Hobart HC24EA5 Owner’s Manual

MODEL HC24EA SERIES

ELECTRIC COUNTERTOP

CONVECTION STEAMERS

ML-136041 HC24EA3 208/240 V. 9.25KW PRO

ML-136042 HC24EA5 208/240 V. 15.75KW PRO

ML-136049 HC24EA3 208/240 V. 8.5KW BASIC

ML-136050 HC24EA3 480 V. 9.25KW PRO

ML-136051 HC24EA3 480 V. 8.5KW BASIC

ML-136052 HC24EA5 208/240 V. 15KW BASIC

ML-136053 HC24EA5 480 V. 15.75KW PRO

ML-136054 HC24EA5 480 V. 15KW BASIC

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

1-888-4HOBART

www.hobartcorp.com

F-35432 (June 2006)

HC24EA SERIES ELECTRIC COUNTERTOP CONVECTION STEAMERS

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

THIS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

© HOBART, 2006

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

— 2 —

HC24EA SERIES ELECTRIC COUNTERTOP CONVECTION STEAMERS

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY....................................................................................................... 2

INTRODUCTION .................................................................................................................................... 5

GENERAL ......................................................................................................................................... 5

INSTALLATION ................................................................................................................................. 5

UNPACKING ..................................................................................................................................... 5

INSTALLATION CODES AND STANDARDS ................................................................................. 5

LOCATION ........................................................................................................................................ 6

LEVELING FEET .............................................................................................................................. 6

LEVELING ......................................................................................................................................... 6

ANCHORING STEAMER ................................................................................................................. 6

STACKING STAND .......................................................................................................................... 6

ELECTRICAL CONNECTION ......................................................................................................... 7

PLUMBING CONNECTIONS ........................................................................................................... 8

Water Requirements ................................................................................................................. 8

Water Treatment ........................................................................................................................ 8

Water Supply Connection.......................................................................................................... 8

DRAIN CONNECTIONS .................................................................................................................. 8

VENT HOOD .................................................................................................................................... 9

OPERATION .........................................................................................................................................10

CONTROLS ....................................................................................................................................10

Drain Handle (Basic model) .....................................................................................................10

Main Power Switch Light (Professional model) ......................................................................10

Ready Light (Professional model)............................................................................................10

Cooking Light (Professional model) ......................................................................................... 10

Timer ..........................................................................................................................................10

START UP (BASIC MODEL) ..........................................................................................................10

OPERATION .............................................................................................................................11

Drain Handle ........................................................................................................................11

Timer ....................................................................................................................................11

PREHEATING ............................................................................................................................11

STEAMING .................................................................................................................................11

SHUTDOWN .............................................................................................................................11

EXTENDED SHUTDOWN ........................................................................................................11

— 3 —

HC24EA SERIES ELECTRIC COUNTERTOP CONVECTION STEAMERS

TABLE OF CONTENTS (CONTINUED)

START UP (PROFESSIONAL MODEL) ........................................................................................ 11

OPERATION ............................................................................................................................. 12

Main Power Switch Light (Professional model) .................................................................12

Timer ....................................................................................................................................12

Ready Light ..........................................................................................................................12

Cooking Light ....................................................................................................................... 12

PREHEATING ............................................................................................................................12

STEAMING .................................................................................................................................12

SHUTDOWN ............................................................................................................................. 12

EXTENDED SHUTDOWN ........................................................................................................12

CLEANING .............................................................................................................................................13

COOKING COMPARTMENT DRAIN ..............................................................................................13

DRAINING GENERATOR ...............................................................................................................13

COMPARTMENT .............................................................................................................................13

DOOR GASKET .............................................................................................................................. 13

LEAVE COMPARTMENT DOOR OPEN ....................................................................................... 13

GUIDELINES FOR MAINTAINING STAINLESS STEEL SURFACES ........................................... 13

MAINTENANCE ..................................................................................................................................... 15

WATER TREATMENT SYSTEM .................................................................................................... 15

REMOVAL OF LIME SCALE DEPOSITS ...................................................................................... 15

Professional model ...................................................................................................................15

Basic model ............................................................................................................................... 16

DOOR GASKET .............................................................................................................................. 17

