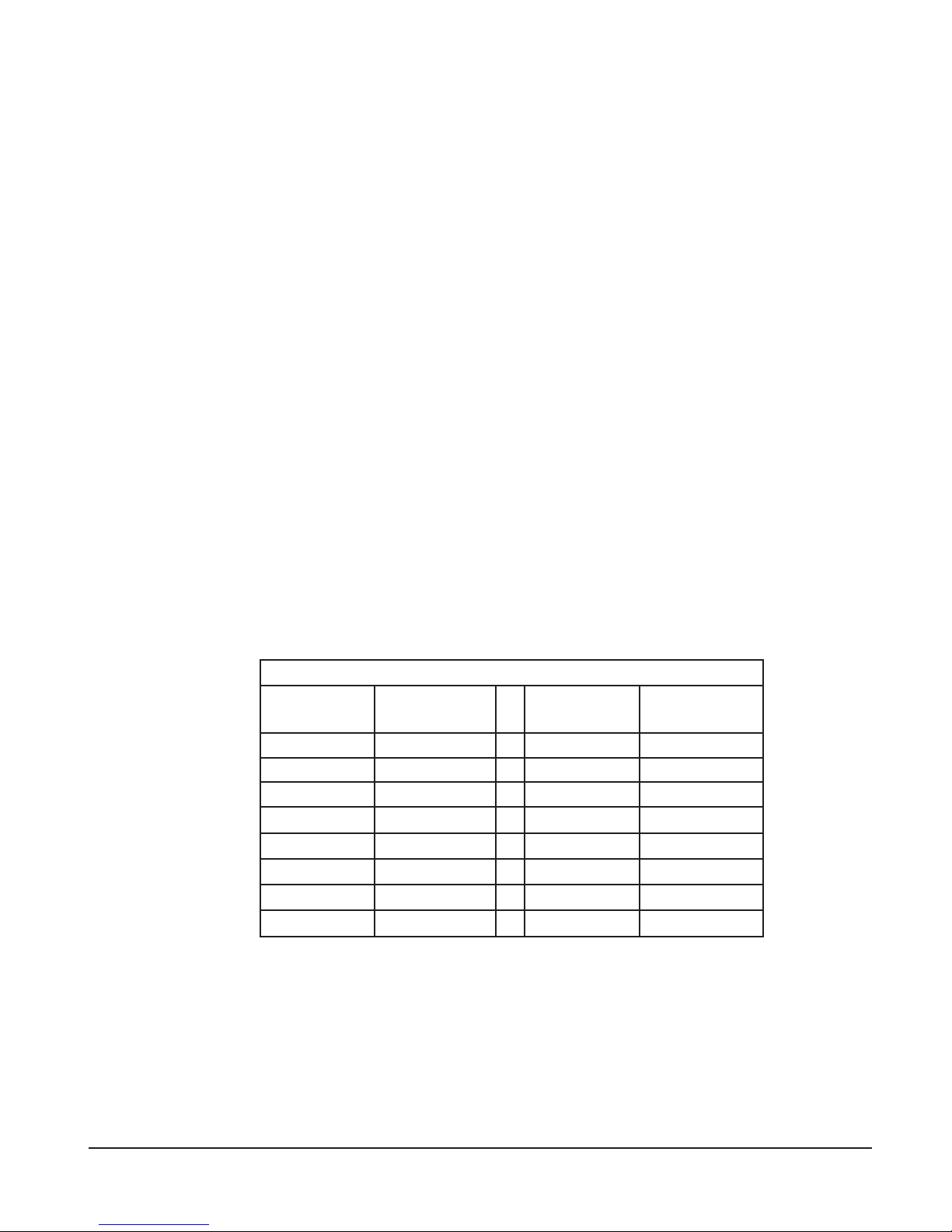

Models PW10eR and PW20eR do not require a Type II vent hood. According to

507.3 of the 2015 IMC, Type II hoods are not required where the heat and moisture

loads is incorporated in the HVAC system design. See Table A for heat dissipation

or heat gain to space.

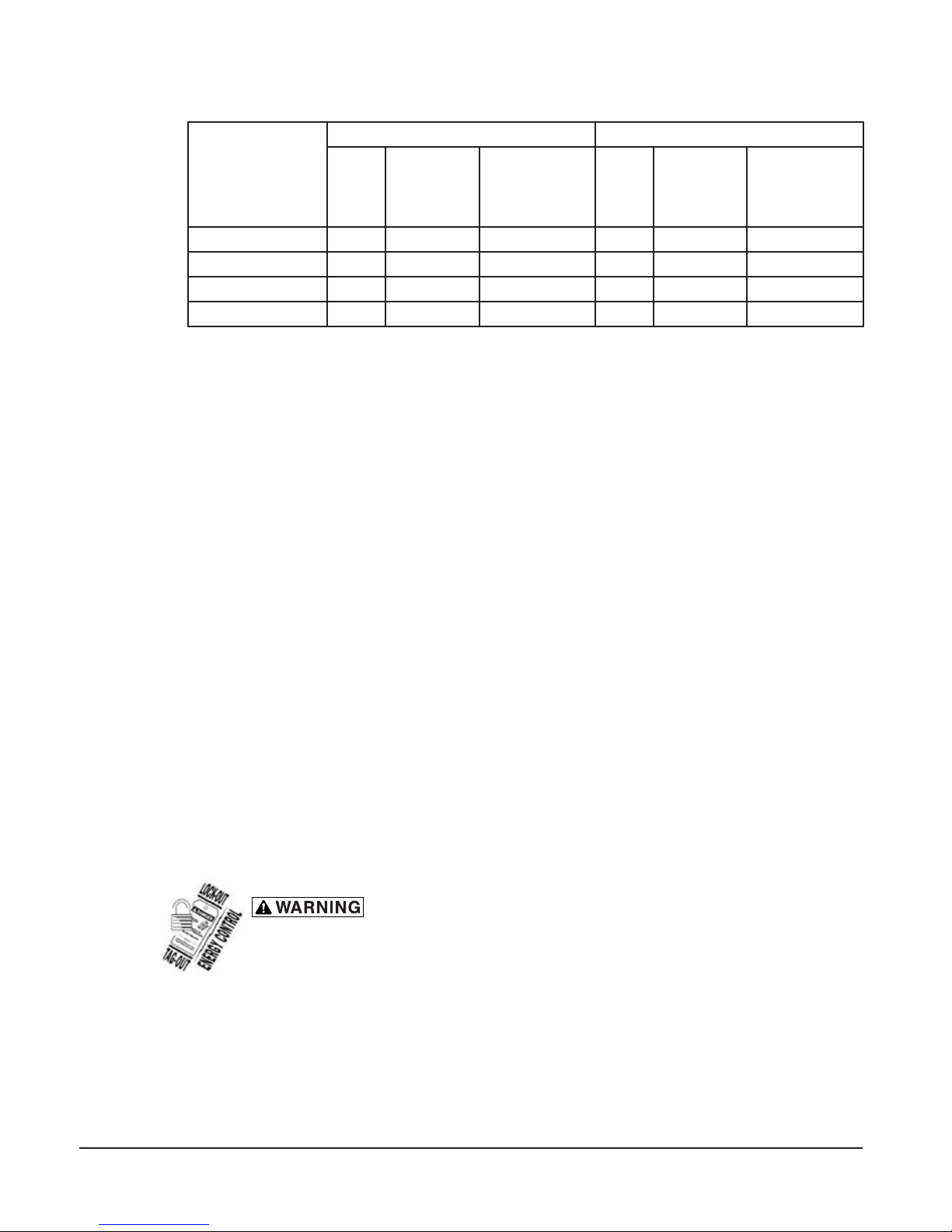

Model Voltage

PW10 208V 13,600 6,000

PW10 240V / 480V 16,800 7,300

PW10eR 208V 16,200 10,000

PW10eR 240V / 480V 20,100 12,300

PW20 208V 17,100 7,500

PW20 240V / 480V 20,400 8,900

PW20eR 208V 20,400 12,500

PW20eR 240V / 480V 24,300 14,800

Chemical Feeder Installations

This machine must be operated with an automatic detergent feeder, including a

visual means to verify that detergents are delivered or a visual or audible alarm to

signal if detergents are not available for delivery to the washing system. Chemical

feeders are supplied by others. For electrical connection, refer to Equipment

Connections, page 21.

Table A

HEAT DISSIPATION

Latent Heat

(BTU/HR)

Sensible Heat

(BTU/HR)

– 18 –

Page 19

Detergent Feeder (Optional By Others)

If installing a detergent feeder (by others), remove cap to expose 7/8” diameter

hole at rear of machine.

Rinse Agent Feeder (Optional By Others)

If a rinse agent feeder (by others) is being installed, remove the 1/8" NPT pipe

plug(s) to access the tapped hole in the rinse tee on the right side of the machine

(PW10/PW10eR) and on the back of the machine (PW20/PW20eR). There are 2

rinse tees for the PW20/PR20eR machines.

Delime Feeder (standard) on Advansys models only (PW10eR/ PW20eR)

A delime feeder with tubing and standpipe is provided to automatically dispense

delime agent when needed.

Vent Exit (PW10 / PW20)

A vent exit (4-9/16 " x 17-3/8") is provided in the top of the machine to allow for

expansion of air. It must not be directly connected to an external vent.

Vent Fan Control (Standard); Power Vent Fan (Optional) PW10/PW20

The Vent Fan Control provides switching for a vent fan (by others). The vent hood

comes on when the PW10/20 is on and goes off when the PW10/20 is off. The

Power Vent Fan option exhausts moist air from the chamber after the rinse cycle is

nished. The Power Vent fan may be selected to operate for 40, 60 or 80 seconds.

The Power Vent Fan kit (eld installed only) extends upward 12 ¼” above the vent

exit (13 5/16” above the top of the wash chamber) and terminates in a round duct

connection for a 101/4" O.D. duct.

Install power vent fan kit using a maximum 60 ft of 10” diameter straight duct; or, 50

ft straight and two (2) 90°elbows, or equivalent. Distances greater than the stated

maximum lengths may reduce venting efciency.

ELECTRICAL CONNECTION(S)

applicable portions of the National Electrical Code (NFPA No. 70, latest edition)

and/or other local electrical codes.

lockout / tagout procedures. There may be multiple circuits. Be sure all circuits

are disconnected.

Electrical and grounding connections must comply with

Disconnect the electrical power to the machine and follow

– 19 –

Page 20

Connect incoming power to the control box in accordance with the wiring diagram

located on the back of the front trim panel.

Volts/Hz/ph Rated Amps Circuit Size* Amps

208/240/60/3 47.6 / 53.0 60 / 70

480/60/3 28.6 35

Volts/Hz/ph Rated Amps Circuit Size* Amps

208/240/60/3 58.6 / 64.0 70 / 80

480/60/3 35.0 45

* Minimum Circuit Size / Maximum Protective Device (Amps) compiled in accordance

with the National Electrical Code (NFPA 70), latest edition.

