Hobart OV500G2 ML- 132498, OV500E2 ML- 132499, OV500E1 ML- 132501, OV500G1 ML- 132500 User Manual

Page 1

SERVICE MANUAL

BAXTER OV500 SERIES

RACK OVEN

OV500G2 MODEL SHOWN

This Manual is prepared for the use of trained Hobart Service Technicians

and should not be used by those not properly qualified.

This manual is not intended to be all encompassing. If you have not

attended a Hobart Service School for this product, you should read, in its

entirety, the repair procedure you wish to perform to determine if you

have the necessary tools, instruments and skills required to perform the

procedure. Procedures for which you do not have the necessary tools,

instruments and skills should be performed by a trained Hobart Service

Technician.

OV500G1

OV500G2

OV500E1

OV500E2

ML- 132500

ML- 132498

ML- 132501

ML- 132499

The reproduction, transfer, sale or other use of this Manual, without the

express written consent of Hobart, is prohibited.

This manual has been provided to you by ITW Food Equipment Group LLC

("ITW FEG") without charge and remains the property of ITW FEG, and by

accepting this manual you agree that you will return it to ITW FEG

promptly upon its request at any time in the future.

A product of BAXTER ORTING, WA 98360-9236

F25361 (January 2010)

Page 2

OV500 SERIES RACK OVEN

TABLE OF CONTENTS

GENERAL ................................................................................3

Introduction ............................................................................ 3

Location .............................................................................. 3

Operation ............................................................................. 3

Cleaning .............................................................................. 3

Lubrication ............................................................................ 3

Control Location ........................................................................ 4

Tools................................................................................. 4

OV500G1 Gas Oven Specifications ......................................................... 5

OV500G2 Gas Oven Specifications ......................................................... 7

OV500E1 Electric Oven Specifications ...................................................... 9

OV500E2 Electric Oven Specifications ..................................................... 11

REMOVAL AND REPLACEMENT OF PARTS ................................................... 13

Steam Panel .......................................................................... 13

Rack Rotator Assembly ................................................................. 13

Rotator Motor ......................................................................... 15

Actuator ............................................................................. 16

Convection Blower/motor ................................................................ 17

Gas Valve ............................................................................ 18

Gas Manifold / Orifices .................................................................. 18

Heat Exchanger .......................................................................19

Ignition Module ........................................................................ 21

Controller ............................................................................21

High Limit Switch ...................................................................... 22

Draft Inducer Motor ..................................................................... 23

Pressure Switches ..................................................................... 24

Oven Cavity Vent Motor ................................................................. 24

Oven Cavity Vent Switch ................................................................ 25

Thermostat (Back Up System Only) ........................................................ 25

Temperature Probe .................................................................... 26

Eprom Replacement .................................................................... 27

Door Swing Change .................................................................... 27

SERVICE PROCEDURES AND ADJUSTMENTS................................................. 28

Controller Input/output Status Diagnostic .................................................... 28

Ignition Module Self Diagnostics .......................................................... 29

Temperature Probe Test ................................................................ 29

Controller Temperature Calibration ........................................................ 29

Controller Settings ..................................................................... 29

Burner Adjustments .................................................................... 34

Flame Sense Location .................................................................. 38

Flame Sense Current Test ............................................................... 38

Combustion Analysis ................................................................... 38

F25361 (January 2010)

Page 2 of 60

Page 3

OV500 SERIES RACK OVEN

Draft Inducer Test ...................................................................... 39

Hood Vent Draft Pressure Test ........................................................... 40

Door Adjustment ....................................................................... 41

Door Switch Adjustment ................................................................. 41

Rack Position Switch Adjustment .......................................................... 42

Rack Position Adjustment................................................................ 42

Rack Height Adjustment .................................................................42

Actuator Lubrication .................................................................... 44

Air and Angle Shutter Adjustments ......................................................... 45

ELECTRICAL OPERATION .................................................................. 47

Component Function ................................................................... 47

Oven Sequence of Operation ............................................................. 49

Burner Sequence of Operation ............................................................ 50

Component Location ................................................................... 52

Wiring Diagrams .......................................................................53

OVEN TROUBLESHOOTING ................................................................ 56

IGNITION MODULE TROUBLESHOOTING ..................................................... 58

BURNER TROUBLESHOOTING .............................................................. 59

© Hobart 2010

Page 3 of 60

F25361 (January 2010)

Page 4

OV500 SERIES RACK OVEN - GENERAL

GENERAL

INTRODUCTION

General

OV500G1 & OV500E1 rack ovens hold one single

rack and OV500G2 & OV500E2 rack ovens hold two

single racks or one double rack.

Oven features:

• Powered rack lift with high temperature

bearings and a clutch rotating system designed

to stop the rack in the event of a jam without

damage to the rotation motor or losing rack

alignment.

• Digital programmable controller with optional

backup control, flush flooring, and field

reversible bake chamber door.

All of the information, illustrations and specifications

contained in this manual are based on the latest

product information available at the time of printing.

Heating

The rack oven reaches baking temperatures of

350EF in approximately 20 minutes; however, a 30

minute preheat is recommended to fully heat the

steam generator.

composite bearings on power rack lift shaft - no

lubrication required.

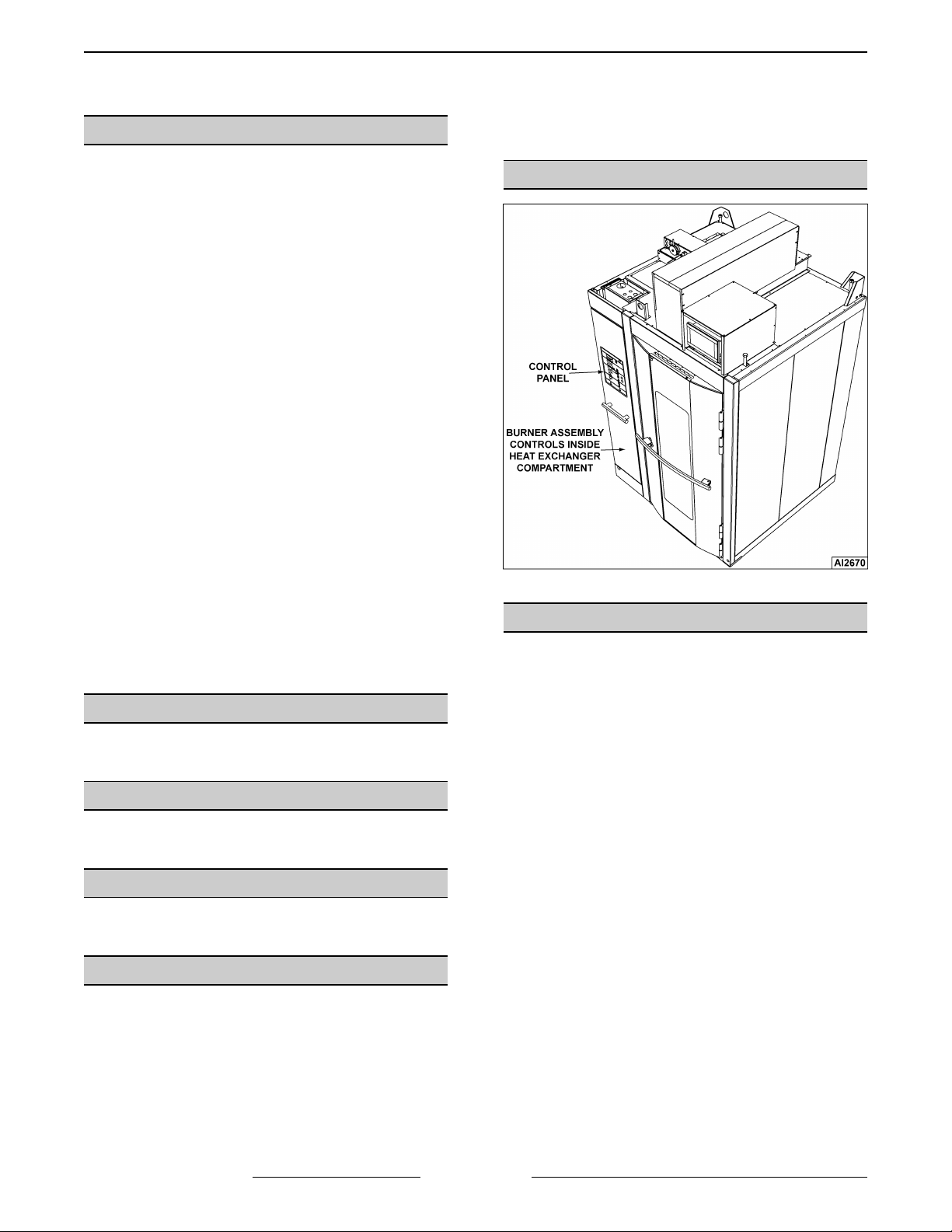

CONTROL LOCATION

Steaming System

Standard on all rack ovens, is a self-contained

spherical cast steam system providing excellent

steaming conditions.

LOCATION

Refer to the Installation Instructions for specific

location requirements.

OPERATION

Refer to the Operation Manual for specific operating

instructions.

CLEANING

Refer to the Operation Manual for specific cleaning

instructions.

LUBRICATION

• Circulation motor upper and lower bearings,

rotator chain, and lift motor spherical bearing

lubricate with high temperature grease every 6

months.

• Lift actuator.

• Oven has high temperature self-lubricating

TOOLS

• Standard set of hand tools

• Oven pressure panel feeler gauge Part No. 011M5689-1 Do not discard feeler gauge

• Multi-Meter that measures 200 micro amps

Grainger No. 6MR09

• Clamp meter Part No. 00-541069 Grainger No.

1ND81 or equivalent

• Temperature tester (thermocouple type) with 10'

probe

• Inclined manometer - Dwyer Cat. #1227 or

equivalent

• Manometer U tube Part No. TL-84908 or

equivalent

• Grounding kit - Static Control Kit Grainger No.

4KK44

• Jeweler's screw driver set - Sears No.

00930448000 or equivalent

• Combustion analyzer Bacharach Fyrite Pro 125

Bacharach model# 24-8105 or Fyrite "Insight"

Model 24-8251(Order from Bakery Support)

• BACHARACH gas leak detector (Order from

Bakery Support)

F25361 (January 2010)

Page 4 of 60

Page 5

OV500 SERIES RACK OVEN - GENERAL

OV500G1 GAS OVEN

SPECIFICATIONS

â WATER:

1/2" NPT, 30-75 PSI cold water required, customer to

install in-line filter, shut off valve and line strainer.

Ï DRAIN:

6 1/4" (front) or 7" (rear) connection A.F.F. (See

notes). Route to air-gap drain. Do not slope drain

upwards. Plug the drain connection that is not in use.

Rear Drain: 1/2" NPTF

Front Drain: 1/2" NPTF

Ð POWER:

Two supplies required.

120/60/1 20 AMP dedicated circuit required and one

of the following voltage options.

Voltage Full Load AMPS

208 - 240/60/1 8.8 - 7.6 AMPS

208 - 240/60/3 5.0 - 4.4 AMPS

440 - 480/60/3 2.4 - 2.2 AMPS

Ñ GAS:

Natural Gas (N.G.)

3/4" NPT, W.C.N.G. (N.G. rated 1025 BTU/CU. FT.

SP. GR. 1.00)

Liquified Propane Gas (L.P.G.)