DRAINING THE GENERATOR .......................................................................................................17

COOKING HINTS ..................................................................................................................................18

PREPARATION ...............................................................................................................................18

Frozen Food Items....................................................................................................................18

Acceptable Pan Sizes ..............................................................................................................18

COOKING GUIDELINES .................................................................................................................18

PRODUCTS TO BE COOKED IN SOLID PANS ..........................................................................19

PRODUCTS TO BE COOKED IN PERFORATED PANS ...........................................................20

TROUBLESHOOTING .......................................................................................................................... 22

SERVICE AND PARTS INFORMATION ..............................................................................................23

— 4 —

HC24EA SERIES ELECTRIC COUNTERTOP CONVECTION STEAMERS

INTRODUCTION

GENERAL

Hobart convection steamers are produced with

quality workmanship and material. Proper

installation, usage and maintenance will result

in many years of satisfactory performance. It is

suggested that you thoroughly read this entire

manual and carefully follow all of the instructions

provided.

The HC24EA3 and HC24EA5 convection

steamers are single compartment, electric,

pressureless steam cookers with an internal

electric steam generator that maintains water

temperature at approximately 195°F. The

HC24EA3 is rated 8.5 KW (Basic model), and

9.25 KW (Professional model). The HC24EA5

is rated 15 KW (Basic) and 15.75 KW

(Professional).

Model HC24EA3 can accommodate three 2 1/2"

deep (6.4 cm) steam pans. Model HC24EA5 can

accommodate five 2 1/2"deep (6.4 cm) steam

pans. The HC24EA3 and HC24EA5 electric

convection steamers are designed for cooking

vegetables, eggs, and other foods, in commercial

kitchens. The steamer has a 0 to 60 minute timer.

The steamers are designed for countertop

installation.

UNPACKING

This steamer was inspected before leaving the

factory. The transportation company assumes

full responsibility for safe delivery upon

acceptance of the shipment. Immediately after

unpacking, check for possible shipping damage.

If steamer damage is found, save the packaging

material and contact the carrier within 15 days

of delivery.

INSTALLATION CODES AND

STANDARDS

In the United States, the Hobart steamer must

be installed in accordance with:

1. State and local codes.

2. National Electrical Code (ANSI/NFPA No.70,

latest edition) available from the National

Fire Protection Association, Batterymarch

Park, Quincy, MA 02269.

3. Vapor Removal from Cooking Equipment,

(NFPA-96, latest edition) available from

NFPA.

In Canada, the Hobart steamer must be installed

in accordance with:

INSTALLATION

Before installing, verify that the electrical supply

agrees with the specifications on the data plate

located on the back panel. If the supply and

equipment requirements do not agree, do not

proceed with the installation. Contact your dealer

or Hobart immediately.

This unit is shipped pre wired for 208/60/3. 240v

& single phase operation require changes to the

heater connection 240/60/3, 240/60/1 and 208/

60/1. This unit will operate at 60Hz or 50Hz.

1. Local codes.

2. Canadian Electrical Code (CSA C22.2 No.3,

latest edition) available from the Canadian

Standards Association, 5060 Spectrum Way,

Mississauga, Ontario, Canada L4W 5N6.

— 5 —

HC24EA SERIES ELECTRIC COUNTERTOP CONVECTION STEAMERS

LOCATION

Allow space for plumbing and electrical

connections. Minimum clearance is 6" (15.2

cm) on the back for proper air circulation. Allow

adequate access for operating and servicing

the steamer (36" at the front of the steamer, 15"

(38 cm) above the steamer and 18" (45.7 cm)

on right side of steamer).

LEVELING FEET

This steamer is shipped with four 2" leveling

feet. Optional 4" leveling feet are available. The

2" feet can be removed and the optional 4" feet

can be threaded into holes on the bottom of the

unit.

LEVELING

Using a spirit level in the bottom of the steamer,

adjust the leveling feet or the feet on the adjustable

legs to level the steamer side to side with a slight

tilt front to back to allow for proper cavity draining.

After the drain is connected, check for level by

pouring water onto the floor of the compartment.

All water should drain through the opening at the

back of the compartment cavity.