** For supply connection, use wires suitable for at least 90°F or equivalent

Rotation of Pump Motor(s)

ELECTRICAL DATA

PW10 / PW10eR (Single Point Connection)

PW20 / PW20eR (Single Point Connection)

Before using the machine, check the pump motor rotation to be sure it is rotating

in the right direction.

PW10 / PW10eR

From the front of the machine, the motor should rotate clockwise. Looking from the

rear of the machine, the correct rotation is counterclockwise. Inspection is easiest

from the rear of the machine using a ashlight and mirror to check the motor fan in

the rear. Be aware that the mirror will reverse the perceived direction.

PW10 (Rear View)

Fig. 16

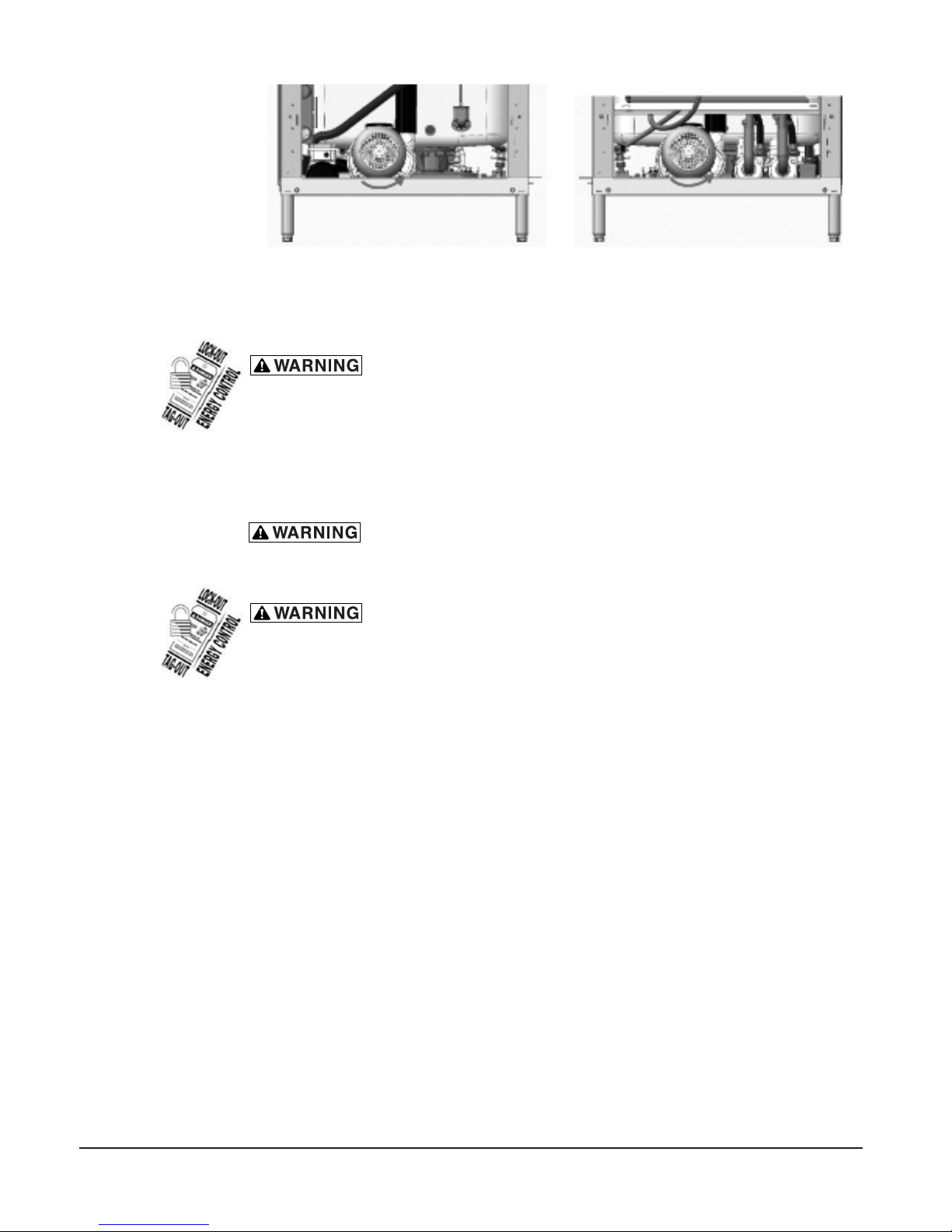

PW20 / PW20eR

Pump motor 1 – Looking from the right side of the machine, the correct rotation

is counterclockwise. Inspection is easiest from the right side using a ashlight to

check the motor fan on the rear of the motor.

Pump motor 2 – Looking from the left side of the machine, the correct rotation is

counterclockwise. Inspection is easiest from the left side using a ashlight to check

the motor fan on the rear of the motor.

– 20 –

Page 21

If the pump motor(s) is/are rotating in the wrong direction, follow this procedure.

lockout / tagout procedures. There may be multiple circuits. Be sure all circuits

are disconnected.

Reverse any two of the three incoming line wires (not the ground wire). Reconnect

and recheck rotation of pump motor.

EQUIPMENT CONNECTIONS

applicable portions of the National Electrical Code (NFPA No. 70, latest edition)

and/or other local electrical codes.

lockout / tagout procedures. There may be multiple circuits. Be sure all circuits

are disconnected.

Vent Fan Control

PW20 (right view) PW20 (left view)

Fig. 17

Disconnect the electrical power to the machine and follow

Electrical and grounding connections must comply with

Disconnect the electrical power to the machine and follow

The vent fan control feature is standard on PW10 and PW20 models. This feature is

not available on PW10eR and PW20eR models. The vent fan control relay provides

switch contacts only and does not provide power to the vent fan motor. The rating

for a vent fan control relay connected to terminals VFC1 and VFC2 is 1.5 amps at

supply voltage. When the prepwasher is connected to the vent fan, the vent fan is

switched on when the prepwasher is on, and off when the prepwasher is off.

Detergent Feeder

The maximum rating for a detergent dispenser connected to DPS1 and DPS2 is 1.5

amps at line voltage. Refer to Chemical Feeder Installations, page 18.

Rinse Aid Feeder

The maximum rating for a rinse aid dispenser connected to RPS1 and RPS2 is 1.5

amps at line voltage. Refer to Chemical Feeder Installations, page 18.

– 21 –

Page 22

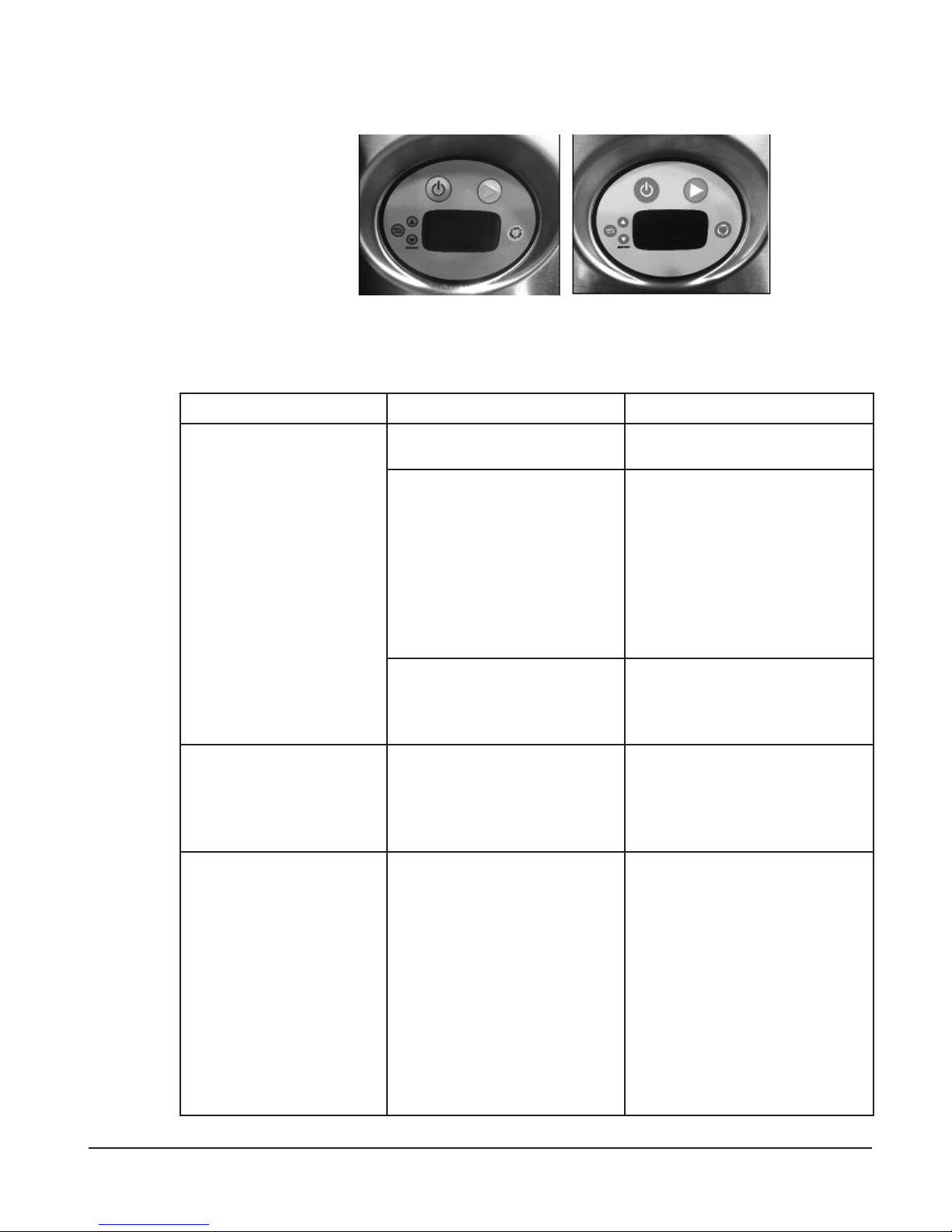

CONTROLS

OPERATION

Fig. 18

Operating the PW Prep Washer

DO THIS DISPLAY SHOWS REMARKS

Press ON Model number Dishwasher performs self-

check. This takes 5 seconds.

Open door; slide rack

out to load ware. When

loading is complete, slide

rack into dishwasher.

Close door.

Press WASH (Green

Arrow).

FILL and ll icon lit; sump

temperature displayed when

machine is lling.

WARMING UP and warming

up icon are displayed when

booster is preheating on

models. This preheat could

take up to 25 minutes.

During ll, sump temperature

is displayed.

READY lit and sump

temperature displayed.

WASH and wash icon lit;

sump temperature displayed

during wash cycle.

Dishwasher lls with water.

If door is opened during ll

cycle, ll will stop. After door is

closed, the process continues

where it stopped.

When lled, machine will

maintain an idle state. Heat is

maintained in both sump and

booster.

