N

S

T

R

U

C

T

I

O

N

S

I

HCM61 & HCM62 FOOD PROCESSORS

MODEL

HCM61 ML-134017

HCM62 ML-134018

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 34468 (Apr. 2000)

Installation, Operation, and Care of

HCM61 & HCM62 Food Processors

SAVE THESE INSTRUCTIONS

GENERAL

The model HCM61 and HCM62 Food Processors are used for

chopping meat, fish, fruits, vegetables, nuts, or dry bread, for

mixing various sauces, mayonnaise, or soups, or for blending or

pureeing various products, such as thickening or desserts. Refer

to Capacity Recommendations, page 6.

The HCM61 has a 1.5

plug, and requires a 20 Amp. electrical service and receptacle. The

machine operates at 1700 rpm with single speed or pulse control.

The HCM62 has a 2.0

phase cord and plug, and requires a 20 Amp. electrical service and

receptacle. The machine operates at 1700 or 3400 rpm with two

speed or pulse control.

HP motor, is provided with 120 Volt cord and

HP motor, is provided with 208 - 240 Volt three

Model HCM61 or HCM62

Food Processor

INSTALLATION

UNPACKING

Immediately after unpacking the food processor, check for possible shipping damage. If this machine

is found to be damaged after unpacking, save the packaging material and contact the carrier within 15

days of delivery.

Prior to installation, test the electrical service to assure that it agrees with the specifications on the

machine data plate.

Lift or move the machine only by using the two handles on the sides of the base.

LOCATION

Place the food processor on a suitable sturdy worktop or table. There should be adequate space

around the machine for the user to operate the controls and install and remove the bowl and knife.

HOBART CORPORATION, 2000

©

– 2 –

ELECTRICAL CONNECTIONS (Cord Connected Machines)

WARNING:

THE ELECTRICAL CORD ON THIS MACHINE IS EQUIPPED WITH A GROUNDING TYPE

PLUG WHICH MUST BE CONNECTED TO A PROPERLY GROUNDED RECEPTACLE. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT

REMOVE THE GROUNDING PRONG FROM THE PLUG.

Refer to the machine data plate and Electrical Data, below.