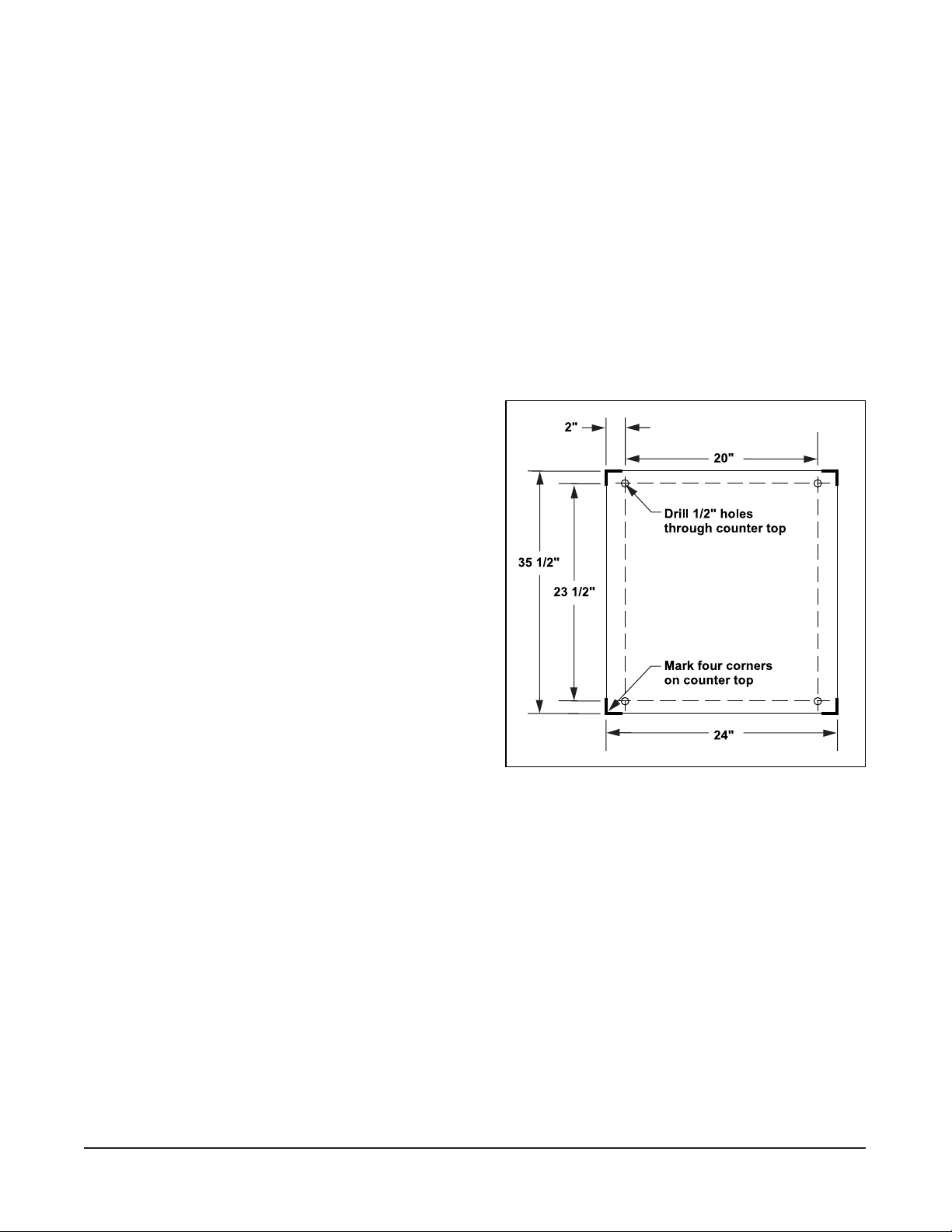

ANCHORING STEAMER

1. Place steamer in the desired location on the

countertop and mark four corners. Remove

the steamer and drill 1/2" holes as indicated in

Figure 1.

2. Apply a bead of RTV or other NSF approved

sealant around the bottom edge of the

steamer. If anchoring the steamer, this

bottom seal is necessary to meet NSF

requirements.

3. Set steamer on countertop and bolt down

securely with 3/8 -16 bolts (not supplied).

Note: Steamer must be installed level side to

side with a slight tilt front to back to allow for

proper draining.