Detergent contacts will be

activated during wash cycle.

Rinse contacts turned on

during rinse cycle for external

dispenser.

Machine initiates a wash and

rinse cycle.

RINSE and rinse icon lit;

rinse temperature displayed

during rinse cycle.

CONDENSE and condense

icon lit (Advansys models

only).

EXHAUST (base models with

Vent Fan Control only).

– 22 –

If door is opened during wash,

rinse, or drain cycle, cycle will

continue at point where door

was opened upon closing door.

If POWER is pressed during

cycle, machine will drain and

shut down

Page 23

DO THIS DISPLAY SHOWS REMARKS

When cycle is complete,

reload machine for next

READY lit and sump

temperature displayed.

wash/rinse cycle; or, if

not in use, machine will

maintain idle mode.

At the end of the day,

press POWER.

DRAIN and SHUTDOWN IN

PROGRESS are displayed;

then the machine shuts

down.

SELECT WASH CYCLE and press START

CYCLE DESCRIPTION

2 A 2-minute wash cycle is followed by a 10 or

12-second fresh water rinse

(Advansys models have 99-190 second condensing

cycle).

4 A 4-minute wash cycle is followed by a 10 or

12-second fresh water rinse.

(Advansys models have 99-190 second condensing

cycle).

6 A 6-minute wash cycle is followed by a 10 or

12-second fresh water rinse.

(Advansys models have 99-190 second condensing

cycle).

All rinse cycles are followed by a 5 second pause.

Minimum Wash tank temperature is 150°F. Minimum Rinse temperature is 180°F.

Machine will drain and shut

down if the four hour idle shutdown time is reached.

When POWER key is pressed,

machine will drain and shut

down.

PROGRAMMING

Manager Mode Programing

The PW series prep washer’s microprocessor allows customization options for

machine operation. To activate or change these features, the programming edit

mode must be entered.

The manager programming mode requires a MANAGER CODE to be entered to

access the options listed in the PARAMETER MENU. The manager codes is 1001.

– 23 –

Page 24

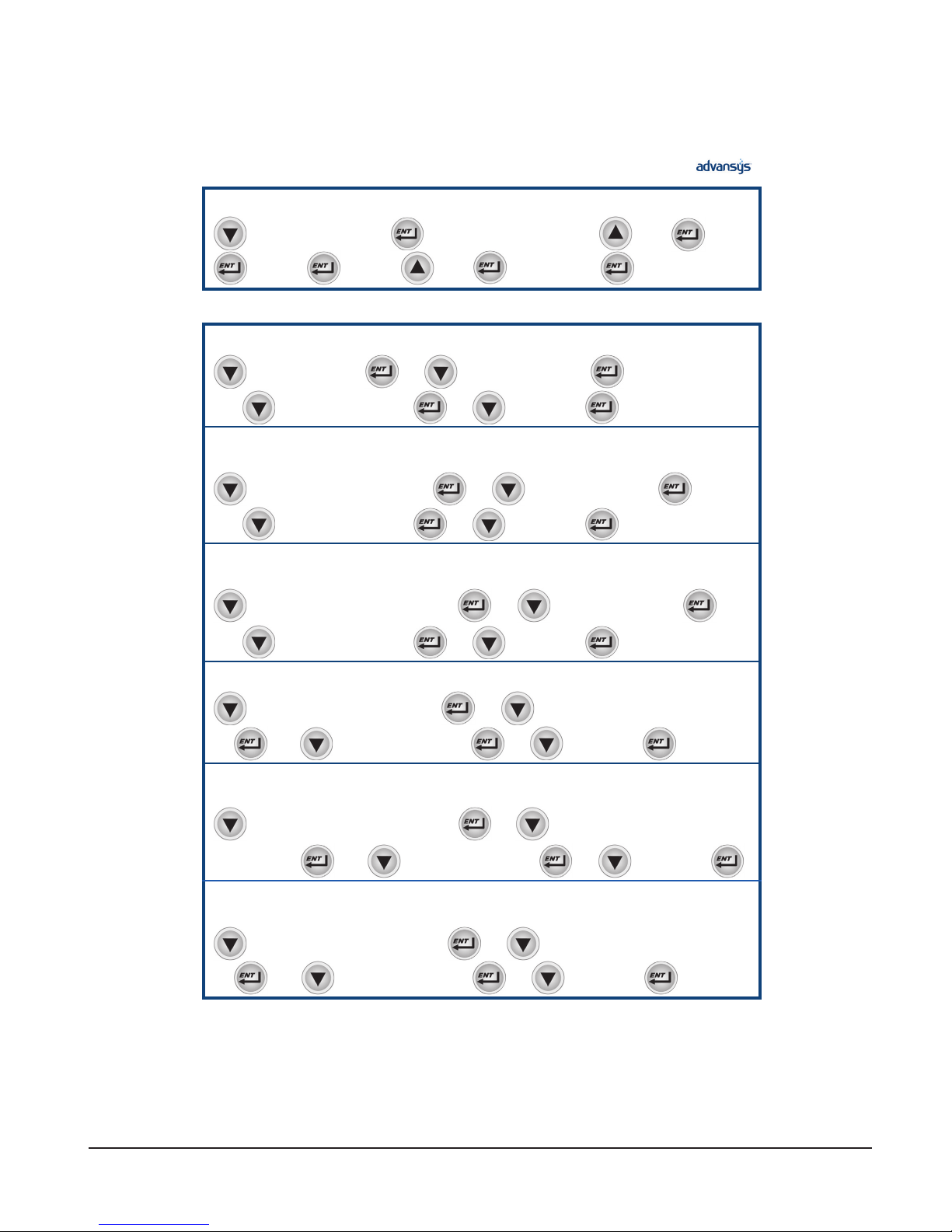

Manager Mode

PW PW

CHANGING PARAMETERS ENTER MANAGER SECURITY CODE: 1001

MANAGER MENU

➜

Programming Card

➜ ➜

ENTER SECURITY CODE

➜

(for 1)

➜

(for 0)

➜

(for 0)

➜

(for 1)

Edit Parameters

CHANGING PARAMETERS IS REQUIRED TO CHANGE ALL CODES BELOW

DELIME enables or disables the delime reminder alert.

OR

➜

until DELIME

➜

➜ ➜

until E XIT MENU

➜ ➜

to enable or disable

until E XIT

➜

➜

LOW TEMP ALARMS enables or disables alert indicating that the final rinse temperature has

been below the minimum temperature for a period of time.

OR

➜

until LOW TEMP A LARMS

➜

until E XIT MENU

➜ ➜

➜ ➜

to enable or disable

until E XIT

➜

➜

END CYCLE AUDIO ALERT enable or disable the unit creating an audio alert at the end of

each wash cycle.

OR

➜

until END CYCLE AUDIO ALERT

➜

until E XIT MENU

➜ ➜

➜ ➜

to enable or disable

until E XIT

➜

➜

TEMPERATURE UNITS allows the choice of Fahrenheit or Celsius.

until TEMPER ATURE UNITS

➜

➜ ➜

to choose Fahrenheit or Celsius

➜

OR ➜

until E XIT MENU

➜ ➜

until E XIT

➜

DIRTY WATER INDICATOR disables or gives a choice of how many cycles the machine will

run between dirty water alert and refresh cycles.

➜

or 60 cycles

until DIRTY WATER INDICATOR

➜

OR ➜

➜ ➜

until E XIT MENU

to Disable, 20 cycles, 40 cycles,

➜ ➜

until E XIT

➜

ENERGY SAVER MODE disables or gives choice of how many hours before the unit will

stay on before entering energy saving mode.

until ENERGY SAVING MODE

➜

➜

OR ➜

➜ ➜

until E XIT MENU

➜ ➜

to Disabled, 1 Hour, 2 Hours, or 3 Hours

until E XIT

➜

– 24 –

Page 25

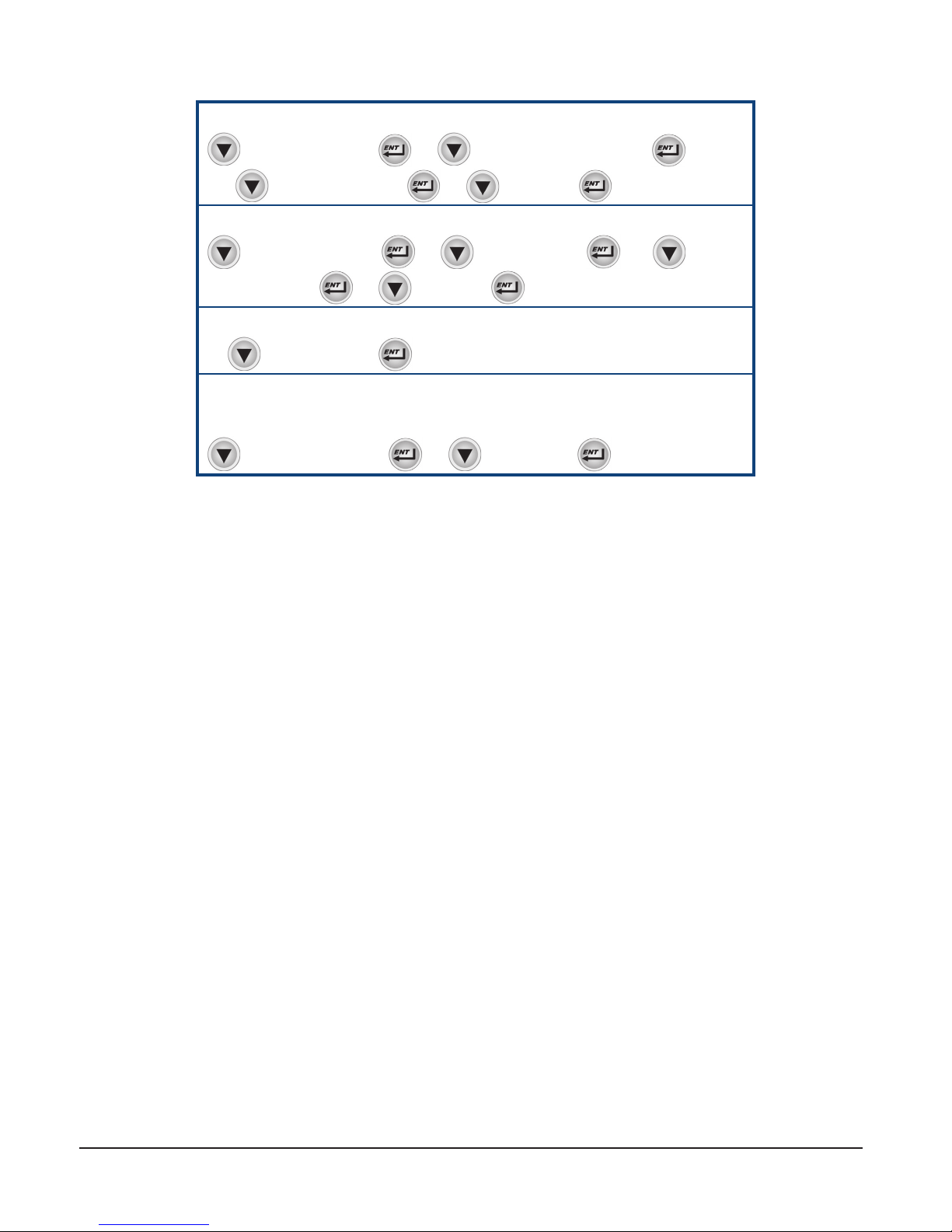

LANGUAGE allows the choice of English, French or Spanish language.