3/4" NPT, W.C.L.P.G. (L.P.G. rated 2440

BTU/CU.FT., SP. GR. 1.52)

Natural Gas Liquified Propane Gas

BTU/HR 180,000 180,000

W.C. 5.0" - 10.0" 12.0" - 14.0"

Ò HOOD VENT:

8" DIA connection collar. Customer to supply duct

and ventilator fan per state and local codes. Air

proving switch factory installed & integrated with

burner system operation. Oven provided relay with

max. 10 amp 1/2 H.P. @ 120V output for fan

operation. If larger, use oven relay to control

additional separately powered contactor / relay for

hood fan. Chamber vents are factory ducted to this

integral hood. 690 CFM required, 0.6" W.C. static

pressure drop through hood. Hood is UL710 Listed

when grease filters are installed. Type B gas vent

can be used except when bake products are grease

laden.

NOTES:

1. A.F.F.: Above finished floor.

2. Customer responsible to finish and install all utilities

to and from oven.

3. All services must comply with all Federal, State and

Local codes.

4. To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with noncombustible flooring and surface finish and with no

combustible material against the underside, or on

non-combustible slabs or arches having no

combustible material against the underside. Such

construction shall in all cases extend not less than 12

inches beyond the equipment on all sides.

5. The floor must be of non-combustible material, and

must be level with surrounding area with a maximum

slope of 1/8" per foot up to 3/4" maximum in all

directions. Floor anchors require a minimum 1" thick

solid floor substrate.

6. Oven is UL/C-UL classified and CSA (AGA/CGA)

approved for 0" clearance on the side and rear walls.

Unit requires 1" to 4" clearance for rear drain

connection.

7. Top of oven requires a minimum of 24" for service

accessibility.

8. Customer responsible to install flue piping. Flue must

be vented outside of building.

9. Manufacturer reserves the right to make changes in

sizes and specifications.

Export Ratings

â WATER:

1/2" NPT, 2.1-5.2 Bar cold water required, customer

to install in-line filter, shut off valve and line strainer.

Flow rate of 8 l/min..

Ð POWER:

Single supply connection provided:

200V/50-60HZ/3PH/5.3A OR 380415V/50HZ/3PH/2.8-2.5 circuit required.

1 kVA transformer supplied for control circuit

operation voltage of 110V. This is a multifunction

transformer, so output voltage should be verified

before operation. Some wiring may be required to

obtain proper output voltage.

Oven fan (1.1kW) 200V/50-60Hz/3ph/5.3A or 380415V/50Hz/3ph/ 2.8 - 2.5A.

ÑGAS:

Natural Gas (N.G.)

3/4" NPT (N.G. Rated 38.2Mj/m3 or 9120 Kcal/m3

SP Gr 1.00)

Liquefied Propane Gas (LPG)

3/4" NPT (LPG Rated 90.9Mj/m3 or 21710 Kcal/m3

SP Gr 1.52)

Natural Gas Liquified Propane Gas

kCAL/HR 45,400 45,400

cm W.C. 12.7 - 25.4 30.5 - 35.6

Mj/HR 190 190

kPa 1.25 - 2.50 3.00 - 3.50

NOTE: Pressure not to exceed 35.6 cm W.C. or 3.5 kPa

Ò HOOD VENT:

20.3 cm DIA. Connection collar. Customer is to

supply duct and ventilator fan per federal and/or local

codes. Chamber vent (steam) and combustion

exhaust are discharged into the hood. An air proving

switch is factory installed and integrated with burner

system operation. If proper ventilation is not

provided, burner will not operate. Oven provides a

relay to activate a customer supplied and powered

contactor/relay, so that when oven is powered up

external fan will operate. The hood requires a

minimum of 19.5 m

3

/min for safe operation. For fan

calculation purposes you should assume 0.15 kPa

resistance through the hood. Grease filters (optional)

may be installed in the hood instead of standard

baffle.

F25361 (January 2010)Page 5 of 60

Page 6

OV500 SERIES RACK OVEN - GENERAL

F25361 (January 2010) Page 6 of 60

Page 7

OV500 SERIES RACK OVEN - GENERAL

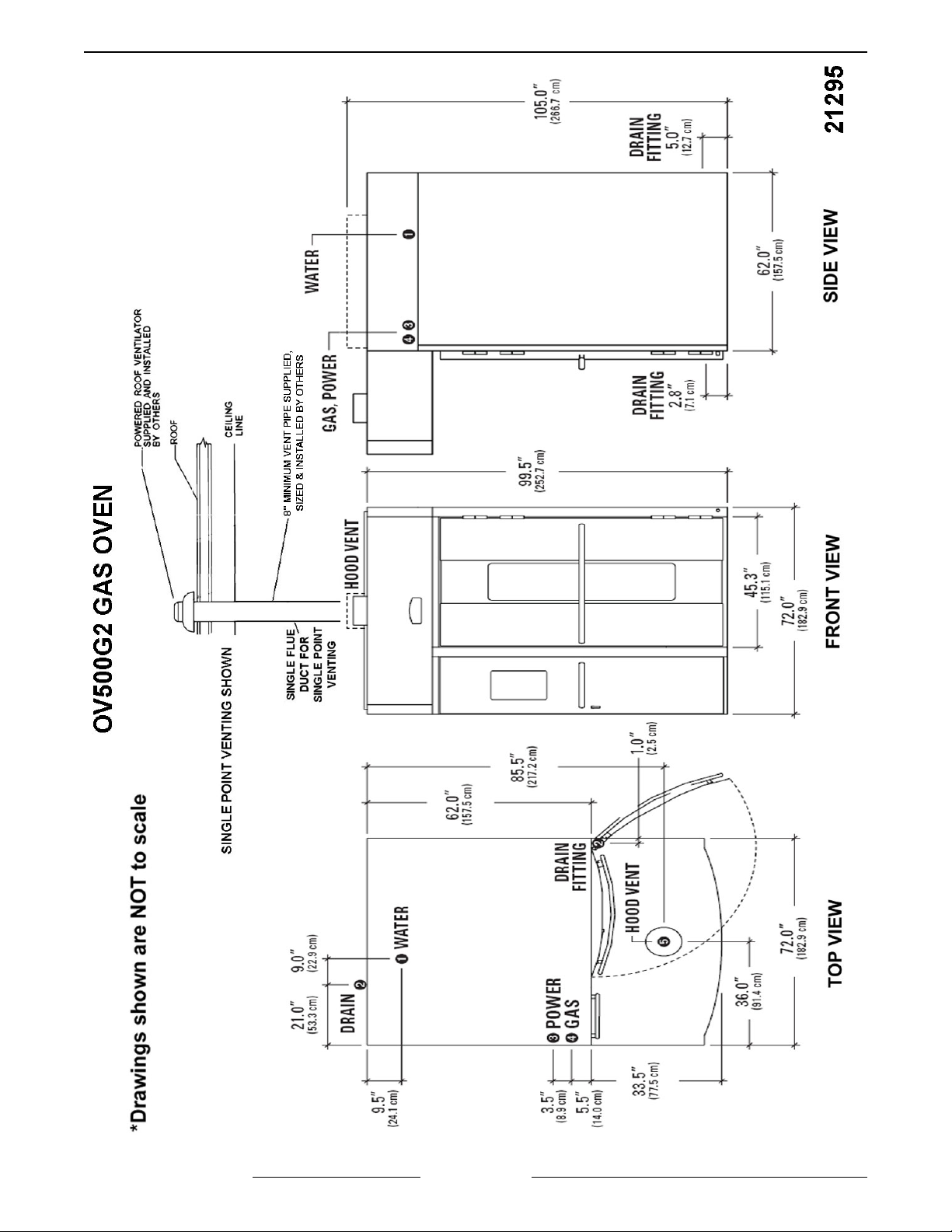

OV500G2 GAS OVEN

SPECIFICATIONS

â WATER:

1/2" NPT, 30-75 PSI cold water required, customer to

install in-line filter, shut off valve and line strainer.

Ï DRAIN:

2 3/4" (front) or 5 1/2" (rear) connection A.F.F. (See

notes). Route to air-gap drain. Do not slope drain

upwards. Plug the drain connection that is not in use.

Kit provided to extend drain to either side of oven.

Rear Drain: 3/4" NPTF

Front Drain: 3/8" NPTF

Ð POWER:

Two supplies required.

120/60/1 20 AMP dedicated circuit required and one

of the following voltage options.

Voltage Full Load AMPS

208 - 240/60/1 8.8 - 7.6 AMPS

208-240/60/3 5.0 - 4.4 AMPS

440 - 480/60/3 2.4 - 2.2 AMPS

Ñ GAS:

Natural Gas (N.G.)

1 1/4" NPT, W.C.N.G. (N.G. rated 1025 BTU/CU.

FT. SP. GR. 1.00)

Liquified Propane Gas (L.P.G.)

1 1/4" NPT, W.C.L.P.G. (L.P.G. rated 2440

BTU/CU.FT., SP. GR. 1.52)

Natural Gas Liquified Propane Gas

BTU/HR 300,000 350,000 300,000 350,000

W.C. 5.0 -14.0" 6.0 - 14.0" 10.0" - 14.0" 12.0 - 14.0"

Ò HOOD VENT:

10" DIA connection collar. Air proving switch factory

installed & integrated with burner system operation.

Oven provided rely with max. 10 amp 1/2 H.P. @

120V output for fan operation. If larger, use oven

relay to control additional separately powered

contactor / relay for hood fan. Customer to supply

duct and ventilator fan per state and local codes.

Chamber vents are factory ducted to this integral

hood. 900 CFM required, 0.6" W.C. static pressure

drop through hood. Hood is UL710 Listed when

grease filters are installed. Type B gas vent can be

used except when bake products are grease laden.

NOTES:

1. A.F.F.: Above finished floor.

2. Customer responsible to finish and install all utilities

to and from oven.

3. All services must comply with all Federal, State and

Local codes.

4. To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with noncombustible flooring and surface finish and with no

combustible material against the underside, or on

non-combustible slabs or arches having no

combustible material against the underside. Such

construction shall in all cases extend not less than 12

inches beyond the equipment on all sides.

5. The floor must be of non-combustible material, and

must be level with surrounding area with a maximum

slope of 1/8" per foot up to 3/4" maximum in all

directions. Floor anchors require a minimum 1" thick

solid floor substrate.

6. Oven is UL/C-UL classified and CSA (AGA/CGA)

approved for 0" clearance on the side and rear walls.

Unit requires 1" to 4" clearance for rear drain

connection.

7. Top of oven requires a minimum of 24" for service

accessibility.

8. Customer responsible to install flue piping. Flue must

be vented outside of building.

9. Manufacturer reserves the right to make changes in

sizes and specifications.

Export Ratings

â WATER:

1/2” NPT, 2.1-5.2 Bar cold water required, customer

to install in-line filter, shut off valve and line strainer.

Flow rate of 8 l/min..

Ð POWER:

Single supply connection provided: 200V/5060Hz/3ph/5.3A or 380-415V/50Hz/3ph/ 2.8 - 2.5A

circuit required.

1 kVA transformer supplied for control circuit

operation voltage of 110V. This is a multifunction

transformer, so output voltage should be verified

before operation. Some wiring may be required to

obtain proper output voltage.

Oven fan (1.1kW) operates @ 380-415V 3ph 50 Hz

2.4- 2.2A

Ñ GAS:

Natural Gas (N.G.)