Figure 1.

STACKING STAND

Instruction to install convection steamers on

stacking stand are included with the stacking

stand.

— 6 —

ELECTRICAL CONNECTION

HC24EA SERIES ELECTRIC COUNTERTOP CONVECTION STEAMERS

WARNING: ELECTRICAL AND GROUNDING

CONNECTIONS MUST COMPLY WITH APPLICABLE PORTIONS

ELECTRICAL

CODE AND/OR OTHER LOCAL

OF THE NATIONAL

The wiring diagram is located on the right side

panel as you face the steamer. This steamer is

hard wired.

ELECTRICAL CODES.

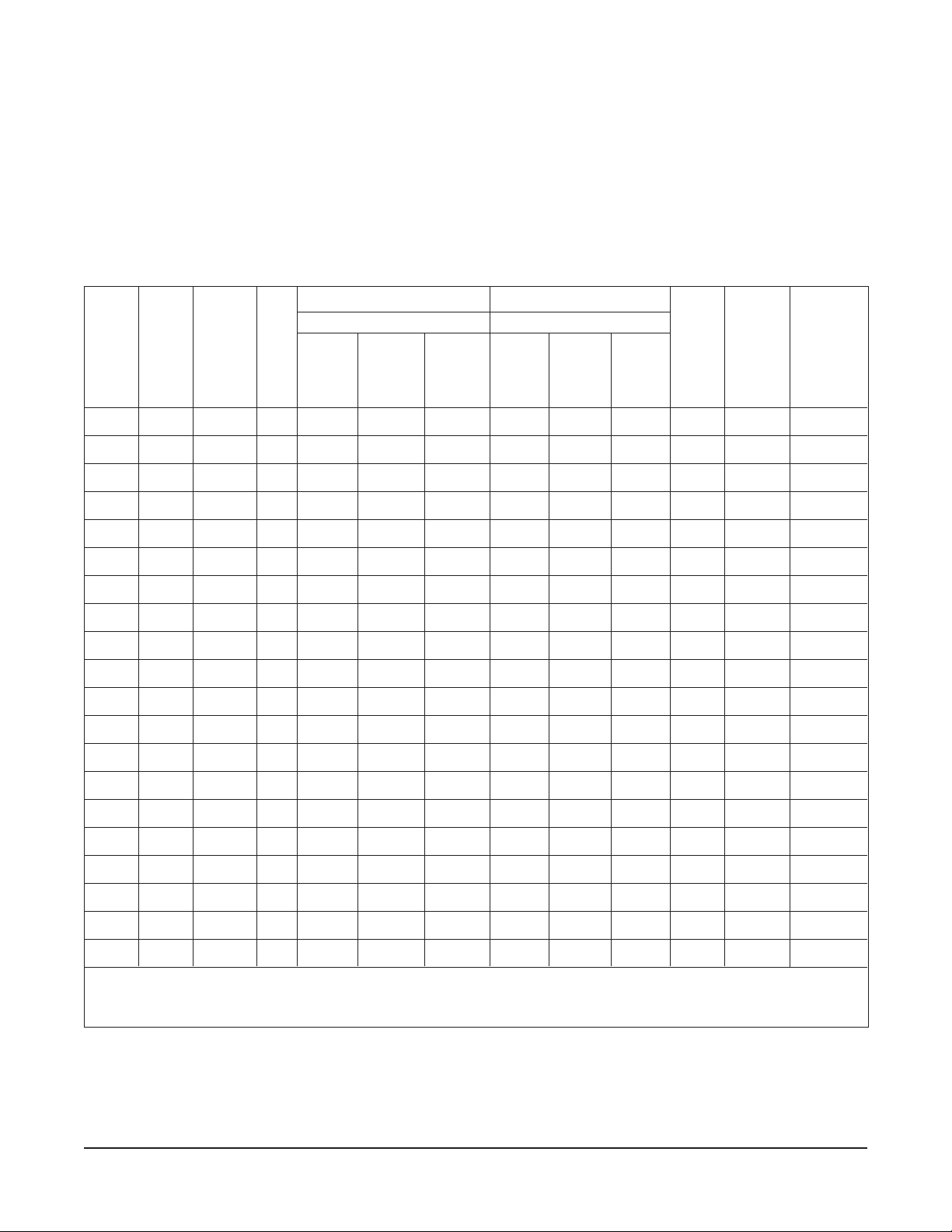

Total Volts Hz Ph KW Per Phase Rated Amps Circuit Fuse

KW

L1-L2 L2-L3 L3-L1 L1 L2 L3

8.5 208 50/60 1 40.87 60 60

8.5 240 50/60 1 35.42 50 50

8.5 208 50/60 3 4.25 2.12 2.12 26.54 26.54 17.70 35 35

8.5 240 50/60 3 2.83 2.83 2.83 20.50 20.50 20.50 30 30

8.5 480 50/60 3 2.83 2.83 2.83 10.30 10.30 10.30 15 15

9.25 208 50/60 1 43.57 60 60

3-Phase Amps per Line

Single Size Size

Phase Amps** or

Circuit

Breaker

(Amps)

Size*

9.25 240 50/60 1 38.54 50 50

9.25 208 50/60 3 4.25 2.69 2.12 26.54 28.88 20.04 40 40

9.25 240 50/60 3 2.83 3.58 2.83 20.45 23.15 23.15 30 30

9.25 480 50/60 3 2.83 3.58 2.83 10.21 11.57 11.57 15 15

15 208 50/60 1 72.12 90 90

15 240 50/60 1 62.50 75 75

15 208 50/60 3 7.50 3.75 3.75 46.84 46.84 31.23 60 60

15 240 50/60 3 5.00 5.00 5.00 36.08 36.08 36.08 50 50

15 480 50/60 3 5.00 5.00 5.00 18.04 18.04 18.04 25 25

15.75 208 50/60 1 74.82 95 95

15.75 240 50/60 1 65.63 85 85

15.75 208 50/60 3 7.50 4.31 3.75 46.84 49.18 33.57 65 65

15.75 240 50/60 3 5.00 5.75 5.00 36.08 38.79 38.79 50 50

15.75 480 50/60 3 5.00 5.75 5.00 18.04 19.40 19.40 25 25

2002 National Electric Code

*Dual Element Time-Delay Fuse or Inverse Time Circuit Breaker