OR

until LANGUAGE

➜

until E XIT MENU

➜

➜ ➜

➜ ➜

to English, French or Spanish

until E XIT

➜

➜

WASH PROGRAM allows the customization of total run time.

until CYCLE TIME

➜

until E XIT MENU

➜ ➜

➜ ➜

until E XIT

EXIT MENU TO MAIN MANAGER MENU

until E XIT MENU

➜

➜

to choose cycle,

➜

➜

OR

➜

DELIME NOW allows for a single delime cycle to be run from the menu at anytime.

Note: this operation takes up to 1 hour 45 minutes depending on conditions. The machine will automatically

shut down at the end of delime cycle.

until DELIME NOW

➜

➜ ➜

to YES or NO

➜

(this will exit menu)

– 25 –

Page 26

Programming Instructions

All customization is performed through the on-screen menu using the UP arrow,

MENU/DOWN arrow, and ENT keys located on the keypad on the lower right of

the machine (Fig. 4).

WASH

POWER

MENU/DOWN ARROW

Menu Display Prompts

The following prompts are used inside the menus:

• The UP arrow and MENU/DOWN arrow keys are used

to change parameter values and to navigate the menu.

• The ENT key is used to accept a value, to perform a

specic action, or to enter a submenu.

On PW10eR and PW20eR Advansys models, the door is locked

and must remain closed until the condensing cycle is completed.

During the condense cycle a countdown icon shows the remaining

cycle time. When the cycle is nished and the condense icon

disappears and the condensing cycle light turns off and the door

is unlocked. Open the door and pull out the rack to remove the

clean ware. Load soiled ware onto rack and push rack into the

machine. Close the door.

UP ARROW

ENTER

CYCLE

DISPLAY

Fig. 19

– 26 –

Page 27

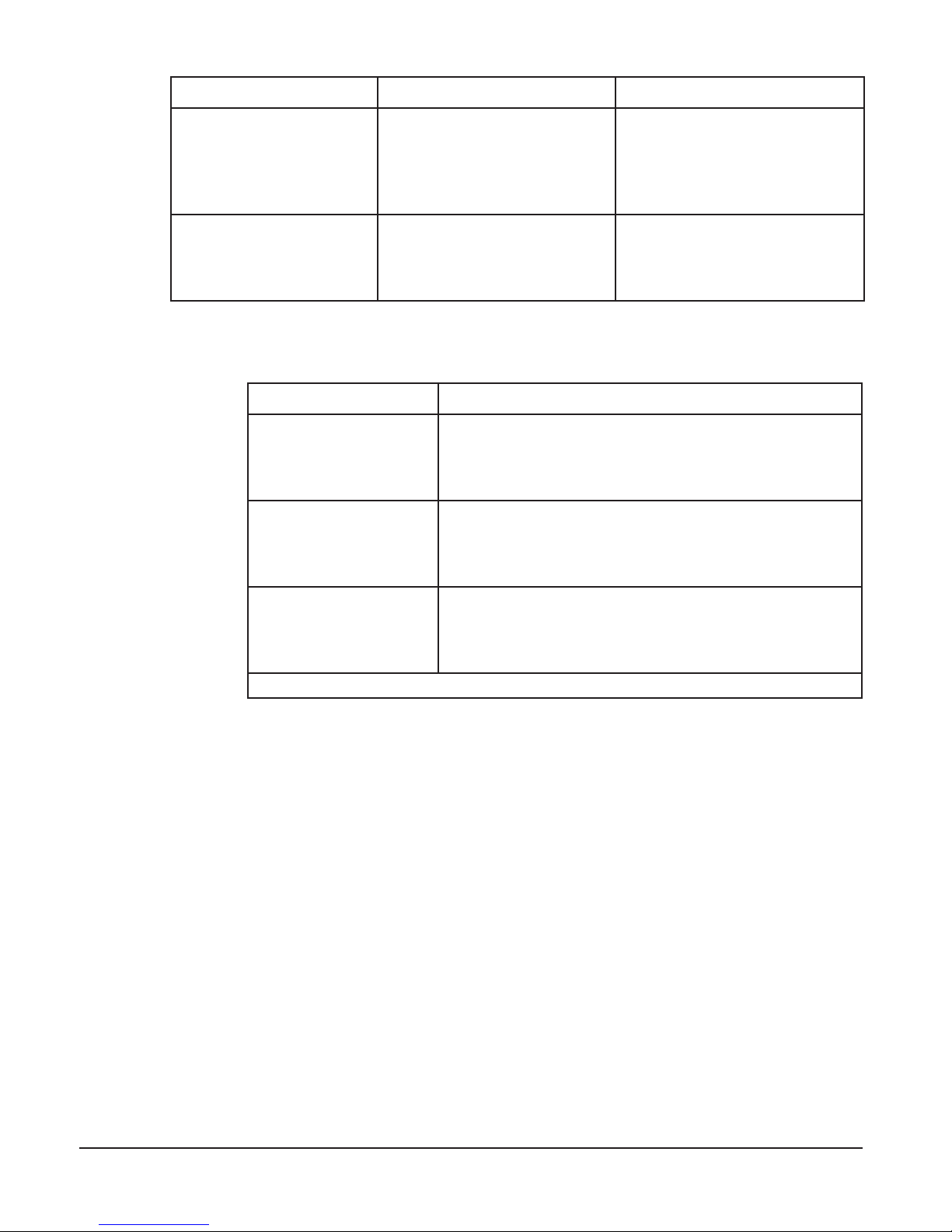

Recommended Condense Time

(Based on Incoming Water Temperature)

Incoming

Water Temp

Rinse

Time

PW10eR PW20eR

Condense

Time

Racks per

Hour

Rinse

Time

Condense

Time

°F (°C)

(Sec.)

(Sec.)

(2 min. cycle)

(Sec.)

(Sec.)

60 (16) – 64 (18) 10 99 13 12 98 13

64 (18) – 72 (22) 12 119 12 14 114 12

72 (22) – 80 (27) 14 139 11 16 131 11

80+ (27+) 16 158 10 18 147 10

For Advansys models only – If excessive amounts of steam or water vapor exit the

machine after condensing cycle light goes out and door is opened, incoming cold

water temperature may be too high.

Contact Hobart Service to adjust the rinse and condense times according to the

adjustment table. Increasing cycle time will increase water consumption and

decrease the racks per hour, but should reduce the water vapor entering the room.

General Operating Instructions

Keep the prep washer clean to provide best results. Do not allow foreign

objects to enter the unit, especially metallic contaminants.

Racks

per Hour

(2 min. cycle)

CLEANING

Do not wash aluminum utensils in the prep washer. The caustic detergent and high

water temperature will cause aluminum oxide formation (black). Copper utensils

may require polishing to remove oxide formation after exposure to utensil washer

cleaning for a period of time. Stainless steel utensils should clean quickly and easily

if the food soil is not baked on.

It may be necessary to scrub or prewash some hard-to-remove substances which

may not come clean in the prep washer with even a 6-minute washing. For stubborn

food soil, a plastic scraper, plastic abrasive pad, nylon bristle brush or sponge with

abrasive surface (Scotch Brite) may be used before washing in the prep washer.

Never use steel wool on ware to be loaded into the prep washer. Use only products

formulated to be safe on stainless steel. Do not use deliming agent on outside of

machine. Rinse items thoroughly after scrubbing to remove metallic debris.

Disconnect the electrical power to the machine and follow

lockout / tagout procedures. There may be multiple circuits. Be sure all circuits

are disconnected.

The prep washer must be thoroughly cleaned at the end of each working shift. Use

only product formulated to be safe on stainless steel. Never use steel wool to clean

machine surfaces.

– 27 –

Page 28

1. Spray down inside of machine with wand (Fig. 20).

Fig. 20

2. Press POWER. The machine will drain. (Fig. 7).

© HOBART 2008

Fig. 21

NOTE: Shutting off the machine causes a full automatic drain, which takes

about 3 minutes for a PW10 and about 3-1/2 minutes for a PW20.

3. Remove tray and racks.

– 28 –

Page 29

4. The wash and rinse arms are easily removed for cleaning. Make sure that

the wash and rinse arms rotate freely and are free of any obstructions. If any

obstructions are present, remove the wash and rinse arms. Clean the wash and

rinse arms under running water in a sink.

a. To remove upper rinse arm and wash arm (Fig. 22):

i. Unscrew the rinse arm by loosening the tabbed ring at top of rinse arm

ii. Remove both Rinse and Wash arms at the same time, being careful

not to drop these arms.

iii. Reverse the process to replace. Spin arms to make sure they spin

freely.

b. To remove lower rinse arm and wash arm (Fig.23).

i. Unscrew the rinse arm by loosening the tabbed ring at bottom of rinse

arm.

ii. Remove both Rinse and Wash arms at the same time, being careful

not to drop these arms.

iii. Reverse the process to replace. Spin arms to make sure they spin

freely.

Fig. 22 Fig. 23

5. Remove the strainer pans and strainer basket (Fig. 5), and empty into a waste

disposer or garbage container. Wash and rinse strainer pans and strainer basket

thoroughly. Do not bang strainers pan or basket on tables to remove food soil

– 29 –

Page 30

6. Spray down sump (Fig. 24).

Fig. 24

7. Turn machine back on for 2 minutes to ll.

8. Turn off machine again to ush sump.

9. With a damp cloth, wipe the interior and exterior of the machine. DO NOT use

steel wool. Remove any remaining debris with a mild cleanser formulated for

stainless steel and a soft cloth or brush.

10. Carefully reinstall the strainer pans and strainer basket.

11. Use a soft, damp cloth or sponge and mild cleanser to clean the control keypad

and display. DO NOT use abrasive or harsh cleaners or scouring pads.

12. Leave the doors open to allow the interior to dry and air out.

Do not use spray hose to spray down exterior of machine.

For Models PW10eR and PW20eR

In addition to normal cleaning, the bafes, located on the upper chamber on the

inside of the machine, may need periodic cleaning. Note that the PW20eR will

have two sets of bafes.

Disconnect the electrical power to the machine and follow

lockout / tagout procedures. There may be multiple circuits. Be sure all circuits

are disconnected.

1. Loosen and remove the nut from the front bafe(s) and remove bafe(s) by

sliding the tab out of the retainer.