3/4” NPT (N.G. Rated 38.2Mj/m3 or 9120 Kcal/m3

SP Gr 1.00)

Liquefied Propane Gas (LPG)

3/4” NPT (LPG Rated 90.9Mj/m3 or 21710 Kcal/m3

SP Gr 1.52)

Natural Gas Liquified Propane Gas

kCAL/HR 75,600 75,600

cm W.C. 12.7 - 25.4 30.5 - 35.6

Mj/HR 317 317

kPa 1.25 - 3.50 3.00 - 3.50

NOTE: Pressure not to exceed 35.6 cm W.C. or 3.5 kPa

Ò HOOD VENT:

25.4 cm DIA. Connection collar. Customer is to

supply duct and ventilator fan per federal and/or local

codes. Chamber vent (steam) and combustion

exhaust are discharged into the hood. An air proving

switch is factory installed and integrated with burner

system operation. If proper ventilation is not

provided, burner will not operate. Oven provides a

relay to activate a customer supplied and powered

contactor/relay, so that when oven is powered up

external fan will operate. The hood requires a

minimum of 25.5 m

3

/min for safe operation. For fan

calculation purposes you should assume 0.15 kPa

resistance through the hood. Grease filters (optional)

may be installed in the hood instead of standard

baffle.

F25361 (January 2010)Page 7 of 60

Page 8

OV500 SERIES RACK OVEN - GENERAL

F25361 (January 2010) Page 8 of 60

Page 9

OV500 SERIES RACK OVEN - GENERAL

OV500E1 ELECTRIC OVEN

SPECIFICATIONS

â WATER:

1/2" NPT, 30-75 PSI cold water required, customer to

install in-line filter, shut off valve and line strainer.

Ï DRAIN:

6 1/4" (front) or 7" (rear) connection A.F.F. (See

notes). Route to air-gap drain. Do not slope drain

upwards. Plug the drain connection that is not in use.

Rear Drain: 1/2" NPTF

Front Drain: 1/2" NPTF

Ð POWER:

Two supplies required.

120/60/1 20 AMP dedicated circuit required and one

of the following voltage options.

Heating Circuit: KW rating in following chart per

supply voltage.

Blower Motor: 1 1/2 H.P.

Voltage Full Load AMPS Heaters Rating

208/60/3 100 AMPS 34 KW

208 - 240/60/3 76 - 87 AMPS 26 - 34 KW

440 - 480/60/3 40 - 43 AMPS 29 - 34 KW

Ñ HOOD VENT:

8" DIA connection collar. Customer to supply duct

and ventilator fan per state and local codes. Oven

provided relay with max. 10 amp 1/2 H.P. @ 120V

output for fan operation. If larger, use oven relay to

control additional separately powered contactor /

relay for hood fan. Chamber vents are factory ducted

to this integral hood. 690 CFM required, 0.6" W.C.

static pressure drop through hood. Hood is UL710

Listed when grease filters are installed. Type B gas

vent can be used except when bake products are

grease laden.

NOTES:

1. A.F.F.: Above finished floor.

2. Customer responsible to finish and install all utilities

to and from oven.

3. All services must comply with all Federal, State and

Local codes.

4. To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with noncombustible flooring and surface finish and with no

combustible material against the underside, or on

non-combustible slabs or arches having no

combustible material against the underside. Such

construction shall in all cases extend not less than 12

inches beyond the equipment on all sides.

5. The floor must be of non-combustible material, and

must be level with surrounding area with a maximum

slope of 1/8" per foot up to 3/4" maximum in all

directions. Floor anchors require a minimum 1" thick

solid floor substrate.

6. Oven is UL/C-UL classified and CSA (AGA/CGA)

approved for 0" clearance on the side and rear walls.

Unit requires 1" to 4" clearance for rear drain

connection.

7. Top of oven requires a minimum of 24" for service

accessibility.

8. Customer responsible to install flue piping. Flue must

be vented outside of building.

9. Manufacturer reserves the right to make changes in

sizes and specifications.

Export Ratings

â WATER:

1/2” NPT, 2.1 - 5.2 Bar cold water required, customer

to install in-line filter, shut off valve and line strainer.

Flow rate of 8 l/min.

Ð POWER:

Single supply connection provided: 200V/5060Hz/3ph/5.3A or 380-415V/50Hz/3ph

circuit required.

1 kVA transformer supplied for control circuit

operation voltage of 110V. This is a multifunction

transformer, so output voltage should be verified

before operation. Some wiring may be required to

obtain proper output voltage.

Oven fan (1.1kW) operates @ 380-415V 3ph 50 Hz

2.4- 2.2A

Voltage Full Load AMPS Heaters Rating

200/50 - 60/3 74 AMPS 24 kW

380 - 415/50/3 46 - 50 AMPS 29 - 34 kW

Ñ HOOD VENT:

20.3 cm DIA. Connection collar. Customer is to

supply duct and ventilator fan per federal and/or local

codes. Chamber vent (steam) and combustion

exhaust are discharged into the hood. Oven provides

a relay to activate a customer supplied and powered

contactor/relay, so that when oven is powered up

external fan will operate. The hood requires a

minimum of 19.5 m

calculation purposes you should assume 0.15 kPa

resistance through the hood. Grease filters (optional)

may be installed in the hood instead of standard

baffle.

3

/min for safe operation. For fan

/ 2.8 - 2.5A

F25361 (January 2010)Page 9 of 60

Page 10

OV500 SERIES RACK OVEN - GENERAL

F25361 (January 2010) Page 10 of 60

Page 11

OV500 SERIES RACK OVEN - GENERAL

OV500E2 ELECTRIC OVEN

SPECIFICATIONS

â WATER:

1/2" NPT, 30-75 PSI cold water required, customer to

install in-line filter, shut off valve and line strainer.

Ï DRAIN:

2 3/4" (front) or 5 1/2" (rear) connection A.F.F. (See

notes). Route to air-gap drain. Do not slope drain

upwards. Plug the drain connection that is not in use.

Kit provided to extend drain to either side of oven.

Rear Drain: 3/4" NPTF

Front Drain: 3/8" NPTF

Ð ELECTRICAL:

Two supplies required.

120/60/1 20 AMP dedicated circuit required and one

of the following voltage options.

Heating Circuit: KW rating in following chart per

supply voltage.

Blower Motor: 1 1/2 H.P.

Voltage Full Load AMPS Heaters Rating

208/60/3 146.4 AMPS 51.3 KW

208-240/60/3 111.2 - 127.2 AMPS 38.5 - 51.3KW

440-480/60/3 59.1 - 64.1 AMPS 43 - 51.3 KW

Ñ HOOD VENT:

10"DIA connection collar. Customer to supply duct

and ventilator fan per state and local codes. Oven

provided relay with max. 10 amp 1/2 H.P. @ 120V

output for fan operation. If larger, use oven relay to

control additional separately powered contactor /

relay for hood fan. Customer to supply duct and

ventilator fan per state and local codes. Chamber

vents are factory ducted to this integral hood. 900

CFM required, 0.6" W.C. static pressure drop

through hood. Hood is UL710 Listed when grease

filters are installed. Type B gas vent can be used

except when bake products are grease laden.

NOTES:

1. A.F.F.: Above finished floor.

2. Customer responsible to finish and install all utilities

to and from oven.

3. All services must comply with all Federal, State and

Local codes.

4. To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with noncombustible flooring and surface finish and with no

combustible material against the underside, or on

non-combustible slabs or arches having no

combustible material against the underside. Such

construction shall in all cases extend not less than 12

inches beyond the equipment on all sides.

5. The floor must be of non-combustible material, and

must be level with surrounding area with a maximum

slope of 1/8" per foot up to 3/4" maximum in all

directions. Floor anchors require a minimum 1" thick

solid floor substrate.

6. Oven is UL/C-UL classified and CSA (AGA/CGA)

approved for 0" clearance on the side and rear walls.

Unit required 1" to 4" clearance for rear drain

connection.

7. Top of oven requires a minimum of 24" for service

accessibility.

8. Customer responsible to install flue piping. Flue must

be vented outside of building.

9. Manufacturer reserves the right to make changes in

sizes and specifications.

Export Ratings

â WATER:

1/2" NPT, 2.1-5.2 Bar cold water required, customer

to install in-line filter, shut off valve and line strainer.

Flow rate of 8 l/min..

Ð ELECTRICAL:

Single supply connection provided: 200V/5060Hz/3ph/5.3A or 380-415V/50Hz/3ph

circuit required.

1 kVA transformer supplied for control circuit

operation voltage of 110V. This is a multifunction

transformer, so output voltage should be verified

before operation. Some wiring may be required to

obtain proper output voltage.

Oven fan (1.1kW) operates @ 380-415V 3ph 50 Hz

2.4- 2.2A

Voltage Full Load AMPS Heaters Rating

200/50 - 60/3 108 AMPS 36 kW

380 - 415/50/3 68 - 73 AMPS 43 - 51 kW

Ñ HOOD VENT:

25.4 cm DIA. Connection collar. Customer is to

supply duct and ventilator fan per federal and/or local

codes. Chamber vent (steam) and combustion

exhaust are discharged into the hood. Oven provides

a relay to activate a customer supplied and powered

contactor/relay, so that when oven is powered up

external fan will operate. The hood requires a

minimum of 25.5 m

calculation purposes you should assume 0.15 kPa

resistance through the hood. Grease filters (optional)

may be installed in the hood instead of standard

baffle.

3

/min for safe operation. For fan

/ 2.8 - 2.5A

F25361 (January 2010)Page 11 of 60

Page 12

OV500 SERIES RACK OVEN - GENERAL

F25361 (January 2010) Page 12 of 60

Page 13

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

STEAM PANEL

NOTE: Hand tighten only, do not use power tools

when installing panel screws.

1. Remove screws securing steam panel to baking

compartment rear wall (through access holes).

4. Reverse the procedure to install.

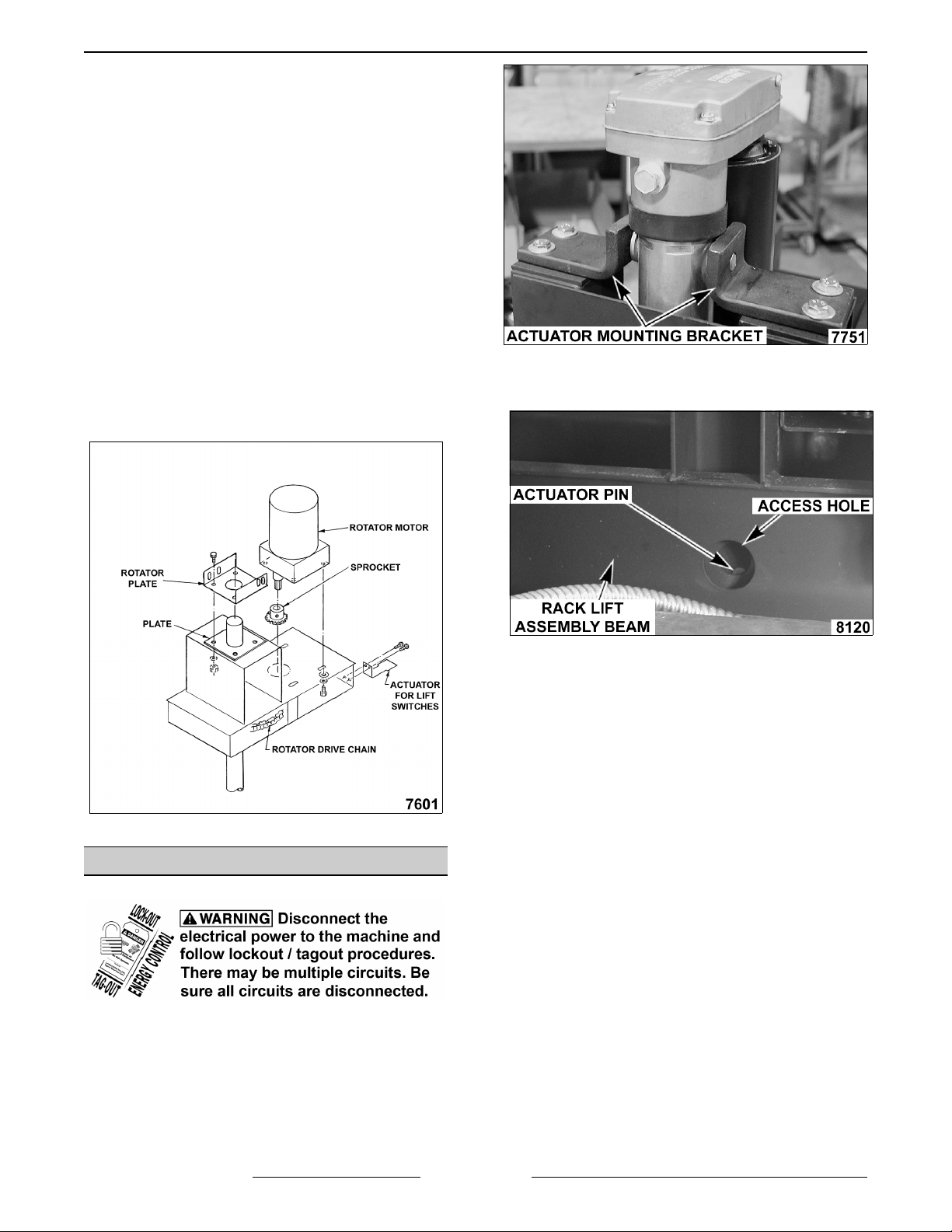

RACK ROTATOR ASSEMBLY

2. Remove screws securing steam panel to left

baking compartment wall.