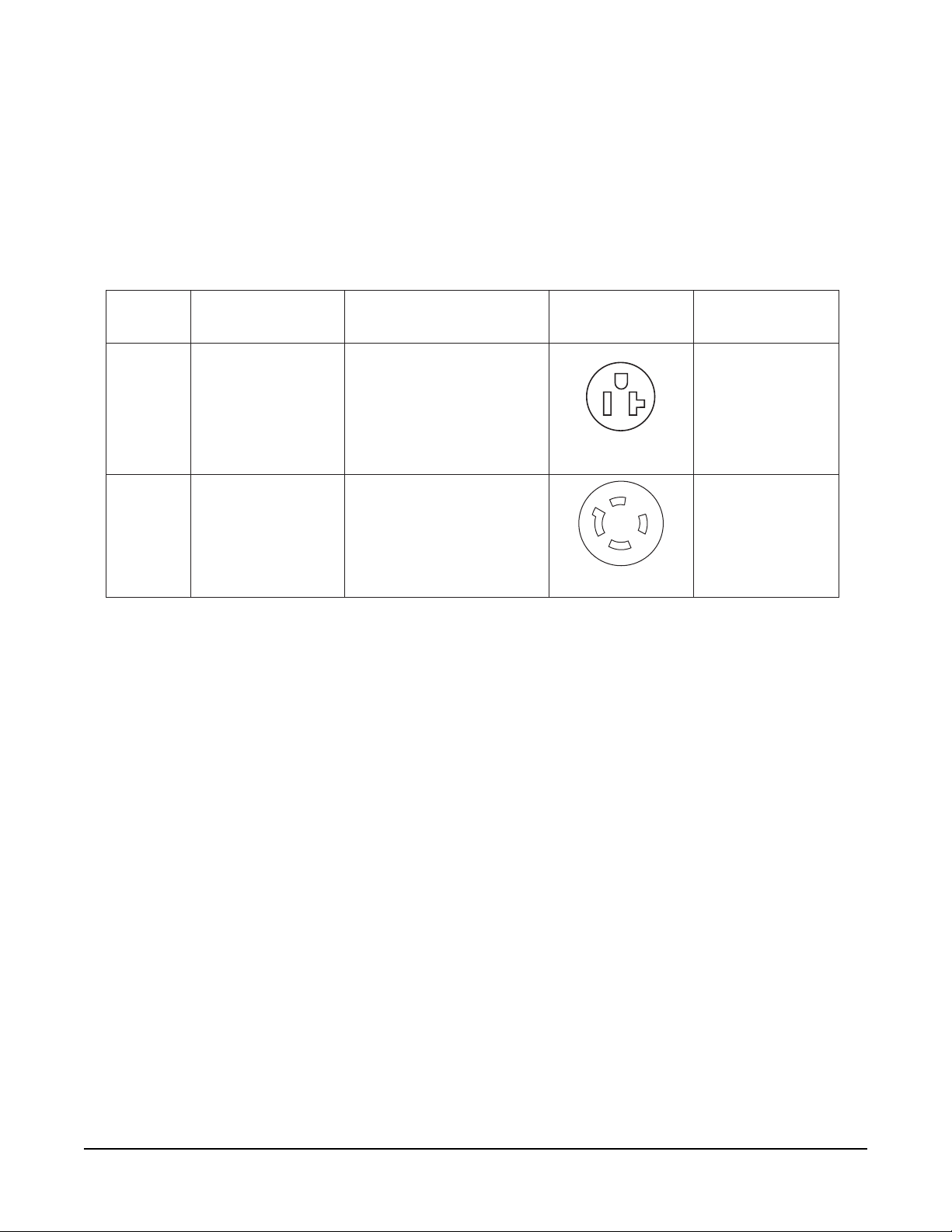

ATADLACIRTCELEATADLACIRTCELE

ATADLACIRTCELEATADLACIRTCELE

ATADLACIRTCELE

yticapmAtiucriCmuminiMyticapmAtiucriCmuminiM

yticapmAtiucriCmuminiMyticapmAtiucriCmuminiM

yticapmAtiucriCmuminiM

ledoMledoM

ledoMledoMesahP/ztreH/stloVesahP/ztreH/stloV

ledoM

16MCH1/06/02102

26MCH3/06/042-80202

esahP/ztreH/stloVesahP/ztreH/stloV

esahP/ztreH/stloV

SPMASPMA

SPMASPMA

SPMA

eciveDevitcetorPmumixaMeciveDevitcetorPmumixaM

eciveDevitcetorPmumixaMeciveDevitcetorPmumixaM

eciveDevitcetorPmumixaM

elcatpeceRelcatpeceR

elcatpeceRelcatpeceRgulPgulP

elcatpeceR

G

W

gulPgulP

gulP

P02-5:gulP

R02-5

X

G

Y

P02-51L:gulP

Z

R02-51L

.noitidetsetal,07APFN,edoClacirtcelElanoitaNehthtiwecnadroccanidelipmoC

CHECK MOTOR ROTATION (Three-Phase Machines Only)

On model HCM62, check the rotation. With all parts in their normal operating positions (pages 4 – 5),

turn the switch to the Pulse position for two seconds and release. The direction of rotation of the knife

should be counterclockwise as viewed from the top.

If the knife rotates clockwise, correct the rotation using the following procedure:

DISCONNECT THE ELECTRICAL POWER SUPPLY. Interchange any two of the incoming power

supply leads in the plug. Reconnect the power supply and turn the switch to the Pulse position to

verify that the knife rotates counterclockwise as viewed from the top.

PRESTART CHECK

With the machine fully assembled (pages 4 – 5), make sure the cutting blades stop within 4 seconds

after the arm is swung back away from the center of the bowl cover.

Make sure the machine cannot be started with the bowl and cover removed but with the arm swung into

position above the center of the drive shaft.

If the machine fails to work properly, contact Service; do not allow the machine to be operated.

– 3 –

BOWL AND KNIFE ASSEMBLY

ARM

Install the Bowl so the center post of the Bowl fits

over the motor shaft, one of the Bowl Pins fits in

the slot at the front of the machine, and the bowl

handles are positioned on left and right (Fig. 1).

Install Knife Shaft over center bowl post so the

slots on the Knife Shaft fit the grooves on the

motor shaft (Fig. 1).

SLOT

Fig. 1

TIP

MOTOR SHAFT

KNIFE SHAFT

BOWL

HANDLE

BOWL

BOWL PIN

PL-41421-1

WIPER

END

The four Bowl Scraper Wipers must be properly

installed in the grooves of the Bowl Scraper. The

upper tips of the wipers point straight up and

slightly toward the center (Fig. 2); the ends of the

wipers are vertical so they do not interfere with

the lip of the Bowl Cover. Do not install the

wipers backwards.

After installing the Lid Plug, turn it so the

underneath side of the plug is flat with the

underneath side of the Bowl Cover (Fig. 3). The

Bowl Cover Gasket must be properly installed in

the groove around the lip of the Bowl Cover

(Fig. 3).