– 30 –

Page 31

REMOVE THIS NUT

FRONT BAFFLE

Fig. 25 Fig. 26

2. Debris may collect on the top surface of bafes and should be washed in a sink

with mild detergent and rinsed.

3. Replace all removed parts.

4. Leave machine door open to allow interior to air out and dry.

DO'S AND DON'TS FOR YOUR NEW HOBART DISHWASHER

DO ensure proper water hardness of 3 grains or less per gallon. Total Dissolved Solids (TDS)

must be 50 ppm or greater. Chlorides must not exceed 50 ppm.

DO pre-scrap dishes thoroughly.

DO use only detergents recommended by your chemical professional.

DO, at the end of the day, complete a manual cleaning cycle as needed; thoroughly cleanse

the machine, rinse, and dry (leave doors open).

DO closely follow the machine's deliming schedule.

RETAINER

DO use only products formulated to be safe on stainless steel.

DO NOT use detergents formulated for residential dishwashers.

DO NOT allow food soil to accumulate on the tank bottom.

DO NOT exceed chemical manufacturer's recommended concentrations for detergent,

rinse aid or lime scale remover.

DO NOT use steel wool to clean ware or dishwasher surface.

DO NOT allow foreign objects to enter the unit, especially metallic contaminants.

NOTE: Failure to follow use, care, and maintenance instructions may void your Hobart dishwasher

warranty.

– 31 –

Page 32

MOTOR

The motor has permanently sealed bearings and requires no lubrication.

WASH AND RINSE ARMS

All wash arms and rinse arms should turn freely and continue turning for a few

seconds after being whirled by hand. To check, DISCONNECT ELECTRIC POWER

SUPPLY, rotate arms and remove any obstructions causing improper operation.

Refer to CLEANING THE PREP WASHER on pages 27-31.

If the strainer pans and strainer basket are not properly in place, obstructions

(such as food particles or toothpicks) may clog the wash arm nozzles.

DELIMING

rinse solution containing bleach. Mixing may cause hazardous gas to form.

This entire procedure must be followed step- by-step for safe and satisfactory

results.

The dishwasher should be delimed on a regular basis as required. How often

depends on the mineral content of the water. Deliming should be done when you

can see clear signs of lime deposits (a white chalky substance) on the inside walls,

on the wash and rinse arms and tank heater. Inspect the machine interior for lime

deposits. If deliming is necessary, a deliming agent (such as Lime-A-Way® or

LSR®) should be used for best results.

MAINTENANCE

Deliming solution must not come in contact with bleach or

All Prep washers are equipped with an automatic delime cycle reminder. It is

recommended that deliming be done when DELIME RECOMMENDED is lit.

PW10eR and PW20eR models are equipped with an internal delime pump which

will automatically pump the required amount of deliming agent into the unit. All

PW10eR/PR20eR models are equipped with an automatic deliming system. At

installation, a qualied Hobart Service technician or your chemical supplier must

adjust the total water hardness setting to properly set the delime intervals.

Remove the deliming agent bottle cap and put the black delivery tube in the

container. Be sure to push the delivery tub standpipe completely to the bottom

of the container. Check to make sure there are no obstructions or kinks in the

delivery tube.

– 32 –

Page 33

After the preprogrammed number of cycles has expired, the control will indicate

the delime request by displaying DELIME RECOMMENDED and will prompt

‘would you like to delime now?’. You must enter ‘Yes’ or ‘No’ to proceed with a

delime cycle or to continue with normal machine operation. If ‘No’ is selected,

the machine will continue to notify the operator at each start-up and power down

until the delime cycle is completed. To delime the unit.

1. Press the MENU/DOWN Arrow key until the ‘>’ symbol is shown to the left of

‘YES’ and press the ENT key.

2. Remove rack from the machine.

3. Remove strainers from the machine and clean. Replace strainers and rack

and close door.

4. On PW10er/PW20eR machines, ensure delimer chemical container is not

empty. Be sure to push the delivery tube standpipe completely to the bottom

of the container. Check to make sure there are no obstructions or kinks in the

delivery tube.

5. Press ENT key to enter the delime mode. The machine will drain and rell with

fresh water.

6. On PW10/PW20 machines, after the deliming agent has been added, close the

door. Press the ENT key to continue the cycle. The machine will enter the wash

mode for about 25 minutes, then will begin two rinse and drain operations. Total

time to complete the delime operation will be about 45 minutes. ON PW10eR/

PW20eR machines, the unit will automatically enter the wash mode for about

40 minutes, then will begin several rinse and drain operations after the ll cycle

is complete. Total time to complete the delime operation will be about 1 hour

40 minutes.

7. After deliming operation is completed, the machine will shut down.

8. Inspect the interior of the machine for lime deposits. If necessary, another delime

cycle can be initiated by entering Manager Programming Mode.

Do not allow deliming agent to remain in the machine longer than

recommended by the deliming agent manufacturer. After deliming, run the

machine through two 6-minute cycles with no utensils in order to rinse and

ush machine interior.

– 33 –

Page 34

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE

Utensils spotted or not

clean

Overloaded rack. Low water level. Water conditions:

— Incorrect rinse water temperature. Refer to WATER SUPPLY

CONNECTION, page 15.

— Excessive water hardness may indicate that a water softener is

needed.

— Incorrect detergent type or concentration for water conditions.

— Incorrect rinse additive for water conditions. Inadequate rinse.

— Dirty line strainer causing reduced water ow. Turn off water supply.

Remove ll hose and check strainer. Withdraw and clean screen.

Reassemble.

— Excessive mineral deposits throughout wash and rinse system.

Deliming may be necessary.

Check water level in tank. The machine won't clean well if there isn't enough

water for the pump to maintain adequate wash pressure.

Loss of water pressure due to pump obstruction.

— DISCONNECT ELECTRIC POWER SUPPLY. Drain tank and check for

obstruction at the strainers, basket and pump intake.

Insufcient detergent dispensing.

— Check supply or detergent supplier.

Excessive mineral deposits throughout wash and rinse system.

— Deliming may be necessary.

— Excessive water hardness may indicate that a water softener is

needed.

Prep washer was not cleaned properly. Refer to CLEANING THE PREP

WASHER. pages 27-31.

Wash arm blocked with debris. Refer to WASH AND RINSE ARMS, page 32

Machine won't operate Fuse blown or circuit breaker tripped.

Check water level in tank.

Leaking valves Solenoid valves.

— Contact service.

— Check valve on spray hose

— Foreign material preventing proper valve operation. A critical period

is soon after installation when pipe compound or metal shavings may

No wash tank heat

No ll or slow ll

lodge at the valve seat.

The low water detector will shut off heat if water level is too low.

— Check water level.

• Fuse blown or circuit breaker tripped.

• Heater failure

• Overtemperature protector tripped

— Contact service.

Dirty line strainer causing reduced water ow.

— Turn off water supply. Disconnect ll hose and remove strainer. Clean

screen. Reassemble.

.

SERVICE

Contact your Hobart service ofce for any repairs or adjustments needed on this

equipment. Long-term service contracts are available on this and other Hobart

products.

– 34 –

Page 35

– 1 –

Page 36

© HOBART 2015

– 2 –

Page 37

TABLE DES MATIÈRES

GÉNÉRAL ....................................................................4

INSTALLATION ................................................................4

DÉBALLAGE ..................................................................5

Retirer la machine de la pallette ................................................6

Retirer la section de récupération d'énergie, au besoin ..............................6

CODES D'INSTALLATION ......................................................10

EMPLACEMENT ..............................................................10

RACCORDS DE PLOMBERIE ...................................................15

Exigences de la qualité d'eau .................................................15

Conduite d'alimentation ......................................................15

Racords de plomberie .......................................................17

Drain ....................................................................17

Exigences de ventilation (PW10 / PW20) ........................................17

Calculs du débit d'échappement ...............................................17

Taille et emplacement de la hotte à auvent .......................................18

Calculs du débit d'échappement ...............................................18

Installations du doseur de produits chimiques .....................................18

Doseur de détergent (factultatif, installé par d'autres fournisseurs) ....................19

Doseur d'agent de rinçage (facultatif, installé par d'autres fournisseurs) ................19

Doseur de détartrant (standard) sur les modèles Advansys seulement (PW10eR/ PW20eR) 19

Évent (PW10 / PW20) .......................................................19

Commande du ventilateur d'évacuation (Standard) ;

Ventilateur d'évacuation forcée (Facultatif) PW10 / PW20 .........................19

RACCORD(S) ÉLECTRIQUE(S) ..................................................19

Direction du(es) moteur(s) de la pompe .........................................20

BRANCHEMENTS DE L'ÉQUIPEMENT ............................................21

Commande du ventilateur d'échappement .......................................21

Doseur de détergent ........................................................21

Doseur d'agent de rinçage ....................................................21

UTILISATION .................................................................22

COMMANDES ................................................................22

Utiliser le lave-batterie PW ...................................................22

PROGRAMMATION ...........................................................23

Programmer le mode de gestion ...............................................23

Instructions de programmation ................................................26

Invites de commande du menu ................................................26

Mode d'emploi général ......................................................27

NETTOYAGE .................................................................27

Pour les Modèles PW10eR et PW20eR .........................................30

ENTRETIEN .................................................................32

GICLEURS DE LAVAGE ET DE RINÇAGE .......................................32

DÉTARTRAGE ............................................................32

DÉPANNAGE ................................................................34

– 3 –

Page 38

Installation, utilisation et entretien du

lave-batterie modèle PW10/PW20

CONSERVEZ CES INSTRUCTIONS

GÉNÉRAL

Le lave-batterie PW10 et PW20 vous permet de laver un grand volume de couverts

dans votre cuisine, pâtisserie ou supermarché. Le PW10/20 occupe un minimum

d'espace de plancher (inférieur à 48 po x 43 po quand les portes sont ouvertes) et

ne demande aucune table à vaisselle supplémentaire. La portion supérieure de la

porte s'ouvre en se glissant vers le haut, tandis que la portion inférieure s'abat vers

l'extérieur pour offrir un plateau égouttoir. Le panier égouttoir peut ensuite être tiré

vers l'extérieur pour un chargement et déchargement facile.

Le clavier de commande permet de choisir un cycle de 2-, 4- ou 6- minutes ; chaque

cycle de lavage est suivi d'un temps d'arrêt et d'un deuxième rinçage de 10 (PW10,

PW10eR, PW20) ou 12 (PW20eR) seconds. Les modèles Advansys comprennent

un délai de condensation de 1½ à 2½ minutes suivant le cycle rinçage. Les gicleurs

de lavage supérieurs et inférieurs fournissent un lavage complet. Les gicleurs de

rinçage supérieurs et inférieurs fournissent un rinçage assainissant à chaque n

de cycle.

DÉBALLAGE

Le PW10/20 n'est disponible qu'avec un chauffage électrique et équippé d'un

surchauffeur électrique. Un boyau avec pistolet d'arrosage est fourni sur le côté

de la machine.