Removal

1. Remove rack carrier.

A. Support rack carrier.

B. Loosen set screws.

C. Remove snap ring from end of shaft.

D. Lower carrier to remove.

2. Remove rotator and lift assembly cover.

3. Remove actuator for rack up and down

switches.

4. Disconnect lead wires from rack pointer

switches, capacitor, and rotator motor.

3. Remove screws securing steam panel to baking

compartment ceiling (left rear corner) Reverse

the procedure to install.

F25361 (January 2010)Page 13 of 60

Page 14

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

5. Lift rack rotator assembly, which will include the

rack lift shaft, from rack lift assembly.

NOTE: Removal of actuator housing bolt may be

necessary for rack rotator assembly removal.

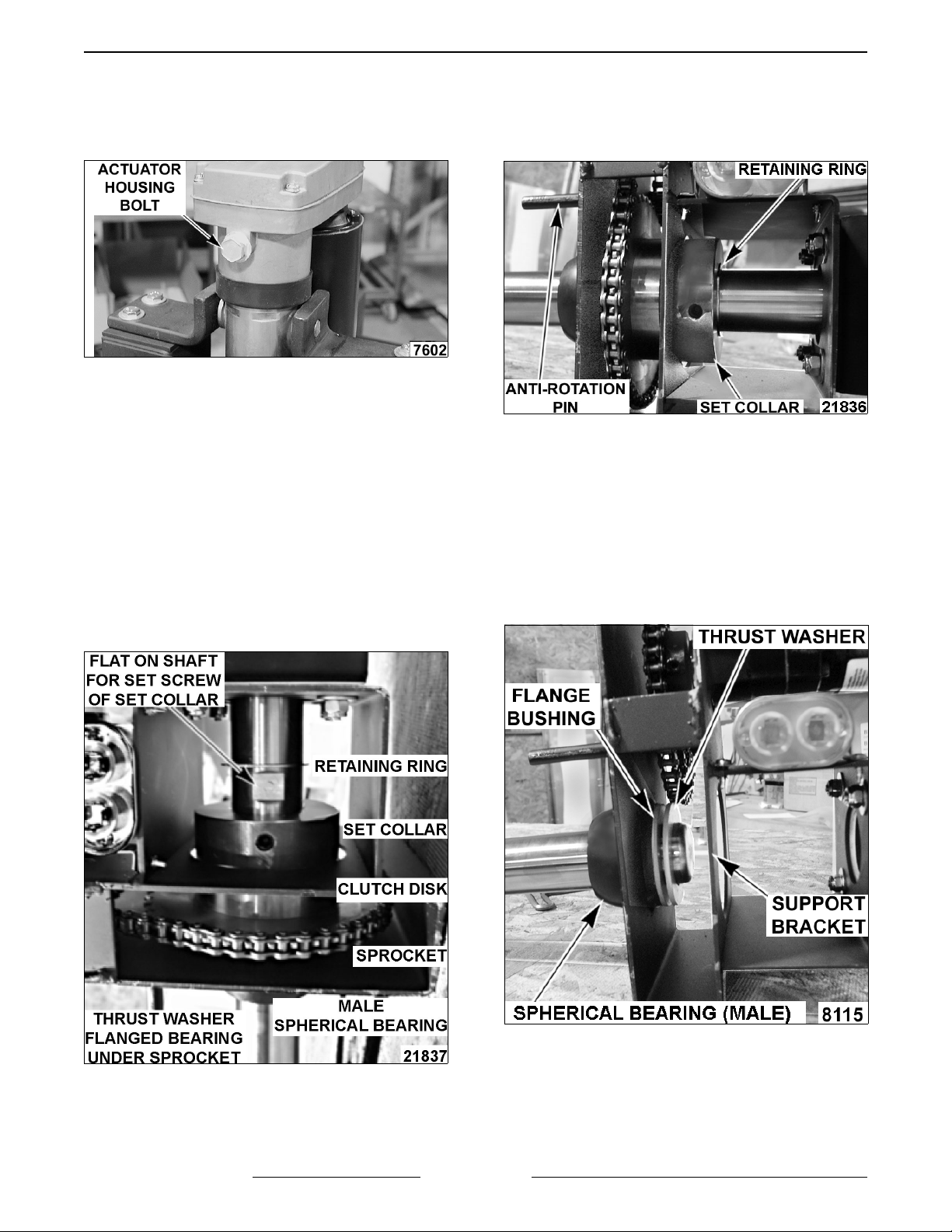

Disassembly

1. Loosen set screw and remove rack pointer from

shaft.

2. Loosen set screws securing the set collar to

rotator shaft.

3. Remove the retaining ring from groove in rotator

shaft.

NOTE: Remove retaining ring from shaft as you are

removing shaft from assembly.

4. Pull rotator shaft from rotator assembly set

collar, clutch disk, drive sprocket, thrush

washer, flanged bearing and male half of

spherical bearing.

lift arm only if replacing.

Assembly

1. Install female half of spherical bearing into the

lift arm if removed.

2. Apply high temperature grease to female half of

spherical bearing. Spread grease evenly across

bearing surface.

3. Install flange bushing into rotator assembly.

4. Install male half of spherical bearing, with taper

to mate with female half, onto flanged bushing.

5. Insert rotator shaft into flange bushing from

bottom of rotator assembly and install thrust

washer.

5. Remove rotator drive chain from sprocket teeth.

6. Remove flange bushing from rotator bracket.

7. Remove female half of spherical bearing from

F25361 (January 2010)

Page 14 of 60

6. Install drive chain around drive sprocket.

7. Continue to push the shaft through the rotator

assembly. As you do, install drive sprocket onto

shaft (tooth side towards thrush washer) before

the shaft is beyond the support bracket.

Page 15

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

8. Install clutch disk.

9. Install set collar with counter bore edge towards

clutch and slide split ring onto shaft.

A. Position set collar so set screw can be

secured onto flat of rack lift shaft.

10. Install retaining ring into groove of rotator shaft.

SERVICE PROCEDURES AND

ADJUSTMENTS.

19. Check for proper operation.

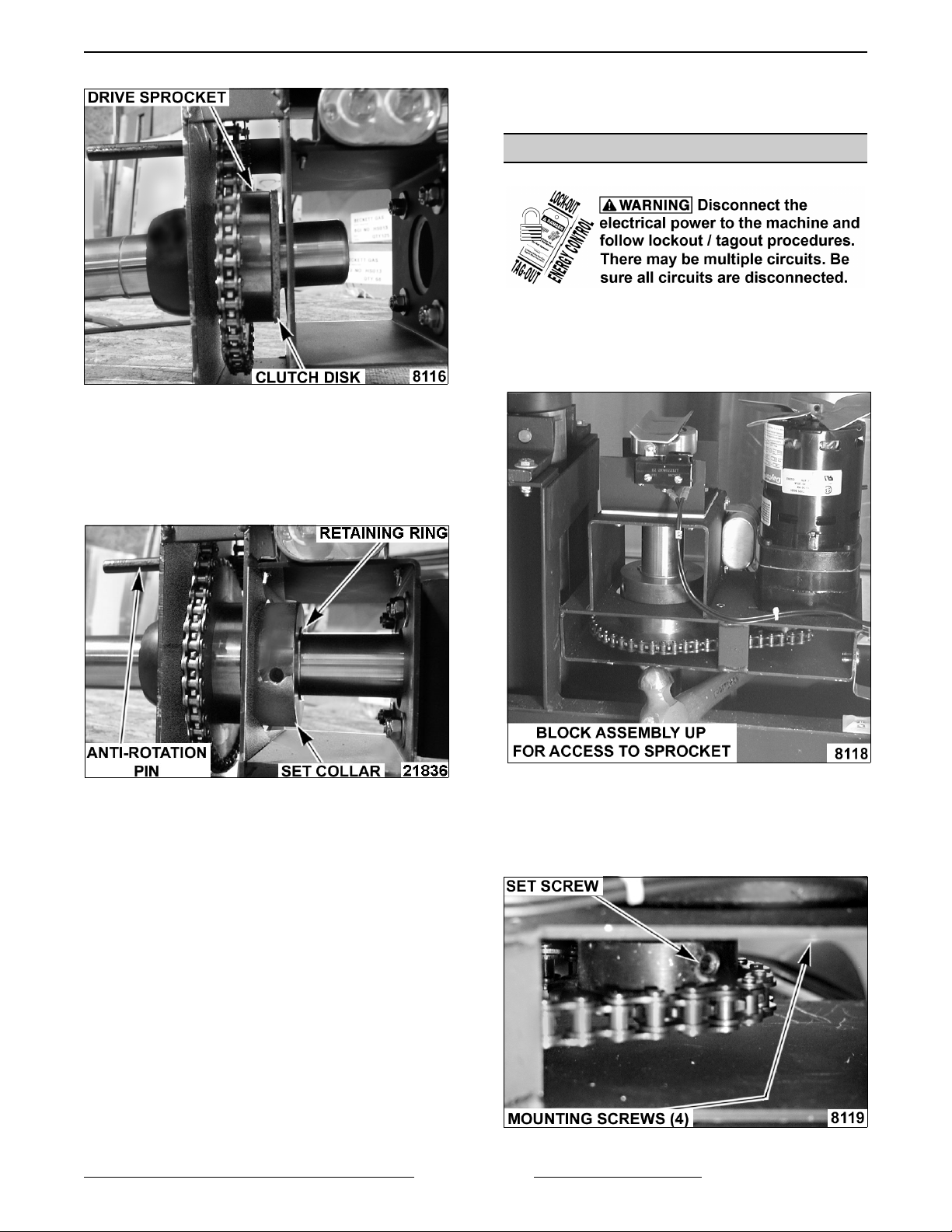

ROTATOR MOTOR

Removal

1. Block the rack rotator assembly in a position to

access the motor mounting bolts and sprocket

set screw.

11. Insert rotator shaft through female half of

spherical bearing in lift arm.

12. Apply high temperature grease to drive chain.

13. Lower rotator assembly. Rotator shaft will align

with bearings in rotator shaft housing.