** Circuit Size (minimum) & Fuse/Circuit Breaker Size (maximum) compiled in accordance with the

National Electrical Code (ANSI/NFPA 70), 2002 Edition.

— 7 —

HC24EA SERIES ELECTRIC COUNTERTOP CONVECTION STEAMERS

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST

COMPLY WITH APPLICABLE SANITARY,

SAFETY AND PLUMBING CODES.

Water Requirements

Proper water quality can improve the taste of

the food prepared in the steamer, reduce liming

in the steam generator and extend equipment

life. Water conditions vary from one location to

another. Ask your municipal water supplier for

details about your local water supply prior to

installation. Presence of sediment, silica, excess

chlorides or other dissolved solids may lead to

a recommendation for alternate form(s) of water

treatment. Test the water with the test strip

included with the steamer. Other factors

affecting steam generation are iron content,

amount of chloridation and dissolved gases.

If the water supply fails to meet these standards,

it will be necessary to install a water conditioner

on the generator water feed. The use of strainers

or filters will not remove minerals from the

water.

Water Supply Connection

Connect the treated cold water supply line to the

3/4" (19 mm) (male hose thread) inlet. Connect

the untreated cold water supply line to the 3/4"

(19 mm) (male hose thread) inlet marked

UNTREATED WATER.

A water treatment system is recommended for

the water supply line going to the treated water

inlet. Follow the recommendations for use and

installation instructions shipped with the water

filter. If a water treatment system is not installed,

the steam generator warranty may be limited.

A manual shutoff valve must be provided in a

convenient location near the steamer.