Le système comprend : un système d'égouttage incliné, drainage à pompe, remplissage

automatique et plateau égouttoir avec cales pour insérer des paniers égouttoirs. Le

plateau peut accomoder le bol de 140 quarts (132.50L) du batteur Hobart.

INSTALLATION

Immédiatement après avoir déballé votre lave-batterie PW10/PW2, vériez qu'il n'a

pas subit d'endommagement lors de sa livraison. En cas de dommage, conservez le

matériel d'emballage et contactez le transporteur dans les 5 jours suivant la livraison.

Avant l'installation, vériez que votre branchement électrique se concorde avec

les spécications de la plaque signalétique située sur la partie inférieure droite de

la porte du haut.

– 4 –

Page 39

Retirer la machine de la palette

Retirez soigneusement la machine de la palette :

1. Enlevez les supports d'expédition de la machine/palette.

Fig. 1

2. Retirez les planches du dessous de la palette à l'aide d'un transpalette.

AVIS

Prendre soin et porter un équipement de protection lors de la manipulation

de planches avec des clous saillants.

Fig. 2 Fig. 3

3. Descendez les pieds en les dévissant.

4. La machine se supportant maintenant par ses pieds, sortez la palette en la

faisant passer par dessous de la machine.

REMARQUE : Sur la machine PW20, vous pourriez avoir à défaire les parties

latérales de la palette pour faciliter la tâche.

– 5 –

Page 40

Retirer la section de récupération d'énergie, au besoin

AVERTISSEMENT

Débranchez l'alimentation électrique à la machine et suivez

les étapes d'étiquetage / verrouillage. Il pourrait avoir plusieurs circuits.

Assurez-vous que tous les circuits sont débranchés.

REMARQUE : Les étapes suivantes démontrent le retrait d'une seule unité

de récupération d'énergie. Si vous retirez les deux unités du modèle PW20

Advansys, répétez les étapes 2 à 10 de chaque côté..

1. Débranchez le boyau d'arrivée d'eau.

Fig. 4

REMARQUE : Videz tout l'excédent d'eau dans le boyau.

2. Retirez les gicleurs de lavage supérieurs et inférieurs.

Fig. 5

3. Retirez les déecteurs. (Situés sous les gicleurs de lavage et de rinçage).

a. Retirez le boulon (1).

b. Faites glisser le déecteur vers le côté pour le déloger de son support (2)

du côté opposé du déecteur.

c. Retirez les quatre écrous (3) qui retiennent le système de récupération

d'énergie à l'intérieur de la zone de lavage.

– 6 –

Page 41

Fig. 6

2. Retirez la coiffe.

Fig. 7

3. Retirez le couvercle de l'assemblage de verrouillage de la porte.

Fig. 8

– 7 –

Page 42

4. Retirez le couvercle de la boîte à bornes.

Fig. 9

5. Étiquetez les câbles du moteur pour les reconnecter plus tard.

6. Débranchez les câbles du moteur.

Fig. 10

– 8 –

Page 43

7. Débranchez les boyaux raccordés à l'assemblage de récupération d'énergie.

Fig. 11

8. Retirez les boulons (Qté 13) autour de l'assemblage de récupération d'énergie.

Fig. 12 Fig. 13

– 9 –

Page 44

9. Soulevez l'assemblage de récupération d'énergie de la machine.

10. Inversez cette procédure pour réinstaller.

REMARQUE : Si vous avez retiré les unités de récupération d'énergie pour

accéder à l'ouverture d'une porte, lorsque vous les réinstallez, retirez le ruban

mousse, nettoyez la surface et installez un nouveau ruban sur la monture

pour assurer un joint étanche.

CODES D'INSTALLATION

L'installation doit se conformer aux codes provinciaux, locaux et le code national

électrique ANSI/NFPA70 (dernière édition). Au Canada, le code d'installation est

le CSA 22.1 (dernière édition).

EMPLACEMENT

Mettre la machine en place après que le dernier recouvrement de plancher est

installé. Assurez-vous que la machine est mise à niveau avant de faire les raccords

de plomberie. Laisser un dégagement d'au moins 3" à l'arrière et de 18" aux abords

de la machine pour permettre un accès de service. Laisser un dégagement d'au

moins 16" à l'avant de la machine pour permettre à la porte de s'ouvrir et un espace

supplémentaire pour permettre à l'utilisateur de travailler.

Fig. 14

– 10 –

Page 45

Les branchements électriques et de mise à la terre

doivent être conformes aux portions applicables du code

électrique national et/ou tout autre code électrique local.

Les raccords de plomberie doivent être conformes aux

codes sanitaires, de sécurité et de plomberies appli-

cables. Les configurations de drain et de conduit

d’alimentation peuvent varier. Quelques méthodes sont

affichées sur ce schéma.

AVERTISSEMENT

REMARQUES SUR LA PLOMBERIE :

La pression d'eau du bâtiment doit être de 15-65 PSIG. Si la pression excède 65 PSIG,

une vanne de régulation de pression doit être installée sur la conduite d'eau en direc-

tion de la machine (non incluse).

LA duretée de l’eau recommandée est de 3 grains ou moins pour obtenir les meilleurs

résultats.

Une jauge de pression d’eau n’est pas nécessaire sur les machines à rincage pompé.

REMARQUES DIVERS :

Prévention de retour effectuée par dispositif d’intervalle d’air approuvée par NSF.

Machines avec raccord à point unique.

Toutes les dimensions prises de la conduite du plancher pourrait augmenter de 1-1/2” selon l’ajustement des

pattes de la machine.

Poids net de la machine : 324 lb

Poids à l’expédition domestique : 387 lb

Dimensions d’expédition :

79-1/8” H X 40-1/4”L X 40”l

Taille des paniers:

23-3/4” X 26-5/8” X 2-1/4”

DÉGAGEMENT MINIMUM

SUGGÉRÉ POUR ACCÈS DE SERVICE

DES DEUX CÔTÉS.

DÉGAGEMENT

REQUIS POUR LE

PISTOLET

D’ARROSAGE

INFORMATION SUR LES RACCORDS

(*AFF - AU DESSUS DU NIVEAU DÉFINITIF DU SOL)

LÉGENDE

E1 RACCORD ÉLECTRIQUE (Y COMPRIS LA CHALEUR ÉLECTIQUE)

1-1/4” DIAMÈTRE DE CONDUIT, 7-1/16“ AFF.

E2 RACCORD ÉLECTRIQUE : DOSEURS DE DÉTERGENT/AGENT DE RINÇAGE ;

8-3/16” AFF.

P1 RACCORD DE L’EAU CHAUDE ENTRANTE : 110’F MINIMUM.

RACCORD FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU DE 6’

INCLUS AVEC LA MACHINE. 7-3/4” AFF.

P2 RACCORD DU DRAIN : RACCORD DE SCELLEMENT À CRAN DE 7/8“, 27-3/8” AFF.

BOYAU DE 7/8“ ET 6‘ DE LONG INCLUS AVEC LA MACHINE.

P4 SONDE DU NIVEAU DE DÉTERGENT ; 14-11/16” AFF.

P5 DOSEUR DE DÉTERGENT : 31-15/16“ AFF.

P6 DOSEUR D’AGENT DE RINÇAGE : 52-5/16” AFF.

V1 ÉVENT : 4-9/16“ X 17-3/8” (STANDARD) POUR PERMETTRE L’EXPANSION DE L’AIR.

(PAS BESOIN DE RACCORDER À UN ÉVENT EXTÉRIEUR) ; AU BESOIN, ASSEMBLAGE DE

VENTILATEUR D’ÉCHAPPEMENT POUR OFFRIR UNE VENTILATION DE 400 CFM.

S1 110’F MIN., RACCORD EN T FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU

DE 12’ INCLUS AVEC LA MACHINE. PEUT ÊTRE INSTALLÉ SUR LES DEUX CÔTÉS.

AVEC PORTE OUVERTE

AVEC PORTE VERS LE HAUT

LIGNE DU PLANCHER

ASSEMBLAGE DU VENTILATEUR D’ÉCHAPPPEMENT

(LORSQUE COMMANDÉ)

LIGNE DU

PLANCHER

ASSEMBLAGE DU VENTILATEUR

D’ÉCHAPPPEMENT FACULTATIF

ASSEMBLAGE DU VENTILATEUR

D’ÉCHAPPPEMENT FACULTATIF

MODÈLE : PW10

ÉLECTRIQUE

00-95-0647

RÉV B.

SPÉC.

ÉLEC.

TENSION

NOMINALE

EN AMPÈRES

INTENSITÉ ADMISSIBLE

MINIMUM DU CIRCUIT

D’ALIMENTATION

DISPOSITIF DE

PROTECTION DE

SURINTENSITÉ MAXIMUM

208/60/3 47.6 60 60

240/60/3 53.0 70 70

480/60/3 28.6 35 35

PW10

– 11 –

Page 46

INFORMATION SUR LES RACCORDS

240/60/3

53.0

70

70

480/60/3

28.6

35

35

À LA PIÈCE SANS HOTTE À AUVENT

(*AFF - AU DESSUS DU NIVEAU DÉFINITIF DU SOL)

AVERTISSEMENT

Les branchements électriques et de mise à la terre

doivent être conformes aux portions applicables du code

électrique national et/ou tout autre code électrique local.

Les raccords de plomberie doivent être conformes aux

codes sanitaires, de sécurité et de plomberies appli-

cables. Les configurations de drain et de conduit

d’alimentation peuvent varier. Quelques méthodes sont

affichées sur ce schéma.

E1 RACCORD ÉLECTRIQUE (Y COMPRIS LA CHALEUR ÉLECTIQUE)

LÉGENDE

1-1/4” DIAMÈTRE DE CONDUIT, 7-1/16“ AFF.

E2 RACCORD ÉLECTRIQUE : DOSEURS DE DÉTERGENT/AGENT DE RINÇAGE ;

8-3/16” AFF.

P1 RACCORD DE L’EAU CHAUDE ENTRANTE : 110’F MINIMUM.

RACCORD FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU DE 6’

INCLUS AVEC LA MACHINE. 7-3/4” AFF.

P3 RACCORD DE L’EAU FROIDE ENTRANTE : 90’F MAXIMUM.

(65’F OPTIMAL) RACCORD FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU DE 6’

INCLUS AVEC LA MACHINE. 76-7/16” AFF.

P2 RACCORD DU DRAIN : RACCORD DE SCELLEMENT À CRAN DE 7/8“, 27-1/2” AFF.

BOYAU DE 7/8“ ET 6‘ DE LONG INCLUS AVEC LA MACHINE.

P4 SONDE DU NIVEAU DE DÉTERGENT ; 14-11/16” AFF.

P5 DOSEUR DE DÉTERGENT : 31-15/16“ AFF.

P6 DOSEUR D’AGENT DE RINÇAGE : 52-5/16” AFF.

S1 110’F MIN., RACCORD EN T FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU

DE 12’ INCLUS AVEC LA MACHINE. PEUT ÊTRE INSTALLÉ SUR LES DEUX CÔTÉS.