NOTE: Anti rotation pin on rotator assembly must

mate with anti rotation slot in lift arm.

14. If removed earlier, install actuator housing

screw and actuator for rack up and down

switches.

15. Install rack pointer onto rotator shaft.

16. Install rack carrier.

17. Adjust RACK POINTER as outlined under

SERVICE PROCEDURES AND

ADJUSTMENTS.

18. Adjust RACK HEIGHT as outlined under

2. Disconnect the rotator motor lead wires.

3. Remove cooling fan from motor.

4. Loosen rotator motor sprocket set screw.

5. Remove rotator motor mounting screws.

6. Lift rotator motor and sprocket will stay in place.

F25361 (January 2010)Page 15 of 60

Page 16

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

Assembly

1. Install rotator motor shaft through rotator

assembly and rotator sprocket.

2. Position sprocket onto rotator motor shaft, collar

side towards motor.

3. Install rotator motor mounting screws and align

sprocket and rotator drive chain. Ensure rotator

drive chain is not in a bind.

4. Secure set screw onto motor shaft.

5. Connect rotator motor lead wires.

NOTE: Shaft rotation viewed from top of oven.

Clockwise Rotation: Red wire= #20, Black wire=

#53, White/White wires, recommended.

6. Install cooling fan to motor shaft.

7. Remove block from rotator assembly.

8. Check for proper operation.

4. Align bottom actuator arm pin with access hole

in side of rack lift assembly beam.

ACTUATOR

1. Block the rack rotator assembly from moving.

2. Disconnect lead wires to actuator motor.

3. Remove top actuator mounting brackets from

rack lift assembly.

5. Block rack lift arm to prevent movement.

6. Remove actuator pin from the assembly and

remove actuator from rack lift assembly.

7. Make sure replacement actuator is fully

retracted. Turn end of actuator arm CCW 12

complete turns.

NOTE: Measure end of actuator arm to bottom of

actuator arm housing, measurement should be

approximately 2 1/2".

F25361 (January 2010) Page 16 of 60

Page 17

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

8. Install lower actuator arm pin through lift pin.

1. If necessary, move the gas line out of the way.

2. Shut off water supply line and remove exterior

water supply that is within the boundary of

blower cover.

3. Disconnect lead wires at motor junction box.

4. Remove motor junction box.

5. Remove probe cover and any existing probes.

6. Remove blower cover supports.

7. Remove blower cover.

9. Position the rack rotator assembly so the top

actuator mounting brackets will align with the

rotator assembly.

10. Reconnect lead wires.

11. Put oven into use and check for proper

operation.

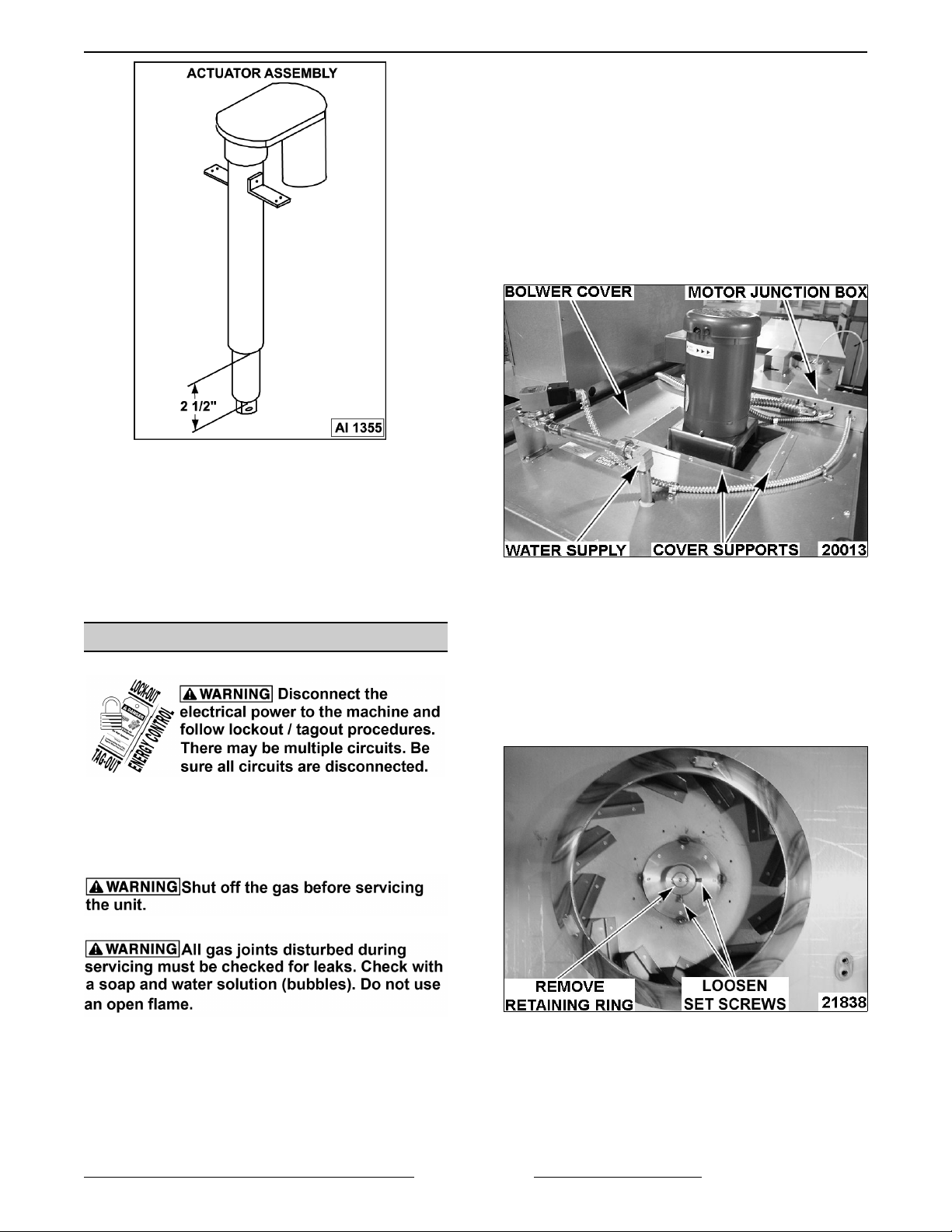

CONVECTION BLOWER/MOTOR

NOTE: To follow this procedure, there must be 24''

of clearance at the top of the oven. If not, the blower

wheel must be accessed thru the heat exchanger

compartment.

8. Remove insulation.

9. Remove screws from blower mounting

assembly and remove complete blower

assembly.

10. Loosen set screws in blower wheel hub.

11. Remove retaining ring from shaft.

12. Remove blower wheel from motor shaft.

A. CHECK ALL JOINTS PRIOR TO THE

GAS VALVE (SOLENOID) BEFORE

LIGHTING UNIT.

B. CHECK ALL JOINTS AFTER TO THE

GAS VALVE (SOLENOID) AFTER THE

UNIT IS LIT.

13. Remove screws securing motor mounting

bracket and remove motor assembly.

F25361 (January 2010)Page 17 of 60

Page 18

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

14. Remove heat slinger and mounting bracket

from motor.

4. Reverse procedure to install.

15. Reverse the procedure to install.

GAS VALVE

A. CHECK ALL JOINTS PRIOR TO THE

GAS VALVE (SOLENOID) BEFORE

LIGHTING UNIT.

B. CHECK ALL JOINTS AFTER TO THE

GAS VALVE (SOLENOID) AFTER THE

UNIT IS LIT.

1. Open control compartment door to gain access

to gas manifold assembly.

2. Disconnect the gas supply union fitting from gas

manifold assembly.

NOTE: The burner mounts may have to be loosened

to allow the gas valve to rotate.

3. Remove the valve from the burner manifold.

5. Check GAS PRESSURE as outlined under

SERVICE PROCEDURES AND

ADJUSTMENTS.

6. Operate oven and check for proper operation.

GAS MANIFOLD / ORIFICES

A. CHECK ALL JOINTS PRIOR TO THE

GAS VALVE (SOLENOID) BEFORE

LIGHTING UNIT.

B. CHECK ALL JOINTS AFTER TO THE

GAS VALVE (SOLENOID) AFTER THE

UNIT IS LIT.

1. Open control compartment door to gain access

to gas manifold assembly.

2. Disconnect lead wires to gas valve, ignitor and

flame sensor.

3. Loosen the gas supply union fitting from gas

manifold assembly.

F25361 (January 2010) Page 18 of 60

Page 19

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

4. Remove screws securing burner cover to oven.

5. Remove all screws securing gas manifold to

burner rack assembly.

A. CHECK ALL JOINTS PRIOR TO THE

GAS VALVE (SOLENOID) BEFORE

LIGHTING UNIT.

B. CHECK ALL JOINTS AFTER TO THE

GAS VALVE (SOLENOID) AFTER THE

UNIT IS LIT.

1. Open control compartment door to gain access

to burner assembly.

2. Remove screws securing burner cover to oven.

6. Disconnect the gas supply union fitting from gas

manifold assembly.

7. Pull gas manifold from burner rack assembly.

8. Remove orifice fitting from gas manifold.

NOTE: Note orifice size for natural or L.P.

9. Reverse the procedure to install.

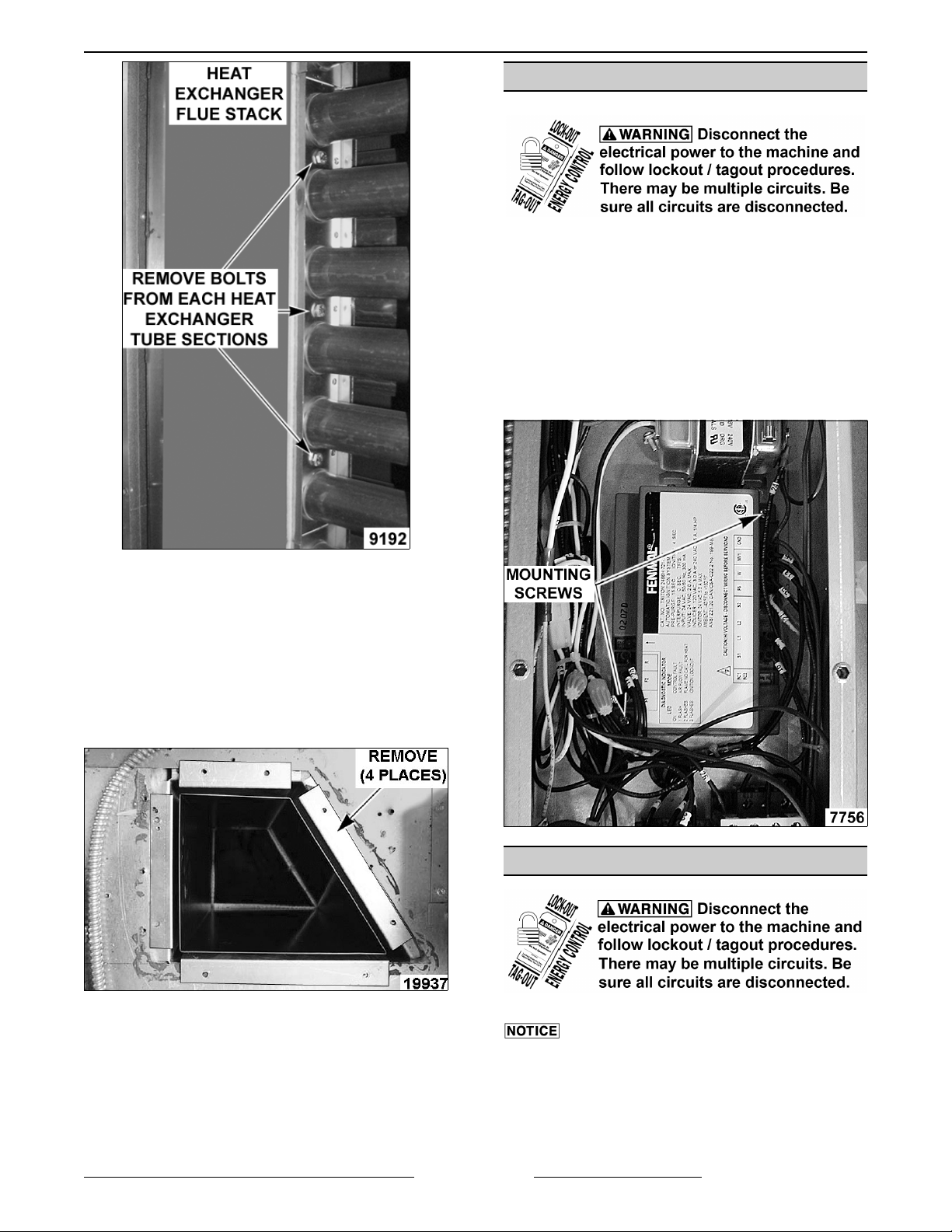

HEAT EXCHANGER

3. Disconnect gas manifold at the union fitting

OV500G1 & OV500G2.