BOWL COVER

LIP

BOWL SCRAPER

PL-41422-1

Fig. 2

BOWL COVER GASKET

ALIGMENT PIN

LID PLUG

PL-41423-1

– 4 –

Fig. 3

Fit the Bowl Cover over the Bowl Scraper so the

center holes align. Fit the Scraper Handle Shaft

through the center hole in the Bowl Cover into

the Slots of the Bowl Scraper. The Bowl Cover

Tab must fit around the 180° Cam on the Scraper

Handle. The Tabs on the Scraper Handle Shaft

must fit through the Slots in the center hole of the

Bowl Scraper.

Place the assembled Bowl Cover / Bowl Scraper/

Scraper Handle on a flat surface. Press down on

the Scraper Handle (Fig. 5) and turn it clockwise

1

/8 turn so the Tabs engage with the bottom of the

Slots. The Bowl Cover / Bowl Scraper / Scraper

Handle are now joined as one piece.

Move the Scraper Handle until it is positioned

over the Lid Plug.

BOWL

COVER

TAB

SHAFT

TAB

PRESS HANDLE DOWN

THEN TURN

CLOCKWISE

1/8 TURN

TO ENGAGE

180° CAM

SLOTS

SCRAPER HANDLE

BOWL

COVER

HANDLE

PL-41424-1

Fig. 4

Place the assembled Bowl Cover / Bowl Scraper/

Scraper Handle in the Bowl. The Bowl Scraper

Legs touch the sides of the Bowl. The Bowl

Cover Handles set directly above the Bowl

Handles (Fig. 6). The Alignment Pins under the

Bowl Cover Handles fit the holes in the Bowl

Handles (Fig. 6).

Swing the Arm forward so the end of the Arm fits

over the center of the Bowl above the Scraper

Handle (Fig. 7). The Arm must be properly

positioned over the center of the Bowl and all

parts must be properly assembled before the

machine will operate.

ARM

ARM

Fig. 5

SCRAPER

HANDLE

BOWL COVER

Fig. 6

BOWL SCRAPER HANDLE

PL-41425-1

BOWL

COVER

HANDLE

ALIGNMEMT

PIN

BOWL HANDLE

BOWL

PL-41426-1

– 5 –

PL-41427-1

Fig. 7

OPERATION

WARNING: ROTATING KNIVES INSIDE. DO NOT OPEN COVER UNTIL KNIFE SHAFT STOPS.

UNPLUG CORD BEFORE INSERTING OR REMOVING ATTACHMENTS, CLEANING OR SERVICING.

CONTROLS

Model HCM61

E

ULS

P

OFF

NO

Model HCM62

E

ULS

P

OFF

LOW

HIGH

When processing is done, turn Arm to rear. Wait for Knife to stop. Unplug machine power cord. Lift

the Bowl Cover, Scraper Handle, and Bowl Scraper straight up. Remove the Knife Shaft. The Bowl

can be removed to empty contents.

OFF — Machine is OFF. Switch machine OFF before unpluging.

ON — Runs motor and knife at 1700 rpm until switch is turned to OFF.

PULSE — Runs motor and knife at 1700 rpm while switch is held. When

switch is released, machine returns to OFF.

OFF — Machine is OFF. Switch machine OFF before unpluging.

LOW — Runs motor and knife at 1700 rpm until switch is turned OFF.

HIGH — Runs motor and knife at 3400 rpm until switch is turned OFF.

PULSE — Runs motor and knife at 1700 rpm while switch is held. When

switch is released, machine returns to OFF.

CAPACITY RECOMMENDATIONS

The maximum quantity that can be processed at one time and the length of time required for processing

are dependent on the product and kind of result desired. Shorter processing times give a coarser

result; longer processing yields a finer consistency. The Capacity Chart shows the maximum quantity

of various products that can be processed in one batch and the approximate processing time.

TRAHCYTICAPACTRAHCYTICAPAC

TRAHCYTICAPACTRAHCYTICAPAC

TRAHCYTICAPAC

TCUDORPTCUDORP

TCUDORPTCUDORPYTITNAUQYTITNAUQ

TCUDORP

pohC,ecniMpohC,ecniM

pohC,ecniMpohC,ecniM

pohC,ecniM

snoinO

storraC

eseehCallerazzoM

staeM

hserF

dekooC

essuoMnomlaS

rataTkaetS

suoenallecsiM

sbmurCdaerB

)enif(eseehCnasemraP

rettuB

esiannoyaM

ecuaSotamoT

diuqiL

41/2 sdnuop

31/2 sdnuop

11/2 sdnuop

11/2 sdnuop

41/2 strauq

41/2 strauq

41/2 strauq

YTITNAUQYTITNAUQEMITEMIT

YTITNAUQ

.sdnuop3

sdnuop3

sdnuop3

sdnuop3

sdnuop3

sdnuop4

EMITEMIT

EMIT

sdnoces02

sdnoces02

sdnoces02

sdnoces03

sdnoces03

sdnoces03

sdnoces03

sdnoces01

etunim1

sdnoces03

sdnoces53

sdnoces02

deriuqersa

– 6 –

PREPARING THE PRODUCT FOR PROCESSING

Cut products such as meat and cheese into equal pieces of approximately 1" cubes for easy

processing.