DÉGAGEMENT

REQUIS POUR LE

PISTOLET

D’ARROSAGE

LIGNE DU

PLANCHER

MODÈLE : PW10eR

ÉLECTRIQUE

00-950647

RÉV B.

LATENT 20 100

LATENT 16 200

SENSIBLE 10 000

SENSIBLE 12 300

208

240/480

APPORT DE CHALEUR APPROXIMATIF

PW10eR

MODÈLE VOLTAGE TYPE BTU/HR

REMARQUES DIVERS :

Prévention de retour effectuée par dispositif d’intervalle d’air approuvée par NSF.

REMARQUES SUR LA PLOMBERIE :

La pression d'eau du bâtiment doit être de 15-65 PSIG. Si la pression excède 65 PSIG,

une vanne de régulation de pression doit être installée sur la conduite d'eau en direc-

tion de la machine (non incluse).

LA duretée de l’eau recommandée est de 3 grains ou moins pour obtenir les meilleurs

résultats.

Machines avec raccord à point unique.

Une jauge de pression d’eau n’est pas nécessaire sur les machines à rincage pompé.

Hotte à auvent non requise grâce au système de consensation interne.

Toutes les dimensions prises de la conduite du plancher pourrait augmenter de 1-1/2”

DES DEUX CÔTÉS.

DÉGAGEMENT MINIMUM

SUGGÉRÉ POUR ACCÈS DE SERVICE

AVEC PORTE OUVERTE

selon l’ajustement des pattes de la machine.

Poids net de la machine : 512 lb

Poids à l’expédition domestique : 575 lb

Dimensions d’expédition :

39-3/4” H X 40-1/4”L X 40”l

Taille des paniers:

23-3/4” X 26-11/16” X 2-1/4”

PW10eR

AVEC PORTE VERS LE HAUT

MUR

DISPOSITIF DE

PROTECTION DE

SURINTENSITÉ MAXIMUM

D’ALIMENTATION

INTENSITÉ ADMISSIBLE

MINIMUM DU CIRCUIT

TENSION

NOMINALE

EN AMPÈRES

LIGNE DU PLANCHER

ÉLEC.

SPÉC.

208/60/3 47.6 60 60

– 12 –

Page 47

INFORMATION SUR LES RACCORDS

(*AFF - AU DESSUS DU NIVEAU DÉFINITIF DU SOL)

E1 RACCORD ÉLECTRIQUE (Y COMPRIS LA CHALEUR ÉLECTIQUE)

1-1/4” DIAMÈTRE DE CONDUIT, 7-1/16“ AFF.

E2 RACCORD ÉLECTRIQUE : DOSEURS DE DÉTERGENT/AGENT DE RINÇAGE ;

7-1/8” AFF.

P1 RACCORD DE L’EAU CHAUDE ENTRANTE : 110’F MINIMUM.

RACCORD FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU DE 6’

INCLUS AVEC LA MACHINE. 7-11/16” AFF.

P2 RACCORD DU DRAIN : RACCORD DE SCELLEMENT À CRAN DE 7/8“, 26-15/16” AFF.

BOYAU DE 7/8“ ET 6‘ DE LONG INCLUS AVEC LA MACHINE.

P4 SONDE DU NIVEAU DE DÉTERGENT ; 14-3/8” AFF.

P5 DOSEUR DE DÉTERGENT : 31-5/8“ AFF.

P6 DOSEUR D’AGENT DE RINÇAGE : 50-5/16” AFF.

LÉGENDE

V1 ÉVENT : 4-9/16“ X 17-3/8” (STANDARD) POUR PERMETTRE L’EXPANSION DE L’AIR.

DÉGAGEMENT

REQUIS POUR LE

PISTOLET

D’ARROSAGE

ASSEMBLAGE DU VENTILATEUR

D’ÉCHAPPPEMENT FACULTATIF

(PAS BESOIN DE RACCORDER À UN ÉVENT EXTÉRIEUR) ; AU BESOIN, ASSEMBLAGE DE

VENTILATEUR D’ÉCHAPPEMENT POUR OFFRIR UNE VENTILATION DE 400 CFM.

S1 110’F MIN., RACCORD EN T FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU

DE 12’ INCLUS AVEC LA MACHINE. PEUT ÊTRE INSTALLÉ SUR LES DEUX CÔTÉS.

ASSEMBLAGE DU VENTILATEUR D’ÉCHAPPPEMENT

(LORSQUE COMMANDÉ)

ASSEMBLAGE DU VENTILATEUR

D’ÉCHAPPPEMENT FACULTATIF

LIGNE DU

PLANCHER

MODÈLE : PW20

ÉLECTRIQUE

00-950648

RÉV B.

AVERTISSEMENT

Les branchements électriques et de mise à la terre

doivent être conformes aux portions applicables du code

électrique national et/ou tout autre code électrique local.

REMARQUES SUR LA PLOMBERIE :

La pression d'eau du bâtiment doit être de 15-65 PSIG. Si la pression excède 65 PSIG,

une vanne de régulation de pression doit être installée sur la conduite d'eau en direc-

tion de la machine (non incluse).

LA duretée de l’eau recommandée est de 3 grains ou moins pour obtenir les meilleurs

Les raccords de plomberie doivent être conformes aux

codes sanitaires, de sécurité et de plomberies appli-

cables. Les configurations de drain et de conduit

d’alimentation peuvent varier. Quelques méthodes sont

affichées sur ce schéma.

résultats.

SUGGÉRÉ POUR ACCÈS

DÉGAGEMENT MINIMUM

DE SERVICE DES DEUX CÔTÉS.

AVEC PORTE OUVERTE

Une jauge de pression d’eau n’est pas nécessaire sur les machines à rincage pompé.

REMARQUES DIVERS :

Prévention de retour effectuée par dispositif d’intervalle d’air approuvée par NSF.

Machines avec raccord à point unique.

Toutes les dimensions prises de la conduite du plancher pourrait augmenter de 1-1/2”

selon l’ajustement des pattes de la machine.

Poids net de la machine : 615 lb

Poids à l’expédition domestique : 705 lb

Dimensions d’expédition :

79-7/8” H X 63-3/4”L X 40”l

Taille des paniers:

48-13/16” X 27-5/8” X 4-13/16”

PW20

– 13 –

AVEC PORTE VERS LE HAUT

MUR

DISPOSITIF DE

PROTECTION DE

SURINTENSITÉ MAXIMUM

D’ALIMENTATION

INTENSITÉ ADMISSIBLE

MINIMUM DU CIRCUIT

TENSION

NOMINALE

LIGNE DU PLANCHER

EN AMPÈRES

ÉLEC.

SPÉC.

208/60/3 58.6 70 70

240/60/3 64.0 80 80

480/60/3 35.0 45 45

Page 48

INFORMATION SUR LES RACCORDS

EN AMPÈRES

D’ALIMENTATION

SURINTENSITÉ MAXIMUM

(*AFF - AU DESSUS DU NIVEAU DÉFINITIF DU SOL)

AVERTISSEMENT

Les branchements électriques et de mise à la terre

doivent être conformes aux portions applicables du code

électrique national et/ou tout autre code électrique local.

Les raccords de plomberie doivent être conformes aux

codes sanitaires, de sécurité et de plomberies appli-

cables. Les configurations de drain et de conduit

d’alimentation peuvent varier. Quelques méthodes sont

affichées sur ce schéma.

E1 RACCORD ÉLECTRIQUE (Y COMPRIS LA CHALEUR ÉLECTIQUE)

LÉGENDE

1-1/4” DIAMÈTRE DE CONDUIT, 7-1/16“ AFF.

E2 RACCORD ÉLECTRIQUE : DOSEURS DE DÉTERGENT/AGENT DE RINÇAGE ;

7-1/8” AFF.

P1 RACCORD DE L’EAU CHAUDE ENTRANTE : 110’F MINIMUM.

RACCORD FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU DE 6’

INCLUS AVEC LA MACHINE. 7-3/4” AFF.

P2 RACCORD DU DRAIN : RACCORD DE SCELLEMENT À CRAN DE 7/8“, 27-1/2” AFF.

BOYAU DE 7/8“ ET 6‘ DE LONG INCLUS AVEC LA MACHINE.

P4 SONDE DU NIVEAU DE DÉTERGENT ; 14-3/8” AFF.

P5 DOSEUR DE DÉTERGENT : 31-5/8“ AFF.

P6 DOSEUR D’AGENT DE RINÇAGE : 52-5/16” AFF.

S1 110’F MIN., RACCORD EN T FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU

DE 12’ INCLUS AVEC LA MACHINE. PEUT ÊTRE INSTALLÉ SUR LES DEUX CÔTÉS.

DÉGAGEMENT

REQUIS POUR LE

PISTOLET

D’ARROSAGE

P3 RACCORD DE L’EAU FROIDE ENTRANTE : 90’F MAXIMUM.

(65’F OPTIMAL) RACCORD FEMELLE DE BOYAU D’ARROSAGE DE 3/4“ SUR BOYAU DE 6’

INCLUS AVEC LA MACHINE. 76-5/8” AFF.

LIGNE DU

PLANCHER

MODÈLE : PW20eR

ÉLECTRIQUE

00-950648

RÉV B.

DÉGAGEMENT MINIMUM

LATENT 24 300

LATENT 20 400

SENSIBLE 12 500

SENSIBLE 14 800

208

240/480

À LA PIÈCE SANS HOTTE À AUVENT

APPORT DE CHALEUR APPROXIMATIF

PW10eR

MODÈLE VOLTAGE TYPE BTU/HR

REMARQUES DIVERS :

Prévention de retour effectuée par dispositif d’intervalle d’air approuvée par NSF.

REMARQUES SUR LA PLOMBERIE :

La pression d'eau du bâtiment doit être de 15-65 PSIG. Si la pression excède 65 PSIG,

une vanne de régulation de pression doit être installée sur la conduite d'eau en direc

tion de la machine (non incluse).

LA duretée de l’eau recommandée est de 3 grains ou moins pour obtenir les meilleurs

résultats.

Machines avec raccord à point unique.

Une jauge de pression d’eau n’est pas nécessaire sur les machines à rincage pompé.

Hotte à auvent non requise grâce au système de consensation interne.

Toutes les dimensions prises de la conduite du plancher pourrait augmenter de 1-1/2”

DES DEUX CÔTÉS.

SUGGÉRÉ POUR ACCÈS DE SERVICE

AVEC PORTE OUVERTE

selon l’ajustement des pattes de la machine.

Poids net de la machine : 725 lb

Poids à l’expédition domestique : 815 lb

Dimensions d’expédition :

89-7/8” H X 63-11/16”L X 40”l

Taille des paniers:

40-13/16” X 27-5/8” X 4-13/16”

PW20eR

– 14 –

AVEC PORTE VERS LE HAUT

MUR

DISPOSITIF DE

PROTECTION DE

INTENSITÉ ADMISSIBLE

MINIMUM DU CIRCUIT

TENSION

LIGNE DU PLANCHER

NOMINALE

ÉLEC.