4. Disconnect flame sensor lead wire OV500 G1 &

OV500G2.

F25361 (January 2010)Page 19 of 60

Page 20

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

5. Remove screw securing hot surface ignitor to

burner side rack assembly, and pull ignitor out.

6. Remove screws securing burner rack enclosure

from oven.

9. Remove steam and exchanger compartment

panels.

10. Remove steam ball assemblies.

11. Access draft inducer box on top of oven and

remove. Disconnect deflector baffle from

hangers above heat exchanger tubes and

remove from top of tubes OV500G1 &

OV500G2.

12. Lower leveling post to allow room at flue

connection and transition chamber.

OV500G2 OVENS

7. Remove burner firing plates OV500G1 &

OV500G2.

8. Remove burner angle rack OV500G1 &

OV500G2.

OV500G1 OVENS

13. Remove screws securing heat exchanger tube

sections from oven. Early modes only have

more than 3 screws.

F25361 (January 2010)

Page 20 of 60

Page 21

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

IGNITION MODULE

1. Open the control compartment door to gain

access to ignition module.

2. Remove control box cover.

3. Disconnect lead wires from the ignition module.

Note Wire locations or refer to wiring diagram.

4. Remove screws securing ignition module to

oven.

5. Reverse the procedure to install.

14. OV500G1 & OV500G2 oven pull rear of heat

exchanger into the oven cavity. As you slide

rear of heat exchanger, pull heat exchanger to

clear baking compartment to free front of heat

exchanger.

15. Replace heat exchanger tubes and flue sections

as needed.

NOTE: To aid installation of new flue, remove the

four exhaust stack retainers.

CONTROLLER

16. Reverse the procedure to install.

Certain components in this system are

subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is available

to prevent damage. The field service grounding kit

must be used anytime the control board is handled.

1. Open the control compartment door to gain

access to controller.

F25361 (January 2010)Page 21 of 60

Page 22

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

2. Remove controller rear cover.

NOTE: When installing ensure stand off spacers are

installed behind controller board.

5. Reverse the procedure to install.

6. Verify controller default settings.

7. Check oven for proper operation.

HIGH LIMIT SWITCH

NOTE: On OV500G1 & OV500G2 oven, access high

limit switch at top of oven in service entrance box.

On OV500E1 & OV500E2 oven, access high limit

switch at the bottom of the control component box.

1. Open control compartment door and remove

component box cover.

3. Disconnect all control harness connections.

NOTE: Ovens with Kosher operation will have a

connector for the key lock switch to be disconnected.

4. Remove nuts and washers securing controller

to controller panel.

2. Disconnect high limit switch lead wires.

3. Remove screws securing high limit switch to

component box or service entrance box.

4. Access high limit probe at top of oven.

5. Remove screws securing probe cover.

6. Remove high limit probe fitting from oven and

pull high limit out.

F25361 (January 2010) Page 22 of 60

Page 23

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

To install:

1. Install high limit in component box or service

entrance box.

2. Connect lead wires to high limit.

3. Route high limit capillary tube to top of oven.

4. Mark 12" from end of probe.

DRAFT INDUCER MOTOR

1. Access draft inducer box from top of oven.

2. Remove vacuum line from fitting on draft

inducer housing.

3. Remove screws securing draft inducer exhaust

duct & collar to hood.

4. Remove screws securing draft inducer cover to

box.

5. Insert male compression fitting onto high limit

probe.

6. Install female fitting into center probe location.

7. Insert 12" of high limit probe into oven. Ensure

that high limit probe goes through both inner

and outer walls of oven.

NOTE: Remove vent lid to aid in feeling for high limit

probe protruding down through oven.

8. Install first set of 3 spacers into high limit fitting.

9. Pack seal gasket material around probe into

high limit fitting.

10. Insert second set of 3 spacers into high limit

fitting.

11. Tighten male compression fitting against

second set of spacers to secure high limit

probe.

5. Remove screws securing draft inducer motor

(flex) conduit clamps from oven.

12. Install probe cover.

13. Check oven for proper operation.

6. Remove screws securing draft inducer box and

lift box from oven.

F25361 (January 2010)Page 23 of 60

Page 24

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

NOTE: Make note of dimension that draft inducer fan

blade is located on motor shaft, for installing fan

blade on to new motor.

7. Loosen set screw securing fan blade from draft

inducer motor shaft.

12. Check for proper operation.

PRESSURE SWITCHES

1. Open control compartment door to gain access

to draft inducer vacuum switch and hood vent

pressure switch.

2. Disconnect lead wires from appropriate

pressure switch.

3. Remove tube from pressure switch.

4. Remove screws securing pressure switch.

8. Disconnect lead wires from draft inducer motor.

9. Remove screws securing draft induce motor

from draft inducer box.

10. Reverse the procedure to install.

11. Verify combustion analyses.

5. Reverse the procedure to install.

OVEN CAVITY VENT MOTOR

1. Remove vent lid.

2. Remove screws securing vent motor cover and

mounting assembly from vent box.

F25361 (January 2010) Page 24 of 60

Page 25

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

3. Disconnect lead wires from vent motor and vent

switch.

4. Loosen vent cam set screw and remove cam

from shaft.

NOTE: Mark location of cam on vent motor shaft.

OVEN CAVITY VENT SWITCH

1. Remove screws securing vent motor cover from

vent motor box.

2. Disconnect lead wires from vent switch.

3. Remove screws securing vent switch from vent

bracket.

4. Reverse procedure to install.

NOTE: When installing, position cam on motor shaft

to prevent rubbing.

5. Remove screws securing vent motor from vent

motor bracket.

THERMOSTAT (BACK UP

SYSTEM ONLY)

1. Open control compartment door to gain access

to backup thermostat.

2. Remove component panel cover.

3. Remove screws securing back up system panel

from control box.

4. Disconnect lead wires from backup thermostat.

5. Remove screws securing thermostat from

backup system panel.

6. Reverse the procedure to install.

F25361 (January 2010)Page 25 of 60

Page 26

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

11. Tighten male compression fitting against

second set of spacers to secure backup

thermostat bulb.

12. Install probe cover.

6. Access the thermostat bulb at top of the oven.

7. Remove screws securing probe cover from

oven.

8. Remove compression fitting and remove

thermostat bulb.

To install:

1. Install backup thermostat in component panel.

13. Check oven for proper operation.

TEMPERATURE PROBE

1. Access the probe at top of the oven.

2. Remove screws securing probe cover from

oven.

3. Remove compression fitting and remove probe

from oven.

2. Connect lead wires to high limit.

3. Route thermostat capillary tube to top of oven.

4. Mark 8 3/4" from end of probe.

5. Insert male compression fitting onto thermostat

probe.

6. Install female fitting into bulb location.

7. Insert 8 3/4" of backup thermostat into oven.

Ensure that backup thermostat bulb doesn't

touch inner walls of oven.

8. Install first set of 3 spacers over capillary tube

and allow them to go into the female

compression fitting.

9. Pack seal gasket material around capillary tube.

10. Insert second set of 3 spacers over capillary

tube and allow them to go into the female

compression fitting.

F25361 (January 2010) Page 26 of 60

4. Open the control compartment door to gain

5. Remove cover from controller box.

6. Disconnect temperature probe lead wires from

7. Remove temperature probe from oven.

NOTE: Temperature probe should be install

approximately 8 3/4" down from top of probe fitting

into oven compartment.

8. Reverse the procedure to install.

access to controller.

controller board.

Page 27

OV500 SERIES RACK OVEN - REMOVAL AND REPLACEMENT OF PARTS

EPROM REPLACEMENT

1. Open the control compartment door to gain

access to controller.

2. Remove the controller box cover.

Static electricity will damage the controller

board. Use an anti-static grounding kit when

servicing the controller.

3. Remove the prom from the controller.

4. Install the new prom. Verify orientation notch

and carefully align pins of prom.

B. The door jamb hinge set screws will need

to be loosened to remove hinge pins and

insert in opposite direction (upward).

5. Re-assembly the oven.

6. Perform CONTROLLER DEFAULT SETTINGS

as outlined under SERVICE PROCEDURES

AND ADJUSTMENTS.

7. Check for proper operation.

DOOR SWING CHANGE

NOTE: If hood installed door can not be lifted to

proper height to clear the hinge pins. Removal of

door hinges from door jamb will be required.

1. Open the door at least 90 degrees.

2. Remove door sweep from door assembly.

3. Use a J bar to support door assembly at center

bottom to assist in door removal.

A. Remove both door jamb hinges from door

jamb and set door & door hinges aside.

NOTE: Ensure hinge pin set screws engage into

notch in pin and tighten set screws.

4. Rotate door such that top of door is at the

bottom and install door & door hinges onto door

jamb.

5. Remove pan head screws on opposite side of

door jamb and install both door jamb hinges

with flat head screws while supporting center

bottom of door assembly with a J bar.

NOTE: Leave one door jamb hinge loose to aid

installation of door assembly.

NOTE: Tighten door jamb hinge if left loose to aid

installation of door assembly.

A. Install pan head screws into other side of

door jamb were hinges removed from.

F25361 (January 2010)Page 27 of 60

Page 28

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

6. Remove door catches from door jamb.

A. Remove screws on opposite side of door

jamb and install door strike.

B. Install screws onto other side of door jamb

catch was removed from.

C. Install both door catches to opposite door

jamb.

7. Adjust the DOOR as outlined under SERVICE

PROCEDURE AND ADJUSTMENTS.

8. Install door sweep onto door assembly at

bottom of door.

SERVICE PROCEDURES AND ADJUSTMENTS

CONTROLLER INPUT/OUTPUT

STATUS DIAGNOSTIC

1. Turn oven on.

2. Check controller input/output status indicator

LED's on back of controller, for proper

input/output operation during various stages of

operation.

NOTE: Use oven sequence of operation in

conjunction with diagram.

3. Correct any improper input/output operation.

F25361 (January 2010) Page 28 of 60

4. Check oven for proper operation.

7598

Page 29

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

IGNITION MODULE SELF

DIAGNOSTICS

Ignition module makes three attempts to light burner

before proceeding to lock-out mode.

1. Turn oven on and set controller to call for heat.

2. Access the ignition module by removing

component panel cover.