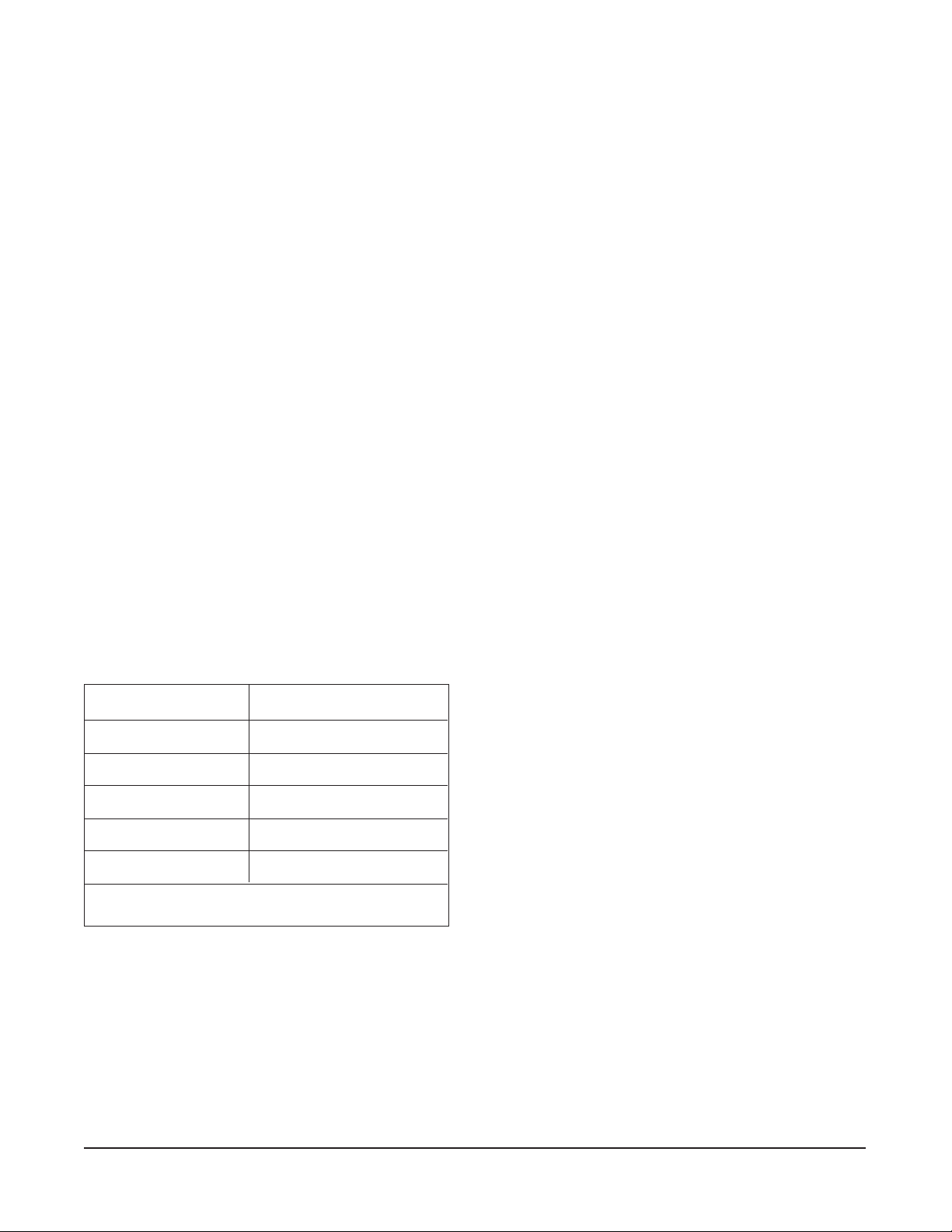

Water Treatment

A local water treatment specialist should be

consulted before installation of steam generating

equipment.

Supply Pressure 20 - 60 psig

Hardness* No more than 3 grains

Silica less than 13 ppm

Total Chlorine less than 4.0 ppm

PH range 6.5 - 8

Undissolved Solids less than 5 microns

*17.1 ppm = 1 grain of hardness

DRAIN CONNECTIONS

The drain connection (Figure 2) must be 1 1/2"

(38 mm) down, preferably with one elbow only,

maximum length of 6' and piped to an open gap

type drain.

CAUTION: In order to avoid any back

pressure in the steamer, do not make a

solid connection to any drain. FAILURE

TO DO SO CAN DAMAGE THE STEAMER

AND VOIDS THE WARRANTY.

A vent must be installed to avoid creating a

vacuum or pressure in the cooking chamber.

— 8 —

Loading...

Loading...