SPÉC.

208/60/3 58.6 70 70

240/60/3 64.0 80 80

480/60/3 35.0 45 45

Page 49

RACCORD(S) DE PLOMBERIE

AVERTISSEMENT

conformes avec les portions applicables du code électrique national (NFPA No.

70, CSA 22.1 dernière édition) et/ou autres codes électriques locaux.

Exigences de la qualité d'eau

Une bonne qualité de l'eau peut améliorer la performance du lavage des couverts

en réduisant les taches d'eau, l'efcacité de la main-d'oeuvre et la durée de vie de

l'équipement. Les conditions de l'eau peuvent varier d'un endroit à l'autre. Le traitement

de l'eau recommandé pour l'utilisation efcace et productive de cet équipement dépend

aussi des conditions locales de l'eau. Demandez à votre spécialiste en eau municipal

au sujet des conditions locales de l'eau avant l'installation.

La duretée de l'eau recommandé est de 3 grains par gallon (42.7mg/l) et moins. Une

dureté supérieure à 3 grains par gallon demande un traitement de l'eau. Le traitement

de l'eau réduit les coûts associés au nettoyage, le nombre de détartrage requis et la

quantité de détergent nécessaire. La teneur en chlorure ne doit pas excéder 50 ppm.

Les raccords électriques et de mise à la terre doivent être

AVIS

Une teneur élevée en fer dans l'eau peut causer des taches et demander

un ltre à fer. Une teneur élevée en chlorures dans l'eau pourrait causer des

piqûres de corrosion et demander l'installation d'un système d'élimination de

chlore. Contactez votre spécialiste en eau local pour des solutions de traitement

de l'eau.

La présence de sédiments dans l'eau pourraient demander l'installation d'un ltre à

particules. La présence de solides dissous pourrait rendre nécessaire l'installation d'un

système de traitement comme un adoussisseur ou un système d'osmose inversée,

etc. Contactez votre spécialiste de traitement de l'eau local pour des solutions de

traitement de l'eau.

Si une inspection du lave-vaisselle ou du surchauffeur révèle une accumulation

de calcaire après un certain temps d'opération, il est recommandé d'installer un

système de traitement de l'eau. Si un adoussisseur est déjà installé, vériez que

le niveau de sel est sufsant. Contactez le bureau de service à la clientèle Hobart

pour des recommandations plus spéciques.

Conduite d'alimentation

La conduite d'alimentation devrait être un boyeau mâle de ¾ po (non-incluse).

Le plombier installateur de cette machine doit s'assurer que les conduites d'eau sont

COMPLÈTEMENT RINÇÉS AVANT de les raccorder au lave-batterie. Ce rinçage est

nécessaire pour éliminer tous les corps étrangers, comme des copeaux de métal

(provenant de la coupe ou du letage des tuyaux), de la pâtes à joint ; ou dans le

cas des raccords de tuyauterie soudus, des particules de soudures ou des retailles

suite à leur coupe. Si ces débris ne sont pas éliminés, ils peuvent se loger dans les

composantes de tuyauterie du lave vaisselle et les rendre défectueuses. L'obstruction

des vannes manuelles ou solénoides par des corps étrangers et tous les frais relatifs

à cette obstruction ne relève PAS de la responsabilité du fabricant et tous les coûts

associés à la réparation ne sont pas couverts par la garantie.

– 15 –

Page 50

Exigences en approvisionnement en eau :

EXIGENCES EN APPROVISIONNEMENT EN EAU

Modèle Approvisionnement Température

PW10 Eau chaude 110°F (43°C) Minimum

PW10eR Eau froide 55°F (13°C) Minimum, 80°F (27°C) Maximum

Eau chaude 110°F (43°C) Minimum

PW20 Eau chaude 110°F (43°C) Minimum

PW20eR Eau froide 55°F (13°C) Minimum, 80°F (27°C) Maximum

Eau chaude 110°F (43°C) Minimum

Les modèles PW10eR et PW20eR demandent des raccords en eau chaude et froide.

AVIS

Sur les installations PW10eR et PW20eR, l'eau froide entrante ne doit

pas excéder 80°F (27°C) pour fonctionner correctement. Pour un résultat

optimal, il pourrait être nécessaire d'utiliser un boyau de ½” pour l'eau froide

et minimiser la distance entre le lave-batterie et son entrée dans le bâtiment.

L'isolation de la tuyauterie peut aussi offrir de meilleurs résultats.

Si la température de l'eau froide s'élève au dessus de 80°F (27°C) de manière

constante ou si une quantité excessive de vapeur d'eau s'échappe dans la pièce

après que le cycle de condensation soit terminé, contactez le service à la clientèle

de Hobart an d'allonger le délai de condensation.

La pression d'eau du bâtiment doit être de 15-65 PSIG. Si la pression excède 65

PSIG, une vanne de régulation de pression doit être installée sur la conduite d'eau

en direction de la machine (non incluse). Si la pression d'eau est inférieure à 15

psi, ceci pourrait causer un fonctionnement inadéquat. Tous les modèles PW sont

dotés d'un système de rinçage à pompe ; donc, une jauge de pression d'eau n'est

pas nécessaire et n'est pas incluse avec la machine.

AVIS

Le régulateur de pression d'eau doit être doté d'une soupape de

pression différentielle. Ne pas utiliser le bon régulateur de pression pourrait

endommager l'unité.

Un robinet de sectionnement (non inclus) devrait être installé en amont du boyau

de remplissage pour permettre l'entretien de la machine.

Il est recommandé d'installer un ltre de conduite d'eau (non inclus) sur la conduite

d'alimentation entre le robinet de sectionnement et le point de raccord de la machine.

Installez les raccords de plomberie avec une tuyauterie de cuivre au diamètre extérieur

de ½” minimum (¾” recommandé), avec un raccord mâle de boyau d'arrosage de

¾” (non inclus). Voir les diagrammes d'installation aux pages 11-14.

– 16 –

Page 51

Raccords de plomberie

AVERTISSEMENT

Les raccords de plomberies doivent être conformes aux codes

sanitaires, de sécurité et de plomberie.

Drain

Un tuyau de drain au diamètre intérieur de ⅞" et d'une longueur de 6' est inclus.

Celui-ci devrait être bien raccordé dans un drain. Faire attention de ne pas couder le

tuyau. Voir les diagrammes d'installation aux pages 11-14. Le pouvoir d'écoulement

du drain doit être d'un minimum de 18 gallons par minutes (68 l/min) pour les modèles

PW10/PW10eR et 26 gallons par minute (98 l/min) pour les modèles PW20/PW20eR.

Exigences de ventilation (PW10 / PW20)

Les hottes à auvent de type I ou II sont recommandés. Les hottes doivent être

installés selon les instructions du fabricant. Un appoint d'air doit être fourni pour

que le débis d'échappement d'air résulte à une pression négative dans la pièce où

l'unité est située (plus d'échappement d'air que d'air à l'extérieur). Les hottes qui ne

sont pas fabriqués en usine, testés selon la norme UL 710 et les fabrications hors-

série doivent se conformer aux spécications suivantes : Acier inoxydable d'une

épaisseur de 0,037 po (0,94 mm) [calibre 20] ou feuilles de cuivre d'au moins 24

onces par pied carré (7 Kg/m2) ; la hotte devrait être xée en place par des supports

ininammables et doit se conformer au CALCULS du DÉBIT D'ÉCHAPPEMENT

à la page suivante.

AVIS

Assurez-vous que l'installation se conforme aux codes du bâtiment

locaux.

Calculs du débit d'échappement (FIG. 14)

Selon le code mécanique international de 2015.

– 17 –

Fig. 15

Page 52

Taille et emplacement de la hotte à auvent

Le rebord inférieur à l'intérieur des hottes à auvent commerciales de type I et II

doit surplomber ou s'étendre d'une distance horizontale d'au moins 6 po (162 mm)

au delà des coins du sommet horizontal de l'appareil dans toutes les directions

dégagées. La distance verticale entre le rebord inférieur à l'extérieur de la hotte et

la surface de l'appareil ne doit pas excéder 4 pieds (1219 mm) ou être inférieur à

1 pied (305 mm).

Surplomb de l'ouverture avant d'un minimum de 18 po.

Le DÉBIT d'air requis pour une hotte à auvent est d'un minimum de 100 CFM par

pied linéaire de longueur de la hotte.

Calculs du débit d'air d'échappement

Selon le code mécanique international de 2015.

Le débit d'air pour les hottes de type II aux fonctions de lave-vaisselle doit être de

100 cfm par pied linéaire de longueur de la hotte. La quantité nette d'échappement

d'air doit être calculée en soustrayant le courant d'air envoyé directement dans une

cavité de hotte du débit d'échappement total d'une hotte.

Les modèles PW10eR et PW20eR n'exigent pas une hotte de type II. Selon l'article

507.3 du IMC 2015, les hottes de type II ne sont pas requises lorsque les charges

de chaleur et d'humidité sont incorporés dans la conception du système CVAC. Voir

tableur A pour les valeurs de dissipation de chaleur ou d'accumulation de chaleur

à la pièce.

Table A

DISSIPATION DE CHALEUR

Modèle Voltage

PW10 208V 13,600 6,000

PW10 240V / 480V 16,800 7,300

PW10eR 208V 16,200 10,000

PW10eR 240V / 480V 20,100 12,300

PW20 208V 17,100 7,500

PW20 240V / 480V 20,400 8,900

PW20eR 208V 20,400 12,500

PW20eR 240V / 480V 24,300 14,800

Chaleur latente

(BTU/HR)

Installations du distributeur de produit chimique

Cette machine doit être utilisée avec un doseur de produits chimiques, avec un

témoin visuel de vérier que les détergents sont injectés ou une alarme visuelle ou

audible pour signaler un problème d'injection des détergents au système de lavage.

Les doseurs de produits chimiques ne sont pas inclus. Pour les branchements

électriques, veuillez vous référer à la section Raccords De L’Equipment, page 21.

Chaleur sensible

(BTU/HR)

– 18 –

Page 53

Doseur de détergent (facultatif, non inclus)

Si installation d'un doseur de détergent (non-inclus), retirez le bouchon pour exposer

le trou de 7/8" de diamètre à l'arrière de la machine.

Agent de rinçage (facultatif, non inclus)

Si installion d'un doseur d'agent de rinçage (non-inlcus), retirez le(s) bouchon(s)

leté(s) de 1/8" NPT pour accéder au trou tarraudé dans la jonction en T sur le côté

droit de la machine (PW10/PW10eR) et à l'arrière de la machine (PW20/PW20eR).

Les machines PW20/PR20eR sont dotés de deux jonctions en T de rinçage.

Doseur de détartrant (standard) pour les modèles Advansys seulement (PW10eR/ PW20eR)