3. Check ignition module indicator LED for fault

codes as stated in following chart.

NOTE: LED will briefly illuminate during pre-purge.

LED DIAGNOSTIC INDICATOR CODES

LED CODES

LED off No Fault

LED on Control Fault

'1' Flash Air Flow Fault

'2' Flash Flame No Call For Heat*

'3' Flash Ignition Lockout

* Flame continues after controller set temperature is

satisfied. (Gas valve sticks open.)

4. Disconnect power to oven.

5. Correct the fault.

6. Re-apply power.

7. Check ignition module for correct operation.

CONTROLLER TEMPERATURE

CALIBRATION

Certain components in this system are

subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is available

to prevent damage. The field service grounding kit

must be used anytime the control board is handled.

1. Check setting of controller temperature offset

(P4) as outlined under CONTROLLER

DEFAULT SETTINGS and record setting.

2. Verify that the probe is functioning properly as

outlined under TEMPERATURE PROBE TEST.

3. Place a thermocouple of a temperature tester in

the center of right incoming air slot of the bake

chamber.

A. Route thermocouple through hinge side of

door to the outside of the oven. Make sure

that the lead wire is kept clear of the rack

carrier.

4. Turn the oven on.

5. Set the controller temperature to 400EF.

6. Allow the oven temperature to stabilize

(minimum 3 cycles).

7. Note temperature reading on temperature tester

and controller at the exact time the heat light on

the controller goes out.

TEMPERATURE PROBE TEST

1. Access controller board.

2. Disconnect temperature probe lead wires from

controller board.

3. Set the multi meter to milli volt scale and

connect positive lead (red) to the (white) probe

lead wire and negative lead (black) to (red)

probe lead wire.

4. Verify the multi meter reading to the

temperature conversion chart as follows.

TEMPERATURE CONVERSION CHART

FAHRENHEIT CELSIUS

100 38 -1.8 to 1.2

200 93 1.5 to 4.3

300 149 4.5 to 7.3

400 204 7.5 to 10.6

5. If multi meter reading indicates an open or is

outside the millivolt range, replace the

temperature probe as outlined under

TEMPERATURE PROBE.

MILLIVOLT

RANGE

8. If the temperature difference between the two

readings is greater than ±2EF or ±1EC, adjust

the temperature offset (P4) as outlined under

CONTROLLER DEFAULT SETTINGS.

A. If temperature test shows a temperature

higher than controller, increase offset (P4)

the amount of difference.

B. If temperature test shows a temperature

lower than controller, decrease offset (P4)

the amount of difference.

C. If temperature difference is greater than

the range of the controller, replace

controller (range ±50EF. or ±10EC.).

9. Check for proper operation.

10. Remove temperature tester thermocouple from

the oven.

CONTROLLER SETTINGS

CLOCK SETTING

1. Press the Power On/Off keypad to turn the

oven on.

2. Press and hold either Auto On/Off Timer

Up/Down Arrows for 3 seconds.

3. After the colon stops flashing use the Up/Down

Arrows to adjust the clock setting.

Page 29 of 60

F25361 (January 2010)

Page 30

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

A. After the desired time is set and the

Up/Down Arrows have not been pressed

for 5 seconds, the colon will start to flash

indicating the clock has continued running.

PARAMETER SETTINGS

1. Press the Power On/Off keypad to turn the

oven off.

2. Access set-up mode by pressing and holding

Start while pressing Power On/Off for 3

CONTROLLER DEFAULT SETTINGS

Set

Temp

Display

P1 Maximum temperature set point

P2 Preheat temperature

P3 Minimum temperature set point

P4 Temperature offset

P5 Heat OFF offset

P6 Heat difference hysteresis

P7 Maximum steam time (in seconds)

P8 EF or EC

P9

P10 Vent evacuate time (in seconds)

P11 Vent open percentage

P12

P13

P14

P15 Interior light brightness

P16 Clock operation

P17

P18 Setback temperature

0= minutes, 1= hours & minutes

End of bake time auto vent enable

Steam time in seconds or Food

Service Mode Steam Interval

300 to 900= Food Service Mode

Set-Up Item Descriptions

This is the maximum temperature at which the

This is the default temperature set point when

the oven is first turned on (program 0). The

preheat temperature cannot be set higher than

This is the minimum temperature at which the

This value permits an offset or correction

between the temperature probe and the real

This value adjusts the temperature difference

between the set point and stopping the heating

This value adjusts the temperature difference

between the on temperature and off temperature

Time set is the maximum time (in seconds) that

water is supplied during the STEAM TIMER

The oven can be set to display temperature in

Bake time mode

0= disable , 1= enable

End of bake time auto vent

(in minutes)

0= seconds,

Temperature setback time

(in minutes)

The BAKE TIMER cab be set up to display

minutes set/minutes remaining or hours and

minutes. Select 0 for minutes set/minutes

remaining or 1 for hours and minutes.

Time set is the time (in seconds) that the vent is

100% open at the beginning of the venting cycle.

This value is the percentage the bake chamber

vent is open after the vent evacuate time has

This value enables the automatic vent cycle.

This is the number of minutes before the end of

the bake cycle that the vent is open.

Displays steam time in seconds or operation in

Food Service Mode. The number of seconds set

is the steam interval. See FOOD SERVICE

STEAM MODE as outlined in this section.

This value is the brightness of the interior lights.

The higher the number, the brighter the lights.

This selects either 12 hour (AM/PM) or 24 hours

real time display. Press the bake time UP button

to switch between the two types of displays.

This selects the elapsed time from the last timed

bake to when the oven will lower the oven set

temperature to the value set in P18.

This selects the oven set temperature that the

oven will change to when the temperature

setback time has been exceeded in P17.

seconds.

3. Press Set Temp Up Arrow to select set-up

item shown in set temp display.

4. Use the Bake Timer Arrows to adjust set-up

values in the bake timer display.

5. Use the following chart to restore default

settings.

oven can be set.

the value in P1.

oven can be set.

baking chamber temperature.

system.

of the heating system.

operation.

Fahrenheit or Celsius.

expired.

Settings Shown In

Bake Timer Display

Set for 525EF (range 50 to 525EF.)

or (10 to 274EC.)

Set for 375EF (range 50 to 525EF.)

or (10 to 274EC.)

Set for 50EF (range 50 to 200EF.)

or (10 to 93EC.)

Default setting 0 (range ± 50)

Default setting -2 (range ± 20)

Default setting 4 (range 0 to 20)

Set for 20 (range 0 to 30 max when

P20 set for 0 = standard) 60 max

when P20 set for 1 = restricted

operator mode)

EF

Set for 0

Set for 90 (range 0 to 180)

Set for 15% (range 5 to 100%)

Set for 0

Set for 1 (range 0 to 99)

Steam time in seconds = 0

Food service Mode (range 300 to

990 seconds)

Set for 90 (range 50 to 100)

Set for A P= 12 hour AM/PM

Set for 24 = 24 hour

Set for 180 (range 10 to 180)

Set for 300EF (range 50 to 300EF.)

or (10 to 149EC.)

F25361 (January 2010) Page 30 of 60

Page 31

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

Lights mode

P19

P20

P21

P22

P23-P24 Unused

P25

0= auto operation

1= continuously ON

Restricted operator mode

0= Standard

1= Restricted Operation Mode

Advanced Energy Saving Mode

0= Standard

1= Advanced Energy Saving

Mode

OV210 Mode

0= Standard

1= OV210 Mode

Communicate Mode

0= Direct Connect

1= NAFEM Protocol

Select 1 for lights on continuously (when oven is

on) or select 0 for automatic operation, lights will

turn off automatically after 30 minutes of no user

activity (door not opened or closed, no buttons

pushed).

Select 1 for Restricted operator mode. When a

program is selected by the operator the Bake

Timer Minutes Set window will display the total

bake time of all steps in the program. Standard

operation only displays the minutes in the

selected step. When a program is selected and

the Start button is pressed the operator cannot

make changes to the Bake Time remaining or

the Oven Set Temp. If set for steam, steam is

produced in 5 second on - 5 second off intervals

for the time set in P7. The maximum solenoid on

time range that can be set in P7 increases to 60

seconds. Change P7 to 60 when P20 is set for

1. When P20 is changed from 1= Restricted

Operator Mode to 0= Standard Mode P7 must

be changed below 30 (range 0 to 30 max) or

solenoid will energize continuously for up to 60

seconds.

Select 1 for Advance Energy Saving. Forcing the

oven into an Advance Auto On - Auto Off Mode

to conserve energy. Several steps are

necessary to enable this mode. Set the Auto On

Time to 60 minutes before the first bake time.

Set the Auto Off Time. Press the Auto On / Auto

Off button to illuminate the Timer On / Off

indicator. Set P17 & P18 to customer settings.

See Advanced Energy Saving Mode as outlined

in this section.

Select 1 for installation of an HBA control panel

and control door on an OV210. When enabled

the OV210 will emulate all the functions of an

HBA.

Select 1 for NAFEM protocol compliant

communication.

Set for 0

Set for 0

(when P20 is changed P7 setting

must be changed to correspond

with mode selection)

Set for 0

Set for 0

Set for 0

Set for 0

NOTE: If P21 is set to 1 and control is programed for Auto On - Auto Off: oven will not start up in Off Time Mode

unless a minimum of 30 minutes is entered into timer within 30 seconds of pressing On/Off keypad. After oven is

started up and timer displays 00 for time and no keypads are pressed for the Set Back Time used inP17, the oven

will then shut down.

NOTE: Before restarting oven, power switch and gas valve must be OFF for a minimum of 5 minutes.

6. Press On/Off to exit set-up mode.

7. Check for proper operation.

BAKERY MODE

The Bakery Mode is the default setting. The value for

parameter P14 is 0 and displayed in the Bake Timer

display. In Bakery Mode the controller will only

initiate one steam cycle, for the set steam time.

FOOD SERVICE STEAM MODE

The food service steam mode has been updated to

provide steam at intervals throughout a bake cycle.

The length of the steam cycle and the interval

between cycles can be set by the operator. Steam

Timer Display will display the steam cycle length and

the displayed cycle length will not count down while

steaming.

1. To enable food service mode:

A. Oven controller off.

B. Press and hold the Start keypad while

Page 31 of 60

pressing the Power On/Off keypad for 3

seconds.

C. Press the Set Timer Arrows to select

parameter P14.

D. Enable Food Service Steam Mode by

pressing the Bake Timer Up Arrow until

display changes to a three digit number.

E. Set desired time (in seconds) between

steam cycles by pressing the Bake Timer

Up/Down Arrows. Range 300 to 990

seconds by increments of 10 seconds.

Example:

Parameter P14 set to 300

Steam Time set to 3

Steam cycle will initiate for 3 seconds after every 300

seconds

2. Press the Power On/Off keypad to save

settings and exit Setup Mode.

F25361 (January 2010)

Page 32

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

OVEN TEMPERATURE SAFETY ALARM

indicator light is illuminated.

NOTE: Standard feature, no parameter setup

required.

If the temperature at the oven probe is between 570

to 600°F. (299 to 316EC.) for ten seconds, the

controller will do the following:

• Shuts off all oven features.

• Sounds alarm and flashes the Oven Temp

display.

• Display SHdn (shutdown) in the Bake Timer

display.

NOTE: The oven will remain in Oven Temperature

Safety Alarm Mode until the 120Volt supply power is

turned off to the oven.

ADVANCED ENERGY SAVING MODE

The Advanced Energy Saving Mode is NOT the

default setting. The default value for parameter P21

is 0.

NOTE: When P21 is set to 1, Advanced Energy

Saving Mode enabled, the Auto On/Off Time can

only be changed in set up mode. To disable the

Auto On/Off Time P21 must be set to 0, disabled.