For bread crumbs or other dry products, place product into the bowl first, turn the machine on, then add

liquid ingredients.

For pureeing products, be sure to move the Scraper Handle back and forth to reintroduce partially cut

product into the cutting zone.

USING THE BOWL SCRAPER DURING PROCESSING

During processing, move the Scraper Handle back and forth to reintroduce partially cut product that

is clinging to the sides of the bowl back into the cutting area. The Bowl Scraper can also be used during

processing to stir or mix liquid products. The Bowl Scraper has four legs and four lid wipers — this

allows a 90° motion to fully wipe the entire Bowl and lid.

USE OF THE FEED TUBE

The Bowl Cover is equipped with a Lid Plug which can be pulled open for adding ingredients. When

replacing the Lid Plug, be sure to turn the Lid Plug so the underneath side of the plug is flat with the

underneath side of the Bowl Cover. With the Lid Plug in closed position, the Scraper Handle should

move back and forth over it.

CLEANING

WARNING: SWITCH OFF AND UNPLUG MACHINE POWER CORD BEFORE BEGINNING ANY

CLEANING PROCEDURE.

The food processor should be thoroughly cleaned after use.

Never use steel wool, abrasive cleaning sponges, or high pressure

hose for cleaning. Do not leave the knife shaft wet or setting on

a stainless steel worktop when not in use.

PRESS HANDLE DOWN

THEN TURN

COUNTERCLOCKWISE

1/8 TURN

TO RELEASE

Swing the Arm to the rear as far as it will go. Remove the Bowl

Cover / Bowl Scraper / Scraper Handle by lifting straight up, out

of the Bowl. Set the assembly on a table or countertop (Fig. 8).

Press the Scraper Handle down (Fig. 8), freeing the tabs of the

Scraper Handle Shaft from the slot restrictions in the Bowl

Scraper. While pressing down, turn the Scraper Handle

1

counterclockwise

/8 turn. Remove the Scraper Handle. Separate

the Bowl Cover and Bowl Scraper. Remove the Bowl Scraper

Fig. 8

PL-41425-2

Wipers from the grooves of the Bowl Scraper.

GASKET GROOVE

Remove the Knife Shaft by lifting it straight up. Remove the

Bowl.

Remove the Bowl Cover Gasket from the Bowl Cover by grasping

the gasket with your finger and thumb at the Indentation where

the Gasket Groove is not present (Fig. 9).

INDENTATION

Wash, rinse, and sanitize all parts in a sink as you would any food

utensil and allow to air dry. Wipe the exterior of the machine with

Fig. 9

PL-41428-1

a damp cloth. Reassemble all parts when dry following the Bowl

and Knife Assembly instructions on pages 4 – 5.

– 7 –

TROUBLESHOOTING

MELBORPESUACELBISSOPNOITCAEVITCERROCDETSEGGUS

.tratst'nowenihcaMrekaerbtiucricroesuF

elihwspotsenihcaM

.tratsert'nowdnagnitarepo

.rewopgnitpurretni

.ecalpnitonlwoB.noitisopreporpnisilwoberusekaM

revonoitisopnitonmrA

.revoClwoBforetnec

.nideggulptonenihcaM.elcatpecerlacirtcelegnitamreporpotnigulP

.dedaolrevorotoM

rekaerbtiucricroesuF

.rewopgnitpurretni

.tiucrickcehcnaicirtceleevaH

lwoBforetnecrevonoitisopreporpnisimrAerusekaM

.eldnaHreparcSfoeroCfopoTdnarevoC

.loocsitinehwtratserlliwrotom;loocotrotomwollA

.loocotrotomehtrofsetunim03ot01ekatyamtI

.tiucrickcehcnaicirtceleevaH

SERVICE

Contact your local Hobart-authorized service office for any repairs or adjustments needed on this

equipment.

FORM 34468 (Apr. 2000) PRINTED IN U.S.A.

– 8 –

Loading...

Loading...