The Advanced Energy Saving Mode automatically

starts the oven at the preset time, sets the

temperature to (P2) default of 375°F. (191°C.) and

the timer is set for 60 minutes and running. When the

oven timer is timed out and no buttons are pushed

on the controller for 15 minutes (P17), the Set Back

Mode will be enabled. The oven will beep twice and

the set temperature reduces to (P18) set at 250°F.

(121°C.). If oven is in Set Back Mode set the bake

temperature and timer for 12 minutes and press start

to prepare the oven for baking. When buzzer sounds

the oven is ready to load. The oven will shut down

automatically at the preset time.

1. To enable the Advanced Energy Saving Mode.

A. Oven controller off.

B. Press and hold the Start keypad while

pressing the Power On/Off keypad for 3

seconds.

C. Press the Set Timer Arrows to select

parameter P21.

D. Enable Advanced Energy Saving Mode by

pressing the Bake Timer Up Arrow to

display 1.

E. Press the Set Timer Arrows to select

parameter P17. Set to 15 using Bake

Timer Up/Down Arrows.

F. Press the Set Timer Arrows to select

parameter P18. Set to 250 using Bake

Timer Up/Down Arrows.

G. Press Timer On/Off Keypad so that the

H. Consult with Bakery Manager for required

start and end of bake time.

I. Press and hold the Auto On Time keypad

while pressing the Up/Down Arrows to set

the Auto On Time 60 minutes prior to the

requested start of bake time.

J. Press and hold the Auto Off Time keypad

while pressing the Up/Down Arrows to set

the Auto Off Time to the requested end of

bake time.

K. Press the Power On/Off keypad to exit

parameter set up mode.

2. Verify proper operation.

A. When in Set Back Mode the damper

should not open.

Advanced Energy Saving Mode Operation

1. Auto On Time will start the oven automatically

at the set time chosen to a preset set

temperature (P2) default 375°F. (191°C.)

A. Oven will not start up unless:

1) Loading door is closed.

2) Hood system is operating gas units

only. Typical hood systems are wired

to turn on automatically when oven

powers on.

B. Controller will set timer for 60 minutes and

start timer.

C. When timer times out showing 0:00 and

buzzer sounds, the oven is ready to use.

The operator may then change the desired

temperature or time.

2. Set Back Function, P17 & P18.

A. Set Back time P17 is set to 15 minutes.

1) Time shows 0:00 and no other

keypads are pushed for 15 minutes,

controller will automatically set

temperature to 250°F. (121°C.), P18.

Oven will beep twice.

B. Vent damper should remain closed while in

Set Back Mode.

C. Exit Set Back Mode.

1) Set temperature to required bake

temperature.

2) Set timer for 12:00 minutes. Press

start.

3) When buzzer sounds oven is ready

for use.

3. Auto off Time shuts down the oven

automatically at the preset time.

F25361 (January 2010)

Page 32 of 60

Page 33

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

A. If time is remaining on timer counting

down, oven will not shut down.

controller will enter Kosher Active Mode, and

have the following operating characteristics:

B. Once timer shows 0:00 the oven will shut

down in 15 minutes, P17.

C. Operator can start oven while in Auto off

Time by pressing the On/Off keypad, set

timer to a minimum of 30 minutes and

press start keypad.

1) Timer must be set and started within

30 seconds of pushing On/Off

keypad.

NOTE: If timer is not started in 30 seconds oven will

shut down immediately.

2) Oven will start as described in Auto

On sequence.

3) Oven will operate normally until timer

shows 0:00 and no keypads are

pressed. Oven will shutdown in 15

minutes, P17.

KOSHER OPERATION MODE

The Kosher Mode can only be ordered from the

factory and has a key operated manual reset. Kosher

Lockout Mode automatically locks out controller

(lock-out mode) if Kosher parameters are not

maintained.

NOTE: Kosher Reset Keys are shipped with the

oven, located inside the controller box, at bottom of

box. Keys should be provided to facilities approved

authority at oven start-up.

A. The minimum set temperature is 200°F.

(93°C.).

B. If the oven temperature falls below 170°F.

(77°C.). an alarm will sound (fast pulse

rate).

NOTE: Alarm will silence if oven temperature

recovers back to 170°F. (77°C.).

C. If the oven temperature falls below 150°F.

(150°C.) the alarm will silence and

controller will go into Kosher Lock-Out

Mode, controller display will read LOC

OUT.

NOTE: In Kosher Lock-Out Mode controller locks out

all controller operations and will need to be reset.

Obtain reset key from the facility's approval authority.

3. To reset a Kosher Lock-Out Mode:

A. Use the reset key and turn the reset switch

full right to the Reset position then back to

the off position.

NOTE: Resetting the switch will put the controller

back into the Kosher Enable Mode. Once oven

temperature reaches 200°F. (93°C.) controller will

enter Kosher Active Mode.

1. To enable Kosher Enable Mode:

A. Oven controller off.

B. Press and hold the Airflow Delay Arrow

keypad while pressing the Power On/Off

keypad for 3 seconds.

NOTE: A flashing 0 in the Bake Timer Display

indicates controller is in the Bakery Mode (non

Kosher Mode).

C. Press the Bake Timer Up Arrow until

display reads 1 (enabling Kosher Enable

Mode).

D. Press the Power On/Off keypad to exit.

2. Once oven temperature reaches 200°F. (93°C.).

Page 33 of 60

B. Verify the Bake Timer Display reads 1

(flashing). If not, press the Bake Timer

Arrows until display reads 1 (flashing).

C. Press the Power On/Off keypad entering

the Kosher Active Mode.

NOTE: The controller will call for heat in the Kosher

Active Mode and maintain the minimum Kosher

temperature 200°F. (93°C.).

F25361 (January 2010)

Page 34

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

4. To disable Kosher Operation Mode - Bakery

Mode:

1. Attach a manometer to 1/8" NPT inlet pressure

tap on gas valve.

A. Oven controller off.

B. Press and hold the Airflow Delay Arrow

keypad while pressing the Power On/Off

keypad for 3 seconds.

C. Press the Bake Timer Arrows until Bake

Timer Display reads 0.

D. Press the Power On/Off keypad, oven in

Bakery Mode (standard operation).

BURNER ADJUSTMENTS

MANIFOLD PRESSURE ADJUSTMENT

NOTE: Verify the type of gas required is the type of

gas supplied.

2. Turn gas supply on to oven and verify that static

supply line pressure to oven does not exceed

14" W.C. (1/2 psig, 35.6 cm W.C., 3.5 kPa) for

either natural gas or propane. If supply line

pressure exceeds 14" W.C. (1/2 psig, 35.6 cm

W.C., 3.5 kPa), adjust pressure regulator. If no

pressure regulator, customer must supply and

install a line pressure regulator. Adjust as

needed.

3. Turn gas off at supply valve.

4. Move manometer to 1/8" NPT outlet pressure

tap on gas valve.

5. Turn gas on at supply valve.

6. Turn gas valve on and set controller to call for

heat.

F25361 (January 2010) Page 34 of 60

Page 35

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

7. With a burner flame established and all other gas equipment on the supply line lite, adjust the manifold

pressure as indicated in the following charts or as indicated on the oven data plate

NOTE: Accurate gas pressure adjustment can only be made with the burner on.

.

NOTE: Turn adjustment screw Clockwise

BTU/HR Nat. Gas 180,000 Propane Gas 180,000

W.C. 3.5" W.C. 10.0" W.C.

kCAL/HR 45,400 45,400

cm W.C. 8.89 25.40

Mj/HR 190 190

kPa 0.87 2.49

300,000 BTU/HR 350,000 BTU/HR 300,000 BTU/HR 350,000 BTU/HR

W.C. 3.0" 4.0" 8.0" 10.0"

kCAL/HR 75,600 88,200 75,600 88,200

cm W.C. 7.61 10.15 20.32 25.40

Mj/HR 317 370 317 370

kPa 0.75 1.00 2.00 2.49

to increase the pressure, Counterclockwise to decrease pressure.

OV500G1

MANIFOLD PRESSURE

NATURAL GAS PROPANE GAS

OV500G2

MANIFOLD PRESSURE

NATURAL GAS PROPANE GAS

NOTE: The following diagram represent a typical style of the combination valve.

F25361 (January 2010)Page 35 of 60

Page 36

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

NOTE: The following chart is for reference only. If the manifold pressure must be adjusted to accommodate the

altitude you must contact Bakery Product Support for a corrected data plate and orifice part number.

ALTITUDE CORRECTION CHART

OV500G1 OV500G1 OV500G2 OV500G2

Natural Gas Propane Gas Natural Gas Propane Gas

ELEVATION

IN FT.

0

(sea level)

3000 158,400 2.7 158,400 7.7 300,000 3.0 300,000 8.0

3500 154,800 2.6 154,800 7.3 300,000 3.0 300,000 8.0

4000 151,200 2.4 151,200 7.0 294,000 2.7 294,000 7.4

4500 147,600 2.3 147,600 6.7 287,000 2.6 287,000 7.1

5000 144,000 2.2 144,000 6.4 280,000 2.5 280,000 6.7

5500 140,400 2.1 140,400 6.0 273,000 2.4 273,000 6.4

6000 136,800 2.0 136,800 5.7 266,000 2.2 266,000 6.1

Orifice #53

Orifice Dia. 0.0595

Oven

Rating

BTU/Hr

180,000 3.5 180,000 10.0 300,000 3.0 300,000 8.0

Manifold

Pressure

“ W.C.

Orifice #63

Orifice Dia. 0.037

Oven

Rating

BTU/Hr

Manifold

Pressure

“W.C.

Orifice #49

Orifice Dia. 0.073

Oven

Rating

BTU/Hr

Manifold

Pressure

“W.C.

Orifice #56

Orifice Dia. 0.046

Oven

Rating

BTU/Hr

ORIFICE DIA. MUST CHANGE 6500 FT. ABOVE SEA LEVEL

Orifice #55

Orifice Dia. 0.052

Orifice #66

Orifice Dia. 0.033

Orifice #52

Orifice Dia. 0.0635

Orifice #60

Orifice Dia. 0.04

Manifold

Pressure

“W.C.

6500 133,200 3.2 133,200 8.6 259,000 3.7 259,000 10.1

7000 129,600 3.1 129,600 8.1 252,000 3.5 252,000 9.5

7500 126,000 2.9 126,000 7.7 245,000 3.3 245,000 9.0

8000 122,400 2.7 122,400 7.3 238,000 3.1 238,000 8.5

8500 118,800 2.6 118,800 6.8 231,000 2.9 231,000 8.0

9000 115,200 2.4 115,200 6.4 224,000 2.8 224,000 7.5

9500 111,600 2.3 111,600 6.0 217,000 2.6 217,000 7.1

10,000 108,000 2.1 108,000 5.7 210,000 2.4 210,000 6.6

F25361 (January 2010) Page 36 of 60

Page 37

OV500 SERIES RACK OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

8. If manifold pressure was unattainable, light burner and all other gas equipment on the supply line and check

gas supply line flow pressure. If gas supply line flow pressure not attainable find the source of the problem.

OV500G1

GAS SUPPLY LINE FLOW PRESSURE

NATURAL GAS PROPANE GAS

BTU/HR 180,000 180,000

W.C. 5.0" - 14.0" 12.0" - 14.0"

kCAL/HR 45,400 45,400

cm W.C. 12.7 - 25.4 30.5 - 35.6

Mj/HR 190 190

kPa 1.25 - 2.50 3.00 - 3.50

OV500G2